Page 1

R

K05

disk drive

(

user's

manual

(

1-

L...-

---

--

digital

equipment corp

oratio

n·

maynard.

massachusetts---

------J

Page 2

R

K05

disk

drive

user's

EK-RKOS-OP-OOI

manual

digital

equipment

corporation.

maynard,

massachusetts

Page 3

Copyright © 1976 by Digital Equipment Corporation

1st Edition, November 1976

The material

purposes and

in this manual

is

subject

is

for informational

to

change without notice.

Digital Equipment Corporation assumes

sibility for any errors which may appear

manual.

Printed in U.s.A.

The following are trademarks

of

Digital Equipment

Corporation, Maynard, Massachusetts:

no

respon·

in this

DEC

DECCOMM

DECsystem·l0

DECSYSTEM·20

DECtape

DECUS

DIGITAL

MASS

BUS

PDP

RSTS

TYPESET·8

TYPESET-II

UNIBUS

Page 4

CONTENTS

Page

CHAPTER 1

1.1

1.2

1.3

1.

4

1.5

1.5.1

1.5.2

1.5.3

1.5.4

1.5.5

1.5.6

1.5.7

1.5.8

CHAPTER 2

2.1

2.2

2.3

2.4

2.5

2.5.1

2.5.2

GENERAL INFORMATION

INTRODUCTION

WARRANTY

SPECIFICATIONS

50/60

Hz POWER OPTION

MAJOR ASSEMBLIES AND SYSTEMS

Controls

Spindle and Drive

Linear

Cartridge-Handling

Logic Assembly

Air

Power Supply

Read/Write Heads

INST ALLA TION

UNPACKING AND INSPECTION

MECHANICAL INSTALLATION AND CHECKOUT .

CARTRIDGE HANDLING PRACTICES AND PRECAUTIONS

CARTRIDGE PACKING

NORMAL OPERATING PROCEDURES

Cartridge

Cartridge Unloading

and Indicators

Positioner .

System .

Loading

..

. .

System

...

AND SHIPPING

..............

..

. .

I-I

I-I

I-I

I-I

I-I

14

14

14

14

1-4

14

14

14

.

2-1

2-3

2-6

2-6

2-7

2-7

2-7

CHAPTER 3

3.1

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

3.2.8

3.2.9

3.2.10

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

3.3.6

3.3 .7

3.3.8

3.3.9

INTERFACE

GENERAL .

INPUT

OUTPUT INTERFACE LINES

INTERFACE LINES

RKII-D

Select

Cylinder Address (8 lines)

Strobe

Head Select

Write Protect Set

Write Data and Clock

Write Gate

Restore

Read Gate

File Ready (Drive Ready)

Read, Write, or

Address Accepted

Address Invalid (Logic Address Interlock)

Seek Incomplete . .

Write Protect

Write Check

Read Data

Read

...

(4

lines)

..

(RTZ)

Clock

. .

..

.

..

. .

..

.

...

.

...

..

. . .

....

.

Seek Ready/On Cylinder

...

....

Status

....

3-1

3-1

3-1

3-1

3-1

3-1

3-3

3-3

3-3

3-3

3-3

3-3

3-3

3-3

3-3

.

3-3

3-3

3-3

3-3

3-3

34

34

iii

Page 5

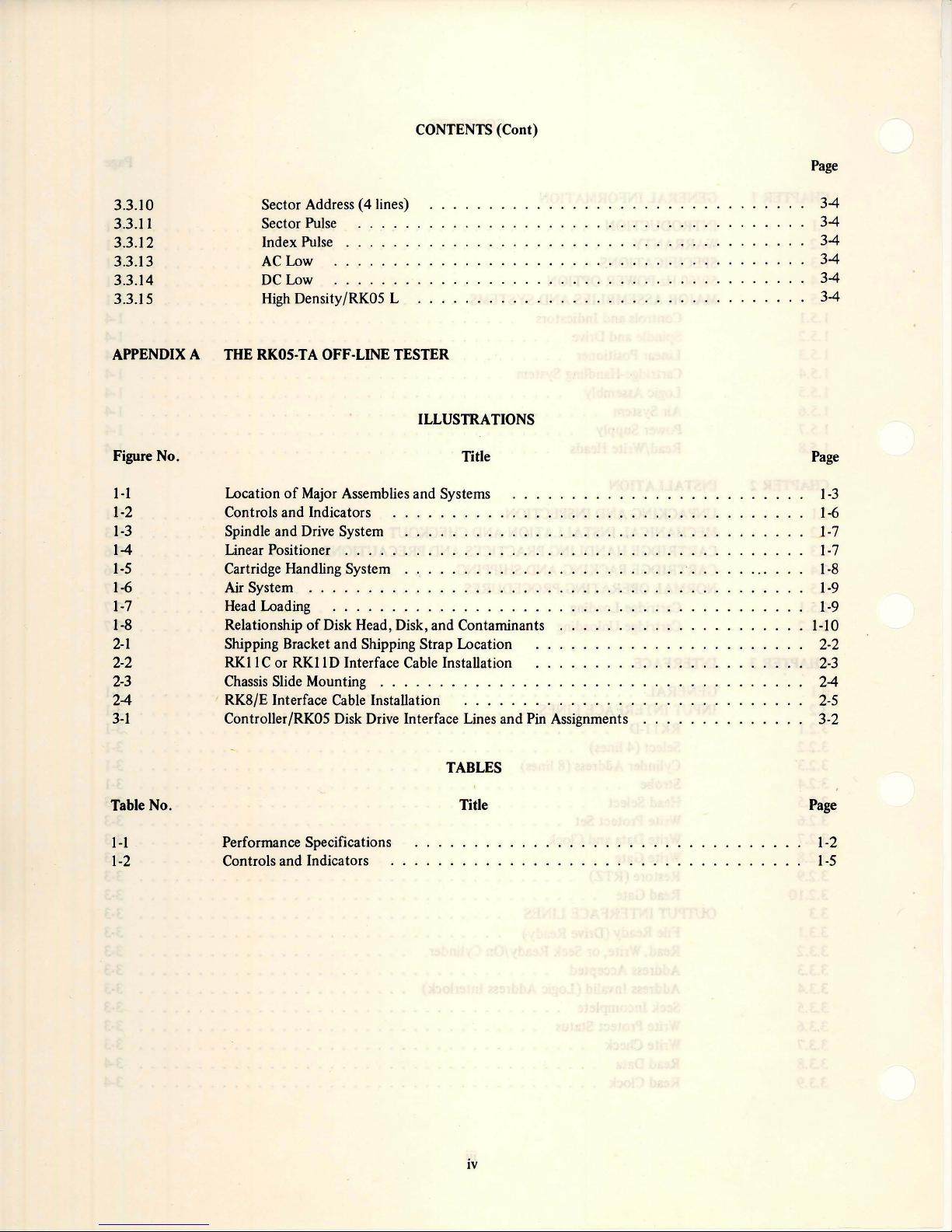

CONTENTS (Cont)

Page

3.3.10

3.3.11

3.3.12

3.3.13

3.3.14

3.3.15

APPENDIX A

Figure No.

1·1

1·2

1·3

14

1·5

1·6

1-7

1-8

2·1

2·2

2-3

24

3-1

Address (4 lines)

Sector

Sector Pulse

Index Pulse

ACLow

DC

Low

High

Density/RK05 L

THE

RK05-TA OFF-LINE TESTER

Title

....

nONS

.

.

ILLUSTRA

Location

Controls

Spindle and Drive System

Linear Positioner

Cartridge Handling System

Air System

Head Loading

Relationship

Shipping Bracket and Shipping Strap Location

RKIIC

Chassis Slide Mounting

, RK8/E Interface Cable Installation

Controller/RK05 Disk Drive Interface Lines and Pin Assignments

of

Major Assemblies and Systems

and Indicators

....

or

RKIID

.......

.....

of

Disk Head, Disk, and Contaminants

Interface Cable Installation

.

.

...........

34

34

34

34

34

34

Page

1·3

1·6

1·7

1·7

1·8

1·9

1·9

1-10

2·2

2·3

24

2·5

3·2

Table No.

