Page 1

DEC4000AXP

ServiceGuide

Order Number: EK–KN430–SV. B01

Digital Equipment Corporation

Maynard, Massachusetts

Page 2

Revised, July 1993

First Printing, December 1992

The information in this document is subject to change without notice and should not be construed

as a commitment by Digital Equipment Corporation.

Digital Equipment Corporation assumes no responsibility for any errors that may appear in this

document.

The software, if any, described in this document is furnished under a license and may be used or

copied only in accordance with the terms of such license. No responsibility is assumed for the use

or reliability of software or equipment that is not supplied by Digital Equipment Corporation or its

affiliated companies.

Copyright © Digital Equipment Corporation, 1992. All Rights Reserved.

The Reader’s Comments form at the end of this document requests your critical evaluation to assist

in preparing future documentation.

The following are trademarks of Digital Equipment Corporation: Alpha AXP, AXP, DEC, DECchip,

DECconnect, DECdirect, DECnet, DECserver, DEC VET, DESTA, MSCP, RRD40, ThinWire,

TMSCP, TU, UETP, ULTRIX, VAX, VAX DOCUMENT, VAXcluster, VMS, the AXP logo, and the

DIGITAL logo.

OSF/1 is a registered trademark of Open Software Foundation, Inc.

All other trademarks and registered trademarks are the property of their respective holders.

FCC NOTICE: The equipment described in this manual generates, uses, and may emit radio

frequency energy. The equipment has been type tested and found to comply with the limits for

a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed

to provide reasonable protection against such radio frequency interference when operated in a

commercial environment. Operation of this equipment in a residential area may cause interference,

in which case the user at his own expense may be required to take measures to correct the

interference.

This document was prepared using VAX DOCUMENT, Version 2.1.

