Deagostini Model Space HUMMER H1 User Manual

HUMMER H1: STEP BY STEP

™

205

Stage 45

The battery box and power

switch – an overview

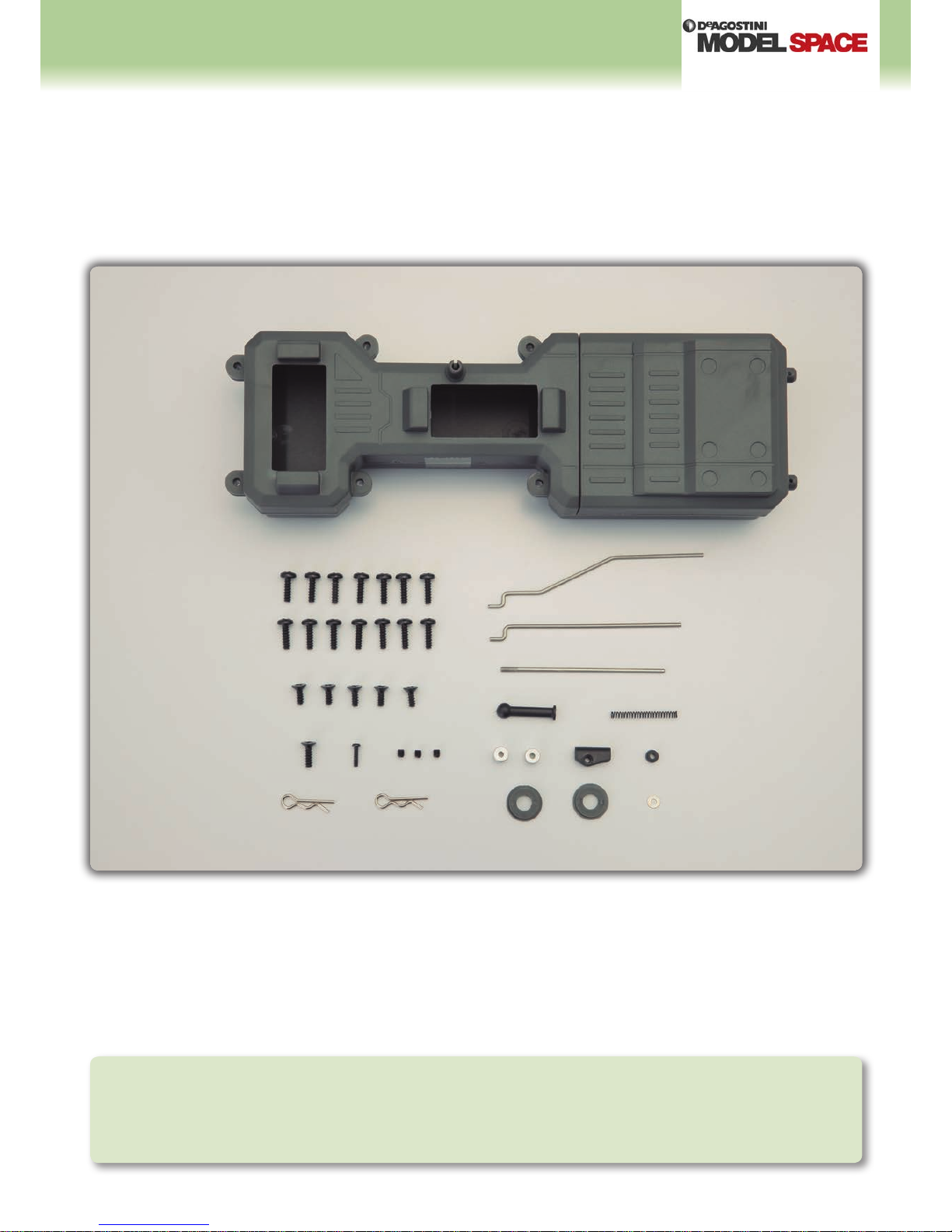

Your parts

Aerial tube

Battery box

Power switch

HUMMER H1: STEP BY STEP

™

206

11

11

33

44

22

The battery box and power switch is located inside the radio box, which

will be tted to the base of the chassis in coming stages. The box is

pictured open here, but during operation is sealed shut using body pins.

