Page 1

EK-ORM05-FG-OOl

RM05 Fault

Isolation

Guide

Prepared

Digital Equipment Corporation

by

Educational Services

of

Page 2

Copyright © 1982 by Digital Equipment Corporation

All

Rights Reserved

The material in this manual is for informational purposes and is subject to change

without notice.

Digital Equipment Corporation assumes no responsibility for any errors which

in

may appear

this manual.

Printed in

U.S.A.

• Class A Computing Devices:

Notice:

The equipment has been type tested and found to comply with the

Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which

are designed to provide reasonable protection against such radio frequency

terference when operated

ment

own expense may

The

chusetts:

This equipment generates, uses, and may emit radio frequency energy.

limits

fc)r

in-

in

a commercial environment. Operation

in

a residential area may cause interference in which case the user at his

of

this equip-

be required to take measures to correct the interference.

following are trademarks of Digital Equipment Corporation, Maynard, Massa-

DEC

DECUS

DIGITAL

Digital Logo

PDP

UNIBUS

VAX

DECnet

DECsystem-10

DECSYSTEM-20

DECwriter

DIBOL

EduSystem

lAS

MASSBUS

OMNIBUS

OS/8

PDT

RSTS

RSX

VMS

VT

a

Page 3

SCOPE

RMSS

FAULT

ISOLATION

GUIDE

This

document

documentation

information.

which

problem

this

The

between

should

cannot

manual,

RMOS

the

has

appl,icable.

Many

or

have

say

accuracy

the

tion

specific

component

been

all

listed

possibilities

of

field.

with

the

is

intended

by

Problems

encompass

be

satisfactorily

the

FSE

a

VDE

two

will

error

(s)

• The

in

t.his

This

document

document

RM05

Field

providing

are

the

is

urged

and

NON-VDE

be

symptoms

most

this

documant.

have

is

Maintenance

to

supplement

additional

listed

majority

to

request

called

can

be

obvious

been

will

be

intended

the

by symptom and

of

all

RMSS

resolved

through

additional

version.

out

in

this

pinpointed

and known

This

of

included.

dependent

to

be

Print

Set.

existing

trou~leshooting

RM05

solution

calls.

the

use

If

a

of

support.

The

to

di

fference

guide

a

module(s)

where

combinations

course

on

used

is

The

inputs

in

not

overall

from

conjunc-

to

i

Page 4

RM95

FAULT

CONTENTS

ISOLATION GUIDE

1.0

2.0

PRELIMINARY ACTION

1.1

1.2

1.3

REQUIRED

GETTING

THINGS

1.3.1

1.3.2

1.3.3

1.3.4

1.3.5

EQUIPMENT

STARTED

TO

BE

AWARE

File

Bad

Corruption

Packs

Environmental

Bus

Loading

Power

Supplies

TROUBLE-SHOOTING AIDS

2.

1

2.2

2.3

ERROR

SITE

CUSTOMER

LOG

MANAGEMENT

DISK

PACK

OF

Problems

GUIDE/LARS

USAGE

LOG

REPORTS

2.4

2.5

ON

LINE DIAGNOSTICS

11/70

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

2.5.6

2.5.7

2.5.8

DIAGNOSTICS

CERHA

CZRML

CZRMM,

CZRMP,

CZRMR,

CZRMT

CZRMU

CZRMV

N,

Q

S

RH70

Formatter

Functional

0

Diskless

Dual

Compatibility

Performance

Extended

Port

Test

Diagnostic

Logic

Exerciser

Drive

Test

Part

Test

l,

Part

Part.

2,

1 &

1 & 2

&

3

2

11

Page 5

RMes

FAULT

ISOLATION GUIDE

3.9

2.6

POWER

3.1

VAX

DIAGNOSTICS

2.6.1

2.6.2

2.6.3

2.6.4

ON

AND

POWER

3.1.1

3.1.2

3.1.3

EVRAA

EVRAC

EVRDA

EVRDB

MOTOR

ON

PROBLEMS

CB1

CB2

CB3

3.1.3.1

3.1.3.2

CONTENTS

SEQUENCE

Trips

Trips

Trips

When

Immediately

Pressed

(CONT)

Reliability

Disk

RMeX

RM0X

Formatter

Diskless

Functional

CB1

Turned

After

On

Start

Switch

Is

3.1.4

3.1.5

3.1.6

3.1.7

3.1.8

3.1.9

3.1.19

3.1.11

3.1.12

3.1.3.3

CB4

CBS

CB7

CB8

All

+29Y

+28V,

High

-46V,

Low

-46V,

Ripple

Trips

Or

CB6

Trips

Trips

DC

Voltages

-29V,

OR

Low

+46V,

+46V And

Too

Shortly

Squealing

Shortly

Trips

Missing

+29V,

And

-16V

High

For

After

After

-9.7V,

-16V

Are

Just

Noise

Are

Motor

Motor

At

Test

+9.7V

All

Missing

One

Voltage

Turns

Turns

Points

Are

Ei

ther

With

and

Either

High

A

No

All

Or

111

Page 6

RMes

FAULT

ISOLATION GUIDE

3.2

3.

3

DRIVE

3.2.2

3.2.3

POWER

MOTOR

Motor

'Motor

Pressed

3.2.2.1

3.2.2.2

3.2.2.3

3.2.2.4

Motor

ON

AND

CONTENTS

Starts

Does

+20v

A1Q4,

+20V

A1Q4,

+20V

A1Q4,

+20V

but

Overheats

MOTOR~

SEQUENCE

(CONT)

When

Not

missing

missing

OK

OK

208+

Turn

and

and

and

and

CBl

9.7V

9.7V

at

208+

at

Pin

VAC

Thermal

VDE

Is

Turned

When

at

Pin

is

OK

at

Pin

is

missing

Pin

3

VAC

3 Of A1Q2,

is

missing

Cutout

DRIVES

Start

3

3

of

is

On

Switch

of

A1Q2,

of

A1Q2,

A1Q2, A1Q3,

OK

at

Pin

AlQ3,

at

Pin

Activates

Is

AIQ3,

AIQ3,

2

AIQ4

2

3.4

POWER

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

ON

PROBLEMS

CBl

CB2

CB3

CB4

CBS

CB6

Trips

Trips

Trips

Trips

Trips

or

CB7

Short

When

In

CBl

Immediatley

Turned

Shortly

Also

Shortly

On

After

a

Squealing

After

Trips

+20Y

is

Turned

Distribution

On

After

Motor

Noise

Motor

Start

Starts

Starts

is

Switch

Turning;

Heard

Turing

is

3.4.7

3.4.B

CBB

All

Trips

DC

Voltages

Iv

Missing

and

no

+20Y

Page 7

RM95

FAULT

ISOLATION

GUIDE

3.5

3.4.9

3.4.19

3.4.11

3.4.12

DRIVE

3.5.1

3.5.2

+28v,

High

-46v,

-46v

Ripple

MOTOR

Drive

Drive

Pressed

3.5.2.1

3.5.2.2

3.5.2.3

3.5.2.4

CONTENTS

+29v,

or

Low

and

+46v

and

+46v

too

High

PROBLEMS

Motor

Motor

Starts

Does

+29Y

+29Y

+20Y

Motor

Activates

(CONT)

-20v,

Are

Missing

for

Missing

is

is

-9.7v,

Both

Just

When

not

CB1

Turn

but

but

OK

OK

and

Overheats

+9.7v

High

one

or

Voltage

Is

When

9.7v

9.7v

208

is

VACC

and Terma1

Are

Low

Turned

St.art

OK

is

Missing

is

Either

On

Switch

Ok

Cutout

All

is

4.8

HEAD

4.

1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

LOAD

SEQUENCE

HEADS

REVERSE

HEADS

DO

REVERSE

CARRIAGE

AND

HEADS

CARRIAGE

AND

HEl~DS

HEADS

(INNER

HEADS

RTZ

:LOAD,

IS

UNABLE

UNABLE

DO

NOT

CURRENT

NOT

CURRENT

HITS

STAY

HITS

RETRACT

LOAD,

GUARD

NON

FUNCTIONAL

TO

SEEK

TO

SEEK

PROBLEMS

LOAD

LOAD

AFTER

IS

AFTER

OK

FORWARD

OUT

ON

FORWARD

HESITATES

BAND)

BUT

UNLOAD,

TO

PRIME

TO

1466

UP

TO

UP

TO

STOP,

CB4

PACK

STOP,

AND

FAULT

THEN

FAULT

CYLINDERS;

(8)

SPEED

SPEED

TRIPS,

CREEPS

LIGHT

TIME

TIME

LIGHT

ON

1,

2,

OUT

OUT

FAULT

ON,

TO

FORWARD

4,

AND

BUT

LIGHT

CB4

- 512

NO

HOLD

ON,

TRIPS

EOT

4.19

UNABLE

TO

FORCE A SEEK

v

ERROR

WITH

FTU

TO

CYL

1467

(8)

Page 8

RM"S

FAULT

ISOLATION GUIDE

5

..