S2384

Page 3

Contents

Preface ................................................ xiii

1 System Maintenance Strategy

1.1 Troubleshooting the System . ....................... 1–1

1.2 Service Delivery Methodology ...................... 1–7

1.3 Product Service Tools and Utilities . . . ............... 1–8

1.4 Information Services ............................. 1–11

1.5 Field Feedback . . . ............................... 1–12

2 Power-On Diagnostics and System LEDs

2.1 Interpreting System LEDs . . ....................... 2–1

2.1.1 Power Supply LEDs ........................... 2–2

2.1.2 Operator Control Panel LEDs ................... 2–7

2.1.3 I/O Panel LEDs .............................. 2–9

2.1.4 Futurebus+ Option LEDs ....................... 2–11

2.1.5 Storage Device LEDs . . . ....................... 2–12

2.2 Power-Up Screens ............................... 2–15

2.2.1 Console Event Log ............................ 2–17

2.2.2 Mass Storage Problems Indicated at Power-Up ...... 2–18

2.2.3 Robust Mode Power-Up . ....................... 2–26

2.3 Power-Up Sequence .............................. 2–27

2.3.1 AC Power-Up Sequence . ....................... 2–27

2.3.2 DC Power-Up Sequence . ....................... 2–29

2.3.3 Firmware Power-Up Diagnostics . . ............... 2–32

2.3.3.1 Serial ROM Diagnostics ..................... 2–32

2.3.3.2 Console Firmware-Based Diagnostics........... 2–33

2.4 Boot Sequence . . . ............................... 2–33

2.4.1 Cold Bootstrapping in a Uniprocessor Environment . . 2–34

2.4.2 Loading of System Software ..................... 2–35

2.4.3 Warm Bootstrapping in a Uniprocessor

Environment . ............................... 2–36

v

Page 4

2.4.4 Multiprocessor Bootstrapping ................... 2–37

2.4.5 Boot Devices . . ............................... 2–37

3 Running System Diagnostics

3.1 Running ROM-Based Diagnostics ................... 3–1

3.1.1 test . ....................................... 3–3

3.1.2 show fru .................................... 3–5

3.1.3 show_status . . ............................... 3–7

3.1.4 show error . . . ............................... 3–8

3.1.5 memexer ................................... 3–10

3.1.6 memexer_mp . ............................... 3–11

3.1.7 exer_read ................................... 3–12

3.1.8 exer_write . . . ............................... 3–14

3.1.9 fbus_diag ................................... 3–16

3.1.10 show_mop_counter ............................ 3–18

3.1.11 clear_mop_counter ............................ 3–19

3.1.12 Loopback Tests............................... 3–20

3.1.12.1 Testing the Auxiliary Console Port (exer) . . ...... 3–20

3.1.12.2 Testing the Ethernet Ports (netexer) ........... 3–20

3.1.13 kill and kill_diags ............................ 3–21

3.1.14 Summary of Diagnostic and Related Commands ..... 3–21

3.2 DSSI Device Internal Tests . ....................... 3–22

3.3 DECVET...................................... 3–25

3.4 Running UETP . . ............................... 3–26

3.4.1 Summary of UETP Operating Instructions . . . ...... 3–26

3.4.2 System Disk Requirements ..................... 3–28

3.4.3 Preparing Additional Disks ..................... 3–28

3.4.4 Preparing Magnetic Tape Drives . . ............... 3–29

3.4.5 Preparing Tape Cartridge Drives . . ............... 3–29

3.4.5.1 TLZ06 Tape Drives. . ....................... 3–30

3.4.6 Preparing RRD42 Compact Disc Drives ............ 3–30

3.4.7 Preparing Terminals and Line Printers ............ 3–30

3.4.8 Preparing Ethernet Adapters .................... 3–30

3.4.9 DECnet for OpenVMS AXP Phase . ............... 3–31

3.4.10 Termination of UETP . . . ....................... 3–32

3.4.11 Interpreting UETP VMS Failures . ............... 3–32

3.4.12 Interpreting UETP Output ..................... 3–32

3.4.12.1 UETP Log Files ........................... 3–33

3.4.12.2 Possible UETP Errors ...................... 3–33

3.5 Acceptance Testing and Initialization. . ............... 3–34

vi

Page 5

4 Error Log Analysis

4.1 Fault Detection and Reporting ...................... 4–1

4.1.1 Machine Check/Interrupts ...................... 4–2

4.1.2 System Bus Transaction Cycle ................... 4–4

4.2 Error Logging and Event Log Entry Format ........... 4–4

4.3 Event Record Translation. . . ....................... 4–6

4.3.1 OpenVMS AXP Translation ..................... 4–6

4.3.2 DEC OSF/1 Translation . ....................... 4–7

4.4 Interpreting System Faults Using ERF and UERF ...... 4–7

4.4.1 Note 1: System Bus Address Cycle Failures . . ...... 4–12

4.4.2 Note 2: System Bus Write-Data Cycle Failures ...... 4–13

4.4.3 Note 3: System Bus Read Parity Error ............ 4–14

4.4.4 Note 4: Backup Cache Uncorrectable Error . . . ...... 4–14

4.4.5 Note 5: Data Delivered to I/O Is Known Bad. . ...... 4–15

4.4.6 Note 6: Futurebus+ DMA Parity Error ............ 4–15

4.4.7 Note 7: Futurebus+ Mailbox Access Parity Error .... 4–16

4.4.8 Note 8: Multi-Event Analysis of Command/Address

Parity, Write-Data Parity, or Read-Data Parity

Errors ..................................... 4–16

4.4.9 Sample System Error Report (ERF) ............... 4–16

4.4.10 Sample System Error Report (UERF) ............. 4–18

5 Repairing the System

5.1 General Guidelines for FRU Removal and Replacement . . 5–1

5.2 Front FRUs .................................... 5–4

5.2.1 Operator Control Panel . ....................... 5–4

5.2.2 Vterm Module ............................... 5–4

5.2.3 Fixed-Media Storage . . . ....................... 5–4

5.2.3.1 3.5-Inch Fast-SCSI Disk Drives (RZ26, RZ27,

RZ35) ................................... 5–4

5.2.3.2 3.5-Inch SCSI Disk Drives ................... 5–5

5.2.3.3 5.25-Inch SCSI Disk Drive ................... 5–6

5.2.3.4 SCSI Storageless Tray Assembly .............. 5–6

5.2.3.5 3.5-Inch DSSI Disk Drive .................... 5–7

5.2.3.6 5.25-Inch DSSI Disk Drive ................... 5–7

5.2.3.7 DSSI Storageless Tray Assembly .............. 5–8

5.2.4 Removable-Media Storage (Tape and Compact

Disc) ....................................... 5–8

5.2.4.1 SCSI Bulkhead Connector ................... 5–8

5.2.4.2 SCSI Continuity Card ...................... 5–8

5.2.5 Fans ....................................... 5–9

vii

Page 6

5.3 Rear FRUs ..................................... 5–16

5.3.1 Modules (CPU, Memory, I/O, Futurebus+) .......... 5–16

5.3.2 Ethernet Fuses .............................. 5–17

5.3.3 Power Supply . ............................... 5–17

5.3.4 Fans ....................................... 5–17

5.4 Backplane ..................................... 5–20

5.5 Repair Data for Returning FRUs .................... 5–22

6 System Configuration and Setup

6.1 Functional Description ............................ 6–1

6.1.1 System Bus . . ............................... 6–7

6.1.1.1 KN430 CPU .............................. 6–7

6.1.1.2 Memory . . ............................... 6–10

6.1.1.3 I/O Module ............................... 6–13

6.1.2 Serial Control Bus ............................ 6–15

6.1.3 Futurebus+ . . ............................... 6–16

6.1.4 Power Subsystem ............................. 6–17

6.1.5 Mass Storage . ............................... 6–19

6.1.5.1 Fixed-Media Compartments . . . ............... 6–19

6.1.5.2 Removable-Media Storage Compartment . . ...... 6–21

6.1.6 System Expansion ............................ 6–23

6.1.6.1 Power Control Bus for Expanded Systems . ...... 6–23

6.2 Examining System Configuration.................... 6–25

6.2.1 show config . . . ............................... 6–25

6.2.2 show device . . ............................... 6–26

6.2.3 show memory . ............................... 6–29

6.3 Setting and Showing Environment Variables ........... 6–29

6.4 Setting and Examining Parameters for DSSI Devices .... 6–33

6.4.1 show device du pu ............................ 6–33

6.4.2 cdp........................................ 6–34

6.4.3 DSSI Device Parameters: Definitions and Function. . 6–36

6.4.3.1 How OpenVMS AXP Uses the DSSI Device

Parameters .............................. 6–38

6.4.3.2 Example: Modifying DSSI Device Parameters .... 6–39

6.5 Console Port Baud Rate ........................... 6–41

6.5.1 Console Serial Port ........................... 6–42

6.5.2 Auxiliary Serial Port . . . ....................... 6–44

viii

Page 7

A Environment Variables

B Power System Controller Fault Displays

C Worksheet for Recording Customer Environment

Variable Settings

Glossary

Index

Examples

3–1 Running DRVTST ............................ 3–24

3–2 Running DRVEXR ............................ 3–25

4–1 ERF-Generated Error Log Entry Indicating CPU

Corrected Error .............................. 4–17

4–2 UERF-Generated Error Log Entry Indicating CPU

Error ...................................... 4–18

Figures

2–1 Power Supply LEDs ........................... 2–3

2–2 LDC and Fan Unit Locations and Error Codes ...... 2–6

2–3 OCP LEDs . . . ............................... 2–7

2–4 Module Locations Corresponding to OCP LEDs ...... 2–9

2–5 I/O Panel LEDs .............................. 2–10

2–6 Futurebus+ Option LEDs ....................... 2–11

2–7 Fixed-Media Mass Storage LEDs (SCSI) ........... 2–13

2–8 Fixed-Media Mass Storage LEDs (DSSI) ........... 2–14

2–9 Power-Up Self-Test Screen ...................... 2–16

2–10 Sample Power-Up Configuration Screen............ 2–17

2–11 Flowchart for Troubleshooting Fixed-Media

Problems ................................... 2–19

2–12 Flowchart for Troubleshooting Fixed-Media Problems

(Continued) . . ............................... 2–20

ix

Page 8

2–13 Flowchart for Troubleshooting Removable-Media

Problems ................................... 2–23

2–14 Flowchart for Troubleshooting Removable-Media

Problems (Continued) . . ....................... 2–24

2–15 AC Power-Up Sequence . ....................... 2–28

2–16 DC Power-Up Sequence . ....................... 2–30

2–17 DC Power-Up Sequence (Continued) .............. 2–31

4–1 ERF/UERF Error Log Format ................... 4–5

5–1 SCSI Continuity Card Placement . . ............... 5–9

5–2 Front FRUs . . ............................... 5–10

5–3 Storage Compartment with Four 3.5-inch Fast-SCSI

Drives (RZ26, RZ27, RZ35)...................... 5–11

5–4 Storage Compartment with Four 3.5-inch SCSI/DSSI

Drives ..................................... 5–12

5–5 3.5-Inch SCSI Drive Resistor Packs and Power

Termination Jumpers . . . ....................... 5–13

5–6 Position of Drives in Relation to Bus Node ID

Numbers ................................... 5–14

5–7 Storage Compartment with One 5.25-inch SCSI/DSSI

Drive ...................................... 5–15

5–8 Rear FRUs . . . ............................... 5–18

5–9 Ethernet Fuses and Ethernet Address ROMs . ...... 5–19

5–10 Removing Shell .............................. 5–21

5–11 Removing Backplane . . . ....................... 5–22

6–1 System Block Diagram . . ....................... 6–3

6–2 System Backplane ............................ 6–4

6–3 BA640 Enclosure (Front) ....................... 6–5

6–4 BA640 Enclosure (Rear) . ....................... 6–6

6–5 CPU Block Diagram ........................... 6–8

6–6 MS430 Memory Block Diagram . . . ............... 6–12

6–7 I/O Module Block Diagram ...................... 6–14

6–8 Serial Control Bus EEPROM Interaction ........... 6–16

6–9 Power Subsystem Block Diagram . . ............... 6–18

6–10 Fixed-Media Storage . . . ....................... 6–20

6–11 Removable-Media Storage ...................... 6–22

6–12 Sample Power Bus Configuration . . ............... 6–24

6–13 Device Name Convention ....................... 6–27

x

Page 9

6–14 How OpenVMS Sees Unit Numbers for DSSI

Devices ..................................... 6–39

6–15 Sample DSSI Buses for an Expanded DEC 4000 AXP

System ..................................... 6–41

6–16 Console Baud Rate Select Switch . . ............... 6–43

Tables

1–1 Recommended Troubleshooting Procedures . . . ...... 1–2

1–2 Diagnostic Flow for Power Problems .............. 1–5

1–3 Diagnostic Flow for Problems Getting to Console

Mode ...................................... 1–5

1–4 Diagnostic Flow for Problems Reported by the Console

Program .................................... 1–6

1–5 Diagnostic Flow for Boot Problems ............... 1–6

1–6 Diagnostic Flow for Errors Reported by the Operating

System ..................................... 1–7

2–1 Interpreting Power Supply LEDs . . ............... 2–4

2–2 Interpreting OCP LEDs . ....................... 2–8

2–3 Interpreting I/O Panel LEDs .................... 2–10

2–4 Interpreting Futurebus+ Option LEDs ............. 2–12

2–5 Interpreting Fixed-Media Mass Storage LEDs . ...... 2–14

2–6 Fixed-Media Mass Storage Problems .............. 2–21

2–7 Removable-Media Mass Storage Problems .......... 2–25

2–8 Supported Boot Devices . ....................... 2–37

3–1 Summary of Diagnostic and Related Commands ..... 3–21

4–1 DEC 4000 AXP Fault Detection and Correction ...... 4–2

4–2 Error Field Bit Definitions for Error Log

Interpretation ............................... 4–8

6–1 Memory Features ............................. 6–11

6–2 Power Control Bus ............................ 6–24

6–3 Environment Variables Set During System

Configuration . ............................... 6–30

6–4 Console Line Baud Rates ....................... 6–43

A–1 Environment Variables ....................... A–1

B–1 Power System Controller Fault ID Display . . . ...... B–1

C–1 Nonvolatile Environment Variables ............... C–1

xi

Page 10

Page 11

Preface

This guide describes the procedures and tests used to service DEC 4000 AXP

systems.

Intended Audience

This guide is intended for use by Digital Equipment Corporation service personnel

and qualified self-maintenance customers.

Conventions

The following coventions are used in this guide.

Convention Meaning

Return

Ctrl/x Ctrl/x indicates that you hold down the Ctrl key while you

bold type In the online book (Bookreader), bold type in examples

lowercase Lowercase letters in commands indicate that commands can be

A key name enclosed in a box indicates that you press that key.

press another key, indicated here by x. In examples, this key

combination is enclosed in a box, for example,

indicates commands and other instructions that you enter

at the keyboard.

entered in uppercase or lowercase.

Ctrl/C

.

xiii

Page 12

In some illustrations, small drawings of the DEC 4000 AXP

system appear in the left margin. Shaded areas help you locate

components on the front or back of the system.

Warning Warnings contain information to prevent personal injury.

Caution Cautions provide information to prevent damage to equipment

[]

console command

abbreviations

boot

italic type Italic type in console command sections indicates a variable.

< > In console mode online help, angle brackets enclose a

{ } In command descriptions, braces containing items separated by

or software.

In command format descriptions, brackets indicate optional

elements.

Console command abbreviations must be entered exactly as

shown.

Console and operating system commands are shown in this

special typeface.

placeholder for which you must specify a value.

commas imply mutually exclusive items.

xiv

Page 13

1

System Maintenance Strategy

Any successful maintenance strategy is based on the proper understanding

and use of information services, service tools, service support and escalation

procedures, field feedback, and troubleshooting procedures. This chapter

describes the maintenance strategy for the DEC 4000 AXP system.

• Section 1.1 provides a diagnostic strategy you should use to troubleshoot a

DEC 4000 AXP system.

• Section 1.2 explains the service delivery methodology.

• Section 1.3 lists the product tools and utilities.

• Section 1.4 lists available information services.

• Section 1.5 describes field feedback procedures.

1.1 Troubleshooting the System

Before troubleshooting any system problem, check the site maintenance log for

the system’s service history. Be sure to ask the system manager the following

questions:

• Has the system been used before and did it work correctly?

• Have changes to hardware or updates to firmware or software been made to

the system recently?

• What is the state of the system—is the operating system up?

If the operating system is down and you are not able to bring it up, use the

console environment diagnostic tools, such as RBDs and LEDs.

If the operating system is up, use the operating system environment

diagnostic tools, such as error logs, crash dumps, DEC VET and UETP

exercisers, and other log files.

