Page 1

KA681/KA691/KA692/KA694CPU

SystemMaintenance

Order Number: EK–498AB–MG. B01

Digital Equipment Corporation

Maynard, Massachusetts

Page 2

August, 1994

Digital Equipment Corporation makes no representations that the use of its products in the

manner described in this publication will not infringe on existing or future patent rights, nor do

the descriptions contained in this publication imply the granting of licenses to make, use, or sell

equipment or software in accordance with the description.

Possession, use, or copying of the software described in this publication is authorized only

pursuant to a valid written license from Digital or an authorized sublicensor.

© Digital Equipment Corporation 1994. All Rights Reserved.

The postpaid Reader’s Comments forms at the end of this document request your critical

evaluation to assist in preparing future documentation.

The following are trademarks of Digital Equipment Corporation: CompacTape, CX, DDCMP,

DEC, DECconnect, DECdirect, DECnet, DECscan, DECserver, DECUS, DECwindows, DELNI,

DEMPR, DESQA, DESTA, DSRVB, DSSI, IVAX, KDA, KLESI, MicroVAX, MSCP, OpenVMS,

Q–bus, Q22–bus, RA, RQDX, RRD40, SDI, ThinWire, TK, TMSCP, TQK50, TQK70, TSV05,

TU, ULTRIX, UNIBUS, VAX, VAX 4000, VAX DOCUMENT, VAXcluster, VAXELN, VAXlab,

VAXserver, VAXsimPLUS, VT, and the DIGITAL logo.

All other trademarks and registered trademarks are the property of their respective holders.

S2651

This document was prepared using VAX DOCUMENT Version 2.1.

Page 3

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 System Maintenance Strategy

1.1 Service Delivery Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.2 Product Service Tools and Utilities . . . . . . . . . . . . . . . . . . . . . . . 1–2

1.3 Information Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1.4 Field Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

2 CPU System Overview

2.1 CPU Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2.2 MS690 Memory Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2.3 (Optional) DSSI Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

2.4 BA440 Enclosure Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

2.4.1 H3604 Console Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

2.4.2 System Control Panel (SCP) . . . . . . . . . . . . . . . . . . . . . . . . . 2–16

2.4.3 BA440 Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–19

2.4.4 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

2.4.5 System Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–23

3 System Setup and Configuration

3.1 CPU and Memory Module Order . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3.1.1 Installing Add-On MS690 Memory Modules . . . . . . . . . . . . . 3–2

3.2 General Module Order for Q–Bus Options . . . . . . . . . . . . . . . . . . 3–4

3.3 Recommended Module Order of Q-Bus Options . . . . . . . . . . . . . . 3–7

3.4 (Optional) DSSI Ports Assignment . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3.5 Mass Storage Options (Internal) . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3.6 System Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

3.6.1 Mass Storage Expanders . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

3.6.2 Q–Bus Expanders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–11

3.6.3 Control Power Bus for Expanders . . . . . . . . . . . . . . . . . . . . . 3–12

iii

Page 4

3.6.4 Adding Options to the System Enclosure . . . . . . . . . . . . . . . . 3–13

3.7 DSSI VAXclusters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–17

3.7.1 DSSI VAXcluster Configuration Rules . . . . . . . . . . . . . . . . . . 3–19

3.8 Firmware Commands and Utilities Used in System

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–24

3.8.1 Examining System Configuration . . . . . . . . . . . . . . . . . . . . . . 3–24

3.8.2 Using the CONFIGURE Command to Determine CSR

Addresses for Q–Bus Modules . . . . . . . . . . . . . . . . . . . . . . . . 3–26

3.8.3 Setting and Examining Parameters for DSSI Devices . . . . . . 3–28

3.8.3.1 DSSI Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 3–29

3.8.3.2 How the OpenVMS Operating System Uses the DSSI

Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–30

3.8.3.3 Entering the DUP Driver Utility from Console Mode . . . 3–36

3.8.3.4 Entering the DUP Driver Utility from the OpenVMS

Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–38

3.8.3.5 Setting Allocation Class . . . . . . . . . . . . . . . . . . . . . . . . . . 3–39

3.8.3.6 Setting Unit Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–39

3.8.3.7 Setting Node Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–42

3.8.3.8 Setting System ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–42

3.8.3.9 Exiting the DUP Driver Utility . . . . . . . . . . . . . . . . . . . . 3–43

3.8.4 Write-Protecting an EF/RF ISE . . . . . . . . . . . . . . . . . . . . . . . 3–46

3.8.4.1 Software Write-Protect for EF/RF-Series ISEs . . . . . . . . . 3–46

3.8.4.2 Hardware Write-Protect for EF/RF ISEs . . . . . . . . . . . . . 3–47

3.8.5 Setting System Parameters: Boot Defaults, Bootflags, Halt

and Restart Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–51

3.8.5.1 Setting the Boot Default . . . . . . . . . . . . . . . . . . . . . . . . . 3–51

3.8.5.2 Setting Boot Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–53

3.8.5.3 Setting the Halt Action . . . . . . . . . . . . . . . . . . . . . . . . . . 3–54

4 System Initialization and Acceptance Testing (Normal

Operation)

4.1 Basic Initialization Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4.2 Power-On Self-Tests (POST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4.2.1 Power-Up Tests for Kernel . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4.2.2 Power-Up Tests for Q–Bus Options . . . . . . . . . . . . . . . . . . . . 4–7

4.2.3 Power-Up Tests for Mass Storage Devices . . . . . . . . . . . . . . . 4–8

4.3 CPU ROM-Based Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

4.3.1 Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–9

4.3.2 Scripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–13

4.4 Basic Acceptance Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 4–15

4.5 Machine State on Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–20

4.6 Main Memory Layout and State . . . . . . . . . . . . . . . . . . . . . . . . . 4–20

iv

Page 5

4.6.1 Reserved Main Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–21

4.6.1.1 PFN Bitmap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–21

4.6.1.2 Scatter/Gather Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

4.6.1.3 Firmware "Scratch Memory" . . . . . . . . . . . . . . . . . . . . . . 4–22

4.6.2 Contents of Main Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

4.6.3 Memory Controller Registers . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

4.6.4 On-Chip Cache . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

4.6.5 Translation Buffer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

4.6.6 Halt-Protected Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

4.7 Operating System Bootstrap . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

4.7.1 Preparing for the Bootstrap . . . . . . . . . . . . . . . . . . . . . . . . . . 4–24

4.7.2 Primary Bootstrap Procedures (VMB) . . . . . . . . . . . . . . . . . . 4–26

4.7.3 Device Dependent Secondary Bootstrap Procedures . . . . . . . . 4–30

4.7.3.1 Disk and Tape Bootstrap Procedure . . . . . . . . . . . . . . . . . 4–30

4.7.3.2 PROM Bootstrap Procedure . . . . . . . . . . . . . . . . . . . . . . . 4–31

4.7.3.3 MOP Ethernet Functions and Network Bootstrap

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–32

4.7.3.4 Network "Listening" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–33

4.8 Operating System Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–39

4.8.1 Locating the RPB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–40

5 System Troubleshooting and Diagnostics

5.1 Basic Troubleshooting Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5.2 Product Fault Management and Symptom-Directed Diagnosis . . . 5–4

5.2.1 General Exception and Interrupt Handling . . . . . . . . . . . . . . 5–4

5.2.2 OpenVMS Operating System Error Handling . . . . . . . . . . . . 5–5

5.2.3 OpenVMS Error Logging and Event Log Entry Format . . . . . 5–7

5.2.4 OpenVMS Operating System Event Record Translation . . . . 5–15

5.2.5 Interpreting CPU Faults Using ANALYZE/ERROR . . . . . . . . 5–16

5.2.6 Interpreting Memory Faults Using ANALYZE/ERROR . . . . . 5–19

5.2.6.1 Uncorrectable ECC Errors . . . . . . . . . . . . . . . . . . . . . . . . 5–19

5.2.6.2 Correctable ECC Errors . . . . . . . . . . . . . . . . . . . . . . . . . . 5–23

5.2.7 Interpreting System Bus Faults Using ANALYZE/ERROR. . . 5–28

5.2.8 Interpreting DMA

ANALYZE/ERROR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–30

5.2.9 VAXsimPLUS and System-Initiated Call Logging (SICL)

Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–32

5.2.9.1 Converting the SICL Service Request MEL File . . . . . . . 5–39

5.2.9.2 VAXsimPLUS Installation Tips . . . . . . . . . . . . . . . . . . . . 5–40

5.2.9.3 VAXsimPLUS Postinstallation Tips . . . . . . . . . . . . . . . . . 5–41

5.2.10 Repair Data for Returning FRUs . . . . . . . . . . . . . . . . . . . . . 5–43

Host Transaction Faults Using

v

Page 6

5.3 Interpreting Power-On Self-Test and ROM-Based Diagnostic

Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–43

5.3.1 FE Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–58

5.3.2 Overriding Halt Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–59

5.3.3 Isolating Memory Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–60

5.4 Testing DSSI Storage Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–62

5.5 Using MOP Ethernet Functions to Isolate Failures . . . . . . . . . . . 5–65

5.6 Interpreting User Environmental Test Package (UETP)

OpenVMS Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–68

5.6.1 Interpreting UETP Output . . . . . . . . . . . . . . . . . . . . . . . . . . 5–69

5.6.1.1 UETP Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–69

5.6.1.2 Possible UETP Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–70

5.7 Using Loopback Tests to Isolate Failures . . . . . . . . . . . . . . . . . . . 5–71

5.7.1 Testing the Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–72

5.7.2 Embedded DSSI Loopback Testing . . . . . . . . . . . . . . . . . . . . . 5–73

5.7.3 Embedded Ethernet Loopback Testing . . . . . . . . . . . . . . . . . . 5–75

5.7.4 Q–Bus Option Loopback Testing . . . . . . . . . . . . . . . . . . . . . . 5–76

6 FEPROM Firmware Update

6.1 Preparing the Processor for a FEPROM Update . . . . . . . . . . . . . 6–2

6.2 Updating Firmware via Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

6.3 Updating Firmware via Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

6.4 FEPROM Update Error Messages . . . . . . . . . . . . . . . . . . . . . . . . 6–7

A KA681/KA691/KA692/KA694 Firmware Commands

A.1 Console I/O Mode Control Characters . . . . . . . . . . . . . . . . . . . . . A–1

A.1.1 Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

A.1.2 Address Specifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

A.1.3 Symbolic Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

A.1.4 Console Numeric Expression Radix Specifiers . . . . . . . . . . . . A–8

A.1.5 Console Command Qualifiers . . . . . . . . . . . . . . . . . . . . . . . . . A–9

A.1.6 Console Command Keywords . . . . . . . . . . . . . . . . . . . . . . . . . A–10

A.2 Console Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–13

A.2.1 BOOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–13

A.2.2 CONFIGURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–15

A.2.3 CONTINUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–17

A.2.4 DEPOSIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–17

A.2.5 EXAMINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–18

A.2.6 FIND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–19

A.2.7 HALT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–20

A.2.8 HELP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–21

vi

Page 7

A.2.9 INITIALIZE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–22

A.2.10 MOVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–23

A.2.11 NEXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–24

A.2.12 REPEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–26

A.2.13 SEARCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–27

A.2.14 SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–29

A.2.15 SHOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–34

A.2.16 START . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–38

A.2.17 TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–38

A.2.18 UNJAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–39

A.2.19 X—Binary Load and Unload . . . . . . . . . . . . . . . . . . . . . . . . . A–39

A.2.20 ! (Comment) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–41

B Address Assignments

B.1 KA681/KA691/KA692/KA694 General Local Address Space

Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

B.2 KA681/KA691/KA692/KA694 Detailed Local Address Space

Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–2

B.3 External Internal Processor Registers . . . . . . . . . . . . . . . . . . . . . B–8

B.4 Global Q22–bus Address Space Map . . . . . . . . . . . . . . . . . . . . . . B–8

B.5 Processor Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–9

B.6 IPR Address Space Decoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–16

C ROM Partitioning

C.1 Firmware EPROM Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

C.1.1 System Identification Registers . . . . . . . . . . . . . . . . . . . . . . . C–3

C.1.1.1 PR$_SID (IPR 62) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–3

C.1.1.2 SIE (20040004) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–3

C.1.2 Call-Back Entry Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–5

C.1.2.1 CP$GETCHAR_R4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–5

C.1.2.2 CP$MSG_OUT_NOLF_R4 . . . . . . . . . . . . . . . . . . . . . . . . C–6

C.1.2.3 CP$READ_WTH_PRMPT_R4 . . . . . . . . . . . . . . . . . . . . . C–7

C.1.3 Boot Information Pointers . . . . . . . . . . . . . . . . . . . . . . . . . . . C–7

vii

Page 8

D Data Structures and Memory Layout

D.1 Halt Dispatch State Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–1

D.2 Restart Parameter Block (RPB) . . . . . . . . . . . . . . . . . . . . . . . . . . D–6

D.3 VMB Argument List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–10

E Configurable Machine State

F NVRAM Partitioning

F.1 SSC RAM Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–1

F.1.1 Public Data Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–1

F.1.2 Console Program MailBox (CPMBX) . . . . . . . . . . . . . . . . . . . F–2

F.1.3 Firmware Stack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–3

F.1.4 Diagnostic State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–3

F.1.5 USER Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–4

G MOP Counters

H Programming the KFQSA Adapter

I Error Messages

I.1 Machine Check Register Dump . . . . . . . . . . . . . . . . . . . . . . . . . . I–1

I.2 Halt Code Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–1

I.3 VMB Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–3

I.4 Console Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–4

J Related Documents

Glossary

Index

viii

Page 9

Examples

3–1 SHOW DSSI Display (Embedded DSSI) . . . . . . . . . . . . . . . . . 3–35

3–2 SHOW UQSSP Display (KFQSA-Based DSSI) . . . . . . . . . . . . 3–36

3–3 Accessing the DUP Driver Utility from Console Mode

(Embedded DSSI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–37

3–4 Accessing the DUP Driver Utility from Console Mode

(KFQSA-Based DSSI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–37

3–5 Accessing the DUP Driver Utility from the OpenVMS

Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–38

3–6 Setting Allocation Class for a Specified Device . . . . . . . . . . . 3–39

3–7 Setting a Unit Number for a Specified Device . . . . . . . . . . . . 3–40

3–8 Changing a Node Name for a Specified Device . . . . . . . . . . . . 3–42

3–9 Changing a System ID for a Specified Device . . . . . . . . . . . . 3–43

3–10 Exiting the DUP Driver Utility for a Specified Device . . . . . . 3–44

3–11 SHOW DSSI Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–45

3–12 SHOW UQSSP Display (KFQSA-Based DSSI) . . . . . . . . . . . . 3–46

3–13 Setting Hardware Write-Protection Through Firmware . . . . . 3–49

3–14 Setting Hardware Write-Protection Through the OpenVMS

Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–50

4–1 Language Selection Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

4–2 Normal Diagnostic Countdown . . . . . . . . . . . . . . . . . . . . . . . . 4–4

4–3 Successful Power-Up to List of Bootable Devices . . . . . . . . . . 4–7

4–4 Test 9E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–10

5–1 Error Log Entry Indicating CPU Error . . . . . . . . . . . . . . . . . 5–17

5–2 SHOW ERROR Display Using the OpenVMS Operating

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–18

5–3 Error Log Entry Indicating Uncorrectable ECC Error . . . . . . 5–21

5–4 SHOW MEMORY Display Under the OpenVMS Operating

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–22

5–5 Using ANALYZE/SYSTEM to Check the Physical Address in

Memory for a Replaced Page . . . . . . . . . . . . . . . . . . . . . . . . . 5–23

5–6 Error Log Entry Indicating Correctable ECC Error . . . . . . . . 5–26

5–7 Error Log Entry Indicating Q-Bus Error . . . . . . . . . . . . . . . . 5–29

5–8 Error Log Entry Indicating Polled Error . . . . . . . . . . . . . . . . 5–30

5–9 Device Attention Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–32

5–10 SICL Service Request with Appended MEL File . . . . . . . . . . 5–40

5–11 Sample Output with Errors . . . . . . . . . . . . . . . . . . . . . . . . . . 5–44

ix

Page 10

5–12 FE Utility Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–59

5–13 Running DRVTST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–64

5–14 Running DRVEXR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–65

6–1 FEPROM Update via Ethernet . . . . . . . . . . . . . . . . . . . . . . . 6–5

6–2 FEPROM Update via Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

Figures

2–1 KA681/KA691/KA692/KA694 CPU Module Component

Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

2–2 KA681/KA691/KA692/KA694 Kernel System Functional

Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

2–3 KA681/KA691/KA692/KA694 CPU Module Block

Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2–4 Ratchet Handles for CPU and Memory Modules . . . . . . . . . . 2–7

2–5 (Optional) DSSI Module Component Side . . . . . . . . . . . . . . . 2–8

2–6 H3604 Console Module (Front) . . . . . . . . . . . . . . . . . . . . . . . . 2–10

2–7 H3604 Console Module (Back) . . . . . . . . . . . . . . . . . . . . . . . . 2–13

2–8 System Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–16

2–9 BA440 Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–19

2–10 H7874 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–20

2–11 Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–23

2–12 Fan Speed Control (FSC) Jumper Location . . . . . . . . . . . . . . 2–24

3–1 Memory Module Ratchet Handles . . . . . . . . . . . . . . . . . . . . . 3–4

3–2 Storage Configuration Example . . . . . . . . . . . . . . . . . . . . . . . 3–9

3–3 Sample Power Bus Configuration . . . . . . . . . . . . . . . . . . . . . . 3–12

3–4 VAX 4000 Model 500A/505A/600A/700A/705A Configuration

Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–14

3–5 DSSI Cabling for a Generic Two-System DSSI VAXcluster

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–18

3–6 Two-System DSSI VAXcluster . . . . . . . . . . . . . . . . . . . . . . . . 3–22

3–7 Expanded Two-System DSSI VAXcluster . . . . . . . . . . . . . . . . 3–23

3–8 OpenVMS Operating System Requires Unique Unit Numbers

for DSSI Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–32

3–9 Sample DSSI Buses for an Expanded VAX 4000 Model 500A

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–34

3–10 Attaching a MSCP Unit Number Label to the Device Front

Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–41

x

Page 11

4–1 Console Banner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

4–2 Memory Layout After Power-Up Diagnostics . . . . . . . . . . . . . 4–21

4–3 Memory Layout Prior to VMB Entry . . . . . . . . . . . . . . . . . . . 4–26

4–4 Memory Layout at VMB Exit . . . . . . . . . . . . . . . . . . . . . . . . . 4–29

4–5 Boot Block Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–31

4–6 Locating the Restart Parameter Block . . . . . . . . . . . . . . . . . 4–40

5–1 Event Log Entry Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–9

5–2 Machine Check Stack Frame Subpacket . . . . . . . . . . . . . . . . 5–10

5–3 Processor Register Subpacket . . . . . . . . . . . . . . . . . . . . . . . . 5–11

5–4 Memory Subpacket for ECC Memory Errors . . . . . . . . . . . . . 5–12

5–5 Memory SBE Reduction Subpacket (Correctable Memory

Errors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–12

5–6 CRD Entry Subpacket Header . . . . . . . . . . . . . . . . . . . . . . . . 5–13

5–7 Correctable Read Data (CRD) Entry . . . . . . . . . . . . . . . . . . . 5–14

5–8 Trigger Flow for the VAXsimPLUS Monitor . . . . . . . . . . . . . . 5–35

5–9 Five-Level VAXsimPLUS Monitor Display . . . . . . . . . . . . . . . 5–37

5–10 H3604 Console Module Fuses . . . . . . . . . . . . . . . . . . . . . . . . 5–72

6–1 Firmware Update Utility Layout . . . . . . . . . . . . . . . . . . . . . . 6–2

6–2 W4 Jumper Setting for Updating Firmware . . . . . . . . . . . . . . 6–3

C–1 KA681/KA691/KA692/KA694 FEPROM Layout . . . . . . . . . . . C–2

C–2 SID: System Identification Register . . . . . . . . . . . . . . . . . . . . C–3

C–3 SIE : System Identification Extension (20040004) . . . . . . . . . C–4

C–4 Boot Information Pointers . . . . . . . . . . . . . . . . . . . . . . . . . . . C–8

F–1 KA681/KA691/KA692/KA694 SSC NVRAM Layout . . . . . . . . F–1

F–2 NVR0 (20140400): Console Program MailBoX (CPMBX) . . . . F–2

F–3 NVR1 (20140401) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–3

F–4 NVR2 (20140402) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–3

Tables

2–1 KA681/KA691/KA692/KA694 CPU Module Components . . . . 2–4

2–2 (Optional) DSSI Bus Daughter Board Components . . . . . . . . 2–9

2–3 H3604 Console Module Controls and Indicators . . . . . . . . . . . 2–11

2–4 H3604 Console Module (Back) . . . . . . . . . . . . . . . . . . . . . . . . 2–14

2–5 System Control Panel Controls and Indicators . . . . . . . . . . . . 2–17

2–6 H7874 Power Supply Switches, Controls, and Indicators . . . . 2–21

3–1 BA440 Module Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

xi

Page 12

3–2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–15

3–3 Boot Devices Supported by the

KA681/KA691/KA692/KA694 . . . . . . . . . . . . . . . . . . . . . . . . . 3–52

3–4 Virtual Memory Bootstrap (VMB) Boot Flags . . . . . . . . . . . . 3–53

3–5 Actions Taken on a Halt . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–55

4–1 Language Inquiry on Power-Up or Reset . . . . . . . . . . . . . . . . 4–2

4–2 LED Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–6

4–3 Scripts Available to Customer Services . . . . . . . . . . . . . . . . . 4–14

4–4 Signature Field Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–17

4–5 Network Maintenance Operations Summary . . . . . . . . . . . . . 4–35

4–6 Supported MOP Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 4–36

4–7 MOP Multicast Addresses and Protocol Specifiers . . . . . . . . . 4–39

5–1 Console Terminal/Console Module Problems . . . . . . . . . . . . . 5–3

5–2 Power Supply Status Indicators . . . . . . . . . . . . . . . . . . . . . . . 5–3

5–3 OpenVMS Operating System Error Handler Entry Types . . . 5–7

5–4 Conditions That Trigger VAXsimPLUS Notification and

Updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–34

5–5 Levels of VAXsimPLUS Monitor Screen Displays . . . . . . . . . . 5–38

5–6 Machine Check Exception During Executive . . . . . . . . . . . . . 5–45

5–7 Exception During Executive with No Parameters . . . . . . . . . 5–46

5–8 Other Exceptions with Parameters, No Machine Check . . . . . 5–46

5–9 KA681/KA691/KA692/KA694 Console Displays As Pointers to

FRUs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–48

5–10 H3604 Console Module Fuses . . . . . . . . . . . . . . . . . . . . . . . . 5–71

5–11 Loopback Connectors for Common Devices . . . . . . . . . . . . . . 5–76

A–1 Console Symbolic Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

A–2 Symbolic Addresses Used in Any Address Space . . . . . . . . . . A–8

A–3 Console Radix Specifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–8

A–4 Console Command Qualifiers . . . . . . . . . . . . . . . . . . . . . . . . . A–9

A–5 Command Keywords by Type . . . . . . . . . . . . . . . . . . . . . . . . . A–11

A–6 Console Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . A–11

B–1 Processor Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–9

B–2 IPR Address Space Decoding . . . . . . . . . . . . . . . . . . . . . . . . . B–16

C–1 System Identification Register . . . . . . . . . . . . . . . . . . . . . . . . C–3

C–2 System Identification Extension . . . . . . . . . . . . . . . . . . . . . . . C–4

C–3 Call-Back Entry Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–5

D–1 Firmware State Transition Table . . . . . . . . . . . . . . . . . . . . . . D–2

xii

Page 13

D–2 Restart Parameter Block Fields . . . . . . . . . . . . . . . . . . . . . . . D–6

D–3 VMB Argument List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–10

F–1 NVR0 (20140400): Console Program MailBoX (CPMBX) . . . . F–2

F–2 NVR1 (20140401) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–3

F–3 NVR2 (20140402) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–3

G–1 MOP Counter Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G–1

H–1 Preferred KFQSA Switch Settings . . . . . . . . . . . . . . . . . . . . . H–1

I–1 HALT Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–2

I–2 VMB Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–3

I–3 Console Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . I–4

xiii

Page 14

Page 15

This guide describes the procedures and tests used to maintain and

troubleshoot VAX 4000 Model 500A, 505A, 600A, 700A, and 705A systems,

which use the following kernels:

System Kernel

VAX 4000 Model 500A KA681

VAX 4000 Model 505A/600A KA691

VAX 4000 Model 700A KA692

VAX 4000 Model 705A KA694

Intended Audience

This guide is intended for use by Digital Equipment Corporation Service

personnel and qualified self-maintenance customers.

Warnings, Cautions, Notes

Warnings, cautions, and notes appear throughout this guide. They have the

following meanings:

Preface

WARNING Provides information to prevent personal injury.

CAUTION Provides information to prevent damage to equipment or software.

NOTE Provides general information about the current topic.

Conventions

The following convention indicates that the user enters the command at the

system prompt.

>>>SHOW DSSI

xv

Page 16

Page 17

System Maintenance Strategy

Any successful maintenance strategy is predicated on the proper understanding

and use of information services, service tools, service support and escalation

procedures, and field feedback. This chapter lists the various service

tools, information services, and service delivery methods used in system

maintenance.

1.1 Service Delivery Methodology

Before beginning any maintenance operation, you should be familiar with the

following:

• The site agreement

• Your local and area geography support and escalation procedures

• Your Digital Services product delivery plan

Service delivery methods are part of the service support and escalation

procedure. When appropriate, remote services should be part of the initial

system installation. Methods of service delivery include the following:

1

• Local support

• Remote call screening

• Remote diagnosis and system initiated service requests (using DSNLink,

SICL, MDS01, modem, etc.)

The recommended system installation includes:

• Hardware installation and acceptance testing. Acceptance testing

(Chapter 4) includes running ROM-based diagnostics and running

MDM to test Q–bus options.

• Software installation and acceptance testing. For example, using OpenVMS

Factory Installed Software (FIS), and then acceptance testing with UETP.

System Maintenance Strategy 1–1

Page 18

System Maintenance Strategy

1.1 Service Delivery Methodology

• Installation of the Symptom-Directed Diagnosis (SDD) toolkit

(VAXsimPLUS and SPEAR) and remote services tools and equipment

(this includes installing DSNlink, modems, etc., and enabling SICL). When

the installation is complete, the system should be able to dial out using

SICL, and the Digital Service Center should be able to call into the system.

Refer to your remote service delivery strategy.

If your service delivery methodology is not followed, service expenses for any

product could be excessive.

1.2 Product Service Tools and Utilities

This section lists the array of service tools and utilities available for acceptance

testing, diagnosis, and overall serviceability; and it provides recommendations

as for their use.

• OpenVMS Operating System Error Handling/Logging

The OpenVMS operating system provides recovery from errors, fault

handling, and event logging. The Error Report Formatter (ERF)

provides bit-to-text translation of the event logs for interpretation.

RECOMMENDED USE: Analysis of error logs is the primary method

of diagnosis and fault isolation. If the system is up, or the customer

allows the service engineer to bring the system up, this information

should be looked at first. Refer to Section 5.2 for information on

Product Fault Management and Symptom-Directed Diagnosis.

• Symptom-Directed Diagnostic (SDD) Tools (VAXsimPLUS)

SDD tools are used primarily for notification of the existence of errors

that have reached a critical threshold. SDD tools must be installed

during system installation or as soon as product support is provided.

SDD tools are not bundled with the OpenVMS operating system.

RECOMMENDED USE: Used primarily for onsite notification to

the user via mail or to a remote Digital support center via System

Initiated Call Logging (SICL). Refer to Section 5.2.9 for information on

VAXsimPLUS and SICL.

1–2 System Maintenance Strategy

Page 19

• ROM-Based Diagnostics

ROM-based diagnostics have significant advantages:

Load time is virtually nonexistent.

The boot path is more reliable.

Diagnosis is done in a more primitive state.

RECOMMENDED USE: The CPU ROM-based diagnostic facility is the

primary means of offline testing and diagnosis of the CPU, memory,

Ethernet, and DSSI subsystems. The ROM-based diagnostics are

used in the acceptance test procedures (Section 4.4) when installing

a system, adding a memory module, or replacing the following: CPU

module, memory module(s), backplane, DSSI device, or H3604 console

module. Use the ROM-based diagnostic error messages in Table 5–9 to

isolate FRUs.

• Firmware Console Commands

Several commands and utilities are needed in configuring a system and

setting and examining system and device parameters. For example, the

CONFIGURE command is used to determine the proper CSR addresses

for modules; the SHOW MEMORY, SHOW DSSI, and SHOW QBUS

commands are used to examine the configuration and memory error

status; and the SET HOST command is used to access the DUP driver

to configure DSSI parameters.

System Maintenance Strategy

1.2 Product Service Tools and Utilities

RECOMMENDED USE: Use console commands to configure the system

and in setting and examining device parameters. Refer to Section 3.8

for information on firmware commands and utilities. Appendix A

provides information on all available console commands.

• Option LEDs During Power-Up

Many options and modules have LEDs that display pass/fail self-test

results.

RECOMMENDED USE: Monitor option and module LEDs during

power-up to see if they pass their self-tests. Refer to Sections 4.2.2 and

4.2.3 for information on power-up tests for Q–bus and mass storage

devices. For more information on individual options, refer to your

Microsystems Options manual.

System Maintenance Strategy 1–3

Page 20

System Maintenance Strategy

1.2 Product Service Tools and Utilities

• Operating System Exercisers (OpenVMS UETP)

The User Environment Test Package (UETP) is an OpenVMS software

package designed to test whether the OpenVMS operating system is

installed correctly.

RECOMMENDED USE: Use UETP as part of acceptance testing to

ensure that the OpenVMS operating system is correctly installed.

UETP is also used to stress test the user’s environment and

configuration by simulating system operation under heavy loads.

• MicroVAX Diagnostic Monitor (MDM)

The loadable diagnostic MDM requires a minimum of Release 139 to

support VAX 4000 Model 500A/505A/600A/700A/705A systems. Consult

your MicroVAX Diagnostic Monitor User’s Guide for instructions on

running MDM.

RECOMMENDED USE: MDM is used primarily for testing Q–bus

options.

• Loopback Tests

Internal and external loopback tests can be used to isolate a failure

by testing segments of a particular control or data path. The loopback

tests are a subset of the ROM-based diagnostics and MDM diagnostics.

RECOMMENDED USE: Loopback tests can be used to isolate problems

with the console port, DSSI adapters, Ethernet controller, and many

common Q–bus options. Refer to Section 5.7 for instructions on

performing loopback tests.

• Crash Dumps

For fatal errors, the OpenVMS operating system will save the contents

of memory to a crash dump file, e.g., fatal bugchecks.

RECOMMENDED USE: Crash dump file analysis should be

performed by support. Saving a crash dump file for analysis requires

proper system settings. Refer to your OpenVMS operating system

documentation for instructions.

1–4 System Maintenance Strategy

Page 21

1.3 Information Services

Digital Services engineers may access several information resources, including

advanced database applications, online training courses, and remote diagnosis

tools. A brief description of some of these resources follows:

• Technical Information Management Architecture (TIMA)

TIMA is used by Digital Services to deliver technical and reference

information to its service engineers. One of the main benefits of TIMA

is the pooling of worldwide knowledge and expertise. Both service and

customer documentation for VAX 4000 systems are available on TIMA.

• Entry Systems Service Information Kits

Service documentation containing information on enclosures, CPUs,

and options, makes up the Entry Systems Service Information Kit.

The manual you are reading is part of the kit. Refer to your Guide

to Entry Systems Service Information Kits (EK–276A*–MI) for more

information.

• Training

Computer Based Instruction (CBI) and lecture lab courses are available

from the Digital training center:

System Maintenance Strategy

1.3 Information Services

VAX 4000 Model 500 System Installation and Troubleshooting (CBI

course, EY–I089E–EO (applicable for VAX 4000 Model 500A/505A

/600A /700A/705A systems)).

MicroVAX Installation and Troubleshooting (Lecture lab course,

EY–9408E–LO)

• Digital Services Product Delivery Plan (Hardware or Software)

The Product Delivery Plan documents Digital Services delivery

commitments. The plan is the communications vehicle used among the

various groups responsible for ensuring consistency between Digital

Services delivery strategies and engineering product strategies.

• Blitzes

Technical updates are ‘‘blitzed’’ to the field using mail and TIMA.

System Maintenance Strategy 1–5

Page 22

System Maintenance Strategy

1.3 Information Services

• Storage and Retrieval System (STARS)

Stars is a worldwide database for storing and retrieving technical

information. The STARS databases, which contain more than 150,000

entries, are updated daily.

Using STARS, a service specialist can quickly retrieve the most

up-to-date technical information via DSNlink or DSIN.

• VAX Notes

The company notes network has many conferences on the VAX. Review

the list of conferences in TURRIS::EASYNET_CONFERENCES.

• DSNlink

DSNlink software application lets the Digital Services Center

communicate electronically with the customer site. DSNlink serves as

the platform for the delivery of electronic services.

1.4 Field Feedback

Providing the proper feedback to the corporation is essential in closing the loop

on any service call. Consider the following when completing a service call:

• Repair tags should be filled out accurately and with as much symptom

information as possible so that repair centers can fix a problem.

• Call closeout information for Labor Activity Reporting System (LARS) or

Call-Handling and Management Planning (CHAMP) needs to be accurate.

• The site maintenance log, whether hardcopy or electronic, should provide a

chronicle of the performed maintenance.

1–6 System Maintenance Strategy

Page 23

CPU System Overview

This chapter provides an overview of the components that make up

KA681/KA691/KA692/KA694-based systems. These components are listed

below:

• CPU: KA681 (L4005–BA), KA691 (L4005–AA), KA692 (L4006–AA), or

KA694 (L4006–BA)

• MS690 memory modules

• BA440 enclosure components

H3604 console module

System control panel (SCP)

BA440 backplanes

Power supply

Fans

Caution

Static electricity can damage integrated circuits. Always use a

grounded wrist strap (PN 29–11762–00) and grounded work surface

when working with the internal parts of a computer system.

2

CPU System Overview 2–1

Page 24

CPU System Overview

2.1 CPU Module Features

2.1 CPU Module Features

The KA681/KA691/KA692/KA694 CPUs are quad-height VAX processor

modules that use the Q22–bus and DSSI bus. The CPUs are used in the

following systems:

System CPU

VAX 4000 Model 500A KA681

VAX 4000 Model 505A/600A KA691

VAX 4000 Model 700A KA692

VAX 4000 Model 705A KA694

The CPU module is designed for use in high-speed, real-time applications

and for multiuser, multitasking environments. The KA681/KA691/KA692

/KA694 employ multiple levels of cache memory to maximize performance. See

Figure 2–1 for a view of the major chips, LEDs, and connectors. Table 2–1

describes the CPU module components. See Figure 2–2 and Figure 2–3 for

block diagrams of the major functions.

The CPU module and MS690 memory modules combine to form the CPU

/memory subsystem that uses DSSI buses to communicate with mass storage

devices, the Q22–bus to communicate with I/O devices, and the Ethernet to

communicate across the network.

The CPU module and optional DSSI daughter board combine to expand the

DSSI buses’ capability to four ports. See Figure 2–5 for a view of the major

chips and connectors.

The CPU module is configured as an arbiter CPU on the Q22–bus, where it

arbitrates bus mastership and fields any on-board interrupt requests.

2–2 CPU System Overview

Page 25

CPU System Overview

2.1 CPU Module Features

Figure 2–1 KA681/KA691/KA692/KA694 CPU Module Component Side

Console Connector, J2

BCache

(Tag

Store)

Run LED

DC246

NVAX

Diagnostic LEDs

DC243

NCA

DC541

SGEC

E-Net ROM

CDAL 2 Connector

DC542

SHAC

CLK

DC511

Firmware

ROMs

SSC

B-CACHE

(Data Store)

Backplane Connector, J1

DC244

NMC

Obit Rams

DC527

CQBIC

CDAL 1 Connector

DC542

SHAC

MLO-010827

CPU System Overview 2–3

Page 26

CPU System Overview

2.1 CPU Module Features

Table 2–1 KA681/KA691/KA692/KA694 CPU Module Components

Components Function

DC246 (NVAX) Central processor unit. Contains a 64-entry translation buffer

KA694: Central processor unit has 9-ns cycle time.)

Backup cache RAMs KA681: 128-KB backup cache (B-cache).

KA694: 2-MB backup cache (B-cache).)

DC243 (NCA) NDAL to CDAL I/O bus interface chip.

DC244 (NMC) Main memory controller (also provides ECC protection).

DC527 (CQBIC) Q22–bus interface.

DC541 (SGEC) Ethernet interface.

Ethernet Station Address ROM Provides unique hardware address.

DC542 (SHAC) DSSI interface chips (2).

DC511 (SSC) System support chip.

DC509 (CLK) Clock.

Firmware ROMs Two resident firmware chips, each 256 K by 8 bits of FLASH

Obit RAMs The ECC protected ownership-bit RAMs provide coherency

Console connector 100-pin for connection to the H3604 console module (J2).

Backplane connector 270-pin for connection to backplane for Q22–bus, DSSI bus,

Run LED Indicates that the CPU module is receiving power.

Diagnostic LEDs A hexadecimal value displays on the four diagnostic LEDs.

integral floating-point unit, 2-KB virtual instruction stream

cache (VIC), 8-KB physical instruction and data stream

primary cache (P-cache), and backup cache control and error

correction code (ECC).

KA681: Central processor unit has 14-ns cycle time.

KA691: Central processor unit has 12-ns cycle time.

KA692: Central processor unit has 10-ns cycle time.

KA691: 512-KB backup cache (B-cache).

KA692: 2-MB backup cache (B-cache).

programmable EPROMS for a total of 512 KB.

between backup cache and memory.

and memory interconnect (J1).

The values correspond to the decimal value displayed on the

H3604 console module LED.

2–4 CPU System Overview

Page 27

CPU System Overview

2.1 CPU Module Features

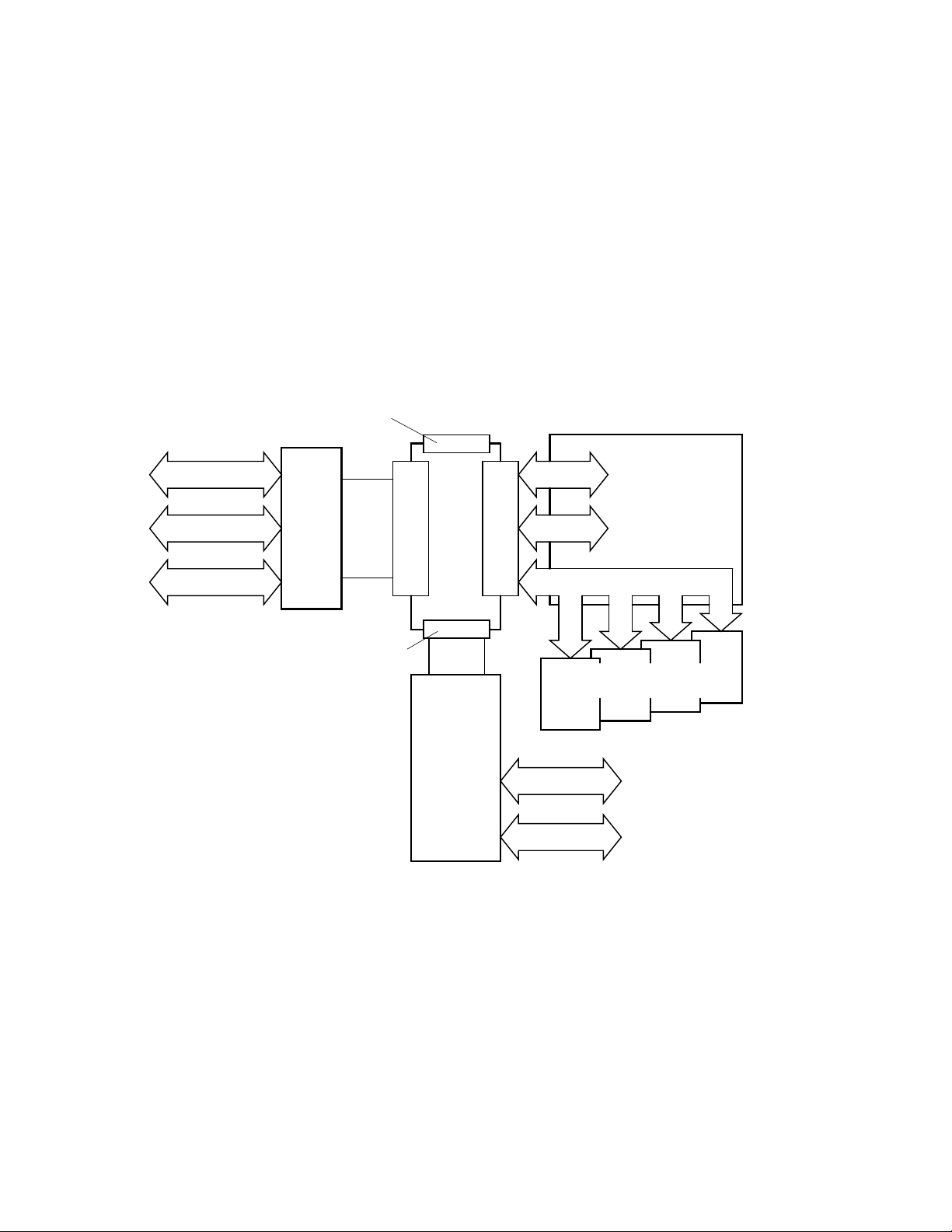

Figure 2–2 KA681/KA691/KA692/KA694 Kernel System Functional Diagram

CDAL 2 Connector

(96-Pin)

Backplane Interconnect

DSSI Bus #1

Ethernet

Serial Line

H3604

Console

Module

CDAL 1 Connector

(96-Pin)

Ribbon

Cable

Console Connector

(100-Pin)

CPU

Module

DSSI

Daughter

Board

Backplane Connector

DSSI Bus #0

(270-Pin)

Q22-bus

NMI Bus (150-Pin)

MS690 Memory Modules

(1 minimum/4 maximum)

DSSI Bus #2

DSSI Bus #3

To Mass Storage

Slots

To Q22-bus Slots

MLO-010206

CPU System Overview 2–5

Page 28

CPU System Overview

2.1 CPU Module Features

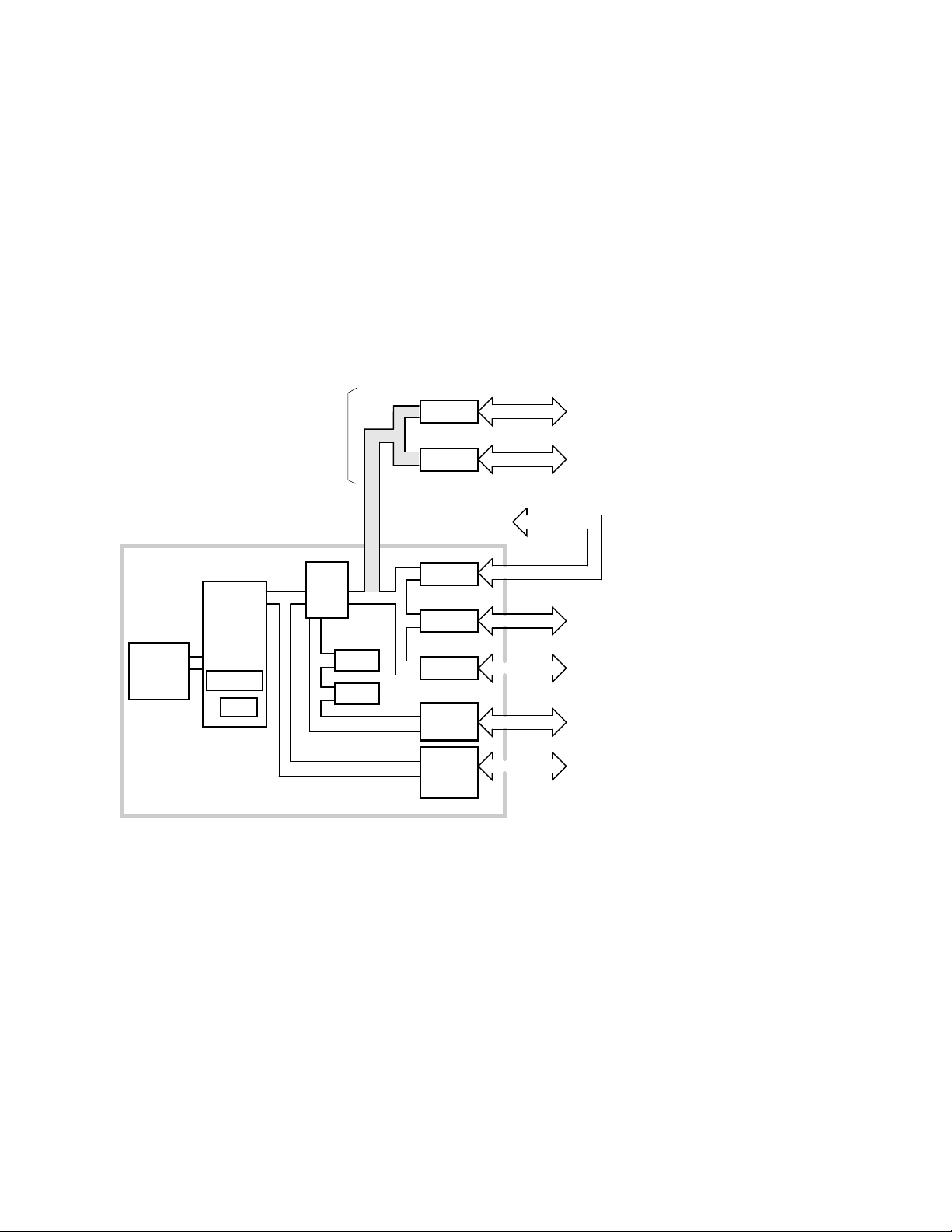

Figure 2–3 KA681/KA691/KA692/KA694 CPU Module Block Diagram

B-cache

Optional

via

KFDDB DSSI

Daughter Board

NVAX

CPU

P-cache

VIC

NDAL

NCA

CDAL 1

SSC

ROM

CDAL 2

SHAC3

SHAC4

To Console Module

SHAC1

SHAC2

SGEC

CQBIC

NMC

DSSI #2

DSSI #3

DSSI #1

DSSI #0

Ethernet

Q22-bus

To Memory

To QBus

Bukkhead

To QBus

Bukkhead

To BA440

Disks

To Console

Module

To BA440

Backplane

MLO-007262

2.2 MS690 Memory Modules

The MS690 memory module is a double-sided, quad-height memory board that

uses a 150-pin, high-density connector to communicate to the CPU module.

MS690 memory modules are ECC protected via the NMC chip on the CPU

module.

The MS690 memories are available in four variations:

• MS690–BA (L4004–BA) 32 MB memory (not used on KA692 or KA694)

• MS690–CA (L4004–CA) 64 MB memory

• MS690–DA (L4004–DA) 128 MB memory

2–6 CPU System Overview

Page 29

CPU System Overview

2.2 MS690 Memory Modules

KA681/KA691/KA692/KA694-based systems allow for any combination of up to

four MS690 memory arrays providing a memory capacity from 32 Mbytes up to

512 Mbytes, with the exception that the MS690-BA may not be used with the

KA692 or KA694.

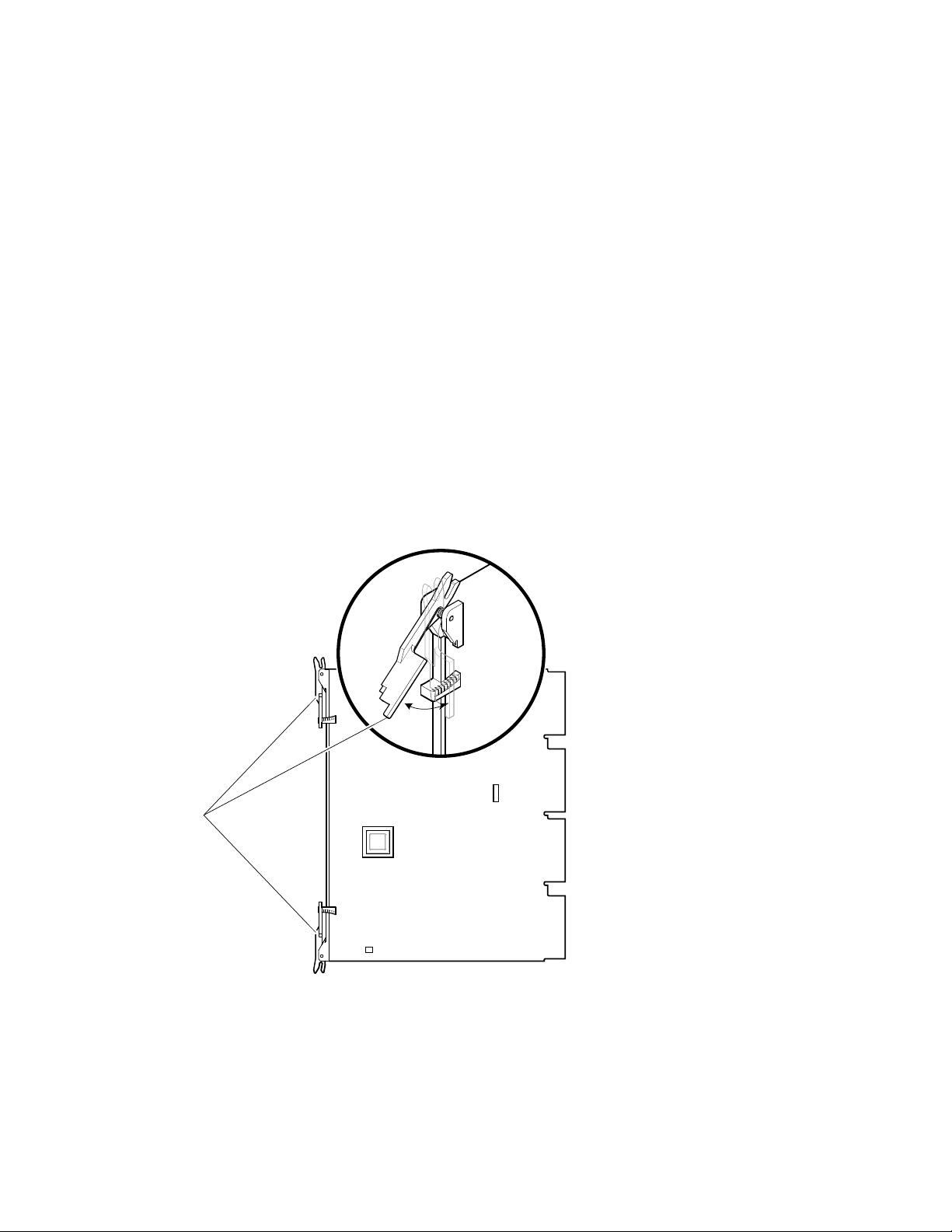

Figure 2–4 shows a sample memory module, which, like the CPU module,

uses ejector handles designed to ensure proper seating of the modules in the

backplane connectors.

Figure 2–4 Ratchet Handles for CPU and Memory Modules

Ejector

Handles

2.3 (Optional) DSSI Daughter Board

KA681/KA691/KA692/KA694-based systems have a connector for an optional

DSSI bus daughter board. The optional DSSI daughter board contains two

SHAC chips which increase the CPU’s total DSSI bus capability to four ports.

See Figure 2–5 for a view of the major chips and connectors. Table 2–2

describes the DSSI bus daughter board components and their functions.

MLO-004227

CPU System Overview 2–7

Page 30

CPU System Overview

2.3 (Optional) DSSI Daughter Board

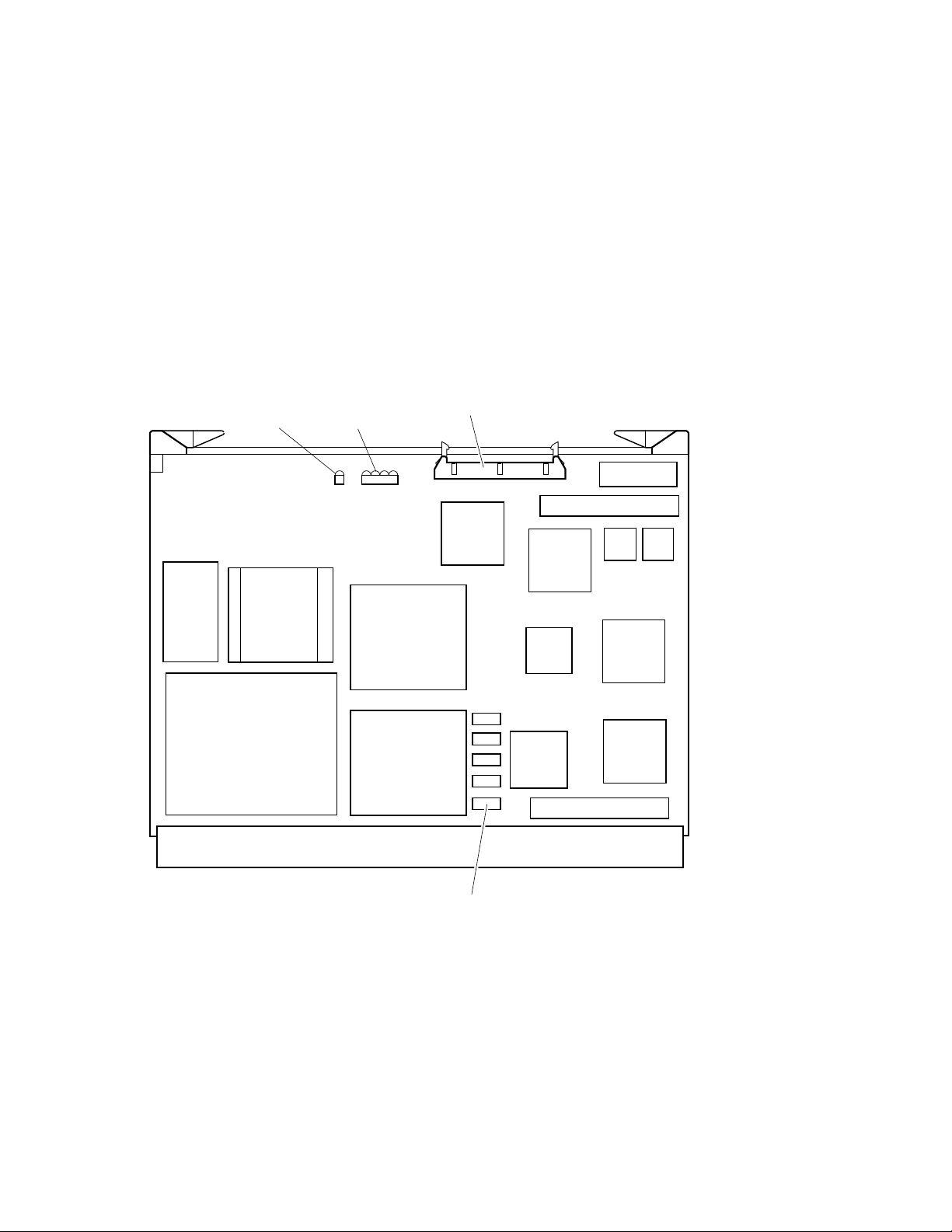

Figure 2–5 (Optional) DSSI Module Component Side

Bus 3

DSSI Connector

DSSI 3

Terminator

Sockets

DC542

SHAC

DC542

SHAC

Bus 2

DSSI Connector

DSSI 2

Terminator

Sockets

96-Pin

Mother Board

Connector

2–8 CPU System Overview

MLO-010209

Page 31

Table 2–2 (Optional) DSSI Bus Daughter Board Components

Components Function

DC542 (SHAC) DSSI interface chips (2).

Bus 2 DSSI connector Connect DSSI bus 2 here.

Bus 3 DSSI connector Connect DSSI bus 3 here.

DSSI Bus 2 terminator sockets Reserved for future use.

DSSI Bus 3 terminator sockets Reserved for future use.

96-pin mother board connector Connects to mother board.

2.4 BA440 Enclosure Components

KA681/KA691/KA692/KA694-based systems use the BA440 enclosure. A brief

description of the components that make up the BA440 enclosure follows.

For information on FRU removal and replacement procedures refer to the

BA430/BA440 Enclosure Maintenance manual.

2.4.1 H3604 Console Module

The H3604 console module covers the five slots dedicated to the CPU and

memory modules (one slot for the KA681/KA691/KA692/KA694, and four

available slots for MS690 memory modules). Switches on the console module

allow you to configure the kernel. The console module also provides the

connectors for a serial line console device, an external DSSI bus, and the

Ethernet. See Figures 2–6 and 2–7.

CPU System Overview

2.3 (Optional) DSSI Daughter Board

CPU System Overview 2–9

Page 32

CPU System Overview

2.4 BA440 Enclosure Components

Figure 2–6 H3604 Console Module (Front)

Console Module

Power-Up

Mode Switch

Baud Rate

Select Switch

LED Display

DSSI

Connectors

(External Bus,

Bus 1)

Baud

300___________0

600___________1

1200__________2

2400__________3

4800__________4

9600__________5

19200_________6

38400_________7

X

Bus 0

Y

Console Jack

Break Enable/

Disable Switch

Bus 1

Bus Node

ID Plugs

Ethernet

Connector

Switch

Standard

Ethernet

Connector

ThinWire

Ethernet

Connector

2–10 CPU System Overview

MLO-006350

Page 33

CPU System Overview

2.4 BA440 Enclosure Components

The front of the console module has the components listed in Table 2–3.

Table 2–3 H3604 Console Module Controls and Indicators

Control/Indicator Function

Power-Up Mode Switch This three-position rotary switch determines how

Baud Rate Select switch The Baud Rate Select switch is used to set the

Console serial MMJ connector This console terminal connector provides the RS–

the system responds at power-up.

Language Inquiry Mode (in the top position,

indicated by a profile of a face) causes the system

to display a language selection menu at power-up

if the console terminal has multinational character

set (MCS) support. Also, if a default boot device

has not been selected, this mode causes the system

to issue a list of bootable devices and prompts you

to select a device from the list. Once a device is

selected, the system autoboots from that device

each time you turn it on.

Run Mode (in the middle position, indicated by an

arrow) is the normal operating setting.

Loopback Test Mode (in the bottom position,

indicated by a T in a circle) causes the system

to run loopback tests on the console serial line at

power-up.

system’s baud rate to match that of the console

terminal. The factory setting is position 5 (9600).

423 interface for the console terminal.

LED Display The LED displays the testing sequence during

power-up.

(continued on next page)

CPU System Overview 2–11

Page 34

CPU System Overview

2.4 BA440 Enclosure Components

Table 2–3 (Cont.) H3604 Console Module Controls and Indicators

Control/Indicator Function

Break Enable/Disable switch When the switch is down (position 0), breaks are

Two DSSI bus node ID plugs KA681/KA691/KA692/KA694-based systems have

disabled. When the switch is up (position 1), breaks

are enabled. When breaks are enabled, pressing

Break

on the console terminal halts the processor

and transfers control to the console program. Using

the console command SET CONTROLP, you can

specify the control character,

Break

to initiate a break signal.

The Break Enable/Disable switch also controls

what happens at power-up. When breaks are

disabled (down, position 0), the system attempts

to automatically boot software at power-up. When

breaks are enabled (up, position 1), the system

enters console mode (indicated by the >>>prompt)

at power-up.

Using the console command, SET HALT REBOOT

or SET HALT RESTART_REBOOT, you can set

your system to automatically boot software after

the system is halted due to pressing

two separate Digital Storage Systems Interconnect

(DSSI) buses. Two DSSI bus node ID plugs, one

for the internal DSSI bus, Bus 0, and one for the

external bus, Bus 1, identify the bus nodes of the

DSSI adapters, which are part of the CPU.

Ctrl/P

, rather than

Break

.

Two DSSI connectors for Bus 1 Two in/out DSSI connectors, labeled X and Y, on the

2–12 CPU System Overview

console module allow you to expand the system by

connecting additional mass storage devices to the

second DSSI bus. You can also share mass storage

devices with another system by forming a DSSI

VAXcluster configuration.

(continued on next page)

Page 35

CPU System Overview

2.4 BA440 Enclosure Components

Table 2–3 (Cont.) H3604 Console Module Controls and Indicators

Control/Indicator Function

Ethernet port features The console module has two Ethernet connectors:

a BNC-type connector for ThinWire Ethernet,

and a 15-pin connector for a standard Ethernet

transceiver cable. The Ethernet connector switch

allows you to set the type of connection. To use

the standard transceiver cable connection, set the

switch to the up position. To use the ThinWire cable

connection, set the switch to the down position. A

green indicator light (LED) for each connector

indicates which connection is active.

Figure 2–7 H3604 Console Module (Back)

Battery Backup Unit

W2

W4

J1

J1 = TOY Clock Battery

J5 = H3604 Power

J6

F2

F1F4

J5

F3

J6 = CPU Interface

W2 = Remote Boot Enable

W4 = FEPROM Write Enable

F1 = ThinWire Ethernet Power, 0.5 A

PN = 12-09159-00

F2 = -12V Power, 0.062 A

PN = 90-09122-00

F3 = DSSI Terminator Power, 2.0 A

PN = 12-10929-06

F4 = Standard Ethernet Power, 1.5 A

PN = 12-10929-08

MLO-006351

CPU System Overview 2–13

Page 36

CPU System Overview

2.4 BA440 Enclosure Components

The back of the console module has the components listed in Table 2–4.

Table 2–4 H3604 Console Module (Back)

Component Function

Battery Backup Unit Provides battery backup power to the SSC

TOY Clock Battery connector (J1) Provides the connection between the

H3604 power connector (J5) Four-pin power connector to power harness

CPU Interface connector (J6) 100-pin connector to the CPU module.

ThinWire Ethernet Power Fuse (F1) Protects ThinWire Ethernet.

-12 V Power Fuse (F2) Protects console serial line.

DSSI Terminator Power Fuse (F3) Protects against shorts from the accidental

Standard Ethernet Power Fuse (F4) Protects Standard Ethernet.

Remote Boot Enable jumper (W2) Not used

RAM.

battery backup unit and the SSC RAM.

module.

grounding of the DSSI cable power pin.

FEPROM Write Enable jumper (W4) This jumper must be in the write enable

-9 V DC/DC converter Generates voltage for the Ethernet

2–14 CPU System Overview

position to update FEPROMs on the CPU

module. Refer to Chapter 6 for procedures

on updating ROMs.

transceiver.

(continued on next page)

Page 37

2.4 BA440 Enclosure Components

Table 2–4 (Cont.) H3604 Console Module (Back)

Component Function

CPU System Overview

Ethernet serial transceiver chip

Serial Interface Adapter (SIA)

TOY clock oscillator Time of year oscillator. Privides TOY signal

Performs Ethernet serial transactions.

for the TOY clock in the system support

chip (SSC) on the CPU module.

CPU System Overview 2–15

Page 38

CPU System Overview

2.4 BA440 Enclosure Components

2.4.2 System Control Panel (SCP)

The system control panel (SCP) (Figure 2–8) provides the controls to halt the

processor (external halt type) and enter console mode, as well as to restart the

system and return the processor state to power-up and self tests.

Figure 2–8 System Control Panel

Over Temperature

Warning Indicator

DC OK Indicator

Halt Button

Restart Button

2–16 CPU System Overview

MLO-008652

Page 39

CPU System Overview

2.4 BA440 Enclosure Components

The SCP has the controls and indicators listed in Table 2–5.

Table 2–5 System Control Panel Controls and Indicators

Control/Indicator Function

Over Temperature Warning

indicator

DC OK indicator The green DC OK indicator shows that the power

Halt Button The Halt button is a two-position button. When you

The red Over Temperature Warning indicator

flashes to indicate that the system’s internal

temperature is approaching a level that may cause

system components to overheat. In addition to the

flashing Over Temperature Warning indicator, an

audible alarm also provides warning of a possible

over temperature condition. If the components

continue to heat, the system will automatically shut

down to prevent components from being damaged.

supply voltages are within the correct operating

range.

press the button, the system halts. A red indicator

on the Halt button lights when the button is set

to the in position. Before you can enter console

commands, press the Halt button again to return

it to the out position. When the Halt button is

returned to the out position, the console mode

prompt >>> is displayed on the console terminal

screen. Now you can enter console commands. If

you inadvertently press the Halt button, type ‘‘c

Return

’’ to continue.

Caution

Pressing the Halt button halts

the system regardless of the

setting of the Break Enable

/Disable switch on the console

module.

(continued on next page)

CPU System Overview 2–17

Page 40

CPU System Overview

2.4 BA440 Enclosure Components

Table 2–5 (Cont.) System Control Panel Controls and Indicators

Control/Indicator Function

Restart Button The Restart button has a green indicator. When

you press the Restart button, the system returns to

a power-up condition and self-tests are run. If you

have specified a device as the boot device and if the

Break/Enable Disable switch is set to disable, the

system will reboot system software.

2–18 CPU System Overview

Page 41

2.4.3 BA440 Backplane

KA681/KA691/KA692/KA694-based systems use the BA440 (54–19354–01)

backplane, shown in Figure 2–9.

Figure 2–9 BA440 Backplane

Mass Storage

Connectors

CPU System Overview

2.4 BA440 Enclosure Components

Vterm Module

SCP

Connector

Module

Connectors

1110 9 8 7 6 4 3 2

12

Q-bus

Option

5

CPU

Power

Board

for H3604

Power Supply

Connectors

1

Fan Connector

Memory

MLO-007695

CPU System Overview 2–19

Page 42

CPU System Overview

2.4 BA440 Enclosure Components

2.4.4 Power Supply

The BA440 enclosure uses the H7874 power supply (Figure 2–10). Table 2–6

describes the power supply components.

Figure 2–10 H7874 Power Supply

Power Switch

AC Present Indicator

DC OK Indicator

Fan Failure

Indicator

Over Temperature

Condition Indicator

Power Bus

Connectors

2–20 CPU System Overview

Power Cable

Connector

MLO-004040

Page 43

CPU System Overview

2.4 BA440 Enclosure Components

Table 2–6 H7874 Power Supply Switches, Controls, and Indicators

Control/Indicator Function

AC Present indicator (orange) Lights when the Power switch is set to on (1), and

Power switch The Power switch is used to turn system power on

DC OK indicator (green) When the DC OK indicator is lit, the voltages are

Fan Failure indicator (amber) The Fan Failure indicator lights if either of the

Over Temperature indicator

(amber)

the ac voltage is present at the input of the power

supply.

and off. The off position is indicated by a 0; the on

position is indicated by a 1.

The Power switch also functions as the system

circuit breaker. In the event of a power surge, the

breaker will trip causing the power switch to return

to the off position (0). Turning on the system resets

the circuit breaker. If the circuit breaker trips, wait

one minute before turning the system back on.

within the correct operating range. An unlit DC OK

indicator shows a problem with the power supply.

two cooling fans stops working. The power supply

will automatically shut down the system as a

precautionary measure when a fan failure is

detected.

The Over Temperature indicator lights if the

system has shut down due to an over temperature

condition.

(continued on next page)

CPU System Overview 2–21

Page 44

CPU System Overview

2.4 BA440 Enclosure Components

Table 2–6 (Cont.) H7874 Power Supply Switches, Controls, and Indicators

Control/Indicator Function

Power bus connectors Three power bus connectors allow you to configure

a power bus for systems expanded with a system

expander. The power bus allows you to turn power

on and off for the system through one power supply

designated as the main power supply: this way, one

power switch can control power for an expanded

system.

Note

DSSI VAXcluster systems

should not be configured with

a power bus. Inadvertently

shutting off a host system

and bringing down the cluster

defeats the added reliability of

a DSSI VAXcluster.

MO The main out connector sends the power control

bus signal to the expander. One end of a power bus

cable is connected here; the other end is connected

to the SI (secondary in) connector of the expander

power supply.

SI The secondary in connector receives the power bus

SO The secondary out connector sends the signal down

2–22 CPU System Overview

control signal from the main power supply. In a

power bus with more than one expander, the power

bus signal is passed along using the secondary in

and out connectors.

the power bus for configurations of more than one

expander.

Page 45

2.4.5 System Airflow

Two fans are located under the card cage (Figure 2–11). The power supply

monitors the fans. If either fan stops working, the Fan Failure indicator

on the power supply lights, and the system automatically shuts down as a

precautionary measure.

Figure 2–11 Fans

CPU System Overview

2.4 BA440 Enclosure Components

Captive Screws

MLO-004220

Some system managers request that the fans run at the maximum rate

at all times to take advantage of a potential increase in system reliability.

The system environment must not exceed the limits described in the Site

Preparation manual. Figure 2–12 shows the location of the fan speed control

(FSC) jumper on the bottom of the power supply. Setting the FSC jumper to

disable causes the fans to run at the maximum rate.

CPU System Overview 2–23

Page 46

CPU System Overview

2.4 BA440 Enclosure Components

Figure 2–12 Fan Speed Control (FSC) Jumper Location

FSC

Enabled

(Factory

Setting)

FSC

Disabled

2–24 CPU System Overview

MLO-004204

Page 47

System Setup and Configuration

This chapter describes the guidelines for the configuration of a KA681/KA691

/KA692/KA694-based system. Configuration issues covered in this chapter

include module order, mass storage configurations, system expansion, DSSI

VAXcluster configurations, and firmware commands and utilities used in

system configuration.

3.1 CPU and Memory Module Order

The five right-most BA440 backplane slots are dedicated to CPU and memory

modules. The number and type of option modules installed in slots 6 through

12 depend on your configuration. If you only have two DSSI ports, then slots

6 through 12 are available for Q–bus option modules. If your system has

four CPU DSSI ports, then slots 6 through 10 are available for Q–bus option

modules and slots 11 and 12 are DSSI bus bulkheads. See Table 3–1.

Table 3–1 BA440 Module Order

Slot Module

3

1 through 4 Reserved for up to four MS690 memory modules. MS690

modules are installed from left to right with no gaps: first

memory module in slot 4, second memory module in slot 3,

and so on.

Note

Proper placement of memory modules

is necessary for FRU isolation using

error logs.

(continued on next page)

System Setup and Configuration 3–1

Page 48

System Setup and Configuration

3.1 CPU and Memory Module Order

Table 3–1 (Cont.) BA440 Module Order

Slot Module

5 CPU module: KA681 (L4005–BA), KA691 (L4005-AA),

6 through 12 Q–bus options

OR

6 through 10 Q–bus options

11 and 12 DSSI ports

OR

6 through 9 Q–bus options

10 and 11 DSSI ports when M9404 is installed in slot 12

KA692 (L4006-AA), KA694 (L4006–BA)

A system can have up to four memory modules. Memory modules are available

in 32 MB (MS690–BA), 64 MB (MS690–CA), and 128 MB (MS690–DA), and

can be used in any combination. The firmware logically configures the memory

modules at power-up.

Note

The MS690–BA may not be used with the KA692 or KA694 CPU

modules.

3.1.1 Installing Add-On MS690 Memory Modules

Perform the following steps to install add-on MS690 memory module(s). You do

not set any jumpers or switches on the memory module. The memory address

for the memory module is mapped by the system.

Turn off the system before installing modules. Installing modules while

this system is powered up can damage the modules.

1. Two captive screws hold the console module (H3604) in place. To loosen,

both screws should be turned counterclockwise. The console module is

hinged on the left. Swing the assembly open.

3–2 System Setup and Configuration

Caution

Page 49

System Setup and Configuration

3.1 CPU and Memory Module Order

Note

Two cables connect to the H3604 console module: a ribbon cable which

connects to the CPU module; and a four-pin power harness connects to

a power harness module (also known as the power board H3604) which

plugs into the backplane. The power harness module is located directly

to the right of the CPU module.

2. Install the module(s) starting with the first empty slot, which is located on

the right side of the power harness module. The power harness module is

located between the CPU module (slot 5) and the first memory module (slot

4).

The memory module(s) must be installed in adjacent slots with no empty

slots between. Slots 12 through 6 are Q–bus slots, or slots 10 through 6 are

Q–bus slots and slots 12 and 11 are optional DSSI slots; slot 5 is the CPU

slot; and slots 4 through 1 are the memory module slots.

3. Make sure the ratchet handles on the memory module are on the right side

of the module.

Wearing the antistatic wrist strap, install the memory module in the first

available memory slot to the right of the CPU. Ensure that the memory

module is vertically aligned. Push the memory module in until the ratchet

handles engage with the enclosure frame. Push the ratchet handles inward

toward the rear of the cabinet until the memory module is firmly seated

in the backplane. When the memory module is firmly seated, the ratchet

handles will lock the module in place.

Note

The CPU and MS690 memory modules are equipped with ratchet

handles (Figure 3–1) which are shipped in a horizontal position. The

ratchet handles are designed to ensure that the modules are properly

seated in the backplane connectors.

4. Close the H3604 console module and lock the 1/4-turn captive screws.

5. To identify the memory module, place the MS690 option label (supplied

in the option kit) in the proper location on the H3604 panel. Indicate the

revision number and memory option (BA, CA, or DA).

System Setup and Configuration 3–3

Page 50

System Setup and Configuration

3.1 CPU and Memory Module Order

Figure 3–1 Memory Module Ratchet Handles

Ejector

Handles

MLO-008453

6. Refer to Chapter 4 for information on initialization and acceptance testing.

3.2 General Module Order for Q–Bus Options

The order of the supported Q–bus options in the backplane depends on four

factors:

• Relative use of devices in the system

• Expected performance of each device relative to other devices

• The ability of a device to tolerate delays between bus requests and bus

grants (called delay tolerance or interrupt latency)

• The tendency of a device to prevent other devices farther from the CPU

from accessing the bus

3–4 System Setup and Configuration

Page 51

System Setup and Configuration

3.2 General Module Order for Q–Bus Options

The supported options arranged by type are:

Communications

CXA16–AA/AF: 16-line DEC–423 asynchronous controller

CXB16–AA/AF: 16-line RS–422 asynchronous controller

CXY08–AA/AF: 8-line RS–232C asynchronous controller with modem

DEFQA–SA/SF: Q–bus FDDI adapter

DEFQA–DA/DF: Q–bus FDDI adapter

DEQRA–CA: Token Ring Network Controller

DESQA–SA/SF: ThinWire Ethernet adapter

DFA01–AA/AF: 2400/1200 BPS modem

DIV32–SA/SF: Q–bus ISDN basic rate access interface

DPV11–SA/SF: Q–bus synchronous programmable interface

DRV1W–SA/SF: General purpose 16-bit parallel DMA interface

DRV1J–SA/SF: Q–bus parallel interface

DSV11–SA/SF: Q–bus 2-line synchronous

KMV1A–SA/SF: Single-line programmable controller with DMA

General

ADQ32–SA/SF: 32-channel ADC module

ADV11–SA/SF: 16-channel ADC module

AXV11–SA/SF: 16-channel ADC, 2-channel DAC module

DRQ3B–SA/SF: Q–bus parallel I/O interface

DTC05–SA: Digital encoded voice, multifunction

IBQ01–SA/SF: DECscan/BITBUS controller

IEQ11–SA/SF: Dual-bit DMA serial Q–bus controller

KITHA–AA: Mira AS option

KWV11–SA/SF: Programmable real-time clock

LPV11–SA/SF: Line printer controller

MRV11: Q–bus, universal socket, 32-Kbyte EPROM

VS30U–GA/G3/G4: Graphics option

Mass Storage, Tape, Pedestal Expansions

EF51R–AA/AF: 107-Mbyte solid state storage element with data retention

EF52R–AA/AF: 205-Mbyte solid state storage element with data retention

EF53–AA/AF: 267-Mbyte solid state storage element without data retention

HSD05–JA/JF: DSSI to SCSI converter

RF35E–AA: 852-Mbyte half-height DSSI integrated storage element

RF352–AA/AF: Two RF35s for installation in one 5.25-inch storage cavity

RF36E–AA/AF: 1.6-Gbyte half-height DSSI integrated storage element

RF362–AA/AF: Two RF36s for installation in one 5.25-inch storage cavity

RF73E–AA/AF: 2.0-Gbyte full-height DSSI integrated storage element

RF72E–AA/AF: 1.0-Gbyte full-height DSSI integrated storage element

System Setup and Configuration 3–5

Page 52

System Setup and Configuration

3.2 General Module Order for Q–Bus Options

RF71E–AA/AF: 400-Mbyte full-height DSSI integrated storage element

RF31E–AA/AF: 381-Mbyte half-height DSSI integrated storage element

RF31T–AA/AF: 381-Mbyte full-height DSSI integrated storage element

RF74E–AA/AF: 3.75-Gbyte full-height DSSI integrated storage element

TF85E–JA/JF: 2.6-Gbyte DSSI integrated storage element with 5.25-inch

cartridge

TF85–TA: 3.75-Gbyte DSSI tape drive in table top enclosure

TF86E–JA/JF: 6.0-Gbyte DSSI tape driver ISE for BA400-series 5.25-inch

storage cavity

TLZ04–JA/JF/GA: 1.2-Gbyte cassette (DAT) tape drive (requires KZQSA

storage adapter)

TLZ06–GA: 2.0-/4.0-Gbyte tabletop 4mm DAT drive (requires KEQSA SCSI

adapter)

TK70E–AA/AF/TQK70–SA/SF: 5.25-inch cartridge, 296-Mbyte tape drive,

tape controller

TK50E–AA/AF/TQK50–SA/SF: 5.25-inch cartridge, 95-Mbyte tape drive,

tape controller

KLESI–SA: Q–bus to LESI adapter

KFQSA–SE/SG: DSSI Q–bus adapter

KZQSA–SA/SF: Storage adapter for TLZ04 tape drive and RRD42 compact

disc drive

RA81/82: Storage array (separate cabinets only)

RA90/92: Storage array (separate cabinets only)

KDA50–SE/SG: SDI Q–bus adapter

KRQ50–SA/SF: Q–bus controller for RRD40–DC

TU81E–SA/SB: Magnetic tape (requires KLESI controller)

TSV05–SE/SF/SH/SJ: Q–bus TS05 magnetic tape controller

B400X: Expansion box with 10 Q–bus slots and up to 4 ISEs

R400X–B9: Expansion box with up to 7 RF-series ISEs