This is to prevent dust and dirt getting inside the components, which can

aect the operation of the parts.

This is the aerial, pictured in its position in the centre of the chassis

with the body frame and panels removed. The length of the wire

will be cut depending on the radio frequency used by the remote

control, but should not be so long that it is folded up, as this will

disturb the signal.

From the front, you can get

an idea of how the aerial

will reach up to the roof

and curve over. This means

that, unlike most RC cars, it

isn’t necessary to cut a hole

in the roof for the aerial.

Fitting the body frame and

panels is straightforward.

Simply lower over the chassis

and aerial carefully, then clip

into place with pins, ready for

action.

Whatever length the aerial is cut to, it will be taller than the roof of

the body panels. This is not an issue, as the soft resin tubing of the

aerial will bend suciently to t inside the body.

The power switch and battery box

The aerial

22

The power supply in your Hummer H1 uses alkaline AA

batteries. It is useful to acquire a battery power checker like the

one in the photo above, to check the power level before tting

replacement batteries.

HUMMER H1: STEP BY STEP

™

207

Radio box upper and lower (temporarily assembled)

Radio box lid (temporarily assembled)

3 × 10mm binding-head self-tapping screws × 14

3 × 8mm self-tapping screws × 5

3 × 10mm self-tapping screw

2 × 8mm self-tapping screw

3 × 3mm set screws x 3

Body pins × 2

Steering rod

Brake rod

Throttle linkage rod

Throttle ball end

Throttle spring

2mm stoppers × 2

Linkage base

Brake collar

Radio box collars × 2

2mm washer

Mounting the radio box

Your parts

Tools and

materials

Phillips screwdriver

Main chassis assembly (Stage 44)

