Page 1

SA7xEnclosure

UserGuide

Order Number: EK–OSA7X–UG. C01

This guide explains how to operate the SA7x family of enclosures: the

SA70, SA71, SA72, and SA73. This guide also includes installation

procedures that can be performed only by trained Digital Multivendor

Customer Services engineers.

Digital Equipment Corporation

Maynard, Massachusetts

Page 2

October 1993

NOTE: This equipment generates, uses, and may emit radio frequency energy. The equipment has

been type tested and found to comply with the limits for a Class A digital device pursuant to Part

15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference in a commercial installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications.

Any changes or modifications made to this equipment may void the user’s authority to operate the

equipment.

Operation of this equipment in a residential area may cause interference in which case the user,

at his own expense, will be required to take whatever measures may be required to correct the

interference.

WARNING

This is a Class A product. In a domestic environment, this product may cause radio interference in

which case the user may be required to take adequate measures.

While Digital believes the information included in this publication is correct as of the date of

publication, it is subject to change without notice.

Digital Equipment Corporation makes no representations that the interconnection of its products

in the manner described in this document will not infringe existing or future patent rights, nor

do the descriptions contained in this document imply the granting of licenses to make, use, or sell

equipment or software in accordance with the description.

©Digital Equipment Corporation 1991, 1992, 1993.

All Rights Reserved.

Printed in the United States of America.

DEC, DECsystem, DSA, DSDF, HSC, HSC50, HSC70, KDA, KDA50, KDB50, KDM, MicroVAX,

PDP-11, RA, SA, SDI, UDA, UNIBUS, VAX, VAXsimPLUS, and the DIGITAL logo are trademarks

of Digital Equipment Corporation.

Page 3

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 Introducing the SA7x Enclosure

1.1 SA7x Enclosure Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.2 RA7x and SA7x Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

1.3 SA7x Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

1.4 User Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

1.4.1 Data Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

1.4.2 Recommended Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . 1–11

1.4.3 Electrostatic Discharge Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–11

2 Operating the SA7x

2.1 SA7x Switches and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.1.1 Using the Switches and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.1.2 Using Drive Power Switches and Indicators . . . . . . . . . . . . . . . . . . . . 2–4

2.2 Using SA7x Rear Panel Switches and Indicator . . . . . . . . . . . . . . . . . . . . . 2–5

2.3 Applying Power to the SA7x Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2.4 Placing RA7x Drives On Line and Off Line . . . . . . . . . . . . . . . . . . . . . . . . 2–7

2.4.1 Placing a Drive On Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

2.4.2 Taking a Drive Off Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

3 Replacing RA7x Disk Drives

3.1 Installing and Removing an RA7x Disk Drive . . . . . . . . . . . . . . . . . . . . . . 3–2

3.1.1 Recording RA7x Disk Drive Serial Numbers . . . . . . . . . . . . . . . . . . . . 3–3

3.1.2 Reversing the RA70 Shoe Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

3.1.3 Installing an RA7x Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3.1.4 Removing an RA7x Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3.2 Installing and Removing a Drive Position Filler . . . . . . . . . . . . . . . . . . . . 3–8

4 Installing the SA7x

4.1 SA7x Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1.1 Power and Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.1.2 Recording Disk Drive Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.2 Selecting Line Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

4.3 Performing a Post-Installation Checkout and Power-Up . . . . . . . . . . . . . . 4–2

4.4 Setting Drive Unit Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

4.5 Installing an Add-On SA7x Enclosure in an SA900 Storage Array . . . . . . 4–6

4.5.1 General Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

4.6 Preparing the SA900 Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–9

4.7 Guide Rail Plate Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–11

iii

Page 4

4.8 Left Position Guide Rail Plate Installation . . . . . . . . . . . . . . . . . . . . . . . . 4–11

4.9 Right Position Guide Rail Plate Installation . . . . . . . . . . . . . . . . . . . . . . . 4–13

4.10 Preparing the SA7X Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–14

4.11 Installing the SA7X Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–15

4.11.1 Completing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–19

5 Troubleshooting the SA7x

5.1 Identifying Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.2 Troubleshooting a Dead Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.2.1 If the Fault Indicator Is Lit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.2.2 If the Fault Indicator Is Not Lit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

