Page 1

8' Railing Installation

Instructions

For each 8' on-center

railing section, you will need:

One 8' Railing kit that contains:

• 2 rails

• 1 in-line hardware kit that contains:

4 in-line brackets

8 – #6 x 2" long #2 square head screws

12 – #4 x 1" long #2 square head screws

• 1 support block kit that contains:

1 support block

2 connectors

2 screws

One cap rail kit (optional) that contains:

• 1 cap rail

• 1 insert rail

• 9 – #4 x 1" long #2 square head screws

22.5˚ and 45˚ adaptor wedges are

available for angled railing applications.

Baluster Options

Classic, Estate, Twist or Ellipse baluster

kits that each contain:

• 10 aluminum balusters

• 20 balusters needed per 8' on-center

railing section (Classic, Estate and Twist)

• 24 balusters needed per 8' on-center

railing section (Ellipse)

Baluster connector or designer baluster

connector kits that each contain:

• 20 baluster connectors

• 1 kit needed per 10 balusters

Traditional baluster kit that contains:

• 10 aluminum balusters

• 40 color-matched, stainless steel screws

• 20 balusters needed per 8' on-center

railing section

Items you will need

• Drill/power screwdriver

• Miter or circular saw with

carbide-tipped blade

• Adjustable wrench or socket

wrench for bolts, etc.

• Assorted fasteners (see instructions)

• Tape measure

Baroque or Arc baluster kits that each

contain:

• 5 aluminum balusters

• 20 color-matched, stainless steel screws

• 20 balusters needed per 8' on-center

railing section

Glass

• 5 glass balusters

• 20 stainless steel screws

• 12 balusters required per 8'

on-center railing section

One post sleeve

One post cap for each post sleeve

(sold separately)

One post base trim for each

post sleeve (sold separately)

Stair rail bracket kits for stair

railing sections. Two kits required

per 8' on-center railing section.

Each kit contains:

• 2 stair brackets

• 4 – #6 x 2" long

#2 square head screws

• 8 – #4 x 1" long

#2 square head screws

Stair baluster connectors kits that

each contain (Classic, Estate, Twist and

Ellipse only):

• 20 stair baluster connectors

• 1 kit needed per 10 balusters

• Hammer

• Marked speed square

• Carpenter’s level

• Carpenter’s pencil

• Safety glasses/goggles

• Two clamps

• Hack saw

• Exterior-grade metal

construction adhesive

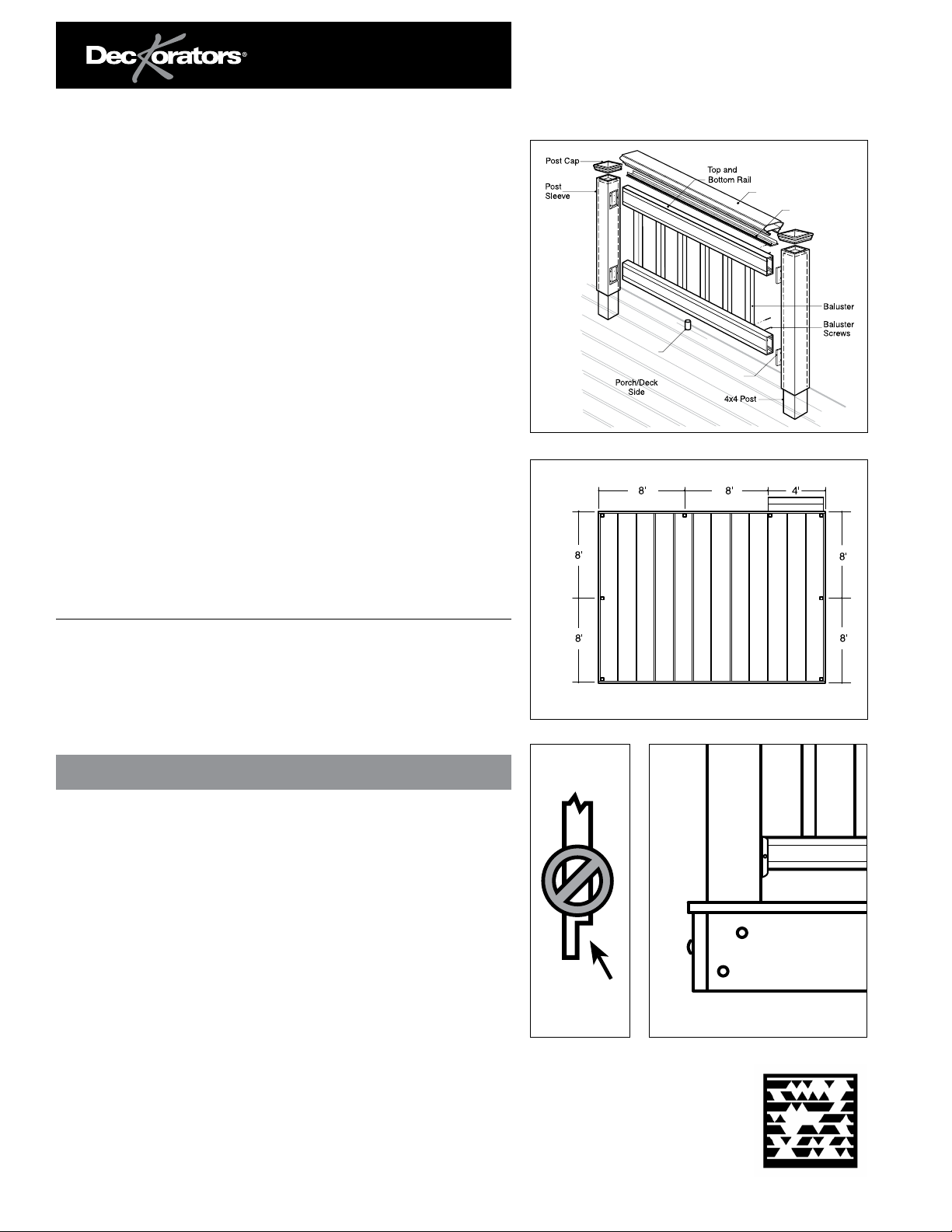

Figure 1

Figure 2

Support

Block

In-Line

Bracket (4)

Cap Rail

Insert Rail

In-Line Railing Installation Instructions

Prior to construction, check with your local regulatory agency for special code

requirements in your area. Common railing height is 36" or 42". Structural support

should come from either the continuation of deck support posts that extend up through

the deck floor or railing posts that are bolted to the inside of the rim or outer joists.

Never span more than 8' on-center between railing posts. Install railing posts before

deck boards are fastened to the joists. Pre-drilling of all railing components is essential

to successful installation. Work area should be kept clean of debris, including metal

shavings that can cause scratching. Do not over-tighten screws. Read instructions

completely to get an understanding of how the product goes together and how each

piece affects the other.

Step 1 Determine the number of railing posts needed for your deck. Post spacing is 8'

on-center. Example: A 16x20 deck attached to a building with a 4' access opening on

one side will require a total of eight posts (Figure 2).

Step 2 Install rail posts prior to installing deck boards. Cedar or pressure-treated pine

4x4 railing posts provide the structural strength for the railing. The length of each

structural post is determined by the total of the joist width (7-1/4") + decking thickness

(1") + railing height (36" or 42") = 44-1/4" or 50-1/4".

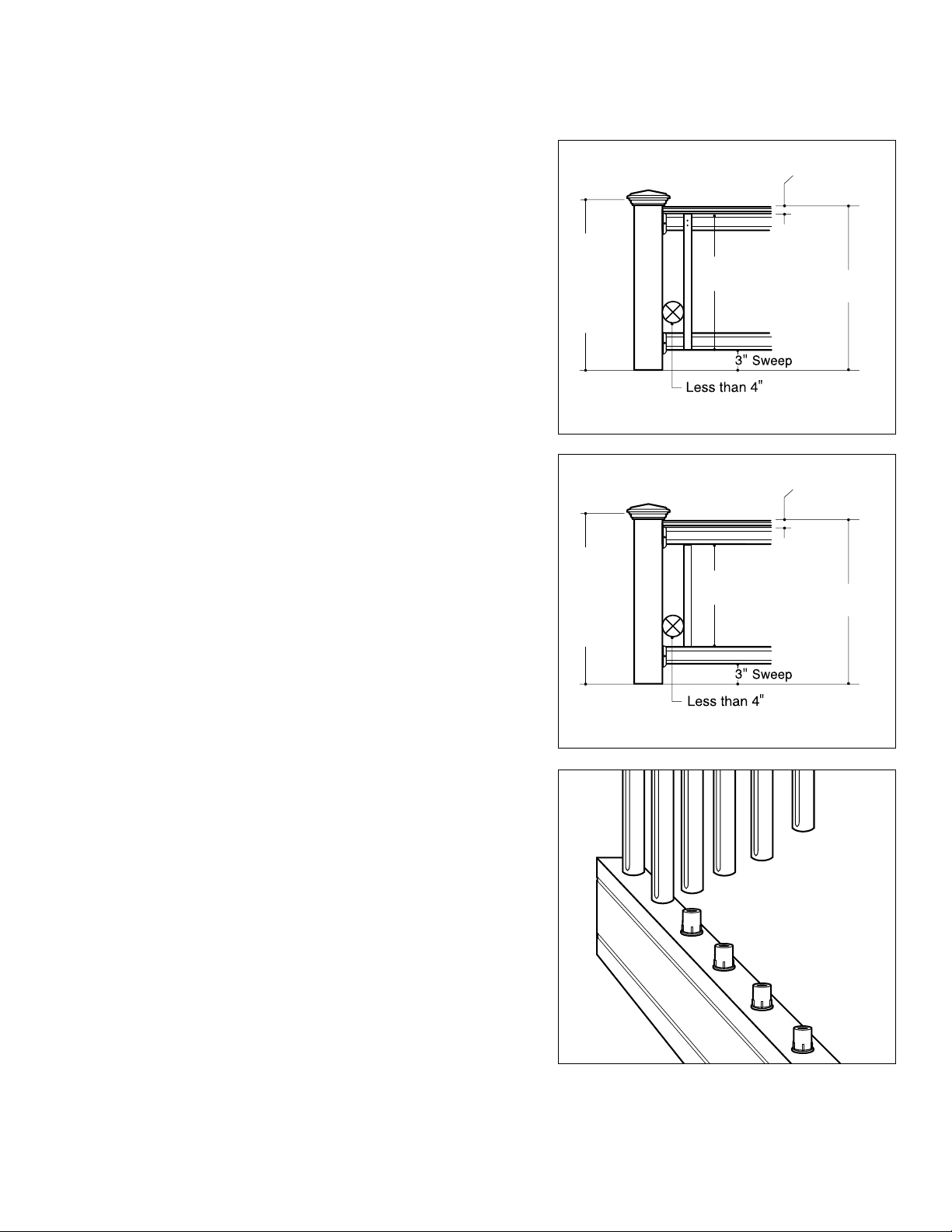

Important: Do not notch the 4x4 railing posts (Figure 3a). Notching will reduce the

strength of the post and could result in railing collapse or failure.

