Page 1

SGC 24 SOL

Gas fired condensing boiler

SOLNEO

User Guide

300017555-001-C

EN

C001764

Page 2

2

SGC 24 SOL 15/10/2009 - 300017555-001-C

.

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 Symbols and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Safety instructions and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.1 Fire hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1.2 Risk of being burnt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

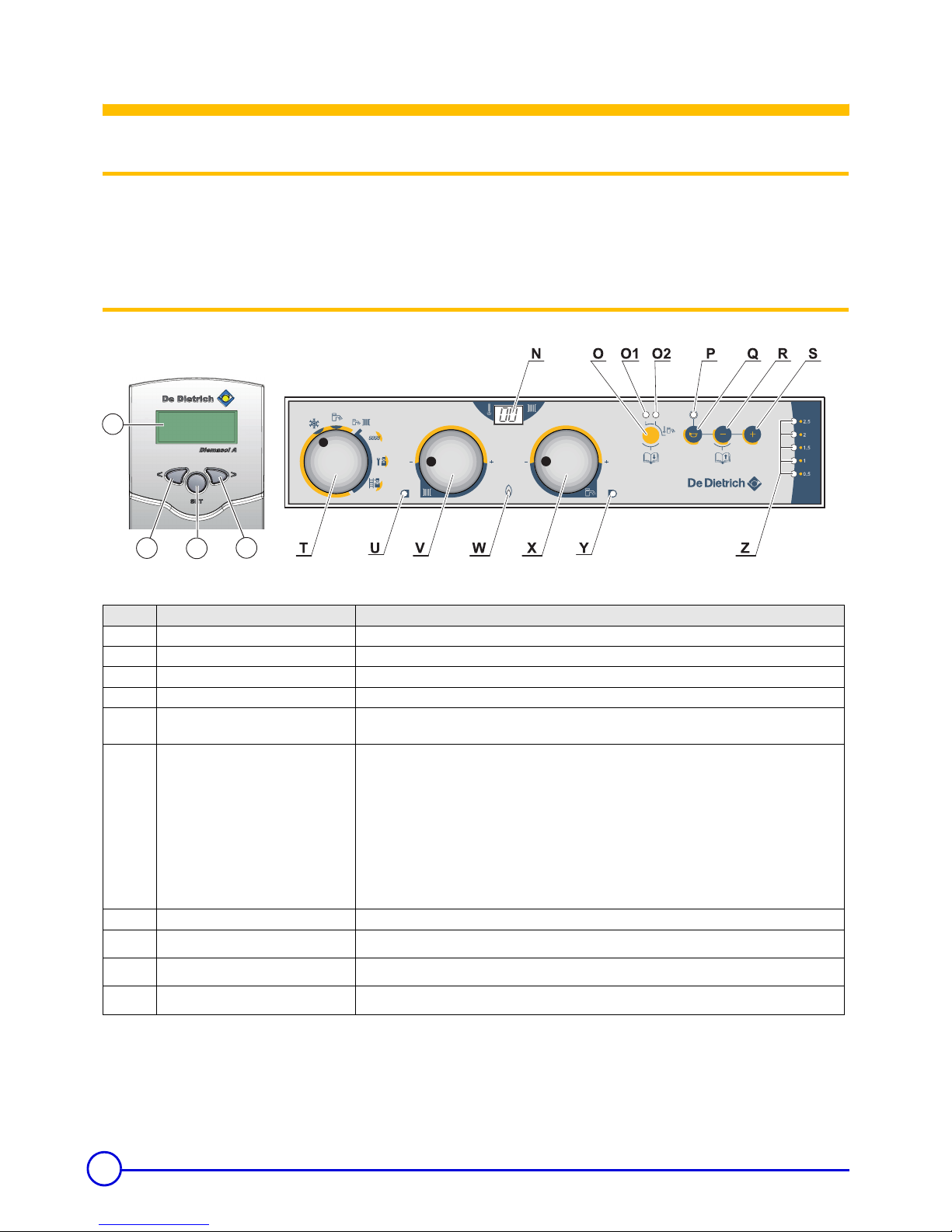

3.2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.3 Parameter display - Diemasol A solar regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.1 Start the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.2 Description of the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.3 Changing the settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3.1 Selecting the operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3.2 Changing the heating temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3.3 Changing the domestic hot water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.4 Stopping the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.5 Prolonged absence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.5.1 Switching off the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.5.2 Antifreeze protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

