Page 1

www.dedicatedmicros.com

INSTALLATION MANUAL

MANUEL D’INSTALLATION

MANUALE D'INSTALLAZIONE

INSTALLATIONSHANDBUCH

MANUAL DE INSTALACIÓN

2025

Page 2

CE NOTICE (EUROPEAN UNION).

Marking by the symbol CE indicates compliance of this DM product (Dennard 2025 CCTV IR Lamp)

to the Electromagnetic Compatibility Directive 89/336/EEC, and the Low Voltage Directive

73/23/EEC of the European Union. Such marking is indicative that this system meets the following

technical standards.

• EN 61000-6-3 EMC Standard Residential, Commercial and Light Industry.

• EN 61000-3-3 Limitations of voltage changes, fluctuations and flicker in public low-voltage

supply systems for equipment with rated current up to 16A.

• EN 61000-3-2 Limits for harmonic current emissions for equipment with rated current up to 16A.

• EN 50130-4 Immunity requirements for components of fire, intruder and social alarm systems.

• EN 60950 Safety of IT and related equipment.

• EN 55022 Class B. Radiated Emissions Standard, suitable for Commercial or Residential use.

• EN 60825-1 Safety standard for LED’s and Lasers.

Further details about these applicable standards can be obtained from Dedicated Micros LTD. 11

Oak Street, Swinton, Manchester, M27 4FL.

A “Declaration of Conformity” with all relevant European Union Directives has been made, is on file

and is available from the Dedicated Micros address immediately above.

CE Mark

This product is marked with the CE symbol and indicates compliance with all

applicable directives.

Directive 89/336/EEC.

A “Declaration of Conformity” is held at Dedicated Micros Ltd.,

11 Oak Street, Swinton, Manchester M27 4FL.

Page 3

Dennard 2025 Installation Manual Page. 1

1. Introduction

Congratulations on choosing the Dennard 2025 infra-red LED illuminator. The product range is

designed for high power and long life illumination for cameras with spectral responses extending

into the infra-red range. With correct use the product will provide over 5 years of maintenance free

operation.

The unit comes with a dedicated power supply which requires a mains input. It must only be used

with this supply.

The illuminator and PSU are rated to IP66.

This operation manual will provide all the information required to set-up, install and run the

Dennard 2025 Illuminator.

Page 4

Dennard 2025 Installation Manual Page. 2

2. Index

Introduction 1

Index 2

Dennard 2025 Outline Drawing 3

Components Supplied 4

General Safety Information 5

Mounting the Illuminator 5

Mounting to a Dennard 2000 Pan and Tilt Unit 6

Mounting to a wall 6

Mounting the Control Unit 6

Wiring connections 9

Configuration 11

Power Settings 12

Control Settings 12

Using the Photocell 12

Remote Switch Inputs 12

Adjusting the Illuminator Angle 14

Maintenance 15

Spares Parts and Accessories 16

Troubleshooting 16

Specifications 17

Page 5

Dennard 2025 Installation Manual Page. 3

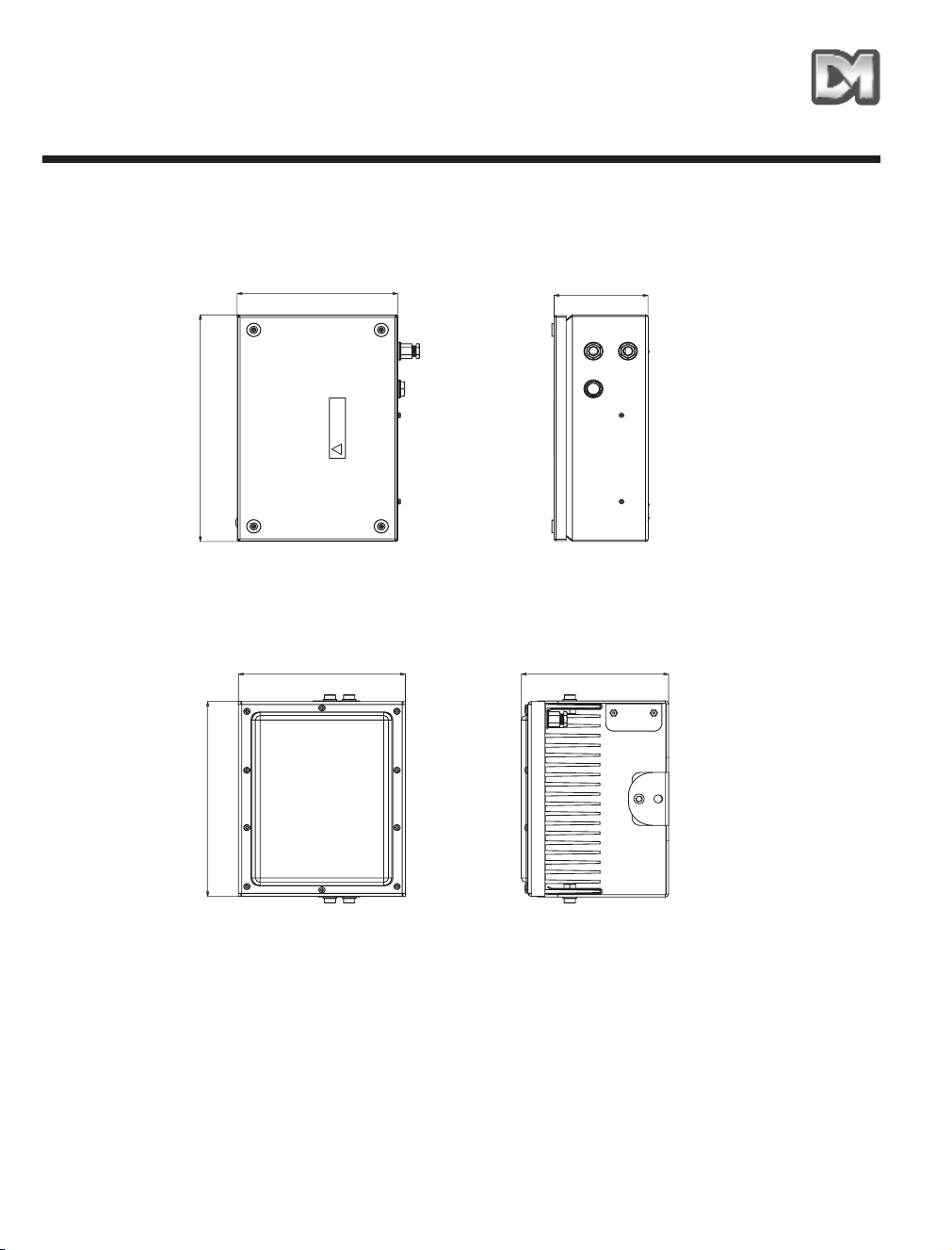

3. Dennard 2025 Outline Drawing

Fig. 1 – Outline Dimensions

117mm

200mm

184mm

208mm

258mm

300mm

PSU

LED illuminator

Page 6

Dennard 2025 Installation Manual Page. 4

4. Components Supplied

Before installation please remove the unit from the packaging and check that all items below have

been supplied.

1 x Dennard 2025 Infra-red LED illuminator

1 x Dennard 2025 Dedicated Power supply

1 x Dennard 2025 Wall bracket

1 x Accessory kit containing

1 x 6mm A/F Hex Wrench

1 x M8 x 20 Socket Cap Head Bolt

1 x M10 x 140 Hex Head Bolt

1 x M10 Nut

2 x M10 Lock Washers

2 x M10 x 16 Hex Head Bolts

2 x M10 Plain Washers

2 x M10 Spring Washers

1 x M8 Plain Washer

1 x M8 Spring Washer

4 x 8mm Woodscrews

4 x Rawlplugs

4 x M8 Rubber Dowty Washers

6 x Cable Ties

Page 7

Dennard 2025 Installation Manual Page. 5

5. General Safety Information

This Dennard 2025 equipment shall only be installed by qualified service personnel.

The final installation must adhere to all national wiring regulations.

The disconnect device must comply with IEC 60947.

WARNINGS

Read instructions before installing and power up.

Instructions should be kept for future reference.

If this unit shows signs of damage or malfunction, disconnect from mains immediately and contact

Dedicated Micros.

6. Mounting the Illuminator

Ensure the illuminator is mounted in a well ventilated area with over 100mm clearance around the

heatsink on all sides.

Avoid mounting the illuminator in direct sunlight or next to other heat sources.

Failure to provide this will shorten the life of the LEDs and decrease the lamp brightness.

WARNING: Ensure the illuminator is mounted a minimum of 2m away from eye level. Do not

look directly at the illuminator for prolonged periods during use.

Page 8

7. Mounting to a Dennard 2000 Pan and

Tilt Unit

Figures 2 and 3 show typical positions for I.R. illuminators when mounted to a remotely controlled

Dennard 2000 pan and tilt head.

Mount the Dennard 2025 illuminator using the M10 fixings supplied with the unit.

Due to the weight of the Dennard 2025 it is not recommended that it is used with the optional side

mounting plate on the pan and tilt unit.

8. Mounting to a wall

The illuminator can be mounted directly to a wall to allow up and down adjustment only.

Alternatively it can be mounted using the wall mounting bracket provided which also allows left to

right adjustment. See Fig. 4.

WARNING: Ensure the wall fixings used are suitable for the type of wall and can support the

full weight of the unit.

9. Mounting the Control Unit

Remove the sealing plugs as shown in Fig. 5 and then use the rawlplugs, screws and rubber

washers provided to mount the control unit to the wall. Use silicon sealant between the wall and

unit to ensure a water tight seal is maintained.

Dennard 2025 Installation Manual Page. 6

Page 9

Fig. 2 – Two illuminator configuration with Dennard 2000 Pan and Tilt Unit

Fig. 3 – Fixing Detail

Fig. 4 – Mounting the Illuminator to a wall using the wall bracket

Dennard 2025 Installation Manual Page. 7

Page 10

Fig. 5 – Removing the sealing plugs

Fig. 6 – Fitting the fixing screws and washers

Dennard 2025 Installation Manual Page. 8

Page 11

Dennard 2025 Installation Manual Page. 9

10. Wiring connections

Electrical connections to the Dennard 2025 illuminator are made via terminal blocks inside the

power supply unit. To access the connections remove the 4 cover screws on the power supply and

remove the top cover.

WARNING: Ensure the mains supply is isolated at all times whilst the cover is removed from

the power supply.

The mains supply should be fitted with a circuit breaker as a method of disconnecting the supply for

maintenance. The circuit breaker shall be accessible and labelled such that it is easily identified as

the disconnect device for this particular unit. The device shall comply with IEC 60947. The

disconnect device and all wiring shall be of adequate rating to comply with the input requirements

of the PSU as stated in the specifications section.

The mains cabling shall comply with national wiring regulations.

Ensure the mains input cable is prepared as in Fig. 8. Feed the cable through the lower cable gland

and secure the gland nut using a torque of 1.8Nm. Use the cable tie to secure the cable to the

mounting post provided as shown in Fig. 7.

