Page 1

PERFECT h EATs'

PROFESSIONAL 30" SELF CLEAN

RANGE

(nstallat(on Manual

MODELS

[] RGSC-305SS

[] RGSC-30SBK

[] RGSC-30SWT

Page 2

NOTE TO [NSTALLER

The DCSProfessional seriesof Ranges and Cooktops are designed with a large number of features available

in a multitude of different combinations.

Foryour convenience,product questions can be answered by a DCSCustomerService Representativeby

phone: 1-888-281-5698,or Fax:714-372-7004,or email: support@dcsappliances.com

or bymail:

DCS

Attention: CustomerService

5800SkylabRoad

Huntington Beach,CA92547

www.dcsappliances.com

WARNING

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or

death,

PRECAUTION

Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other @pliance,

FOR YOUR SAFETY

If you smell gas:

n Do not try to light any appliance,

n Do not touch any electrical switch; do not use any phone in your

building,

@ Immediately call your gas supplier from a neighbor's phone, Follow

the gas supplier's instructions,

Installation and service must be performed by a qualified installer,

service agency or the gas supplier,

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE,

Page 3

UNPACKING AND HANDLING

Step 3: Unpacking, Moving and Phdng the Range ................................................................................7-8

ELECTRICAL/GAS CONNECTIONS

Step 4: HectricaH Connections .............................................................................................................................9

Step S:Gas ..................................................................................................................................................................9

TABLE OF CONTENTS

CLEANING EXTERIORSURFACES

Step 1O:CHeaning Exterior Surfaces ...............................................................................................................13

INSTALLER FINAL CHECKLIST .........................................................................................................................14

WARRANTY .......................................................................................................................................................................1s

SERVICE .................................................................................................................................................................................16

Page 4

PLANNING THE INSTALLATION

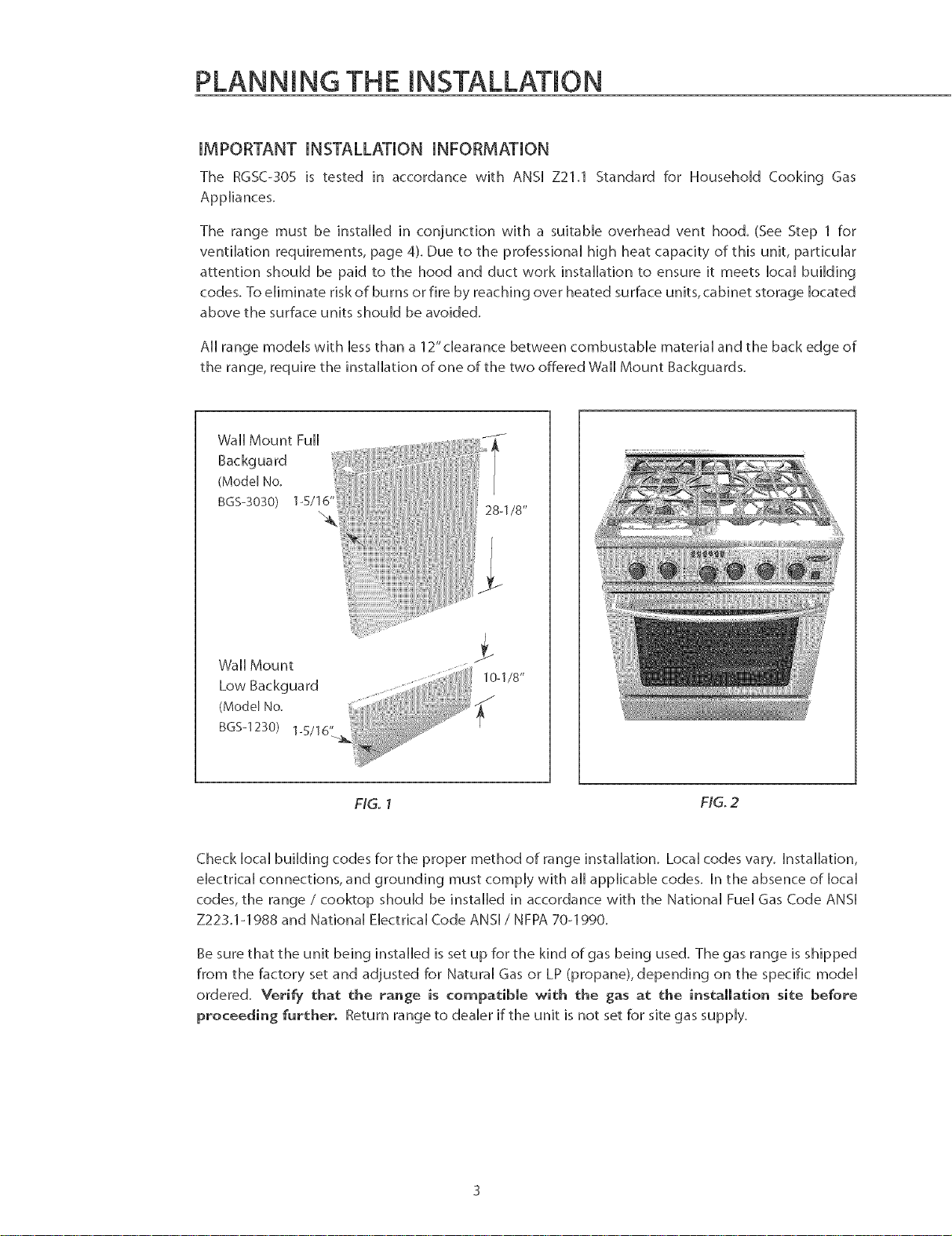

IMPORTANT INSTALLATION INFORMATION

The RGSC-305 is tested in accordance with ANSI Z21.1 Standard for Household Cooking Gas

App[hnces.

The range must be installed in conjunction with a suitable overhead vent hood. (See Step I for

ventilation requirements, page 4). Due to the professiona[ high heat capacity of this unit, particuHar

attention should be paid to the hood and duct work instaHHation to ensure it meets [oca[ building

codes. To eHiminate risk of burns or fire by reaching over heated surface units, cabinet storage [ocated

above the surface units should be avoided.

All range models with less than a 12"clearance between combustable material and the back edge of

the range, require the installation of one of the two offered Wall Mount Backguards.

Wa[[Mount Fuji

Backguard

(ModeINo.

BGS-3030)

28-1/8"

Wall Mount

FIG. 1 FIG. 2

Check local building codes for the proper method of range installation. Local codes vary. Installation,

electrical connections, and grounding must comply with all applicable codes. In the absence of local

codes, the range / cooktop should be installed in accordance with the National Fuel Gas Code ANSI

Z223.1q 988 and National Electrical Code ANSI/NFPA 70-1990.

Be sure that the unit being installed is set up for the kind of gas being used. The gas range is shipped

from the factory set and adjusted for Natural Gas or LP (propane), depending on the specific mode[

ordered. Verify that the range is compatible with the gas at the installation site before

proceeding further. Return range to dealer if the unit is not set for site gas supply.

Page 5

PLANNING THE INSTALLATION

Recommended Installation Instruction (when using BGS-3030 Backguard)

Install components in the following order:

a.Vent Hood b. gackguard System c. Range

1.Locate and [eve[ range according to Range installation instructions.

2. Measure distance from floor to top of isHand trim on range adding ]/8" for backguard cHearance.

3.Transfer this measurement to the waHL This wH[ mark the bottom of your backguard.

4. From this [ine measure 28-1/8" up wall[ to mark top of 30" backguard. This is the minimum height

that the bottom of your vent hood can be instaHHed.

