Page 1

EN

Independent domestic hot water tanks

BL 150...500

M001635-B

Installation, User

and Service

Manual

300019417-001-C

Page 2

Contents

1 Introduction ................................................................................................4

1.1 Used symbols .......................................................4

1.2 Abbreviations ........................................................4

1.3 General ..................................................................4

1.3.1 Manufacturer's liability .............................................4

1.3.2 Installer's liability .....................................................5

1.3.3 User's liability ..........................................................5

1.4 Homologations ......................................................6

1.4.1 Certifications ...........................................................6

1.4.2 Directive 97/23/EC ..................................................6

1.4.3 Factory test .............................................................6

2 Safety instructions and recommendations ..............................................7

2.1 Safety instructions ...............................................7

2.2 Recommendations ................................................7

3 Technical description ................................................................................8

3.1 General description ..............................................8

3.2 Technical characteristics .....................................8

3.2.1 Characteristics of the DHW calorifier ......................8

3.2.2 Specifications of the DHW sensor ...........................9

4 Installation ................................................................................................10

4.1 Regulations governing installation ...................10

4.2 Package list .........................................................10

4.2.1 Standard delivery ..................................................10

4.2.2 Accessories ...........................................................10

4.3 Choice of the location ........................................11

4.3.1 Data plate ..............................................................11

4.3.2 Location of the appliance ......................................11

4.3.3 Main dimensions ...................................................12

4.4 Levelling ..............................................................13

4.5 Hydraulic installation diagram ..........................13

4.5.1 Safety unit (For France ) .......................................14

1

01/03/2011 - 300019417-001-C

Page 3

4.6 Hydraulic connections .......................................15

4.6.1 Hydraulic connection of the primary circuit (exchanger

circuit) ....................................................................15

4.6.2 Connecting the tank to the domestic water circuit

(secondary circuit) .................................................15

4.7 Electrical connections ........................................17

4.7.1 Recommendations ................................................17

4.7.2 Fitting the DHW sensor .........................................18

5 Commissioning ........................................................................................19

5.1 Putting the appliance into operation ................19

6 Checking and maintenance .....................................................................20

6.1 General instructions ...........................................20

6.2 Checking the magnesium anode .......................20

6.3 Safety valve or safety unit .................................20

6.4 Cleaning the casing material .............................20

6.5 Replacing the magnesium anode and

descaling .............................................................20

6.6 Maintenance form ...............................................22

7 Spare parts ................................................................................................23

7.1 General ................................................................23

7.2 Spare parts ..........................................................23

7.2.1 Domestic hot water tanks ......................................24

7.2.2 Options ..................................................................29

8 Warranty ....................................................................................................34

8.1 General ................................................................34

8.2 Warranty terms ...................................................34

Contents

2

01/03/2011 - 300019417-001-C

Page 4

3

01/03/2011 - 300019417-001-C

Page 5

1 Introduction

1.1 Used symbols

In these instructions, various danger levels are employed to draw the

user's attention to particular information. In so doing, we wish to

safeguard the user's safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

CAUTION

Risk of material damage.

Signals important information.

¼ Signals a referral to other instructions or other pages in the

instructions.

1.2 Abbreviations

4 CFC: Chlorofluorocarbon

4 DHW: Domestic hot water

1.3 General

1.3.1. Manufacturer's liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

BL 150...500

1. Introduction

01/03/2011 - 300019417-001-C

4

Page 6

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.3.2. Installer's liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.3.3. User's liability

To guarantee optimum operation of the appliance, the user must

respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Call on qualified professionals to carry out installation and initial

start up.

4 Get your fitter to explain your installation to you.

4 Have the required checks and services done.

4 Keep the instruction manuals in good condition close to the

appliance.

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

1. Introduction

BL 150...500

5

01/03/2011 - 300019417-001-C

Page 7

1.4 Homologations

1.4.1. Certifications

This product complies to the requirements to the european directives

and following standards:

4 2006/95/EC Low Voltage Directive.

Reference Standard: EN 60.335.1.

4 2004/108/EC Electromagnetic Compatibility Directive.

Reference Standards: EN 50.081.1, EN 50.082.1, EN 55.014

1.4.2. Directive 97/23/EC

This product conforms to the requirements of european directive 97 /

23 / EC, article 3, paragraph 3, on pressure equipment.

1.4.3. Factory test

Before leaving the factory, each appliance is tested for the following:

4 Water tightness

4 Air tightness

4 Electrical safety.

BL 150...500 1. Introduction

01/03/2011 - 300019417-001-C

6

Page 8

2 Safety instructions and

recommendations

2.1 Safety instructions

CAUTION

Before any work, switch off the mains supply to the

appliance.

CAUTION

In order to limit the risk of being scalded, the installation of

a thermostatic mixing valve on the domestic hot water flow

piping is compulsory.

2.2 Recommendations

CAUTION

Do not neglect to service the appliance. Service the

appliance regularly to ensure that it operates correctly.

WARNING

Only qualified professionals are authorised to work on the

appliance and the instalation.

WARNING

Heating water and domestic water must not come into

contact with each other. Domestic water must not circulate

via the exchanger.

4 To take advantage of the guarantee, no modifications must be

made to the appliance.

4 To reduce heat losses as much as possible, insulate the pipes.

Casing components

Only remove the casing for maintenance and repair operations. Put

the casing back in place after maintenance and repair operations.

Instructions stickers

The instructions and warnings affixed to the appliance must never be

removed or covered and must remain legible during the entire lifespan

of the appliance. Immediately replace damaged or illegible

instructions and warning stickers.

2. Safety instructions and recommendations

BL 150...500

7

01/03/2011 - 300019417-001-C

Page 9

3 Technical description

3.1 General description

BL 150...500 are high performance independent domestic hot water

tanks.

DHW calorifiers BL 150...500 can be connected to central heating

boilers used for heating domestic hot water.

