A B D F

C E G

H

I

J

M K

Thank You for your purchase of a finely

crafted piece of furniture from Decko Woods.

The following contains instructions for

assembly as well as care and maintenance

instructions. Please take a moment to

completely read and familiarize yourself with

this information. You will then be ready to

assemble your furniture. If you have any

questions regarding your purchase, please

contact us at 1-800-495-9278

Tools Needed:

-Phillips Head Screwdriver

-Adjustable wrench

NOTE: It is NOT recommended to use power

tools for assembly. They may cause over

tightening and damage to your chair.

Parts List & Hardware

Item Qty Description

A 1 Back Assembly

B 1 Seat Assembly

C 1 Left Leg

D 1 Left Arm

E 1 Right Leg

F 1 Right Arm

G 2 Back Supports

H 10 Machine Screw 6 x 50 mm

I 10 Washer - 6mm

J 10 Nut - 6mm

M 10 Wood Screw - 4mm x 40mm

K 2 Wood Screw 5 x 60mm

CARE & MAINTENACE ADIRONDACK CHAIR ASSEMBLY AND CARE INSTRUCTIONS

For Model# 82004

FINISHING TIPS (For unfinished wood)

Your Decko Woods furniture is made from high quality, select grade fir. It is naturally resistant to

rot and decay. Proper finishing will help assure the beauty and durability of your chair. If you

choose to paint your chair, you should use an exterior grade primer followed by a high quality

exterior oil or latex based paint. If you choose to have the product retain its natural color, you

should apply a natural oil-based stain or preservative annually or as needed. When finishing,

make sure you also treat the ends of the wood parts that come in contact with the ground.

If you leave the chair without adding any finish, it will weather to a silver gray color.

Contact your local paint store, home center or hardware store for other finishing

recommendations.

MAINTENANCE

Very little maintenance is required for your furniture. Periodically check all fasteners to make

sure they are properly secured. Re-tighten if necessary.

MANUFACTURER’S LIMITED WARRANTY

This product is covered under the manufacturer’s 1 year limited warranty against defect in

workmanship and materials. If your furniture fails structurally during normal use within on year of

purchase, the manufacturer will repair or replace the defective piece at no charge.

The warranty excludes furniture used for commercial purposes, furniture damaged by acts of

nature, abuse or lack of proper care or corrosion or rusting of hardware.

Proof of purchase (dated register receipt) is required for warranty claims.

Decko Products

2301 Traffic St. NE

Minneapolis, MN 55413

1-800-495-9278

NOTE: Diagrams are not drawn to scale. Construction in diagrams may differ from actual chair.

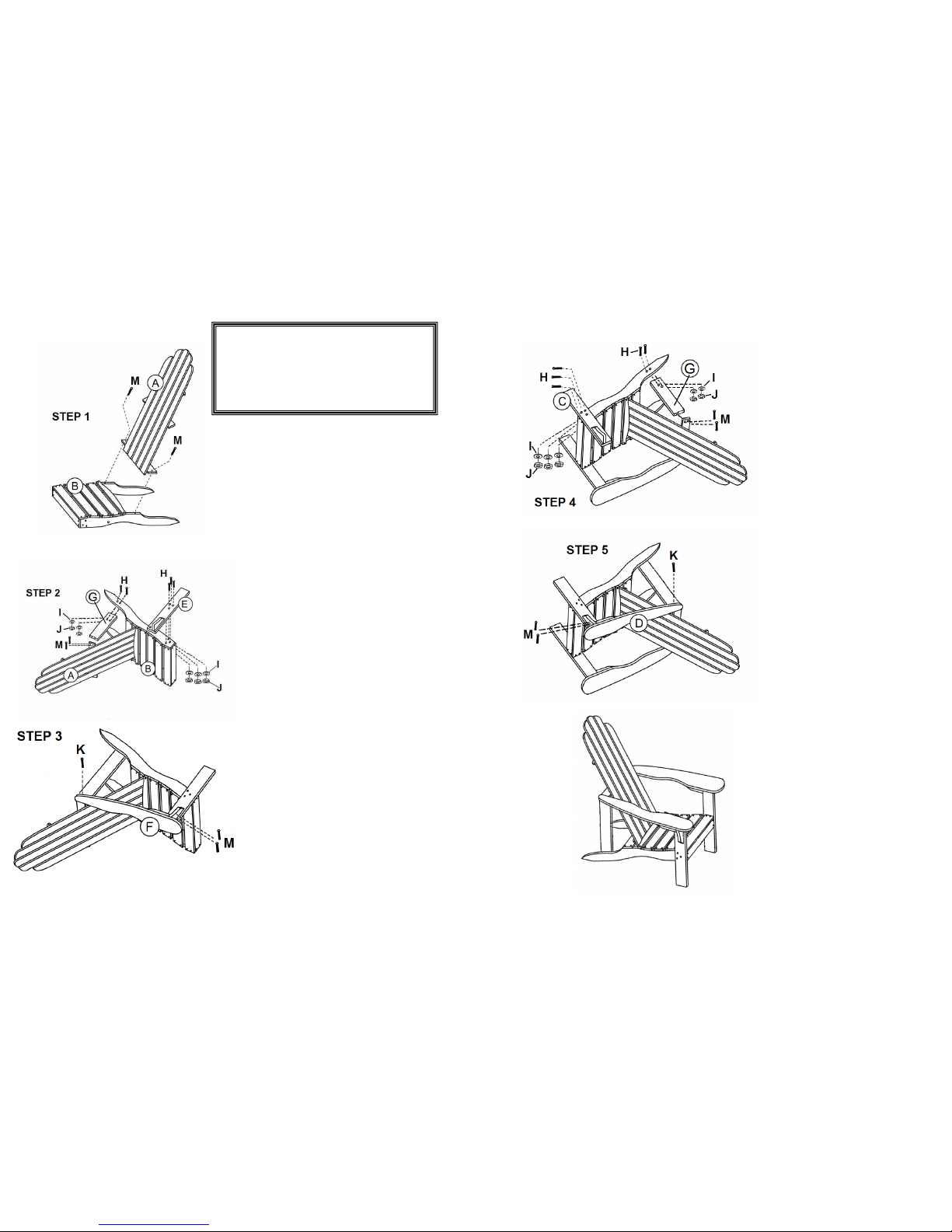

STEP 1

Lay seat assembly (B) flat on the

ground. Using two 4 x 40 mm wood

screws (M), attach the back assembly

(A) to the seat assembly. (NOTE:

There are no pre-drilled holes in the

seat assembly. The screws will self

thread into the wood).

STEP 2

Carefully lay the chair on its side as

shown. Using three 6 x 50 mm machine

screws (H) with flat washers (I) and nuts

(J) attach the right leg (E) to the seat

assembly. (The leg will be positioned

with the arm brace facing upward and to

the front of the seat assembly)

Using two 6 x 50 mm machine screws (H)

with flat washers (I) and nuts (J) attach

one back support (G) to the seat

assembly. Attach other end of back

support to back assembly using two 4 x

40 mm wood screws (M)

NOTE: Do not completely tighten all

fasteners at this time. Leave them a

bit loose until the final step.

STEP 3

Using two 4 x 40 mm wood screws (M)

attach the right arm (F) to the leg.

Attach the back of the arm to the back

assembly using one 5 x 60 mm wood

screw (K)

STEP 4

Turn chair onto its other side. Using

instructions from STEP 2 attach the

left leg (C) and back support (G) to the

seat and back assembly.

STEP 5

Using instructions from STEP 3 attach

the left arm (D) to the leg and back

support assembly

STEP 6

Completely tighten all fasteners and

enjoy your new chair.

ASSEMBLY TIPS

-Carefully read all of the steps and acquaint yourself with the

wood parts and fastener sizes before starting assembly.

-Separate fasteners by size before starting assembly

-During assembly all hardware should be semi tightened until the

final step

Loading...

Loading...