Page 1

KD2 Pro

Thermal Properties Analyzer

Operator’s Manual

Version 10

Page 2

Decagon Devices, Inc.

2365 NE Hopkins Ct.

Pullman, WA 99163 USA

Tel: 1-509-332-2756

Fax: 1-509-332-5158

Trademarks:

“KD2 Pro” is a registered trademark of

Decagon Devices, Inc.

©2008-2011 Decagon Devices, Inc.

All rights reserved.

Page 3

KD2 Pro Operator’s Manual

Table of Contents

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . 1

About the KD2 Pro . . . . . . . . . . . . . . . . . . . . . . . . . 1

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . 2

Seller’s Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Repair Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Repair Costs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. KD2 Pro Overview . . . . . . . . . . . . . . . . . . . 4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Choosing a Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installing the Sensors . . . . . . . . . . . . . . . . . . . . . . . 13

Measurements In Concrete. . . . . . . . . . . . . . . . . . . 14

Measurements In Insulation . . . . . . . . . . . . . . . . . . 14

3. The Menus . . . . . . . . . . . . . . . . . . . . . . . . 15

The Main Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Taking a Measurement . . . . . . . . . . . . . . . . . . . . . . 16

The Data Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

The Configuration Menu . . . . . . . . . . . . . . . . . . . . 21

The Auto Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4. The KD2 Pro Utility. . . . . . . . . . . . . . . . . 27

System Requirements . . . . . . . . . . . . . . . . . . . . . . . 27

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

How Saved Data Are Organized . . . . . . . . . . . . . . 30

Erasing Your Data. . . . . . . . . . . . . . . . . . . . . . . . . . 32

i

Page 4

KD2 Pro Operator’s Manual

Table of Contents

Setting the Date and Time. . . . . . . . . . . . . . . . . . . .32

Setting the Auto Mode . . . . . . . . . . . . . . . . . . . . . .33

Viewing KD2 Pro Information. . . . . . . . . . . . . . . . 36

The Menus and Their Functions. . . . . . . . . . . . . . .36

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5. Good Practices . . . . . . . . . . . . . . . . . . . . .43

6. Measuring Liquids. . . . . . . . . . . . . . . . . .46

Liquid Sample Temperature Control . . . . . . . . . . . 48

7. Care and Maintenance . . . . . . . . . . . . . . .50

Cleaning & Caring for the Sensors . . . . . . . . . . . . .50

Changing the Batteries. . . . . . . . . . . . . . . . . . . . . . .50

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Verifying Sensor Performance . . . . . . . . . . . . . . . .51

8. KD2 Pro Theory . . . . . . . . . . . . . . . . . . . .54

Further Reading . . . . . . . . . . . . . . . . . . . . . .60

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . .61

Table of Thermal Units . . . . . . . . . . . . . . . . . . . . . .61

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . .62

Send Feedback to Decagon. . . . . . . . . . . . . . . . . . .62

KD2 Pro CE Compliance . . . . . . . . . . . . . . .63

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

ii

Page 5

KD2 Pro Operator’s Manual

1. Introduction

1. Introduction

Welcome to your new KD2 Pro Thermal Properties Analyzer.

This guide is designed to help you understand and use your

instrument to the best of its capability.

About the KD2 Pro

The KD2 Pro is a handheld device used to measure thermal

properties. It consists of a handheld controller and sensors that

can be inserted into the medium you wish to measure. The single-needle sensors measure thermal conductivity and resistivity;

while the dual-needle sensor also measures volumetric specific

heat capacity and diffusivity. Further details about the measurements and how they’re made are given in chapters 2 and 3 of

this guide.

Customer Support

If you ever need assistance with your KD2 Pro, or if you just

have questions or feedback, there are several ways to contact

us. Customer service representatives are available to speak

with you Monday thru Friday, between 8am and 5pm Pacific

time.

Phone:

1-800-755-2751 (Toll free to customers in US and Canada)

1-509-332-2756 (for international customers)

Fax:

1-509-332-5158

E-mail:

support@decagon.com or sales@decagon.com

1

Page 6

KD2 Pro Operator’s Manual

1. Introduction

If contacting us by email or fax, please include as part of your

message your instrument’s serial number, your name, address,

phone, and fax number.

NOTE: If you purchased your KD2 Pro through a distributor, please contact them for assistance.

Warranty Information

The KD2 Pro has a 30-day satisfaction guarantee and a oneyear warranty.

Seller’s Liability

Seller warrants new equipment of its own manufacture against

defective workmanship and materials for a period of one year

from date of receipt of equipment (the results of ordinary wear

and tear, neglect, misuse, accident and excessive deterioration

due to corrosion from any cause are not to be considered a

defect); but Seller’s liability for defective parts shall in no event

exceed the furnishing of replacement parts F.O.B. the factory

where originally manufactured. Material and equipment covered hereby which is not manufactured by Seller shall be covered only by the warranty of its manufacturer. Seller shall not be

liable to Buyer for loss, damage or injuries to persons (including

death), or to property or things of whatsoever kind (including,

but not without limitation, loss of anticipated profits), occasioned by or arising out of the installation, operation, use, misuse, non-use, repair, or replacement of said material and

equipment, or out of the use of any method or process for

which the same may be employed. The use of this equipment

constitutes Buyer’s acceptance of the terms set forth in this

warranty. There are no understandings, representations, or warranties of any kind, express, implied, statutory or otherwise

(including, but without limitation, the implied warranties of

2

Page 7

KD2 Pro Operator’s Manual

1. Introduction

merchantability and fitness for a particular purpose), not

expressly set forth herein.

Repair Instructions

If your KD2 Pro should ever require a repair, call Decagon at

(509) 332-2756 or 1-800-755-2751 (United States and Canada). We will ask you for your address, phone number, your

KD2 Pro’s serial number, and your current firmware version.

For non-warranty repairs, we will also ask for a method of

payment.

Before shipping your instrument to Decagon, please

contact Decagon to obtain a Request Maintenance

Authorization Number (RMA). This will allow Decagon’s

repair staff to keep track of your KD2 Pro. Once you have

acquired an RMA, send your KD2 Pro to Decagon. Please

include a document listing the complete shipping address,

name, and department of the person responsible for the

instrument, as well as a description of the problem. This will

better help our technicians and shipping department to expedite repair on your KD2 Pro, and ship it back to you.

Please pack your KD2 Pro carefully. Ship it back in the carrying case, preferably inside a cardboard box. Ship to:

Decagon Devices Inc.

2365 NE Hopkins Court

Pullman, WA 99163

Repair Costs

Manufacturer’s defects and instruments under warranty will be

repaired at no cost. For non-warranty repairs, costs for parts,

labor, and shipping will be billed to you.

3

Page 8

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

2. KD2 Pro Overview

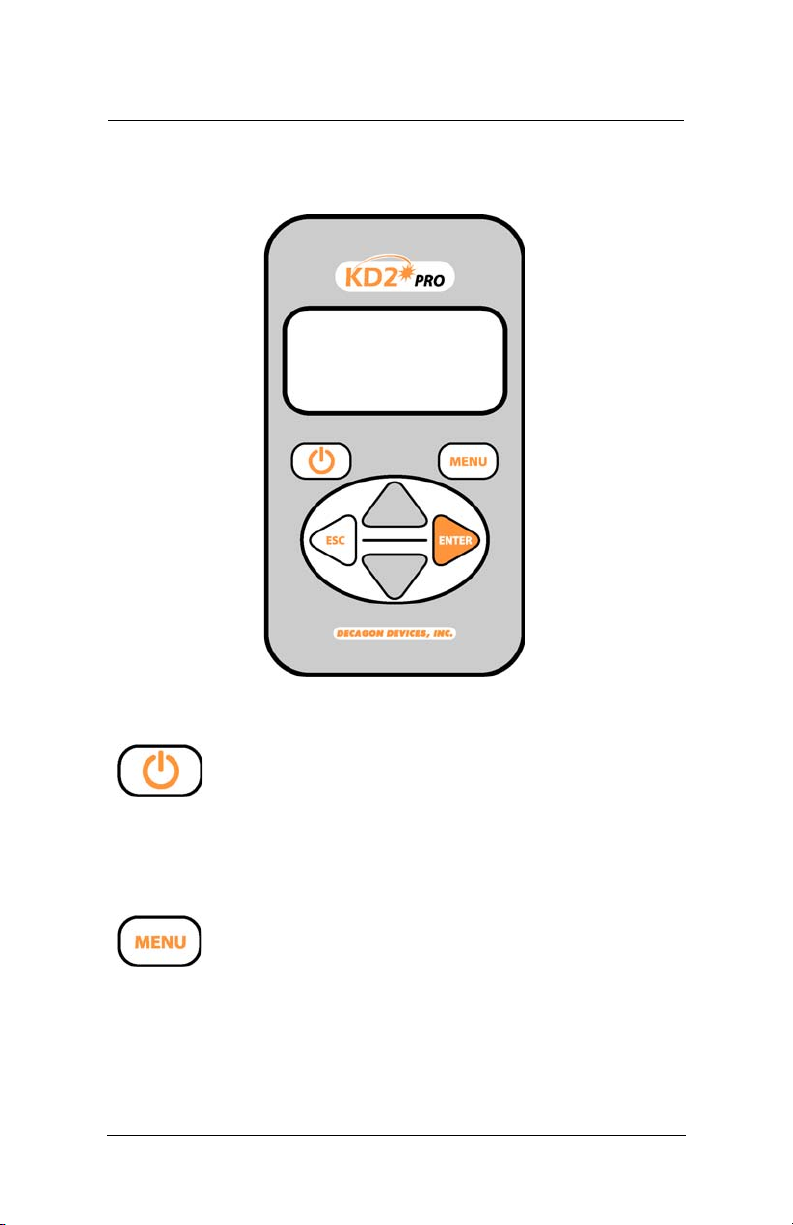

The KD2 Pro is a battery-operated, menu-driven device that

measures thermal conductivity and resistivity, volumetric specific heat capacity and thermal diffusivity. The KD2 Pro has

been designed for ease of use and maximum functionality.