5 Checking and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.1 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.2 Periodic checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.3 Topping up the boiler with water (If the option is connected) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5.4 Bleeding the heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.5 Draining the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.1 Breakdown codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.1.1 Safety alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.1.2 Sensor alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.2 Before contacting the installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.3 Incidents and solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.3.1 The burner is not working. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.3.2 The burner is operating but the radiators are cold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.3.3 The domestic hot water does not appear hot enough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.3.4 Hot water takes a very long time to reach certain draw-off points and not others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

7 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

8 Energy savings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

8.1 Energy-saving advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

8.2 Room thermostat and settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 3

3

15/10/2009 - 300017555-001-C SGC 24 SOL

1. Introduction

1 Introduction

1.1 Symbols and abbreviations

In these instructions, various markings and pictograms are used to

draw your attention to particular information. In so doing,

De Dietrich Thermique S.A.S. wishes to safeguard the user's safety,

obviate hazards and guarantee correct operation of the boiler.

CRC: Communicating remote controller

CFC: Chlorofluorocarbon

DHW: Domestic hot water

Caution danger

Risk of injury and damage to equipment.

Attention must be paid to the warnings on safety of

persons and equipment.

Important information

Information must be kept in mind to maintain comfort.

Z

Reference

Refer to another manual or other pages in this instruction

manual.

1.2 General

1.2.1 Manufacturer's liability

Our products are manufactured in compliance with the essential

requirements of the various Directives applicable. They are therefore

delivered with 1 marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

` Incorrect use of the appliance.

` Faulty or insufficient maintenance of the appliance.

` Incorrect installation of the appliance.

1.2.2 Installer's liability

The installer is responsible for the installation and inital start up of the

appliance.

The installer must respect the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance.

` Carry out installation in compliance with the prevailing

legislation and standards.

` Perform the initial start up and carry out any checks necessary.

` Explain the installation to the user.

` Warn the user of the obligation to check the appliance and

maintain it in good working order.

` Give all the instruction manuals to the user.

1.2.3 User's liability

To ensure the optimum operation of your appliance, we strongly

recommend that you abide by the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance.

` Call on qualified professionals to carry out installation and initial

start up.

` Get your fitter to explain your installation to you.

` Have the required checks and services done.

` Keep the instruction manuals in good condition close to the

appliance.

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

Page 4

4

SGC 24 SOL 15/10/2009 - 300017555-001-C

1. Introduction

1.3 Certifications

* Except Belgium and France

(x) For Germany only

CE identification no CE-0085BQ0052

Type of connection Chimney: B

23P

- B

33

Forced flue: C

13(x)

- C

33(x)

- C

43(x)

- C53 - C

63(x) *

- C

83(x)

- C

93(x)

Ignition Automatic

Page 5

5

15/10/2009 - 300017555-001-C SGC 24 SOL

2. Safety instructions and recommendations

2 Safety instructions and recommendations

2.1 Safety instructions

2.1.1 Fire hazard

DANGER

If you smell gas:

1. Do not use a bare flame, do not smoke, do not actuate electrical

contacts or switches ( doorbell, light, motor, lift, etc..).

2. Cut the gas supply.

3. Open the windows.

4. Evacuate the premises.

5. Call your fitter.

DANGER

If you smell flue gases:

1. Switch the appliance off

2. Open the windows.

3. Evacuate the premises

4. Call your fitter

2.1.2 Risk of being burnt

DANGER

Depending on the settings of the appliance:

` The temperature of the flue gas conduits may exceed 60°C.

` The temperature of the radiators may reach 95°C.

` The temperature of the domestic hot water may reach 65°C.

Avoid direct contact with the flame viewport.

