decon E-Drive PLUS Service Manual

4FSWJDFmanual

E-Drive PLUS

#SVLBSNBOVBMWFSTJPO

Foreword

NOTICE

WARNING

This Service Manual describes the procedures for inspecting, adjusting, and assembling the E-Drive PLUS,

as well as how to handle errors.

Symbols Used in This Manual

Items concerning proper handling are indicated with the following symbols.

Indicates that misuse may lead to fatal or severe injury, or

disability.

Indicates that misuse may lead to material damage.

Indicates correct methods and key points when operating the

product.

Other Precautions

• For product improvement purposes, the descriptions and specifications in this manual are

subject to change without notice.

• Due to changes in the specifications, some of the photos and descriptions may differ from

the actual product.

• This manual is intended for use by persons possessing the basic technical knowledge and

skills.

• Persons who do not possess the general service skills and knowledge should not rely solely

on this service manual to perform inspection, adjustment, disassembly, or reassembly.

Failure to observe this precaution can lead to maintenance problems or mechanical dam-

age.

Table of Contents

1. Product Overview 5

1.1. Product Features 5

1.2. Variations 6

2.

Wheelchair Frame Conditions for Installing the E-Drive PLUS

2.1. Strength Conditions 7

2.2. Structure Conditions 7

2.3. Functional Conditions 8

2.4. Other 8

2.5. Assistant Controller 9

7

3. Installation Procedure 10

3.1. Supplied Parts Check 10

3.2. Power Unit Installation 17

3.3. Separate Battery Seat Installation 22

3.4. Controller Installation 23

3.5. Anti-tip Device Adjustment 31

3.6. Clutch Lever Position Adjustment 32

3.7. Wheel Cap Installation (20", 22" and 24" Models) 32

3.8. Check Items after Power Unit Installation 33

4.

5.

Optional Part Installation and Adjustment Procedures

4.1. Battery Seat Oset Parts 34

4.2. Joystick Knob and Return Spring Replacement 37

4.3. Power Switch and Speed Switch Replacement 41

4.4. Hand Rim Replacement (20", 22", and 24" Models) 43

4.5. Wheel Cap Replacement (20", 22", and 24" Models) 44

Installation, Removal, Disassembly, Assembly, and Adjustment Procedures of Each Part

5.1. Wheel Assembly Removal and Installation 46

5.2. Drive Unit Removal and Installation

(Fixed Axle Models) 47

5.3. Motor Control Unit (Printed Circuit Board) Removal

and Installation 48

34

46

5.4. Wire Harness and Lead Wire Removal

and Installation 50

5.5. Clutch Lever Removal and Installation

(20", 22" and 24" Models) 50

5.6. Clutch Switch Adjustment 52

5.7. Controller Removal, Installation, and Position

Adjustment 52

5.8. Switching the Controller Left/Right Side Position 54

5.9. Controller Disassembly, Assembly, and Parts

Replacement 57

5.10. Assistant Controller (Option) Disassembly

and Assembly 59

6. Settings the Parameters 60

6.1. Operation Overview 60

6.2. Driving Parameters ~Preset Mode~ Setting Method 63

6.3. Driving Parameters ~Free Mode~ Setting Method 65

6.4. Function Parameters Setting Method 73

6.5. Method for Restoring Factory Settings 77

7. Other Settings 78

7.1. Joystick Range of Motion Adjustment 78

7.2. Anti-tampering Function Setting 80

8. Warnings 82

8.1. List of Warnings 82

9. Self-Diagnosis 85

9.1. Self-Diagnosis Function 85

9.2. List of Detected Malfunctions 85

9.3. History Display of Detected Malfunctions Using the

Self-Diagnosis 91

10. Inspection and Maintenance 93

10.1. Inspection Item 93

11. Specications and Other Information 94

11.1. Table of Specications 94

11. 2. W i r i n g Diagram 98

1.

Product Overview

1.1. Product Features

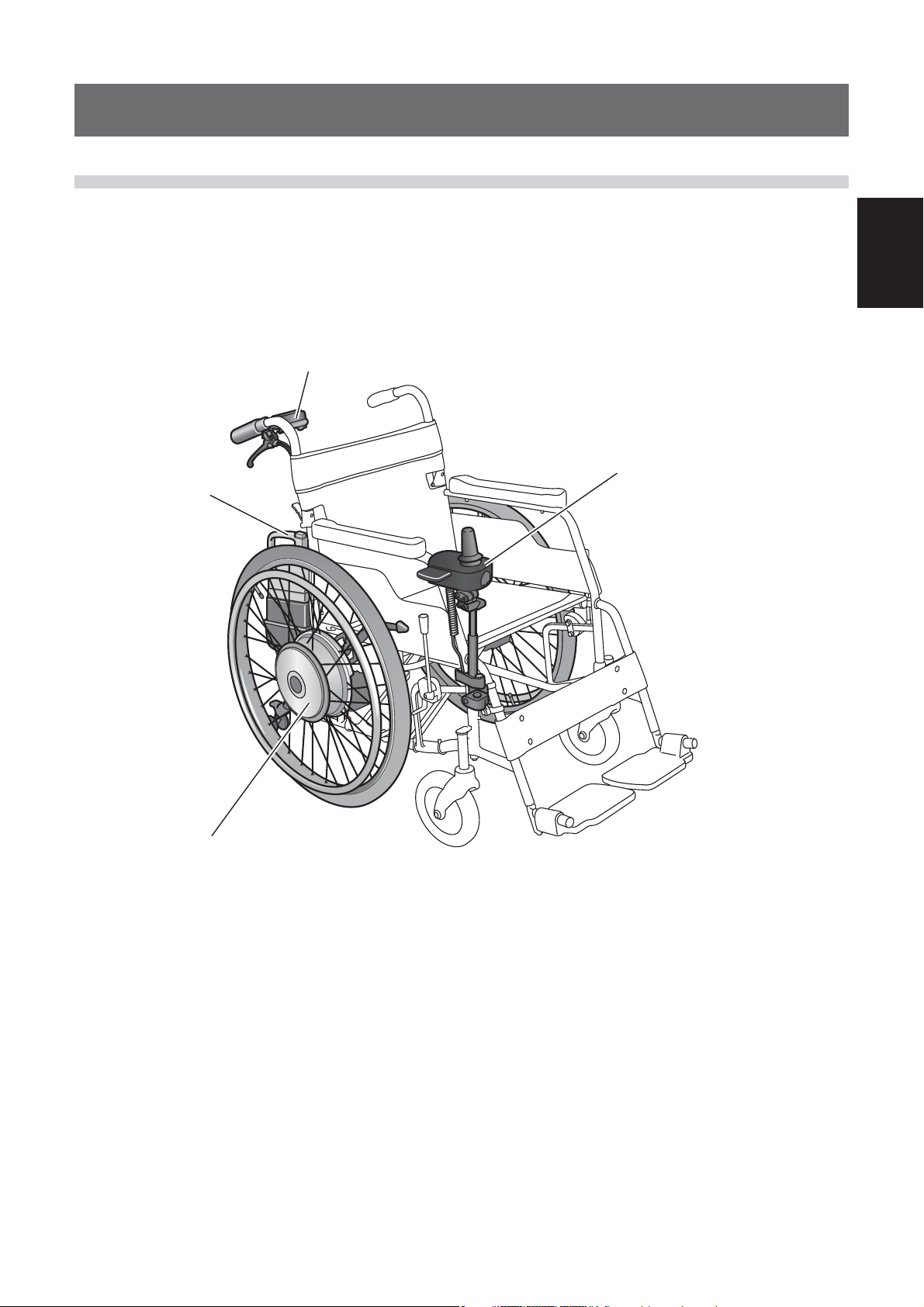

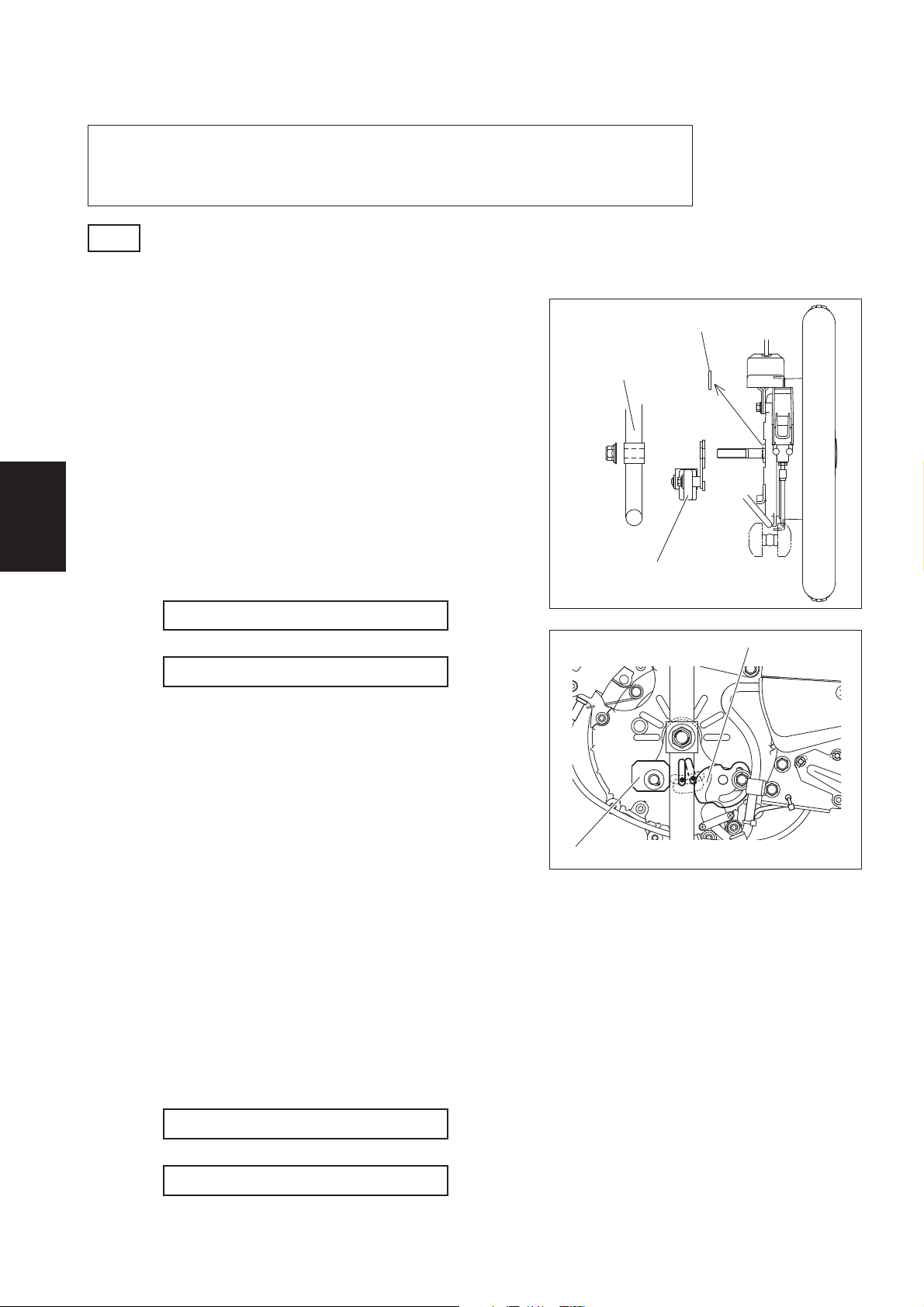

Example of installed E-Drive PLUS

4

3

1

2

1

1 Drive unit with AC servo flat motor.

2 Joystick controller.

3 Dedicated battery with built-in microcomputer.

(Nickel metal hydride battery or lithium ion battery)

4 Assistant controller (optional)

5

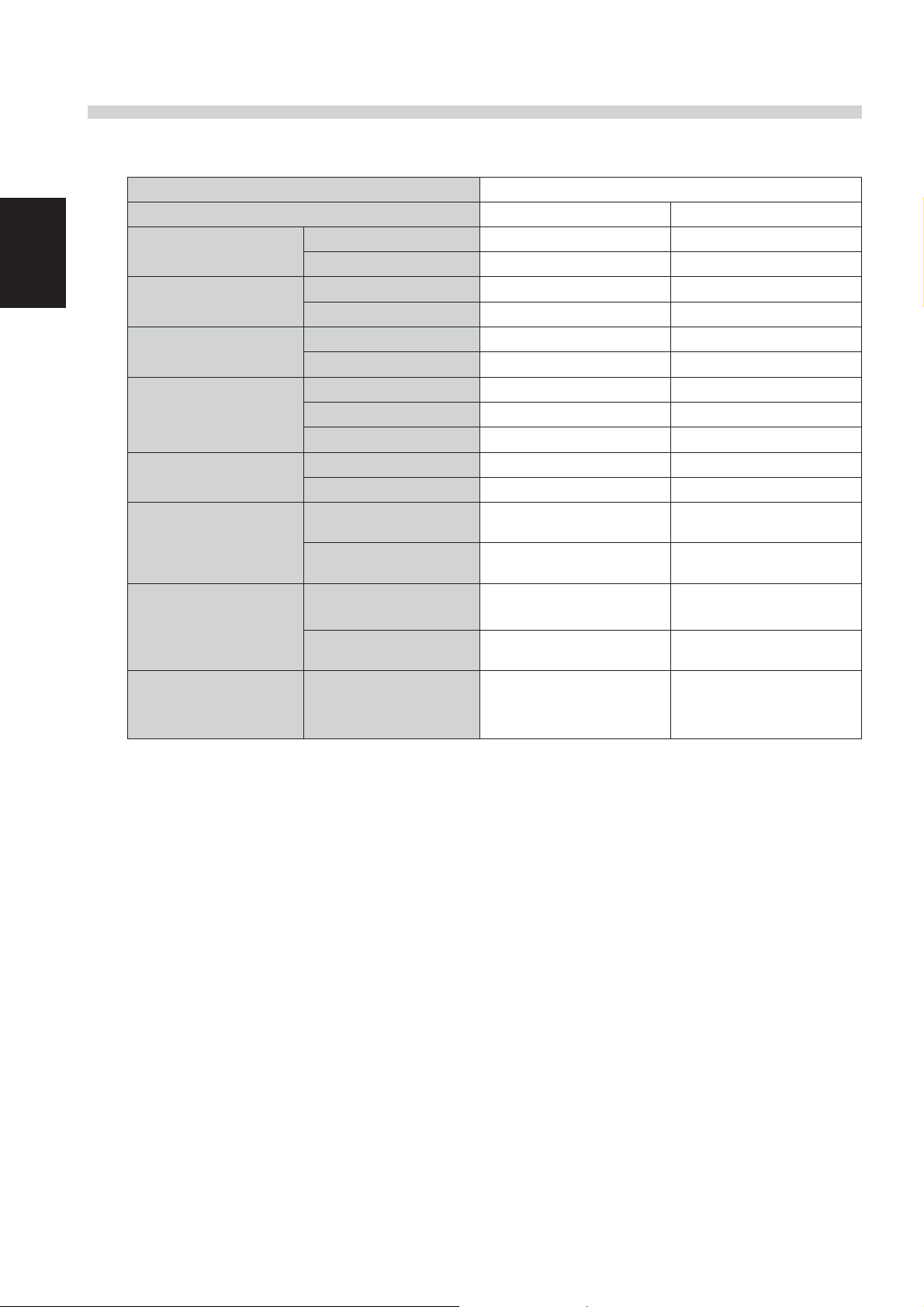

1.2. Variations

(1) Power Unit for Wheelchairs

1

Model

Tire size 20", 22" and 24" 16"