System Maintenance Strategy 1–1

Page 14

System problems can be classified into the following five categories:

1. Power problems

2. Problems getting to the console

3. Failures reported by the console subsystem

4. Boot failures

5. Failures reported by the operating system

Using these categories, you can quickly determine a starting point for diagnosis

and eliminate the unlikely sources of the problem. Table 1–1 provides the

recommended tools or resources you should use to isolate problems in each

category.

Table 1–1 Recommended Troubleshooting Procedures

Description

1. Power Problems (Table 1–2)

Diagnostic

Tools/Resources Reference

No power at system

enclosure or trouble with

power supply subsystem, as

indicated by LEDs.

2. Problems Getting to Console Mode (Table 1–3)

System powers up, but

does not display power-up

screen.

Power supply

subsystem

LEDs

OCP LEDs Refer to Section 2.1.2 for information on

Console

terminal

troubleshooting

flow

Power-up

sequence

description

Robust mode

power-up

Refer to Section 2.1.1 for information on

interpreting power supply LEDs.

interpreting OCP LEDs.

Refer to Table 1–3 for information

on troubleshooting console terminal

problems.

Refer to Section 2.3 and 2.3.3 for a

description of the power-up and self-test

sequence.

Refer to Section 2.2.3 for a description of

robust mode power-up and its functions.

(continued on next page)

1–2 System Maintenance Strategy

Page 15

Table 1–1 (Cont.) Recommended Troubleshooting Procedures

Description

3. Failures Reported by the Console Program (Table 1–4)

Diagnostic

Tools/Resources Reference

Power-up console screens

indicate a failure.

4. Boot Failures (Table 1–5)

System fails to boot

operating system.

Power-up

screens

Console event

log

RBD device

tests

Console

commands

(to examine

environment

variables

and device

parameters)

Storage device

troubleshooting

flowcharts

RBD device

tests

Boot sequence

description

Refer to Section 2.2 for information on

interpreting power-up self-tests.

Refer to Section 2.2 for information on

the console event log.

Refer to Section 3.1 for information on

running RBD device tests.

Refer to Chapter 6 for instructions on

setting and examining environment

variables and device parameters.

Refer to Section 2.2.2.

Refer to Section 3.1 for information on

running RBD device tests.

Refer to Section 2.4 for a description of

the boot sequence.

(continued on next page)

System Maintenance Strategy 1–3

Page 16

Table 1–1 (Cont.) Recommended Troubleshooting Procedures

Description

5. Failures Reported by the Operating System (Table 1–6)

Diagnostic

Tools/Resources Reference

Operating system generates

error logs; process hangs or

operating system crashes.

Error logs Refer to Chapter 4 for information on

Crash dump Refer to OpenVMS AXP Alpha System

DEC VET or

UETP

Other log files Refer to Chapter 4 for information on

interpreting error logs.

Dump Analyzer Utility Manual for

information on how to interpret

OpenVMS crash dump files.

Refer to the Guide to Kernel Debugging

(AA–PS2TA–TE) for information on

using the DEC OSF/1 Krash Utility.

Refer to Section 3.3 for a description

of DEC VET, and Section 3.4 for

information on running UETP software

exercisers.

using log files such as SETHOST.LOG

and OPERATOR.LOG to aid in

troubleshooting.

Use the following tables to identify the diagnostic flow for the five types of system

problems:

• Table 1–2 provides the diagnostic flow for power problems.

• Table 1–3 provides the diagnostic flow for problems getting to console mode.

• Table 1–4 provides the diagnostic flow for problems reported by the console

program.

• Table 1–5 provides the diagnostic flow for boot problems.

• Table 1–6 provides the diagnostic flow for errors reported by the operating

system.

1–4 System Maintenance Strategy

Page 17

Table 1–2 Diagnostic Flow for Power Problems

Symptom Action Reference

No AC power at system

as indicated by AC

present LED.

AC power is present, but

system does not power

on.

Check the power source and power cord.

Check the system AC circuit breaker

setting.

Check the DC on/off switch setting.

Examine power supply subsystem LEDs

to determine if a power supply unit

or fan has failed, or if the system has

shut down due to an overtemperature

condition.

Section 2.1.1

Table 1–3 Diagnostic Flow for Problems Getting to Console Mode

Symptom Action Reference

Power-up screens (or

console event log) are

not displayed.

Check OCP LEDs for a failure during

self-tests. If two OCP LEDs remain lit,

either option could be at fault.

Check baud rate setting for console

terminal and system. The system default

baud rate setting is 9600.

Try connecting the console terminal to

the auxiliary console port.

Note: No console output is directed to

the auxiliary console port untill the

power-up self-tests have completed and

you press the Enter key or Ctrl/x.

For certain situations, power up under

robust mode to bypass the power-up

script and get to a low-level console.

From console mode, you can then edit the

nvram file, set and examine environment

variables, or initialize individual phases

of drivers.

Section 2.1.2

Section 6.5

Section 2.2.3

System Maintenance Strategy 1–5

Page 18

Table 1–4 Diagnostic Flow for Problems Reported by the Console Program

Symptom Action Reference

Power-up screens are

displayed, but tests do

not complete.

Console program reports

error.

Use power-up display and/or OCP LEDs

to determine error.

Examine the console event log to check

for embedded error messages recorded

during power-up.

If power-up screens indicate problems

with mass storage devices, use the

troubleshooting flow charts to determine

the problems.

Run RBD tests to verify problem. Section 3.1

Use the

examine error information contained

in serial control bus EEPROMs.

show error

command to

Section 2.2 and

Section 2.1.2

Section 2.2.1

Section 2.2.2

Section 3.1.4

Table 1–5 Diagnostic Flow for Boot Problems

Symptom Action Reference

System cannot find boot

device.

Device does not boot. Run device test to check that boot device

Check system configuration for correct

device parameters (node ID, device name,

and so on) and environment variables

(bootdef_dev, boot_file, boot_osflags).

is operating.

Section 6.2.1,

Section 6.3, and

Section 6.4

Section 3.2

1–6 System Maintenance Strategy

Page 19

Table 1–6 Diagnostic Flow for Errors Reported by the Operating System

Symptom Action Reference

System is hung or has

crashed.

Operating system is up. Examine the operating system error log

Examine the crash dump file. Operating system

Use the

examine error information contained

in serial control bus EEPROMs (console

environment error log).

files to isolate the problem.

If the problem occurs intermittently, run

DEC VET or UETP to stress the system.

Examine other log files, such as

SETHOST.LOG, OPCOM.LOG, and

OPERATOR.LOG.

show error

command to

documentation

Section 3.1.4

Chapter 4

Section 3.3 and

Section 3.4

1.2 Service Delivery Methodology

Before beginning any maintenance operation, you should be familiar with the

following:

• The site agreement

• Your local and area geography support and escalation procedures

• Your Digital Services product delivery plan

System Maintenance Strategy 1–7

Page 20

Service delivery methods are part of the service support and escalation

procedure. When appropriate, remote services should be part of the initial

system installation. Methods of service delivery include the following:

• Local support

• Remote call screening

• Remote diagnosis (using modem support)

Recommended System Installation

The recommended system installation includes:

1. Hardware installation and acceptance testing. Acceptance testing includes

running ROM-based diagnostics.

2. Software installation and acceptance testing. For example, using OpenVMS

Factory Installed Software (FIS), and then acceptance testing with DEC VET

or UETP.

3. Installation of the remote service tools and equipment to allow a Digital

Service Center to dial in to the system. Refer to your remote service delivery

strategy.

If you do not follow your service delivery methodology, you risk incurring

excessive service expenses for any product.

1.3 Product Service Tools and Utilities

This section lists the array of service tools and utilities available for acceptance

testing, diagnosis, and serviceability and provides recommendations for their use.

Error Handling/Logging

OpenVMS and DEC OSF/1 operating systems provide recovery from errors,

fault handling, and event logging. The OpenVMS Error Report Formatter

(ERF) provides bit-to-text translation of the event logs for interpretation.

DEC OSF/1 uses UERF to capture the same kinds of information.

RECOMMENDED USE: Analysis of error logs is the primary method of

diagnosis and fault isolation. If the system is up, or the customer allows the

service representative to bring the system up, look at this information first.

Refer to Chapter 4 for information on using error logs to isolate faults.

1–8 System Maintenance Strategy

Page 21

ROM-Based Diagnostics (RBDs)

ROM-based diagnostics have significant advantages:

• There is no load time.

• The boot path is more reliable.

• Diagnosis is done in console mode.

RECOMMENDED USE: The ROM-based diagnostic facility is the primary

means of console environment testing and diagnosis of the CPU, memory,

Ethernet, Futurebus+, and SCSI and DSSI subsystems. Use ROM-based

diagnostics in the acceptance test procedures when you install a system,

add a memory module, or replace the following: CPU module, memory

module, backplane, I/O module, Futurebus+ device, or storage device. Refer

to Section 3.1 for information on running ROM-based diagnostics.

Loopback Tests

Internal and external loopback tests are used to isolate a failure by testing

segments of a particular control or data path. The loopback tests are a subset

of the ROM-based diagnostics.

RECOMMENDED USE: Use loopback tests to isolate problems with the

auxiliary console port and Ethernet controllers. Refer to Section 3.1.12 for

instructions on performing loopback tests.