6.9

9

4.11

4.12

PCMER

5.1

5.2

5.3

ERROR

6.1

HEADS

START

DRIVE

AND

DO

LIGHT

MOTOR

POWER

NOT

IS

BRAKE

FAIL

UNLOAD

MASSFAIL

AC

LO -UNSAFE

DC

LO -RM

BITS -CONTROL,

CONTROL

6.1.1

6.1.2

6.1.3

ADAPTER

REGISTER

MCPE

TRE

SC

Bit

Bit

CONTENTS

WHEN

OFF,

PROBLEMS

STATUS

Bit

PACK

IS

INOPERATIVE

176700

13

14

15

(CONT)

START

SPINNING

AND

ERROR

SWITCH

REGISTERS

IS

~TURNED

OFF,

6.2

6.3

STATUS

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.2.6

6.2.7

6.2.8

ERROR

6.3.1

6.3.2

6.3.3

REGISTER

MOPE

MXF

PGE

NEM

NED

PE,

UPE

weE

DLT

REGISTER

ILF

ILR

RMR

176710

Bit

Bit

Bit

Bit

Bit

Bit

Bit

1

Bit

Bit

Bit

08

09

10

11

12

Bit

13

14

15

176714

"0

01

92

6.3.4

6.3.5

PAR

FER

Bit

Bit

"3

04

vi

Page 9

MIS

FAULT

ISOLATION GUIDE

6.4

6.3.6

6.3.7

6.3.8

6.3.9

6.3.10

6.3.11

6.3.12

6.3.13

6.3.14

6.3.15

6.3.16

ERROR

CONTENTS

WCF

ECH

HCE

HCRC

AOE

IAE

WLE

DTE

OPI

UNS

OCR

REGISTER 2

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

(CONT)

05

06

07

08

09

10

11

12

13

14

15

176740

7.8

n.e

6.4.1

6.4.2

6.4.3

6.4.4

6.4.5

6.4.6

6.4.7

6.4.8

ERROR

COMPATIBILITY

8.1

8.2

8.3

BOOTSTRAP

PROBLEM

CAUSES

ERROR

SYMPTOMS

DPE

DVC

LBC

LSC

IVC

OPE

SKI

BSE

DEFINITION

Bit

Bit

Bit

Bit

Bit

Bit

Bit

Bit

PROBLEMS

03

07

10

11

12

13

14

15

vii

Page 10

RMI5

FAULT

ISOLATION GUIDE

9.9

11.1

11.9

12.0

13.9

14.9

15.9

DATA

DRIVE

DUAL

PACK

BASE

PORT

CORRUPTION

NOT

READY

PROBLEMS

ERRORS

UNEXPECTED

ADJUSTMENTS

FLOW

DIAGRAMS/TEST POINTS

CONTENTS

OR

DRIVE

ATTENTIONS

(CONT)

HANGS

viii

Page 11

1.0

PRELIMINARY

ACTION

1.1

The

RM05

REQUIRED

following

in

minimum

1.

Spares

a.

b.

c.

d.

2.

3.

4.

5.

6.

Scratch

CE

Field

Maintenance

Manuals

a.

b.

c.

d.

EQUIPMENT

equipment

time:

Ki

ts

Spares

Spares

MBA

RHXX

Kit

Kit

Controller

Spares

Pack

Pack

Test

30-17108-00

Unit

Print

(on

micro

RM05 -Service

RM05 -User's

BK7BIE/F

BK7BIE/F

Technical

Illustrated

should

11

12

29-23600

29-23601

Kit

30-17107-00

Set

fiche)

Manual

Guide

be

available

MP0175

and/or

- EK-RM05-SV

- EK-ORM05-UG

Description

Parts

Breakdown

Micro

Manual-

to

troubleshoot

fiche

-

an

reader.

ER-BK7B1-TM

ER-BK7BI-IP

7.

8.

9.

10.

11.

Special

a.

b.

c.

Tools

15"

*2

"C"

Ring

Heavy

DVM

Oscilloscope

Field

Service

Diagnostics

-

other

Phillips

than

screwdriver

Removal/Replacement

Duty

Spring

Replacement

(calibrated)

-

Tool

up

to

Kit

date.

with

in

Spares

dental

Tool

Tool

mirror

Kit

Set

(spring

,2

and

hook)

penlight.

1

Page 12

1.2

GETTING

STARTED

Customer

Many

Inputs

problems

comprehensive

object

was

of

really

the

procedures,

each

is

poss

situation,

also

ible.

1.

2.

3.

4.

advisable

What

How

Can

Can

scoping)

5.

Has

recently?

6.

Did

troubleshooting

customer

you

you

isolate

can

investigation

questions

a

hardware

or

software

but

to

are

the

often

the

problem

the

•

any

this

disk

problem

input,

actually

do,

use

and

be

asked

malfunction,

are

some

verify

apparent

does

the

problem

related

have

Section

fix

eliminated

of

will

at

fault.

of

the

major

the

answers

symptoms?

problem

be

demonstrated?

frequency

hardware

ever

occur

"tools"

you

should

a

problem

6

the

specific

at

the

symptoms.

be

to

or

The

points

occur?

be

before

described

be

able

in

of

this

malfunction.

this

stage

determine

if

the

pack,

questions

are

listed

you

get

(If

by

so,

increased?

or

software

the

change?

in

Section

to

determine

the

RM05

documentation

by

doing

Obviously,

whether

operational

will

vary

below.

other

do

means

itl)

(For

been

changed

Using

1.1

and

whether

subsystem.

to

a

the

there

in

It

if

easier

the

the

If

help

1.3

1.3.1

Frequently

loads

softwa

the

or

re

console

a.

b.

THINGS

File

Corruption

the

runs

properly.

usuall

or

Is

this

(both

in

the

disk)

Is

this

and a

check.

AND

START

VAX

the

PROTECT

TO

BE

AWARE

disk

y

is

is

at

errorlog,

a

relatively

utilities

way bad

pack

read

Run

only

either

204,

Formatter

THE

DRIVEl

blamed

While

faul

check

have

blocks

any

exercise

"R"

OF

for

this

t.

If

the

new

disk

bugs

are

good?

A

may

the

Performance

COMMAND,

(EVRAC)

I I

2

a

file

can

be

no

device

following

created

that

can

handled,

block

pick

SWR

- 3

"Read

or

task

caused

er

rors

key

points:

by

cause

never

may

have

up a bad

Exerciser

for

a

All"

Command.

that

by

hardware,

are

Preserve

file

corruption

trust

just

header

(CZRMU)

11/70,

no

longer

the

shown on

or

DSC?

a

new

gone

or

bad

data

LOAD

or

for

WRITE

a

Page 13

c.

Has

If

the

device

affected

errors

software

are

shown,

been

keep

changed

reading.

recently?

1.3.2

It

is

suddenly

the

for

backup

it

may

clean,

will

image

1.3.3

This

Bad

amazing

giving

bad

area

pack

maintenance

pack.

happen

ask

show

up

that

Environmental

is

a

electromagnetic

frequent

recently

for

heavy

shutdowns,

forklifts

have

the

only

problems,

changed

idle

(the

caused

way

specialist.

Packs

how

many

errors.

is

(header,

Look

during

the

customer

on

Errorlog

is

bad.

broad

radiation.

and

equipment

time

spark

problems.

to

be

inc1ud

for

the

Problems

field

so

verify

pay

on

etc.

coil),

sure

calls

The

result

symptoms

data,

ing

similarities

same

to

use

provided

that

that

attention

the

In

general

and

If

you

is

etc.).

bad

function

a

backup

it

covers

Power

same

have

to

consult

from

can

The

block

in

the

is

not

and

the

to

configuration

when

p~

keep

computer

reason

a

previously

vary

according

customer

mapping,

failure

and,

pack.

if

Obvious

Errorlog

temperature,

grounding

the

errors

(or

your

close

eyes

room

to

suspect

an

local

trusted

is

responsible

and

that

diagnostics

or

power

are

has

occur.

by),

open;

air

conditioners

environment,

environmental

to

keeping

indicate

bad

the

system

the

not

radios;

pack

where

a

run

areas

and

most

been

L60k

plant

1.3.4

A.C.

the

usually

major

(with

large

Bus

Unibus

Unibus

intermi

clue

a

scope,

enough

Troubleshooting

loading

1.3.5

Check

scope

Also

for

Power

all

for

check

supplies

ripple

the

Loading

loading

and

thE~

ttent,

is

to

hopefully),

to

Guide

more

detail.

