Deckma Hamburg OMD-2008 Instruction Manual

INSTRUCTION MANUAL

15ppm Bilge Alarm

OMD-2008

Versions with

Electric Valve (EV)

Flow Control (FC)

Manual Cleaning Unit (MCU)

DECKMA HAMBURG GmbH

Kieler Straße 316, D-22525 Hamburg - Germany

Tel.: +49 (0) 40 54 88 76-0, Fax: +49 (0) 40 54 88 76-10

Internet: www.deckma.com eMail: post@deckma.com

MOTEC

Marine & Offshore Technology

DECKMA HAMBURG GmbH

Issue: 08.07.2015 Instruction Manual OMD-2008 (EV, FC, MCU Versions) Page 1 of 28

IMPORTANT NOTICE

Replacement components for 15ppm Bilge Alarms.

General

All monitors in our range are inspected and tested to the related I.M.O. requirements at

our factories prior to delivery.

In normal use the units should operate correctly and without fault over a long period of

time requiring only small amounts of maintenance to be carried out as outlined in the

instruction manuals.

Service Exchange Units

In the event of a monitor malfunction due to electrical or electronic component failure it

is our recommendation that a service exchange unit be ordered.

The defective instrument should be returned to our works within 30 days of supplying

the service exchange unit, then only the repair charge is payable. Otherwise the whole

cost of a service exchange unit becomes payable.

This procedure is by far the easiest and most cost effective way of ensuring the monitor

on board conforms to I.M.O. resolution MEPC.107(49).

Remark:

According the MEPC.107(49) § 4.2.11 the unit has to be checked at IOPP Certificate

renewal survey by the manufacturer or persons authorized by the manufacturer.

Alternatively the unit may be replaced by a calibrated 15 ppm Bilge Alarm.

The OMD-2008 EVFC is designed in that way, that only the measuring cell needs to be

changed, as this unit carries the Calibration Certificate. The Calibration Certificate with

the date of the last calibration check should be retained onboard for inspection

purposes.

If for some reasons the computer unit needs to be changed, it has to make sure, that

the memory card will remain on board for at least 18 month. The new computer unit will

carry its own memory card. The old card can be insert into the new unit only for reading.

Writing is only possible with the card delivered with the new computer unit. For details

see section 13.1.

Warranty

Our warranty terms are12 months after installation but maximum 18 months after

delivery ex works. The maker undertakes to remedy any defect resulting from faulty

materials of workmanship except wearing parts.

The maker's obligation is limited to the repairs or replacement of such defective parts by

his own plant or one of his authorized service stations.

The purchaser shall bear the cost and risk of transport of defective parts and repaired

parts supplied in replacement of such defective parts.

ANY DISMANTLING OR BREAKING OF A SEAL WILL VOID THE WARRANTY

DECKMA HAMBURG GmbH

Issue: 08.07.2015 Instruction Manual OMD-2008 (EV, FC, MCU Versions) Page 2 of 28