Step 3 Position, plumb with a level, and clamp the rail post on the interior face of the

joist. Plumb again. The 4x4 railing post should be bolted to the inside of the joists using

two 1/2"x6" galvanized carriage bolts. Corner posts use a third carriage bolt inserted

through the adjacent joist (Figure 3b).

Step 4 Install decking; notch deck boards to fit around the 4x4 railing posts.

Figure 3a

Scan code to get more

information about installing

Deckorators Alumimum Railing.

Get the free mobile app at

http ://gettag.mobi

Figure 3b

Page 2

Step 5 Trim 4x4 post sleeves to length. Post sleeves should be a minimum of 1-1/2" longer

than the overall railing height (Figure 4a and 4b). Allow an additional 1-1/2" in your calculation if installing the optional cap rail. Example: For a 36" high railing, trim post sleeve to a

minimum of 37-1/2" (39" with cap rail). Post sleeve can be left longer if desired.

Some wood preservatives may cause an undesirable reaction when directly in contact

with aluminum. The inside of the post sleeve includes a liner to prevent direct contact with

treated structural posts. If your decking is pressure-treated, place shims under the post

sleeve or run a bead of caulk along the bottom edge of the post prior to installing the post

sleeve. This will keep the aluminum from direct contact with the treated decking and will be

concealed by the post base trim. Slide a trimmed post sleeve over each 4x4 railing post.

Slide a post base trim over each post sleeve. Add a bead of caulk to the underside of the

post base trim when using treated decking.

Step 6 Measure the distance between installed post sleeves to determine the length of

the top and bottom rails (Figure 1). The distance between the post and first baluster

should be less than 4" and equal on both ends (Figure 4a and 4b). Remove an

additional 1/4" on both ends (1/2" overall) for the bracket to fit between the rail and post.

Trim the top and bottom rails to length.

Angle adaptor wedges are available for 22.5˚ and 45˚ rail angles. Important: the holes in

the angle adaptor wedges line up with the stair rail connectors (sold separately). If installing a 22.5˚ angle railing, attach the stair connectors and wedges centered on the posts. If

installing a 45˚ angle railing, attach the 45˚ adaptor wedges centered on the posts. Attach

stair connectors to the 45˚ using the provided screws.

Measure the distance between the installed angle connectors to determine the length of

the top and bottom rails. Cut the top and bottom rails to length.

Step 7 Determine the spacing of the balusters.

Classic, Estate and Twist balusters: The rails are pre-drilled with the proper spacing.

Attach baluster connectors to the top and bottom rails. Do not over-tighten screws.

Apply silicone caulk on each connector to prevent balusters from turning or rattling after

installation is complete. The caulk should be on the outside of the round connector, and

on the inside of the designer baluster connectors.

Ellipse balusters: Both top and bottom rails will be installed with the pre-drilled holes

facing down to prevent water from collecting in the rail. 4-1/ 4" on-center and equal

spacing for the end spacing. Start by finding the center of the rail. Rail length ÷ 2 = center

of rail. Mark every 4-1/4" from the center line to each end. This will leave the end spacing

4" or less on both ends and require 24 Ellipse balusters. Attach connectors to both rails

on marked locations.

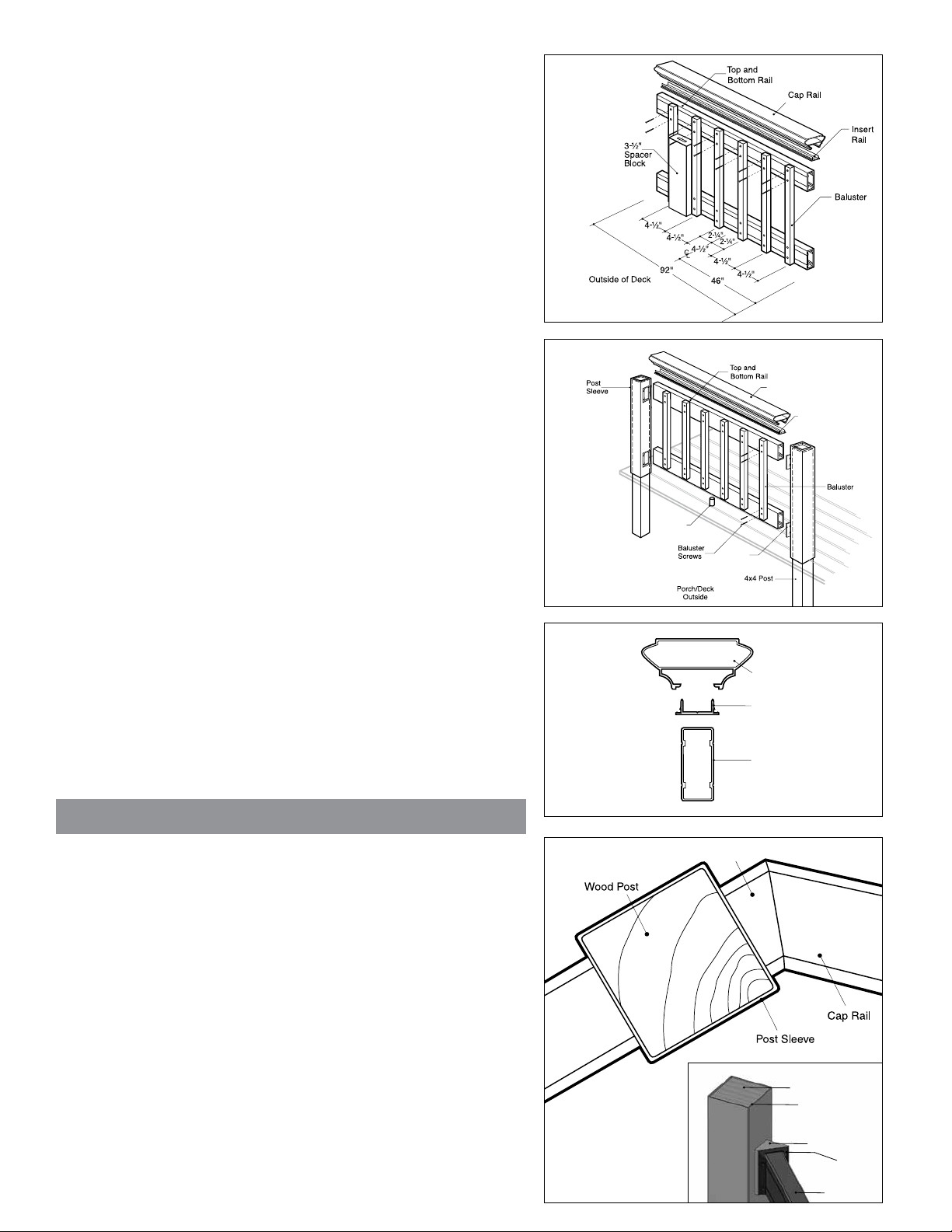

Traditional, Baroque and Arc balusters: Both top and bottom rails will be installed with

the pre-drilled holes facing down to prevent water from collecting in the rail. Maximum

4-1/2" on-center and equal spacing for the end spacing. Start by finding the center of the

rail. Rail length ÷ 2 = center of rail. Start the first aluminum balusters 2-1/4" on-center each

side of the center line. Mark every 4-1/2" from these lines to each end. This will leave the

end spacing less than 4" on both ends and require 20 aluminum balusters (Figure 5). Tip:

Use a piece of 2x4 (3-1/2" actual) as a spacer block for the spacing between balusters.

Glass balusters: Both top and bottom rails will be installed with the pre-drilled holes facing down to prevent water from collecting in the rail. 7-1/2" on-center and equal spacing

for the end spacing. Start by finding the center of the rail. Rail length ÷ 2 = center of rail.

Start the first glass baluster 2-1/4" on-center of each side of the center line. Mark every

7-1/2" from the center line to each end. This will leave the end spacing 4" or less on both

ends and require 12 glass balusters. If installing using connectors, attach connectors to

both rails on marked locations. Tip: If face-mounting to rail, use a piece of 2x4 (3-1/2"

actual) as a spacer block for the spacing between balusters (Figure 5).

Step 8 Position the bottom rail between posts and center. Check building code

Spacing of 3" is recommended, but can be more or less if codes allow (Figure 4a and 4b).

Mark the location of the bracket on both posts. Remove rail. Mark the screw locations and

pre-drill through the post sleeve only, using a 1/4" drill bit. Attach each bracket to the post

with two 2" long screws.

Step 9 A support block is needed at the center of each rail. Cut the support block to

the proper height. Attach to the bottom of the lower rail (refer to Figure 1). Find the

center of the rail and pre-drill using a 1/8" drill bit. Attach the support block connector

using the included screw. Mark the location of the support block on the deck surface and

attach the other support block connector to the deck using the included screw. Install the

bottom rail between the posts. Using the brackets as a guide, pre-drill each screw hole

using a 1/8" drill bit and attach each end to brackets using two 1" long screws. Tip: Use a

driver extension bit to avoid marring the rail or post sleeve with the drill chuck.

Step 10 Figure 4a and 4b illustrate how a 36" high railing might be sized. If you want to

have your railing at a different height, use Figure 4a and 4b as planning tools to determine

the height to cut the post sleeves and support blocks. Note: Use a fixture to ensure a

consistent length (+/- 1/16").

38"

Post

Sleeve

Height

(Rail

Height

plus 1-

Figure 4a

39"

Post

Sleeve

Height

(Rail

Height

plus 1-

Figure 4b

Figure 4c

1

1-

/2"

Cap Rail

32" Baluster

Height

36-1/2" Rail

Height

1

/2")

1

1-

/2"

Cap Rail

26" Baluster

Height

37-1/2" Rail

Height

1

/2")

Page 3

Cap Rail

Insert Rail

To p Rail

Classic, Estate, Twist and Ellipse balusters; and Glass balusters using connectors:

Attach balusters to the lower rail by sliding onto connectors (Figure 4c).

