Page 1

AquaLab

Water Activity Meter

Operator’s Manual

For Series 4TE, 4TEV, DUO

Version 4

Decagon Devices, Inc.

Page 2

Decagon Devices, Inc

2365 NE Hopkins Court

Pullman WA 99163

(509)332-2756

fax: (509)332-5158

www.aqualab.com

support@decagon.com

sales@decagon.com

Trademarks

AquaLab is a registered trademark of

Decagon Devices, Inc.

©2008-2009 Decagon Devices, Inc.

Page 3

Contents

1. Introduction .................................1

About this Manual ....................................1

Customer Support .....................................1

Warranty ...................................................2

Seller’s Liability ..........................................2

2. About AquaLab ...........................4

AquaLab Model and Options ....................4

AquaLab 4 Instrument Specifications ........4

AquaLab 4 DUO Specifications .................5

How AquaLab Works ................................6

AquaLab and Temperature ........................6

Chilled Mirror Dewpoint Limitations .......8

3. Water Activity eory ...................9

Moisture Content ......................................9

Water Activity............................................9

Water Potential ........................................12

Sorption Isotherms ..................................13

4. Getting Started ...........................15

Components of your AquaLab ................. 15

Choosing a Location ...............................15

Preparing AquaLab for Operation ............16

5. Menus ......................................... 18

Measurement Tab .................................... 18

i

Page 4

Configuration Tab ...................................19

Admin Settings ........................................25

Data Tab .................................................30

6. Cleaning and Maintenance ........ 32

Cleaning the Block and Sensors ...............33

Cleaning Procedure: ...............................34

Verification of Calibration .......................36

7. Verification and Calibration ........37

Water Activity Verification .......................37

Verification of Calibration .......................38

8. Sample Preparation ....................46

Preparing the Sample ...............................46

Samples Needing Special Preparation ......47

Slow Water-Emitting Samples ..................48

Volatile Samples .......................................49

Low Water Activity ..................................49

Samples not at Room Temperature ..........50

9. Taking a Reading ....................... 51

Measurement Steps ..................................51

How AquaLab Takes Readings ................ 51

10. Duo Operation (Optional) .......54

Obtaining Product Isotherm Models .......55

Loading and Organizing Product Models 55

11. Computer Interface ...................60

AquaLink RG ..........................................60

Using Windows Hyperterminal .............60

ii

Page 5

12. Troubleshooting .......................62

Diagnostic Screen ....................................72

13. Support and Repair .................. 73

Repair Costs ............................................ 74

Loaner Service .........................................74

14. Further Reading ....................... 75

Water Activity eory & Measurement ...75

Food Quality and Safety ..........................78

Water Activity and Microbiology .............80

Water Activity in Foods ...........................83

Appendix A .....................................93

Preparing Salt Solution ............................93

Appendix B .....................................95

Temperature Correction ..........................95

Appendix C .....................................96

AquaLab Calibration Standards ..............96

Declaration of Conformity ........... 101

Certificate of Traceability .............102

iii

Page 6

iv

Page 7

AquaLab

1. Introduction

1. In t r o d u c t I o n

Welcome to Decagon’s AquaLab Series 4TE, 4TEV, and DUO, the

industry standard for measuring water activity (aw). AquaLab is the

quickest, most accurate, and most reliable instrument available for

measuring water activity. Whether you are researching or working

on the production line, AquaLab will suit your needs. It is easy to

use and provides accurate and timely results.

About this Manual

Included in this manual are instructions for setting up your AquaLab,

verifying the calibration of the instrument, preparing samples, and

maintaining and caring for your instrument. Please read these instructions before operating AquaLab to ensure that the instrument

performs to its full potential.

Customer Support

If you ever need assistance with your AquaLab, or if you just have

questions or feedback, there are several ways to contact us:

NOTE: If you purchased your AquaLab through a distributor, please

contact them for assistance.

E-mail

support@decagon.com

Please include your name, contact information, instrument serial

number(s), and a description of your problem or question.

sales@decagon.com

Please include your name, address, phone number, the items you

wish to order and a purchase order number. Credit card numbers

should always be called in.

1

Page 8

AquaLab

1. Introduction

Phone

1-800-755-2751 (USA and Canada Only)

1-509-332-2756 International

Our Customer Support and Sales Representatives are available

Monday thru Friday.

Fax

1-509-332-5158

Warranty

AquaLab has a 30-day satisfaction guarantee and a three-year warranty on parts and labor. Your warranty is automatically validated

upon receipt of the instrument. We will contact you within the first

90 days of your purchase to see how the AquaLab is working for

you.

Seller’s Liability

Seller warrants new equipment of its own manufacture against defective workmanship and materials for a period of three years from

date of receipt of equipment (the results of ordinary wear and tear,

neglect, misuse, accident and excessive deterioration due to corrosion from any cause are not to be considered a defect); but Seller’s

liability for defective parts shall in no event exceed the furnishing

of replacement parts Freight On Board the factory where originally

manufactured. Material and equipment covered hereby which is

not manufactured by Seller shall be covered only by the warranty

of its manufacturer. Seller shall not be liable to Buyer for loss, dam-

2

Page 9

AquaLab

1. Introduction

age or injuries to persons (including death), or to property or things

of whatsoever kind (including, but not without limitation, loss of

anticipated profits), occasioned by or arising out of the installation,

operation, use, misuse, nonuse, repair, or replacement of said material and equipment, or out of the use of any method or process

for which the same may be employed. e use of this equipment

constitutes Buyer’s acceptance of the terms set forth in this warranty.

ere are no understandings, representations, or warranties of any

kind, express, implied, statutory or otherwise (including, but without limitation, the implied warranties of merchantability and fitness

for a particular purpose), not expressly set forth herein.

3

Page 10

AquaLab

2. About AquaLab

2. About AquaLab

AquaLab is the fastest and most accurate instrument for measuring

water activity, giving readings in five minutes or less. Its readings

are reliable, providing ±0.003 aw accuracy. e instrument is easy

to clean and checking calibration is simple.

AquaLab Model and Options

Series 4TE: User-selectable internal temperature control model,

uses thermoelectric (Peltier) components to maintain internal temperature.

Series 4TEV: Uses both a chilled-mirror dewpoint sensor and a capacitance sensor for measuring non-volatile and volatile substances,

respectively. Either sensor is easily selected using the instrument’s

menu system.

Series 4TE DUO: Uses chilled-mirror dewpoint and programmed

models obtained from isotherm data to give the user both water activity and moisture content simultaneously in five minutes or less.

AquaLab 4 Instrument Specifications

Water Activity Range: 0.050 to 1.000 a

Water Activity Accuracy: ±0.003 (4TE Dew Point Mode)

Water Activity Accuracy: ±0.015 (4TEV Capacitance Mode)

Water Activity Resolution: 0.0001

Read Time1: ≤5 min.

Sample Temperature Range: 15 to 50° C

Sample Temperature Accuracy: ±0.2° C

4

w

Page 11

AquaLab

2. About AquaLab

Sample Temperature Resolution: 0.01° C

Sample Dish Capacity: 15ml Full

Operating Environment: 5 to 50° C 20 to 80% Humidity

Case Dimensions: 26.7 x 17.8 x 12.7cm

Weight: 3.1 Kg

Case Material: Lustran 433 (ABS) with fire retardant

Display: 64 x 128 Graphical

Data Communications: RS232A Serial, 9600 to 115200 baud

Power: 110 to 220 VAC, 50/60Hz

Warranty: 3 year parts and labor

1

On samples with no significant impedance to vapor loss

AquaLab 4 DUO Specifications

Moisture Content Repeatability: 0.02%

Accuracy to Moisture Content Ref.: 0.1% to 0.5%

AquaLab and Water Activity

Water activity (aw) is a measurement of the energy status of the water

in a system. It indicates how tightly water is “bound”, structurally

or chemically, within a substance. Water activity is the relative humidity of air in equilibrium with a sample in a sealed measurement

chamber. e concept of water activity is of particular importance

in determining product quality and safety. Water activity influences

color, odor, flavor, texture and shelf-life of many products. It predicts safety and stability with respect to microbial growth, chemical

and biochemical reaction rates, and physical properties. For a more

detailed description of water activity as it pertains to products,

please refer to Chapter 3 of this manual, titled “ Water Activity

eory”.

5

Page 12

AquaLab

2. About AquaLab

How AquaLab Works

AquaLab uses the chilled-mirror dewpoint technique to measure the

water activity of a sample. In an instrument that uses the dewpoint

technique, the sample is equilibrated with the head-space of a sealed

chamber that contains a mirror and a means of detecting condensation on the mirror. At equilibrium, the relative humidity of the air

in the chamber is the same as the water activity of the sample. In

the AquaLab, the mirror temperature is precisely controlled by a

thermoelectric (Peltier) cooler. Detection of the exact point at which

condensation first appears on the mirror is observed with a photoelectric cell. A beam of light is directed onto the mirror and reflected

into a photo detector cell. e photo detector senses the change

in reflectance when condensation occurs on the mirror. A thermocouple attached to the mirror then records the temperature at which

condensation occurs. AquaLab then signals you by beeping and displays the final water activity and temperature.

In addition to the technique described above, AquaLab uses an internal fan that circulates the air within the sample chamber to reduce

equilibrium time. Since both dewpoint and sample surface temperatures are simultaneously measured, the need for complete thermal

equilibrium is eliminated, which reduces measurement times to less

than five minutes.

AquaLab and Temperature

Samples not read at room temperature during the read cycle will

equilibrate with the AquaLab’s temperature before the water activity

is displayed. Large temperature differences will cause longer reading

times, since a complete and accurate reading will not be made until

the sample and the instrument are within 2°C of each other.

6

Page 13

AquaLab

2. About AquaLab

ere are several advantages in having a temperature-controlled water activity meter. A few major reasons are:

1. Research purposes. Temperature control can be used to study

the effects of temperature on the water activity of a sample, make a

comparison of the water activity of different samples independent

of temperature, and conduct accelerated shelf-life studies or other

water activity studies where temperature control is critical. ere are

many shelf-life, packaging, and isotherm studies in which temperature control would be very beneficial.

2. To comply with government or internal regulations for specific

products. ough the water activity of most products varies by less

than ± 0.002 per °C, some regulations require measurement at a specific temperature. e most common specification is 25°C, though

20°C is sometimes indicated.

3. To minimize extreme ambient temperature fluctuations. If the

environmental and AquaLab temperatures fluctuate by as much as ±

5°C daily, water activity readings will vary by ± 0.01 aw. Temperature

control eliminates variations due to changes in ambient conditions.

Series 4TE/4TEV/4TE-DUO

e AquaLab Series 4TE models have thermoelectric components

installed to allow the instrument to maintain a set chamber temperature. e temperature is set using the configuration menu of any

of the Series 4 models.

7

Page 14

AquaLab

2. About AquaLab

Chilled Mirror Dewpoint Limitations

AquaLab’s limitation is its ability to accurately measure samples with

high concentrations (typically >1%) of certain volatiles such as ethanol or propylene glycol, which can condense on the surface of the

chilled mirror. e extent of the effect is determined by how readily

the material volatilizes, which is both concentration- and matrixdependent. erefore, even if your sample contains materials that

could volatilize, it may still be possible to make accurate readings

using the chilled mirror dewpoint sensor.

AquaLab Series 4TEV which incorporates both a chilled mirror sensor and a capacitance sensor for measuring volatile substances is

Decagon’s solution for products containing volatile materials. If you

are unsure if you need the TEV model, please call and discuss your

product with a Decagon Representative. Refer to Chapter 8’s section

titled ”Volatile Samples” or call Decagon for more details.

