Page 1

DECstation 5000/

DECsystem 5000

Model 200

MaintenanceGuide

EK-370AA-MG-002

digital equipment corporation

maynard, massachusetts

Page 2

First printing, April 1990

Second printing, October 1990

The information in this document is subject to change without notice and should

not be construed as a commitment by Digital Equipment Corporation. Digital

Equipment Corporation assumes no responsibility for any errors that may appear

in this document.

The software described in this document is furnished under a license and may be

used or copied only in accordance with the terms of such license.

Digital Equipment Corporation assumes no responsibility for the use or reliability

of its software on equipment that is not supplied by Digital or its affiliated

companies.

© Digital Equipment Corporation 1990.

All Rights Reserved

Printed in U.S.A.

USA

This equipment generates, uses, and may emit radio frequency energy. The

equipment has been type tested and found to comply with the limits for a Class

A computing device pursuant to Subpart J of Part 15 of FCC Rules, which

are designed to provide reasonable protection against such radio frequency

interference. Operation of this equipment in a residential area may cause

interference in which case the user at his own expense will be required to take

whatever measures may be required to correct the interference.

The following are trademarks of Digital Equipment Corporation:

DEC PDP VAXBI

DECnet ThinWire VAXcluster

DECstation TURBOchannel VAXstation

DECsystem ULTRIX VMS

DECUS ULTRIX-32 VT

MicroVAX UNIBUS

MicroVMS VAX

dt

Page 3

Contents

Using This Guide ........................................... xvii

1 A Look at DECstation/DECsystem 5000 Model 200

Hardware

System Hardware Configurations . . . .................... 1–2

Basic System Hardware............................... 1–4

System Unit . . .................................... 1–4

System Unit Controls and Indicators................. 1–6

System Unit Connectors............................ 1–7

Hardware Options.................................... 1–9

Additional Memory Modules ........................ 1–9

Optional TURBOchannel Modules ................... 1–10

Drives ........................................... 1–10

Monitors and Terminals ............................ 1–10

Keyboard and Mouse . . ............................ 1–10

For Further Information . . ............................ 1–10

2 Service Operations

Using an Antistatic Kit . . . ............................ 2–2

Using an Alternate Terminal........................... 2–3

Removing and Installing the System Unit Cover .......... 2–5

To Remove the System Unit Cover ................... 2–6

To Install the System Unit Cover .................... 2–6

Removing and Installing the Front Cover Plate........... 2–7

To Remove the Front Cover Plate.................... 2–8

To Install the Front Cover Plate . .................... 2–8

iii

Page 4

Removing and Installing a Serial Number Plate .......... 2–9

To Remove a Serial Number Plate ................... 2–9

To Install a Serial Number Plate .................... 2–9

Removing and Installing Loopback Connectors and

Terminators ......................................... 2–11

To Remove a ThinWire Terminator................... 2–12

To Install a ThinWire Terminator.................... 2–12

To Remove a ThickWire Loopback Connector .......... 2–13

To Install a ThickWire Loopback Connector ........... 2–13

To Remove a Communications Loopback Connector . . . . 2–14

To Install a Communications Loopback Connector. . .. . . 2–14

To Remove a SCSI Chain Terminator ................ 2–15

To Install a SCSI Chain Terminator ................. 2–15

To Remove a Communications Line Adapter .......... 2–16

To Install a Communications Line Adapter. ........... 2–16

Entering Console and Operating Modes ................. 2–17

To Enter Console Mode ............................ 2–18

To Enter Operating Mode .......................... 2–18

Using Console Command Passwords .................... 2–19

To Set or Change a Password . . . .................... 2–19

To Remove a Requirement for a Password . ........... 2–19

To Erase a Password You Do Not Know . . . ........... 2–20

Inserting and removing a clear-NVR jumper . . . . 2–21

Booting the System Software .......................... 2–23

Shutting Down the System Software .................... 2–24

3 Troubleshooting Tools

Using Tests ......................................... 3–2

Using Slot Numbers in Test Commands and Error

Messages ........................................ 3–2

Running Power-Up Self-Tests .......................... 3–3

Running Subtests .................................... 3–4

Running Individual Tests........................... 3–4

Running Test Scripts . . ............................ 3–5

Displaying Lists of Available Tests ................... 3–5

To display existing scripts that test an individual

module .................................... 3–6

Creating Test Scripts . . ............................ 3–7

Interpreting Test Error Messages . . . .................... 3–8

Using Error Logs .................................... 3–9

Examining Error Logs . ............................ 3–9

iv

Page 5

Distinguishing Event Types......................... 3–11

Memory error logs........................... 3–11

Error and status register error logs . ........... 3–13

System overheat error messages............... 3–14

For Further Error Log Information .................. 3–14

4 Identifying Failed FRUs

Troubleshooting Process . . . ............................ 4–2

Interpreting Test Results . . ............................ 4–3

Interpreting Error Messages That Appear on the

Monitor .......................................... 4–3

Interpreting LED Displays ......................... 4–3

Troubleshooting When the Power-Up Self-Test Does Not

Complete ........................................... 4–6

Using Error Logs to Troubleshoot. . . .................... 4–7

Memory Error Logs................................ 4–8

Error and Status Register Error Logs ................ 4–8

Overheat Error Messages .......................... 4–9

Troubleshooting When a Printer, Modem, or Alternate

Terminal Does Not Operate Properly .................... 4–10

For Further Information . . ............................ 4–11

5 Basic Hardware

System Module and Chassis ........................... 5–2

System Module and Chassis Hardware ............... 5–2

Troubleshooting the System Module.................. 5–3

Replacing a System Module and Chassis . . ........... 5–4

To remove and install an ESAR chip ........... 5–8

Memory Modules . .................................... 5–9

Memory Module Hardware ......................... 5–9

Troubleshooting the Memory Modules ................ 5–11

RAM board test . ............................ 5–11

Removing and Installing a Memory Module ........... 5–13

Keyboard and Mouse ................................. 5–15

Keyboard and Mouse Hardware . .................... 5–15

Troubleshooting the Keyboard and Mouse. . ........... 5–16

Keyboard test . . ............................ 5–17

Mouse test ................................. 5–17

v

Page 6

Removing and Installing the Keyboard and Mouse . . . . . 5–18

To remove the keyboard and mouse and their

cables . .................................... 5–19

To install the keyboard and mouse and their

cables . .................................... 5–19

Power Supply........................................ 5–20

Power Supply Hardware ........................... 5–20

Troubleshooting the Power Supply ................... 5–21

Troubleshooting if the system unit has no

power . .................................... 5–21

Troubleshooting if the system unit overheats . . . . 5–23

Removing and Installing the Power Supply ........... 5–25

For Further Information . . ............................ 5–26

A Equipment Specifications

B Recommended Spares List

C Console Commands

Entering Console Commands .......................... C–2

Rules for Entering Console Commands ............... C–2

Conventions Used in This Chapter................... C–3

Some Terms Used in This Chapter................... C–3

Console Command Reference........................... C–4

Console Command Format Summary................. C–5

? Command . . .................................... C–7

boot Command.................................... C–7

Important information about typing the boot

command .................................. C–8

cat Command. .................................... C–9

cnfg Command.................................... C–10

General system configuration displays.......... C–10

Base system configuration displays . ........... C–12

Ethernet controller configuration displays . . . . . . C–12

SCSI controller displays . . .................... C–13

Color frame-buffer graphics module configuration

displays.................................... C–14

2D graphics accelerator module configuration

displays.................................... C–15

3D graphics module configuration displays...... C–15

d Command . . .................................... C–16

vi

Page 7

e Command . . .................................... C–17

erl Command . .................................... C–19

go Command . .................................... C–19

init Command .................................... C–20

ls Command . . .................................... C–20

passwd Command ................................. C–20

printenv Command ................................ C–21

restart Command ................................. C–21

script Command .................................. C–21

setenv Command.................................. C–22

sh Command . .................................... C–24

t Command . . .................................... C–25

test Command .................................... C–25

unsetenv Command . . . ............................ C–25

Console Command Error Messages . .................... C–26

D Test Commands and Messages

Locating Individual Tests in This Appendix . . . ........... D–2

System Module Tests ................................. D–4

Cache Data Test .................................. D–4

Cache data test error information . . ........... D–4

Cache Isolate Test ................................. D–6

Cache isolate test error messages. . . ........... D–6

Cache Reload Test................................. D–7

Cache reload test error information . ........... D–7

Cache Segment Test . . . ............................ D–8

Cache segment test error messages . ........... D–8

Serial Line Silo Alarm Test ......................... D–10

Serial line silo alarm test error messages ....... D–10

Modem and Printer Test ........................... D–11

Modem and printer test error messages ........ D–11

Serial Line Silo Overflow Test. . . .................... D–12

