Page 1

Dean

™

®

HD Series Gas Fryers -CE

Models

HD150G

HD250G

HD350G

HD450G

Shown with optional filtration

HD250G

HD550G

HD650G

HD160G

HD260G

HD360G

HD460G

HD560G

HD660G

HD163G

HD263G

HD363G

HD463G

HD563G

HD663G

HD165G*

HD265G

Standard Features

• High-efficiency Thermo-Tube frypot design

• Oil capacity

HD50G -- 50-lb. (25 liter)

HD60G -- 80 lb. (40 liter)

HD63G -- 90 lb. (45 liter)

HD65G -- 100 lb. (50 liter)

• Btu/hr input

HD50G -- 92,150 (23,212 kcal/hr.) (27 kw/hr.)

HD60G -- 115,000 (28,967 kcal/hr.) (33.7 kw/hr.)

HD63G -- 115,000 (28,967 kcal/hr.) (33.7 kw/hr.)

HD65G -- 115,000 (28,967 kcal/hr.) (33.7 kw/hr.)

• Frying area

HD50G -- 14” x 14” x 3-3/4” (35 x 35 x 9.5 cm)

HD60G -- 18” x 18” x 3-3/4” (46 x 46 x 9.5 cm)

HD63G -- 18” x 18” x 4-5/8” (46 x 46 x 11.8 cm)

HD65G -- 18” x 18” x 5-3/4” (46 x 46 x 14.6 cm)

• SMART4U® 3000 controller (120V required)

• Electronic ignition

• Robust, RTD, 1° compensating temperature probe

• Large capacity, high performance gas fryers suitable

for volume frying

• Stainless steel frypot, front, door and sides

•Two twin baskets

• Wide cold zone, 1-1/4” to 1-1/2” full-port IPS ball-

type drain valve

• Gas connection -- see chart on back

• Combination gas valve with regulator

Project

Item

Quantity

CSI Section 11400

Approval

Date

HD365G

HD465G

HD565G

HD665G

• Melt cycle and boil-out mode

• Drain safety switch

• 6” (15 cm) steel legs with 1” adjustment

*Spreader

cabinet required

for optional

filtration.

Options & Accessories

Built-in filtration available on single frypot

fryers (HD50, HD60 and HD63)

Built-in filtration available on single frypot

fryers including a spreader cabinet and on

multiple frypot batteries -- 2 to 6 fryers can

be batteried to right side of filter

HD50GDD model to use a match for HD60G,

HD63G and D60 fryers

Automatic basket lifts

Spreader cabinet and holding station

External oil discharge -- available on built-

in filter batteries of 2 or more frypots or a

frypot/spreader -- must specify front or rear

connection

Frypot covers

Triplet baskets

Sediment tray

Casters

See Dean Domestic price list for other available

options and accessories.

HD Series Gas Fryers - CE

Specifications

Designed for high-volume frying and maximum

energy efficiency

Maximize your profits and make the most of your

energy dollars with innovative design changes that have

improved the efficiency of the Decathlon fryers over

40%. The MVPs of high-efficiency, tube-type frying, the

HD gas fryers have low idle costs, offer low gas consumption per pound of food cooked and extend oil life.

6” versus 4” diameter tubes provide 36% more surface

area for heat transfer from the input energy to the oil.

This minimizes the heat stress on the oil, preserving oil

life. The exclusive Thermo-Tube design and proprietary

baffles efficiently transfer the fryer’s energy input into

the oil. Less heat goes unused up the vent and into the

kitchen. This saves energy dollars and keeps the kitchen

cooler.

Instant and controlled response to changes in cooking loads lowers gas consumption per pound of food

cooked and reduces idle costs. High-production cooking capacity and fast recovery meet high-volume, peak

demands while realizing energy savings.

5489 Campus Drive

Shreveport, LA 71129

USA

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

3000 controller has operation management features that

monitor and help control food and oil quality, oil life and

equipment performance. Has 20 programmable cook

buttons and auto adjusts cook time to load size.

The wide cold zone and forward-sloping bottom help

collect and remove sediment from the frypot to safeguard oil quality and make routine frypot cleaning

easy. The bottom of the frypot is equipped with fullport drain valves as follows: HD50G -- 1-1/4“ (3.2 cm) ,

HD60G/HD63G/HD65G -- 1-1/2” (3.8 cm). The 3” (7.6 cm)

drain line allows quick oil and sediment draining.

Multiple customization options allow you to combine

two or more units into a single battery.