8

Page 15

AquaLab

3. Water Activity eory

3. Water Activity eory

Water is a major component of foods, pharmaceuticals, and cosmetics. Water influences the texture, appearance, taste and spoilage of these

products. ere are two basic types of water analysis: moisture content

and water activity.

Moisture Content

e meaning of the term moisture content is familiar to most people.

It implies a quantitative analysis to determine the total amount of

water present in a sample. Primary methods for determining moisture content are loss on drying and Karlf Fisher titration, but secondary methods such as infrared and NMR are also used. Moisture

content determination is essential in meeting product nutritional

labeling regulations, specifying recipes and monitoring processes.

However, moisture content alone is not a reliable indicator for predicting microbial responses and chemical reactions in materials.

e limitations of moisture content measurement are attributed to

differences in the intensity with which water associates with other

components.

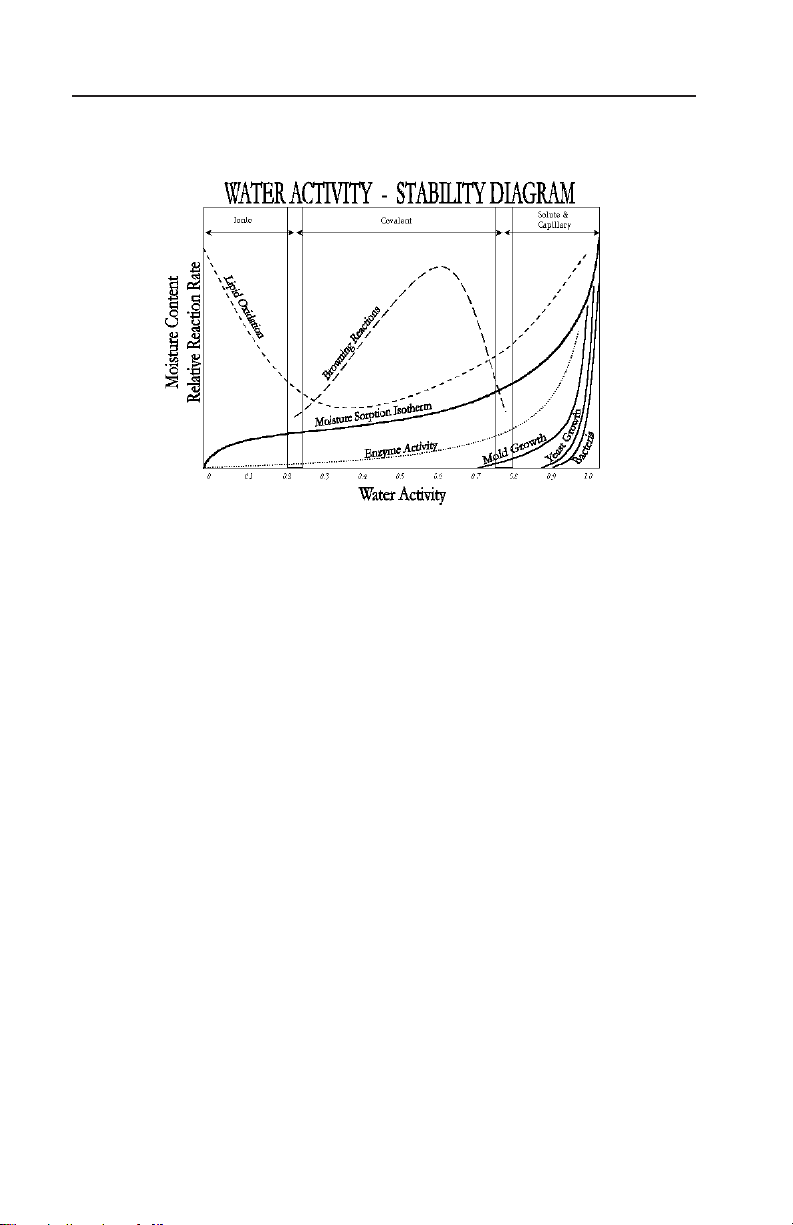

Water Activity

Water activity is a measure of the energy status of the water in a

system, and thus is a far better indicator of perishability than water

content. Figure 1 shows how the relative activity of microorganisms,

lipids and enzymes relate to water activity. While other factors, such

as nutrient availability and temperature, can affect the relationships,

water activity is the best single measure of how water affects these

processes.

9

Page 16

AquaLab

3. Water Activity eory

Fig. 1: Water Activity Diagram—adapted from Labuza

Water activity of a system is measured by equilibrating the liquid

phase water in the sample with the vapor phase water in the headspace and measuring the relative humidity of the head-space. In

the AquaLab, a sample is placed in a sample cup which is sealed

inside a sample chamber. Inside the sample chamber is a fan, a dew

point sensor, a temperature sensor, and an infrared thermometer.

e dewpoint sensor measures the dewpoint temperature of the air

in the chamber, and the infrared thermometer measures the sample

temperature. From these measurements, the relative humidity of

the head-space is computed as the ratio of dewpoint temperature

saturation vapor pressure to saturation vapor pressure at the sample

temperature. When the water activity of the sample and the relative humidity of the air are in equilibrium, the measurement of the

head-space humidity gives the water activity of the sample. e purpose of the fan is to speed equilibrium and to control the boundary

layer conductance of the dewpoint sensor.

10

Page 17

AquaLab

3. Water Activity eory

In addition to equilibrium between the liquid phase water in the

sample and the vapor phase, the internal equilibrium of the sample

is important. If a system is not at internal equilibrium, one might

measure a steady vapor pressure (over the period of measurement)

which is not the true water activity of the system. An example of

this might be a baked good or a multi-component food. Initially out

of the oven, a baked good is not at internal equilibrium; the outer

surface is at a lower water activity than the center of the baked good.

One must wait a period of time in order for the water to migrate

and the system to come to internal equilibrium. It is important to

remember the restriction of the definition of water activity to equilibrium.

Temperature Effects

Temperature plays a critical role in water activity determination.

Most critical is the measurement of the difference between sample

and dewpoint temperature. If this temperature difference were in error by 1°C, an error of up to 0.06 aw could result. In order for water

activity measurements to be accurate to 0.001, temperature difference measurements need to be accurate to 0.017°C. AquaLab’s infrared thermometer measures the difference in temperature between

the sample and the block. It is carefully calibrated to minimize temperature errors, but achieving 0.017°C accuracy is difficult when

temperature differences are large. Best accuracy is therefore obtained

when the sample is near chamber temperature.

Another effect of temperature on water activity occurs when samples are near saturation. A sample that is close to 1.0 aw and is only

slightly warmer than the sensor block will condense water within the

block. is will cause errors in the measurement, and in subsequent

measurements until the condensation disappears. A sample at 0.75 aw

needs to be approximately 4°C above the chamber temperature to

11

Page 18

AquaLab

3. Water Activity eory

cause condensation. e AquaLab warns the user if a sample is more

than 4°C above the chamber temperature, but for high water activity

samples the operator needs to be aware that condensation can occur

if a sample that is warmer than the block is put in the AquaLab.

Water Potential

Some additional information may be useful for understanding what

water activity is and why it is such a useful measure of moisture

status in products. Water activity is closely related to a thermodynamic property called the water potential, or chemical potential (µ)

of water, which is the change in Gibbs free energy (∆G) when water

concentration changes. Equilibrium occurs in a system when (µ) is

the same everywhere in the system. Equilibrium between the liquid

and the vapor phases implies that () is the same in both phases. It

is this fact that allows us to measure the water potential of the vapor

phase and use that to determine the water potential of the liquid

phase. Gradients in (µ) are driving forces for moisture movement.

us, in an isothermal system, water tends to move from regions of

high water potential (high aw) to regions of low water potential (low

aw). Water content is not a driving force for water movement, and

therefore can not be used to predict the direction of water movement, except in homogeneous materials.

Factors In Determining Water Potential

e water potential of the water in a system is influenced by factors

that effect the binding of water. ey include osmotic, matric, and

pressure effects. Typically water activity is measured at atmospheric

pressure, so only the osmotic and matric effects are important.

Osmotic Effects

Osmotic effects are well known from biology and physical chemistry. Water is diluted when a solute is added. If this diluted water is

12

Page 19

AquaLab

3. Water Activity eory

separated from pure water by a semi-permeable membrane, water

tends to move from the pure water side through the membrane to

the side with the added solute. If sufficient pressure is applied to the

solute-water mixture to just stop the flow, this pressure is a measure

of the osmotic potential of the solution. Addition of one mole of an

ideal solute to a kilogram of water produces an osmotic pressure of

22.4 atm. is lowers the water activity of the solution from 1.0 to

0.98 aw. For a given amount of solute, increasing the water content

of the systems dilutes the solute, decreasing the osmotic pressure,

and increasing the water activity. Since microbial cells are high concentrations of solute surrounded by semi-permeable membranes,

the osmotic effect on the free energy of the water is important for

determining microbial water relations and therefore their activity.

Matric Effects

e sample matrix affects water activity by physically binding water

within its structure through adhesive and cohesive forces that hold water

in pores and capillaries, and to particle surfaces. If cellulose or protein

were added to water, the energy status of the water would be reduced.

Work would need to be done to extract the water from this matrix. is

reduction in energy status of the water is not osmotic, because the cellulose or protein concentrations are far too low to produce any significant

dilution of water. e reduction in energy is the result of direct physical

binding of water to the cellulose or protein matrix by hydrogen bonding

and van der Waal forces. At higher water activity levels, capillary forces

and surface tension can also play a role.

Sorption Isotherms

Relating Water Activity to Water Content

Changes in water content affect both the osmotic and matric binding of water in a product. us a relationship exists between the

water activity and water content of a product. is relationship is

13

Page 20

AquaLab

3. Water Activity eory

called the sorption isotherm, and is unique for each product. Besides

being unique to each product, the isotherm changes depending on

whether it was obtained by drying or wetting the sample. ese factors need to be kept in mind if one tries to use water content to infer

the stability or safety of a product. Typically, large safety margins are

built into water content specifications to allow for these uncertainties.

While the sorption isotherm is often used to infer water activity from

water content, one could easily go the other direction and use the

water activity to infer the water content. is is particularly attractive because water activity is much more quickly measured than water content. is method gives particularly good precision in the

center of the isotherm. In order to infer water content from water

activity, one needs an isotherm for the particular product. Decagon

sells an Isotherm Generator called the AquaSorp IG or you can also

have Decagon run the isotherm for a fee.

For example, if one were using the AquaLab to monitor the water

content of dried potato flakes, one would measure the water activity

and water content of potato flakes dried to varying degrees using the

standard drying process for those flakes. An isotherm would be constructed using those data, and the water content would be inferred

using the measured water activity of samples and that isotherm. We

have an upgrade available to Series 4TE users that would allow you

to determine moisture content and water activity simultaneously.

is instrument is called the Series 4TE DUO.

e importance of the concept of water activity of foods, pharmaceuticals, and cosmetics cannot be over emphasized. Water activity is

a measure of the energy status of the water in a system. More importantly, the usefulness of water activity in relation to microbial growth,

chemical reactivity, and stability over water content has been shown.

14

Page 21

AquaLab

4. Getting Started

4. Getting Started

Components of your AquaLab

Your AquaLab should have been shipped with the following items:

AquaLab water activity meter•

Calibration Certificate•

Power cord•

RS-232 interface cable•

100 disposable sample cups•

Operator’s Manual•

Quick Start guide•

Cleaning Kit•

3 vials each of the following verification solutions:•

1.000 a

0.760 a

0.500 aw 8.57 molal LiCl

0.250 aw 13.41 molal LiCl

Distilled Water

w

6.0 molal NaCl

w

Choosing a Location

To ensure that your AquaLab operates correctly and consistently,

place it on a level surface. is reduces the chance that sample material will spill and contaminate the sample chamber. Also select a

location where the temperature remains fairly stable to avoid temperature changes that can affect accuracy. is location should be

well away from air conditioner and heater vents, open windows, etc.