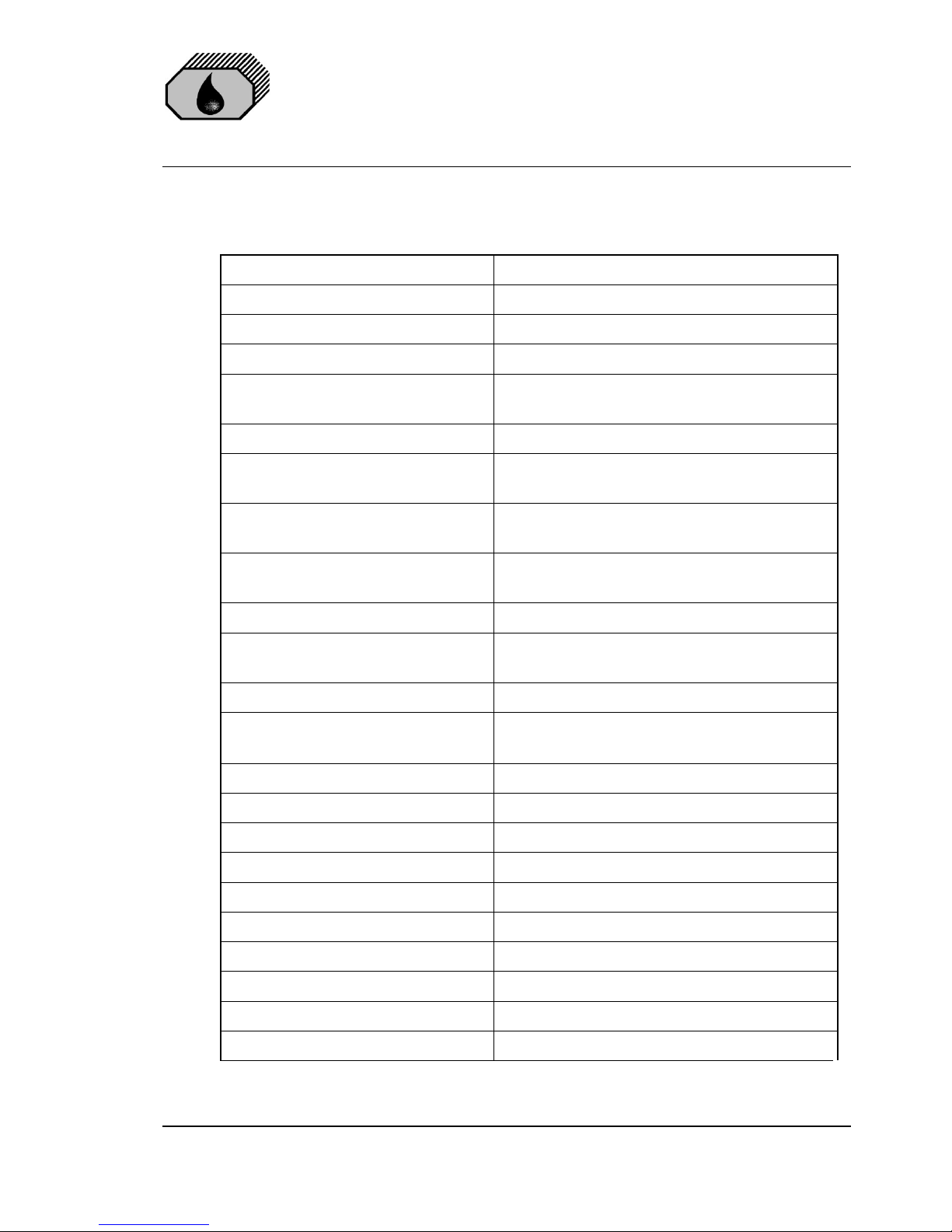

SECTION

TITLE

PAGE

1

Introduction

3

2

Important Notes

3

3

Principle of Operation

4

3.1

Measuring Principle

4

3.2

Features

4

3.3

Adjustment

4

3.4

Displays and Alarms

4

3.5

FC (Flow Control)

5

3.6

EV (Electric clean water Valve)

5

3.7

MCU (Manual Cleaning Unit)

5

4

Specification

6

5

Construction

7

6

Installation

8

7

Piping

10

8

Wiring

11

8.1

Typical Control System

13

9

Power Supply

13

10

Commissioning

14

10.1

Electrical and Piping

14

10.2

Flow Rate Adjustment

14

10.3

Functional Tests

15

10.4

Programming Mode

16

11

Operating Instructions

20

11.1

Operator Notes

20

12

Operator Maintenance

22

12.1

Manual Cell Clean Unit

21

Important Information: Cleaning of Glass Tube

23

13

Fault Finding

24

13.1

Memory Card

25

14

Calibration

25

14.1

Calibration and Repeatability Check

26

14.2

Function Test at Classification Survey

and Port State Control

26

15

Spare Parts

27

15.1

Recommended On Board Spares

27

16

Remarks

28

DECKMA HAMBURG GmbH

Issue: 08.07.2015 Instruction Manual OMD-2008 (EV, FC, MCU Versions) Page 3 of 28

1 Introduction

The OMD-2008 EV-FC Bilge Alarm Unit has been designed specifically for use in

conjunction with 15 ppm oil-water separator units and has a specification and

performance which exceeds the requirements of the International Maritime

Organization specifications for 15ppm Bilge Alarms contained in Resolution

MEPC. 107 (49).