2.2 Recommendations

The installation and the first start-up must be performed by a qualified

professional.

Only qualified professionals are authorised to work on the

appliance and the instalation.

` Regularly check the water pressure in the installation (minimum

pressure 0.8 bar, recommended pressure between 1.5 and 2

bar).

` Keep the appliance accessible at all times.

` Never remove or cover labels and rating plates affixed to the

appliance. Labels and rating plates must be legible throughout

the entire lifetime of the appliance.

Aeration

The air inlet into the premises must in no event be obstructed, even

partially.

Maintenance

Do not neglect to service the appliance:

For completely safe and optimum operation, you must

have your boiler regularly serviced by an approved

installer.

The servicing and cleaning of the boiler and the sweeping of the flue

gas pipe and the bleed pot must be done at least once a year by a

qualified professional.

We recommend that you take out a maintenance contract.

Precautions against frost

The boiler is fitted with an antifreeze system. In the event of total

shutdown of the heating in winter which may lead to the danger of

freezing (switching off of radiators and current), we recommend using

a correctly dosed anti-freeze product to stop the heating water

freezing. Failing this, drain the installation completely (in all cases,

consult your fitter).

Page 6

6

SGC 24 SOL 15/10/2009 - 300017555-001-C

3. Description

3 Description

3.1 General description

The SGC 24 SOL solar column is a multi-energy unit which includes

a gas-fired condensing boiler and a 200-litre solar domestic hot water

tank in the same casing.

The boiler is preset in the factory to operate on natural gases H and

E (Operating pressure: 20 mbar).

The boiler is fitted with a system to protect against overheating.

3.2 Control panel

C001771B

1

2

3

4

Position Key Description

1 Alphanumeric LCD display Displays the settings for the solar circuit.

2

< Returns to the previous menu or reduces the value of a setting.

3 > Moves to the next menu or increases the value of a setting.

4

SET Allows the displayed parameter to be accessed and modified.

N Temperature display The display shows the temperature of the water in the domestic hot water heating outlet when there is

a request for domestic hot water.

O

I

Domestic hot water temperature

maintenance override button

For SGC 24 SOL with Easymatic or Easyradio remote control:

Pressing the button for 1 second makes it possible to override domestic hot water tank loading

outside the time period programmed in the control unit up to midnight (indicator light O2 flash).

- Light O1 lit : The burner is ignited to reheat the domestic hot water tank.

- Light O2 off : No override or programme running.

- Light O2 lit : Comfort programme activated.

For SGC 24 SOL without remote control:

Light O1 lit : The burner is ignited to reheat the domestic hot water tank.

A power cut does not modify the selected operating mode.

P Safety shutdown light Indicates an error in the boiler.

Q

Unlock button To restart the boiler after safety shutdown.

R

H

Button Used only in measurement 8888, installer K and sweep M mode.

S Button Used only in sweep mode M.

Page 7

7

15/10/2009 - 300017555-001-C SGC 24 SOL

3. Description

3.3 Parameter display - Diemasol A solar regulator

` To scroll the parameters, push on key < or >.

T 6-position switch - . : Shutdown/antifreeze/vent.

-

: Domestic hot water (Summer).

-

"

: Heating and domestic hot water (Winter).

-

V

: Measurement mode (Key to access the parameters reserved for the installer).

-

K

: Fitter mode (Key to access the parameters reserved for the installer).

-

M

: Sweeping mode (Key to access the parameters reserved for the installer).

U "Heating" on light The light is on when the heating/domestic hot water reversal valve is in the heating position and the

circulator pump is operating.

V Heating temperature setting Adjustment range : 30 °C to 90 °C (Hard spot at 68°C).

W Flame presence light The light is on when the burner is operating.

X Setting the domestic water

temperature

Adjustment range : 40 °C to 60 °C (Hard spot at 55°C).

Y "Domestic hot water" on light The light is on when the heating/domestic hot water reversal valve is in the domestic hot water

position and the circulator pump is operating.

Z Pressure indicator Indicates the pressure in the heating circuit from 0.5 to 2.5 bar.