Place the AquaLab in a location where cleanliness can be maintained

to prevent contamination of the sample chamber.

15

Page 22

AquaLab

4. Getting Started

Preparing AquaLab for Operation

After finding a good location for your AquaLab, plug the power cord

into the back of the unit. e ON/OFF switch is located on the

lower left corner of the AquaLab’s back panel. When the AquaLab

is turned on, you should see a model name/number screen and then

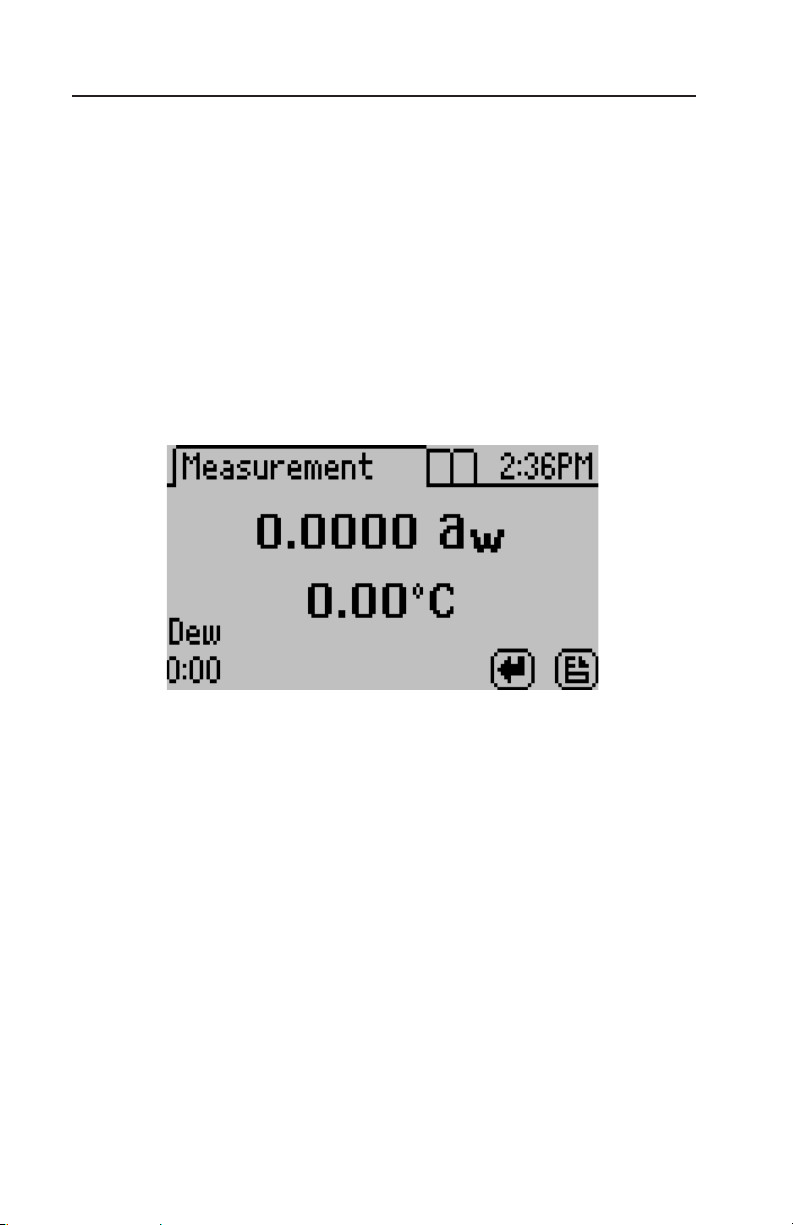

the main screen as shown below.

e main screen shows the water activity (aw) in the middle of the

screen and the sample temperature right below. On the Series 4TEV

model you will also see either DEW or CAP indicating whether you

are using the dewpoint or capacitance sensor respectively.

NOTE: In order to provide the most accurate readings, your AquaLab

should be allowed a 15 minute warm-up period.

16

Page 23

AquaLab

4. Getting Started

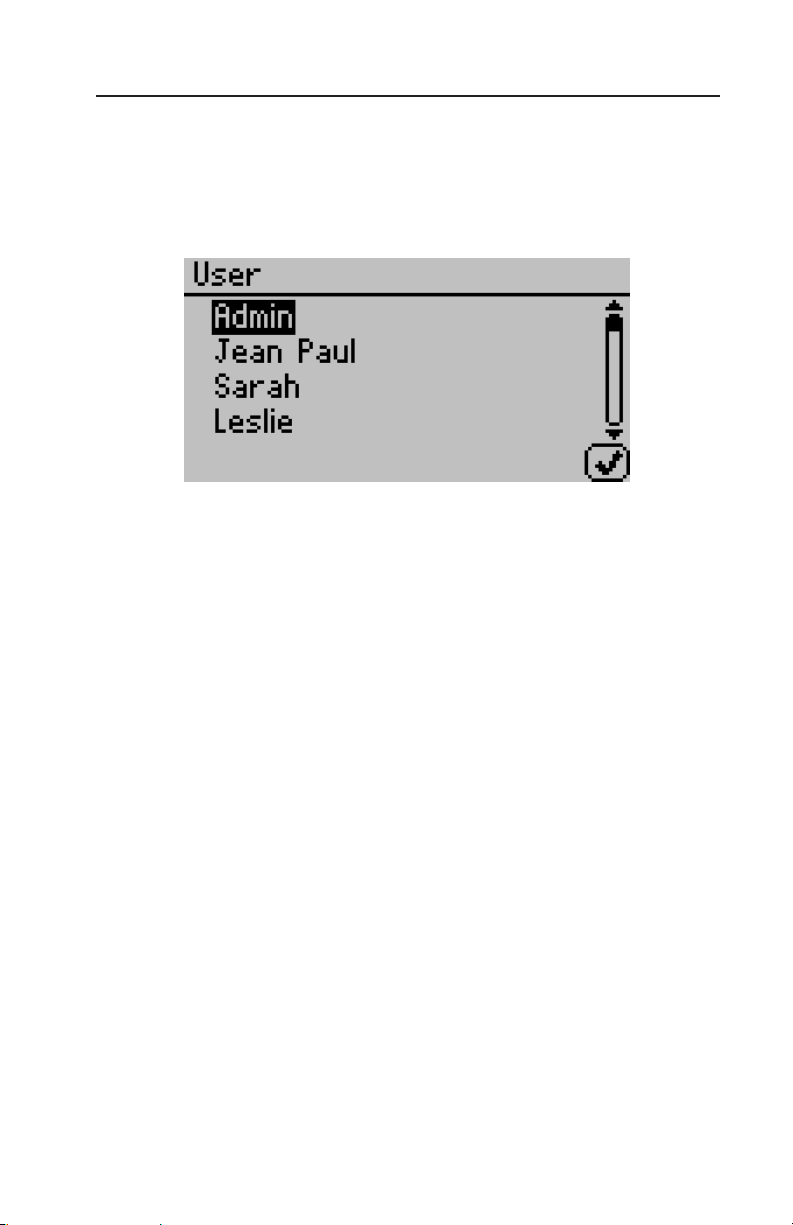

If users have been setup on the instrument, the following screen will

appear instead of the main screen. (See Chapter 5 for more information on administrative settings and user setup).

Select the appropriate user and login to begin.

17

Page 24

AquaLab

5. Menus

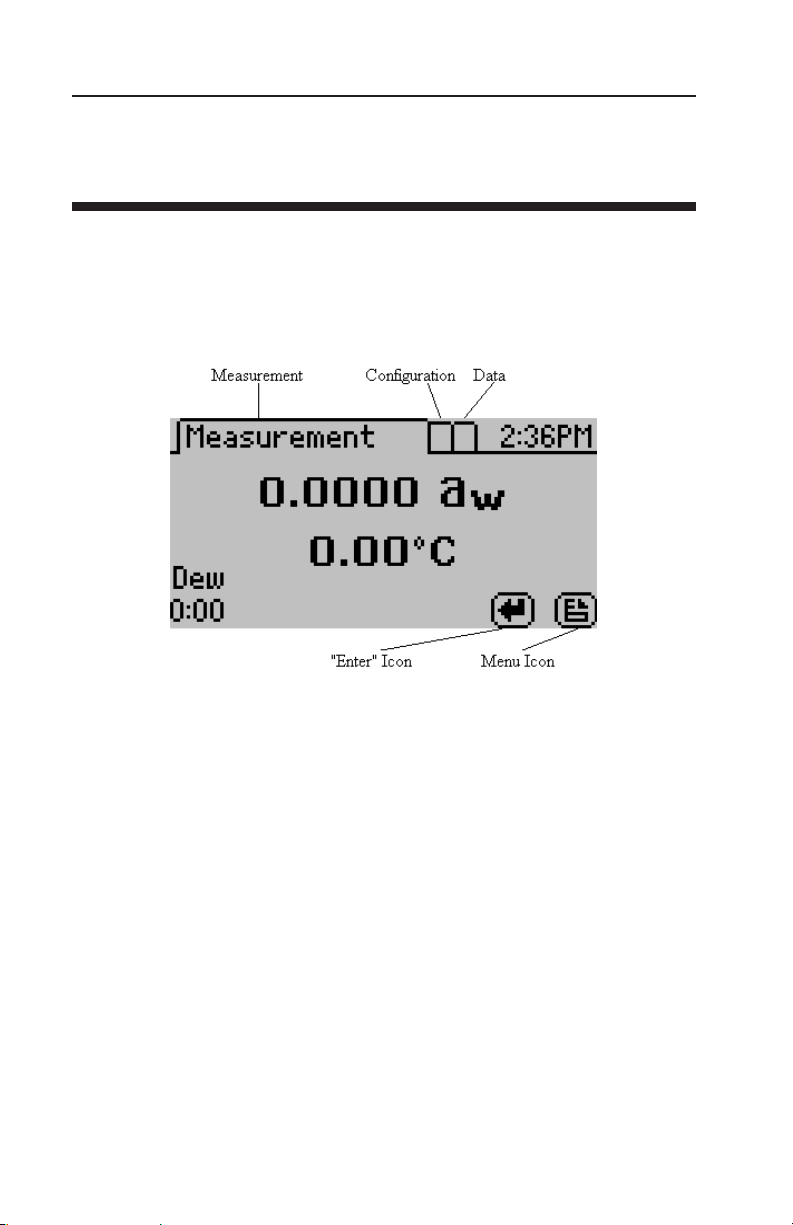

5. Menus

At the top of the display screen there are three tabs: Measurement,

Configuration, and Data. ese tabs indicate the three menus you

can access. To change between the tabs press the right most button

below the document icon.

e enter icon is the read or enter button. Once the latch is set to the

read position, the document icon will switch to an “X” icon, which

allows the user to stop the current reading. During a reading, pressing enter again will restart the reading.

Measurement Tab

e measurement tab, as seen above, is the main screen which displays each time you turn on your AquaLab. If this screen doesn’t

appear, refer to Chapter 12 for troubleshooting instructions. As

mentioned earlier, the water activity and sample temperature are

displayed on the screen.