Step 11 Position the top rail between the posts. Check for level end-to-end and vertically.

Mark the bracket location on post sleeve and remove rail. Mark the screw locations using

the bracket as a guide, and pre-drill using a 1/4" drill bit through the post sleeve only.

Attach bracket to the post with two 2" long screws at one end. Repeat for the other end.

Classic, Estate, Twist and Ellipse balusters; and Glass balusters using connectors:

Lower the top rail into position, placing the balusters onto the connectors while working

from one end of the railing to the other. Tap with a rubber mallet if needed to eliminate any

gaps. Attach the rail to each bracket by pre-drilling with a 1/8" drill bit and using three 1"

long screws. Tip: Use a driver extension bit to avoid marring the rail or post sleeve with the

drill chuck.

Traditional, Baroque, Arc balusters; and Face-Mount Glass balusters: Place the top rail in

position. Attach the rail to each bracket by pre-drilling with a 1/8" drill bit and using three

1" long screws. Tip: Use a driver extension bit to avoid marring the rail or post sleeve with

the drill chuck.

Step 12 Traditional, Baroque, Arc balusters; and Face-Mount Glass balusters: Start the

first two balusters 2-1/4" on-center each side of the center of the rail and work out to each

end. Using the baluster as a guide, drill 9/64" holes in the rails at each baluster location.

Use a 2x4 as a spacer block to space the next baluster. Working toward the ends, drill and

attach each baluster with the screws provided (Figures 5 & 6).

Step 13 (optional) Cut the cap rail and cap rail insert to length. (Note: the cap rail will be

1/2" longer than the top and bottom rails.) Center the cap rail insert on top of the top rail

and pre-drill seven 1/8" pilot holes. Attach the cap rail insert to the top rail with seven 1/2"

long screws. Apply exterior-grade metal construction adhesive to the mating edges of the

insert rail. Position cap rail over the insert rail (Figure 7). Install by pressing down, starting

from one end and working to the other until the cap rail snaps into place. Gently tap with

a rubber mallet if needed.

Angled Railings: For 22.5° rail angles, cut the cap rail and cap rail insert to length and

angle using a miter saw. Sand the ends and apply touch-up paint as needed (sold separately).Attach to the top rail following the steps above.

45° rail angles will require a cap rail wedge on top of the 45° adaptor (Figure 8). The cap

rail wedge will be cut out of the cap rail. The wedge will require a straight cut on the end in

contact with the post and a 22.5° cut on the opposite end. The distance from the post to

the wide edge of the wedge is 1-3/4”. Cut two cap rail and insert wedges using a miter saw

and install to the top of the 45° adaptors following the steps above. The cap rail will require

a 22.5° cut on both ends to match the width of the cap rail wedges. Measure the distance

between the installed wedges and cut both ends to length and angle using a miter saw. Sand

the cut ends and apply touch-up paint as needed (sold separately) to make the seam less

noticeable. Attach the cap rail to the top rail following the steps above.

Step 14 Apply exterior-grade metal construction adhesive to the inside edges of the post

caps and place over each post sleeve.

Figure 5

Figure 6

Figure 7

Support

Block

In-Line

Bracket (4)

Cap Rail

Insert Rail

Stair Railing Installation Instructions

Step 1 Cedar or pressure-treated pine 4x4 railing posts provide the structural strength for

the railing. The length of each structural post is determined by the total of the stair stringer

width (7-1/4") + decking thickness (1") + railing height (36" or 42") = 44-1/4” or 50-1/4”.

Step 2 Position, plumb with a level, and clamp the rail post on the interior face of the

stair stringer. Plumb again. The 4x4 railing post should be bolted to the inside of the stair

stringer using two 1/2" x 6" galvanized carriage bolts. Corner posts use a third carriage bolt

inserted through the adjacent joist (refer to Figure 3b). Ground level posts should be set

in concrete.

Step 3 Complete stair tread installation prior to installing post sleeves. Trim 4x4

post sleeves to length. If using post caps, post sleeves should be a minimum of

1-1/2" longer than the overall railing height (Figure 4a). Allow an additional 1-1/2" in your

calculation if installing the optional cap rail. Example: For a 36" high railing, trim post sleeve

to a minimum of 37-1/2" (39” with cap rail). Post sleeve can be left longer if desired.

Some wood preservatives may cause an undesirable reaction when directly in contact

with aluminum. The inside of the post sleeve includes a liner to prevent direct contact with

treated structural posts. If your decking is pressure-treated, place shims under the post

sleeve or run a bead of caulk along the bottom edge of the post prior to installing the post

sleeve. This will keep the aluminum from direct contact with the treated decking and will be

concealed by the post base trim. Slide a trimmed post sleeve over each 4x4 railing post.

Slide post base trim over each post sleeve. Add a bead of caulk to the underside of the post

base trim when using treated decking.

Top View

Figure 8:

45° Angle Installation

Cap Rail Wedge

Wood Post

Aluminum

Post Sleeve

45˚Adaptor

Stair Rail

Bracket

2x4 Rail

Page 4

Step 4 Measure the distance between installed post sleeves to determine the length

of the top and bottom rails. Lay bottom rail on stairs with the pre-drilled holes facing

down. The distance between the post and first baluster should be less than 4" and equal

on both ends. Mark the angle and length. Do the same with the top rail. Remove an

additional 1/4" on both ends (1/2" overall) for the bracket to fit between the rail and post.

Trim the top and bottom rails to length with the same angle (Figure 9).

Step 5 Determine the spacing of the balusters, 4-1/2" maximum on-center (7-1/2" oncenter if using glass balusters, 4-1/4" on-center if using Ellipse balusters), and equal spacing for the end spacing. See Step 7 of the in-line instructions for details.

If using Classic, Estate, Twist or Ellipse balusters, use a 1/8" drill bit to open up the predrilled holes to the angle of the stairs. The top and bottom connectors will be facing opposite directions. Attach stair baluster connectors to the rails. Do not over-tighten screws.

Apply silicone caulk on each connector to prevent balusters from turning or rattling after

installation is complete. The caulk should be on the outside of the round connector and on

the inside of the designer baluster connector.

Step 6 Position the bottom rail between posts and center. Check building code

requirements for maximum spacing on a staircase, typically less than 6". A 6" ball cannot

pass through the triangle formed by the bottom rail, tread and riser (Figure 10). Mark the

location of the bracket on both posts. Remove rail. Mark the screw locations and pre-drill

through the post sleeve only using a 1/4" drill bit. Attach each bracket to the post with two

2" long screws.

Step 7 A support block is needed at the center of each rail. Cut the support block to

desired height. Attach to the bottom of the lower rail (refer to Figure 1). Find the center

of the rail and pre-drill using a 1/8" drill bit. Attach the support block connector using the

included screw. Mark the location of the support block on the step tread and attach the

other support block connector to the step tread using the included screw.

Step 8 Position the bottom rail between the posts. Pre-drill with a 1/8" drill bit and

attach the rail to the stair brackets using four 1" screws on both ends. Tip: Use a driver

extension bit to avoid marring the rail or post sleeve with the drill chuck.

Figure 9

Top and

Bottom Rail

Stair

Bracket (4)

Classic, Estate, Twist and Ellipse balusters: Attach balusters to the lower rail by sliding

onto connectors.

Step 9 Position the top rail between the posts. Check for plumb end-to end-and

vertically. Mark the bracket location on post sleeve and remove rail. Mark the screw

locations using the bracket as a guide, and pre-drill using a 1/4" drill bit through the post

sleeve only. Attach bracket to the post with two 2" long screws at one end. Repeat for the

other end.

Classic, Estate, Twist and Ellipse balusters: Lower the top rail into position, placing the

balusters onto the stair connectors while working from one end of the railing to the other.

Tap with a rubber mallet if needed to eliminate any gaps. Attach the rail to each bracket

by pre-drilling with 1/8" drill bit and using four 1" screws. Tip: Use a driver extension bit to

avoid marring the rail or post sleeve with the drill chuck.

Traditional, Baroque, Arc and Glass balusters: Place the top rail in position. Attach the

rail to each bracket by pre-drilling with a 1/8" drill bit and using four 1" screws. Tip: Use a

driver extension bit to avoid marring the rail or post sleeve with the drill chuck.

Step 10 Traditional, Baroque and Arc balusters: Place a baluster on the rails on-center

of one of the marked positions (4-1/2" on-center or 7-1/2" on-center for glass). Make sure

the baluster is plumb. Using the baluster as a guide, drill 9/64" holes in the top and bottom

rails. Drill and attach baluster with the screws provided. Use a 2x4 spacer block to space

next baluster. Drill and attach each baluster to the top and bottom rails with the screws

provided. Using a pair of clamps to hold baluster in place while fastening will make this

step easier (Figure 10).

Step 11 (optional) Cut the cap rail and cap rail insert to length (Note: the cap rail will be

1/2" longer than the top and bottom rails.) Center the cap rail insert on top of the top rail

and pre-drill seven 1/8" pilot holes. Attach the cap rail insert to the top rail with seven 1/2”

long screws. Apply exterior-grade metal construction adhesive to the mating edges of the

insert rail. Position cap rail over the insert rail. Install by pressing down, starting from one

end and working to the other until the cap rail snaps into place. Gently tap with a rubber

mallet if needed.

Figure 10

The diagrams and instructions in this brochure are for illustration purposes only

and are not meant to replace a licensed professional. Any construction or use of

the product must be in accordance with all local zoning and/or building codes.

The consumer assumes all risks and liability associated with the construction or

use of this product. The consumer or contractor should take all necessary steps

to ensure the safety of everyone involved in the project, including, but not limited

to, wearing the appropriate safety equipment.

Except as contained in the written limited warranty, the warrantor does not

provide any other warranty, either express or implied, and shall not be liable

for any damages, including consequential damages.

Deckorators is a registered trademark

of Universal Consumer Products, Inc. in the U.S.

www.deckorators.com

©2012, 2014 Universal Forest Products

933 US Route 202

Greene, ME 04236-3466

All rights reserved.

7551_3/14

Step 12 Apply exterior-grade metal construction adhesive to the inside edges of the post

caps and place over each post sleeve.