5. FoHHowvent hood manufacturer's instaHHation instructions to install[ vent hood.

6. Follow backguard installation instructions to install backguard.

7. Connect gas and electric connections and slide range into position.

VENTILATION REQUIREMENTS

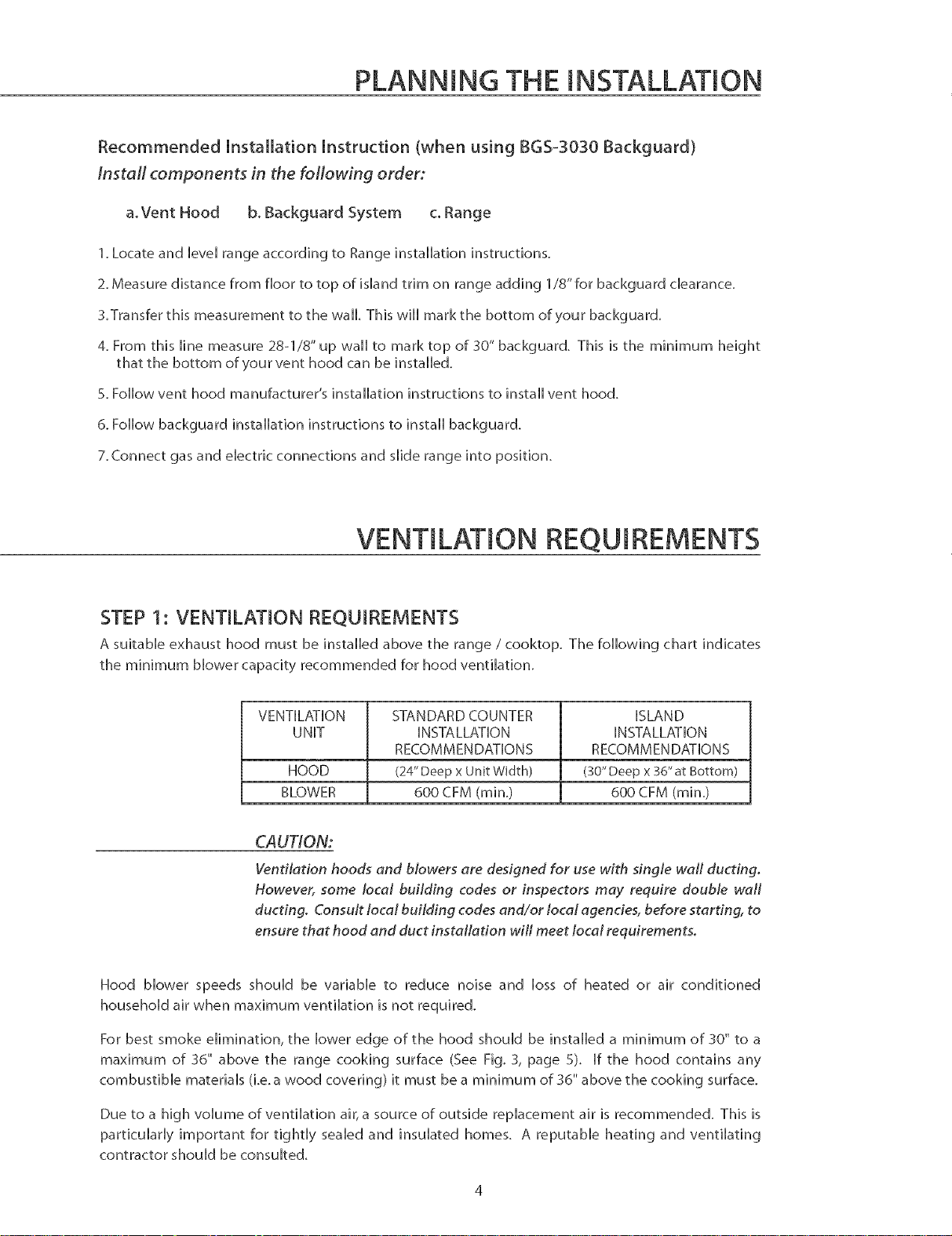

STEP 1: VENTILATION REQUIREMENTS

A suitable exhaust hood must be installed above the range / cooktop. The following chart indicates

the minimum blower capacity recommended for hood ventilation.

VENTILATION STANDARD COUNTER ISLAND

UNIT INSTALLATION INSTALLATION

RECOMMENDATIONS RECOMMENDATIONS

HOOD (24" Deep x Unit Width) (30"Deep x 36"at Bottom)-"

BLOWER 600 CFM (rain.) 600 CFM (rain.)

CAUTION:

Ventilation hoods and blowers are designed for use with single wall ducting.

However, some local building codes or inspectors may require double wall

ducting. Consult local buiMing codes and/or local agencies, before starting, to

ensure that hood and duct installation will meet local requirements.

Hood blower speeds should be variable to reduce noise and loss of heated or air conditioned

household air when maximum ventilation is not required.

For best smoke elimination, the lower edge of the hood should be installed a minimum of 30" to a

maximum of 36" above the range cooking surface (See Fig. 3, page 5). If the hood contains any

combustible materials (i.e.a wood covering) it must be a minimum of 36" above the cooking surface.

Due to a high volume of ventilation air, a source of outside replacement air is recommended. This is

particularly important for tightly sealed and insulated homes. A reputable heating and ventilating

contractor should be consulted.

Page 6

CABINET PREPARATION

STEP 2: CABmNET PREPARATmON

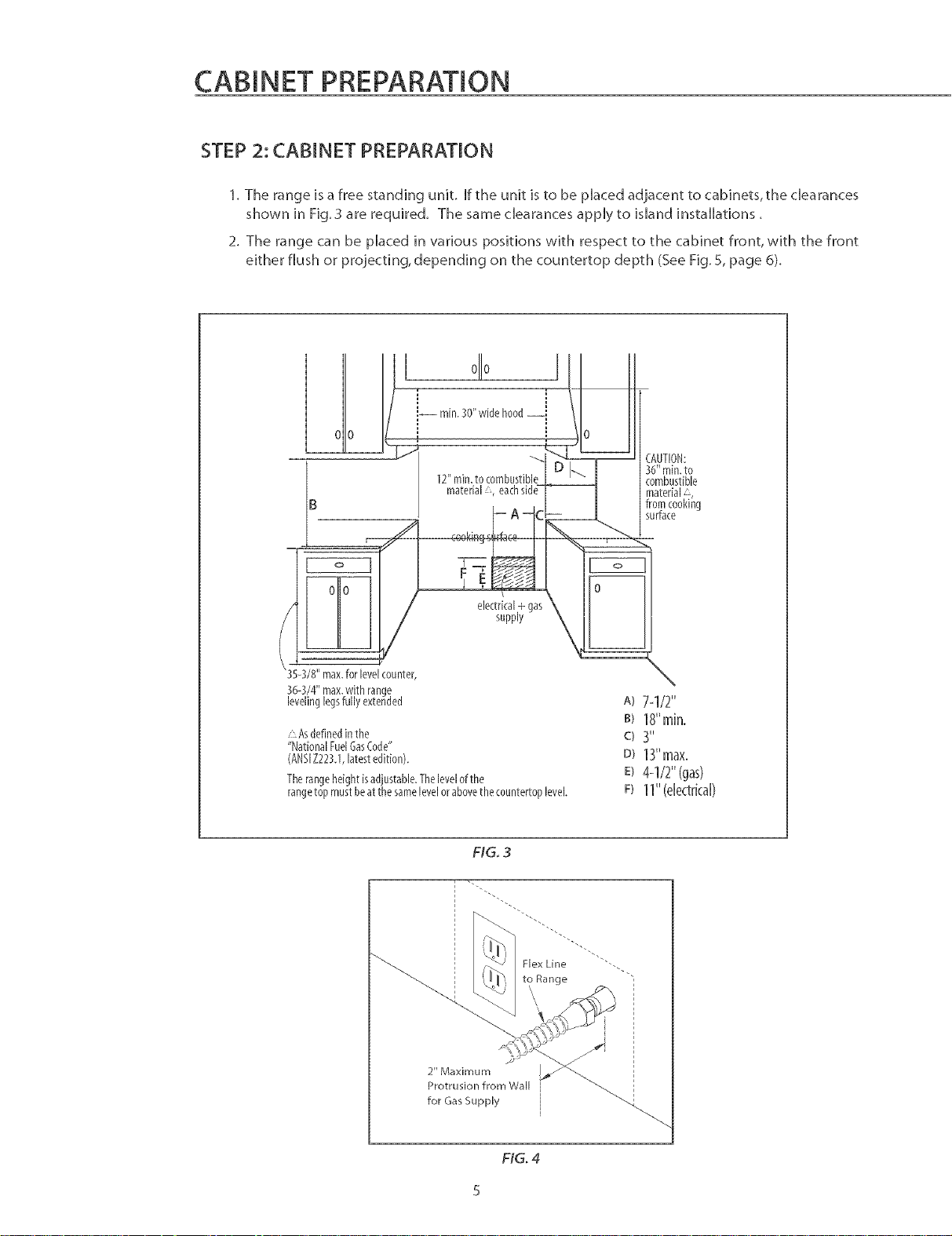

1. The range is a free standing unit. Hfthe unit is to be placed adjacent to cabinets, the clearances

shown in Fig. 3 are required. The same cHearances appHy to isHand instaHHations.

2. The range can be pHaced in various positions with respect to the cabinet front, with the front

either flush or projecting, depending on the countertop depth (See Fig. 5, page 6).

00 L !

35-3/8"max.forlevelcounter,

3&3/4" max.withrange

levelinglegsfullyextended

"As definedinthe

"NationalFuelGasCode"

(ANSIZ223J,latestedition).

Therangeheight[sadjustable.The[eve[ofthe

rangetopmustbeatthesame[eve[orabovethec0untertoplevel.

FIG. 3

Flex Line "'-..

to Range

2" Maximum

Protrusion from Wall

for Gas Supply

A) 7q/2"

m 18"mJn.

C) 3"

D) 13"max.

E) 4-1/2" (gas)

F) 11"(electrkal)