Pen

Plastic bag

Stage 46

HUMMER H1: STEP BY STEP

™

208

221144

33

66

55

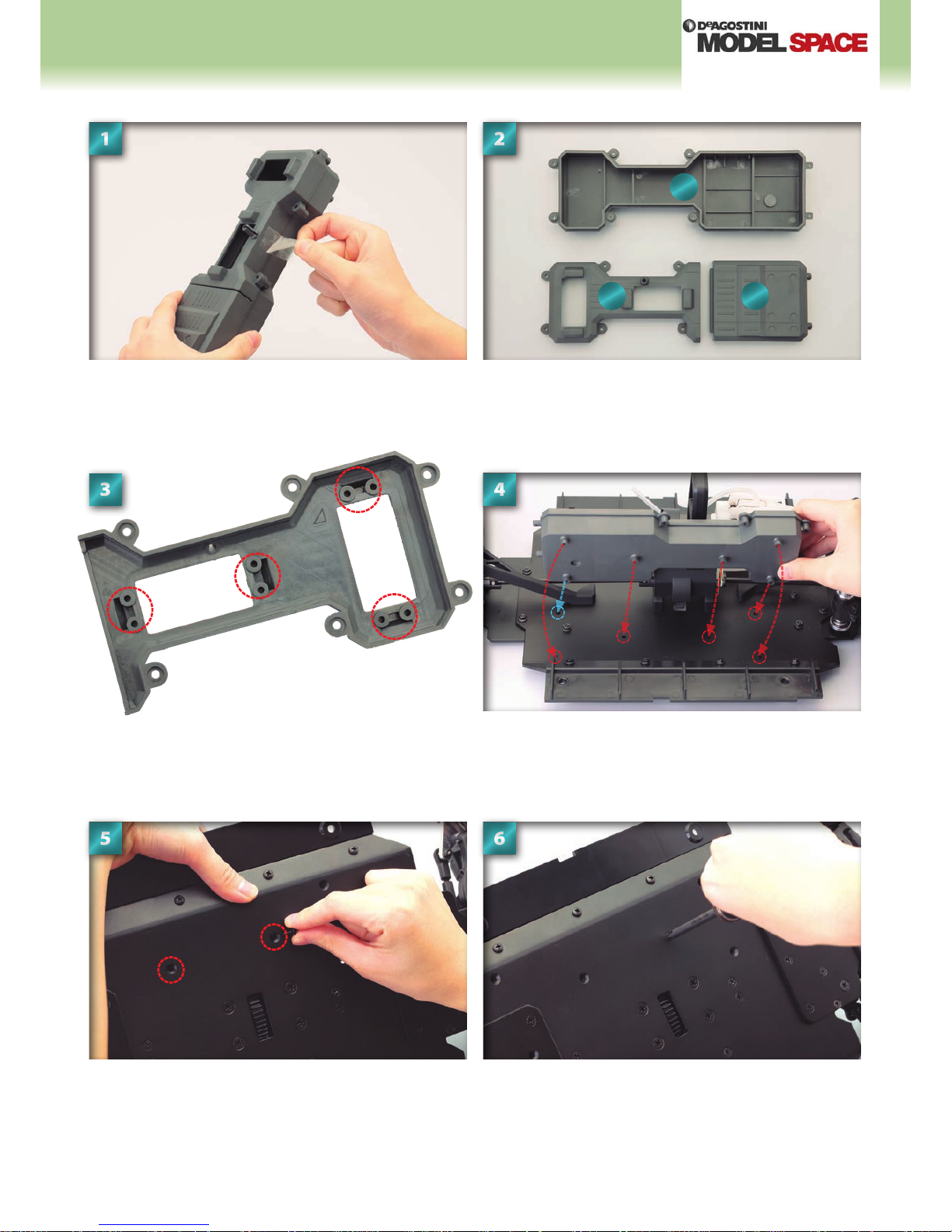

Lay out the parts and make a note of which is which. To the

bottom left (1) is the box upper, at the top is the box lower (2)

and to the bottom right (3) is the lid. Also make a note of their

orientation, as this is the position in which they will be tted

onto the chassis.

Remove the cellophane tape holding together the parts that

make up the radio box.

Line up the radio box lower with the six holes circled on the

surface of the chassis. The hole circled in blue marks the hole

through which you will t the 3 × 10mm self-tapping screw.

Inspect the underside of the radio box upper. There are four sets

of screw holes lining the rectangular openings. These will be

used in the coming steps.

Tighten the screw with a screwdriver.When the projections on the underside of the radio box are

lined up with the six holes circled in Step 4, begin inserting

the 3 × 8mm self-tapping screws, starting with the two central

holes circled above. Place the screw into the hole nearest the

front rst.