Specifications

Operating Environment:

Controller: 0 to 50 °C

Sensors: -50 to +150 °C

Power: 4 AA cells

Battery Life: At least 500 readings in constant use or 3 years

with no use (battery drain in sleep mode < 50 uA)

Case Size: 15.5 cm x 9.5 cm x 3.5 cm

Display: 3 cm x 6 cm, 128 x 64 pixel graphics LCD

Keypad: 6 key, sealed membrane

Data Storage: 4095 measurements in flash memory (both

raw and processed data are stored for download)

Interface: 9-pin serial

Read Modes: Manual and Auto Read

4

Page 9

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

Sensors:

60 mm (small) single-needle (KS-1):

Size: 1.3 mm diameter x 60 mm long

Range: 0.02 to 2.00 W/(m· K) (thermal conductivity)

50 to 5000 °C·cm/W (thermal resistivity)

Accuracy (Conductivity): ± 5% from 0.2 - 2 W/(m· K)

±0.01 W/(m· K) from 0.02 - 0.2 W/(m· K)

Cable length: 0.8 m

100 mm (large) single-needle (TR-1):

Size: 2.4 mm diameter x 100 mm long

Range: 0.10 to 4.00 W/(m· K) (thermal conductivity)

25 to 1000 °C·cm/W (thermal resistivity)

Accuracy (Conductivity): ±10% from 0.2 - 4 W/(m· K)

±0.02 W/(m· K) from 0.1 - 0.2 W/(m· K)

Cable length: 0.8 m

30 mm dual-needle (SH-1):

Size: 1.3 mm diameter x 30 mm long, 6 mm spacing

Range: 0.02 to 2.00 W /(m· K) (thermal conductivity)

50 to 5000 °C·cm/W (thermal resistivity)

0.1 to 1 mm2/s (diffusivity)

3

0.5 to 4 mJ/(m

K) (volumetric specific heat)

Accuracy: (Conductivity) ± 10% from 0.2 - 2 W/(m· K)

±0.01 W/(m· K) from 0.02 - 0.2 W/(m· K)

(Diffusivity) ±10% at conductivities above

0.1 W/(m· K)

(Volumetric Specific Heat) ±10% at conductivi-

ties above 0.1 W/(m· K)

Cable length: 0.8 m

5

Page 10

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

Keypad Operation

POWER: Located to the left below the screen,

this key activates and deactivates the KD2 Pro.

(Note: The device will automatically turn off if

not used for more than 10 minutes, except while running in

Auto Mode.)

MENU: Located to the right below the screen,

this key cycles between the menus at the top of

the screen.

6

Page 11

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

ARROW KEYS: Located in the center of the

keypad, these keys navigate within menus and

sub-menus, and modify different settings in sub-

menus. Holding down an arrow key allows you to

scroll between different options quickly.

ESCAPE: This key backs out of sub-menus and

can be used to cancel certain actions (see “Erase,”

in “Data Menu,” Chapter 2).

ENTER: This key is used to make selections

within menus and sub-menus, and also begins

taking measurements (see “Making a Measure-

ment,” “Main Menu,” below).

Choosing a Sensor

The KD2 Pro comes with three separate sensors, each of

which is designed for measurements in specific sample types.

KS-1

The small (60 mm long, 1.3 mm diameter) single needle KS-1

sensor measures thermal conductivity and thermal resistivity. It

is designed primarily for liquid samples and insulating materials

(thermal conductivity < 0.1 W (W/m· K)). The KS-1 sensor

applies a very small amount of heat to the needle which helps to

prevent free convection in liquid samples (see Chapter 6 in this

manual regarding measurement in liquid samples for more information). However, the small size of the needle and typically

short heating time make the KS-1 a poor choice for granular

samples such as soil and powders where contact resistance can

be an important source of error. In insulating materials, the

7

Page 12

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

errors from contact resistance become negligible making the KS1 sensor a good choice.

TR-1

The large (100 mm long, 2.4 mm diameter) single needle TR-1

sensor measures thermal conductivity and thermal resistivity.

It is designed primarily for soil, concrete, rock, and other granular or solid materials. The relatively large diameter and typically longer heating time of the TR-1 sensor minimize errors

from contact resistance in granular samples or solid samples

with pilot holes. The TR-1 needle heats the sample significantly more than the KS-1 sensor, which allows it to measure

higher thermal conductivity samples (see specifications), but

means that you

TR-1 sensor

should not measure liquid samples with the

. The large diameter of the TR-1 is more robust

than the KS-1, meaning that it is less likely to be damaged by

normal usage conditions in soil or other solid materials. Additionally, the dimensions of the TR-1 sensor conform to the

specifications for the Lab Probe called out by the IEEE 442-03

Guide for Soil Thermal Resistivity Measurements.

SH-1

The dual needle SH-1 sensor measures volumetric heat capacity, thermal diffusivity, thermal conductivity, and thermal resistivity. The SH-1 is compatible with most solid and granular

materials, but should not be used in liquids due to the

large heat pulse and possible resulting free convection in liquid samples.

Read Time

The read time is the time, in minutes, during which data are

taken to compute thermal properties. Heat is applied for half

of the time, and measurements are taken over the full time.

8

Page 13

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

Thirty seconds are allowed for temperature equilibration

before heating starts, so the entire time for a measurement is

the time set here plus 30 seconds. Sixty temperature readings

are taken during the read time, so the number entered here is

also the number of seconds between temperature readings.

This number is displayed in the upper right corner of the

screen, and is available with each data record after downloading. Default read times are 1 minute for the KS-1 sensor, 2

minutes for the SH-1 sensor and 5 minutes for the TR-1 sensor.

The longer read time for the TR-1 sensor helps to prevent

errors caused by effects of the large diameter needle and contact resistance between the sensor and the sample in granular

and solid materials. If you wish to measure thermal properties

of a sample with large grains or of a solid sample with a pilot

hole that is significantly larger in diameter than the sensor, it is

best to use the TR-1 needle and configure the read time to the

maximum allowed 10 minutes.

The shorter read time for the KS-1 sensor reduces the amount

of heat input into the sample. This is especially important

with liquid samples where excessive sample heating can cause

errors from free convection (see section on measuring liquid

samples for more details). In low viscosity samples (e.g. water

and aqueous solutions), the KS-1 read time should be configured to the minimum allowed 1 minute.

To set the read time, go to the Read Time menu selection and

press Enter. Arrow down to the probe for which you want to

set the read time and press Enter, Arrow up or down to the

read time you want and press Enter.

9

Page 14

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

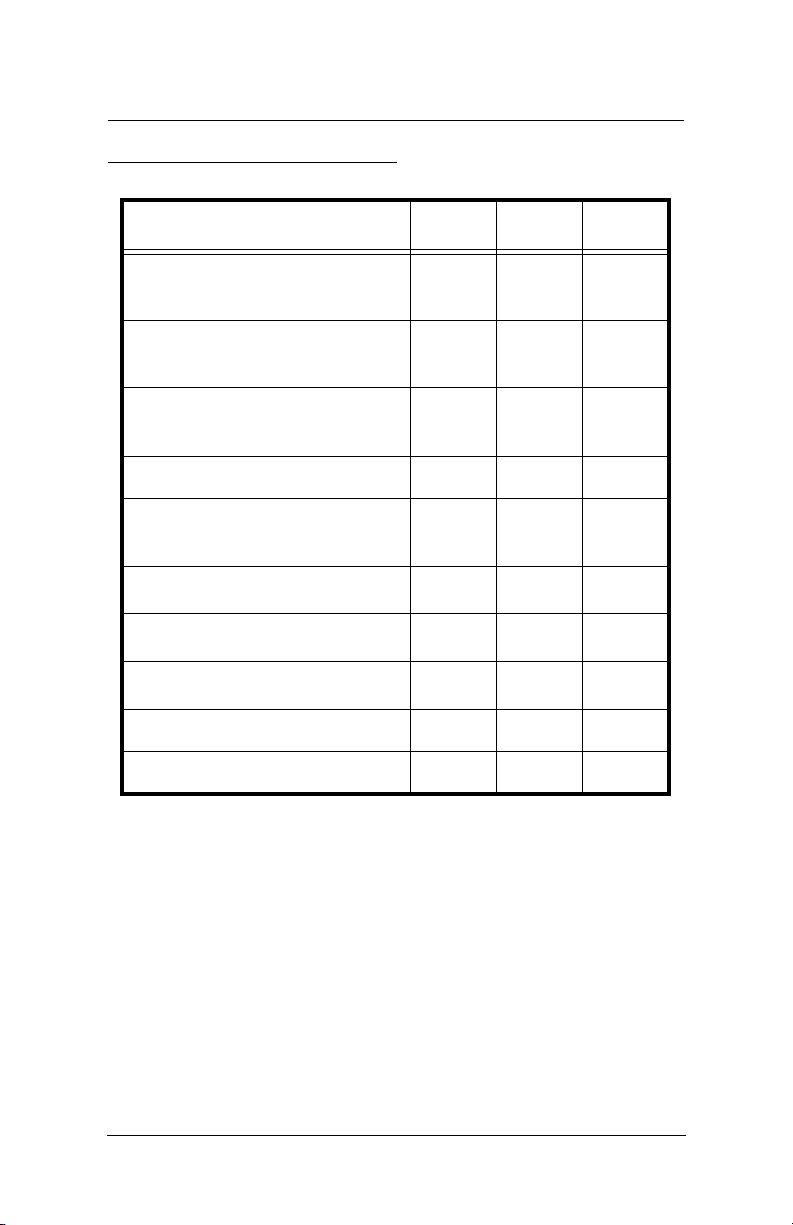

KD2 Pro Sensor Compatibility

Sample Material KS-1 TR-1 SH-1

Low viscosityliquids

Best

1

No No

(e.g. water)

High viscosity liquids

Best

2

Ok

2

No

(e.g. glycerol, oil)

3

Insulation and insulating

Best

Ok Ok

materials

Moist soil No Best Ok

4

Dry soil, powders, granu-

No

Best

Ok

lar materials

Concrete No

Rock No

Other solids No

Best

Best

Best

5

5

5

Ok

Ok

Ok

6

6

Volumetric specific heat No No Best

Thermal diffusivity No No Best

1

In low viscosity liquids, the read time should be set to the

minimum allowed 1 minute and should only be used in low

power mode to avoid free convection.

