CS8

Service Manual

Klark Teknik Building

Walter Nash Road

Kidderminster

Worcestershire

DY11 7HJ

Tel: +44 (0) 1562 741515

Fax: +44 (0) 1562 745371

Email: info@uk.telex.com

Website: www.ddaconsoles.com

CS8 Service Manual

Telex Communications (UK) Limited

In line with the company’s policy of continual improvement, specifications and function maybe subject

to change without notice. This Operator Manual was correct at the time of writing. E&OE.

2

Contents

INTRODUCTION ......................................................................................... 4

CS8 SPECIFICA TIONS ................................................................................. 9

OPTIONS ...................................................................................................... 9

CS8 DIMENSIONS AND WEIGHTS ........................................................ 10

DECLARA TION OF CONFORMITY ........................................................ 11

INST ALLA TION GUIDE............................................................................. 12

ATTENTION ............................................................................................... 13

CIRCUIT DESCRIPTIONS .......................................................................... 14

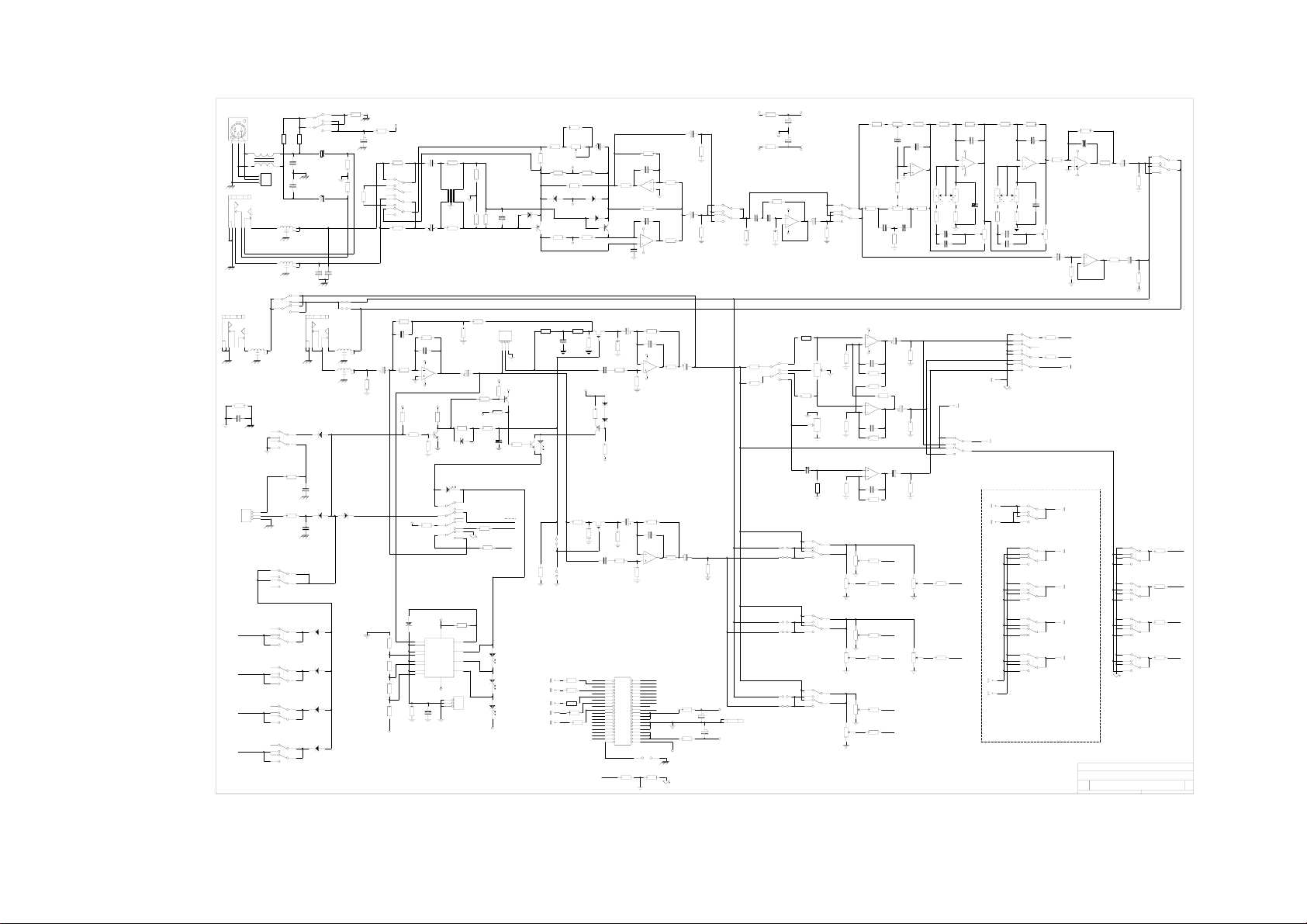

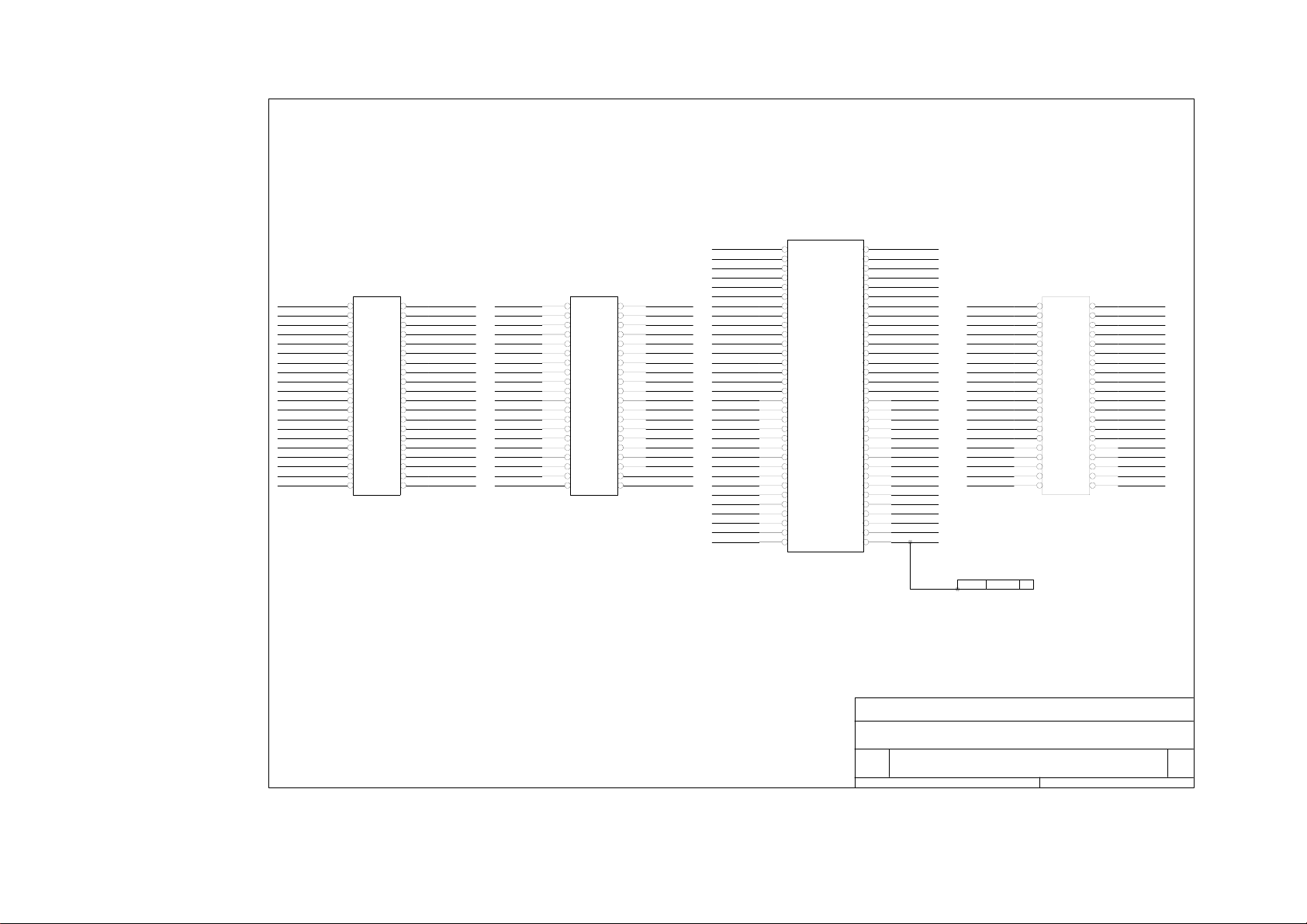

INPUT MODULE (CD1279) ..................................................................... 1 4

INPUT MODULE LINKS ........................................................................... 19

INPUT MODULE BLOCK DIAGRAM ..................................................... 20

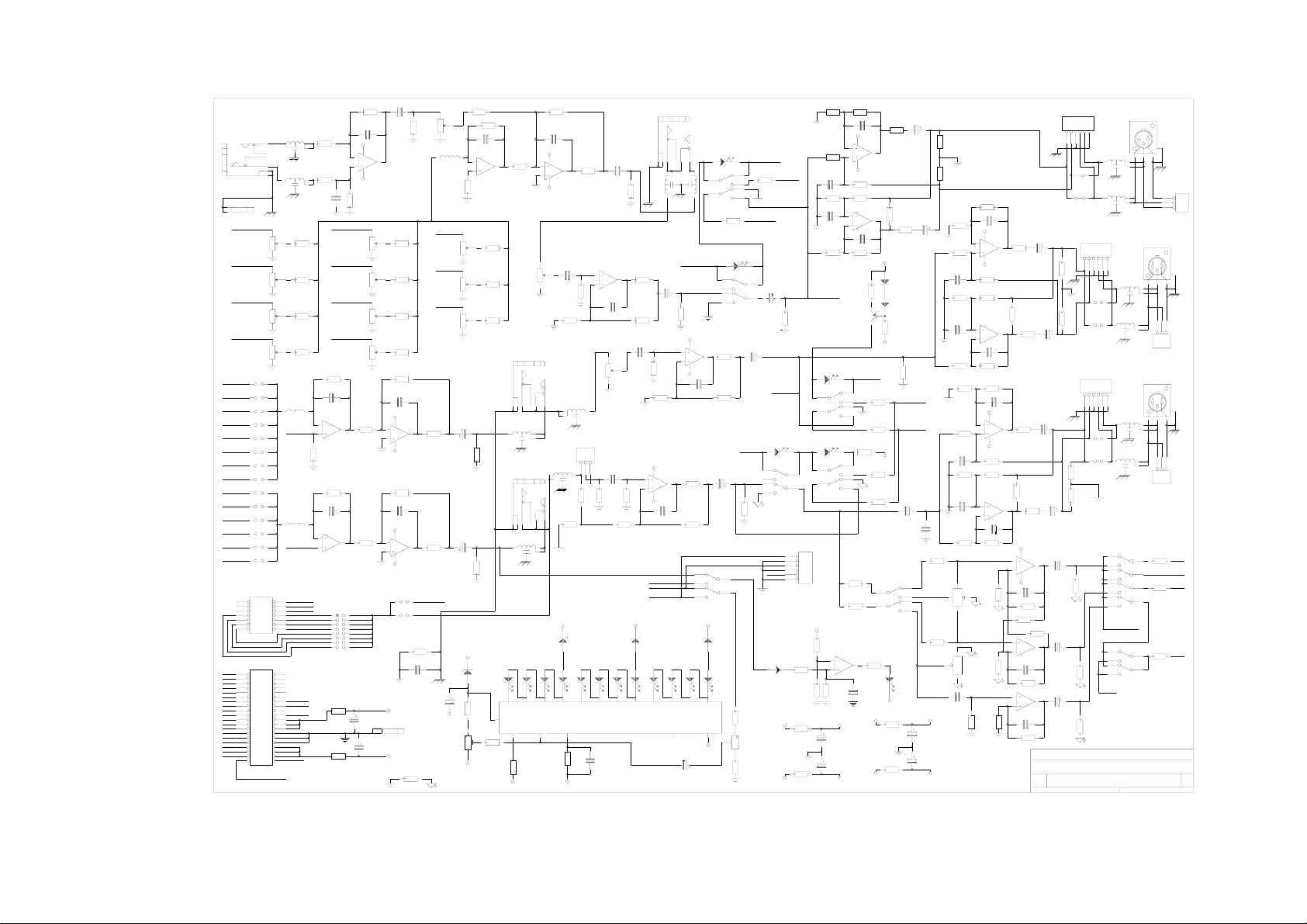

THE STEREO INPUT MODULE (CD1302/3).......................................... 21

STEREO INPUT LINKS .............................................................................. 25

STEREO INPUT MODULE BLOCK DIAGRAM ..................................... 26

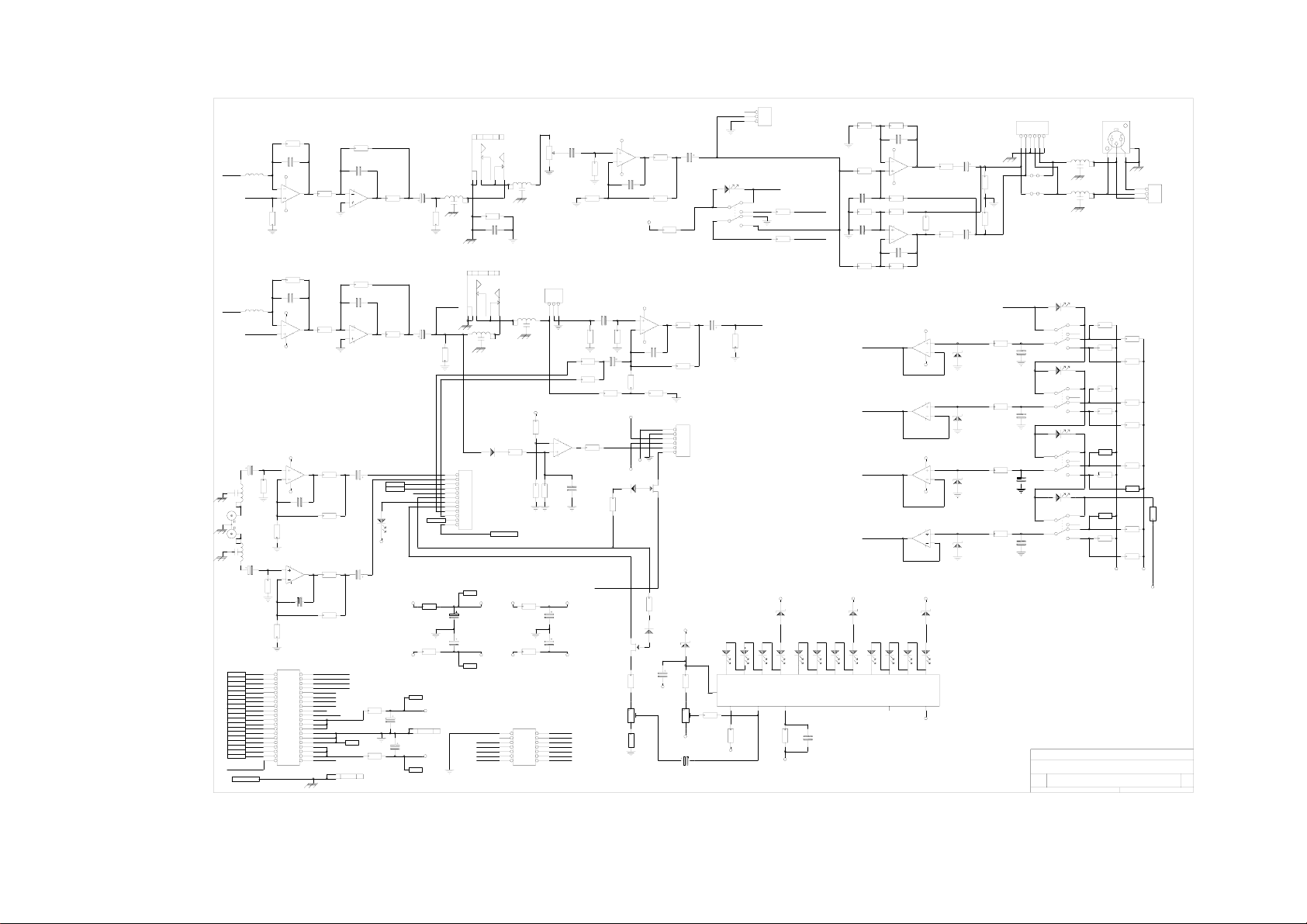

THE GROUP OUTPUTS (CD1280/CD1286) .......................................... 2 7

GROUP OUTPUT LINKS (MA TRIX)........................................................ 31

GROUP OUTPUT LINKS (RETURN) ....................................................... 32

GROUP OUTPUTS 1-6 BLOCK DIAGRAM ........................................... 33

GROUP OUTPUTS 7-8 BLOCK DIAGRAM ........................................... 34

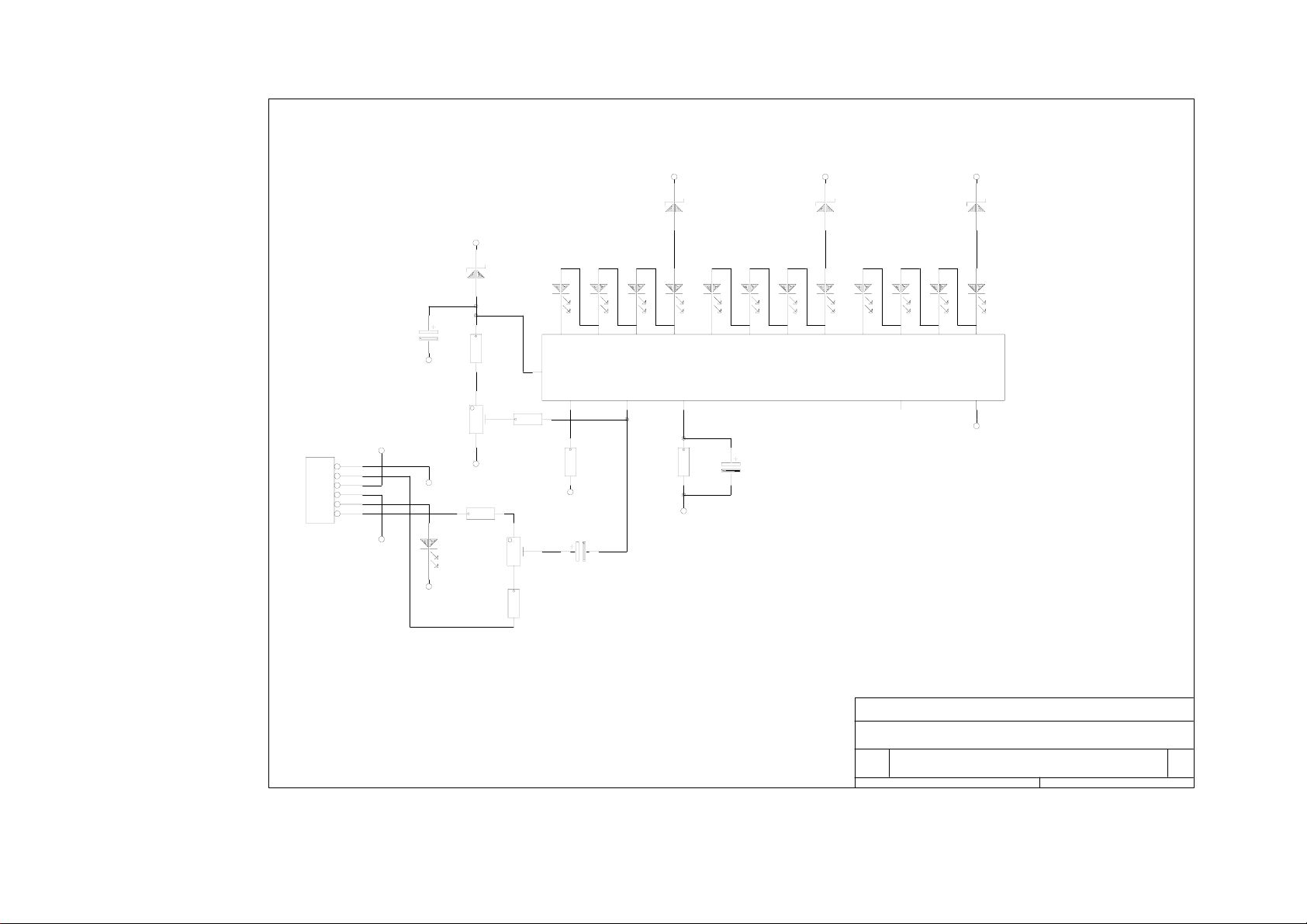

THE MASTER MODULE........................................................................... 35

MASTER MODULE LINKS ....................................................................... 39

MASTER MODULE BLOCK DIAGRAM................................................. 41

THE BUS LINKING PORT......................................................................... 42

THE METERBRIDGE ................................................................................. 43

THE POWER SUPPL Y ............................................................................... 45

BUS CONNECTOR PIN OUT ................................................................... 47

CS8 MA TRIX CONNECTO R ..................................................................... 48

BUS LINK CONNECTOR .......................................................................... 49

CS8 P AR TS LISTING .................................................................................. 50

SER VICE INFORMA TION ......................................................................... 58

CS8 CIRCUIT DIAGRAMS ........................................................................ 60

The information in this manual has been carefully verified and is believed to be

correct, however, EVI Pro Audio reserves the right to modify the product

described in this manual at any time. This document may not be copied or

reproduced by any method whatsoever, whether in part or in whole, without

the written permission of EVI Pro Audio.

© Copyright 1997 EVI Pro Audio Group. All rights reserved.

Manual Version DOC03-CS12M/A.

3

INTRODUCTION

The CS8 console has been designed to provide the consultant,

contractor, installer and user with a cost effective system which

will perform to accepted professional standards, be simple for the

untrained user to operate, and be tolerant of wiring and installation

problems. There can be no excuse for a system which is over sensitive

to the wiring and installation conventions used, and hums at every

opportunity.

High quality balanced inputs and outputs are only part of the story.

Equally important is the way in which the console grounding system

works, because it is through the console ground that all the noisy

ground currents from the cable screens will flow. Any part of the

audio signal path which shares the cable screen to console ground

path within the console will effectively have the cable screen noise

added to that signal path. The current flowing in cable shields in

typical installations has be shown to be substantial (in the order of

100mA and above) and is caused by the difference in potential

between the ground connection at each end of the cable screens.

Of comparable importance to any system performance is the power

supply. Internal linear power supplies may be less expensive, but

are usually responsible for inducing noise into the audio and

generating substantial amounts of heat, making it uncomfortable

for the operator. Internal switch mode supplies may be cool running,

but are usually even more of a problem with regard to noise.

Another often overlooked point with internal power supplies is

how to provide auto-switchover between 2 supplies without

extensive modification thereby nullifying the warranty. Internal

supplies are also a potential problem from a maintenance point of

view.

Most service technicians can easily fault find and repair a linear

supply with commonly found components, but a switch mode supply

does not make use of common off the shelf components. Although

more expensive, a separate and generously rated linear power