I-I

1-2

Performance SpeCifications

Controls and Indicators

TABLES

Title

iv

Page

1·2

1·5

Page 6

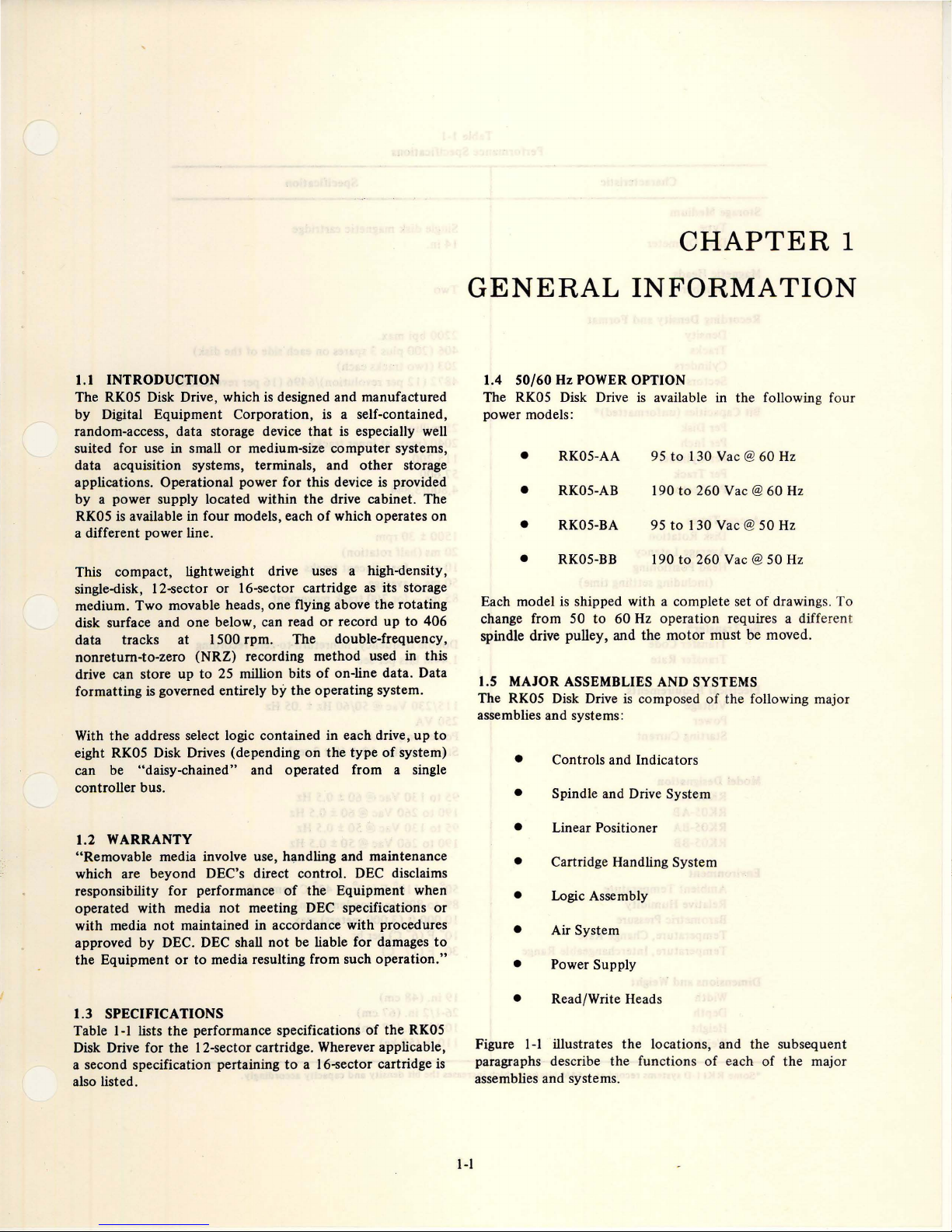

CHAPTER

1

1.1 INTRODUCTION

The RK05 Disk Drive, which

by Digital Equipment Corporation, is a self-contained,

random-access, data storage device

suited for use in small

data acquisition systems, terminals, and

applications. Operational power for this device is provided

by a power supply located within the drive cabinet. The

RK05 is available in four models, each

a different power line.

This compact, lightweight drive uses a high-density,

single-disk, 12-sector or 16-sector cartridge

medium. Two movable heads, one flying above the rotating

disk surface and one below, can read

data tracks at 1500 rpm. The double-frequency,

nonretum-to-zero (NRZ) recording method used in this

drive can store up

formatting is governed entirely

the

With

eight RK05 Disk Drives (depending on the type

can be

controller bus.

address select logic contained in each drive,

"daisy-chained" and operated from a single

to

is

designed and manufactured

that

is

especially well

or

medium-size computer systems,

other

of

which operates

as

or

record

25 million bits

of

on-line data . Data

by the operating system.

storage

on

its storage

up

to

406

up

to

of

system)

GENERAL

50/60

1.4

The RK05 Disk Drive

power models:

Each model is shipped with a complete set

change from

spindle drive pulley, and the

l.S

MAJOR ASSEMBLIES AND SYSTEMS

The RK05 Disk Drive

assemblies and systems:

Hz POWER OPTION

RK05-AA

•

RK05-AB

•

RK05-BA

•

RK05-BB

•

50

Controls and Indicators

•

Spindle and Drive System

•

INFORMATION

is

available

95

to

130 Vac @ 60

to

260 Vac @

190

95

to

130 Vac @ 50

to

260 Vac @ 50

190

to

60

Hz

operation requires a different

motor

must

is

composed

of

in

the following four

Hz

60

Hz

Hz

Hz

of

drawing

be moved.

the following ma

s.

To

jor

1.2 WARRANTY

"Removable media involve use, handling and maintenance

which are beyond DEC's direct control.

responsibility for performance

operated with media

with media

approved by DEC. DEC shall

the Equipment

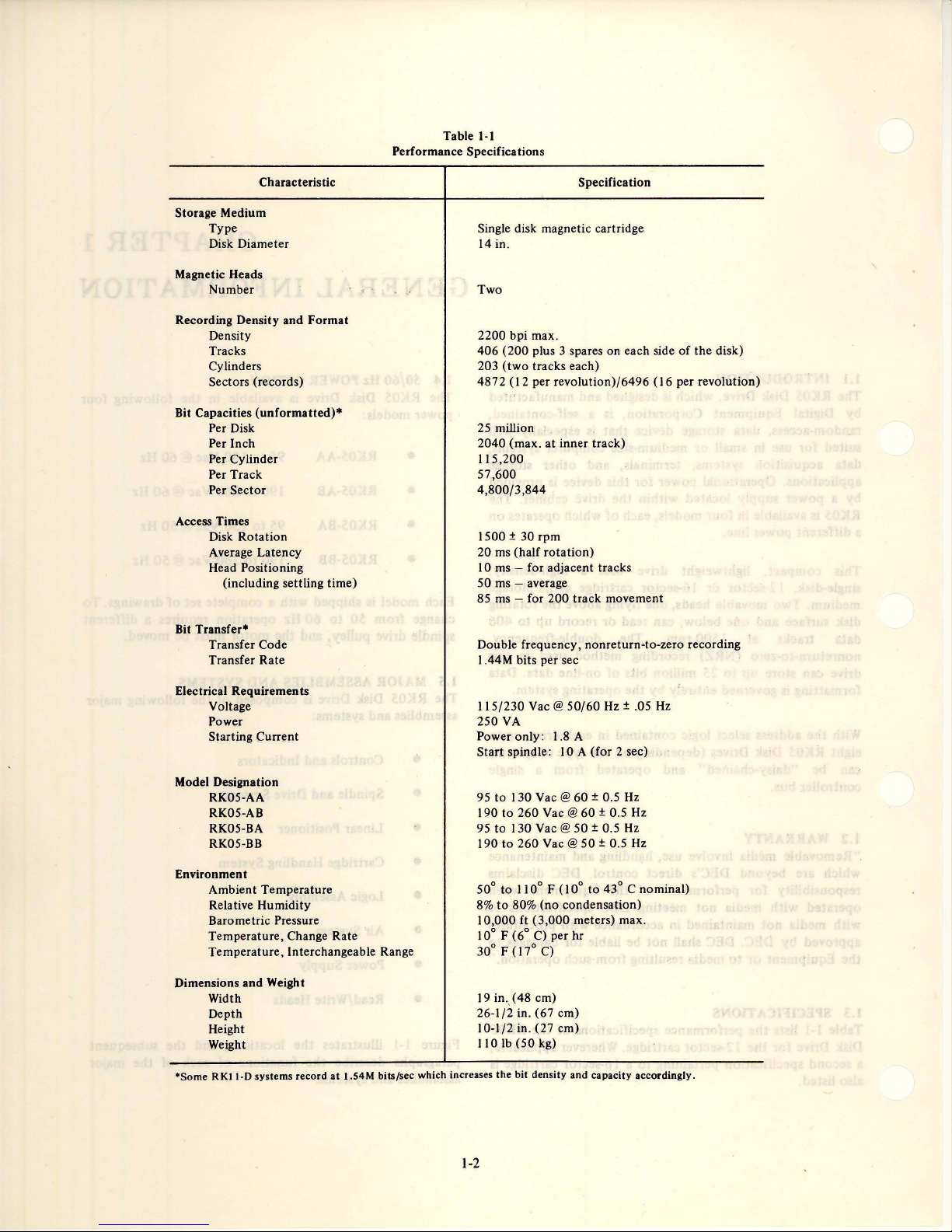

1.3 SPECIFICATIONS

Table I-I lists the performance specifications

Disk Drive for the 12-sector cartridge. Wherever applicable,

a second specification pertaining

also listed.

not

not

maintained in accordance with procedures

or

to

media resulting from such operation."