Front

Back

1

2

3

HUMMER H1: STEP BY STEP

™

209

778899

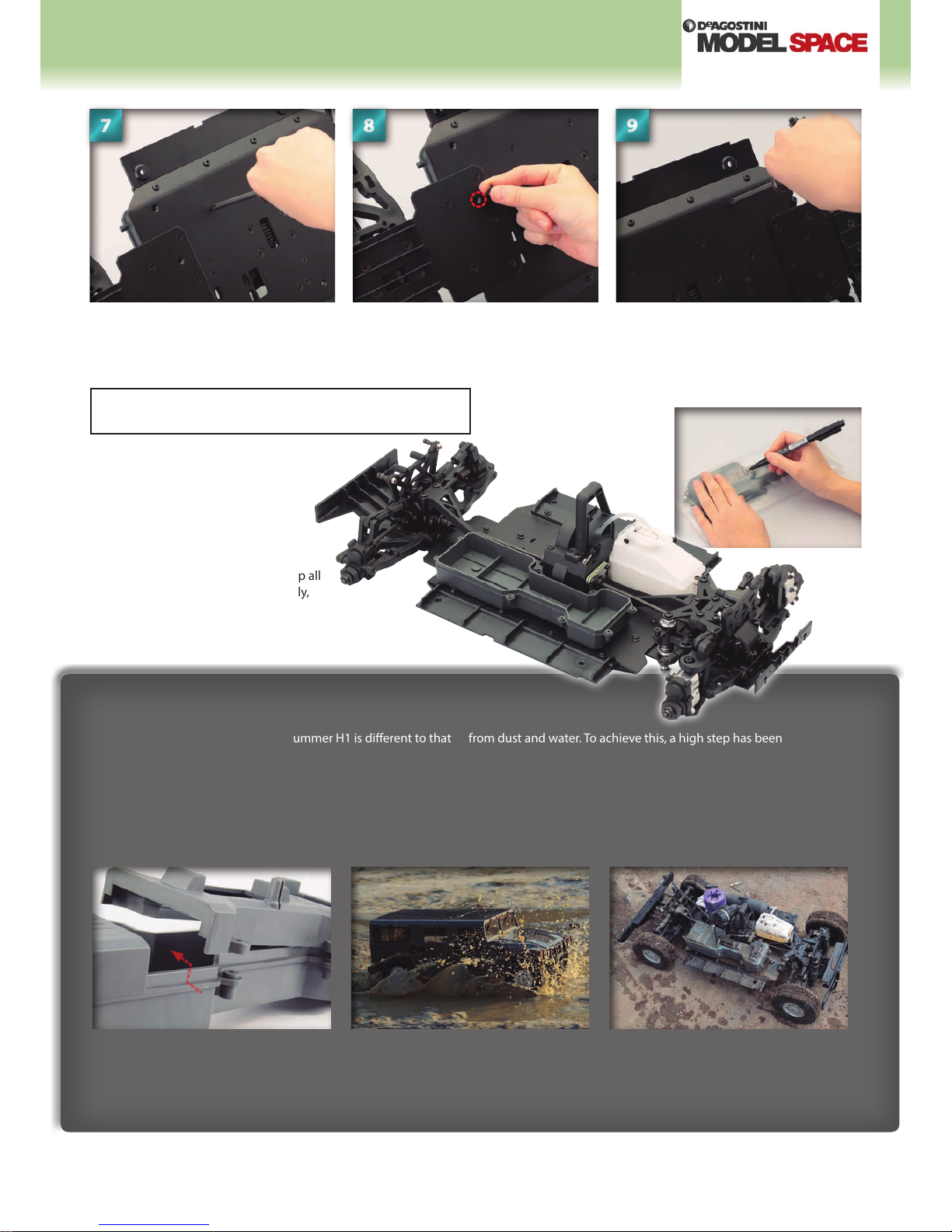

Next, t and tighten the second 3 × 8mm

self-tapping screw into the adjacent hole.

Place the 3 × 10mm self-tapping screw into

the hole that sits on the joint between the

chassis’s main and rear plates. This was the

hole marked in blue in Step 4.

Fit the remaining 3 × 8mm self-tapping

screws into the last three holes that were

marked in Step 4. Tighten each fully with

a screwdriver.

This stage is complete. Be sure to keep all

the unused parts in a plastic bag safely,

marked for reference.

Sealing the radio box

The radio box tted inside your RC Hummer H1 is dierent to that

of most radio-controlled cars. Due the heavier, o-road nature

of its use, your Hummer’s radio box requires a considerable

amount of protection. As such , the radio box is designed and

tted in such a way that it is able to operate under even the

most ambitious driver. Firstly, the radio box itself is made of thick

impact-resistant plastic, moulded to provide excellent protection

from dust and water. To achieve this, a high step has been

moulded along the edges of the upper and lower box sections

(see photo below left). Then, the box is tted several millimetres

above the chassis base, rather than on it, so that the box receives

fewer of the vibrations or jolts experienced by the rest of the

chassis, as these can aect the smooth running of the radio

control components within the box.

The joint between the edges of the radio

box’s upper and lower sections features

a high step to prevent dust particles or

water entering.

It is possible to run your Hummer H1

through puddles, as the crucial radio box

is so well sealed and protected.

The chassis and components stripped

of the body casing after driving through

water. It is advised that the model be

cleaned thoroughly after use.