supply is used with the CS8 keeping heat and noise away from the

console. Rack mounting ears are available for permanent

installations, and the supply is UL and CSA approved.

At this point it is useful to look at some of the features of the CS8.

PAN AND ROUTING

The pan pot can be switched between stereo panning mode, and

left/centre/right panning mode. Left-centre-right panning to the

master outputs provides much improved spatial positioning. The

technique has been used for many years in the film industry where

its benefits are well known.

4

In music systems the centre channel generates a more solid centre

image, especially for the “star” of the show, and helps to maintain

a stereo image across a wider sound stage. In mixed media

productions and in church applications the use of a speech optimised

centre cluster can improve intelligibility without compromising the

music system performance.

If only a stereo system is being run, and the pan pot is switched to

stereo mode, then the centre output is individually assignable from

each input or the from a sum of the left/right mix to provide a

separate mono output for broadcast/film feeds etc.

Another unique feature for a mixer in this class is individual sub

group routing instead of the inconvenient and inflexible paired

routing which always requires the use of the pan pot to route a

channel to a single sub group. There is always a crosstalk

performance compromise involved and it is done solely for economic

rather than for operational reasons, as it halves the number of

routing switches and removes the need for a pan in/out switch.

The CS8 allows routing to the sub groups either individually or in

pairs via the pan pot.

EQUALISATION

The CS8 input module has a 4 band equaliser with high and low

frequency boost/cut controls and two swept frequency middle

sections. There is more than two octaves of overlap between the

frequency ranges of the mid equalisers while the frequency span

extends to from 70Hz to 10kHz.

AUXILIARIES

The CS8 has 8 full time auxiliary send controls allowing easy session

setup. These are normally post fade but can be switched pre fade.

Normally the pre fade signal is pre fade post cut but byusing internal

links it can be changed to the pre equaliser signal. Auxiliaries 7 and

8 can be used in stereo where stereo foldback, for example, is

required.

CHANNEL CUT

The channel cut is a silent FET switch which can be remotely

controlled through a connector on the rear of each channel by a

simple connection to ground. In addition, when the channel cut

switch is pressed, another contact is grounded on the Mute Remote

connector. This can be used to control a Midi Mute controller, cue

lights, or even to control another channel on the mixer by linking

the mute out pin of one channel to the mute in pin of any other

channel(s). Such an application could be a podium switch which

would allow the speaker to override other channels for example.

5

SOLO/PFL MONITORING

While it is normal to find PFL/AFL on almost all mixers, the CS8

goes a step further. The input solo is arranged to have priority over

the output solo. This means that there is no need to de-select an

output solo when selecting one or more input solo controls, and

when the input solo is released, the output solo is re-established. A

master solo level trim control is located on the master module for

level matching, and the level of the solo signal is displayed on the

left mix bargraph.

An additional solo feature provided is Solo In Place. In this mode,

soloing any input channel will cause all other input channels to be

cut, thereby allowing only itself to be heard in the mix, correctly

panned and at the right level, along with any stereo effect return

channels. This is of great benefit during set-up and rehearsal and is

much more useful than the standard PFL. A switch on the master

module selects Solo In Place mode.

SIGNAL LED’s

The value of effective metering of signal levels throughout the

signal path cannot be overestimated. Signal present and 0dB LED’s

on all input channels give confidence to the operator while peak

overload LED’s indicate when the channel is being driven close to

clipping. However, it is unusual to find a peak overload LED at the

very place where it is most needed, at the summing bus mix

amplifiers, operating independently of the output meters. If the

mix amplifier is overloaded and starts to clip, the only thing that

can be done to rectify the situation is to pull down all input faders.

On the CS8, there are overload warning LED’s on each of the sub

group mix amplifiers as well as on the left, centre and right mix

amplifiers. When the output meters are switched to observe the

matrix outputs the bus peak leds also monitor the matrix bus.

INSERTS

Inserts are used to patch in external pieces of equipment such as

equalisers, limiters etc. and are provided on all channels, group

outputs, mix outputs and auxiliary outputs. To be useful and

useable, the inserts should be at a level which is compatible with

this external equipment. Sadly, this is often not the case. Some

mixers have inserts at odd levels which will preclude their efficient

use because of the noise penalty. All inserts on the CS8 are at a

consistent level which is at the internal operating level of 0dBu.

AUXILIARY INSER TS

In most installations, it is quite normal to place an equaliser in the

stage monitor sends, but this is normally external to the mixer. This

of course means that the only way of listening to the monitor sends

(internal to the mixer) is via the solo system.

6

Herein lies a problem. The operator does not hear the effect of the

external equalisation. Also, any noise introduced by the external

device is constant and not proportional to the setting of the send

control. The ideal place to insert an external device is pre the send

master control and this is the case in the CS8.

EQUALISER CUR VES

The following graphs illustrate the equalisation and filtering

responses of the CS8 console.