Position Key Description

Abbreviation Parameter Range

TC Collector temperature [-50.0...+250.0°C]

TS Tank temperature [-50.0...+250.0°C]

kWh Amount of heat [0...9999 kWh]

PC Pump regime [0...100 %]

tc Self-calibration time [0...5] minutes

TR Return temperature [-50.0...+250.0°C]

TM Additional temperature

with S3 sensor only (optional)

[-50.0...+250.0°C]

Page 8

8

SGC 24 SOL 15/10/2009 - 300017555-001-C

4. Operating instructions

4 Operating instructions

4.1 Start the boiler

` Check the water pressure in the installation several times a

year.

If necessary, top up the boiler with water.

The water pressure in the installation must be between 1.5 and

2 bar.

` Open the gas valve.

` Set the 6-position switch T to

(summer mode) or

"

(winter mode).

` If using a room temperature thermostat or a communicating

remote control, turn them to heating request.

`

` The boiler will begin an automatic venting-programme (which

lasts approx. 3 minutes) and will do this every time the power

supply is isolated.

` The regulator starts an initialisation phase during which the LED

flashes red and green. When initialisation is complete, the

regulator changes to automatic mode. The factory settings for

this mode give optimum performance with most installations.

4.2 Description of the parameters

LED state:

C001790

T

M000391-B

Display Action

Continuously green Regulation operating normally (System Operating).

Solar system Operating.

Continuously red The installation is stopped.

The solar collectors are not hot enough (parameter TC) to enable operation.

Flashing green/red Initialisation phase

The installation is in manual mode

Maximum water tank temperature exceeded

Maximum solar collector temperature exceeded

Sensor fault

Off Control system power fault

Page 9

9

15/10/2009 - 300017555-001-C SGC 24 SOL

4. Operating instructions

4.3 Changing the settings

4.3.1 Selecting the operating mode

` Set the 6-position switch T to the desired operating mode.

-- . : Shutdown/antifreeze/vent.

--

: Domestic hot water (Summer).

--

"

: Heating and domestic hot water (Winter).

4.3.2 Changing the heating temperature

` Set the temperature of the heating water using button V.

- Minimum = 30 °C

-Maximum=90°C

- Hard point = 68 °C

` The temperature set in shown on the display.

If using an outside temperature sensor, the heating flow

temperature is adjusted automatically.

4.3.3 Changing the domestic hot water temperature

` Set the domestic hot water temperature using button X.

- Minimum = 40 °C

-Maximum=60°C

- Recommended temperature = 55 °C (Hard point) to combine

comfort and economy.

` The temperature set in shown on the display.

4.4 Stopping the boiler

` Set the 6-position switch T to . (stop / antifreeze / vent).

The boiler goes into standby mode.

The display shows " .. ".

In this operating scenario, the boiler and the domestic hot water

tank are protected against the risk of frost.

Do not shut down power to the control system or drain the

heat-exchanging fluid.

The system is designed in such a way that no special precautions are

necessary during long periods of absence in summer.

The Diemasol A solar control system protects the installation from

overheating.

C000879-B

C000880-C

C000881-C

C001793-B

T

Page 10

10

SGC 24 SOL 15/10/2009 - 300017555-001-C

4. Operating instructions

4.5 Prolonged absence

4.5.1 Switching off the appliance

If the central heating system is not used for a long period, we

recommend switching the boiler off.

1. Switch the boiler off.

2. Cut the power supply to the boiler.

3. Close the gas valve.

4.5.2 Antifreeze protection

The boiler must be installed in a frost-free environment.

We recommend setting the boiler thermostat to a value off 10°C if

using a classic installation.

If the temperature of the central heating water in the boiler falls too

much, the integrated protection device switches itself on:

- If the water temperature is lower than 7°C, the circulating pump is

activated.

- If the water temperature is lower than 3°C, the boiler is activated.

- When the water temperature is above 10 °C, the boiler is switched

off and the circulation pump runs for another 15 minutes.