2

In high viscosity liquids, the KS-1 or TR-1 sensor should

only be used in low power mode.

3

The KS-1 or TR-1 needles in low power mode with 10 min

read time give good results with insulation. Heater temperatures with high power mode are quite high for insulation measurements.

10

Page 15

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

4

In dry granular materials where contact resistance can be significant, extending the read time to the maximum allowed 10

minutes will produce the most accurate results.

5

In solid materials where a pilot hole has been drilled and

contact resistance can be significant, using thermal grease and

extending the read time to the maximum allowed 10 minutes

will produce the most accurate results.

6

The SH-1 sensor will take accurate measurements in rock

and cured concrete, but it is very difficult to drill small diameter, parallel holes in these materials to accommodate the SH-1

needles.

Power Mode

With the KD2 Pro, you have the ability to configure the

device to measure each of the three sensor types in either high

power mode or low power mode. In high power mode, the

KD2 Pro applies a relatively large heating current to the sensor during a measurement resulting in greater sensor heating.

In low power mode, the KD2 Pro applies a small current to

the sensor resulting in less heating of the sensor. The KS-1

sensor defaults to low power mode, while the TR-1 and SH-1

needles both default to high power mode. We recommend

that the power mode only be changed from the default settings for special measurements by expert users. In all but a

few cases, changing the power mode from the default settings

will result in poorer accuracy than can be expected in the

default power mode. Do not change the power mode from

the default settings unless you are an expert user and are making a specialized measurement. Feel free to contact Decagon

to discuss specifics of your measurement before changing

from the default power mode setting. More specific comments regarding power mode adjustment include:

11

Page 16

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

• Do NOT attempt to make measurements in liquids with

the KS-1 or TR-1 in high power mode. The additional

heating from the higher heat input will cause free convection and compromise the measurement (see Chapter

6 for more information on free convection).

• Do not attempt to make measurements in low viscosity

fluids with the SH-1 (dual needle) sensor in either high

power or low power mode.

• One motivation behind allowing power mode configuration is to allow the TR-1 and SH-1 sensors to make better measurements in frozen materials where the

decreased heat input in low power mode is less likely to

cause phase change (melting) of the frozen sample.

One situation where we do recommend a non-default

power mode setting is the measurement of thermal conductivity of snow. In this case, we recommend using the

TR-1 needle to reduce issues with contact resistance,

and we recommend configuring the sensor to low

power mode to reduce issues with melting.

Installing the Sensors

The KD2 Pro’s three sensors have been designed for ease of

installation and use. The following considerations should be

observed when installing the sensors.

• The sensor should be inserted all the way into the

medium to be measured.

• For the single-needle 10cm sensor, a drill bit has been

included that can be used to drill a pilot hole in material

such as wood or hard soil. For rock (or cured concrete),

a 1/8” hole can be drilled with a rotohammer and filled

12

Page 17

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

with thermal grease to provide optimal contact between

the needle and the rock.

• For the dual-needle sensor, the needles must remain

parallel to each other during insertion to make an

accurate reading. Therefore, take care in tough material,

which can splay the prongs and adversely affect readings. Use the provided red tab with pilot holes to make

sure that the needles have the correct spacing.

• Because the sensors give off a heat pulse, you must

allow a minimum of 1.5 cm of material parallel to the

sensor in all directions, or errors will occur.

• DO NOT BEND THE NEEDLES, as this can damage the sensor beyond repair. If the needle becomes

bent, do not bend it back; contact Decagon for a

replacement.

• Good thermal contact between the sensors and the

medium being measured is critical for accurate measurements if a hole is drilled for sensor insertion. Make

sure that the sensor fits tightly into the hole. Use the

thermal grease included with your KD2 Pro to improve

contact in larger holes or grainy samples.

Measurements In Concrete

If the KD2 Pro is to be used for measurements in concrete, it

is preferrable to mold pilot holes in wet concrete using the

pilot pins furnished with your KD2 Pro using the following

procedure.

• Coat pilot pin with vaseline.

• Install pin at least 100mm deep while concrete is wet.

• Remove pin when concrete has dried.

• Coat the single 10cm sensor with thermal grease, insert

sensor into the cast hole and begin to take readings.

13

Page 18

KD2 Pro Operator’s Manual

2. KD2 Pro Overview

If measurements need to be made in concrete that has already

been cured, holes can be drilled into the sample using the procedure outlined above in the section titled “Installing the Sensors.”

Measurements In Insulation

Insulation measurements are best made with the KS-1 probe

using a 10 minute read time. The long read time minimizes

contact resistance errors, and the low heat of the KS-1 needle

reduces free convection errors. In foam insulation a hole

should be drilled for the probe. Simply pushing in the needle

can cause the insulation to bunch in front of the needle tip

resulting in a poor fit and a consequently a faulty reading. In

fiber type insulation materials, assure that the insulating materials are not unduly disturbed by the needle insertion. (i.e.

pushed in front of the needle tip). Do not allow the probe to

move during the measurement.

14

Page 19

KD2 Pro Operator’s Manual

1

2

4

5

7

6

8

3

3. The Menus

3. The Menus

The KD2 Pro features four main menus: MAIN, DATA,

CONFIG, and AUTO (respectively). These menus access the

KD2 Pro’s features, and have been designed for ease of use.

Here is a more detailed description of each menu.

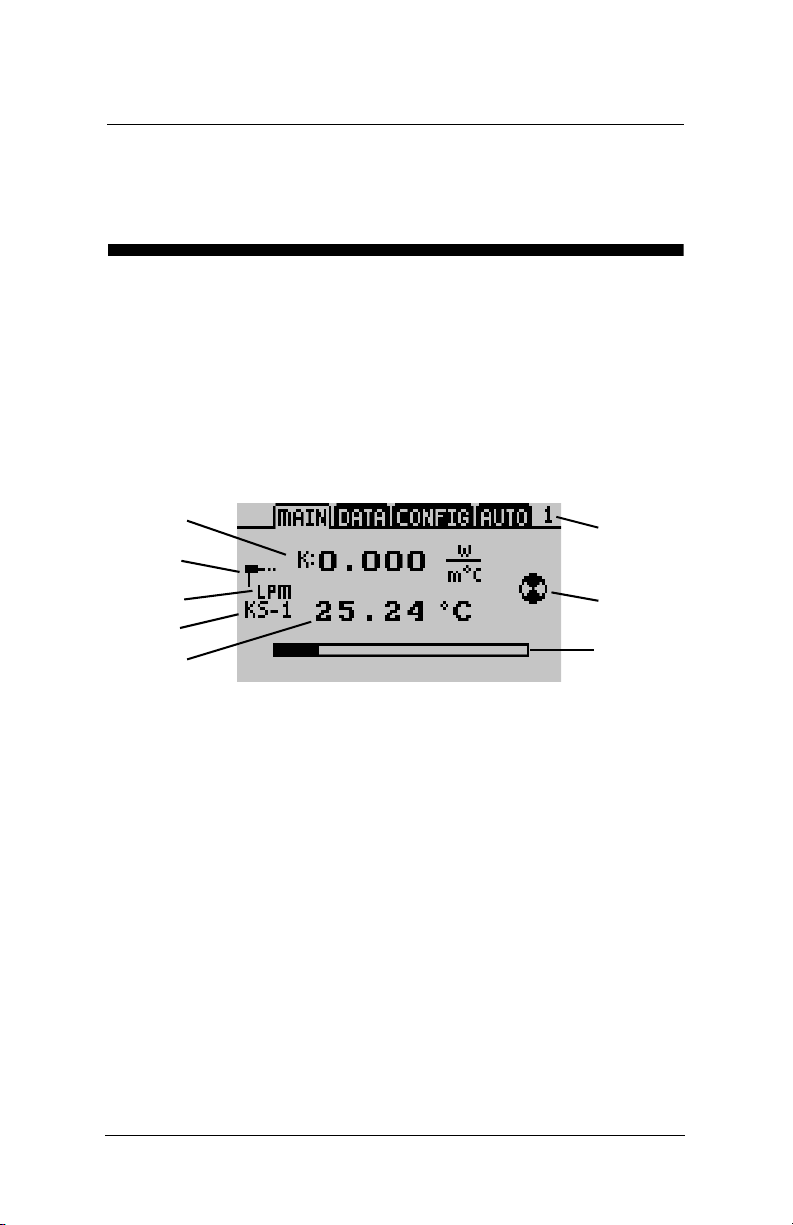

The Main Menu

The Main Menu is responsible for taking measurements from

whatever medium a sensor is inserted into.