5.3 Troubleshooting a Flashing Drive Power Indicator . . . . . . . . . . . . . . . . . . 5–3

5.4 Troubleshooting Excessive Drive Errors or a Fault Condition . . . . . . . . . . 5–5

5.5 Reading OCP Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–5

5.6 Troubleshooting a Drive Not Visible to the Controller . . . . . . . . . . . . . . . . 5–6

5.7 Troubleshooting the OCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

A Environmental Stabilization

B RA7x Error Rates

B.1 RA7x Error Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

C Revision Support

Index

Figures

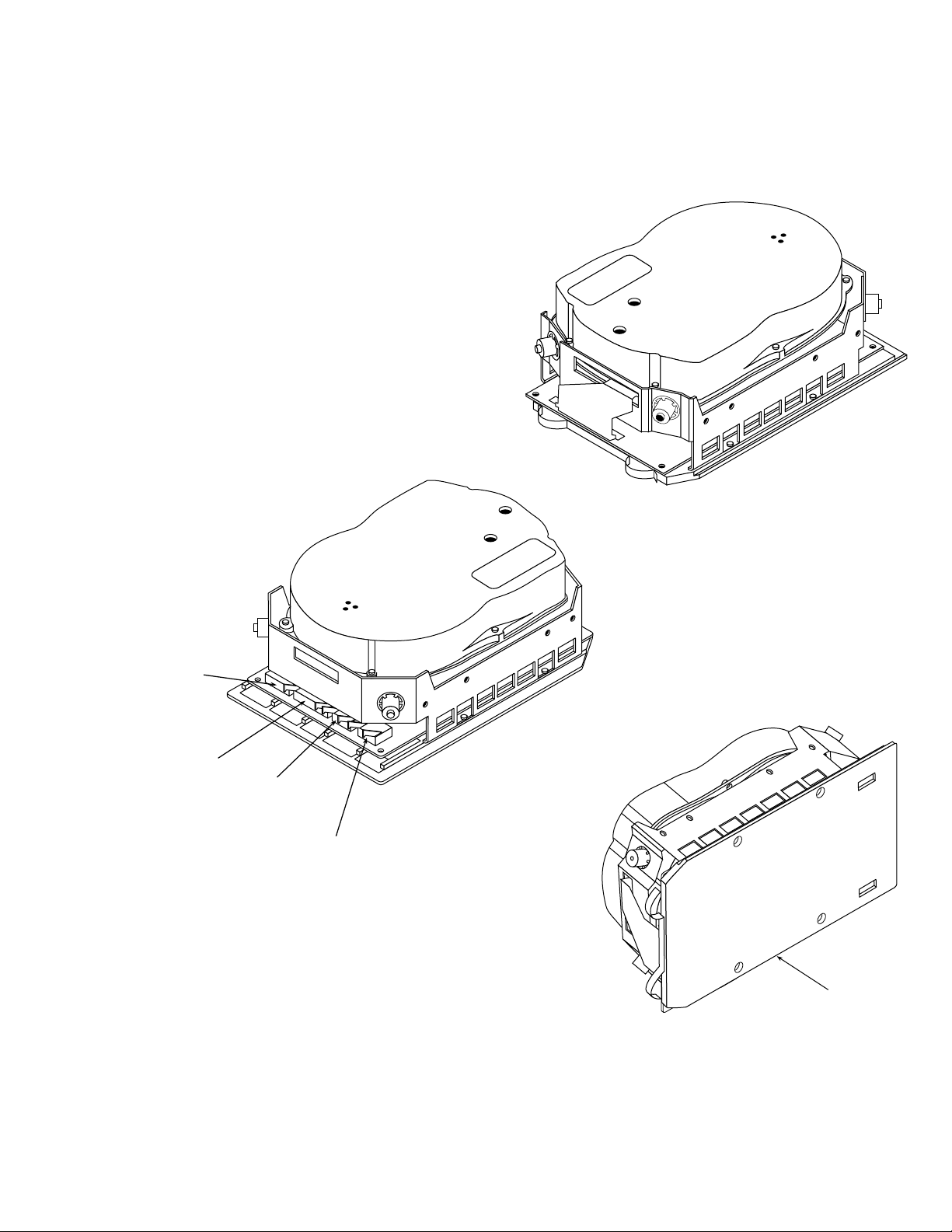

1–1 SA7x Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

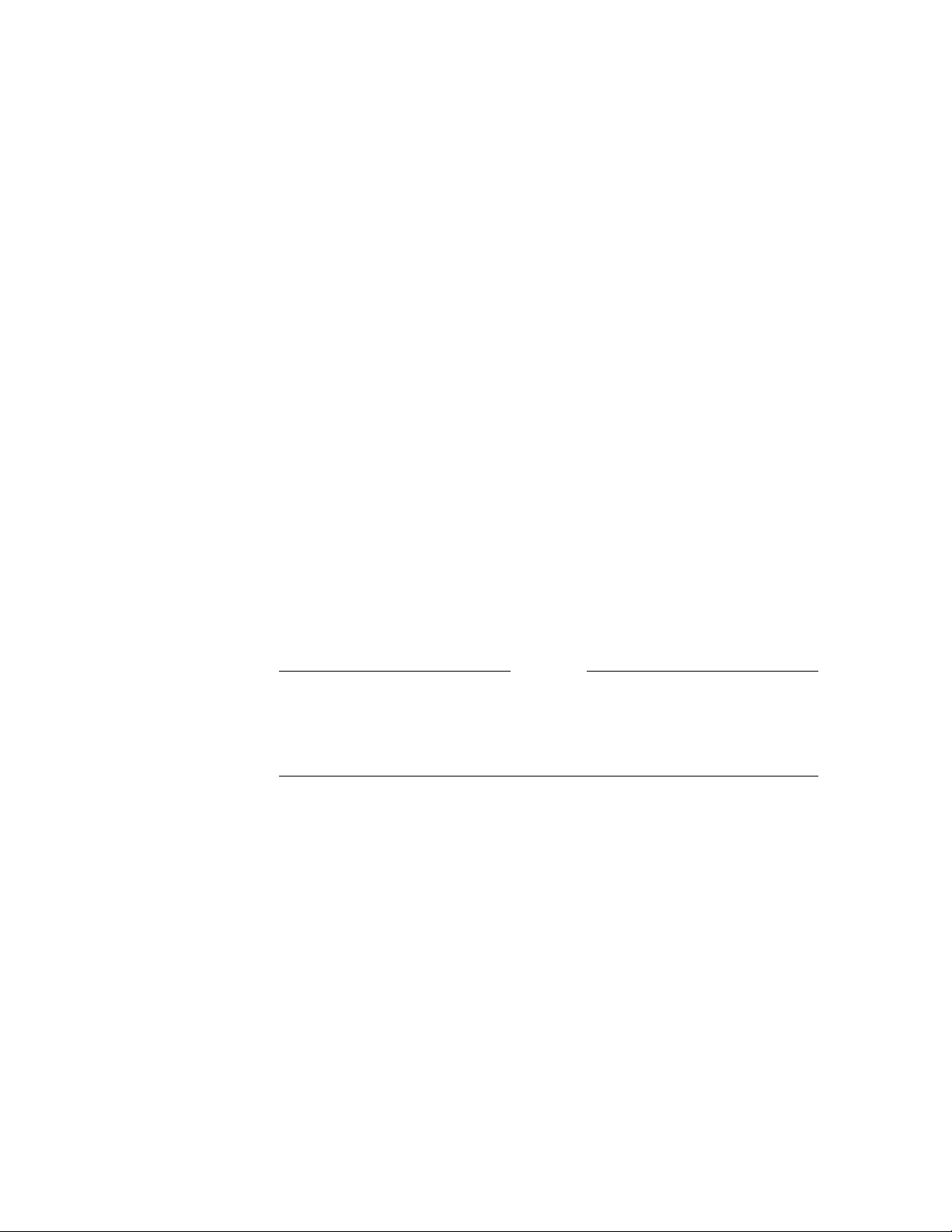

1–2 RA70 Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

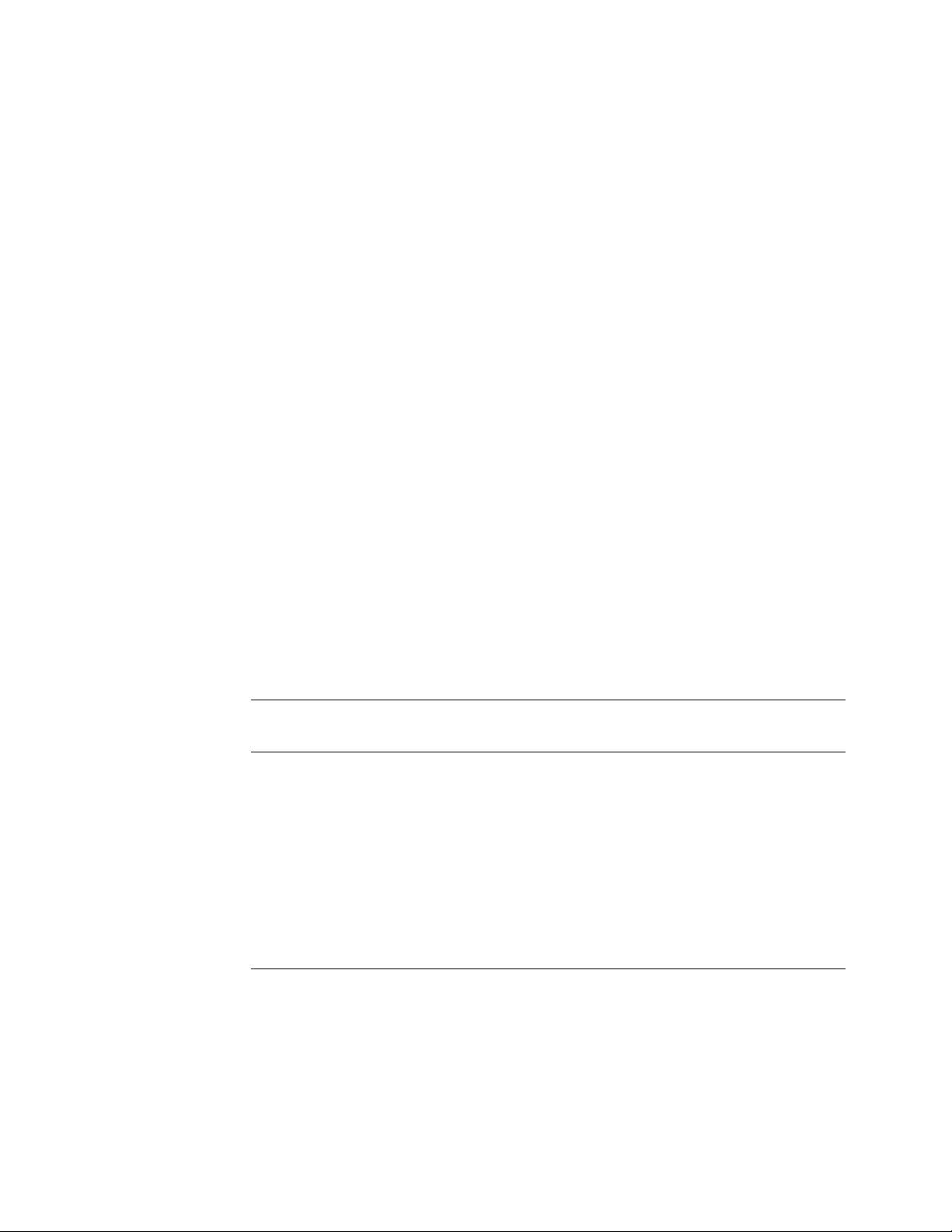

1–3 RA71 Through RA73 Disk Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1–4 Using the ESD Grounding Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–12

2–1 SA7x Enclosure Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2–2 SA7x Enclosure Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

3–1 SA70 Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

3–2 RA7x Disk Drive Serial Number Location . . . . . . . . . . . . . . . . . . . . . . 3–4

3–3 Reversing the RA7x Shoe Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

3–4 Replacing RA70 Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

4–1 SA7x Enclosure Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4–2 Storage Device Add-On Sequence for the SA900 Storage Array (Front

View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–7

4–3 SA7x Front Clamping Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

4–4 SA900 and SA7x Chassis Retaining Brackets . . . . . . . . . . . . . . . . . . . 4–9

4–5 SA7x Enclosure Guide Rail Assembly Installation . . . . . . . . . . . . . . . . 4–10

4–6 SA900 Mounting Rail Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–12

4–7 Installing the SA7x Enclosure in the SA900 . . . . . . . . . . . . . . . . . . . . 4–16

4–8 SA900 SDI Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–18

iv

Page 5

4–9 SA900 Power Cords—SA7x Enclosures . . . . . . . . . . . . . . . . . . . . . . . . 4–20

5–1 SA7x Enclosure Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Tables

1 Related Courses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

2 Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

1–1 Authorized Disk Drive Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1–2 RA7x Fixed Disk Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

1–3 SA7x Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

1–4 SA7x Enclosure Recommended Environmental Limits . . . . . . . . . . . . . 1–9

1–5 SA7x Enclosure Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–9

2–1 SA7x Switch and Indicator Functions . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

2–2 OCP Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

2–3 Power Supply Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

3–1 Authorized Disk Drives Installations . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

4–1 RA7x Drive Unit Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

4–2 H9A00 External SDI Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–17

5–1 SA7x Problems and Troubleshooting References . . . . . . . . . . . . . . . . . 5–1

A–1 Thermal Stabilization Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

B–1 RA71-RA72 System Error Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

C–1 VAX Diagnostics for RA71–RA73 Drives . . . . . . . . . . . . . . . . . . . . . . . C–1

C–2 Retired VAX Supervisor Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–2

C–3 Operating Systems for RA71–RA73 Drives . . . . . . . . . . . . . . . . . . . . . C–2

C–4 SDI Controllers for RA71–RA73 Drives . . . . . . . . . . . . . . . . . . . . . . . . C–2

v

Page 6

Page 7

The SA7x Enclosure User Guide explains how to operate the SA7x family of

enclosures: the SA70, SA71, SA72, and SA73. The guide is intended for end

users, but it includes installation procedures that should be performed only by

trained Digital Multivendor Customer Services engineers.

The SA70, SA71, SA72, and SA73 enclosures are physically identical. They are

differentiated only by the RA7x disk drives they contain:

• The SA70 accommodates one to four RA70 disk drives (280 MB each).

• The SA71 accommodates one to four RA71 disk drives (700 MB each).

• The SA72 accommodates one to four RA72 disk drives (1 GB each).

• The SA73 accommodates one to four RA73 disk drives (2 GB each).

Conventions

Special terminology used in the publication includes:

• SA7x refers to the SA70, SA71, SA72, and SA73 enclosures collectively.

• RA7x refers to the RA70, RA71, RA72, and RA73 disk drives collectively.

• RA71-RA73 refers to the RA71, RA72, and RA73 disk drives collectively.

Preface

The following notations are used in this manual:

• Note

Identifies information that is of special interest

• CAUTION

Identifies information that pertains to the protection of the equipment or loss

of data

• WARNING

Identifies information that pertains to your safety

vii

Page 8

Related Courses and Documentation

Table 1 lists the Digital courses related to the SA7x enclosure.

Table 1 Related Courses

Title Order Number

AC Power & Grounding EY–B730–PO

Electrical Safety EY–B737E–PO

Electrical Safety and Lockout/Tagout Procedures EY–E038E–SO

RA70/BA27 Disk Drive Maintenance Course EY–5805E–IV

DSA Architecture Level 1 Course EY–5593E–IV

VAXsimPLUS Maintenance Course EY–7687E–PO

DSA Troubleshooting Course EY–9422E–LO

Table 2 lists the documentation related to the SA7x enclosure.

Table 2 Related Documentation

Title Order Number

DSA Troubleshooting Flowchart EK–DSATF–TM

Disk Drive Technical Description Manual EK–ORA70–TD

BA72 Field Maintenance Print Set MP–01429

RA7x Disk Drive Service Manual EK–ORA7X–SM

RA7x/SA7x Pocket Reference Guide EK–RSA7X–PG

RA70 Field Maintenance Print Set MP–01428

RA71/RA72 Support Print Set EM–01434

RA71/RA72 Field Maintenance Print Set MP–01434

RA73 Field Maintenance Print Set MP–01439

SAxxx Storage Array Configuration Guide EK–SAXXX–CG

SA7x Enclosure Service Manual EK–OSA7X–SM

SA7x Support Print Set EM–01435

SA7x Field Maintenance Print Set MP–01435

viii

Page 9

Introducing the SA7x Enclosure

This chapter is an overview of the SA7x enclosure, lists SA7x configurations and

specifications, and discusses user precautions.

1.1 SA7x Enclosure Overview

The term ‘‘SA7x’’ refers to the family of enclosures that includes:

• The SA70—Accommodates one to four RA70 disk drives (280 MB each)

• The SA71—Accommodates one to four RA71 disk drives (700 MB each)

• The SA72—Accommodates one to four RA72 disk drives (1 GB each)

• The SA73—Accommodates one to four RA73 disk drives (2 GB each)

For all of these designations, the enclosure itself is physically identical. What

differentiates an SA70 enclosure from an SA71 enclosure is the type of drives

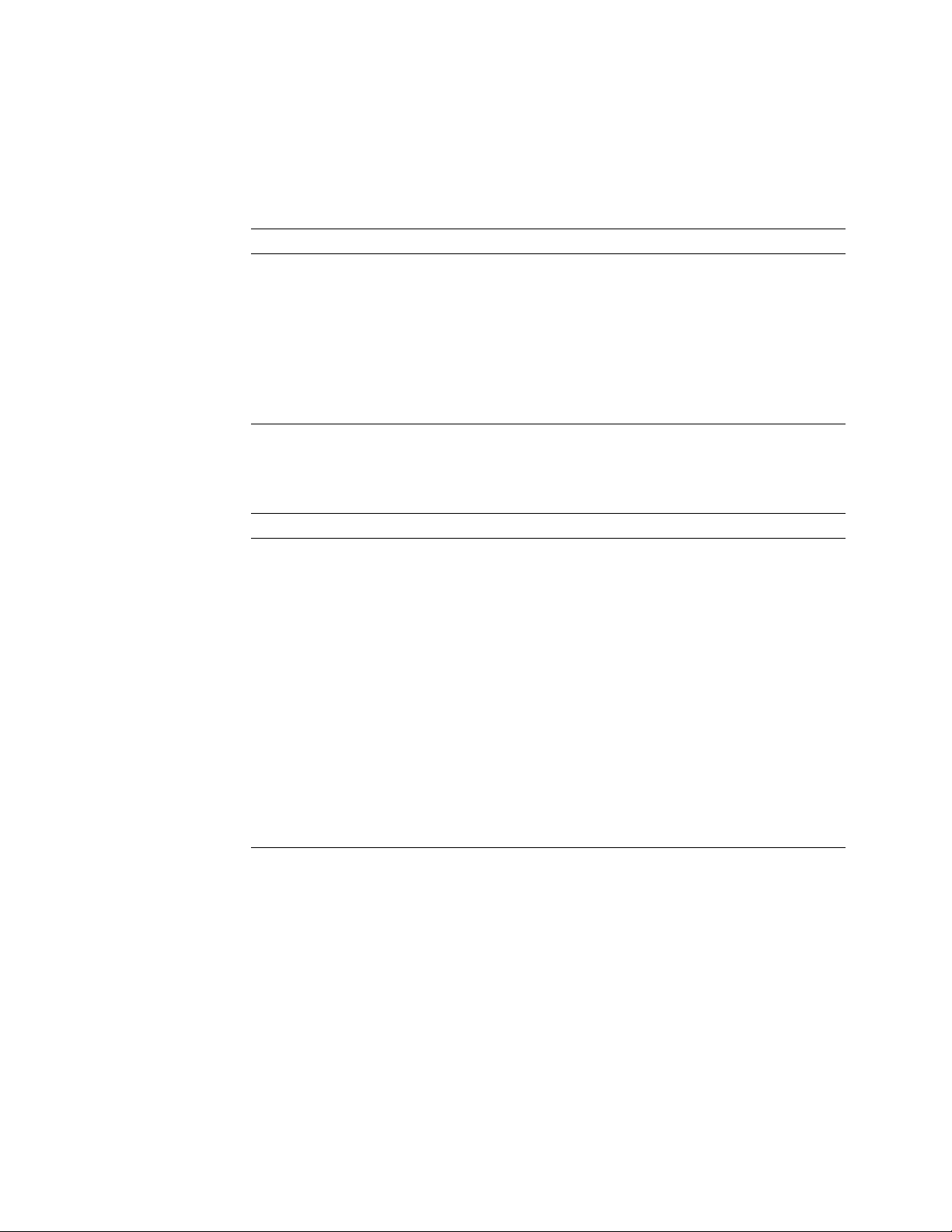

installed in each (RA70s and RA71s). See Figure 1–1 for an illustration of an

SA7x enclosure.