Controller

Controller mounting

Speed

Mounting brackets

Battery seat

Battery location (when

using the integrated

battery seat)

Battery types

Left

Right

Standard

Swing out

4.5 km/h type

6.0 km/h type

Cramp bracket

Bracket A –

Bracket B –

Integrated

Separate –

No offset

Offset (28.5 mm)

Nickel metal hydride

battery

Lithium ion battery

{{

{{

{{

{{

{{

{{

{

{{

{{

{{

{{

{{

E-Drive PLUS

–

{

{

{

Assistant controller

(optional, right-hand

operation only)

Assistant controller

included

{{

6

2.

WARNING

Do not install the E-Drive PLUS on a wheelchair frame that has insufficient strength.

Do not install the E-Drive PLUS on a wheelchair frame that does not meet the installation condi-

tions. Even if it can be installed on the frame, it may malfunction during use if the conditions are

not met, which could injure the user.

Wheelchair Frame Conditions for Installing the E-Drive PLUS

2.1. Strength Conditions

In order to ensure that the entire wheelchair has sufficient strength, the wheelchair frame on which

the E-Drive PLUS is installed must meet the following conditions.

(1) It must have strength equivalent to that required by JIS standards (T9203).

(2) The axle sleeve bracket is securely installed and does not have any looseness.

(3) It must not have a camber angle.

(4) It must have sufficient strength. (There is the chance that wheelchair frames that have

been used for a long time will lose some of their strength.)

(5) It must not have a camber angle.

(6) It must have sufficient strength.

(There is the chance that wheelchair frames that have been used for a long time will lose

some of their strength.)

2

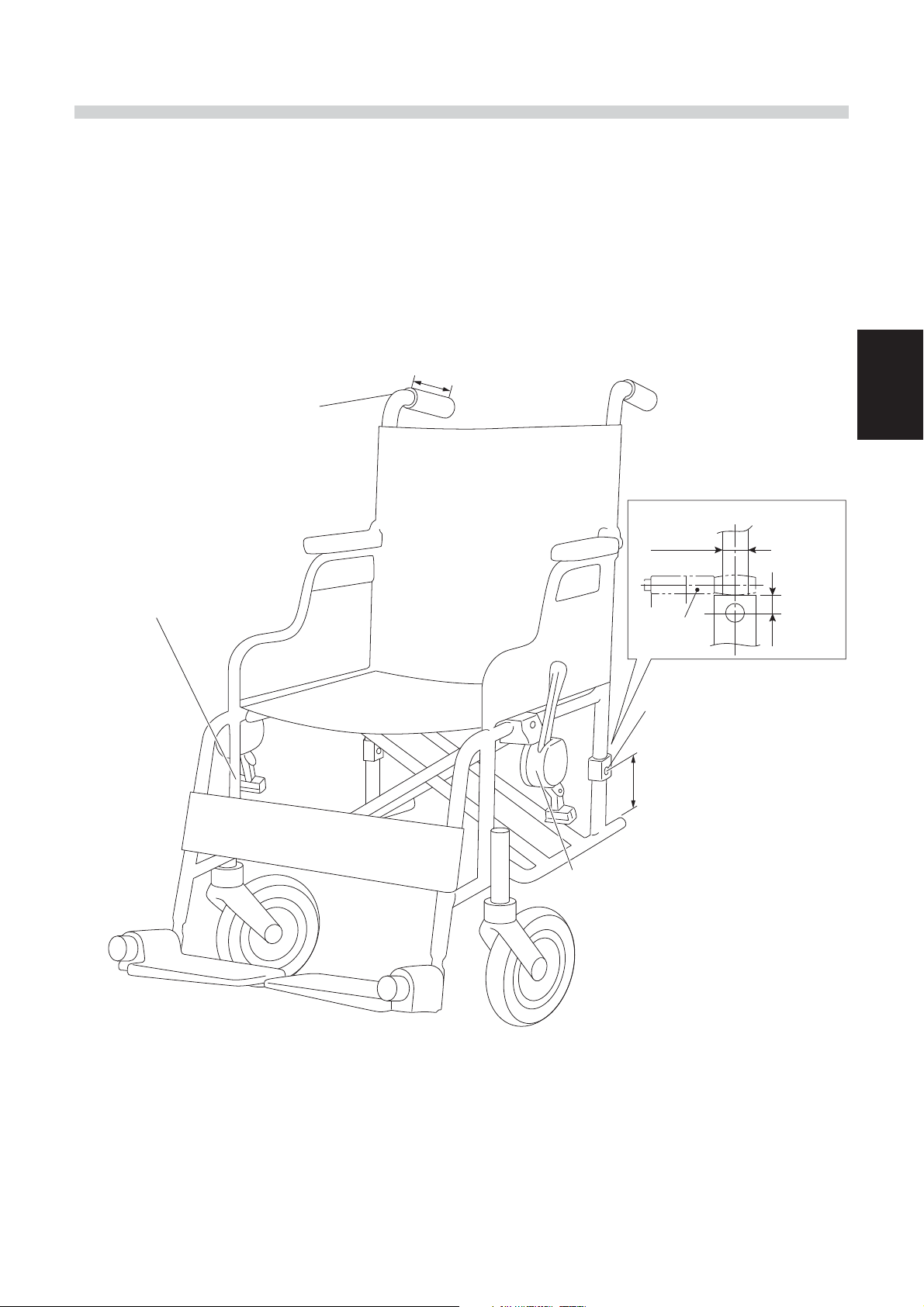

2.2. Structure Conditions

The wheelchair frame must have the following structure.

(1) The diameter of the axle hole is 12.5 to 13.5 mm. (Fixed type case)

(2) The location that the nuts are in contact with around the axle hole must be flat and have

a sufficient surface area. (Fixed type case)

(3) The distance from the center of the axle hole to the base pipe must be at least 70 mm (16"

model bracket A case) or 80 mm (20, 22, 24" model case)

(4) The back pipe diameter must be ø22, and the height of the square lock portion from the

axle hole center must be 20 mm or shorter. (16" model bracket B case)

(5) When attached, the wheelchair frame and the E-Drive must not interfere with each other.

• If installing the adjustment washers in the shaft in order to prevent interference, use up

to 3 per side.

16" Model

[Bracket A] [Bracket B]

7

2

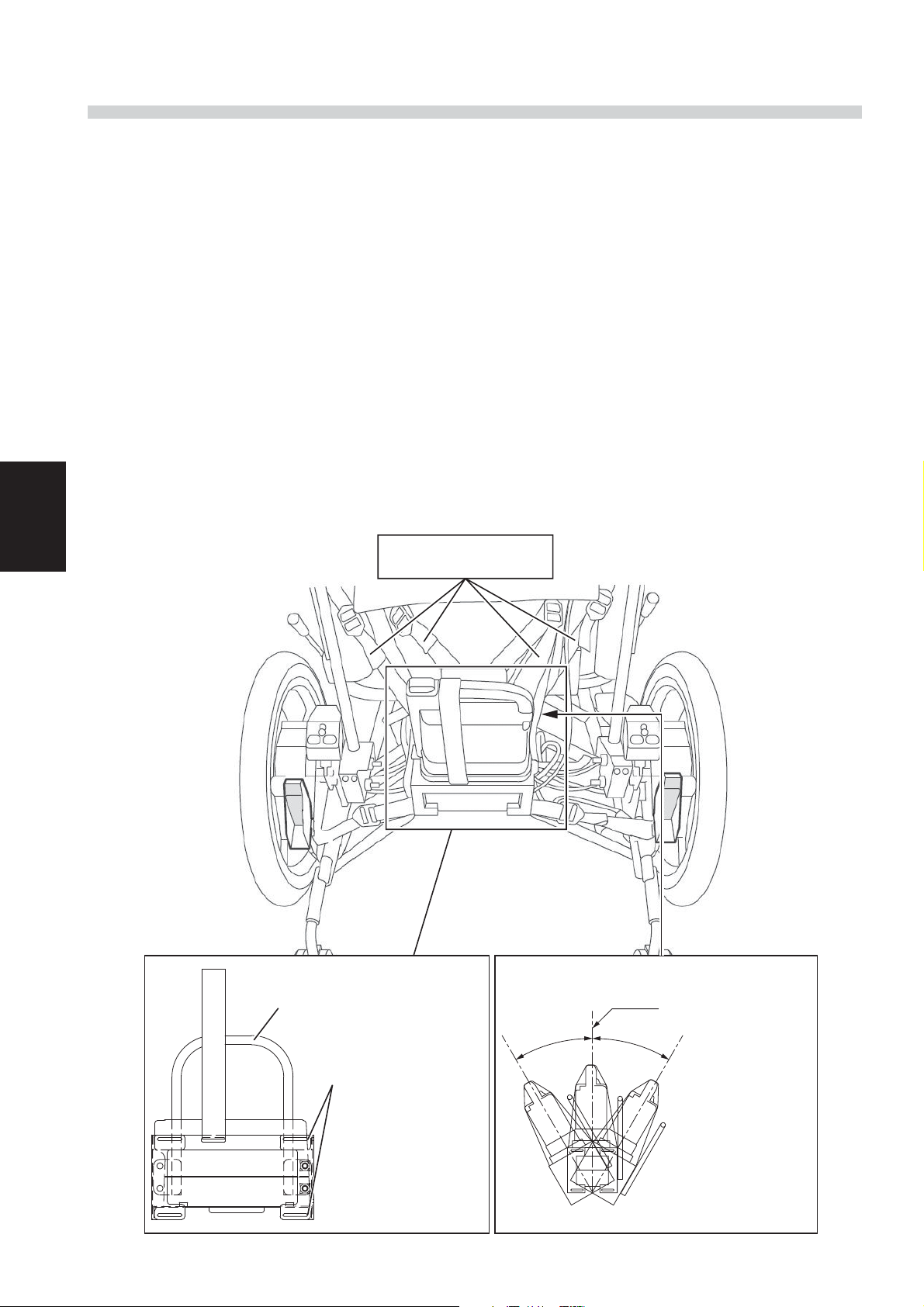

2.3. Functional Conditions

The wheelchair on which the E-Drive PLUS is installed must have the following functions in order to

ensure an appropriate sitting position.

(1) The suitable size of the wheels must be 16, 20, 22 and 24 inches.

(2) Parking brakes must be installed and adjusted to the proper position for the tires. When the E-Drive

PLUS is installed, it must be able to stop the wheelchair at a forward-reverse angle of 7 degrees

when the parking brakes are applied.

(3) When the E-Drive PLUS is installed, a forward-backward tip angle of at least 20 degrees and a side

tip angle of at least 15 degrees must be ensured. (See diagram below) A backward tip angle of at

least 25 degrees is recommended.

(4) Please ensure that the functions of the wheelchair frame are not impaired when the E-Drive PLUS

is installed.

Examples) The movable arm supports can move, the folding feature, reclining feature,

and parking brakes are functional, etc.

2.4. Other

Front casters at least 7 inches in diameter are recommended.

During power driving, operations like caster lifting are not possible. If the casters are small, it is

difficult to get over large bumps. The impact is also greater if the casters are small.