Main parts:

4 The tanks are made of high quality steel lined with food quality

standard enamel vitrified at 850°C, which protects the tank from

corrosion.

4 The heat exchanger welded into the tank is made of smooth

tubing, the external surface of which, which is in contact with

domestic water, is enamelled.

4 The appliance is insulated by CFC-free polyurethane foam, which

reduces heat losses to a minimum

4 The insulating material can be easily detached from the tank. This

measure facilitates the recycling of materials.

4 The tank is protected against corrosion by a magnesium anode

which should be checked every 2 years and replaced if need be.

The tanks with the greatest capacity (BL 300, BL 400, BL 500) are

fitted with 2 protection anodes.

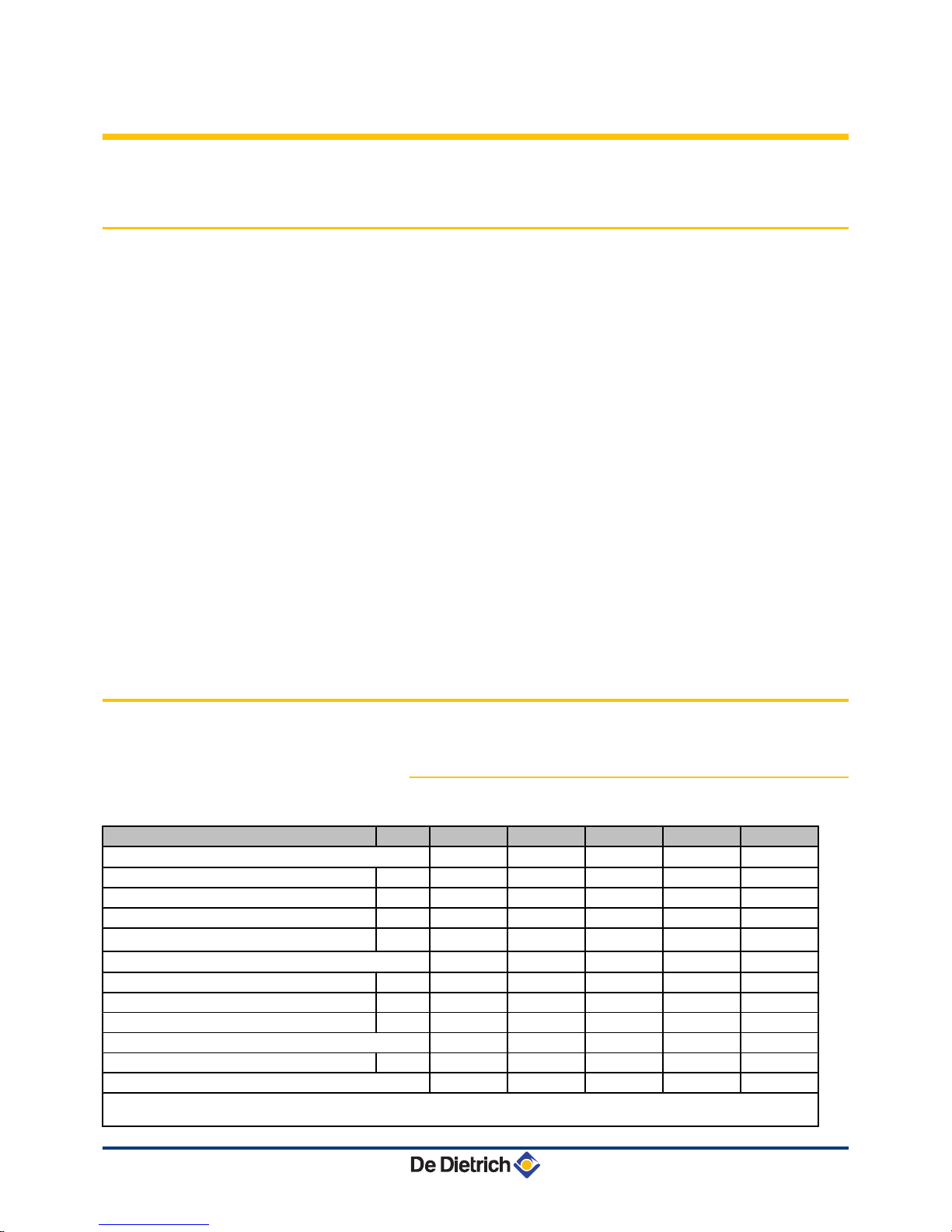

3.2 Technical characteristics

3.2.1. Characteristics of the DHW calorifier

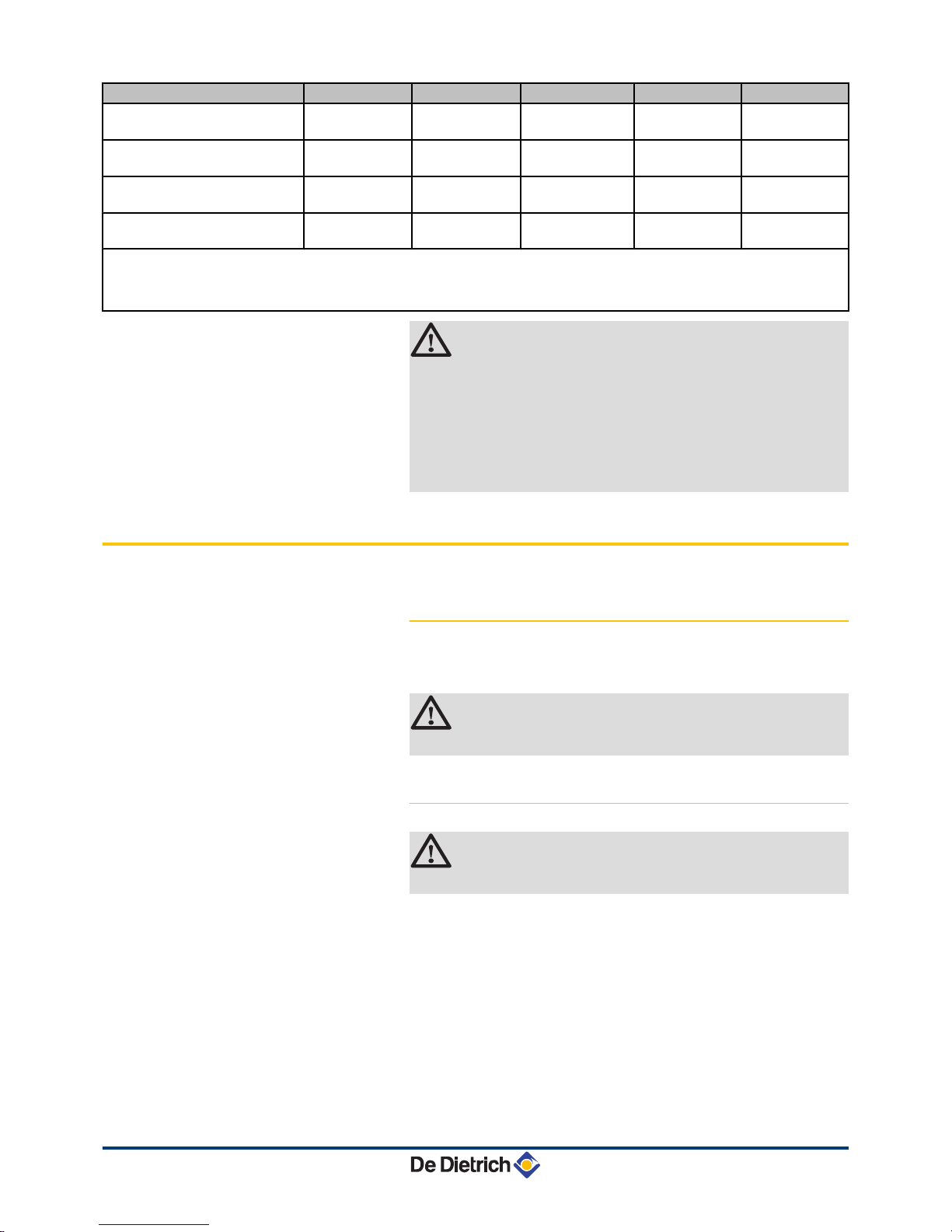

BL 150 BL 200 BL 300 BL 400 BL 500

Primary circuit (heating water)

Maximum operating temperature °C 90 90 90 90 90

Maximum operating pressure bar 10 10 10 10 10

Exchanger capacity l 4.9 5.7 8.0 11.2 14.9

Exchange surface

m

2

0.72 0.84 1.19 1.67 2.22

Secondary circuit (domestic water)

Maximum operating temperature °C 90 90 90 90 90

Maximum operating pressure bar 10 10 10 10 10

Water content l 150 200 300 400 500

Weight

Shipping weight - DHW tank package kg 88.5 107.5 155 238 290