Connect the cable from the illuminator into the connector and earth point as shown in Fig. 7. Use

the cable ties provided to attach the cable to the photocell wires which are routed around the right

hand side of the enclosure. Ensure the correct polarity is observed. The red sheathed wire

connects to the positive terminal, labelled as ‘LED ARRAY +ve’ on the PCB.

WARNING: Do not increase the cable length, as this may cause performance problems with

the unit. You may shorten the cable to a minimum length of 1m.

Page 12

The unit is supplied with a photocell connected and configured to switch the lamp on when light

levels fall below 25 lux. If you want the lamp to run continuously or to use an alternative switching

source please refer to the section ‘Remote Switch Inputs’.

Fig. 7 – Customer wiring

Dennard 2025 Installation Manual Page. 10

Feed mains cable through lower gland

and fasten to post with cable tie provided

Connect mains into terminal block green/yellow

to earth, brown to live (‘L’) blue to Neutral (‘N’)

Feed illuminator cable through upper

gland and secure to photocell wiring

using cable ties provided

Connect illuminator cable to terminal block,

observe correct polarity

Page 13

Fig. 8 - Mains Cable Preparation

11. Configuration

Power Settings

It is possible to configure the supply at 4 different power levels. The factory setting is high power.

If using the lamp at temperatures above 40°C or using continuously it is recommended that you use

Medium power or lower to maximise the life of the LEDs.

Switch 1 and 10 in the switch bank control the power level settings. The factory default setting is

high power.

Dennard 2025 Installation Manual Page. 11

CONNECTION TO DENNARD 2025 PSU

6mm STRIP AND

PREP FOR

TERMINAL

BLOCK

GREEN/YELLOW

EARTH

BLUE - NEUTRAL

BROWN LIVE

4-6mm OUTER

INSULATION DIAMETER

24mm MIN

20mm MAX OUTER

INSULATION REMOVED

CONNECTION TO CUSTOMER WIRING

BROWN - LIVE

GREEN/YELLOW

EARTH

BLUE - NEUTRAL

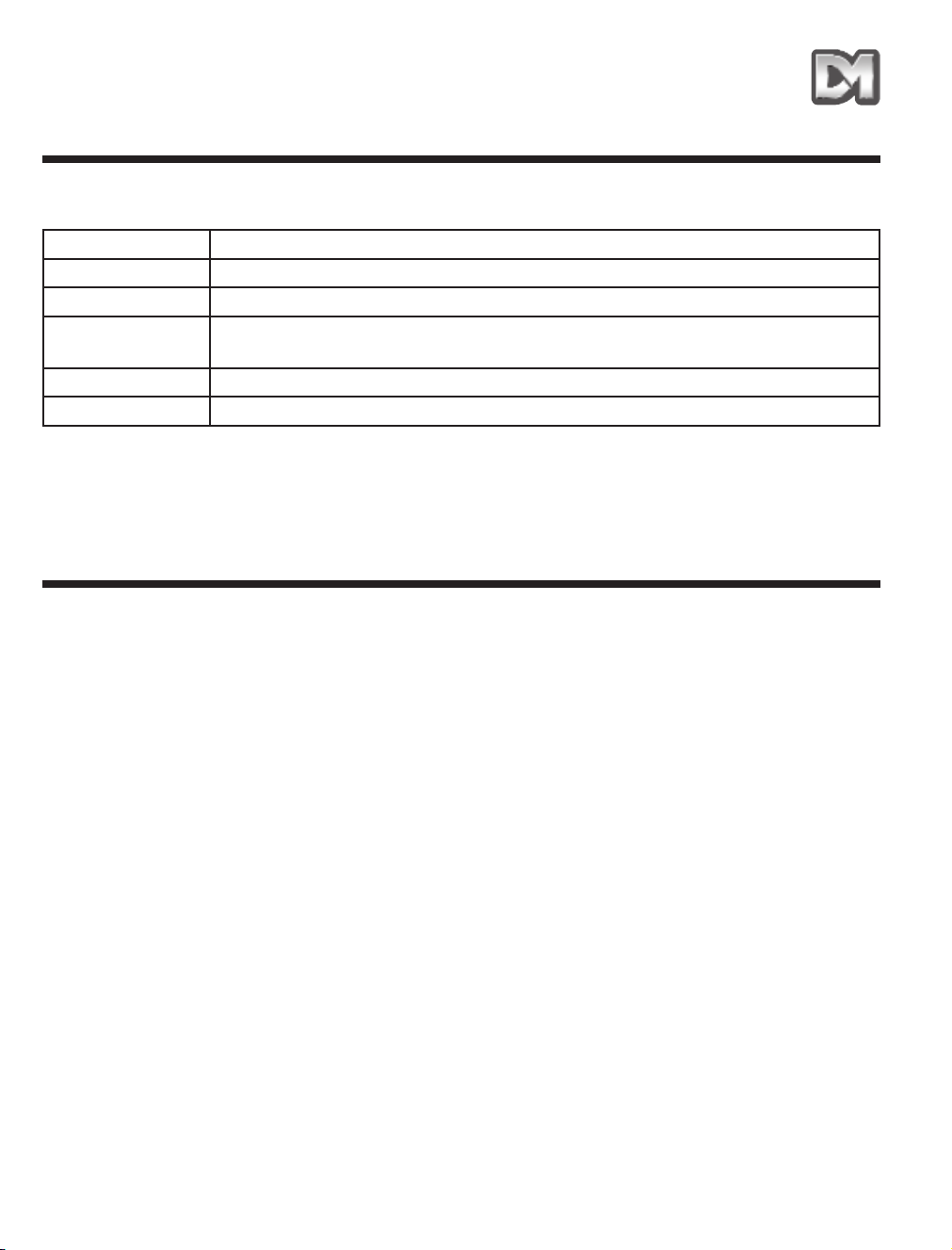

Switch 1 Switch 10 Power mode

ON ON Ultra low

ON OFF Low

OFF ON Medium

OFF OFF High

Page 14

12. Control Settings

The Denanrd 2025 illuminator can be switched from any one of three 12V switch inputs. The unit

comes configured to use the photocell supplied which switches the lamp on at light levels below 25

lux.

Using the Photocell

The unit is supplied and configured to use a photocell located inside the power supply unit. The

photocell relies on detecting ambient light to function correctly. Ensure that the control unit is

mounted with the cell pointing to one side or below the unit (not facing upwards). It needs to be

away from sources of artificial light and not blanked off or sitting in permanently dark conditions.

An extension kit is available for mounting the photocell remotely if required see ‘Spares and

Accessories’.

Remote Switch Inputs

There are a further two switch inputs designed for 5-12V devices. These can be configured to

accept a range of different signals, for example a closed contact input from a PIR detector or an

external control unit.

The inputs are configured as per the following table.

Dennard 2025 Installation Manual Page. 12

Page 15

E.g. To add another control input to the unit, wire it into the terminal block marked with CTRL I/P 2

then set switch bank switches 6 and 7 on. When the contacts on the input switch are closed the

light will come on, if you want the light to come on when the input contacts are open then set bank

switch 7 to off.

If multiple switches are connected the light will switch on when any of the switches are on (OR

control).

Dennard 2025 Installation Manual Page. 13

No.. Description ON= OFF= Factory Setting

1

POWER CONTROL 1

SEE POWER SETTINGS TABLE OFF

2 UNUSED OFF

3 ENABLE CONTROL

INPUTS

ALWAYS IN ON

POSITION

- ON

4 CTRL I/P 1 ENABLE

(PHOTOCELL)

INPUT ENABLED INPUT DISABLED ON

5 CTRL I/P 1 TYPE

(PHOTOCELL)

CLOSED SWITCH

INPUT = ARRAY ON

OPEN SWITCH

INPUT= ARRAY ON

ON

6 CTRL I/P 2 ENABLE INPUT ENABLED INPUT DISABLED OFF

7 CTRL I/P 2 TYPE CLOSED SWITCH

INPUT = ARRAY ON

OPEN SWITCH

INPUT= ARRAY ON

OFF

8 CTRL I/P 3 TYPE INPUT ENABLED INPUT DISABLED OFF

9 CTRL I/P 3 TYPE CLOSED SWITCH

INPUT = ARRAY ON

OPEN SWITCH

INPUT= ARRAY ON

OFF

10 POWER CONTROL 2 SEE POWER SETTINGS TABLE OFF

Page 16

13. Adjusting the Illuminator Angle

Once you have completed the connections and have powered on the illuminator you will need to

set the angle to get the best possible performance.

• View the area you wish to illuminate through a camera and monitor.

• If you are using the wall bracket then loosen the bolt on the bracket and move the illuminator so

it is pointing towards the area you wish to see. Tighten the bolt.

• Loosen the bolts on the side of the illuminator and tilt the lamp downwards until the near part of

the view is clearly illuminated. (viewed via the monitor).

• Slowly tilt the lamp upwards until the far part of the field of view is also illuminated. Tighten the

bolts to set this position.

Fig. 10 – Adjusting the Illuminator Angle

Dennard 2025 Installation Manual Page. 14

IR Illumination

Nearest Object

Furthest Object

Page 17

Dennard 2025 Installation Manual Page. 15

14. Maintenance

The only serviceable part in the illuminator assembly is the front window. This shall only be serviced

by trained staff. No other parts of the unit are serviceable.

The only serviceable parts inside the PSU are the fuses.

Mains input fuse: This is identified as F1 on the label inside the PSU. This is a time lag (slow

blow) fuse with 2A current rating, 250V rating and high breaking capacity.

Illuminator output fuse: This is identified as F2. This is a time lag (slow blow) fuse with 10A

current rating, 250V rating and high breaking capacity.

To change a fuse, remove the black fuse holder from the terminal block by pulling upwards.

Remove the old fuse and replace with the new component. The new fuse must have the same

ratings as detailed above. Replace the fuse holder into the terminal block.

In case of a fault with the unit, consult the troubleshooting section in the manual.

Page 18

15. Spares Parts and Accessories

16. Troubleshooting

WARNINGS

Disconnect from mains before removing the cover

If this unit shows signs of damage or malfunction, disconnect from mains immediately and contact

Dedicated Micros.

• In dark conditions you will be able to see a faint red glow from the LEDs. In daylight you will not

see anything at all unless you look at the lamp with a camera.

• Check mains supply is connected correctly and switched on. Supply should be 100-240V ~.

• Check polarity of connections to lamp.

• Check the photocell function (put opaque tape over photocell) and wait for a few seconds to see

if the product switches on.

• Check the 2A and 10A fuses inside the PSU and replace if necessary.

• Disconnect all control devices and switch all switches in the switch bank to the off position, to

check if the lamp illuminates.

Dennard 2025 Installation Manual Page. 16

Part no. Description

Dennard 95083 Replacement power supply unit

Dennard 95084 Replacement illuminator unit 850nm/30 degree angle

Dennard 94032 Photocell extension kit – kit to allow photocell to be mounted remotely from

PSU

Dennard 95086 Replacement window

Dennard 95087 Replacement photocell

Page 19

Dennard 2025 Installation Manual Page. 17

17. Specifications

Voltage Input: 100-240V~ 50-60Hz

Power Input: 120W

Mains input Fuse: 2A, time lag, high breaking capacity.