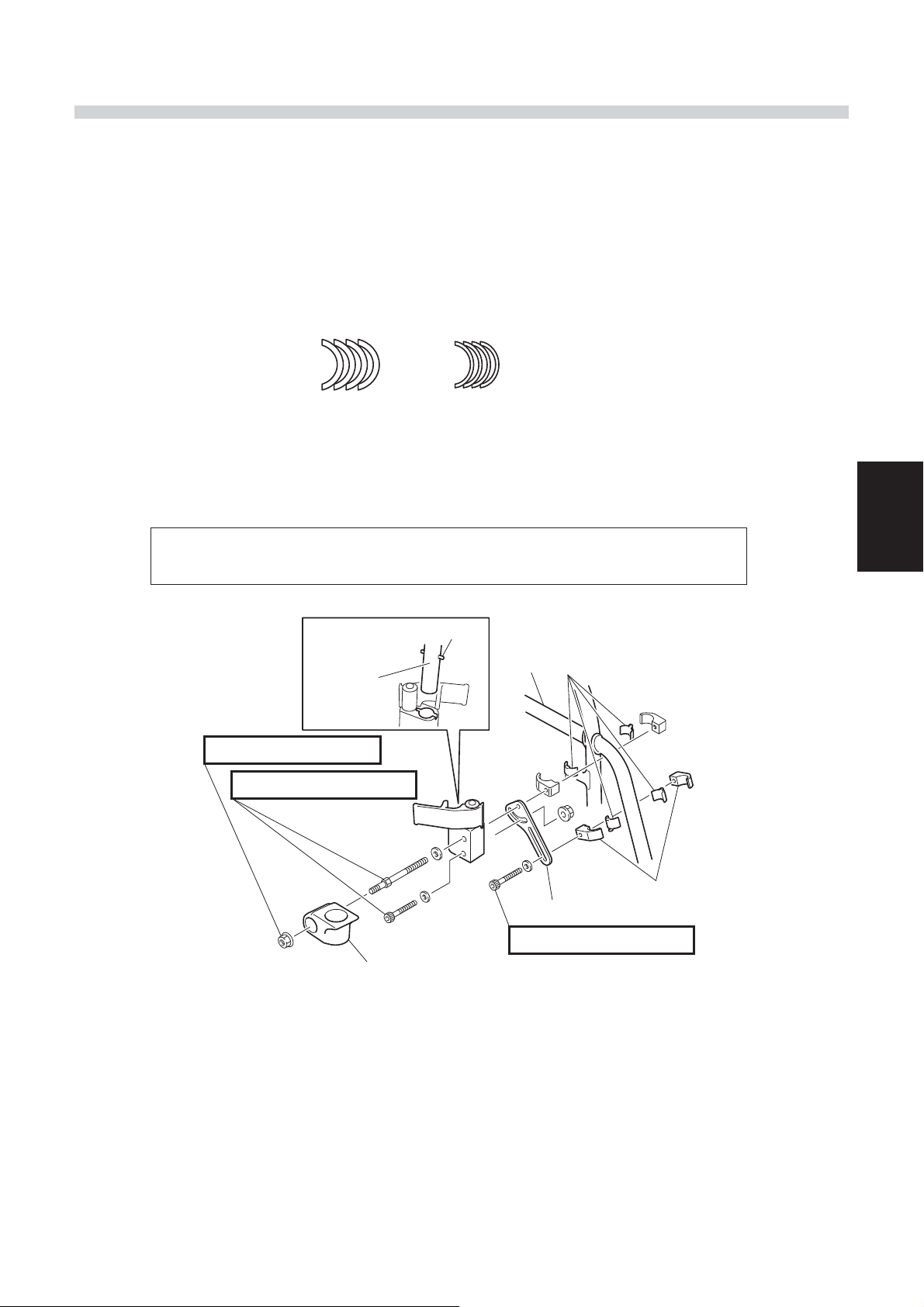

Large diameter (easy to get over bumps) Small diameter (difficult to get over bumps)

8

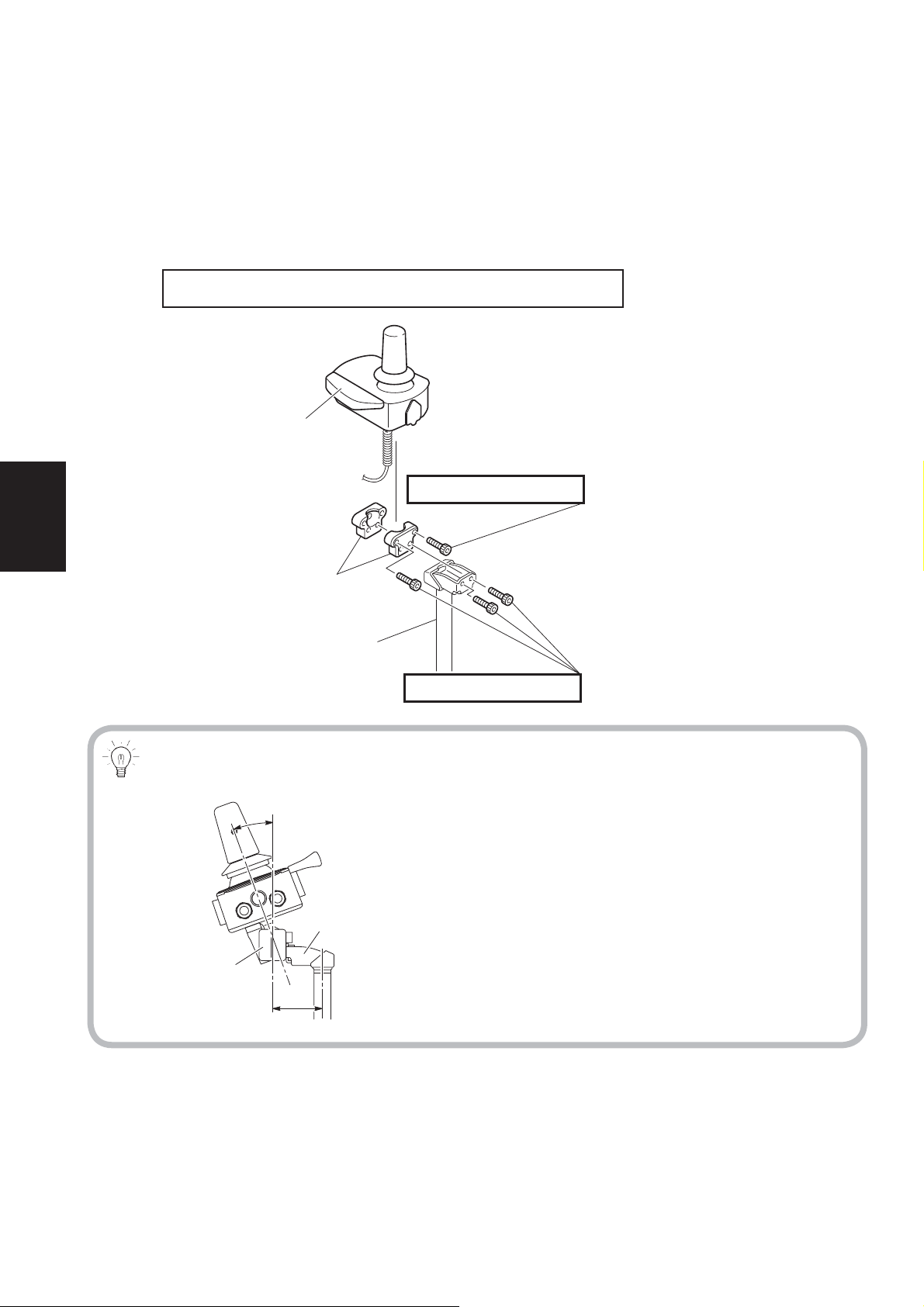

2.5. Assistant Controller

If installing the optional assistant controller:

(1) The push grip pipe must have a maximum outer diameter of 22 mm.

(2) The push grip pipe must have a minimum inner diameter of 16 mm.

(3) The straight section from the end of the push grip pipe must be 90 mm or longer.

Attaching the assistant controller

Maximum outer pipe diameter 22 mm

Minimum inner pipe diameter 16 mm

Straight section 90 mm or longer

Attaching the controller

Under holder attachment

Pipe diameter ø22, ø19, ø16 mm

Straight section

When using bracket B

ø22 mm

Maximum

20 mm

Bracket B

Wheel hole diameter

ø12.5-13. 5

(Fixed type case)

When using bracket A

At least 70 mm to base pipe

2

When the parking brakes are installed on

E-Drive PLUS models, you can adjust and

move them to the proper position for

16-inch tires.

Front casters with a minimum

size of 7 inches

(recommended)

9

3.

Installation Procedure

3.1. Supplied Parts Check

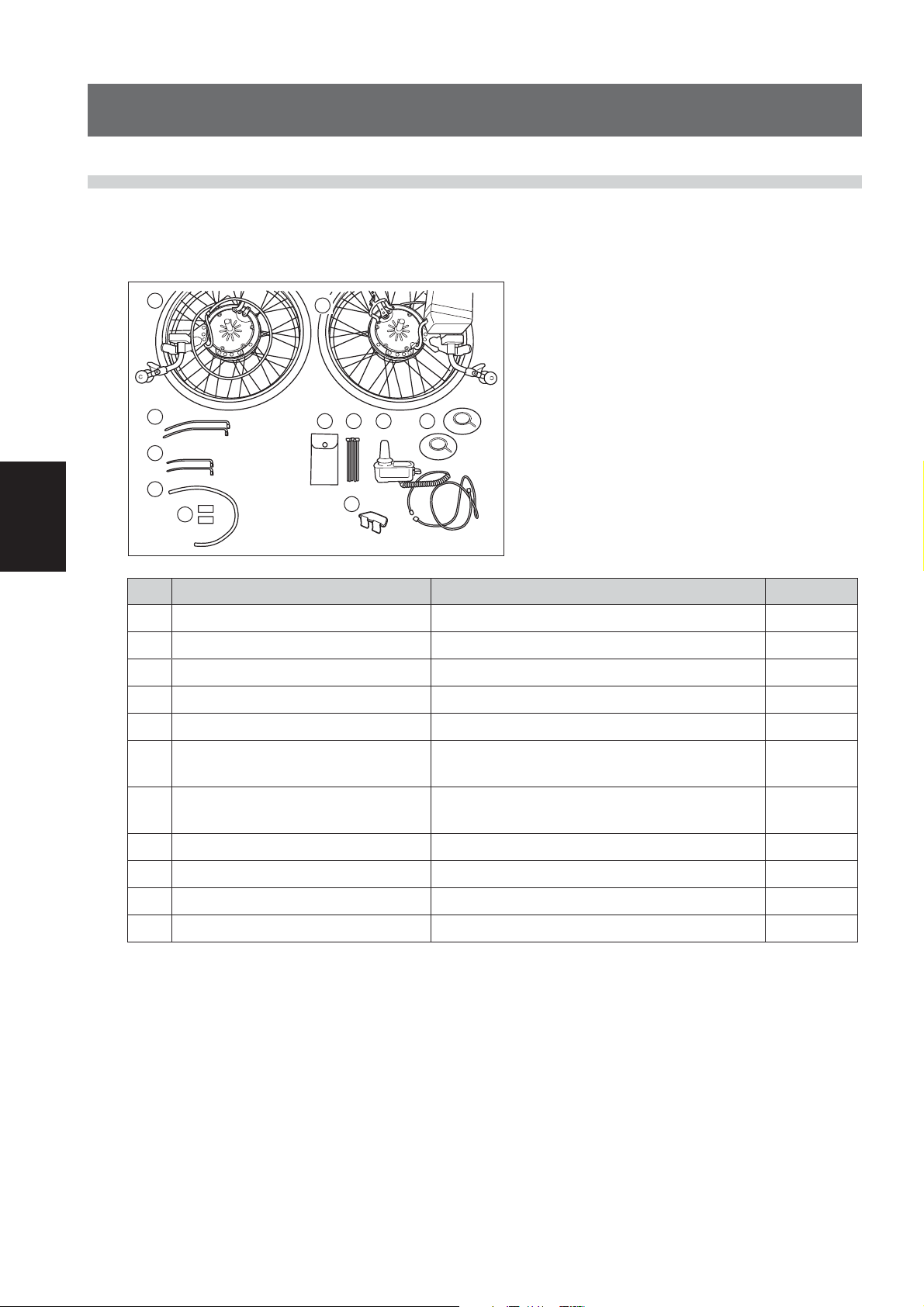

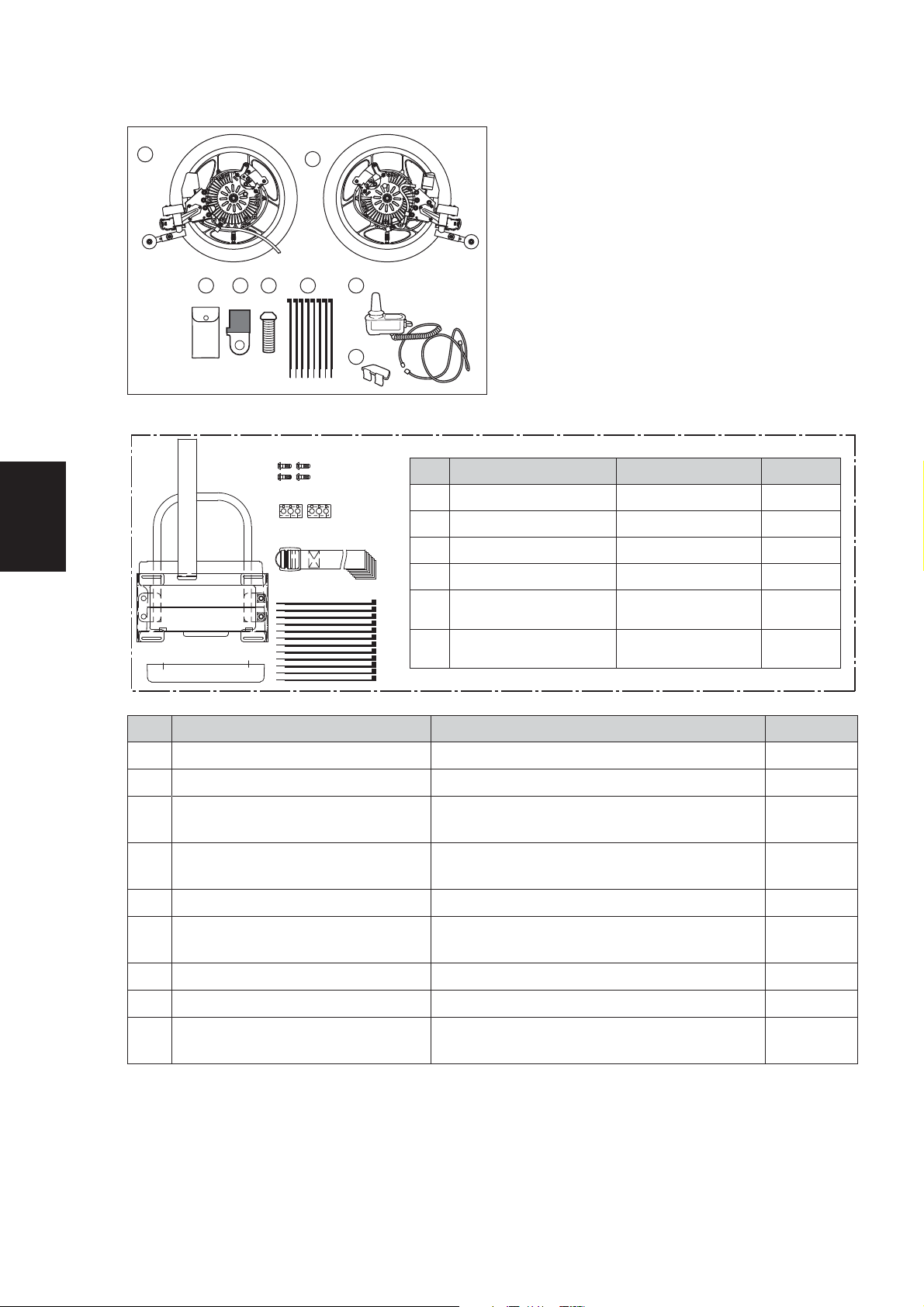

3.1.1. Supplied Parts Check for 20", 22" and 24" Models

(1) Standard Supplied Parts

3

1

3

4

5

6

Product Name Remarks Quantity

1

Left drive unit assembly 1

2

Right drive unit assembly 1

3

Large clamp For securing the wire harness 2

4

Small clamp For securing the wire harness 2

5

Spiral tube For protecting the wire harness 1

6

Sticker

7

Supplied tools

8

Clamp For securing the wire harness 18

9

Controller assembly 1

:

Plate assembly 1

A

Wheel cap Installed to the drive units 2

2

8

7

10

9

11

For affixing to the manual and power

drive positions

Two 8×10 mm open-end wrenches, and

one 5 mm hexagon wrench

3 each

1

10

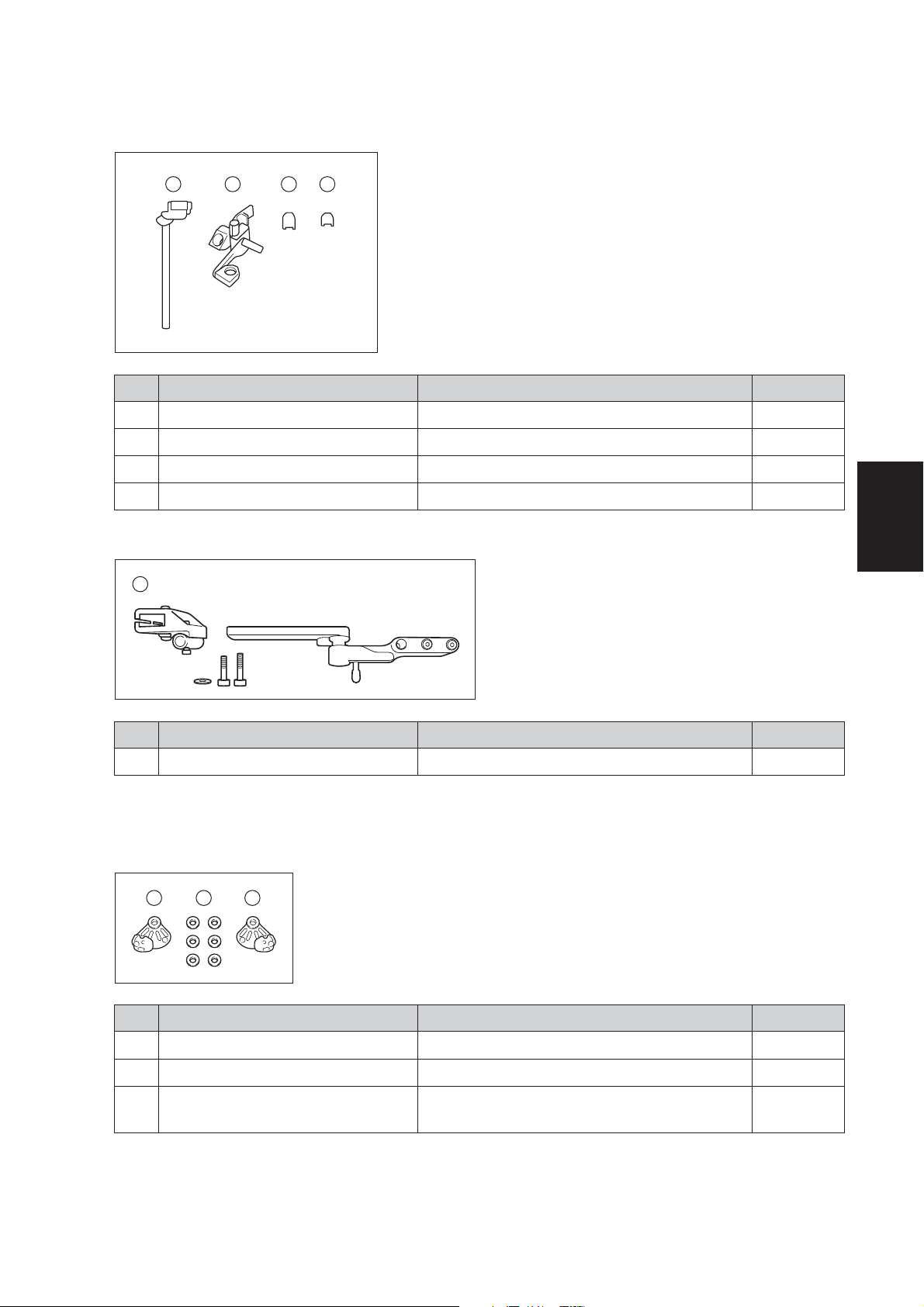

(2) Controller Installation

[Standard]

1 2

Product Name Remarks Quantity

1

Upper holder assembly For installing the controller 1

2

Under holder assembly For installing the controller 1

3

Side plate for ø19–20 For installing the under holder 4

4

Side plate for ø16–17 For installing the under holder 4

[Swing Out Bracket]

1

3 4

3

1

Swing out bracket For installing the controller 1

(3) Battery Location

[No Offset]

1 3 2

1

Left clamp bracket For installing the drive unit 1

2

Right clamp bracket For installing the drive unit 1

3

Plate washer

Product Name Remarks Quantity

Product Name Remarks Quantity

For adjusting the outward position of

the drive unit

6

11

3

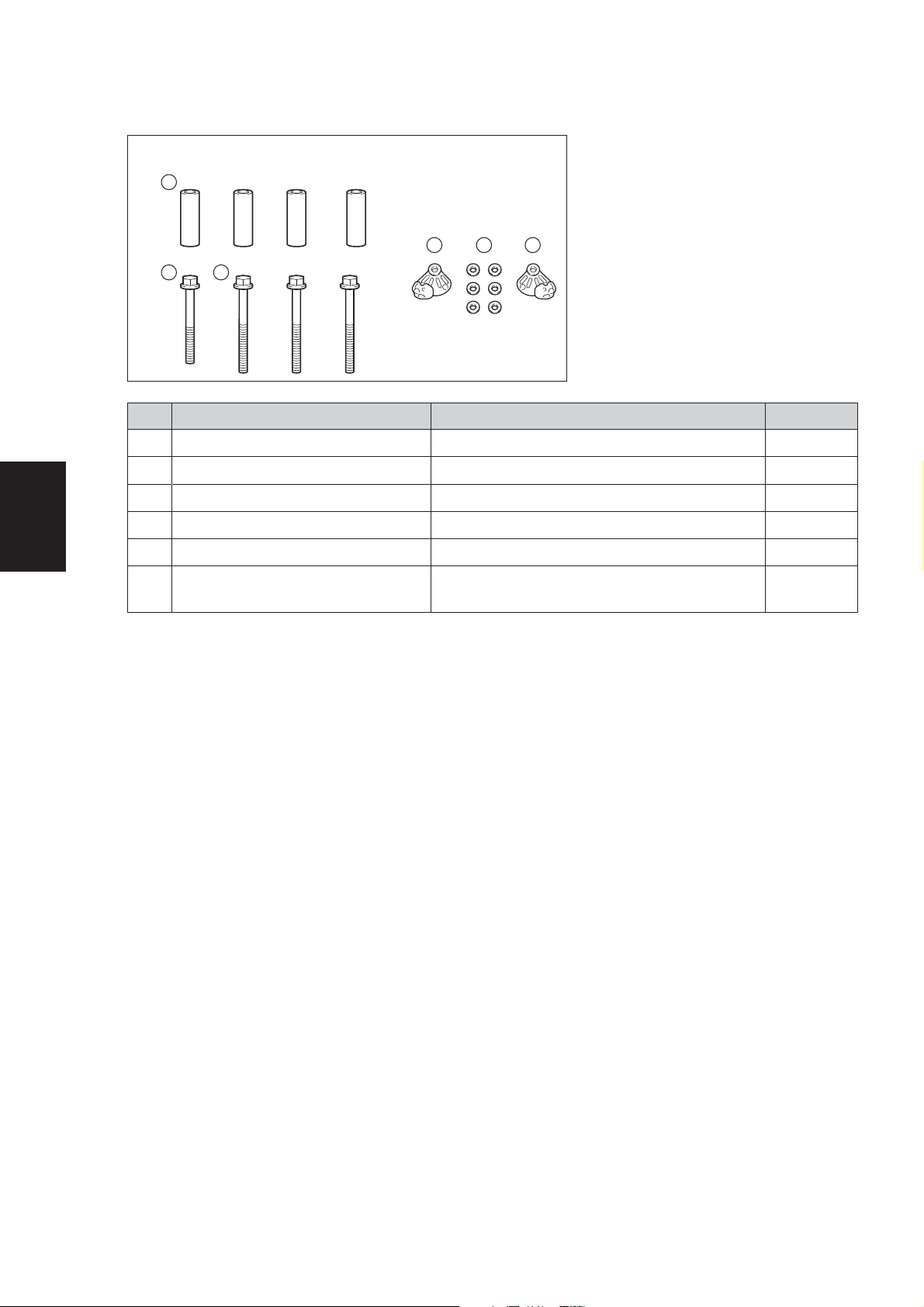

[Offset]

Battery Seat Offset Parts (Optional)

28.5 mm Offset

1

32

Product Name Remarks Quantity

1

Spacer 28.5 mm 4

2

Flange bolt 40 mm 1

3

Flange bolt 45 mm 3

4

Left clamp bracket For installing the drive unit 1

5

Right clamp bracket For installing the drive unit 1

6

Plate washer

4 6 5

For adjusting the outward position of

the drive unit

6

12

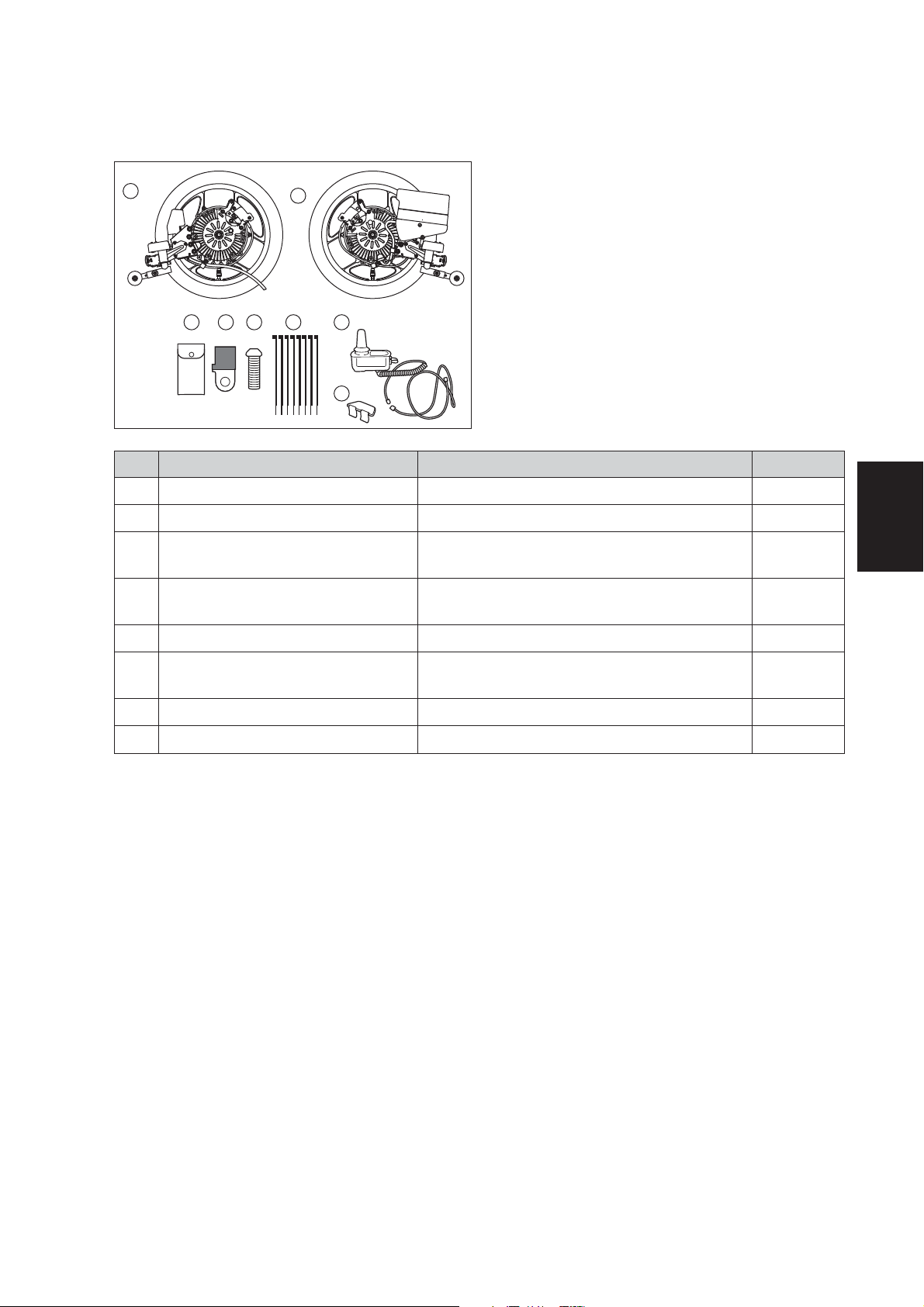

3.1.2. Supplied Parts Check for 16" Model

(1) Standard Supplied Parts ~Integrated Battery Seat~

1

4 5 6 7

3

Product Name Remarks Quantity

1

Left drive unit assembly 1

2

Right drive unit assembly 1

3

Supplied tools

4

Clamp 1

5

Screw for clamp 1 Used when necessary 1

6

Clamp 2

7

Controller assembly 1

8

Plate assembly 1

2

8

Two 8×10 mm open-end wrenches, and

one 5 mm hexagon wrench

For securing the wire harness to the unit

(used when necessary)

For securing the wire harness to the

wheelchair frame

3

1

1

8

13

(2) Standard Supplied Parts ~Separate Battery Seat~

3

1

4 5 6 7

3

2

8

:

c.

a.

b.

d.

e.

f.

a.

b.

c.

d.

e.

f.