What you see:

1. The thermal property reading and the currently selected

unit. The type of reading is indicated by the letter to the

left of the reading:

K = thermal conductivity

C = specific heat capacity

D = thermal diffusivity

rho = thermal resistivity

NOTE: When the spinner icon is visible, press the arrow keys to

scroll through and change the current unit and measurement type.

15

Page 20

KD2 Pro Operator’s Manual

3. The Menus

2. Icon showing connected sensor type.

3. Indicator for high power mode (HPM) or low power

mode (LPM).

4. The currently connected sensor type and sensor name.

5. The measurement temperature in °C or °F.

6. Indicates the length of the reading in minutes

7. Indicates the status of a reading.

8. Progress bar that displays elapsed time.

The purpose of the Main Menu is to take measurements. The

next section will explain how to do this.

Taking a Measurement

It is easy to take measurements with the KD2 Pro. Do the following to make a measurement:

NOTE: If the temperature of the sample is different from

the temperature of the needle, the needle must equilibrate

to the surrounding temperature before beginning a reading.

1. Attach appropriate sensor then turn on the KD2 Pro.

2. Properly insert the sensor into the material to be measured. (See “Installing the sensors” in this chapter for

instructions.)

16

Page 21

KD2 Pro Operator’s Manual

3. The Menus

3. When the KD2 Pro turns on, you should be in the Main

Menu. If not, press the Menu key until you arrive there.

Press Enter to begin the measurement.

4. An icon will appear on the left and right side of the screen.

The icon at left indicates the type of sensor connected.

The circular icon indicates that a reading is underway. It

will change to a thermometer icon to indicate whether the

measurement is currently in heating or cooling mode;

when the thermometer is rising, heat is applied to the needle, and when it is falling, heat is off. A progress bar shows

the elapsed time.

5. When the progress bar has fully darkened, the results are

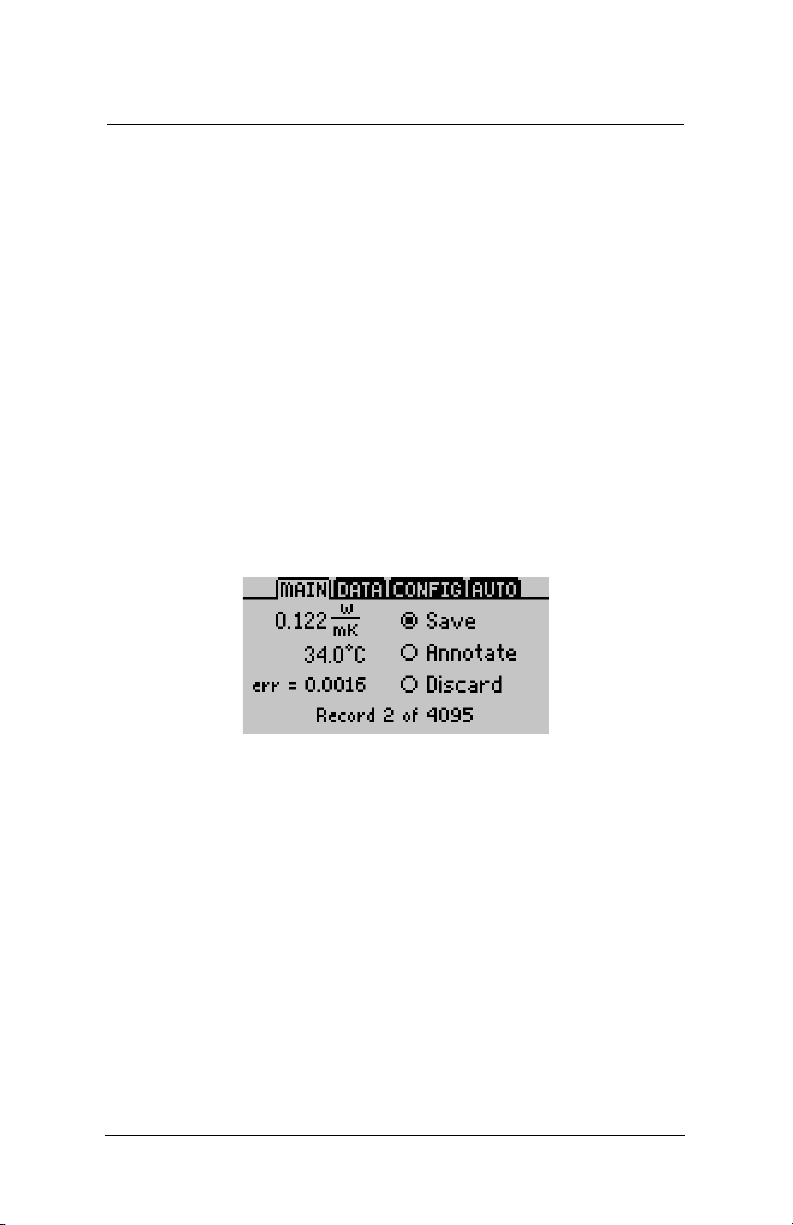

displayed as follows:

On the left side of the screen are three measured

values:

• Thermal Properties Reading - The calculated thermal

measurement.

• Starting Temperature - The initial tempera- ture prior

to any heating or cooling.

•

Err Value-

The err value is the relative goodness of fit or

relative error for the data set. It is a measure of how well

the model fits the data (the Theory chapter of this manual describes the model that is fit to the data). If the

model fits the data perfectly, then err = 0.0000. The pur-

17

Page 22

KD2 Pro Operator’s Manual

3. The Menus

pose of displaying this reading is to indicate possible

problems with the data. A good data set will give err values below 0.0100, except at very low thermal conductivity (e.g. insulation materials). If the err value is unusually

large, discard the data, wait fifteen minutes and take

another reading.

On the right side of the screen are three save options:

• Save - You can save your reading as is;

• Annotate - You can attach a sample ID to your reading;

• Discard - Cancel the current reading and return to the

main screen.

NOTE: If the data memory is full or the sample temperature was unstable during a reading, an error message is

displayed at the bottom of the screen. If this should happen, you may still take readings but you will be unable to

save them to the KD2 Pro.

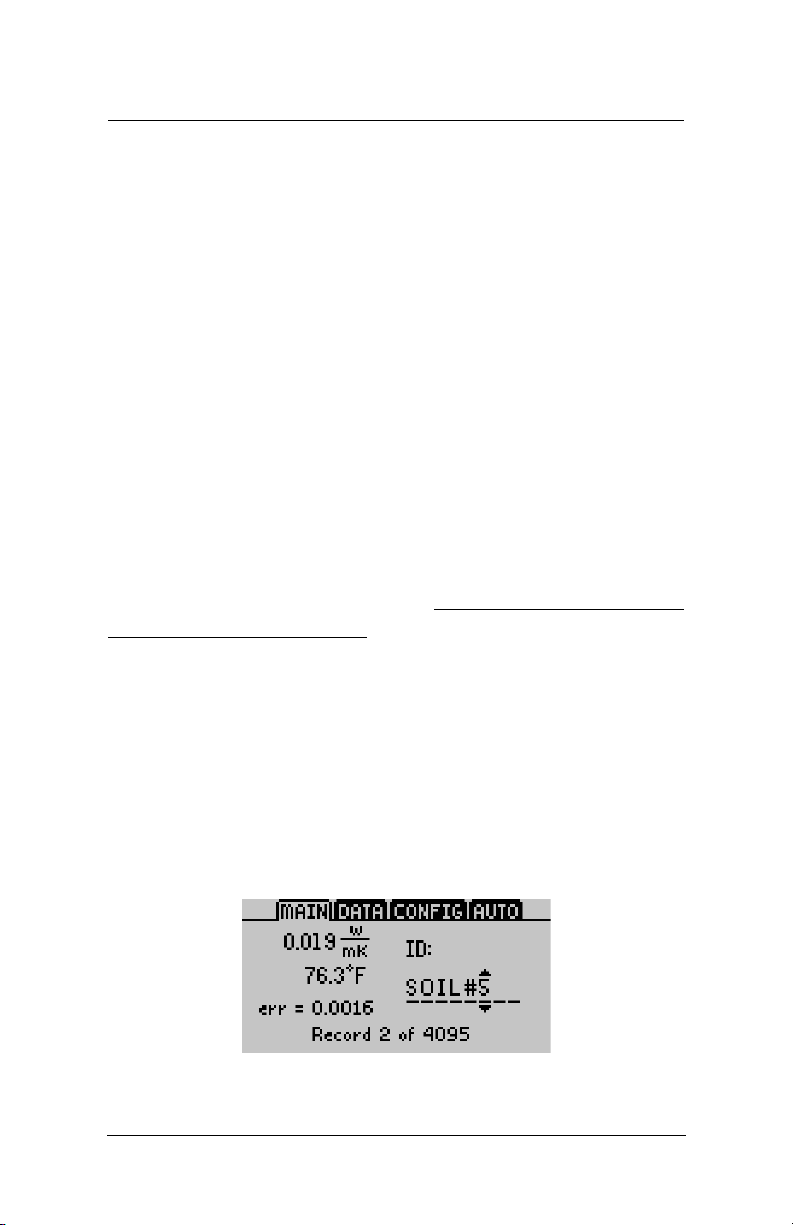

How to annotate a reading: When you select the “Anno-

tate” option, you will see a series of lines with an arrow above

and below the first position. Use the up and down arrow keys

to select a letter or number and press Enter to move to the

next character (as shown below). If you have annotated a previous reading, the old annotation will remain to be modified

or deleted.