Supplies

connections.

look

on

can

fast

cause

for

the

cause

devices

and

at

a

a

(on

microfiche-red

voltage

supplies;

virtually

see

diagnostics

working

and

gate

look

transition.

with

a

See

table

any

error

it

first.

usually

bus

for

with

dropouts

section)

a

DVM

primecause

3-1.

on

The

don'

everything

See

if

available.

of

any

device

symptoms

t

fail.

running

in

the

the

signals

Unibus

section

intermittents.

on

Then

on

are

The

AC

3

Page 14

2.g

TROUBLESHOOTING

AIDS

2.1

This

is

ERROR

one

maintenance.

operating

wIll.

Guide.

The

There

operation

Error

1.

2.

log

Was

What

of

semi-solid

system,

and

will

filter

day

LOG

of

the

If

you

the

procedure

should

printout

Be

certain

time

of

you're

terminated

available

generator.

errors

aid

in

there

out

is

common

environmental

most

valuable

don't

customer

should

be

a

of

the

that

the

using,

so

to

Otherwise,

you

are

determining:

actually

corrupted

between

hardware

know how

and

be

software

Error

NOTE

the

failure

and

that

that

the

the

looking

a

hardware

file

errors?

problems

problems.

and

least

to

DEC

entered

manual

Log.

error

is

error

current

errorlog

you

for.

type

used

run

it

software

in

on

file

on

the

logging

may

miss

error?

problems.

The

show

for

personnel

the

site

for

disk

file

report

bad

up

here,

tools

the

Site

deta:iling

the

is

is

the

This

blocks

for

system

particular

probably

Management

helps

and

as

do

time

most

the

you

3.

4.

5.

2.2

Look

Pa y

parts

from

SITE

up

spec

were

the

indicates

maintenance

alignments

situations

How

often

is

that

What

was

task

fa

i 1

ure?

involved?

What

pre

do

- d i a 9

exercise

have

to

MANAGEMENT

the

disk

i a 1

at

changed.

customer.

a

on

against

indicating

did

you

the

or

function

the

nos

harder.

work

history

ten t ion

problem

the

the

will

system

see

error

'a

doing

occur?

diagnostic

always

Are

tic

error

there

symptoms

i n d i

cat

On

system

ion

intermi

with.

GUIDE/LARS REPORTS

in

to

Correlate

It

is

wh

not

the

a t

LARS

ad j us

this

unusual

starting

device.

the

customer's

unreadable

Also,

packs.

Tells

failure.

at

the

time?

happening

or

indicate?

0 f

wh

ttents,

reports

tme

n t s

to

the

to

find

immediately

check

disk

you

Is

at

the

other

dev

This

at

to

this

or

we

may

maintenance

r e mad e

information

that

after

information

pack

usage

how

one

time

1

00

the

gives

likely

particular

of

ice

k

be

er

for,

all

c:lnd

you

error

the

on

log

ror

you

log.

wh

have

last

head

it

the

s

a

0 r

you

i c h

log

in

4

Page 15

2.3

CUSTOMER

DISK

PACK

USAGE

LOG

Customers

and

bad

a

potential

and

identify

2.4

These

great

diagnostics

help

release

time

them

found

and

in

in

2.5

In

many

tool.

ind

Consequently

ividua1

diagnostics

Reliability,

providing

At

the

time

are:

should

blocks.

pack

bad

keep

This

information

problem.

blocks

track

on

ON-LINE DIAGNOSTICS

are

generally

in

si

tuations

the

system.

if

the

easily.

the

customer's

OFF-LINE

cases,

di

agnostics

listed

system

DIAGNOSTICS

off-line

Unfortunately,

doesn't

The

diagnostic

software

diagnostics

it

is

and

are

all

Functional,

that

of

a

this

scratch

writing,

Verify

a

where

a

good

exactl

and

pack

of

pack

regular

quite

have

manual

idea

off-line

Formatter

is

the

current

usage,

is

quite

that

the

basis.

easy

the

customer

they

them,

operating

will

to

y

what

but

mounted

formatting,

useful

customer

to

are

you

won't

manuals

set.

be

be

very

they

the

can

on

the

diagnostics

when·

run

and

does

installed

be

the

only

familiar

test.

VAX

be

tested

backups,

looking

does

look

can

not

able

are

want

at

usually

sysgen

to

available

with

The

diagnostics;

run

on

drive(s).

for

the

for

for

be

put

the

11/70

line

RM05

of

to

PDPll

tZRML

CZRMM

CZRMN

CZRMO

DIAGNOSTICS

RM02/03/05

-

-

RM02/03/05

-

RM02/03/05

-

RM02/03/05

CZRMP -RM02/03/05

CZRMQ

CZRMR

CZRMS

CZRMT

CZRMU

-

RM02/03/05

-

RM02/03/05

-

RM02/03/0S

-

RM02/03/0S

-

RM02/03/05

CZRMV -RM02/03/0S

Formatter

Functional

Functional

Functional

Diskless

Diskless

Dual

Dual

Diagnostic

Diagnostic

Port

Port

Compatabi1ity

Performance

Extented

Drive

Test

Test

Test

Logic

Logic

Test

Exerciser

1

2

3

Test

Test

Test

Part

Part

Part

Part

1

2

1

2

5

Page 16

VAX

DIAGNOSTICS

EVRAA

EVRAC

EVRDA

EVRDB

There

are

The

Reliability

Disk

RM0X

RM0X

are

"buildup"

buildup

catastrophic

to

verify

starting

unknown

The

elements.

"breakdown"

intermittant

gets

the

errors.

cause

exercised

is

isolated.

Neither

of

diagnostics

system

work.

diagnostics

more

an

Section

detailed

indication

6.0.

Formatter

Diskless

Functional

many

techniques

and

approach

and a work

each

with

known good

problems

A

of

the

with

more

these

generally

However,

can

be

description

of

"breakdown".

is

ing

section,

approach

where

general

exerciser

error,

specific

approaches

overlap

if

an

effective

the

proper

in

using

commonly

system

in

an

equipment

to

diagnosticS'

basically

and

diagnostics

is

and

you

of

are

the

ones

diagnostics

used

is

effort

is

run

then

perfect

assume

aware

isolation

diagnostics

to

"bui1

to

and

is

the

the

until

that

of

method.

use

but

when

tup"

find

gradually

generally

system

to

get

suspect

the

in

all

the

in

under

the

using

the

an

other

1imi

You

this

the

most

failure

diagnostics

failure

adding

applied

works"

indication

sections

failing

cases,

parts

tations,

will

section

the

Error

common

the

but

are

section

as

the

of

the

the

find

and

Bit

is

by

to

it

of

a

2.5.1

Listed

As:

Special

Test

Description:

transfers

Suggested

working

Comments:

give

errors

CERHA

RH70

Controller

Requirements:

and some

Use:

RM05

This

is

if

When

available.

diagnostic

the

Functional

Tests

register-

a

media

Diagnostics

the

check.

controller

uses

is

bad.

Drive

RH70

using

Cylinder"

6

and

a

register

of

Scratch

disk

is

the

Pack.

drive

suspect

disk,

for

and

data

and a

could

Page 17

2.5.2

CZRML

Listed:

Special

Test

Description:

Suggested

Comments:

times

because

format.

to

isolate

To

access

at

2e4.

2.5.3

Listed

Special

as:

Requirements:

1.

2.

RMe2/03/05

Requirements:

Use:

Be

Pack

sure

possibly

A

pack

a

the

CZRMM,

with

read

Bad

CZRMN,

problem.

RM02/03/05

Formatted

Certain

areas

Formatter

A

Formats

formatting

the

scratch

the

a known

Sector

CZRMO

Functional

pack

for

on

working

disk

next

good

File

Parts

the

pack

RM05

and

and

media

time

format

utility

Test

2

must

subsystem

updates

updating

is

properly

the

system

is

routine,

Part

and

3.

be

and

the

Bad

the

Bad

may

invaluable

star.t

1,

2,

error

free.

scratch

Sector

Sector

formatted

not

be

when

the

& 3

pack.

File.

File.

at

all

able

to

trying

program

Test

tested

Description:

wi

read/write

Part

l:

register,

Part

header

check

2:

Performs

and

of

mid-transfer

Part

and wr i

implied

peak

3:

te

shift

Performs

seek.

multi-sectors

Suggested

1.