Product Name Remarks Quantity

Battery box 1

Bottom lid 1

Screw for bottom lid 4

Grommet 2

Band

Clamp

For securing the

battery box

For securing the

wire harness

12

8

Product Name Remarks Quantity

1

Left drive unit assembly 1

2

Right drive unit assembly 1

3

Supplied tools

4

Clamp 1

5

Screw for clamp 1 Used when necessary 1

6

Clamp 2

7

Controller assembly 1

8

Plate assembly 1

9

Battery box assembly

Two 8×10 mm open-end wrenches, and

one 5 mm hexagon wrench

For securing the wire harness to the unit

(used when necessary)

For securing the wire harness to the

wheelchair frame

See the diagram above for the parts

configuration.

1

1

8

1 set

14

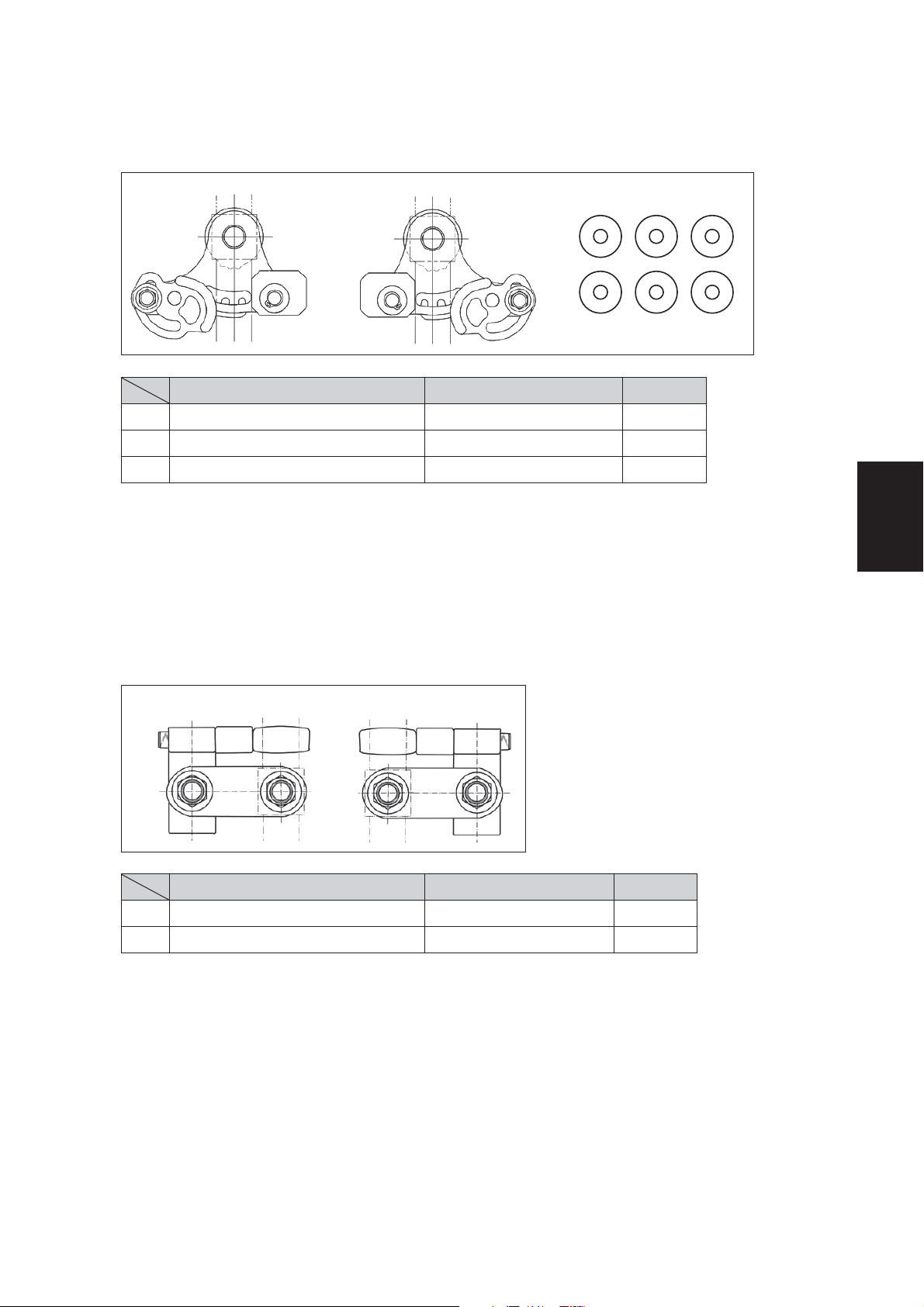

(3) Installation Brackets

1 Bracket A

a. b. c.

Product Name Remarks Quantity

a. Bracket A for left unit 1

b.

Bracket A for right unit 1

c.

Width adjustment washer Used when necessary 6

* Please use a maximum of 3 washers per side.

3

2 Bracket B

a. b.

Product Name Remarks Quantity

a. Bracket B for left unit 1

b.

Bracket B for right unit 1

Use bracket B when the backward tip angle is small.

If bracket B is used, the axles of the E-Drive PLUS can be moved and installed 53.5mm back from

the back pipe of the wheelchair frame.

15

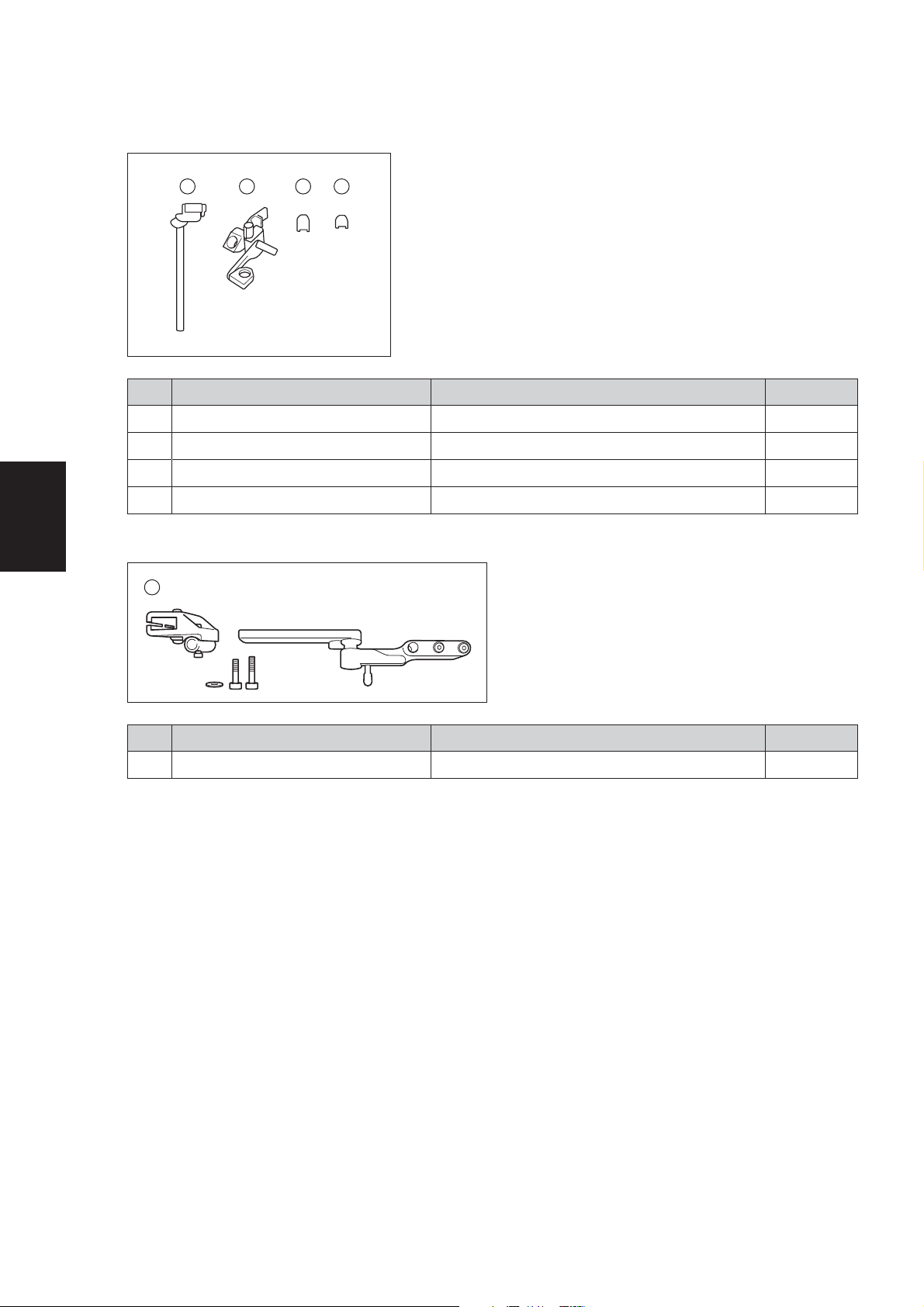

(4) Controller Installation

[Standard]

1 2 3 4

Product Name Remarks Quantity

1

Upper holder assembly For installing the controller 1

2

Under holder assembly For installing the controller 1

3

Side plate for ø19–20 For installing the under holder 4

4

Side plate for ø16–17 For installing the under holder 4

3

[Swing Out Bracket]

1

Product Name Remarks Quantity

1

Swing out bracket For installing the controller 1

16

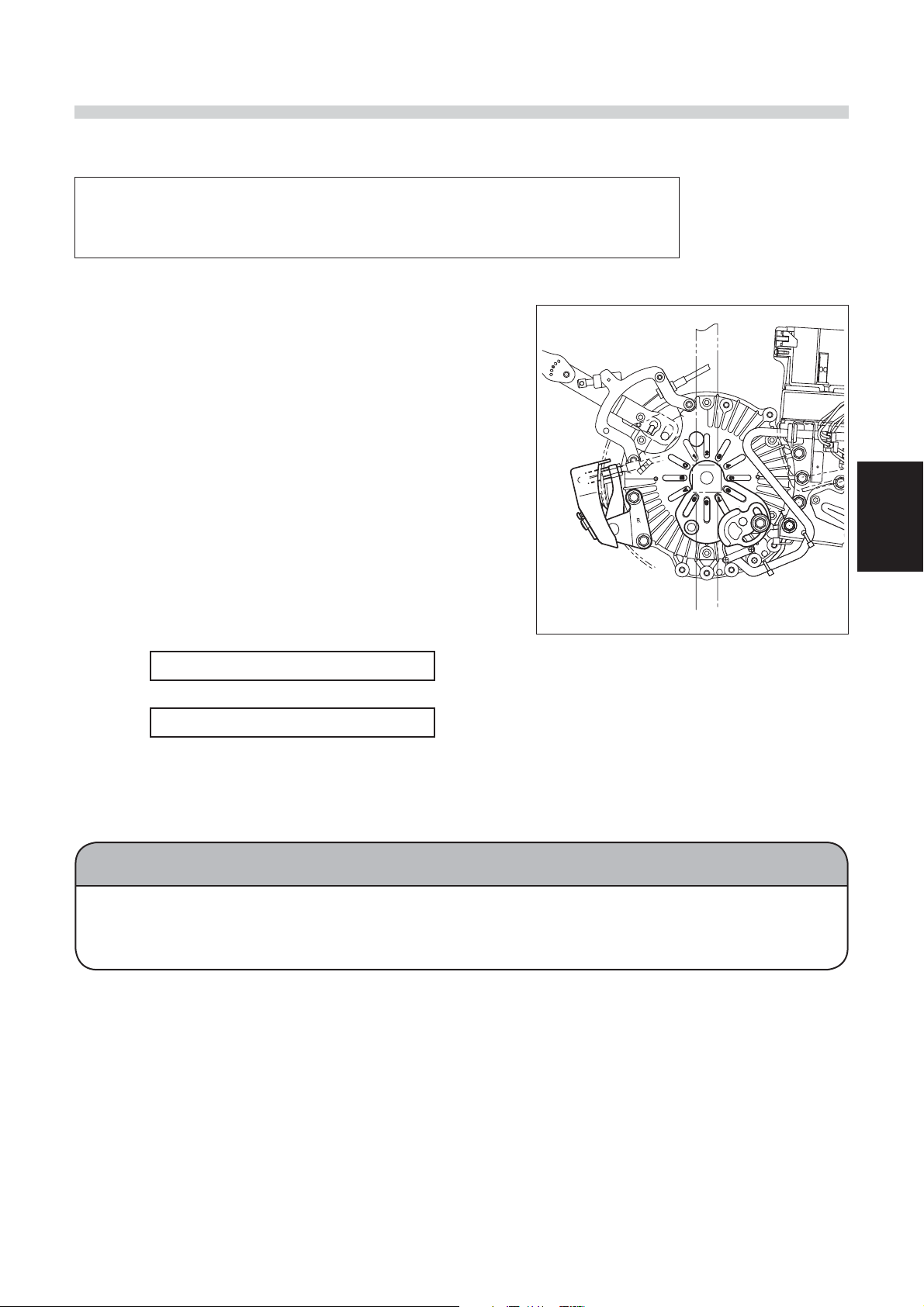

3.2. Power Unit Installation

NOTICE

When the E-Drive PLUS unit is installed, the unit and the wheelchair frame must not interfere with

each other. When installing the width adjustment washers to the shaft in order to prevent interference, use up to 3 washers per side.