CS8HFLF HF/LF EQUALISER RESPONSE

CS8MID MID FREQUENCY EQUALISER BANDWIDTH

ADJUSTMENT

CS8MID1 MID FREQUENCY EQUALISER AMPLITUDE

ADJUSTMENT

CS8MID2 MID FREQUENCY EQUALISER FREQUENCY

ADJUSTMENT

CS8HP HIGH P ASS FIL TER RESPONSE

7

AUDIO PRECISION CS8HFLF vs 11 APR 97 11:31:21

20 100 1k 10k 20k

FREQ(Hz)

-20.00

-15.00

-10.00

-5.000

0.0

5.0000

10.000

15.000

20.000

AMPL(dBr)

AUDIO PRECISION CS8HPF vs 11 APR 97 11:43:15

20.000

15.000

10.000

5.0000

0.0

-5.000

-10.00

-15.00

-20.00

20 100 1k 10k 20k

AMPL(dBr)

FREQ(Hz)

THE HIGH AND LOW

FREQUENCY EQUALISER

RESPONSE

AUDIO PRECISION CS8HIMID vs 11 APR 97 11:37:11

20.000

15.000

10.000

5.0000

0.0

-5.000

-10.00

-15.00

-20.00

20 100 1k 10k 20k

AUDIO PRECISION CS8LOMID vs 11 APR 97 11:41:51

20.000

15.000

10.000

5.0000

0.0

-5.000

-10.00

-15.00

-20.00

20 100 1k 10k 20k

AMPL(dBr)

AMPL(dBr)

FREQ(Hz)

FREQ(Hz)

THE HI-MID FREQUENCY

EQUALISER RESPONSE

SHOWING FREQUENCY

RANGE

THE LO-MID FREQUENCY

EQUALISER RESPONSE

SHOWING FREQUENCY

RANGE

THE HIGH PASS FILTER

RESPONSE.

8

CS8 SPECIFICA TIONS

Nominal Operating Level +4dBu with a unity gain structure.

Frequency Response 20Hz - 20kHz +/-0.5dB any input to any output

at a gain < 50dB.

EQ range

HF +/-15dB @ 10kHz shelving

LF +/-15dB @ 100Hz shelving

Hi Mid +/-15dB 470Hz - 15kHz, Q = 1.4

Lo Mid +/-15dB 70Hz - 2.2kHz, Q = 1.4

Channel Routing Attenuation > 90dB @ 1kHz

Channel Mute Attenuation > 95dB @ 1kHz

Channel Fader Attenuation > 85dB @ 1kHz

Distortion

0.005% @1kHz any input to any output at a gain < 50dB.

Noise: -82dBu (24 channels routed and cut)

EIN: -127.5dBu ref 200 ohms

EIN: -128.7dBu ref 150 ohms

Maximum output level: +20dBu into a bridging load

Output impedance: <75R

Maximum input level: +30dBu

Phono connector levels: Nominal -10dBV

Signal present threshold: -21dBu

Peak led threshold: 3dB below clipping

Power consumption: < 600 Watts

OPTIONS

Input transformers Multipole connectors

Output transformers Bus linking cable

LED Meterbridge Flight case

VU Meterbridge Spare power supply with auto

Flight Case switchover

9

CS8 DIMENSIONS AND WEIGHTS

48 CHANNEL 1930.50mm(76.00")

40 CHANNEL 1681.50mm(66.20")

32 CHANNEL 1432.50mm(56.40")

MASTER AND

OUTPUT SECTION

4

STEREO

MODULES

16 CHANNEL 934.50mm(36.70")

24 CHANNEL 1183.50mm(46.60")

Meterbridge Widths:

VU 46.6 inches/1183.5mm (This cannot be fitted to a 16 input console)

LED As per corresponding console width.

Console weights (packed):

16 26.4kg/58lbs LED m/b 4.7kg/10.4lbs Combined 31.1kg/68.4lbs

24 36kg/80lbs LED m/b 6.0kg/13.3lbs Combined 42.0kg/93.3lbs

32 45.6kg/100lbs LED m/b 7.4kg/16.3lbs Combined 53.0kg/116.3lbs

40 55.2kg/122lbs LED m/b 8.6kg/19.0lbs Combined 63.8kg/141lbs

48 64.8kg/143lbs LED m/b 10.0kg/22.0lbs Combined 74.8kg/165lbs

VU Meterbridge 6.5kg/14.5lbs (Add to weight without LED meterbridge)

These weights assume a fully fitted console. Meterbridges are shipped in with

the console but not mounted on the console.

Power Supply Weight (packed): 7.8kg(17.2lbs)

Dimensions: 2U Rack Mounting with a depth of 265mm(10.43")

DIMENSIONS AND WEIGHTS

10

Declaration of Conformity

The Manufacturer of the Products covered by this Declaration is

Klark Teknik Building, Walter Nash Road, Kidderminster,

Worcestershire, DY11 7HJ.

The Directives Covered by this Declaration.

89/336/EEC Electromagnetic Compatibility Directive, amended by 92/31/EEC & 93/68/EEC

73/23/EEC Low Voltage Equipment Directive, amended by 93/68/EEC.

The Products Covered by this Declaration.

Model CS3 Mixing Console.

Model CS8 Mixing Console.

Model CS12M Mixing Console.

The Basis on which Conformity is being Declared

The products identified above comply with the protection requirements of the EMC Directive and with the principal elements of the safety objectives of the Low Voltage Directive, and the manufacturer has applied the following standards:

EN 55013 : 1990

Limits and methods of measurement of radio disturbance characteristics of Broadcast

Receivers and Associated Equipment.

EN55020 : 1988

Sound and Television Broadcast Receivers and Associated Equipment, Electromagnetic

Compatibility.

EN 60065 : 1994

Safety requirements for mains operated electronic related apparatus for household

and similar general use.

The technical documentation required to demonstrate that the products meet

the requirements of the Low Voltage Directive has been compiled by the

signatory below and is available for inspection by the relevant enforcement

authorities. The CE mark was first applied in 1996

Signed: ................................ G.M.Squires

Authority: Product Support Manager.

Date: 1st, January 1997.

Attention

The attention of the specifier, purchaser, installer, or user is drawn to special

measures and limitations to use which must be observed when these products

are taken into service to maintain compliance with the above directives.

Details of these special measures and limitations to use are available on

request, and are also contained in product manuals.

11

INST ALLA TION GUIDE

There are a number of points to consider when installing a mixing

console. Many of these points will have been addressed before the

console is even unpacked but it is worth repeating them again.

POSITION

The console should be located in a convenient space commensurate

with the use to which the console is being put. Ideally a cool area is

preferred not in close proximity to power distribution equipment

or other potential sources of interference. Provision should be made

for some flat surface surrounding the console to prevent people

using it as a table top. One of the worst fates that can befall a

console is for a cup of coffee to be tipped into it by someone resting

it on the control surface!

POWER

The power supply should be located as far from the console as the

connecting cable will allow, a 5 metre power cable is supplied with

the console. It should be set for the appropriate line voltage and

plugged into the mains outlet using the supplied cable. If the power

supply is rack mounted then be sure to leave space above for

ventilation - 2U is suggested.

SLEEVE TIPRING

TIP CO NN EC TI ON

RING CON N ECTION

SLEEV E CONNECTION AND CABLE CLAM P

1/4 INCH TRS 'A' GAUGE JA C K PLUG

FEM A LE XLR-3MALE XLR-3

12

3

12

3

PHONO SO CK ETS

PHONO PLU G

12

WIRING

The console uses four different connector styles:TRS jack sockets, XLR male connectors, XLR female connectors and

phono connectors.

The cables used should be of as high a quality as possible. Many

installation problems can be traced back to poor or faulty cables

and connectors.

There are two different conventions for the wiring of XLR

connectors. The international convention uses pin 2 as the hot pin

while the older American convention uses pin 3 as the hot pin.

When going from balanced input to balanced output this is of little

consequence but when unbalanced signals such as those found on

the insert points are used then phase reversal can result. The CS8

and all DDA products are wired PIN 2 HOT.

ATTENTION

CABLES

This product should only be used with high quality, screened twisted

pair audio cables, terminated with metal bodied 3-pin XLR

connectors. The cable shield should be connected to Pin 1. Any

other cable type or configuration for the audio signals may result

in degraded performance due to electromagnetic interference.

ELECTRIC FIELDS

Should this product be used in an electromagnetic field that is

amplitude modulated by an audio frequency signal (20Hz - 20kHz),

the signal to noise ratio may be degraded. Degradation of up to

60dB at a frequency corresponding to the modulation signal may

be experienced under extreme conditions (3V/m, 90% modulation).

No permanent damage or degradation of performance will be

caused by these conditions.

13

CIRCUIT DESCRIPTIONS

The following gives a brief description of each module as an aide

to understanding the signal flow within the console. Many

references are made to the circuit diagrams with the reference

number for the appropriate diagram being given at the beginning

of each module. The master module uses two circuit boards

requiring four circuit diagrams.

INPUT MODULE (CD1279)

The input module contains eight input channels mounted on a

common set of metalwork. The channels are identical and a console

is constructed by using 2 or more input modules together with an

output module and a master module within a frame.

THE INPUT ST AGE (CD1279)

The same input stage is used for both the microphone and the line

input. CON2, an XLR style connector, is used for the microphone

input which is wired to the inner contacts of CON3, the line input

TRS jack. With nothing inserted into the jack socket the signal

connects to the normal contacts and is then fed to an attenuator

which is activated by selection of the line input. Resistors R2 and

R3 feed phantom power to the microphone input and this is DC

blocked from the line input amplifier by C2 and C3. SP1, SP2 and

SP6 are filters providing protection from high frequency signals

entering the inputs. Additional filtering is carried out by capacitors

C37, C38, C39 and C40. CON9 (optional) is wired in parallel with

the XLR which allows for wiring the input to a multipole connector

mounted on the console frame.

Resistors R7, R8 and R9 form an attenuator when the line input is

selected, reducing the input signal by 30dB. C45 and C46 again

provide DC isolation and there is provision at this point for the

insertion of an input balancing transformer. Note that if a

transformer is fitted R14 should be changed to 1k. Where a

transformer is not fitted two 10R resistors (R10, R11) carry the signal

through to the input amplifier. D1, D2, D3 and D4 provide clamping

for excessive input voltages and the signal is applied to the bases

of transistors Tr5 and Tr7. VR1 is the front panel gain control and

this is connected through the MIC/LINE switch such that in the MIC

position the gain range is 20 to 70dB while in the LINE position it is

-10 to 20dB.

Signal is taken from the collectors of Trs 5 and 7 and applied

differentially to the input of IC1A. The output from here is fed

back to the emitters of the input transistors through 56k resistors

with one side being phase inverted by IC1B. The phase reverse

14

switch, SW3, selects either the normal or the phase inverted signal

and feeds it to the high pass filter stage. This is a three pole high

pass filter operating at 80Hz giving a roll off of 18dB per octave.

When not required this can be completely bypassed by SW4. The

output of SW4 after buffering by IC8B is known as PRE1 and is the

pre equaliser signal. PRE1 is a source for the auxiliary sends which

will be referred to later.

THE EQUALISER

The signal is presented to the equaliser which is a four band design.

The high and low frequency sections are built around IC2B with

VR7 providing low frequency boost and cut while VR2 provides

high frequency boost and cut. The middle frequency sections are

built around IC3 and use a Wein bridge as the frequency

determining network. VR3 selects the frequency of operation and

VR4 determines the amount of boost or cut given to the hi mid

signals while VR5 alters the frequency and VR6 the boost or cut for

the lo mid signals. The output from the equaliser connects to SW5

the EQ IN/OUT switch where either the pre equaliser sinal or the

equalised signal can be selected to be passed to the insert send.

CON5, a Tip, Ring and Sleeve jack, is used for the insert point with

the Tip being used as the send. SP3 and SP4 are filters preventing

noise from entering the console. The insert return signal is buffered

by IC7A and is then presented to the channel fader. The output

from the fader feeds the channel cut circuit.

The pre fader signal feeds the auxiliary cut circuit, the solo bus

when a solo is requested and finally the 3 led signal meter which is

driven from IC6, a quad comparator. There are SIGNAL PRESENT,

0dB and PEAK indicators which are powered from a current source

built around Tr8. The auxiliary cut allows the creation of a PRE

FADE POST MUTE signal, which can be defeated if required, in

addition to the POST FADE POST MUTE signal.

THE MUTE CIRCUIT

Tr1 is the CHANNEL MUTE fet which is buffered by IC4A and

following this the signal is known as POST. This signal routes to the

groups when panning is not used and also feeds the auxiliary sends

when selected as POST. The pre fade signal goes through a second

AUXILIARY MUTE circuit built around Tr2 to give a PRE FADE POST

MUTE signal called PRE2. LK1 is normally installed allowing the

PRE FADE signal to be muted when the channel mute is operated.

By removing LK1 and installing LK2 the PRE FADE signal will not

mute with operation of the channel mute switch.

15

In order to improve the attenuation of the mute circuits a small

amount of signal is fed forward to cancel with any residual from

the output of the fets. Resistors R140, R141 and R142 perform the

feed forward for the channel signal while R99, R100 and R101 are

used for the auxiliary cut circuit.

The mute circuit can be remotely controlled either through the

external remote connector or from the four mute groups provided.

A SAFE button allows the mute groups to be disabled on the

module. When the local mute button is pressed a ground is placed

onto the remote control connector. This can be used to operate

external equipment such as a midi sequencer or it could be

connected to other channels so that when one channel is muted

others will also mute. Led 1 indicates a MUTE whether it is local or

remote. In every case a MUTE request grounds the base of Tr6

causing it to switch off and hence its collector to go high. This is

applied to the gates of Tr1 and Tr2 causing them to switch off since

they are P channel fets. Tr4 will also turn off causing Tr3 to turn off

allowing led 1 to indicate the mute condition.

THE P AN CIRCUIT

The POST signal next goes to the pan circuit. This circuit can be

switched between stereo (L/R) and left/centre/right (LCR) modes

using SW15. The output of the pan pot can be routed to the mix or

the groups. If panning to groups is not selected then the groups

receive the POST signal while, with panning selected, they receive

the output of the pan pot (PANL and PANR). If LCR panning is

selected then assigning to mix (SW13) will send signal to the left

centre and right buses.

If L/R mode is selected no signal will appear on the centre output

except by pressing the MONO button (SW27) when the POST signal

will be routed to the centre bus. The groups can only use the left

and right pan pot outputs and therefore if LCR panning is selected,

panning to groups will not function in the expected manner.