Page 11

11

15/10/2009 - 300017555-001-C SGC 24 SOL

5. Checking and maintenance

5 Checking and maintenance

5.1 General instructions

An annual inspection is compulsory.

We recommend that you take out a maintenance contract.

Maintenance operations must be done by a qualified

professional.

Only original spare parts must be used.

5.2 Periodic checks

` Regularly check the water pressure in the installation (minimum

pressure 0.8 bar, recommended pressure between 1.5 and 2

bar).

If the water pressure is too low, add more water to the

installation (See

Topping up the boiler with water).

` Carry out a visual check for the presence of any water leaks.

` Open and close the radiator valves several times a year (this

prevents the valves from seizing up).

` Clean the outside of the boiler using a damp cloth and a light

detergent.

Only a qualified professional is authorised to clean the

inside of the boiler.

5.3 Topping up the boiler with water (If the option is connected)

` Regularly check the level of water in the system and top up if

required, taking care that cold water is not added suddenly into

the boiler when it is hot.

This operation must be carried out several times per season ; if

not, look for the probable leak and immediately fix it.

` Contact the fitter.

Do not drain the installation, except in cases of absolute

necessity.

C002174-A

1

2

3

4

T000181-B

Page 12

12

SGC 24 SOL 15/10/2009 - 300017555-001-C

5. Checking and maintenance

5.4 Bleeding the heating system

It is essential that you vent any air in the appliance, the ducts or the

valves to prevent the noise annoyance likely to be produced during

heating or water draw-off.

To do this, proceed as follows:

1. Open the valves on all radiators connected to the heating system.

2. Set the heating set point to as high a temperature as possible.

3. Wait until the radiators are hot.

4. Switch the boiler off.

5. Wait around 10 minutes until the radiators are cold.

6. Bleed the radiators.

Start with the lower floors.

7. Open the bleed connection using the bleed key, keeping a rag

pressed against the connection.

8. Wait until water begins to come out of the bleed valve, then close

the bleed connection.

The water may still be hot.

9. Turn the boiler on.

10. Check the pressure of the installation.

If the water pressure is too low, add more water to the installation

(See Topping up the boiler with water).

11. Set the heating set point.

1

2

3

4

T000181-B

T000184-A

T000185-A

T000854-A

3

1

4

5

2

Page 13

13

15/10/2009 - 300017555-001-C SGC 24 SOL

5. Checking and maintenance

5.5 Draining the installation

It may become necessary to empty the water from the heating system

when the radiators have to be replaced, should there be a major

water leak or a risk of frost.

To do this, proceed as follows

1. Open the valves on all radiators connected to the heating system.

2. Cut the power supply to the boiler.

3. Wait around 10 minutes until the radiators are cold.

4. Connect an evacuation hose to the plug located at the lowest

level.

5. Place the end of the hose in a discharge sump or in a place where

the water discharged from the valve can not do any damage.

6. Open the filling/draw-off valve on the heating system.

The water may still be hot.

7. When no more water comes out of the drainage plug, close the

drainage valve.

1

2

3

4

T000181-B

T000185-A

T000858-A

Page 14

14

SGC 24 SOL 15/10/2009 - 300017555-001-C

6. Troubleshooting

6 Troubleshooting

6.1 Breakdown codes

In the event of a fault, the display indicates an alarm message by

alternately showing AL and a code from which the type of fault can

be determined.

6.1.1 Safety alarms

6.1.2 Sensor alarms

6.2 Before contacting the installer

` Try to restart the boiler once by pressing the key Q on the

control panel.

` If this fails after a second try to restart, inform the professional

responsible for maintaining the boiler.

` Note the following information on the appliance's rating plate:

- Boiler type

- Date of manufacture

- Serial no. of the appliance

- Type of gas used.

Alarm code Meaning

cA Igniter fault

cI Ionization error

tS Overheating alarm

PA No water

cd Communication error with the safety control box (card side)

c8 Internal error safety control box

A1 Communication error with the safety control box (box side)

tH Communication with the communicating remote interrupted

Alarm code Meaning

40 Fault external sensor

41 No outside sensor on start-up if outlet sensor B present

42 Fault outlet sensor B

50 or 51 DHW outlet sensor error DHW

58 or 59 Fault electronic manometer

D001040

Page 15

15

15/10/2009 - 300017555-001-C SGC 24 SOL

6. Troubleshooting

6.3 Incidents and solutions

Checks to make before calling your fitter

6.3.1 The burner is not working

It is cold.