The unit is supplied with 2 works-adjusted alarms at 15 ppm. Other set points

(10 ppm or 5 ppm) are possible and can be adjusted on site at any time by using

the buttons at the front panel.

Instruments with maximum Alarm set-points of 10 ppm or 5 ppm respectively are

available.

If an alarm set point is exceed, the alarms are visible at the front panel and the

appropriate relays are switched. In case of malfunction the System LED at the

front panel will change from blinking green to permanent red.

For the data logging function the unit requires a status input from the separator.

A 0(4) - 20 mA (equal to 0 - 30 ppm) signal output is available for driving a

recorder or external meter.

The OMD-2008 EV-FC is be equipped with an electric switchover valve for clean

water usage and a Flow Sensor. A Manual Cleaning Unit is available as an

option (MCU). Different instrument versions are covered in this document. Please

verify instrument version on site and refer to the relevant sections of this manual.

2 Important Notes

a) This equipment must be installed and operated in strict accordance with the

instructions contained in this manual. Failure to do so will impair the protection

provided.

b) Installation and servicing must be undertaken by a competent and suitable

skilled person.

c) The equipment must be connected to the ground according relevant

requirements.

d) The unit must be isolated from the electrical supply before any maintenance of

the equipment is attempted.

e) All National or local codes of practice or regulations must be observed and,

where applicable, are deemed to take precedence over any directive or

information contained in this manual.

f) In case of freezing conditions the measuring cell should be emptied

completely.

DECKMA HAMBURG GmbH

Issue: 08.07.2015 Instruction Manual OMD-2008 (EV, FC, MCU Versions) Page 4 of 28

3 Principle of operation

3.1 Measuring Principle

An optical sensor array measures a combination of light scattered and absorbed

by oil droplets in the sample stream. The sensor signals are processed by a

microprocessor to produce linearized output.

If an alarm (works set point 15 ppm, or 10 ppm or 5 ppm respectively) occurs, the

two oil alarm relays are activated after the adjusted time delay.

The microprocessor continuously monitors the condition of the sensor

components and associated electronics to ensure that calibration accuracy is

maintained over time and extremes of environmental conditions.

3.2 Features

Robust construction

Solid suppression capability

Low maintenance

Easy installation

Constant readiness

Low spare part stock holding

Works adjustment

Easy settings via menu

3.3 Adjustment

The unit is delivered with a works calibration according the IMO-requirements.

The alarm points are set to 15 ppm (or 10 ppm, or 5 ppm for certain versions).

The "Zero" point is also works calibrated and can be re-adjusted on site by using

the programming mode and clean water. See Section 10.4 “Settings-Offset”. A

calibration is not permitted. This has to be done according IMO Regulations by

the manufacturer or persons authorized by the manufacturer.

3.4 Displays and Alarms

In the unit there are two independent oil alarm circuits available. Both can be set

separately from 1 to 15 ppm. From the manufacturing both alarms are set to

15 ppm (according IMO). The set points can be changed according to the

requirements on site, for example to 10 ppm or 5 ppm. An alarm point setting

above 15 ppm is not possible. The adjustment can be done in the programming

mode as described in Section 10.4.

DECKMA HAMBURG GmbH

Issue: 08.07.2015 Instruction Manual OMD-2008 (EV, FC, MCU Versions) Page 5 of 28

In this mode also the individual adjustment of the time delays for the alarms can

be done.

Both alarm circuits are also related to an alarm LED on the front panel.

In case of malfunction the “System” LED will indicate any type of internal fault of

the unit. This LED is flashing green in normal conditions and is red in alarm

conditions.

Additional to the alarm LEDs each alarm circuit is equipped with a relay with

potential free alarm contacts. These contacts can be used for external processing

of the signal or for control of further functions.

If a malfunction or failure of the power supply occurs, all three relays (both alarm

relays and the SYSTEMFAULT relay) will switch to alarm condition.

3.5 FC (Flow Control)

OMD-2008 EV-FC instruments are equipped with a Flow Sensor. The Flow

Sensor is connected in the Drain line of the Measuring Cell. If the flow rate

through the Measuring Cell is too low, or if the sample is not flowing at all, the

Instrument will go to Alarm condition and issue a “Status: Flow?” message.

3.6 EV (Electric clean water Valve)

OMD-2008 EV instruments are equipped with an electric switchover valve for the

clean water stream. The valve can be controlled via the menues, or remotely

using the control input.

3.7 MCU (Manual Cleaning Unit)

Optionally the instruments can be fitted with a Manual Cleaning Unit. The Manual

Cleaning Unit allows to clean the sample glass tube without opening the

Measuring Cell Head Screw, and without interrupting the normal sample flow.

Maintenance is made easier with the MCU. Please note that operating the MCU

may set the instrument to alarm condition for a few seconds.

DECKMA HAMBURG GmbH

Issue: 08.07.2015 Instruction Manual OMD-2008 (EV, FC, MCU Versions) Page 6 of 28

4 Specification OMD-2008 EV FC

Range:

0 – 30 ppm, Trend indication 50ppm

Accuracy

According IMO MEPC. 107(49)

Linearity

Up to 30 ppm better than ± 2 %

Display

Yellow Graphic Display

Power Supply:

24 V - 240V AC or DC

Automatic Voltage selection

Consumption:

< 10 VA

Alarm Points 1 + 2:

Adjustable between 1 - 15 ppm

(Works adjustment 15 ppm)

Alarm 1 Operating Delay:

(for annunciation purpose)

Adjustable between 1 – 540 sec.

(Works adjustment 2 sec)

Alarm 2 Operating Delay:

(for control purposes)

Adjustable between 1 – 10 sec.

(Works adjustment 10 sec)

System Fault Alarm:

Red LED

Alarm Contact Rating:

Potential free 1 pole change over contacts,

3 A / 240 V

Alarm Indication:

Red LEDs

Output Signal:

0 – 20 mA or 4 – 20 selectable

ext. Load < 150

Sample Water Pressure:

0,1 – 10 bar

Sample Flow:

Approx. 0,1 - 3 l/min depending on pressure

Ambient Temperature:

+ 1 to + 55° C

Sample Water Temperature:

+ 1 to + 65° C

Roll:

Up to 45°

Size (Computer Unit)

200 mm W x 200 mm H x 100 mm D

Size (EV-FC-Arrangement)

150 mm W x 290 mm H x 140 mm D

Degree of Protection:

IP 65

Weight:

5,9 kg

Pipe Connections:

for 6mm OD Cu or SS pipe

Technical specifications are subject to change without notification

DECKMA HAMBURG GmbH

Issue: 08.07.2015 Instruction Manual OMD-2008 (EV, FC, MCU Versions) Page 7 of 28

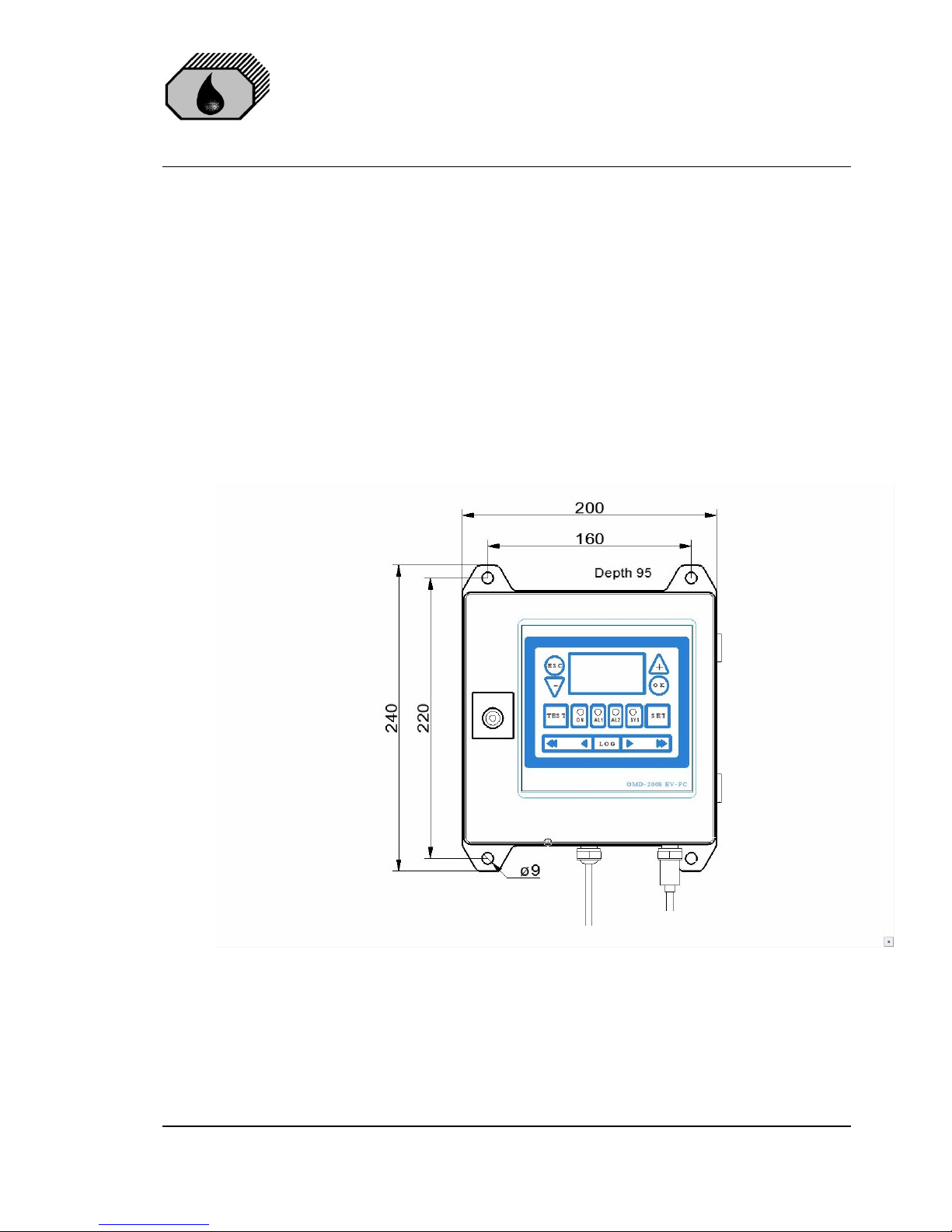

5 Construction

OMD-2008 EV-FC consists of two main components:

The computer unit contains the display PCB with the data logger and the

terminals for external connections.

The measuring cell is built out of an all-aluminium, nickel plated body with inlet

and outlet block from stainless steel. It contains optics and electronics and is

connected with the computer unit via a plugged data cable. It is mounted onto a

stainless steel support that also holds the valve assembly and the Flow Sensor.

An electric valve controls sample water and clean water usage.

The OMD-2008 EV-FC can easily be mounted in wall or bulkhead installation.

1

Computer Unit

4

Flow Sensor

2

Measuring Cell

5

Clean Water Valve EV

3

Manual Cleaning Unit

(MCU) (Option)

Fig. 1

DECKMA HAMBURG GmbH

Issue: 08.07.2015 Instruction Manual OMD-2008 (EV, FC, MCU Versions) Page 8 of 28

6 INSTALLATION (REFER TO FIG. 2 AND FIG. 3)

See Section 2 for important notes concerning installation.

The OMD-2008 EV-FC Monitor should be located as close as possible to the oily

water separator to minimize response delays. According MEPC.107(49) the

layout of the installation should be arranged so that the overall response time

(including the response time of the 15 ppm Bilge Alarm, which is less than 5 s.)

between an effluent discharge from the 15 ppm Bilge Separator exceeding 15

ppm, and the operation of the Automatic Stopping Device preventing overboard

discharge, should be as short as possible and in any case not more than 20 s.

Mount the OMD-2008 EV-FC Computer Unit by means of M6 or M8 screws on to

a rigid vertical surface and preferably with the display panel of the monitor at eye

level. For service and maintenance sufficient space to all sides should be

available.

Fig. 2a: Dimensions of Computer Unit

Computer Unit and Measuring Cell assembly should be mounted close to each

other.

Loading...

Loading...