of

the Equipment when

meeting DEC specifications

not

be liable for damages

to

a 16-sector cartridge

DEC

of

disclaims

or

to

the RK05

Linear Positioner

•

Cartridge Handling System

•

Logic Assembly

•

Air System

•

Power Supply

•

Read/Write Heads

•

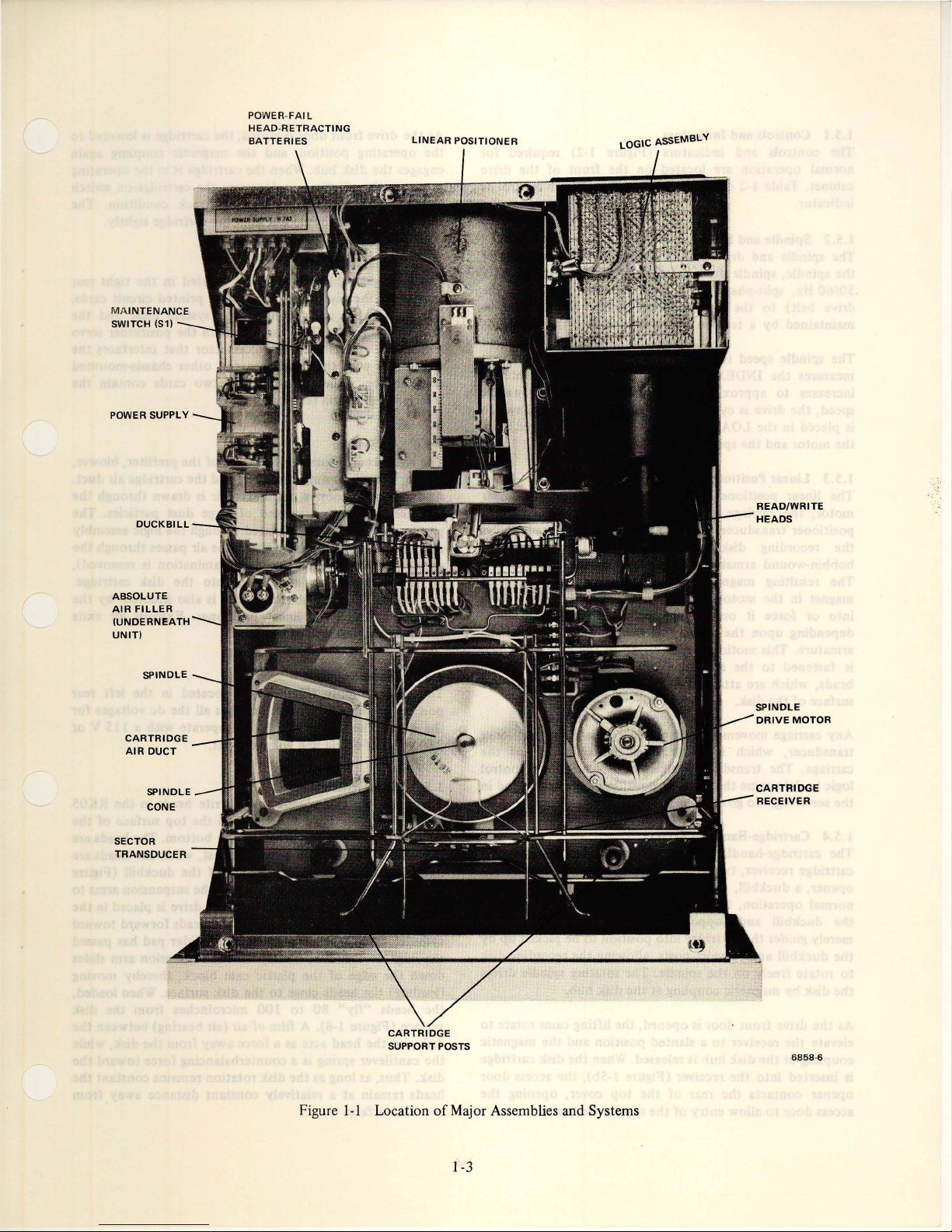

Figure I-I illustrates the locations, and the subsequent

of

paragraphs describe the functions

is

assemblies and systems.

I-I

each

of

the major

Page 7

Table

1-1

Performance Specifications

Characteristic

Storage Medium

Type

Disk Diameter

Magnetic Heads

Number

Recording Density and Format

Density

Tracks

Cylinders

Sectors (records)

Bit Capacities

(unformatted)·

Per Disk

Per Inch

Per Cylinder

Per Track

Per

Sector

Access Times

Disk Rotation

Average Latency

Head Positioning

(including settling time)

Transfer·

Bit

Transfer Code

Transfer Rate

Specification

Single disk magnetic cartridge

14 in.

Two

2200 bpi max.

406

(200

203

(two

tracks each)

4872 (12 per revolution)/6496

plus 3 spares on each side

of

the disk)

(16

per revolution)

25 million

2040 (max. at inner track)

115,200

57,600

4,800/3,844

1500 ± 30 rpm

20 ms (half

rotation)

10 ms - for adjacent tracks

50 ms - average

~

85 ms

for 200 track movement

Double frequency, nonreturn-to-zero recording

1.44M bits per sec

Electrical Requirements

Voltage

Power

Starting Current

Model Designation

RK05-AA

RK05-AB

RK05-BA

RK05-BB

Environment

Ambient Temperature

Relative Humidity

Barometric Pressure

Temperature, Change Rate

Temperature, Interchangeable Range

Dimensions

and

Weight

Width

Depth

Height

Weight

.Some

RKII-D

systems

record

at

I.S4M

bits/sec

which

115/230

250

VA

Vac @

50/60

Power only: 1.8 A

Start spindle:

130 Vac @ 60 ± 0.5

95 to

190 to 260

95

to

130 Vac @ 50 ± 0.5

190

to

50°

to

8%

to

80% (no condensation)

lOA

Vac@60±

260 Vac @ 50 ± 0.5

110° F (10°

10,000 ft (3,000 meters) max.

10° F (6° C) per hr

30° F (17° C)

19

in.,( 48 cm)

26-1/2 in. (67 cm)

10-1/2 in. (27 cm)

110

Ib

(50

kg)

increases

the

bit

density

and

Hz

± .05

(for 2 sec)

Hz

0.5

Hz

Hz

Hz

to

43° C nominal)

capacity

accordingly.

Hz

1-2

Page 8

MA

INTENANCE

SWITCH (S1)

POWER SUPPLY

POWER-

FAIL

HEAD-RETRACTING

BATTERIES

LINEAR

POSITIONER

LOGIC ASSEMBLY

READ/WRITE

HEADS

ABSOLUTE

AIR

FILLER

(UNDERNEATH

UNIT)

SPINDLE

CARTRIDGE

AIR

DUCT

SPINDLE

CONE

SECTOR

TRANSDUCER

CARTRIDGE

SUPPORT POSTS

CARTRIDGE

6858

-6

Figure

1-1

Location

of

Major Assemblies and Systems

1-3

Page 9

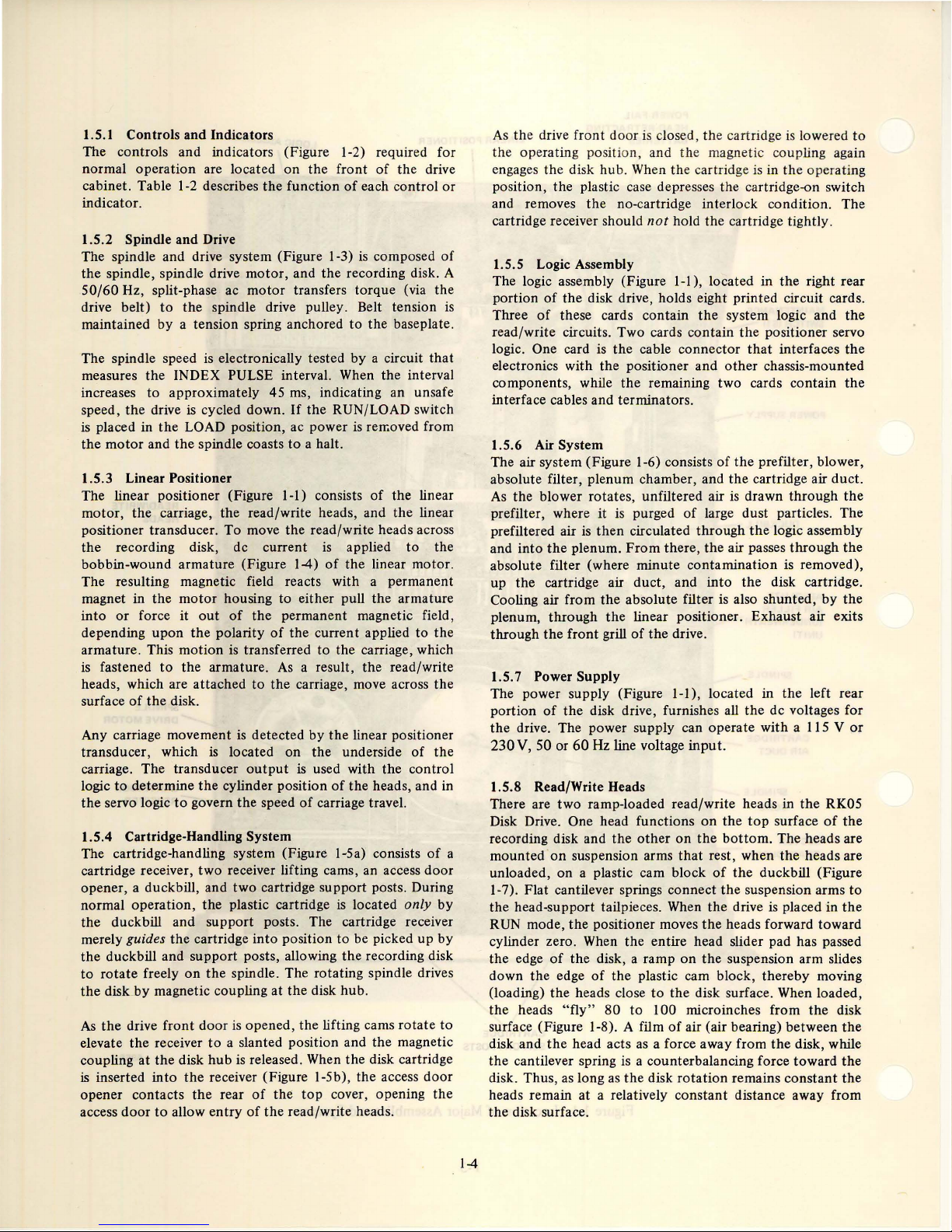

1.5.1 Controls and Indicators

The controls and indicators (Figure 1-2) required for

normal

cabinet. Table 1-2 describes

operation

are located

the

on

the

function

front

of

of

each control

the drive

or

indicator.

1.5.2 Spindle

The spindle and drive system (Figure 1-3)

the

spindle, spindle drive

50/60

Hz, split-phase ac

drive belt)

maintained by a tension spring anchored

The spindle speed

measures

increases

speed,

the

is

placed in

the

motor

1.5.3 Linear

The linear positioner (Figure

motor,

positioner transducer. To move

the

recording disk, dc current

bobbin-wound armature (Figure

and

Drive

is

motor,

and

the

recording disk. A

motor

transfers

to

the

spindle drive pulley. Belt tension

is

electronically tested by a circuit

the

INDEX PULSE interval. When

to

approximately 45 ms, indicating an unsafe

drive

is

cycled down.

the

LOAD position, ac power

and

the

spindle coasts

If

to

the

a halt.

torque

to

the

RUN/LOAD switch

is

rerr.oved from

Positioner

I-I)

the

carriage,

consists

the

read/write heads, and

the

read/write heads across

14)

is

of

of

applied

the

composed

(via

of

the

baseplate.

that

the

interval

the

linear

the

linear

to

the

linear motor.