` Check the boiler thermostat settings.

` If using a room temperature thermostat or a remote control

(Easymatic or Easyradio), check that it is set according to the

instructions.

It is cold. There is no domestic hot water

` Note the code displayed AL + _ _.

` Press button Q

until the red light goes out.

` Release the button. The boiler restarts.

` If there is a problem, contact your fitter, specifying the alarm

code.

C002175-A

Page 16

16

SGC 24 SOL 15/10/2009 - 300017555-001-C

6. Troubleshooting

6.3.2 The burner is operating but the radiators are cold

Air and water noise in the radiators

` Bleed the radiators.

` Top up the heating circuit with water.

` If it is often necessary to top up the installation with water,

contact your fitter.

` If the problem persists, consult your fitter.

The burner is operating but the radiators are cold

` Check that the boiler heating pump is operating correctly.

` If the problem persists, consult your fitter

6.3.3 The domestic hot water does not appear hot enough

Flow of water from the tap too high.

The higher the flow, the lower the temperature.

` Reduce the flow from the hot water tap.

` If several draw-off points are open at the same time, close one

or other of the points.

6.3.4 Hot water takes a very long time to reach certain draw-off points and not others

This is due to the length of the hot water pipes between the draw-off

points and the boiler.

The greater the length, the longer the time necessary for the hot

water to replace the colder water in the pipes.

Page 17

17

15/10/2009 - 300017555-001-C SGC 24 SOL

7. Technical characteristics

7 Technical characteristics

Boiler SGC 24 SOL

General Useful output 50 / 30 °C

(heating and DHW modes)

Nominal output kW 23.7

Minimum output

kW 6.0

Useful output 80 / 60 °C

(heating and DHW modes)

Nominal output kW 22.0

Minimum output kW 5.7

Power input

(heating and DHW modes)

Nominal output kW 22.8

Minimum output kW 5.9

Operating efficiency 80 / 60 °C (4) % 107.8

40 / 30 °C (4) % 110.1

Load and water temperature efficiency 100% Pn, Average temperature 70 °C % 96.8

30% Pn,Return temperature 30 °C % 110

Gas flow rate at Pn (15 °C- 1013 mbar) Natural gas H (G20)

m

3

/h

2.41

Natural gas L (G25)

m

3

/h

2.80

Gas flow rate at Pn Butane (G30) Kg/h 1.79

Maximum temperature (Safety thermostat cut-off) °C 110

Characteristics of the heating

circuit

Nominal water flow (

∆T = 20 K) l/h 1000

Rated net head (1000 l/h) mCE 1

Flow temperature °C 30 - 90

Maximum pressure bar 3

Expansion vessel l 12

Initial pressure of the expansion vessel bar 0.75

Minimum operating pressure bar 0.3

Characteristics of the

domestic hot water circuit

Specific flow at ∆T = 30K (2) (3) l/min 19

Flow per hour at ∆T = 35K (1) (3) l/h 560

Flow in 10 min at ∆T = 30K (2) (3) l/10 mm 190

Double coil hot water tank Water content Top up volume Aux V l 100

Solar volume Sun V l 100

Max operating pressure, DHW bar 10

Boiler heat exchanger Maximum operating temperature °C 90

Water content l 4.7

Exchange surface

m

2

0.7

Solar exchanger Glycol water capacity l 5.0

Exchange surface

m

2

1.0

Performance Standby consumption ∆T = 45K, TotalV kWh/24h 2.3

Cooling constant Cr Wh/24h·L·K 0.26

Diemasol A solar regulator Ambient temperature °C 0 - 40

Storage temperature °C -20 - +70

Range of measurement °C -40 - +250

Max. current A / V 4 / 250

Power consumption VA about 2

Electrical specifications Electrical connection V / Hz / A 230 / 50 / 6

Power consumption W 1 - 134

Insulation class DIN 40050 IP 42 (IPX2D)