Firmware Console Commands

Console commands are used to set and examine environment variables and

device parameters. For example, the

and

show device

set

(bootdef_dev, auto_action, and boot_osflags) commands are used to set

environment variables; and the

parameters.

RECOMMENDED USE: Use console commands to set and examine

environment variables and device parameters. Refer to Section 6.2 for

information on firmware commands and utilities.

commands are used to examine the configuration; the

show memory,show configuration

cdp

command is used to configure DSSI

System Maintenance Strategy 1–9

,

Page 22

Option LEDs During Power-Up

The power supply LEDs display pass/fail test results for the power supply

subsystem; the operator control panel (OCP) LEDs display pass/fail self-test

results for CPU, memory, I/O, and Futurebus+ modules. Storage devices and

Futurebus+ modules have their own LEDs as well.

RECOMMENDED USE: Monitor LEDs during power-up to see if the devices

pass their self-tests. Refer to Chapter 2 for information on LEDs and powerup tests.

Operating System Exercisers (DEC VET or UETP)

The Digital Verifier and Exerciser Tool (DEC VET) is supported by the

OpenVMS and DEC OSF/1 operating systems. DEC VET performs exerciseroriented maintenance testing of both hardware and operating system. UETP

is included with OpenVMS and is designed to test whether the OpenVMS

operating system is installed correctly.

RECOMMENDED USE: Use DEC VET or UETP as part of acceptance testing

to ensure that the CPU, memory, disk, tape, file system, and network are

interacting properly. Also use DEC VET or UETP to stress test the user’s

environment and configuration by simulating system operation under heavy

loads to diagnose intermittent system failures.

Crash Dumps

For fatal errors, such as fatal bugchecks, OpenVMS and DEC OSF/1 operating

systems will save the contents of memory to a crash dump file.

RECOMMENDED USE: The support representative should analyze crash

dump files. To save a crash dump file for analysis, you need to know

proper system settings. Refer to the OpenVMS AXP Alpha System Dump

Analyzer Utility Manual or the Guide to Kernel Debugging (AA–PS2TA–TE)

for instructions.

Other Log Files

Several types of log files, such as operator log, console event log, sethost log,

and accounting file (accounting.dat) are useful in troubleshooting.

RECOMMENDED USE: Use the sethost log and other log files to

capture/examine the console output and compare with event logs and crash

dumps in order to see what the system was doing at the time of the error.

1–10 System Maintenance Strategy

Page 23

1.4 Information Services

As a Digital service representative, you may access several information resources,

including advanced database applications, online training courses, and remote

diagnostic tools. A brief description of some of these resources follows.

Technical Information Management Architecture (TIMA)

TIMA is an online database that delivers technical and reference information

to service representatives. A key benefit of TIMA is the pooling of worldwide

knowledge and expertise.

DEC 4000 AXP Model 600 Series Information Set

The DEC 4000 AXP Model 600 Series Information Set consists of service

documentation that contains information on installing and using, servicing

and upgrading, and understanding the system. The guide you are reading

is part of the set. The hardcopy kit number is EK–KN430–DK. The set is

also available on TIMA. Refer to your DEC 4000 Model 600 Information Map

(EK–KN430–IN) for detailed information.

Training

Computer Based Training (CBT) and lecture lab courses are available from

the Digital training center:

• DEC 4000 System Installation and Troubleshooting (CBT course, EY–

I090E–CO)

• Alpha Architecture Concepts (CBT course, EY–K725E–MT—magnetic

tape; EY–K725E–TK—TK50 tape)

• Futurebus+ Concepts (EY–F479E–CO)

Digital Services Product Delivery Plan (Hardware or Software)

The Product Delivery Plan documents Digital Services’ delivery commitments.

The plan is the communications vehicle used among the various groups

responsible for ensuring consistency between Digital Services’ delivery

strategies and engineering product strategies.

Blitzes

Technical updates are ‘‘blitzed’’ to the field using online mail and TIMA.

System Maintenance Strategy 1–11

Page 24

Storage and Retrieval System (STARS)

STARS is a worldwide database for storing and retrieving technical

information. The STARS databases, which contain more than 150,000 entries,

are updated daily.

Using STARS, you can quickly retrieve the most up-to-date technical

information via DSNlink or DSIN.

1.5 Field Feedback

Providing the proper feedback to the corporation is essential in closing the loop

on any service call. Consider the following when completing a service call:

• Fill out repair tags accurately and with as much symptom information as

possible so that repair centers can fix a problem.

• Provide accurate call closeout information for Labor Activity Reporting

System (LARS) or Call-Handling and Management Planning (CHAMP).

• Keep an up-to-date site maintenance log, whether hardcopy or electronic, to

provide a record of the performed maintenance.

1–12 System Maintenance Strategy

Page 25

2

Power-On Diagnostics and System

LEDs

This chapter provides information on how to interpret system LEDs and the

power-up console screens. In addition, a description of the power-up and

bootstrap sequence is provided as a resource to aid in troubleshooting.

• Section 2.1 describes how to interpret system LEDs.

• Section 2.2 describes how to interpret the power-up screens.

• Section 2.3 describes the power-up sequence.

• Section 2.3.3 describes power-on self-tests.

• Section 2.4 describes the boot sequence.

2.1 Interpreting System LEDs

DEC 4000 AXP systems have several diagnostic LEDs that indicate whether

modules and subsystems have passed self-tests. The power system controller

constantly monitors the power supply subsystem and can indicate several types

of failures. The system LEDs are used primarily to troubleshoot power problems

and problems getting to the console program.

This section describes the function of each of the following types of system LEDs,

and what action to take when a failure is indicated.

• Power supply LEDs

• Operator control panel (OCP) LEDs

• I/O panel LEDs

• Futurebus+ option LEDs

• Storage device LEDs

Power-On Diagnostics and System LEDs 2–1

Page 26

2.1.1 Power Supply LEDs

The power supply LEDs (Figure 2–1) are used to indicate the status of the

components that make up the power supply subsystem. The following types of

failures will cause the power system controller to shut down the system:

• Power system controller (PSC) failure

• Fan failure

• Overtemperature condition

• Power regulator failures (indicated by the DC3 or DC5 failure LEDs)

• Front end unit (FEU) failure

Note

The AC circuit breaker will also shut down the system. If a power surge

occurs, the breaker will trip, causing the switch to return to the off

position (0). If the circuit breaker trips, wait 30 seconds before setting the

switch to the on position (1).

Refer to Table 2–1 for information on interpreting the LEDs and determining

what actions to take when a failure is indicated.

Figure 2–2 shows the local disk converter (LDC) and fan locations as they

correspond to the fault ID display.

2–2 Power-On Diagnostics and System LEDs

Page 27

Figure 2–1 Power Supply LEDs

PSC DC3FEU DC5

MO

SI

SO

AC Circuit

Breaker

FEU Failure

FEU OK

DC3 Failure

DC3 OK

DC5 Failure

DC5 OK

PSC Failure

PSC OK

Over

Overtemperature

Shutdown

Fan Failure

Disk Power Failure

Fault ID Display

AC Present

LJ-02011-TI0

Power-On Diagnostics and System LEDs 2–3

Page 28

Table 2–1 Interpreting Power Supply LEDs

Indicator Meaning Action on Error

Front End Unit (FEU)

AC Present When lit, indicates AC power

is present at the AC input

connector (regardless of circuit

breaker position).

FEU OK When lit, indicates DC output

voltages for the FEU are above

the specified minimum.

FEU Failure When lit, indicates DC output

voltages for the FEU are less

than the specified minimum.

If AC power is not present, check

the power source and power cord.

If the system will not power up and

the AC LED is the only lit LED,

check if the system AC circuit

breaker has tripped. Replace the

front end unit (Chapter 5) if the

system circuit breaker is broken.

Replace front end unit (Chapter 5).

(continued on next page)

2–4 Power-On Diagnostics and System LEDs

Page 29

Table 2–1 (Cont.) Interpreting Power Supply LEDs

Indicator Meaning Action on Error

Power System Controller (PSC)

PSC OK When blinking, indicates the

PSC Failure When lit, indicates the PSC has

Disk Power

Failure

Fan Failure When lit, indicates a fan has

Overtemperature

Shutdown

PSC is performing power-up

self-tests.

When steady, indicates the PSC

is functioning normally.

detected a fault in itself.

When lit, indicates a disk

power problem for the storage

compartment specified in the

hexadecimal fault ID display.

The most likely failing unit is

the local disk converter, but a

shorting cable or drive could also

be at fault.

failed or a cable guide is not

properly secured. The failure is

identified by a number displayed

in the hexadecimal fault ID

display.

When lit, indicates the PSC has

shut down the system due to

excessive internal temperature.

Replace power system controller

(Chapter 5).

To isolate the local disk converter,

disconnect the drives on the

specified bus and then power

up the system. If the Disk Power

Failure LED lights with the drives

disconnected, replace the failing

local disk converter (Chapter 5).

Refer to Figure 2–2 to locate the

local disk converter specified by

the fault ID display. A is the top

compartment, D is the bottom

compartment.

Refer to Figure 2–2 to locate the

failure specified by the fault ID

display.

Replace the failing fan (Chapter 5).

Set the AC circuit breaker to off (0)

and wait one minute before turning

on the system.

Make sure the air intake is

unobstructed and that the room

temperature does not exceed

maximum requirement as

described in the DEC 4000 Site

Preparation Checklist.