Page 5

Instructions d’installation

pour la traverse de 8 pi

Pour chaque section de traverse de 8 pi

centre-à-centre, vous aurez besoin de :

Une trousse de traverse de 8 pi qui contient

• 2 traverses

• 1 trousse de quincaillerie en-ligne qui

contient :

4 fixations en-ligne

8 - N° 6 x 2 po de long, vis à tête carrée N° 2

12 - N° 4 x 1 po de long, vis à tête carrée N° 2

• 1 trousse de bloc de support qui contient :

1 bloc de support

2 raccords

2 vis

Une trousse de traverses à chapeau

(optionnel) qui contient :

• 1 traverse à chapeau

• 1 traverse à insertion

• 9 - N° 4 x 1 po de long, vis à tête carrée N° 2

Des coins adaptateurs de 22,5˚ et 45˚ sont

disponibles pour les applications de rampes

inclinées.

Options de balustres

Trousses de balustres Classique, Estate,

Twist ou Ellipse qui contiennent chacune :

• 10 balustres d’aluminium

• 20 balustres nécessaire par section de

traverses de 8 pi centre-à-centre

(Classique, Estate et Twist)

• 24 balustres nécessaire par section de

traverses de 6 pi centre-à-centre (Ellipse)

Trousses de raccord de balustres de designers

ou raccord de balustre qui contiennent

chacune :

• 20 raccords de balustres

• 1 trousse nécessaire par 10 balustres

Trousse de balustre Traditionnel qui contient :

• 10 balustres d’aluminium

• 40 vis d’acier inoxydable, de couleurs

assorties

• 20 balustres nécessaire par section de

traverses de 6 pi centre-à-centre

Trousses de balustre Baroque ou Arc qui

contiennent chacune :

• 5 balustres d’aluminium

• 20 vis d’acier inoxydable, de couleurs

assorties

• 20 balustres nécessaire par section de

traverses de 6 pi centre-à-centre

Trousse de balustre Verre qui contient :

• 5 balustres de verre

• 20 vis d’acier inoxydable

• 12 balustres requis par section de 8 pi

de traverse centre-à-centre

Un manchon de poteaux

Un chapeau de poteau pour chaque manchon

de poteau (vendu séparément)

Une garniture de base de poteau pour chaque

manchon de poteau (vendue séparément)

Trousses de fixations de traverses de

marches pour les sections de traverses de

marches Deux trousses requises par section

de traverse de 8 pi centre-à-centre

Chaque trousse contient :

• 2 fixations de marche

• 4 - N° 6 x 2 po de long, vis à tête carrée N° 2

• 8 - N° 4 x 1 po de long, vis à tête carrée N° 2

Trousses de raccords de balustres d’escaliers

qui contiennent chacune (Classique, Estate,

Twist et Ellipse seulement) :

• 20 raccords de balustres d’escaliers

• 1 trousse nécessaire par 10 balustres

Chapeau

de poteau

Manchon

de poteau

Figure 1

Bloc de

support

Porche/Côté

de terrasse

Traverse du haut

et du bas

Fixation

en-ligne (4)

Traverse à chapeau

Poteau 4x4

Traverse à inser tion

Balustre

Vis de

balustre

Articles dont vous aurez besoin :

• Tournevis électrique/perceuse

• Scie circulaire ou à onglet avec lame

à pointe au carbure

• Clé ajustable ou clé à douille pour

les boulons, etc.

• Attaches assorties (voir les instructions)

• Ruban à mesurer

• Marteau

• Équerre vitesse marquée

• Niveau de menuisier

• Crayon de menuisier

• Lunettes de sécurité

• Deux pinces

• Scie à métaux

• Adhésif de construction métallique de

qualité extérieure

Instructions d’installation pour la traverse en-ligne

Avant la construction, consultez l’agence réglementaire locale pour toutes exigences spéciales

du code dans votre région. La hauteur courante de traverse est de 36 ou de 42 po. Le support

structural devrait provenir soit de la suite des poteaux de soutien de la terrasse qui se prolonge vers

le haut par le plancher de la terrasse ou des poteaux de traverse qui sont boulonnés à l’intérieur

du bord ou des solides extérieures. Ne couvrez jamais plus de 8 pi centre-à-centre entre les

poteaux de traverses. Installez les poteaux de traverse avant que les planches de la terrasse soient

attachées aux solives. Prépercer tous les composants de la traverse est essentiel pour réussir

l’installation. L’aire de travail doit être libre de débris, incluant les copeaux de métal qui pourraient

mener à des égratignures. Ne resserrez pas trop les vis. Lisez toutes les instructions pour bien

comprendre comment assembler le produit et comment chaque pièce affecte les autres.

Étape 1 : Déterminez le nombre de poteaux de traverse nécessaires pour votre terrasse. Leu r

espacement devrait être de 8 pi centre-à-centre, Exemple : une terrasse de 16x20 attachée à un

édifice avec une ouverture d’accès de 4 pi d’un côté exigera en tout huit poteaux (figure 2).

Étape 2 : installez les poteaux de traverse avant d’installer les planches de la terrasse. Les poteaux

de traverse 4x4 de pin traité sous pression ou de cèdre fournissent la force structurale voulue pour

le garde-corps. La longueur de chaque poteau structural est déterminée par le total de la largeur

de solive (7 1/4 po) + l’épaisseur de la terrasse (1 po) + hauteur de la traverse (36 ou 42 po)= 44

1/4 po ou 50 1/4 po.

Important : Ne faites pas d’encoche dans les poteaux de traverse de 4x4 (figure 3a). Cela réduira

la force du poteau et pourrait mener à une défaillance ou l’écrasement des traverses.

Étape 3 : Placez, mettez à niveau avec un niveau et pincez le poteau de traverse sur la face intérieure

de la solive. Remettez à niveau. Le poteau de traverse 4x4 devrait être boulonné à l’intérieur des

solives en utilisant deux boulons de carrosserie galvanisés 1/2 x 6 po. Les poteaux de coin utilisent

un troisième boulon de carrosserie inséré à travers la solive adjacente (figure 3b).

Étape 4 : Installez la terrasse, rainez les planches de terrasse pour ajuster autour des poteaux de

traverse 4x4.

Figure 2

Figure 3a

Figure 3b

Balayez le code pour obtenir

plus d’information au sujet

de l’installation de la traverse

d’aluminium Deckorators.

Obtenez l’application mobile

gratuite à http://gettag.mobi

Page 6

Étape 5 : Taillez les manchons de poteaux 4x4 pour la longueur. Les manchons de poteaux devraient

être d’un moins 1 1/2 po plus longs que la hauteur d’ensemble des traverses (figure 4a et 4b).

Prévoyez un autre 1 1/2 po dans votre calcul si vous installez la traverse à chapeau optionnelle.

Exemple : Pour une traverse de 36 po de haut, taillez le manchon de poteau à au moins 37 1/2 po (39

avec la traverse à chapeau). Si vous le désirez, le manchon de poteau peut rester plus long.

Certains agents de conservation du bois peuvent causer une réaction indésirable en contact

direct avec l’aluminium. L’intérieur du manchon de poteau inclut une doublure pour éviter le contact

direct avec les poteaux structuraux traités. Si votre terrasse est traitée sous pression, placez les

cales sous le manchon du poteau ou ajoutez un boudin de mastic le long du bord inférieur du

poteau avant d’installer le manchon du poteau. Ceci préviendra le contact direct de l’aluminium

avec la terrasse traitée et cachera la garniture de la base du poteau. Glissez un manchon de

poteau taillé sur chaque poteau de traverse de 4x4. Glissez une garniture de base de poteau sur

chaque manchon de poteau. Ajoutez un boudin de mastic sous la garniture de base du poteau

lorsque vous utilisez une terrasse traitée.

Étape 6 : Mesurez la distance entre les manchons de poteaux installés pour déterminer la longueur

des traverses du haut et du bas (figure 1). La distance entre le poteau et le premier balustre devrait

être de moins de 4 po et égale des deux côtés (figure 4a et 4b). Retirez un autre 1/4 po aux deux

extrémités (1/2 po en tout) pour la fixation pour s’ajuster entre la traverse et le poteau. Taillez les

traverses du haut et du bas selon la longueur.

Des coins adaptateurs inclinés sont disponibles pour des angles de rampes de 22,5˚ et 45˚.

Important : les trous dans les coins adaptateurs inclinés s’alignent avec les raccords de rampes

d’escalier (vendues séparément). Si vous installez une rampe inclinée à un angle de 22,5˚, attachez

les raccords d’escalier et les coins centrés sur les poteaux. Si vous installez une rampe inclinée à un

angle de 45˚, attachez les coins adaptateurs de 45˚centrés sur les poteaux. Attachez les raccords de

rampes à 45˚ en utilisant les vis fournies.

Mesurez la distance entre les raccords inclinés installés pour déterminer la longueur des traverses du

haut et du bas. Taillez les traverses du haut et du bas selon la longueur.

Étape 7 : Déterminez l’espacement des balustres.

Balustres Classique, Estate et Twist : les traverses sont pré-percées avec l’espacement

approprié. Installez les raccords de balustre sur les traverses du haut et du bas. Ne resserrez pas trop

les vis. Appliquez un mastic de silicone sur chaque raccord pour empêcher les balustres de tourner

ou de cliqueter après la fin de l’installation. Le mastic devrait être à l’extérieur du raccord rond, et à

l’intérieur des raccords de balustre de designer.

Balustres de Ellipse : Les traverses du haut et du bas seront installées avec les trous pré-percés

face vers le bas pour empêcher l’eau de s’accumuler dans la traverse. 4 1/4 po de centre-à-centre

et espacement égal pour l’espacement d’extrémité. Commencez en trouvant le centre de la traverse.

Longueur de traverse ÷ 2 = centre de la traverse. Commencez le premier balustre de verre de centreà-centre de la ligne centrale. Marquez tous les 4 1/4 po de la ligne centrale à chaque extrémité. Ceci

laissera l’espacement d’extrémité à 4 po ou moins aux deux extrémités et exige 24 balustres de Ellipse.

Attacher des raccords aux deux traverses aux emplacements marqués.

Balustres Traditionnel, Baroque et Arc : Les traverses du haut et du bas seront installées avec

les trous pré-percés face vers le bas pour empêcher l’eau de s’accumuler dans la traverse. Maxi

mum de 4 1/2 de centre-à-centre et espacement égal pour l’espacement d’extrémité. Commencez

en trouvant le centre de la traverse. Longueur de traverse ÷ 2 = centre de la traverse. Commencez

les premiers balustres d’aluminium 2 1/4 po de centre-à-centre chaque côté de la ligne centrale.

Marquez tous les 4 1/2 po de ces lignes à chaque extrémité. Ceci laissera l’espacement d’extrémité à

moins de 4 po aux deux extrémités et exige 20 balustres d’aluminium (figure 5). Conseil : Utilisez une

pièce de 2x4 (3 1/2 po en fait) comme bloc d’espacement pour l’écart entre les balustres.