2.

Verify

Check

Comments:

if

not

halted

th

and

Tests

seek

data,

lis

seeks.

check

tests,

Use:

This

the

:Oiskless

servo

error

command,

wr i te

write

&

0's,

write

mul

Also

write

in

offset

logic

basic

program

properly

These

logic.

detect

and

and

format

and

ti

pIe

error

and

mode.

in

drive

with

diagnostics

Diagnostics.

log

offse~

read

check

of

write

sectors,

logic

read

RM

Adapter

read/write

will

disturb

a

Control

ic,

command.

of

header

multiple

check

(HCE,

each

not

test

error

header

and

data;

wr i

te

IVC),

track,

tested

and

the

"C".

It

abort

&

data,

sectors,

and

seek

header

RM

Adapter

also

log

data;

0's

wr i

write

read

by

functions.

tests

ic,

I

sector

write

error

and

te

current

and

write

Diskless

format

logic

the

look

and

lis,

check

1 &

of

dr

ahead

wr i te

write

logic,

write

wi

tests,

check

a

pack

not

ive

th

2.

7

Page 18

2.5.4

CZRMP,

CZRMQ

Listed

as:

Special

and

dr

ive

Test

the

Description:

RM

subsystem

performed

Suggested

Part

logic;

1:

command

seqencer.

Part

2:

sequencer;

Comments:

1.

2.

RM02/03/05

Requirements:

power

turned

up

on

the

RH70

Use:

Tests

To

basic

detect

decode;

Tests

ECC

The

The

as

additional

logic.

drive

multiple

the

drive

is

Diskless

Dr

ive

on.

Parts

to

the

and

1

and 2 combined,

drive

it

errors

handshaking;

port

used

for

sector

interface.

interface

is

reguest;

error

unit

transfer

Controller

interface.

assumed

and

faults

register

detect

selection.

logic

Part

cables

verify

No

to

work.

in

transfer;

attention

logic;

is

1 &

must

the

specific

the

RM

logic;

CRe

not

Part

be

plugged

operation

Adapter.

error

logic;

tested

2

tests

detect

control

as

in

of

are

data

well

2.5.5

Listed

Special

Test

also

Part

select

Suggested

log

lc.

CZRMR,

As:

RM02/03/05

Requirements:

1.

2.

3.

4.

Dual

Dual

Power

Operator

Description:

Part

1

tests

checks

2

tests

switch

Use:

Comments: Use

dual

port

operation.

CZRMS

Controller

Controller

off

drives

intervention

the

the

the

ability

timeout

duration

which

To

test

Performance

See

Dual

Option.

Test

not

release.

requires

the

Para.

Port

Logic

Cable

being

-

Part

to

seize

of

the

manual

basic

Exerciser

2.5.7

Test

PIN

70-10507-02.

tested.

2.

and

timeout

intervention.

operation

CZRMU

Part

release

release

of

to

1 &

the

test

Part

each

and

port

the

2

port.

the

select

dynamic.;

It

port

8

Page 19

2.5.6

CZRMT

Listed

Special

Test

following

between

As:

Require.en~s:

Description:

conditions

drives.

1.

2.

3.

4.

5.

Head

Positioner

Spindle/pack

Improper

Incorrect

Suggested

incompatibility

Comments:

should

drive

it

mechanical

2.5.7

can

be

(write

be

CZRMU

run

mis-alignments

Compatibility

.

mis-alignment

lateral

level

addressing

Use:

is

suspected

Funct:ional

first

current).

assumed

that

Formatted

This

which

interface

of

This

Test

to

eliminate

If

drive

or

scratch

diagnostic

most

commonly

mis-alignment

runout

write

current

of

read/write

program

between

Part

errors

3 and

then

incompatibility

tolerances.

pack.

is

designed

is

obviously

drives.

Extended

electrical

occur

cause

heads

problems

with

to

detect

incompatibility

used

Dr

ive

with

this

is

diagnostic;

attributed

Test

the

when

20

the

to

Listed

As:

Special

1.

2.

Test

Description~

purpose,

activity

are

words

Data

selected

transferred

Mode:

available

~ectors

per

efficient

Change

204.

Seek

parameter

Verification

exercises

transferred

RM02/03/05

Requirements:

Forma

tted

pack.

defaul t mode,

compare

Addresses

f~rrors.

of

operating

rate

on a RM05

by

the

per

Default

memory, up

command

run

tim1e:

"Passes"

Mode:

the

servo

per

command.

Performance

Packs

of

the

known bad

Performance

system

subsystem.

"Si

ze"

read

or

mode

to

8192

rather

than

Parameter

to

Selected

more

than

Exerciser

using

Extended

spots

tests

Dr

on

Exerciser

like

exerciser

It

parameter.

write

and

words.

order.

selects

single

This

sector

"Random" = 1 and

99

for

long

by

setting

Data

Mode

16,

ive

the

that

has

"Si

"Size",

mode

runs.

since

17,

Test,

pack.

is

a

maintains

two

ze"

basic

is

transfers

transfers.

the

Load

"Size"

only

and

will

give

good,

modes

the

number

depending

SWR

II:

and

to

256.

one

sector

21

out

data

general

a

high

that

multiple

For

most

000001.

start

This

of

of

on

at

is

9

Page 20

Suggested

Use:

1.

2.

3.

4.

5.

Comments:

1.

2.

2.5.8

CZRMV

As

a

To

surface

status

To

check

To

check

bad

final

block

overall

intermittents

information.

for

multiple

customer

file.

DRIVEI1! Load and

Dynamic

SWR

and

This

dual

=

is

port

00~001.

the

best

exerciser.

In

many

the

sections

cases

lower

level

faster

it

diagnsotics,

and more

subsystem

drive

packs

See

Start

testing

data

will

be

checkout.

and

give

interaction.

for

Para.

at

204,

-

bad

spots

9.8.

SWR= 3 and

use

transfer

faster

to

as

thoroughly.

additional

seek

test

isolate

they,

not

WRITE

logged

PROTECT

"R"

verification

and

problems

exercise

error

in

and

the

THE

Commana:-

mode

c)ver

all

with

isolated

Listed

as:

Special

formatted

Test

Description:

exercises

i

tse1

f.

the

drive

present,

Suggested

1.

2.

RM02/03/05

Requirements:

pack.

the

mechanical

The

the

sector/track

and

RM

mechanical

Test

and

and

the

the

Adapter

11

Test

Servo

default

operator.

Use:

When

When

up"

mechanics

RH/RM

approach)

Extended

Test

assumes

timing

is

an

21

system.

mode

of

Adapter

KW-11P

and

data

addressing

are

thoroughly

of

NOTE

extensive

is

a

stress

and

a

drive

tests

Drive

Clock

a

working

transfer

the

They

aust

are

have

Test

for

timing

RH

ability

and

posi

checked.

drive

is

positioning

test

are

be

of

not

selected

suspect.

shown no

and

tioning

verified.

test

the

R/W

run

by

er

tests,

RM

Adalpter and

of

t.he

portions

If

a }(W-IIP

in

ro-rs.

and a

drive

of

is

("build

3.

Checking

mechanical

performance

10

during

P.M.

Page 21

4.

In

conjunction

drive

interaction

with

Performance

problems.

Exerciser

to

isolate

s.

Comments:

1.

2.

3.

2.6

2.6.1

VAX

EVRAA

Doing

IC,

Timing

A

better

due

R

to

servo

for

tests

mechanical

run

Not a good

used

extensively.

Test

pattel~ns

data

for

Test

why

compare

Performance

28

test

DIAGNOSTICS

adjustments

test

1

run

time

RH/RM

16,

17,

when

last

21

is

or

2.

regularly

exerciser

and

operation.

Adapter

CAUTION

and

used

errors

Exerciser.

to

restore

not

by

check

21 a1

alone.

if

run

modifying

can

track

than

as

ters

This

the

pack

Always

the

pack

in

default

the

parameters,

mechanical

Performance

all

the

commands

data

causes

is

used

run

(that's

mode).

wear.

Exerciser

are

not

LC,

Listed

Special

(VMS)

Test

with

Description:

sections.

1.

2.

3.

As:

RK06/RK07/RP0X/RM0X/RL02/TUS8/RX02

Requirements:

a volume name

Qualification

support

Seek

Timing

mili-seconds,

(1,2,4,8,16,-

from

Media

sector

It

file.

goes

different

Test

on

doesn't

After

into

addresses

all

the

a mode

..