18

Page 25

AquaLab

5. Menus

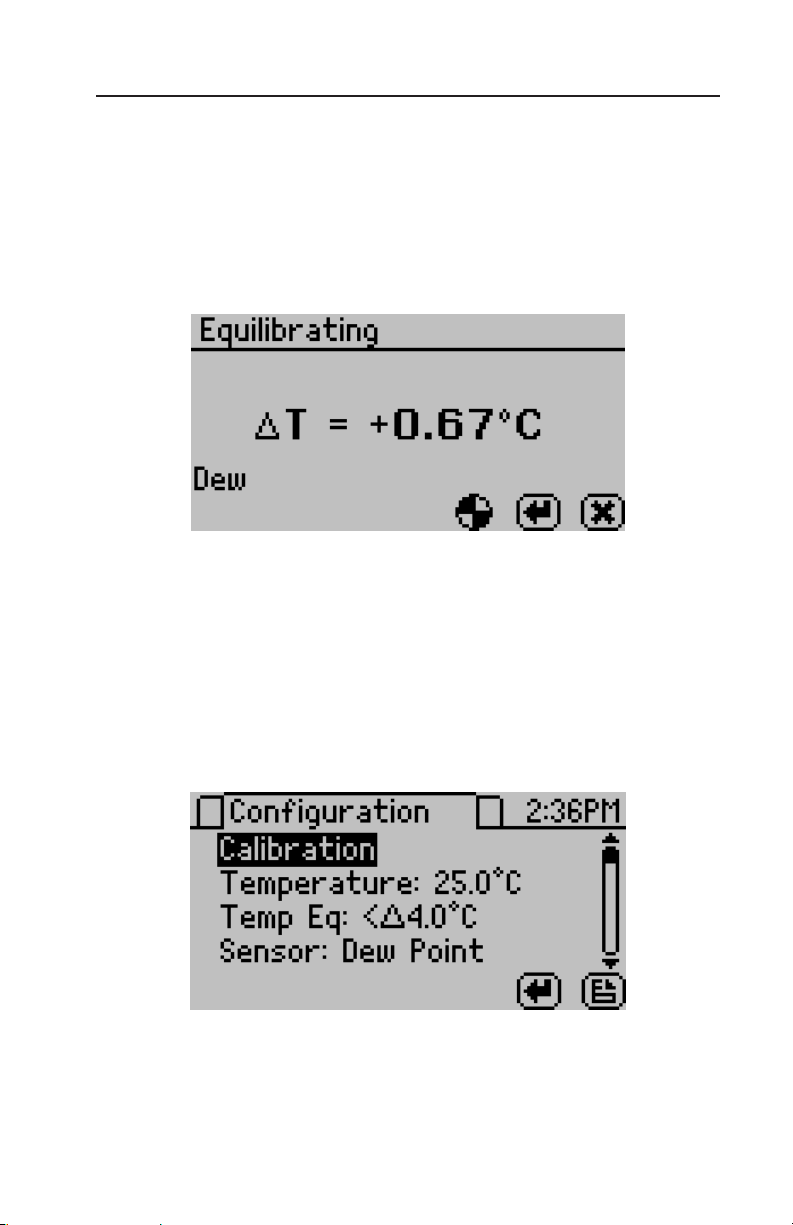

Pushing the right or left arrow keys will change the display to a

temperature equilibration screen shown below. is screen shows the

temperature difference between the sample temperature and the block

temperature.

Configuration Tab

When at the configuration screen, pressing the up and down arrow

keys moves the cursor through the various configuration options

Press the left and right arrows to page through the options. e

enter button will allow you to change the highlighted setting.

19

Page 26

AquaLab

5. Menus

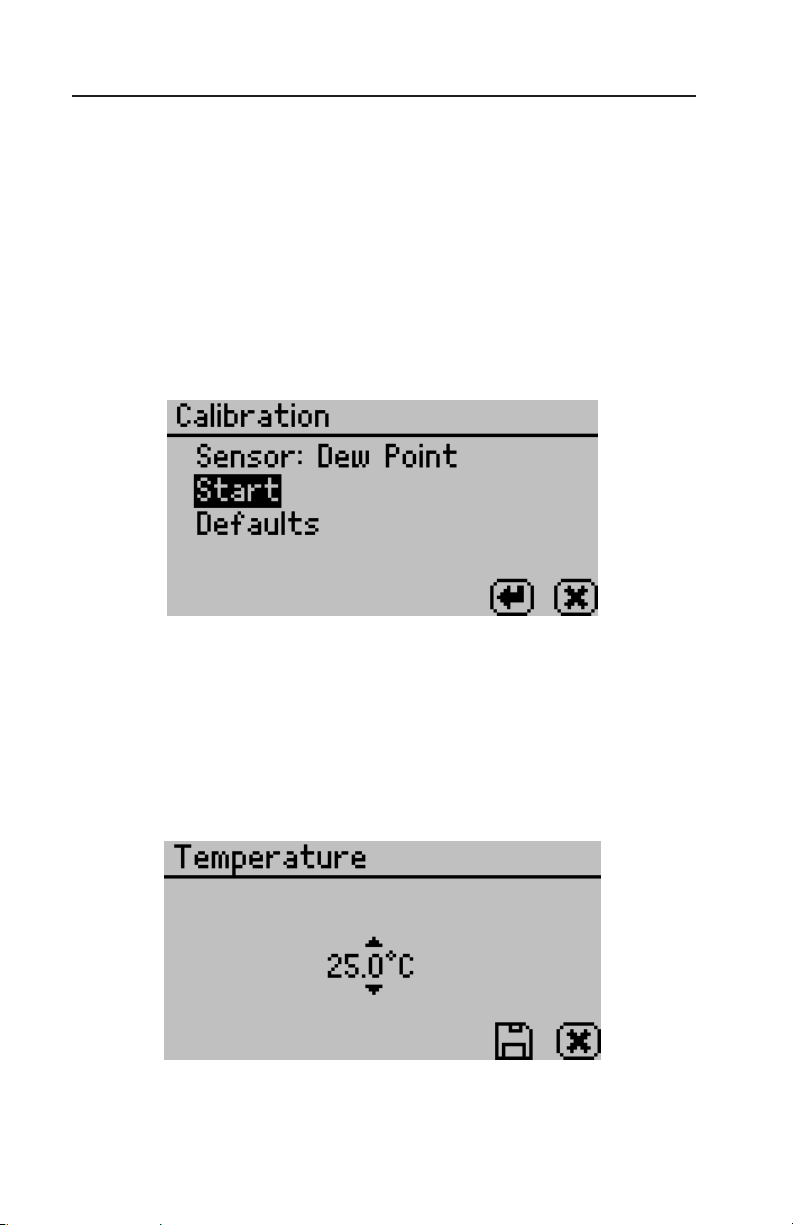

Calibration:

Pressing the Enter button when Calibration is highlighted starts the

verification process. For more details on the verification procedure

refer to Chapter 7. You may also reset the calibration to the factory defaults by highlighting the Defaults option and pressing Enter.

is will reset all options to the way they were when the instrument

arrived at your location.

Temperature:

e default temperature is 25°C. Press the enter button to change

the temperature setting. e AquaLab Series 4TE models may be set

between 15 and 50°C by 0.1°C intervals. Using the up and down

arrows, set the AquaLab to your desired temperature and press the

save button.

20

Page 27

AquaLab

5. Menus

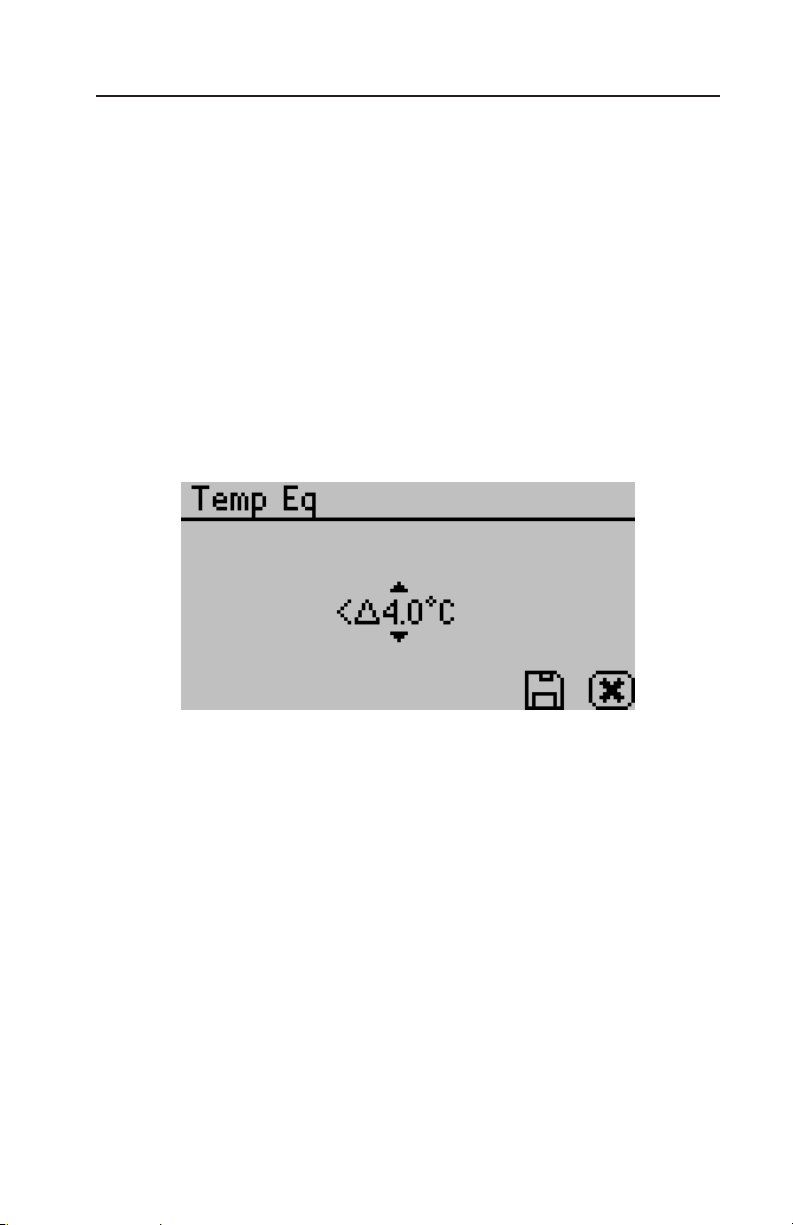

Temp Eq:

e Temperature Equilibration option allows you to set the level of

temperature equilibration desired before the water activity measurement begins. e range is 0.5 to 4.0°C. A setting of 4.0°C begins

the measurement immediately (assuming the sample is not >4.0°C

above or below the block temperature). A setting of 0.5 °C will

cause the instrument to wait until the sample temperature is within

<0.5°C of the block temperature before starting the water activity

measurement.

Sensor:

In the AquaLab Series 4TEV model only, this option indicates the

selected sensor type, either dewpoint or capacitance (e Series 4TE

models will always be Dewpoint). Pressing Enter when the Sensor

option is highlighted allows you to change between a chilled mirror

dewpoint or capacitance sensor for sampling with or without volatiles, respectively.