Balustres de verre : Les traverses du haut et du bas seront installées avec les trous pré-percés

face vers le bas pour empêcher l’eau de s’accumuler dans la traverse. 7 1/2 po de centre-à-centre

et espacement égal pour l’espacement d’extrémité. Commencez en trouvant le centre de la traverse.

Longueur de traverse ÷ 2 = centre de la traverse. Commencez le premier balustre de verre de 2 1/4

po de centre-à-centre chaque côté de la ligne centrale. Marquez tous les 7 1/2 po de la ligne centrale

à chaque extrémité. Ceci laissera l’espacement d’extrémité à 4 po ou moins aux deux extrémités

et exige 12 balustres de verre. Si vous installez avec des raccords, attachez des raccords aux deux

traverses aux emplacements marqués. Conseil : Si vous montez à l’avant à la traverse, utilisez une

pièce de 2x4 (3 1/2 po en fait) comme bloc d’espacement pour l’écart entre les balustres (figure 5).

Étape 8 : Placez la traverse du bas entre les poteaux et le centre. Vérifiez les exigences du code de

la construction pour l’espacement maximum entre la surface de la terrasse et le bas de la traverse

(balayage). Un espacement de 3 po est recommandé, mais peut être plus ou moins élevé si les codes

le permettent (figures 4a et 4b). Marquez la position de la fixation sur les deux poteaux. Retirez la

traverse. Marquez les emplacements des vis et pré-percez à travers le manchon du poteau en utilisant

un foret de 1/4 po. Installez chaque fixation au poteau avec deux longues vis de 2 po.

Étape 9 : Il faut un bloc de support au centre de chaque traverse. Taillez le bloc de support à

la bonne hauteur. Installez au bas de la traverse inférieure (reportez-vous à la figure 1). Trouvez

le centre de la traverse et pré-percez avec un foret de 1/8 po. Installez le raccord du bloc de

support avec la vis incluse. Marquez l’emplacement du bloc de support sur la surface de la

terrasse et attachez l’autre raccord du bloc de support à la terrasse avec la vis incluse. Installez la

traverse inférieure entre les poteaux. Utilisez les fixations comme guide, pré-percez chaque trou de

vis avec un foret de 1/8 po et fixez chaque extrémité aux fixations avec deux vis longues de 1 po.

Conseil : Utilisez un foret rallonge de tournevis pour éviter de tacher la traverse ou le manchon du

poteau avec le mandrin porte-foret.

Étape 10 : Les figures 4a et 4b montrent comment dimensionner une traverse de 36 po de haut. Si

vous désirez avoir une traverse à une hauteur différente, utilisez les figures 4a et 4b comme outils de

planification pour déterminer la hauteur de coupe des manchons de poteaux et les blocs de support.

Remarque : Utilisez une fixture pour assurer une longueur constante (+/- 1/16 po).

Hauteur de

manchon de

poteau de

38 po

(hauteur de

traverse plus

1 1/2 po)

Hauteur de

manchon de

poteau de 39

po (hauteur

de traverse

plus 1 1/2 po)

-

Figure 4a

Figure 4b

Figure 4c

Hauteur

de balustre

de 32 po

Balayage de 3 po

Moins de 4 po

Hauteur

de balustre

de 26 po

Balayage de 3 po

Moins de 4 po

Traverse

à chapeau

de 1 1/2 po

Hauteur

de traverse

de 36 1/2 po

Traverse

à chapeau

de 1 1/2 po

Hauteur

de traverse

de 37 1/2 po

Page 7

Balustres Classique, Estate, Twist et Ellipse; et balustres en verre utilisant des

Manchon de poteau

Poteau de bois

Adaptateur de traverse à chapeau

Traverse à chapeau

Traverse à chapeau

Traverse à insertion

Traverse du haut

raccords :Attachez les balustres à la traverse inférieure en glissant sur les raccords (figure 4c).

Étape 11 : Placez la traverse du haut entre les poteaux. Vérifiez le niveau d’une extrémité à l’autre

et verticalement. Marquez l’emplacement de la fixation sur le manchon du poteau et retirez la

traverse. Marquez les emplacements des vis en utilisant la fixation comme guide et pré-percez

utilisant un foret de 1/4 po par le manchon de poteau seulement. Installez la fixation au poteau

avec deux vis de 2 po de long à une extrémité. Répétez à l’autre extrémité.

Balustres Classique, Estate, Twist et Ellipse; et balustres en verre utilisant des

raccords : Abaissez la traverse du haut en position, placez les balustres sur les raccords tout en

fonctionnant d’une extrémité de la traverse à l’autre. Frappez avec un maillet de caoutchouc au

besoin pour éliminer tous écarts. Fixez la traverse à chaque fixation en pré-perçant avec un foret

de 1/8 po et trois vis de 1 po de long. Conseil : Utilisez un foret rallonge de tournevis pour éviter de

tacher la traverse ou le manchon du poteau avec le mandrin porte-foret.

Balustres Traditionnel, Baroque, Arc; et balustres en verre à montage avant : Placez la

traverse du haut en position. Fixez la traverse à chaque fixation en pré-perçant avec un foret de

1/8 po et trois vis de 1 po de long. Conseil : Utilisez un foret rallonge de tournevis pour éviter de

tacher la traverse ou le manchon du poteau avec le mandrin porte-foret.

Étape 12

Balustres Traditionnel, Baroque, Arc; et balustres en verre à montage avant :

Commencez les deux premiers balustres à 2 1/4 po de centre-à-centre chaque côté du centre de

la traverse et continuez jusqu’à chaque extrémité. Utilisez le balustre comme guide, percez des

trous de 9/ 64 po dans les traverses à chaque emplacement de balustre. Utilisez une pièce de 2x4

comme bloc d’espacement pour l’écart avec le balustre suivant. Travaillez vers les extrémités et

percez et attachez chaque balustre avec les vis fournies (figure 5 et figure 6).

Étape 13 (optionnel) : Coupez la traverse à chapeau et l’insertion de traverse à chapeau selon

la longueur. (Remarque : la traverse à chapeau sera de 1/2 po plus long que les traverses du

haut et du bas). Centrez l’insertion de traverse du chapeau sur le dessus de la traverse du haut et

pré-percez sept trous pilotes de 1/8 po. Fixez l’insertion de la traverse à chapeau sur la traverse

du haut avec sept vis de 1/2 po de long. Appliquez un adhésif de construction métallique de

qualité extérieure aux bords homologues de la rampe à insérer. Placez la traverse à chapeau sur la

traverse d’insertion (figure 7). Installez en enfonçant en commençant à une extrémité et en allant

vers l’autre jusqu’à ce que la traverse à chapeau s’enclenche en place. Frappez délicatement avec

un maillet de caoutchouc, si nécessaire.

Traverses inclinées : pour les traverses de 22,5° , coupez la traverse à chapeau et l’insertion de

travers à chapeau selon la longueur et à l’angle en utilisant une scie à onglet. Poncez les extrémités

et appliquez une peinture de retouche au besoin (vendue séparément). Installez à la traverse du

haut suivant les étapes précédentes.

Les traverses de 45° exigeront un coin de travers à chapeau sur le dessus de l’adaptateur de

45° (figure 8).

Le coin de traverse à chapeau sera découpé de la traverse à chapeau.

Le coin

exigera une coupe droite à l’extrémité en contact avec le poteau et une coupe de 22,5° à l’extrémité

opposée. La distance du poteau au bord large du coin est de 1 3 /4 po. Coupez deux coins

d’insertion et de traverse à chapeau en utilisant une scie à onglet et installez sur le dessus des

adaptateurs de 45° en suivant les étapes plus haut. La traverse à chapeau exigera une coupe de

22,5° aux deux extrémités pour correspondre à la largeur de coins de traverse à chapeau. Mesurez

la distance entre les coins installés et coupez les deux extrémités à la longueur et angle en utilisant

une scie à onglets. Poncez les extrémités de coupe et appliquez de la peinture de retouche au

besoin (vendue séparément) pour que les coutures soient moins remarquables. Fixez la traverse

à chapeau sur la traverse du haut en suivant les étapes précédentes.

Étape 14 : Appliquez un adhésif de construction métallique de qualité extérieure aux bords

intérieurs du chapeau de poteauxet placez sur chaque manchon de poteau.

Instructions d’installation pour la traverse d’escalier

Traverse

du haut

et du bas

Traverse à chapeau

Traverse à

Bloc

d'espacement

de 3 1/2 po

4 1/2 po

Extérieur de terrasse

4 1/2 po

po

4 1/2 po

2 1/4 po

4 1/2 po

2 1/4 po

po

4 1/2 po

insertion

Balustre

Figure 5

Traverse

Manchon

de poteau

du haut

et du bas

Traverse à chapeau

Traverse à inser tion

Balustre

Bloc de

support

Vis de

Fixation

balustre

en-ligne (4)

Figure 6

Porche/Extérieur

de terrasse

Poteau 4x4

Figure 7

Étape 1 : Les poteaux de traverse 4x4 de pin traité sous pression ou de cèdre fournissent la force

structurale voulue pour le garde-corps. La longueur de chaque poteau structural est déterminée

par le total de la largeur du longeron d’escalier (7 1/4 po) + l’épaisseur de la terrasse (1 po) +

hauteur de la traverse (36 ou 42 po)=44 1/4 po ou 50 1/4 po.

Étape 2 : Placez, mettez à niveau avec un niveau et pincez le poteau de traverse sur la face

intérieure du longeron d’escalier. Remettez à niveau. Le poteau de traverse 4x4 devrait être boulonné

à l’intérieur du longeron d’escalier en utilisant deux boulons de carrosserie galvanisés 1/2 x 6 po.

Les poteaux de coin utilisent un troisième boulon de carrosserie inséré à travers la solive adjacente

(reportez-vous à la figure 3b). Les poteaux au niveau du sol devraient être installés dans le béton.

Étape 3 : Terminez l’installation des filets d’escalier avant d’installer les manchons de poteaux.

Taillez les manchons de poteaux 4x4 pour la longueur. Si vous utilisez des chapeaux de poteaux,

les manchons de poteaux devraient être d’au moins 1 1/2 po plus longs que la hauteur d’ensemble

des traverses (figure 4). Prévoyez un autre 1 1/2 po dans votre calcul si vous installez la traverse à

chapeau optionnelle. Exemple : Pour une traverse de 36 po de haut, taillez le manchon de poteau

à au moins 37 1/2 po (39 avec la traverse à chapeau). Si vous le désirez, le manchon de poteau

peut rester plus long.