The resulting magnetic field reacts with a permanent

magnet in

into

depending

armature. This

is

fastened

heads, which are

surface

Any carriage movement

transducer, which

carriage. The transducer

logic

the

servo logic

or

force it

of

the

to

determine

the

motor

out

upon

the

motion

to

the armature.

attached

disk.

the

to

govern

housing to either pull

of

the

permanent magnetic field,

polarity

is

of

the

is

transferred to

As

to

the

is

detected

located on

output

current applied

a result,

carriage, move across

by

the

is

used with

cylinder position

the

speed

of

carriage travel.

the

armature

the

carriage, which

the

read/write

the

linear positioner

underside

the

of

the heads, and in

to

the

the

of

the

control

1.5.4 Cartridge-Handling System

The cartridge-handling system (Figure

cartridge receiver,

opener, a duckbill, and

normal

operation,

two

receiver lifting cams, an access

two

cartridge support posts. During

the

plastic cartridge

I -Sa) consists

is

located only

of

door

by

the duckbill and support posts. The cartridge receiver

merely

guides

the

cartridge

the

duckbill and

to

rotate

freely

the

disk by magnetic coupling

As

the

drive

elevate

coupling

is

opener

access

the

at

inserted

contacts

door

on

front

receiver

the

disk

into

the

to

allow

support

door

the

into

position

posts, allowing

the

spindle. The rotating spindle drives

at

the

is

opened,

to

a slanted position and

hub

is released. When

receiver (Figure 1-5b),

rear

of

the

entry

of

the

read/write heads.

to

the

disk hub.

the

lifting cams

the

top

cover, opening

be picked

recording disk

the

disk cartridge

the

access

up

by

rotate

to

magnetic

door

the

As

the

drive front

the operating position , and

engages the disk hub. When

position,

the

and removes

cartridge receiver should

door

is

closed, the cartridge is low ered

the

magnetic coupling again

the

cartridge

is

plastic case depresses the cartridge-on switch

the

no-cartridge interlock

not

hold

the

cartridge tightly.

1.5.5 Logic Assembly

The logic assembly (Figure

of

the

is

portion

Three

of

disk drive, holds eight printed circuit cards.

these cards contain

read/write circuits . Two cards contain

One card is

logic.

electronics with

components, while

the

the

positioner and

the

I-I),

cable

connector

remaining

located in

the

system logic and

the

that

other

two

cards contain

interface cables and terminators.

1.5.6 Air System

The air system (Figure 1-6) consists

absolute filter, plenum chamber, and

As

the

blower rotates, unfiltered air

prefilter, where it

prefiltered air

and

into

the

is

then

plenum.

is

purged

circulated

From

there,

absolute filter (where minute

up

the

cartridge air

Cooling air

plenum,

through

1.5.7

through

the

Power Supply

from

front

duct,

the

absolute filter

the

linear positioner. Exhaust air exits

grill

of

the

The power supply (Figure

portion

the

230V, 50 or 60

of

the

disk drive, furnishes all

drive. The power supply can operate

Hz

line voltage

of

the

prefilter, blower,

the

cartridge air

is

drawn

of

large dust particles. The

through

the

air passes

the

contamination

and

into

the

is

also shunted,

drive.

I-I),

located in

the

with a liS V or

input

.

1.5.8 Read/Write Heads

There are

Disk Drive. One head functions

recording disk and

a

mounted'

unloaded, on a plastic cam block

1-7). Flat cantilever springs connect

the

RUN mode,

two

ramp-loaded read/write heads in

the

other

on

on

suspension arms

that

head-support tailpieces. When

the

positioner moves

on

the

top

the

bottom.

rest, when

of

the

the

suspension arms

the

drive is placed in

the

heads forward

duckbill (Figure

cylinder zero. When the entire head slider pad has passed

the

edge

of

the

disk, a ramp

down

the

edge

of

the

(loading)

the

heads

the

heads close

"fly"

80

to

surface (Figure 1-8). A film

disk and

the

disk. Thus, as long as

heads remain

the

the

head acts as a force away from

cantilever spring is a counterbalancing force toward

the

at

a relatively

disk surface.

on

the

suspension arm slides

plastic cam block,

to

the

disk surface. When loaded,

100 micro inches from

of

air (air bearing) between

disk

rotation

constant

remains

distance away from

thereby

to

in

the

operating

condition

the

. The

right rear

the

positioner servo

interfaces

the

chassis-mounted

the

duct.

through

the

logic assembly

through

the

is removed),

disk cartridge.

by

the

the

left rear

dc voltages for

the

RK05

surface

of

the

The heads are

the

heads are

to

the

toward

moving

the

disk

the

the

disk, while

the

constant

the

14

Page 10

Table 1-2

Controls and Indicators

Controls and Indicators

RUN/LOAD

(rocker switch)

WTPROT

(rocker switch spring-loaded off)

Description

Placing this switch in the RUN position (providing

a.

locks the drive front door

to

b. accelerates the disk

operating speed

c. loads the read/write heads

d. lights the

RDY indicator.

Placing this switch in the LOAD position:

a.

unloads the read/write

b.

stops the disk rotation

c.

unlocks the drive front door when the disk has stopped

d.

lights the LOAD indicator.

head~

CAUTION

Do

not

switch

operation; this results

Placing this momentary contact switch in the

to

the LOAD position during a write

in

erroneous data being recorded.

WT

PROT indicator and prevents a write operation;

indicator, if

that

is

lit.

that

all interlocks are safe):

PROT posistion lights the

it

also turns off the FAULT

WT

PWR

(indicator)

RDY

(indicator)

ONCYL

(indicator)

WT

Depressing this switch in the

PROT position a second time turns

PROT indicator and allows a write operation.

is

Lights when operating power

present. Goes

Lights when:

a. the disk

is

rotating at the correct operating speed.

b. the heads are loaded.

c.

no

other

conditions are present (all interlocks safe)

or

read,

Goes off when

write operation.

the

RUN/LOAD switch is set

Lights when:

a.

the drive is in the Ready condition.

Goes

b. a seek

c.

off

during a seek

or

restore operation

is

not being performed.

the read/write heads are positioned and settled.

or

restore operation.

off

when operating power

to

LOAD.

off

is

removed.

to

prevent a seek,

the

WT

1-5

Page 11

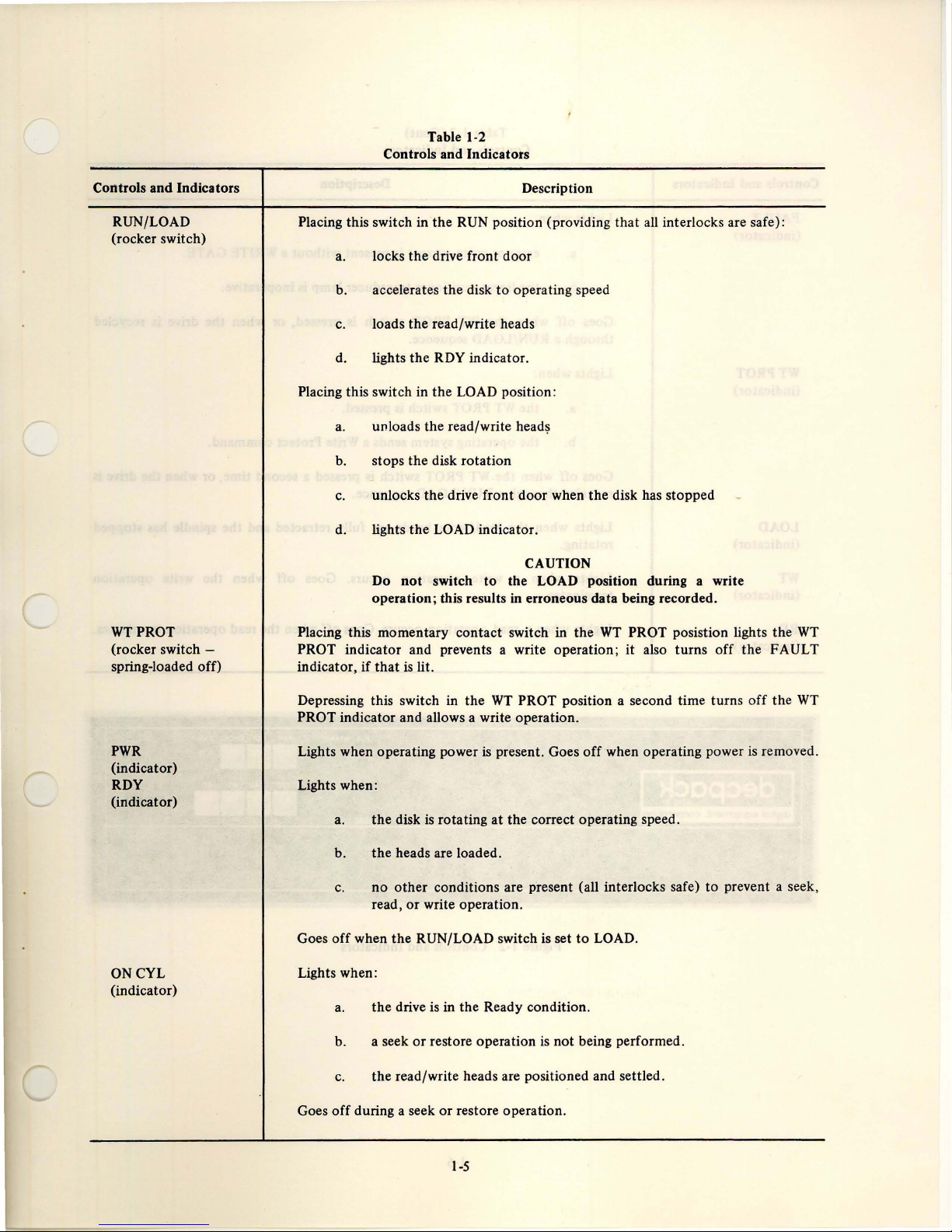

Table

1-2

(Cont)

Controls and Indicators

Controls

FAULT

(indicator)

WTPROT

(indicator)

LOAD

(indicator)

WT

(indicator)

RD

(indicator)

and

Indicators

Description

Lights when:

a. erase

b.

off

Goes

through a

Lights when:

a.

b.