A

This

-

disk

from

512).

terminals,

-

Write

disk

report

all

formatted

o~

"Scratch"

program

verifies

drive

this

cylinder

and

(except

bad

the

sectors

wi

th

pack

contains

the

commands.

gives

If

there

the

Write

sectors

random

Reliability

which

or

"Diagnostic".

is

five

the

"0"

seek

drive

average

to

are

Checks

to

each

two

times

drives

5

home and bad

listed

have

been

in

written

patterns

not

RM03/05

be

seek

prime

"Mounted"

related

tested

times

cylinder

under

are

invalid.

patterns

sector

the

bad

,

files).

the

and random

will

in

test

every

sector

test

disk

11

Page 22

4.

Multi-Drive

random

data

concurrent

Test

to

mode.

-

tests

random

The

function

up

to

addresses

sequence

8

to

drives,

all

is:

transferring

drives

in

a

5.

Suggested

give

additional

problems.

Comments:

2.6.2

Listed

As:

Special

Test

File.

Description:

It

a.

c.

d.

e.

b.

Drive

Write

Write

Read

Data

data

compare

Conversation

and

as

drives

run

Seek,

simple

simultaneously

addresses

Use:

As

status

Run

Functional

EVRAC

Vax

Disk

Requirements:

is

broken

clear

random

Check

Mode

Read,

and

data

a

final

Formatter

Diagnostic

Formats

into

data

data

test

Wr i te,

and

EVRDB

six

-

allows

routines.

Wr i te

with

patterns.

overall

error

for

the

pack

areas.

the

Field

Selectable

Check

selectable

subsystem

information

worst

case

Supervisor

and

Engineer

can

checkout.

seek

reference

wr i tes

functions

be

or

for

testing.

the

to

design

run

up

random

to

disk

Also

intermittant

manuals.

Bad

Sector

such

8

to

1.

2.

INIT

-

This

assigns

determines

also

one

adjusts

track

multi-track

PACK

File

Bad

INIT

on

all

Sector

time.

a

channel,

if

transfers

transfers

sectors

File,

section

the

buffer

Format

is

builds

media

sizes.

and

of

the

are

are

the

pack

12

run

prior

a

is

a

done.

done.

writes

last

is

device

scratch

If

in

a

track.

formatted

to

all

dependent

pack

user

If

zero

mode (VMS),

in

entry

After

sections.

or

stand

reading

one

track

table,

not.

Bc3d

and

Init

only

alone,

Sector

the

at

It

a

Page 23

a.

This

unless

subsystem

is

missing

b.

This

new

packs

Sector

c.

The

written

section.

section

the

is

section

Files

new

until

user

OK

or

corrupted.

which

written.

Bad

CAUTIONS

should

verifies

and

has

do

the

to

not

Sector

the

end

be

never

Bad

used

have

File

of

the

Sector

to

the

is

the

be

disk

Pile

format

Verify

run

Bad

not

3.

4.

5.

6.

Suggested

Comments:

of

all

implications

FORMAT -Reads

formats

not

VERIFY -

reads

and

File

READ

data

that

precaution,

FLAG

File.

will

section

bad

sectors

with

Use:

This

one

read,

the

Reads

the

whole

entered

can

not

ALL

errors

may

-

Reads

found.

have

WRITE

BAD -Allows

CAUTION,

be

rewritten

is

great

show

the

Formatter.

Pack

formatting

program

and

and

track

program

and

in

the

be

read,

bad

can

inform

validates

at

validates

pack.

Bad

every

This

spots

PROTECT

for

if

this

with

for

up

only

rendor

a

time.

is

aborted.

Any

Sector

the

program

sector

is

THE

the

manual

section

a

updating

.under

and

customer

the

customer

the

If

the

bad

sectors

File.

on

ideal

that

are

DRIVEl

is

label

the

VMS

updating

Bad

Sector

the

Bad

Sector

is

aborted.

a

for

not

update

used

of

Bad

or

the

packs

of

File

Bad

Sector

.

File

found

If

the

pack

and

checking

flagged.

of

the

,

the

·Scratch".

Sector

diagnostics

Bad

Sector

useless.

your

intentions.

are

Bad

pr

user

Bad

home

File

and

File

and

flagged

Sector

ints

packs

As a

Sector

block

but

File.

Beware

then

is

then

the

This

when

not

2.6.3

Listed

Special

the

drive

Test

verify

It

does

module)

EVRDA

As:

RM03/05

Requirements:

power

Description:

the

operation

not

test

except

tur.ned

the

for

the

Diskless

The

on.

This

of

the

dr

ive

drive

Diagnostic

drive

Diagnostic

diagnostic

RM

Adapter

interface

select

13

interface

Supervisor.

consists

up

(RD

lines

must

to

and

that

be

of

the

sections

are

connected

80

tests

drive

used.

with

Which

interface.

of

the

CS

Page 24

Suggested

subsystem

Use:

To

independent

verify

of

the

the

drive.

operation

of.

the

RM03/05

disk

Comments:

diagnosing

2.6.4

Listed

EVRDB

As:

Special

Diagnostic

Test

which

Description:

can

line.

1.

2.

3.

This

disk

diagnostic

subsystem

RM03/05

Requirements:

Supervisor

be

selected

Data

verifies

of

Seek

which

Transfers

all

sector/tracks

Tests

verify

header

centerline

out

Timing

the

speed;

servo

Tests

minimum,

should

problems.

Functional

Test

Scratch

running.

This

diagnstic

via

-

Executes

a

section

logic.

and

This

seek,

command

section

recalibrate,

fUQctions.

electro-mechanical

-

This

section

average,

It

the

and

always

pack

contains

switch

all

data

also

error

contains

verifies

maximum

mounted

transfer

checks

detect

offset,

These

hardware.

be

used

four

in

the

the

positioning

test

the

pack

seek

fi

rst

and

test

Start

on

sections

Command

commands

addressability

logic.

and

r~eturn

throughly

rotational

times.

when

line.

and

tests

to

check

4.

Suggested

the

Diskless

read/write

Manual

Intervention

interventions;

address

Use:

plugs,

Verifies

Diagnostic

and

seeks.

pack

and

logic

and

Tests

acknowledge,

write

tests

not

lock

tested

basic

read

switch.

in

drive

Tests

in

the

all

preset,

RM

Adapter

functions

operator

operator

with

such

as

14

Page 25

3.0

POWER

ON

AND

MOTOR

SEQUENCE

NON-VDE

DRIVES

This

swi

section

tch

success

thorough

all

areas

1.

2.

3.

concerns

is

pressed,

of

troubleshooting

and

careful

is

in

order

Check

all

and

visual

for

circuit

CB6, CB7, and CB8.

Check

air

cleaning

If

rep 1 ace

loaded

Check

voltage

supply

of

and

filter

the

60

50

adj

Table

for

and

air

th

e f i 1 t e r •

at

cylinder

Hz Hz -

the

RM

and

if

the

usting

3-1.

blower

at

also

pressure

.15

.10

Adapter

ripple

voltage

it

from

the

any

the

or

or

back

the

dr

time

ive

motor

power on

observations.

power

breakers

motor

operation.

bottom

check

0.

less,

less,

is

Air

and

the

low,

p.r

replace

replace

drive

levels.

is

grossly

to

normal

CBl

problems

or

motor

-

CBl,

of

absolute

check

e s s

ute

power

Replace

level.

is

turned

comes up

is

A

general

problems.

CB2, CB3, CB4,

Inspect

the

drive

filter

for

rea

din

gsa

filter.

filter.

supplies

any

adjustable

out

of

tolerance

on,

to

s·peed.

dependent

inspection

the

for

air

air

leaks

r e

See

para.

the

primary

need

pressure.

wit

h he

for

proper

instead

start

The

upon

of

CBS,

of

and/or

ads

power

14.0.

3.