The pan pot is built around VR16, a dual pot, and IC5. When in L/R

mode only one section of the pot (VR16A) is used and it simply

reduces the resistance to ground of the left or right signal

depending upon the direction of rotation. This reduces the

amplitude of the signal on one side while increasing it on the other

to create the panning effect.

When LCR mode is selected the input signal is fed to a centre tap

on VR16A. Signal can thus only appear on the left or right output

of this section of the pan circuit (but not both together) with the

amplitude depending again on the rotation of the pan pot.

16

The centre output is derived from the same input signal and VR16B

is used to control its amplitude by decreasing the resistance to

ground when the pot is rotated away from its central position.

IC5B buffers the centre signal.

THE AUXILIARY SENDS

The auxiliary sends can use the following three signals :PRE1, PRE2 and POST.

PRE1 is the pre equaliser signal, PRE2 is the pre fader post mute

signal and POST is the post fader post mute signal.

All auxiliaries will normally receive the POST signal, however, there

are PRE switches associated with the auxiliaries allowing the pre

fader signal to be selected. The default condition is that PR2 shall

be the pre signal although links allow this to be changed to the

PRE1 signal. Only one link of a pair should ever be inserted.

Auxiliaries 1, 2, 3

Link 4 PRE1

Link 3 PRE2

Auxiliaries 4, 5, 6

Link 5 PRE1

Link 6 PRE2

Auxiliaries 7, 8

Link 7 PRE1

Link 8 PRE 2

THE SOLO FUNCTION

SW22 is the solo or PFL switch. When operated it places DC onto

the IPCUEDC bus which is detected by the master module. The audio

signal INS_RET is fed onto the IPCUE bus and fed to the monitoring

system on the master module. If Solo In Place mode is selected

then the module initiating the solo will have its solo switch

depressed and the incoming SIP signal will have no effect. If the

module did not originate the solo in place the solo switch will not

be depressed and the SIP signal will cause the channel to mute.

THE DIRECT OUTPUT

The direct output is available at CON5, a jack connector. The signal

is unbalanced, at a nominal level of 0dBu and by default is the

POST signal. SW28 allows the PRE1 signal to be used.

17

Switches 9, 10, 11, 12, 23, 24, 25 and 26 route the signal to the

groups. Switch 27 routes signal to the MONO (CENTRE) bus and

SW13 routes to the stereo MIX bus.

ROUTING AND MUTE GROUPS

Switches 18, 19, 20 and 21 select the mute group buses. They are

combined through diodes D11 through D14 and then go to the

SAFE switch SW17 before combining with the local and remote

MUTE signals.

GROUNDING

All routing to buses is through 10k resistors. All connectors are

grounded to the metalwork (chassis) ground. This is connected to

0V by a 100R resistor in parallel with a 10n capacitor. BUSREF is

taken from 0V through a 10k resistor.

There is provision for an external meter output on CON8 (option).

18

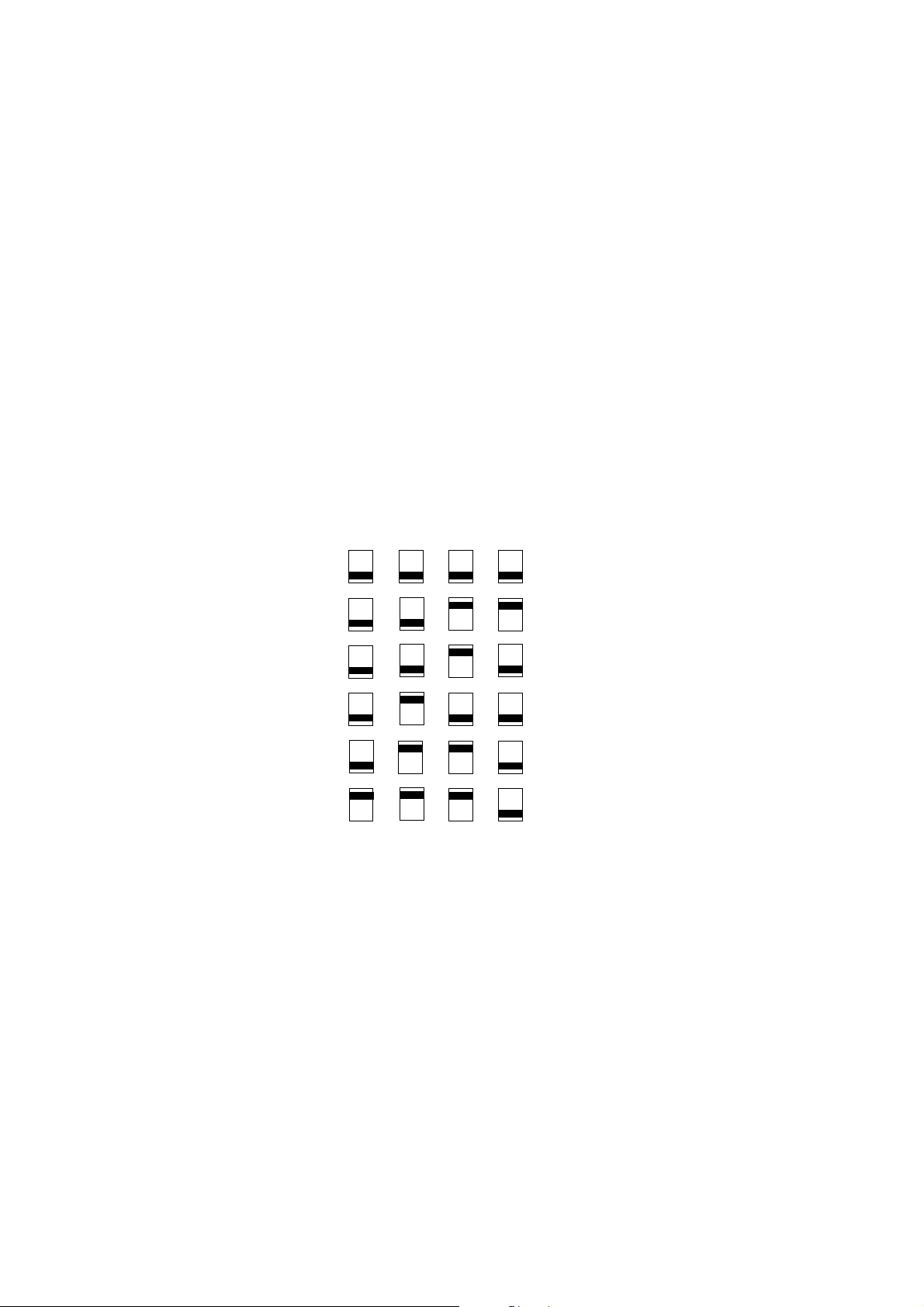

INPUT MODULE LINKS

INPUT MODULE PC1394

LIN K FU N CTION

1AUXILIARY CUT ENA BL E YES

2AUXILIARY CUT DISA BLE

3PRE FA D ER TO AUX 1-3YES

4PRE EQ TO AUX 1-3

5PRE EQ TO AUX 4-6

6PRE FA D ER TO AUX 4-6YES

7PRE EQ TO AUX 7-8

8PRE FA D ER TO AUX 7-8YES

9N/A

10 N /A

11 PRE EQ TO DIR OUT YES

12 PO ST EQ TO DIR OUT

FI TTED AS

SU PPLI ED

NOTES

INSTALL

ONLY ONE

LINK

INSTALL

ONLY ONE

LINK

INSTALL

ONLY ONE

LINK

INSTALL

ONLY ONE

LINK

INSTALL

ONLY ONE

LINK

19

MONO

MIX RIGHT

MIX LEFT

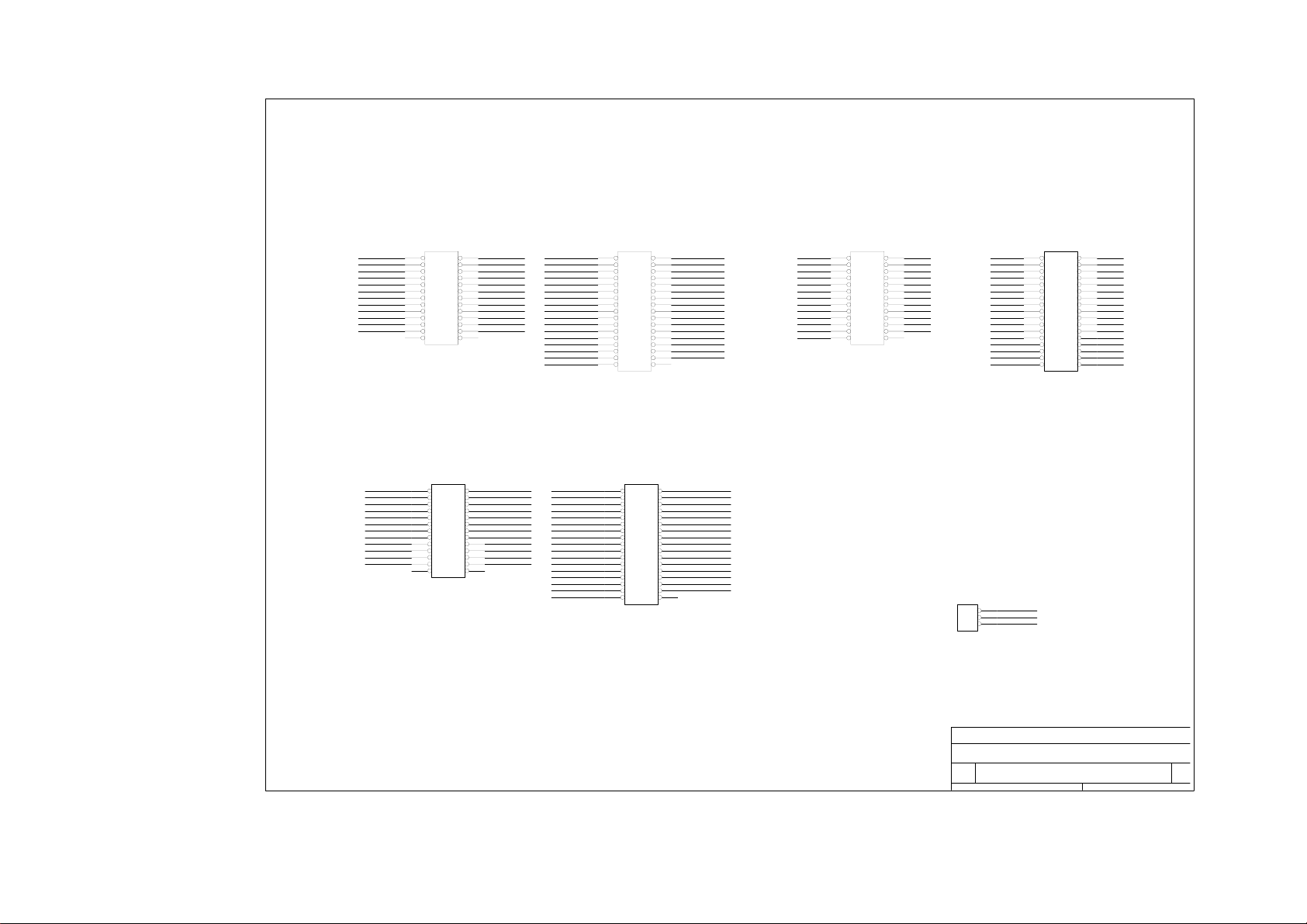

INPUT MODULE BLOCK DIAGRAM

MUTE GROUP 4

MUTE GROUP 3

MUTE GROUP 2

MUTE GROUP 1

PFL

AFL

AUXILIARY 8

AUXILIARY 7

AUXILIARY 6

AUXILIARY 5

AUXILIARY 4

AUXILIARY 3

AUXILIARY 2

AUXILIARY 1

GROUP 8

GROUP 7

GROUP 6

GROUP 5

GROUP 4

GROUP 3

GROUP 2

GROUP 1

56

12

34

ROUTING

78

TO GROUPS

PAN

+/-

15dB

freq.

4 BAND EQUALISER

HI

LO

GAIN

20 to 70dB

-10 to20dB

GAIN

OPTIONAL TX

INPUT

OPTION:

INPUT

MULTIPOLE CONNECTOR

MONO

EQ

HFLF

HI

MID

LO

MID

HPF

PHASE

LK11

LK12

48V

MIX

SIS

PAN

FADER

OUTPUT

EXTERNAL METER

PRE

DIR

SIS

+10dB

PEAK

0dB

DIRECT OUTPUT

LK1,2

SIGNAL PRESENT

1

PRE

LK3

PFL

EXTERNAL MUTE IN/OUT

CHANNEL

1

INSERT POINT

2

LK4

MUTE

3

SAFE

3

PRE

6

4

7

5

8

PRE

LK6

LK5

LK8

LK7

123

4

MUTE GROUP 1

MUTE GROUP 3

MUTE GROUP 2

MUTE GROUP 4

20

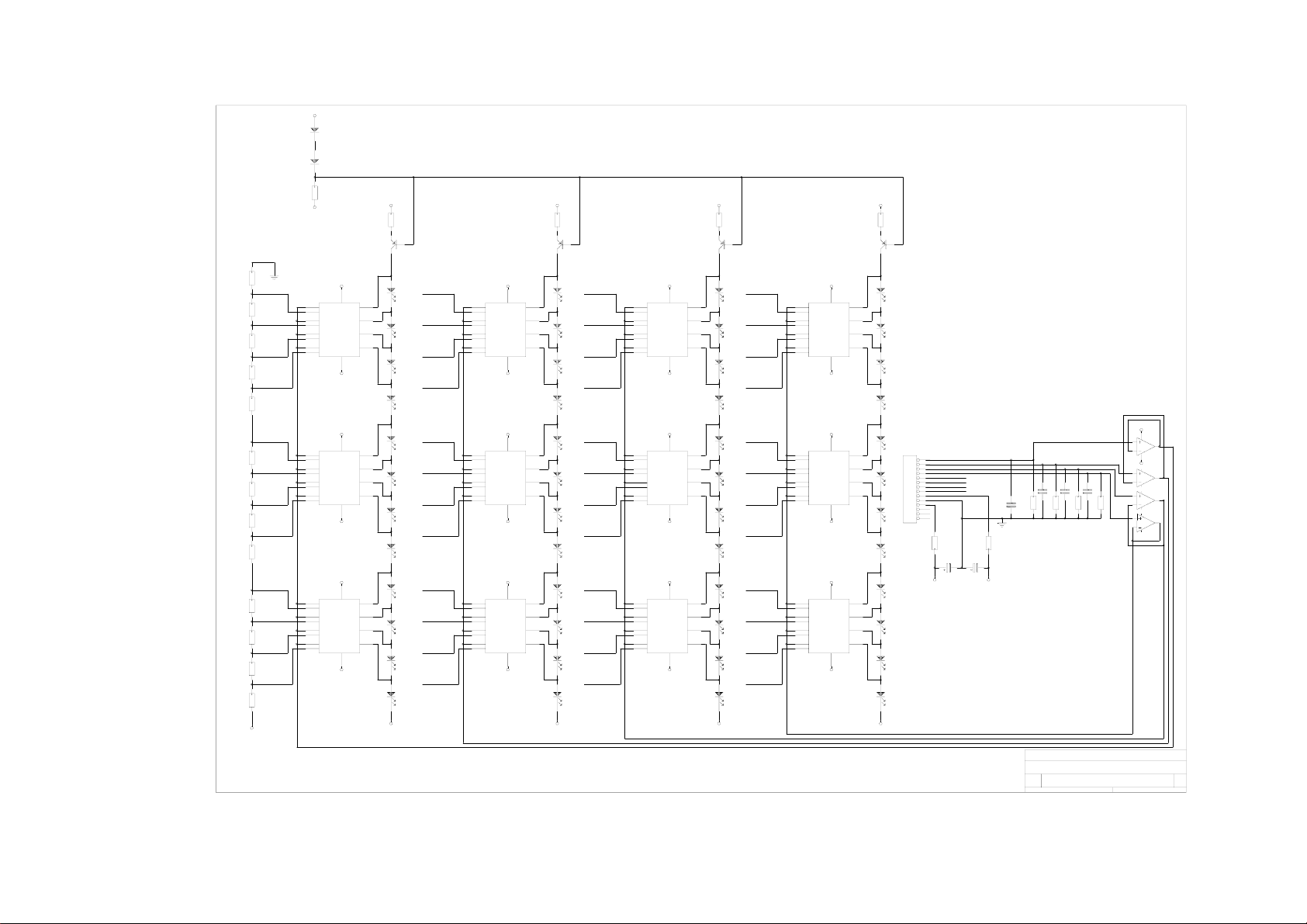

THE STEREO INPUT MODULE (CD1302/3)

THE INPUT ST AGE

The same input stage is used for both microphone and line inputs.

Looking at the left signal path, CON2, an XLR style connector, is

used for the microphone input which is wired to the inner contacts

of CON3, the line input TRS jack. With nothing inserted into the

jack socket the signal connects to the normal contacts and is then

fed to an attenuator which is activated by selection of the line

input. Resistors R2 and R3 feed phantom power to the microphone

input and this is DC blocked from the line input amplifier by C2

and C3. SP1, SP2 and SP3 are filters providing protection from high

frequency signals entering the inputs. Additional filtering is carried

out by capacitors C37, C38, C39 and C40.

Resistors R7, R8 and R9 form an attenuator when the line input is

selected, reducing the input signal by 30dB. C45 and C46 again

provide DC isolation and there is provision at this point for the

insertion of an input balancing transformer. Note that if a

transformer is fitted R14 (R214) should be changed to 1k. Where a

transformer is not fitted two 10R resistors (R10, R11) carry the signal

through to the input amplifier. D1, D2, D3 and D4 provide clamping

for excessive input voltages and the signal is applied to the bases

of transistors Tr4 and Tr5. VR1A is the front panel gain control and

this is connected through the MIC/LINE switch such that in the MIC

position the gain range is 20 to 70dB while in the LINE position it is

-10 to 20dB.

Signal is taken from the collectors of Trs 4 and 5 and applied

differentially to the input of IC1A. The output of IC1A is fed back

to the emitters of the input transistors through 27k resistors with

one side being phase inverted by IC1B. The phase reverse switch

SW28 (located in the left signal path only) selects the normal or

phase inverted signal and passes it to the high pass filter formed

around IC2A. This is a three pole high pass filter operating at 80Hz

giving a roll off of 18dB per octave. When not required this can be

completely by-passed by SW3. The output of SW3 passes through

SW19, the MONO R switch to become PRE-L1 which is the pre

equaliser signal (left). It is a source for the auxiliary sends which

will be referred to later.

SUMMING AMPLIFIER

IC11A sums the left and right signals together to create a mono

signal which has its polarity restored by IC11B before being

presented to switches SW19 and SW20 (the left and right signal

cut switches). When Mono R (switch 19) is pressed the left signal is

cut and replace by the right signal. Similarly when Mono L (switch

20) is pressed the right signal is cut and replaced by the left signal.

If both switches are pressed the output of IC11B (a mono signal) is

fed to both left and right signal paths.

21

THE EQUALISER

PRE1 L1 is presented to the equaliser which is a four band design.

The high and low frequency sections are built around IC9A with

VR6 providing low frequency boost and cut while VR2 provides

high frequency boost and cut. The lo middle frequency section is

built around IC8/IC202A. VR15 selects the frequency of operation

and VR14 determines the amount of boost or cut given to a signal.

The hi middle frequncy section is built around IC15B and IC16A.

VR17 determines the frequency of operation while VR18 determines

the amount of boost or cut. The equaliser output feeds the EQ IN/

OUT switch, SW29 allowing the pre or post equaliser signal to be

selected.

IC7A buffers the equaliser output and feeds it to the fader. The

equaliser output is also used to derive the PFL signal and to drive

the SIGNAL PRESENT, 0dB and PEAK indicators.

THE CUT CIRCUIT

The signal path splits at this point to go through two cut circuits.

This allows the creation of a PRE FADE POST MUTE signal (which

can be defeated if required) in addition to the POST FADE POST

MUTE signal. Tr1 is the CHANNEL MUTE fet and the post cut signal

is buffered by IC4A. The signal leaving IC4A is the POST FADE signal

which is then fed through a pan pot that can be routed to the

groups or the L/R mix. The pre fade signal goes through an

AUXILIARY MUTE circuit built around Tr2 to give a PRE FADE POST

MUTE signal called PRE2. LK1 is normally installed allowing the

PRE FADE signal to be muted when the channel mute is operated.

By removing LK1 and installing LK2 the PRE FADE signal will be

unaffected by operation of the channel mute switch. IC12A is used

to combine the left and right post fade signals for sending to the

auxiliaries. IC12B is used to combine the left and right pre fade

signals for sending to the auxiliaries.

As with the input module a small amount of signal is fed forward

to cancel any residual from the fets to improve the mute

attenuation.

THE BALANCE CIRCUIT

The post fade signal next goes to the balance circuit. The output of

the balance pot can be routed to the mix or the groups. The groups

normally receive the mono post fade signal but with the PAN switch

depressed they will receive the outputs of the balance pot built

around VR16. By default the balance control works as a pan pot

with full attenuation of the unwanted side. A more limited range

of adjustment can be obtained by changing the circuit as follows :-

22

Move R140 to R141 and R341 to R340 leaving the positions for

R140 and R341 blank.

Make R142 and R342 both 10k (they are 0R links).

This will then give a balance range of +3/-6dB.

PEAK AND SIGNAL PRESENT LEDS

A PEAK indicator and a SIGNAL PRESENT indicator are driven from

the post equaliser signal. IC14 is used as a voltage comparator and

directly drives leds 5 and 6. A reference voltage is applied to pins 5

and 7 while audio is applied to pins 3 and 5. The PEAK led comes

on 3dB before clipping while the SIGNAL PRESENT led comes on

with a signal level higher than -18dBu.

THE AUXILIARIES

With the exception of auxiliaries 7 and 8 the auxiliaries work in

mono using mixed left and right signals which are derived either

pre or post fade. The following three signals are available :PRE1, PRE2 and POST.

PRE1 is the pre equaliser signal, PRE2 is the pre fader post cut signal

and POST is the post fader post cut signal.

When PRE is selected the PRE2 signal is the factory default setting.

Links enable the default settings to be changed.

AUX 1-3

Remove link 3 and install link 4 for PRE1.

AUX 4-6

Remove link 6 and install link 7 for PRE1.

AUX 7-8

Remove link 11 and install link 12 for PRE1.

Auxiliaries 7 and 8 may be used as a stereo pair by depressing SW22,

the STEREO switch.

23

THE CUT CIRCUIT LOGIC

SW6 is the mechanically latching CUT switch which when operated

places a ground on the cathode of D15 causing the base of Tr3 to

go low and therefore the collector to go high. D9 will now stop

conducting enabling LED1 to illuminate indicating a cut. The

collector of Tr3 is applied via R118 and R98 to the gate of Tr1, an P

channel FET, causing it to stop conducting hence muting the signal.

D10 is used to create different on and off switching times for the

FET.

As the attenuation of the FET is not perfect a feedforward technique

is used to cancel any residual signal. A small fraction of the channel

signal is fed to the non inverting input of IC4A where it will sum

with the residual but in anti-phase to it thus cancelling it completely.

The operation of the AUXILIARY CUT is similar to that of the

CHANNEL CUT. Links 1 and 2 exist to disable the auxiliary cut if

required. In this case Link 1 should be removed and Link 2 installed.

An external input and output are available for the CUT function.

The external cut output simply extends a ground onto the connector

when the cut switch is depressed. The external cut input requires

to ground the cathode of D7 which then has the same effect as the

cut switch grounding D6. A simple latching switch contact is

sufficient.

THE SOLO FUNCTION

SW18 is the solo or PFL switch. When operated it places DC onto

the IPCUEDC bus which is detected by the master module enabling

it to replace the selected monitor signal with signal from the solo

bus (IPCUE). The equaliser outputs are mixed to mono for use as

the solo signal. If Solo In Place mode is selected then the module

initiating the solo will have its solo switch depressed and the

returned SIP signal from the master module will have no effect. If

the module did not originate the solo in place the solo switch will

not be depressed and the SIP signal will cause the channel to mute.

Thus only the module initiating the solo will be left uncut. In this

mode no change takes place on the master module and only the

module initiating the solo in place will be heard through the

monitoring system.

There is provision for an external meter on connector CON4 (option).

ROUTING AND GROUNDING

All routing to buses is through 10k resistors. All connectors are

grounded to the metalwork (chassis) ground. This is connected to

0V by a 100R resistor in parallel with a 10n capacitor. BUSREF is

taken from 0V through a 10k resistor.

24

STEREO INPUT LINKS

STEREO INPUT MODULE PC1418

LINK FU NCTION

1

2

3

4

6

7

11

12

AUXILI ARY CUT

ENA BLE (LEFT)

AUXILI ARY CUT

DISA BLE (LE F T )

PRE FA D ER MONO

TO AUX 1-3

PRE EQ MONO TO

AUX 1-3

PRE FA D ER MONO

TO AUX 4-6

PRE EQ MONO TO

AUX 4-6

PRE FA D ER MONO

TO AUX 7-8

PRE EQ MONO TO

AUX 7-8

FI TTED AS

SU PPLI ED

YES

YES

YES

YES

NOTES

INSTA LL ONLY

ONE LINK

INSTA LL ONLY

ONE LINK

INSTA LL ONLY

ONE LINK

INSTA LL ONLY

ONE LINK

17

18

21

22

201

202

PRE EQ LEFT TO

AUX 7-8

PRE EQ RIGHT TO

AUX 7-8

PRE FA D ER LEFT

TO AUX 7-8

PRE FA D ER RIGHT

TO AUX 7-8

AUXILI ARY CUT

ENA BL E (RIGHT)

AUXILI ARY CUT

DISA BLE (RIGHT)

25

FI T AS A PA IR

YES

FI T AS A PA IR

YES

YES

INSTA LL ONLY

ONE LINK

STEREO INPUT MODULE BLOCK DIAGRAM

MUTE GROUP 4

MUTE GROUP 3

MUTE GROUP 2

MUTE GROUP 1

PFL

AFL

AUXILIARY 8

AUXILIARY 7

AUXILIARY 6

AUXILIARY 5

AUXILIARY 4

AUXILIARY 3

AUXILIARY 2

AUXILIARY 1

GROUP 8

GROUP 7

GROUP 6

GROUP 5

GROUP 4

GROUP 3

GROUP 2

GROUP 1

MONO

MIX RIGHT

MIX LEFT

8

1234567

FADER

ROUTING

+/-

15dB

freq

4 BAND EQUALISER

R BOTH

HI

LO

GAIN

20 to 70dB

-10 to20dB

GAIN

INPUT

OPTION:

MULTIPOLE CONNECTOR

HI

LO

HPF

MID

MID

LF HF

PHASE

EQ

STER

MIX

MONO

7

3

1

2

6

4

5

8

HI

LO

MID

MID

LF HF

L BOTH

PRE

HPF

PRE M1

BALANCE

PRE

POST M

PRE M2

PRE

STEREO

GAIN

PEAK

123

PRE L1

PRE R1

PRE L2

PRE R2

SIGNAL

OdB

MUTE

SAFE

4

PFL

LEFT INPUT

48V

RIGHT INPUT

INPUT

OPTION:

MULTIPOLE CONNECTOR

26

OUTPUT

OPTION:

EXTERNAL METER

EXTERNAL MUTE IN/OUT

1

3

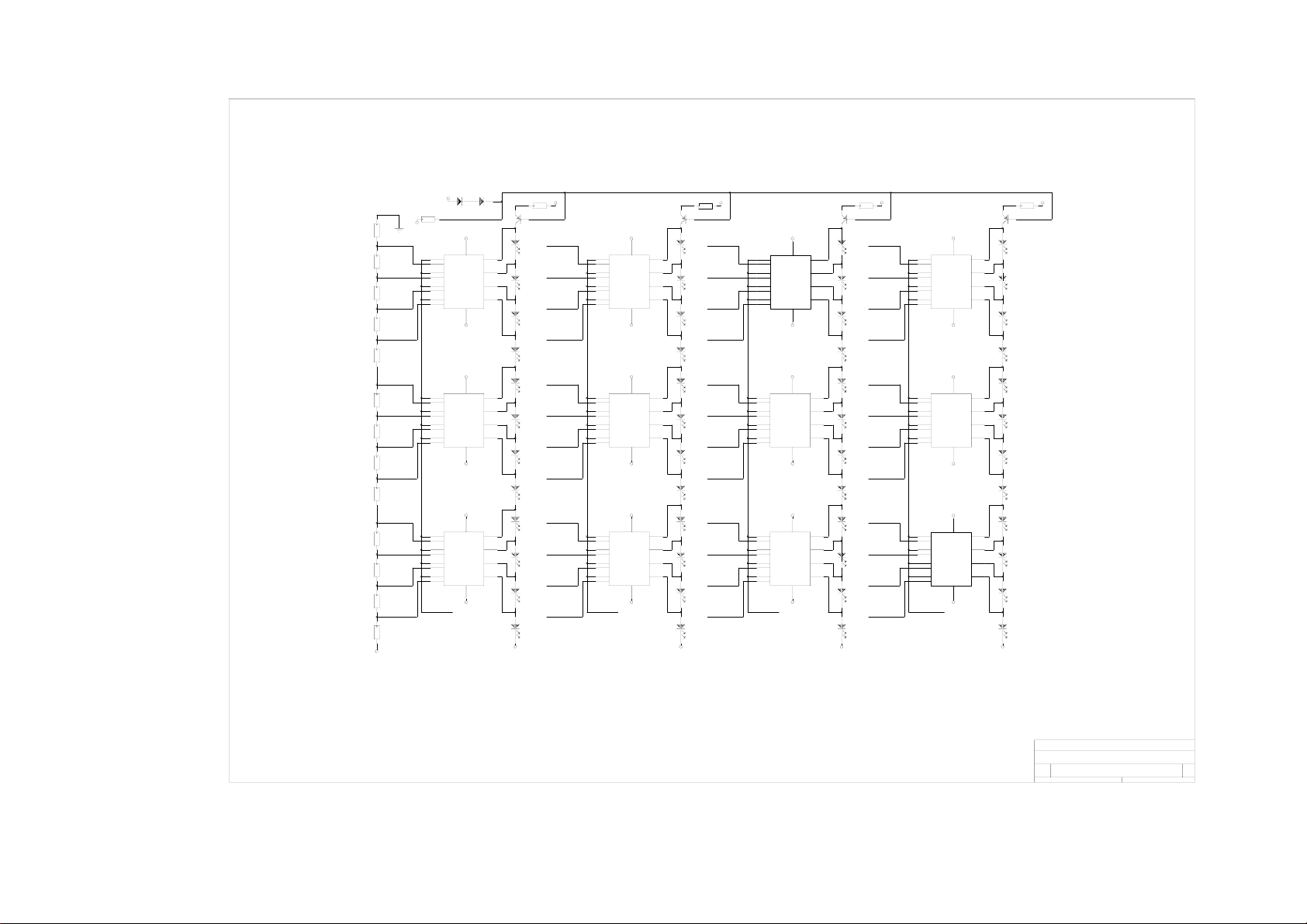

THE GROUP OUTPUTS (CD1280/CD1286)

There are two different kinds of output module. Numbers 1 - 6

carry a matrix section and auxiliary output while numbers 7 and 8

carry a stereo return section and an auxiliary output in addition to

the group output stage.

THE GROUP OUTPUT (CD1286)

Links 1, 2, 3, 4, 14, 15, 24 and 25 determine which of the group

buses will be assigned to the output. Only one link should ever be

installed. IC7B mixes the bus signals and presents them to IC7A

which simply phase inverts the signal before feeding the group

insert point, CON4. This is unbalanced and the send signal is applied

to the tip of the jack. When no plug is inserted the signal is

normalled through the RING contact and sent to the group fader.

This is followed by a buffer (IC8A) with 10dB of gain in order that

the fader can be run with 10dB of gain in hand.

A BUS PEAK indicator is fed from the pre insert signal to give

warning of high signals on the group bus. D5 half wave rectifies

the audio signal which is then presented to IC11B. This is used as a

voltage comparator and drives LED13 when the signal exceeds the

voltage on pin 6 of IC11B. Any signal greater than 3dB below

clipping level will cause an indication.

An AFL feed to the solo system is taken from the output of the

fader buffer. It is fed to the OPCUE bus through switch SW9 which

also applies DC to the OPCUEDC bus.

The group signal goes to the MUTE switch, SW8, from where it

splits off to the meter, the group output, and the sub mix circuitry.

The balanced output stage built around IC10 will simulate a

transformer so that it may be used into unbalanced loads without

any ill effect. Links 7 and 8 are used to bypass the output transformer

connector (CON10) and must be removed if a transformer is used.

CON15 may optionally be fitted where the output is to be wired to

a multipole connector.

The meter is built around IC12, a BA683A, giving a 12 segment

display with a range of +12dB to -21dB. PR1 is used to calibrate the

0dB point while PR2 is used to set the DC offset for the low end of

the scale. SW1 selects the group or the matrix signal to the meter.

Note that the BUS PEAK indicator is also switched between the

group and the matrix.

CON17 may optionally be fitted to provide signals for a meterbridge.

CON17 is switched by SW1 to carry the group or the matrix meter

signals.

27

There is a feed to an matrix connector (CON7) and links 5 and 6

determine whether the signal is pre or post fade. Link 5 is normally

installed giving a POST FADER signal to the matrix. Link 13 is used

to select the matrix bus.

The group can be sub mixed onto the main L/R and centre buses of

the console. A pan control is required to pan the mono group signal

onto the L/R and centre buses and this is constructed around VR15,

a dual pot, and IC9. When in L/R mode only one section of the pot

is used and it simply reduces the resistance to ground of the left or

right signal depending upon the direction of rotation. This reduces

the amplitude of the signal on one side while increasing it on the

other to create the panning effect. When LCR mode is selected the

input signal is fed to a centre tap on the pot. Signal will thus only

appear on the left or right output of this section of the pan circuit

with the amplitude depending again on the rotation of the pan

pot.

The centre output is derived from the same input signal as the left

and right outputs. VR15B is used to control the amplitude of the

centre signal and it is buffered by IC8B. The output of IC8B is fed to

the centre bus of the console when LCR mode is selected and the

MIX switch, SW6, is pressed. The POST signal may be fed to the

centre output of the console by pressing SW5 (MONO) which will

over ride the centre output of the pan pot in LCR mode.

AUXILIARY MASTER (CD1286)

Links 9, 10, 11, 12, 20, 21, 22 and 23 determine which of the auxiliary

buses will be sent to the output. Only one link should ever be

installed. IC4B mixes the bus signals and presents them to IC4A

which simply phase inverts the signal before feeding the auxiliary

insert point CON11. This is unbalanced and the send signal is applied

to the TIP of the jack through SUP11. With no plug inserted the

signal is normalled through the RING contact and sent to the

auxiliary master level control, VR1. This is followed by a buffer

(IC11A) with 10dB of gain in order that the level control can be run

with 10dB of gain in hand. An AFL feed to the solo system is taken

from the output of the buffer. It is fed to the OPCUE bus through

switch SW2 and DC is applied to the OPCUEDC bus.

The buffer output feeds the balanced output stage built around

IC6. This stage will simulate a transformer so that it may be used

into unbalanced loads without any ill effect. Links 18 and 19 are

used to bypass the output transformer connector (CON2) and must

be removed if a transformer is used. Components labelled SUP are

provided for the purposes of interference suppression and are fitted

to all input and output connections.

28

CON16 may be optionally fitted to feed a meterbridge.

THE MATRIX SECTION (CD1286)

A 12 by 6 matrix is formed by output modules 3 through 8. The

groups account for eight of the inputs with remainder being used

by the left, centre and right mixes and an external input.

CON12, a TRS jack, is used as the external input feeding IC1A which

unbalances the signal and feeds VR2, the level control. The output

of VR2 is combined with the group and mix inputs to the matrix at

IC2A with IC2B being used to phase invert the group/mix signals

which are simply brought in through level control pots VR3-VR10.

The combined signal goes to the matrix insert point, CON3, before

going through the matrix output level control, VR14. This is followed

by a buffer with 10dB of gain allowing the fader to be used with

10dB of gain in hand. The output of the MUTE switch is used to

feed the AFL switch, SW4, in addition to feeding the balanced

output stage built around IC3.

This stage will simulate a transformer so that it may be used into

unbalanced loads without any ill effect. Links 16 and 17 are used

to bypass the output transformer connector (CON9) and must be

removed if a transformer is used. Components labelled SUP are

provided for the purposes of interference suppression and are fitted

to all input and output connections.

STEREO INPUT (CD1280)

The stereo input is a line level stereo input which can be routed to

the group, auxiliary and mix outputs of the console. Note that if a

mono input is available then only the left input need be used as it

will be normalled to the right signal path if no jack is inserted into

the right input. IC1 forms the stereo balanced input from where

the signal goes through a gain control stage using IC2 and VR1

followed by the two band equaliser using IC3. The output of the

equaliser is summed to mono to create the PRE-M signal used to

feed PFL through SW8 and the auxiliaries. When SW8 is operated

DC is fed onto the IPCUEDC bus to signal the master module that a

solo has been requested and audio is placed on the IPCUE bus.

The equaliser is followed by the MUTE switch, SW14, and from

there the signal goes through a stereo fader. This is followed by a

buffer stage with 10dB of gain in order that the fader can work

with 10dB of gain in hand.

29

The post fader stage is presented to a balance control constructed

around VR4 and is mixed to mono to create the POST-M signal

used to feed the auxiliaries. The balance control is buffered by IC5

giving unity gain with the control in its central position. With the

control rotated to the right, for example, the right signal will

increase by 3dB while the left signal will be fully attenuated.

The output of the buffer is fed to the MIX switch, SW2 and the

group routing switches, SW4 through SW7. The feed to the mono

bus is through SW3 using the POST-M signal. Auxiliaries 5 through

8 can be accessed by the stereo input.

The PRE switch, SW1, allows the auxiliaries to be sent pre fade

mono signal rather than the post fade mono signal. The STEREO

switch, SW13, allows auxiliaries 7 and 8 to be used as a stereo

auxiliary using either the pre or post fade stereo signals.

THE GROUP OUTPUT (CD1280)

Links 1 and 2 determine which of the group buses will be assigned

to the output. Only one link should ever be installed. IC7B mixes

the bus signals and presents them to IC7A which simply phase inverts

the signal before feeding the group insert point. This is unbalanced

and the send signal is applied to the TIP of the jack. When no plug

is inserted the signal is normalled through the RING contact and

sent to the group fader. This is followed by a buffer with 10dB of

gain in order that the fader can be run with 10dB of gain in hand.

A BUS PEAK indicator is fed from the pre insert signal to give

warning of high signals on the group bus. D5 half wave rectifies

the audio signal which is then presented to IC11B. This is used as a

voltage comparator and drives LED18 when the signal exceeds the

voltage on pin 6 of IC11B. Any signal greater than 3dB below

clipping level will cause an indication.

An AFL feed to the solo system is taken from the output of the

fader buffer. It is fed to the OPCUE bus through switch SW12 which

also applies DC to the OPCUEDC bus. The group signal then goes to

the CUT switch SW10 from where it splits off to the meter, the

group output, and the sub mix circuitry.

The balanced output stage built around IC10 will simulate a

transformer so that it may be used into unbalanced loads without

any ill effect. Links 7 and 8 are used to bypass the output transformer

connector (CON5) and must be removed if a transformer is used.

30

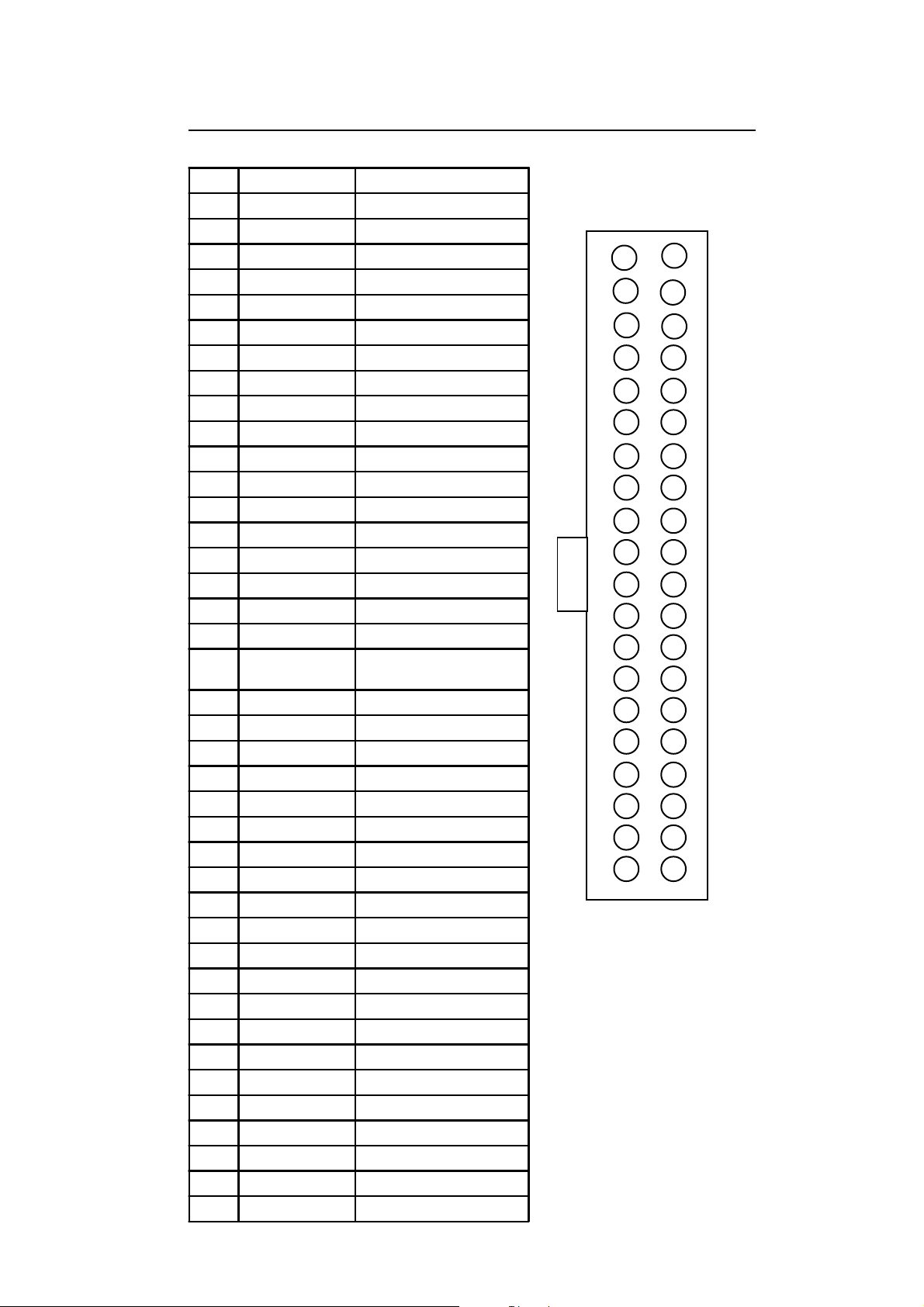

GROUP OUTPUT LINKS (MA TRIX)