Goes

off

when

recycled through a RUN/LOAD sequence.

Lights when

rotating.

Lights when a write operation occurs. Goes

terminates.

Lights when a read operation occurs. Goes

or

write current

the

linear positioner transducer lamp

when

the

WT

PROT switch

RUN/LOAD sequence.

the

WT

PROT switch

the

operating system sends a Write Protect command.

the

WT

PROT switch

the

read/write heads are fully retracted and

is

present

is

pressed.

without

is

pressed,

is

pressed a second time,

off

a WRITE GATE.

is

inoperative.

or

when

the

off

when the write operation

when the read

the

drive is recycled

or

when

the

spindle

operation

h~s

terminates.

drive

is

stopped

g5ecpa£~

..

.

~.

. .

...

.

RUN

LOAD

Figure ]-2 Controls and Indicators

1-6

WTPROT

ROV

ONCYl

"\'IR

FAULT

......

111111

WT

PROT LOAD

WT

RO

11111111

Page 12

TENSION

SPRING

DRIVE

BELT

SPINDLE

PULLEY

DRIVE

TRACK

MOTOR

POSITION

SCALE

Figure

LINEAR

(UNDER

1-3

Spindle and Drive System

TRANSDUCER

CARRIAGE)

HEAD

ADJUSTMENT

SCREWS

LOWER

CLAMP

UPPER

CLAMP

READ/WRITE

HEAD

SCREW

HEAD

SCREW

HEADS

6544-4

MOTOR

(PERMANENT

HOUSING

MAGNET

INSIDE)

ARMATURE

Figure

CARRIAGE

1-4

Linear Positioner

1-7

CARRIAGE

SLIDE

DUCKBILL

6858

-5

Page 13

LIFTI

NG

D

RIVE

FRONT DOOR

MOTOR

a.

Cartridge Removed

DOOR OPENER

CARTRIDGE

AIR

CARTRIDGE

ACCESS

DOOR

DUCT

b.

Cartridge Inserted

Figure 1·5 Cartridge Handling System

1·8

6858

-'

Page 14

CARTRIDGE

AIR

DUCT

ABSOLUTE

FILTER

PREFILTER

CP-0272

Figure 1-6 Air System

1-7

Figure

Head Loading

1-9

Page 15

Figure

1-8

Relationship

The

DOWN (UPPER) HEAD

throughout

the

UP (LOWER) HEAD faces up. These designations were

created

the

computer

to

describe heads loaded

is

so-called by convention

industry because it faces

onto

a multisurface

20) cartridge.

The recording device (read/write head)

ferrite core with an air gap. As current flows

is

a coil-wound

thwugh

of

Disk Head, Disk, and Contaminants

coil,

the

induced flux magnetizes

down

;

passing

under

the

current direction in the coil is reversed , a flux reversal

(10

or

recorded on

the

previously-recorded flux

the

current in

head . Any flux reversal

surface produces a pulse.

the

08-0884

the

gap. During a write

surface

operation,

of

when

disk. During a read operation,

pattern

on

the

disk induces

on

the

recording

the

disk

the

is

the

1-10

Page 16

CHAPTER

2

2.1 UNPACKING AND INSPECTION

The

RKOS

Disk Drive can be shipped in a rack as an integral

of

part

shipped in a rack,

installation location and unpacked as follows:

a system

I. Remove

2. Remove

3.

4.

S.

6.

or

in a separate container.

the

rack should be positioned in the final

the

shipping brackets from

by

removing

lowest drive.

bracket and latch molding

drive.

Do

not

pull

the

Slide

the

and pull

sides

of

back

onto

screws.

Slide

the

access

directly above

two

these

Repeat

Remove

screws

brackets

the

snap-on bezel beneath

the

screws attaching

CAUTION

use

the

drive

front

drive

out

from

the

drive

out

about

the

shipping brackets

the

drive.

Attach

the

drive .with

lowest drive

to

the

shipping brackets on

it

shipping brackets.

Steps 3 and 4 for each drive in

the

drive

that

attach

to

the

baseplate (Figure

out

and remove

bottom

the

three internal shipping

to

both

door

rack.

3 inches from

the

the

shipping bracket

far enough

the

cover and remove

If

the

drive is

the

drive

the

shipping

sides

of

handle

to

the

rack

out

from

latch molding

to

gain

the

drive

screws from

the

rack.

2-la).

the

the

the

the

INST

7.

If

RKOS

drives are "daisy-chained"

drives in a multidrive installation, arrange

RKOSs

the bus

and

carried by

possible, all

bus

cables between their

2-2).

Remove

8.

mounting screw and shipping strap from

linear positioner (Figure

shipping strap upward and replace it on

linear positioner, making sure it

secured.

Retain all packing material for possible

9.

reshipment. Inspect

damage. Report any damage

to

In

10.

reshipment, replace

shipping strap in

this unpacking and inspection procedure when

the

consecutively at the controller end

to

avoid

DC

LOW interface lines, which are

the

RK03s.

RKOSs

by

RK03s must be connected

the

drive

Digital

Equipment

the

case

of

drive is reinstalled.

ALLATION

interruption

If

that

106 connections (Figure

top

the

Corporation.

RKOS

Disk Drive relocation

the

the

shipping position; repeat

of

this arrangement

are separated

cover and remove

2-lb).

drive for possible

to

shipping brackets and

with

the

by

Turn

the

carrier and

RK03

AC

is

on

separate

is

tightly

the

of

LOW

not

not

the

the

the

the

the

or

CAUTION

Do

not

operate drive with shipping

brackets

attached.

If

the

drive is shipped in a separate container, use care while

unpacking it. Do

unreasonable impact.

2-1

not

drop

the

drive

or

subject it

to

Page 17

SHIPPING

BRACKET

BRACKET

SCREW

SHIPPING

STRAP

SHIPPING

a.

Shipping Brackets

MO

UNTING

SCREW

BRACKETS

P2

LINEAR

POSITIONER

Figure

b. Shipping Strap

2·1

Shipping Bracket and Shipping Strap Locations

2-2

Page 18

INTERFACE CABLE

JOG

2.2 MECHANICAL

If

the

RK05 Disk Drive

the

chassis slides should first be installed

2-3). The disk drive should be

as follows:

(If

INSTALLATION

is

to

be installed in an existing rack,

mounted. on

necessary, refer

Figure 2-2 RK

AND

in

to

the RK05

II

CHECKOUT

the

rack (Figure

the

chassis slides

C

or

Option

RK

Configuration Dwg. No. D-OC-RK05-0-15 for detailed

mechanical specifications

I.

Install cabinet stabilizers before

drive, unless

to

prevent tipping when

of

a muItidrive installation.)

the

weight

of

the

rack

the

drive

mounting

is

sufficient

is

the

fully

extended.

2. Pull

the

extended

chassis slides

position.

out

until

they

lock in

the

II

D Interface Cable Installation

3. Slide

the

locks.

4. Remove

screws

that

brackets

5. Remove

mounting

linear positioner (Figure

shipping strap upward and replace it

linear positioner. Pull

as possible

1-7) and confirm

return

the

2-3

drive

onto

the

chassis slides until it

the

drive

attach

to

the

baseplate (Figure

the

drive

bottom

cover and remove

the

three

internal

top

cover and remove

2-la).

screw and shipping strap from

2-1

b).

Turn

the

heads forward as far

without

heads

going

that

the

to

the

home position.

off

the

ramp

batteries (Figure

the

shipping

the

the

the

on

the

(Figure

I-I)

Page 19

BOTTOM

PAN

L.

H. RAI

L-.

. r

to.44

r

42.22

7L

~

1.47

317T

21.22

T

10.72

1

r-;--

"..;-

11

. :

~

j

:1

:1

:1

I

,

,

---

8.

If

RKOS

RACK

r

-

rn

[]

ODD.

0000

CCC.

0000

--,-

-+,

1.1-- R.H.

:

--t

!'!.

I:

r-- RKOS

RA

IL

CHASSIS

SLIDE

--

drives in a multidrive installation, arrange

RKOSs

the

and

carried by

possible, connect all

on

cables between their

2-2).

If

the

9.

RK

interface cables as follows:

a. Remove

b.

I:

rn

000.

0000

I:

ill

DOO.

0000

:

(fiRST

HOLE

,

44

j

-

--

r·

,

-

CP-0273

c.

d. Place

10.

If

the

RKll-D

either as described in Step 9, above, (which is

preferable)

drives are daisy-chained with RK03

consecutively at

bus

to

avoid

interruption

DC

LOW

interface lines, which are

the

RK03s.

the bus by RK03s by means

drive

is

to be connected

ll-C

or

RK

II-D

the

Route

the

interface cables through

prefilter opening and reinstall

and frame so

slot on

Route

fold

fold in

to

the

side

the

cables over

them

as

the

cable retaining bracket over

the

cables and fasten

the

chassis.

drive

is

to

be connected

controller, install

or

as

follows:

the

controller end

of

If

this arrangement

RKOSs

prefilter and frame.

that

indicated in Figure 2-4.

that

J06

connections (Figure

to

controller, install

the

cables fit

of

the

frame (Figure 2-4).

the

to

the

interface cables

the

the

AC

LOW

not

is

not

are separated

of

separate

other

than

the

the

the

filter

into

the

prefilter and

the

the

bracket

an RK

ll-C

of

an

or

Figure 2-3 Chassis Slide Mounting

6. Inspect P2 (Figure 2-1) and the spindle pulley

to

ensure

for

two

115

jumper,

The operating frequency

spindle pulley.