Certains agents de conservation du bois peuvent causer une réaction indésirable en contact direct

avec l’aluminium. L’intérieur du manchon de poteau inclut une doublure pour éviter le contact

direct avec les poteaux structuraux traités. Si votre terrasse est traitée sous pression, placez les

cales sous le manchon du poteau ou ajoutez un boudin de mastic le long du bord inférieur du poteau

avant d’installer le manchon du poteau. Ceci préviendra le contact direct de l,aluminium avec

la terrasse traitée et cachera la garniture de la base du poteau. Glissez un manchon de poteau

taillé sur chaque poteau de traverse de 4x4. Glissez une garniture de base de poteau sur chaque

manchon de poteau. Ajoutez un boudin de mastic sous la garniture de base du poteau lorsque

vous utilisez une terrasse traitée.

Vue du haut

Figure 8 : Installation

d’angle 45°

Coin de traverse à chapeau

Poteau de bois

Aluminium

manchon de poteau

Adaptateur

de 45˚

Fixation de

traverse de

marches

Rampe 2x4

Page 8

Étape 4 : Mesurez la distance entre les manchons de poteaux installés pour déterminer la longueur

des traverses du haut et du bas. Déposez la traverse inférieure sur les marches avec les trous

pré-percés face vers le bas. La distance entre le poteau et le premier balustre devrait être de

moins de 4 po et égale aux deux extrémités. Marquez l’angle et la longueur. Faites de même avec

la traverse du haut. Retirez un autre 1/4 po aux deux extrémités (1/2 po en tout) pour la fixation

pour s’ajuster entre la traverse et le poteau. Taillez les traverses du haut et du bas selon la longueur

avec le même angle (figure 9).

Étape 5 : Déterminez l’écart de balustres, 4 1/2 po maximum de centre-à-centre (7 1/2 po de

centre-à-centre si vous utilisez des balustres de verre, 4 1/4 po de centre-à-centre si vous utilisez

des balustres de Ellipse), et un espacement égal pour l’espacement d’extrémité. Voir l’étape 7 des

instructions en ligne pour les détails.

Si vous utilisez des balustres Classique, Estate, Twist et Ellipse, utilisez un foret de 1/8 po pour

ouvrir les trous pré-percés à l’angle des marches. Les raccords supérieur et inférieur seront face

à des directions opposées. Installez les raccords de balustre sur les marches aux traverses. Ne

resserrez pas trop les vis. Appliquez un mastic de silicone sur chaque raccord pour empêcher les

balustres de tourner ou de cliqueter après la fin de l’installation. Le mastic devrait être à l’extérieur

du raccord rond, et à l’intérieur du raccord de balustre de designer.

Étape 6 : Placez la traverse du bas entre les poteaux et le centre. Vérifiez les exigences du code

de la construction pour l’espacement maximum sur un escalier, typiquement moins que 6 po.

Une bille de 6 po ne peut pas passer par le triangle formé par la traverse du bas, le filet et la tige

(figure 10). Marquez la position de la fixation sur les deux poteaux. Retirez la traverse. Marquez

les emplacements des vis et pré-percez à travers le manchon du poteau en utilisant seulement un

foret de 1/4 po. Installez chaque fixation au poteau avec deux longues vis de 2 po.

Étape 7 : Il faut un bloc de support au centre de chaque traverse. Coupez le bloc de support à la

hauteur voulue. Installez au bas de la traverse inférieure (reportez-vous à la figure 1). Trouvez le

centre de la traverse et pré-percez avec un foret de 1/8 po. Installez le raccord du bloc de support

avec la vis incluse. Marquez l’emplacement du bloc de support sur le filet de la marche et attachez

l’autre raccord de bloc de support au filet de la marche avec la vis fournie.

Étape 8 : Placez la traverse du bas entre les poteaux. Pré-percez avec un foret de 1/ 8 po et

fixez la traverse aux fixations des marches en utilisant quatre vis de 1 po aux deux extrémités.

Conseil : Utilisez un foret rallonge de tournevis pour éviter de tacher la traverse ou le manchon du

poteau avec le mandrin porte-foret.

Balustres Classique, Estate, Twist et Ellipse : Attachez les balustres à la traverse inférieure en

glissant sur les raccords.

Étape 9 : Placez la traverse du haut entre les poteaux. Vérifiez le niveau d’une extrémité à l’autre

et verticalement. Marquez l’emplacement de la fixation sur le manchon du poteau et retirez la

traverse. Marquez les emplacements des vis en utilisant la fixation comme guide et pré-percez

utilisant un foret de 1/4 po par le manchon de poteau seulement. Installez la fixation au poteau

avec deux vis de 2 po de long à une extrémité. Répétez à l’autre extrémité.

Balustres Classique, Estate, Twist et Ellipse : Abaissez la traverse du haut en position, placez les

balustres sur les raccords des marches tout en fonctionnant d’une extrémité de la traverse à l’autre.

Frappez avec un maillet de caoutchouc au besoin pour éliminer tous écarts. Fixez la traverse à

chaque fixation en pré-perçant avec un foret de 1/8 po et quatre vis de 1 po. Conseil : Utilisez

un foret rallonge de tournevis pour éviter de tacher la traverse ou le manchon du poteau avec le

mandrin porte-foret.

Balustres Traditionnel, Baroque, Arc et Verre : Placez la traverse du haut en position. Fixez la

traverse à chaque fixation en pré-perçant avec un foret de 1/8 po et quatre vis de 1 po. Conseil :

Utilisez un foret rallonge de tournevis pour éviter de tacher la traverse ou le manchon du poteau

avec le mandrin porte-foret.

Étape 10 Balustres Traditionnel, Baroque et Arc : Placez un balustre sur les rails de centre-àcentre d’une des positions marquées (4 1/2 po de centre-à-centre ou 7 1/2 po de centre-à-centre

pour le verre). Assurez-vous que le balustre est à niveau. Utilisez le balustre comme guide, percez

des trous de 9/64 po dans les traverses du haut et du bas. Percez et attachez le balustre avec

les vis fournies. Utilisez un bloc d’espacement 2x4 pour l’écart avec le balustre suivant. Percez et

fixez chaque balustre sur les traverses du haut et du bas avec les vis fournies. Utiliser une paire de

pinces pour garder le balustre en place tout en attachant facilitera cette étape (figure 10).

Étape 11 (optionnel) : Coupez la traverse à chapeau et l’insertion de traverse à chapeau selon la

longueur. (Remarque : la traverse à chapeau sera 1/2 po plus long que les traverses du haut et

du bas). Centrez l’insertion de traverse du chapeau sur le dessus de la traverse du haut et prépercez sept trous pilotes de 1/8 po. Fixez l’insertion de la traverse à chapeau sur la traverse du

haut avec sept vis de 1/2 po de long. Appliquez un adhésif de construction métallique de qualité

extérieure aux bords homologues de la rampe à insérer. Placez la traverse à chapeau sur la tra

verse d’insertion. Installez en enfonçant en commençant à une extrémité et en allant vers l’autre

jusqu’à ce que la traverse à chapeau s’enclenche en place. Frappez délicatement avec un maillet

de caoutchouc, si nécessaire.

Manchon

de poteau

Distance

entre les

Manchon

de poteau

Figure 9

poteaux

Marquez la traverse

pour la longueur

et l'angle

Traverse

du haut

et du bas

Chapeau

de poteau

Manchon

de poteau

Figure 10

Les diagrammes et instructions de cet te brochure sont à des fins d’illustration

seulement et non pas pour remplacer un professionnel agréé. Toute construction ou utilisation de ce produit doit être conforme aux codes locaux de

construction et/ou de zonage. Le client assume tous les risques et responsabilités associés à la construction ou à l’utilisation de ce produit. Le client

ou l’entrepreneur doit prendre toutes les mesures néce ssaires pour assurer

la sécurité de toute personne impliquée dans le projet, incluant, mais sans s’y

limiter, porter un équipement de sécurité approprié.

Sauf indication dans la garantie limitée écrite, le garant ne fournit pas

d’autre garantie, expresse ou implicite, et ne sera pas responsable de tous

dommages, incluant des dommages consécutifs.

Deckorators est une marque commerciale déposée

d’Universal Consumer Products, Inc., aux É.-U.

-

Bord extérieur des marches

www.deckorators.com

©2012, 2014 Universal Forest Products

933 US Route 202

Greene, ME 04236-3466

Tous droits réservés.

7551frn-8 3/14

Moins de 6 po

Moins de 4 po

Traverse du haut

et du bas

Marquez

la traverse

pour la

longueur

et l'angle

Fixation de

marche (4)

Balustre

Étape 12 : Appliquez un adhésif de construction métallique de qualité extérieure aux bords

intérieurs du chapeau de poteaux et placez sur chaque manchon de poteau.

Page 9

Instrucciones para

la instalación de

barandal de 8'

Para cada sección de barandal de 8’ de

centro a centro, usted necesitará:

Un kit de Barandal de 8' que contenga:

• 2 barandales

• 1 kit de sujetadores en línea que contenga:

4 soportes en línea

8 – tornillos #2 de cabeza cuadrada

#6 x 2” de largo

12 – tornillos #2 de cabeza cuadrada

#4 x 1” de largo

• 1 kit de bloque de apoyo que contenga:

1 bloque de apoyo

2 conectores

2 tornillos

Un kit de barandal de tope (opcional)

que contenga:

• 1 barandal de tope

• 1 barandal de inserción

• 9 – tornillos #2 de cabeza cuadrada

#4 x 1” de largo

Las cuñas para el adaptador de 22.5˚

y 45˚ están disponibles para las aplicaciones

de los barandales en ángulo.