Table 1–1 lists the the types of disk drives that are authorized for installation in

each SA7x enclosure.

1

Table 1–1 Authorized Disk Drive Installations

Enclosure RA70 RA71 RA72 RA73

SA70 Yes No No No

SA71 Yes Yes Yes Yes

SA72 Yes Yes Yes Yes

SA73 Yes Yes Yes Yes

1

A maximum of three drives may be installed.

The SA7x enclosure provides mounting space, power, cooling, and control for up

to four RA7x disk drives. Each disk drive is independently powered and operated

by the enclosure.

The enclosure is installed as a component in a storage array cabinet.

The RA7x disk drive used in the SA7x enclosure is a random-access Winchester

technology drive with a formatted storage capacity of 280 MB to 2 GB. The drive

features modular components that can be replaced with minimum down time.

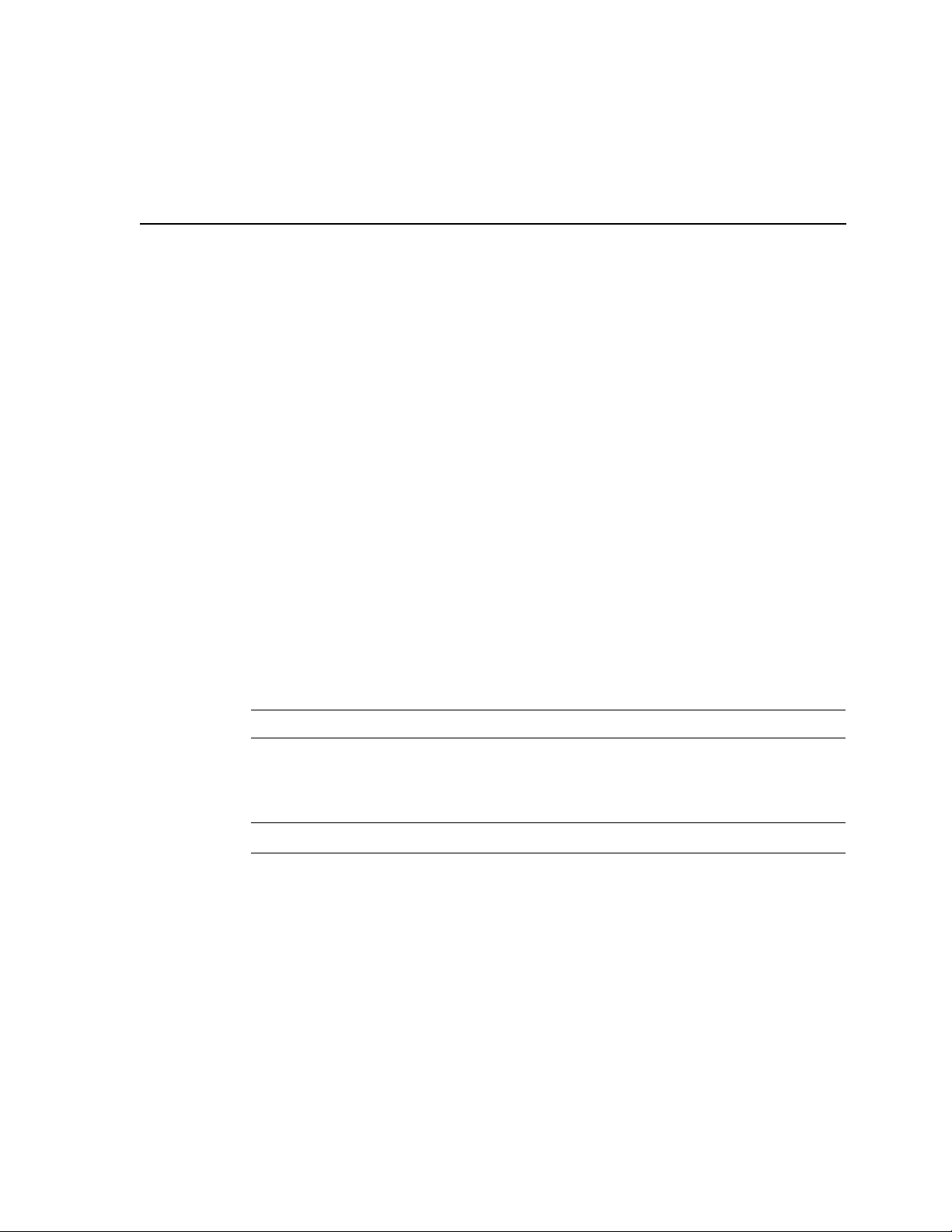

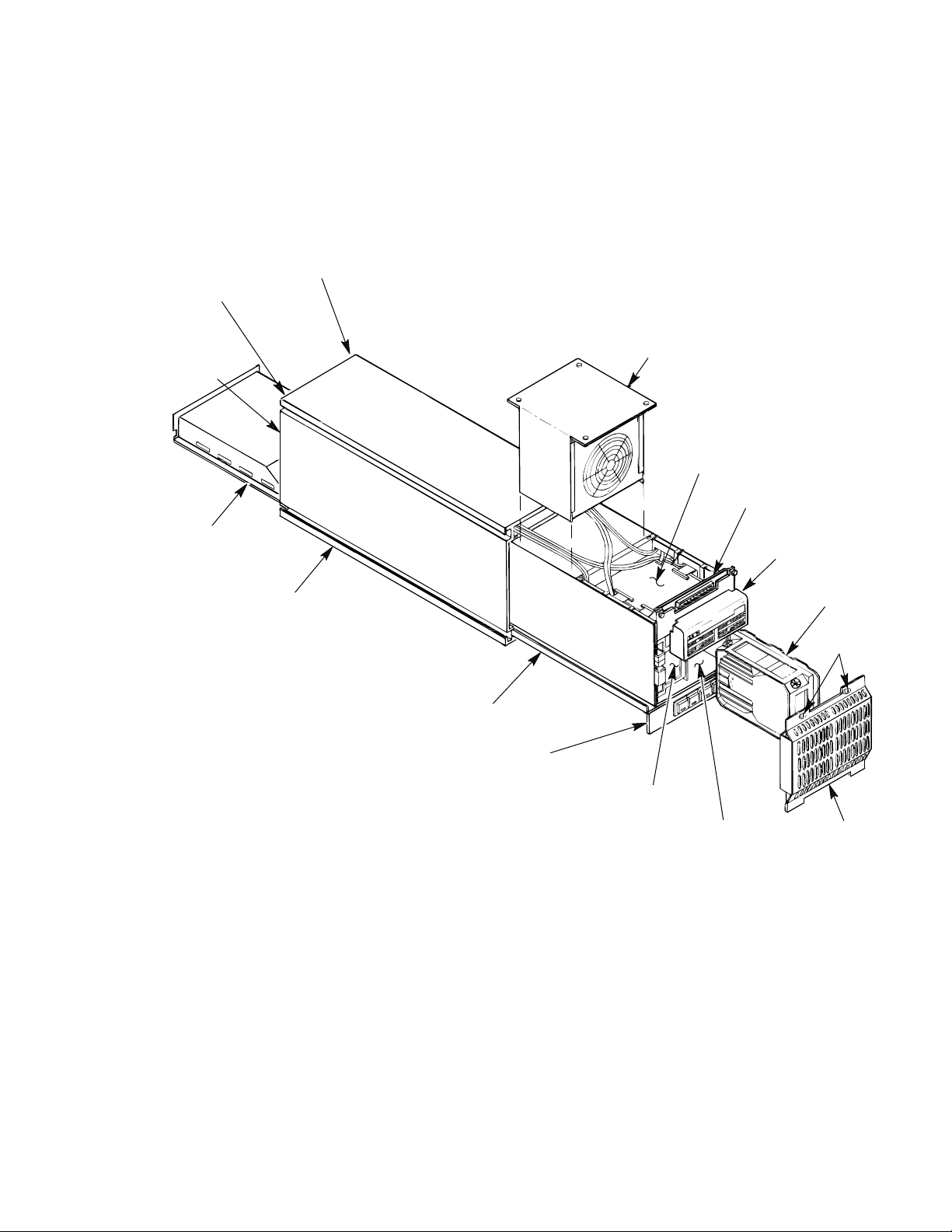

Figure 1–2 shows an RA70 disk drive. Figure 1–3 shows an RA71 through RA73

disk drive.

1

1

Introducing the SA7x Enclosure 1–1

Page 10

Introducing the SA7x Enclosure

1.1 SA7x Enclosure Overview

Figure 1–1 SA7x Enclosure

RIGHT REAR

LEFT REAR

DISK DRIVE

POSITION

REAR

COVER

(NOT

SHOWN)

POWER

SUPPLY

DISK DRIVE

POSITION

CHASSIS

FAN

TRANSITION

BOARD 2

TRANSITION

BOARD 1

OPERATOR

CONTROL

PANEL

RA70 DISK

DRIVE SHOWN

MOUNTING

SCREWS

FRAME

DRIVE POWER

SWITCH PANEL

LEFT FRONT

DISK DRIVE

POSITION

RIGHT FRONT

DISK DRIVE

POSITION

FRONT

COVER

CXO-1845D_S

You can combine SA7x enclosures into shadow sets. When using shadow sets,

remember that when replacing the power supply or transition boards 1 or 2, you

need to remove the power from the enclosure.

RA7x disk drive can be used with any disk drive controller using a standard

disk interface (SDI), including KDA50, KDB50, or KDM50 controller modules,

hierarchical storage controllers (HSCs), and UDA controllers. The drive is

compatible with the Digital Storage Architecture (DSA) and Mass Storage Control

Protocol (MSCP).

1–2 Introducing the SA7x Enclosure

Page 11

Figure 1–2 RA70 Disk Drive

Introducing the SA7x Enclosure

1.1 SA7x Enclosure Overview

SERIAL

NUMBER

LABEL

HDA

CHASSIS

FRONT PANEL

CONTROLS AND

INDICATORS

SERIAL

NUMBER

LOCATION

SHOE

PLATE

J4 4-PIN

POWER

J3 20-PIN REMOTE

OPERATOR CONTROL

PANEL CONNECTOR

J2 8-PIN SDI

CONNECTOR

(PORT B)

HDA

CHASSIS

SHOE

PLATE

ELECTRONIC

CONTROL

MODULE (ECM)

SET

J1 8-PIN SDI

CONNECTOR

(PORT A)

CXO-1878B_S

Introducing the SA7x Enclosure 1–3

Page 12

Introducing the SA7x Enclosure

1.1 SA7x Enclosure Overview

Figure 1–3 RA71 Through RA73 Disk Drives

FRONT VIEW

4-PIN

POWER

20-PIN

OCP

8-PIN

SDI-PORT B

8-PIN

SDI-PORT A

REAR VIEW

BOTTOM VIEW

SHOE

PLATE

CXO-3518A-MC

1–4 Introducing the SA7x Enclosure

Page 13

Introducing the SA7x Enclosure

1.1 SA7x Enclosure Overview

The major subassemblies of the SA7x enclosure are:

• Chassis

• Frame

• Operator control panel (OCP)

• Transition board 1 (TB1)

• Transition board 2 (TB2)

• Power supply

• Fan assembly

• Enclosure-internal cables

Figure 1–1 shows the major subassemblies of the SA7x enclosure. Except for the

RA70 disk drive description, Figure 1–1 is accurate for all SA7x enclosures.

The frame slides into the chassis and contains the mounting facilities for the

other subassemblies. The disk drives fit into recesses located in the front and

rear of the frame. The OCP is mounted above the front disk drives and plugs

into TB1. TB1 interfaces the OCP to TB2. TB2 is located above the front disk

drives and interfaces drive signals through TB1 to the OCP. The power supply

is located in the rear of the frame, below the rear disk drives. The fan assembly

is fitted into the central portion of the frame. Interconnecting cables for the

subassemblies run along the outer sides of the frame behind acoustic paneling.

RA7x disk drives may be mounted in any of the four disk drive positions.

Installation procedures suggest to install the first two drives in the rear positions

and the second two drives in the front positions.