21

Page 28

AquaLab

5. Menus

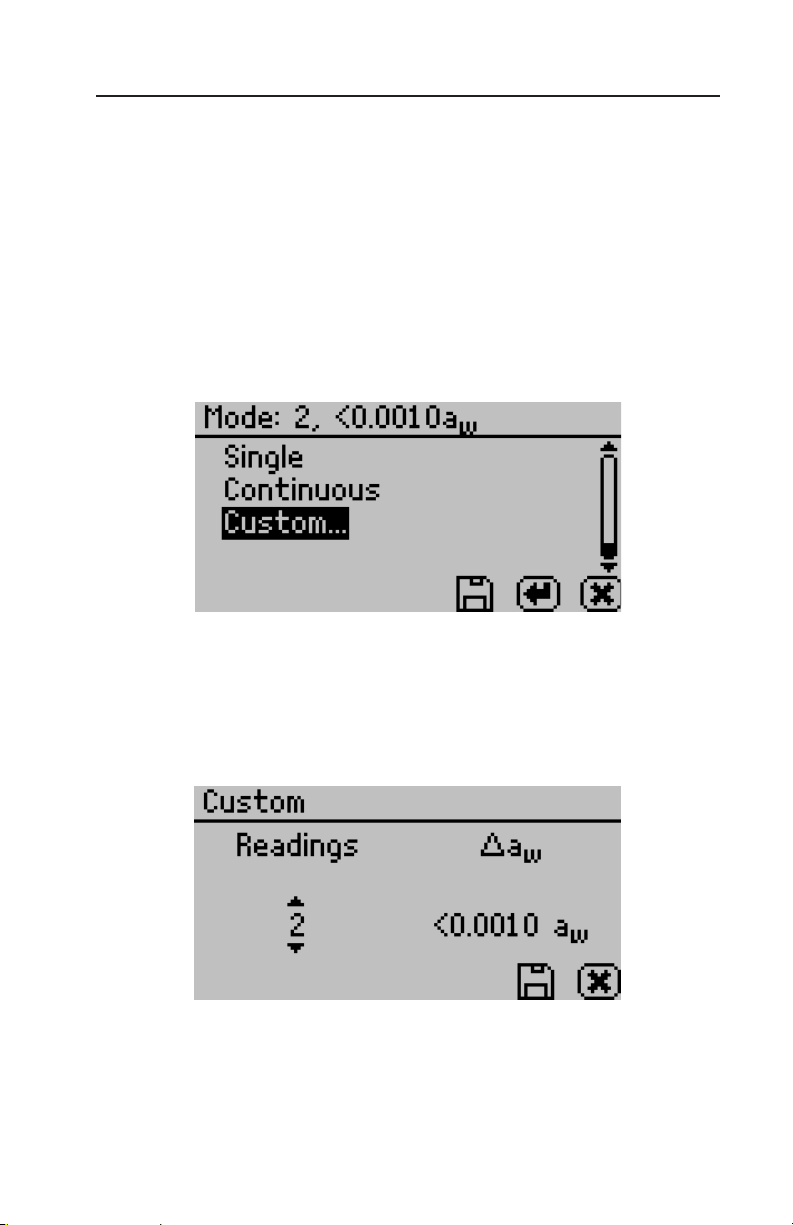

Mode:

Users may choose between single, continuous, or custom mode by

pushing the save button.

Single Mode

Single mode reads the sample once, after which the instrument notifies you that it is finished and the water activity and temperature are

displayed on the screen.

Continuous Mode

Continuous mode reads your sample until you open the chamber

lid or stop the test using the stop button. AquaLab reads the sample,

displays the water activity and temperature, then begins another read

cycle without further input from the user. Between samples, the machine will signal you with beeps. is mode eliminates the possibility

of moisture exchange with the environment outside the chamber in

between readings. A time on the bottom left of the screen tracks the

cumulative read time. All readings taken during continuous mode

are saved on the instrument’s memory if the autosave feature is selected (see Auto Save below). If AquaLab is connected to a computer

using AquaLink RG (See Chapter 11), all readings taken during continuous mode will be downloaded to the AquaLink RG software.

Custom Mode

Custom mode allows a sample to be read multiple times until

a desired level of stability is achieved. e user determines how

many consecutive tests they want to be within a given water activity stability setting. For instance, the customer can choose to

have 4 consecutive tests be within +/- 0.001aw. e instrument

will continue to run tests until it records 4 tests that are within +/-

0.001aw and then will stop and report the value of the final test. If

autosave is turned on, all test readings will be saved to the instruments memory, but only the final reading will appear on the main

22

Page 29

AquaLab

5. Menus

measurement screen. If AquaLab is connected to a computer using

AquaLink RG (See Chapter 11), all readings taken during a custom mode test will be downloaded to the AquaLink RG software.

On the mode screen, at the top of the page, will appear the current

mode settings with the number of tests appearing first, followed by the

stability value (∆aw). Pressing enter with the custom mode highlighted will allow the number of tests and stability settings to be changed.

To change the number of readings, use the right/left arrow buttons to highlight the number under Readings, and then use the

up and down buttons to change to any value between 2 and 9.

To change the stability setting, use the right/left arrow buttons to

23

Page 30

AquaLab

5. Menus

highlight the number under ∆aw, and then use the up and down buttons to change to any value between 0.0005 and 0.0030. To save the

settings and finish, press the save button (to exit without updating,

press the cancel button). e mode screen will now appear with the

updated custom settings appearing at the top of the screen. Press the

save button to return to the configuration screen and begin using the

custom mode (To exit without updating, press the cancel button).

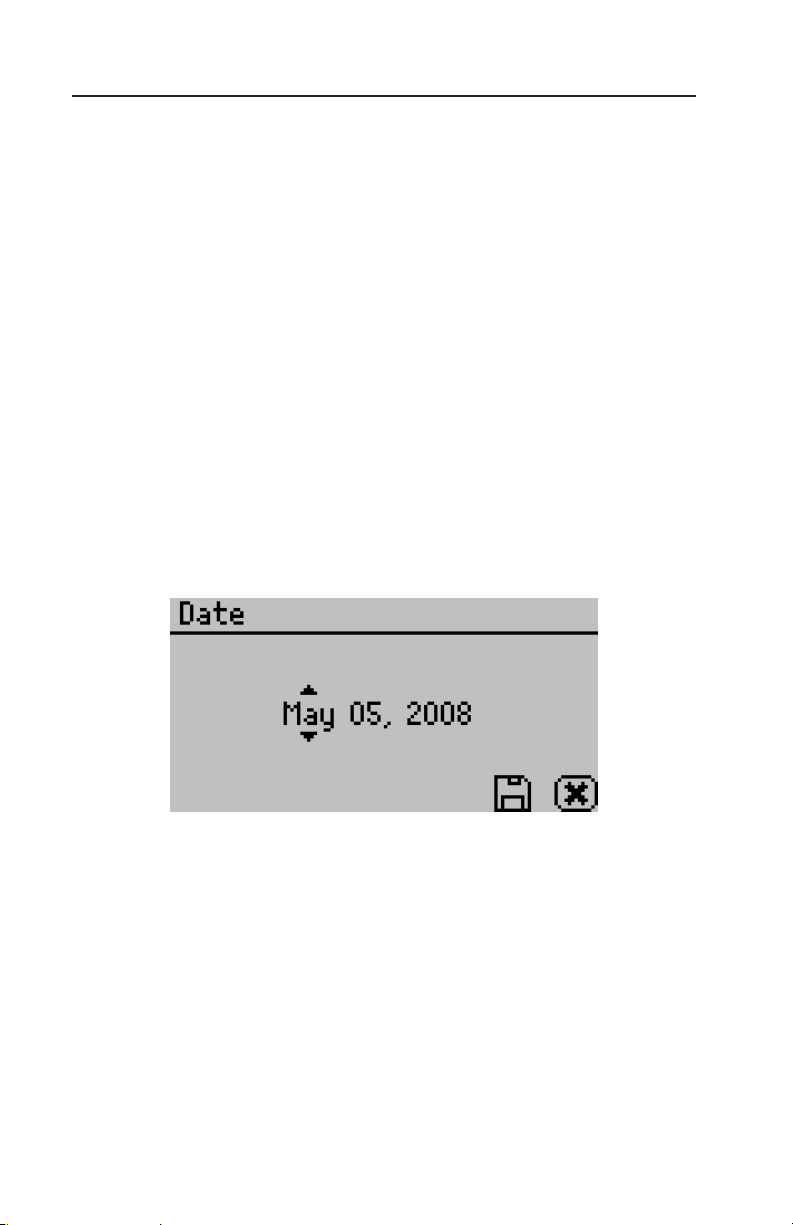

Date:

AquaLab Series 4 models now have an internal calendar and clock.

e time and date are recorded with each water activity reading.

Pressing Enter when the Date option is highlighted allows you to set

the date in the instrument. Press the left and right arrows to change

between the month, day and year. Press the up or down arrows to

change any of the individual values.

Time:

Pressing Enter when the Time option is highlighted allows you to

set the current local time. Press the up or down arrows to change

any of the individual values. Press the left or right buttons to change

between hour and minutes. e hour setting automatically changes

between AM and PM.

24

Page 31

AquaLab

5. Menus

Regional Formatting:

Allows you to configure how all Series 4 models will display information. You may choose the temperature scale (Celsius vs Fahrenheit), the date display (mm/dd/yy vs. dd/mm/yy), the hour format

(12 vs 24 hour) and the language.

Admin Settings

Allows you to create an administrator password as well as create, edit

and delete additional users.

25

Page 32

AquaLab

5. Menus

e admin option allows the administrator to grant or block access

to some or all of the configuration options in all Series 4 models. For

example: If the administrator wanted to make sure that all samples

were read at 25°C the administrator would set their temperature to

25°C and then would lock all other users out of that configuration

screen. is is accomplished by entering the Access function and

selecting the desired option to toggle it on and off.

Additionally you can lock and unlock all of them at once. For example, if you do not want John Doe changing the instruments measurement temperature, the administrator can lock that function for John.

e areas that can be locked are calibration, temperature, temperature equilibration, sensor selection, mode, date/time, region, password, auto-save, number of beeps, contrast, and delete functions.

26

Page 33

AquaLab

5. Menus

User Setup:

Users can be added, edited or deleted from this screen. An alphabet

screen will appear where a name can be entered using lower case,

upper case and accents.

NOTE: User setup is not required for instrument operation. It is in place

for users wanting to be compliant with 21 CFR Part 11 or who want to

maintain the settings they have selected.

Auto Save:

AquaLab Series 4 models have the ability to store water activity

readings within the instrument. By selecting Auto Save “On” every

water activity reading will be automatically stored in the instruments

internal memory. AquaLab Series 4 can store up to 10,000 records

before the memory is full. If you select Auto Save “off” then no

data is automatically stored, although any individual reading may be

manually stored at any time.

To manually store a water activity or append an annotation to the

active reading that has been autosaved. Press the save icon button

after the water activity measurement is completed. Pressing the icon

opens a “name” screen. You may give this reading a name by pressing the arrow buttons to highlight the letter and then pressing the

27

Page 34

AquaLab

5. Menus

“Check” icon button. Press the save icon to save this data record

with the name you have specified.

NOTE: Pressing the save icon button without giving it a name will save

the reading without a name.

Beeps:

Allows you to set the reading finished notification from 4 beeps to

continuous beeps. You may also turn the audible notification off.

Contrast:

Allows you to set the contrast of the screen to your liking. Viewing

the screen from a sitting versus a standing position may require contrast adjustment for the best visibility in that position.

Diagnostics:

For the chilled-mirror dewpoint sensor it provides you with lid, base,

sample and mirror temperature as well as an optical voltage.

28

Page 35

AquaLab

5. Menus

For the capacitance sensor (TEV Models only) it provides you lid,

base, and sample temperatures as well as relative humidity.

About:

is screen provides important information including the serial

number and code version of your instrument.

29

Page 36

AquaLab

5. Menus

Data Tab

View:

is selection will allow you to view your stored measurements. e

up/down arrows will move you through the stored data with the

most recent measurements at the top of the table. You may also press

the left and right arrows to page quickly through the data. See Chapter

11: Computer Interface for information about downloading these

readings to a computer.

When you are viewing the summary screen, you may press the enter

button on a highlighted reading to get detailed information on the

reading as shown below.

30

Page 37

AquaLab

5. Menus

e information shown is the water activity of the sample, the temperature, the time the reading took, the user who ran the test (if

setup), the date of the reading, the sensor used (4TEV only), the

time the reading was taken, and the sequence number of the stored

reading.

Delete:

Selecting this option will delete all of the information currently

stored in the instrument. If you have not backed up this information

you will be reminded of this by the following message:

NOTE: You will NOT be able to recover deleted data.