FIG. 4

Page 7

CABINET PREPARATION

3. The gas and eHectrkaH suppHy shouHd be within the zones shown in Fig.3 & Fig.4, page 5.

4. The maximum depth of over head cabinets instaHHedon either side of the hood is 13".

5. Any openings in the waHHbehind the range and in the floor under the range must be seamed.

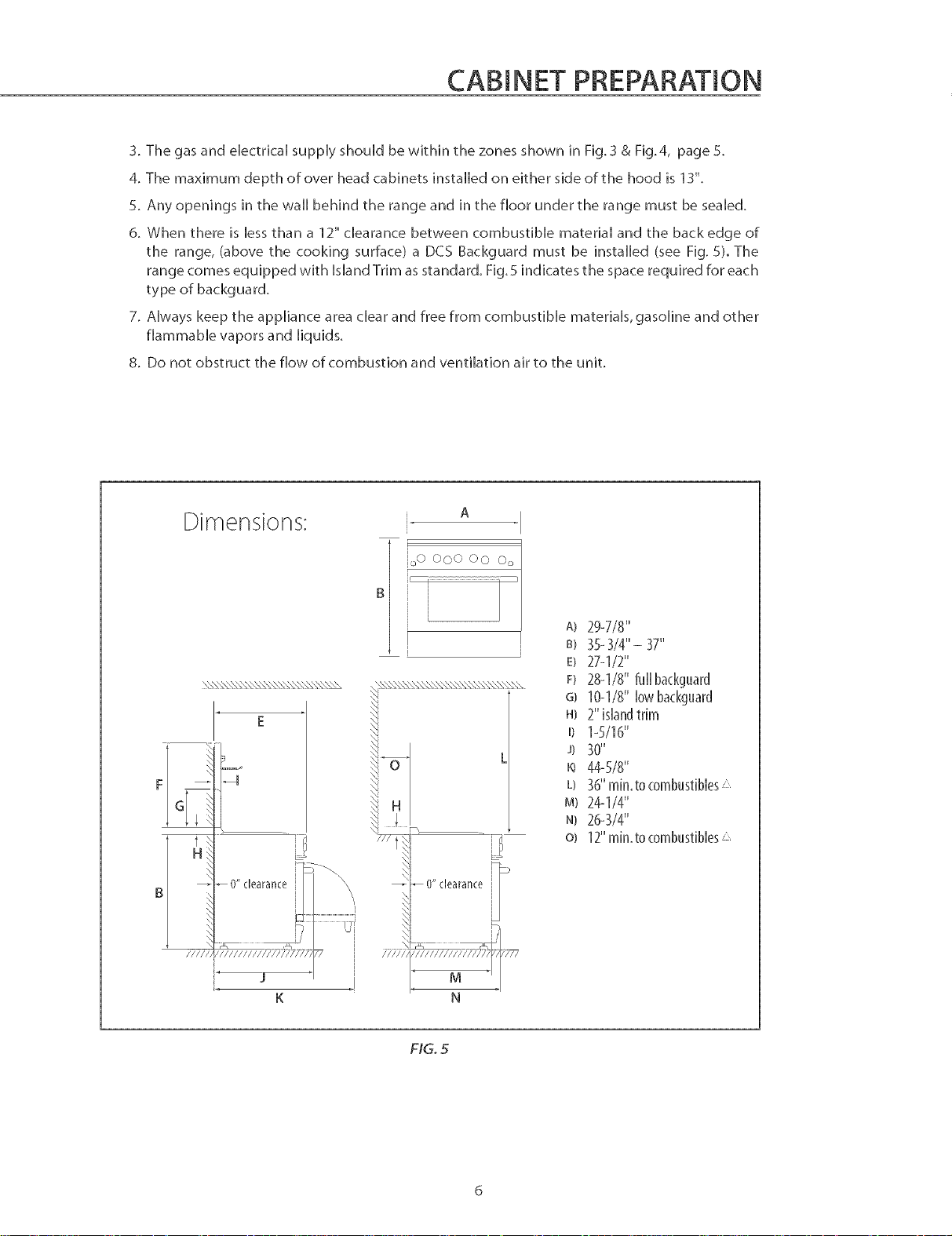

6. When there is Hessthan a 12" cHearance between combustibHe materhH and the back edge of

the range, (above the cooking surface) a DCS gackguard must be instaHHed (see Fig. 5). The

range comes equipped with HsHandTrim asstandard. Fig.5 indicates the space required for each

type of backguard.

7. AHways keep the appHhnce area dear and free from combustibHe materiaHs, gasoHine and other

flammabHe vapors and Hiquids.

8. Do not obstruct the flow of combustion and ventiHation air to the unit.

Dimensions:

i

joO 000 O0 O,s

\\\\\\\\\\_-_%\_\\\\\\\\X_

E

0"clearance

B

XX\\X\%\X\\N \\\_ \\\\\\\X%\\\\%

0" clearance

A) 29-7/8"

B) 39 3/4"- 37"

E} 27-1/2"

F) 28-1/8"fullbackguacd

G/ 10-1/8" 10wbackguard

H) 2"Bland tc[m

i) 14/J6"

J) 30"

m 44-5/8"

L) 36"min,tocombustibles

M) 24-1/4"

N) 264/4"

o) 12"rain.tocombustibles'

FIG. 5

Page 8

UNPACKING AND HANDLING

STEP 3: UNPACKING, MOVING

AND PLACING THE RANGE

CAUTION:

PROPER EQUIPMENT AND

ADEQUATE MANPO WERMUST

BE USED IN MOVING THE

RANGE TO AVOID DAMAGE TO

THE UNIT OR THE FLOOR. THE

UNIT 15HEAVY AND RESTS ON

ADJUSTABLE STEEL LEGS.

WARNING:

DO NOT LiFT THE RANGE BY

THE OVEN DOOR HANDLES !!

Kick Panel

The range has a shipping weight of approxF

mateHy 408 pounds or 354 pounds after removaH

of packing materhHs. Htis recommended that the

door, grates and front kick paneH be removed to

facilitate handHing. This wHHreduce the weight to

about 230 pounds. It may be necessary to remove

the oven doors and knobs to pass through some

doorways. With the doors and knobs removed, a

2%3/8" wide opening is required. Without

removing the door, a 30"wide opening is required.

Remove the outer carton and packing materiaH

from the shipping base.

CAUTION:

Before using range, be sure to

remove shipping spacer insert

in broiler (See Fig. 7).

Remove the kick panel by removing two screws at

the top and pulling forward. The range is held to

the skid by two brackets in the front behind the

kick panel (See Rg.6) and two L-brackets located

on the bottom flange of the range back (See

Fig. 8). After removing the screws and

brackets,the range must be lifted and removed

from the skid. Due to the weight, a doily with soft

wheels should be used to move this unit. The

weight must be supported, uniformly across the

bottom (See Fig.9, page 8).

FIG, 6

FIG. 7

Left Rear Shipping

Screws

FIG. 8

Page 9

UNPACKING AND HANDUNG

To remove the door, open the door and

hoHd it aH the way open. CHose the

hinge Hatches (See Fig. 10) and reHease

the door. The door can then be

Rangeblust

be Uniformly

Supported

on E_Faces

/

22"

/

LevelingLegs

FIG. 9

installed (Step 8) before the range usplaced in its final position. Hfthe unit is to be converted to LP gas,

it can be done with the range in place (See page 10).

removed by gently lifting and pulling

the door, with the hinges up and out of

the frame.

The professionaH range shouHd be

transported by a dolly chose to its finaH

Hocation. The range can be tipped back

and supported on the rear Hegswhile

the dolly is removed. The floor under

the legs should be protected (wood

strips, carpet, paneming,etc°) before

pushing the unit back into position.

E[ectdc and gas connections should be

made (Steps 4,5 & 6),the anti-tip device

installed (Step 7), and the backguard

For proper performance, the professional range should be [eve[. To achieve a flush fit of the range to

adjoinin 9 countertops, it will be necessary to have level cabinets (front to back, and left to right across

the opening of the range). After checking the countertops for level and before sliding the range into

place, measure the distance from the floor to

the top of the counter work surface in the

rear left and right corners. Adjust the

corresponding rear corner of the range to an

DOOR HINGI ROLLER

equal height of the counter, as the rear

leveling legs are not accessible once the

range is pushed into place. Once the range

is in place, the front leg levelers can be

accessed to level the front of the range.

Replace the kick panel and oven doors by

reversing the procedure described

previously, it is important that the two

screws retaining the kick panel are secure

to prevent accidental access to live

emectrical components and wires (See Fig.

6, page 7},

UN-LOCK

NOTE: For ease of installation, be sure to

install vent hood and backguard

system before sliding range into

position.

FIG. 10

Page 10

ELECTRiCAL/GAS CONNECTIONS

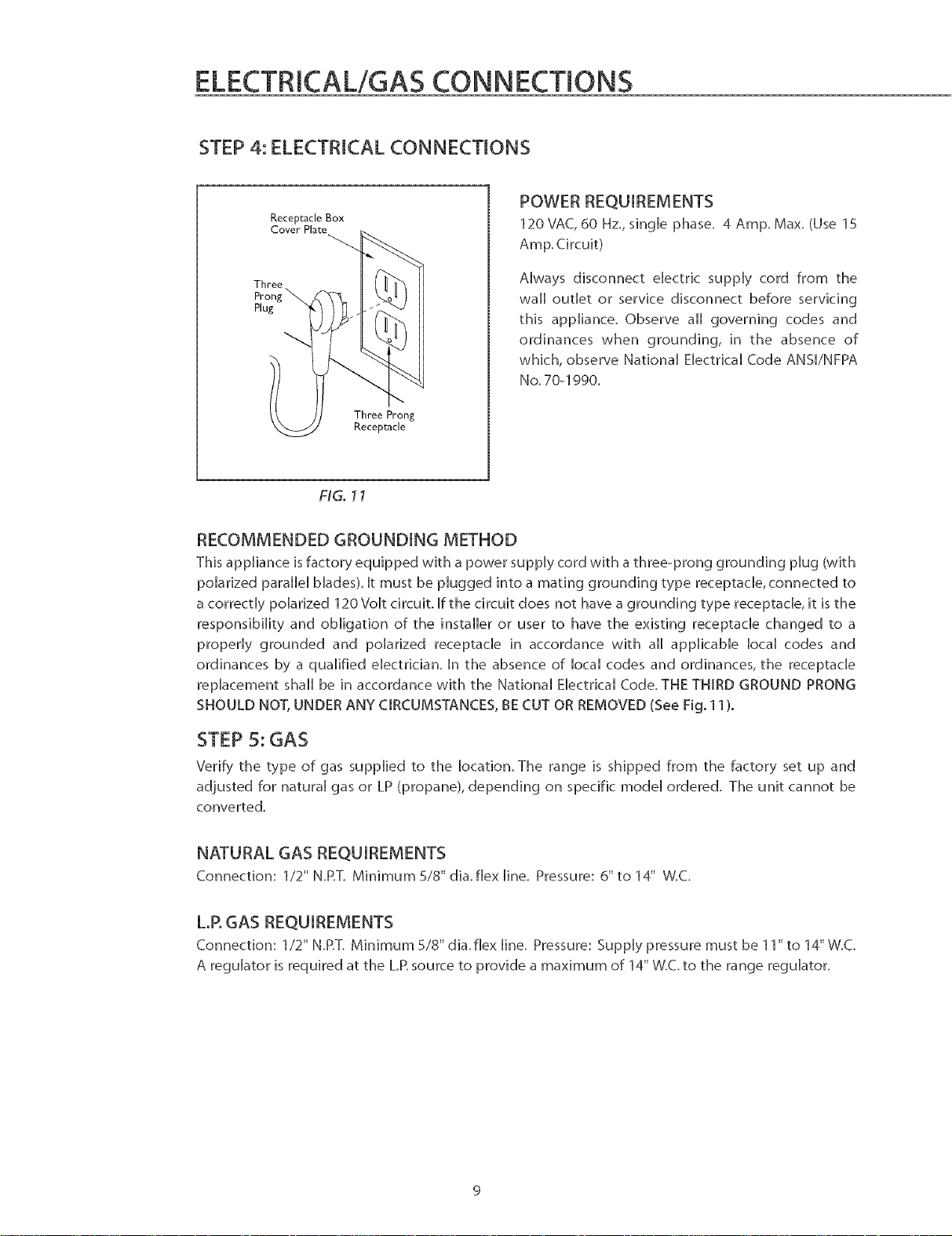

STEP 4: ELECTRICAL CONNECTIONS

POWER REQUIREMENTS

Receptacle Box

Cover Plate

120 VAC, 60 Hz., singHe phase. 4 Amp. Max. (Use 15

Amp. Circuit)

Three

Pror

Plug

FIG. 71

Three Prong

Receptacle

Always disconnect e[ectdc supply cord from the

waHHoutlet or service disconnect before servicing

this appHiance. Observe aHHgoverning codes and

ordinances when grounding, in the absence of

which, observe NationaH EHectdcaHCode ANSH/NFPA

No. 70-1990.