7. Check

are

cable card

assembly.

system,

daisy-chain, ensure

card (Dwg. No.

interface card position.

that

the

the

input

power

jumpers,

Vac operation.

the

bent

the

the

supply is configured for

logic assembly

or

broken , and

into

card position 7

If

there

or

if this

drive

is

configured properly

to

be used.

supply

If

P2 contains only one

then

is

only

is

the

that

RKOS-O-2)

If

is

configured for

is

stamped on

to

ensure

plug

or 8 of

one

last drive

an M930

is

in

P2 contains

230

Vac.

the

that

no pins

the

interface

the

logic

drive in the

of

the

terminator

the

unused

2-4

Fold

the

a.

through

at

2-4).

b. Hold

the

To avoid random errors, confirm

II.

grounding strap

base plate and

mounted

Confirm

place.

Configure the

12.

valid drive

Plug

13.

the

receptacle.

interface cables and

the

slot just below

the

rear

of

the

the

cables in position and replace

bottom

that

power cord

cover.

is

firmly in place between

the

chassis, and

securely and in

all connectors are securely in

M7700 select switch

(Paragraph 3.2.2).

into

route

them

the

prefilter

drive cabinet (Figure

that the

the

that

brushes are

the

proper plane.

to

address a

the

switched ac line

Page 20

A = SINGLE

B =

DOUBLE

FOLD

FOLD

i

__

B_b

A

B

A

Figure

2-4

RK8/E Interface Cable Installation

2-5

Page 21

14. Turn the processor keyswitch

power

to

the

drive.

15

. Check

2.3

CARTRIDGE HANDLING PRACTICES AND

that

heads are

the spindle

not

bent

or

is

dirty.

ON

to

apply

clean, and that the

PRECAUTIONS

To obtain maximum performance and high reliability from

the RK05 Disk Drive, the following precautions and

cartridge-handling practices must be observed:

1.

Store cartridges in a clean, dry area away from

direct sunlight. Do not expose cartridges

heat. They may be stored on edge

however, stacks

should be avoided. Do

the

plastic cartridge cases. Do

cartridges on

of

more than 3

top

of

not

place heavy items

computer cabinets

or

or

4 cartridges

not

to

stacked;

on

store

or

in

places where dirt can be blown by fans into

cartridge interiors.

2. Whenever a cartridge

in a plastic bag

3.

Professional cartridge disassembly and cleaning

is

to

exclude dust

not

in a drive, enclose it

or

dirt.

is required every six months; however, disks

should be cleaned whenever they are

sively dirty,

is

encountered. In such instances, a disk-

cleaning service, listed

or

when a high transient error rate

by

Corporation, should be contacted

Place stiff cardboard

4.

the

molded

cartridge without

placed .

on

fram~

any

at

the front edge

u~jng

other

part

Or

plastic labels only in

any adhesives. Labels

of

interfere with the drive operation

contamination into the drive

the

cartridge.

5.

Allo~

the temperature

of

Digital Equipment

at

the

cartridge may

or

the

the cartridge to

once.

of

the disk

or

introduce

interior

exces-

of

become stabilized with the room temperature

If

before using the cartridge.

to

exposed

outside temperature extremes,

cartridges are

or

if

the temperature differential between drive and

cartridge

stabilization period

exceeds 20° F, a two-hour

is

necessary.

Although cartridges recorded on RK03s and

6.

RK05s are fully interchangeable, allow them

stabilize before new data

is

recorded on them.

Data interchangeability between drives

guaranteed if

not

exceed 30° F (17° C), even though a

the

temperature difference does

is

to

only

specific drive/cartridge combination may

of

50°

operate over a temperature range

110° F

(l00

to

43° C).

7. Keep the spindle hub clean and free

fr~m

to

nicks

and burrs to ensure reliable cartridge operation.

Because the hub

expose it

the

to

mounting surface. Periodically inspect

coupling hub

is

slightly magnetic, do

metal chips

on

the

that

could adhere

bottom

of

not

to

the

the disk

cartridge for dirt, metal chips, plastic chips in

cone, etc.

8. A sustained tinging, scratching, or rumbling

sound

(not

to be confused with spindle ground

is

brushes) that

the result

contact may occur if the cartridge

properly seated

on

the spindle, if excessive

contamination has built up in

the

cartridge,

defective.

or

If

this sound

if the cartridge

is

drive immediately to avoid damage

of

head-to-disk

is

not

the

or

interior

the

of

drive

heard, shut down the

to

the

read/write heads. Remove the disk cartridge

and examine

dirt.

If

not

reuse

the

heads for damage

necessary, clean

the

cartridge without first checking it

or

replace the heads. Do

or

excessive

for surface damage.

CAUTION

NEVER CYCLE A

BAD

CARTRIDGE

THROUGH AN INSTALLATION OF

SEVERAL DRIVES. This practice can

ruin all the read/write heads

or

contaminate all drives in a multidrive

installation, which will, in turn, damage

all

other

cartridges run in these drives.

of

9. Always keep the front door

and keep all covers

of

entry

2.4

CARTRIDGE PACKING AND SHIPPING

atmospheric dirt or dust.

on

to

the drive closed

prevent unnecessary

Data recorded on disk cartridges may be degraded by

exposure

contact with the disk surface .

in

against possible exposure

physical separation from the magnetic source

the

cargo hold

to

any sort

of

small magnet brought into intimate

If

cartridges are

of

an aircraft, precautions are necessary

to

magnetic sources. Because

to

be shipped

is

the best

is

2-6

Page 22

protection

cartridges should

box.

protect

encountered

unnecessary

2.5 NORMAL OPERATING

All drives in a multidrive system must have operating

applied even when

unused drives should

RUN/LOAD

IMPORT ANT:

DRIVES EQUIPPED WITH A POWER

DO

OPERA TION

AN

INDIVIDUAL

Because

drives

disables all

controlled

against accidental erasure

be

packed

This

amount

against

to

of

separation should be

any

magnetic sources likely

during

transportation,

ship cartridges in specially shielded boxes.

the

be

NOT

switch in

USE

ON

THE

the

EARLIER

ON/OFF

TO REMOVE OPERATING POWER FROM

DRIVE.

the

DC LOW interface signal

in

a multi drive system, a

the

drives in

by

a processor keyswitch, all drive

of

a cartridge,

at

least three inches within

adequate

making it generally

PROCEDURES

drive

is

not

in use. In

addition,

left write-enabled, and with

LOAD position.

MODEL

RKOS

ON/OFF

SWITCH,

SWITCH DURING SYSTEM

is

common

power

loss in

anyone

the

system.

If

the

drive power

ON/OFF

the

to

power

DISK

to

drive

switches should be left ON; however, all RUN/LOAD

switches should be set

to

LOAD before system power

removed.

2.5.1 Cartridge Loading

The procedure for cartridge loading

1.

Set

the

RUN LOAD switch

LOAD and observe

is

that

as follows:

on

all drives

the

LOAD

indicator

lights.

to

be

the

all

to

If

the

LOAD

door

to

is

force

front

2.

front

attempt

Open the

insert a clean, operable disk cartridge fully

the

cartridge receiver. DO NOT TWIST

FORCE

THE

INSERTION!

Close

the

3.

front

RUN/LOAD switch

4. Wait for

light,

read,

2.5.2 Cartridge

the

the

drive

or

write operations.

Unloading

The procedure for cartridge unloading

I.

Set

the

is

observe

RUN/LOAD switch

that

approximately

2.

3.

4.

will light.

Open

the

drive

the

disk cartridge.

If

another

drive

front

door

of

atmospheric dirt

Store

the

cartridge in a clean plastic bag.

cartridge

is

CAUTION

indicator

locked.

the

door

is

In

front

of

not

lit,

this case,

door

the

CARTRIDGE

door

of

the

drive

to

RUN.

RDY and ON CYL

is

now

ready

is

as follows:

the

RDY

indicator

30

seconds,

front

to

or

the

door

and

is

not

loaded, close

prevent unnecessary

dust.

the

do

open.

drive

indicators

to

perform

to

goes

LOAD

gently

and

drive

not

and

gently

into

OR

DURING

set

the

to

seek,

LOAD and

out.

After

indicator

withdraw

the

entry

2-7

Page 23

3.1

GENERAL

The flexibility achieved with

the

eight-position address select switch permits

Disk Drive

systems. hi'

drives can be

RK

Il-D

connected.

Interface, cable conne.

to

card position 7

positions are parallel-wired so

daisy-chained in a multidrive configuration;

position 7

position 7

card position 7 is used

used for

system, an M930

unused interface card position; if there

drive in

the

M930

position. The

M930

approximately +0.5 Vdc, and a negation,

approximately +3.5 Vdc.

to

be connected

the

RKI1-C

seri~lly

system,

or 8 of

or 8 of

output

the

system, only

terminator

terminator

up

ction

or 8 of

the

the

succeeding drive, etc. (By convention,

for

signals.)

t'erininatorcard

card in

interfa'ce signal levels are determinea

card. An assertion,

the

address select logic and

to

a variety

and

RK8/E

connected

to

eight drives can be serially

of

the

the

electronic module. These card

first drive

input

If

there

the

last drive

systems,

to

a single bus; in

RK05 Disk Drive

that

several drives may be

is

connected

signals; card position 8

is

only one drive in

must be installed in

is

on

the

the

unused interface card

or

the

RK05

of

computer

up

to

is

made

that

is, card

to

card

more

than

bus must have

by

logic

I,

or

logic

0,

four

the

is

the

the

one

the

is

is

CHAPTER

INTERFACE

3.2.2 , Select

BUS

SEL DR

conjunction

eightcposition address select switch

determine

of

one

a.

b.

(4Iines)

0/

A/E, 1

/B/F,

2/C/H, and

with

the

RK II-D interface line and an

the

drive address assignment and selection by

the

following

With a logical 0 on

selection circuit is configured

four selection lines as a linear set.

particular drive, only

internally connected (via positions

of

control

places a logical I

line remains

data transfer

With a logical I

selection

selection lines as a binary-encoded set.

a drive,

code, which

on

translated

to

switch positions.

two

methods:

the

the

address seleCt switch) '

logic.

To

select a drive,

on

the

at

logi~al

or

control

on

the

is

configured

th

,e controller places a 3-bit binary

corresppnds

these select lines. This binary code

by

a three-line-to-eight-line

activate only

one

of

3/D/J L operate

on

the

M7700 card

RKII-D

one

I

operation.