(continued on next page)

Power-On Diagnostics and System LEDs 2–5

Page 30

Table 2–1 (Cont.) Interpreting Power Supply LEDs

Indicator Meaning Action on Error

DC–DC Converter (DC3)

DC3 OK When lit, indicates that all the

DC3 output voltages are within

specified tolerances.

DC3 Failure When lit, indicates that one of

the output voltages is outside

Replace the DC3 converter

(Chapter 5).

specified tolerances.

DC–DC Converter (DC5)

DC5 OK When lit, indicates the DC5

output voltage is within specified

tolerances.

DC5 Failure When lit, indicates the DC5

output voltage is outside

Replace the DC5 converter

(Chapter 5).

specified tolerances.

Figure 2–2 LDC and Fan Unit Locations and Error Codes

Fan Error Codes

Local Disk

Converter A

Local Disk

Converter B

Local Disk

Converter C

Local Disk

Converter D

Fan 3 Fan 4 Fan 1

3

1 - Rear left

2 - Rear right

3 - Front left

4 - Front right

9 - A cable guide is not

properly secured or

two or more fans have

failed.

4

Fans are located

behind the cable guides

Fan 2

1

2

MLO-010872

2–6 Power-On Diagnostics and System LEDs

Page 31

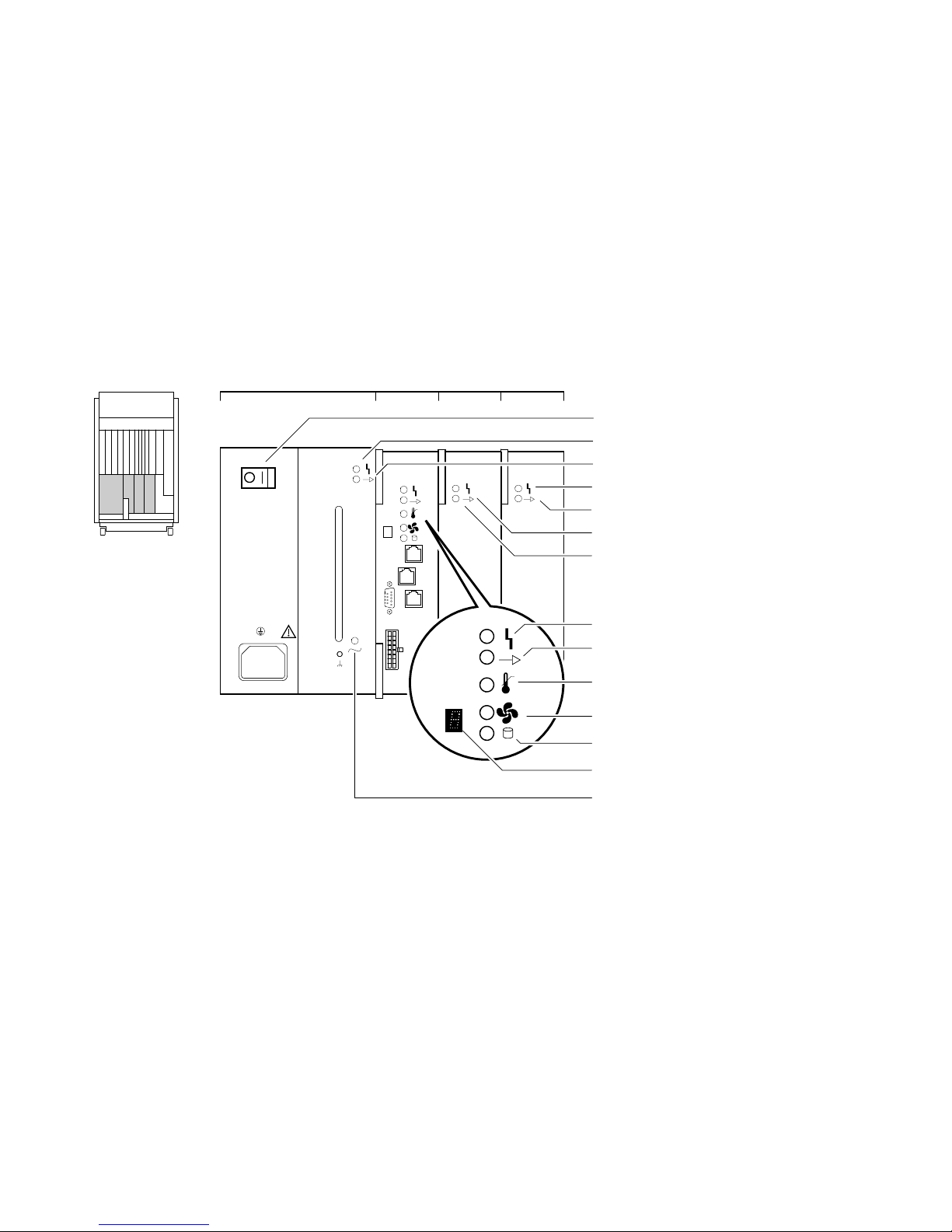

2.1.2 Operator Control Panel LEDs

The OCP LEDs (Figure 2–3) are used to indicate the progress and result of

self-tests for Futurebus+, memory, CPU, and I/O modules. These LEDs are

the primary diagnostic tool for troubleshooting problems getting to the console

program.

Note

A failure in the CPU, memory module, or I/O module can cause both the

I/O and CPU LEDs or I/O and memory LEDs to indicate self-test failures

even if only one of the modules is failing. If two LEDs are lit, the I/O

module is the more likely source of the failure.

Figure 2–3 OCP LEDs

DC On/Off

Switch

DC Power

LED

Self-Test

Status LEDs

Reset Halt

6-1 3 2 1 0 0 1

MEM CPU I/O

LJ-02008-TI0

Power-On Diagnostics and System LEDs 2–7

Page 32

Refer to Table 2–2 for information on interpreting the OCP LEDs and

determining what actions to take when a failure is indicated.

Figure 2–4 shows the module locations as they correspond to the LEDs.

Table 2–2 Interpreting OCP LEDs

Indicator Meaning Action on Error

Futurebus+ 6–1 Remains lit if a Futurebus+

option has failed power-on

diagnostics.

MEM 3, 2, 1, 0 Remains lit if a memory module

has failed power-on diagnostics.

If no good memory is found, all

four memory LEDs may remain

lit even if there are less than

four memory modules present.

CPU 0, 1 Remains lit if a CPU module has

failed power-on diagnostics.

I/O Remains lit if the I/O module

has failed power-on diagnostics.

DC Power When lit indicates the proper

DC power is present. When

unlit, indicates no DC power is

present.

Examine LEDs on the Futurebus+

options to determine which option

to replace.

Replace the failed module

(Chapter 5).

Replace the failed module

(Chapter 5).

Replace the I/O module (Chapter 5).

If no DC power is indicated, set

the DC on/off switch to on (1) and

examine the power supply LEDs.

2–8 Power-On Diagnostics and System LEDs

Page 33

Figure 2–4 Module Locations Corresponding to OCP LEDs

F1

0

F2

F3

6

4321

5

3210

MEM

01

CPU

1

F4

I/O

LJ-02052-TI0

2.1.3 I/O Panel LEDs

The I/O panel LEDs (Figure 2–5) are used to indicate the status of ThinWire and

thickwire (standard) Ethernet fuses.

Refer to Table 2–3 for information on interpreting the LEDs and determining

what actions to take when a failure is indicated.

Power-On Diagnostics and System LEDs 2–9

Page 34

Figure 2–5 I/O Panel LEDs

F1

F2

F3

F4

ThinWire Ethernet Fuse OK

0

Thickwire Ethernet Fuse OK

ThinWire Ethernet Fuse OK

1

Thickwire Ethernet Fuse OK

LJ-02012-TI0

Table 2–3 Interpreting I/O Panel LEDs

Indicator Meaning Action on Error

ThinWire

Ethernet Fuse

OK

Thickwire

Ethernet Fuse

OK

When lit, indicates ThinWire

fuse is good; unlit indicates fuse

has blown.

When lit, indicates thickwire

fuse is good; unlit indicates fuse

has blown.

Replace fuse (refer to Chapter 5).

Replace fuse (refer to Chapter 5).

2–10 Power-On Diagnostics and System LEDs

Page 35

2.1.4 Futurebus+ Option LEDs

The Futurebus+ option LEDs (Figure 2–6) are used to indicate the progress and

result of self-tests for a specific Futurebus+ option.

Refer to Table 2–4 for information on interpreting the LEDs and determining

what actions to take when a failure is indicated.

Figure 2–6 Futurebus+ Option LEDs

Fault

Run

LJ-02010-TI0

Power-On Diagnostics and System LEDs 2–11

Page 36

Table 2–4 Interpreting Futurebus+ Option LEDs

Indicator Meaning Action on Error

Fault The Fault indicator lights during

self-tests. If it remains lit, the

module has failed self tests.

Run The Run indicator blinks during

self-tests and remains lit if the

module passes self-tests.

Replace module.

2.1.5 Storage Device LEDs

Storage device LEDs are used to indicate the status of the device. The LEDs for

fixed-media storage devices are shown in Figures 2–7 and Figure 2–8. Refer to

the DEC 4000 Model 600 Series Owner’s Guide for information on LEDs for the

removable-media devices.

Refer to Table 2–5 for information on interpreting the LEDs and determining

what actions to take when a failure is indicated.