RECOMMENDED GROUNDING METHOD

This appHhnce isfactory equipped with a power suppHy cord with a three-prong grounding pHug (with

pohrized paraHeHbhdes). Htmust be pHugged into a mating grounding type receptacle, connected to

a correctly polarized 120'v'olt circuit. If the circuit does not have a grounding type receptacle, it is the

responsibility and obligation of the installer or user to have the existing receptacle changed to a

properly grounded and polarized receptacle in accordance with all applicable local codes and

ordinances by a qualified electrician. In the absence of local codes and ordinances, the receptacle

replacement shall be in accordance with the National Electrical Code. THE THIRD GROUND PRONG

SHOULD NOT, UNDER ANY CIRCUMSTANCES, BE CUT OR REMOVED (See Fig. 11).

STEP 5: GAS

Verify the type of gas supplied to the location. The range is shipped from the factory set up and

adjusted for natural gas or LP (propane), depending on specific model ordered. The unit cannot be

converted.

NATURAL GAS REQUIREMENTS

Connection: 1/2" N.RT. Minimum 5/8" dia.flex line. Pressure: 6" to 14" W.C.

L°R GAS REQUIREMENTS

Connection: 1/2" N.RT. Minimum 518" dia. flex line. Pressure: Supply pressure must be 11" to 14" W.C.

A regulator is required at the L.R source to provide a maximum of 14" W.C.to the range regulator.

Page 11

HOOKUP TO GAS SUPPLY

STEP 6: HOOKUP

A manual valve is installed in an accessible location from the front for the purpose of shutting off the

gas supply.The supply line must not protrude beyond the back of the unit.Make sure the gas supply

is turned off before connecting the app[hnce.

The flex line for the gas supply must be metal and be approved by CSA, AGA, CGA OR UL. Only use a

metal supply hose, as the heat may cause a rubber hose to melt and develop leaks.

The gas supply connections should be made by a qualified technician and in accordance with local

codes or ordinances, in the absence of a local code, the installation must conform to the National Fuel

Gas Code ANSi 223.1-1988, latest edition.

CAUTION:

The appliance must be isolated from the buiiding's gas supply piping system

by dosing its individual manual shut-off valve during any pressure testing of

the gas supply piping system at test pressures equal to or less than 1/2 psig

(3.5kPa.)

The appliance and its individual shut-off valve must be disconnected from

the gas supply piping system during any pressure testing of the system at the

test pressures in excess of 1/2 psig (3.5kPa.).

When checking the manifold gas pressure, the inlet pressure to the regulator

should be at [east 7.0"W.C. for natural gas or 12.0"for LP.

When hooking up the gas supply from range rear hard pipe to wail hard pipe, installation length of

flex line between range/wail hard piping must accommodate the range being pulled from wail for

cleaning or servicing purpose. When range is pulled from wail, no strain should occur at range or wail

hard pipe connections (See Fig. 12 below).

, ManualShut-Off

Valvemustbe

EasilyAccessible

Hard Pipe J

1/2" NPT Metal Flex Gas Line

FIG. 12

10

Page 12

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

STEP 7: ANTra-TIP DEVmCE[NSTALLATION

AH ranges must have an anti-tip device correctly installed as per these instructions. If you pun the

range out from the wan for any reason, make sure that the device is properBy engaged when you

push the range back against the waN. If it is not, there is a possibBe risk of the range tipping over

and causing injury if you or a cMd stand, sit or Bean on an open door.

INCLUDED PARTS:

hduded with this kit are:

(4) #10 x 2" wood screws,

(1) Anti-tip bracket, and (1)

HnstaHHationInstructions.

(2)Small Holes for

Wood Installations

(2) Wood Screws

into Back Wall (ALL

Installations)

INSTALLING THE KIT:

Instructions are provided

for wood and cement

floors. Any other type or

construction may require

special installation

techniques as deemed

necessary to provide

adequate fastening of the

Anti-tip bracket to the floor

and wall. The use of this

bracket does not preclude

tipping of the range when

not properly installed.

(2) Large Holes for

Concrete Installations

WOOD

CONSTRUCTION:

Place the bracket against

the back wail, into the right rear corner where the range is to be located. Leave a gap between the wail

(or side of range) and the bracket of 3/4'_ Drill (2) 1/8" diameter pilot holes in the center of the small

holes. A mail or awl may be used if a drill is not available. Fasten the bracket securely to the floor and

wail See Fig. 13.

FIG. 13

BACK

WALL

CONCRETE OR CEMENT CONSTRUCTION:

HARDWARE REQUIRED: (2) sleeve anchors, lag bolts,

and washers (not provided). Locate the bracket as

described above. Drill the recommended size holes

for the hardware. Install the sleeve anchors into the

holes and then install the lag bolts through the

bracket. The bolts must be properly tightened as

recommended for the hardware. Fasten the bracket

securely to the floor and wall.

_ WARNING

ALL RANGES CAN TIP

INJURY COULD RESULT

INSTALL ANTI=TIP

BRACRET PACRED

INSIDE OVEN

® SEE INSTRUCTIONS

ONCE mNSTALLED:

Complete the range installation per the instructions provided with the product. Check for proper

installation of the Range and Anti-tip device by grasping the back of the unit and carefully attempt to

tilt the range forward.

11

Page 13

BACKGUARD INSTALLATION

STEP 8: BACKGUARD [NSTALLATION

The backguard must be installed when there is less

than a 12" clearance between combustibles and the

back of the range (above the cooking surface) (See

Fig. 3, page 5).

BACKGUARD KITS:

The backguard is located, as shown in Fig. 14.

Secure the backguard to the waN[ behind the range.

Specific instructions for instaHHation of the fuN[

backguard or How backguard can be found packaged

with the backguard.

FLAME CHARACTERISTICS

Wain Mount Full Backguard

(30") (Model No. BGS-3030) 6_,_

Wail Mount Low Backguard

(12") (Model No. BGS-1230) _ _'_

FIG. 14

STEP 9: PROPER FLAME SIZES

OVEN BURNER

FIG. 15

SEALED TOP BURNER LIGHTING

NOTE:

The seaHed top burners have an infinite

number of heat settings and there are no

fixed positions on the contro[ knobs

between Hi and LO.To turn the seaHed top

burner on, push in on the contro[ knob and

turn it countercHockwise to the "LITE"

position. An audible clicking sound will be

heard. When the gas has been ignited by

the electronic spark igniter, turn the knob

to the desired setting.

\.

BLUE FLAME

iNFRARED BROIL BURNER

S

FIG. 16

COOKTOP BURNER

FIG. 17

12

Page 14

FLAME CHARACTERISTICS

CAUTION:

IA/hen turning on any sealed top burner, be sure to stop at the "LITE" position

before turning the burner to a flame setting for cooking. If the burner is not lit and

it is turned beyond the "LITE"position, to HI,MEDIUM, or LQ there will be a burst of

flame when the burner does light. This could cause burns or damage to the

surrounding countertop.

CAUTION:

The oven infra-red broiler burner has no air shutter and is not adjustable. The oven

bake burner has an air shutter and is adjustable. It is necessary to operate the

oven broiler for 45 minutes to eliminate the harsh odor of the insulation binder.

This must be done BEFORE using the range for the first time and with proper

ventilation.

CAUTION:

For Warranty coverage, DCS requires that burner adjustments be made by a

qualified techn ician at the time of installation.Extreme care should be used when

adjustments are made after installation.

Improper or lack of adjustments will void your warranty°

Check for the proper burner flame characteristics (See Figs. 15-17, page 12).

Burner flames should be blue and stable with no yellow tips, excessive noise or lifting of the flame from

the burner. If any of these conditions exist, check that the air shutter (oven burner only) or burner

ports are not blocked. If this condition persists, contact a qualified technician.

The sealed top burner flames should be approximately 1q/2" high.The oven burner flames should be

1q/2" to 2".The infrared broil burner flames should be approximately 1/8" high over the entire burner

screen (See Figs. 1B-17, page 12).

CLEANING EXTERIOR SURFACES

STEP 10: CLEANING EXTERIOR SURFACES

The stainless steel surfaces may be cleaned by wiping with a damp soapy cloth.Any mild glass cleaner

will remove fingerprints and smears. Do not use steel wool as it will scratch this surface. Small

scratches may be removed by lightly sanding with the grain, using 200 grit paper.

13

Page 15

INSTALLER FINAL CHECKLIST

GENERAL

,I Placement of Unit.

,I Specified clearance maintained to cabinet surfaces.

_1 Unit Leve[- front to back, side to side.

_1 A[[ packaging material and tie straps removed, drip pans dean and empty.

_1 Backguard wall[ system instaHHedif there is Hessthan 12" cHearance above the cooking surface

to combustibHes behind unit.

ELECTRICAL

_1 Receptacle with 15 ampere over-current protection is provided for service cord connection.

,I Adequate ground connection.

_1 Kick pane[ (See Fig.6, page 7)in place and two (2) screws secure.

GAS SUPPLY

_1 Connection: 1/2 NPT with a minimum 5/8" diameter metal flex Nine.

_1 The pressure regulator which is connected to the manifoHd is set for 5.0" W.C. for natural gas

or 10.0" W.C.for LR

_1 Manual gas shut offvalve installed in an accessible location.

,I Unit tested and free of gas leaks.

OPERATION

_1 All internal packing materials removed. Check below grate and inside oven.

_1 Bezels centered on burner knobs and knobs turn freely.

_1 Each burner lights satisfactorily, both individually and with other burners operating at the

same time.