Performances related to the boiler type

(1) Primary temperature: 80 °C - Domestic cold water inlet: 10 °C - Domestic hot water outlet: 45 °C - Primary flow rate: 3 m3/h

(2) Primary temperature: 80 °C - Domestic cold water inlet: 10 °C - Domestic hot water outlet: 40 °C - Domestic hot water storage: 60 °C

BL 150...500 3. Technical description

01/03/2011 - 300019417-001-C

8

Page 10

BL 150 BL 200 BL 300 BL 400 BL 500

Power exchanged

(1)

kW 28 33 44 55 70

Flow per hour (∆T = 35 °C)

(1)

l/h 690 810 1080 1350 1720

Specific flow (∆T = 30 °C) (10 minutes)

(2)

l/h 220 325 510 620 780

(1) Primary temperature: 80 °C - Domestic cold water inlet: 10 °C - Domestic hot water outlet: 45 °C - Primary flow rate: 3 m3/h

(2) Primary temperature: 80 °C - Domestic cold water inlet: 10 °C - Domestic hot water outlet: 40 °C - Domestic hot water storage: 60 °C

3.2.2. Specifications of the DHW sensor

Temperature in °C 10 20 25 30 40 50 60 70 80

Resistance in ohm 19691 12474 10000 8080 5372 3661 2536 1794 1290

3. Technical description BL 150...500

9

01/03/2011 - 300019417-001-C

Page 11

4 Installation

4.1 Regulations governing installation

CAUTION

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

CAUTION

France: The installation must comply in all matters to the

standards and rules which govern the work and

interventions in individual and collective homes, and other

constructions.