Opciones de balaustre

Kits de balaustre Classic, Estate, Twist o

Ellipse que contenga cada uno:

• 10 balaustres de aluminio

• 20 balaustres necesarios por cada sección

de barandal de 8’ de centro a centro

(Classic, Estate y Twist)

• 24 balaustres necesarios por cada sección

de barandal de 8’ de centro a centro (Ellipse)

Kits de conector de balaustre o de conector

de balaustre de diseñador que contenga

cada uno:

• 20 conectores de balaustre

• 1 kit necesario por 10 balaustres

Kit de balaustre Traditional que contenga:

• 10 balaustres de aluminio

• 40 tornillos de acero inoxidable que

correspondan al color del barandal

• 20 balaustres requeridos por sección

de barandal de 8' de centro a centro

Kits de balaustre Baroque o Arc que

contenga cada uno:

• 5 balaustres de aluminio

• 20 tornillos de acero inoxidable que

correspondan al color del barandal

• 20 balaustres requeridos por sección

de barandal de 8' de centro a centro

Vidrio

• 5 balaustres de vidrio

• 20 tornillos de acero inoxidable

• 12 balaustres requeridos por sección

de barandal de 8' de centro a centro

Una cobertura para poste

Un tope para poste por cada cobertura

para poste (se venden por separado)

Un modelo base para poste por cada cobertura

para poste (se venden por separado)

Kits de soporte de barandales para escalera

para las secciones de barandales para escalera.

Se requieren dos kits por sección de barandal

de 8' de centro a centro.

Cada kit contiene:

• 2 soportes para escalera

• 4 – tornillos #2 de cabeza cuadrada

#6 x 2" de largo

• 8 – tornillos #2 de cabeza cuadrada

#4 x 1" de largo

Kits de conectores de balaustres para

escalera que contengan cada uno (únicamente Classic, Estate, Twist y Ellipse):

• 20 conectores de balaustres para escalera

• 1 kit necesario por 10 balaustres

Tope para

poste

Cobertura

para

poste

Figura 1

Bloque de

apoyo

Deslizamiento para

porche/terraza

Barandal superior

e inferior

Soporte en

línea (4)

Poste de 4x4

Barandal de tope

Barandal de inserción

Balaustre

Tornillos para

balaustre

Elementos que necesitará

• Taladro/destornillador eléctrico

• Sierra ingletadora o circular

con hoja

de filo de carbono

• Llave ajustable o llave tubular

para pernos, etc.

• Herrajes variados (vea las instrucciones)

• Cinta métrica

• Martillo

• Escuadra triangular

de acero con medidas

• Nivel de carpintero

• Lápiz de carpintero

• Lentes de seguridad

• Dos abrazaderas

• Segueta

• Pegamento para construcción de metales

para exteriores

Instrucciones para la instalación de barandal en línea

Antes de iniciar la construcción, consulte en la correspondiente agencia local sobre la normativa

y/o reglamentación especial que sea de aplicación en su región. La altura del barandal común

es de 36" o 42" (91.44 cm o 1.066 m). El apoyo estructural deberá provenir de la continuación

de los postes de apoyo de la terraza que se extienden a través del piso de la terraza o de los

postes de barandal que están sujetos al interior de las vigas periféricas o exteriores. No deje

nunca una separación superior a 8' (2.4 m) entre los centros de los postes del barandal. Instale

los postes del barandal antes de que las tablas de la terraza se sujeten a las vigas. Taladrar

previamente todos los componentes del barandal es esencial para una instalación exitosa.

El área de trabajo deberá mantenerse limpia de residuos, incluyendo virutas de metal que

puedan causar rasguños. No apriete demasiado los tornillos. Lea las instrucciones por completo

para comprender la forma en que debe montarse el producto, y la forma en que cada pieza

afecta al resto.

Paso 1 Determine la cantidad necesaria de postes de barandal para su terraza. El espaciamiento

entre postes es de 8' medido de centro a centro. Ejemplo: Una terraza de 16x20 sujeta a una

construcción con una abertura de acceso de 4' a un lado requerirá de un total de ocho postes

(Figura 2).

Paso 2 Instale los postes de barandal antes de instalar las tablas de la terraza. Los postes de

barandal de cedro o pino tratado a presión de 4x4 proporcionan la fuerza estructural para el

barandal. La longitud de cada poste estructural se determina por el total del ancho de la viga

(7-1 /4") + el grosor de la terraza (1") + la altura del barandal (36" o 42") = 44-1/4" o 5 0 -1 / 4".

Importante: No haga perforaciones en los postes de barandal de 4x4 (Figura 3a). Perforar

reducirá la fuerza del poste y podría resultar en el colapso o falla del barandal.

Paso 3 Coloque en su lug ar, aplome con un nivel y asegure con una abraz adera el poste de barandal

en la cara interior de la viga. Aplome de nuevo. El poste de barandal de 4x4 deberá sujetarse a la

parte interior de las vigas usando dos tirafondos galvanizados de 1/2"x6". Los postes de esquina

usan un tercer tirafondo insertado a través de la viga adyacente (Figura 3b).

Figura 2

Figura 3a

Figura 3b

Escaneé el código para obtener

más información sobre la

instalación de los barandales

de aluminio Deckorators.

Obtenga gratis la aplicación para

su celular en http://gettag.mobii

Page 10

Paso 4 Instale la terraza; corte agujeros o muescas en las tablas de la terraza para ajustarlas

alrededor de los postes de barandal de 4x4.

Paso 5 Recorte las coberturas para poste de 4x4 a la longitud deseada. Las coberturas para

poste deberán ser mínimo 1-1/2" más largas que la altura general del barandal (Figura 4a y

4b). Deje 1-1/2" adicional en su cálculo si instala el barandal de tope opcional. Ejemplo: Para

un barandal de 36" de altura, recorte la cobertura para poste a un mínimo de 37-1/2" (39" con

barandal de tope). La cobertura para poste se puede dejar más larga si lo desea.

Algunos conservadores de madera pueden causar una reacción no deseada cuando entran en

contacto directo con el aluminio. El interior de la cobertura para poste incluye un revestimiento

para prevenir el contacto directo con los postes estructurales tratados. Si su terraza está tratada

a presión, coloque separadores debajo de la cobertura para poste o ponga una cama de sellador

a lo largo del borde inferior del poste antes de instalar la cobertura para poste. Esto evitará que

el aluminio entre en contacto directo con la terraza tratada y quedará escondido bajo el modelo

base para poste. Deslice una cobertura para poste recortada sobre cada poste de barandal de

4x4. Deslice un modelo base para poste sobre cada cobertura para poste. Agregue una cama

de sellador a la parte inferior del modelo base para poste cuando use una terraza tratada.

Paso 6 Mida la distancia entre las coberturas para poste instaladas para determinar la longitud

de los barandales superior e inferior (Figura 1). La distancia entre el poste y el primer balaustre

deberá ser menor de 4” y ser igual en ambos extremos (Figura 4a y 4b). Recorte 1/4” adicional

en ambos extremos (1/2” en total) para que el soporte quepa entre el barandal y el poste. Recorte

los barandales superior e inferior a la longitud deseada.

Las cuñas de ángulo para adaptador están disponibles para barandales de ángulo de 22.5˚ y

45˚. Importante : los orificios en las cuñas de ángulo para adaptador se alinean con los conectores del barandal para escaleras (se venden por separado). Si instala un barandal de ángulo de

22.5°, sujete los conectores para escalera y las cuñas en forma centrada en los postes. Si instala

un barandal de ángulo de 45°, sujete las cuñas para adaptador de 45° en forma centrada en los

postes. Sujete los conectores para escaleras a 45˚ utilizando los tornillos proporcionados.

Mida la distancia entre los conectores de ángulo instalados para determinar la longitud de los

barandales superior e inferior. Recorte los barandales superior e inferior a la longitud deseada.

Paso 7 Determine el espaciamiento de los balaustres.

Balaustres Classic, Estate y Twist: Los barandales son taladrados previamente con el

espaciamiento adecuado. Sujete los conectores para balaustres a los barandales superior

e inferior. No apriete demasiado los tornillos. Aplique sellador de silicona en cada conector

para evitar que los b alaustres se muevan o vibren después de l a instalación. El sellador deberá

colocarse en la parte exterior del conector redondo, y en la parte interior de los conectores para

balaustres de diseñador.

Balaustres Ellipse: Los barandales superior e inferior se instalarán con los orificios taladrados

previamente hacia abajo para evitar que se acumule agua en el barandal. 4-1/4" medido de

centro a centro y un espaciamiento equivalente para el espaciamiento del extremo. Comience

ubicando el centro del barandal. Longitud del barandal ÷ 2 = centro del barandal. Comience

con el primer balaustre de vidrio de centro a centro a partir de la línea del centro. Marque

cada 4 -1/4" a partir de la línea del centro hacia cada extremo. Esto dejará el espaciamiento

del extremo en 4" o menos en ambos extremos y requiere de 24 balaustres de Ellipse. Fije los

conectores a ambos barandales en los lugares marcados.

Balaustres Traditional, Baroque y Arc: Los barandales superior e inferior se instalarán con

los orificios taladrados previamente hacia abajo para evitar que se acumule agua en el barandal.

Espaciamiento máximo de 4-1/2" medido de centro a centro y un espaciamiento equivalente

para el espaciamiento del extremo. Comience ubicando el centro del barandal. Longitud del

barandal ÷ 2 = centro del barandal. Comience con los primeros balaustres de aluminio a 2-1/4"

de centro a centro a cada lado de la línea del centro. Marque cada 4-1/2" a partir de estas

líneas hacia cada extremo. Esto dejará el espaciamiento del extremo en menos de 4" en ambos

extremos y requiere de 20 balaustres de aluminio (Figura 5). Consejo: Use una pieza de 2x4

(3 -1/2" actual) como bloque de espaciador para el espaciamiento entre balaustres.

Balaustres de vidrio: Los barandales superior e inferior se instalarán con los orificios taladrados

previamente hacia abajo para evitar que se acumule agua en el barandal.

centro a centro y un espaciamiento equivalente para el espaciamiento del extremo. Comience

ubicando el centro del barandal. Longitud del barandal ÷ 2 = centro del barandal. Comience

con el primer balaustre de vidrio a 2-1/4" del centro de cada lado de la línea central. Marque

cada 7-1/2" a partir de la línea del centro hacia cada extremo. Esto dejará el espaciamiento

del extremo en 4" o menos en ambos extremos y requiere de 12 balaustres de vidrio. Si instala

usando conectores, acople los conectores a ambos barandales en las ubicaciones marcadas.

Consejo: Si realiza el montaje sobre la superficie de la cara del barandal, use una pieza de 2x4

(3 -1/2" real) como bloque espaciador para el espaciado entre los balaustres (Figura 5).

Paso 8 Coloque el barandal inferior entre los postes y centre. Revise los requisitos del código

de construcción para el espaciamiento máximo entre la superficie de la terraza y la parte

inferior del barandal (barrido). Se recomienda un espaciamiento de 3", pero puede ser mayor

o menor si lo permiten los códigos (Figura 4a y 4b). Marque la ubicación del soporte en ambos

postes. Quite el barandal. Marque la ubicación de los tornillos y taladre previamente sólo a

través de la cobertura para poste, usando una broca de 1/4". Una cada soporte al poste con

dos tornillos de 2" de largo.