Caution

The SA7x enclosure will accommodate a single RA7x disk drive. However,

if only one drive is installed in the enclosure, a drive position filler is

required to route cooling air and prevent overheating. See Section 3.2 for

instructions on installing and removing a drive position filler.

The disk drive is installed in an enclosure with the rear panel of the drive, which

contains interface connectors, facing outward. The drives are operated from four

sets of switches and indicators on the enclosure OCP, one set for each disk drive

in the enclosure.

SDI bus cables from the disk drives are routed inside the enclosure to a cable

bulkhead at the top rear of the enclosure.

The enclosure power supply provides operating power to the major subassemblies

of the enclosure. The rear panel of the power supply contains the Master On/Off

switch for the enclosure.

Each RA7x disk drive is powered and controlled independently. A drive can be

operated with other disk drive positions unoccupied or while maintenance is

being performed on another drive. The power switches for the disk drives are

located on the front panel of the enclosure. Each drive power switch contains a

symbol to indicate its associated drive and an indicator that lights when power is

applied to the drive.

Introducing the SA7x Enclosure 1–5

Page 14

Introducing the SA7x Enclosure

1.1 SA7x Enclosure Overview

The fan assembly circulates cooling air throughout the frame of the SA7x

enclosure. The air is drawn in through holes in the front panel on the enclosure

and is exhausted through holes in the rear panel.

The SA7x enclosure meets the following environmental and safety standards:

• DEC Standard 102 for environment

• DEC Standard 103 for electromagnetic emissions

• DEC Standard 104 for computer room noise level

• DEC Standard 119 for product safety

• National and international regulatory agency requirements, including FCC,

UL, IEC, CSA, and VDE

Your Digital sales representative can answer specific questions related to the

various environmental and safety standards.

1.2 RA7x and SA7x Configurations

Tables 1–2 and 1–3 show authorized RA7x disk drive and SA7x enclosure

configurations.

The description column of the RA7x configuration table contains the following

information:

Authorized installation:

Factory installation—Only installed at the factory.

Field add-on—Only installed in the field.

Enclosure:

Enclosures in which the disk drive may be installed.

Table 1–2 RA7x Fixed Disk Configurations

Formatted

RA7x Disk

Drive Description

RA70–A Field add-on: SA70 options in storage arrays. 0.28 GB

RA70E–SA Factory installation: MicroVAX 3500, 3600, and 3900 0.28 GB

RA70E–SF Field add-on: MicroVAX 3500, 3600, and 3900 0.28 GB

RA71–AF Factory installation: SA71 enclosure 0.70 GB

RA71–AK Field add-on: SA71 enclosure 0.70 GB

RA72–AF Factory installation: SA71 enclosure 1.0 GB

RA72–AK Field add-on: SA72 enclosure 1.0 GB

RA73–AF Factory installation: SA73 enclosure 2.0 GB

RA73–AK Field add-on: SA73 enclosure 2.0 GB

Storage

Capacity

The description column of the SA7x configuration table contains the following

information:

Authorized installation:

Factory installation—Only installed at the factory.

Field add-on—Only installed in the field.

1–6 Introducing the SA7x Enclosure

Page 15

Storage Array:

Systems and storage arrays in which the disk drive or enclosure may be

installed.

Table 1–3 SA7x Configurations

Enclosure Description

RA70

Disk

Drive

Introducing the SA7x Enclosure

1.2 RA7x and SA7x Configurations

RA71

Disk

Drive

RA72

Disk

Drive

RA73

Disk

Drive

Formatted

Storage

Capacity

SA70–HK Field add-on

SA550/SA650/SA850

1

120-240 Vac, 50-60 Hz

SA70–JK Field add-on

SA550/SA650/SA850

1

120-240 Vac, 50-60 Hz

SA70–LK Storage array building block

DECsystem 5800/VAX 6000

120-240 Vac, 50-60 Hz

SA70–MK Storage array building block

DECsystem 5800/VAX 6000

120-240 Vac, 50-60 Hz

SA71–CK Field add-on

SA550/SA650/SA850

120-240 Vac, 50-60 Hz

SA71–EK Field add-on

SA900

120-240 Vac, 50-60 Hz

SA71–FK Field add-on

SA900

120-240 Vac, 50-60 Hz

SA71–GK Factory installation

SA900

120-240 Vac, 50-60 Hz

SA71–HK Factory installation

SA900

120-240 Vac, 50-60 Hz

SA71–JK Field add-on

SA550/SA650/SA850

120-240 Vac, 50-60 Hz

SA71–LK Field add-on

SA600/SA800

120-240 Vac, 50-60 Hz

SA71–MK Field add-on

SA600/SA800

120-240 Vac, 50-60 Hz

SA72–CK Field add-on

SA550/SA650/SA850

120-240 Vac, 50-60 Hz

2 0 0 0 0.56 GB

4 0 0 0 1.12 GB

2

2

2 0 0 0 0.56 GB

4 0 0 0 1.12 GB

0 1 0 0 0.70 GB

0 1 0 0 0.70 GB

0 4 0 0 2.8 GB

0 1 0 0 0.70 GB

0 4 0 0 2.8 GB

0 4 0 0 2.8 GB

0 1 0 0 0.70 GB

0 4 0 0 2.8 GB

0 0 1 0 1.0 GB

1

To install in an SA600 or SA800 storage array first upgrade the storage array as described in Chapter 5.

2

Adding the first SA7x to a VAX 6000 or DECsystem 5800 system without internal storage devices requires an upgrade

kit:

60 Hz system—Upgrade Kit 62X34–UA

50 Hz system—Upgrade Kit 62X34–UB

Continued on next page

Introducing the SA7x Enclosure 1–7

Page 16

Introducing the SA7x Enclosure

1.2 RA7x and SA7x Configurations

Table 1–3 (Continued) SA7x Configurations

Enclosure Description

SA72–EK Field add-on

SA900

120-240 Vac, 50-60 Hz

SA72–FK Field add-on

SA900

120-240 Vac, 50-60 Hz

SA72–GK Factory installation

SA900

120-240 Vac, 50-60 Hz

SA72–HK Factory installation

SA900

120-240 Vac, 50-60 Hz

SA72–JK Field add-on

SA550/SA650/SA850

120-240 Vac, 50-60 Hz

SA72–LK Field add-on

SA600/SA800

120-240 Vac, 50-60 Hz

SA72–MK Field add-on

SA600/SA800

120-240 Vac, 50-60 Hz

SA73–CK Field add-on

SA550/SA650/SA850

120-240 Vac, 50-60 Hz

SA73–EK Field add-on

SA900

120-240 Vac, 50-60 Hz

SA73–FK Field add-on

SA900

120-240 Vac, 50-60 Hz

SA73–GK Factory installation

SA900

120-240 Vac, 50-60 Hz

SA73–HK Factory installation

SA900

120-240 Vac, 50-60 Hz

SA73–JK Field add-on

SA550/SA650/SA850

120-240 Vac, 50-60 Hz

SA73–LK Field add-on

SA600/SA800

120-240 Vac, 50-60 Hz

SA73–MK Field add-on

SA600/SA800

120-240 Vac, 50-60 Hz

RA70

Disk

Drive

0 0 1 0 1.0 GB

0 0 4 0 4.0 GB

0 0 1 0 1.0 GB

0 0 4 0 4.0 GB

0 0 4 0 4.0 GB

0 0 0 1 1.0 GB

0 0 4 0 4.0 GB

0 0 1 0 2.0 GB

0 0 0 1 2.0 GB

0 0 0 4 8.0 GB

0 0 0 1 2.0 GB

0 0 0 4 8.0 GB

0 0 0 4 8.0 GB

0 0 0 1 2.0 GB

0 0 0 4 8.0 GB

RA71

Disk

Drive

RA72

Disk

Drive

RA73

Disk

Drive

Formatted

Storage

Capacity

1–8 Introducing the SA7x Enclosure

Page 17

Introducing the SA7x Enclosure

1.3 SA7x Specifications

1.3 SA7x Specifications

Recommended environmental limits for operating the SA7x enclosure are listed in

Table 1–4. General specifications for the SA7x enclosure are shown in Table 1–5.

Caution

For the SA7x enclosure and installed RA7x disk drives to perform at

the optimal level and maintain high reliability, they should be used in

environments recommended in the following tables.

Table 1–4 SA7x Enclosure Recommended Environmental Limits

Characteristic Min. Max. Units

Operating temperature 65

18

Operating temperature rate of change – 5.4

Operating temperature step change – 5.4

Operating relative humidity 40 60 Percent relative humidity

Operating relative humidity rate of change – 10 Percent relative humidity

Storage temperature 65

18

Storage humidity – 50 Percent relative humidity

75

24

3

3

85

29

Degrees Fahrenheit

Degrees Celsius

Degrees per hour Fahrenheit

Degrees per hour Celsius

Degrees per hour Fahrenheit

Degrees per hour Celsius

(noncondensing)

(noncondensing) per hour

Degrees Fahrenheit

Degrees Celsius

(noncondensing)

Table 1–5 SA7x Enclosure Specifications

Characteristic Specification

Number of disk drive positions Four

Maximum formatted storage capacity:

SA70 enclosure

SA71 enclosure

SA72 enclosure

SA73 enclosure

Dimensions (nominal) 26.7 cm (10.5 in) high

Weight (nominal):

SA70 enclosure

SA71, SA72, or SA73 enclosures

1.12 GB

2.8 GB

4.0 GB

8.0 GB

22.2 cm (8.75 in) wide

71.1 cm (28 in) deep

21 kg (46 lb) empty

40 kg (88 lb) with four disk drives

21 kg (46 lb) empty

31.7 kg (72 lb) with four disk drives

Continued on next page

Introducing the SA7x Enclosure 1–9

Page 18

Introducing the SA7x Enclosure

1.3 SA7x Specifications

Table 1–5 (Continued) SA7x Enclosure Specifications

Characteristic Specification

Operating temperature +10° C to +40° C (+50° F to +104°

Operating humidity 10% to 85% @ maximum wet bulb

Operating altitude Up to 2,400 m (8,000 ft)

Nonoperating temperature -40° C to +66° C (-40° F to +151° F)

Nonoperating relative humidity 8% to 80% relative humidity,

Nonoperating altitude 4,900 m (16,000 ft)

Shock and vibration Complies with DEC Standard 102

Enclosure acoustic noise

(with four RA7x disk drives)

Fan operating parameters:

Low speed operation Below +28° C (+82° F), +/- 1° C (1.8°

High speed operation Above +30° C (+86° F), +/- 1° C (1.8°

Nominal airflow through the enclosure Between 45 and 65 cubic ft per

Input power requirements (47 to 63 Hz) 4.6 A @ 100 to 120 Vac (60 Hz), 2.3 A

F). Derate 1.8° C for each 1,000 m

altitude or 1.0° F for each 1,000 ft

altitude.

temperature +32° C (+90° F) and

minimum dew point of +2° C (+36° F)

noncondensing

Complies with DEC Standard 102

F)

F)

minute

@ 220 to 240 Vac (50 Hz)

1.4 User Precautions

Digital recommends that certain precautions be taken to protect equipment and

user data. These precautions involve backup methods, recommended operating

temperatures, and electrostatic discharge (ESD) protection, all of which are

discussed in this section.

1.4.1 Data Recovery

Data is not recoverable from an inoperable head disk assembly (HDA). Therefore,

it is your responsibility to make sure data is protected using proper backup

procedures. Digital recommends the following backup methods for RA7x disk

drives:

• File duplication—This method normally involves copying data onto removable

media, such as magnetic tape.

• Journaling—This method is recommended for files in a transaction processing

application. Journaling allows reconstruction of files up to the last checkpoint

or backup.

1–10 Introducing the SA7x Enclosure

Page 19

1.4.2 Recommended Operating Temperature

The SA7x enclosure and its installed drives can operate within a temperature

range of +10° to +40° C (+50° to +104° F). However, Digital recommends that the

enclosure and its drives be operated in a temperature range of +18° to +24° C

(+64° to +75° F) to increase reliability and product life.

Caution

Disk drives and enclosures must be environmentally stabilized in their

protective barrier bags at the installation site. Failure to environmentally

stabilize the equipment may result in damage to the drive media or

electronic components. For more information about environmental

stabilization, see Appendix A.