18

Page 23

KD2 Pro Operator’s Manual

3. The Menus

Repeat this until you reach the last character. When finished,

simply continue to press Enter until you reach the end of the

row. Holding Enter or Escape will allow you to scroll left and

right through the Sample ID quickly.

NOTE: It is important to wait for about fifteen minutes

between readings, if the sensor is left in the same location! If multiple measurements of a sample are made too rap-

idly in succession, the sample’s temperature will not have had

enough time to equilibrate from the previous reading, and the

resulting measurement will be inaccurate. For best results, the

sample should be as close to equilibrium as possible. A good

environment for equilibration can be provided by placing the

KD2 Pro sensor and sample in an isothermal chamber or styrofoam box.

The Data Menu

The Data Menu allows you to view stored data, download data

to a computer, and erase the data from your KD2 Pro. It also

displays how many readings have been recorded out of the

total 4,095 that can be stored.

Here is description of each sub-menu:

VIEW: This menu allows you to view all data currently stored

on your KD2 Pro. Press Enter to access the readings, and use

19

Page 24

KD2 Pro Operator’s Manual

3. The Menus

the arrow keys to scroll through them. By pressing Enter a

second time, you can see more detail about a reading.

DOWNLOAD: This menu sends the data saved in the KD2

Pro to your computer. You have two download options:

• Download All - This downloads the temperature read-

ings as well as the measured thermal properties.

• Download Summary - This downloads just the mea-

sured thermal properties.

NOTE: Your KD2 Pro comes with KD2 Pro Utility software

for use with Microsoft Windows. The Utility makes downloading data to your computer very easy. In general, you

should use the KD2 Pro Utility to download data instead of

the download option on the KD2 Pro.

If you are unable to use the KD2 Pro Utility, you can use terminal software to transfer the data from your KD2 Pro to

your computer. The following steps should apply to most terminal software programs:

1. Configure your terminal software with the following settings:

• 9600 baud

• 8 data bits, 1 stop bit, no parity

• No software/hardware flow control

• Append line feeds to incoming line ends

• Echo typed characters locally.

2. Connect your KD2 Pro to an available serial port on your

computer using the included RS-232 serial cable.

3. Set your terminal software to capture received data if you

want to save the data.

20

Page 25

KD2 Pro Operator’s Manual

3. The Menus

4. Select the appropriate option from the Download menu in

the KD2 Pro.

ERASE: This will erase all stored data on your KD2 Pro.

WARNING! This feature will completely erase all data

on your KD2 Pro, and once activated, it cannot be

undone!

To erase data:

1. Press Enter to select the Erase sub-menu. The screen

“Erase all stored data?” will appear.

2. Press Enter again to erase the memory or Escape if you

decide not to continue. “Erasing...” will be displayed as

data is being removed, which usually takes about 6 seconds.

3. When this is complete, you will be returned to the Data

Menu.

The Configuration Menu

The Configuration Menu allows you to change system settings

such as the date, time, measurement units, and also view information about your KD2 Pro. A battery icon will also display

the remaining percentage of battery power. A description of

each sub-menu follows.

21

Page 26

KD2 Pro Operator’s Manual

3. The Menus

DATE: To change the current date,

1. Press Enter to select the date display.

2. The current date will appear in the center of the screen, in

day/month/year format. A pair of arrows will be present

above and below the first number.

3. Use the up & down arrow keys to change this number.

4. Press Enter to move to the next number, and repeat step

#3. If you need to return to the previous number, press

Escape.

5. When you have finished changing the last number, press

Enter and you will be returned to the Configuration

Menu.

TIME: To change the current time,

1. Press Enter to select the Time display.

2. The current time will appear in the center of the screen, in

24-hour format. A pair of arrows will be present above

and below the first number.

3. Use the up & down arrow keys to change this number.

22

Page 27

KD2 Pro Operator’s Manual

SI and English Unit Equivalents

Thermal

Conductivity

(K)

Thermal

Resistivity

()

Volu me tr ic

specific heat

(C)

Thermal

Diffusivity

(D)

SI W

(m· K)

°C · cm

W

MJ

(m

3

· K)

mm

2

s

English BTU

hr· ft °F

hr· ft °F

BTU

BTU

°F· ft

3

ft

2

hr

3. The Menus

4. Press Enter to move to the next number, and repeat step

#3. If you need to return to the previous number, press

Escape.

5. When you have finished changing the last number, press

Enter and you will be returned to the Configuration

Menu.

UNITS: You can choose to represent measurement data in

either SI or English units. Press Enter to select an option.

When you return to the Main Menu, pressing the arrow keys

allows you to scroll through and change the current unit and

measurement type.

NOTE:

(m °C) are the same as readings in watts per meters

Kelvin (W/m· K), as Celsius and Kelvin degrees are on

the same temperature scale.

READ TIME: Allows you to change the read time duration

for each sensor type. To change a read time select the sensor

and press enter. Using the up/down arrows to select the new

read time. Press enter to save the changes or ESC to cancel

Readings in watts per meters-degree Celsius W/

23

Page 28

KD2 Pro Operator’s Manual

3. The Menus

with out saving the changes. For more information refer to

the read time section in chapter 2.

POWER MODE: Allows you to change the power mode to

be used for each sensor type. Do not change the power

mode from the default settings unless you are an expert

user and are making a specialized measurement. To

change the power mode, select the sensor and press enter to

toggle between high and low power mode. Press ESC or

MENU to accept the changes and exit the power mode menu.

For more information on situations where you might want to

change from the default power mode, see the Power Mode

section in Chapter 2.

CONTRAST: Allows you to change the screen contrast level.

Press Enter and follow the on-screen instructions to modify

the contrast.

24

Page 29

KD2 Pro Operator’s Manual

1

7

2

5

8

9

10

6

3

4

3. The Menus

ABOUT: Displays the serial number and firmware version of

your KD2 Pro.

The Auto Mode

The Auto Mode allows you to set up the KD2 Pro to take

readings automatically. You can select a measurement time in

intervals of 15 minutes. The reading will be taken in the currently selected units from the Main Menu, and will begin as

soon as you select this option. NOTE: Should the KD2 Pro’s

data memory ever become full (4,095 readings), you may still

take readings, but you cannot save them until you erase the

stored readings.

25

Page 30

KD2 Pro Operator’s Manual

3. The Menus

What you see:

1. Final measurement displayed in the selected units.

2. Icon showing connected sensor type.

3. Indicator for high power mode (HPM) or low power

mode (LPM).

4. Currently connected sensor type.

5. Measurement temperature in °C or ºF.

6. Indicates the length of the reading in minutes

7. Measurement interval. This time interval can be set either

in the CONFIG menu or in the KD2 Pro Utility. NOTE:

When the spinner icon is visible, press the arrow keys to

change the interval time.

8. Hourglass icon indicating that time is elapsing until the

next measurement.

9. Number of readings taken.

10. The err value of your data (see description of err value in

the “Main Menu” section of this chapter for more details).

NOTE: The KD2 Pro Utility gives you more options to

control how Auto Mode operates, including different time

intervals, delayed start times, and others. Refer to the

next chapter for more information.

26

Page 31

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

4. The KD2 Pro Utility

KD2 Pro Utility main screen

The KD2 Pro Utility is a program designed specifically for

interfacing with the KD2 Pro. Use this program to download

measurement data to your computer, erase measurement data

stored in the KD2 Pro, set the date and time, configure the

KD2 Pro to take readings automatically, and see information

about your KD2 Pro.

System Requirements

To use the KD2 Pro Utility, your computer must meet the following minimum system requirements:

27

Page 32

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

• Microsoft Windows 98 or NT 4 (SP 5) or better

• Intel Pentium Pro or better processor

• One available serial port or one available USB port (most

models of USB-to-serial adapters supported)

• Microsoft Excel 97 or better (for saving data as .xls files)

Installation

You can install the KD2 Pro Utility using the included CDROM (found in the inside cover of the KD2 Pro Operator’s

Manual). You can also download and install the latest version

of the Utility on Decagon’s download section of www.decagon.com.

Downloading Data

This will transfer all saved measurement data on the KD2 Pro

to your computer. Do the following:

1. Make sure the RS-232 cable is connected to the KD2 Pro,

and to a COM port on your computer.

2. Open the KD2 Pro Utility.

3. Choose the appropriate serial communication (COM) port

from the “Use computer communication port” control on

the main screen.

4. Click the “Download” button in the lower right-hand corner. You can also go to the File Menu, and select one of

two options:

1) Download Summary Data - Downloads and summarizes

the data readings, but does not display per-second readings.

2) Download All Data - Downloads all data currently stored

in the KD2 Pro’s memory. It displays complete data for

28

Page 33

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

each measurement, including per-second readings.

If you encounter an error message after clicking this

button, please refer to the Troubleshooting section

for instructions.

Name your data file, select where it will be saved to, and in

what format. You may choose between the fol-lowing formats:

• Microsoft Excel Workbook (*.xls);

• Comma delimited (*.csv);

• Tab delimited (*.txt);

• Raw data (also *.txt)

5. Click “Save” to download your data to the specified location. The progress bar shows the status of the download

process:

KD2 Pro download dialog

NOTE: You can cancel a download in progress using the

cancel button. If you cancel, no downloaded data are saved.