Serial line silo overflow test error messages . . . . . D–12

Serial Line Single Silo Test ......................... D–14

Serial line single silo test error messages ....... D–14

Serial Line Mixed Silo Test ......................... D–16

Serial line mixed silo test error messages ....... D–16

Serial Line Transmit and Receive Test ............... D–18

Serial line transmit and receive test error

messages .................................. D–18

Error-Correcting Code (ECC) Generate Test ........... D–20

ECC generate test error codes ................ D–20

vii

Page 8

Floating-Point Unit (FPU) Test. . .................... D–21

FPU test error messages . .................... D–21

RAM Select Lines Test . ............................ D–23

RAM select lines test error messages .......... D–23

Keyboard Test .................................... D–24

Keyboard test error messages ................. D–24

Mouse Test . . . .................................... D–25

Mouse test error messages ................... D–25

RAM Refresh Test ................................. D–26

RAM refresh test error messages . . . ........... D–26

Overheat Detect Test . . ............................ D–26

Overheat detect test error message . ........... D–26

Partial Write Test ................................. D–27

Partial write test error messages . . . ........... D–27

Nonvolatile RAM (NVR) test ........................ D–28

NVR test error messages . .................... D–28

Real-Time Clock (RTC) Period Test .................. D–29

RTC period test error messages ............... D–29

Real-Time Clock Register Test . . .................... D–30

Real-time clock register test error messages. . . . . D–30

Real-Time Test.................................... D–31

Real-time test error codes .................... D–31

Translation Lookaside Buffer (TLB) Probe Test ........ D–32

TLB probe test error messages ................ D–32

Translation Lookaside Buffer (TLB) Registers Test . . . . . D–33

TLB registers test and error messages ......... D–33

Memory Module Tests ................................ D–34

RAM Board Test .................................. D–34

RAM board test error messages ............... D–34

Floating 1/0 Memory Test .......................... D–36

Floating 1/0 memory test error messages ....... D–36

Zero Memory Utility . . . ............................ D–36

Power-Up LED Displays . . ............................ D–37

E Console Commands Generated by Version PDE3

ROM Chips

Information About Using Console Commands . ........... E–2

Rules for Typing Console Commands................. E–2

Conventions Used in This Appendix ................. E–3

Displaying Information About System Hardware.......... E–5

viii

Page 9

cnfg Command.................................... E–5

Configuration summary . . .................... E–5

SCSI, Ethernet, and graphics configurations . . . . E–7

System and memory module configurations . . . . . E–9

Driver configurations ........................ E–10

scsi prb Command................................. E–11

Setting Environment Variables ......................... E–12

printenv Command .......................... E–15

setenv Command.................................. E–16

unsetenv Command . . . ............................ E–16

Writing Data into Memory. ............................ E–17

d (deposit) Command . . ............................ E–17

fill Command . .................................... E–18

Setting Serial Line Connections ........................ E–19

disable Command ................................. E–19

Enable Command ................................. E–20

Examining Memory Contents .......................... E–21

dump Command .................................. E–21

e (examine) Command . ............................ E–23

ctrs Command .................................... E–24

Entering a Specific Address............................ E–24

Displaying Console Command Formats .................. E–25

help Command ................................... E–25

? Command . . .................................... E–25

t ? Command. .................................... E–26

Resetting the System ................................. E–26

init Command .................................... E–26

scsi rst Command ................................. E–26

Booting the System Software . . . .................... E–27

F Test Commands and Messages Produced by Version

PDE3 ROM Chips

System Module Tests ................................. F–2

FPUTest ........................................ F–2

Serial Line Test ................................... F–4

Serial Line Silo Alarm Test ......................... F–6

Serial Line Single Silo Test ......................... F–7

Serial Line Silo Overflow Test. . . .................... F–8

FPU test error messages . .................... F–2

Serial line test parameters and error messages . . F–4

Serial line silo alarm test error messages ....... F–6

Serial line single silo test error messages ....... F–7

Serial line silo overflow test error messages . . . . . F–8

ix

Page 10

Serial Line Mixed Silo Test ......................... F–9

Serial line single silo parameters and error

messages .................................. F–9

Modem and Printer Test ........................... F–10

Modem and printer test parameters and error

messages .................................. F–10

Keyboard and Mouse Test .......................... F–11

Keyboard and mouse test parameters and error

messages .................................. F–11

Real-Time Clock Register Test . . .................... F–12

Real-time clock register test error codes ........ F–12

Real-Time Test.................................... F–12

Real-time test parameters and error messages . . F–12

Real-Time Clock Period Test ........................ F–14

Real-time clock period test error messages . . . . . . F–14

Cache Data Test .................................. F–15

Cache data test parameters and error

messages .................................. F–15

Cache Isolate Test ................................. F–17

Cache isolate test parameters and error

messages .................................. F–17

Overtemp Detect Test . . ............................ F–18

Overtemp detect test error messages ........... F–18

Show Versions Utility . . ............................ F–19

Test Error Control Host Tests . . . .................... F–19

Show Error History Utility ......................... F–19

Script Acquire Utility . . ............................ F–20

Display Tests Utility . . . ............................ F–20

Memory Module Tests ................................ F–21

RAM Data Test ................................... F–21

RAM data test error messages ................ F–21

RAM Configuration Test............................ F–22

RAM configuration test error messages ......... F–22

Error Correcting Code Generate Test................. F–23

ECC generate test error messages . . ........... F–23

ECC Single Bit Error Fix Test . . .................... F–24

ECC SBE fix test error messages . . . ........... F–24

Partial Write Test ................................. F–26

Partial write test error messages . . . ........... F–26

Build Bitmap Utility. . . ............................ F–27

Zero RAM Test ................................... F–27

RAM Refresh Test ................................. F–27

RAM Refresh test error messages . . ........... F–27

Ethernet Tests . . . .................................... F–28

x

Page 11

Registers Test .................................... F–28

Registers test parameters and error codes . . . . . . F–28

Internal Loopback Test. ............................ F–29

Internal loopback test parameters and error

codes . . .................................... F–29

External Loopback Test ............................ F–30

External loopback test parameters and error

codes . . .................................... F–30

Cyclic Redundancy Code Detect Test ................. F–31

CRC detect test parameters and error codes . . . . F–31

Collision Test . .................................... F–33

Collision test parameters and error codes ....... F–33

Promiscuous Mode Test ............................ F–34

Promiscuous mode test parameters and error

codes . . .................................... F–34

Multicast Test .................................... F–35

Multicast test parameters and error codes . . . . . . F–36

Interrupt Request Test . ............................ F–37

IRQ test parameters and error codes ........... F–37

Ethernet RAM Test................................ F–38

Ethernet RAM test parameters and error

codes . . .................................... F–38

Ethernet Station Address ROM Test ................. F–39

ESAR test error codes . . . .................... F–39

SCSI Controller Tests ................................. F–40

SCSI Controller Chip Test .......................... F–40

SCSI controller chip test parameters and error

codes . . .................................... F–40

SCSI Buffer Test .................................. F–41

SCSI buffer test parameters and error codes . . . . F–41

SCSI RAM Test ................................... F–42

SCSI RAM test parameters and error codes . . . . . F–42

SCSI Port Test.................................... F–43

SCSI port test parameters and error codes . . . . . . F–43

Graphics Module Tests ................................ F–44

Initialize Video Digital to Analog Converter Registers

Test............................................. F–44

Initialize VDAC registers test parameters and

error codes ................................. F–44

Video RAM Test................................... F–45

Video RAM test parameters and error codes . . . . F–45

Font Test ........................................ F–46

Font test parameters and error codes .......... F–46

Interrupt Test .................................... F–46

Interrupt test error codes .................... F–46

xi

Page 12

BoxTest......................................... F–46

Box test parameters and error codes ........... F–46

Cursor Test . . .................................... F–47

Cursor test parameters and error codes ........ F–47

Analog Video Output Test .......................... F–48

Analog video output test parameters and error

codes . . .................................... F–48

Initial Power-Up Tests ................................ F–49

G Console Status and Error Message Codes

Generated by Version PDE3 ROM Chips

Major Error and Status Code Numbers and Phrases . . . . . . G–2

Minor Console Error and Status Error Codes. . ........... G–4

Index

Figures

1-1 Possible system hardware configurations ................. 1–3

1-2 System unit .......................................... 1–5

1-3 System controls and indicators .......................... 1–6

1-4 DECstation/DECsystem 5000 connectors.................. 1–8

1-5 Location of memory and expansion slots on the system

module . ............................................. 1–9

2-1 Using an antistatic kit ................................. 2–2

2-2 Connecting an alternate terminal........................ 2–3

2-3 Remove and installing the system unit cover . . . ........... 2–5

2-4 Removing and installing the front cover plate . . ........... 2–7

2-5 Removing and installing a serial number plate . ........... 2–10

2-6 Removing and installing a ThinWire Ethernet terminator . . . 2–12

2-7 Removing and installing a ThickWire loopback connector . . . 2–13

2-8 Removing and installing a communications loopback

connector ............................................ 2–14

2-9 Removing and installing a SCSI chain terminator ......... 2–15

2-10 Removing and installing a communications line adapter . . . . 2–16

2-11 Inserting and removing a clear-NVR jumper . . . ........... 2–21

3-1 Slot numbers for system hardware. . . .................... 3–2

5-1 System module and chassis . ............................ 5–2

xii

Page 13

5-2 Removing hardware from an old system module ........... 5–5

5-3 Installing hardware on a new system module . . ........... 5–7

5-4 ESAR chip location .................................... 5–8

5-5 Memory module. . . .................................... 5–9

5-6 Removing and installing a memory module ............... 5–13

5-7 Keyboard and mouse hardware.......................... 5–15

5-8 Removing and installing a keyboard and mouse ........... 5–18

5-9 Power supply hardware ................................ 5–20

5-10 System module power cord connections ................... 5–22

5-11 Checking the power supply fan assembly connection ....... 5–24

5-12 Removing and installing the power supply ................ 5–25

B-1 DECstation 5000 Unit Assembly ........................ B–2

Tables

1 Conventions Used in This Guide ........................ xix

3-1 Slot Numbers Used in Test Commands ................... 3–4

4-1 Interpreting Test Error Messages Displayed on the

Monitor . ............................................. 4–4

4-2 Troubleshooting When the Power-Up Self-Test Does Not

Complete ............................................ 4–6

4-3 Error Log Event Types ................................. 4–7

4-4 Hardware Physical Addresses ........................... 4–9

5-1 Interpreting System Module Error Messages . . . ........... 5–3

5-2 Memory Module Address Ranges ........................ 5–10

A-1 System Unit Description . . . ............................ A–2

A-2 System Unit Specifications . ............................ A–2

A-3 System Unit Operating Conditions. . . .................... A–2

A-4 System Unit Nonoperating Conditions.................... A–2

A-5 LK201 Keyboard Description............................ A–3

A-6 LK201 Keyboard Specifications.......................... A–3

A-7 LK201 Keyboard Operating Conditions ................... A–3

A-8 LK201 Keyboard Nonoperating Conditions ................ A–4

A-9 VSXXX-AA Mouse Description .......................... A–5

A-10 VSXXX-AA Mouse Specifications ........................ A–5

A-11 VSXXX-AA Mouse Operating Conditions.................. A–5

A-12 VSXXX-AA Mouse Nonoperating Conditions............... A–6

B-1 Loopback Connectors, Plugs, Test Media, and Miscellaneous

Items . . . ............................................. B–1

xiii

Page 14

B-2 Major FRUs .......................................... B–3

B-3 Basic Components . .................................... B–3

B-4 Cords, Cables, and Connectors .......................... B–4

B-5 Software Documentation . . . ............................ B–5

B-6 Hardware Documentation . . ............................ B–5

C-1 Console Command Functions ........................... C–6

C-2 Environment Variables in the Environment Variable

Display . ............................................. C–23

C-3 Console Command Error Messages . . .................... C–26

D-1 Individual Tests and Utilities for Each Module ............ D–2

D-2 Cache Data Test Error Messages ........................ D–5

D-3 Cache Isolate Test Error Codes.......................... D–6

D-4 Cache Reload Test Error Descriptions .................... D–8

D-5 Cache Segment Test Error Codes and Descriptions ......... D–9

D-6 Serial Line Silo Alarm Test Error Descriptions . ........... D–10

D-7 Modem and Printer Test Error Descriptions ............... D–11

D-8 Serial Line Silo Overflow Test Error Descriptions .......... D–13

D-9 Serial Line Single Silo Test Error Descriptions . ........... D–15

D-10 Serial Line Mixed Silo Test Error Descriptions . ........... D–17

D-11 Serial Line Transmit and Receive Test Error Descriptions . . . D–19

D-12 ECC Generate Test Error Codes ......................... D–20

D-13 FPU Test Error Codes ................................. D–22

D-14 Keyboard Test Error Descriptions........................ D–24

D-15 Mouse Test Error Descriptions .......................... D–25

D-16 Partial Write Test Error Codes .......................... D–27

D-17 NVR Test Error Codes and Descriptions .................. D–28

D-18 RTC Period Test Error Codes ........................... D–29

D-19 Real-Time Clock Register Test Error Codes and

Descriptions .......................................... D–30

D-20 Real-Time Test Error Codes ............................ D–31

D-21 TLB Registers Test Error Codes ......................... D–33

D-22 RAM Board Test Error Codes and Descriptions . ........... D–35

D-23 Power-Up LED Displays . . . ............................ D–37

E-1 Console Commands.................................... E–4

E-2 Symbols Used in Optional Module Configuration Displays. . . E–8

E-3 Environment Variables Set by the User .................. E–13

E-4 Environment Variables Set by the System ................ E–15

F-1 FPU Error Codes . .................................... F–3

F-2 Serial Line Test Parameters ............................ F–4

xiv

Page 15

F-3 Serial Line Test Error Codes ............................ F–5

F-4 Serial Line Silo Alarm Test Parameters .................. F–6

F-5 Serial Line Silo Alarm Test Error Codes.................. F–6

F-6 Serial Line Silo Alarm Test Parameters .................. F–7

F-7 Serial Line Single Silo Test Error Codes .................. F–7

F-8 Serial Line Silo Overflow Test Parameters ................ F–8

F-9 Serial Line Silo Overflow Test Error Codes ............... F–8

F-10 Serial Line Mixed Silo Test Parameters .................. F–9

F-11 Serial Line Mixed Silo Test Error Codes .................. F–9

F-12 Modem and Printer Test Parameters . .................... F–10

F-13 Modem and Printer Test Error Codes .................... F–10

F-14 Keyboard and Mouse Test Parameters.................... F–11

F-15 Keyboard and Mouse Test Error Codes ................... F–12

F-16 Real-Time Clock Register Test Error Codes ............... F–12

F-17 Real-Time Test Error Codes ............................ F–13

F-18 Real-Time Test Error Codes ............................ F–14

F-19 Cache Data Test Parameters ............................ F–15

F-20 Cache Data Test Error Codes ........................... F–15

F-21 Cache Isolate Test Parameters .......................... F–17

F-22 Cache Isolate Test Error Codes .......................... F–17

F-23 TECH Tests, Utilities, and Commands ................... F–19

F-24 RAM Data Test Error Parameters . . . .................... F–21

F-25 RAM Data Test Error Codes ............................ F–21

F-26 RAM Configuration Test Error Codes .................... F–22

F-27 ECC Generate Test Parameters ......................... F–23

F-28 ECC Generate Test Error Codes ......................... F–23

F-29 ECC SBE Fix Test Parameters .......................... F–24

F-30 ECC SBE Fix Test Error Codes ......................... F–24

F-31 Partial Write Test Parameters .......................... F–26

F-32 Partial Write Test Error Codes .......................... F–26

F-33 RAM Refresh Test Error Codes .......................... F–27

F-34 Registers Test Error Codes . ............................ F–28

F-35 Internal Loopback Test Parameters . . .................... F–29

F-36 Internal Loopback Test Error Codes . .................... F–29

F-37 External Loopback Test Parameters. . .................... F–30

F-38 External Loopback Test Error Codes . .................... F–30

F-39 CRC Detect Test Parameters............................ F–31

F-40 CRC Detect Error Codes . . . ............................ F–32

F-41 Collision Test Parameters . . ............................ F–33

xv

Page 16

F-42 Collision Test Error Codes . . ............................ F–33

F-43 Promiscuous Mode Test Parameters . . .................... F–34

F-44 Promiscuous Mode Test Error Codes . .................... F–35

F-45 Multicast Test Parameters . . ............................ F–36

F-46 Multicast Test Error Codes . ............................ F–36

F-47 IRQ Test Parameters .................................. F–37

F-48 IRQ Test Error Codes .................................. F–37

F-49 Ethernet RAM Test Parameters ......................... F–38

F-50 RAM Test Error Codes ................................. F–38

F-51 ESAR Test Error Codes ................................ F–39

F-52 SCSI Controller Chip Test Parameters ................... F–40

F-53 SCSI Controller Chip Test Error Codes ................... F–40

F-54 SCSI Buffer Test Parameters ........................... F–41

F-55 SCSI Buffer Test Error Codes ........................... F–41

F-56 SCSI RAM Test Parameters ............................ F–42

F-57 SCSI Port Test Parameters . ............................ F–43

F-58 SCSI Port Test Error Codes. ............................ F–43

F-59 Initialize VDAC Registers Test Parameters ............... F–44

F-60 Initialize VDAC Registers Test Error Codes ............... F–44

F-61 Video RAM Test Parameters ............................ F–45

F-62 Video RAM Test Error Codes ........................... F–45

F-63 Cursor Test Parameters ................................ F–47

F-64 Cursor Test Error Codes . . . ............................ F–47

F-65 Analog Video Output Test Parameters.................... F–48

F-66 Analog Video Output Test Error Codes ................... F–48

F-67 Initial Power-Up Test Error Codes . . . .................... F–49

G-1 Major Error and Status Error Codes . .................... G–2

G-2 Minor Error and Status Error Codes . .................... G–4

xvi

Page 17

Intended Audience

This guide is for Digital customer service representatives who

have completed training in DECstation/DECsystem 5000 Model

200 maintenance. This guide assumes that you are familiar

with basic maintenance and troubleshooting operations and

that you have experience with desktop computer systems.

How To Use This Guide

This guide explains how to identify and replace failed field-

replaceable units (FRUs). 1, 2, and 3 give background

information about the system hardware and operations

regularly used for customer service. Chapter 4 describes how

to determine which FRU failed. Chapter 5 provides detailed

information about troubleshooting and replacing individual

FRUs.

Using This Guide

For an overview of the system hardware and its configurations,

refer to Chapter 1, ‘‘A Look at DECstation/DECsystem 5000

Model 200 Hardware.’’

To perform routine service operations, refer to Chapter 2,

‘‘Service Operations.’’

To run tests and interpret their error codes, refer to Chapter 3,

‘‘Troubleshooting Tools.’’

xvii

Page 18

To identify failed FRUs, refer to Chapter 4, ‘‘Identifying Failed

FRUs.’’

For a description of the hardware, troubleshooting procedures,

and replacement procedures for base system FRUs, refer to

Chapter 5.

For a description of the hardware, troubleshooting procedures,

and replacement procedures for TURBOchannel options, drives,

and monitors, refer to the TURBOchannel Maintenance Guide.

For equipment specifications, refer to Appendix A.

For equipment part numbers and a recommended spares list,

refer to Appendix B.

For an explanation of console commands, refer to Appendix C.

For an explanation of individual system module and memory

module tests, refer to Appendix D.

For information about R3000 CPU registers, refer to

Appendix E.

For an explanation of console commands used by Version PDE3

ROM chips that are in some systems, refer to Appendix G.

For an explanation of individual test commands and error

messages used by VERSIon PDE3 ROM chips, refer to

Appendix G.

About the Scope of This Guide

This guide discusses current DECstation/DECsystem 5000

hardware only. The maintenance guide will be revised as

additional options become available. Some of these future

options are three-dimensional graphics option modules.

xviii

Page 19

Conventions Used in This Guide

Table 1. Conventions Used in This Guide

Convention Use

Monospace

type

Boldface

type

Italic type Any part of a command that you replace with an actual

Anything that appears on your monitor screen

is set in monospace type, like this.

Anything you are asked to type is set in boldface

type, like this.

value is set in italic type, like this.

xix

Page 20

1

A Look at DECstation/DECsystem 5000

Model 200 Hardware

This chapter describes

Possible system hardware configurations

Basic system hardware

Optional system hardware

A Look at DECstation/DECsystem 5000 Model 200 Hardware 1–1

Page 21

System Hardware Configurations

The DECstation/DECsystem 5000 Model 200 is a reduced

instruction set computer (RISC), ULTRIX-based desktop sys-

tem. Depending on the actual hardware, the system operates

as either a server or a workstation. DECstation/DECsystem

5000 Model 200 system hardware includes basic hardware that

supports graphics, drives, additional Ethernet connections, and

additional memory.

Figure 1-1 shows the possible configurations of the basic

and optional system hardware. Each item in Figure 1-1 is a

field-replaceable unit (FRU).

1–2 A Look at DECstation/DECsystem 5000 Model 200 Hardware

Page 22

Ethernet

WSE2M001

drives

Up to seven

Page 23

Basic System Hardware

The basic system hardware includes a system unit with

controls, indicators, and system connectors.

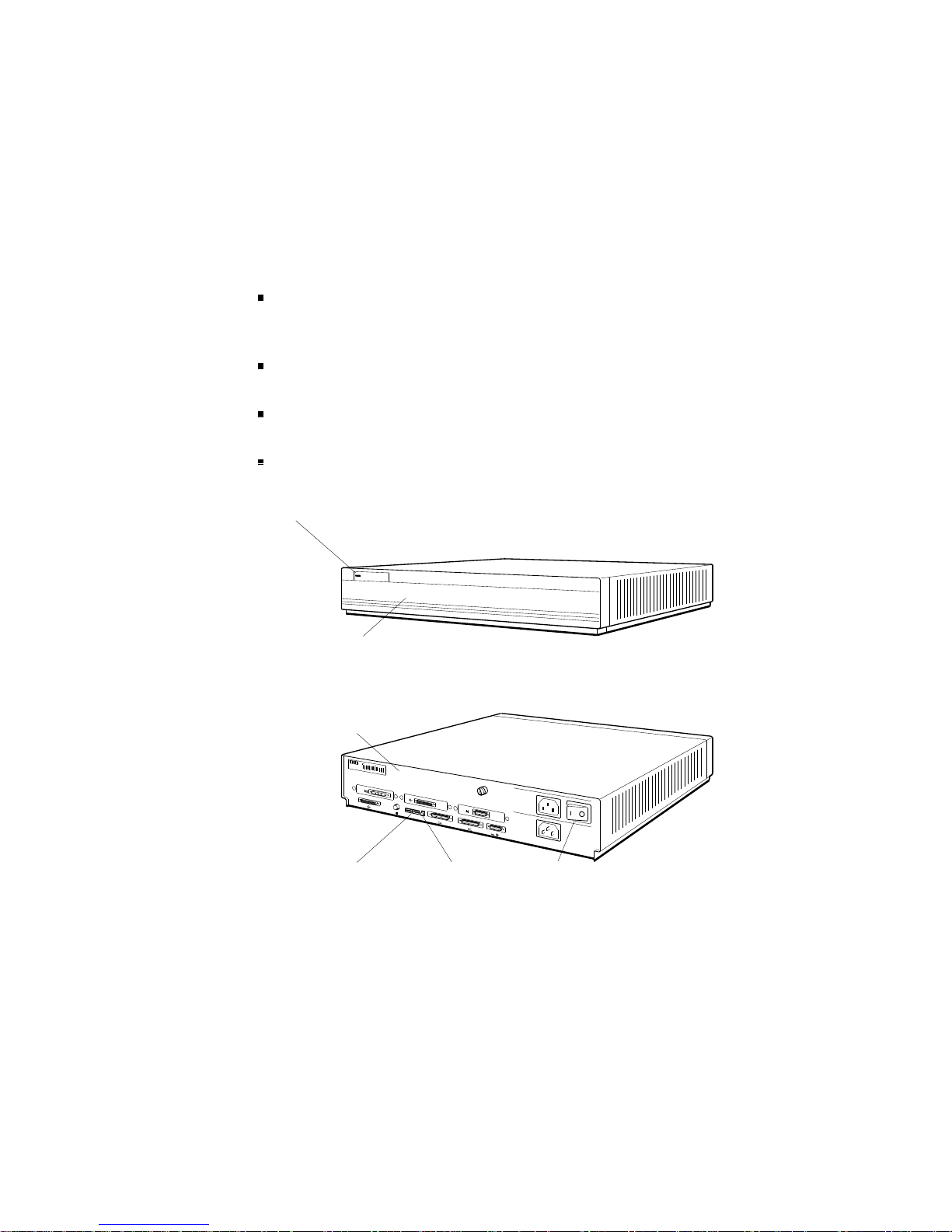

System Unit

The system unit, shown in Figure 1-2, includes the following:

One system module and chassis, which includes

One central processing unit (CPU)

One floating-point unit (FPU)

One small computer system interface (SCSI) controller

One serial line controller

One ThinWire Ethernet controller

Fifteen slots for memory modules

Three slots for optional graphics, SCSI, and ThickWire

Ethernet modules

One metal chassis that holds the system module

One 8-Mbyte memory module connected to the system

module

One power supply, which has three cooling fans

A removable system unit cover and front cover plate

1–4 A Look at DECstation/DECsystem 5000 Model 200 Hardware

Page 24

Page 25

System Unit Controls and Indicators

The system unit controls and indicators, shown in Figure 1-3,

have the following uses:

The on/off switch turns the system on and off. Press down

the 0 on the switch to turn off the power. Press down the 1

on the switch to turn on the power.

The power indicator glows green when the power supply is

operating properly.

The diagnostic LEDs display binary error codes that

indicate test results.

The reset button initializes the system.

Power

supply

LED

DEC station 5000

Front view

Back view

d

i

g

i

t

a

l

0

Diagnostic

LEDs

PMAG-C

1

PMAZ-A

PMAD-A

3

Reset

button

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

On/off

switch

Figure 1-3. System controls and indicators

1–6 A Look at DECstation/DECsystem 5000 Model 200 Hardware

WSE2M003

Page 26

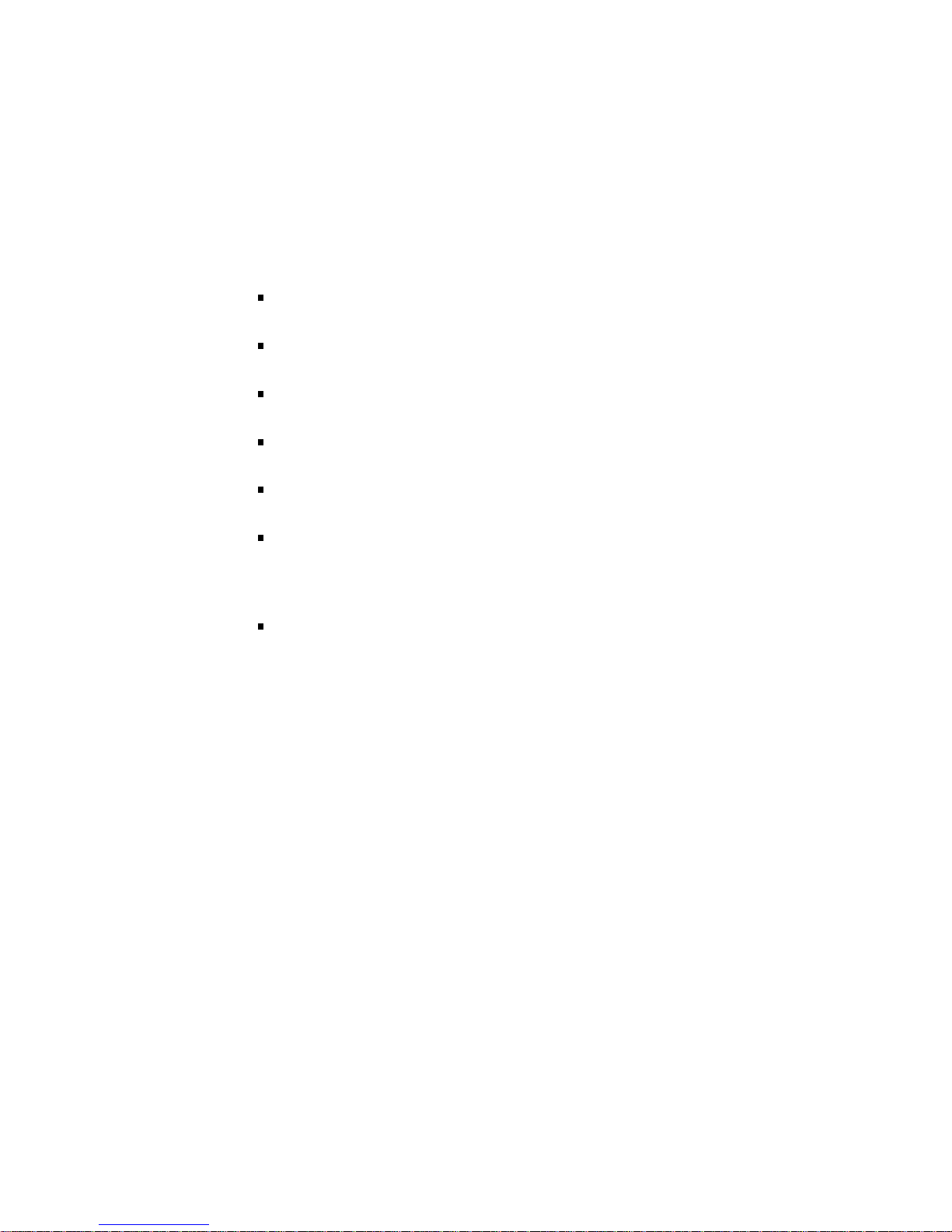

System Unit Connectors

The system unit connectors, shown in Figure 1-4, have the

following purposes:

The power connector connects the system unit power supply

and the system unit power cord.

The monitor-to-system-unit connector provides electric

power to the monitor power cord.

The ThinWire Ethernet connector links the system unit to

a ThinWire Ethernet.

The SCSI connector connects the base system SCSI

controller to a chain of external drives.

The keyboard-mouse connector links the system unit to the

keyboard-mouse cable.

The communications connectors provide printer, modem,

and console terminal connections. If there is a console

terminal, the terminal usually connects to the left

communications connector.

The option module connectors connect option modules to

external hardware. The number printed above each option

module connector is the slot number for any option module

in that slot.

A Look at DECstation/DECsystem 5000 Model 200 Hardware 1–7

Page 27

SCSI

connector

Option module

connectors

d

i

g

i

t

a

l

0

PMAG-C

Monitor-to-system-unit

connector

1

PMAZ-A

PMAD-A

3

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

ThinWire

Ethernet

connector

Communications

connectors

Keyboard-mouse

connector

Figure 1-4. DECstation/DECsystem 5000 connectors

Power

connector

WSE2M004

1–8 A Look at DECstation/DECsystem 5000 Model 200 Hardware

Page 28

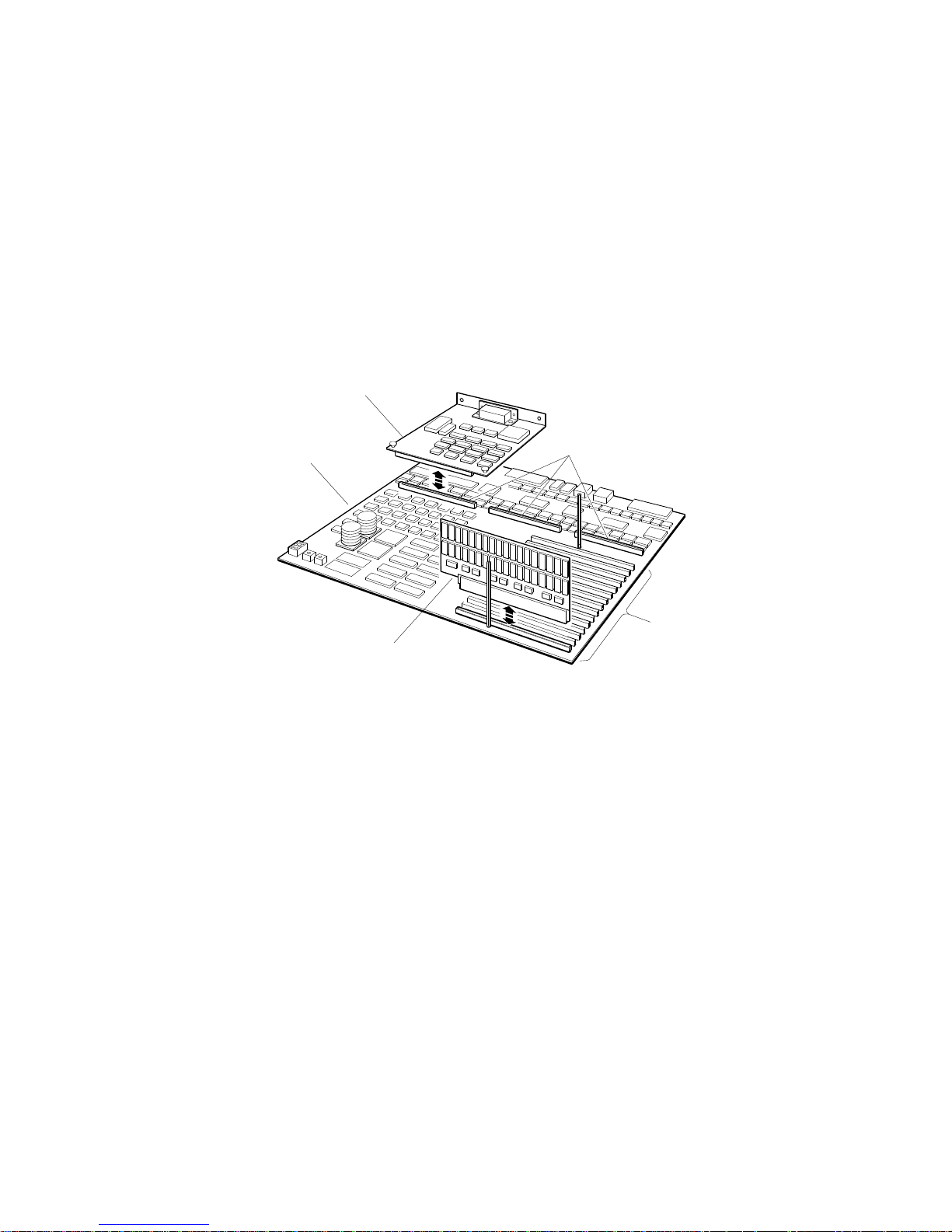

Hardware Options

The system module has slots for additional memory and

TURBOchannel option modules.

Figure 1-5 shows the location of memory and option module

expansion slots on the system module.

Option module

System

module

Memory module

Option module

expansion slots

Memory

module

expansion

slots

WSE2M005

Figure 1-5. Location of memory and expansion slots on the system

module

Additional Memory Modules

The system module has 15 expansion slots for additional

memory modules. Each memory slot can support one 8-Mbyte

memory module.

A Look at DECstation/DECsystem 5000 Model 200 Hardware 1–9

Page 29

Optional TURBOchannel Modules

The three TURBOchannel expansion slots on the system unit

support a maximum of three option modules.

Any optional SCSI or Ethernet controller modules operate in

addition to the SCSI and ThickWire Ethernet controller built in

to the system module.

Drives

Each SCSI controller supports up to seven drives that connect

in a chain that attaches to the SCSI controller through the back

of the system unit.

Monitors and Terminals

The system supports different monitors, depending on the

graphics option modules that are in the system. Refer to the

TURBOchannel Maintenance Guide for a description of the

monitors that graphics option modules support.

The system can also display text on a VT320 terminal attached

to the communications connector on the left as you face the

back of the system unit.

Keyboard and Mouse

The system uses an LK201 keyboard and VSXXX-AA mouse

that connect to the back of the system unit through the

keyboard-mouse cable.

For Further Information

For further information about the hardware described in this

chapter, refer to later chapters that discuss the hardware in

which you are interested.

For further information about TURBOchannel option modules,

drives, or monitors, refer to the TURBOchannel Maintenance

Guide.

1–10 A Look at DECstation/DECsystem 5000 Model 200 Hardware

Page 30

Service Operations

This chapter explains how to perform routine service

operations. It explains how to

Avoid electrostatic damage when handling components

Use an alternate terminal

Remove the system unit cover

Remove the front cover plate

Remove and replace the serial number plate

Install and remove terminators and loopback connectors

Enter console mode and operating mode

Use console command passwords

Boot the system software

Shut down the system software

2

Service Operations 2–1

Page 31

Using an Antistatic Kit

The Digital antistatic kit contains the equipment you need

to handle static-sensitive materials safely. When handling

static-sensitive materials, always

Place the antistatic wrist strap around your wrist and

attach the other end of the strap to the snap-on fastener

attached to the antistatic mat before you handle any

static-sensitive item.

Place the static-sensitive item on the antistatic mat when

you set it down.

Figure 2-1 shows the antistatic kit parts and their proper use.

Antistatic mat

WSE2M012

Figure 2-1. Using an antistatic kit

Wrist strap

2–2 Service Operations

Page 32

Using an Alternate Terminal

If the original monitor is not working properly, you can use an

alternate terminal to run tests.

When the alternate console is set, the alternate terminal

displays the same text as a regular system monitor. You can

use either the original or alternate keyboard to type commands.

Use a VT320 terminal set to 9600 baud.

Figure 2-2 shows how to connect an alternate terminal.

VT320 terminal

R

G

B

0

PMAG-C

1

V~100-120 A 3.0

V~220-240 A 1.7

2

PMAD-A

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

1

VT320 cable

WSE2M008

Figure 2-2. Connecting an alternate terminal

Communications

connector

3

Communications

line adapter

Service Operations 2–3

Page 33

Note: Remove any graphics modules installed in the system before

you enable the alternate terminal.

1. Install a communications line adapter on the commu-

nications line that is on the left as you face the back of

the system. Refer to ‘‘Removing and Installing Loopback

Connectors and Terminators’’ later in this chapter for

directions.

2. Insert the end of the keyboard cable into the keyboard cable

connector on the alternate terminal.

3. Insert the end of the VT320 cable into the communications

line adapter on the back of the system unit.

4. Turn on the alternate terminal.

5. Turn on the system unit. The system automatically enables

the alternate terminal after you turn on the system unit

power.

A display should appear on the alternate terminal.

To return to using the original monitor, replace the graphics

module that was installed in the system unit. After you turn on

the power, the system returns to using the original monitor.

2–4 Service Operations

Page 34

Removing and Installing the System Unit Cover

Figure 2-3 shows how to remove and install the system unit

cover.

d

i

g

i

t

a

l

0

PMAG-C

1

PMAZ-A

PMAD-A

3

Captive screw On/off switch

Figure 2-3. Remove and installing the system unit cover

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

WSE2M013

Service Operations 2–5

Page 35

To Remove the System Unit Cover

1. Turn off the system power.

2. Disconnect the system unit power cord.

3. Loosen the captive screw that holds the cover.

4. Face the front of the system unit and grip each side of the

system unit cover.

5. Pull the cover toward you until it comes loose from the

chassis. Then lift the cover up and away from the system

unit.

To Install the System Unit Cover

6. Place the system unit cover on the chassis. Leave at least 2

inches between the cover and the back of the system unit.

7. Slide the system unit cover toward the back of the system

unit until it pops into place.

8. Tighten the captive screw.

9. Reconnect the system unit power cord to the system unit

power connector.

2–6 Service Operations

Page 36

Removing and Installing the Front Cover Plate

Figure 2-4 shows how to remove and install the front cover

plate.

Captive

screw

Front

cover

plate

WSE2M014

Captive

screw

Figure 2-4. Removing and installing the front cover plate

System

unit

chassis

Service Operations 2–7

Page 37

To Remove the Front Cover Plate

1. Make sure the system power is off.

2. Remove the system unit cover. Refer to the previous section

for directions.

3. Loosen the two captive screws.

4. Tilt the top of the plate down and lift it away from the

chassis.

To Install the Front Cover Plate

5. Make sure the system power is off.

6. Insert the tabs on the bottom of the plate into the slots in

the front of the chassis.

7. Tilt the plate forward.

8. Tighten the two captive screws.

2–8 Service Operations

Page 38

Removing and Installing a Serial Number Plate

To Remove a Serial Number Plate

1. Turn off the system unit power.

2. Remove the system unit cover. Refer to ‘‘Removing and

Installing the System Unit Cover’’ earlier in this chapter

for directions.

3. Peel the tamper-proof tape off the two nuts that hold the

serial number plate.

4. Use a crescent wrench to remove the two nuts that hold the

serial number plate.

5. Pull the serial number plate away from the system unit.

To Install a Serial Number Plate

1. Make sure the system unit power is off and the system unit

cover is removed.

2. Pass the two posts on the back of the serial number plate

through the holes in the back of the system unit.

3. Tighten the two nuts onto the posts.

4. Apply one piece of security tape over each nut and the post

surrounding it.

Service Operations 2–9

Page 39

W 359

Hz 50-60

A 7.9/4.2

V~100-120/220-240

WSE2M050

Page 40

Removing and Installing Loopback Connectors and

Terminators

To remove and install a ThinWire terminator, follow the

directions in Figure 2-6.

To remove and install a ThickWire loopback connector,

follow the directions in Figure 2-7.

To remove and install a communications loopback connector,

follow the directions in Figure 2-8.

To remove and install a SCSI chain terminator, follow the

directions in Figure 2-9.

To remove and install a communications line adapter, follow

the directions in Figure 2-10.

Service Operations 2–11

Page 41

To Remove a ThinWire Terminator

1. Twist the collar on the ThinWire T-connector as far as

possible to the left.

2. Pull the T-connector off of the system unit connector.

To Install a ThinWire Terminator

1. Press a terminator onto each unused end of the T-connector.

Turn the terminator to the right until it locks into place.

2. Push the T-connector collar onto the ThinWire connector on

the system unit.

3. Turn the T-connector collar to the right until it slips past

the connector tabs and slides into place.

ThinWire T-connector

ThinWire terminators

d

i

g

i

t

a

l

PMAG-C

ThinWire Ethernet connector

0

1

PMAZ-A

PMAD-A

3

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

WSE2M009

Figure 2-6. Removing and installing a ThinWire Ethernet terminator

2–12 Service Operations

Page 42

To Remove a ThickWire Loopback Connector

1. Firmly grip the ThickWire loopback connector.

2. Pull the ThickWire loopback connector away from the

ThickWire connector on the system unit.

To Install a ThickWire Loopback Connector

1. Align the wide end of the loopback connector and the wide

end of the ThickWire Ethernet connector.

2. Firmly press the loopback connector onto the ThickWire

Ethernet connector.

System unit

ThickWire connector

ThickWire

loopback

connector

Figure 2-7. Removing and installing a ThickWire loopback connector

0

PMAG-C

1

PMAZ-A

PMAD-A

3

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

WSE2I026

Service Operations 2–13

Page 43

To Remove a Communications Loopback Connector

1. Firmly grip the communications loopback connector.

2. Pull the communications loopback connector away from the

communications connector.

To Install a Communications Loopback Connector

1. Align the wide end of the loopback connector and the wide

end of the communications connector.

2. Firmly press the loopback connector onto the communica-

tions connector.

0

PMAG-C

1

PMAD-A

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

Communications

loopback

connector

Figure 2-8. Removing and installing a communications loopback

2–14 Service Operations

connector

1

Communications

connector

3

WSE2M048

Page 44

To Remove a SCSI Chain Terminator

1. Push the wire brackets away from the terminator.

2. Pull the terminator off of the SCSI connector.

To Install a SCSI Chain Terminator

1. Firmly press the chain terminator onto the unused

connector on the drive at the end of the chain.

2. Fasten the SCSI connector wire brackets onto the SCSI

terminator.

Wire brackets

SCSI chain terminator

WSE2M040

Figure 2-9. Removing and installing a SCSI chain terminator

Service Operations 2–15

Page 45

To Remove a Communications Line Adapter

1. Loosen the two screws that hold the adapter to the

communications connector.

2. Pull the communications line adapter away from the system

unit.

To Install a Communications Line Adapter

1. Firmly press the communications line adapter onto the

communications connector.

2. Tighten the two screws.

0

PMAG-C

1

PMAD-A

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

Figure 2-10. Removing and installing a communications line adapter

2–16 Service Operations

1

3

Communications

connector

Communications

line adapter

WSE2M037

Page 46

Entering Console and Operating Modes

The system operates in either of two modes:

Console mode

Use console mode to

Run tests

Display hardware configurations

Set environment variables

Boot the system software

In console mode, the system displays the prompt

R>. The system displays the prompt >> whenever you

>> or

can use all console commands. If the system displays the

prompt R>, you can use only the boot and password console

commands until you enter the password.

Operating mode

In operating mode, the system displays the appropriate

ULTRIX prompt. Use operating mode for regular system

operation.

Service Operations 2–17

Page 47

To Enter Console Mode

Enter console mode by turning on the system power or pressing

the reset button. If the system is running software, shut down

the system software before you enter console mode. When you

turn on the system power, the system completes a power-up

self-test before displaying the console prompt.

If the system displays the prompt

R>, you can use only the boot

and password commands until you enter a password. To enter

the password, type passwd and press Return. At the prompt

pwd:, type the password and press Return. When you have

access to all console commands, the system displays the prompt

>>.

For information about setting and removing console command

passwords, refer to ‘‘Using Console Command Passwords’’ later

in this chapter.

To Enter Operating Mode

Enter operating mode by booting the system. Refer to ‘‘Booting

the System Software’’ later in this chapter for directions.

2–18 Service Operations

Page 48

Using Console Command Passwords

You can set the system so that you can use only the boot and

password commands until you enter a password. A system that

requires a password before you can use all console commands

displays the prompt R> until you enter the correct password.

To be able to use all console commands on a system that

requires a password, type passwd at the prompt R>. Then type

the password and press Return. The system then allows you to

use all console commands. Whenever all console commands are

available, the system uses the prompt >>.

To Set or Change a Password

To set or change a password, use the password command with

the -s option.

1. Type passwd -s at the prompt >> and press Return.

2. At the prompt pwd:, type the new password and press

Return.

3. The system repeats the prompt pwd:. Enter the password a

second time at the prompt

pwd:.

Note that passwords must

Have at least six characters

Have no more than 32 characters

Use uppercase and lowercase letters the same as when you

first entered the password

If the two password entries match, the entry becomes the new

password. If the two entries do not match, the old password

remains in effect.

To Remove a Requirement for a Password

To remove a requirement for a password, type passwd -c at the

prompt

>> and press Return.

Service Operations 2–19

Page 49

To Erase a Password You Do Not Know

You can erase a password by inserting a clear-nonvolatile-RAM

(NVR) jumper. After you insert a clear-NVR jumper, you will

need to reset all environment variables.

To erase a password you do not know,

1. Turn off the system power.

2. Install the clear-NVR jumper. Refer to the following section

for installation directions.

3. Turn on the system and wait for the console prompt to

appear.

4. Turn off the system again.

5. Remove the clear-NVR jumper.

6. Turn on the system power.

7. Use the setenv command to reset environment variables to

the values you want.

After you erase the password, the console commands have no

password protection until you set a new password.

2–20 Service Operations

Page 50

Inserting and removing a clear-NVR jumper

Figure 2-11 shows how to insert and remove the clear-NVR

jumper.

Clear NVR

Clear NVR pins

System module

Figure 2-11. Inserting and removing a clear-NVR jumper

WSE2M047

Service Operations 2–21

Page 51

To insert the jumper,

1. Turn off the system unit.

2. Remove the system unit cover. Refer to ‘‘Removing and

Installing the System Unit Cover’’ earlier in this chapter

for directions.

3. Locate the clear-NVR pins on the system module. The

clear-NVR jumper pins are a two-pin fixture.

4. Slide the jumper entirely over the clear-NVR pins.

To remove the jumper,

1. Make sure the system power is off.

2. Remove the system unit cover if it is on the system unit.

3. Slide the jumper up and away from the clear-NVR pins.

2–22 Service Operations

Page 52

Booting the System Software

To boot the system, use the boot command.

Booting a system can take several minutes. If the system

displays the ULTRIX prompt

appears, press Ctrl-D to continue with the boot operation.

If the boot is successful, the monitor displays the prompt

login:.

If the system fails to boot, do the following:

1. Use the printenv command to display the environment

variables table.

2. Use the setenv command to set the boot environment

variable to a hard disk or to the network that contains the

system software.

3. Use the boot command to boot the system.

For a detailed explanation of these console commands, refer to

Appendix C.

If the system still does not boot, check any boot error messages

that appear on the monitor. Refer to Appendix C to find the

meaning of boot error messages.

# before the prompt login:

Service Operations 2–23

Page 53

Shutting Down the System Software

If the system is running ULTRIX software, shut down the

system before you perform customer service. To shut down the

software, type the following command at the ULTRIX prompt:

/etc/shutdown -h (now| hhmm| +n)

Specify the now parameter to shut down the software

immediately.

Specify hhmm to shut down the software at a specified

time. Replace hhmm with the hour and minute the

shutdown begins, where

hh represents the hour to begin the shutdown.

mm represents the minute to begin the shutdown.

Specify +n to shut down the software in a specified number

of minutes. Replace n with the number of minutes until

shutdown begins.

The monitor displays the prompt >> or R> when shutdown is

complete.

2–24 Service Operations

Page 54

Troubleshooting Tools

This chapter explains the system troubleshooting tools. It

explains how to

Use different types of tests

Set up tests for groups of selected modules

Interpret test results

Examine and interpret error logs

Use boot error messages

Use console status messages

3

Troubleshooting Tools 3–1

Page 55

Using Tests

The system uses two types of tests to check system hardware

operation:

Subtests can be individual tests or test scripts, which are

groups of individual tests. If you run a test script, you can

select one of several prepared scripts or create your own.

Using Slot Numbers in Test Commands and Error Messages

Test commands and error messages include slot numbers that

identify the hardware to which the test command or error

message refers.

The slot number for the system module and memory modules

is always 7. Figure 3-1 shows the slot numbers for the SCSI

and ThinWire controllers on the system module and the option

modules.

Power-up self-tests, which run a comprehensive test of the

system hardware

Subtests, which test individual modules that you choose

Slot number 0 refers

to the module in

option slot 0. option slot 1.

Slot number 5 refers

to the SCSI controller

on the system module.

Figure 3-1. Slot numbers for system hardware

3–2 Troubleshooting Tools

Slot number 1 refers Slot number 2 refers

to the module in

to the module in

option slot 2.

0

1

PMAD-A

3

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

Slot number 6 refers

to the ThinWire Ethernet

controller on the system module.

WSE2M060

Page 56

Running Power-Up Self-Tests

The system runs a power-up self-test when you turn on the

system power. The monitor and diagnostic LEDs report any

errors the power-up self-test detects. To find the corrective

action for any error codes the power-up self-test reports, refer

to Chapter 4.

Note: If the monitor displays the message PDE3: x, where x

represents an option module slot number, the system contains

incompatible ROM chips. Upgrade the system ROM chips if the

PDE3: x message appears.

You can specify a quick or thorough power-up self-test script to

run when the system powers up.

The quick test script is a limited script that minimizes the

time until the system boots.

The thorough script runs an extensive check of system

hardware. The thorough power-up self-test script is most

useful for field service troubleshooting.

To select a power-up self-test script, use the setenv command

to set the testaction environment variable. Type setenv

testaction (q|t) and press Return.

Specify q to select the quick test.

Specify t to select the thorough test.

Troubleshooting Tools 3–3

Page 57

Running Subtests

In addition to the power-up self-test, you can use subtests to

troubleshoot. Subtests run individual tests or test scripts.

Running Individual Tests

To run an individual test, type

t [-l] slot/test [arg1][arg2][arg3]...

When you type an individual test command,

t is the command to run a test.

Include the optional -l parameter to make the test repeat

continuously until you type Ctrl-C or reset the system.

Replace slot with the slot number of the module to be

tested. Table 3-1 lists the slot numbers assigned to each

module.

Replace test with the name of the particular test you want

to run.

The optional extended arguments (arg-1 and so on) specify

individual test conditions. Refer to Appendix D for an

explanation of the arguments used for each test.

Table 3-1. Slot Numbers Used in Test Commands

Slot Number Unit Tested

0 Option module in slot 0 (slot farthest from the power switch)

1 Option module in slot 1 (middle option slot)

2 Option module in slot 2 (slot nearest the power switch)

3 Reserved

4 Reserved

5 SCSI controller on the system module

6 Ethernet controller on the system module

7 System module or memory module

3–4 Troubleshooting Tools

Page 58

Running Test Scripts

Use the sh command to run a test script.

To run a test script once and then stop, type sh script,

where you replace script with the name of the test script

you want to run. Then press Return.

To have a test script run and keep repeating until you press

Ctrl-C, include the optional -l parameter in the command.

Type sh -l script, where you replace script with the name of

the test script you want to run. Then press Return.

Displaying Lists of Available Tests

To display all individual tests available for a specific module,

type t slot/?, where you replace slot with the slot number of the

module for which you want a test listing. Then press Return.

A list of tests similar to this sample listing of tests for the

system module appears on the monitor:

cache/data I or D[D] address[80050000]

cache/isol I or D[D]

cache/reload I or D[D] address[80050000]

cache/seg I or D[D] address[80050000]

ecc/gen address[A0100000]

fpu

mem board[0] thrsld[10] pattern[55555555]

mem/init

mem/float10 address[A0100000]

mem/select

mfg/done

misc/pstemp

misc/refresh

misc/wbpart

rtc/nv pattern[55]

rtc/period

rtc/regs

rtc/time

tlb/probe

tlb/reg pattern[55555555]

In this list,

The leftmost column lists the commands for tests that are

available for the specific module.

Troubleshooting Tools 3–5

Page 59

Entries in the other columns represent the individual test

parameters, if any. The value in brackets next to each

parameter is the default value for that parameter.

For a detailed explanation of individual self-tests and their

parameters, refer to Appendix D.

To display existing scripts that test an individual module

To display all the scripts that do not loop, type ls slot, where

slot represents the slot number of the module for which you

want all test scripts listed. Then press Return.

A display of scripts and other objects that are in the module

then appears on the screen. This sample listing is a portion

of the ls display for slot 7. This portion lists some of the test

scripts present in the system module and memory module.

7/pst-m

7/pst-q

7/pst-t

7/test-cpu

7/test-dz-m

7/test-dz-q

7/test-dz-t

7/test-misc

7/test-rtc

7/test-mem-m

7/test-mem-q

7/test/mem-t

3–6 Troubleshooting Tools

Page 60

Creating Test Scripts

You can create test scripts that test modules under test

conditions you choose.

To create a test script,

1. Type script name, where you replace name with the name

that you want to give the script you are creating. Then

press Return.

2. Type the test commands for the tests that you want to

include in the script. When you type test commands,

Type test commands in the same order that you want

the tests to run in the test script.

Specify any options that you want to include in each

test when you type the test command.

Press Return after you finish typing each individual

test command.

3. Finish creating the test script by pressing Return twice

after you enter the name of the last test in the test script.

4. To run the script you just created, type sh name, where

you replace name with the name you assigned the script,

and press Return.

Note: The system stores this test script in volatile memory. The test

script is lost when you turn off the system unit or press the reset

button. You can store only one script at a time.

Troubleshooting Tools 3–7

Page 61

Interpreting Test Error Messages

For every error that a self-test detects, an error message

appears on the screen. Error messages appear in the following

format:

?TFL slot/test (code: description)[module].

?TFL indicates that an error occurred.

slot represents the slot number of the module that reported

the error.

test represents the individual test that failed.

code represents a code that indicates which part of the test

failed.

description represents a possible message that describes the

failure.

module represents the module identification number.

For an explanation of individual system module and memory

module error messages, refer to Appendix D.

For an explanation of individual SCSI, Ethernet, and

TURBOchannel option error messages, refer to the

TURBOchannel Maintenance Guide.

This is a sample error message:

?TFL 7/dz/alrm (bad interrupt) [KN02-AA]

This error message states that the module in slot number 7, the

system module, failed the serial line silo alarm test.

The additional message

failed the interrupt operation.

3–8 Troubleshooting Tools

(bad interrupt) indicates that the test

Page 62

Using Error Logs

The system records events and errors in the ULTRIX error logs.

Use the memory error, error and status register, and system

overheat error logs to troubleshoot intermittent problems.

Note: The ULTRIX error logs are not the same as the test error logs

that appear when you use the erl console command. The test error log

is a record of errors reported by tests run in console mode.

The following paragraphs describe ULTRIX error log formats

and error log parts useful in troubleshooting.

Examining Error Logs

You must be in ULTRIX to examine error logs. At the ULTRIX

prompt, type /etc/uerf -R| more and press Return. A full

display of error log entries appears on the monitor.

The first part of each error log describes the type of error and

system conditions in effect when the error occurred. The last

part of each log provides specific information about the error

and its location.

The first part of all error logs is similar to this:

----- EVENT INFORMATION ----EVENT CLASS OPERATIONAL EVENT

OS EVENT TYPE 300. SYSTEM STARTUP

SEQUENCE NUMBER 0.

OPERATING SYSTEM ULTRIX 32

OCCURRED/LOGGED ON Tue Oct 24 09:06:16 1989

OCCURRED ON SYSTEM GRANITE

SYSTEM ID x82020120 HW REV: x20

FW REV: x1

CPU TYPE: R2000A/R3000

PROCESSOR TYPE KN02/R3000

Troubleshooting Tools 3–9

Page 63

In this display,

EVENT CLASS lists the error log’s general category.

Possible EVENT CLASS categories are

Operational events, which are changes in system

operation that are not errors

Error events, which are actual errors in system

operation

OS EVENT TYPE describes the type of error or event

recorded in the log. Table 4-3 lists possible operating

system event types and their codes. For information about

memory, error and status register, and overheat error logs,

refer to the following section ‘‘Distinguishing Event Types’’

and to the discussion of the particular log in which you are

interested.

SEQUENCE NUMBER lists the order in which the system

logged the event.

OPERATING SYSTEM lists the system’s version of

ULTRIX.

OCCURRED/LOGGED ON shows the time the error

occurred.

OCCURRED ON SYSTEM lists the individual system that

reported the error.

SYSTEM ID includes several listings:

The first number to the right of SYSTEM ID is the

system ID.

HW REV lists the system hardware revision number.

FW REV lists the system firmware revision number.

CPU TYPE shows the type of CPU used in the system.

PROCESSOR TYPE lists the type of processor chip used in

the system.

The remaining error log entry is different for each error log

event type. For an explanation of entries contained in memory,

error and status register, and overheat error logs, refer to the

next section.

3–10 Troubleshooting Tools

Page 64

Distinguishing Event Types

The second line of each error log lists the code number and

name of the error log event type.

The following sections describe memory, error and status, and

system overheat error logs. For a detailed explanation of other

error logs that involve the system unit, refer to the ULTRIX

documentation.

Memory error logs

Memory error logs record errors that occur in the memory

modules. This is a sample of the error log sections that are

unique to memory error logs.

----- UNIT INFORMATION ----UNIT CLASS MEMORY

UNIT TYPE KN02 MEMORY

ERROR SYNDROME MEMORY CRD ERROR

----- ERROR & STATUS REGS ----EPC x8006DF4C

KN02 STAT REG x07C20001 IO INT 0 PENDING

19,200 BAUD

8 MB MEM MODULE

ECC CMD x0

IO INT 1 ENABLED

IO INT 6 ENABLED

IO INT 7 ENABLED

NORMAL MODE

REFRESH EVEN MEM MODULES

ERROR ADDR REG xD01B37BA

PHYSICAL ERROR ADDR x006CDEE8

CHECK SYNDROME x00108884 SYND BITS x4

----- ADDITIONAL INFO ----CONTROLLER NO. 1.

ERRS ON THIS ADDR 1.

UNSECURE

CPU MEM READ ECC

SINGLE BIT ERROR

CHECK BITS x8

MODULE NUM. x0

ERROR COUNT 1.

INVALID PC MEMINTR

Troubleshooting Tools 3–11

Page 65

The UNIT INFORMATION section describes the type of module

that reported the error.

UNIT CLASS shows that the error occurred in a memory

module.

UNIT TYPE lists the particular type of memory module in

which the error occurred.

ERROR SYNDROME describes the nature of the error.

The ERROR & STATUS REGS section lists the error and status

register contents followed by phrases that describe the register

contents.

EPC indicates that this is an exception program counter.

KN02 STAT REG lists the contents of the CPU status

register (CSR).

ERROR ADDR REG describe the specific error type.

PHYSICAL ERROR ADDR is the address in the hardware

where the error occurred.

CHECK SYNDROME entries describe the actual error and

the module where it occurred.

SYND BITS lists the bits in the check syndrome

register.

The second line states whether this is a single bit or a

mulitbit error.

The third line shows the check bits.