Battery backup (Control panel) 2 years

minimum

Page 18

18

SGC 24 SOL 15/10/2009 - 300017555-001-C

7. Technical characteristics

(1) Heat exchanger inlet temperature: 80 °C

Domestic hot water temperature: 45 °C

(2) DHW setting: 60 °C

Average domestic hot water temperature: 40 °C

Boiler setting: 80 °C

(3) Cold water temperature: 10 °C

8 Energy savings

8.1 Energy-saving advice

` Keep the room in which the boiler is installed well ventilated.

` Do not obstruct aeration grates (even partially). They help to

reduce humidity in the home. The more humid a home, the

more heating it consumes.

` Do not cover the radiators. Do not hang curtains in front of the

radiators.

` Install reflector panels behind the radiators.

` Insulate pipes to prevent thermal losses and condensation.

` Turn heating off when airing a room (5 minutes a day is

sufficient)

Avoid deregulating the thermostat. Place the start/stop switch

on Off.

` Close the radiators in rooms not in use.

` Do not run hot (or cold) water pointlessly.

` Fit a water-saving shower head to save up to 40 energy.

` Take showers rather than baths.A bath consumes twice as

much water and energy.

` Do not shut down heating completely if you are absent.

Lower the thermostat by 3-4°C.

` Use the sun's heat as much as possible.

8.2 Room thermostat and settings

The type of thermostat and its setting have a considerable influence

on energy consumption.

A few tips:

` A modulable thermostat, possibly in combination with

thermostatic valve radiators, saves energy and offers

considerable comfort. This combination allows you to set the

temperature on each flow.

In the room in which the room thermostat is installed, do not fit

thermostatic valve radiators.

` Completely closing and opening thermostatic valve radiators

causes undesirable temperature fluctuations.

Open and close thermostatic valves in small steps.

` Lower the room thermostat when you air the rooms.

` When setting an hourly programmable thermostat, bear days

when you are absent and holidays in mind.

Dimensions Height mm 1710

Width mm 600

Depth mm 657

Shipping weight kg 196

Boiler SGC 24 SOL

Page 19

19

15/10/2009 - 300017555-001-C SGC 24 SOL

7. Technical characteristics

Warranty

You have just purchased one of our appliances and we thank you

for the trust you have placed in our products. Please note that your

appliance will provide good service for a longer period of time if it is

regularly checked and maintained. Your fitter and our customer

support network are at your disposal at all times.

Warranty terms

Starting from the purchase date shown on the original fitter's

invoice, your appliance has a contractual guarantee against any

manufacturing defect.

The length of the guarantee is mentioned in the price catalogue.

The manufacturer is not liable for any improper use of the appliance

or failure to maintain or install the unit correctly (the user shall take

care to ensure that the system is installed by a qualified fitter). In

particular, the manufacturer shall not be held responsible for any

damage, loss or injury caused by installations which do not comply

with the following:

- applicable local laws and regulations

- specific requirements relating to the installation, such as national

and/or local regulations

- the manufacturer's instructions, in particular those relating to the

regular maintenance of the unit

- the rules of the profession

The warranty is limited to the exchange or repair of such parts as

have been recognised to be faulty by our technical department and

does not cover labour, travel and carriage costs. The warranty shall

not apply to the replacement or repair of parts damaged by normal

wear and tear, negligence, repairs by unqualified parties, faulty or

insufficient monitoring and maintenance, faulty power supply or the

use of unsuitable fuel. Sub-assemblies such as motors, pumps,

electric valves etc. are guaranteed only if they have never been

dismantled.

France

The preceding dispositions are not exclusive of benefits for the

purchaser of the legal guarantee as stated in Civil Code articles

1641 to 1648.

Poland

Warranty conditions are included in the warranty card.

Switzerland

The application of the warranty is subject to the terms and

conditions of sale, delivery and warranty of the company marketing

our products.