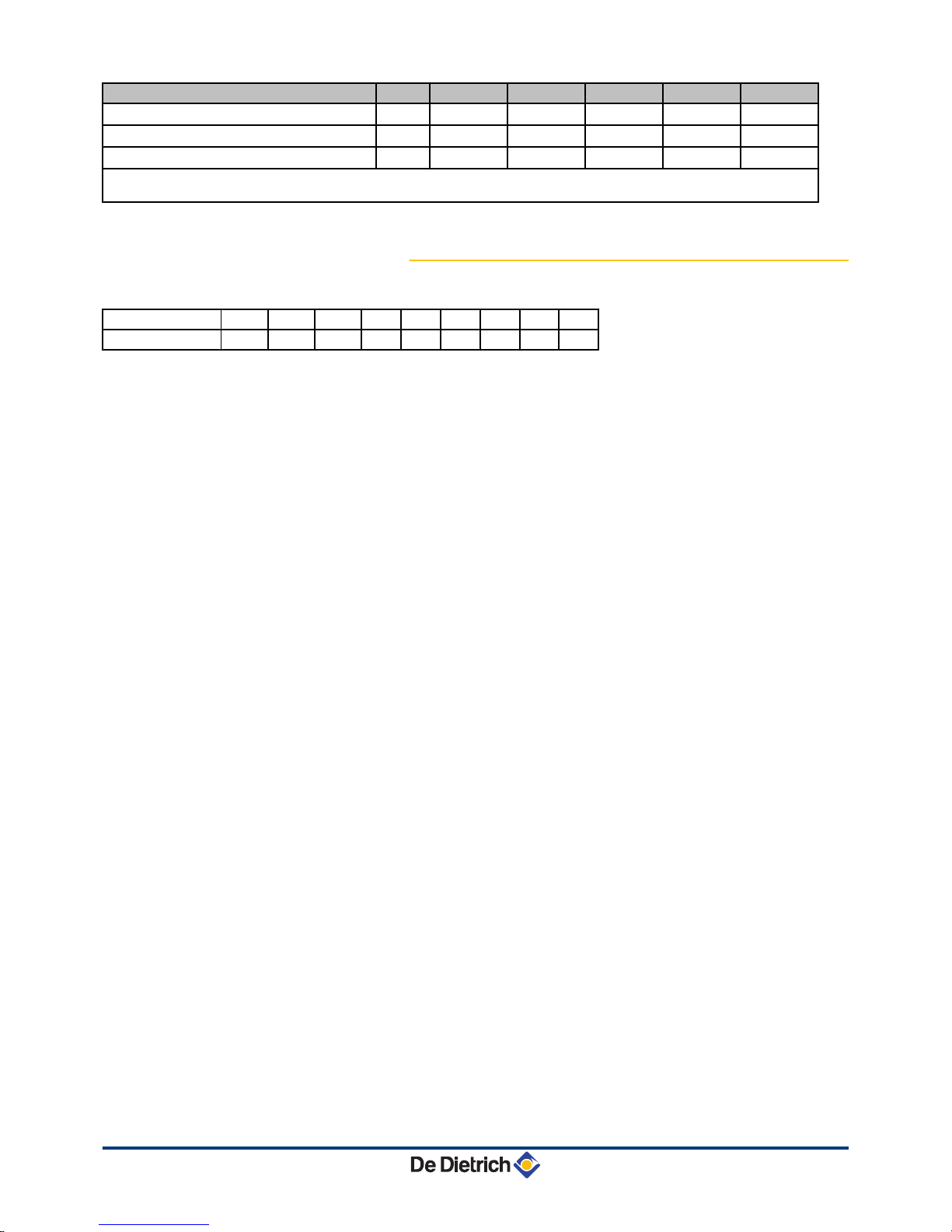

4.2 Package list

4.2.1. Standard delivery

The delivery includes:

4 One DHW tank.

4 One installation, use and service manual.

BL 150 BL 200 BL 300 BL 400 BL 500

DHW tank package

EC 441 EC 442 EC 443 EC 444 EC 445

4.2.2. Accessories

Various options are available depending on the configuration of the

installation:

BL 150 BL 200 BL 300 BL 400 BL 500

Impressed current anode

AJ 38 AJ 38 AJ 38 AM 7 AM 7

Titanium anode

(1)

EC 414 EC 414 - - -

Single phase shielded resistor

2.2 kW

EC 410 - - - -

Multi-voltage shielded resistor

3.3 kW

- - EC 412 - -

(1) The titanium anode can only be fitted to the DHW tank if this is connected to a boiler equipped with a Diematic 3 control panel which

incorporates the TAS ® function.

(2) The EG 88 steatite heating resistance must be accompanied by the installation of the AJ 38 impressed current anode in the top buffer tank

in order to ensure adequate protection of the tank against corrosion.

BL 150...500 4. Installation

01/03/2011 - 300019417-001-C

10

Page 12

BL 150 BL 200 BL 300 BL 400 BL 500

Multi-voltage shielded resistor

4.5 kW

- - - EC 413 EC 413

Multi-voltage steatite heating

resistance 2.4 kW

- EC 411 - - -

Multi-voltage steatite heating

resistance 3 kW

- -

EG 88

(2)

- -

SLA2 control system for load

pump

EC 320 EC 320 EC 320 EC 320 EC 320

(1) The titanium anode can only be fitted to the DHW tank if this is connected to a boiler equipped with a Diematic 3 control panel which

incorporates the TAS ® function.

(2) The EG 88 steatite heating resistance must be accompanied by the installation of the AJ 38 impressed current anode in the top buffer tank

in order to ensure adequate protection of the tank against corrosion.

WARNING

4 The impressed current anode and the shielded

electrical resistor cannot be fitted simultaneously.

4 Respect the recommended anode / electrical resistor

combinations as the electrical resistor is combined

with a magnesium anode which, with the anode in the

top section already in place, is calculated to protect

the enamelled tank correctly.

4.3 Choice of the location

4.3.1. Data plate

The nameplate affixed to the tank provides important information

regarding the appliance: serial number, model, etc.

CAUTION

The rating plate must be accessible at all times.

4.3.2. Location of the appliance

CAUTION

Put the appliance in a frost-free location.

4 Place the appliance as close as possible to draw-off points in order

to minimise energy losses through the pipes.

4 Place the appliance on a base frame to facilitate cleaning of the

premises.