GROUP MOD U LE 1-6 PC1398

LINK FUNCTION

1BUS 3 SELEC T

2BUS 4 SELECT

3BUS 5 SELECT

4BUS 6 SELECT

5MATRIX PO ST FA D ER Y ES

6MATRIX PRE FA D ER

7

8

9AUX 3 SELECT

10 AUX 4 SELECT

11 AU X 5 SELECT

12 AUX 6 SELECT

13 M ATRIX ASSIGN

14 N /A

GROUP OUTPUT

TRAN SF O RM ER BYPASS

GROUP OUTPUT

TRAN SF O RM ER BYPASS

FITTED AS

SU PPLIED

YES

YES

NOTES

M ODULE PO SITION

D EPEN DEN T

REM OVE IF AN

O UTPU T

TRA N SFORM ER IS

FITTED

M ODULE PO SITION

D EPEN DEN T

15 N /A

16

17

18

19

20 AU X 1 SELECT

21 AUX 2 SELECT

22 AU X 7 SELECT

23 AU X 8 SELECT

24 BU S 1 SELECT

25 BU S 2 SELECT

MATRIX OUTPUT

TRAN SF O RM ER BYPASS

MATRIX OUTPUT

TRAN SF O RM ER BYPASS

AUXILI ARY OUTPUT

TRAN SF O RM ER BYPASS

AUXILI ARY OUTPUT

TRAN SF O RM ER BYPASS

31

YES

YES

YES

YES

REM O VE IF

TR A N SFO RM ERS

ARE USED

M ODULE PO SITION

D EPEN DEN T

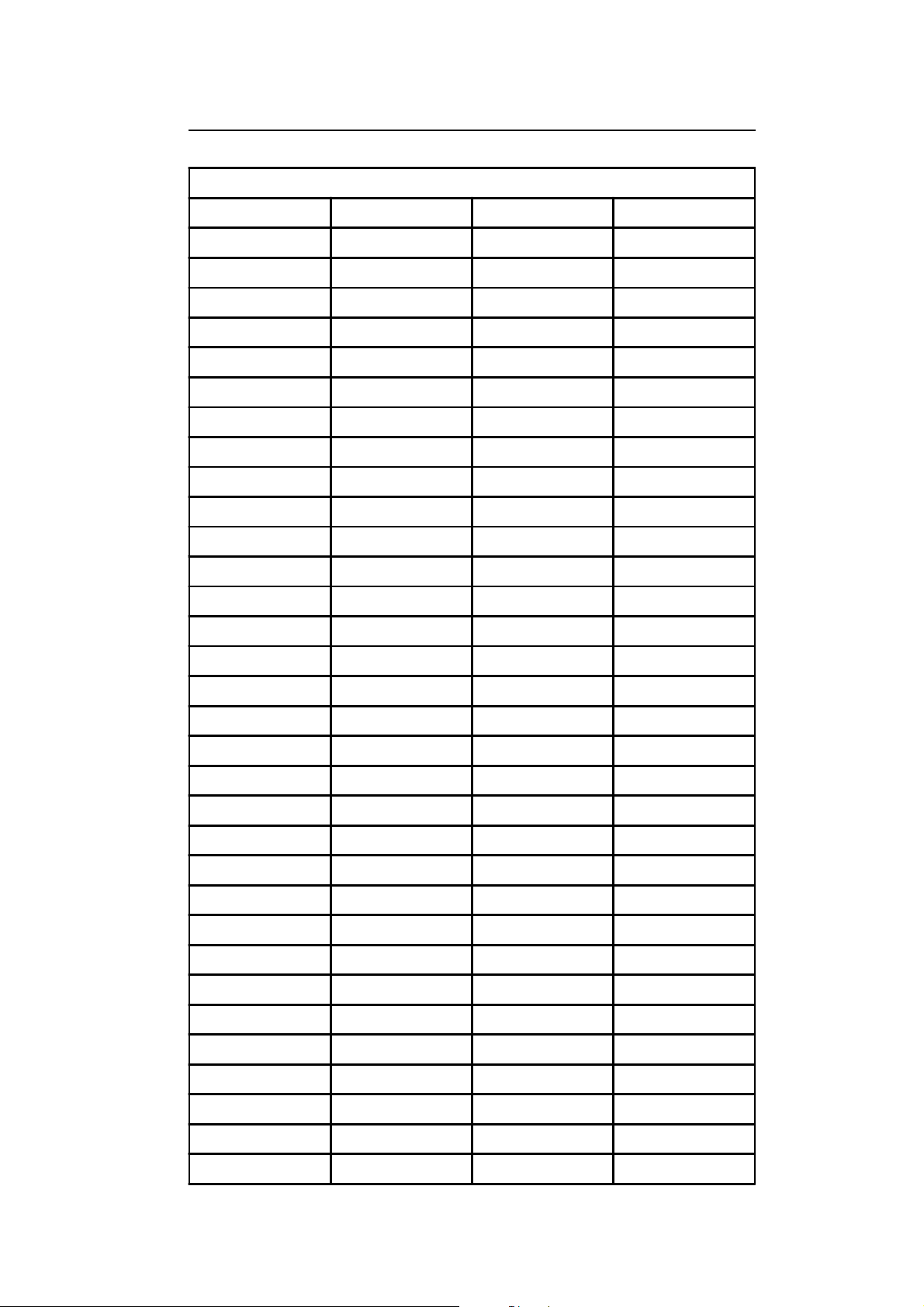

GROUP OUTPUT LINKS (RETURN)

GROUP MODULE 7-8 PC1395

LINK FUNCTION

1BUS 7 SELECT

2BUS 8 SELECT

3

4

5MATRIX PO ST YES

6MATRIX PRE

7

8

MATRIX GROUP 7

ASSIGN

MATRIX GROUP 8

ASSIGN

TRA NSF ORM ER

BYPASS

TRA NSF ORM ER

BYPASS

FITTED AS

SU PPLI ED

YES

YES

NOTES

MODULE PO SI TION

DEPENDENT

MODULE PO SITION

DEPENDENT

INSTALL ONLY ONE

LINK

REM OVE BOTH

WHEN AN OUTPUT

TRA N SFO RM ER IS

USED

32

GROUP OUTPUTS 1-6 BLOCK DIAGRAM

MIX LEFT

MIX RIGHT

MONO

GROUP 1

GROUP 2

GROUP 3

GROUP 4

GROUP 5

GROUP 6

GROUP 7

GROUP 8

AUXILIARY 1

AUXILIARY 2

AUXILIARY 3

AUXILIARY 4

AUXILIARY 5

AUXILIARY 6

AUXILIARY 7

AUXILIARY 8

BUS

PEAK

AFL

PFL

GROUP FADER

GROUP OUTPUT

AUXILIARY

OUTPUT

EXTERNAL INPUT

TO METER

MUTE

AFL

EXT

1

2

3

4

5

6

7

8

L

R

C

TX OPTION

PAN

TX OPTION

AFL

TO METER

TO METER

MATRIX OUTPUT

GROUP INSERT

POINT

OPTION:

MULTIPOLE CONNECTOR

OUTPUT

GROUP OUTPUT

MIX

SIS

AUXILIARY INSERT

POINT

OPTION:

MULTIPOLE CONNECTOR

AUXILIARIES 1-6

BUS

MATRIX INSERT

PEAK

MUTE

TX OPTION

AFL

MONO

OUTPUT

POINT

GROUP SUMMING

AMPLIFIER

MATRIX SUMMING

AMPLIFIER

AUXILIARY

MULTIPOLE CONNECTOR

GROUP

MATRIX

OPTION:

OUTPUT

GROUP

MATRIX

BUS PEAK

METER

EXTERNAL METER

OUTPUT

33

N

GROUP OUTPUTS 7-8 BLOCK DIAGRAM

I

SIS

OUTPUT

EXTERNAL METER

METER

TX OPTION

MUTE

PAN

AFL

BUS PEAK

GROUP FADER

GROUP OUTPUT

PFL

AFL

AUXILIARY 8

AUXILIARY 7

AUXILIARY 6

AUXILIARY 5

AUXILIARY 4

AUXILIARy 3

AUXILIARY 2

AUXILIARY 1

GROUP 8

GROUP 7

GROUP 6

GROUP 5

GROUP 4

GROUP 3

GROUP 2

GROUP 1

MONO

MIX RIGHT

MIX LEFT

1/2

3/4

5/6

ROUTING

7/8

MIX

MONO

POST L

MUTE

STEREO INPUT FADER

EQUALISER

BALANCE

6

5

STEREO

PRE

POST R

PRE MONO

PRE L

STEREO INPUT

7

POST MONO

PRE R

8

PFL

LEFT/MONO

34

RIGHT

THE MASTER MODULE

The Master Module supports a number of functions including the

main mix outputs, two auxiliary outputs, a tape return input and

the monitoring system. Two circuit boards are used with signals

passing between them when required.

AUXILIARY SENDS (CD1281)

Auxiliaries 7 and 8 are located on the master module and their

function is identical to the auxiliary masters located on the group

modules.

Looking at Auxiliary 7 IC1A mixes the auxiliary 7 bus signals and

presents them to IC1B which simply phase inverts the signal before

feeding the auxiliary insert point. This is unbalanced and the send

signal is applied to the TIP of the jack. When no plug is inserted the

signal is normalled through the RING contact and sent to the

auxiliary master level control, VR1. This is followed by a buffer with

10dB of gain in order that the level control can be run with 10dB

of gain in hand. An AFL feed to the solo system is taken from the

output of the buffer. This is fed to the OPCUE bus through switch

SW1 and DC is applied to the OPCUEDC bus.

The output of the buffer feeds the balanced output stage built

around IC3. This stage will simulate a transformer so that it may be

used into unbalanced loads without any ill effect. Links 1 and 2 are

used to bypass the output transformer connector (CON13) and must

be removed if a transformer is used.

LEFT , CENTRE AND RIGHT MIX (CD1281/2)

IC4A mixes the left bus signals and presents them to IC4B which

simply phase inverts the signal before feeding the auxiliary insert

point. This is unbalanced and the send signal is applied to the TIP

of the jack. An unbalanced feed to a tape recorder is also taken

from this point and is suitable for machines operating at -10dBV. A

feed of the CENTRE or MONO mix is also summed with the left and

right signals for sending to the tape recorder outputs. When no

plug is inserted in the insert jack the signal is normalled through

the RING contact and sent to the master fader. A BUS PEAK indicator

is fed from the pre insert signal to give warning of high signals on

the master bus. D11 half wave rectifies the audio signal which is

then presented to IC7A used as a voltage comparator to drive LED13.

Any signal greater than 3dB below clipping level will cause an

indication.

35

The master fader is followed by a buffer with 10dB of gain in order

that the fader can be run with 10dB of gain in hand. The output of

the buffer feeds the balanced output stage built around IC8. This

stage will simulate a transformer so that it may be used into

unbalanced loads without any ill effect. Links 3 and 4 are used to

bypass the output transformer connector (CON14) and must be

removed if a transformer is used. A feed of the fader buffer output

is also used to feed the centre output of the console when SW8 is

depressed.

The signal paths for the RIGHT and CENTRE signals are identical to

that described for the left signal.

MONITORING

There are left, centre and right outputs for speakers, a stereo

headphone output and 3 master meters. Solo audio is automatically

switched on to the monitor outputs when a solo is active and there

is an external tape input which can be assigned as a monitor source

or to the left and right outputs of the console.

T APE PLA Y INPUT (CD1283)

The external tape input is unbalanced and buffered by IC5 having

a non inverting gain of 5.5dB. The signal passes through CON11

(CD1283) to CON10 (CD1282) and from there to the level control

VR2. The inputs to the level control are also taken to the TAPE

switch SW6. The outputs of the level control feed IC13 which has

6dB of gain before being presented to switches SW2 and SW3 which

route it the L/R and MONO outputs of the console. The signals are

applied to the fader buffers and hence the master faders will not

affect the level of the tape signal when assigned to the mix outputs

of the console. This means that a tape can be played through the

console outputs with the main faders closed to suppress other signal

sources and is known as an intermission playback facility.

In addition to the TAPE switch the monitor path has a MIX TO MON

switch (SW4) and a CENTRE TO MON switch (SW5). The selected

source is applied to fets Tr1, Tr2 and T18 which will normally pass

the signal. If a solo is active then Tr1, Tr2 and Tr18 will cease to

conduct and Tr3, Tr4 and Tr19 will conduct to allow the solo bus to

be fed to the monitor outputs of the console. LMON, RMON and

CMON are the signals presented to the monitor outputs.

SOLO LOGIC (CD1282)

There are two solo DC buses, IPCUEDC and OPCUEDC which allow

input and output solos to be treated differently.

If an input solo is requested the IPCUEDC bus will go high causing

Tr7 to turn on and hence its collector to go low.

36

This switches off Tr8 which allows Led 16 to turn on indicating an

input solo. The collector of Tr7 is connected through SW7 (the SIP

switch) to the gate of Tr6, causing Tr6 to switch off.