29

Page 34

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

How Saved Data Are Organized

Measurement Data from the KD2 Pro is saved in the same

basic format regardless of the file format chosen. You can

choose to download just the summary data or all the measurement data which includes additional information. A description of each type of download follows.

Clicking the Download button or choosing “Download Summary Data” from the File Menu creates a file with the following columns:

• Measurement Time - Date and time when the reading

was taken.

• Sensor - The model number of the sensor used for this

reading.

• K (Thermal Conductivity) - as W/(m· k) or BTU/(hr·

ft· °F).

• rho (Thermal Resistivity) - as °C·cm/W or hr· ft· °F/

BTU.

• C (Specific Heat) - as MJ/(m3· K) or BTU/( °F· ft3).

Columns for Specific Heat and Thermal Diffusivity are

only included when the downloaded data contains measurements made with SH-1.

2

• D (Thermal Diffusivity) - as mm

/s or ft2/hr (dual-nee-

dle sensors only).

• Err- Quality of fit of the data to the KD2 Pro theoretical

model.

• Temp(0) - Initial temperature of the sample as °C or °F.

• Sample ID - If saved with the measurement.

• Read Time - as minutes from the start of heating. The

interval between readings is also Read Time (in sec).

30

Page 35

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

• Power Mode - Power mode selected during measure-

ment.

Choosing “Download All Data” from the File Menu creates a

file with all the data included in the summary file (listed above)

and adds the following columns:

• Power - as W/m.

• Current - as amps.

The next 60 columns in the row hold the individual temperature reading the KD2 Pro uses to calculate the thermal properties of the sample. The data are shown as °C or °F.

Note that the time interval between the 60 individual temperature readings is scaled according to the read time selected. For

instance, if a one minute read time has been selected, each of

the 60 temperature readings are at 1 second intervals, while a 5

minute read time produces 60 temperature readings at 5 second intervals, etc.

The KD2 Pro Utility formats measurement dates according to

the Windows Local settings found in the Control Panel under

“Regional and Language Options” (“Regional Settings” in

Windows 98). You can override this by going to the Preferences Menu > Data File tab, and selecting an option under

“Date/Time Format”. You can set this value to day/month/

year format, using a 12- or 24-hour clock. (The Preferences

Menu is explained in more detail later in this chapter.)

Erasing Your Data

This will erase all data stored on your KD2 Pro.

WARNING!

Once this feature is activated, all data will

31

Page 36

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

be permanently deleted from the KD2 Pro, and cannot

be recovered!

To erase the data, do the following:

1. Make sure that the RS-232 cable is connected to the KD2

Pro, and to a COM port on your computer.

2. Choose the appropriate COM port from the “Use computer communications port” control on the main screen

3. Click “Erase,” in the lower left-hand corner, or select

“Erase Data...” from the File Menu.

If you encounter an error message after clicking this

button, please refer to the Troubleshooting section

for instructions.

4. A progress bar shows the status of the erase process.

Setting the Date and Time

You can set the KD2 Pro’s date and time by selecting “Set

KD2 Pro Date/Time...” from the Actions Menu. This will

automatically sync the KD2 Pro’s date and time to your computer’s time.

Setting the Auto Mode

The Auto mode of the KD2 Pro allows you to perform automated, unattended measurements at specified time intervals.

The KD2 Pro has pre-set measurement intervals to select for

this mode, but you can better customize how the KD2 Pro

operates in Auto mode using the KD2 Pro Utility software.

For example, you can select specific measurement intervals,

32

Page 37

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

delayed start times, and the number of measurements from

this menu.

To configure Auto Mode with the KD2 Pro Utility:

1. Connect your KD2 Pro to an available serial communication port on your computer. Select the name of your chosen serial port in the “Use computer communication

port” control.

2. Choose “Configure Auto Mode...” from the Actions

Menu. The following screen appears:

3. Choose values for Measurement Interval, Start Time, and

Number of Measurements. Each of these values is

explained below.

33

Page 38

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

Measurement Interval

This is the time interval (in minutes) that you want the KD2

Pro to wait between measurements. The instrument must

have a minimum of 15 minutes between measurements to

allow for thermal gradients to dissipate. Therefore, you can

select any number over 15 minutes, up to 1440 minutes (24

hours).

Start Time

You can select when you want the auto measurement to begin.

You can choose start times ranging from “Start Now” to

delaying the start for 24 hours. If you select “Start Now,” you

will have about 30 seconds to connect your thermal properties

sensor to the KD2 Pro before the reading will start.

Number of Measurements

This is the total number of measurements that you want the

KD2 Pro to make while in Auto Mode. The number is

between 1 and the amount of available memory. As you

change this value, the Experiment Duration value will change.

The KD2 pro will store up to 4095 readings.

Experiment Duration

This is the total amount of time that your KD2 Pro will operate in Auto Mode, according to your measurement interval

and number of measurements selected. This gives you an idea

of how long the total Auto Mode experiment time will take.

Avai la bl e Me mo ry

This shows how much memory you have available for storing

measurements. The KD2 Pro Utility prevents you from defining an experiment that could exceed the amount of available

memory. If you reach the limit of memory storage, the KD2

Pro will stop taking measurements in Auto Mode.

34

Page 39

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

KD2 Pro Date/Time

This shows the current time in your KD2 Pro. If the time is

not correct, click the Cancel button, then choose “Set KD2

Pro Date/Time...” from the Actions Menu.

4. Click on the Start button. The KD2 Pro Utility will then

send your settings to the KD2 Pro.

5. Unplug the serial cable from the KD2 Pro, then connect

the desired thermal properties sensor to the instrument.

Your KD2 Pro is now ready to make unattended measurements as you have programmed it.

Viewing KD2 Pro Information

Choose “View KD2 Pro Information...” from the Actions

Menu to see information about your KD2 Pro:

KD2 Pro Information screen

35

Page 40

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

This displays useful info about your KD2 Pro, including its

serial number, firmware version and status, battery status, the

number of currently stored measurements, and current data

and time in the KD2 Pro’s operating system.

The Menus and Their Functions

The KD2 Pro Utility features four main menus. These allow

you to change program settings, as well as settings on the

KD2 Pro. Below is a description of each menu and their functions.

File

Download Summary Data/Download All Data. Please see the

“Download Data” section of this chapter for a description of

these options.

Erase Data...Erases all data in your KD2 Pro.

Edit

Preferences... This sub-menu modifies program settings, and settings for communicating with your KD2 Pro. It is divided into

three sections called “tabs”.

36

Page 41

1. Data File

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

Preferences - Data File tab

Measurement Units:

If you select “Use KD2 Pro Settings,” this

will save all downloaded measurement data in the units used

on the KD2 Pro. You can also choose to override the settings in the KD2 Pro and save your measurement data using

either SI (metric) or English units.

Column Headers: This option includes column headers (i.e.

“Measurement Time,” “Sample ID,” etc.) for downloaded

data.

Date/Time Format: Sets the date and time format for downloaded data files. See “How Saved Data are Organized”

for more information.

37

Page 42

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

2. Communications

Preferences - Communications tab

Command Retries: If you encounter difficulty communicat-

ing with your KD2 Pro, you can set the number of times

the computer should automatically try re-sending communications commands (up to 10).

Maximum Baud Rate: You can set the maximum baud rate

for talking to your KD2 Pro. Choose a lower baud rate if

you are not getting reliable communications from your

device.

Force Find all Communications Ports: This will detect all COM

ports on your computer, and should be used if your serialto-USB adapter does not appear in the “Use computer

communication port” control.

38

Page 43

3. Application

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

Preferences - Application tab

Automatic Internet Version Checks: If you select this option,

the KD2 Pro Utility will automatically check for a newer

version using Decagon’s internet version check engine. It

will notify you when a newer version is available when

your computer is connected to the internet. You can turn

off the automatic check by un-checking this option. You

can manually check for updates anytime using the “Check

for Utility Updates...” option in the Help Menu.

Automatic Clock Synchronization: Automatically sets the KD2

Pro’s time to your computer’s time, when you are connected to it. (See instructions above for setting this manually.)

39

Page 44

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

Error Log File: This adds more troubleshooting messages

to the error log, which can be sent to Decagon.

Actions

Set KD2 Pro Date/Time... See “Setting Date and Time” section

earlier in this chapter for more information.

Set Auto Mode. Allows you customize how the KD2 Pro operates in Auto mode using the KD2 Pro Utility software. You

can program specific time intervals and start times in this

menu. See “Setting the Auto Mode” section earlier in this

chapter for more information.

View KD2 Pro Information... Displays information about your

KD2 Pro. See “Viewing KD2 Pro Information” section earlier in this chapter for more information.

Help

Help. Accesses the KD2 Pro Utility help file, which provides

detailed information on how to use the program.

Send Feedback to Decagon

This menu item helps you send product feedback, bug

reports, or feature requests to Decagon. Your computer must

be connected to the internet for this feature to work. See

Appendix B for more information.

Check for Utility Updates... If you select this function when connected to the internet, the KD2 Pro Utility will check for a

newer version using Decagon's internet version check engine.

It will notify you if a newer version is available.

40

Page 45

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

Check for Firmware Updates... If you select this function when

connected to the internet, the KD2 Pro Utility will check for

updates for the KD2 Pro’s operating system (firmware).

About KD2 Pro Utility... Displays the current program version

and Decagon contact information.

Troubleshooting

The following descriptions should help you if you encounter

any difficulty using the KD2 Pro Utility.

PROBLEM: The KD2 Pro Utility tells me the communication port I want to use is in use by another application,

but I don’t think any other programs are running.