2–12 Power-On Diagnostics and System LEDs

Page 37

Figure 2–7 Fixed-Media Mass Storage LEDs (SCSI)

Fast SCSI

3.5-Inch SCSI

5.25-Inch SCSI

Fault

Local Disk

Converter OK

Online

Fault

Local Disk

Converter OK

Online

SCSI

Terminator

Local Disk

Converter OK

SCSI

Terminator

LJ-02486-TI0

Power-On Diagnostics and System LEDs 2–13

Page 38

Figure 2–8 Fixed-Media Mass Storage LEDs (DSSI)

3.5-Inch DSSI

5.25-Inch DSSI

Fault

Local Disk

Converter OK

Online

DSSI Terminator

with LED

Fault

Write Protect

Local Disk

Converter OK

Run/Ready

DSSI Terminator

with LED

LJ-02483-TI0

Table 2–5 Interpreting Fixed-Media Mass Storage LEDs

Indicator Meaning Action on Error

Fault When lit, indicates an error

condition in the device. The

Fault indicator may light

temporarily during self-tests.

Online DSSI: When lit, indicates the

device is on line and available

for use. Under normal operation,

flashes as seek operations are

performed.

SCSI: Flashes as seek operations

are performed; indicates drive

activity.

2–14 Power-On Diagnostics and System LEDs

Run device RBD tests and internal

device tests to determine the

nature of the error, and replace

device.

(continued on next page)

Page 39

Table 2–5 (Cont.) Interpreting Fixed-Media Mass Storage LEDs

Indicator Meaning Action on Error

DSSI Terminator When lit, indicates DSSI

Local Disk

Converter OK

termination power is present.

When lit, indicates local disk

converter for the specified

storage compartment has power

(this LED is located on the

local disk power supply module

behind the front panel of the

storage compartment).

If the DSSI terminator LED does

not light, check the DSSI bus

connections for that bus. If bus

connections seem secure, the local

disk converter module or DC5

converter may need to be replaced

(Section 5.2):

• Local disk converters (located

in the fixed-media storage

compartments) supply

termination power for fixedmedia storage devices.

• The DC5 converter (part of

the power supply subsystem)

supplies termination power

for storageless fixed-media

compartments.

Confirm that the system power

supply is working properly (by

checking power supply LEDs).

Replace the local disk converter

module (Section 5.2).

2.2 Power-Up Screens

During power-up self-tests a screen similar to the one shown in Figure 2–9 is

displayed on the console terminal. The screen shows the status and result of the

self-tests.

Power-On Diagnostics and System LEDs 2–15

Page 40

Figure 2–9 Power-Up Self-Test Screen

VMS PAlcode Xn.nnX, OSF PAlcode Xn.nnX (CPU 1 of 1, DECchip 21064)

17:33:56 Tuesday, January 26, 1993

Digital Equipment Corporation

DEC 4000 AXP

\ Executing Power-Up Diagnostics

Memory Storage Net

CPU

APBPCPDPEP0P1P1 2 3 4 5 60P1 0 123

P

* Test in progress P Pass F Fail - Not Present

TM

Futurebus+

TM

? Sizing

LJ-02266-TI0

A power-on self-test failure indicated under Storage A–E may represent

a failure of an embedded storage adapter (A–E) or failure of a drive on

the specified bus. Check the console event log for additional information

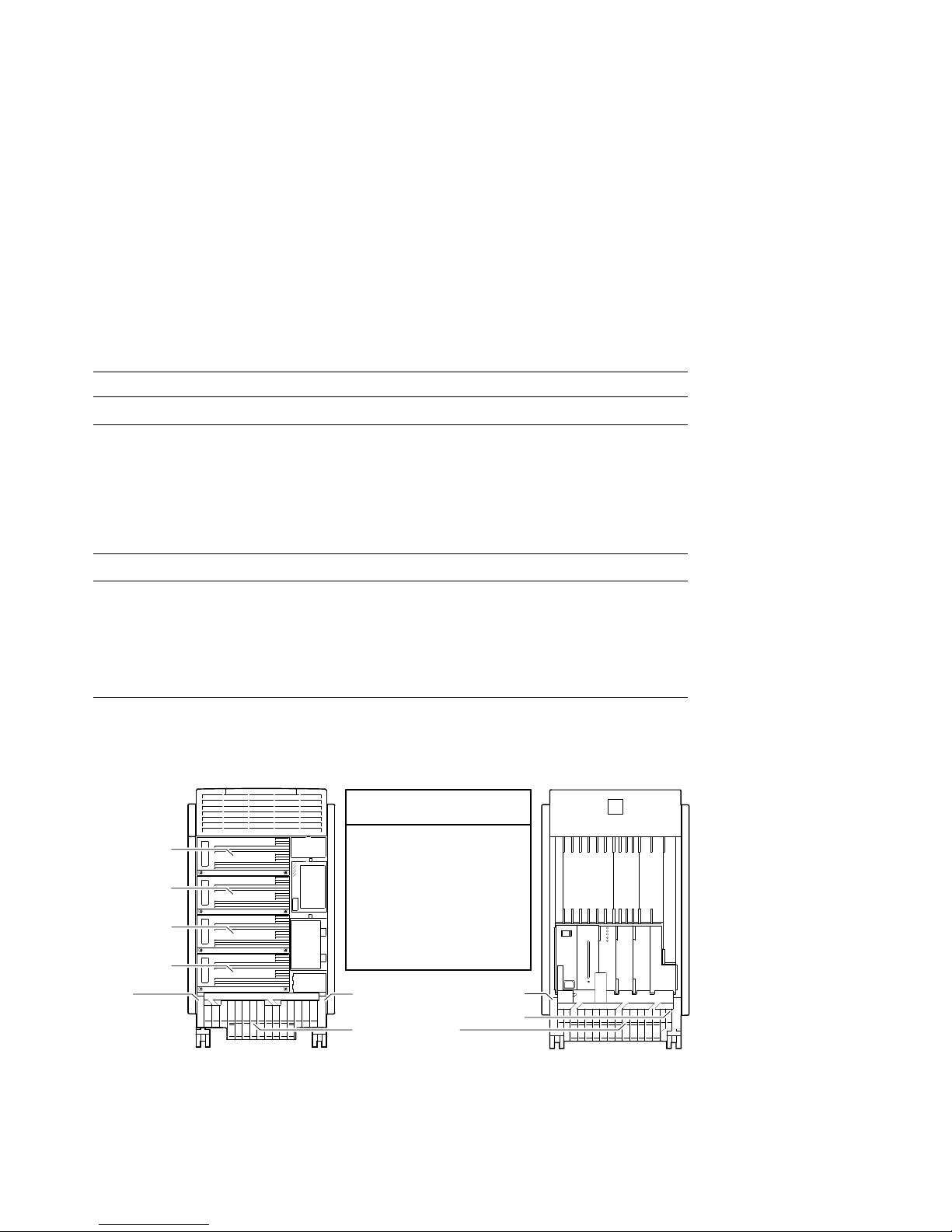

(Section 2.2.1).

Power-on self-tests failures indicated for all six Futurebus+ slots indicate

a failure of the Futurebus+ bridge on the I/O module. Replace the I/O

module in the event that all six Futurebus+ slots show failures.

When the power-up diagnostics are completed, a second screen similar to the

one shown in Figure 2–10 is displayed. This screen provides configuration

information for the system.

2–16 Power-On Diagnostics and System LEDs

Note

Page 41

Figure 2–10 Sample Power-Up Configuration Screen

Console Vn.n-nnnn VMS PALcode Xn.nnX, OSF PALcode Xn.nnX

CPU 0

CPU 1

Memory 0

Memory 1

Memory 2

Memory 3

Ethernet 0

Ethernet 1

A SCSI

B DSSI

C DSSI

D DSSI

E SCSI

Futurebus+

B2001-AA DECchip 21064-2

P

-

-

-

B2002-DA 128 MB

P

Address 08-00-2B-2A-D6-97

P

Address 08-00-2B-2A-D6-A6

P

ID 1 ID 2 ID 3 ID 4 ID 5 ID 6 ID 7

ID 0

RZ73

P

RF73

P

P

P

P

P

TZ85

RRD42

FBA0

TM

-----

Host

Host

Host

Host

Host

Host

Host

System Status Pass

>>>

Type

b

to boot dka0.0.0.0.0

LJ-02267-TI0

2.2.1 Console Event Log

DEC 4000 AXP systems maintain a console event log consisting of status

messages received during power-on self-tests. If there are problems during

power-up, standard error messages may be embedded in the console event log. To

display a console event log, use the

Use the

set screen_mode off

log during power-up, rather than the two power-up screens.

The following example shows an abbreviated console event log that contains two

standard error messages: The first (a hard error) indicates a failure with storage

bus B. This failure could be caused by a bad LDC, improperly seated storage

drawer, or a disconnected power cable within the storage drawer. The second (a

soft error) indicates a SCSI continuity card is missing from the removable-media

storage compartment.

cat el

command.

command if you want to display the console event

Power-On Diagnostics and System LEDs 2–17

Page 42

>>>

cat el

Starting console.

halt code = 1

PC=0

initialized idle PCB

initializing semaphores

.

.