4. Installation

BL 150...500

11

01/03/2011 - 300019417-001-C

Page 13

4.3.3. Main dimensions

M001637-C

Ø G

BL 150BL 200-500

H

A

30

B

C

D

E

F

J

1

7

7

7

11

11

2

3

4

5

6

1

BL 200

A

Domestic hot water outlet (G 1)

Z

Exchanger inlet (G 1)

E

Circulation (G ¾)

R

Domestic cold water inlet (G 1)

BL 150 - BL 200 - BL 300: Drain opening

T

Exchanger outlet (G 1)

Y

Drain opening (G 1)

except BL 150 - BL 200 - BL 300

U

Magnesium anode

BL 200: no anode on the side trap

a

Domestic hot water sensor

(1) : Adjustable feet

G : Exterior cylindrical threading, sealed by sheet gasket

BL 150 BL 200 BL 300 BL 400 BL 500

A

- - - 68 68

B

188 188 188 211 206

C

268 268 268 302 304

D

493 408 543 804 791

E

588 633 768 991 986

F

- 948 1488 1381 1468

G (Ø)

600 600 600 750 750

H

900 1180 1754 1589 1725

J

941 - - - -

BL 150...500 4. Installation

01/03/2011 - 300019417-001-C

12

Page 14

4.4 Levelling

The DHW tank is levelled using the feet (delivered in the instructions

pack) to be screwed to the bottom of the DHW tank:

4 BL 150 - BL 200 - BL 300: 3 adjustable feet

4 BL 400 - BL 500: 4 adjustable feet

(1) Adjustment range: 30 to 40 mm

WARNING

4 We recommend removing the flexible casing before

handling (installation of the adjustable feet,

placement of the domestic hot water tank, electrical

connection, etc.).

4 Put the casing back in place when work has been

completed.

4.5 Hydraulic installation diagram

1

Heating flow

2

Heating return

3

3-bar safety valve

4

Pressure gauge

7

Automatic air vent

9

Isolating valve

16

Expansion vessel

M001639-C

M001640-A

30

4. Installation BL 150...500

13

01/03/2011 - 300019417-001-C

Page 15

17

Drain cock

18

Filling the heating circuit

24

DHW tank heat exchanger primary inlet

25

DHW tank heat exchanger primary outlet

26

DHW pump

27

Non-return valve

28

Domestic cold water inlet

29

Safety unit

7-bar safety valve

30

Safety unit

32

D.H.W. loop back pump

51

Thermostatic valve

54

End of the discharge pipe free and visible 2 to 4 cm above

the flow funnel

56

Circulation

57

Domestic hot water outlet

64

Circuit A: direct heating circuit (example: radiators)

4.5.1. Safety unit (For France )

9

Isolating valve

28

Domestic cold water inlet

29

Pressure reducer

30

Safety unit

54

End of the discharge pipe free and visible 2 to 4 cm above

the flow funnel

n

Details of the safety unit

a

Cold water inlet with an integrated non-return valve

b

Connection to the DHW tank cold water inlet

c

Stop cock

d

7-bar safety valve

e

Drain opening

C000711-D

a

b

c

d

(54)

2 cm

e

28

30

9 29

BL 150...500 4. Installation

01/03/2011 - 300019417-001-C

14

Page 16

4.6 Hydraulic connections

4.6.1. Hydraulic connection of the primary circuit

(exchanger circuit)

¼ See diagram : "Hydraulic installation diagram", page 13.

For the hydraulic connection of 150 l to 300 l tanks and the boiler (right

or left), we offer optional hydraulic connection kits.

For connection using these kits, refer to the instructions delivered with

them.

4.6.2. Connecting the tank to the domestic water

circuit (secondary circuit)

When making the connections, it is imperative that the standards and

corresponding local directives are respected.

n

Specific precautions

Before making the connection, rinse the drinking water inlet

pipes in order not to introduce metal or other particles into the

appliance's tank.

n

Provision for Switzerland

Make the connections according to the instructions of the Société

Suisse de l'Industrie du Gaz et des Eaux. Comply with local

instructions from water distribution plants.

n

Safety valve

CAUTION

In accordance with safety rules, a safety valve sealed at

7 bar is fitted to the domestic cold water inlet on the DHW

tank.

France: We recommend NF-marked hydraulic membrance safety

control units.

4 Integrate the safety valve in the cold water circuit.

4 Install the safety valve close to the tank in a place which is easy

to access.

n

Size

The safety device and its connection to the DHW tank must be of at

least the same diameter as the domestic cold water supply pipe of

the tank domestic circuit.

4. Installation

BL 150...500

15

01/03/2011 - 300019417-001-C

Page 17

No isolating devices should be located between the valve or safety

device and tank.

The safety device drain pipe must have a uniform and sufficient

gradient and its diameter must be at least equal to that of the outlet

opening of the safety device (to prevent the flow of water being

hindered if the pressure is too high).

The outlet pipe in the valve or safety assembly must not be blocked.

Germany: Define the dimensions of the safety valve in accordance

with the DIN 1988 standard.

Capacity (litres)

Dimension of the valve

Min. dimension of the inlet

connection

Heating output

(kW) (max)

< 200 R or Rp 1/2 75

200 to 1000 R or Rp 3/4 150

Fit the safety valve above the tank to avoid draining the tank during

servicing.

Install a drainage valve at the lowest point on the tank.

n

Isolating valves

Hydraulically isolate the primary and secondary circuits using stop

valves to facilitate maintenance operations on the unit. The valves

make it possible to carry out maintenance on the tank and its

components without draining the entire installation.

These valves are also used to isolate the tank unit when conducting

a pressurised check on the leak tightness of the installation if the test

pressure is greater than the admissible operating pressure.

CAUTION

If the mains pipes are made of copper, fit a sleeve made

of steel, cast iron or any other insulating material between

the tank's hot water outlet and the pipes to prevent

corrosion to the connection.

n

Connecting the domestic cold water

Make the connection to the cold water supply according to the

hydraulic installation diagram.

¼ Refer to the installation and maintenance instructions of the

boiler.

Install a water drain in the boiler room and a "funnel-siphon" for the

safety unit.

The components used for the connection to the cold water supply

must comply with the prevailing standards and regulations in the

country concerned. Fit a one-way valve to the domestic cold water

circuit.