_1 Check flame characteristics on all burners and adjust as specified per instructions on page 12

(See Figs. 15-17, page 12).

,I Oven door hingesseated and door opens and doses properly.

_I Burner gratescorrectlypositioned,level,and do not rock.

14

Page 16

LENGTH OFWARRANTY

One (1) Year FuJI- Covers the entire product

Five (5)Years Limited - Surface burners, Oven burner

Ten (10) Years Limited - PorceHain oven, PorceHain inner door paneH

DCS WILL PAY FOR:

AHHrepair Habor and repHacement parts, for parts found to be defective due to materiaHs or

workmanship. Service must be provided by Authorized Factory Agent during normaH working hours.

DCS WILL NOT PAY FOR:

m hstaHation or start-up.

m Shipping damage.

n Service by an unauthorized agency.

n Damage or repairs due to service by an unauthorized agency or the use of unauthorized parts.

n Service during other than normaH working hours.

n Hmproper installation, such as improper hook-up, etc.

m Service visits to teach you how to use the appHiance; correct the installation; reset circuit

breakers or replace home fuses.

n Repairs due to other than normal house hold use.

m Damage caused from accident, abuse, alteration, misuse, incorrect installation or installation not

in accordance with local codes.

m Units installed in non-residential application such as day care center, bed and breakfast centers,

churches, nursing homes, restaurants, hotels, schools, eL

This warranty applies to appliances used in residential applications; it does not cover their use in

commercial situations.

This warranty is for products purchased and retained in the 50 states of the U.S.A., the District of

Columbia and Canada. This warranty applies even if you should move during the warranty period.

Should the appliance be sold by the original purchaser during the warranty period, the new owner

continues to be protected until the expiration date of the original purchaser's warranty period.

This warranty gives you specific legal rights. You may also have other rights which vary from state to

state.

15

Page 17

HOW TO OBTAIN SERVICE:

For warranty service, contact DCS Customer Service at (888) 281-5698. Before you call, pHeasehave

the following information ready:

[]Modal Number

[] SeriaHNumber

[] Date of installation

[] A brief description of the proNem

Your satisfaction is of the utmost importance to us, Hfa problem cannot be resolved to your

satisfaction, please write or fax or emaH us at:

Write:

DCS

Attention: Customer Service

5800 Sky[ab Road

Huntington Beach,CA 92647

Fax: (714) 372-7004

EmaH: support@dcsa pp[ia nces,com

BEFORE YOU CALL FOR SERVICE:

1.Is the circuit breaker tripped or the fuse blown?

2. Is there a power outage in the area?

16

Page 18

PERFECT _EAT: _

cU

A GAZ

Manuel D'lnstallation

30 PO

MODULES :

II RGSC_305SS

w RGSO3OSBK

l! RGSC-3OSWT

Page 19

AVIS A L'iNSTALLATEUR

Les cuisini_res et tables de cuisson de s6de professionne]]e DCS sont dot6es de nombreuses fonctions

offertes dans une gamme de combinaisons vari_es.

Si vous avez des questions au sujet de notre produi% communiquez avec un repr_sentant du service _ la

client@le DCS par tdl_phone : 1-888-281-5698, ou par tdl_copieur : 714_677-1270, ou par email :

support@dcsappliances.com

ou par courrier :

DCS

Attention : Customer Service,

.5800Skylab Road,

Huntington Beach, CA 92647

www.dcsappfiances.com

AVERTISSEMENT

Si les informetions de ce manuel ne sont pes suivies _ la lettre, un incendie ou

une expioMon peuvent se produire et causer des dommeges met_de/s, des

b/assures ou la mort.

MESURE DE PRECAUTION

Evitez de stocker ou d'utiliser de I'essence ou toutes autres vapeurs et fiquides

inflammables a proximit_ de cat appareil ou de tout autre appareiL

POUR VOTRE SECURITE

Si vous sentez une odeur de gaz :

n N'essayez pes d'aflumer des eppareils _lectrom_nagers.

n Ne touchez eucun interrupteur _lectrique; n'utifisez aucun t_l_phone dans

I'_difice.

m Appelez imm_diatement votre fournisseur de gez de chez un voiMn. Suivez

les instructions du fournisseur de gez.

Toute installation ou service dolt _tre confi_ _ un insteflateur quelifi_, un

orgenisme de service ou le fournisseur de gaz.

VEUILLEZ CONSERVER CE MANUEL A TITRE DE REFERENCEo

Page 20

TABLE DES MATJ[:RES

PLANIFICATION DE L'INSTALLATION

[mportantes informations concernant Hnsta[[ation ...................................................................................3

hstructions concernant FinstaHation recommand_e ................................................................................4

EXIGENCES EN MATIERE DE VENTILATION

Etape 1: Exigences en mati_re de ventilation ..............................................................................................4

DIeBALLAGE ETMANIPULATION

Etape 3 : D_ba[[age, d_p[acement et placement de [a cuisini@e ......................................................7-8

BRANCHEMENT teLECTRIQUEOU DU GAZ

Etape 4 : Raccordements _[ectdques ...............................................................................................................9

Etape 5 :Gaz ..............................................................................................................................................................9

BRANCHEMENT DU GAZ

Etape 6 : Branchement ........................................................................................................................................10

INSTALLATION DU DISPOSITIF ANTIBASCULEMENT

Etape 7 : Installation du dispositif antibascuHement ................................................................................11

INSTALLATION DU DOSSERET

Etape 8 : InstaLLation du dosseret ....................................................................................................................12

CARACTIeRISTIQUESDE LA FLAMME

Etape 9 : Nivea ux de flam me corrects .....................................................................................................12-13

NETTOYAGE DESSURFACESEXTIeRIEURES

Etape ] 0 : Nettoyage des surfaces ext@ieures ..........................................................................................13

MSTE DE CONTROLE FINALE DE L'INSTALLATEUR .....................................................................14

GARANTIE ...........................................................................................................................................................................is

SERVICE .................................................................................................................................................................................16

Page 21

PLANIFiCATION DE L'iNSTALLATION

iMPORTANTES iNFORMATiONS CONCERNANT UiNSTALLATiON

Le modS[e RGSC-305 a StS tests conformSment _ [a norme ANSHZ21.1 pour [es apparei[s S[ectromS-

nagers domestiques de cuisson _ gaz.

La cuisiniSre doit Stre insta[[Se avec une hotte de ventilation suspendue appropriSe. ('v'oir ['Etape 1en

ce qui concerne Hesexigences en matiSre de ventiHation, page 4.) E_tant donnSe Hapuissance de feu

professionnelle SlevSe de cet appareil, faites particuliSrement attention _ I'installation de la hotte et de

ses conduites de maniSre _ respecter les codes du b_timent en vigueur.Afin d'Sliminer les risques de

br01ures ou d'incendie qui peuvent se produire Iorsqu'on s'Stire au-dessus d'appareils aux surfaces

chauffantes, Svitez de placer des armoires de cuisine au-dessus de I'appareil.

Vous devez installer ['un des deux dosserets muraux disponib[es si [e dSgagement entre [es matSriaux

combustibles et le bord arriSre de la cuisiniSre (au-dessus de la surface de cuisson) est infSrieur _ 30,5

cm/12 po.

Dosseret mural

intSgral

(N° ModUle

BGS-3030)

I-5/16

Dosseret mural

FIG, I FIG. 2

Prenez soin de consulter [es codes du b_itiment en vigueur au sujet de [a mSthode &suivre concernant

I'installation de la cuisiniSre. Les codes peuvent varier d'une rSgion _ I'autre. L'installation, les

connecteurs Slectriques et la raise & la terre doivent Stre conformes _ tousles codes en vigueur. En

I'absence de tels codes, I'appareil doit Stre installs conformSment _ la norme ANSI Z223.1-1988 du

National Fuel Gas Code et la norme 70-1990 ANSI/NFPA du National Electrical Code.

Assurez-vous que I'appareil installs est rSglS selon le type de gaz utilisS. La cuisiniSre &gaz est rSglSe

en usine pour fonctionner au gaz natural ou propane salon le modSle spScifique commandS. Avant

d'aller plus loin, v_ri[_ez que la cuisini_re _. gaz est compatible avec le gaz du site o_ elle

doit &tre install6e. Renvoyez la cuisiniSre _ gaz au distributeur si elle n'est pas rSglSe pour

fonctionner avec [e gaz du site.

71,44 cm/

28-1/8 po

Page 22

PLAN[F[CAT[ON DE L'[NSTALLAT[ON

INSTRUCTIONS CONCERNANT L'INSTALLATION RECOMMANDCE (AVEC DOSSERET

BGS-3030)

tnstattez les composants dans t'ordre suivant :

a. Hotte de ventilation b. Dosseret c. Cuisini_re

1.Positionnez [a cuisini_re en [a mettant de niveau conform_ment aux instructions d'insta[[ation

fournies.

2.Mesurez Hadistance entre HepHancher et Hehaut de Hagarniture d'iHot de HacuisinDre en ajoutant

3,5 ram/l/8 po pour Hed_gagement du dosseret.

3. Reportez cette mesure au tour. Ced indique Hapattie inf_rieure du dosseret.

4. A partir de cette [igne, mesurez 71,5 cm/28 1/8 po Helong du tour pour indiquer Hehaut du

dosseret de 762 cm/30 po.C'est Hahauteur minimum _ laquelle la pattie inf_rieure de la hotte

de ventilation peut _tre install_e.

5. Suivez les instructions du fabricant de la hotte de ventilation pour installer celle-ci.

6. Suivez les instructions du fabricant du dosseret pour installer celui-ci.

7. granchez le gazet les connexions _lectriques, puis glissez la cuisini_re b sa place.

EX[GENCES EN MAT[[ERE DE VENTILATION

[_TAPE t : EX[GENCES EN MAT[JEREDE VENTILATION

Vous devez installer une hotte _ _vacuation appropri_e au-dessus de la cuisini_re/table de cuisson, Le

tableau suivant indique la capacit_ minimum du ventilateur recommand_e pour a_rer la hotte,

APPAREIL COMPTOIR STANDARD [LOT

DE INSTALLATION INSTALLATION

VENTILATION RECOMMANDE'E RECOMMANDE'E

HOTTE (prof.24 pox larg. de ['apparei[) (prof. 30 pox 91 cm/3d po au bas)

VENTILATEUR 1 w m/min - 600 pP/min (min.) 17 m/rain - 600 pP/min (min.)