31

Page 38

AquaLab

6. Cleaning and Maintenance

6. Cleaning and Maintenance

Keeping your AquaLab clean is vital to maintaining the accuracy

of your instrument. Dust and sampling debris can contaminate the

sampling chamber and must therefore be regularly cleaned out. To

clean your instrument, carefully follow these instructions and refer

to the labeled diagram below.

32

Page 39

AquaLab

6. Cleaning and Maintenance

Purpose

e purpose for the cleaning procedure is to remove grease, dirt and

other soluble substances which can absorb/release water during verification, calibration, and/or sample testing. For a smooth and even

dew formation, it requires the mirror to be perfectly clean. If there

are any contaminants (e.g. fingerprints) on the mirror, the dew will

form unevenly and thus affect the accuracy of the reading.

Materials Needed

A thin plastic rod or other non-metal implement•

Distilled Water•

Isopropyl Alcohol (IPA) or Decagon Cleaning Solution•

Kimwipes®•

You may also purchase the AquaLab Cleaning Kit which comes

with all the above materials except the Isopropyl Alcohol and Distilled Water.

NOTE: Wash your hands with soap and water and/or use clean lab gloves

before starting the cleaning procedure. is will prevent oils from contaminating the cleaning materials, the sample chamber and/or the sensors.

Cleaning the Block and Sensors

Accessing the Sample Chamber

Turn the power off on your AquaLab. If latched, move the lever

over to the open position. Lift the chamber cover to expose the

sample chamber and sensors. e sample chamber consists of all

surfaces inside the red o-ring when the lid is closed.

NOTE for Series 4TEV: If cleaning an AquaLab Series 4TEV, follow

the cleaning procedures listed below being careful not to get cleaning

solution or alcohol on the capacitance sensor filter (see illustration on

33

Page 40

AquaLab

6. Cleaning and Maintenance

previous page) Repeated exposure of cleaning materials or contaminants

to the filter may cause inaccurate readings. If the filter appears contaminated, replace it while being careful not to disturb the sensor behind the

filter.

Cleaning Procedure:

Cleaning your AquaLab is a multi-step procedure which involves

washing, rinsing, and drying for each specific area as outlined

below:

Cleaning the Sample Chamber1.

Note: Be extremely careful not to damage the fan blades (see illustration) when cleaning the chamber.

Remove any debris that may have collected within or around a.

the sample chanber.

Wrap a NEW Kimwipe around the end of the thin plastic b.

rod (spatula) and moisten it with isopropyl alcohol or Decagon Cleaning Solution. Note: Do NOT dip a used Kimwipe

into your container of IPA or cleaning solution (the IPA or

cleaning solution will become contaminated).

WASHClean upper chamber, o-ring, and all surfaces of the c.

block within the o-ring. You may need to replace the Kimwipe if it becomes too dirty during this process.

Clean lower block with a fresh Kimwipe. Be sure to clean d.

the entire block surface.

RINSERepeat steps b-d using new Kimwipes with distilled e.

water.

DRYRepeat steps b-d using new, dry Kimwipes to help f.

remove any moisture remaining from the cleaning.

Visually inspect the sample chamber for cleanliness. Re-clean g.

if necessary. Note: Do not reuse Kimwipes.

34

Page 41

AquaLab

6. Cleaning and Maintenance

Clean the Mirror2.

Wrap a new Kimwipe around the end of the thin plastic rod a.

(spatula) and moisten it with isopropyl alcohol or Decagon

Cleaning Solution.

WASHSwipe the moistened Kimwipe across the mirror b.

once. (A single swipe is usually sufficient to remove contaminants.)

RINSERepeat steps a-b using new Kimwipes moisted with c.

distilled water instead of cleaning solution.

DRYRepeat steps a-b using new, dry Kimwipes to help d.

remove any moisture remaining from the cleaning.

Visually inspect the mirror for cleanliness. Re-clean if neces-e.

sary.

Clean the ermopile and Optical Sensor3.

Wrap a new Kimwipe around the end of the thin plastic rod a.

(spatula) and moisten it with isopropyl alcohol or Decagon

Cleaning Solution.

WASHSwipe the moistened Kimwipe across thermopile b.

and optical sensor. (A single swipe across the sensor is usually sufficient to remove contaminants.)

RINSERepeat steps a-b using new Kimwipes moistened c.

with distilled water instead of cleaning solution.

DRYRepeat steps a-b but use a new, d. dry Kimwipe to help

remove any moisture remaining from the cleaning.

Visually inspect the thermopile and optical sensor for cleanli-e.

ness. Re-clean if necessary.

Additional Drying Time4.

Visually inspect the sample chamber and sensors for contami-a.

nants, including moisture. If necessary, repeat the cleaning

process using new Kimwipes.

Let stand for about 5 minutes to ensure the sample chamber b.

is dry.

35

Page 42

AquaLab

6. Cleaning and Maintenance

Verification of Calibration

After you have cleaned the chamber and other parts of your AquaLab,

it is important to check the instrument’s performance in order to

correct for any linear offset that may have occurred during the cleaning process.

Before you check the instrument we recommend that you run a

sample of the activated charcoal pellets provided in your AquaLab

cleaning kit. is cleans the air inside the chamber, helping it come

back to a stable sampling environment.

Verify the linear offset against known verification standards according to the procedure described in the next chapter. If a linear offset

has occurred, refer to “adjust for linear offset” section in Chapter 7

for directions on how to correct for linear offset. If, after adjusting

for linear offset, your instrument is still not reading samples correctly, please contact Decagon for support.

36

Page 43

AquaLab

7. Verification and Calibration

7. Verification and Calibration

It is important to verify AquaLab’s water activity calibration against

known standards to guarantee optimal performance and accuracy.

Decagon recommends verification daily, once per shift or before

each use.

Water Activity Verification

AquaLab uses the chilled-mirror dewpoint technique to determine

water activity. Because this is a primary measurement of relative humidity, no calibration is necessary; however, it is important to verify

for linear offset periodically. e components used by the instrument to measure water activity are subject to contamination which

may affect the AquaLab’s performance. When this occurs, it changes

the accuracy of the instrument. is is what is called a “linear offset.”

erefore, frequent verification assures you that your AquaLab is

performing correctly. Linear offset is checked by using two different

verification standards.

Verification Standards

Verification standards are specially prepared unsatuarated salt solutions having a specific molality and water activity constant which are

accurately measurable. e verification standards that were sent with

your initial shipment are very accurate and readily available from

Decagon. Using verification standards to verify accuracy can greatly

reduce preparation errors. For these reasons, we recommend using

standards available through Decagon for the most accurate verification of your AquaLab’s performance.

Performance Verification Standards come in five water activity levels: 1.000, 0.984, 0.760, 0.500, and 0.250 aw. e standards are

37

Page 44

AquaLab

7. Verification and Calibration

produced under a strict quality assurance regime. Please contact

Decagon Devices to order additional standards via sales@decagon.

com or 1-800-755-2751.

Verication Standard

@ 25°C

Distilled Water 1.000 ±0.003

0.5m KCl 0.984 ±0.003

6.0m NaCl 0.760 ±0.003

8.57m LiCl 0.500 ±0.003

13.41m LiCl 0.250 ±0.003

NOTE: If you need to obtain a Material Safety Data Sheet (MSDS)

for any of these standards, a printable version is available on our website at www.decagon.com/msds.

To use a verification standard, remove the twist top and pour the

contents into an AquaLab sample cup. If for some reason you cannot obtain Decagon’s verification standards and need to make a saturated salt solution for verification, refer to Appendix A.

Water Activity

Verification of Calibration

When to Verify for Linear Offset

Linear offset should be checked against two known verification

standards daily, either once per shift or before each use. Linear offset

should never be verified solely against distilled water, since it does

not give an accurate representation of the linear offset. For batch processing, the instrument should be checked regularly against a known

standard of similar water activity. It is also a good idea to check

the offset with a standard of similar water activity when the general

38

Page 45

AquaLab

7. Verification and Calibration

water activity range of your sample is changing. Checking the water

activity of a standard solution will alert you to the possibility of unit

contamination or shifts in the linear offset from other causes.

Note: e verification process is the same for both the dewpoint and

capacitance sensors in TEV models except that the accuracy for the capacitance sensor is ± 0.015 aw .

Verification

To verify for linear offset of your AquaLab, do the following:

1. Choose a verification standard that is close to the water activity of

the sample you are measuring. Note: e AquaLab needs to warm

up for approximately 15 minutes to make accurate readings.

2. Empty a vial of solution into a sample cup and place it in the

AquaLab’s testing chamber. Make sure that your standard is as close

to the instrument temperature as possible.

Note: Make sure the rim and outside of the sample cup are clean.

3. Carefully close the lid and move the lever to the READ position.

4. Take two readings. e water activity readings should be within

± 0.003 aw of the given value for the verification standard. See Ap-

pendix B for the correct water activity value of Decagon’s standards

at temperatures other than 25°C.

5. If your AquaLab is reading within ±0.003 aw of the verification

standard, chose a second verification standard that would border the

range of water activity you plan to test. For example, if you plan

39

Page 46

AquaLab

7. Verification and Calibration

to test for water activity readings ranging between 0.713 and 0.621

you should use the 6.0M, NaCl (0.76aw)standard for your first verification and the 8.57M LiCl (0.50aw) for the second verification.

6. Prepare a sample cup of the second verification standard and

make two readings. e second water activity reading for the second

verification standard should be within ±0.003 aw.

7. If either of the verification standards is not correct, it is probably

due to contamination of the sensor chamber. For cleaning instructions, see Chapter 6. After cleaning, repeat verification from step

two.

8. If you are consistently getting readings outside the water activity of

your first verification standard by more than ±0.003 aw, a linear offset

has probably occurred. In this case, adjust the reading to match the

verification standard’s correct value as outlined in the next section.

40

Page 47

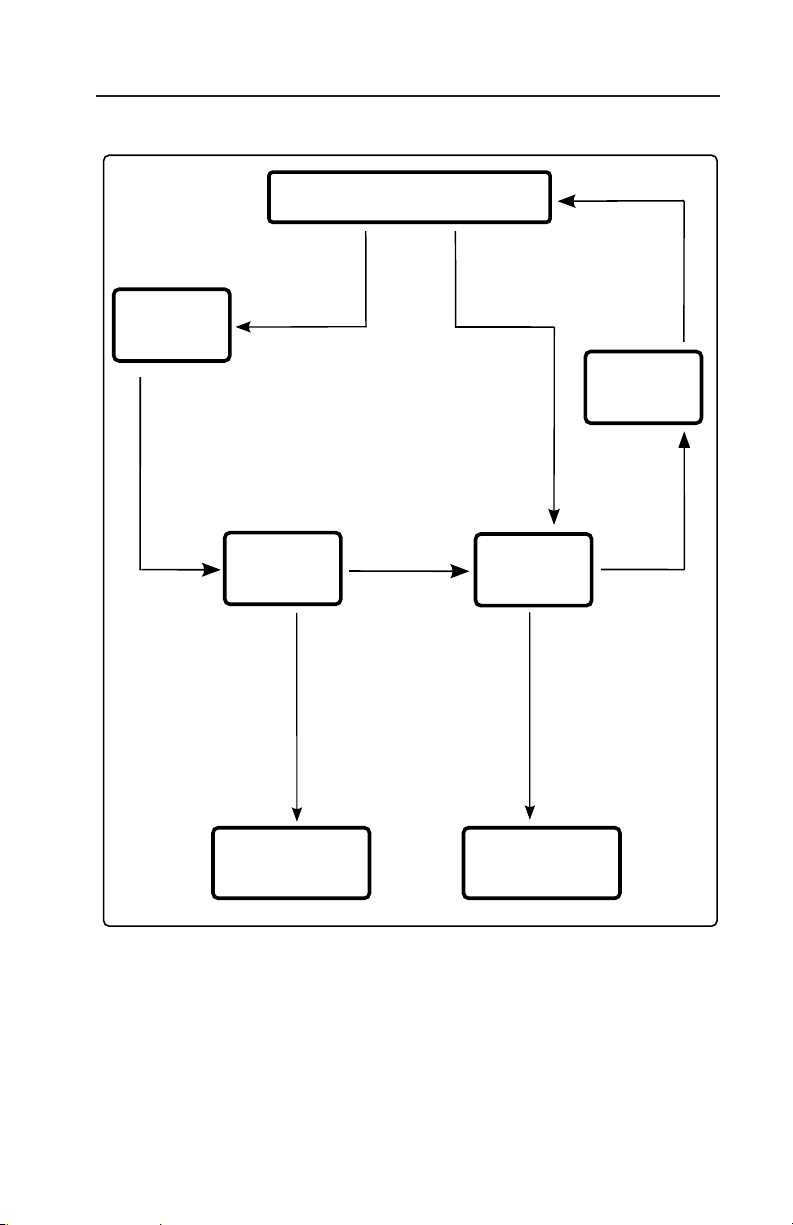

AquaLab

Correct

Not Correct

Next

Correct

Not

Correct

Measure Verification Standard

Correct

Not Correct

Repeat Process

Go to Linear

Offset Procedure

Go to Sampling

Procedure

Clean Sample

Chamber

Re-Read

Standard

Measure 2nd

Standard

Clean Sample

Chamber

7. Verification and Calibration

is flowchart is a graphical representation of the directions given above

for checking for linear offset.

