Page 1

WP

4C

Dewpoint PotentiaMeter

Operator’s Manual

Version 1

Page 2

Decagon Devices, Inc.

2365 NE Hopkins Court

Pullman WA 99163

tel: (509) 332-2756

fax: (509) 332-5158

www.decagon.com

support@decagon.com

Trademarks

“WP4C PotentiaMeter” is a

registered trademark of Decagon Devices, Inc.

©2010 Decagon Devices, Inc., All rights reserved.

Page 3

WP4C PotentiaMeter

Table of Contents

i

Contents

ContentsContents

Contents

1. Introduction . . . . . . . . . . . . . . . . . .1

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Customer Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Note to our WP4C Users . . . . . . . . . . . . . . . . . . . . . . . 2

Seller’s Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. About the WP4C . . . . . . . . . . . . . .4

Instrument Specifications . . . . . . . . . . . . . . . . . . . . . . . 4

WP4C and Water Potential . . . . . . . . . . . . . . . . . . . . 5

How the WP4C works . . . . . . . . . . . . . . . . . . . . . . . . . . 5

WP4C and Temperature . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Getting Started . . . . . . . . . . . . . . .7

Components of your WP4C . . . . . . . . . . . . . . . . . . . . 7

Choosing a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Preparing the WP4C for Operation . . . . . . . . . . . . 9

Portability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. The Menus . . . . . . . . . . . . . . . . . . .12

The Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Changing Languages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reading Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sample Equilibration Screen . . . . . . . . . . . . . . . . . . . . 20

Page 4

WP4C PotentiaMeter

Table of Contents

ii

5. Calibration and Verification . . 21

Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Verification Standards . . . . . . . . . . . . . . . . . . . . . . . . . . 21

When to Verify Calibration . . . . . . . . . . . . . . . . . . . . 22

How to Verify and Calibrate the WP4C . . . . . . . 22

6. Sample Preparation . . . . . . . . . . 25

Choosing a Sample Cup . . . . . . . . . . . . . . . . . . . . . . . . . 25

Preparing the Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dry Samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Samples and Temperature . . . . . . . . . . . . . . . . . . . . . . 27

Measuring Plant Samples . . . . . . . . . . . . . . . . . . . . . . . 29

7. Taking a Reading . . . . . . . . . . . . 30

How WP4C takes Readings . . . . . . . . . . . . . . . . . . . . 31

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8. Computer Interface . . . . . . . . . . . 33

9. Theory: Water Potential . . . . . . 35

Water Potential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Measuring Water Potential . . . . . . . . . . . . . . . . . . . . . 35

Effect of Temperature on Water Potential . . . . . 37

Estimating Osmotic Potential . . . . . . . . . . . . . . . . . . . 38

10. Cleaning and Maintenance . . . 39

Tools Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Accessing the Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning Procedure: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Checking Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Page 5

WP4C PotentiaMeter

Table of Contents

iii

11. Repair Instructions . . . . . . . . . . . .45

Shipping Directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Repair Costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Loaner Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12. Troubleshooting . . . . . . . . . . . . .48

Problems and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Sensor Performance Screen . . . . . . . . . . . . . . . . . . . . . 54

13. Further Reading . . . . . . . . . . . . . .56

References: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Application Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Appendix A . . . . . . . . . . . . . . . . . . . .58

Preparing Salt Solutions . . . . . . . . . . . . . . . . . . . . . . . . . 58

Index . . . . . . . . . . . . . . . . . . . . . . . . . .61

Page 6

WP4C PotentiaMeter

Table of Contents

iv

Page 7

WP4C PotentiaMeter

1. Introduction

1

1. Introduction

Welcome to Decagon’s WP4C Dewpoint PotentiaMeter,

the research standard for measuring water potential.

WP4C is the fastest, most accurate, and most reliable

instrument available for measuring water potential using

the chilled-mirror dewpoint technique. Whether you are a

scientist or a student, WP4C will suit your needs. It is easy

to use and provides fast, accurate results. We hope you

find this manual informative and helpful in understanding

how to maximize the capabilities of your WP4C.

About this Manual

Included in this manual are instructions for setting up

your WP4C, calibration, and maintaining and caring for

your instrument. Please read these instructions before

operating WP4C to ensure that the instrument performs

to its full potential.

Customer Service

If you ever need assistance with your WP4C, or if you just

have questions, there are several ways to contact us:

NOTE: If you purchased your WP4C through a distributor, please

contact them for assistance.

Page 8

WP4C PotentiaMeter

1. Introduction

2

Phone:

Our toll-free customer service number is available to our

customers in the US, Monday through Friday, between 8

a.m. and 5 p.m. Pacific time at 1-800-755-2751. For our

customers outside of the US, our regular telephone num-

ber is (509) 332-2756.

Fax:

Our fax number is (509) 332-5158. When you fax us,

please include your WP4C’s serial number, your name,

address, phone and fax number along with a description

of your problem.

E-mail:

If you need technical support or have questions about

your application with WP4C, you can send us messages via

e-mail at support@decagon.com. Again, please include

as part of your message your WP4C’s serial number, your

name, address, phone, fax number, and return e-mail

address.

Warranty

WP4C has a 30-day satisfaction guarantee and a one-year

warranty on parts and labor.

Note to our WP4C Users

This manual is written to aid the end user in understanding the basic concepts of water potential, enabling them to

use our instrument with confidence. Every effort has been

Page 9

WP4C PotentiaMeter

1. Introduction

3

made to ensure that the content of this manual is correct

and scientifically sound.

Seller’s Liability

Seller warrants new equipment of its own manufacture

against defective workmanship and materials for a period

of one year from date of receipt of equipment (the results

of ordinary wear and tear, neglect, misuse, accident and

excessive deterioration due to corrosion from any cause

are not to be considered a defect); but Seller’s liability for

defective parts shall in no event exceed the furnishing of

replacement parts F.O.B. the factory where originally manufactured. Material and equipment covered hereby which

is not manufactured by Seller shall be covered only by the

warranty of its manufacturer. Seller shall not be liable to

Buyer for loss, damage or injuries to persons (including

death), or to property or things of whatsoever kind

(including, but not without limitation, loss of anticipated

profits), occasioned by or arising out of the installation,

operation, use, misuse, nonuse, repair, or replacement of

said material and equipment, or out of the use of any

method or process for which the same may be employed.

The use of this equipment constitutes Buyer’s acceptance

of the terms set forth in this warranty. There are no understandings, representations, or warranties of any kind,

express, implied, statutory or otherwise (including, but

without limitation, the implied warranties of merchantability and fitness for a particular purpose), not expressly set

forth herein.

Page 10

WP4C PotentiaMeter

2. About the WP4C

4

2. About the WP4C

Instrument Specifications

Range: 0 to -300MPa*

Accuracy: ±0.05MPa* from 0 to -5 MPa

1% from -5 to -300 MPa

Measurement time:

~10-15 min. for most soil samples in precise mode

~20 min. for plant tissue samples

<5 minutes in fast mode (reduced accuracy)

Temperature Control: 15 to 40° C (±0.2° C)

Operating Environment: 5 to 40° C (41 to 104° F)

Sensor Type: 1) Chilled-mirror dewpoint sensor

2) Infrared temperature sensor

Sample Cup Capacity: 7 ml recommended (15 ml full)

Dimensions: 24.1 x 22.9 x 8.9 cm (9.5 x 9.0 x 3.5 in)

Weight: 3.2 Kg (7.1 lbs)

Case Material: Powder Painted Aluminum

Display: 20 x 2 alphanumeric LCD with backlighting

Data Communication: RS232A compatible, 8-data bit

ASCII code, 9600 baud, no parity, 1 stop bit

Power: 110VAC to 220 VAC, 50/60 Hz

Interface Cable: Standard RS232 serial cable (included)

Compatible Standards: ASTM D6836-07

Warranty: 1 year parts and labor

* Note that the WP4C (and all vapor pressure instruments) are

Page 11

WP4C PotentiaMeter

2. About the WP4C

5

limited by accuracy in the wet end of the water potential range. The

range of 0 to -5 MPa has an accuracy of 0.05 MPa. For example,

a measurement at -0.1MPa has an accuracy of ±50% of the reading, and -1 MPa has an accuracy of ±5% of the reading. Functionally this means that the WP4C will not measure water potential

accurately near field capacity.

WP4C and Water Potential

Water potential is a measurement of the energy status of

the water in a system. It indicates how tightly water is

bound, structurally or chemically, within a substance.

Water potential can be computed from the vapor pressure

of air in equilibrium with a sample in a sealed measurement chamber. For a more detailed description of water

potential, please refer to Chapter 9, titled “Theory: Water

Potential” of this manual.

How the WP4C works

WP4C uses the chilled-mirror dewpoint technique to measure the water potential of a sample. In this type of instrument, the sample is equilibrated with the headspace of a

sealed chamber that contains a mirror and a means of

detecting condensation on the mirror. At equilibrium, the

water potential of the air in the chamber is the same as the

water potential of the sample. In the WP4C, the mirror

temperature is precisely controlled by a thermoelectric

(Peltier) cooler. Detection of the exact point at which condensation first appears on the mirror is observed with a

photoelectric cell. A beam of light is directed onto the

Page 12

WP4C PotentiaMeter

2. About the WP4C

6

mirror and reflected into a photodetector. The photodetector senses the change in reflectance when condensation

occurs on the mirror. A thermocouple attached to the

mirror then records the temperature at which condensation occurs. Values begin to be displayed indicating that

initial measurements are being taken. WP4C then signals

you by flashing a green LED and/or beeping when final

values are reached. The final water potential and temperature of the sample is displayed.

In addition to the technique described above, WP4C uses an

internal fan that circulates the air within the sample chamber

to reduce time to equilibrium. Since both dewpoint and

sample surface temperatures are simultaneously measured,

the need for complete thermal equilibrium is eliminated.

The WP4C controls the sample temperature by means of

an internal thermo-electrical module that monitors and

stabilizes the sample block temperature according to how

it is set.

WP4C and Temperature

Large temperature differences, between sample and block,

will cause longer reading times, since a complete and accurate reading will not be made until the difference between

the sample tempeature and the block temperature is less than

1.0 degree. To help you monitor the temperature difference

between your sample and the block, you can access a sample

equilibration screen at the main menu.

Page 13

WP4C PotentiaMeter

3. Getting Started

7

3. Getting Started

Components of your WP4C

Your WP4C should have been shipped with the following

items:

• WP4C main unit

• Quickstart guide

• Certificate of Calibration

• Power cord

• RS-232 interface cable

• 25 plastic sample cups and lids

• 10 Stainless Steel sample cups

• Operator’s Manual

• 12 vials of 0.5 Molal KCl

• Cleaning Kit

Page 14

WP4C PotentiaMeter

3. Getting Started

8

Choosing a Location

To ensure that your WP4C operates correctly and consistently, place it on a level surface. This reduces the chance

that sample material will spill and contaminate the inside

of the instrument. To protect the internal electrical components, and to avoid inaccurate readings, place your

WP4C in a location where the temperature remains fairly

stable. This location should be well away from air conditioner and heater vents, open windows, outside doors,

refrigerator exhausts, or other items that may cause rapid

temperature fluctuation.

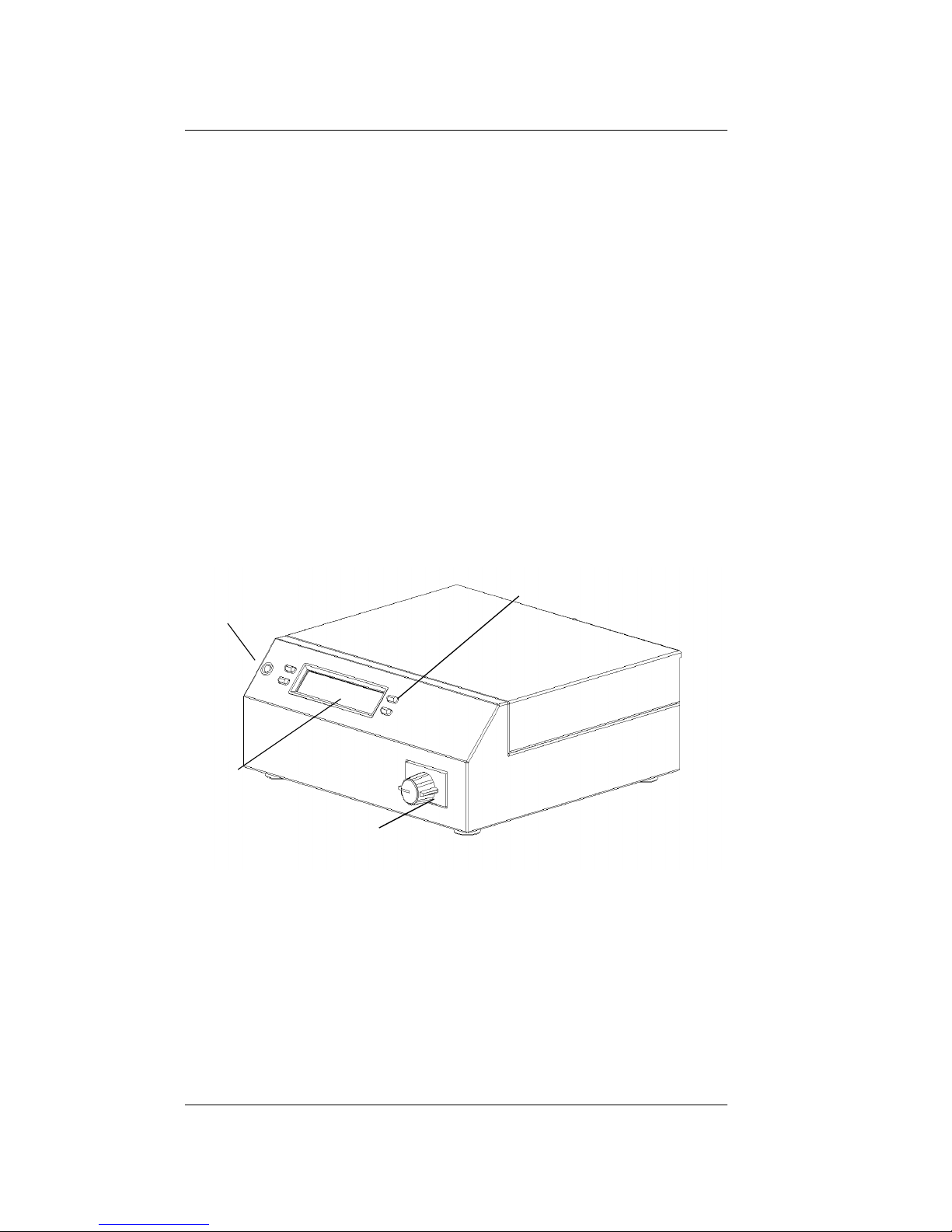

Features

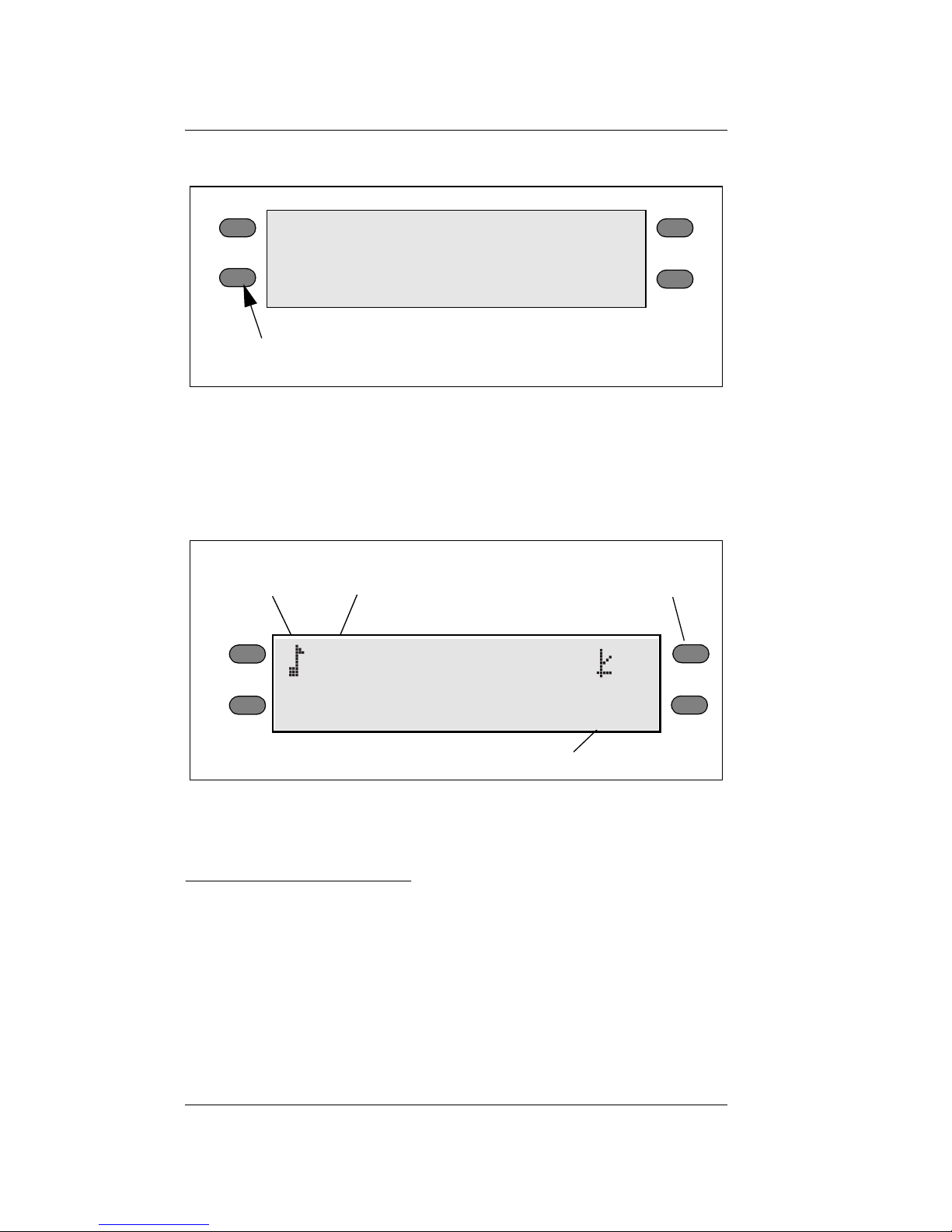

Front view of WP4C

LED indicator

light

LCD

Function Keys

Sample drawer

Page 15

WP4C PotentiaMeter

3. Getting Started

9

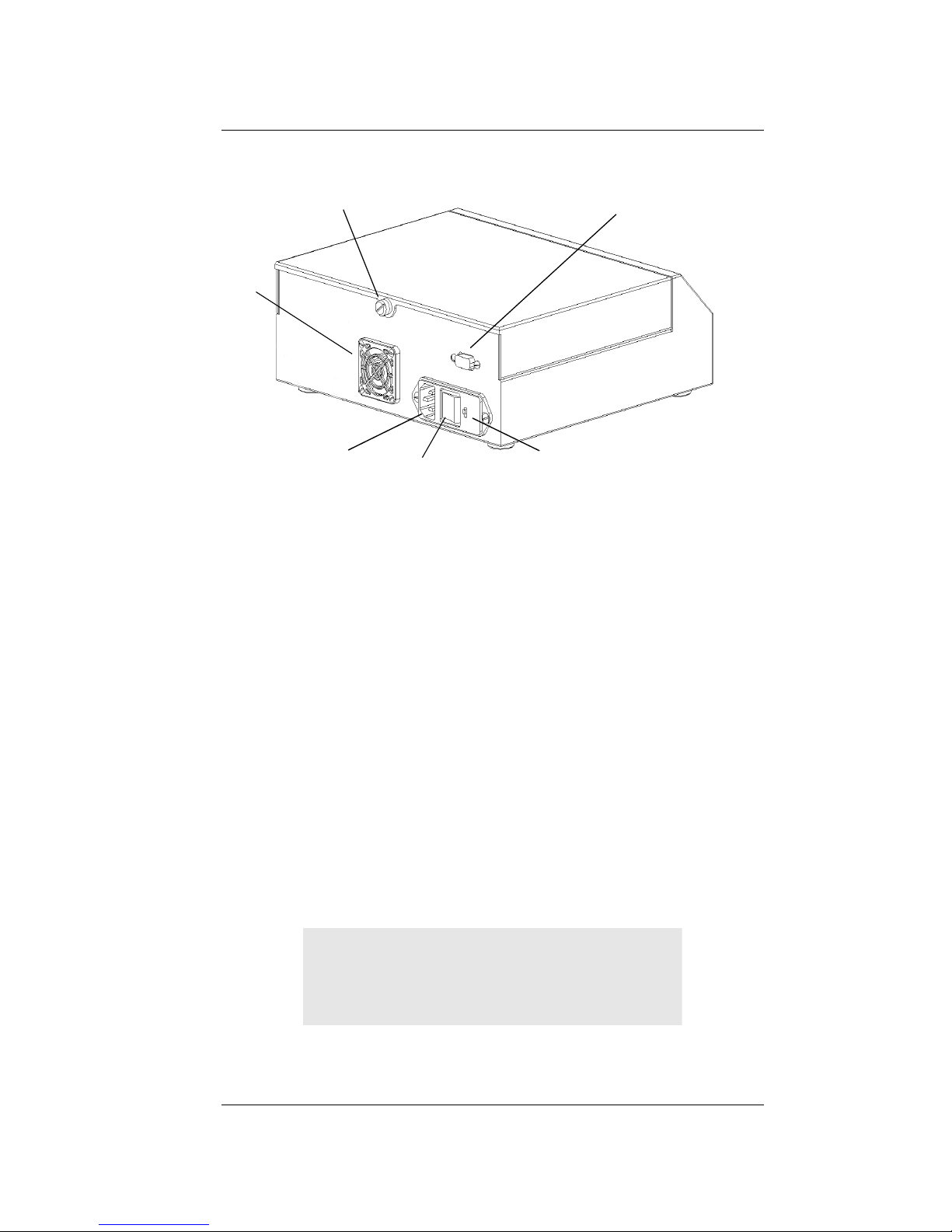

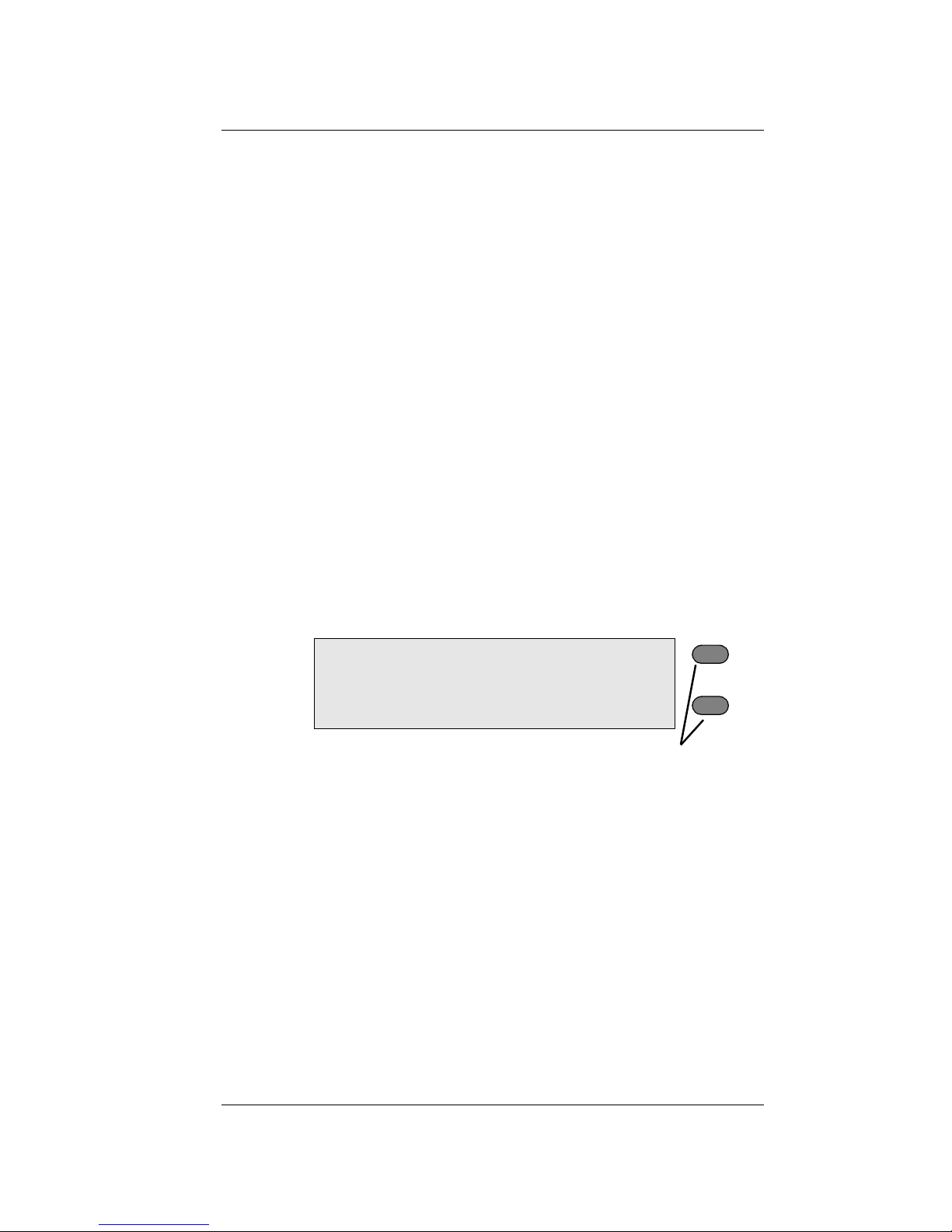

Back view of WP4C

Preparing the WP4C for Operation

After finding a good location for your WP4C, plug the

power cord to the back of the unit. Before turning it on,

pull open the sample drawer (turn the knob to the

“OPEN/LOAD” position). An empty disposable sample

cup is usually placed upside-down in the drawer to protect

it during shipment. Remove this sample cup and turn the

instrument on. The ON/OFF switch is located on the

lower right corner of the WP4C’s back panel. The following screens will appear on the LCD:

RS-232 interface

fuse well

ON/OFF Switch

Power cord

Plug

Fan

Lid thumb-screw

Model WP4C

PotentiaMeter

v4.03

Page 16

WP4C PotentiaMeter

3. Getting Started

10

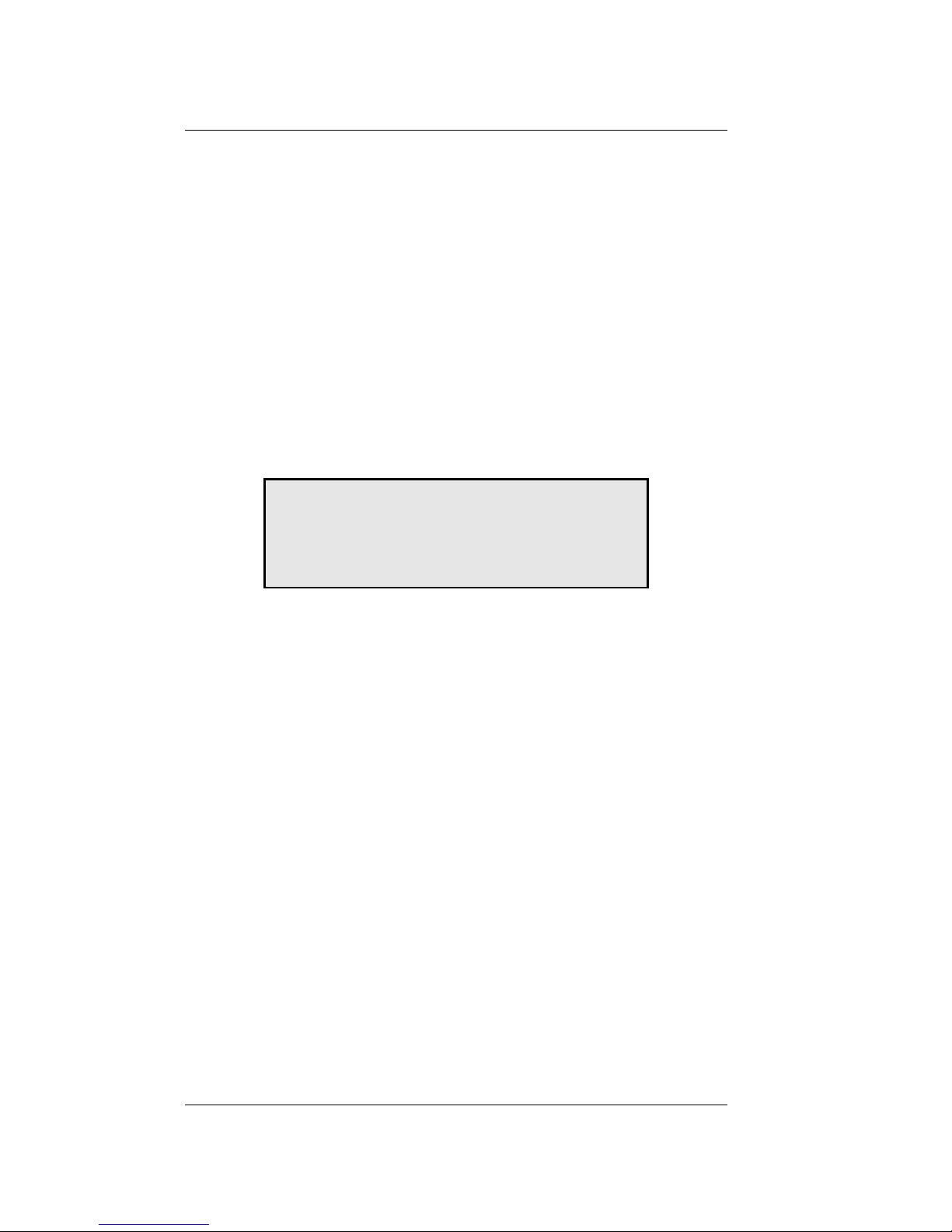

Then:

This is the main menu, displaying the water potential in

both MegaPascals (MPa) and pF, and the sample temperature in °C.

In order to provide the most accurate readings, WP4C

should ideally be allowed a warm-up period of 15-30 minutes after turning it on. When you insert a sample into the

chamber drawer and turn the drawer knob to the

“READ” position, the instrument will begin the read cycle

to measure the water potential of your sample.

Portability

On occasion you may want to take water potential measurements in the field where it is not feasible to take samples and return to the lab. The following is a procedure for

powering your WP4C using your vehicle as a power source

at sites where AC power is not readily available.

1. Purchase a portable power inverter that plugs into the

12V output (cigarette lighter) of your vehicle. The

inverter should have a continuous output of at least

140 Watts.

2. Place the WP4C on a level surface. Care should be

0.0°C

0.00 MPa

pF 0.00

p

Page 17

WP4C PotentiaMeter

3. Getting Started

11

taken to minimize temperature gradients that may

affect the instrument while in the field. A Styrofoam

box, for example, will help minimize temperature

effects.

3. Plug the 12-volt inverter to the 12-volt output of the

vehicle, or directly to the battery itself.

4. Plug the WP4C to the inverter, and turn it on. When

the instrument is on, it draws up to 1 amp. Check the

rating of your battery if you want to know how long it

will power the instrument (for example, if your battery

is rated for 60 amp hours, it will work for 60 hours

when the vehicle isn’t running.

5. Allow the instrument to warm up for 15-30 minutes as

you would in the lab. Check the calibration of the

instrument before proceeding with reading.

Page 18

WP4C PotentiaMeter

4. The Menus

12

4. The Menus

The Main Menu

Every time you turn on your WP4C, it will come to this

screen. If this screen doesn’t appear, refer to Chapter 12

for troubleshooting instructions. As mentioned earlier, the

water potential and sample temperature are displayed on

the screen. On each side of the LCD there are buttons.

Each button performs a different function depending on

which mode you want. Following is a description of the

modes and options you may use, and the buttons used to

set them.

0.0°C

0.00 MPa

pF 0.00

p

sample temperature menu system setup

language

selection

0.0°C

0.00 MPa

pF 0.00

p

precise/continuous/fast mode

Page 19

WP4C PotentiaMeter

4. The Menus

13

Changing Languages

The WP4C comes to you with English as the default onscreen user language. If you prefer not to use English, you

can change it to one of a variety of other languages: German, French, Spanish, Italian, Swedish, Danish, Norwegian, Czech, Portuguese, Japanese, Polish or Finnish. This

is done simply by pressing the upper right button of the

instrument while it is not reading a sample. You will see

the following screen:

Press the upper right key again, and the next language

option (German) will appear:

Each time you press the right button, the display will scroll

to the next language option. Select the desired language,

then press the lower left button to exit.

Reading Modes

Precise Mode

The first time you turn on the WP4C, it will be in precise

mode. In this mode, measurements on a sample are

English

-Exit-

Deutsch

-zurück-

Page 20

WP4C PotentiaMeter

4. The Menus

14

repeated until successive readings agree within a preset

tolerance (0.03MPa for Ψ>-40MPa; otherwise 0.3MPa) .

The WP4C always starts in precise mode. To toggle

between the precise, continuous and fast modes, press the

top left button. The display will show a small p, c or f to

the left of the water potential readings:

main menu with continuous mode enabled

Here is a brief summary of the precise mode features:

• Precise water potential value is insured by repeating measurements on a sample.

• Read time is typically 10-15 minutes.

• Green LED blinks until you turn the drawer knob

to the OPEN/LOAD position.

Continuous Mode

Continuous mode measures the water potential of your

sample continuously until you turn the drawer knob to the

OPEN/LOAD position. This can be useful in doing long

term monitoring of samples that take an especially long

c

“c” for continuous mode

0.0°C

0.00 MPa

pF 0.00

Page 21

WP4C PotentiaMeter

4. The Menus

15

time to come to vapor equilibrium, such as plant samples

and moist soil samples with water potential > -0.5MPa. In

this mode the WP4C will measure the sample, stop to display the water potential and sample temperature, then

begin another read cycle. Between samples, it will signal

you with the green LED flash, accompanied by the

beeper, if it is enabled. Some find it helpful to connect

their WP4C to a computer while in continuous mode in

order to log and store data over time. For instructions on

how to do this, see Chapter 8.

Fast Mode

In fast mode, the sample is measured only once. Read time

is typically 3-5 minutes. Readings are less precise, particularly in the wet range. However, fast mode is recommended for dry soil samples with water potential <-40

MPa.

System Configuration

If you press the bottom left button while in the main

menu, it will bring you to the system configuration menu.

This menu allows you to make minor system changes.

Page 22

WP4C PotentiaMeter

4. The Menus

16

You can change how the beeper signals after each reading

and enter the calibration menu as well.

System configuration menu

Changing the beeper

When you are reading, the WP4C has two ways of notifying you that the water potential reading is completed for

your sample: the beeper and a flashing green LED, located

on the left front corner of the WP4C’s case. In fast and

precise reading modes, the LED will flash once when a

sample is started. When it is finished the LED will flash

system configuration menu button

0.0°C

pF 0.00

p

0.00 MPa

Beeper

Beeper

Mode indicator

Calibration

menu

Icon

(4 beeps shown)

temperature set

+

-

-Exit-

4x

set T

Page 23

WP4C PotentiaMeter

4. The Menus

17

continuously until the knob is moved to the OPEN/

LOAD position (if not operating in continuous mode).

You cannot turn off or change the LED flashing functions.

There are three beeper options, represented by three

icons:

definition of beeper icons

The beeper can be turned off completely, it can beep

momentarily (4 times) when the sample is finished and

then stop, or it can beep continuously until the knob is

turned to the OPEN/LOAD position. After you have

adjusted the beeper setting, it will remain as you have set it

until you change it again, and will not be affected by turning the instrument on or off.

EXIT

You may press the -Exit- button (the lower left button)

to exit back to the main menu at any time.

Adjusting Calibration

When you need to adjust calibration, press the upper right

button in the system configuration menu, and you will be

brought to the calibration menu. For more details on calibration and how to verify it, please refer to the next chapter.

0x

4x

No beeping.

Beeps four times, then stops.

Beeps continuously until drawer is opened.

x

Page 24

WP4C PotentiaMeter

4. The Menus

18

Setting the Temperature

The WP4C gives you the ability to manually set your

instrument’s sample chamber temperature. This is done by

pressing the lower right button next to the “

set T

” in

the system configuration menu. The following screen will

appear:

Adjusting the Setpoint Temperature

Use the buttons next to + and - to adjust the target setpoint temperature (displayed in the lower right corner). If

you press either button it adjusts in increments of .1°C.

Note: Holding down the button will rapidly increment the value.

The target setpoint temperature roughly corresponds to

the temperature at which you wish the sample to read.

Therefore, adjust the setpoint to the temperature that you

want, then begin measurements to see how close your

WP4C comes to your desired temperature (this works best

by putting the WP4C in continuous mode). After several

samples, it should show consistent temperature readings.

At this point, make any needed adjustment to the setpoint

index number to reach your desired temperature. You will

be able to adjust the index number between 15° and 50°C.

If you press the - button after you reach 15°, it will disable

Adjust setpoint

-Exit-

25.0

+

-

Page 25

WP4C PotentiaMeter

4. The Menus

19

the temperature control function until you raise the index

number again. When the temperature control is disabled

the diplay will show ‘off ’ in place of the temperature setting

Important tips with the WP4C

• Before reading, wait for approximately 30 minutes

to let the chamber’s temperature stabilize after

turning it on.

• Cool samples to a temperature slightly below

chamber temperature before starting a reading.

• For slow equilibration samples such as plant and

moist soil samples (> -0.5 MPa), precise reading

mode may yield small errors. For these types of

samples, it is recommended to use continuous

mode and log data over time (See Chapter 8) to

determine when equilibrium conditions are

reached.

• For samples with very little water holding capacity (i.e. dry sand samples), small leaks in the sample chamber can cause water potential to drift

down over time. Fast mode is recommended for

these samples.

• For best results, run in precise mode for most soil

samples.

Page 26

WP4C PotentiaMeter

4. The Menus

20

• Never place a hot or warm sample in a cooled

chamber, because condensation will form inside

the chamber, causing errors in reading.

Sample Equilibration Screen

To see the temperature difference between your sample

and the WP4C, press the lower right button at the main

menu. This screen can only be accessed when the drawer

knob is in the OPEN/LOAD position. The following

screen will appear:

This screen shows the temperature difference between the

sample (Ts) and the chamber block (Tb), allowing you to

quickly check if the sample is too hot, which may cause

condensation inside the chamber. Press the lower right

button to exit.

Ts - Tb = -0.07

Tb = 24.9

Page 27

WP4C PotentiaMeter

5. Calibration and Verification

21

5. Calibration and Verification

Verification

WP4C uses the chilled mirror dewpoint technique for measuring water potential. This is a primary method but cleanliness of the instrument can affect the calibration. The

calibration slope is fixed during factory calibration. The user

just adjusts the zero offset. Calibration can be done with

any solution of known water potential. We recommend

using the 0.5 molal KCl verification standard from Decagon.

Verification Standards

Verification standards are specially prepared salt solutions

that have a specific molality and water potential. The

potassium chloride (KCl) verification standards are accurate, easy to use, and readily available from Decagon

Devices. Most importantly, they greatly reduce preparation errors. We therefore recommend using Decagon’s

KCl Performance Verification Standard for the most accurate verification of your WP4C’s performance.

The standards are produced under a strict quality assurance regime and are shelf stable for one year. If for some

reason you cannot obtain Decagon’s verification standards

and need to make a salt solution for verification, refer to

Appendix A.

Page 28

WP4C PotentiaMeter

5. Calibration and Verification

22

When to Verify Calibration

The calibration of your WP4C should be checked with

the KCl standard before each use. It can also be checked

by measuring distilled water, but this is often not a good

choice for checking calibration. When using distilled

water, the humidity of the chamber approaches 100%

which can cause condensation to occur if the sample is

warmer than the chamber. For batch processing, the

instrument should be checked regularly against the KCl

standard. This will alert you to the possibility of contamination of the unit or shifts in the calibration from other

causes.

How to Verify and Calibrate the WP4C

Since errors in the calibration value result in errors in all

values subsequently measured, care should be taken to do

it right.

Checking and Adjusting Calibration

1. Press the upper right button in the system configuration menu to enter the calibration menu. You will be

guided through the calibration routine. The following

screen will appear:

Place standard

in drawer and read

Page 29

WP4C PotentiaMeter

5. Calibration and Verification

23

2. Empty the whole vial of KCl solution into a sample

cup and place it in the WP4C’s sample drawer. Make

sure you calibrate using the same type of sample cup

(plastic of stainless steel) that you will make subsequent measurements with.

3. Carefully slide the drawer closed, being especially care-

ful so the solution does not splash or spill and contaminate the chamber. Check to be sure the sample

temperature is below chamber temperature (lower

right button).

4. Turn the drawer knob to the READ position to make

a reading. When the reading is complete, the following

screen will appear:

NOTE:

The WP4C will automatically shift to precise sam-

pling mode for the verification/calibration.

The reading should be within ± 0.05 MPa of the correct

reading of the KCl standard at that temperature. At 20 °C

this should be -2.19 MPa. At 25 °C this should be -2.22

MPa.

adjust +

-Exit- -184.95 -

use these buttons to adjust the value

Page 30

WP4C PotentiaMeter

5. Calibration and Verification

24

5. If your WP4C is reading within 0.05 MPa of the KCl

solution, press

-Exit-

and proceed with reading. If it

is not, a change in calibration may have occurred, or

the sensor chamber may be contaminated. For cleaning

instructions, see Chapter 10. After cleaning, repeat

these instructions.

6. If, after cleaning, you consistently get readings that

differ from the correct water potential of the KCl by

more than ±0.05 MPa, a change in calibration has

probably occurred. Press the upper right button to

move the value up, the lower right button to move it

down. When it is at the correct value for the verification standard, press the -Exit- button. The value

will be stored.

Note: This is the only menu where these buttons can change the calibration, so you won’t hurt anything by pressing these buttons in other

menus.

7. Read the KCl standard again in the normal reading

mode. It should read the proper value.

8. If after adjusting the calibration and cleaning the chamber you still are getting incorrect readings when reading the KCl, contact Decagon at 509 332-2756 (1-800755-2751 in US and Canada) for further instructions.

Page 31

WP4C PotentiaMeter

6. Sample Preparation

25

6. Sample Preparation

Your WP4C will continually provide accurate water potential measurements as long as its internal sensors are not

contaminated. Careful preparation and loading of samples

will lengthen time between cleanings and will help you

avoid downtime and repairs.

Choosing a Sample Cup

The WP4C comes with two types of samples cups: disposable plastic cups and stainless steel cups. The disposable

plastic cups are adequate for most samples, but are not

good for samples in the wet end. If you are measuring

samples with water potential wetter than -1 MPa, you

should use the stainless steel sample cups. You can also

oven dry soil samples directly in the stainless steel cups to

determine water content gravimetrically, which is convenient if you are generating soil moisture characteristic

curves. It is important to note that you must thoroughly

clean the stainless steel cups using de-ionized water

between uses to prevent solutes from contaminating subsequent samples and causing artificially negative osmotic

potential. Finally, if you calibrate the WP4C (see chapter

5), be sure to calibrate using the same type of sample cup

that you intend to use for subsequent measurements.

Page 32

WP4C PotentiaMeter

6. Sample Preparation

26

Preparing the Sample

To prepare a sample, follow these steps:

1.

Place the sample in a disposable sample cup, completely covering the bottom of the cup, if possible.

WP4C may not be able to accurately measure a sample

that does not (or cannot) cover the bottom of the cup.

A larger sample surface area speeds up the reading by

shortening the time needed to reach vapor equilibrium.

It also increases instrument accuracy by providing more

stable infrared sample temperature measurements.

2. Do not fill the sample cup more than half full.

Overfilled cups may contaminate the sensors in

the chamber (more is not necessarily better!)

3. Make sure that the rim and outside of the sample

cup are clean. Wipe any excess sample material from

the rim of the cup with a clean tissue. Material left on

the rim or the outside of the cup will contaminate the

sensor chamber and will be transferred to subsequent

samples. The rim of the cup forms a vapor seal with

the sensor block when the drawer knob is turned to

the READ position. Therefore, any sample material

left on the cup rim will be transferred to the block,

preventing this seal and contaminating future samples.

4. If a sample will be read at some future time, put

the sample cup’s disposable lid on the cup to

Page 33

WP4C PotentiaMeter

6. Sample Preparation

27

restrict water transfer. For short-term storage (< 3

hours) the cup lid is acceptable. If it will be a long time

before the measurement is made, seal the lid with tape

or Parafilm completely around the cup/lid junction.

Dry Samples

Samples that have a water potential drier than about -300

MPa cannot be accurately measured with the WP4C.

However, samples with such dry water potential values are

rare. When a sample’s water potential value is drier than

about -300 MPa, WP4C will display an error message indicating the lowest reading it could make on that particular

sample. For example, if you were measuring a dry sample

and the following screen appeared:

this screen indicates that the last water potential reading

the WP4C measured on this sample was -301.8 Megapascals. Therefore, the actual water potential of the sample is

lower than the instrument can measure.

Samples and Temperature

If samples are warmer than the chamber when they are

placed in it (Ts-Tb is a positive number), condensation

may occur and moisture may condense inside the block. In

order to prevent this, do the following:

< -820 MPa

Page 34

WP4C PotentiaMeter

6. Sample Preparation

28

1. Place your sample in the chamber, slide the drawer

closed and press the lower right button to access the

sample temperature screen and look at the temperature difference. If the sample temperature is shown to

be a positive number, take the sample out immediately

and let it cool on a cold surface with the cup lid on it

to preserve the moisture. Do not cool the sample too

much, or the equilibrium time will be lengthened (ideally the Ts-Tb will be between -0.5 and 0) .

2. After cooling it for a minute or so, place the sample

back in and note the temperature difference. If it is

close enough to the block temperature, turn the knob

to the READ position to begin reading.

There is a linear relationship between the sample’s

dewpoint temperature and its water potential. The

dewpoint decreases -0.12 °C per MPa. For example, a very

dry sample at -40MPa can be 4.8 °C (-.12 x -40) above the

chamber temperature without condensing. A sample at -1

MPa (fairly dry for most soils) can be 0.12°C above the

chamber temperature without condensing. Therefore, if

you know the general range of your sample’s water

potential, you can gage at which temperature it will

condense moisture.

For samples that are more than 1°C below chamber

temperature, the WP4C waits until their temperature

increases to 1 °C below chamber temperature to start a

Page 35

WP4C PotentiaMeter

6. Sample Preparation

29

reading. Readings are therefore speeded up if sample

temperature is just a little below chamber temperature.

Measuring Plant Samples

The WP4C can be used to measure the water potential of

leaves and plant material. Please refer to the application

note: Measurement of Leaf Water Potential Using the

WP4, which can be found at www.decagon.com.

Page 36

WP4C PotentiaMeter

7. Taking a Reading

30

7. Taking a Reading

Once you have prepared your sample, you are ready to

take readings.

1. Turn the sample drawer knob to the OPEN/LOAD

position and pull the drawer open.

2. Place your prepared sample in the drawer. Check the

top lip of the cup to make sure it is free from sample

residue (remember, an over-filled sample cup will contaminate the chamber’s sensors).

3. Carefully slide the drawer closed, being especially careful if you have a liquid sample that may splash or spill

and contaminate the chamber.

4. Access the sample temperature menu (press lower

right button) to watch the temperature difference

between the sample and the instrument.

5. Turn the sample drawer knob to the READ position

to seal the sample cup with the chamber. The instrument will beep once, and the green light will flash

once to indicate that the reading cycle has started. In

about 40 seconds, the first measurement will be displayed.

Page 37

WP4C PotentiaMeter

7. Taking a Reading

31

How WP4C takes Readings

WP4C’s cooled mirror is controlled at the chamber dew

point and its temperature is measured.. When the instrument has finished its read cycle, the water potential is displayed, accompanied by the LED flash and beeper (if you

have the beeper enabled).

Cautions

• Never leave a sample in your WP4C after a reading has

finished. The sample may spill and contaminate the

instrument’s chamber if the instrument is accidentally

moved or jolted.

• Never try to move your instrument after a sample has

been loaded. Movement may cause the sample material to spill and contaminate the sample chamber.

• Take special care not to move the sample drawer too

quickly when loading or unloading liquid samples, in

order to avoid spilling.

• If a sample has a temperature that is higher than the

WP4C’s chamber (Ts-Tb is a positive number), take

the sample out immediately, put a cap on it, and cool

it. Warm samples can cause condensation in the

chamber and adversely affect subsequent readings.

Page 38

WP4C PotentiaMeter

7. Taking a Reading

32

• The physical temperature of the instrument should be

between 5°C—43°C. Between these temperatures,

WP4C will measure samples of similar temperature

quickly and accurately.

• If you are reading and a triangular warning symbol

appears in the top right corner of the display, this indicates that the mirror has become too dirty to give

accurate measurements. You will need to clean the

mirror and chamber before continuing to sample. For

more details about this symbol, please refer to Chapter

12. For cleaning instructions, refer to Chapter 10.

C

pF 7.38 24.9°C

-1.84 MPa

p

Page 39

WP4C PotentiaMeter

8. Computer Interface

33

8. Computer Interface

Your WP4C was shipped to you with a standard RS-232A

interface cable. Using this, you can use your computer’s

terminal program1 to send water potential data to your

computer for further analysis and storage. Set up your terminal program as follows:

1. Select the COM Port your RS-232 cable is connected to.

2. Settings are the following: Bits per second, 9600; 8

databits, no parity, 1 stop bit, and flow control set to

hardware. Click OK.

3. Plug your RS-232 cable to the COM port you selected

and connect it to your WP4C. Begin reading. Your

WP4C’s data will be displayed on screen as it samples.

It will be output in the following format:

4. When you are finished reading, you can print the data

3, 24.3, -2.19, 4.16

time (minutes)

since sample

was started

temp

(°C)

Water

potential

pF

(MPa)

Page 40

WP4C PotentiaMeter

8. Computer Interface

34

in the terminal session, or cut and paste it to a spreadsheet or text editor.

1

A good, free terminal program can be found at

http://ttssh2.sourceforge.jp.

Page 41

WP4C PotentiaMeter

9. Theory: Water Potential

35

9. Theory: Water Potential

Water Potential

Water potential is defined as the potential energy per unit

volume of water in a sample. The total water potential of a

sample is the sum of four component potentials: gravitational, matric, osmotic, and pressure. Gravitational potential depends on the position of the water in a gravitational

field. Matric potential depends on the adsorptive forces

binding water to a matrix. Osmotic potential depends on

the concentration of dissolved substance in the water.

Pressure potential depends on the hydrostatic or pneumatic pressure on the water.

The WP4C measures the sum of the osmotic and matric

potentials in a sample. Often one or the other of these

potentials will be the dominant factor in determining the

total potential. For example, solutions like the KCl calibration standard have only an osmotic component. Soils bind

water mainly through matric forces, and therefore have

mainly a matric component (though salt-affected soils can

have a significant osmotic component).

Measuring Water Potential

The water potential of a solid or liquid sample can be

found by relating the sample water potential reading to the

Page 42

WP4C PotentiaMeter

9. Theory: Water Potential

36

vapor pressure of air in equilibrium with the sample. The

relationship between the sample’s water potential (Ψ) and

the vapor pressure of the air is:

where p is the vapor pressure of the air, po is the saturation

vapor pressure at sample temperature, R is the gas constant (8.31 J/mol K), T is the Kelvin temperature of the

sample, and M is the molecular mass of water. The vapor

pressure of the air can be measured using a chilled mirror,

and po is computed from sample temperature.

The WP4C measures water potential by equilibrating the

liquid phase water of the sample with the vapor phase

water in the headspace of a closed chamber, then measuring the vapor pressure of that headspace. In the WP4C, a

sample is placed in a sample cup, which is sealed against a

sensor block. Inside the sensor block is a fan, a dew point

sensor, a temperature sensor, and an infrared thermometer. The dew point sensor measures the dew point temperature of the air, and the infrared thermometer measures

the sample temperature. The purpose of the fan is to

speed equilibrium and to control the boundary layer conductance of the dew point sensor.

From these measurements, the vapor pressure of the air in

the headspace is computed as the saturation vapor pres-

Ψ

RT

M

-------

p

p

o

-----ln⋅=

Page 43

WP4C PotentiaMeter

9. Theory: Water Potential

37

sure at dewpoint temperature. When the water potential

of the sample and the headspace air are in equilibrium, the

measurement of the headspace vapor pressure and sample

temperature (from which saturation vapor pressure is calculated) gives the water potential of the sample.

In addition to equilibrium between the liquid phase water

in the sample and the vapor phase, the internal equilibrium of the sample itself is important. If the sample is not

at internal equilibrium, one might measure a steady vapor

pressure (over the period of measurement) which is not

the true water potential of the sample.

Effect of Temperature on Water

Potential

Temperature plays a critical role in water potential determinations. Most critical is the measurement of the difference between sample and dew point temperature. If this

temperature difference were in error by 1°C, an error of 8

MPa would result. In order for water potential measurements to be accurate to 0.05 MPa, temperature difference

measurements need to be accurate to 0.006°C.

WP4C’s infrared thermometer measures the difference in

temperature between the sample and the block. It is carefully calibrated to minimize temperature errors, but

achieving 0.006°C accuracy is difficult when temperature

differences are large. Best accuracy is therefore obtained

when the sample is near chamber temperature.

Page 44

WP4C PotentiaMeter

9. Theory: Water Potential

38

Another effect of temperature on water potential occurs

with samples that are near saturation (like many soil samples). A sample that is close to 0.00 MPa and is only

slightly warmer than the sensor block will condense water

within the block. This will cause errors in the measurement, and in subsequent measurements until the condensation disappears. The Ts-Tb function helps the user

ensure that the sample won’t condense on the sensor

block.

Estimating Osmotic Potential

The WP4C measures the sum of osmotic and matric

potential. An approximate value for the osmotic potential

can be found by measuring the electrical conductivity

(EC) of the saturation extract of the soil. The osmotic

potential of the saturation extract is computed from:

Ψ

os

(MPa) = -0.036EC (dS/m)

The osmotic component of the water potential is then

computed from:

where θ is the volumetric water content of the sample and

θs is the volumetric water content at saturation. The

matric potential is the total potential minus the osmotic.

Ψ Ψ

os

θ

s

θ

-----

=

Page 45

WP4C PotentiaMeter

10. Cleaning and Maintenance

39

10. Cleaning and Maintenance

The accuracy of your WP4C is vitally dependent on keeping your instrument clean. Dust and sample debris can

contaminate the sampling chamber and must therefore be

regularly cleaned out. To clean your instrument, carefully

follow these instructions.

Tools Needed

• WP4C Cleaning Kit

Note: Kimwipes® are included in the WP4C Cleaning Kit. They

are ideal for cleaning because they don’t leave much of a lint residue

like most tissues. They also don’t have any other compounds in the

tissue that may contaminate the sensors in the WP4C’s block. Never

use cotton swabs to clean the block sensors. Most cotton swabs contain adhesives and other compounds that are released and transferred

to the mirror and other surfaces, contaminating them.

Accessing the Block

1. Unplug your WP4C.

2. Remove the case lid screw located on the back panel.

Carefully remove the lid by pulling the back of the lid

Page 46

WP4C PotentiaMeter

10. Cleaning and Maintenance

40

upward and then sliding the lid back (away from the

front of the case) and off.

3. Unscrew the two thumbscrews that secure the sensor

block.

4. Unplug the cable with the 20-pin socket that attaches

the block to the main circuit board by releasing the

two locking levers that are on either side of the socket.

5. Carefully lift the block straight up from its mount.

Turn the block over to expose the chamber cavity as

shown in the illustration:

View of inside block chamber

thermopile

mirror

optical sensor

chamber fan

Page 47

WP4C PotentiaMeter

10. Cleaning and Maintenance

41

Cleaning Procedure:

Cleaning your WPC4 is a multi-step procedure which

involves washing, rinsing, and drying for each specific area

as outlined below:

1. Cleaning the Inside Chamber

Note: Be extremely careful not to damage the fan blades in the chamber. The fan blades are very fragile; if one of them breaks, your

instrument won’t work properly. Therefore, take extra care when

cleaning this portion.

a. Remove any debris that may have collected within or

around the sample chamber.

b. Wrap a NEW Kimwipe around the end of the thin

plastic rod (spatula) and moisten it with isopropyl

alcohol or Decagon Cleaning Solution. Note: Do

NOT dip a used Kimwipe into your container of IPA

or cleaning solution (the IPA or cleaning solution will

become contaminated).

c. WASH--Clean all surface edges of the samples cham-

ber including the edge where the sample cup seals to

the chamber block. You may need to replace the Kimwipe if it becomes too dirty during this process.

d. RINSE--Repeat steps b and c using new Kimwipes

with distilled water.

e. DRY--Repeat steps b and c using new, dry Kimwipes

to help remove any moisture remaining from the

cleaning.

Page 48

WP4C PotentiaMeter

10. Cleaning and Maintenance

42

f. Visually inspect the sample chamber for cleanliness.

Re-clean if necessary. Note: Do not reuse Kimwipes.

2. Cleaning the Mirror

NOTE: Wash hands with soap and water (to prevent oils from contaminating the Kimwipe tissue and being transferred to the mirror).

a. Wrap a NEW Kimwipe around the end of the thin

plastic rod (spatula) and moisten it with isopropyl

alcohol or Decagon Cleaning Solution.

b. WASH--Carefully clean the mirror with the moist

Kimwipe.

c. RINSE--Repeat steps b and c using new Kimwipes

with distilled water.

d. DRY--Repeat steps b and c using new, dry Kimwipes

to help remove any moisture remaining from the

cleaning.

e. Visually inspect the mirror for cleanliness. Re-clean if

necessary. Note: Do not reuse Kimwipes.

3. Cleaning the Optical Sensor

You will probably clean the optical sensor while you are

cleaning the mirror, since they face each other in a very

small gap. Clean it in the same manner as described above

for the mirror.

Page 49

WP4C PotentiaMeter

10. Cleaning and Maintenance

43

4. Cleaning the Thermopile

a. Wrap a new Kimwipe around the end of the thin plas-

tic rod (spatula) and moisten it with isopropyl alcohol

or Decagon Cleaning Solution.

b. WASH--Swipe the moistened Kimwipe across ther-

mopile. (A single swipe is usually sufficient to remove

contaminants.)

c. RINSE--Repeat steps a-b using new Kimwipes moist-

ened with distilled water instead of cleaning solution.

d. DRY--Repeat steps a-b but use a new, dry Kimwipe to

help remove any moisture remaining from the cleaning.

e. Visually inspect the thermopile for cleanliness. This

sensor must be free of all dirt and lint. Re-clean if necessary.

5. Inside Case

1. Clean the sample drawer and drawer base as described

above for the thermopile. Remove any debris that may

have collected inside the case.

2. Check once more to make sure there is no contamina-

tion of the sample chamber cavity.

3. Replace the block, and insert the ribbon cable socket

into to the 20-pin plug on the block. Lock it in place

with the locking levers.

Page 50

WP4C PotentiaMeter

10. Cleaning and Maintenance

44

4. Screw the thumb-screws on the block back in until

they are hand-tight.

5. Replace the case lid and secure the lid screw.

6. Connect the WP4C’s power cord.

Checking Calibration

After you have cleaned the chamber and other parts of

your WP4C, it is important to check the instrument’s performance in order to correct for any calibration change

that may have occurred during cleaning procedures.

Check the calibration of your instrument by measuring the

water potential of the KCl standard. If a change has

occurred, refer to chapter 5 for directions on how to recalibrate. If, after adjusting calibration your instrument is

still not reading samples correctly, contact Decagon for

technical support.

Page 51

WP4C PotentiaMeter

11. Repair Instructions

45

11. Repair Instructions

If your WP4C ever needs to be sent in for service or

repair*, call Decagon at (509) 332-2756 or 1-800-755-

2751, or fax us at (509) 332-5158. We will ask you for

your address, phone number, and serial number. For nonwarranty repairs, we will also ask for a payment method

(such as a purchase order or credit card number), a repair

budget, and billing address.

*Note: If you purchased your WP4C from one of our international

distributors, please contact them before contacting Decagon. They

may be able to provide you with local service and help you remedy the

problem.

Shipping Directions

When you ship your instrument back to us, please include

with it a document with the complete shipping address,

name and department of the person responsible for the

instrument, and (most importantly) a description of the

problem. This information will better help our technicians

and our shipping department to expedite repair on your

instrument and ship it back to you in good time.

All WP4Cs returning to Decagon for servicing must be

accompanied with a Return Material Authorization (RMA)

Page 52

WP4C PotentiaMeter

11. Repair Instructions

46

form. Prior to shipping the instrument, please contact a

Decagon customer support representative to obtain a

Return Merchandise Authorization (RMA).

Following are steps that will help in safely shipping your

instrument back to us:

1. If possible, ship your WP4C back in its original cardboard box with foam inserts. If this is not possible, use

a box that has at least 4 inches of space between your

instrument and each wall of the box. If you aren’t

using the foam inserts, pack the box moderately tight

with packing material, like styrofoam peanuts

2. Put your instrument in a plastic bag to avoid disfiguring marks from the packaging.

3. Don’t ship your WP4C to us with the power cord; we

have plenty here to use with your instrument, and it

may damage the instrument in shipment.

4. Please review the RMA form and verify the ship to

and bill to information, contact name, and problem

description. If anything is incorrect, please contact a

Decagon representative.

5. Tape the box in both directions so it will not break

open in shipment.

6. Include the RMA number in the attention line on the

shipping label.

Page 53

WP4C PotentiaMeter

11. Repair Instructions

47

Ship to:

Decagon Devices Inc.

ATTN: Repair Department RMA#_______

2365 NE Hopkins Court

Pullman, WA 99163

Repair Costs

Manufacturer’s defects and instruments within the oneyear warranty will be repaired at no cost. For non-warranty repairs (including cleanings for instruments in their

warranty period), costs for parts, labor, and shipping will

be billed to you. We have a minimum repair charge, and an

extra fee will be charged for rush work. Decagon will provide an estimated repair cost, if requested.

Loaner Service

We have loaner instruments that can be provided while

your instrument is being serviced. There is, however, a

limited number of loaner instruments. They are granted

on a “first-come-first-served” basis. This service is in

place to help you if your WP4C needs service during critical operations.

Page 54

WP4C PotentiaMeter

12. Troubleshooting

48

12. Troubleshooting

WP4C is a high performance instrument, designed to have

low maintenance and few problems if used with care.

Unfortunately, sometimes even the best operators using

the best instruments encounter technical difficulties. Here

is a list of some problems that may occur. If you have

encountered a problem that isn’t addressed here, or if

these remedies still don’t resolve your problem, contact

Decagon at 1-800-755-2751 (US only) or (509) 332-2756

(for those outside the US). If purchased from a distributor, please contact the distributor for assistance first.

Problems and Solutions

The following table is a brief guide to help you quickly

define solutions to your problems. For more detailed

descriptions of these problems and their solutions, see the

explanations below the table.

Table 1: Troubleshooting

Problem Possible Solutions

1. Won’t turn on • Power cord discon-

nected

• Blown fuse

Page 55

WP4C PotentiaMeter

12. Troubleshooting

49

2. Long read time • Dirty sample chamber

• Sample desorbs slowly

• Broken or bent chamber

fan blade

3. Readings on KCl

standards are too high/

low to adjust

• Dirty thermopile

• If using own salt solu-

tion, it may not be in

equilibrium

4. < -301.8 MPa • Sample too dry to accu-

rately measure

• Dirty chamber or mirror

5. Triangle appears in

upper right corner

• Mirror is dirty

6. “block failure”

appears on screen after

turning on WP4C

• Block is disconnected

from motherboard

• Block memory compo-

nent has failed

7.

7.7.

7. “set T” option no

longer appears on system config screen

Temperature control mod-

ule in WP4C is broken

or not functioning

Table 1: Troubleshooting

Problem Possible Solutions

Page 56

WP4C PotentiaMeter

12. Troubleshooting

50

1. PROBLEM:

WP4C won’t turn on.

SOLUTION:

• Check to make sure your power cord is securely

attached the back of the instrument, and into the

power outlet.

• A power surge may have caused a fuse to blow. To

change the fuses, follow these instructions:

1. Unplug the power cord from the wall and the instrument.

2. Locate the panel where the power cord plugs in. The

fuse box is on the right side of that panel. Press in on

the release tab and pull the fuse-holder out.

3. Pull the broken fuse(s) out and replace with a 2.0 Amp

250V fuse.

Caution: Do not use any other kind of fuse or you will risk damage

to your instrument and void your warranty.

4. Replace the fuse-holder and push it into the fuse-well

until the release tab snaps in place.

5. Re-connect the power cord and turn your instrument

Page 57

WP4C PotentiaMeter

12. Troubleshooting

51

on. If the fuse blows again, a failed component may be

causing the problem. Contact Decagon to make

arrangements for repairs.

2. PROBLEM:

Readings are slow or inconsistent.

SOLUTION:

• The sample chamber may be dirty. Refer to Chap-

ter 10 of the manual for directions on cleaning the

sample chamber.

• Some samples absorb or desorb moisture very

slowly, causing measurements to take longer than

usual, and nothing can be done to speed up the process. Refer to Chapter 6 for further explanation.

•

The fan blade inside the block chamber may be broken.

If even the KCl standard takes a long time to read,

and the sample chamber is clean, you may have a broken or

bent chamber fan blade. This is especially likely if you have

just cleaned the chamber. If you suspect this may have happened, contact Decagon for details on replacement.

3. PROBLEM:

Water potential readings on KCl standards are too

high/low and a calibration adjustment cannot be made

any higher/lower.

Page 58

WP4C PotentiaMeter

12. Troubleshooting

52

SOLUTION:

• The thermopile in your chamber, which measures

sample temperature, may have become contaminated. Refer to Chapter 10 for directions on cleaning.

• If you weren’t using Decagon’s KCl verification

standards, high readings may indicate that the salt

solution you are using is not in equilibrium.

4. PROBLEM:

Message on screen displays the following (example):

SOLUTION:

• The sample is too dry for the instrument to read

accurately. If your sample has a water potential that is

above the detection limits of the instrument, this message will come up. Essentially, it means that there is

not enough sample moisture to condense on the mirror and provide a reading.

• The mirror may be dirty. Try cleaning the mirror

and chamber and measuring the sample again.

< -820 MPa

Page 59

WP4C PotentiaMeter

12. Troubleshooting

53

5. PROBLEM:

A small triangle appears in the upper right corner after

reading:

SOLUTION:

The mirror needs to be cleaned, along with the rest of the

sample chamber, until it disappears. This triangle is a mirror

performance indicator. When the WP4C senses that the

mirror performance has dropped to unacceptable levels, it

will display the triangular warning sign after the sample has

been measured. When this appears, you should stop sampling and clean the chamber. If the triangle is still on the

screen after cleaning, the mirror is most likely still dirty and

you will need to clean it until the triangle disappears.

6. PROBLEM:

The following screen comes up after turning on the

machine:

C

pF 7.38 24.9°C

-1.84 MPa

p

block failure

Page 60

WP4C PotentiaMeter

12. Troubleshooting

54

SOLUTION:

• The block is not plugged in to the motherboard. Open

the case and check to make sure that the small ribbon

cable that connects the block to the motherboard is

snapped and locked in place.

• One or more components has failed on the block’s circuit board. If the block is properly plugged in to the

motherboard and this message appears, it is likely that

one or more of the components have failed on the

block’s circuit board.

Sensor Performance Screen

If, after cleaning your instrument and reading the other

troubleshooting hints, you have reason to believe that one

of the components of your WP4C may be causing measurement error, you can access a screen that will display

values for component performance. This is done by holding down the lower right button while turning on the

instrument. After it initializes, it will beep and come to the

following screen:

This screen gives you four values. The top left value is the

value the thermocouple is reading. It is basically the differ-

-Exit-

sensors

3.36 0.030

23.5 0.665

Page 61

WP4C PotentiaMeter

12. Troubleshooting

55

ence in temperature between the block and the mirror. If

this is zero, there is something wrong with the thermocouple. The top right value is the value read by the thermopile, which is the temperature difference between the

block and what it “sees” below it (the sample, when reading). This value is variable, but should never be zero. The

bottom left value is the block temperature. This value

should be around ambient temperature. The bottom right

value is the mirror reflectance voltage, in units of volts.

This value should normally be around 0.5 or above, but if

it drops below 0.3, there is something wrong.

You can’t change anything in this screen, but it is here to

give you an indication of the component performance. If

you notice that any of these values are not what they

should be, contact Decagon at support@decagon.com

for further instruction. Press the button next to

-Exit-

to get back to the main menu.

Page 62

WP4C PotentiaMeter

13. Further Reading

56

13. Further Reading

References:

Brye, K.R. (2003) Long-term effects of cultivation on par-

ticle size and water-retention characteristics determined using wetting curves. Soil Science Society of

America 168:7 459-468.

Campbell, E.C., G.S. Campbell, and W.K. Barlow. (1973) A

dewpoint hygrometer for water potential measurement. Agric. Meteor. 12:113-121.

G.W. Gee, M.D. Campbell, G.S. Campbell, and J.H. Camp-

bell. (1992) Rapid measurement of low soil water

potentials using a water activity meter. Soil Science

Society of America 56:4 1068-1070.

Papendick, R.I. and G.S. Campbell. (1980) Theory and

measurement of water potential. in Water Potential

Relations in Soil Microbiology. Soil Science Society of America. Madison, Wisconsin. pp.1-22.

Page 63

WP4C PotentiaMeter

13. Further Reading

57

Application Notes

The following WP4C application notes are available from

Decagon by request and via our website under the education tab, choose WP4C.

• Generating a Soil Moisture Characteristic with the

WP4C.

• Measuring Leaf Water Potential using the WP4C.

• Field Portability Instructions for the WP4C.

• Water Potential: The Key to Successful Seed Priming.

• Seed Longevity in Storage is Enhanced by Controlling

Water Activity.

• Classification of Expansive Soils using the WP4C

Dewpoint PotentiaMeter

Page 64

WP4C PotentiaMeter

Appendix A

58

Appendix A

Preparing Salt Solutions

Following is a table showing the water potential at given

concentrations of NaCl and KCl at 20°C.

Table 2: Water Potential of NaCl and KCl in

Megapascals (MPa)

Concentration

(Moles/kg)

NaCl KCl

0.05 -0.232 -0.232

0.10 -0.454 -0.452

0.20 -0.901 -0.888

0.30 -1.349 -1.326

0.40 -1.793 -1.760

0.50 -2.242 -2.190

0.60 -2.699 -2.622

0.70 -3.159 -3.061

0.80 -3.618 -3.501

0.90 -4.087 -3.931

1.00 -4.558 -4.372

Page 65

WP4C PotentiaMeter

Appendix A

59

Page 66

WP4C PotentiaMeter

Appendix A

60

Page 67

Index

A

Accessories 7

Application notes 57

B

Beeper 16

changing

Block

sensors 39

Block failure 49,53

Buttons

for menu selection 12

C

c for continuous mode 14

Calibration

changes in 21

menu 17

steps 22–24

when to check 22

Calibration drift 21

Cautions 31

Checking calibration 44

Chilled-mirror technique 5

Cleaning 39

inside case 43

optical sensor 42

sensor block 39

Components 7

Computer interface 33

Continuous mode 14

Page 68

Cotton swabs

not used for cleaning 39

Customer service 1

Czech 13

D

Danish 13

Dirty mirror indicator 32

Distilled water 22

Dry samples 52

Dry water potential 27

E

E-mail address 2

Error messages 48,52

Exit 17

F

Fan

inside sample chamber 6

Fast mode 15

Fax number 2

Features 8

Field measurements 10

Flashing. See LED

French 13

Further reading 56

Fuse

changing 50

G

German 13

Gravitational potential 35

Page 69

I

Instrument 4

Italian 13

K

KCl standards 21

L

Languages

changing 13

Leaf

measuring water potential in continuous mode 15

LED 16

Linear offset

how to adjust for 22

Loaners 47

Location

for reading 8

M

Main menu 10, 12

Maintenance 39

Manual 1

Matric potential 35

Menus

main menu 12

system configuration 15

Molality

of verification standards 21

N

Norwegian 13

Page 70

O

Osmotic 35

Osmotic potential 38

P

Peltier cooler 5

Plant samples 29

Portability 10

Portuguese 13

Precise mode 13

Preparing salt solutions 58

Pressure potential 35

R

Read time

affected by sample temp. 27

long read time 49, 51

Reading modes 13

Continuous 14

Fast 15

Precise 13

Readings

cautions 31

how WP4C takes 31

taking readings 30

References 56

Repair

costs 47

instructions for 45

shipping 45

S

Salt standards. See verification standards

Sample

Page 71

dry water potential 27

not at room temperature 27

preparation 25

slow water-emitting 51

too dry 52

too hot 31

Sample cups

cleaning 26

filling level 26

sealing 26

Sample equilibration screen 6, 20

Saturated salts 58

Seller’s liability 3

Sensor performance screen 54

Shipping for repair 45

Spanish 13

Spilling the sample 31

Swedish 13

T

TE set 18

Technical support 1

Telephone number 2

Temperature

effects on reading 6

effects on water potential 37

hot samples 31

of instrument 31

samples not at room temp. 27

Time

long read times 51

Toll-free number 2

Triangle 32

Page 72

Triangle 53

Troubleshooting 48

V

Vapor pressure 5, 36

Verification standards 21

long read times for 51

water potential readings too high/low for 51

W

Warm-up 10

Warranty 2

Water content

definition 35

vs. water potential 35

Water potential 58

definition 5, 35

displayed 10

equation 36

measuring 35

theory 35

WP4C

and temperature 6

Chilled mirror dewpoint technique 5

important tips 19

measuring water potential 36

preparing for operation 9

theory 35

Loading...

Loading...