Illuminator input fuse: 10A, time lag, high breaking capacity.

IP Rating: B.S. EN 60529, IP 66

Other Approvals: EN 61000-6-3 EMC Standard Residential, Commercial and Light Industry.

EN 61000-3-3 Limitations of voltage changes, fluctuations and flicker in public low-voltage supply

systems for equipment with rated current up to 16A.

EN 61000-3-2 Limits for harmonic current emissions for equipment with rated current up to 16A.

EN 50130-4 Immunity requirements for components of fire, intruder and social alarm systems.

EN 60950 Safety of IT and related equipment.

EN 55022 Class B. Radiated Emissions Standard, suitable for Commercial or Residential use.

EN 60825-1 Safety standard for LED’s and Lasers.

Operating temperature: -20°C to 50°C. Out of direct sunlight.

Weight: Illuminator unit and main bracket: 7 kg

Wall bracket: 1 kg

PSU: 5 kg

Page 20

Notes

Page 21

2025

MANUEL D’INSTALLATION

Page 22

Dennard 2025 Manuel d’installation Page 20

1. Introduction

Nous vous félicitons d’avoir choisi le projecteur à DEL infrarouge Dennard 2025. La gamme de

produits est conçue pour assurer une source d’éclairage haute puissance et de longue durée aux

caméras à réponse spectrale s’étendant dans la zone infrarouge. Utilisé correctement, ce

projecteur assurera un fonctionnement sans maintenance pendant 5 ans.

Le projecteur est fourni avec un bloc d’alimentation électrique dédié qui requiert une alimentation

secteur. Il ne doit être utilisé qu’avec cette alimentation.

Le projecteur et le bloc d’alimentation ont un niveau de protection contre les intempéries IP66.

Le manuel d’installation offre toutes les informations requises pour configurer, installer et utiliser le

projecteur Dennard 2025.

Page 23

Dennard 2025 Manuel d’installation Page 21

2. Index

Introduction 20

Index 21

Plan de forme Dennard 2025 22

Composants fournis 23

Informations générales de sécurité 24

Montage du projecteur 24

Montage sur une caméra panoramique et inclinaison Dennard 2000 25

Fixation murale 25

Montage de l’unité de commande 25

Raccordements de câbles 28

Configuration 30

Réglages de puissance 31

Réglages de commande 31

Utilisation de la cellule photoélectrique 31

Entrées de commutation à distance 31

Réglage de l’angle du projecteur 33

Maintenance 34

Pièces de rechange et accessoires 35

Dépannage 35

Caractéristiques 36

Page 24

Dennard 2025 Manuel d’installation Page 22

3. Plan de forme Dennard 2025

Fig. 1 – Dimensions extérieures

117mm

200mm

184mm

208mm

258mm

300mm

Bloc d'alimentation électrique

LED illuminator

Page 25

Dennard 2025 Manuel d’installation Page 23

4. Composants fournis

Avant de procéder à l’installation, veuillez sortir le projecteur de l’emballage et vérifier que tous les

éléments listés ci-dessous sont inclus.

1 projecteur à DEL infrarouge Dennard 2025

1 bloc d’alimentation dédié Dennard 2025

1 support mural Dennard 2025

1 kit d’accessoires contenant

1 clé hexagonale 6 mm

1 vis à tête creuse M8 x 20

1 vis à tête à six pans M10 x 140

1 écrou M10

2 rondelles frein M10

2 vis à tête à six pans M10 x 16

2 rondelles lisses M10

2 rondelles élastiques M10

1 rondelle lisse M8

1 rondelle élastique M8

4 vis à bois 8 mm

4 chevilles

4 rondelles caoutchouc

6 attache-câbles

Page 26

Dennard 2025 Manuel d’installation Page 24

5. Informations générales de sécurité

Ce projecteur Dennard 2025 ne doit être installé que par des techniciens qualifiés.

L’installation finale doit être conforme à la réglementation nationale en vigueur en matière de

câblage.

Le sectionneur doit être conforme à la norme IEC 60947.

MISE EN GARDE

Veuillez lire les instructions avant de procéder à l’installation et la mise sous tension.

Conservez les instructions pour référence ultérieure.

En cas de signes de dégâts ou de dysfonctionnement de ce matériel, isolez-le électriquement au

niveau du sectionneur de l’alimentation secteur et contactez Dedicated Micros.

6. Montage du projecteur

Veillez à ce que le projecteur soit monté dans un endroit bien ventilé et avec un espace de 100 mm

sur tous les côtés du dissipateur thermique.

Evitez de monter le projecteur en plein soleil ou à proximité d’autres sources de chaleur,

car ceci écourterait la durée de vie des diodes électroluminescentes et réduirait la luminosité du

projecteur.

MISE EN GARDE : Veillez à ce que le projecteur soit monté à 2 m au moins de la hauteur des

yeux. Ne regardez pas directement le projecteur pendant des périodes prolongées lorsqu’il

est allumé.

Page 27

7. Montage sur une caméra panoramique et

inclinaison Dennard 2000

Les Figures 2 et 3 illustrent les positions typiques des projecteurs infrarouge lorsqu’ils sont montés

sur une tête panoramique et inclinaison Dennard 2000 télécommandée.

Montez le projecteur Dennard 2025 à l’aide des fixations M10 fournies avec le projecteur.

En raison du poids du Dennard 2025, nous déconseillons son utilisation avec la plateforme de

montage latérale en option de la caméra panoramique et inclinaison.

8. Fixation murale

Le projecteur peut être monté directement sur un mur, auquel cas il n’est réglable qu’en hauteur. Il

peut aussi être monté à l’aide du support de fixation murale fourni, auquel cas il est également

réglable latéralement. Voir la Fig. 4.

MISE EN GARDE : Veillez à ce que les fixations murales utilisées soient compatibles avec le

type de mur et capables de supporter le poids total du projecteur.

9. Montage de l’unité de commande

Retirez les obturateurs comme illustré à la Fig. 5, puis utilisez les chevilles, vis et rondelles

caoutchouc fournies pour fixer l’unité de commande au mur. Utilisez du mastic silicone entre le mur

et le projecteur pour assurer le maintien de l’étanchéité.

Dennard 2025 Manuel d’installation Page 25

Page 28

Fig. 2 – Configuration à deux projecteurs avec caméra panoramique et inclinaison Dennard 2000

Fig. 3 – Détail de la fixation

Fig. 4 – Fixation au mur du projecteur à l’aide du support mural

Dennard 2025 Manuel d’installation Page 26

Page 29

Fig. 5 – Retrait des obturateurs

Fig. 6 – Pose des vis et rondelles de fixation

Dennard 2025 Manuel d’installation Page 27

Page 30

Dennard 2025 Manuel d’installation Page 28

10. Raccordements de câbles

Les raccordements électriques au projecteur Dennard 2025 s’effectuent au moyen de borniers

situés à l’intérieur du bloc d’alimentation. Pour accéder aux raccordements retirez les 4 vis du capot

du bloc s’alimentation et retirez le capot du dessus.

MISE EN GARDE : Veillez à ce que l’alimentation secteur soit isolée à tout moment lorsque

le capot est retiré du bloc d’alimentation.

L’alimentation secteur doit être dotée d’un disjoncteur à fonction de dispositif de coupure de

l’alimentation aux fins de maintenance. Le disjoncteur doit être accessible et étiqueté de manière à

pouvoir être facilement identifié comme étant le dispositif de coupure réservé à cet équipement. Le

dispositif doit être conforme à la norme IEC 60947. Le dispositif de coupure et tout le câblage

doivent être de l’intensité adéquate pour répondre aux besoins en alimentation du bloc

d’alimentation spécifiés dans la section Caractéristiques.

Le câblage de l’alimentation secteur doit être conforme à la réglementation nationale en vigueur en

matière de câblage.

Veillez à ce que le câble d’alimentation secteur soit préparé comme illustré à la Fig. 8. Passez le

câble dans le presse-étoupe inférieur et serrez l’écrou de la presse-étoupe au couple de 1,8 Nm.

Utilisez l’attache-câble fournie pour immobiliser le câble sur le support comme illustré à la Fig. 7.

Raccordez le câble du projecteur au connecteur et à la mise à la terre comme illustré à la Fig 7.

Utilisez les attache-câbles fournies pour attacher le câble aux fils de la cellule photoélectrique qui

sont acheminés à droite du caisson. Veillez à respecter la polarité. Le fil blindé rouge est raccordé

à la borne positive, étiquetée ‘LED ARRAY +ve’ sur la carte à circuits imprimés.

MISE EN GARDE : Ne rallongez pas le câble, ceci risquerait de compromettre la performance

de l’équipement. Vous pouvez raccourcir le câble d’une longueur minimum de 1 m.

Page 31

Le projecteur est fourni avec une cellule photoélectrique raccordée et configurée pour que le

projecteur s’allume lorsque le niveau d’éclairage baisse en dessous de 25 lux. Si vous voulez que

le projecteur fonctionne continuellement ou utiliser une autre source de commutation, veuillez vous

reporter à la section ‘Entrées de commutation à distance’.

Fig. 7 – Câblage à effectuer par le client

Dennard 2025 Manuel d’installation Page 29

Passez le câble d’alimentation secteur

dans le presse-étoupe du bas et fixez-le

sur le support avec l’attache-câble fournie

Raccordez l’alimentation secteur au bornier, fil

vert/jaune à la terre, fil marron au fil sous

tension (‘L’) bleu au fil Neutre (‘N’)

Passez le câble du projecteur dans le

presse-étoupe du haut et immobilisez

le câblage de la cellule photoélectrique

avec les attache-câbles fournies

Raccordez le câble du projecteur au bornier en

respectant la polarité

Page 32

Fig. 8 - Préparation du câble d’alimentation secteur

11. Configuration

Réglages de puissance

Il est possible de configurer l’alimentation à 4 différents niveaux de puissance. Le réglage usine est

le réglage haute puissance.

Si le projecteur fonctionne à des températures supérieures à 40°C ou continuellement, nous vous

conseillons d’utiliser une puissance moyenne ou basse pour maximiser la durée de vie des diodes.

Les commutateurs 1 et 10 de la rangée de commutateurs commandent les réglages de niveau de

puissance. Le réglage usine par défaut est le réglage haute puissance.