1

3.1.1

3.1.2

3.1.2.1

3.1.3

POWER

CBl

Trips

AlQl,

Blower

Time

Meter

AICl,

YEN,

YFN

CRI-CR4

Tl,

T2

eBI

CB2

Trips

AlQl,

T3

CB2

Short

K6,

YFN,

CB3

Trips

ON

PR,OBLEMS

AIQ5

Motor

AIC2 -

AIQ5

In

+29Y

K7,

1<8

YEN

CAUTION:

Distribution

Capacitors

charged

15

Page 26

3.1.3.1

When

CBl

AIQ2, AIQ3

Is

Turned

On

3.1.3.3

Immediately

Parking

Motor

Shortly

Noise

Belt

Tension

Shortly

Belt

Tension

Motor

CB4

Trips

Carriage

Head Load

A17

Servo

Po

K7

Voice

.22uf

Coil

Capacitor

CB4

After

B-rake

After

Is

Heard

After

Lock

Pin

Switch

we r Amp

Assembly

Motor

Motor

Bad

at

TB6

The

Start

Starts

Starts

Or

Misadjusted

Pins

Switch

Turning

Turning

7 & B

Is

Turned

Also

On

a

Squealing

3.1.5

3.1.6

_3.1.7

CBS

OR

5

Volt

Module

Servo

YFN

Control

CBS

or

CB7

Trips

Module

A2

Backplane

CBB

Trips

E"1

A2

Backplane

CBB

CB6

Trips

Regulator

Preamp

Panel

CB6

A10, A14,

short

short

(CBS

AlS,

only)

A16,

A17,

AlB

16

Page 27

~~.1.8

All

DC

Vol

CB2

Tripped

YEN

A1Q1

CBS

or

CB6

T3

+20Y

may be

Paragraph

tages

-

See

Missing

para

bad -interlock

loaded

3.1.2.1

At

3.1.2

down

~rest

Points

contacts

but

CB2

is

and

No

not

+20Y

tripped

see

3.1.9

:3

.1.10

3.1.11

3.1.12

3.2

+28V,

AC

-20V,

input

+20V,

A1C2 -CAUTION:

T2

-46V,

AC

+46V

input

I~ND

A1C1

T1

-46V,

+46V,

AND

A1QS

YFN

-9.7V

Ripple

YEN

YFN

DRIVE

missing

Too

for

for

MOTOR

High

all

DC

just

PROBLEMS

-16V

-9.7V,

Capacitor

-16V

Are

-16V

For

Just

voltages

Are

+9.7V

charged

All

Ei

Missing

One

except

Are

ther

Voltage

-16V

Either

High

or

All

Low

High

or

Low

3.2.1

3.2.2

3.2.2.1

Drive

A08

YFN

Start

Drive

+21Y

OJ(

YFN

A08

Motor

Starts

Switch

Motor Does

Missing

At

When

Not

Pin

CBl

Turn

3

17

Is

Turned

When

of

Start

AIQ2, AIQ3, AIQ4,

On

Switch

Is

Pressed

AND

9.7V

Is

Page 28

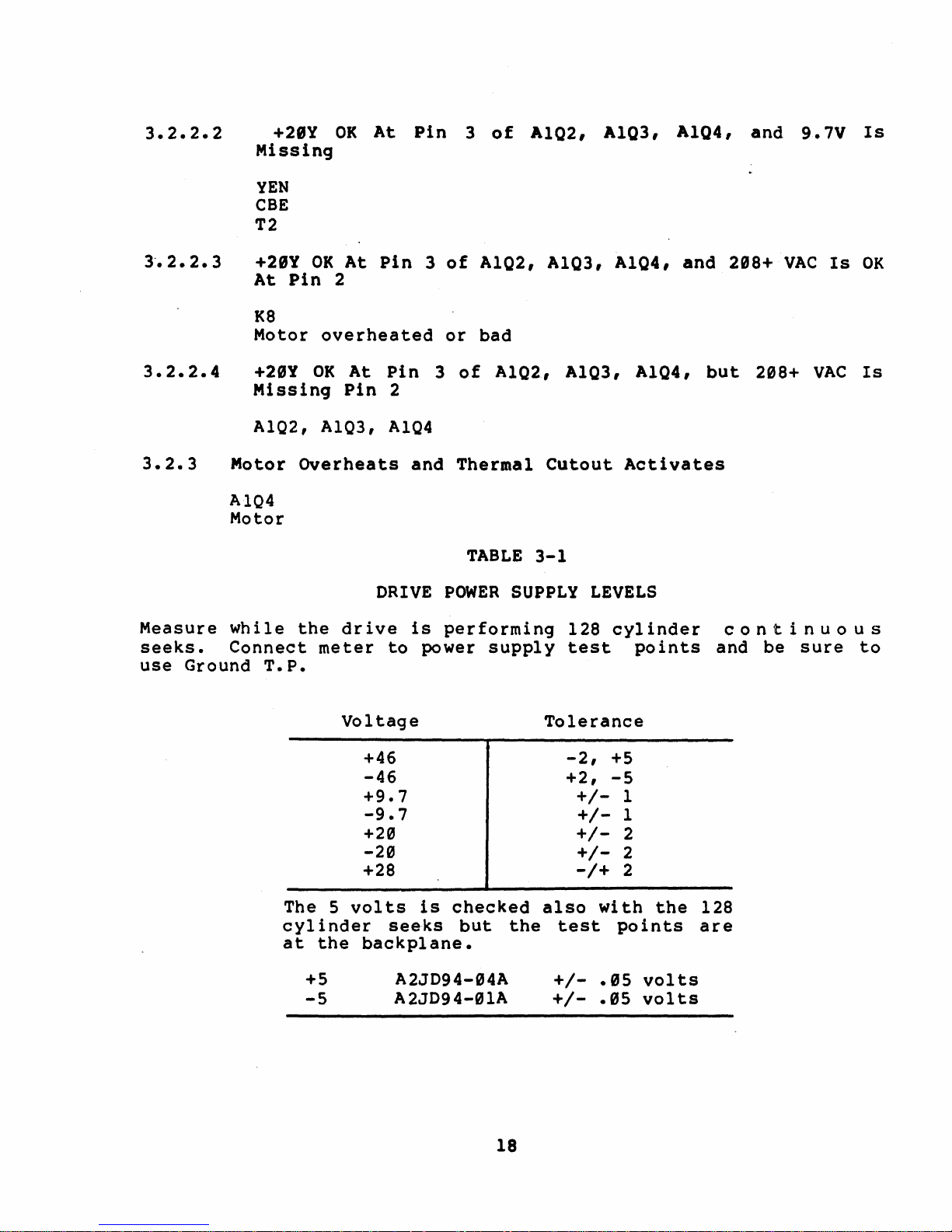

3.2.2.2

+28Y

Missing

YEN

CBE

T2

OK

At

Pin

3

of

A1Q2,

A1Q3,

A1Q4,

and

9.

7V

Is

3".2.2.3

3.2.2.4

3.2.3

Measure

seeks.

use

Ground

+28Y

At

K8

OK

Pin

Motor

+29Y

OK

Missing

AIQ2, AIQ3,

Motor

Overheats

AIQ4

Motor

while

the

Connect

T.P.

At

Pin

2

overheated

At

Pin

Pin

2

AIQ4

DRIVE

drive

meter

to

3

of

or

3

of

and

Thermal

POWER

is

performing

power

A1Q2,

A1Q3, A1Q4,

bad

A1Q2, A1Q3,

Cutout

TABLE

3-1

SUPPLY

supply

LEVELS

128

test

A1Q4,

Activates

cylinder

points

and

but

con

and

298+

208+

tin

be

VAC

sure

Is

VAC

U 0 U 5

OK

Is

to

Voltage

+46

-46

+9.7

-9.7

+20

-20

+28

The 5 volts

cylinder

at

the

backplane.