41

Page 48

AquaLab

7. Verification and Calibration

Adjust for Linear Offset

1. Once you are certain a linear offset has occurred, toggle to the

Configuration tab by pressing the Menu icon button. Calibration is

the first option highlighted in the configuration tab. Press the Enter

icon button to begin the verification process. You will be guided

through the linear offset routine through on screen commands. e

following screen will appear:

2. Press the Enter button to start the linear offset process. To

return to the main menu, press the cancel button. After pressing

the enter button, the following screen will appear:

3. Empty the whole vial of solution into a sample cup. We recommend using the 6.0 NaCl (0.76aw). Do not adjust for the offset us-

42

Page 49

AquaLab

7. Verification and Calibration

ing distilled water. Ensure the rim and outside of the cup are clean.

Place the sample cup in the AquaLab’s sample chamber.

NOTE: e same verification standard may be used to verify and

adjust the linear offset.

4. Carefully close the lid and move the lever to the READ position.

Press the Check icon button to begin testing.

NOTE: If you decide at this point not to continue with the linear offset

program, just return the lever to the OPEN position or press the cancel

button and you will be returned to the previous screen.

5. After your AquaLab has finished measuring the verification standard, it will display the following screen:

6. Press the up and down arrows to adjust the water activity reading

to its proper value for the particular verification standard you are

measuring. When the correct value is displayed, press the Save icon

button to store this new value. To cancel and return to the main

menu, press the cancel button and no changes will be made.

7. Re-measure the verification standard again in normal sampling

mode. It should read the proper value (within ±0.003 aw ) at a given

43

Page 50

AquaLab

7. Verification and Calibration

temperature for your particular standard (see Appendix B for temperatures other than 25°C ).

Measure the water activity of a second verification standard according to the verification procedure described above. If both verification readings are within ±0.003 aw then the instrument is ready to

begin testing.

If you still have incorrect verification standard readings after cleaning the chamber and adjusting for linear offset, contact Decagon

by email at support@decagon.com or by phone at 509-332-2756

(800-755-2751 in US and Canada) for further instructions. If you

purchased your Decagon instrument from one of our international

distributors, please contact them for local service and support.

How to Restore Factory Defaults

To restore original calibration settings, do the following:

1. Toggle to the Configuration tab by pressing the Menu icon button. Select Calibration and press the Enter button.

2. Scroll down to Defaults and press the Enter icon button to access

44

Page 51

AquaLab

7. Verification and Calibration

the Restore Factory Defaults routine. To cancel and return to the

main menu, press the Cancel icon button. After pushing the Enter

icon button, the following screen will appear:

NOTE: For TEV models make sure you have the correct sensor selected.

3. To restore the factory calibration values, press the Check icon

button. To cancel and return to the main menu, press the cancel

button. After pressing the Check icon button, the following screen

will appear:

4. To return to the main menu screen, press the Check icon button.

45

Page 52

AquaLab

8. Sample Preparation

8. Sample Preparation

Proper sample preparation is an important step in keeping your

AquaLab clean and achieving repeatable results. Careful preparation

and loading of samples will lengthen time between cleanings and

help you avoid downtime.

Preparing the Sample

1. Make sure the sample to be measured is homogeneous. Multi-

component samples (e.g., muffins with raisins) or samples that have

outside coatings (like deep-fried, breaded foods) can be measured,

but may take longer to equilibrate. For samples like these, AquaLab

may take more than five minutes to give an accurate reading, or may

require multiple readings of the same sample. Measuring the water

activity of these types of products is discussed in detail later in this

chapter (see Samples Needing Special Preparation).

2. Place the sample in a disposable sample cup, completely cov-

ering the bottom of the cup, if possible. AquaLab is able to accurately measure a sample that does not (or cannot) cover the bottom

of the cup. For example, raisins only need to be placed in the cup

and not flattened to cover the bottom. A larger sample surface area

increases instrument efficiency by providing more stable infrared

sample temperatures. It also speeds up the reading by shortening the

time needed to reach vapor equilibrium.

3. Do not fill the sample cup more than half full. Overfilled cups

will contaminate the sensors in the sensor chamber. Filling the

sample cup will not make the readings faster or more accurate. ere

only needs to be enough sample in the cup to allow the water in

the sample to equilibrate with the water in the vapor phase and not

46

Page 53

AquaLab

8. Sample Preparation

change the moisture content of the sample. Covering the bottom of

the sample cup provides enough sample to get an accurate reading.

4. Make sure the rim and outside of the sample cup are clean.

Wipe any excess sample material from the rim of the cup with a

clean Kimwipe. Material left on the rim or the outside of the cup

can contaminate the sensor chamber and be transferred to subsequent samples.

5. If a sample will be read at some other time, put the sample

cup’s disposable lid on the cup to restrict water transfer. For longterm storage, seal the lid by placing tape or Parafilm® completely

around the cup/lid junction. It is necessary to seal the cup if it will

not be measured immediately.

6. Be consistent in sample preparation practices.

If you crush, grind, or slice your sample, be consistent in the method

you use in order to obtain reproducible results.

Samples Needing Special Preparation

AquaLab reads most materials in five minutes or less. Some samples, however, may require longer reading times, due to their nature. ese materials need additional preparation to ensure quick,

accurate readings. To find out whether special sample preparation is

necessary, take several readings to see if readings (a

lize. If continued readings take longer than six minutes, remove the

sample and take a reading of a verification standard. is will ensure

the sample itself is causing the long read time, and that there is not a

problem with your instrument. If the verification standard also takes

longer than six minutes to sample, the chamber may be dirty. Refer

to Chapter 6 for cleaning procedures.

47

and time) stabi-

w

Page 54

AquaLab

8. Sample Preparation

Coated and Dried Samples

Samples with coatings such as sugar or fat often require multiple

readings, because it takes longer for them to equilibrate. If this is the

case for your samples, it is not a problem with your instrument; it

simply means that your particular sample takes longer than most to

equilibrate.

To reduce the time needed to take an water activity reading for coated or dried samples, you can crush or slice the sample before sampling. is increases the surface area of the sample, thus decreasing

reading times. Keep in mind, however, that modifying some samples

may alter their water activity readings.

For example, a candy may have a soft chocolate center and a hard

outer coating. e water activity reading for the center and the outer

coating are different, so one would need to evaluate which part of the

sample needed to be measured before crushing it. When the candy is

crushed, the water activity will represent the average water activity of

the entire sample; whereas leaving the candy whole will give a reading for the coating, which may act as a barrier to the center.

Slow Water-Emitting Samples

Some extremely dry, dehydrated, highly viscous water-in-oil (butter), high fat, or glassy compositions may require multiple tests due

to their slow water-emitting properties. is is because the slow

emission of water decreases the change in water activity sufficiently

that the instrument determines the test to be complete, even though

changes in water activity are still occuring. e most effective way to

test these types of samples is to run them in the AquaLab using the

continous or custom mode and wait for the water activity readings

to stablize.

48

Page 55

AquaLab

8. Sample Preparation

For faster reading, it is important to have the water activity of the

chamber at or below the water activity of these type of samples. is

causes the sample to release water to the vapor phase and equilibrate

with the chamber. If the water activity of the head-space is greater

than this type of sample, a long period of time will be required to

reach equilibrium and the water activity of the sample may be affected.

Volatile Samples

AquaLab will give accurate readings on most samples. However,

samples with certain volatiles in high enough concentrations may

give inaccurate water activity values. is is because the volatiles

condense on the mirror during the reading process, but do not

evaporate from the mirror as water does. As a result, the reading

on volatiles will not be accurate. e concentration of volatiles that

will cause interference is variable and matrix dependent. e most

effective method to determine if volatiles are a problem is to look for

incorrect standard readings after reading the sample.

Decagon’s Series 4TEV is designed for measuring volatiles such as

propylene glycol and ethanol. e Series 4TEV contains both a

chilled-mirror dewpoint and a capacitance sensor. Simply choose

the sensor you want to use from the menu in the instrument. e

only difference in operation is a lower accuracy of ±0.015 aw for

the capacitance sensor. All other operations and features will be the

same, including measurement times and adjusting for linear offset.

After measuring volatiles with the volatiles sensor it is a good idea

to clean the chamber and run charcoal before switching to the dew

point sensor.

Low Water Activity

When a sample’s water activity value is below the cooling capacity of

49

Page 56

AquaLab

8. Sample Preparation

the Series 4, your AquaLab will display an error message indicating

the lowest reading it attained on that particular sample. See Chapter 12’s

troubleshooting problem #5 for possible solutions.

If your sample is not below 0.03 aw but is still getting the error message, refer to Chapter 12 for other possible explanations.

Samples not at Room Temperature

Samples that are 4°C colder or warmer than the instrument (chamber) temperature will need to equilibrate to instrument temperature before a fast, accurate reading can be made. Rapid changes in

temperature over short periods of time will cause the water activity readings to rise or fall until the temperature stabilizes. When

the temperature stabilizes within one or two degrees of the chamber

temperature, you can proceed with normal measurements.

High-water activity samples that are warmer than the chamber temperature can cause condensation inside the measuring chamber, which

will adversely affect subsequent readings. A warning message appears

(Sample too hot) if the sample temperature is more than 4°C above

chamber temperature. If this message appears, immediately remove

the sample from the instrument, place a lid on the cup, and allow the

sample to cool to within 4°C of the instrument before measuring.

Samples that are lower than 4°C of the instrument’s temperature

will cause long read times. e sample temperature must be within

one or two degrees of the chamber temperature before fast, accurate

readings can be made.

NOTE: Powdery substances can be blown by the fan so be sure not to

overfill the sample cup and verify the cleanliness of the sample chamber

before reading a new sample.

50

Page 57

AquaLab

9. Taking a Reading

9. Taking a Reading

Measurement Steps

Once you have verified for cleanliness, calibration and prepared your

sample, you are ready to take readings. e process is simple:

Move the chamber lever to the Open position and lift the cham-•

ber lid.

Check the top lip and outside of the sample cup to make sure •

they are free from sample residue and that sample cup isn’t overfilled. (remember, an over-filled sample cup may contaminate

the chamber’s sensors).