Dennard 2025 Manuel d’installation Page 30

RACCORDEMENT AU BLOC D’ALIMENTATION DU DENNARD 2025

6 mm DENUDER

ET PREP. POUR

BORNIER

TERRE

VERT/JAUNE

BLEU - NEUTRE

MARRON SOUS

TENSION

4-6mm DIAMETRE

ISOLATION EXTERIEURE

24 mm MIN

20 mm MAX ISOLATION

EXTERIEURE RETIREE

RACCORDEMENT AU CABLAGE DU CLIENT

MARRON SOUS TENSION

TERRE

VERT/JAUNE

BLEU - NEUTRE

Commutateur 1 Commutateur 10 Mode de puissance

ON ON Ultra Basse

ON OFF Basse

OFF ON Moyenne

OFF OFF Haute

Page 33

Dennard 2025 Manuel d’installation Page 31

12. Réglages de commande

Le projecteur Dennard 2025 peut être commuté à partir de l’une de trois entrées de commutation

12 V. Le projecteur est livré configuré pour utiliser la cellule photolélectrique fournie qui allume le

projecteur à des niveaux de luminosité en dessous de 25 lux.

Utilisation de la cellule photoélectrique

Le projecteur est fourni et configuré pour utiliser une cellule photoélectrique située à l’intérieur du

bloc d’alimentation. La cellule photoélectrique dépend de la détection de la luminosité ambiante

pour fonctionner correctement. Veillez à ce que l’unité de commande soit montée avec la cellule

dirigée vers un côté ou sous l’unité (et non pas dirigée vers le haut). Elle doit être éloignée des

sources d’éclairage artificiel et ne pas être masquée, ou ne pas résider dans des endroits sombres

en permanence.

Un kit de rallonge est disponible pour le montage à distance de la cellule photoélectrique si besoin

est. Voir ‘Pièces de rechange et accessoires’.

Entrées de commutation à distance

Deux autres entrées de commutation conçues pour des dispositifs de 5-12 V sont également

présentes. Elles peuvent être configurées pour accepter une gamme de différents signaux, à savoir

signaux d’entrée de contact fermé depuis un détecteur PIR ou d’une unité de commande externe.

Les entrées doivent être configurées conformément au tableau suivant.

Page 34

Exemple : pour ajouter une autre entrée de commande à l’unité, raccordez-la au bornier repéré

CTRL I/P 2 puis, activez les commutateurs 6 et 7 de la rangée de commutateurs (ON). Lorsque les

contacts du commutateur d’entrée sont fermés, le projecteur s’allume, si vous voulez qu’il s’allume

lorsque les contacts d’entrée sont ouverts, désactivez alors le commutateur 7 (OFF).

Si des commutateurs multiples sont raccordés, le projecteur s’allume lorsque l’un des

commutateurs quel qu’il soit est activé (ON) (OU commande).

Dennard 2025 Manuel d’installation Page 32

No. Désignation ON= OFF= Réglage usine

1

COMMANDE DE

PUISSANCE 1

VOIR LE TABLEAU DES REGLAGES DE

PUISSANCE

OFF

2

NON UTILISE

OFF

3

ACTIVATION ENTREES

COMMANDE

TOUJOURS SUR ‘ON’ -

ON

4

CTRL I/P 1 ACTIVATION

(CELLULE

PHOTOELECTRIQUE)

ENTREE ACTIVEE ENTREE DESACTIVEE

ON

5

CTRL I/P 1 TYPE

(CELLULE

PHOTOELECTRIQUE)

ENTREE COMMUTATION

FERMEE = MATRICE

ACTIVEE (ON)

ENTREE COMMUTATION

OUVERTE = MATRICE

ACTIVEE (ON)

ON

6

CTRL I/P 2 ACTIVATION ENTREE ACTIVEE ENTREE DESACTIVEE

OFF

7

CTRL I/P 2 TYPE ENTREE COMMUTATION

FERMEE = MATRICE

ACTIVEE (ON)

ENTREE COMMUTATION

OUVERTE = MATRICE

ACTIVEE (ON)

OFF

8

CTRL I/P 3 TYPE ENTREE ACTIVEE ENTREE DESACTIVEE

OFF

9

CTRL I/P 3 TYPE ENTREE COMMUTATION

FERMEE = MATRICE

ACTIVEE (ON)

ENTREE COMMUTATION

OUVERTE = MATRICE

ACTIVEE (ON)

OFF

10

COMMANDE DE

PUISSANCE 2

VOIR LE TABLEAU DES REGLAGES DE

PUISSANCE

OFF

Page 35

Dennard 2025 Manuel d’installation Page 33

13. Réglage de l’angle du projecteur

Une fois les raccordements effectués le projecteur mis sous tension, vous devrez régler l’angle

pour assurer les performances optimales.

• Visualisez l’endroit que vous souhaitez éclairer sur une caméra ou écran.

• Si vous utilisez le support mural, desserrez alors le boulon sur le support et déplacez le

projecteur de manière à le diriger vers la zone que vous souhaitez voir. Serrez le boulon.

• Desserrez les boulons sur le côté du projecteur et inclinez-le vers le bas jusqu’à ce que la partie

du champ de vision la plus proche soit clairement éclairé. (tel que vu à l’écran).

• Inclinez lentement le projecteur vers le haut jusqu’à ce que la partie du champ de vision la plus

éloignée soit également éclairée. Serrez les boulons pour régler cette position.

Fig. 10 – Réglage de l’angle du projecteur

Eclairage IR

Objet le plus proche

Objet le plus loin

Page 36

Dennard 2025 Manuel d’installation Page 34

14. Maintenance

La seule pièce remplaçable du projecteur est la vitre avant. Ne confiez cette intervention qu’au le

personnel ayant reçu la formation appropriée. Aucun autre composant du projecteur n’est

remplaçable.

Les seules pièces remplaçables à l’intérieur du bloc d’alimentation sont les fusibles.

Fusible d’entrée d’alimentation secteur : Ce fusible est identifié F1 sur l’étiquette à l’intérieur du

bloc d’alimentation. Ceci est un fusible à retardement de 2 A, 250 V et haute puissance de rupture.

Fusible de sortie du projecteur : Identifié sous F2. Ceci est un fusible à retardement de 10 A, 250

V et haute puissance de rupture.

Pour remplacer un fusible, retirez le porte-fusibles noir du bornier en tirant vers le haut. Retirez le

fusible à remplacer et remplacez-le par le fusible neuf. Le fusible neuf doit avoir les mêmes

puissances nominales que ci-dessus. Remettez le porte-fusibles dans le bornier.

En cas de panne du projecteur, reportez-vous à la section dépannage du manuel.

Page 37

Dennard 2025 Manuel d’installation Page 35

15. Pièces de rechange et accessoires

16. Dépannage

MISE EN GARDE

Débranchez de l’alimentation secteur avant de retirer le couvercle.

En cas de signes de dégâts ou de dysfonctionnement de ce matériel, isolez-le électriquement au

niveau du sectionneur de l’alimentation secteur et contactez Dedicated Micros.

• Dans un milieu sombre, vous constaterez une faible lueur rouge au niveau des diodes. En plein

jour, vous ne verrez rien sauf si vous regardez le projecteur avec la caméra.

• Vérifiez que l’alimentation secteur est correctement raccordée et sous tension. L’alimentation

doit être de 100-240V ~.

• Contrôlez la polarité des raccordements au projecteur.

• Contrôlez le fonctionnement de la cellule photoélectrique (cellule masquée par du ruban) et

attendez quelques secondes pour voir si le projecteur s’allume.

• Contrôlez les fusibles 2A et 10A à l’intérieur du bloc d’alimentation et remplacez-les le cas

échéant.

• Débranchez tous les dispositifs de contrôle et mettez tous les commutateurs de la banque de

commutateurs en position désactivée (OFF), pour voir si le projecteur s’allume.

Pièce no. Désignation

Dennard 95083 Bloc d’alimentation de rechange

Dennard 95084

Projecteur de rechange 850 nm/angle de 30°

Dennard 94032 Kit de rallonge de cellule photoélectrique – kit permettant de monter la cellule

photoélectrique à distance du bloc d’alimentation

Dennard 95086 Vitre de rechange

Dennard 95087 Cellule photoélectrique de rechange

Page 38

Dennard 2025 Manuel d’installation Page 36

17. Caractéristiques

Entrée de tension : 100 - 240 V~ 50 - 60 Hz

Entrée d’alimentation : 120 W

Fusible d’entrée d’alimentation secteur : 2 A, à retardement, haute puissance de rupture.

Fusible d’entrée de projecteur : 10 A, à retardement, haute puissance de rupture.

Indice IP : Norme B.S. EN 60529, IP 66

Autres homologations : EN 61000-6-3 Norme CEM Environnements résidentiels, commerciaux et

de l’industrie légère.

EN 61000-3-3 Limitations de changements de tension, fluctuations et vacillement de réseau de

distribution publique pour équipements d’une intensité de courant nominale de jusqu’à 16 A.

EN 61000-3-2 Limites des émissions de courant harmonique pour équipements d’une intensité de

courant nominale de jusqu’à 16A.

EN 50130-4 Prescriptions relatives à l’immunité des composants de systèmes de détection

d’incendie, d’intrusion et d’alarme sociale.

EN 60950 Sécurité des équipements informatiques et connexes.

EN 55022 Classe B. Norme concernant les émissions rayonnées, applicable aux équipements à

usage commercial ou résidentiel.

EN 60825-1 Norme de sécurité pour les diodes électroluminescentes et lasers.

Température de fonctionnement : -20°C à 50°C. Pas en plein soleil.

Poids : Support principal du projecteur : 7 kg

Support mural : 1 kg

Bloc d’alimentation électrique : 5 kg

Page 39

Note

Page 40

Note

Page 41

2025

MANUALE D'INSTALLAZIONE

Page 42

Dennard 2025 Manuale d’installazione Pagina.40

1. Introduzione

Congratulazioni per aver scelto un proiettore a infrarossi Dennard 2025. La gamma di questi

prodotti è progettata per l’illuminazione di elevata potenza e lunga resistenza delle videocamere

con risposta spettrale che si estende alla gamma infrarossi. Se utilizzato correttamente, il prodotto

può garantire 5 anni di funzionamento senza necessità di manutenzione.

L’unità viene fornita con una linea di alimentazione dedicata che richiede un terminale di ingresso.

L’unità deve essere utilizzata solo con questa alimentazione.

Il proiettore e la spina PSU hanno un livello di protezione IP66.

Questo manuale fornisce tutte le informazioni necessarie per impostare, installare e far funzionare il

proiettore Dennard 2025.

Page 43

Dennard 2025 Manuale d’installazione Pagina.41

2. Indice

Introduzione 40

Indice 41

Schema generale Dennard 2025 42

Componenti forniti 43

Informazioni generali sulla sicurezza 46

Montaggio del proiettore 46

Montaggio in un’unità di panoramica e inclinazione Dennard 2000 47

Montaggio a parete 47

Montaggio dell’unità di controllo 47

Connessioni per il cablaggio 48

Configurazione 50

Impostazioni per l’alimentazione 50

Impostazioni dei tasti di comando 51

Utilizzo della fotocellula 51

Ingressi dei selettori remoti 51

Regolazione dell’angolo del proiettore 53

Manutenzione 54

Accessori e parti di ricambio 55

Risoluzione dei problemi 55

Specifiche 56

Page 44

Dennard 2025 Manuale d’installazione Pagina.42

3. Schema generale Dennard 2025

Fig. 1 – Dimensioni schema

117200

184208

258

300

PSU

LED

Page 45

Dennard 2025 Manuale d’installazione Pagina.43

4. Componenti forniti

Prima di procedere all’installazione, rimuovere l’unità dall’imballaggio e verificare che siano presenti

tutti gli elementi elencati di seguito.