The effect of this is to disable any output solo audio that is active,

giving the console input solo priority. The cathode of D7 is now

low causing Trs 1, 2, 12 and 18 to turn off. Tr11 inverts the output

of Tr7 causing Trs 3, 4, 13 and 19 to turn on.

Thus the normal monitor source is silenced while the solo audio is

allowed onto the monitor outputs in addition to the left meter

now showing solo audio level instead of the left mix signal. The

operation of an output solo is very similar other than for the fact

that it cannot disable input solos. During a solo the centre and

right meters are muted by fets Trs 5 and 6 (CD1283). Solo audio is

mixed by IC11B and this is where the solo meter feed is derived.

Signal can be adjusted in level by VR3 before going to the monitor

system without affecting the meter readings.

A Solo In Place mode can also be selected and when this is the case

the output of Tr7 feeds Tr14 causing it to turn on and therefore

Tr15 to turn on. This causes a logic low to be placed on the SIP bus

which mutes any input module not having its solo switch depressed.

The master meters are built around BA683A ICs, giving a 12 segment

display with a range of +12dB to -21dB.

Auxiliary 8 and the centre output are as for auxiliary 7 and the left

output description previously given.

THE MONITOR OUTPUTS (CD1284)

The selected monitor signals LMON, RMON and CMON are fed to a

volume control VR4 which is buffered by IC10/11. A PHONES switch

(SW14) selects the headphone or loudspeaker outputs. The

loudspeaker outputs are built around IC12, IC13 and IC14 and are

similar to the balanced outputs used for the main outputs of the

console. Transformer balancing is not available for the monitor

outputs.

The headphones outputs are designed to feed a low impedance

load and have a transistor output stage. IC17, transistors 1 through

4 and associated components form the stereo headphone amplifier.

TALKBACK

IC15 is the talkback microphone amplifier with gain being

adjustable by VR3. Link 1 may be installed if a phantom powered

microphone is to be used. When the talkback key is pressed Rs 114,

115 and 116 connect with the monitor signals to form a DIM circuit

of around 15dB.

37

Talkback can be routed to the auxiliaries, the mix or the groups.

There are also sine and pink noise generators. They can be switched

on using SW7 and the appropriate source selected by SW6. The

routing for these generators is as for the talkback. VR2 is a level

control for the selected oscillator.

Pink noise is generated from diodes D16 and D17 which are

differentially applied to IC7A. The output from IC7 is taken through

the ON switch, SW7, and then applied to IC7B for amplification

before filtering by resistors R86—R91 and capacitors C45—C49. The

output of the filter is buffered and amplified by IC6B from where

it goes to the SINE/PINK selector switch, SW6.

A 1kHz sine wave is generated by IC16 with D18 and D19 being

used to stabilise the amplitude.

IC16A along with C53, C54 and R97 form a bandpass filter

determining the frequency of oscillation.

38

MASTER MODULE LINKS

MASTER MODULE PC1396

LINK FUNCTION

AUXILI ARY 1

1

2

3

4

5

6

TRA NSF ORM ER

BYPASS

AUXILI ARY 1

TRA NSF ORM ER

BYPASS

LEFT MIX

TRA NSF ORM ER

BYPASS

LEFT MIX

TRA NSF ORM ER

BYPASS

RIGHT MIX

TRA NSF ORM ER

BYPASS

RIGHT MIX

TRA NSF ORM ER

BYPASS

FI TTED AS

SU PPLIED

YES

YES

YES

YES

YES

YES

NOTES

REM OVE WHEN

FI TTING AN

OUTUT

TRA NSF ORM ER

REM OVE WHEN

FI TTING AN

OUTUT

TRA NSF ORM ER

REM OVE WHEN

FI TTING AN

OUTUT

TRA NSF ORM ER

CENTRE MIX

7

8

9METER ENA BLE YES

TRA NSF ORM ER

BYPASS

CENTRE MIX

TRA NSF ORM ER

BYPASS

YES

YES

39

REM OVE WHEN

FI TTING AN

OUTUT

TRA NSF ORM ER

REM OVE WHEN

M ETERBRIDGE IS

FITTED

COM M S MODULE PC1397

LINK FUNCTION

TALKBACK

1

MICROPHONE

PHA NTO M PO W ER

AUXILI ARY 2

2

TRANSFORM ER

BYPASS

AUXILI ARY 2

3

TRANSFORM ER

BYPASS

FI TTED AS

SU PPLI ED

YES

YES

NOTES

REM OVE WHEN

FITTING OUTPUT

TRA NSF ORM ERS

40

MASTER MODULE BLOCK DIAGRAM

LEFT/SOLO METER

OUTPUT

EXTERNAL METER

R POST

L POST

C POST

AUX

OUTPUT

OPTION:

MULTIPOLE CONNECTOR

AUXILIARY OUTPUT 1

PHONES

MONITOR LEVEL

OUTPUT

LPOST

OPTION:

MULTIPOLE CONNECTOR

MIX OUTPUT LEFT

LOCAL MONITOR L

-

+

MIX TAPE

LOCAL MONITOR R

-

+

C

CENTRE

RPOST

LOCAL MONITOR C

-

+

TALKBACK

CENTRE METER

OUTPUT

OPTION:

MULTIPOLE CONNECTOR

MIX OUTPUT RIGHT

HEADPHONES

INPUT

TALKBACK MICROPHONE

AUX 1-3

AUX 4-6

AUX 7-8

MIX

BUS

SINE

OUTPUT

OPTION:

MULTIPOLE CONNECTOR

MIX OUTPUT CENTRE

ON

PINK

SOLO LOGIC

TX

OPTIONAL

+

INSERT POINT

BUS PEAK

TX

OPTIONAL

-

MUTE

CUT

-

+

L/R

TO CENTRE

TAPE LEVEL

INSERT POINT

BUS PEAK

L

AUXILIARY OUTPUT 2 IS SIMILAR TO AUXILIARY 1

AUX 1

TAPE

SEND RET

L

L+R TO

CENTRE

L/R

OPTIONAL

INSERT POINT

41

TX

MUTE

BUS PEAK

R

TX

OPTIONAL

-

+

-

+

MUTE

SOLO LEVEL

INSERT POINT

BUS PEAK

C

INPUT SOLO

OUTPUT SOLO

R

C

I/P SOLO

O/P SOLO

IPCUEDC

OPCUEDC

SIP

THE BUS LINKING POR T

The bus linking port enables two consoles to be used together in a

master slave configuration. The bus structure is broken between

the input modules and the group modules although in normal use

a shielded connector is used to join the two sections. If the console

is to be used as a master the connector is removed and the master

end of a link cable put in its place. This retains the link between

the buses and connects the input modules of the slave console to

the buses of the master console. If the console is to be used as a

slave the slave end of the link cable is used which breaks the link

between the buses and feeds the input modules over to the master

console. This of course means that the group and master modules

of the slave console are not used as only one master per function

can be allowed access to the bus.

During unlinked operation a blanking plug must be inserted to

connect the input and output buses.

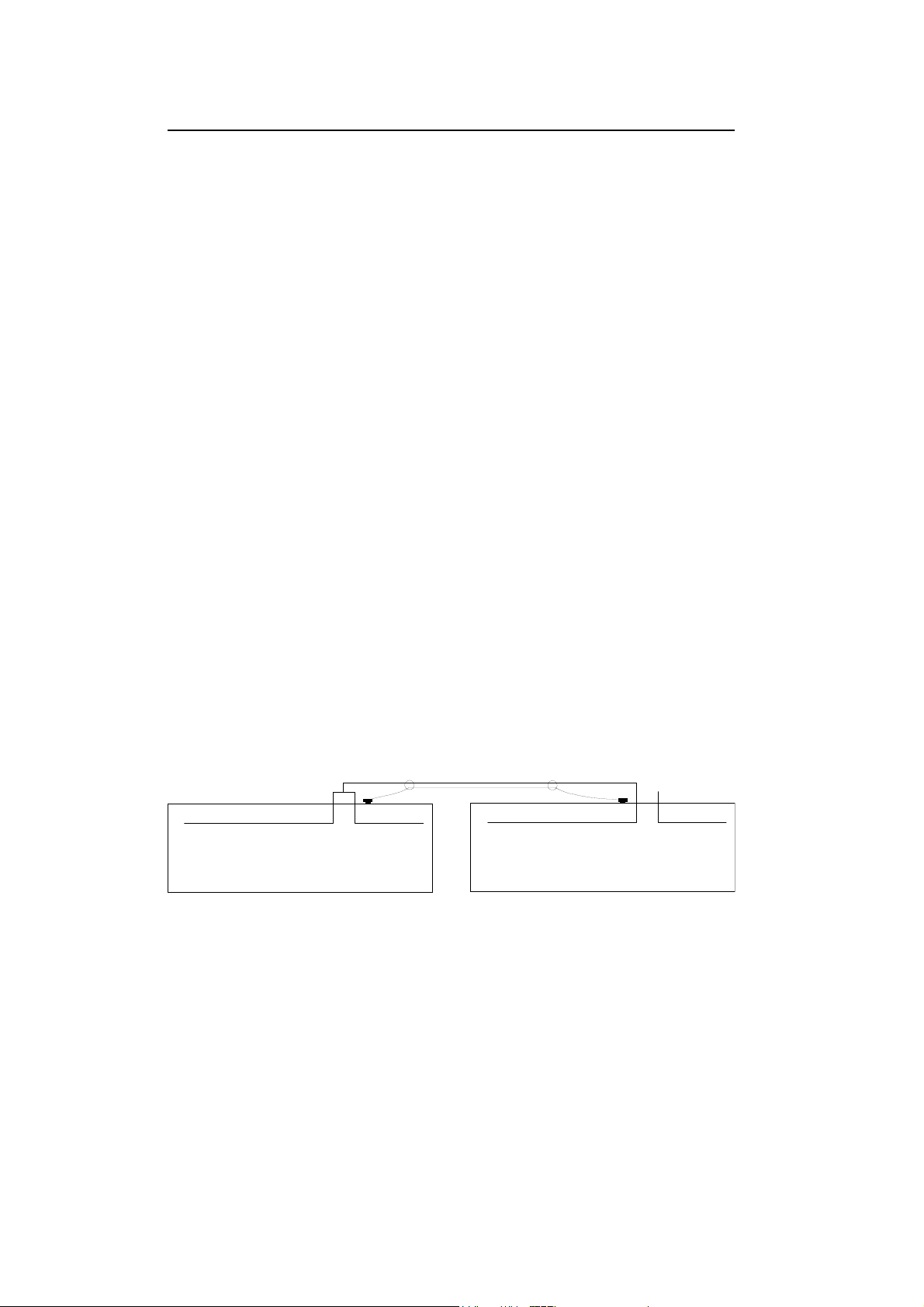

CD1308

This shows the Bus Link Blanking Plug.

CD1306

This shows the Bus Link PCB. There are two input connectors to

allow consoles where the master modules are located in the centre.

and one output connector. The output and input connectors are

connected by the blanking plug during normal (unlinked)

operation.

GROUND

STU D

BUS LINK PORT

BUS LINK PORT

GROUND

INPUT BUS OUTPUT BUS

MASTER CONSOLE

STU D

INPUT BUS OUTPUT BUS

SLA V E CONSO LE

42

THE METERBRIDGE

VU METERBRIDGE (CD1310)

The VU Meterbridge carries 11 meters indicating the three main

console outputs in addition to either the matrix, group or auxiliary

outputs of the console.

Signal selection is carried out by switches SW1 — SW3 while C1

ensures that on power up the GROUP signals will be displayed.

IC1 is a dual SR Flip Flop and normally the Reset input will be held

low by the pull down resitor R3. The Set input is wired to Vss and is

thus always low. When SW1 is pressed, or C1 is charging immediately

after switch on, Vdd is connected through D1 and R3 to Vss. Current

therefore flows and a voltage is created across R3 which is enought

to make the Reset input if IC1a see a logic high. The Q output is

thus set to a logic low while the Qbar output will be a logic high. A

similar situation will arise on IC1b and therefore the A and B control

inputs of the 4052 multiplexers will both be low allowing the X0

and Y0 input signals through which are the group signals. IC12a

also reads the control lines. As both are low and the IC is connected

as an invertor the output will go high causing LED1 to illuminate.

If neither or only one of the control lines is low the output will not

go high enough to turn on LED1.

If the matrix output is required then SW2 should be pressed. This

will cause C2 to charge through R1 creating a +ve pulse on the

clock input of IC1A. Assuming that we are in GROUP mode the

Data input will see the logic high from the Qbar output and this

will be clocked through to the Q output. The A control line now

goes high while the B control line stays low causing the multiplexers

to allow through the signals on the X1 and Y1 inputs which are the

matrix signals.

If the auxiliary outputs are required then SW3 should be pressed.

IC1B is clocked by a +ve going pulse from C3. Again the Data input

which is high will be clocked through to the Q output causing the

B control line to go high. The multiplexers will now allow through

signals connected to the X3 and Y3 inputs which are the auxiliary

output signals. The B control line is connected through to the RESET

pin of IC1A and when the auxiliary signal is selected a pulse will be

created through C6 causing IC1A to reset. When the auxiliary signals

are deselected the B control line will go low causing a -ve going

pulse. To prevent this from causing damage to the circuit

components it is clamped by D3 and thus prevented from driving

the reset pin more than 0.6V below ground. C7 and D4 perform

similar functions on IC1B.

43

When the A control line is high the output of IC11b will go low

causing the MATRIX indicator to illuminate while if the B control

line is high the output of IC12b will go low causing the Auxiliary

indicator to illuminate.

The outputs of the multiplexers are fed through buffer amplifiers

with some gain adjustment to allow for calibration of the meters.

Resistors attenuate the signal input to the multiplexers when a

signal is not selected in order to prevent breakthrough of any high

level audio signals. The signals for the left, centre and right mixes

do not travel through any multiplexers and are permanently

selected. There are of course only 6 matrix outputs and meters 7

and 8 will therefore not indicate during the period that the

meterbridge is being used to indicate MATRIX signals.

LED METERBRIDGE OUTPUT SIGNAL PROCESSING (CD1312)

The signal input to the led meterbridge output section is identical