MISE EN GARDE :

les hottes etles ventilateurs sont congus pour _tre utilis@s avec des conduits 8

paroi Mmple. II se peut toutefois que certains codes du batiment ou

inspecteurs Iocaux exigent des patois doubles. Consultez les codes du

badment ou organismes locaux avant de commencer afin de vous assurer qua

I'instafladon de lahotte et des conduits est conforme aux normes en vigueur.

La vitesse du ventiHateur de Hahotte doit _tre variabHe afin de permettre de r_duire Heniveau de bruit

ainsi qua [a perte d'air chauff_ ou conditionn_ [orsqu'une ventilation maximum n'est pas requise.

Pour _vacuer Hafum_e de HameiHHeurefa_on, Hebord inf_rieur de Hahotte doit _tre instaHHS_ un

minimum de 76 cm/30 poet un maximum de 91 cm/36 po au-dessus de la surface de cuisson de la

cuisini&re (voir Fig, 3, p, 5), Si la hotte contient des mat_riaux combustibles (par ex, un rev_tement en

bois),elle doit _tre plac_e _ au moins 91 cm/36 po au-dessus de la surface de cuisson,

A cause du volume 6[ev_ d'air de ventilation, i[ est recommand_ d'assurer une source d'air frais. Ceci

est particulDrement important pour les r@sidences tr@sisol@es.Consultez un sp_cialiste en chauffage

et a_ration r@put&

4

Page 23

PRIePARATION DES ARMOIRES

¢TAPE 2 : PREPARATION DES ARMOIRES

I. La cuisinDre est un apparei[ ind_pendant, Respectez [es mesures de d_gagement indiqu_es

[a Fig. 3 si vous comptez [a placer _ c6t_ d'arrnoires de cuisine. Les rn#rnes d_gagernents

s'app[iquent _ une installation en ilot.

2, La cuisinDre peut #tre plac_e de diverses fa_ons par rapport au devant d'une armoire :ceHe<i

peut affleurer ou d_passer FappareH, selon Haprofondeur du cornptoir (voir Fig, 5, page 6),

00

IISE EN GARDE : voir

les figures 2a et 2b.

91,5 cm/36 po min.

s_parant les mat6riaux

combustibles _ de [a

surface de cuisson

90 . -. . pour un

comptoir de niveau

93,5 cm/36 3/4 po max. avec

pieds d'inclinaison de cuisini_re

sortis entierement

ATel que d6fini dans [e < National Fuel Gas Code >_

(norme ANSI Z223.1 derni@e (Sdition).

La hauteur de la cuisini6re est r#giabie.

Le niveau du haut de [a cuisJni@e doit #tre au m#me

niveau ou au dessus de celui du comptoir.

Alimentation _lectrique

et en gaz. -Voir Fig. 4

A) 19,1cm/7-1/2p0

B) 45,5cm/18p0min.

c) 7,dcm/3pB

D) 33cm/13poma×.

E) 11,4cm/4-1/2p0(gaz)

F) 27,9cm/11po(@ctffque)

FIG. 3

Protub@ance de

5 cm/2 po maximum

du mur pour

I'alimentation en gaz

Page 24

PRIePARATION DES ARMOIRES

3. La source d'aHimentation en gaz ou 6]ectrique doit se trouver dans ]es zones indiqu6es aux

figures 3 et 4, p.5.

4. La profondeur maximum des armoires suspendues de chaque c6t6 de Hahotte est de 33 cm/] 3

po.

_5.Toute ouverture dans Hetour derriere Hacuisini_re et dans Hephncher sous Hacuisini_re doit #ire

sceH6e.

6.

Vous devez insta[[er un dosseret DCS (voir Fig. 5) si [e d6gagement entre [es mat6rhux

combustibles et le bord arri&re de la cuisini_re (au-dessus de la surface de cuisson) est inf6rieur

30,5 cm/] 2 po. La cuisini_re comporte une garniture d'ilot comme 6quipement standard. Les

figures 5 indiquent les espaces requis pour chaque type de dosseret.

7,

Gardez toujours [a zone entourant ['apparei[ d6gag6e et exempte de mat6riaux combustib[es,

d'essence et autres vapeurs et [iquides inf[arnmab[es.

8.

N'obstruez pas le riot d'air de combustion et de ventilation dirig6 vers l'appareil.

DIMENSIONS

,\\\\ ,\\\\ ,\\\\ : _\ ,\

E

//'//%

_\:: ,_\\\\ ,_\\\\ ,_\\\\

/// i

. l)egagement lie

0 cm/[Jo

M

F/Go 5

A)

75,9cm/29-7/8p0

B)

90,8cm- 94cm135-3/4p0- 37p0

E)

69,9cm/27-I/2p0

F)

71,4cm/28-I/8p0d0%eretmuralintegral

G)

25,7cm/!0-1/8po dosseretmuralinf6rieur

H)

5,! cm/2pogarnitured'iDt

b

3,3cm/I-5/16po

J)

76,2cm/30po

K)

113,3cm/44-5/8po

L)

9!,4cm/36pomin.jusqu'aumat#riaux

combustibles'

M)

6!,6crn/24-!/4po

N)

67,9cm/26-3/4po

O)

30,5cm/12pomin.jusqu'aumat#riaux

combustibles

Page 25

D[ BALLAGE ET MANIPULATION

[_TAPE 3 : D[_BALLAGE, DISPLACEMENT ET PLACEMENT DE LA

MISE EN GARDE :

UTILISEZ UN ¢_QUIPEMENT ET UN

NOMBRE DE PERSONNES

APPROPRIES POUR DE'PLACER LA

CUISINIERE AFIN D'EWTER

D'ENDOMMAGER L'APPAREIL OU LE

PLANCHER. L'APPAREIL EST LOURD

ET REPOSE SUR DES PIEDS EN ACIER

AJUSTABLES.

AVERTISSEMENT:

NE 50ULEVEZ PAS LA CUISINIERE

PARLES POIGNEES DE LA PORTE DU

FOUR!!

Panneau de

Le poids de [a cuisinDre _ ['exp6dition est d'environ

185 kg/408 [b ou 160 kg/354 [b apr_s retrMt du

mat6de[ d'emba[[age. HIest recommand6 d'en[ever [a

porte, [es grilles et [e panneau de seuH de porte avant

afin de facHiter [a manipulation de ['appareH, ce qui

permet de r6duire son poids _ environ 104 kg/230 [b.[[

peut s'av6rer n6cessaire de retirer [es portes et

boutons du four pour traverser certaines entr6es de

porte. Une fois [a porte et [es boutons en[ev6s,

['apparei[ peut passer par une ouverture de 72 cm/2%

3/8 po. Si [a porte n'est pas retir6e, ['ouverture doit

mesurer 76 cm/30 po.

seuil de porte

FIG. 6

Retirez [e carton ext6rieur et [e mat6rie[ d'emba[[age

de [a base de transport.

MISE EN GARDE :

avont d'utifiser Io cuiMni_re, prenez

soin de retirer I'espoceur de

transport du grilloir (voir Fig. 7).

Retirez [e panneau de seui[ de porte en en[evant [es

deux vis du haut et en tira nt vers vous. Lacuisini@re est

retenue sur la plateforme par deux supports b I'avant,

derrDre le panneau de seuil de porte (voir Fig. 6), et

deux supports en L situ6s sur la bride inf@ieure

I'arrDre de la cuisini@re (voir Fi9. 8). Apr&s le retrait des

vis et des supports, soulevez la cuisinDre et d6gagez-

la de la plateforme. Du fair de son poids, servez-vous

d'un chariot & roues douces pour d6placer I'appareil.

Le poids doit 6tre support6 de mani@e uniforme sur

route la partie inf@ieure (voir Fig.9, page 8).

FIG. 7

Gauche : vis de

transport arri6re

FIG. 8

Page 26

DIeBALLAGE ET MANIPULATION

Pour refirer [a porte, ouvrez-[a et gardez-

[a grand ouverte. Fermez [es verrous de

charni&re (voir Fig. 10) et reH_chez Ha

porte. Refirez ensuite Ha porte en Ha

La cosini6re doit

etre soutenue

unfform6ment

par des renforts

FIG. 9

converti au gaz propane, ce[a peut 6tre fait sans [e d6p[acer (voir page 10).

souHevant doucement et en Hafirant

pour faire sorfir [es charni@res du cadre.

La cuMni_re professionne[[e doit 6tre

transport6e par chariot jusqu'_ son

empHacement final Pour refirer He

chariot, faites pencher ['appareH vers

['arrDre en He soutenant sur ses pieds

ard_re. Veuimmez_ prot4ger meplan€her

sous [es pieds (parquet en [ames,

tapis, panneaux, etc.) avant de

pousserrappareimpourmemnettre en

pmace° Effectuez les branchements

61ectriques et _ gaz (6tapes 4, 5 et 6),

installez le dispositif antibasculement

(6tape 7) ainsi que le dosseret (6tape 8)

avant de placer [a cuisinDre sur sa

position finale. Si ['apparei[ doit 6tre

La cuisinDre professionne[[e doit 6tre de niveau

pour bien fonctionner. Si vous voulez que

I'appareil affleure parfaitement les comptoirs

adjacents, il est imp6ratif que les armoires soient

de niveau (de I'avant _ I'arrDre et de gauche

droite sur route la largeur de la cuisinDre). Apr_s

avoir v6rifi6 que les comptoirs sont de niveau et

avant de glisser la cuisini_re _ sa place, mesurez la

distance entre le plancher et le dessus de la

surface de travail du comptoir, aux coins arri_re

gauche et droit. Aiustez les coins artiste

correspondants de la cuisini_re afin qu'ils soient

une hauteur 6gale par rapport au comptoir car les

pieds d'inclinaison arrDre de I'appareil ne sont

plus accessibles une lois la cuisinDre raise _ sa

place. Une fois la cuisini_re en place, les pieds

d'inclinaison avant demeurent accessibles afin de

pouvoir mettre I'avant de la cuisini_re de niveau.