3.2.1. Installation for E-Drive PLUS 20", 22", and 24" Fixed Axle Models

Required tools: 10 mm and 17 mm sockets, socket wrench, and torque

wrench

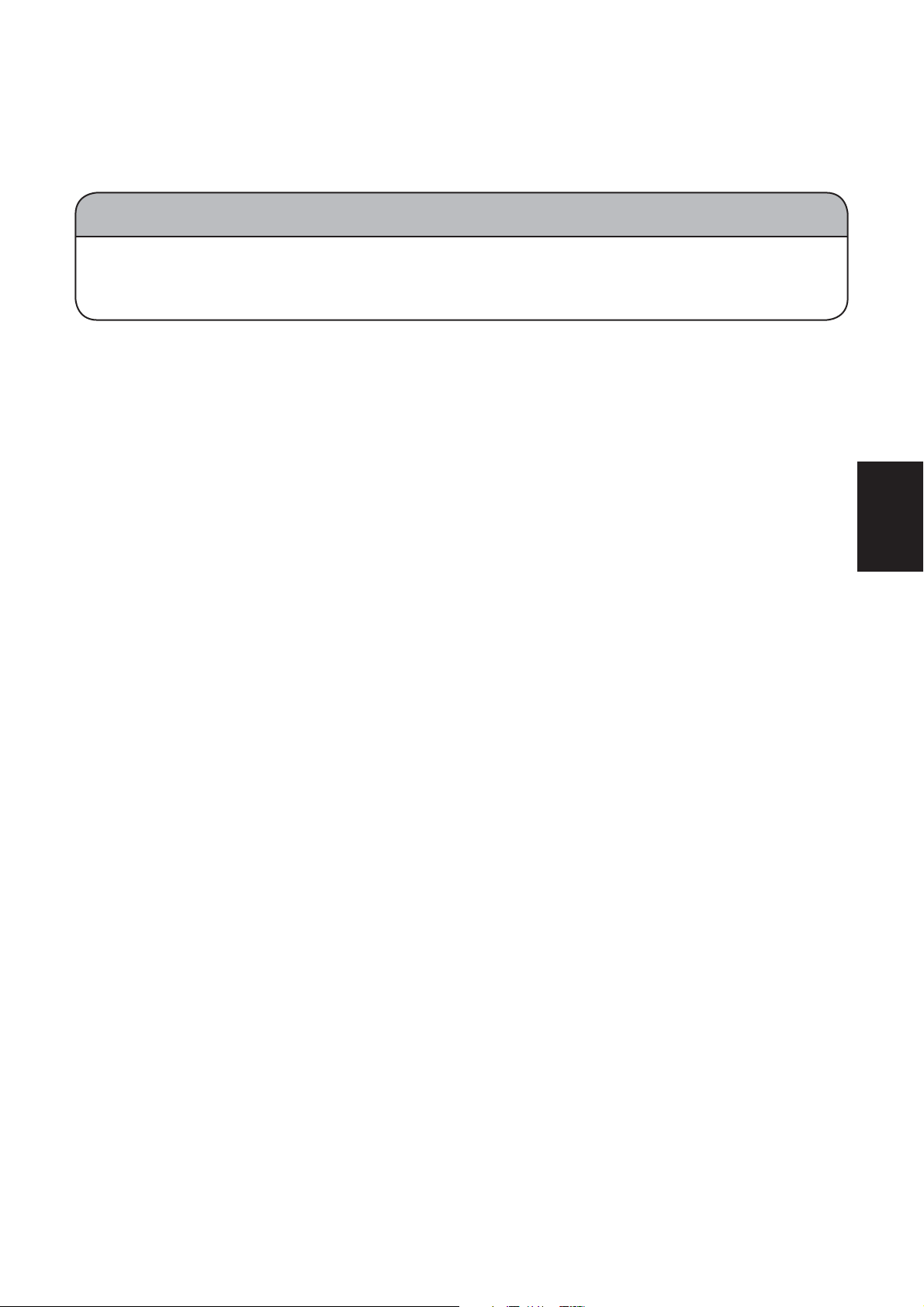

(1) Right Drive Unit Installation

1

Install the clamp bracket for the right unit to

the E-Drive PLUS unit. Fit the projections on

the unit into the slots in the clamp bracket.

(The standard slots are Nos. 6, 7, 8, and 9.)

2

While keeping the clamp bracket and right

unit in this condition, install the unit to the

wheelchair frame. Fit the back pipe of the

wheelchair frame between the post and

stopper of the clamp bracket.

3

Temporarily tighten the axle using the nut

(tightening torque: approximately 5 Nm) so

that there is no looseness in the axle.

4

Move the stopper so that there are no gaps

between the clamp bracket post, frame,

and stopper, and then tighten the stopper

bolt.

3

Tightening torque: 11 to 15 Nm

5

Tighten the axle mounting nut.

Tightening torque: 40 to 50 Nm

(2) Left Drive Unit Installation

Install the left unit in the same way as the right unit.

(3) Angle Adjustment

To adjust the angle 30°, shift the clamp bracket slots by 1 projection on the unit.

17

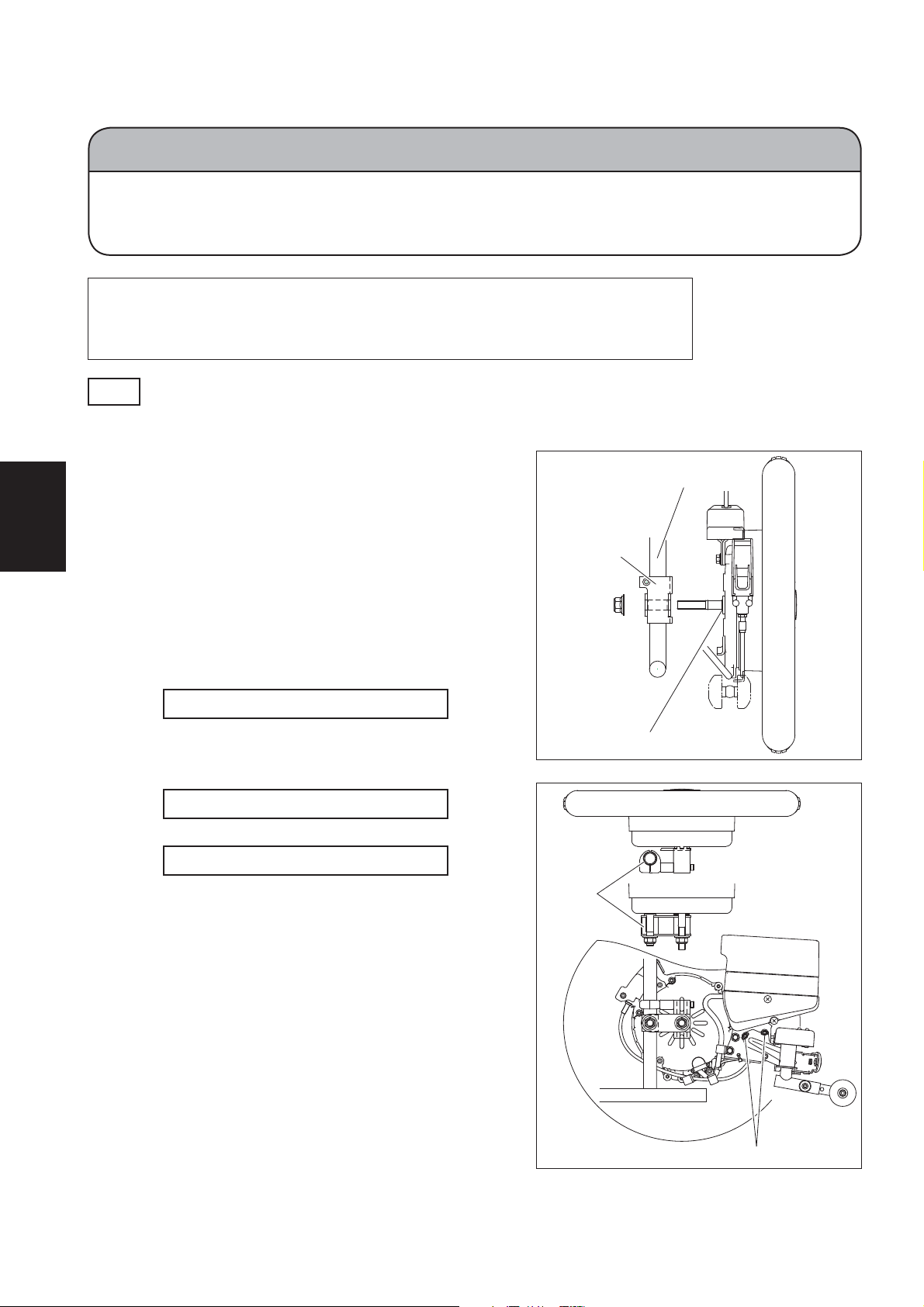

3.2.2. Installation for E-Drive PLUS 16" Fixed Axle Model (When Using Bracket A)

Required tools: 10 mm and 17 mm sockets, socket wrench, and torque

wrench

3

Note

(1) Right Drive Unit Installation

Remove the washers and O rings attached to the axle before installation.

1

Install bracket A for the right unit to the E-

Drive PLUS. Fit the projections on the unit into

the slots in bracket A.

2

While keeping bracket A and the right

unit in this condition, install the unit to the

wheelchair frame. Fit the back pipe of the

wheelchair frame between stopper 1 and

stopper 2 of bracket A.

3

Temporarily tighten the axle using the nut

(tightening torque: approximately 5 Nm) so

that there is no looseness in the axle.

4

Move stopper 1 so that there are no gaps

between the frame, stopper 1, and stopper

2, and then tighten the stopper bolt.

Tightening torque: 9 to 11 Nm

5

Tighten the axle mounting nut.

Tightening torque: 40 to 50 Nm

Remove the washers and O rings

Frame pipe

Bracket A

Stopper 1

(2) Left Drive Unit Installation

1

Install bracket A for the left unit to the E-Drive PLUS. Fit the projections on the unit into the

slots in bracket A.

2

While keeping bracket A and the left unit in this condition, install the unit to the wheel-

chair frame. Fit the back pipe of the wheelchair frame between stopper 1 and stopper

2 of bracket A.

3

Temporarily tighten the axle using the nut (tightening torque: approximately 5 Nm) so

that there is no looseness in the axle.

4

Move stopper 1 so that there are no gaps between the frame, stopper 1, and stopper

2, and then tighten the stopper bolt.

Tightening torque: 9 to 11 Nm

5

Tighten the axle mounting nut.

Tightening torque: 40 to 50 Nm

18

Stopper 2

(3) Angle Adjustment

NOTICE

When the E-Drive PLUS unit is installed, the unit and the wheelchair frame must not interfere with

each other. When installing the width adjustment washers to the shaft in order to prevent interference, use up to 3 washers per side.

1

To adjust the angle 5°, turn stopper 2 on bracket A to change the contact surface of

stopper 2 and the frame.

2

To adjust the angle 15°, shift the bracket A slots by 1 projection on the unit.