RKII-D

the

line,

the

M7700

to

decode

In

of

the

four

lines is

0

through

to

the

drive

the

controller

desired select line. This

throughout

to

decode

to

the

eight address select

the

entire

line,

the

M7700

the

To

select

drive address,

is

decoder

3

in

to

the

a

3

four

then

3-1

Figure

the

bus signals, operate according to negative logic;

asserted low. Appendix A contains a glossary

backplane connections.

3.2

3.2.1

This line (BUS RK

the

controller type. A logical

controller

an RK

drives

controller is an

illustrates and

function

INPUT INTERFACE LINES

address select logic

of

each

RKII-D

is

not

an

ll-C

or

an

RK8/E,

on

a single bus), while a logical I indicates

RKII-D.

the

following paragraphs describe

interface

II-D

RKlI-D

line. The signals listed, being

L) transmits a signal

to

0 on this line indicates

(thus,

both

operate with a particular

the

of

which

that

controller

control

they

are

of

RK05

configures

that

the

is

either

only four

that

the

3.2.3

Cylinder Address

BUS

CYL ADD 0 L through BUS CYL ADD 7 L determine

the

cylinder position

move

the

heads

to

corresponding 8-bit binary code

202

through

to

position

code remains

Acknowledged

from

the

3.2.4

Strobe

BUS

STROBE L transmits a signal

Address

the

Strobe line, only

Restore signals are fully settled on their respective lines.

3-1

).

10

the

heads at

on

or

drive (Paragraph 3.3.3).

or

Restore line. The controller places a logical I

(8

lines) ,

of

the

read/write heads. In

a desired cylinder,

on

the

These lines are gated

the

selected cylinder. The binary

the

lines until either

the

Address Invalid signal is

that

after

the

Cylinder Address

the

controller places a

lines (valid codes=O

by

the

Strobe signal

the

gates

the

order

to

Address

returned

Cylinder

on

or

the

Page 24

Ir

IA.I

oJ

oJ

0

Ir

I-

~

u

2

0

Ir

10-

I-

:::l

Q.

Z

-

II')

0

:10:

Ir

CONTROLLER

•

Ir

IA.I

oJ

oJ

0

Ir

I-

~

u

0

II-

:::l

Q.

I-

:::l

0

II')

0

:10:

Ir

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

BUS

8US

BUS

BUS

BUS

RKt1D-L

SEL

DR

f/A/E

SEL

SEL

SEL

CYL

CYL

CYL

CYL

CYL

CYL

CYL

CYL

STROBE

HEAD

WT

WT

WT

tlB/F L A 07

DR

DR

21C/H

DR

3/D/J

ADD

ADD

ADD

ADD

ADD

ADD

ADD

ADD

L B

SELECT

PROTECT

DATA

GATE

RESTORE

RD

GATE

L B

FILE

READY

R/W/S

ROY

ADDRESS

ADDRESS

SEEK

INCOMPLETE

WT

PROT

WT

CHK

L B

RD

DATA

RD

CLK

L B

CNTR

SEC

SEC

CNTR

SEC

CNTR

SEC

CNTR

SEC

PLS

INDX

PLS

AC

LO

L

LO

DC

L

RK05/HIGH

A 07

A

A

A

A

A

A

A

A

07

07

07

07

07

07

07

07

0

I L

2

3 L

4 L

L

L

L

L

L

5 L A 07

A

A

07

07

6

L

7

L

07

a

L

L

L

L

CLK

L

B

B

A

B

A

07

07

07

07

07

07

B

A

A

A

08

08

08

08

08

L

L

ACCEPTED

INVALID

STATUS

L A

L B 08

L

L

08

L B 08

08

13

L

I

L

2

L

3

L

B 08

A

08

B

08

B

08

L B 08

L

DENSITY

L

B08

B

B

B

08

08

08

UI

J2

K2

L2

M2

K1

01

LI

CI

F1

JI

E1

H1

HI

M2

R2

F2

L2

MI

R1

NI

H2

R2

T2

S2

PI

K1

S2

SI

L1

P2

K2

JI

N2

MI

FI

F2

P2

Figure 3-1 Controller/RKOS Disk Drive Interface Lines and Pin Assignments

3-2

CP

- 0141

Page 25

The Strobe line remains

drive.

Select

the

or

two

Acknowledged

the

from

3.2.5 Head

BUS

SEL UPPER

which

of

controller places a logical I

head, and a logical 0

remains on

the

at

logical I

the

Address Invalid signal

HD

L transmits a signal

read/write heads

on

to

select

the

line

throughout

until

either

the

is

that

determines

is

to

be selected. The

this line

to

select

the

lower head. Either signal

the entire read

operation.

3.2.6 Write

BUS

Protect

WT

PROTECT L transmits a signal

drive write amplifiers

controller places a logical

Set

that

to

prevent a write operation. The

Ion

this line

to

disables

set

the

Protect flip-flop and inhibit the write capability

drive. The Write Protect flip-flop

indicator is

off

and

the

is

operator

also set if

presses

the

the

WT

WT

switch (Paragraph 1.4.1).

3.2.7 Write Data

BUS

WT

DATA & CLK L transmits multiplexed data and

clock pulses

to

and

the

disk drive.

Clock

3.2.8 Write Gate

BUS

WT

GATE L transmits a signal

on

both

the

write and erase

head. The controller places a logical I

to

transmitting

throughout

3.2.9 Restore

BUS

RESTORE L transmits a signal

read/write heads

logical I

STROBE

drive

returns

address register, and moves

Restore line remains

Acknowledged signal

the

write data. This line remains

the

data transmission time.

(RTZ)

at

cylinder zero. The controller places a

on

this line prior

L) signal.

About 2 /1s

an Address Acknowledged signal, clears

the

at

logical I until

is

received by

to

simultaneously

current

in

the

on

this line I

selected write

at

to

position

to

issuing

after this signal

the

Strobe (BUS

is

issued,

heads to cylinder zero. The

the

the

controller.

3.2.10 Read Gate

BUS RD GATE L transmits a signal

read from

line

This line remains

to

the

drive. The controller places a logical I on this

enable

the

Read Clock and Read Data

at

logical I

that

throughout

allows data

output

the

entire read

operation.

Address

returned

upper

or

write

the

Write

of

the

PROT

PROT

turn

/1S

prior

logical I

the

the

the

Address

to

be

lines.

c.

The drive

d.

RUN/LOAD switch

e.

Spindle

f.

Read/write heads are loaded.

front

is

rotating

door

at

is

closed.

is

in

the

the

correct speed.

RUN position.

g. Write Check is false.

or

Seek

3.3 .2 Read, Write,

BUS

R/W /S RDY L transmits a logical I

the

drive

is

in

the

File Ready condition (Paragraph 3.3.1)

is

not

and

performing a seek

Ready/On

operation

Cylinder

to

.

indicate

that

3.3.3 Address Accepted

BUS

ADDRESS ACCEPTED L transmits a

pulse

to

indicate

command

with

has begun. The negative pulse

receipt

the

of

the

present address.

3.3.4 Address Invalid (Logic Address

BUS

LOG ADD INT L transmits a

indicate

that

that

the

drive has accepted a Seek

a valid address and

Strobe signal, even

the

is

generated

if

there is no change from

Interlock)

5-/1s

the

drive has received a nonexecutable Seek

command with a cylinder address greater

the

case,

heads are

as for

3.3.5 Seek

BUS

malfunctio

Seek command is suppressed in

not

moved. The pulse generation time is

the

Address Acknowledged signal.

Incomplete

SIN L transmits a logical I

.p.

in

the

drive did

not

allow

to

the

5-/1s

command

about 2 /1S

negative pulse

than

202.

the

drive and the

indicate

seek

operation

negative

execution

after

For

this

the

same

that

some

to

to

be completed. This line remains low until a Restore

is

command

switch

received

to

LOAD and

3.3.6 Write Protect

BUS

WT

PROT STATUS L transmits a logical 1

that

the

write capability

protected). When this line

indicator on

1.4.1

).

or

the

then

back to RUN.

operator

sets

the

RUN/LOAD

Status

of

the

drive

is

inhibited (write

is

at logical 1,

the

drive control panel lights (Paragraph

the

to

indicate

WT

PROT

3.3.7 Write Check

BUS

WT

CHK L transmits a logical 1 to indicate

the

following conditions :

3.3

OUTPUT

INTERF

ACE LINES

3.3.1 File Ready (Drive Ready)

BUS

FILE

RDY L transmits a logical I

following conditions :

a. Drive operating power

b. A disk cartridge

is

correct .

is

properly loaded.

to

indicate

the

a.

Erase

or

write current

b.

Inoperative linear positioner transducer lamp.

the

When

commands

indicator

condition

Write Check signal

to

the

drive are suppressed and

on

the

drive

is

temporary,

FAULT indicator by pressing

3-3

control

the

without

is

at

a logical

panel lights.

operator

the

WT

a WRITE GATE.

I,

all external

the

FAULT

If

the

fault

may

turn

off

the

PROT switch. This

Page 26

action, however, causes the

the

WT

PROT switch must be pressed a second time

off

the

WT

PROT indicator (Paragraph 1.4.1).

WT

PROT indicator

to

to

light;

turn

after the last sector pulse and

index slot (unique slot)

transducer.

is

generated each time the

is

detected by the sector

3.3.8 Read Data

BUS

RD DATA transmits read data only (160-ns pulses).

3.3.9 Read Clock

BUS

RD CLK L transmits read clock pulses only (160-ns

pulses).

3.3.10 Sector Address

BUS

SEC CNTR 0 through 3 L indicate which sector is

passing under the read/write heads. The sector address

(4

lines)

is

4-bit binary code derived from the Sector Address counter.

3.3.11 Sector Pulse

BUS

SEC PLS L transmits a

2-p.s

negative pulse each time a

sector slot passes the sector transducer. The index slot

(unique slot) is suppressed in this line and is transmitted

on

a separate Index Pulse line.