.

test Storage Bus B

ncr1, loopback connector attached OR

SCSI bus failure, could not acquire bus; Control Lines:ff Data lines:ff

ncr1 SCSI bus failure

*** Hard Error - Error #800 Diagnostic Name ID Device Pass Test Hard/Soft 7-OCT-1970

powerup 00000004 ncr1 0 0 1 0 10:48:58

Storage Bus B failure

*** End of Error ***

enable ncr2 ACK

test Storage Bus C

port p_c0.7.0.2.0 initialized, scripts are at 1d07e0

SCSI device found on pkc.0.0.2.0

loading SCSI driver for port p_c0.7.0.2.0

.

.

.

*** Soft Error - Error #1 - Lower SCSI Continuity Card Missing (connector J7)

Diagnostic Name ID Device Pass Test Hard/Soft 7-OCT-1992

io_test 00000067 scsi_low_con 1 1 0 1 11:25:53

*** End of Error ***

device mud9.5.0.3.0 (TF85) found on pud0.5.0.3.0

>>>

2.2.2 Mass Storage Problems Indicated at Power-Up

Mass storage failures at power-up are usually indicated in one of two ways:

• The power-up screens report a storage adapter port failure (indicated by an

‘‘F’’).

• One or more drives are missing from the configuration screen display (or too

many drives are displayed).

Figures 2–11 and 2–12 provide a flowchart for troubleshooting fixed-media mass

storage problems indicated at power-up. Use the flowchart to diagnose the likely

cause of the problem. Table 2–6 lists the symptoms and corrective action for each

of the possible problems.

2–18 Power-On Diagnostics and System LEDs

Page 43

Figure 2–11 Flowchart for Troubleshooting Fixed-Media Problems

Does the disk drive have power?

Check the Disk Power Failure LED on the PSC.

LED off LED on Likely LDC failure

Check the LDC OK LED on the storage compartment front panel.

LED on LED off

Continue

Has the disk drive failed?

Check the drive’s fault LED.

LED on (steady) Drive failure

LED off

LED flashing

Continue

Are bus node ID plugs improperly set?

Check that all drives on the bus have unique bus node ID numbers (no duplicates).

Duplicate bus node IDs Configuration rule violation

Check that no drive is set to bus node ID 7 (reserved for host ID).

Drive set to host ID 7

Continue

Is the storage drawer properly seated?

Power down, remove drawer and inspect connectors, reseat drawer and power up.

LDC failure

Drive is performing

extended calibration;

wait for tests to complete

Configuration rule violation

Problems persist

Continue

Problems solved Drawer not properly seated

LJ-02548-TI0A

Power-On Diagnostics and System LEDs 2–19

Page 44

Figure 2–12 Flowchart for Troubleshooting Fixed-Media Problems (Continued)

Are cables loose or missing?

Power down, remove drawer and check all cable connections, reseat drawer and power up.

Problems persist

Continue

Is the storage bus terminated?

Check that a terminator is in place.

Check that terminator power is present. For DSSI buses, check that the terminator LED is on.

For SCSI buses use a volt meter on the port connector (termination power is supplied by pin 38,

ground on pin 1).

Power present

Continue

Is the I/O module the source of the problem?

Swap the failing drive drawer to another compartment.

Likely problem with drive, drawer, or cables. Check again before continuing.

Is the backplane the source of the problem?

Eliminate all of the preceding problem sources before suspecting the backplane.

The backplane is the least likely to fail.

Disassemble the system as described in Section 5.4. Inspect the two

backplane interconnect cables.

Problems solved

Terminator missing Terminator missingTerminator present

No termination power LDC failure (with fixed-media devices)

Problems solvedProblems persist

Cable disconnected

-

-

DC5 failure (for storageless fixed-media

compartments)

I/O module failure

Cables are OK

Replace backplane assembly as described in Section 5.4.

Cable connections are Backplane interconnect cable failure

loose or damaged

2–20 Power-On Diagnostics and System LEDs

LJ-02548-TI0B

Page 45

Table 2–6 Fixed-Media Mass Storage Problems

Problem Symptom Corrective Action

LDC failure Disk power failure LED on PSC

Drive failure Fault LED for drive is on

Duplicate bus

node ID plugs

(or a missing

plug)

Bus node ID set

to 7 (reserved

for host ID)

Storage drawer

not properly

seated

is on.

LDC OK LED on storage

compartment front panel is

off.

Power-up screen reports a failing

storage adapter port.

(steady).

Drives with duplicate bus node

ID plugs are missing from the

configuration screen display.

A drive with no bus node ID plug

defaults to zero.

Valid drives are missing from

the configuration screen display.

One drive may appear seven

times on the configuration screen

display.

Disk power failure LED on PSC

is on.

LDC OK LED on storage

compartment front panel is

off.

Power-up screen reports a failing

storage adapter port.

Replace LDC.

Replace drive.

Correct bus node ID plugs.

Correct bus node ID plugs.

Remove drawer and check its

connectors. Reseat drawer.

(continued on next page)

Power-On Diagnostics and System LEDs 2–21

Page 46

Table 2–6 (Cont.) Fixed-Media Mass Storage Problems

Problem Symptom Corrective Action

Missing or loose

cables

Terminator

missing

No termination

power

I/O module

failure

Backplane

failure

Cable: storage device to ID

panel—Bus node ID defaults to

zero; online LEDs do not come

on.

Flex circuit: LDC to storage

interface module—Disk power

failure LED on PSC is on;

LDC OK LED on storage

compartment front panel is

off; and power-up screen reports

a failing storage adapter port.

Cable: LDC to storage interface

module—Power-up screen

reports a failing storage adapter

port; drive LEDs do not come on

at power-up.

Cable: LDC to storage device—

Drive does not show up in

configuration screen display.

Read/write errors in console

event log; storage adapter port

may fail

DSSI terminator LED is off, or

no termination voltage measured

at SCSI connector (pin 38,

ground pin 1); Read/write errors;

storage adapter port may fail.

The storage drawer exhibits no

problems when moved to another

compartment.

Replacing the I/O module does

not solve problem. The port

continues to fail and the problem

is not with the storage drawer.

Remove storage drawer and inspect

cable connections.

Attach terminator to connector

port.

Replace LDC (termination power

source for fixed-media storage

compartments).

Replace DC5 converter (termination power source for storageless

fixed-media storage compartments).

Replace I/O module.

Disassemble system and inspect

backplane interconnect cables. If

the cables and cable connections

do not appear to be the problem,

replace the backplane.

Figures 2–13 and 2–14 provide a flowchart for troubleshooting removable-media

storage problems indicated at power-up. Use the flowchart to diagnose the likely

cause of the problem. Table 2–7 lists the symptoms and corrective action for each

of the possible problems.

2–22 Power-On Diagnostics and System LEDs

Page 47

Figure 2–13 Flowchart for Troubleshooting Removable-Media Problems

Has the drive failed?

Check the drive’s fault LED.

LED off LED on (steady) Drive failure

Continue

Are bus node ID plugs improperly set?

Check that all drives on the bus have unique bus node ID numbers (no duplicates).

Duplicate bus node IDs Configuration rule violation

Check that no drive is set to bus node ID 7 (reserved for host ID).

Drive set to host ID 7

Continue

Is the SCSI continuity card missing?

Check the console event log for an error message indicating a SCSI continuity card

is missing. If the top and/or bottom storage compartments do not have half-height

drives, a SCSI continuity card is needed to continue the bus. Refer to Section 6.1.5.2

for more information.

Half-height drive or

SCSI continuity card

present

If console event log reports erroneously that the SCSI continuity card is missing,

replace the Vterm module. The Vterm module contains the logic for reporting

SCSI continuity card errors.

Continue

missing

Configuration rule violation

SCSI continuity card missingSCSI continuity card

LJ-02549-TI0A

Power-On Diagnostics and System LEDs 2–23

Page 48

Figure 2–14 Flowchart for Troubleshooting Removable-Media Problems

(Continued)

Are cables loose or missing?

Power down, remove drive and check all cable connections, replace drive and power up.

Problems persist

Continue

Is the storage bus terminated?

Check that a terminator is in place.

Check that terminator power is present. Use a voltmeter on the port connector

(termination power is supplied by pin 38, ground on pin 1).

Power present

Continue

Is the I/O module the source of the problem?

Replace the I/O module.

Likely problem with drive or cables. Check again before continuing.

Is the backplane the source of the problem?

Eliminate all of the preceding problem sources before suspecting the backplane.

The backplane is the least likely to fail.

Disassemble the system as described in Section 5.4. Inspect the two

backplane interconnect cables.

Problems solved

Terminator missing Terminator missingTerminator present

No termination power Vterm module failure

Problems solvedProblems persist

Cable disconnected

I/O module failure

Cables are OK

Replace backplane assembly as described in Section 5.4.

Cable connections are Backplane interconnect cable failure

loose or damaged

2–24 Power-On Diagnostics and System LEDs

LJ-02549-TI0B

Page 49

Table 2–7 Removable-Media Mass Storage Problems

Problem Symptom Corrective Action

Drive failure Fault LED for drive is on

Duplicate bus

node ID plugs

(or a missing

plug)

Bus node ID set

to 7 (reserved

for host ID)

SCSI continuity

card missing

Missing or loose

cables

Terminator

missing

Vterm module

failure

(steady).

Drives with duplicate bus node

ID plugs are missing from the

configuration screen display.

A drive with no bus node ID plug

defaults to zero.

Valid drives are missing from

the configuration screen display.