Get superior results with the 92,150 Btu/hr. (23,212 kcal/

hr.) (27 kw/hr.) or 115,000 Btu/hr. (28,9676 kcal/hr.) (33.7

kw/hr.) input for frying large quantities fast.

www.frymaster.com

Bulletin No. 830-0127

Revised 6/20/13

Page 2

Dean

™

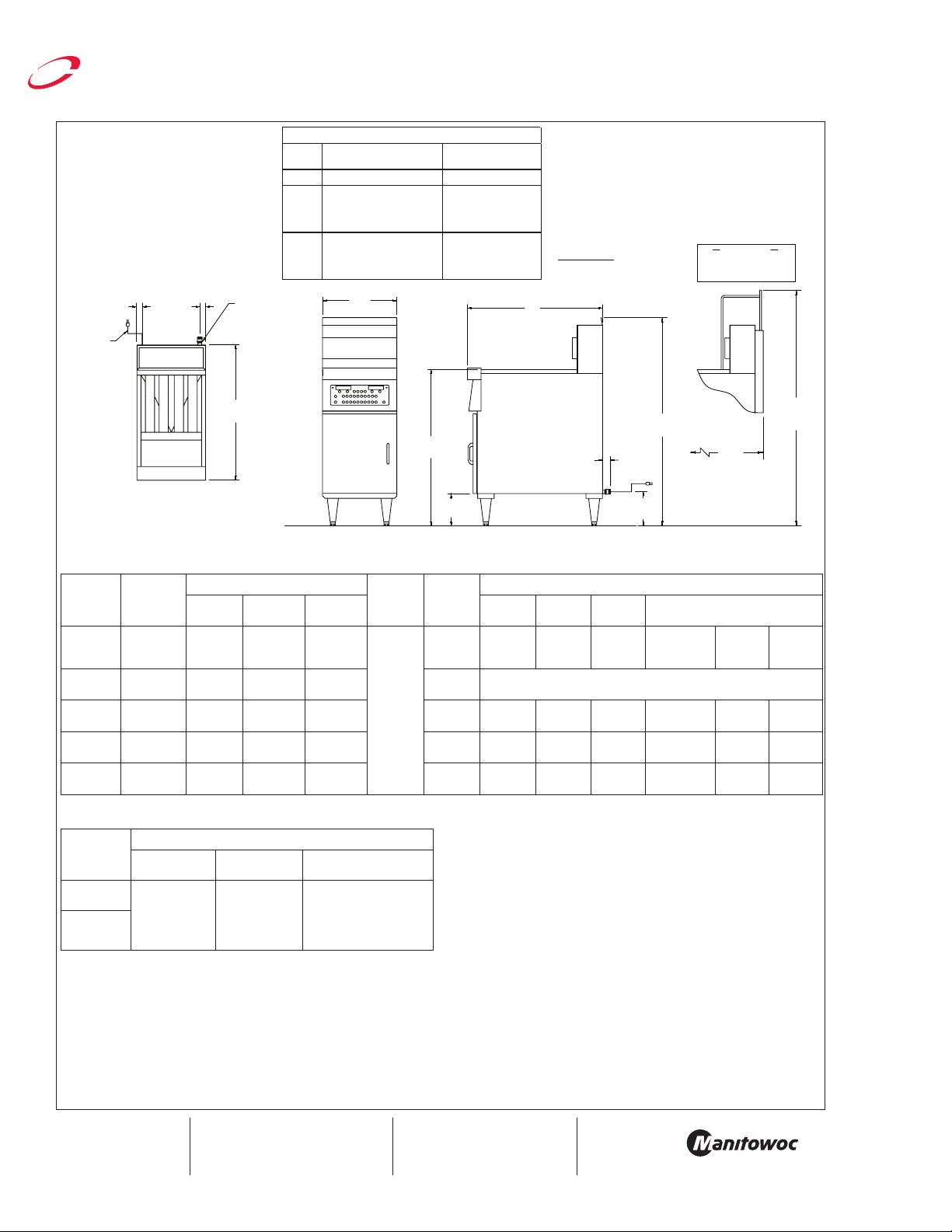

6' POWER

CORD

(183)

2.60

(6)

2.60

(6)

®

No. of

Fryers

2-4 Standard 3/4" gas

5-8 Standard two 1" gas

GAS LINE

CONNECTION

w/ 3/4" NPT PIPE

Gas Connection Requirements

Gas Connection Size

(Without Filtration)

Gas Connection Size

(With Filtration)

1 3/4” 3/4”

connection per frypot

(optional manifold to

include one 1" gas line)

connections (optional

manifold to include two

1" gas lines)

B

1”

Two 1”

C

INCHES

(cm)

OPTIONAL

AUTO-BASKET LIFTS

SHOWN IN RAISE

POSITION

HD Series Gas Fryers - CE

C

35.00

(89)

TOP VIEW

7.20

(18)

FRONT VIEW SIDE VIEW

DIMENSIONS

MODEL

NO.