Replacez le panneau de seuil de porte et la porte

du four en inversant la proc6dure d6crite

auparavant, imest essentie[ que ruesdeux vis

retenant mepanneau de seuii de porte soient

bien fix4es afin d_4viter tout ac¢4s ac¢identem

(voltFig.6,page 7).

ROULEAU DE CHARNIERE DE PORTE

l "I VERROUILLER

FIG. 70

des ¢omposants et fiis 4mectriques sous tension

(FERHER)

DEVERROUILLER

REMARQUE : afin de vous facfliter I'instal/ation, prenez soin dVnstaller la hotte de ventilation et le

dosseret avant de glisser /a cuisini_re a sa place.

Page 27

BRANCHEMENT CLECTRIQUE OU DU GAZ

¢TAPE 4 :RACCORDEMENTS ¢LECTRIQUES

BESOINS ENALIMENTATION

Plaque de

120 V c.a., 60 Hz, courant monophas@

4 A max. (utHisez un circuit de 15 A)

Fiche bipolaire

avec terre

Prise _ trois alveoles

mise _ la l:erre

F/G. 11

METHODE DE MISE A LA TERRE RECOMMANDEE

Cet apparei[ est _quip_ d'un cordon d'a[imentation _ fiche bipohire avec terre dot6e de Names

paraH&[es pohris_es. La fiche doit _tre branch_e dans une prise avec raise _ la terre correspondante

connect_e _ un circuit correctement pohris_ de ] 20 V.Si le circuit ne poss&de pas ce genre de prise,

Hnstalhteur ou I'utilisateur a la responsabilit_ et le devoir de faire remphcer, par un technicien

qualifi_, la prise existante par une prise pohris_e correctement raise _ la terre conform_ment aux

codes et r_g[ementations en vigueur. En ['absence de te[s codes et r_g[ementations, Heremp[acement

de la prise doit _tre effectu_ conform_ment au National Electrical Code. LA TROISI_:ME BROCHE DE

TERRE NE DOlT JAMAIS ETRECOUPCE OU ENLEVEE (Voir Fig. 11 ).

D6branchez toujours [e cordon d'aJimen =

tation 6[ectdque de [a prise muraJe ou

coupez He courant avant d'effectuer

H'entretien de H'appareH. Respectez tous Hes

codes et r6gHementations en vigueur

concernant Haraise _ Haterre. S'iHn'y en a pas,

respectez Hanorme ANS[/NFPA No. 70=1990

du NationaH EHectricaHCode.

¢TAPE 5 :GAZ

V_rifiez le type de gaz alimentant le site. La cuisini_re _ gaz est r_gl_e en usine pour fonctionner au

gaz naturel ou propane selon le mod&le sp_cifique command_. L'appareil ne peut pas _tre converti.

EXIGENCES EN GAZ NATUREL

Connexion :conduite flexible de 1/2 po N.RT.de 5/8 po diam. minimum. Pression :de 6 _ 14 po C.E.

EXIGENCES EN GAZ PROPANE

Connexion : conduite flexible de 1/2 po N.RT. de 5/8 po diam. minimum. Pression : La pression

d'alimentation doit se situer entre 1]et 14 po C.E. Un r_guhteur est requis _ la source d'alimentation

en gaz propane afin d'assurer une pression de 14 po C.E.maximum au r_guhteur de la cuisini_re.

Page 28

BRANCHEMENT DU GAZ

¢TAPE 6 : BRANCHEMENT

Un robinet manue[ doit _tre install6 sur Hedevant, dans un endroit accessiNe, afin de permettre de

couper [e 9az. La conduite d'a[imentation ne doit pas d_passer ['arrDre de ['appareH. Avant de brancher

['appareH, prenez soin de couper [e gaz.

La conduite flexible de ['a[imentation en gaz doit _tre m_ta[[ique et homo[ogu_e CSA,AGA, CGA ou UL.

UtiHisez uniquement un tuyau m_taHHique car HachaHeur peut faire fondre un tuyau en caoutchouc et

produire des fuites.

Toutes [es connexions d'a[imentation en gaz doivent 6tre effectu6es par un technMen qua[ifi6 confor-

m6ment aux codes et r_gHements en vigueur. En ['absence de codes [ocaux, ['instaHHation doit 6tre

conforme _ la norme ANSI 223.1-1988, derni_re 6dition, du National Fuel Gas Code.

MISE EN GARDE :

I'opporeil doit _tre isofd du syst_me d'Mimentotion en goz en fermont son robinet

d'orr_t duront les tests de pression si Io pression est inf_rieure ou _gole _ 3,5 kPo

(1/2 psi).

L'oppnrefl et son robinet d'nrr_t doivent _tre d_connect_s du syst_me d'MJmen-

tntion en gnz dumnt /es tests de pression Iorsque In pression est sup_rieure _ 3,.5

kPn (1/2 psi).

Lots de In v_rificntion de Inpression de gnz du distributeur, In pression d'nrriv_e du

r_gulnteur doit _tre d'ou moins 7,0 po CE. pour du gnz nnturel ou 12 po _our du

gnz propnne.

Lorsque vous branchez ['a[imentation en gaz du tuyau rigide arri@re de [a cuisini&re au tuyau Ngide du

tour, faites en sorte que la conduite flexible reliant les deux tuyaux rigides soit suffisamment Iongue

pour permettre d'#loigner la cuisini@re du tour en cas de nettoyage ou d'entretien. Dans ce cas, il ne

doit y avoir aucune tension au niveau des connexions des tuyaux rigides de la cuisini@re et du tour

(voir Fig. 12 ci-dessous).

Ler0binet

d'arr_tmanuel

d0it_tre I_1_

facilement

accessible tlu

Tuyaurigide J

1/2po NPT Conduitede gazflexible m_tallique

10

FIG. 12

Page 29

INSTRUCTIONS D'iNSTALLATION DU DISPOSmF

ANTIBASCULEMENT

ETAPE 7 :INSTALLATION DU DISPOSITIF ANTIBASCULEMENT

Un dispositif antibascu[ement doit _tre insta[[_ correctement sur toutes [es cuisini_res conforo

m_ment _ ces instructions. Si vous devez tirer [a cuisini_re du tour pour que[que raison que ce

soit, veiBRez& bien Baremettre en pBace Borsque vous Barepoussez contre Betour. EIBerisque sinon

de bascuBer et de bBesser queBqu'un si vous ou un enfant vous tenez debout, vous asseyez ou

vous appuyez contre une porte ouverte.

Ce kit comprend Hes _H_ments

suivants :(4) vis _ bois no. 10 x 2 po,

(1) support antibascuHement et des

instructions d'instalhtion.

(2) petits trous pour une

installation sur du bois

(2) vis & bog dans le tour

arri@re (pour TOUTES les

installations)

INSTALLATION DU KIT :

Ces instructions s'appliquent _ des

phnchers de bois ou en ciment.

Tout autre type de mat_riau peut

exiger des techniques d'instalhtion

sp_ciales afin d'assurer la bonne

fixation du support antibas-

culement au phncher et au tour. Le

support ne peut emp_cher le

basculement de la cuisini_re s'il

n'est pas install_ correctement.

(2) gros trous pour une

installation sur du b_ton

1,9 cm/3/4 po

MUR

ARRIERE

J

s

CONSTRUCTION EN 8OIS :

Phcez le support contre le tour

ard_re, au coin arri_re droit ou doit

6tre phc6e la cuisini_re. Laissez un

espace de 1,9 cm/3/4 po entre le

tour (ou paroi [at_ra[e de [a cuisini_re) et [e support. Percez (2) trous de guidage de 3,5 ram/l/8 po de

diam_tre au centre des petits trous. Servez-vous d'un clou ou d'un poinqon si vous ne disposez pas

d'une perceuse. Fixez solidement le support au plancher et au mur.Voir Fi9. 13.

FIG. 13

CONSTRUCTION EN BETON OU EN CIMENT :

MATERIEL REQUIS : (2) ancres _ douille de s_curit_, tire-

fonds et rondelles (non fournis). Phcez le support tel que

d_crit ci-dessus. Percez les trous selon les dimensions

indiqu_es pour la quincaillerie. Installez les ancres _ douille

de s_curit_ dans les trous, puis passez les tire-fonds dans le

support. Les tire-fonds doivent _tre correctement serf, s

tel que recommand_ pour la quincaillerie. Fixez

solidement le support au phncher et au tour.

_AVERTISSEMENT

® TOUTES LES CU_S_NIIERES

PEUVENT BASCULER

® DES BLESSURES

POURRAJENT EN RESULTER

INSTALLEZ LE SUPPORT

ANT_BASCULEMENT

EMBALLE A L'INTE_EUR

DU FOUR

® VOIR LES INSTRUCTIONS

UNE FOIS INSTALLE :

Effectuez I'instalhtion de la cuisini&re conform_ment aux instructions fournies avec le produit.V_rifiez

la bonne installation de la cuisini_re et du dispositif antibasculement en saisissant I'arri_re de I'appareil

et en essayant de I'incliner avec precaution vers I'avant.

11

Page 30

INSTALLATION DU DOSSERET

[_TAPE 8 :INSTALLATION DU

Dosseret mural int__gral

(76 cm/30 po) (N° ModUle e--

Insta[[ez [e dosseret apr_s [e branchement au gaz.

Le dosseret doit 6tre install6 [orsque [e

d6gagement entre [es mat6daux combustibles et

['arrDre de [a cuisinDre (au-dessus de [a surface de

cuisson) est inf_deur _ 30,5 cm/12 po (voir Fig. 3,

page 5).

BGS-3030)

Dosseret mural _nf_rieur

(30,5 cm/12 po)(N Mod_

BGS1230)

L

KITS DE DOSSERET :

PHacez He dosseret tell qu'indiqu6 _ Ha Fig. 14.