BL 150...500

4. Installation

01/03/2011 - 300019417-001-C

16

Page 18

n

Pressure reducer

If the mains pressure exceeds 80% of the valve or safety unit setpoint

(e.g.: 5.5 bar for a safety unit set at 7 bar), a pressure reducer must

be fitted upstream of the appliance. Install the pressure reducer

downstream the water meter in such a way as to ensure the same

pressure in all of the installation pipes.

n

Domestic hot water circulation loop

To guarantee the availability of hot water as soon as the taps are

turned on, a circulation loop between the draw-off points and the

recirculation pipes in the DHW tank can be installed. A non-return

valve must be included in this loop.

n

Measures to take to prevent hot water flow reversal

Fit a one-way valve to the domestic cold water circuit.

4.7 Electrical connections

4.7.1. Recommendations

WARNING

Only qualified professionnals may carry out electrical

connections, always with the power off.

4. Installation BL 150...500

17

01/03/2011 - 300019417-001-C

Page 19

4.7.2. Fitting the DHW sensor

D000882

1

3

2

4

5

3

BL 150...500 4. Installation

01/03/2011 - 300019417-001-C

18

Page 20

5 Commissioning

5.1 Putting the appliance into operation

CAUTION

Initial commissioning must be done by a qualified

professional.

1. Flush the domestic circuit and fill the tank through the cold water

inlet tube.

2. Open a hot water tap.

3. Completely fill the DHW tank via the cold water inlet pipe, leaving

the hot water valve open.

4. Close the hot water valve when the water flow is regular, without

noise in the pipes.

5. Degas all DHW pipes by repeating steps 2 to 4 for each hot water

tap.

Carefully degas the DHW tank and the distribution network

in order to eliminate noises and hammering caused by

trapped air moving in the pipes during draw-off.

6. Vent the tank exchanger circuit using the bleed valve provided for

this purpose.

7. Check the safety devices (particularly the valve or safety unit),

referring to the instructions provided with these components.

CAUTION

"During the heating process, a certain amount of water

may flow through the valve or safety unit; this is caused by

water expansion. This phenomenon is completely normal

and must in no event be hindered".

5. Commissioning BL 150...500

19

01/03/2011 - 300019417-001-C

Page 21

6 Checking and maintenance

6.1 General instructions

CAUTION

4 Maintenance operations must be done by a qualified

engineer.

4 Only original spare parts must be used.

6.2 Checking the magnesium anode

Carry out a visual check of the anode.

¼ See chapter: "Replacing the magnesium anode and

descaling", page 20.

4 The anode must be replaced if its diameter is less than 15 mm.

4 The magnesium anode must be checked at least every 2 years.

After the first check, determine the frequency of future checks on

the basis of anode wear.

6.3 Safety valve or safety unit

The valve or safety assembly must be operated at least once a

month in order to ensure that it is operating correctly and to prevent

possible overpressure which would damage the DHW tank.

WARNING

Failure to comply with this maintenance rule may cause

deterioration of the DHW tank and the cancellation of the

guarantee.

6.4 Cleaning the casing material

Clean the outside of appliances using a damp cloth and a mild

detergent.

6.5 Replacing the magnesium anode and descaling

In regions with hard water, annual descaling of the appliance is

recommended in order to maintain its performance.

BL 150...500

6. Checking and maintenance

01/03/2011 - 300019417-001-C

20

Page 22

Have a lip gasket and a retainer ring on hand for the

inspection trap.

1. Cut off the cold water supply and drain the DHW tank.

2. Remove the inspection traps.

Model BL 150 BL 200 BL 300 BL 400 BL 500

Diagram B A + C A + B A + D A + D

3. Check the anodes and replace them if necessary.

4. Remove limescale deposits in the form of sludge or strips in the

bottom of the tank. On the other hand, do not touch limescale

adhering to the walls of the tank as it provides effective protection

against corrosion and improves the insulation of the DHW tank.

5. Remove limescale deposits from the exchanger to guarantee its

performance.

6. Replace the gasket A and position it in the inspection hatch,

taking care to place its lug (lip gasket) towards the outside of the

DHW tank.

CAUTION

Each time it is opened, the lip gasket + retainer ring unit

must be replaced to guarantee tightness.

7. Fit the unit together.

CAUTION

Use a dynamometric spanner.

The flange mounting bolts must not be excessively tight.

Torque load:

Lip gasket 6 N·m +1/-0

Sheet gasket 15 N·m

Approximately 6 N·m is obtained by manipulating the box

spanner with the small lever and 15 N·m by manipulating

it with the large lever.

8. After reassembly, check the watertightness of the lateral flange.

9. Switch on.

M001642-F

6x

1

A

M001641-E

6x

1

B

M001647-D

6x

1

C

M001643-E

8x

1

D

6. Checking and maintenance

BL 150...500

21

01/03/2011 - 300019417-001-C

Page 23

6.6 Maintenance form

No.

_____

Date

_________

Checks made

______________________________

Remarks

_____________________By_______________

Signature

____________

BL 150...500 6. Checking and maintenance

01/03/2011 - 300019417-001-C

22

Page 24

7 Spare parts

7.1 General

When it is observed subsequent to inspection or maintenance work

that a component in the appliance needs to be replaced, use only

original spare parts or recommended spare parts and equipment.

To order a spare part, give the reference number shown

on the list.

7.2 Spare parts

Spare parts list reference: 300019417-002-C

7. Spare parts BL 150...500

23

01/03/2011 - 300019417-001-C

Page 25

7.2.1. Domestic hot water tanks

n

BL 150

L000115-C

1

4

2

3

7

6

5

10

12

8

9

13

11

3x

Markers Reference Description

1

200015416 Top black casing

2

200007092 Complete top mounting

3

89705511 Seal kit 7 mm + retainer ring

4

97860646 Adjustable foot M10 x 35

5

89658518 Side cover Ø 82 with anode + seal

6

95013133 Lip seal outside Ø 82

7

89708901 Complete anode Ø 33 length 330

8

94974527 Nylon brace

9

95014035 Seal ø 35 x 8.5 x 2

10

200015430 Complete side cover

11

300019410 Casing ferrule

12

95365009 Sensor attachment lug

13

200017440 Casing screw

BL 150...500 7. Spare parts

01/03/2011 - 300019417-001-C

24

Page 26

n

BL 200

L000116-D

15

16

21

22

23

17

24

20

19

18

12

13

11

3x

Markers Reference Description

11

300019411 Casing ferrule

12

95365009 Sensor attachment lug

13

200017440 Casing screw

15

300019414 Top cover

16

89555506 Complete top mounting Ø 112

17

89705511 Seal kit 7 mm + retainer ring

18

97860646 Adjustable foot M10 x 35

19

89658526 Complete lateral trap ø 82

20

95013133 Lip seal outside Ø 82

21

89608950 Complete anode Ø 33 length 420

22

94974527 Nylon brace

23

95014035 Seal ø 35 x 8.5 x 2

24

200015430 Complete side cover

7. Spare parts BL 150...500

25

01/03/2011 - 300019417-001-C

Page 27

n

BL 300

L000113-D

13

11

3x

12

30

31

32

36

39

38

37

40

34

35

33

34

35

Markers Reference Description

11

300019412 Casing ferrule

12

95365009 Sensor attachment lug

13

200017440 Casing screw

30

300019414 Top black casing

31

89555501 Complete top mounting Ø 112

32

89705511 Seal kit 7 mm + retainer ring

33

89588912 Complete anode Ø 33 length 290

34

94974527 Nylon brace

35

95014035 Seal ø 35 x 8.5 x 2

36

97860646 Adjustable foot M10 x 35

37

Side cover Ø 82 with anode + seal

38

95013133 Lip seal outside Ø 82

39

89708901 Complete anode Ø 33 length 330

40

200015430 Complete side cover

BL 150...500 7. Spare parts

01/03/2011 - 300019417-001-C

26

Page 28

n

BL 400

L000114-D

12

13

11

3x

45

46

47

48

49

50

55

53

52

51

54

49

50

Markers Reference Description

11

300019422 Casing ferrule

12

95365009 Sensor attachment lug

13

200017440 Casing screw

45

300019421 Top black casing

46

89555505 Cover Ø 112 with seal + screws

47

89705511 Seal kit 7 mm + retainer ring

48

89708901 Complete anode Ø 33 length 230

49

94974527 Nylon brace

50

95014035 Seal ø 35 x 8.5 x 2

51

97860646 Adjustable foot M10 x 35

52

200007111 Complete lateral trap ø 170

53

95013141 Sheet gasket Ø 170x117x3

54

89608950 Complete anode Ø 33 length 420

55

200015439 Complete side cover

7. Spare parts BL 150...500

27

01/03/2011 - 300019417-001-C

Page 29

n

BL 500

M001646-F

13

11

3x

12

60

63

64

65

69

68

67

66

63

64

65

61

62

Markers Reference Description

11

300019423 Casing ferrule

12

95365009 Sensor attachment lug

13

200017440 Casing screw

60

300019421 Top black casing

61

200007273 Cover Ø 112 with seal + screws

62

89705511 Seal kit 7 mm + retainer ring

63

89628562 Complete anode Ø 33 length 450

64

94974527 Nylon brace

65

95014035 Seal ø 35 x 8.5 x 2

66

97860646 Adjustable foot M10 x 35

67

200007112 Side cover Ø 170 with anode + seal

68

95013141 Sheet gasket Ø 170x117x3

69

200015439 Complete side cover

BL 150...500 7. Spare parts

01/03/2011 - 300019417-001-C

28

Page 30

7.2.2. Options

n

Titanium anode - Package EC 414

30 32

31

M000743

Markers Reference Description

30

200000093 Titanium anode

31

88014964 Wiring

32

200007959 Screw bag

n

2.2 kW heating element - Package EC 410 - Ø 82

A

Markers

Reference Description

41

95013133 Lip gasket Ø 82

42

200008223 Heating element 2200 W

43

89625506 Magnesium anode Ø 40 - Length 410

44

95014035 Seal ø 25 x 8.5 x 2

45

94974527 Nylon brace

46

89658553 Complete dielectric spacer

7. Spare parts BL 150...500

29

01/03/2011 - 300019417-001-C

Page 31

Markers Reference Description

47

200008224 Clamping flange

Holes, diameter 82

48

89624900 Earth wire

49

89624901 Resistance cables

50

89625507 Earthing

68

89604901 Earth wire

70

95363327 Thermostat

n

2.4 kW heating element - Package EC 411 - Ø 82

41

-B

58

Markers

Reference Description

41

95013133 Lip gasket Ø 82

53

97863579 Heating element 2400 W - Three-phase

54

97862390 Heating body

55

97866635 Fastening plate

56

200006681 Power supply wires (x3)

57

95363327 Thermostat

58

200011080 Black wire (x3)

BL 150...500 7. Spare parts

01/03/2011 - 300019417-001-C

30

Page 32

n

3.3 kW heating element - Package EC 412 - Ø 82

A

Markers Reference Description

41

95013133 Lip gasket Ø 82

42

200008225 Heating element 3300 W

43

89625506 Magnesium anode Ø 40 - Length 410

44

95014035 Seal ø 25 x 8.5 x 2

45

94974527 Nylon brace

46

89658553 Complete dielectric spacer

47

200008224 Clamping flange

Holes, diameter 82

48

89624900 Earth wire

49

89624901 Resistance cables

50

89625507 Earthing

68

89604901 Earth wire

70

95363327 Thermostat

7. Spare parts BL 150...500

31

01/03/2011 - 300019417-001-C

Page 33

n

4.5 kW heating element - Package EC 413 - Ø 82

A

Markers Reference Description

60

95013141 Sheet gasket Ø 170

61

200008220 Heating element 4500 W

62

200007580 Complete Anode

63

95014035 Seal ø 25 x 8.5 x 2

64

94974527 Nylon brace

65

89624902 Resistance cables

66

89658560 Complete dielectric spacer

67

200008221 Clamping flange

Holes, diameter 82

68

89604901 Earth wire

69

89625507 Earthing

70

95363327 Thermostat

BL 150...500 7. Spare parts

01/03/2011 - 300019417-001-C

32

Page 34

n

3 kW heating element - Package EG 88

41

-B

58

Markers Reference Description

41

95013133 Lip gasket Ø 82

53

97863562 Heating element 3000 W - Three-phase

54

97862759 Heating body

55

97866635 Fastening plate

56

200006681 Power supply wires (x3)

57

95363327 Thermostat

58

200011080 Black wire (x3)

7. Spare parts BL 150...500

33

01/03/2011 - 300019417-001-C

Page 35

8 Warranty

8.1 General

You have just purchased one of our appliances and we thank you for

the trust you have placed in our products.

Please note that your appliance will provide good service for a longer

period of time if it is regularly checked and maintained.

Your fitter and our customer support network are at your disposal at

all times.

8.2 Warranty terms

France: The following provisions are not exlcusive of the

buyer being able to benefit from the legal warranty

stipulated in Articles 1641 to 1648 of the Civil Code.

Belgium: The following provisions regarding the

contractual warranty are not exclusive of the buyer being

able to benefit from the legal provisions applicable in

Belgium regarding hidden defects.

Portugal: The following provisions do not adversely affect

consumers' rights, as laid down in Decree-Law 67/2003 of

8 April amended by Decree-Law 84/2008 of 21 May,

warranties relating to sales of consumer goods and other

implementing rules.

Other countries: The following provisions are not

exclusive of the buyer being able benefit from the legal

provisions applicable regarding hidden defects in the

buyer's country.

Starting from the purchase date shown on the original fitter's invoice,

your appliance has a contractual guarantee against any

manufacturing defect.

The length of the guarantee is mentioned in the price catalogue.

The manufacturer is not liable for any improper use of the appliance

or failure to maintain or install the unit correctly (the user shall take

care to ensure that the system is installed by a qualified engineer).

In particular, the manufacturer shall not be held responsible for any

damage, loss or injury caused by installations which do not comply

with the following:

4 applicable local laws and regulations,

4 specific requirements relating to the installation, such as national

and/or local regulations,

4 the manufacturer's instructions, in particular those relating to the

regular maintenance of the unit,

BL 150...500

8. Warranty

01/03/2011 - 300019417-001-C

34

Page 36

4 the rules of the profession.

The warranty is limited to the exchange or repair of such parts as have

been recognised to be faulty by our technical department and does

not cover labour, travel and carriage costs.

The warranty shall not apply to the replacement or repair of parts

damaged by normal wear and tear, negligence, repairs by unqualified

parties, faulty or insufficient monitoring and maintenance, faulty

power supply or the use of unsuitable fuel.

Sub-assemblies such as motors, pumps, electric valves etc. are

guaranteed only if they have never been dismantled.

The legislation laid down by european directive 99/44/EEC,

transposed by legislative decree No. 24 of 2 February 2002 published

in O.J. No. 57 of 8 March 2002, continues to apply.

8. Warranty BL 150...500

35

01/03/2011 - 300019417-001-C

Page 37

BL 150...500 8. Warranty

01/03/2011 - 300019417-001-C

36

Page 38

Page 39

Page 40

DE DIETRICH THERMIQUE S.A.S.

www.dedietrich-thermique.fr

DE DIETRICH REMEHA GmbH

www.dedietrich-remeha.de

VAN MARCKE

www.vanmarcke.be

WALTER MEIER (Klima Schweiz) AG

www.waltermeier.com

DE

BE

CH

NEUBERG S.A.

www.dedietrich-heating.com

LU

FR

DE DIETRICH

www.dedietrich-otoplenie.ru

RU

ÖAG AG

www.oeag.at

AT

Direction des Ventes France

57, rue de la Gare

F- 67580 MERTZWILLER

+33 (0)3 88 80 27 00

+33 (0)3 88 80 27 99

Rheiner Strasse 151

D- 48282 EMSDETTEN

+49 (0)25 72 / 23-5

+49 (0)25 72 / 23-102

info@dedietrich.de

Weggevoerdenlaan 5

B- 8500 KORTRIJK

+32 (0)56/23 75 11

Bahnstrasse 24

CH-8603 SCHWERZENBACH

+41 (0) 44 806 44 24

+41 (0) 44 806 44 25

39 rue Jacques Stas

L- 2010 LUXEMBOURG

+352 (0)2 401 401

ул. Гиляровского, д. 8

129090 г. Москва

+7 495 988-43-04

+7 495 988-43-04

dedietrich@nnt.ru

Schemmerlstrasse 66-70

A-1110 WIEN

+43 (0)50406 - 61624

+43 (0)50406 - 61569

dedietrich@oeag.at

ch.klima@waltermeier.com

DE DIETRICH

www.dedietrich-heating.com

CN

Room 512, Tower A, Kelun Building

12A Guanghua Rd, Chaoyang District

C-100020 BEIJING

+86 (0)106.581.4017

+86 (0)106.581.4018

+86 (0)106.581.7056

+86 (0)106.581.4019

contactBJ@dedietrich.com.cn

Serviceline +41 (0)8 00 846 846

WALTER MEIER (Climat Suisse) SA

Z.I. de la Veyre B, St-Légier

CH-1800 VEVEY 1

+41 (0) 21 943 02 22

+41 (0) 21 943 02 33

ch.climat@waltermeier.com

Serviceline +41 (0)8 00 846 846

AD001-AC

офис 52

© Copyright

All technical and technological information contained in these technical instructions,

as well as any drawings and technical descriptions supplied, remain our property

and shall not be multiplied without our prior consent in writing.

01/03/2011

DEDIETRICH THERMIQUE

57,ruedelaGareF-67580MERTZWILLER-BP 30

Loading...

Loading...