SOLUTION: Some PDA synchronization software monitor

serial communication ports. Disable Microsoft’s ActiveSync or

Palm’s HotSync system software while using the serial port

with the KD2 Pro Utility.

PROBLEM: My USB to Serial adapter is not showing in

the communication port picker.

SOLUTION: Enable “Force find all Communication Ports”

in Preferences by going to the Edit > Preferences, and to the

Communication tab. Enable the check box at the bottom of

the screen. Enabling this option may find other serial ports

that are not available for use by the KD2 Pro Utility (for

example, modems installed in your computer).

PROBLEM: Downloading data stops in the middle with

an error message saying the Utility lost connection with

the KD2 Pro.

41

Page 46

KD2 Pro Operator’s Manual

4. The KD2 Pro Utility

SOLUTION: A noisy serial connection can disrupt the connection between the Utility and the KD2 Pro. If this error

happens regularly, you can try setting your baud rate lower or

increasing the number of times a command is sent to the KD2

Pro. Choose the “Communications” tab in Preferences to

alter this.

42

Page 47

KD2 Pro Operator’s Manual

5. Good Practices

5. Good Practices

The quality of the measurements you get with the KD2 Pro

can be strongly affected by your experimental technique. The

following suggestions will help you to recognize and avoid pitfalls in data collection so that the data you obtain can be as

accurate as possible.

1. Keep the temperature of the sample as constant as

possible during the measurement. The measurement is

made by heating a needle that is placed in the sample and

monitoring either the temperature of that needle or a second needle adjacent to the heater. The heat input is made

as small as possible to avoid thermally driven redistribution of moisture in the sample. The temperature change

from heating may therefore be only a few tenths of a

degree. Sample temperature changes during the measurement period degrade the data and make it difficult for the

inverse calculation to find the correct values for the thermal properties. The algorithms in the KD2 Pro are several

orders of magnitude less sensitive to these errors than the

conventional approach (plotting temperature vs. log time

during heating and looking for a linear portion of the

graph) but there can still be errors if the temperature

changes too rapidly during a measurement. To minimize

these sources of error:

a. In the laboratory, allow samples and sensors to

come to temperature equilibrium before the measurement starts. Fifteen to twenty minutes is a reasonable

rule of thumb.

43

Page 48

KD2 Pro Operator’s Manual

5. Good Practices

b. Allow time between readings for temperatures to reequilibrate. Fifteen minutes between readings isn't too

much.

c. If measurements are made in an oven or a freezer,

make sure the sample temperature is relatively constant before the measurement starts. Measurements

made on a sample taken from an oven and cooling to

room temperature can show significant errors if the

cool rate is too fast.

d. When measuring thermal properties in the field,

allow a minute or so after sensor insertion for temperature equilibration.

2. Minimize contact resistance. In granular materials, or in

solids where a hole has been drilled to accommodate the

sensor, there is an additional thermal resistance between

the heated sensor and the material into which the sensor is

inserted. This extra resistance is called a contact resistance,

and it decreases the thermal conductivity value registered

by the sensor. This effect can be minimized by applying

thermal grease to the sensor prior to inserting it as

described in the Decagon Application Note “Reducing

Contact Resistance Errors in KD2 Thermal Properties

Measurements” located in the literature section of

www.decagon.com/thermal. When a hole is drilled for the

sensor, make sure the fit of the sensor in the hole is as

tight as possible. Thermal grease can be injected into the

hole to improve contact.

Long read times also decrease the effect of contact resistance.

If you are measuring a sample that might give errors from

contact resistance, increase the read time from the default to

the maximum (10 minutes) for most accurate results. Finally,

44

Page 49

KD2 Pro Operator’s Manual

5. Good Practices

dry granular materials and powders have large contact resistance. Always use the TR-1 or SH-1 sensor in these types of

materials.

Avoid convection in liquid samples. See the next chapter

for a more detailed explanation about this.

3. Don't bend the needles. Needle spacing on the dual

needle sensor is critical for accurate measurements. A 1%

change in needle spacing results in a 2% error in measurement of diffusivity and specific heat. A guide is provided

for maintaining proper needle spacing during insertion of

the sensor into a sample. The Delrin verification block

included with your system shows the correct sensor spacing. If a needle is slightly bent, it can be carefully straightened until the tip spacing matches the hole spacing in the

calibration block.

45

Page 50

KD2 Pro Operator’s Manual

6. Measuring Liquids

6. Measuring Liquids

The KD2 Pro KS-1 sensor is specifically designed to measure

thermal conductivity/resistivity of liquid samples. However,

measuring thermal properties of liquids is difficult, and great

care must be taken for accurate and repeatable results. For an

accurate measurement of thermal properties of a liquid sample, the sample must be absolutely still in relation to the KS-1

sensor. Convection, or bulk movement of the sample, will

result in error in the thermal properties measurement. Error

from convective heat exchange is often very large, rendering

the thermal properties measurement useless, and must be

avoided. Please note that the TR-1 and SH-1 sensors are

not designed for thermal properties measurement in liquids, and will not give accurate results in those materials.

Convective heat exchange in fluids can be broken down into

two categories: forced and free convection. Forced convection occurs when the fluid is agitated or mixed by mechanical

forces. Free convection may occur when a body of higher or

lower temperature is inserted into a fluid. The temperature

difference between the body and fluid creates density gradients in the fluid, and these density gradients cause the fluid to

mix. From a practical standpoint certain steps can be taken to

minimize both forced and free convective heat exchange.

To eliminate forced convection, the fluid sample and the sensor must be absolutely still during the measurement. Even

minute vibrations in the sample are often enough to compromise the thermal properties measurement. Some common

46

Page 51

KD2 Pro Operator’s Manual

6. Measuring Liquids

sources of vibrations found in the laboratory that have been

shown to affect thermal properties measurement in liquids

and must be avoided include:

• Vibration from HVAC (Heating, Ventilating, and Air

Conditioning) systems

• Vibration from computer fans that are near the measure-

ment apparatus

• Vibration from people moving around the lab

• Vibration from other laboratory equipment

If sources of vibration are present in laboratory, it may be necessary to place the sample on a vibration isolation table to prevent errors from convection. Another common strategy is to

configure the KD2 Pro in auto mode and make measurements

overnight after turning off the HVAC system and any other

lab equipment that might cause vibrations.

The KD2 Pro KS-1 sensor is specially designed to add a very

small amount of heat to the sample during measurement and

thereby minimize problems with free convection. In high viscosity liquids (e.g. oils, glycerin), free convection is generally

not an issue. However, in low viscosity liquids like water or

aqueous solutions, there are several important steps that will

aid in accurate measurements.

• When dealing with low viscosity liquid samples, the

duration of the read time should be minimized to minimize the amount of heat added to the sample.

• The default read time for the KS-1 sensor is 1 minute. If

you are measuring in low viscosity liquids, use this read

time.

47

Page 52

KD2 Pro Operator’s Manual

6. Measuring Liquids

• In liquid samples, the KS-1 sensor needle should be ori-

ented vertically during the measurement to help prevent

free convection.

• Never use the KS-1 sensor in high power mode in liq-

uids. The sensor must be configured in low power

mode to prevent free convection.

Liquid Sample Temperature Control

Often it is desirable to control the temperature of the liquid

sample above or below ambient temperature during thermal

properties measurement. It is important that the act of heating or cooling the sample doesn't cause forced or free convection as mentioned above. There are several things that should

be avoided when measuring thermal properties of heated or

cooled samples.

• Do not heat the sample from the bottom (e.g. on a hot

plate). The temperature gradient from the heating will

cause free convection.

• Do not make measurements in a conventional refrigera-

tor or freezer. Conventional cooling devices have very

large cyclical temperature cycles which can cause excessive sample temperature drift and poor measurements.

Vibrations from the compressor will also cause forced

convection in the sample.

• Do not measure the thermal properties of the sample

while it is in a circulating water bath. The vibrations

from the water bath pump and from the circulating

water will cause forced convection in the sample.

According to several researchers who use the KD2 Pro with

liquid samples, the best method for controlling temperature of

liquid samples is as follows.

48

Page 53

KD2 Pro Operator’s Manual

6. Measuring Liquids

1. Heat or cool the sample (with sensor inserted) in a water

bath.

2. Once the sample temperature has equilibrated to the

desired water bath temperature, turn the water bath off.

3. Allow enough time for the water bath to become absolutely still, and make the measurement.

NOTE: Experimental results from researchers have shown that the

KD2-Pro KS-1 sensor can make accurate measurements in water and

aqueous solutions up to about 50 C. Above this temperature, the viscosity of the water becomes too low and free convection begins to affect the

measurement.

For a more in-depth discussion of measuring thermal properties of liquids, download the application note or watch the

video on this subject from www.decagon.com.

49

Page 54

KD2 Pro Operator’s Manual

7. Care and Maintenance

7. Care and Maintenance

Although the KD2 Pro has been built to high construction

standards, proper care must be taken to ensure continuing

operation.

Cleaning & Caring for the Sensors

The sensors are easy to clean. The sensor needles are stainless

steel, and as such, when they need cleaning, wipe them with a

damp cloth. Take care never to bend the needles. If the sensor

becomes badly bent, do not attempt to bend it back

it. You will need to contact Decagon to obtain a replacement

sensor.

Changing the Batteries

; this may break

Although the KD2 Pro has been designed to provide an excellent battery lifespan, the batteries will eventually require

changing. When this happens, a low-battery indicator will

appear in the upper left hand corner of the screen. The KD2

Pro requires four alkaline “AA” batteries. To change the batteries:

1. Turn over the KD2 Pro and locate the battery cover.

2. Place your thumb on the grooves and push upward to

loosen the cover.