1 proiettore ad infrarossi Dennard 2025

1 unità di alimentazione Dennard 2025

1 supporto a parete Dennard 2025

1 kit accessori contenente

1 chiave per vite esagonale da 6 mm A/F

1 vite cilindrica M8 x 20

1 vite esagonale M10 x 140

1 dado M10

2 rondelle di sicurezza M10

2 viti esagonali M10 x 16

2 rondelle piane M10

2 rondelle elastiche M10

1 rondella piana M8

1 rondella elastica M8

4 viti per legno da 8 mm

4 tasselli

4 rondelle di gomma dowty M8

6 fascette stringicavi

Page 46

Dennard 2025 Manuale d’installazione Pagina.44

5. Informazioni generali sulla sicurezza

L’apparecchio Dennard 2025 deve essere installato esclusivamente da personale qualificato.

L’installazione finale deve essere conforme a tutte le normative nazionali in materia di cablaggio.

Il dispositivo per la disconnessione deve essere conforme alla normativa IEC 60947.

ATTENZIONE:

Leggere attentamente le istruzioni prima di installare e accendere l’apparecchio.

Conservare le istruzioni per riferimento futuro.

Se l’unità mostra segni di danneggiamento o cattivo funzionamento, disconnettere immediatamente

dalla linea di alimentazione e contattare Dedicated Micros.

6. Montaggio del proiettore

Assicurarsi che il proiettore sia montato in un luogo ben ventilato con circa 100 mm di spazio libero

attorno al dissipatore di calore da tutti i lati.

Evitare di montare il proiettore alla luce diretta del sole o accanto ad altre fonti di calore.

In caso contrario, la durata operativa dei LED e la luminosità della lampada verranno

compromesse.

ATTENZIONE: assicurarsi che il proiettore sia montato ad una distanza di almeno 2 metri

dagli occhi. Non guardare direttamente il proiettore per lunghi periodi durante il suo utilizzo.

Page 47

7. Montaggio su un’unità di panoramica e

inclinazione di Dennard 2000

Le Figure 2 e 3 mostrano il posizionamento tipico dei proiettori a infrarossi, quando vengono

montati su un gruppo di panoramica e inclinazione Dennard 2000 controllato remotamente.

Montare il proiettore Dennard 2025 utilizzando i supporti di fissaggio M10 forniti con l’unità.

Dato il peso dell’unità, non è consigliabile utilizzarla con la piastra di montaggio laterale opzionale

sull’unità di panoramica e inclinazione.

8. Montaggio a parete

Il proiettore può essere montato direttamente a muro per consentire la sola regolazione in alto o in

basso. In alternativa, può essere montato utilizzando il supporto per il montaggio a parete fornito

che consente anche la regolazione verso destra o sinistra. Vedere la Fig. 4.

ATTENZIONE: assicurarsi che i supporti di fissaggio a parete siano adatti al tipo di parete e

possano sostenere il peso dell’unità.

9. Montaggio dell’unità di controllo

Rimuovere le spine di riempimento come mostrato nella Fig. 5, quindi utilizzare i tasselli, le viti e le

rondelle in gomma fornite per montare l’unità sulla parete. Utilizzare del sigillante in silicone tra la

parete e l’unità per garantire la tenuta stagna del sigillo.

Dennard 2025 Manuale d’installazione Pagina.45

Page 48

Fig. 2 – Configurazione dei due proiettori con l’unità di panoramica e inclinazione Dennard 2000

Fig. 3 – Dettaglio di fissaggio

Fig. 4 – Montaggio del proiettore alla parete utilizzando l’apposito supporto

Dennard 2025 Manuale d’installazione Pagina.46

Page 49

Fig. 5 – Rimozione delle spine per riempimento

Fig. 6 – Montaggio delle viti e delle rondelle di fissaggio

Dennard 2025 Manuale d’installazione Pagina.47

Page 50

Dennard 2025 Manuale d’installazione Pagina.48

10. Connessioni per il cablaggio

I collegamenti elettrici al proiettore Dennard 2025 vengono realizzati attraverso le morsettiere

collocate all’interno dell’unità di alimentazione.

Per accedere ai collegamenti, rimuovere le 4 viti del coperchio dell’unità e il coperchio superiore.

ATTENZIONE: Assicurarsi che la linea di alimentazione sia sempre isolata quando il

coperchio viene staccato dalla stessa.

La linea di alimentazione dovrebbe essere dotata di un interruttore di circuito per essere

disconnessa quando si deve eseguire la manutenzione. L’interruttore deve essere accessibile ed

etichettato per essere identificato facilmente come dispositivo di disconnessione per questa

particolare unità. Il dispositivo deve essere conforme con la norma IEC 60947. Il dispositivo e tutto

il cablaggio devono essere conformi ai requisiti della PSU come richiesto nella sezione delle

specifiche.

I cavi della linea di alimentazione devono essere conformi alle relative normative nazionali.

Assicurarsi che il cavo di entrata dell’alimentazione sia predisposto come nella Fig. 8. Inserire il

cavo attraverso il pressacavi e assicurare quest’ultimo utilizzando una coppia di 1,8 Nm. Utilizzare

la fascetta stingicavi per fissare il cavo al supporto di montaggio fornito, come mostrato nella

Fig. 7.

Collegare il cavo dal proiettore al connettore e alla presa di terra come mostrato nella Fig. 7.

Utilizzare le fascette stringicavi forniti per fissare il cavo ai fili della fotocellula che sono situati sul

lato destro della struttura. Assicurare la corretta polarità. Il cavo contrassegnato dal rosso si collega

al terminale positivo, etichettato come ‘LED ARRAY +ve’ dul PCB.

ATTENZIONE: non aumentare la lunghezza del cavo, per non compromettere le prestazione

dell’unità. È possibile accorciare il cavo fino a una lunghezza minima di 1 m.

Page 51

L’unità viene fornita con una fotocellula collegata e configurata per accendere la lampada quando il

livello di illuminazione scende sotto i 25 lux. Se si desidera che la lampada funzioni

ininterrottamente oppure si preferisce usare un’altra fonte di commutazione, fare riferimento alla

sezione “Ingressi dei selettori remoti”.

Fig. 7 – Cablaggio dell’utente

Dennard 2025 Manuale d’installazione Pagina.49

Inserire il cavo di alimentazione nel

pressacavi e serrare con la fascetta

stingicavi fornita.

Collegare la linea di alimentazione al morsetto

verde/giallo nella presa a terra, marrone in ‘L’,

blu in Neutro (‘N’).

Inserire il cavo del proiettore nel

pressacavi superiore e fissarlo ai fili

della fotocellula utilizzando le

fascette stringicavi fornite.

Collegare il cavo del proiettore al morsetto,

rispettando la corretta polarità.

Page 52

Fig. 8 - Predisposizione del cavo di alimentazione

11. Configurazione

Impostazioni per l’alimentazione

È possibile configurare l’alimentazione su 4 livelli diversi. L’’impostazione di fabbrica

dell’alimentazione è elevata.

Se la lampada viene utilizzata a temperature superiori ai 40°C o in modo continuativo, si consiglia

un’alimentazione bassa o minima per una maggiore durata dei LED.

Gli interruttori 1 e 10 del commutatore controllano le impostazioni dei livelli di alimentazione.

L’impostazione predefinita di fabbrica dell’alimentazione è elevata.

Dennard 2025 Manuale d’installazione Pagina.50

CONNESSIONE ALLA PSU DENNARD 2025

FASCETTE da 6 mm e

PREDISPOSIZIONE

PER MORSETTO

VERDE/GIALLO

TERRA

BLU - NEUTRO

MARRON

E - FASE

DIAMETRO DI ISOLAMENTO

ESTERNO 4 - 6 mm

MIN 24 mm

MASSIMO ISOLAMENTO ESTERNO

da 20 mm RIMOSSO

CONNESSIONE AL CABLAGGIO DELL’UTENTE

MARRONE FASE

VERDE/GIALLO

TERRA

BLU - NEUTRO

Selettore 1 Selettore 10 Modalità di alimentazione

ON ON Molto basso

ON OFF Basso

OFF ON Medio

OFF OFF Alto

Page 53

Dennard 2025 Manuale d’installazione Pagina.51

12. Impostazioni dei tasti di comando

Il proiettore Dennard 2025 può essere azionato da uno dei tre ingressi dei selettori da 12V. L’unità

viene fornita configurata per l’utilizzo con la fotocellula fornita che accende la lampada ogni volta

che il livello di illuminazione scende sotto i 25 lux.

Utilizzo della fotocellula

L’unità viene fornita configurata per l’utilizzo con la fotocellula collocata all’interno dell’unità di

alimentazione. Per funzionare correttamente, la fotocellula rileva la luce ambiente. Assicurarsi che

l’unità di controllo sia montata con la cellula puntata su un lato o sotto l’unità (non rivolta verso

l’alto). L’unità deve restare lontana da fonti di luce artificiale, non deve essere coperta o essere

rivolta sempre verso zone scure.

Un kit di estensione è disponibile per il montaggio remoto della cellula, se necessario. Vedere la

sezione “Accessori e parti di ricambio”.

Ingressi dei selettori remoti

Esistono altri due ingressi dei selettori progettati per dispositivi da 5 -12V. Questi possono essere

configurati in modo da accettare una serie di segnali diversi, ad esempio, un ingresso di contatto

chiuso da un sensore PIR oppure un’unità di controllo esterna.

Gli ingressi sono configurati come riportato di seguito.

Page 54

Ad esempio, per aggiungere un altro ingresso di controllo, collegarlo al morsetto contrassegnato

con CTRL I/P 2 quindi impostare i selettori 6 e 7 del commutatore. Quando i contatti del selettore di

ingresso sono chiusi, la luce si accende; se si desidera che la luce si accenda quando i contatti

d’ingresso sono aperti, impostare il selettore 7 su OFF.

Se sono collegati più selettori, la luce si accende quando sono tutti in posizione ON (OPPURE

controllo).

Dennard 2025 Manuale d’installazione Pagina.52

N. Descrizione ON= OFF= Impostazione

di fabbrica

1

CONTROLLO

ALIMENTAZIONE 1

VEDERE TABELLA IMPOSTAZIONI ALIMENTAZIONE OFF

2 NON UTILIZZATA OFF

3 ATTIVARE INGRESSI DI

CONTROLLO

SEMPRE IN POSIZIONEON- ON

4 CTRL I/P 1 ATTIVARE

(FOTOCELL)

INGRESSO ATTIVATO INGRESSO DISATTIVATO ON

5 CTRL I/P 1 TIPO

(FOTOCELL)

INGRESSO SELETTORE

CHIUSO = ARRAY ON

INGRESSO SELETTORE

APERTO = ARRAY ON

ON

6 CTRL I/P 2 ATTIVARE INGRESSO ATTIVATO INGRESSO DISATTIVATO OFF

7 CTRL I/P 2 TIPO INGRESSO SELETTORE

CHIUSO = ARRAY ON

INGRESSO SELETTORE

APERTO = ARRAY ON

OFF

8 CTRL I/P 3 TIPO INGRESSO ATTIVATO INGRESSO DISATTIVATO OFF

9 CTRL I/P 3 TIPO INGRESSO SELETTORE

CHIUSO = ARRAY ON

INGRESSO SELETTORE

APERTO = ARRAY ON

OFF

10 CONTROLLO

ALIMENTAZIONE 2

VEDERE TABELLA IMPOSTAZIONI ALIMENTAZIONE OFF

Page 55

Dennard 2025 Manuale d’installazione Pagina.53

13. Regolazione dell’angolo del proiettore

Dopo avere predisposto i collegamenti e acceso il proiettore, è necessario impostare l’angolo per

ottenere le migliori prestazioni.

• Visualizzare l’area che si desidera illuminare attraverso la videocamera e il monitor.

• Se si utilizza il supporto per parete, allentare la vite di quest’ultimo e spostare il proiettore in

modo che punti sull’area visualizzata. Serrare la vite.

• Allentare le viti a lato del proiettore e inclinare la lampada fino a quando la zona accanto a

quella visualizzata risulti chiaramente illuminata (se la si visualizza mediante monitor).

• Inclinare la lampada verso l’alto fino a quando la parte più lontana del campo visivo risulti

anch’essa illuminata. Serrare le viti per fissare questa posizione.

Fig. 10 – Regolazione dell’angolo del proiettore

Illuminazione IR

Elemento più prossimo

Elemento più lontano

Page 56

Dennard 2025 Manuale d’installazione Pagina.54

14. Manutenzione

L’unica parte del gruppo proiettore che può essere soggetta a manutenzione è la finestra anteriore

e deve essere riparata solo da personale specializzato. Le altre parti non sono soggette a

manutenzione.

Le uniche parti soggette a manutenzione all’interno della PSU sono i fusibili.

Fusibile di ingresso dell’alimentazione: identificato come F1 sull’etichetta all’interno della PSU.

È un fusibile ritardato da 2A, 250V e un’elevata capacità di interruzione.

Fusibile di uscita del proiettore: identificato come F2. È un fusibile ritardato da 10A, 250V e

un’elevata capacità di interruzione.

Per sostituire un fusibile, rimuovere il portafusibile nero dalla morsettiera, sollevandolo verso l’alto.

Rimuovere il vecchio fusibile e sostituirlo con uno nuovo. Questo deve avere le stesse

caratteristiche del precedente. Reinserire il portafusibile nella morsettiera.

Nel caso in cui l’unità non funzioni, vedere la sezione relativa alla risoluzione dei problemi in questo

manuale.

Page 57

Dennard 2025 Manuale d’installazione Pagina.55

15. Accessori e parti di ricambio

16. Risoluzione dei problemi

ATTENZIONE

Prima di rimuovere il coperchio, disconnettere l’apparecchio dalla linea di alimentazione.

Se l’unità mostra segni di danneggiamento o cattivo funzionamento, disconnetterla immediatamente

dalla linea di alimentazione e contattare Dedicated Micros.

• In condizioni di scarsa luminosità, si noterà una luce rossa proveniente dai LED. In condizioni di

normale luminosità, non si vedrà niente, a meno che non si guardi la lampada con una

videocamera.

• Verificare che la linea di alimentazione sia connessa correttamente e attivata. L’alimentazione

erogata dovrebbe essere a 100-240V ~.

• Verificare la polarità delle connessioni alla lampada.

• Controllare il funzionamento della fotocellula (nastro sulla fotocellula) e attendere alcuni secondi

per vedere se l’apparecchio si accende.

• Verificare i fusibili da 2 e 10 A all’interno della PSU e sostituirli, se necessario.

• Disconnettere tutti i dispositivi di controllo e collocare tutti i selettori nel commutatore in

posizione OFF per verificare che la lampada funzioni.

N. parte Descrizione

Dennard 95083 Sostituzione dell’unità di alimentazione

Dennard 95084 Unità di sostituzione del proiettore, angolo 850 nm/30°

Dennard 94032 Kit di estensione della fotocellula – per il montaggio remoto della fotocellula

dalla PSU

Dennard 95086 Finestra di sostituzione

Dennard 95087 Fotocellula di sostituzione

Page 58

Dennard 2025 Manuale d’installazione Pagina.56

17. Specifiche

Tensione di ingresso : 100 - 240 V~ 50-60 Hz

Ingresso di alimentazione : 120 W

Fusibile di ingresso dell’alimentazione : 2A, ritardato, elevata capacità di interruzione.

Fusibile di ingresso dell’alimentazione : 10A, ritardato, elevata capacità di interruzione.

Indice di protezione IP: B.S. EN 60529, IP 66

Altre approvazioni : EN 61000-6-3 EMC Normativa per ambienti residenziali, commerciali e per

l’industria leggera.

EN 61000-3-3 Limitazioni di variazioni, fluttuazioni e sbalzi di tensione nei sistemi pubblici di

alimentazione a basso voltaggio per apparecchiature con corrente nominale massima di 16A.

EN 61000-3-2 Limiti per le emissioni di corrente armonica (apparecchiature con corrente nominale

massima di 16 A).

EN 50130-4 Requisiti di immunità per componenti di sistemi antincendio, antintrusione e di allarme

personale.

EN 60950 Sicurezza delle apparecchiature per la tecnologia dell’informazione comprese le

apparecchiature elettriche per ufficio.

EN 55022 Class B. Normativa per emissioni irradiate, adatta per uso commerciale o residenziale.

EN 60825-1 Standard di sicurezza per LED e laser.

Temperatura di funzionamento: -20°C - 50°C. Evitare l’esposizione alla luce diretta del sole.

Peso : Unità proiettore e supporto principale : 7 kg

Supporto a parete : 1 kg

PSU : 5 kg

Page 59

Nota

Page 60

Nota

Page 61

2025

INSTALLATIONSHANDBUCH

Page 62

Dennard 2025 Installationshandbuch Seite. 60

1. Einleitung

Herzlichen Glückwunsch zur Wahl des Dennard 2025 IR-LED-IIluminators. Diese Produktpalette

wurde als leistungsstarke und und langlebige Lichtquelle für Kameras entwickelt, deren

Spektralempfindlichkeit sich auf den Infrarotbereich erstreckt. Bei ordnungsgemäßer Verwendung

bietet dieses Produkt Ihnen über 5 Jahre wartungsfreien Betrieb.

Das Gerät wird mit einem dedizierten Netzteil geliefert, das einen Netzanschluss erfordert. Es darf

nur mit diesem Netzteil eingesetzt werden.

Der Illuminator und das Netzteil sind wetterfest nach Schutzklasse IP66.

Dieses Handbuch bietet alle erforderlichen Informationen für die Einrichtung, Installation und den

Betrieb der Illuminatoren aus der Dennard 2025.

Page 63

Dennard 2025 Installationshandbuch Seite. 61

2. Inhaltsverzeichnis

Einleitung 60

Inhaltsverzeichnis 61

Skizze der Dennard 2025 62

Im Lieferumfang enthaltene Komponenten 63

Allgemeine Sicherheitshinweise 64

Montage des Illuminators 64

Befestigung an einem Schwenk- und Neigekopf der Dennard 2000 65

Wandbefestigung 65

Befestigung der Steuerung 65

Leitungsanschlüsse 68

Konfiguration 70

Leistungseinstellungen 71

Steuerungseinstellungen 71

Verwendung der Fotozelle 71

Fernschaltereingänge 71

Anpassen des Beleuchtungswinkels 73

Wartung & Instandhaltung 74

Ersatzteile und Zubehör 75

Fehlersuche 75

Technische Details 76

Page 64

Dennard 2025 Installationshandbuch Seite. 62

3. Skizze der Dennard 2025

Abbildung 1 - Allgemeine Abmessungen

117mm

200mm

184mm

208mm

258mm

300mm

PSU

LED-Illuminator

Page 65

Dennard 2025 Installationshandbuch Seite. 63

4. Im Lieferumfang enthaltene Komponenten

Entnehmen Sie den Illuminator vor der Installation bitte aus der Verpackung und vergewissern Sie

sich, dass alle nachfolgend aufgeführten Artikel vorhanden sind.

1 x Dennard 2025 IR-LED-Illuminator

1 x Dennard 2025 dediziertes Netzteil

1 x Dennard 2025 Wandhalterung

1 x Zubehörsatz bestehend aus:

1 x 6 mm Inbusschlüssel

1 x M8 x 20 Zylinderschrauben

1 x M10 x 140 Sechskantschraube

1 x M10 Mutter

2 x M10 Schraubensicherung

2 x M10 x 16 Sechskantschrauben

2 x M10 Unterlegscheiben

2 x M10 Federscheiben

1 x M8 Unterlegscheibe

1 x M8 Unterlegscheibe

4 x 8 mm Holzschrauben

4 x Dübel

4 x M8 Gummischeiben (Dowty)

6 x Kabelbinder

Page 66

Dennard 2025 Installationshandbuch Seite. 64

5. Allgemeine Sicherheitshinweise

Dieses Gerät der Serie Dennard 2025 sollte nur von qualifizierten Fachkräften installiert werden.

Die endgültige Installation muss unter Einhaltung aller nationalen Verkabelungsvorschriften

erfolgen.

Der Trennschalter muss die Anforderungen der IEC 60947 erfüllen.

WARNUNG:

Lesen Sie diese Anweisungen vor Installation und Inbetriebnahme.

Anweisungen zur spätere Bezugnahme aufbewahren.

Wenn dieses Gerät Anzeichen von Schäden oder Funktionsstörungen aufweist, trennen Sie es

sofort vom Stromnetz und nehmen Sie Kontakt mit Dedicated Micros. auf.

6. Montage des Illuminators

Achten Sie darauf, dass der Illuminator an einem gut belüfteten Ort aufgestellt wird und auf allen

Seiten ein Mindestabstand von 100 mm zur Wärmesenke eingehalten wird.

Vermeiden Sie es, den Illuminator in direktem Sonnenlicht oder in der Nähe anderer Hitzequellen

aufzustellen.

Missachtung verkürzt die Lebensdauer der LEDs und reduziert die Helligkeit der Lampe.

WARNUNG: Achten Sie bei der Montage des Illuminators darauf, in Augenhöhe einen

Mindestabstand von 2 m einzuhalten. Schauen Sie während des Gebrauchs nicht längere

Zeit direkt in den Illuminator.

Page 67

7. Befestigung an einem Schwenk- und

Neigekopf der Dennard 2000

Abbildungen 2 & 3 zeigen typischen Positionen für Infrarot-Illuminatoren, die an einem

ferngesteuerten Schwenk- und Neigekopf des Dennard 2000 befestigt sind.

Befestigen Sie den Dennard 2025 Illuminator mithilfe der M10 Schrauben, die im Lieferumfang

enthalten sind.

Aufgrund seines Gewichstes sollte dieser Illuminator nicht mithilfe der optionalen

Seitenbefestigungsplatte am Schwenk- und Neigekopf montiert werden.

8. Wandbefestigung

Der Illuminator kann direkt an einer Wand befestigt werden und bewegt sich dann nur nach oben

und unten. Sie können zur Montage auch eine Wandhalterung benutzen, um auch seitliche

Bewegungen zu ermöglichen. Siehe Abb. 4.

WARNUNG: Vergewissern Sie sich, dass die Wandbefestigungen für die Art der Wand

geeignet sind und das gesamte Gewicht des Gerätes tragen können.

9. Befestigung der Steuerung

Entfernen Sie die Verschlussstopfen, wie in Abb. 5 dargestellt, und befestigen Sie die Steuerung

dann mithilfe der Dübel, Schrauben und Gummischeiben an der Wand. Tragen Sie zwischen Wand

und Gerät einen Silikon-Dichtstoff auf, um eine wasserfeste Abdichtung zu gewährleisten.

Dennard 2025 Installationshandbuch Seite. 65

Page 68

Abbildung 2 - Konfiguration mit zwei Illuminatoren an einem Dennard 2000

Schwenk- und Neigekopf

Abbildung 3 - Befestigungsdetails

Abbildung 4 - Befestigung des Illuminators an einer Wand unter Einsatz einer Wandhalterung

Dennard 2025 Installationshandbuch Seite. 66

Page 69

Abbildung 5 - Entfernen der Verschlussstopfen

Abbildung 6 - Anbringen der Befestigungsschrauben und Unterlegscheiben

Dennard 2025 Installationshandbuch Seite. 67

Page 70

Dennard 2025 Installationshandbuch Seite. 68

10. Leitungsanschlüsse

Die elektrischen Anschlüsse an den Dennard 2025 Illuminator erfolgen über Klemmenblöcke im

Netzgerät.

Für Zugang zu den Anschlüssen lösen Sie die 4 Schrauben der Netzgerätabdeckung und entfernen

Sie die obere Abdeckung.

WARNUNG: Achten Sie darauf, dass die Stromzufuhr isoliert ist, solange die Abdeckung des

Netzgerätes abgehoben ist.

Die Netzstromversorgung sollte mit einem Überlastschalter ausgestattet werden, um die

Stromzufuhr zu Wartungszwecken zu unterbrechen. Der Überlastschalter sollte frei zugänglich und

so beschildert sein, dass er leicht als Trennschalter für dieses Gerät zu erkennen ist. Das Gerät

muss die Anforderungen der IEC 60947 erfüllen. Der Trennschalter und alle Verkabelungen müssen

eine angemessene Bemessung aufweisen, um die Eingangsspannung des Netzgerätes zu erfüllen,

wie unter den technischen Details angegeben.

Die Netzverkabelung muss die Anforderungen der nationalen Verkabelungsvorschriften einhalten.

Achten Sie darauf, dass das Netzkabel so vorbereitet wird, wie in Abb. 8 dargestellt. Führen Sie

das Kabel durch den unteren Kabelstutzen und sichern Sie die Dichtungsmuffe mit einem

Drehmoment von 1,8 Nm. Benutzen Sie den Kabelbinder, um das Kabel an der beigefügten

Befestigungssäule zu sichern, wie in Abb. 7 dargestellt.

Schließen Sie das Kabel des Illuminators an den Verbindungsstecker und die Erdung an, wie in

Abb. 7 dargestellt. Befestigen Sie das Kabel mithilfe der Kabelbinder an den Drähten der Fotozelle,

die entlang der rechten Seite des Gehäuses verlaufen. Achten Sie auf korrekte Polarität. Der rot

ummantelte Draht wird an den Pluspol angeschlossen, der auf der Platine mit “LED ARRAY +ve”

beschriftet ist.

WARNUNG: Verlängern Sie das Kabel nicht, da dies die Leistung des Gerätes

beeinträchtigen könnte. Sie können das Kabel auf eine Mindestlänge von 1 m kürzen.

Page 71

Das Gerät wird mit einer Fotozelle geliefert, die so angeschlossen und konfiguriert ist, dass die

Lampe sich einschaltet, wenn die Beleuchtungsstärke unter 25 Lux abfällt. Möchten Sie die Lampe

ständig betreiben oder eine andere Schaltquelle verwenden, so lesen Sie bitte den Abschnitt

“Fernschaltereingänge”.

Abbildung 7 - Verkabelung des Kunden

Dennard 2025 Installationshandbuch Seite. 69

Netzkabel durch unteren Kabelstutzen

führen und mit beigefügtem Kabelbinder

an der Säule befestigen.

Schließen Sie die Netzversorgung an den

Klemmenblock an - grün/gelb an Erde (PE),

braun an Phase (L) und blau an den Nulleiter (N).

Illuminatorkabel durch oberen

Kabelstutzen führen und mit

beigefügten Kabelbindern an

Fotozellenkabeln sichern.

Illuminatorkabel an Klemmenblock anschließen,

dabei auf korrekte Polarität achten.

Page 72

Abbildung 8 - Vorbereitung des Netzkabels

11. Konfiguration

Leistungseinstellungen

Es ist möglich, das Netzgerät auf 4 verschiedene Leistungsstufen einzustellen. Das Gerät ist

werkseitig auf hohe Leistung eingestellt.

Wird die Lampe bei Temperaturen über 40°C bzw. kontinuierlich verwendet, empfehlen wir den

Betrieb bei mittlerer oder geringer Leistung, um die Lebensdauer der LEDs zu maximieren.

Schalter 1 und 10 in der Schalterbank steuern die Einstellungen der Leistungsstufen. Das Gerät ist

werkseitig auf hohe Leistung eingestellt.

Dennard 2025 Installationshandbuch Seite. 70

ANSCHLUSS AN DENNARD 2025 NETZGERÄT

6 mm ABISOLIEREN UND

FÜR KLEMMENBLOCK

VORBEREITEN

GRÜN/GELB -

ERDE

BLAU - NEUTRAL

BRAUN PHASE

4-6 mm DURCHMESSER

SCHUTZMANTEL

MIN 24 mm

max. 20 mm SCHUTZMANTEL

ABGEZOGEN

ANSCHLUSS AN VERKABELUNG DES KUNDEN

BRAUN PHASE

GRÜN/GELB ERDE

BLAU - NEUTRAL

Schalter 1 Schalter 10 Leistungsstufe

AN AN Sehr niedrig

AN AUS Niedrig

AUS AN Mittel

AUS AUS Hoch

Page 73

Dennard 2025 Installationshandbuch Seite. 71

12. Steuerungseinstellungen

Der Illuminator der Dennard 2025 kann über einen der drei 12V Schaltereingänge geschaltet

werden. Das Gerät ist werkseitig für die Verwendung der Fotozelle konfiguriert, die die Lampe bei

eine Beleuchtungsstärke unter 25 Lux einschaltet.

Verwendung der Fotozelle

Das Gerät ist im Auslieferungszustand für die Verwendung einer Fotozelle konfiguriert, die sich im

Netzgerät befindet. Die Funktion der Fotozelle wird über die Erkennung des Umgebungslichtes

gesteuert. Vergewissern Sie sich, dass die Steuerung so ausgerichtet wird, dass die Zelle sich auf

einer Seite oder an der Unterseite des Gerätes befindet (nicht nach oben zeigend). Sie muss

Abstand zu Quellen künstlichen Lichts haben und darf weder abgeschirmt werden noch sich

ständig im Dunkeln befinden.

Zur Befestigung der Fotozelle auf Abstand ist ein Erweiterungssatz erhältlich. Informationen dazu

finden Sie unter “Ersatzteile und Zubehör”.

Fernschaltereingänge

Es gibt zwei weitere Schaltereingänge für Geräte mit 5-12V. Diese können für eine Reihe

unterschiedlicher Signale konfiguriert werden, z.B. für einen Öffnereingang von einem PIR-Melder

oder einer externen Steuerung.

Die Eingänge werden gemäß folgender Tabelle konfiguriert.

Page 74

Beispiel: Um einen weiteren Steuerungseingang zum Gerät hinzuzufügen, verkabeln Sie es mit

dem Klemmenblock, der mit CTRL I/P2 markiert und stellen Sie die Bankschalter 6 und 7 auf “Ein”.

Wenn die Kontakte am Eingangsschalter geschlossen sind, wird das Licht eingeschaltet. Soll das

Licht eingeschaltet werden, wenn die Eingangskontakte geöffnet sind, so stellen Sie Bankschalter 7

auf “Aus”.

Wenn mehrere Schalter angeschlossen sind, schaltet das Licht sich ein, wenn ein beliebiger dieser

Schalter (ODER die Steuerung) eingeschaltet ist.

Dennard 2025 Installationshandbuch Seite. 72

Nr.

Beschreibung AN= AUS=

Werksein-

stellung

1

LEISTUNGSSTEUERUNG

1

SIEHE TABELLE DER LEISTUNGSEINSTELLUNGEN

AUS

2

UNBELEGT

AUS

3

STEUERUNGSEINGÄNGE

AKTIVIEREN

IMMER EINGESCHALTET -

AN

4

CTRL I/P 1 AKTIVIEREN

(FOTOZELLE)

EINGANG AKTIVIERT EINGANG DEAKTIVIERT

AN

5

CTRL I/P 1 TYP

(FOTOZELLE)

GESCHLOSSENER

SCHALTEREINGANG =

ARRAY AN

GEÖFFNETER

SCHALTEREINGANG =

ARRAY AN

AN

6

CTRL I/P 2 AKTIVIEREN EINGANG AKTIVIERT EINGANG DEAKTIVIERT

AUS

7

CTRL I/P 2 TYP GESCHLOSSENER

SCHALTEREINGANG =

ARRAY AN

GEÖFFNETER

SCHALTEREINGANG =

ARRAY AN

AUS

8

CTRL I/P 3 TYP EINGANG AKTIVIERT EINGANG DEAKTIVIERT

AUS

9

CTRL I/P 3 TYP GESCHLOSSENER

SCHALTEREINGANG =

ARRAY AN

GEÖFFNETER

SCHALTEREINGANG =

ARRAY AN

AUS

10

LEISTUNGSSTEUERUNG2SIEHE TABELLE DER LEISTUNGSEINSTELLUNGEN

AUS

Page 75

Dennard 2025 Installationshandbuch Seite. 73

13. Anpassen des Beleuchtungswinkels

Wenn Sie die Anschlüsse vorgenommen und den Illuminator eingeschaltet haben, müssen Sie den

Beleuchtungswinkel für die bestmögliche Leistung einstellen.

• Betrachten Sie die Fläche, die Sie beleuchten möchten, über eine Kamera und einen Monitor.

• Wenn Sie eine Wandhalterung verwenden, lockern Sie die Schraube an der Halterung und

bewegen Sie den Illuminator, sodass er auf den Bereich zeigt, den Sie sehen möchten. Ziehen

Sie die Schraube fest.