Belgium

The preceding dispositions about the contractual guarantee are not

exclusive of profit if the need arises for the purchaser in Belgium of

the applicable legal dispositions on hidden defects.

Italy

The duration of our warranty is shown on the certificate delivered

with the appliance.

Our liability as manufacturer may not be invoked in respect of

incorrect use of the appliance, incorrect or insufficient maintenance

thereof, or incorrect installation of the appliance (you must

therefore ensure that installation and maintenance operations are

carried out respectively by a qualified professional and by an after

sales service company).

The legislation laid down by European Directive 99/44/EEC,

transposed by Legislative Decree No. 24 of 2 February 2002

published in O.J. No. 57 of 8 March 2002, continues to apply.

Russia

The foregoing provisions in no way affect the rights of the

consumer, which are guaranteed by the legislation of the Russian

Federation as regards hidden defects.

The terms and conditions of warranty and the terms and conditions

of application of the warranty are indicated on the warranty form.

The warranty shall not apply as regards the replacement or repair

of wearing parts under normal use. Such parts include

thermocouples, injection nozzles, flame control and ignition

systems, fuses and gaskets.

Turkey

Due to the laws and regulations the product life for this product is

10 years. During that time the producer and/or the distributor has

to provide after sales services and spare parts.

Other countries

The above provisions do not restrict the benefit of the legal laws

regarding hidden defects applicable in the buyer's country.

Page 20

© Copyright

All technical and technological information contained in these technical instructions, as well as any

drawings and technical descriptions supplied, remain our property and shall not be multiplied

without our prior consent in writing.

Subject to alterations.

15/10/2009

T000249-B

DE DIETRICH THERMIQUE

57, rue de la Gare F- 67580 MERTZWILLER - BP 30

DE DIETRICH THERMIQUE S.A.S.

www.dedietrich-thermique.fr

FR

Direction des Ventes France

57, rue de la Gare

F- 67580 MERTZWILLER

+33 (0)3 88 80 27 00

+33 (0)3 88 80 27 99

DE DIETRICH REMEHA GmbH

www.dedietrich-remeha.de

VAN MARCKE

www.vanmarcke.be

WALTER MEIER (Klima Schweiz) AG

www.waltermeier.com

DE

BE

CH

NEUBERG S.A.

www.dedietrich-heating.com

LU

DE DIETRICH

RU

Rheiner Strasse 151

D- 48282 EMSDETTEN

+49 (0)25 72 / 23-5

+49 (0)25 72 / 23-102

info@dedietrich.de

Weggevoerdenlaan 5

B- 8500 KORTRIJK

+32 (0)56/23 75 11

Bahnstrasse 24

CH-8603 SCHWERZENBACH

+41 (0) 44 806 44 24

+41 (0) 44 806 44 25

39 rue Jacques Stas

L- 2010 LUXEMBOURG

+352 (0)2 401 401

ch.klima@waltermeier.com

DE DIETRICH

www.dedietrich-heating.com

CN

Room 512, Tower A, Kelun Building

12A Guanghua Rd, Chaoyang District

C-100020 BEIJING

+86 (0)106.581.4017

+86 (0)106.581.4018

+86 (0)106.581.7056

+86 (0)106.581.4019

contactBJ@dedietrich.com.cn

Serviceline +41 (0)8 00 846 846

WALTER MEIER (Climat Suisse) SA

www.waltermeier.com

Z.I. de la Veyre B, St-Légier

CH-1800 VEVEY 1

+41 (0) 21 943 02 22

+41 (0) 21 943 02 33

ch.climat@waltermeier.com

Serviceline +41 (0)8 00 846 846

ÖAG AG

www.oeag.at

AT

Schemmerlstrasse 66-70

A-1110 WIEN

+43 (0)50406 - 61624

+43 (0)50406 - 61569

dedietrich@oeag.at

AD001NU-AC

www.dedietrich-otoplenie.ru

ул. Гил яр ов ск ого, д. 8

129090 г. Москва

+7 495 988-43-04

+7 495 988-43-04

dedietrich@nnt.ru

офис 52

Loading...

Loading...