+5

-5

is

checked

seeks

but

A2JD94-94A

A2JD94-01A

the

18

Tolerance

-2,

+5

+2,

-5

+/-

+/-

+/+/-

-/+

also

with

test

+/-

.95

+/-

.95

1

1

2

2

2

the

points

volts

volts

128

are

Page 29

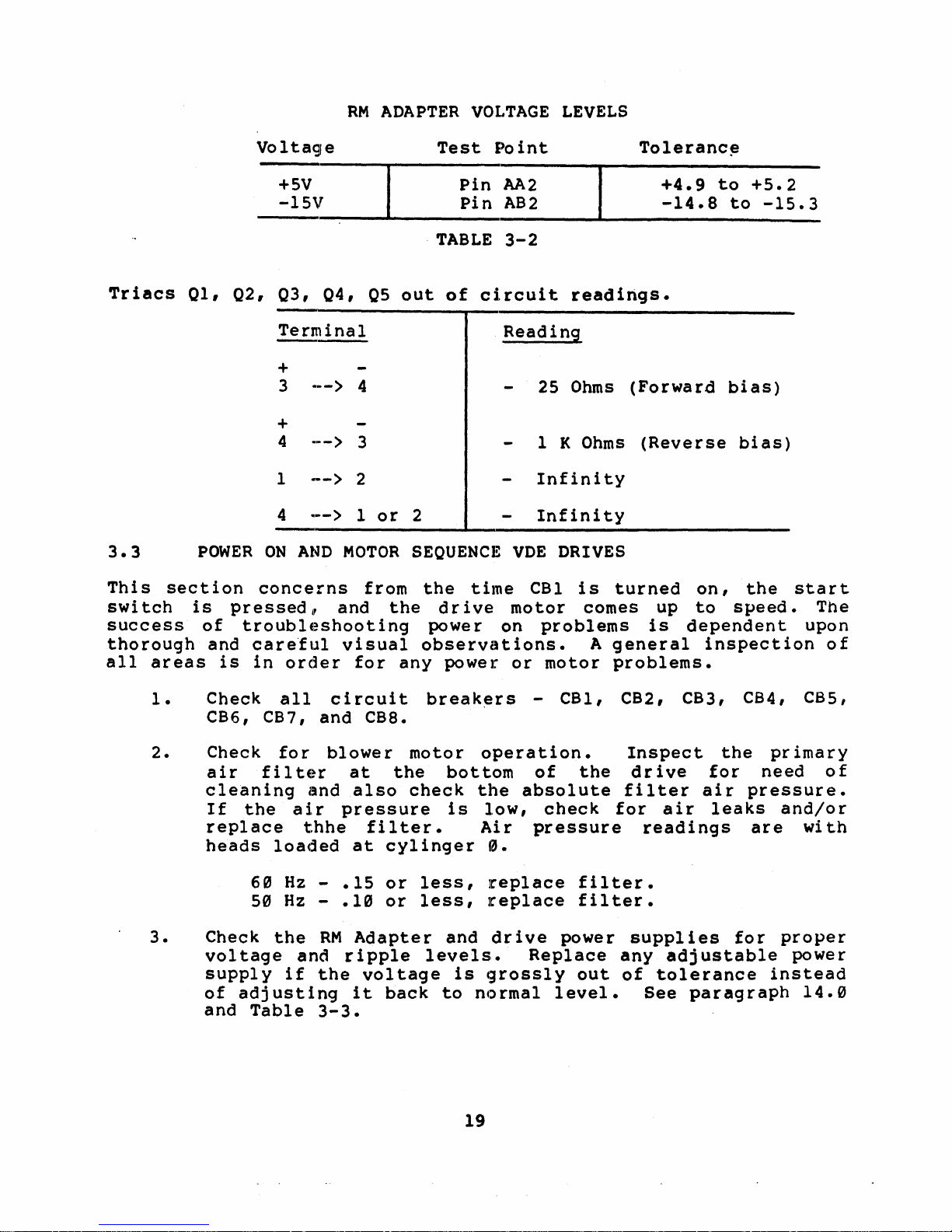

RM

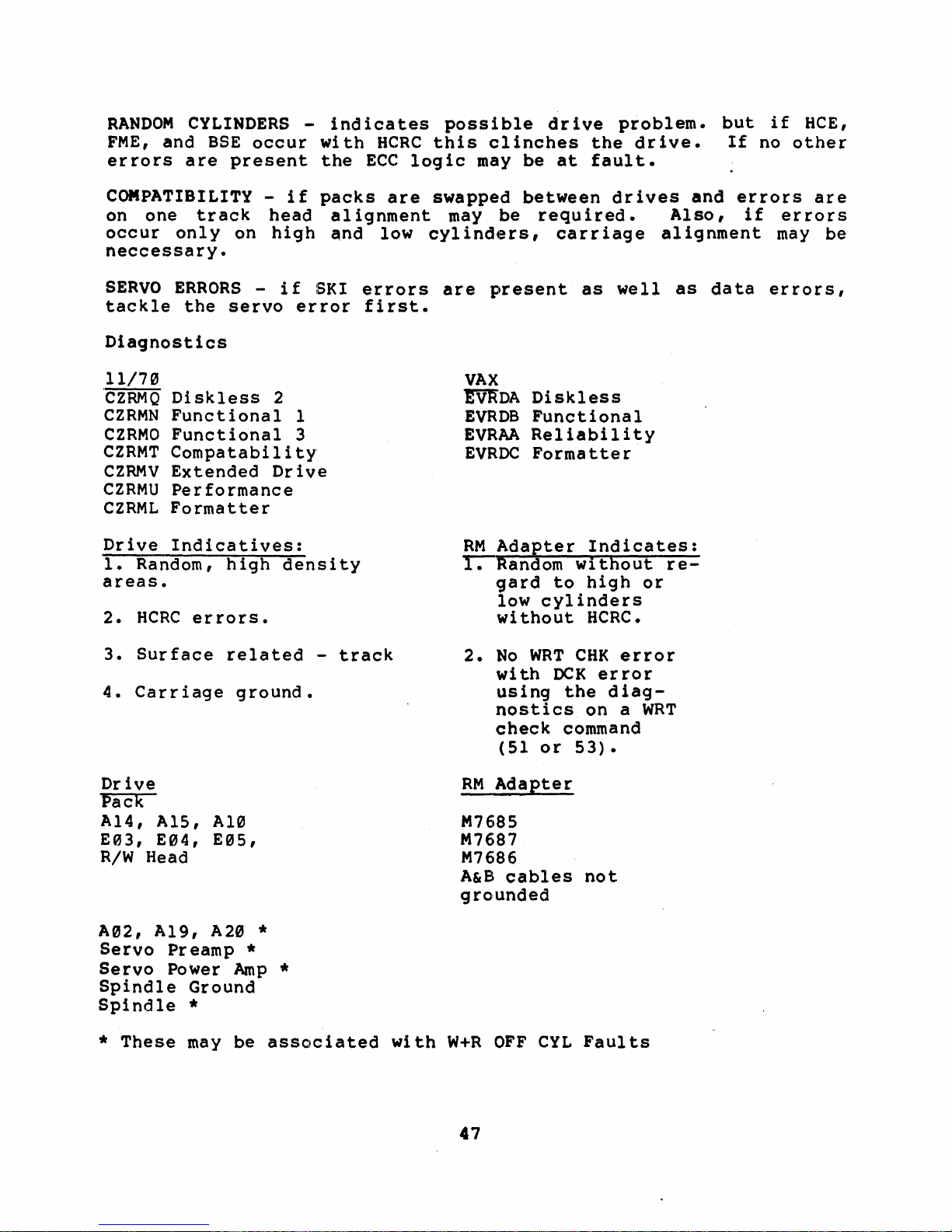

ADAPTER

VOLTAGE

LEVELS

Triacs

3.3

This

swi

section

tch

success

thorough

all

areas

01,

02, 03,

POWER

is

pressed

of

and

is

Voltage

Test

+5V

-15V

TABLE

04,

05

out

of

Terminal

+

••

_>

3

+

4

1

4

ON

AND

concerns

troubl~:~shooting

careful

in

order

.•

_>

-->

..

-->

11

and

4

3

2

1

or

MOTOR

from

the

visual

for

any

2

SEOUENCE

the

dr

power on

observations.

power

Pin

Pin

circuit

time

ive

Point

AA2

AB2

3-2

Reading

25

1

Infinity

Infinity

VDE

CB1

motor

problems

or

motor

readirtgs.

Ohms

K

Ohms

DRIVES

is

turned

comes up

A

general

problems.

Toleranc~

+4.9

-14.8

(Forward

to

to

bias)

(Reverse

on,

to

speed.

is

dependent

inspection

+5.2

-15.3

bias)

the

start

The

upon

of

1.

2.

3.

Check

all

CB6, CB7,

Check

air

for

filter

cleaning

If

the

air

replace

heads

Check

loaded

6~

5~

the

Hz

Hz

voltage

supply

of

adjusting

and

if

Table

and

and

t.hhe

-

-

RM

and

the

3-3.

circuit

CB8.

blower

at

also

pressure

filter.

at

.15

.1~

Adapter

ripple

voltage

it

break~rs

motor

the

bottom

check

is

cylinger

or

less,

or

less,

and

levels.

back

to

operation.

the

low,

Air

0.

replace

replace

drive

is

grossly

normal

19

- CB1, CB2, CB3, CB4, CBS,

of

the

absolute

check

pressure

Inspect

drive

filter

for

readings

air

the

for

air

leaks

primary

need

pressure.

and/or

are

with

filter.

filter.

power

Replace

out

level.