• Lockern Sie die Schrauben an der Seite des Illuminators und neigen Sie die Lampe nach unten,

bis der nahe Bereich des Sichtfeldes gut erleuchtet ist (bei Betrachtung auf einem Monitor).

• Neigen Sie die Lampe langsam nach oben, bis der entfernte Bereich des Sichtfeldes auch

erleuchtet ist. Ziehen Sie die Schrauben in dieser Position fest.

Abbildung 10 - Anpassen des Beleuchtungswinkels

IR-Illumination

Dichtestes Objekt

Entferntestes Objekt

Page 76

Dennard 2025 Installationshandbuch Seite. 74

14. Wartung & Instandhaltung

Das einzige Teil dieses Illuminators, das gewartet werden kann, ist die Vorderscheibe. Diese sollte

nur von Fachkräften gewartet werden. Alle anderen Teile können nicht gewartet werden.

Die einzigen Teile im Netzgerät, die gewartet werden können, sind die Sicherungen.

Netzeingangssicherung: Diese wird auf dem Schild im Inneren des Netzgerätes mit F1

bezeichnet, Es handelt sich um eine zeitverzögerte (träge) Sicherung mit einer Bemessung von

2A, 250V und einer hohen Ausschaltleistung.

Illuminator-Ausgangssicherung: Diese wird mit F2 bezeichnet. Es handelt sich um eine

zeitverzögerte (träge) Sicherung mit einer Bemessung von 10A, 250V und einer hohen

Ausschaltleistung.

Zum Auswechseln einer Sicherung entnehmen Sie die schwarze Sicherungsfassung aus dem

Klemmenblock, indem sie sie nach oben ziehen. Entnehmen Sie die alte Sicherung und ersetzen

Sie diese durch eine neue. Die neue Sicherung muss die selbe Bemessung haben wie oben

angegeben. Setzen Sie die Sicherungsfassung wieder in den Klemmenblock ein.

Im Falle einer Funktionsstörung des Gerätes lesen Sie bitte den Abschnitt “Fehlersuche” in diesem

Handbuch.

Page 77

Dennard 2025 Installationshandbuch Seite. 75

15. Ersatzteile und Zubehör

16. Fehlersuche

WARNUNG

Trennen Sie die Netzstromzufuhr, bevor Sie die Abdeckung entfernen.

Wenn dieses Gerät Anzeichen von Schäden oder Funktionsstörungen aufweist, trennen Sie es

sofort vom Stromnetz und nehmen Sie Kontakt mit Dedicated Micros. auf.

• Bei schlechten Lichtverhältnissen geben die LEDs ein schwach rotes Licht ab. Bei Tageslicht

sehen Sie nur dann etwas, wenn Sie mit einer Kamera auf die Lampe gucken.

• Vergewissern Sie sich, dass die Verbindung zum Netzanschluss korrekt vorgenommen wurde

und eingeschaltet ist. Die Spannung sollte bei 100-1240 V ~ liegen.

• Überprüfen Sie die Polarität der Anschlüsse an die Lampe.

• Überprüfen Sie die Funktion der Fotozelle (überkleben Sie die Fotozelle) und warten Sie einige

Sekunden, ob das Produkt sich einschaltet.

• Überprüfen Sie die 2A und 10A Sicherungen im Netzgerät und ersetzen Sie diese ggf.

• Trennen Sie die Verbindung zu allen Steuerungen und stellen Sie alle Schalter der Schalterbank

auf “Aus”, um zu überprüfen, ob die Lampe sich einschaltet.

Art.Nr. Beschreibung

Dennard 95083 Ersatz-Netzgerät

Dennard 95084 Ersatz-Illuminator 850 nm/30 Grad Winkel

Dennard 94032 Fotozellenerweiterungssatz - ermöglicht die Anbringung der Fotozelle in

einiger Entfernung vom Netzgerät.

Dennard 95086 Ersatzfenster

Dennard 95087 Ersatz-Fotozelle

Page 78

Dennard 2025 Installationshandbuch Seite. 76

17. Technische Details

Eingangsspannung : 100-240V~ 50-60Hz

Eingangsleistung : 120W

Netzeingangssicherung : 2A, zeitverzögert, hohe Ausschaltleistung.

Illuminator-Eingangssicherung : 10A, zeitverzögert, hohe Ausschaltleistung.

IP-Schutzklasse : B.S. EN 60529, IP 66

Andere Zulassungen: EN 61000-6-3 EMV Fachgrundnormen - Wohnbereich, Geschäfts- und

Gewerbebereiche sowie Kleinbetriebe.

EN61000-3-3 Begrenzung von Spannungsänderungen, Spannungsschwankungen und Flicker in

öffentlichen Niederspannungs-Versorgungsnetzen für Geräte mit einem Bemessungsstrom <= 16A

je Leiter.

EN 61000-3-2 Grenzwerte für Oberschwingungsströme (Geräte-Eingangsstrom <= 16 A je Leiter).

EN 50130-4 Anforderungen an die Störfestigkeit von Anlageteilen für Brand- und

Einbruchmeldeanlagen sowie Personen-Hilferufanlagen.

EN 60950 Einrichtungen der Informationstechnik - Sicherheit.

EN 55022 Klasse B. Gestrahlte Störaussendungen, geeignet für Wohnbereiche und

Gewerbegebiete.

EN 60825-1 Sicherheit von Laser-Einrichtungen.

Betriebstemperatur : -20°C bis 50°C. Direkte Sonneneinwirkung vermeiden.

Gewicht : Illuminator und Haupthalterung :7 kg

Wandhalterung : 1 kg

Netzgerät (PSU) : 5 kg

Page 79

Notizen

Page 80

Notizen

Page 81

2025

MANUEL D’INSTALLATION

Page 82

Dennard 2025 Manual de instalación Página. 80

1. Introducción

Gracias por elegir el iluminador LED (diodo emisor de luz) de infrarrojos Dennard 2025. La gama

de productos está diseñada para dotar de iluminación duradera y de alta potencia a cámaras con

respuesta espectral que abarca el área de infrarrojos. Usándolo correctamente, el producto durará

más de 5 años sin necesidad de mantenimiento.

La unidad se ofrece con un suministro eléctrico especial que requiere una entrada de suministro.

Sólo debe utilizarse con este suministro.

El proyector y la fuente de alimentación incorporan protección IP66.

Este manual de funcionamiento contiene toda la información necesaria para configurar, instalar y

poner en funcionamiento el proyector Dennard 2025.

Page 83

Dennard 2025 Manual de instalación Página. 81

2. Índice

Introducción 80

Índice 81

Diagrama general de la Dennard 2025 82

Componentes suministrados 83

Información sobre seguridad general 84

Montaje del proyector 84

Montaje de una unidad de toma panorámica e inclinación Dennard 2000 85

Montaje en pared 85

Montaje de la unidad de control 85

Conexiones de cableado 88

Configuración 90

Configuración de potencia 91

Configuración de control 91

Uso de la fotocélula 91

Entradas para interruptores 91

Ajuste del ángulo del proyector 93

Mantenimiento 94

Piezas de repuesto y accesorios 95

Resolución de problemas 95

Características técnicas 96

Page 84

Dennard 2025 Manual de instalación Página. 82

3. Diagrama general de la Dennard 2025

Figura 1 - Dimensiones generales

117mm200mm

184mm208mm

258mm

300mm

PSU

Iluminador LED

Page 85

Dennard 2025 Manual de instalación Página. 83

4. Componentes suministrados

Antes de proceder a la instalación extraiga la unidad de la caja y asegúrese de que incluye todos

los elementos que se indican a continuación.

1 Iluminador LED de infrarrojos Dennard 2025

1 suministro eléctrico especial Dennard 2025

1 soporte para pared Dennard 2025

1 conjunto de accesorios que contiene:

1 llave hexagonal A/F de 6 mm

1 perno de cabeza hueca M8 X 20

1 perno de cabeza hexagonal M10 X 140

1 tuerca M10

2 arandelas planas M10

2 perno de cabeza hexagonal M10 X 16

2 arandelas planas M10

2 arandelas elásticas M10

1 arandela plana M8

1 arandela elástica M8

4 tirafondos de 8 mm

4 tacos de plástico

4 arandelas de plástico M8

6 zunchos de cableado

Page 86

Dennard 2025 Manual de instalación Página. 84

5. Información sobre seguridad general

Este equipo Dennard 2025 sólo será instalado por personal de mantenimiento cualificado.

La instalación definitiva debe cumplir con toda la normativa de cableado nacional.

El dispositivo de desconexión debe cumplir con la normativa IEC 60947.

ADVERTENCIA

Lea las instrucciones antes de instalar y aplicar corriente eléctrica.

Guarde las instrucciones para futuras consultas.

Si las unidades muestras señales de deterioro o mal funcionamiento, desconecte inmediatamente

el equipo y póngase en contacto con Dedicated Micros.

6. Montaje del proyector

Asegúrese de que el proyector se monta en una zona bien ventilada con un espacio circundante de

100mm alrededor del disipador de calor.

No monte el proyector en un lugar sometido a la luz solar directa o cerca de otras fuentes de calor.

De hacerlo, puede acortarse la vida de los indicadores luminosos y reducirse la luminosidad de la

lámpara.

ADVERTENCIA: Asegúrese de que el proyector se monta a una distancia mínima de 2

metros del nivel de los ojos. No mire directamente al proyector durante períodos

prolongados durante su uso.

Page 87

7. Montaje de una unidad de toma panorámica

e inclinación Dennard 2000

Las Fig. 2 y 3 muestran las posiciones típicas de los proyectores por infrarrojos cuando se montan

en un cabezal de toma panorámica e inclinación Dennard 2000 controlado de forma remota. Monte

el proyector Dennard 2025 utilizando las fijaciones M10 que se incluyen con la unidad.

Debido al peso del proyector Dennard 2025, no recomendamos que se utilice con la placa de

montaje lateral opcional en la unidad de toma panorámica e inclinación.

8. Montaje en pared

El proyector puede montarse directamente en una pared para permitir solamente el ajuste arriba y

abajo. También puede montarse utilizando el soporte de montaje en pared que se incluye, que

también permite el ajuste a derecha e izquierda. Véase la Fig. 4.

ADVERTENCIA: Asegúrese de que las fijaciones de la pared son adecuadas para el tipo de

pared y que pueden soportar todo el peso de la unidad.

9. Montaje de la unidad de control

Quite los tapones obturadores tal y como se muestra en la Fig. 5 y después utilice los tacos de

plástico, los tornillos y las arandelas de plástico para montar la unidad de control en la pared.

Utilice sellador de silicona entre la pared y la unidad para evitar la entrada de agua.

Dennard 2025 Manual de instalación Página. 85

Page 88

Figura 2 - Configuración de dos iluminadores con unidad de toma panorámica e inclinación

Dennard 2000

Figura 3 - Detalle del montaje

Figura 4 - Montaje del proyector en una pared utilizando el soporte de pared