Place your prepared sample cup in the chamber. •

Close the chamber lid and move the lever to the Read position. •

This will seal the chamber and start the reading.

In 1 to 2 minutes, the first water activity measurement will be displayed on the LCD. Length of read times may vary depending on

temperature differences between the chamber and your sample, and

other properties of your sample.

How AquaLab Takes Readings

AquaLab’s reading cycle continues until the rate of change of three

consecutive readings are less than 0.0005 aw of each other. e instrument crosses the dew threshold numerous times to ensure equilibrium and the accuracy of readings. When the instrument has finished its read cycle, the water activity is displayed, the read time is

displayed, the spinning measurement icon is replaced by the Store

51

Page 58

AquaLab

9. Taking a Reading

icon and, if enabled, you will hear a series of beeps.

Cautions!

Never leave a sample in your AquaLab after a reading has •

been taken. The sample may spill and contaminate the instrument’s chamber if the instrument is accidentally moved

or jolted.

Never try to move your instrument after a sample has been •

loaded. Movement may cause the sample material to spill

and contaminate the sample chamber.

If a sample has a temperature that is 4°C higher (or more) •

than the AquaLab’s chamber, the instrument will beep and

display a warning as shown below. Remove the sample until

it is at room temperature.

Although the instrument will measure warmer samples, the readings

may be inaccurate. Warm samples can cause condensation in the

chamber if they have a high water activity. It is best to remove the

sample from the instrument, place a lid on the cup and allow the

sample to cool before reading.

52

Page 59

AquaLab

9. Taking a Reading

The • physical temperature of the instrument should be between

15 - 50°C. Between these ambient temperatures, AquaLab will

measure samples of similar temperature quickly and accurately.

The AquaLab Series 4TE has temperature control capabilities

that enable it to read samples at temperatures different from ambient temperature, but no higher than 50°C.

If a sample has a water activity lower than about 0.03, AquaLab •

will display the < symbol (see below) notifying you that your

sample is too dry to be accurately measured by the AquaLab.

If you know that your sample’s water activity is above what the •

screen is telling you, your instrument’s sensors may have been

contaminated and will need to be cleaned (see Chapter 6) or

serviced (see Chapter 13).

53

Page 60

AquaLab

10. Duo Operation (Optional)

10. Duo Operation (Optional)

Previously, measuring moisture content and water activity required

different instruments. Now it is possible to determine both moisture

content and water activity with one machine. e Series 4TE can be

upgraded to Series 4TE DUO which can display moisture content

simultaneously with water activity. To calculate moisture content

using water activity requires an understanding of the relationship

between the two parameters. is relationship, referred to as the

moisture sorption isotherm, is complex and unique to each product

type. A product’s isotherm can be used to calculate moisture content

based on a water activity measurement. is is most easily accomplished using a model that characterizes the isotherm. For additional

information about sorption isotherms and models, please refer to

Chapter 3. e DUO generates water activity values just as a Series

4TE, but then it uses preloaded product specific isotherm models

to calculate moisture content and present it on the screen with the

water activity. For information about upgrading your Series 4TE to

a Series 4TE DUO, please contact Decagon Devices.

54

Page 61

AquaLab

10. Duo Operation (Optional)

Obtaining Product Isotherm Models

Since the isotherm relationship for each product is unique, each product’s isotherm model must be determined experimentally. is only

needs to be done once, but must be done prior to testing moisture content with the DUO. To obtain an isotherm model for a product, samples of the product need to be sent to Decagon for isotherm analysis.

Decagon will send instructions and a packing kit to assist in submitting samples for analysis. Upon completion of the isotherm, Decagon

will generate a product model file to be loaded onto the instrument.

Loading and Organizing Product Models

A Product’s model must be loaded into the Series 4TE DUO before

it can calculate moisture content. Each product must have its own

model and the model can either be loaded at the factory by Decagon

or by using the AquaLink RG software program. is software is

included with each DUO purchase or upgrade. Product model files

generated by Decagon are sent to customers via email and can then

be loaded into the instrument by connecting to the instrument using the AquaLink RG software. e software uses a model loading

tool to add and remove product models from the Series 4TE DUO,

55

Page 62

AquaLab

10. Duo Operation (Optional)

allowing the user to control and organize their product models. e

AquaLink RG software can also download data (including moisture

content) from the instrument, present the data in table form, filter

the data, and print reports.

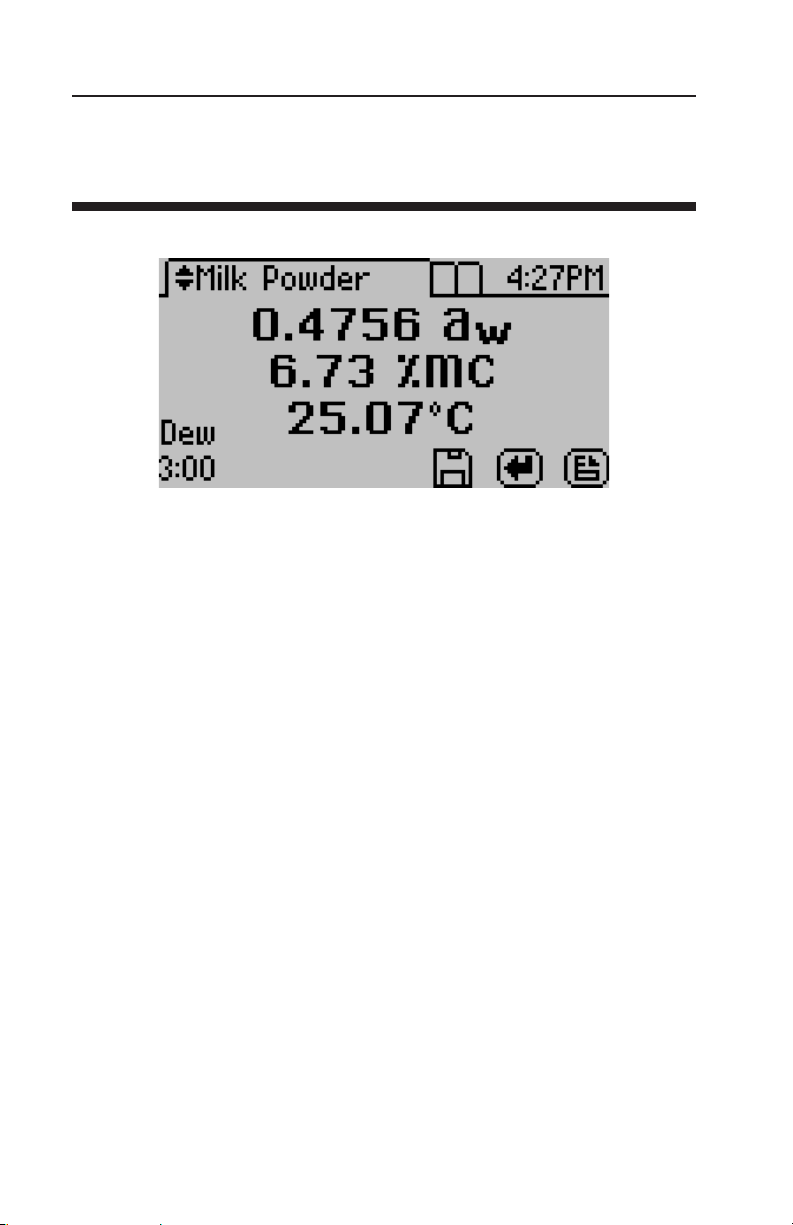

Measuring Moisture Content

With the product models loaded into the instrument, the Series

4TE DUO can generate moisture content and water activity simultaneously.

Selecting a Product for Analysis

With the Series 4TE DUO turned on, toggle to the configura-•

tion screen by pressing the menu button.

At the configuration screen, scroll down and select moisture •

content.

56

Page 63

AquaLab

10. Duo Operation (Optional)

A list of available models will be listed by name.•

Select the model for the product to be analyzed. Selecting “None” •

will not select any model.

Taking a Reading

Readings are taken with the DUO the same as outlined in Chap-•

ter 9. First, return to the main screen.

The product chosen for analysis will be shown in the tab at the •

top of the screen. If a different product is desired to be analyzed,

it is possible to scroll through all of the available product models

on the screen by pressing the up and down buttons. This elimi-

57

Page 64

AquaLab

10. Duo Operation (Optional)

nates the need to return to the configuration screen to change

products. When the tab at the top shows “Measurement”, no

model is selected and only water activity will be displayed on the

screen.

Place a sample in the chamber and begin testing by sliding the •

lever left to the read position. For information about sample

preparation, please see Chapter 8 and for additional information

about running a test, please see Chapter 9.

When the test is complete, the screen will display the water activ-•

ity and moisture content for the product selected. If the wrong

model was selected by accident, the up and down buttons can be

used to toggle through all of the product models and the moisture content value will adjust based on the model selected.

58

Page 65

AquaLab

10. Duo Operation (Optional)

The test can be saved to the instrument’s memory by pressing •

the button under the save icon. An annotation can be added if

desired. If autosave has been selected, the data will already be

saved but without any annotation.

The results can be viewed by moving to the data screen (press the

right most button, which is below the document icon, to toggle

between tabs) as shown in Chapter 5 under the Data Tab section.

The only difference will be that moisture content data will now appear in the upper right column on the detailed information screen.

59

Page 66

AquaLab

11. Computer Interface

11. Computer Interface

Your AquaLab was shipped to you with a standard RS-232 interface

cable. Using this, you can load data to a computer using Decagon’s

AquaLink RG program or your computer’s terminal program for

further analysis and storage.

AquaLink RG

An optional software program, AquaLink Report Generator (RG),

is available for use with your AquaLab. AquaLink RG is a Windows

based program designed for data collection and customized report

generation for all Series 4 AquaLab models. AquaLink RG logs

water activity, temperature, time of measurement, and date stamps

along with other information. AquaLink RG also has sample identification and comment fields that you can use to help annotate the

data your AquaLab is gathering.

A 30 day trial cd of this program is attached to the front cover of

this manual. If you are interested in purchasing the full version of

AquaLink RG, contact Decagon or your local distributor. If you

have purchased the AquaLab 4TE DUO you will automatically

receive the full version of AquaLink RG with your manual.

Using Windows Hyperterminal

To use Hyperterminal with your AquaLab, follow these steps:

On your computer, press the Start button and select Programs •

> Accessories > Hyperterminal and click on the Hyperterminal

icon.

60

Page 67

AquaLab

11. Computer Interface

At the prompt, choose a name for this program (AquaLab is a •

good one) and choose an arbitrary icon above to represent it. In

future downloads, you will be able to click on this icon in have it

already set up for you to download. Click the OK button.

A pop-up menu labeled “Connect To” will appear. Click on the •

scroll bar on the bottom of the screen labeled “Connect Using”

and select the COM Port your RS-232 cable is connected to.

A pop-up menu labeled “• COM Properties” will appear, showing

the port settings for the COM port you selected. Make sure the

settings are the following: Bits per second, 9600; 8 databits, no

parity, 1 stop bit, and flow control set to hardware. Click OK.

Plug your RS-232 cable to the COM port you selected and con-•

nect it to your AquaLab. Begin sampling. AquaLab’s data will be

displayed on screen as it samples.

When you are finished sampling, you can print the data in the •

terminal session, or cut and paste it to a spreadsheet or text

editor. To save the data, go into the Transfers menu and select

“Capture text,” and designate where it should be saved.

61

Page 68

AquaLab

12. Troubleshooting

12. Troubleshooting

AquaLab is a high performance, low maintenance instrument, designed to have few problems if used with care. Unfortunately, sometimes even the best operators using the best instruments encounter

technical difficulties. Below is quick reference guide that will direct

you to detailed solutions of some problems that may occur. If these