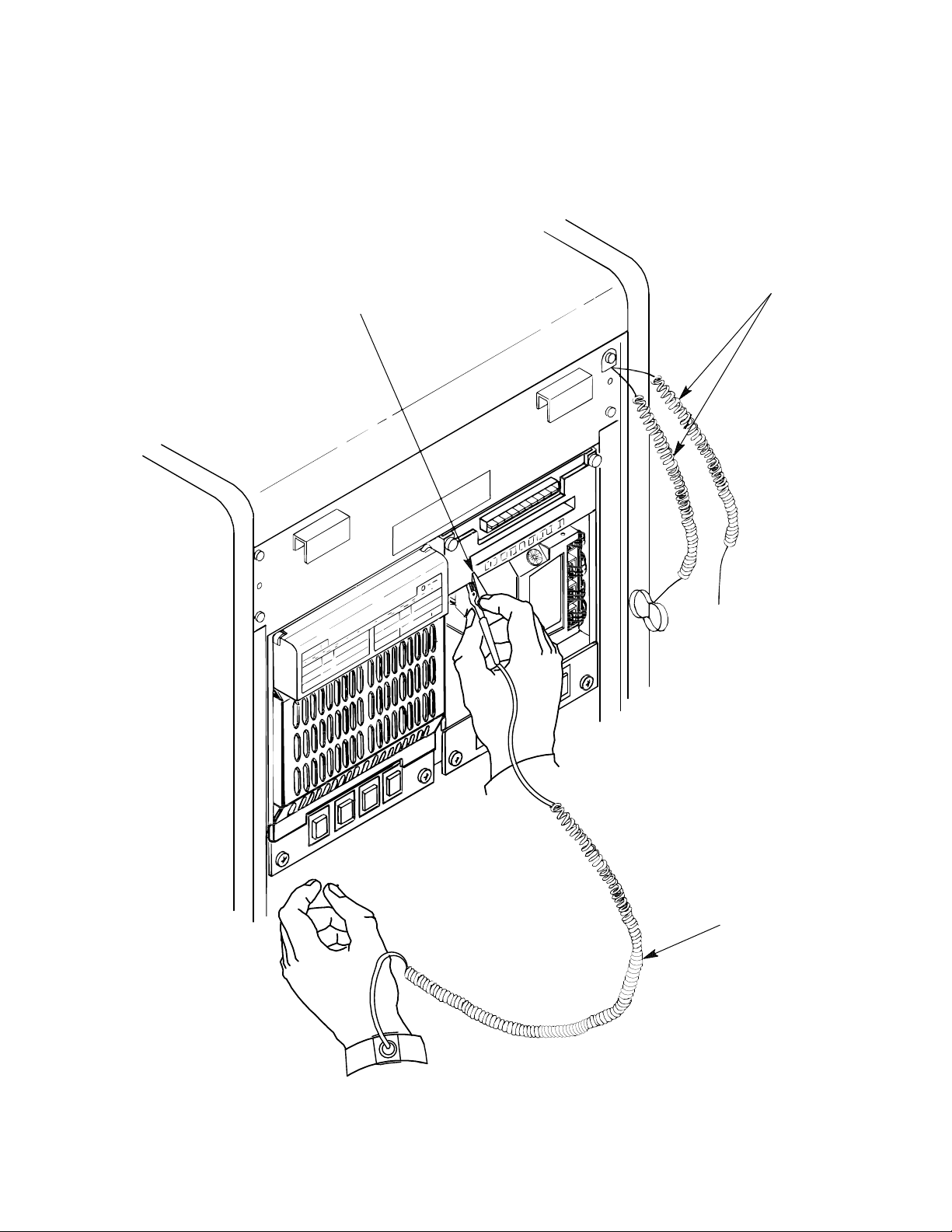

1.4.3 Electrostatic Discharge Protection

Electrostatic discharge (ESD) is caused by the buildup and release of static

electricity. An electrical charge from a person or object can damage hardware

components and result in premature device or option failure.

Observe the following guidelines when handling static-sensitive components:

Introducing the SA7x Enclosure

1.4 User Precautions

1. Read all instructions and installation procedures included with static control

materials.

2. Wear a properly grounded ESD wrist strap. (See Figure 1–4.)

When using an ESD wrist strap:

• Ensure that the wrist strap fits snugly for proper conductivity.

• Connect the alligator clip securely to a clean, unpainted, grounded metal

surface, such as the drive or cabinet chassis.

• Do not overextend the grounding cord.

3. Use static-protective containers to transfer modules and components.

Introducing the SA7x Enclosure 1–11

Page 20

Introducing the SA7x Enclosure

1.4 User Precautions

Figure 1–4 Using the ESD Grounding Strap

ESD GROUNDING STRAP

GROUNDED TO SA7x

ENCLOSURE CHASSIS

ESD GROUNDING

STRAP SUPPLIED

WITH 60-INCH CABINET

1–12 Introducing the SA7x Enclosure

OPERATOR’S ESD

GROUNDING STRAP

CXO-2609B_S

Page 21

This chapter describes the SA7x enclosure’s front and rear panel switches and

indicators and explains how to use them. It also explains how to apply power to

the enclosure and how to place drives on line and off line.

You must be a qualified Digital Multivendor Customer Services engineer

to perform procedures that involve the drive power switches or internal

storage array cabinet switches and indicators.

2.1 SA7x Switches and Indicators

The SA7x switches and indicators are located on both the front and rear panels.

The front panel contains the operator control panel (OCP) and the drive dc

power switches. The rear panel contains the power supply related switches and

indicators. Figure 2–1 shows the SA7x enclosure front panel. The OCP is located

along the top enclosure and contains the Unit Select switch and four identical

sets of switches and indicators. Each set of switches and indicators is dedicated

to one of the four disk drive positions in the enclosure. Drive power switches and

indicators for the four disk drive positions are located at the bottom.

2

Operating the SA7x

Note

The switch and indicator set for each disk drive position is operational

ONLY when the disk drive is powered up.

2.1.1 Using the Switches and Indicators

Table 2–1 is a summary of SA7x control and indicator functions. Table 2–2 is a

detailed description of OCP control and indicator functions. The following general

comments are also applicable:

• During power-on and spin-up of a drive, the OCP switches and indicators

have slightly modified meanings, as described in Section 2.4.1.

• The control set for each disk drive position contains Ready and Unit Number

indicators and switches for run operation, fault conditions, write protection,

unit number selection, and A/B port selection.

Note

Operating the SA7x 2–1

Page 22

Operating the SA7x

2.1 SA7x Switches and Indicators

Figure 2–1 SA7x Enclosure Front Panel

LEFT

REAR

LEFT

FRONT

Run

PORT SWITCHES

Fault/

Ready Ready

Set No. Set No.

Unit No.

A A

Write Write

Protect Protect

B

Run

Fault/

PORT SWITCHES

Unit No.

Unit Select

B

RIGHT

REAR

RIGHT

FRONT

FRONT

COVER

DRIVE

POWER SWITCHES

LEFT

FRONT

LEFT

REAR

RIGHT

REAR

RIGHT

FRONT

CXO-1867D_S

• All switches, except the Fault/Set No. switch, are set by pressing them in.

These switches hold the set position until you release them by pressing them

again. An indicator lights in each switch to show the status of the drive

function.

2–2 Operating the SA7x

Page 23

Operating the SA7x

2.1 SA7x Switches and Indicators

• The Fault/Set No. switch is a momentary pushbutton. When you press the

switch and hold it, it is set; when you release the switch, it is reset.

Table 2–1 SA7x Switch and Indicator Functions

Operator Control Panel Controls and Indicators

Switch/(Indicator

Color) Switch Function Indicator Function

Run (yellow) Press to spin up the drive.

Fault/Set No.

(red)

Ready (green) None. On when drive ready to

Unit Number

(red)

Write Protect

(yellow)

Port A (yellow) Press to enable Port A for controller

Port B (yellow) Press to enable Port B for controller

Unit Select Press to enable Unit Selected mode. None.

Drive Power

(green),

one switch for

each drive

Release to spin down the drive.

Changes the drive unit number when in

the Unit Select Mode.

Press and hold to test indicator functions.

All OCP indicators should be on.

None. Displays the drive unit

Press to enable write protect. On when write protect

selection.

selection.

Lower Front Panel

Press to apply power and start drive

self-test.

On when drive has spun

up.

Off when the drive spindle

has stopped.

On when a fault detected.

read/write.

number.

enabled.

On when Port A is on line

to system drive controller.

On when Port A is on line

to system drive controller.

On when power applied to

drive.

Rear Panel Power Supply Chassis

Master On/Off Apply line voltage to the power supply. None.

Line voltage

selector

Fault (red) None. On when there is a fault

Selects power supply operating voltage:

either 120 Vac, 60 Hz or 240 Vac, 50 Hz.

None.

or an overtemperature

condition.

This indicator is inside the

power supply and is visible

through the power supply

grillwork.

Operating the SA7x 2–3

Page 24

Operating the SA7x

2.1 SA7x Switches and Indicators

Table 2–2 OCP Controls and Indicators

Control

(Indicator) Function

Run Pressing the Run switch spins up the drive. The yellow Run

Fault/Set No. Pressing and holding the Fault/Set No. switch during normal

Ready The green Ready indicator lights to show that the drive is ready

Unit Number The unit number for the disk drive is displayed next to the Ready

Write Protect Setting the Write Protect switch disables writing to the drive. This

Port A

Port B

indicator lights after the drive spindle reaches operating speed.

Pressing the Run switch again releases the switch and spins down

the drive. The yellow Run indicator goes out only after the drive

spindle comes to a complete stop.

operation causes all OCP indicators to light as a lamp test. If all

indicators do not light, there may be a problem with the OCP. See

Chapter 5 for information.

When a fault condition is detected in a disk drive, the red Fault/Set

No. indicator lights. Pressing the Fault/Set No. switch once after a

drive fault places the drive off line and causes all indicators in the

drive’s control set, including the Fault/Set No. indicator, to blink an

error condition code. The light pattern converts to a two-character

error code. (See Chapter 5 for information.) Pressing the Fault/Set

No. switch a second time commands the drive to attempt to clear

the error and return on line.

You also use the Fault/Set No. to set the drive unit number, as

described in Section 4.4.

for read/write operations. This indicator is activated only after you

press the Run switch and the yellow Run indicator lights. After

spin-up, this indicator blinks during self-test. The Ready indicator

remains on during normal operations, but may blink or go out

during heavy disk accesses. The Ready indicator must light within

60 seconds after you press the Run switch; failure to do so indicates

a problem in the drive.

indicator. The unit number can be set to any number from either

000 to 255, or 000 to 999, as described in Section 4.4. Placement of

unit numbers in an actual installation is shown in Figure 2–1 (unit

numbers 000 through 003 in this example).

function keeps the drive data from being written over and lost.

The yellow Write Protect indicator lights to show that a drive is

write protected. The drive may also be write protected by a system

controller command; this also causes the Write Protect indicator to

light.

Ports A and B are enabled with the Port A and Port B select

switches. Yellow indicators in each switch light to show that the

system controller has selected the port.

2.1.2 Using Drive Power Switches and Indicators

The lower part of the front panel contains a set of four drive power switches that

you use to apply power to the disk drives. Each drive power switch is associated

with a disk drive position, as shown in Figure 2–1. A green indicator in each

drive power switch lights to show that power is being applied to the associated

disk drive.

Setting a drive power switch connects power to the associated disk drive and

causes the drive to run a self-test. During self-test, all OCP indicators are lit.

After setting the drive power switch, you must press the Run switch on the OCP

to spin up the drive.

2–4 Operating the SA7x

Page 25

2.2 Using SA7x Rear Panel Switches and Indicator

2.2 Using SA7x Rear Panel Switches and Indicator

Two rear panel switches and an indicator are located on the power supply chassis,

as shown in Figure 2–2. These switches and indicator affect how the entire

SA7x enclosure operates. Table 2–3 is a summary of the rear panel switches and

indicators.

WARNING

Hazardous voltages are present inside the storage array cabinet and

enclosures. You must be a qualified Digital Services engineer to perform

installation procedures. Otherwise, you may injure yourself or others and

you may damage the equipment.

Table 2–3 Power Supply Controls and Indicators

Control/Indicator Function

Operating the SA7x

Master On/Off The rocker-type Master On/Off switch for the SA7x enclosure

Line Voltage Selector

switch

is located in the center of the rear panel.

Press the side of the switch labeled ‘‘1’’ (on) to apply power to

the SA7x enclosure.

Press the side of the switch labeled ‘‘0’’ (off) to remove power

from the enclosure.

As you face the rear panel, the Line Voltage Selector switch is

located to the right of the Master On/Off switch. It is visible

through a hole in the rear panel. You must set this switch

to the available line voltage during installation. The selected

voltage is shown on the switch element.

CAUTION

The SA7x enclosure power supply is universal for both 120 Vac (60 Hz) or

240 Vac (50 Hz). The power supply is set to 240 Vac (50 Hz) at the factory

and must be reset to 120 Vac (60 Hz) for some installations. Selecting the

wrong voltage will damage the power supply.

Fault indicator (red) The red Fault indicator is visible through holes in the right

side of the power supply back panel. When the power supply

detects an overtemperature or overvoltage condition, it

automatically shuts down power to the enclosure and the

Fault indicator lights. If the Fault indicator lights, turn off

the Master On/Off switch and refer to Chapter 5 to correct the

condition.

Operating the SA7x 2–5

Page 26

Operating the SA7x

2.3 Applying Power to the SA7x Enclosure

Figure 2–2 SA7x Enclosure Rear Panel

SDI INTERFACE

CONNECTOR

PORT B

REAR

BULKHEAD

PORT A

SILK SCREEN

SDI INTERFACE

CONNECTOR

PORT A

PORT B

SILK SCREEN

REAR

COVER

OVERTEMPERATURE

INDICATOR

(BEHIND PANEL)

MOUNTING

SCREW

MOUNTING

POWER

SUPPLY

TABS

SCREW

LINE VOLTAGE

CONNECTOR

2.3 Applying Power to the SA7x Enclosure

CAUTION

Before applying power to the SA7x enclosure, ensure that the Line

Selector Voltage switch on the enclosure, located behind the SA7x rear

panel, is set to the proper line voltage. Otherwise, you will damage the

power supply. (See Figure 2–2.)

To apply power to the SA7x enclosure, use the following procedure:

1. Verify that the Master On/Off switch on the power supply is set to off.

2. Verify that the drive power switches are set to off (switch button released).

2–6 Operating the SA7x

LINE VOLTAGE

SELECTOR SWITCH

(BEHIND PANEL)

MASTER

ON/OFF

SWITCH

CXO-2658C

Page 27

2.3 Applying Power to the SA7x Enclosure

3. Restore power to the enclosure by turning on the Master On/Off switch.

4. Verify the power is on by checking that the fan is operating. Do this by

feeling for airflow out of the rear of the enclosure.

2.4 Placing RA7x Drives On Line and Off Line

This section explains how to place RA7x disk drives on line and off line.

2.4.1 Placing a Drive On Line

After applying power to the SA7x enclosure, use the following procedure to place

a drive on line:

1. Press the drive power switch for the drive you want to bring online. (Refer

to Figure 2–1.) If power to the drive is within specifications, the green drive

power indicator lights. If the indicator does not light, see Chapter 5.

Note

Setting a drive power switch to on does not spin up the associated drive.

Operating the SA7x

Applying power to the disk drive starts the drive’s internal power-on

diagnostics. These diagnostics are signaled at the OCP by the following

sequence of indicator lights:

a. All indicators light for about eight seconds.

b. If the drive completes the power-on diagnostics without detecting a fault,

all indicators go out.

c. If the Fault/Set No. indicator remains lit, the drive has detected a fault.

Press the Fault/Set No. switch to obtain a blinking OCP error code. The

light pattern converts to a two-character error code. (See Chapter 5.)

Pressing the Fault/Set No. switch a second time commands the drive to

attempt to clear the error and return online.

2. Press the Run switch on the OCP to spin up the drive. (Refer to Figure 2–1.)

The following sequence of indicator lights occurs during spinup:

a. The Run indicator lights to show that you have commanded spinup. All

other indicators remain off. (If you have powered up the drive with the

Run switch set, you must either momentarily release, then reset, the Run

switch, or enter a MOUNT command from your system to initiate spinup.

The Run indicator lights to show that spinup was initiated through either

of these actions.)

b. When the drive completes spinup, the Ready indicator lights to show that

the drive is read/write ready.

c. The Ready indicator then flashes while the internal read/write and seek

diagnostics run.

d. Upon completion of the read/write and seek diagnostics, the Ready

indicator remains lit.

e. The Fault/Set No. indicator lights if the drive detects fault during spinup.

Operating the SA7x 2–7

Page 28

Operating the SA7x

2.4 Placing RA7x Drives On Line and Off Line

f. If the Fault/Set No. indicator remains lit, the drive has detected a fault.

Press the Fault/Set No. switch to obtain a blinking OCP error code. The

light pattern converts to a two-character error code. (See Chapter 5.)

Pressing the Fault/Set No. switch a second time commands the drive to

attempt to clear the error and return online.

3. Press the Port A, Port B, and Write Protect switches as required. These

functions are turned off by pressing the switch a second time.

The Ready and Run indicators remain lit during normal operation, although the

Ready indicator may flicker during heavy activity. The Write Protect indicator is

lit if the drive is write protected and off if the drive is write enabled. The Port A

and Port B indicators light only while their respective ports are selected by the

system controller.

2.4.2 Taking a Drive Off Line

Taking a disk off line first requires you to dismount the drive as described in

Steps 1 and 2 of the following procedure. To remove the drive from the enclosure

you must complete Steps 3 through 5.

1. Dismount the disk drive using the proper system commands.

2. Press and release the Port A and Port B switches to turn off both ports of the

disk drive. (Refer to Figure 2–1.) Wait for the port indicators to go out.

3. Press and release the appropriate Run switch on the OCP. Wait for the Run

indicator to go out.

4. Set the drive power switch to off. The switch indicator goes out to show that

power has been removed from the drive. If the indicator does not go out,

there may be a faulty switch.

5. Remove power from the enclosure by turning off the Master On/Off switch.

(See Figure 2–2.)

You are now ready to remove the disk drive from the enclosure. Refer to

Chapter 3 for complete instructions.

2–8 Operating the SA7x

Page 29

3

Replacing RA7x Disk Drives

This chapter explains how to install and remove an RA7x disk drive in an SA7x

enclosure.

Table 3–1 lists the the types of disk drives that are authorized for installation in

each SA7x enclosure. Unless otherwise specified, a maximum of four disk drives

of each type, or a combination of disk drives can be installed in an enclosure.

Table 3–1 Authorized Disk Drives Installations

Enclosure RA70 RA71 RA72 RA73

SA70 Yes No No No

SA71 Yes Yes Yes Yes

SA72 Yes Yes Yes Yes

SA73 Yes Yes Yes Yes

1

A maximum of three drives may be installed.

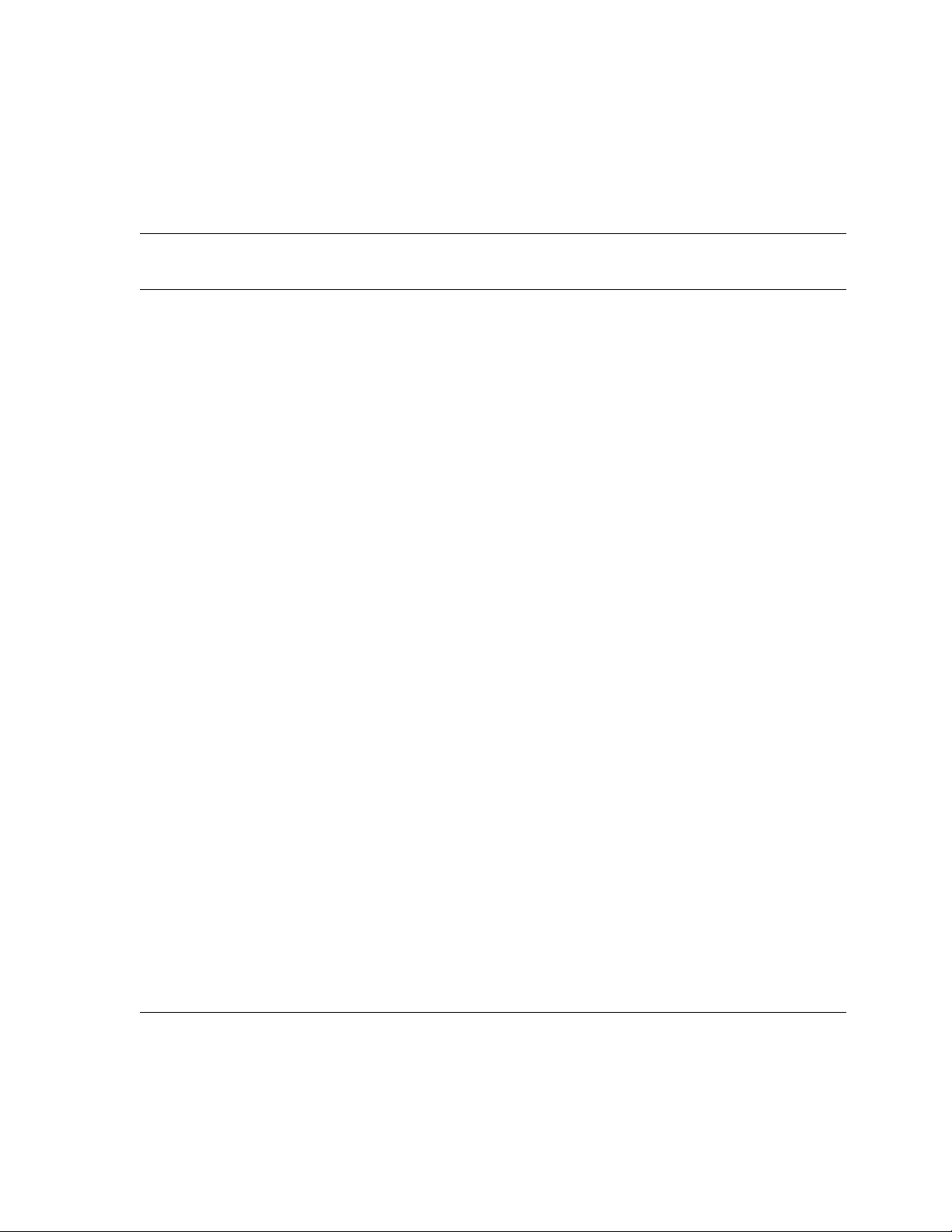

Figure 3–1 shows the major subassemblies of the SA7x enclosure. Except for

the RA70 disk drive designation, this illustration is accurate for all the SA7x

enclosures.

CAUTION

Do not attempt to install a disk drive unless you have received training

in electrostatic discharge (ESD) procedures and have taken proper

precautions against ESD. Wear an ESD grounding strap properly

connected to a known ground. Refer to Figure 1–4 for the proper use of

an ESD grounding strap.

Note

If the SA7x enclosure is installed in a storage array cabinet when you are

attempting to install or remove an RA7x disk drive, you must first remove

or open either the cabinet’s front or rear panel. See the appropriate

storage array guide for instructions on removing and installing cabinet

panels.

1

1

Replacing RA7x Disk Drives 3–1

Page 30

Replacing RA7x Disk Drives

3.1 Installing and Removing an RA7x Disk Drive

3.1 Installing and Removing an RA7x Disk Drive

The RA70 disk drive is physically different from RA71, RA72, and RA73 disk

drives. The main physical difference between these drives (RA70 and RA71

through RA73), concerning installation, is the design of the shoe plate. The

procedures for installing and removing the disk drives (RA70 and RA71 through

RA73) are virtually the same.

CAUTIONs

• The SA7x enclosure is designed to have disk drives installed in a

certain sequence for proper airflow, especially if the enclosure is not

fully configured. Digital recommends installing the first drive in one

of the two rear positions in the cabinet, the second drive in the other

rear position, the third drive in one of the two front positions, and the

fourth drive in the other front position.

• The SA7x enclosure accommodates a single RA7x disk drive. However,

if only one drive is installed in the enclosure, a drive position filler

is required to route cooling air and prevent overheating. If you are

adding a second drive to an enclosure and the drive position filler is

already installed, you must remove it. See Section 3.2 for instructions

for installing and removing a drive position filler.

• Disk drives and enclosures must be environmentally stabilized in

their protective barrier bags at the installation site. Failure to

environmentally stabilize the equipment may result in damage to the

drive media or electronic components. For more information about

environmental stabilization, see Appendix A.

Notes

• When an RA7x disk drive is installed in an SA7x enclosure, it is not

possible to set the drive unit number using the dip switches on the

drive itself. Unit numbers for all RA7x disk drives are set from the

SA7x operator control panel (OCP) as explained in Chapter 4.

• Before installing an RA71/RA72 disk drive, verify that the capacity

indicator switch on the drive is set correctly. See the RA7x Disk Drive

Service Manual for more information.

3–2 Replacing RA7x Disk Drives

Page 31

Figure 3–1 SA70 Enclosure

RIGHT REAR

LEFT REAR

DISK DRIVE

POSITION

REAR

COVER

(NOT

SHOWN)

POWER

SUPPLY

DISK DRIVE

POSITION

CHASSIS

Replacing RA7x Disk Drives

3.1 Installing and Removing an RA7x Disk Drive

FAN

TRANSITION

BOARD 2

TRANSITION

BOARD 1

OPERATOR

CONTROL

PANEL

RA70 DISK

DRIVE SHOWN

FRAME

DRIVE POWER

SWITCH PANEL

3.1.1 Recording RA7x Disk Drive Serial Numbers

All add-on or replacement disk drives have a serial number tag affixed to the disk

drive. The adhesive serial number label included with the drive is for mounting

on the enclosure.

Affix the serial number label to the front cover of the SA7x enclosure. Place it so

that it corresponds with the position of the disk drive in the enclosure, as shown

in Figure 3–2.

LEFT FRONT

DISK DRIVE

POSITION

RIGHT FRONT

DISK DRIVE

POSITION

MOUNTING

SCREWS

FRONT

COVER

CXO-1845D_S

Replacing RA7x Disk Drives 3–3

Page 32

Replacing RA7x Disk Drives

3.1 Installing and Removing an RA7x Disk Drive

Figure 3–2 RA7x Disk Drive Serial Number Location

LEFT REAR

DISK DRIVE

SERIAL NUMBER

LABEL

LEFT FRONT

DISK DRIVE

SERIAL NUMBER

LABEL

Record the disk drive serial number in the site log and the labor activity reporting

system (LARS) report. (You may also want to record the head disk assembly

[HDA] serial number at this time. This number is located on the front of the

HDA.)

Serial numbers are in the following format:

RIGHT REAR

DISK DRIVE

SERIAL NUMBER

LABEL

RIGHT FRONT

DISK DRIVE

SERIAL NUMBER

LABEL

SA7X ENCLOSURE

FRONT COVER

COM-0104

• Manufacturing location code (two characters)

• Date code (three digits)

• Component serial number (five digits)

For LARS, record only the manufacturing (MFG) location code and the component

serial number in the following form:

• MFG location code (two characters)

• Component serial number (five digits)

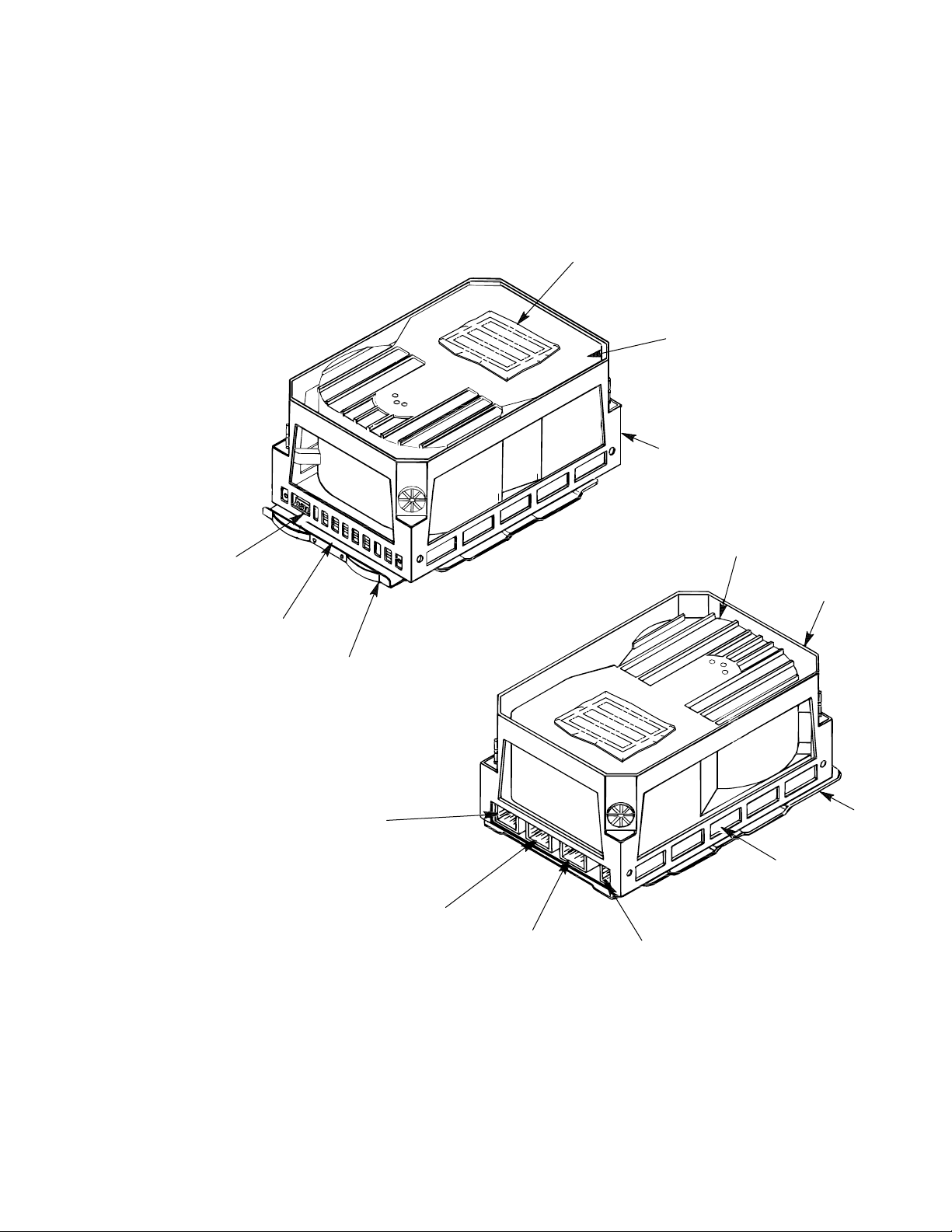

3.1.2 Reversing the RA70 Shoe Plate

When the RA70 disk drive is to be installed in an SA7x enclosure, the shoe plate

may need to be reversed on the drive so that it will mate with the shoe plate

guide and shoe plate retaining clip in the SA7x enclosure. Figure 3–3 shows the

proper shoe plate alignment.

To reverse the shoe plate on the RA70 disk drive, see Figure 3–3 and use the

following procedure:

1. Wear an ESD grounding strap with the clip connected to the enclosure

chassis, not to the disk drive.

2. Place the disk drive on a grounded antistatic work surface with the shoe plate

facing up.

3. Remove the screws in each of the four corners of the drive chassis that secure

the shoe plate to the chassis.

3–4 Replacing RA7x Disk Drives

Page 33

3.1 Installing and Removing an RA7x Disk Drive

Figure 3–3 Reversing the RA7x Shoe Plate

FACTORY SHOE PLATE ORIENTATION

CONNECTOR

END

SHOE PLATE

RETAINING TAB

Replacing RA7x Disk Drives

RA70

CHASSIS

SHOE

PLATE

SA70 SHOE PLATE ORIENTATION

CONNECTOR

END

SCREW

SHOE

PLATE

SCREW

RA70

CHASSIS

SHOE PLATE

RETAINING TAB

CXO-2610A

4. Grasp the shoe plate and pull upward to free it from the chassis. Hold the

drive down with the hand wearing the ESD strap.

5. Turn the plate around to orient the shoe plate tab at the connector end of the

drive. Replace the plate on the chassis.

Replacing RA7x Disk Drives 3–5

Page 34

Replacing RA7x Disk Drives

3.1 Installing and Removing an RA7x Disk Drive

6. Reinstall the four shoe plate mounting screws. Do not over tighten.

WARNING

An RA70 disk drive weighs 4.8 kgs (10.5 lbs). The RA71 through RA73

disk drives weigh 2.9 kgs (6.4 lbs). Be prepared to handle this weight

when the drive comes free from the disk drive position. Otherwise, you

may cause personal injury or damage the equipment.

CAUTION

Do not place the disk drive on anything other than a properly grounded

antistatic work surface. Failure to observe this precaution may result in

ESD damage to the drives.

3.1.3 Installing an RA7x Disk Drive

Use the following procedure to install the RA7x disk drive:

1. Make sure the drive power switch for the drive position you are using is

turned off.

2. Depending on where the disk drive is located in the SA7x enclosure, remove

either the front or rear enclosure cover. Loosen or remove the two mounting

screws in the upper corners of the cover, then lift the cover up and outward to

clear the enclosure. (See Figure 3–1.)

3. Use the ESD grounding strap furnished with the cabinet, or connect your

ESD grounding strap to the enclosure chassis.

4. Orient the disk drive so that the shoe plate and shoe plate guide are side by

side. Hold the connectors clear of the drive and slide the disk drive into the

selected position in the enclosure as shown in Figure 3–4.

5. Verify the disk drive is locked into the enclosure with the shoe plate retaining

clip.

6. Connect the 4-pin drive power cable, the 20-pin OCP cable, and the two SDI

cables (in that order) to the rear panel of the disk drive.

7. Remove the ESD grounding strap and replace the covers on the enclosure.

You are now ready to place the drive on line. See Chapter 2 for instructions.

3.1.4 Removing an RA7x Disk Drive

To remove an RA7x disk drive from an SA7x enclosure, use the following

procedure:

1. Take off line the drive you are going to remove as explained in Chapter 2.

2. Make sure the drive power switch for the drive you are removing is turned

off.

3. Remove the front or rear enclosure cover, depending on which drive you are

going to remove.

3–6 Replacing RA7x Disk Drives

Page 35

Figure 3–4 Replacing RA70 Disk Drive

SILK SCREEN OF

CONFIGURATION RULES

Replacing RA7x Disk Drives

3.1 Installing and Removing an RA7x Disk Drive

LR

1

LF

RR

2

RF

4

3

SHOE PLATE

RETAINING CLIP

SHOE PLATE

SHOE PLATE

RETAINING TAB

LOCATION

INTERNAL

SDI CABLES

20-PIN

OCP

CABLE

SHOE PLATE

GUIDE

4-PIN DRIVE

POWER CABLE

RA70 DISK DRIVE

REAR PANEL

CXO-1870D_S

Replacing RA7x Disk Drives 3–7

Page 36

Replacing RA7x Disk Drives

3.1 Installing and Removing an RA7x Disk Drive

4. Loosen the two mounting screws in the upper corners of the cover, then lift

the cover up and outward to clear the enclosure, as shown in Figure 3–1.

5. Use the ESD grounding strap furnished with the cabinet, or connect your

ESD grounding strap to the enclosure chassis.

6. Disconnect the 4-pin drive power cable, the 20-pin OCP cable, and the two

internal SDI cables from the drive, as shown in Figure 3–4.

CAUTION

Grasp the paper tab on the OCP cable to disconnect the cable from drive.

Otherwise, you may damage the OCP connector strain relief.

7. The drive is held in place with a shoe plate retaining clip on the outside wall

of the chassis disk position. The retaining clip locks with a tab on the drive

shoe plate. (Refer to Figures 3–3 and 3–4.) Release this retaining clip and

pull the drive out straight. After the drive is released, pull it slightly forward.

8. Grasp the drive firmly and remove it from the disk drive position. Be careful

not to damage the cables as you slide the drive out of the enclosure frame.

3.2 Installing and Removing a Drive Position Filler

The SA7x enclosure accommodates a single RA7x disk drive. However, if only

one drive is installed in the enclosure, a drive position filler is required to route

cooling air and prevent overheating. If you are adding a second drive to an

enclosure and the drive position filler is already installed, you must remove it.

The drive position filler is a Styrofoam block in the shape of a disk drive with

a shoe plate attached. It is installed in the drive position next to the single

installed drive (which should be installed in the rear of the enclosure).

To install the drive position filler in the SA7x enclosure, use the following

procedure:

1. Make sure the drive power switch for the drive position you are using is

turned off.

2. Remove the rear cover from the enclosure. Loosen the two mounting screws

in the upper corners of the cover, then lift the cover up and outward to clear

the enclosure. (Refer to Figure 3–1.)

3. Position the drive position filler so that the shoe plate and shoe plate guide

are side by side. Hold the connectors clear of the filler and slide it into the

selected position in the enclosure. (Refer to Figure 3–4.)

4. Verify that the drive position filler is locked into the enclosure with the shoe

plate retaining clip.

To remove the drive position filler, use the following procedure:

1. Make sure the drive power switch for the drive position you are using is

turned off.

2. Remove the rear cover from the enclosure. Loosen the two mounting screws

in the upper corners of the cover, then lift the cover up and outward to clear

the enclosure. (Refer to Figure 3–1.)

3–8 Replacing RA7x Disk Drives

Page 37

Replacing RA7x Disk Drives

3.2 Installing and Removing a Drive Position Filler

3. The drive position filler is held in place with a shoe plate retaining clip on

the outside wall of the chassis disk position. The retaining clip locks with

a tab on the drive shoe plate. (Refer to Figures 3–3 and 3–4.) Release this

retaining clip and pull straight out on the drive position filler. After the filler

is released, pull it slightly forward.

4. Grasp the drive position filler firmly and remove it from the disk drive

position.

Replacing RA7x Disk Drives 3–9

Page 38

Page 39

This chapter is an overview of SA7x installation. This chapter also explains how

to select the correct line input voltage, set drive unit numbers on the operator

control panel (OCP), and perform a post-installation checkout.

Instructions for installing RA7x disk drives, installing a drive position filler, and

recording disk drive serial numbers are provided in Chapter 3.

4.1 SA7x Installation Overview

The SA7x enclosure can be installed in a variety of storage arrays. Complete

instructions for installing the enclosure in each of these arrays are provided in

the appropriate storage array guide.

4.1.1 Power and Safety

The SA7x enclosure does not present any unusual fire or safety hazards. Be

sure to verify that the site has adequate power reserves to support the planned

number of SA7x enclosures.

4

Installing the SA7x

WARNING

Hazardous voltages are present inside the storage array cabinet and

enclosures. You must be a qualified Digital Multivendor Customer

Services engineer to perform installation procedures. Otherwise, you may

injure yourself or others and you may damage the equipment.

A Digital Multivendor Customer Services engineer is qualified to install the

SA7x enclosure upon successful completion of the courses listed in Table 1 in the

Preface.

4.1.2 Recording Disk Drive Serial Numbers

When installing add-on or replacement enclosures, verify that the serial number

on the disk drives are properly recorded on the enclosure. Also, record the serial

numbers in the site log and the labor activity reporting system (LARS).

For complete instructions on recording disk drive serial numbers, see Chapter 3.

Installing the SA7x 4–1

Page 40

Installing the SA7x

4.2 Selecting Line Input Voltage

4.2 Selecting Line Input Voltage

The SA7x enclosure power supply can be set to operate from either 120 Vac (60

Hz) or 220 Vac (50 Hz). Use the following procedure to set the line voltage:

1. Verify that all front panel drive power switches and the Master On/Off power

switch on the rear panel of the power supply are off.

2. Locate the Line Voltage Selector switch on the power supply. The switch is

accessible through a cutout in the rear panel of the power supply just to the

right of the line input connector.

3. Using a small screwdriver, set the Line Voltage Selector switch to the correct

line voltage. The voltage selected, either 120 Vac or 240 Vac, is displayed on

the switch.

The SA7x enclosure power supply is universal for both 120 Vac (60 Hz) or

240 Vac (50 Hz). The power supply voltage frequency is factory set to 240

Vac and must be reset for 120 Vac operation. Using the wrong setting will

damage the power supply.

caution

4.3 Performing a Post-Installation Checkout and Power-Up

Use the following procedure to verify normal operation of the power supply, OCP,

and fan assembly before operating the SA7x enclosure. It is best to perform this

procedure after all disk drives are installed in all the enclosures in the storage

array cabinet, but not yet connected to power.

CAUTION

Before performing this checkout and power-up procedure, be sure the

enclosure frame is secured in the chassis and the front and rear enclosure

covers are installed. Failure to do so will defeat the cooling airflow of

the enclosure and may result in permanent damage to the disk drives or

power supply.

1. Verify that all power and interface connections to the rear of the enclosure

are correct and secure.

2. Verify that the Line Voltage Selector switch on the power supply of the SA7x

enclosure has been set to the proper source voltage. If not, set the switch as

described in Section 4.2.

3. Verify that the drive power switches are turned off.

4. Verify that the enclosure power cord is securely connected to the cabinet

power controller.

5. Set the enclosure Master On/Off switch to on.

6. Verify the power is on by checking that the fan is operating. Do this by

feeling for airflow out the rear of the enclosure. If the fan does not start,

recheck the power connections. If power connections are connected properly,

verify that the power supply is firmly seated in its connector. If the power

still does not come on, see Chapter 5 for more information.

4–2 Installing the SA7x

Page 41

Installing the SA7x

4.3 Performing a Post-Installation Checkout and Power-Up

7. Turn on the drive power switch for one of the disk drives. This switch is

shown in Figure 4–1.

8. Verify power application to the disk drive position by noting that the indicator

element in the drive power switch lights. If the indicator element does not

light, verify that the power supply is firmly seated in its connector. If power

still does not come on, see Chapter 5.

Note

Turning a drive power switch on does not actually start the associated

drive motor.

9. Press the Run switch on the OCP for the desired drive. This action starts

the drive motor. When the Ready light comes on, the drive has completed its

internal diagnostics and is ready for operation. If the Fault light comes on,

see Chapter 5 for more information.

10. Set the drive unit number. (Refer to Section 4.4 for this procedure.)

11. Select Port A or Port B and Write Protect. The Write Protect indicator lights

when the switch is set; the Port A and B indicators light only when the host

system controller has selected that port for read/write operations. During the

checkout and power-up procedure, verify that the associated OCP indicators

light. If the indicators do not light, see the Chapter 5 for more information.

You can turn off write protection by pressing the Write Protect switch a

second time.

12. Complete the checkout of the disk drive by running the applicable diagnostics

from the host system controller as described in the RA7x Disk Drive Service

Manual.

13. Repeat steps 7 through 12 for each RA7x disk drive installed in the

enclosure.

Installing the SA7x 4–3

Page 42

Installing the SA7x

4.3 Performing a Post-Installation Checkout and Power-Up

Figure 4–1 SA7x Enclosure Front Panel

LEFT

REAR

LEFT

FRONT

Run

PORT SWITCHES

Fault/

Ready Ready

Set No. Set No.

Unit No.

A A

Write Write

Protect Protect

B

Run

Fault/

PORT SWITCHES

Unit No.

Unit Select

B

RIGHT

REAR

RIGHT

FRONT

LEFT

FRONT

LEFT

REAR

FRONT

COVER

DRIVE

POWER SWITCHES

RIGHT

REAR

RIGHT

FRONT

CXO-1867D_S

4–4 Installing the SA7x

Page 43

4.4 Setting Drive Unit Numbers

When you install an RA7x disk drive in an enclosure, the drive unit number DIP

switches are disabled. You then set the drive unit number at the enclosure OCP

as described below.

The RA7x disk drives have two drive unit number ranges: 000 through 255, and

000 through 999, which are dependent on the following three factors:

• The drive model

The RA70 disk drive can only use the drive unit numbers in the range

000 through 255.

• The RA7x microcode revision level

• The TB2 revision level

The device unit number range available for the RA71, RA72, and RA73 are

determined as described in Table 4–1.

Installing the SA7x

4.4 Setting Drive Unit Numbers

Note

Table 4–1 RA7x Drive Unit Numbers

Microcode Version TB2 Revision Drive Unit Number Range

Old New Old New

X – X – Yes No

X – – X Yes No

– X X – Yes No

– X – X Yes Yes

1

‘‘D-Etch, part revision F03’’ or later.

2

The RA70 can only use this range.

1

000-255

2

000-999

Two factors ensure that you do not select an invalid address. First, the drive unit

number of the drive being replaced is stored by TB2 . Second is that the RA7x

drive automatically configures itself to match the TB2 version. When you insert

a drive in the enclosure whose address range is 000 through 255 and the TB2

stored unit number is greater than 255, TB2 will signal the drive to go off line

and cause the OCP display to flash until you reset the address to 255 or less. Use

the following procedure to reset the address to 255:

1. Press the Unit Select switch in the upper-right corner of the OCP until

it locks in the in position. The unit select numbers for all drives in the

enclosure will flash indicating that the OCP is in unit select mode.

2. Press the Fault/Set No. switch for the first drive. Pressing the switch once

increments the disk unit number by one. Pressing and holding the switch

rapidly increments the disk unit number.

a. When the drive microcode is an older revision level you can only set the

drive unit number to a number in the range of 000 through 255.

b. When the new microcode is installed you can set the drive unit number to

any number from 000 through 999 providing that the correct version TB2

is installed.

Installing the SA7x 4–5

Page 44

Installing the SA7x

4.4 Setting Drive Unit Numbers

3. Repeat Steps 1 and 2 until all drive unit numbers have been set.

4. Restore the OCP to normal operation by pressing the Unit Select switch.

5. When you are changing the address to correct an error condition that caused

the unit select numbers to flash, you must press the drive dc power switch to

turn the drive off. After the drive has spun down, press the drive dc power

switch to spin up the drive and place it on line.

4.5 Installing an Add-On SA7x Enclosure in an SA900 Storage

Array

WARNING

To maintain cabinet stability, always install components in the order

shown in Figure 4–2.

4.5.1 General Installation Considerations

Internal SDI cables and power cords are installed in SA900 storage arrays only

when a storage device is installed. The internal SDI cables and power cords are

shipped with each add-on and you must install them. The contents of the SA7x

add-on kit are:

• SA7x enclosure

• Guide rail plate assembly

• Hardware mounting kit

• Internal SDI cables

• Power cord

4–6 Installing the SA7x

Page 45

Installing the SA7x

4.5 Installing an Add-On SA7x Enclosure in an SA900 Storage Array

Figure 4–2 Storage Device Add-On Sequence for the SA900 Storage Array

(Front View)

9

7 6

5 4

3 2

1

ADD-ON SEQUENCE

RA9x DISK DRIVES

ONLY

8

0

9

3 2

1 0

5 4

7

ADD-ON SEQUENCE

SA7x ENCLOSURES

ONLY

8

6

9

7 6

5 4

3 2

1

ADD-ON SEQUENCE

MIXED RA9x DISK DRIVES

AND SA7x ENCLOSURES

FIRST, LOAD ALL RA9x DISK

DRIVES SEQUENTIALLY.

THEN, LOAD SA7x ENCLOSURES

SEQUENTIALLY.

8

0

CXO-3568A-MC

The hardware mounting kit includes two sets of chassis retaining brackets.

• The top and bottom chassis retaining brackets, shown in Figure 4–3, are for

the H9646 cabinet. These brackets mate to the chassis retainer attached to

the SA7x enclosure guide rail.

Installing the SA7x 4–7

Page 46

Installing the SA7x

4.5 Installing an Add-On SA7x Enclosure in an SA900 Storage Array

Figure 4–3 SA7x Front Clamping Assembly

SA70

ENCLOSURE

CHASSIS

RAIL

CHASSIS

ASSEMBLY

FLATHEAD

SCREW

CONICAL

WASHER/SCREW

TOP

CHASSIS

RETAINING

BRACKET

FLAT

WASHER

FLATHEAD

SCREW

FLAT

WASHER

CONICAL

WASHER/SCREW

CHASSIS

RETAINER

CHASSIS

RETAINER

SEMS

SCREWS

SEMS

SCREWS

GUIDE

RAIL

ASSEMBLY

CABINET

FRONT

VERTICAL

UPRIGHT

BOTTOM

CHASSIS

RETAINING

BRACKET

CXO-2442B_S

• The chassis retaining brackets, shown in Figure 4–4, are for the H9A00

cabinet. They attach to SA7x enclosure guide rail and the cabinet frame.

4–8 Installing the SA7x

Page 47

4.5 Installing an Add-On SA7x Enclosure in an SA900 Storage Array

Figure 4–4 SA900 and SA7x Chassis Retaining Brackets

TB1

ATTACH

RIGHT

OCP

Installing the SA7x

ATTACH

LEFT

OCP

CHASSIS RETAINING

BRACKET

4.6 Preparing the SA900 Cabinet

Each SA7x enclosure is mounted in the cabinet with one guide rail plate assembly

as shown in Figure 4–5. The guide rail plate is attached to the cabinet’s internal

vertical uprights, and it supports the enclosure from one side. Grooves machined