supplies

any

of

tolerance

adjustable

See

for

instead

paragraph

proper

power

14.0

of

Page 30

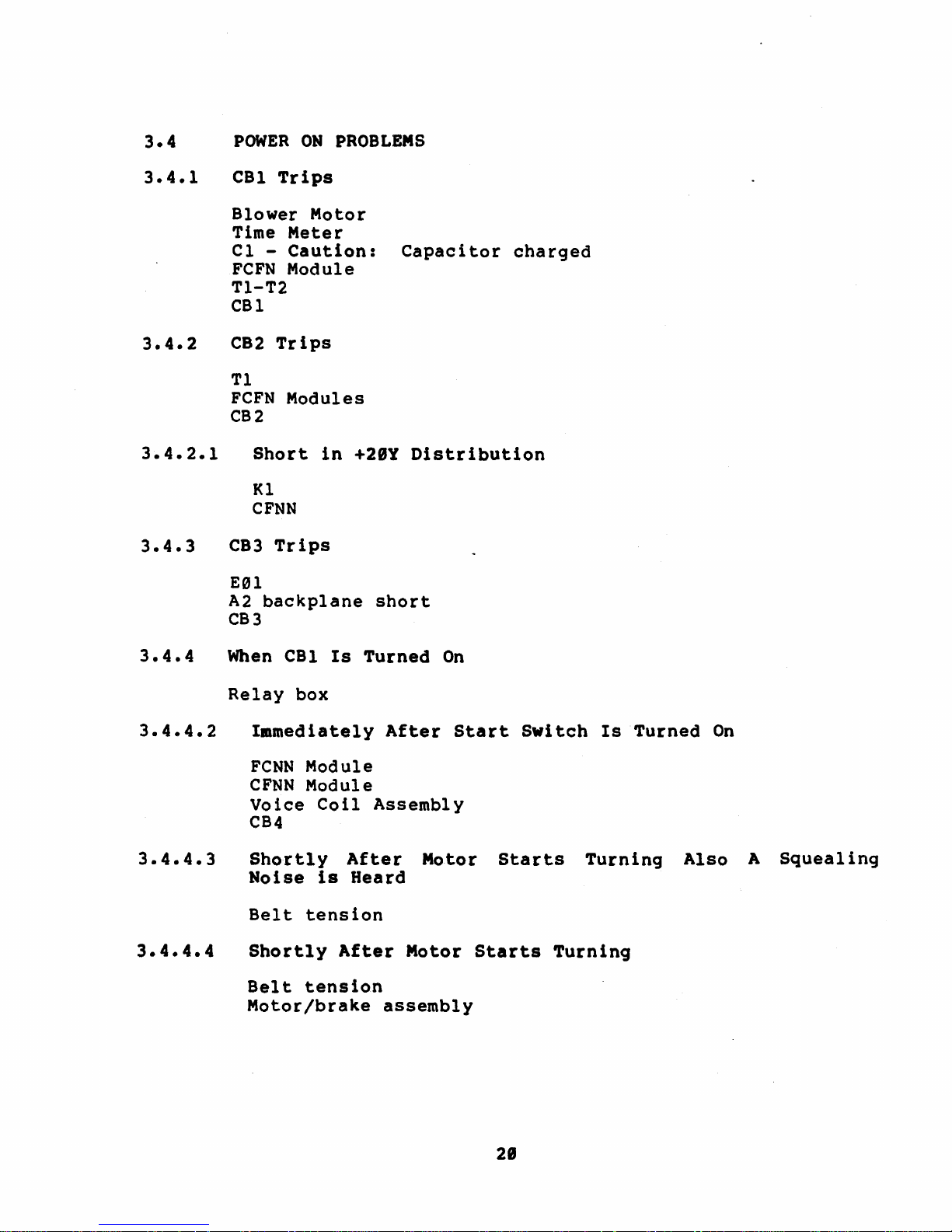

3.4

POWER

ON

PROBLEMS

3.4.1

3.4.2

3.4.3

CBl

Trips

Blower

Time

Motor

Meter

Cl -Caution:

FCFN

Module

TI-T2

CBl

C82

Trips

Tl

FeFN

Modules

CB2

Short

in

Kl

CFNN

C83

Trips

Eel

A2

backplane

CB3

+28Y

short

Capacitor

Distribution

charged

3.4.4.3

3.4.4.4

When

Relay

CBl

box

Immediately

FCNN

CFNN

Module

Module

Voice

CB4

Shortly

Noise

Belt

tension

Shortly

Belt

tension

Motor/brake

Is

Coil

After

is

After

Turned

After

Assembly

Heard

Motor

assembly

On

Start

Motor

Starts

Starts

Switch

Turning

Is

Turned

Turning

On

Also

A

Squeal

ing

28

Page 31

3.4.5

CBS

Trips

3.4.7

3.4.8

CFNN

module

Carriage

Voice

K2

CB6

5

volt

CCBN

CB6

CB8

coil

on

CFNN

or

module

or

Trips

Module

A2

backplane

All

DC

T2

FI-F8

CCBN

FCFN

module

module

Auxiliary

Breakers

Tl

CB2

locking

pin

assembly

module

CB7

Trips

regulator

module

CB7

Ale,

A14,

AlS,

short

Votalges

Missing

circuit

CB3, CB6, CB7,

A16,

and

CB8

~17,

no

+2ey

Al8

3.4.9

3.4.18

3.4.11

3.4.12

3.5

+28v,

T2

CCBN

-46v

T2

CCBN

-46v

CCBN

46"

AC

Ripple

CCBN

DRIVE

+29v,

mod

ul

e·

and

+46v

mocule

and

+46v

module

input

Too High

Module

MOTOR

-2ev,

Are

(CRl,

-9.7v,

Both

CR2, CRS, CRle)

Missing

(CRl,

CR2, CR9, CRIe)

for

Just

PROBLEMS

Are

High

one

Either

or

Low

Voltage

All

High

or

Low

21

Page 32

3.5.1

Drive

A98

module

Relay

Start

Motor

box

switch

Starts

When

CBl

is

Turned

On

3.5.2

3.5.2.1

3.5.2.2

3.5.2.3

3.5.2.4

3.6

The

drive

is

performing

power

point.

Drive

+21Y

CFNN

A98

+29Y

CCBN

CB6

+20Y

K3

Motor/brake

Motor

Relay

Motor/brake

DRIVE

power

supply

Refer

Motor· Does

is

OK

module

is

OK

module

or

CB7

is

OK

and

in

relay

Overheats

box

POWER

SUPPLY

supply

128

test

to

cyl

points

table

not

Turn

but

9.7v

But

9.7v

298

VAC

box

overheating

and

assembly

LEVELS

voltage

inder

3-3

continuous

and

be

for

When

is

Missing

is

Missing

is

or

Termal

levels

sure

voltage

Start

OK

bad

Cutout

are

seeks.

to

use

tolerances.

Switch

Activates

measured

ground

is

while

Connect

test

Pressed

the

drive

meter

to

The 5

cylinder

chassis

volts

is

continuous

backplane.

also

Refer

Voltage

+46

-46

+9.7

-9.7

+29

-29

+28

checked

seeks.

to

while

The

Table

Table

22

the

test

3-4.

3-3

drive

points

Tolerance

-2v,

+2v,

+Sv

+5v

+lv

+lv

+2v

+2v

+2v

is

perfolC'ming 128

are

on

the

logic

Page 33

Table

3-4

3.7

The

peak

measure

jack

and

Refer

3.8

The

RM

if

out

and

tolerance.

PEAK

to

the

voltage

to

Table

RM

adapter

of

tolerance.

Voltage

+5v

-5v

TO

PEAK

peak

ripple

ripple

3-5

ADAPTER

voltage

RIPPLE

should

peak

test

for

jacks

peak

Voltage

+46

-46

+20

-20

+28

VOLTAGE

levels

Refer

Test

to

peak

LEVELS

Point

A2JD94-04A

A2JD94-0lA

be

checked

ripple

on

the

to

peak

Table

ripple

3-5

should

to

Table

voltage

power

Ripple

4.5v

4.5v

1.0v

1.0v

1.0v

also

3-6

Tolerance

+.05

+.05

using

supply

voltage.

be

checked,

for

voltage,

volts

volts

an

oscilloscope

between

control

the

and

test

to

ground

panel.

adjusted

points,

Voltage

+Sv

-lSv

Table

Test

Pin

Pin

Point

AA2

AB2

3-6

Tolerance

+4.9v

-14.8v

to

to

+5.2v

-l5.3v

23

Page 34

4.9

HEAD

LOAD

SEQUENCE

PROBLEMS

This

section

operation

speed.

braking.

they

will

4.1

4.

2

4.3

after

It

also

If

the

be

called

HEADS

DO

REVERSE

concerns

the

start

includes

possible

out.

NOT

CURRENT

problems

switch

causes

LOAD

the

AFTER

NON-VDE

Head Load Swi

Servo

Power

tch

Amp

K7

Voice

HEADS

REVERSE

Coil

DO

IS

NOT

OK,

LOAD

FOR

AFTER

BOTH

A20, A07, A12, A08, Al7

Servo

CARRIAGE

HEADS