3.3.12 Index Pulse

BUS INDX PLS L transmits a single

each revolution

of

the disk. The Index Pulse occurs 600

2-p.s

negative pulse for

p.s

3.3.13

BUS

more than 45 ms)

AC

Low

AC

LO L transmits a logical 1 when there

of

the 30 Vac within the drive. When

is

a loss (for

AC

Low occurs, the drive finishes reading/writing the current

sector,

cycle.

completely retracted, the safety relay is de-energized

then

initiates a normal head-retract and unload

If

a total power loss occurs before the heads are

to

retract the heads under battery power (emergency retract).

a

3.3.14

BUS

within the drive drops

is

DC

Low

DC

LO L transmits a logical I when the ±15 Vdc

to

12 Vdc

or

below. When

generated, the safety relay is de-energized

to

heads under battery power (emergency retract).

RUN gate

DC

of

each drive

Low signal from

is

connected to the

anyone

drive in a multidrive system

DC

DC

Low

retract the

Since the

Low bus, a

disables all the drives in the system.

3.3.15 High Density/RK05 L

BUS

RK05 L transmits a logical 1 (indicating high density

only) whenever the drive

is

selected. (All RK05s are high

density.)

34

Page 27

APPENDIX

A

THE

A.I

MOVE FUNCTIONS

1.

STEP - incrementing cylinder seek

2. ALT (Alternate) - an incrementing seek from

3.

OSC - oscillate between 0 and

4. RAND - random cylinder seek.

5. Drive Selector - selects

6. RUN - enables all move functions.

7. RTZ - forces a zero recalibrate.

8.

FOR/REV

- selects

the

the

the

drive

initial drive motion

RK05-TA

to

limit and a.high speed return.

the

cylinder address selected.

cylinder address selected

number

selected on

in

the

step and alternate.

OFF-LINE

(not

affected

M7700 module in

by

the

TESTER

FOR/REV).

RKOS

.

9. Cylinder Address - selects any cylinder address from 0

INDICATORS

1.

Address invalid,-

2.

Seek incomplete - excess time

3.

Power

on

-

cyli~der

indicatespow'~r

address set

to

perform

is

applied

up

to

an illegaladdress; i.e., > 202.

the

seek.

to

the

drive.

A·I

to

202.

.

0

Page 28

A.2 WRITE FUNCTIONS

1.

*Write sector - selects a sector (from sectors 0 through 9 only) to write

"All"

simulates a write all. Note: the unit cannot read to check headers.

2.

Head select - selects

thus only one surface

or

enables either the upper

is

written on .

on

and simulates a write data.

or

lower head. Only one head can be selected at a time;

3. *Write

button

causes a write one-shot to write

or

erase on the sector selected

selected).

4. *Constant write - when set, writes continuously on the sector selected ; the write

pressed.

S.

*OC erase - when ON, enables erase on a sector (or sectors) when the WRITE

OFF,

enables writing on a sector (sectors) when the WRITE button

-:-

6. Data bits

-After

the

RKOS·T has

sets a 4-bit data

been

A.3 CONNECTING THE

used

to

RKOS-T

pattem

perform

write

or

erase

OFF-LINE TESTER

to be written on the sector selected.

operations,

the

disk will have

to

is

be

pressed.

1. Disconnect the ac line cord.

a. Remove

b. Check the

them (slot 7

c. Connect a BCII-A cable from slot I

d. Disconnect connector

the

interface cable from the

RKOS

and the tester to ensure that a M930 Terminator module

or 8 of

the

RKOS

11

in the

RKOS.

, or slot 2

or 2 of

RKOS

of

the

RKOS-TA

the tester

Off-Line Tester).

to

slot 7

(logic voltage connector) .

or 8 in

(or

reformatted.

the

RKOS.

the track, if

button

button

is

is

present in one

"All"

is

need

not

be

pressed; when

of

e. Plug one end

f.

Check for proper keying

female connector

of

the tester power cable into the tester.

of

the pins and plug the male connector

of

J I.

g. Connect the remaining connector

h. Reconnect

i. Toggle RTZ

the

ac line cord.

to

initialize and clear all error conditions and proceed with testing.

to

the plug leading

A-2

to

the logic block

of

the power cable into the

of

the

RKOS.

Page 29

RKOS

DISK DRIVE

USER'S

EK·RKOS·OP·OOI

Your

our

What

wri

tten

What features are most useful?

MANUAL

comments

publications.

is

your

general reaction

, etc.?

Is

and

suggestions will help us in

it easy

to

use?

to

this manual? In

our

continuous

your

judgment

effort

is

it

R

to improve

complete,

eader

the

accurate, well organized, well

's C

quality

omments

and usefulness

of

What faults

Does this manual satisfy

it

Does

Would

Please describe

Name

do

you

find with

satisfy

you

your

needs?

please indicate any factual errors

your

position.

the

the

need

manual?

you

think

it was intended

Why?

you

have found.

Organization

to

satisfy?

_________________________________

__

Street

City

______________________________________

__________

_

State

____________

Department

_

Zip

or

Country

Page 30

- - - - - - - - - - -- Fold Here .- - - - - - - - - - -

- - -

--

----

--

--

BUSINESS REPLY MAIL

NO

POST AGE STAMP NECESSARY IF MAILED IN THE UNITED STATES

Postage will be paid by:

Digital Equipment Corporation

Technical Documentation Department

Maynard, Massachusetts

Do

Not

Tear - Fold Here and Staple - -

01754

--

--

-- --

FIRST CLASS

PERMIT NO.

MAYNARD, MASS.

-- --

33

Page 31

DIGITAL EQUIPMENT CORPORATION

Maynard, Massachusetls .

NORTHEAST

REGIONAL OFf iCE: PrInc

23S

Wyman Street.

T

elephone: (61

CONNECTICUr

Menden

240

Telephone

FairfIeld

1

275

Tetephone: (203)

NEW

Rochest

1

30

Telephone: (716) Syracuse

6700 Thompson

Telep

MASSACHUSETTS

Marlbor

One Iron

Marlborough

Te

lephone : (617)·481·

MID-ATLANTIC

REGIONAL OFFICE:

U.S. Aoute

Te

lephone : (

F

LORIDA

Orlando

Suite

Te

leph one: (305)·

GEORGIA

At

lanta

2815

A

tlan

Telephone: (404)·451·7411

NORTH C ARO

Durham/Chapel

Ex

ecutive

37

00

Durham. N

Telephone: (919)

NEW JERSEY

Fairfiel d

253 Passaic

Telephone: (201)·

Metuche

95 M ain

Telephone

EUROPEAN HEADQUARTERS

Dig

ita! Equi

81

route

12

11

Telephone: 42

FRANCE

Digital

Centre

9<1533

Telephone :

GRENOBLE

Di

gital

Tour

16

Rue

38100

Telep

GERMAN

Dig

ital Equi p

MUNICH

8Muenchenl3

Tele p

COLOGNE

5 Koeln 41,

Telephone' 0221-44·40 ·

Teleg

FRANKFURT

6078

Am

T

elephone: 06102·5526

HANNOV

3

Hllnnove

Telephone: 0511-69-70-95

STUTTGART

0·7301 Kemnflt. St

rco·Po

Ma

Telephone '

AUSTR

Diqital Equip me

VIENN

Mar

Telephone: 855

UNIT

Dinit1l

U_K. HE

Fountllin HOllse.

Reading RGI 70N. E

Telephone: (0734)·583555 T

BIRMINGHAM

Mllney

29/3

W<Jrwicksh

Telephone:

BRI

STOL

F,

sh Ponds Road . Fish Ponds

Bri

stol.

Telephone' Bristol 651·0431

EAl/NG

Billo

Telephone' 01·579·2334

EDINBURGH

Sh,el

We

st

elephone: 32705

T

LONDON

Manaljement

43

P<Jrkf'r St . Hol

WC

T

el~hone

MANCHESTER

Arndale HOl.se

Chesler Road. Stre tford.

Telephone-

Walt

ham.

Mass. 021

7)-890-0330/0310 D

Pome

roy

Ave .. Me r iden. Conn.

: (

203)-237

Post Ro ad, Fair field. Conn .

-255-5991

YORK

er

Alfens

Creek

Aoad. Rochester.

461-1700

ROlld,

hon

e: (315).4 3 7

ough

Way

, Mas s 0 1

1.

Prin ce

609

)·452·2940

1~

.

7

001

Lake E

851.4450

Clearview

Place . Su ite 100

ta.

Geor

gia

(3)4()

LIN

Hill

Park

Chap

el Hill

or

th

Carol

·489·334

Ave ,.

227

n

Street.

Met

: (

201)-549·4100/2000

pme

nt Corporation

de r

Aire

Geneva

26

.

S

wit ~er

79

50

Equipment

Sillc -Cidex L225

Rungis, France

68

7-23·

Equipm

ent

Mangin

Du

Gal

Mangin

Grenoble

. Fr ance

hone : (76)·87-56·01 Telel(: 212-32882

FEDER

ment GmbH

, Wallenllteinplatz2

hone

: 0811

·35031

Aachener

rllm , Flip C h

ip

Neu·lsen

burg 2

Forst

llUS Gr

avebruch

ER

r. Podbi elskist

lo· St

rflsse

(0771)·

4:;

IA

nt Corpo

A

iah ilfer

strllsse

1 86

ED KINGDOM

1 Equipment Co .

ADQUARTERS

Butts

Buildlnqs

1 Bi r

minqham

ire . Engla'rM

02\·3

55-5501

En!lland BS16:\HO

n House . Uxbridge Aoad

House.

Craigsh

Loth'an.

Scot

House

born

2B

5PT. Enqland

:

01·405·261

(061)·865·7011 Telex: 668686

ataphone: 617

-844117466

Datilphonc-203·

06430

Dataphone : 716·

Syracus

e. New

·1

593/

7085

Dataphone

752

7400

Tel e

... , 710·347·0348

ton. New

Jersey

lleno

r Dr ive .

Orlllndo

Dataphone: