DEC DECstation 5000 Model 200, DECsystem 5000 Model 200 Maintenance Manual

DECstation 5000/

DECsystem 5000

Model 200

MaintenanceGuide

EK-370AA-MG-002

digital equipment corporation

maynard, massachusetts

First printing, April 1990

Second printing, October 1990

The information in this document is subject to change without notice and should

not be construed as a commitment by Digital Equipment Corporation. Digital

Equipment Corporation assumes no responsibility for any errors that may appear

in this document.

The software described in this document is furnished under a license and may be

used or copied only in accordance with the terms of such license.

Digital Equipment Corporation assumes no responsibility for the use or reliability

of its software on equipment that is not supplied by Digital or its affiliated

companies.

© Digital Equipment Corporation 1990.

All Rights Reserved

Printed in U.S.A.

USA

This equipment generates, uses, and may emit radio frequency energy. The

equipment has been type tested and found to comply with the limits for a Class

A computing device pursuant to Subpart J of Part 15 of FCC Rules, which

are designed to provide reasonable protection against such radio frequency

interference. Operation of this equipment in a residential area may cause

interference in which case the user at his own expense will be required to take

whatever measures may be required to correct the interference.

The following are trademarks of Digital Equipment Corporation:

DEC PDP VAXBI

DECnet ThinWire VAXcluster

DECstation TURBOchannel VAXstation

DECsystem ULTRIX VMS

DECUS ULTRIX-32 VT

MicroVAX UNIBUS

MicroVMS VAX

dt

Contents

Using This Guide ........................................... xvii

1 A Look at DECstation/DECsystem 5000 Model 200

Hardware

System Hardware Configurations . . . .................... 1–2

Basic System Hardware............................... 1–4

System Unit . . .................................... 1–4

System Unit Controls and Indicators................. 1–6

System Unit Connectors............................ 1–7

Hardware Options.................................... 1–9

Additional Memory Modules ........................ 1–9

Optional TURBOchannel Modules ................... 1–10

Drives ........................................... 1–10

Monitors and Terminals ............................ 1–10

Keyboard and Mouse . . ............................ 1–10

For Further Information . . ............................ 1–10

2 Service Operations

Using an Antistatic Kit . . . ............................ 2–2

Using an Alternate Terminal........................... 2–3

Removing and Installing the System Unit Cover .......... 2–5

To Remove the System Unit Cover ................... 2–6

To Install the System Unit Cover .................... 2–6

Removing and Installing the Front Cover Plate........... 2–7

To Remove the Front Cover Plate.................... 2–8

To Install the Front Cover Plate . .................... 2–8

iii

Removing and Installing a Serial Number Plate .......... 2–9

To Remove a Serial Number Plate ................... 2–9

To Install a Serial Number Plate .................... 2–9

Removing and Installing Loopback Connectors and

Terminators ......................................... 2–11

To Remove a ThinWire Terminator................... 2–12

To Install a ThinWire Terminator.................... 2–12

To Remove a ThickWire Loopback Connector .......... 2–13

To Install a ThickWire Loopback Connector ........... 2–13

To Remove a Communications Loopback Connector . . . . 2–14

To Install a Communications Loopback Connector. . .. . . 2–14

To Remove a SCSI Chain Terminator ................ 2–15

To Install a SCSI Chain Terminator ................. 2–15

To Remove a Communications Line Adapter .......... 2–16

To Install a Communications Line Adapter. ........... 2–16

Entering Console and Operating Modes ................. 2–17

To Enter Console Mode ............................ 2–18

To Enter Operating Mode .......................... 2–18

Using Console Command Passwords .................... 2–19

To Set or Change a Password . . . .................... 2–19

To Remove a Requirement for a Password . ........... 2–19

To Erase a Password You Do Not Know . . . ........... 2–20

Inserting and removing a clear-NVR jumper . . . . 2–21

Booting the System Software .......................... 2–23

Shutting Down the System Software .................... 2–24

3 Troubleshooting Tools

Using Tests ......................................... 3–2

Using Slot Numbers in Test Commands and Error

Messages ........................................ 3–2

Running Power-Up Self-Tests .......................... 3–3

Running Subtests .................................... 3–4

Running Individual Tests........................... 3–4

Running Test Scripts . . ............................ 3–5

Displaying Lists of Available Tests ................... 3–5

To display existing scripts that test an individual

module .................................... 3–6

Creating Test Scripts . . ............................ 3–7

Interpreting Test Error Messages . . . .................... 3–8

Using Error Logs .................................... 3–9

Examining Error Logs . ............................ 3–9

iv

Distinguishing Event Types......................... 3–11

Memory error logs........................... 3–11

Error and status register error logs . ........... 3–13

System overheat error messages............... 3–14

For Further Error Log Information .................. 3–14

4 Identifying Failed FRUs

Troubleshooting Process . . . ............................ 4–2

Interpreting Test Results . . ............................ 4–3

Interpreting Error Messages That Appear on the

Monitor .......................................... 4–3

Interpreting LED Displays ......................... 4–3

Troubleshooting When the Power-Up Self-Test Does Not

Complete ........................................... 4–6

Using Error Logs to Troubleshoot. . . .................... 4–7

Memory Error Logs................................ 4–8

Error and Status Register Error Logs ................ 4–8

Overheat Error Messages .......................... 4–9

Troubleshooting When a Printer, Modem, or Alternate

Terminal Does Not Operate Properly .................... 4–10

For Further Information . . ............................ 4–11

5 Basic Hardware

System Module and Chassis ........................... 5–2

System Module and Chassis Hardware ............... 5–2

Troubleshooting the System Module.................. 5–3

Replacing a System Module and Chassis . . ........... 5–4

To remove and install an ESAR chip ........... 5–8

Memory Modules . .................................... 5–9

Memory Module Hardware ......................... 5–9

Troubleshooting the Memory Modules ................ 5–11

RAM board test . ............................ 5–11

Removing and Installing a Memory Module ........... 5–13

Keyboard and Mouse ................................. 5–15

Keyboard and Mouse Hardware . .................... 5–15

Troubleshooting the Keyboard and Mouse. . ........... 5–16

Keyboard test . . ............................ 5–17

Mouse test ................................. 5–17

v

Removing and Installing the Keyboard and Mouse . . . . . 5–18

To remove the keyboard and mouse and their

cables . .................................... 5–19

To install the keyboard and mouse and their

cables . .................................... 5–19

Power Supply........................................ 5–20

Power Supply Hardware ........................... 5–20

Troubleshooting the Power Supply ................... 5–21

Troubleshooting if the system unit has no

power . .................................... 5–21

Troubleshooting if the system unit overheats . . . . 5–23

Removing and Installing the Power Supply ........... 5–25

For Further Information . . ............................ 5–26

A Equipment Specifications

B Recommended Spares List

C Console Commands

Entering Console Commands .......................... C–2

Rules for Entering Console Commands ............... C–2

Conventions Used in This Chapter................... C–3

Some Terms Used in This Chapter................... C–3

Console Command Reference........................... C–4

Console Command Format Summary................. C–5

? Command . . .................................... C–7

boot Command.................................... C–7

Important information about typing the boot

command .................................. C–8

cat Command. .................................... C–9

cnfg Command.................................... C–10

General system configuration displays.......... C–10

Base system configuration displays . ........... C–12

Ethernet controller configuration displays . . . . . . C–12

SCSI controller displays . . .................... C–13

Color frame-buffer graphics module configuration

displays.................................... C–14

2D graphics accelerator module configuration

displays.................................... C–15

3D graphics module configuration displays...... C–15

d Command . . .................................... C–16

vi

e Command . . .................................... C–17

erl Command . .................................... C–19

go Command . .................................... C–19

init Command .................................... C–20

ls Command . . .................................... C–20

passwd Command ................................. C–20

printenv Command ................................ C–21

restart Command ................................. C–21

script Command .................................. C–21

setenv Command.................................. C–22

sh Command . .................................... C–24

t Command . . .................................... C–25

test Command .................................... C–25

unsetenv Command . . . ............................ C–25

Console Command Error Messages . .................... C–26

D Test Commands and Messages

Locating Individual Tests in This Appendix . . . ........... D–2

System Module Tests ................................. D–4

Cache Data Test .................................. D–4

Cache data test error information . . ........... D–4

Cache Isolate Test ................................. D–6

Cache isolate test error messages. . . ........... D–6

Cache Reload Test................................. D–7

Cache reload test error information . ........... D–7

Cache Segment Test . . . ............................ D–8

Cache segment test error messages . ........... D–8

Serial Line Silo Alarm Test ......................... D–10

Serial line silo alarm test error messages ....... D–10

Modem and Printer Test ........................... D–11

Modem and printer test error messages ........ D–11

Serial Line Silo Overflow Test. . . .................... D–12

Serial line silo overflow test error messages . . . . . D–12

Serial Line Single Silo Test ......................... D–14

Serial line single silo test error messages ....... D–14

Serial Line Mixed Silo Test ......................... D–16

Serial line mixed silo test error messages ....... D–16

Serial Line Transmit and Receive Test ............... D–18

Serial line transmit and receive test error

messages .................................. D–18

Error-Correcting Code (ECC) Generate Test ........... D–20

ECC generate test error codes ................ D–20

vii

Floating-Point Unit (FPU) Test. . .................... D–21

FPU test error messages . .................... D–21

RAM Select Lines Test . ............................ D–23

RAM select lines test error messages .......... D–23

Keyboard Test .................................... D–24

Keyboard test error messages ................. D–24

Mouse Test . . . .................................... D–25

Mouse test error messages ................... D–25

RAM Refresh Test ................................. D–26

RAM refresh test error messages . . . ........... D–26

Overheat Detect Test . . ............................ D–26

Overheat detect test error message . ........... D–26

Partial Write Test ................................. D–27

Partial write test error messages . . . ........... D–27

Nonvolatile RAM (NVR) test ........................ D–28

NVR test error messages . .................... D–28

Real-Time Clock (RTC) Period Test .................. D–29

RTC period test error messages ............... D–29

Real-Time Clock Register Test . . .................... D–30

Real-time clock register test error messages. . . . . D–30

Real-Time Test.................................... D–31

Real-time test error codes .................... D–31

Translation Lookaside Buffer (TLB) Probe Test ........ D–32

TLB probe test error messages ................ D–32

Translation Lookaside Buffer (TLB) Registers Test . . . . . D–33

TLB registers test and error messages ......... D–33

Memory Module Tests ................................ D–34

RAM Board Test .................................. D–34

RAM board test error messages ............... D–34

Floating 1/0 Memory Test .......................... D–36

Floating 1/0 memory test error messages ....... D–36

Zero Memory Utility . . . ............................ D–36

Power-Up LED Displays . . ............................ D–37

E Console Commands Generated by Version PDE3

ROM Chips

Information About Using Console Commands . ........... E–2

Rules for Typing Console Commands................. E–2

Conventions Used in This Appendix ................. E–3

Displaying Information About System Hardware.......... E–5

viii

cnfg Command.................................... E–5

Configuration summary . . .................... E–5

SCSI, Ethernet, and graphics configurations . . . . E–7

System and memory module configurations . . . . . E–9

Driver configurations ........................ E–10

scsi prb Command................................. E–11

Setting Environment Variables ......................... E–12

printenv Command .......................... E–15

setenv Command.................................. E–16

unsetenv Command . . . ............................ E–16

Writing Data into Memory. ............................ E–17

d (deposit) Command . . ............................ E–17

fill Command . .................................... E–18

Setting Serial Line Connections ........................ E–19

disable Command ................................. E–19

Enable Command ................................. E–20

Examining Memory Contents .......................... E–21

dump Command .................................. E–21

e (examine) Command . ............................ E–23

ctrs Command .................................... E–24

Entering a Specific Address............................ E–24

Displaying Console Command Formats .................. E–25

help Command ................................... E–25

? Command . . .................................... E–25

t ? Command. .................................... E–26

Resetting the System ................................. E–26

init Command .................................... E–26

scsi rst Command ................................. E–26

Booting the System Software . . . .................... E–27

F Test Commands and Messages Produced by Version

PDE3 ROM Chips

System Module Tests ................................. F–2

FPUTest ........................................ F–2

Serial Line Test ................................... F–4

Serial Line Silo Alarm Test ......................... F–6

Serial Line Single Silo Test ......................... F–7

Serial Line Silo Overflow Test. . . .................... F–8

FPU test error messages . .................... F–2

Serial line test parameters and error messages . . F–4

Serial line silo alarm test error messages ....... F–6

Serial line single silo test error messages ....... F–7

Serial line silo overflow test error messages . . . . . F–8

ix

Serial Line Mixed Silo Test ......................... F–9

Serial line single silo parameters and error

messages .................................. F–9

Modem and Printer Test ........................... F–10

Modem and printer test parameters and error

messages .................................. F–10

Keyboard and Mouse Test .......................... F–11

Keyboard and mouse test parameters and error

messages .................................. F–11

Real-Time Clock Register Test . . .................... F–12

Real-time clock register test error codes ........ F–12

Real-Time Test.................................... F–12

Real-time test parameters and error messages . . F–12

Real-Time Clock Period Test ........................ F–14

Real-time clock period test error messages . . . . . . F–14

Cache Data Test .................................. F–15

Cache data test parameters and error

messages .................................. F–15

Cache Isolate Test ................................. F–17

Cache isolate test parameters and error

messages .................................. F–17

Overtemp Detect Test . . ............................ F–18

Overtemp detect test error messages ........... F–18

Show Versions Utility . . ............................ F–19

Test Error Control Host Tests . . . .................... F–19

Show Error History Utility ......................... F–19

Script Acquire Utility . . ............................ F–20

Display Tests Utility . . . ............................ F–20

Memory Module Tests ................................ F–21

RAM Data Test ................................... F–21

RAM data test error messages ................ F–21

RAM Configuration Test............................ F–22

RAM configuration test error messages ......... F–22

Error Correcting Code Generate Test................. F–23

ECC generate test error messages . . ........... F–23

ECC Single Bit Error Fix Test . . .................... F–24

ECC SBE fix test error messages . . . ........... F–24

Partial Write Test ................................. F–26

Partial write test error messages . . . ........... F–26

Build Bitmap Utility. . . ............................ F–27

Zero RAM Test ................................... F–27

RAM Refresh Test ................................. F–27

RAM Refresh test error messages . . ........... F–27

Ethernet Tests . . . .................................... F–28

x

Registers Test .................................... F–28

Registers test parameters and error codes . . . . . . F–28

Internal Loopback Test. ............................ F–29

Internal loopback test parameters and error

codes . . .................................... F–29

External Loopback Test ............................ F–30

External loopback test parameters and error

codes . . .................................... F–30

Cyclic Redundancy Code Detect Test ................. F–31

CRC detect test parameters and error codes . . . . F–31

Collision Test . .................................... F–33

Collision test parameters and error codes ....... F–33

Promiscuous Mode Test ............................ F–34

Promiscuous mode test parameters and error

codes . . .................................... F–34

Multicast Test .................................... F–35

Multicast test parameters and error codes . . . . . . F–36

Interrupt Request Test . ............................ F–37

IRQ test parameters and error codes ........... F–37

Ethernet RAM Test................................ F–38

Ethernet RAM test parameters and error

codes . . .................................... F–38

Ethernet Station Address ROM Test ................. F–39

ESAR test error codes . . . .................... F–39

SCSI Controller Tests ................................. F–40

SCSI Controller Chip Test .......................... F–40

SCSI controller chip test parameters and error

codes . . .................................... F–40

SCSI Buffer Test .................................. F–41

SCSI buffer test parameters and error codes . . . . F–41

SCSI RAM Test ................................... F–42

SCSI RAM test parameters and error codes . . . . . F–42

SCSI Port Test.................................... F–43

SCSI port test parameters and error codes . . . . . . F–43

Graphics Module Tests ................................ F–44

Initialize Video Digital to Analog Converter Registers

Test............................................. F–44

Initialize VDAC registers test parameters and

error codes ................................. F–44

Video RAM Test................................... F–45

Video RAM test parameters and error codes . . . . F–45

Font Test ........................................ F–46

Font test parameters and error codes .......... F–46

Interrupt Test .................................... F–46

Interrupt test error codes .................... F–46

xi

BoxTest......................................... F–46

Box test parameters and error codes ........... F–46

Cursor Test . . .................................... F–47

Cursor test parameters and error codes ........ F–47

Analog Video Output Test .......................... F–48

Analog video output test parameters and error

codes . . .................................... F–48

Initial Power-Up Tests ................................ F–49

G Console Status and Error Message Codes

Generated by Version PDE3 ROM Chips

Major Error and Status Code Numbers and Phrases . . . . . . G–2

Minor Console Error and Status Error Codes. . ........... G–4

Index

Figures

1-1 Possible system hardware configurations ................. 1–3

1-2 System unit .......................................... 1–5

1-3 System controls and indicators .......................... 1–6

1-4 DECstation/DECsystem 5000 connectors.................. 1–8

1-5 Location of memory and expansion slots on the system

module . ............................................. 1–9

2-1 Using an antistatic kit ................................. 2–2

2-2 Connecting an alternate terminal........................ 2–3

2-3 Remove and installing the system unit cover . . . ........... 2–5

2-4 Removing and installing the front cover plate . . ........... 2–7

2-5 Removing and installing a serial number plate . ........... 2–10

2-6 Removing and installing a ThinWire Ethernet terminator . . . 2–12

2-7 Removing and installing a ThickWire loopback connector . . . 2–13

2-8 Removing and installing a communications loopback

connector ............................................ 2–14

2-9 Removing and installing a SCSI chain terminator ......... 2–15

2-10 Removing and installing a communications line adapter . . . . 2–16

2-11 Inserting and removing a clear-NVR jumper . . . ........... 2–21

3-1 Slot numbers for system hardware. . . .................... 3–2

5-1 System module and chassis . ............................ 5–2

xii

5-2 Removing hardware from an old system module ........... 5–5

5-3 Installing hardware on a new system module . . ........... 5–7

5-4 ESAR chip location .................................... 5–8

5-5 Memory module. . . .................................... 5–9

5-6 Removing and installing a memory module ............... 5–13

5-7 Keyboard and mouse hardware.......................... 5–15

5-8 Removing and installing a keyboard and mouse ........... 5–18

5-9 Power supply hardware ................................ 5–20

5-10 System module power cord connections ................... 5–22

5-11 Checking the power supply fan assembly connection ....... 5–24

5-12 Removing and installing the power supply ................ 5–25

B-1 DECstation 5000 Unit Assembly ........................ B–2

Tables

1 Conventions Used in This Guide ........................ xix

3-1 Slot Numbers Used in Test Commands ................... 3–4

4-1 Interpreting Test Error Messages Displayed on the

Monitor . ............................................. 4–4

4-2 Troubleshooting When the Power-Up Self-Test Does Not

Complete ............................................ 4–6

4-3 Error Log Event Types ................................. 4–7

4-4 Hardware Physical Addresses ........................... 4–9

5-1 Interpreting System Module Error Messages . . . ........... 5–3

5-2 Memory Module Address Ranges ........................ 5–10

A-1 System Unit Description . . . ............................ A–2

A-2 System Unit Specifications . ............................ A–2

A-3 System Unit Operating Conditions. . . .................... A–2

A-4 System Unit Nonoperating Conditions.................... A–2

A-5 LK201 Keyboard Description............................ A–3

A-6 LK201 Keyboard Specifications.......................... A–3

A-7 LK201 Keyboard Operating Conditions ................... A–3

A-8 LK201 Keyboard Nonoperating Conditions ................ A–4

A-9 VSXXX-AA Mouse Description .......................... A–5

A-10 VSXXX-AA Mouse Specifications ........................ A–5

A-11 VSXXX-AA Mouse Operating Conditions.................. A–5

A-12 VSXXX-AA Mouse Nonoperating Conditions............... A–6

B-1 Loopback Connectors, Plugs, Test Media, and Miscellaneous

Items . . . ............................................. B–1

xiii

B-2 Major FRUs .......................................... B–3

B-3 Basic Components . .................................... B–3

B-4 Cords, Cables, and Connectors .......................... B–4

B-5 Software Documentation . . . ............................ B–5

B-6 Hardware Documentation . . ............................ B–5

C-1 Console Command Functions ........................... C–6

C-2 Environment Variables in the Environment Variable

Display . ............................................. C–23

C-3 Console Command Error Messages . . .................... C–26

D-1 Individual Tests and Utilities for Each Module ............ D–2

D-2 Cache Data Test Error Messages ........................ D–5

D-3 Cache Isolate Test Error Codes.......................... D–6

D-4 Cache Reload Test Error Descriptions .................... D–8

D-5 Cache Segment Test Error Codes and Descriptions ......... D–9

D-6 Serial Line Silo Alarm Test Error Descriptions . ........... D–10

D-7 Modem and Printer Test Error Descriptions ............... D–11

D-8 Serial Line Silo Overflow Test Error Descriptions .......... D–13

D-9 Serial Line Single Silo Test Error Descriptions . ........... D–15

D-10 Serial Line Mixed Silo Test Error Descriptions . ........... D–17

D-11 Serial Line Transmit and Receive Test Error Descriptions . . . D–19

D-12 ECC Generate Test Error Codes ......................... D–20

D-13 FPU Test Error Codes ................................. D–22

D-14 Keyboard Test Error Descriptions........................ D–24

D-15 Mouse Test Error Descriptions .......................... D–25

D-16 Partial Write Test Error Codes .......................... D–27

D-17 NVR Test Error Codes and Descriptions .................. D–28

D-18 RTC Period Test Error Codes ........................... D–29

D-19 Real-Time Clock Register Test Error Codes and

Descriptions .......................................... D–30

D-20 Real-Time Test Error Codes ............................ D–31

D-21 TLB Registers Test Error Codes ......................... D–33

D-22 RAM Board Test Error Codes and Descriptions . ........... D–35

D-23 Power-Up LED Displays . . . ............................ D–37

E-1 Console Commands.................................... E–4

E-2 Symbols Used in Optional Module Configuration Displays. . . E–8

E-3 Environment Variables Set by the User .................. E–13

E-4 Environment Variables Set by the System ................ E–15

F-1 FPU Error Codes . .................................... F–3

F-2 Serial Line Test Parameters ............................ F–4

xiv

F-3 Serial Line Test Error Codes ............................ F–5

F-4 Serial Line Silo Alarm Test Parameters .................. F–6

F-5 Serial Line Silo Alarm Test Error Codes.................. F–6

F-6 Serial Line Silo Alarm Test Parameters .................. F–7

F-7 Serial Line Single Silo Test Error Codes .................. F–7

F-8 Serial Line Silo Overflow Test Parameters ................ F–8

F-9 Serial Line Silo Overflow Test Error Codes ............... F–8

F-10 Serial Line Mixed Silo Test Parameters .................. F–9

F-11 Serial Line Mixed Silo Test Error Codes .................. F–9

F-12 Modem and Printer Test Parameters . .................... F–10

F-13 Modem and Printer Test Error Codes .................... F–10

F-14 Keyboard and Mouse Test Parameters.................... F–11

F-15 Keyboard and Mouse Test Error Codes ................... F–12

F-16 Real-Time Clock Register Test Error Codes ............... F–12

F-17 Real-Time Test Error Codes ............................ F–13

F-18 Real-Time Test Error Codes ............................ F–14

F-19 Cache Data Test Parameters ............................ F–15

F-20 Cache Data Test Error Codes ........................... F–15

F-21 Cache Isolate Test Parameters .......................... F–17

F-22 Cache Isolate Test Error Codes .......................... F–17

F-23 TECH Tests, Utilities, and Commands ................... F–19

F-24 RAM Data Test Error Parameters . . . .................... F–21

F-25 RAM Data Test Error Codes ............................ F–21

F-26 RAM Configuration Test Error Codes .................... F–22

F-27 ECC Generate Test Parameters ......................... F–23

F-28 ECC Generate Test Error Codes ......................... F–23

F-29 ECC SBE Fix Test Parameters .......................... F–24

F-30 ECC SBE Fix Test Error Codes ......................... F–24

F-31 Partial Write Test Parameters .......................... F–26

F-32 Partial Write Test Error Codes .......................... F–26

F-33 RAM Refresh Test Error Codes .......................... F–27

F-34 Registers Test Error Codes . ............................ F–28

F-35 Internal Loopback Test Parameters . . .................... F–29

F-36 Internal Loopback Test Error Codes . .................... F–29

F-37 External Loopback Test Parameters. . .................... F–30

F-38 External Loopback Test Error Codes . .................... F–30

F-39 CRC Detect Test Parameters............................ F–31

F-40 CRC Detect Error Codes . . . ............................ F–32

F-41 Collision Test Parameters . . ............................ F–33

xv

F-42 Collision Test Error Codes . . ............................ F–33

F-43 Promiscuous Mode Test Parameters . . .................... F–34

F-44 Promiscuous Mode Test Error Codes . .................... F–35

F-45 Multicast Test Parameters . . ............................ F–36

F-46 Multicast Test Error Codes . ............................ F–36

F-47 IRQ Test Parameters .................................. F–37

F-48 IRQ Test Error Codes .................................. F–37

F-49 Ethernet RAM Test Parameters ......................... F–38

F-50 RAM Test Error Codes ................................. F–38

F-51 ESAR Test Error Codes ................................ F–39

F-52 SCSI Controller Chip Test Parameters ................... F–40

F-53 SCSI Controller Chip Test Error Codes ................... F–40

F-54 SCSI Buffer Test Parameters ........................... F–41

F-55 SCSI Buffer Test Error Codes ........................... F–41

F-56 SCSI RAM Test Parameters ............................ F–42

F-57 SCSI Port Test Parameters . ............................ F–43

F-58 SCSI Port Test Error Codes. ............................ F–43

F-59 Initialize VDAC Registers Test Parameters ............... F–44

F-60 Initialize VDAC Registers Test Error Codes ............... F–44

F-61 Video RAM Test Parameters ............................ F–45

F-62 Video RAM Test Error Codes ........................... F–45

F-63 Cursor Test Parameters ................................ F–47

F-64 Cursor Test Error Codes . . . ............................ F–47

F-65 Analog Video Output Test Parameters.................... F–48

F-66 Analog Video Output Test Error Codes ................... F–48

F-67 Initial Power-Up Test Error Codes . . . .................... F–49

G-1 Major Error and Status Error Codes . .................... G–2

G-2 Minor Error and Status Error Codes . .................... G–4

xvi

Intended Audience

This guide is for Digital customer service representatives who

have completed training in DECstation/DECsystem 5000 Model

200 maintenance. This guide assumes that you are familiar

with basic maintenance and troubleshooting operations and

that you have experience with desktop computer systems.

How To Use This Guide

This guide explains how to identify and replace failed field-

replaceable units (FRUs). 1, 2, and 3 give background

information about the system hardware and operations

regularly used for customer service. Chapter 4 describes how

to determine which FRU failed. Chapter 5 provides detailed

information about troubleshooting and replacing individual

FRUs.

Using This Guide

For an overview of the system hardware and its configurations,

refer to Chapter 1, ‘‘A Look at DECstation/DECsystem 5000

Model 200 Hardware.’’

To perform routine service operations, refer to Chapter 2,

‘‘Service Operations.’’

To run tests and interpret their error codes, refer to Chapter 3,

‘‘Troubleshooting Tools.’’

xvii

To identify failed FRUs, refer to Chapter 4, ‘‘Identifying Failed

FRUs.’’

For a description of the hardware, troubleshooting procedures,

and replacement procedures for base system FRUs, refer to

Chapter 5.

For a description of the hardware, troubleshooting procedures,

and replacement procedures for TURBOchannel options, drives,

and monitors, refer to the TURBOchannel Maintenance Guide.

For equipment specifications, refer to Appendix A.

For equipment part numbers and a recommended spares list,

refer to Appendix B.

For an explanation of console commands, refer to Appendix C.

For an explanation of individual system module and memory

module tests, refer to Appendix D.

For information about R3000 CPU registers, refer to

Appendix E.

For an explanation of console commands used by Version PDE3

ROM chips that are in some systems, refer to Appendix G.

For an explanation of individual test commands and error

messages used by VERSIon PDE3 ROM chips, refer to

Appendix G.

About the Scope of This Guide

This guide discusses current DECstation/DECsystem 5000

hardware only. The maintenance guide will be revised as

additional options become available. Some of these future

options are three-dimensional graphics option modules.

xviii

Conventions Used in This Guide

Table 1. Conventions Used in This Guide

Convention Use

Monospace

type

Boldface

type

Italic type Any part of a command that you replace with an actual

Anything that appears on your monitor screen

is set in monospace type, like this.

Anything you are asked to type is set in boldface

type, like this.

value is set in italic type, like this.

xix

1

A Look at DECstation/DECsystem 5000

Model 200 Hardware

This chapter describes

Possible system hardware configurations

Basic system hardware

Optional system hardware

A Look at DECstation/DECsystem 5000 Model 200 Hardware 1–1

System Hardware Configurations

The DECstation/DECsystem 5000 Model 200 is a reduced

instruction set computer (RISC), ULTRIX-based desktop sys-

tem. Depending on the actual hardware, the system operates

as either a server or a workstation. DECstation/DECsystem

5000 Model 200 system hardware includes basic hardware that

supports graphics, drives, additional Ethernet connections, and

additional memory.

Figure 1-1 shows the possible configurations of the basic

and optional system hardware. Each item in Figure 1-1 is a

field-replaceable unit (FRU).

1–2 A Look at DECstation/DECsystem 5000 Model 200 Hardware

Ethernet

WSE2M001

drives

Up to seven

Basic System Hardware

The basic system hardware includes a system unit with

controls, indicators, and system connectors.

System Unit

The system unit, shown in Figure 1-2, includes the following:

One system module and chassis, which includes

One central processing unit (CPU)

One floating-point unit (FPU)

One small computer system interface (SCSI) controller

One serial line controller

One ThinWire Ethernet controller

Fifteen slots for memory modules

Three slots for optional graphics, SCSI, and ThickWire

Ethernet modules

One metal chassis that holds the system module

One 8-Mbyte memory module connected to the system

module

One power supply, which has three cooling fans

A removable system unit cover and front cover plate

1–4 A Look at DECstation/DECsystem 5000 Model 200 Hardware

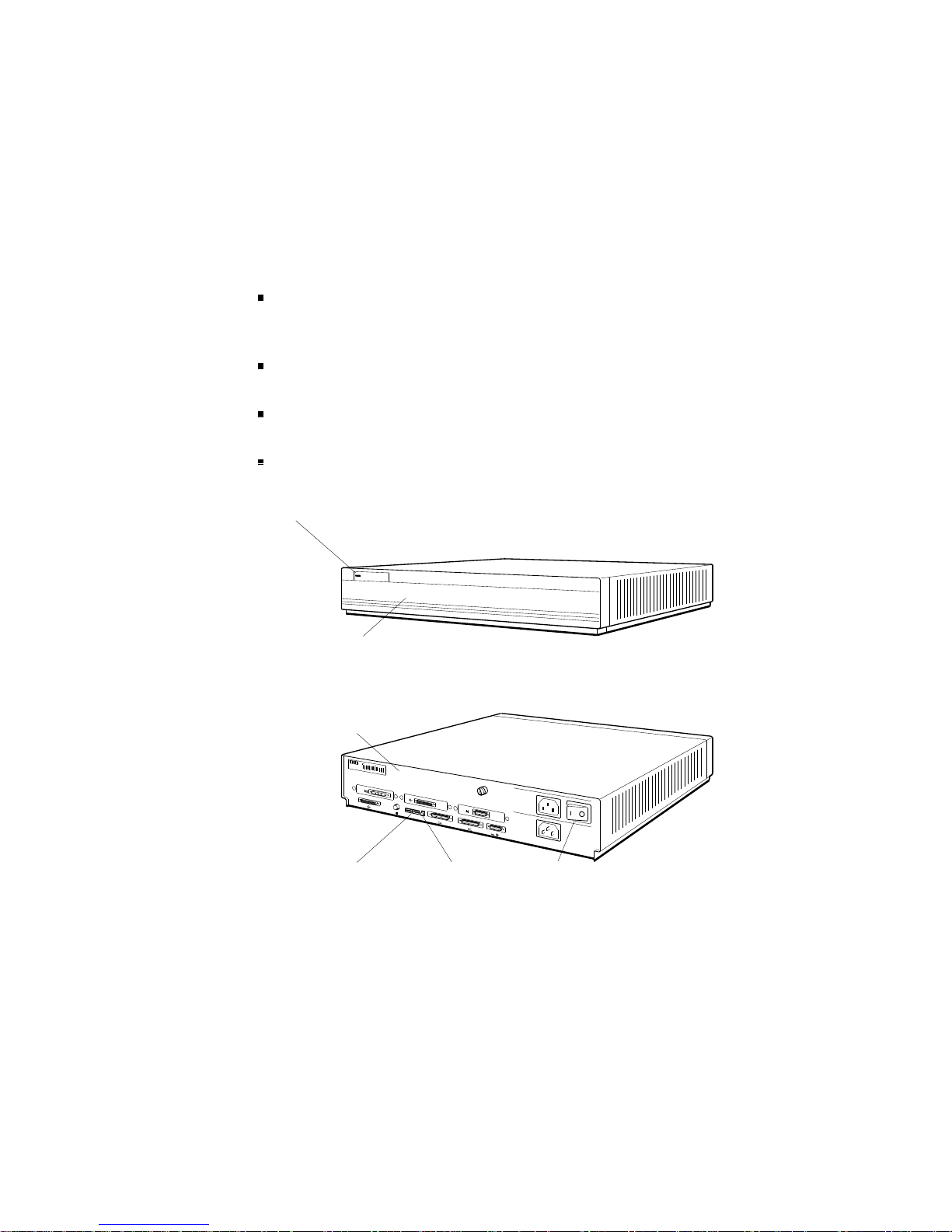

System Unit Controls and Indicators

The system unit controls and indicators, shown in Figure 1-3,

have the following uses:

The on/off switch turns the system on and off. Press down

the 0 on the switch to turn off the power. Press down the 1

on the switch to turn on the power.

The power indicator glows green when the power supply is

operating properly.

The diagnostic LEDs display binary error codes that

indicate test results.

The reset button initializes the system.

Power

supply

LED

DEC station 5000

Front view

Back view

d

i

g

i

t

a

l

0

Diagnostic

LEDs

PMAG-C

1

PMAZ-A

PMAD-A

3

Reset

button

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

On/off

switch

Figure 1-3. System controls and indicators

1–6 A Look at DECstation/DECsystem 5000 Model 200 Hardware

WSE2M003

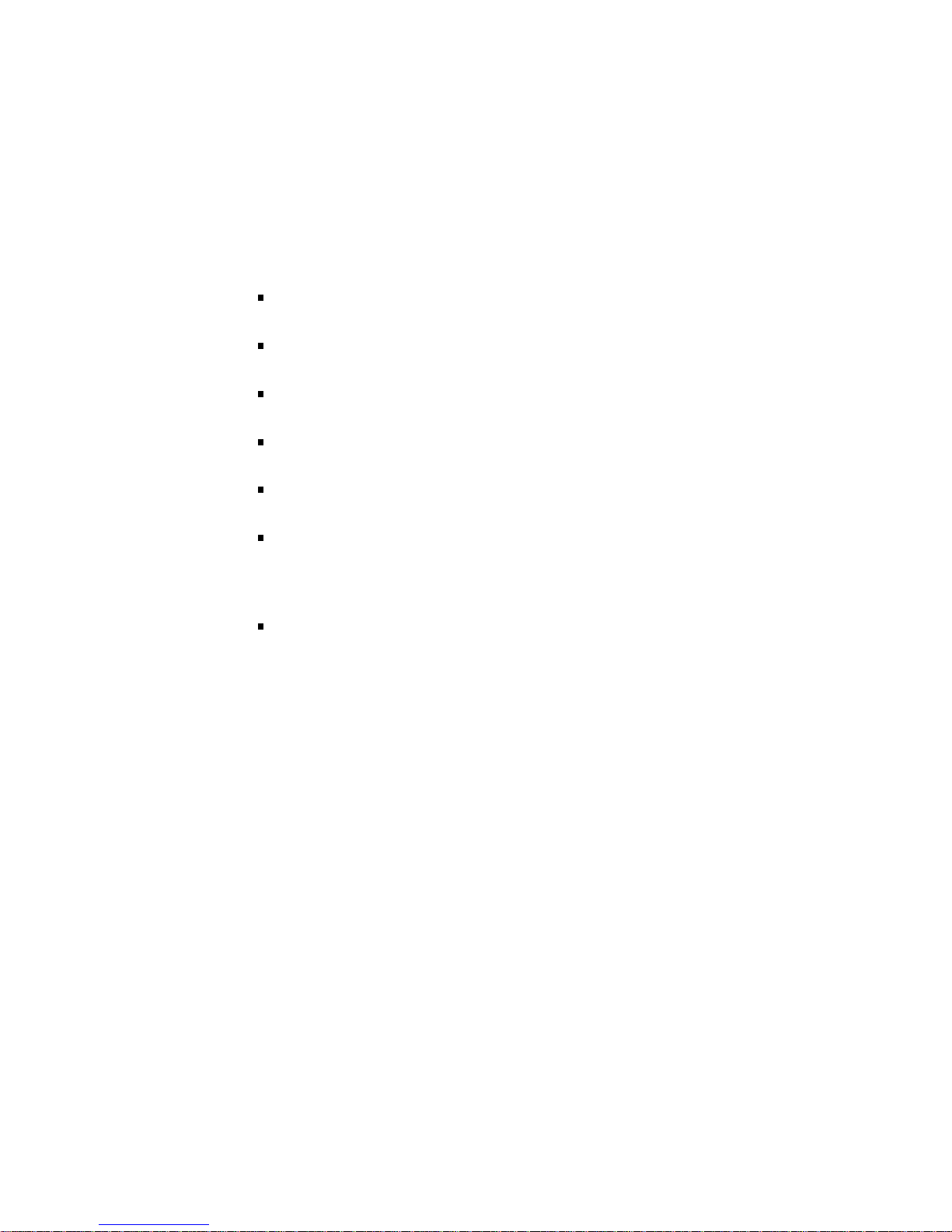

System Unit Connectors

The system unit connectors, shown in Figure 1-4, have the

following purposes:

The power connector connects the system unit power supply

and the system unit power cord.

The monitor-to-system-unit connector provides electric

power to the monitor power cord.

The ThinWire Ethernet connector links the system unit to

a ThinWire Ethernet.

The SCSI connector connects the base system SCSI

controller to a chain of external drives.

The keyboard-mouse connector links the system unit to the

keyboard-mouse cable.

The communications connectors provide printer, modem,

and console terminal connections. If there is a console

terminal, the terminal usually connects to the left

communications connector.

The option module connectors connect option modules to

external hardware. The number printed above each option

module connector is the slot number for any option module

in that slot.

A Look at DECstation/DECsystem 5000 Model 200 Hardware 1–7

SCSI

connector

Option module

connectors

d

i

g

i

t

a

l

0

PMAG-C

Monitor-to-system-unit

connector

1

PMAZ-A

PMAD-A

3

V~100-120 A 3.0

V~220-240 A 1.7

2

V~100-120/220-240

A 7.9/4.2

Hz 50-60

W 359

2

ThinWire

Ethernet

connector

Communications

connectors

Keyboard-mouse

connector

Figure 1-4. DECstation/DECsystem 5000 connectors

Power

connector

WSE2M004

1–8 A Look at DECstation/DECsystem 5000 Model 200 Hardware

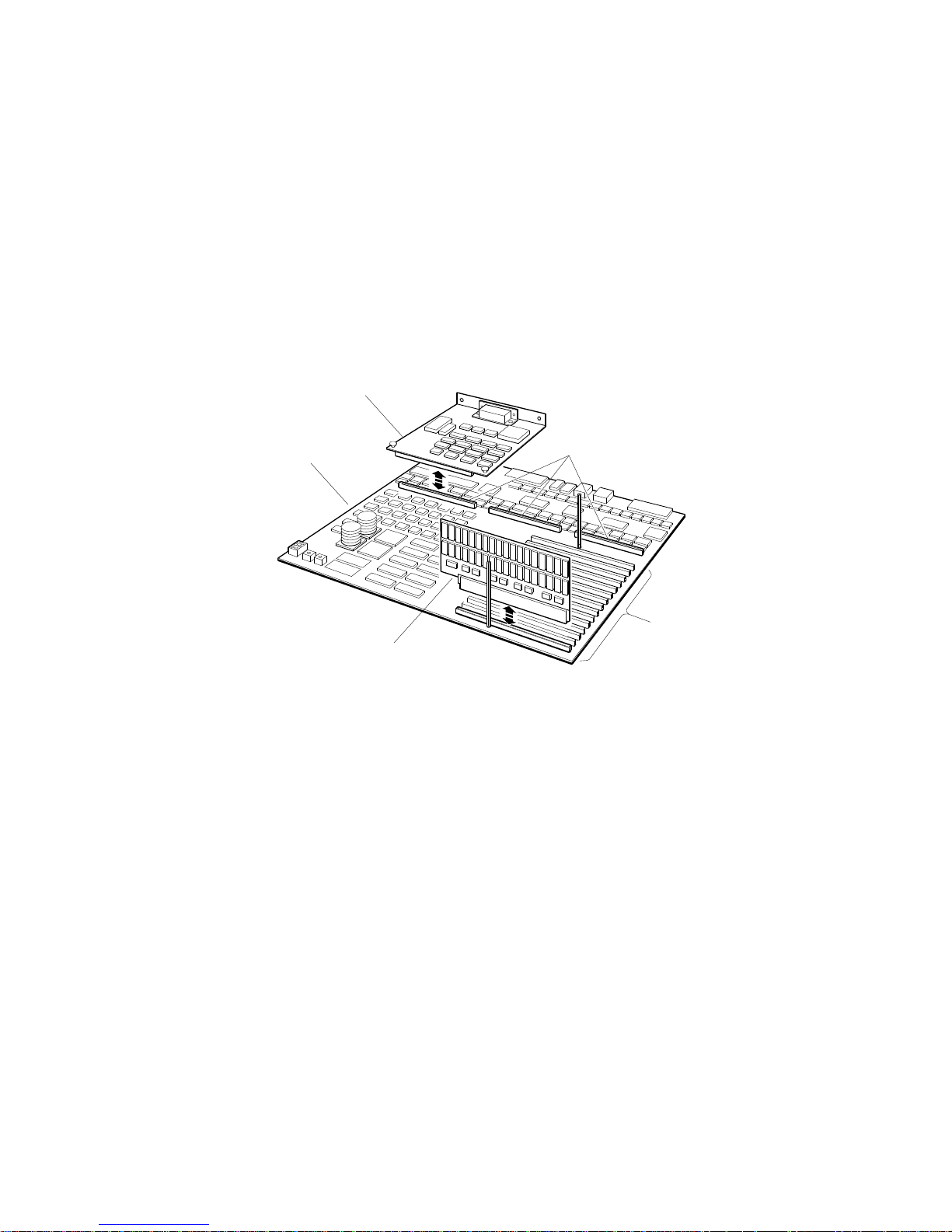

Hardware Options

The system module has slots for additional memory and

TURBOchannel option modules.

Figure 1-5 shows the location of memory and option module

expansion slots on the system module.

Option module

System

module

Memory module

Option module

expansion slots

Memory

module

expansion

slots

WSE2M005

Figure 1-5. Location of memory and expansion slots on the system

module

Additional Memory Modules

The system module has 15 expansion slots for additional

memory modules. Each memory slot can support one 8-Mbyte

memory module.

A Look at DECstation/DECsystem 5000 Model 200 Hardware 1–9

Optional TURBOchannel Modules

The three TURBOchannel expansion slots on the system unit

support a maximum of three option modules.

Any optional SCSI or Ethernet controller modules operate in

addition to the SCSI and ThickWire Ethernet controller built in

to the system module.

Drives

Each SCSI controller supports up to seven drives that connect

in a chain that attaches to the SCSI controller through the back

of the system unit.

Monitors and Terminals

The system supports different monitors, depending on the

graphics option modules that are in the system. Refer to the

TURBOchannel Maintenance Guide for a description of the

monitors that graphics option modules support.

The system can also display text on a VT320 terminal attached

to the communications connector on the left as you face the

back of the system unit.

Keyboard and Mouse

The system uses an LK201 keyboard and VSXXX-AA mouse

that connect to the back of the system unit through the

keyboard-mouse cable.

For Further Information

For further information about the hardware described in this

chapter, refer to later chapters that discuss the hardware in

which you are interested.

For further information about TURBOchannel option modules,

drives, or monitors, refer to the TURBOchannel Maintenance

Guide.

1–10 A Look at DECstation/DECsystem 5000 Model 200 Hardware

Service Operations

This chapter explains how to perform routine service

operations. It explains how to

Avoid electrostatic damage when handling components

Use an alternate terminal

Remove the system unit cover

Remove the front cover plate

Remove and replace the serial number plate

Install and remove terminators and loopback connectors

Enter console mode and operating mode

Use console command passwords

Boot the system software

Shut down the system software

2

Service Operations 2–1

Loading...

Loading...