Paso 9 Se necesita un bloque de apoyo en el centro de cada barandal. Corte el bloque de

apoyo a la altura adecuada. Sujete a la parte de abajo del barandal inferior (consulte la Figura

1). Encuentre el centro del barandal y taladre previamente usando una broca de 1/8". Sujete el

conector del bloque de apoyo usando el tornillo que se incluye. Marque la ubicación del bloque

de apoyo en la superficie de la terraza y sujete el otro conector del bloque de apoyo a la terraza

usando el tornillo que se incluye. Instale el barandal inferior entre los postes. Usando los soportes como guía, taladre previamente cada orificio para tornillo usando una broca de 1/8" y

sujete cada extremo a los soportes usando dos tornillos de 1" de largo. Consejo: Use una broca

de extensión para evitar estropear el barandal o la cobertura para poste con el portabrocas.

7-1/ 2" medido de

Altura

de la

cobertura

para poste

de 38"

(Altura del

barandal

1

más 1-

/2")

Figura 4a

Altura

de la

cobertura

para poste

de 39"

(Altura del

barandal

1

más 1-

/2")

Figura 4b

Figura 4c

Altura del

balaustre de 32"

Barrido de 3"

Menos de 4"

Altura del

balaustre de 26"

Barrido de 3"

Menos de 4"

Barandal de

tope de 1-

1

Altura del

barandal

de 36-

Barandal de

tope de 1-

1

Altura del

barandal

1

de 37-

/2"

1

/2"

/2"

/2"

Page 11

Paso 10 Las Figuras 4a y 4b ilustran cómo debe medirse un barandal de 36" de altura. Si

Cobertura para poste

Poste de madera

Adaptador para barandal de tope

Barandal de tope

Barandal de tope

Barandal de inserción

Barandal superior

desea tener su barandal a una altura diferente, use las Figuras 4a y 4b como herramientas de

planeación para determinar la altura y cortar las coberturas para poste y los bloques de apoyo.

Nota: Use un dispositivo para asegurar una longitud consistente (+/- 1/16").

Los balaustres Classic, Estate, Twist y Ellipse; y balaustres de vidrio que usan conectores:

Sujete los balaustres al barandal inferior deslizándolos sobre los conectores (Figura 4c).

Pa s o 11 Coloque el barandal superior entre los postes. Revise con un nivel de extremo a extremo

y verticalmente. Marque la ubicación del soporte en la cobertura para poste y quite el barandal.

Marque la ubicación de los tornillos usando el soporte como guía, y taladre previamente usando

una broca de 1/4" sólo a través de la cobertura para poste. Sujete el soporte al poste con dos

tornillos de 2" de largo en un extremo. Repita para el otro extremo.

Los balaustres Classic, Estate, Twist y Ellipse; y balaustres de vidrio que usan conectores:

Baje el barandal superior en posición, colocando los balaustres en los conectores mientras

trabaja de un extremo del barandal al otro. Golpee con un mazo de goma si lo necesita para

eliminar cualquier abertura. Sujete el barandal a cada soporte taladrando previamente con una

broca de 1/ 8" y usando tres tornillos de 1" de largo. Consejo: Use una broca de extensión para

evitar estropear el barandal o la cobertura para poste con el portabrocas.

Balaustres Traditional, Baroque, Arc; y balaustres de vidrio para montaje sobre la superficie de

la cara: Coloque en posición el barandal superior. Sujete el barandal a cada soporte taladrando

previamente con una broca de 1/8" y usando tres tornillos de 1" de largo. Consejo: Use una

broca de extensión para evitar estropear el barandal o la cobertura para poste con el portabrocas.

Paso 12 Balaustres Traditional, Baroque, Arc; y balaustres de vidrio para montaje sobre la

superficie de la cara: Comience colocando los primeros dos balaustres a 2-1/4" de centro a

centro a cada lado del centro del barandal y trabaje hacia cada extremo. Usando el balaustre

como guía, taladre orificios de 9/ 64" en los barandales en cada ubicación de los balaustres. Use

un 2x4 como bloque espaciador para establecer el espacio del siguiente balaustre. Trabajando

hacia los extremos, taladre y sujete cada balaustre con los tornillos provistos (Figura 5 y figura 6).

Paso 13 (opcional) Corte el barandal de tope y el inserto para barandal de tope a la longitud correcta. (Not a: el barandal de tope será 1 /2" más largo que los barandales super ior e inferior.) Centre

el inserto para barandal de tope en la parte de arriba del barandal de tope y taladre previamente

siete orificios guía de 1/8". Sujete el inserto para barandal de tope al barandal superior con siete

tornillos de 1 /2" de largo. Aplique pegamento para c onstrucción de metales para ex teriores en los

bordes de contacto del barandal de inserción. Coloque el barandal de tope sobre el barandal de

inserción (Figura 7). Instale presionando hacia abajo, comenzando desde un extremo y trabajando hacia el otro hasta que el barandal de tope cierre a presión. Golpee suavemente con

un mazo de goma si lo necesita.

Barandales en ángulo: Para barandales de 22.5°, corte el barandal de tope y el inserto para

barandal de tope a la longitud y ángulo correctos usando una sierra ingletadora. Lije los

extremos y aplique pintura de retoque donde sea necesario (se vende por separado). Sujete al

barandal superior siguiendo los pasos de arriba.

Los barandales de 45° requerirán de una cuña para barandal de tope en la parte superior del

adaptador de 45° (Figura 8). La cuña para el barandal del tope se cortará del barandal del tope.

La cuña requerirá de un corte recto en el extremo que entra en contacto con el poste y un corte

de 22.5° en el extremo opuesto. La distancia del poste al borde ancho de la cuña es de 1-3/4".

Corte dos barandales de tope y cuñas de inserción usando una sierra ingletadora e instale en

la parte superior de los adaptadores de 45° siguiendo los pasos de arriba. El barandal de tope

requerirá de un corte a 22.5° en ambos extremos para igualar el ancho de las cuñas del barandal de tope. Mida la distancia entre las cuñas instaladas y corte ambos extremos a la longitud y

ángulo correctos usando una sierra ingletadora. Lije los extremos cortados y aplique pintura de

retoque conforme lo necesite (se vende por separado) para que la unión se note menos. Sujete

el barandal de tope al barandal superior siguiendo los pasos de arriba.

Paso 14 Aplique pegamento para construcción de metales para exteriores en los extremos

interiores de los topes para poste y colóquelas sobre cada cobertura de poste.

Bloque

espaciador

de 3-

Parte exterior

de la terraza

Figure 5

Cobertura

para poste

Figura 6

Figura 7

Barandal superior

e inferior

Barandal de tope

Barandal de

inserción

"

Balaustre

Bloque

de apoyo

Tornillos para

balaustre

Parte exterior del

porche/la terraza

Barandal superior

e inferior

Soporte

en línea (4)

Poste de 4x4

Barandal de tope

Barandal de

inserción

Balaustre

Instrucciones para la instalación de barandal para escalera

Paso 1 Los postes de barandal de cedro o pino tratado a presión de 4x4 proporcionan la fuerza

estructural para el barandal. La longitud de cada poste estructural se determina por el total del

ancho del larguero para escaleras (7-1/4") + el grosor de la terraza (1") + la altura del barandal

(36" o 42") = 44-1/4" o 50-1/4".

Paso 2 Coloque en su lugar, aplome con un nivel y asegure con una abrazadera el poste de

barandal en la cara interior del larguero para escaleras. Aplome de nuevo. El poste de barandal

de 4x4 deberá sujetarse a la parte interior del larguero para escaleras usando dos tirafondos

galvanizados de 1/2"x6". Los postes de esquina usan un tercer tirafondo insertado a través de la

viga adyacente (Figura 3b). Los postes a nivel de piso se deberán colocar en concreto.

Paso 3 Complete la instalación de los peldaños de la escalera antes de instalar las coberturas para

postes. Recorte las coberturas para postes de 4x4 a la longitud correcta. Si usa topes para postes,

las coberturas para postes deberán ser mínimo 1-1/2" más largas que la altura total del barandal

(Figura 4). Deje 1-1/2" adicional en su cálculo si instala el barandal de tope opcional. Ejemplo:

Para un barandal de 36" de altura, recorte la cobertura para poste a un mínimo de 37-1/2" (39"

con barandal de tope). La cobertura para poste se puede dejar más larga si lo desea.

Algunos conservadores de madera pueden causar una reacción no deseada cuando entran en

contacto directo con el aluminio. El interior de la cobertura para poste incluye un revestimiento

para prevenir el contacto directo con los postes estructurales tratados. Si su terraza está tratada

a presión, coloque separadores debajo de la cobertura para poste o ponga una cama de sellador

a lo largo del borde inferior del poste antes de instalar la cobertura para poste. Esto evitará que

el aluminio entre en contacto directo con la terraza tratada y quedará escondido bajo el modelo

base para poste. Deslice una cobertura para poste recortada sobre cada poste de barandal de

4x4. Deslice un modelo base para poste sobre cada cobertura para poste. Agregue una cama

de sellador a la parte inferior del modelo base para poste cuando use una terraza tratada.

Cuña para barandal del tope

Vista superior

Figura 8: Instalación en

ángulo de 45 °

Poste de madera

Aluminio cobertura

de poste

Adaptador

de 45˚

Soporte de

barandales para

escalera

Barandal 2x4

Page 12

Paso 4 Mida la distancia entre las coberturas para postes instaladas para determinar la longitud

de los barandales superior e inferior. Coloque el barandal inferior en la escalera con los orificios

taladrados previamente hacia abajo. La distancia entre el poste y el primer balaustre deberá ser

menor de 4" y ser igual en ambos extremos. Marque el ángulo y la longitud. Haga lo mismo con

el barandal superior. Recorte 1/4" adicional en ambos extremos (1/2" en total) para que el soporte quepa entre el barandal y el poste. Recorte los barandales superior e inferior a la longitud

correcta con el mismo ángulo (Figura 9).

Paso 5 Determine el espaciamiento de los balaustres, 4-1/2" máximo medido de centro a centro

(7-1 / 2" de centro a centro si usa balaustres de vidrio, 4-1/4" de centro a centro si usa balaustres

de Ellipse), y un espaciamiento igual para el espaciamiento del extremo. Consulte el Paso 7 de

las instrucciones para instalación en línea para obtener más detalles.