3. Remove the old batteries and insert new ones. Be sure to

orient the fresh batteries according to the polarity marks

shown in the case.

50

Page 55

KD2 Pro Operator’s Manual

7. Care and Maintenance

4. Update the time and date either in the Configuration

Menu of the KD2 Pro, or by using the KD2 Pro

Utility.

Troubleshooting

If you encounter problems with your KD2 Pro, refer to the

following items to see if they resolve your problem.

PROBLEM: I am getting poor or inconsistent readings.

SOLUTION: Review section 5 of this manual.

PROBLEM: The KD2 Pro says it does not recognize the

connected sensor.

SOLUTION: Make sure the connection between the sensor

and the KD2 Pro is secure, and that none of the connector

pins are bent or broken off. If the KD2 Pro still fails to recognize the sensor, the sensor may be malfunctioning. Contact

Decagon for more assistance.

Verifying Sensor Performance

With your KD2 Pro, you have received three standard materials with which you can verify that your KD2 Pro is working

correctly and maintaining accuracy: a clear vial of glycerin

(glycerol) for the KS-1 Sensor, a white plastic cylinder for the

SH-1 needle sensor and a black plastic cylinder for the TR-1

single needle sensor.

The glycerol should be used to verify performance of the KS1 sensor. The cap of the vial is equipped with a septum allowing direct insertion of the needle into the vial through the cap.

51

Page 56

KD2 Pro Operator’s Manual

7. Care and Maintenance

Note: After repeated use the septum may begin to leak. Replacement

septums have been provided with your instrument. To replace simply

remove the cap, press the old septum out and press new one back in.

To conduct a performance verification, insert the needle fully

into the glycerol. The needle should be oriented vertically, and

it is best to turn the vial of glycerol upside-down on top of the

needle, so that any bubbles in the glycerol float to the top

away from the needle. The needle should be approximately

centered in the vial, and must not be touching a side of the

vial. Before taking a measurement in the glycerol, make sure

that the system is not undergoing rapid temperature drift.

Even the heat from holding the vial in your hand for a few

seconds, or the cooling from direct air conditioning flow can

decrease the accuracy of the measurement. It is best to place

the needle and vial in an isothermal environment (e.g. insulated chamber or cooler), and allow 15 minutes of equilibration time before taking the measurement. The thermal

conductivity of the glycerol is 0.285 W/(m· K) at 20 °C.

The two-hole Delrin block should be used to verify the performance of the dual-needle (SH-1) sensor. The sensor should

be fully inserted into the pre-drilled holes in the Delrin, and

allowed to equilibrate for at least 15 minutes before taking the

measurement. Again, make sure that the system is not undergoing rapid temperature drift. Even the heat from holding the

block in your hand for a few seconds, or the cooling from

direct air conditioning flow can decrease the accuracy of the

measurement. It is best to place the needle and block in an

isothermal environment (e.g. insulated chamber or cooler),

and allow 15 minutes of equilibration time before taking the

measurement. The Delrin blocks have slightly different thermal conductivities from lot to lot, so the correct values for K,

52

Page 57

KD2 Pro Operator’s Manual

7. Care and Maintenance

C, and D for your individual Delrin block are recorded on

your Certificate of Quality Assurance.

Verification for the TR-1 is similar to that for the SH-1. Place

the needle in the block and take a reading, taking care to minimize temperature distrubances. The reading should correspond to the value recorded on your Certificate of Quality

Assurance.

At the request of multiple KD2 Pro users, we have characterized the temperature dependence of the thermal conductivity

of the black plastic TR-1 verification cylinder. Measurements

were collected on three black plastic cylinders from different

lots of material over the temperature range of -20 to 60 C (see

figure below). We found little temperature dependence on any

of the samples with maximum differences over the -20 to 60 C

range never being greater than 0.004 W m-1 K-1 (~1%).

Thermal conductivity as a function of temperature for three TR-1 verification cylinders from different lots of material. Error bars represent ±1

standard deviation in five replicated measurements.

53

Page 58

KD2 Pro Operator’s Manual

8. KD2 Pro Theory

8. KD2 Pro Theory

Transient line heat source methods have been used for over 50

years to measure thermal conductivity of porous materials.

Typically a probe for this measurement consists of a needle

with a heater and temperature sensor inside. A current is

passed through the heater and the temperature of the probe is

monitored over time. An analysis of the probe temperature is

used to determine thermal conductivity. More recently the

heater and temperature sensor have been placed in separate

needles. In the dual probe the analysis of the temperature vs

time relationship for the separated probes yields information

on diffusivity and heat capacity as well as conductivity.

An ideal sensor would have a very small diameter, and a length

perhaps 100 times its diameter. It would be in intimate contact with the surrounding material and would measure the

temperature of the material during heating and cooling. Ideally the temperature and composition of the material being

measured would not change during the measurement.

Real sensors fall short of the ideal in several ways. A probe

small enough to be ideal would be too fragile for most applications. Measurements in outdoor environments involve changing temperatures; the ambient temperature generally is not

constant. Heating moist, unsaturated soil causes water to

move away from the heat source, thus altering the water content in the region of measurement, and the hole made for the

probe often disturbs the material around it causing a contact

resistance between the probe and the material.

It is a challenge to design a probe that gives accurate measurements under all conditions. If the probe is too small it is fragile, and the contact resistance can be high in dry, porous

54

Page 59

KD2 Pro Operator’s Manual

8. KD2 Pro Theory

materials. A long heating time is required for a large probe,

but the long heating time drives water away from the probe

and can cause free convection in liquid samples, thus altering

the reading. A high heating rate makes temperature changes

easier to read and less susceptible to temperature drift errors,

but results in water movement out of the measuring region

and free convection in liquids. Long heating times are also

recommended to minimize contact resistance, but, again,

result in water movement away from the probe.

Decagon's KD2 Pro design attempts to optimize thermal

properties measurements relative to these issues. Probes are

relatively large and robust making them easy to use. Heating

times are kept as short as possible to minimize thermally

induced water movement and minimize time required for a

measurement. Heat input is minimized to minimize water

movement and free convection. Use of relatively short heating times and low heating rates requires high resolution temperature measurements and special algorithms to measure

thermal properties. The KD2 Pro resolves 0.001 C in temperature. It uses special algorithms to analyze measurements

made during a heating and a cooling interval. It also uses special algorithms to separate out the effects of the heat pulse

from ambient temperature changes. Two different algorithms

are used, one for the dual needle probe and one for the single

needle. Both are based on the line heat source analysis given

in Carslaw and Jaeger (1959) and Kluitenberg et al. (1993).

Dual Needle Algorithm

Heat is applied to the heated needle for a set heating time, th,

and temperature is measured in the monitoring needle, 6 mm

distant during heating and during the cooling period following

heating. The readings are then processed by subtracting the

ambient temperature at time 0, multiplying by 4and dividing

55

Page 60

KD2 Pro Operator’s Manual

T

b0tb1Ei

b

2

t

-----

+=

T

b0tb1Ei

b

2

t

-----

Ei

b

2

tt

h

–

----------------

–

+=

T

4 TT

o

–

q

-------------------------- -=

k

1

b

1

-----=

8. KD2 Pro Theory

by the heat per unit length, q. The resulting data are fit to the

following equations using a non-linear least squares procedure.

(1)

where:

(2)

Here, Ei is the exponential integral (Abramowitz and Stegun,

1972), and b

, b1 and b2 are the constants to be fit. To is the

o

temperature at the start of the measurement and q is the heat

input. The first equation applies for the first t

seconds, while

h

the heat is on. The second equation applies when the heat is

off. The thermal conductivity is computed from

(3)

56

Page 61

KD2 Pro Operator’s Manual

D

r

2

4b

2

--------=

Tm0m2tm3tln++=

8. KD2 Pro Theory

The diffusivity is

(4)

The conductivity and diffusivity are found by fitting eqs. 1 to

the transformed data. The correct values of b

, b1 and b2 are

o

the ones which minimize the sum of squares of error between

the equations and the measurements. The values are found

using the Marquardt (1963) non-linear least squares procedure. This procedure is susceptible to getting stuck in local

minima and failing to find a global minimum in some problems (the single needle problem is a perfect example of a bad

non-linear least squares problem) but the dual needle problem

typically works well. Finding just three model parameters is

quick in the KD2 Pro.

Single Needle Algorithm

Heat is applied to a single needle for a time, th, and temperature is monitored in that needle during heating and for an

additional time equal to th after heating. Two needle sizes are

used. One (the KS-1) is 1.2 mm diameter and 60 mm long.

The other (the TR-1) is 2.4 mm diameter and 100 mm long.

The temperature during heating is computed from

57

(5)

Page 62

KD2 Pro Operator’s Manual

Tm1m2tm

3

t

tt

h

–

----------------

ln++=

k

q

4m

3

-------------=

8. KD2 Pro Theory

m0 is the ambient temperature during heating (which could

include some offset for contact resistance and the heating

element being adjacent to the temperature sensor inside the

needle), m2 is the rate of background temperature drift, and

m3 is the slope of a line relating temperature rise to

logarithm of temperature.

During cooling the model is

(6)

The thermal conductivity is computed from

Since these equations are long-time approximations to the

exponential integral equations (eq. 1), we use only the final 2/

3 of the data collected (ignore early-time data) during heating

and cooling. This approach has several advantages. One is

that effects of contact resistance appear mainly in these earlytime data, so by analyzing only the later time data the measurement better represents the thermal conductivity of the sample

of interest. Another advantage is that equations 5 and 6 can be