Assembled parts

HUMMER H1: STEP BY STEP

™

210

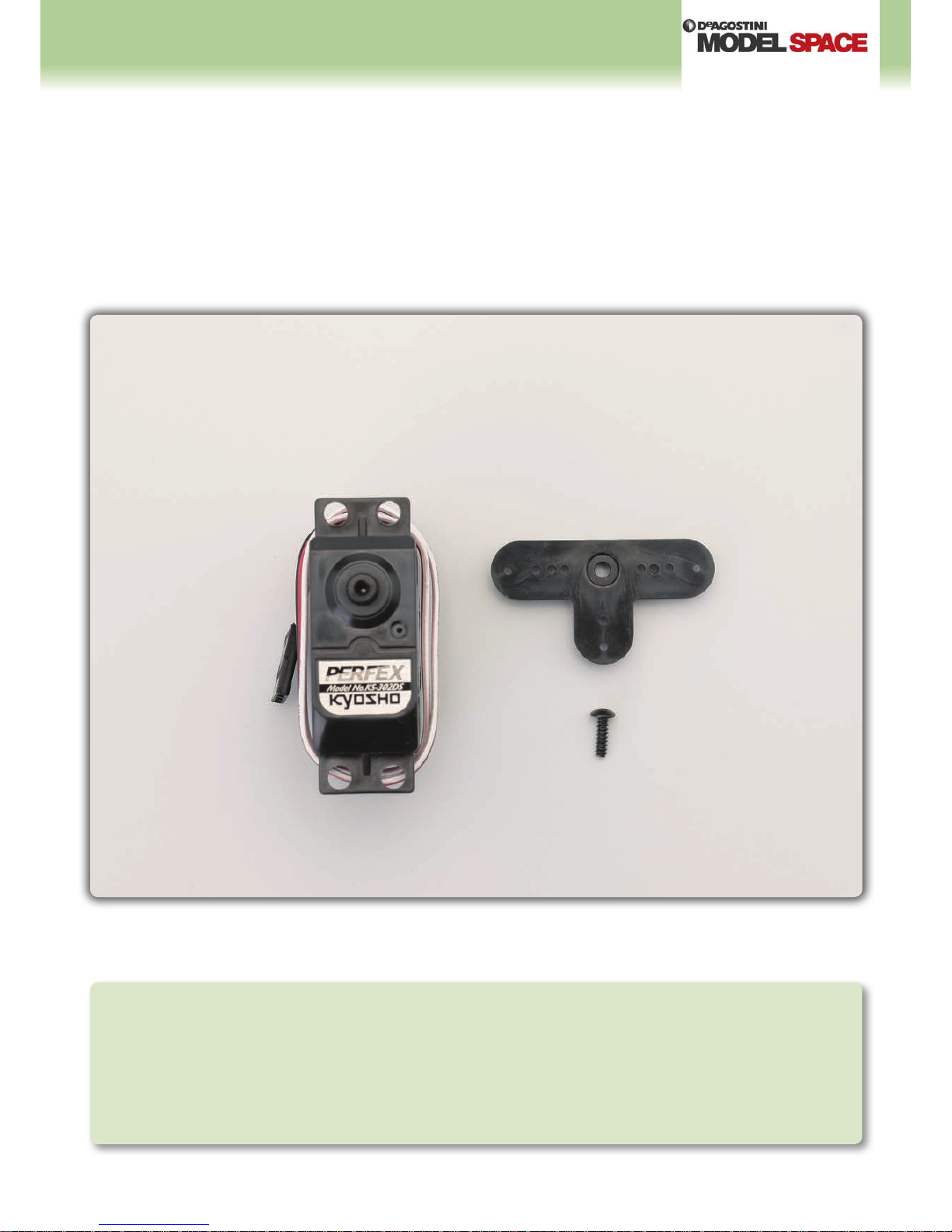

Steering servo (KS-302DS)

Servo horn

2.6 × 10mm servo horn screw

Installing the steering servo

Your parts

Tools and

materials

Philllips screwdriver

Needle-nose pliers

1.5mm Allen key (Stage 11)

Main chassis assembly (Stage 46)

Radio box (Stage 46)

Steering rod (Stage 46)

3 × 10mm self-tapping screws × 4 (Stage 46)

3 × 3mm set screw (Stage 46)

Paper towel or tissue

Thread-locking agent (or rubber-based adhesive)

Stage 47

Loading...

Loading...