3

19

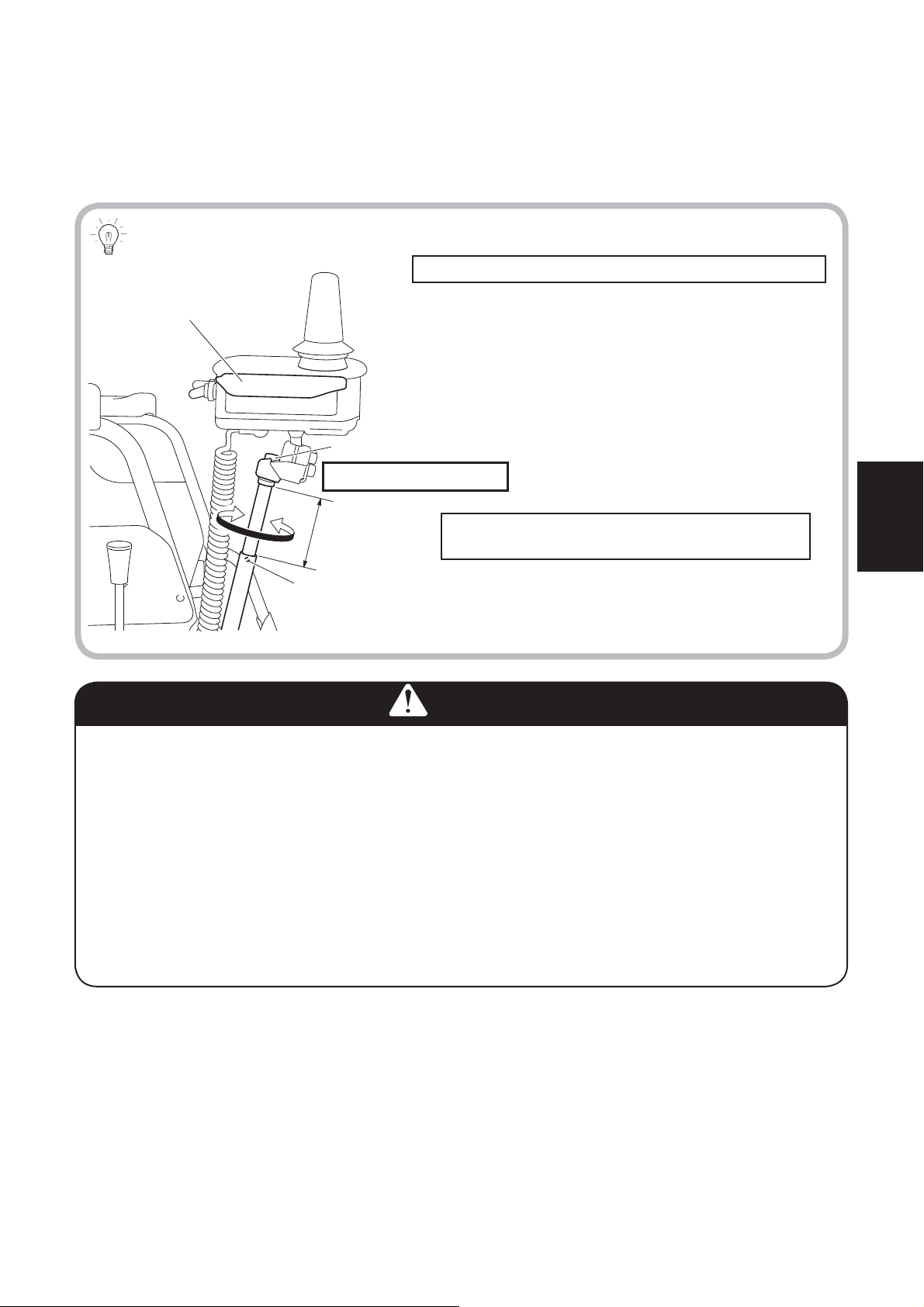

3.2.3. Installation for E-Drive PLUS 16" Fixed Axle Model (When Using Bracket B)

NOTICE

When using bracket B to install the power unit to the wheelchair frame, be sure to

leave the O rings and washers attached to the axle. If the O rings and washers are

removed, the power unit will be damaged.

Required tools: 17 mm socket, socket wrench, torque wrench, 17×19

mm open-end wrench, and 5 mm hexagon wrench

3

Note

(1) Right Drive Unit Installation

Leave the washers and O rings attached to the axle during installation.

1

Temporarily tighten bracket B for the right

unit to the back pipe using the frame axle

hole. Align the holes in the plate and boss

and tighten sufficiently to remove any

looseness.

2

Temporarily tighten the drive unit using the

mounting nut. The nut is temporarily tightened to prevent the drive unit from falling;

therefore, do not tighten the nut forcefully.

3

Fully tighten the nut that was temporarily

tightened to the frame axle hole.

Tightening torque: 40 to 50 Nm

4

Fit the projections on the back of the drive

unit into the slots in bracket B, and then

fully tighten the axle.

Tightening torque: 40 to 50 Nm

5

Fully tighten the bolt.

Frame pipe

Bracket B

Washer and O ring

Tightening torque: 14 to 16 Nm

Frame

pipe

20

Adjusting holes

(2) Left Drive Unit Installation

1

Temporarily tighten bracket B for the left unit to the back pipe using the frame axle

hole. Align the holes in the plate and boss and tighten sufficiently to remove any

looseness.

2

Temporarily tighten the drive unit using the mounting nut. The nut is temporarily tight-

ened to prevent the drive unit from falling; therefore, do not tighten the nut forcefully.

3

Fully tighten the nut that was temporarily tightened to the frame axle hole.

Tightening torque: 40 to 50 Nm

4

Fit the projections on the back of the drive unit into the slots in bracket B, and then

fully tighten the axle.

Tightening torque: 40 to 50 Nm

5

Fully tighten the bolt.

Tightening torque: 14 to 16 Nm

(3) Angle Adjustment

To adjust the angle 30°, shift the clamp bracket slots by 1 projection on the unit.

3

21

3

3.3. Separate Battery Seat Installation

If using the separate battery seat, secure the battery box to the wheelchair frame.

(1) Pass the belts through the elongated holes on the battery box.

(A total of 8 belts are used.)

(2) Secure the battery box to the wheelchair frame.

Please secure the battery box so that the U bracket goes backwards.

After the belts are passed through the elongated holes and U bracket of the battery box,

pass them through parts of the frame, such as the seat and back pipe.

(A total of 8 belts are used.)

Position the battery box with the 4 belts on top, then add tension and secure it with the 4

on the bottom.

(3) After the battery is installed, ensure that it is firmly secured. If the ends of the belts hang

down, ensure that they do not interfere with the turning and moving parts of the wheelchair

frame.

Use all of the belts

(8 in total).

22

U bracket

There are elongated

holes that the belts

pass through on the

top and bottom of

the battery box

frame.

Align them with the

wheelchair frame.

Vertical

Maximum 30° Maximum 30°

Ensure that the

battery box is

installed at an angle

of no more than 30°

from vertical.

3.4. Controller Installation

(1) Under Holder Assembly Installation

Install the under holder onto the wheelchair frame.

1

From the temporarily-assembled under holder assembly, remove the under holder

piece.

2

Mount the assembly onto the wheelchair frame. If necessary, insert the side plates

between the brackets and the wheelchair frame.

For Ǿ16

<Side plates (included)>

3

Attach the under holder piece.

Required tools: 10 mm socket, socket wrench, torque wrench

8×10 mm open-end wrench, 5 mm hexagon wrench

Anti-swivel pin

Upper

holder

For Ǿ19

Wheelchair

frame

Tightening torque: 5 to 8 Nm

Tightening torque: 14 to 16 Nm

3

Side plates

Brackets

Plate stopper

Tightening torque: 14 to 16 Nm

Under holder

* The illustration above is for the right-hand drive model. For the left-hand drive

model, the placement of the parts will be the opposite of the above illustration.

Insert it so that the anti-swivel

pin faces forward, and secure

it with the bolt.

23

3

(2) Upper Holder Assembly and Controller Installation

Install the upper holder onto the controller and adjust the position.

1

Remove the bracket from the upper holder and install it onto the controller.

2

Install the bracket onto the upper holder.

Required tools: 5 mm hexagon wrench, torque wrench

Hand rest plate

Tightening torque: 6 to 8 Nm

Brackets

Upper holder assembly

Tightening torque: 6 to 8 Nm

Adjusting the Installation Position of the Controller (Part 1)

20°

Holder

Bracket

48 mm

• The brackets can be installed on the outside

of the holder.

• The angle of the controller can be changed

within a 20-degree span.

24

3

WARNING

Removal of the Controller

For example, when the customer wants to sit close to a table, the controller can be

detached with moving the under holder locking lever.

Do not remove the controller from the under holder while the power is switched ON.

Once you remove the controller from the under holder, do not switch the power ON.

The control lever may tilt to cause the wheelchair to move unexpectedly, and you

or other people around you may get injured.

In addition, if you removed the retaining bolt, you can use the supplied hand-tight-

ened screw.

Adjust the installation position.

Adjust the controller to a position that is easiest to operate by taking the height,

angle, and its distance to the arm support into consideration.

Adjusting the Installation Position of the Controller (Part 2)

Required tools: 5 mm hexagon wrench

Hand rest plate

• Adjust the height so that the punch mark (adjustment limit punch mark) remains hidden.

Height-adjusting bolt

Tightening torque: 14 to 16 Nm

Maximum 60 mm

Punch mark

Switching the hand rest plate to the left- or

right-hand side

On the left-hand drive model, remove the hand

rest plate by pulling it upward, change the rubber plate direction and relocate it to the left.

3

25

3

(3) Swing Out Bracket

1

Fit bar 1 into the pipe. Make sure that bar 1

is installed in the correct direction.

Install the holder, and then tighten the bolt.

Front (25 mm)

Tightening torque: 6 to 8 Nm

Rear (40 mm or 45 mm)

Tightening torque: 2 to 3 Nm

2

Install the upper holder assembly to the

holder and temporarily tighten it.

3

Install the upper holder assembly to the

controller and temporarily tighten it.

26

(4) Wire Routing

WARNING

Route and secure the wires correctly not to

entwine or touch to the unit rotating parts,

even the unit is detachable one and when the

wire connectors are disconnected.

When cutting off excess tie strap, do not cut

diagonally, and cut as close to the knot as

possible. If you leave the straps with sharp

ends, the customer may get injured.

Route the controller lead wire and the left unit harness, and connect to the power unit.

1

Route the lead wires for the controller/assistant controller and the left unit harness.

Required tools: Wire cutters

Route the wires in such a way to meet the following requirements.

• Run the wire along the top and inner sides of the pipe, secure it with tie straps.

• Fasten the tie straps in 5 to 10 cm intervals.

• Make sure the wire does not interfere with the rear tire.

• Make sure the wire does not interfere with or get caught between moving parts

like the anti-tip bars of the wheelchair frame.

* Pay special attention when tilting or reclining.

• When folding up the wheelchair, make sure the wire does not get caught by the

crossbar.

• Fasten the tie straps loosely at the junction between the crossbar and the pipe,

so that the lead wire does not get twisted.

• In case the unit is detachable one,

make sure to secure the wires to make

appropriate margin length for the connecting/disconnecting.

• Use single edged nippers to cut the

ends of the tie straps.

• In case the separated battery seat

type unit, make sure not to connect

the left/right wires in reverse.

Example of wire routing

3

2

Remove the cover under the battery seat.

27

3

(5) Wire Routing for Left-Side Installation of Control-

ler

1

With the controller installed on the left side

of the wheelchair, route the lead wires from

below the under holder toward the battery

seat. Route the lead wires along the frame

and crossbars, securing the lead wires at 5

to 10 cm intervals. (See diagram at right.)

2

When routing the lead wires along the base

pipe, route them on top of the pipe and

secure them.

3

When routing the lead wires along the

crossbars, route the leads so that they will

not be pinched by the pipes, be pulled, or

become twisted or slack when the wheelchair is folded.

4

Use wire cutters or a similar tool to cut

off the excess ends of clamps so that the

ends do not protrude.

5

Connect the control unit according to the

instructions in “(8) Connecting the Control

Unit and Lead Wires” in 3.4.

Tie straps Tie straps

Tie straps

Crossbars

(Bottom view)

Tie straps

Tie straps

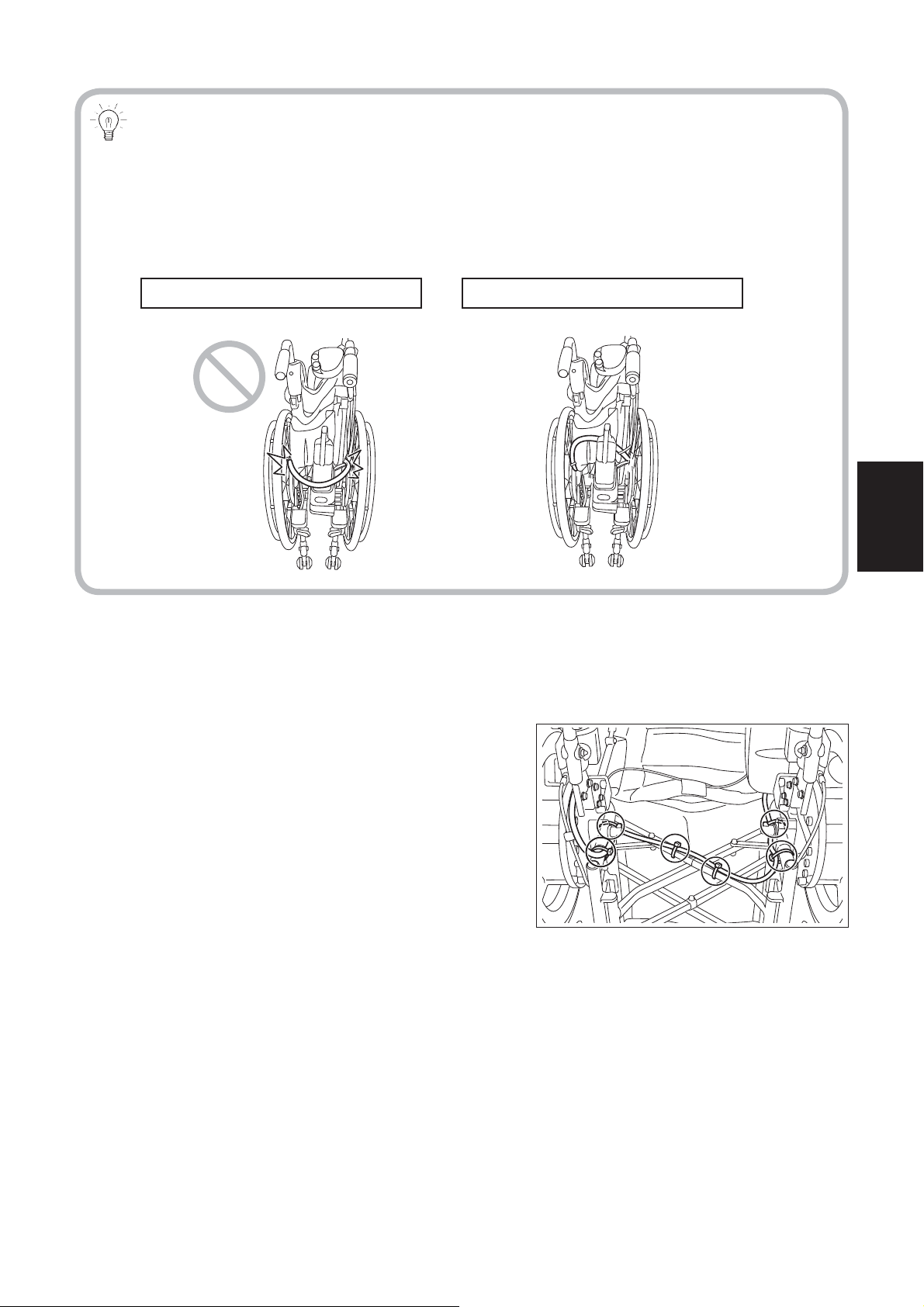

(6) Wire Harness Routing for the Left Drive Unit

(20", 22", and 24" Models)

1

Route the wire harness so that it forms

an upward arch and adjust the length of

the harness so that it will not be pulled

or become too slack. (If the wire harness

is hanging down, it can easily become

caught, causing a malfunction.)

2

Adjust the position of the arched portion of

the wire harness so that any items will not

rest on top of the wire harness. If necessary, use the 2 large clamps and 2 small

clamps that are supplied to secure the wire

harness.

(Fixed Axle Model Sample)

28

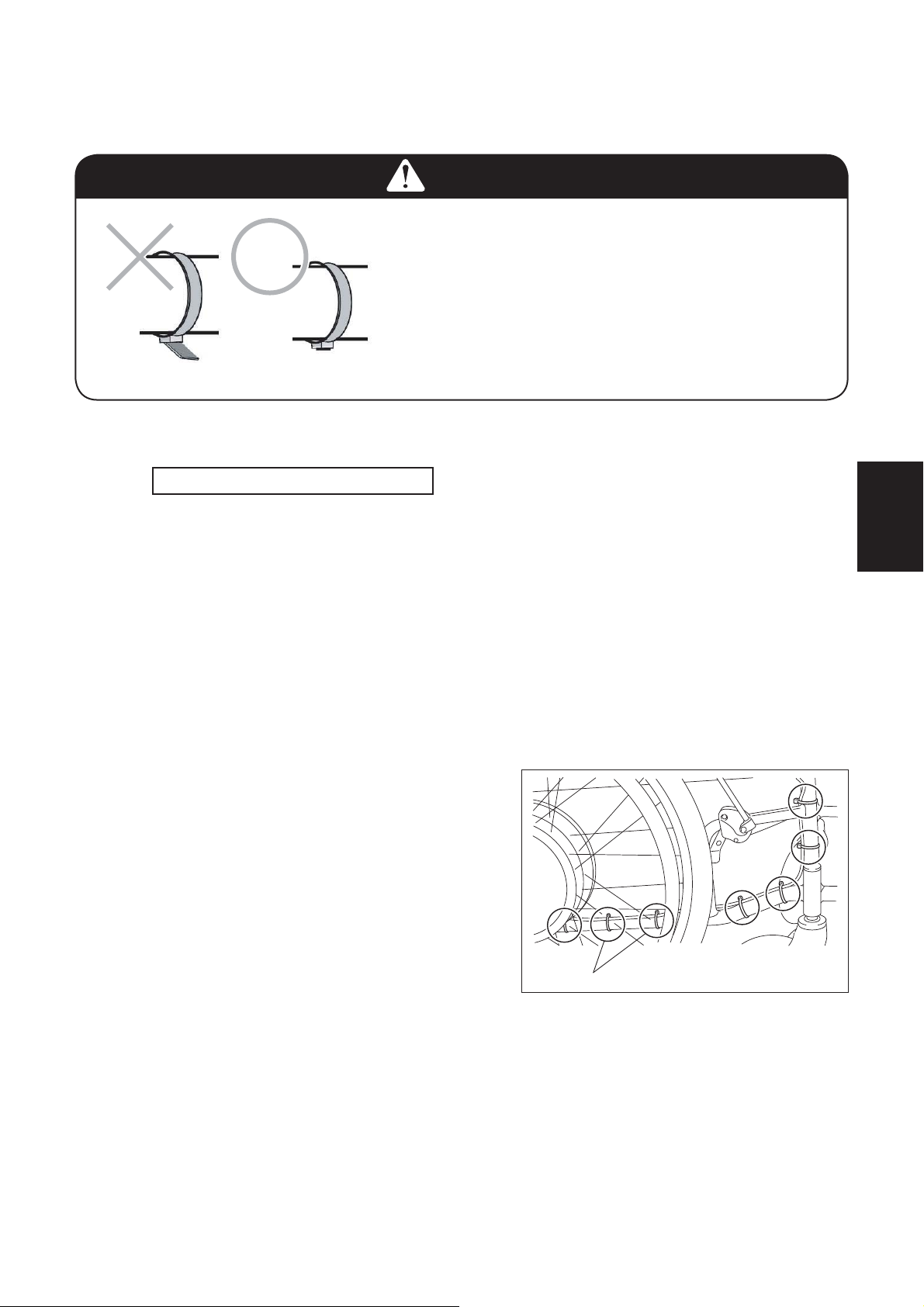

Secure the wire harness if necessary.

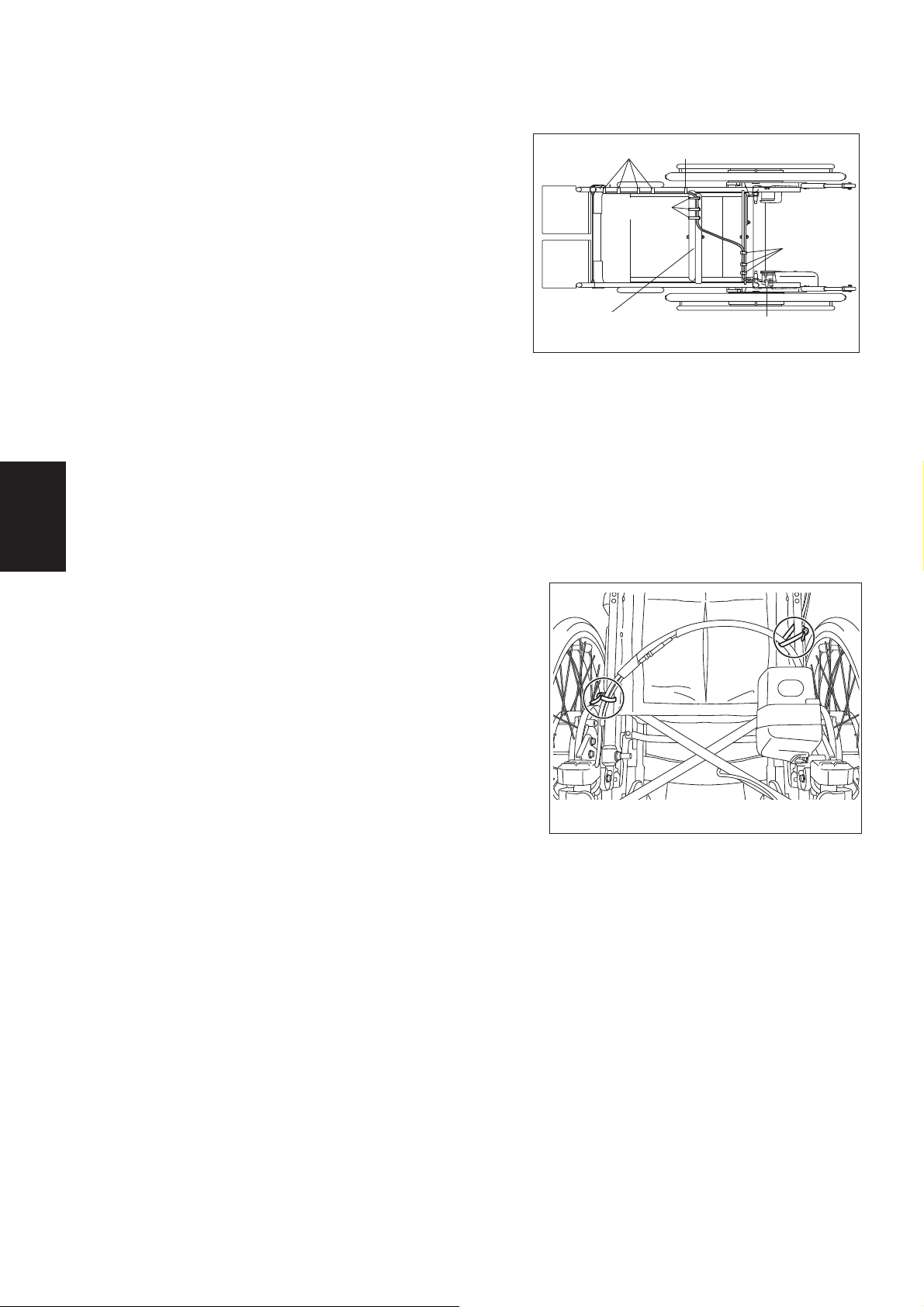

If the wire harness behind the seat back is not secured, the battery may be positioned to the inside of the harness as shown in the “×” diagram (lower left) when the

wheelchair is folded.

If the wheelchair is unfolded in this condition, an excessive force will be applied to

the wire harness and the wire harness could be damaged.

When not secured

3

Connect the control unit according to the instructions in “(8) Connecting the Control

Unit and Lead Wires” in 3.4.

(7) Wire Harness Routing for the Left Drive Unit (16"

Model)

1

Route the wire harness along the frame

and temporarily secure it using clamps.

2

Adjust the wire harness so that it will not

be pulled or become too slack.

3

Check that the wire harness is not pulled

when the frame is folded.

4

Use single edged nippers or a similar tool

to cut off the excess ends of clamps so

that the ends do not protrude.

5

Connect the control unit according to the

instructions in “(8) Connecting the Control

Unit and Lead Wires” in 3.4.

When secured

3

29

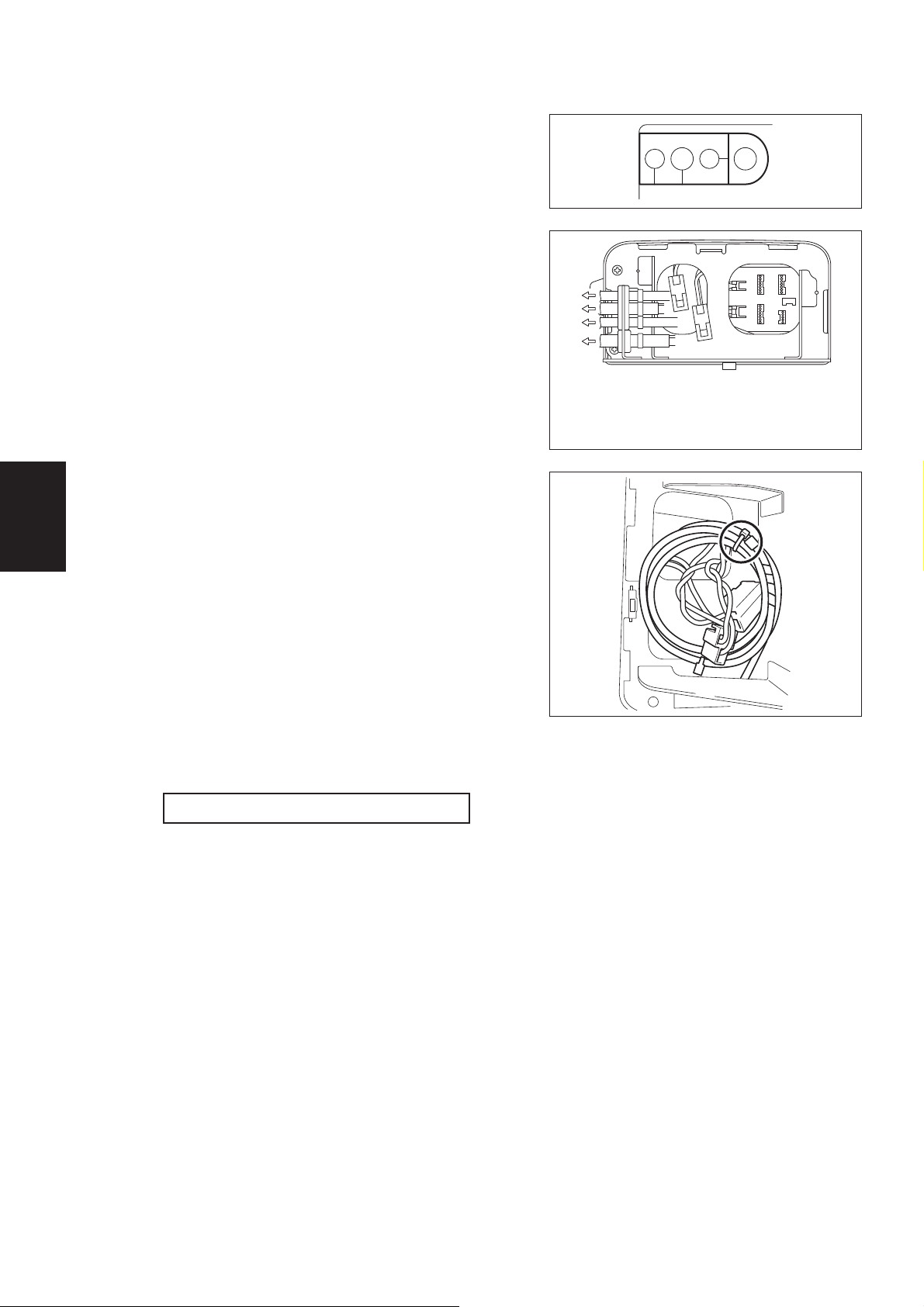

(8) Connecting the Control Unit and Lead Wires

1

Remove the cover under the battery seat.

2

Route the lead wires and wire harness

through the grommet.

Inner 1: Controller lead wire

Center L: Left unit wire harness

Outer 2: Assistant controller lead wire

2L1

3

3

Connect the connectors to the control unit

assembly. The connectors can be connect-

ed to any receptacle as long as the shapes

match.

4

Coil the excess lead wires and left unit wire

harness, and bind them with a clamp.

5

Install the plate cover. Make sure not to

pinch the lead wires and wire harness

when installing the cover.

a.

b.

c.

d.

a. To the assistant controller

b. To the left motor control

c. To the controller

d. To the right motor control

Tightening torque: 1.5 to 2.5 Nm

30

Loading...

Loading...