One drive may appear seven

times on the configuration screen

display.

Power-up screen reports a

failing storage adapter port;

console event log contains soft

error message reporting a SCSI

continuity card is missing; drives

on Bus E are not displayed on

configuration screen; possible

read/write errors.

Cable: storage device to ID

panel—Bus node ID defaults to

zero; online LED does not come

on.

Cable: Power—Drive does not

show up in configuration screen

display.

Read/write errors in console

event log; storage adapter port

may fail

No termination voltage

measured at Bus E SCSI

connector (pin 38, ground pin

1); Read/write errors; storage

adapter port may fail; or

console erroneously reports

SCSI continuity card as missing.

Replace drive.

Correct bus node ID plugs.

Correct bus node ID plugs.

Attach SCSI continuity card

(Section 6.1.5.2).

If console erroneously reports

SCSI continuity card as missing,

replace the Vterm module. The

Vterm module contains the logic

for reporting SCSI continuity card

errors.

Remove device and inspect cable

connections.

Attach terminator to connector

port.

Replace Vterm module (termination power source for removablemedia storage compartment).

(continued on next page)

Power-On Diagnostics and System LEDs 2–25

Page 50

Table 2–7 (Cont.) Removable-Media Mass Storage Problems

Problem Symptom Corrective Action

I/O module

failure

Backplane

failure

Problems persist after

eliminating the above problem

sources.

Replacing the I/O module does

not solve problem—the port

continues to fail and the problem

is not with the device or cables.

Replace I/O module.

Disassemble system and inspect

backplane interconnect cables. If

the cables and cable connections

do not appear to be the problem,

replace the backplane.

2.2.3 Robust Mode Power-Up

Robust mode allows you to power up without initiating drivers or running

power-up diagnostics.

Robust mode permits you to get to the console program when one of the following

is the cause of a problem getting to the console program under normal power-up:

• An error in the nonvolatile nvram file

• An incorrect environment variable setting

• A driver error

Note

The console program has limited functionality in robust mode.

Once in console mode, you can:

• Edit the nvram file (using the

• Assign a correct value to an environment variable (using the

commands)

• Start individual classes or sets of drivers, called phases (using the

-driver #

command. The pound sign (#) is the phase number 2, 3, 4, or 5,

and each phase is started individually in increasing order.

2–26 Power-On Diagnostics and System LEDs

edit

command)

show

and

init

set

Page 51

Note

The nonvolatile file, nvram, is shipped from the factory with no contents.

The customer can use the

command file that is executed as the last step of every power-up.

To set the system to robust mode, set the baud rate select switch located behind

the OCP to 0, as shown in Section 6.5. The robust mode setting uses a 9600

console baud rate.

edit

command to create a customized script or

2.3 Power-Up Sequence

During the DEC 4000 AXP power-up sequence, the power supplies are stabilized

and tested and the system is initialized and tested via the firmware power-on

self-tests.

The power-up sequence includes the following:

• Power supply power-up:

– Includes AC power-up and power supply self-test.

– Includes DC power-up and power supply self-tests.

• Two sets of power-on diagnostics:

– Serial ROM diagnostics

– Console firmware-based diagnostics

2.3.1 AC Power-Up Sequence

With no AC power applied, no energy is supplied to the entire enclosure. AC

power is applied to the system with the AC circuit breaker on the front end unit

(FEU) of the power supply (see Figure 2–1) . With just AC power applied, the AC

present LED is the only LED illuminated on the power supply.

Figure 2–15 provides a description of the AC power-up sequence.

Failures during AC power-up are indicated by the power supply subsystem LEDs.

Additional error information is displayed on the PSC Fault ID display. Refer to

Appendix B for PSC fault display information.

Power-On Diagnostics and System LEDs 2–27

Page 52

Figure 2–15 AC Power-Up Sequence

AC plug is inserted into wall outlet

AC circuit breaker is set to on (1)

AC power (country-specific voltage) enters FEU module

FEU creates two +48V outputs:

+48 VDC enters PSC, energizes microprocessor power system

PSC module verifies microprocessor power

OK FAILED Micro power system output not valid

PSC microprocessor performs internal self-test and PSC interface test

OK FAILED

PSC microprocessor self-test passed, PSC OK LED is turned on

PSC verifies +48 VDC BUS_DIRECT output is okay, turns on FEU OK LED

PSC verifies input voltage conditions: AC_POWER, FEU_HVDC, DIRECT_48V

All three are okay

-

AC power

-

FEU high voltage (HVDC)

-

+48V BUS_DIRECT

1.BUS_DIRECT +48 VDC output (always on) immediately

goes to +48 DC inputs on DC5, DC3 and PSC modules

2.BUS_SWITCHED (+V-V) +48 VDC output (off) goes to

+48 VDC input on LDCs and Futurebus+ modules

-

-

FEU failure LED is turned on

-

PSC microprocessor latches into shutdown

-

PSC microprocessor failed self-test

-

PSC failure LED is turned on

-

PSC microprocessor latches into shutdown

If BUS_DIRECT and AC power are not okay,

the system is in AC low line condition

-

PSC waits for either output to become okay

-

NO FEU LEDs are turned on

PSC waits for power-up command

PSC loops in routine checking status

WAIT

2–28 Power-On Diagnostics and System LEDs

If +48 VDC BUS_DIRECT is not asserted,

but AC power is okay, FEU has failed

-

FEU failure LED comes on

-

PSC latches in shutdown

LJ-02484-TI0

Page 53

2.3.2 DC Power-Up Sequence

DC power is applied to the system with the DC on/off switch on the operator

control panel.

Figures 2–16 and 2–17 provide a description of the DC power-up sequence.

Failures during DC power-up are indicated by the power supply subsystem LEDs.

Additional error information is displayed on the PSC Fault ID display. Refer to

Appendix B for PSC fault display information.

Power-On Diagnostics and System LEDs 2–29

Page 54

Figure 2–16 DC Power-Up Sequence

DC on/off switch set to on (1)

PSC starts DC power-up sequence and status check

PSC checks temperature sensor

OK FAILED

PSC checks overtemperature status (onboard)

OK FAILED

PSC commands FEU to start fans by asserting FAN_POWER_ENABLE H.

All fans are started at maximum speed, rotation speed is verified.

OK FAILED

PSC negates ASYNC_RESET signal to system CPU

PSC commands FEU to turn on +48 VDC BUS_SWITCHED output

PSC waits 100 ms for FEU to assert BUS_SWTCHD_OK signal

OK FAILED

FEU +48 VDC switched output (+V-V) goes to local disk

converters (LDCs) and Futurebus+ slots

PSC commands DC3 to turn on +3.3 VDC output

PSC waits 50 ms for +3.3 VDC to reach regulation

-

Failed PSC fault LED is turned on

-

Fans operate at full speed

-

Fans kept running while orderly shutdown is initiated

-

Fan Failure LED is turned on

-

Fans turned off after 30-sec. delay

-

One or more fans fail to start

-

Fans kept running while orderly shutdown is initiated

-

Overtemperature shutdown LED is turned on

and fan number is displayed

and fan number is displayed

-

Fans turned off after 30-sec. delay

-

BUS_SWTCHD_OK did not assert within 100 ms

-

Fans are turned off

-

FEU OK LED is turned off

-

FEU failure LED is turned on

-

PSC latches in shutdown mode

OK FAILED

PSC commands DC5 to turn on +5.1 VDC output

Go to next page

2–30 Power-On Diagnostics and System LEDs

-

Output did not reach regulation in time

-

Fans and active DC outputs are turned off

-

Failure LED on DC3 module is turned on

-

PSC latches in shutdown mode

LJ-02485-TI0A

Page 55

Figure 2–17 DC Power-Up Sequence (Continued)

PSC waits 30 ms for +5.1 VDC to reach regulation

-

-

OK FAILED

DC5 OK LED is turned on

PSC commands DC3 to turn on +2.1 VDC output

PSC waits 20 ms for +2.1 VDC to reach regulation

OK FAILED

PSC commands DC3 to turn on +12 VDC output

PSC waits 100 ms for +12 VDC to reach regulation

-

Output did not reach regulation in time

-

Fans and active DC outputs are turned off

-

Failure LED on DC5 module is turned on

-

PSC latches in shutdown mode

-

-

Output did not reach regulation in time

-

Fans and active DC outputs are turned off

-

Failure LED on DC3 module is turned on

-

PSC latches in shutdown mode

OK FAILED

DC3 OK LED is turned on

All DC outputs except LDCs are energized

PSC checks status of entire power system and delays for 45 ms

PSC negates ASYNC_REST_L and asserts POK_H; begins powering LDCs

Each LDC has an enable bit that, when asserted, starts a timer.

The LDC has 50 ms to respond with its LDC_OK signal asserted.

OK FAILED

LDC_OK is received within 50 ms, a 5-sec. timeout is initiated for disk spin-up time.

System power-up is complete

PSC microprocessor begins ongoing status monitoring

-

Output did not reach regulation in time

-

Fans and active DC outputs are turned off

-

Failure LED on DC3 module is turned on

-

PSC latches in shutdown mode

-OK FAILED

One of the above outputs has failed;

failure mode indicated as described

above for the appropriate output.

-

-

LDC did not respond in time allowed

-

Disk power failure LED is turned on

-

Corresponding letter (A, B, C, or D) is

displayed on fault ID display

-