HD50G 50 lb.

HD50GDD 50 lb.

HD60G 80 lb.

HD63G 90 lb.

HD65G 100 lb.

*without basket lifts

POWER REQUIREMENTS

MODEL

NO.

HD50G/

HD50GDD

HD60G/

HD63G/

HD65G

HOW TO SPECIFY

The following description will assist with ordering the features desired for this equipment:

HD50G 50-lb. high eciency tube-type gas fryer with 3000 controller, electronic ignition, RTD

HD60G 80-lb. high eciency tube-type gas fryer with 3000 controller, electronic ignition, RTD

HD63G 85-lb. high eciency tube-type gas fryer with 3000 controller, electronic ignition, RTD

HD65G 100-lb. high eciency tube-type gas fryer with 3000 controller, electronic ignition,

OIL

CAPACITY

(25 liter)

(25 liter)

(40 liter)

(45 liter)

(50 liter)

CONTROLS/

FRYPOT

230V 1 A 230V 4 A 230V 2 A

1° compensating temperature probe, 14” x 14” x 3-3/4” (35 x 35 x 7.6 cm) frying area.

1° compensating temperature probe, 18” x 18” x 3-3/4” (46 x 46 x 8.9 cm) frying area.

1° compensating temperature probe, 18” x 18” x 4-5/8” (46 x 46 x 10.8 cm) frying area.

RTD 1° compensating temperature probe, 18” x 18” x 5-3/4” (46 x 46 x 14 cm) frying

area.

OVERALLSIZE cm DRAIN

WIDTH

B

15-1/2”

(39.4)

15-1/2”

(39.4)

20”

(50.8)

20”

(50.8)

20”

(50.8)

DEPTH

C

31-1/4”*

(79.4)

36-3/4”*

(93.4)

36-3/4”*

(93.4)

36-3/4”*

(93.4)

36-3/4”*

(93.4)

OPTIONS CE

FILTER BASKET LIFTS/FRYPOT

HEIGHT

A*

45”

(114.3)

45”

(114.3)

45”

(114.3)

45”

(114.3)

43”

(109.2)

HEIGHT

cm

12-1/2”

(31.8)

NO. OF

TUBES

WEIGHT CLASS CU. FT. DIMENSIONS cm

4 180 lbs.

(82 kg)

4 Shipping information will depend upon equipment in the battery.

5 255 lbs.

(116 kg)

5 255 lbs.

(116 kg)

5 255 lbs.

(116 kg)

54.25

(138)

HEIGHT

D

H

48-1/2”

(123.2)

55”

(140.0)

55”

(140.0)

55”

(140.0)

22”

(56.0)

(74.0)

(74.0)

(74.0)

(60G,63G)

38.75

(98)

(50G)

33.10

(84)

DEPTH

36”

(91.4)

43”

(109.2)

43”

(109.2)

43”

(109.2)

A

2.00

(5)

7.62

(19)

SHIPPING INFORMATION

85 22 W

85 40 29”

85 40 29”

85 40 29”

NOTES

• 1-1/2” (3.8 cm) kitchen main manifold gas supply line

required. Gas inlet size (I.D.) should be no smaller than

that provided for connection to the fryers. See service

manual and/or plumbing codes for proper pipe sizing.

Recommended minimum store manifold pressure to be 6”

W.C. for natural gas and 11” W.C. for L.P. gas. Check plumbing

codes for proper supply line sizing to attain burner manifold

pressure of 3.0” W.C. natural or 8.25” W.C. L.P.

• POWER CORDS: On 1 to 2 battery units, 1 power cord sup-

• Please specify: Natural or LP gas; altitude if between 2,000 -

6,000 feet (610 - 1,829 Meters).

DO NOT CURB MOUNT

•

CLEARANCE INFORMATION

• A minimum of 24” (61.0 cm) should be provided at the front of

the unit for servicing and proper operation, and 6” (15.2 cm)

between the sides and rear of the fryer to any combustible

material.

plied

On 3 to 4 battery units, 2 power cords supplied

On 5 to 6 battery units, 3 power cords supplied

Model #_______________

CSI Section 11400

5489 Campus Drive

Shreveport, LA 71129

USA

We reserve the right to change specications appearing in this bulletin without incurring any obligation for equipment previously or subsequently sold.

Check www.frymaster.com for updates.

Tel: 318-865-1711

Tel: 1-800-221-4583

Fax: 318-868-5987

E-mail: info@frymaster.com

www.frymaster.com

Bulletin No. 830-0127

Revised 6/20/13

Litho in U.S.A. ©Frymaster

Loading...

Loading...