Fixez-He au tour, derrDre Ha cuisini_re. Chaque

dosseret (int6gra[ ou inf_rieur) est fourni avec ses

instructions d'insta[[afion.

CARACTCRISTIQUES DE LA FLAMME

I

FIG_ 14

[_TAPE 9 : NIVEAUX DE FLAMME CORRECTS

BROLEUR DU FOUR

_ 4c_m-5cm

Jf)](I-I_2_ po)-(2po)

FIG_15

BRULEUR DE GRILLOIR A INFRAROUGE

\

FLAMME

BLEUE

FIG_ 16

BROLEUR DETABLE DE CUISSON

4_m

REMARQUE CONCERNANT UAL-

LUMAGE DU BROLEUR SCELLE

SUPERIEUR :

Les brOleurs _ t6te scell6e permettent un

r6glage continu de la flamme et leurs boutons

de r6g[age ne comportent pas de position fixe

entre les niveaux HI et LO. Pour allumer le

brOleur & t6te scell6e, enfoncez le bouton de

r6g[age et tournezqe vers [a gauche _ [a position " LFE ".Vous devriez entendre un d6c[ic. Une fois [e

gaz allure6 par I'allumeur 61ectronique, tournez le bouton au r6glage voulu.

FIG, 17

(1-1/2po)

12

Page 31

CARACT :RISTIQUES DE LA FLAMME

MISE EN GARDE :

quand vous allumez un 6r_leur _ t_te scelt@, prenez soin de vous arr_ter 6 ta

position "LtTE "avant de sdlectionner un niveau de flamme pour la cuisson. Si le

br_leur n'est pas allured et qu'il est tournd au-delb de la position "LITE ", sur HI,

MEDIUM ou LO,un dclat de flamme se produit Iorsque le br_leur finit par s'allumer.

Cela peut entrafner des blessures ou endommager le comptoir

adjacent.

MISE EN GARDE :

le br_leur infrarouge du grilloir ne comporte pas d'obturateur d'air et n'est pas

r_glable. Le brOleur de cuisson comporte un obturateur d'air et il est r_glable. II est

imp_ratif de faire fonctionner /e grilloir pendant 45 minutes pour _liminer la forte

odeur de I'isolant. Ceci doit _tre fair AVANT d'utiliser la cuisini_re pour la premiere

lois et en assurant une bonne ventilation.

MISE EN GARDE :

aux fins de la garantie, DC5 exige que le r_glage des brOleurs soit effectu_ par un

technicien qualifi# au moment de I'installation. Faites extr_mement attention

quand des r_glages sont effectu_s apr_s I'installation.

La garantie sera annul_e si les r_glages sont effectu_s incorrectement ou pas

du tout.

V#rifiez que la flamme du brOleu rest correcte (voir les figures 15 a 17, page 12).

Les flammes du brOieur doivent #tre bieues et stables, sans pointe }aune ni bruit excessif, et ne doivent

pas tirer vers [e haut. Si ['une de ces situations se produit, assurez-vous que ['obturateur d'air (brOieur

du four uniquement) ou [es ports des brOieurs ne sont pas bouch#s. Si [e probi6me persiste, fares

appel _ un technicien qualifi#.

La hauteur des flammes des brOleurs _ t6te scell6e doit 6tre d'environ 4 cm/1-1/2 po.Celle des flammes

du brQleur du four doit se situer entre 4 et 5 cm (de 1-1/2 a 2 po). Celle du brOleur de grilloir

infrarouge doit 6tre d'environ 3 ram/1/8 po sur tout le p6rim6tre du brQleur (voir Fig. 15-17, page 12).

NETTOYAGE DES SURFACES EXTIeRIEURES

ETAPE 10 : NETTOYAGE DES SURFACES EXTERIEURES

Pour nettoyer les surfaces en acier inoxydable, essuyezqes _ I'aide d'un linge imbib_ d'eau savonneuse.

Un nettoyant pour vitres doux permettra d'#liminer les empreintes digitales et les taches. N'utilisez pas

de laine d'acier au risque d'_gratigner la surface. Pour vous d_barrasser des petites #gratignures,

frottez I#g&rement dans le sens du grain avec du papier de verre 200.

13

Page 32

L[STE DE CONTROLE FINALE DE L'[NSTALLATEUR

,I Emplacement de ['appareH,

,I D#gagement sp_cifi# respect_ par rapport aux surfaces de ['armoire,

_1AppareH de niveau - de ['avant _ ['arrDre, d'un c6t@& ['autre,

_1 Mat@de[ d'embaHHage et courroies d'attache enHev@s,[_chefrites propres et vides,

_1 Dosseret mura[ instaH[@si Hed@gagement entre [es mat@rhux combustibHes et ['arrDre de Ha

cuisinDre (au-dessus de Hasurface de cuisson) est inf@rieur _ 30,5 cm/12 po,

CARACTCRISTIQUES I_LECTRIQUES

_1 Prise avec protection de surintensit_ de courant de 15 amperes pour brancher [e cordon

d'a[imentation,

,I Connexion de raise b [a terre adequate,

_1 Panneau de seui[ de porte (voir Fig, d, page 7) en place et deux (2) vis bien raises,

ALIMENTATION EN GAZ

_1 Connexion : 1/2 NPT avec conduite flexible m_ta[[ique de _5/8 po de diam_tre minimum.

_1Le r_gu[ateur de pression connect_ au distributeur est r_g[_ sur _5,0po C.E.pour du gaz nature[

ou 10,0 po C.E. pour du gaz propane.

_1 Robinet d'arr_t manuel insta[[_ dans un endroit facile d'acc_s.

,I Apparei[ test_ et exempt de fuites.

FONCTiONNEMENT

_1 Tout [e materiel d'emba[[age interne a _t_ en[ev_.V_rifiez en dessous de [agrille et _ ['int_rieur

du four.

_1Cadrans centr_s sur [es boutons des brO[eurs et boutons tournant [ibrement,

_1Chaque brOleur s'allume correctement, qu'il fonctionne seul ou avec les autres brOleurs,

_1 V_rifiez les caract_ristiques de la flamme sur tousles brOleurs et effectuez tout r_glage

conform_ment aux instructions des pages 12 (voir Fig, 15q 7, page 12),

,I Les charni_res de la porte sont bien Iog_es et la porte s'ouvre et se ferme correctement,

_1 Les grilles des brOleurs sont correctement plac_es, de niveau et ne remuent pas,

14

Page 33

GARANTJE

DUREE DE LA GARANTBE

Un (1) an surtout [e produit

Cinq (5) ans de garantie [imit_e sur [es br0ieurs de surface et Hebr0ieur du four

Dix (10) ans de garantie [imit_e sur [e four en porce[Mne et[e panneau de porte int_rieur en

porceiaine

DCS COUVRE LES FRAIS SUIVANTS :

FrMs de mMn-d'c_uvre et de r_paration de pi_ces jug_es d_fectueuses pour cause de vice de mati@e

ou de fabrication. Le service doit _tre foumi par un agent agr_ de ['usine durant [es heures ouvrabies

normales.

DCS NE COUVRE PAS LES FRAIS SUIVANTS :

minstallation ou d_marrage.

mDommages subis durant [e transport.

mService effectu_ par un centre non agr##.

mDommages ou r#parations causes par un service effectu_ par un centre non agr## ou par I'utii-

isation de pi6ces non autoris_es.

mService effectu_ en dehors des heures ouvrables normales.

mMauvaise installation, teiie qu'un branchement incorrect, etc.

mVisites de service pour vous apprendre comment utiiiser ['appareii, corriger ['installation, r#armer

les disjoncteurs ou remplacer les fusibles de la maison.

mR#parations dues a une utiiisation autre qu'une utiiisation domestique normaie.

mDommages causes par accident, abus, ait6ration, mauvaise utiiisation, installation incorrecte ou

installation non conforme aux codes en vigueur.

mAppareiis instaii#s dans [e cadre d'appiications non r_sidentieiies teiies que garderies, auberges,

[ieux de cuite, maisons de soin, restaurants, h6teis, #coies, etc.

Cette garantie s_applique aux appareils utilis6s dans des applications r6sidentielles. Elle ne couvre pas

les utilisations commerciales.

Cette garantie couvre [es produits achet_s et utiiis_s dans [es 50 _tats des Etats-Unis, [e District de

Columbia et au Canada. La garantie s'appiique m&me si vous d_m#nagez durant [a p@iode de

garantie. Si ['apparei[ est vendu par ['acheteur initial durant [a p6riode de garantie, [e nouveau

propri#taire continue de b6n#ficier de [a protection jusqu'_ [a date d'expiration de [a p6riode de

garantie de ['acheteur initial

Cette garantie vous donne des droits juridiques sp6cifiques, il se peut que vous ayez d'autres droits

pouvant varier d'une juridiction a I'autre.

15

Page 34

SERVICE

POUR L'OBTENTION DU SERVICE DE GARANTIE :

Pour [e service sous garantie, contactez [e centre DCS agr_ [e plus proche au (888) 281-5698.

Avant d'appeHer, veuHHez avoir Hesinformations suivantes _ port_e de main :

m Num@o de rood&He

m Num_ro de s_rie

m Date d'instaHHation

m Br_ve description du probH_me

Votre satisfaction rev&t [a plus haute importance pour nous. Si un prob[_me n'est pas r_so[u b votre

enti_re satisfaction,veuHHez communiquer avec nous :

Ecrivez-nous _ Fadresse suivante :

DCS

Attention: Customer Service

5800 Skyhb Road

Huntington Beach, CA 92647

Faxez-nous au num6ro suivant :(714) 372-7004

AVANT D'APPELER LE SERVICETECHNIQUE :

1.Est-ce que le dis]oncteur s'est d_dench_ ou que le fusible est grill_?

2.Y a-tdl une coupure de courant dans le secteur?

16

Page 35

17

Page 36

18

Page 37

19

Page 38

PERFECT h EATs'

5800 Skylab Road, Huntington Beach, CA. 92647

Tel:(714) 372-7000 Fax:(714) 372-700"1

Customer Service: (888) 281-5698

www.dcsappFiances.com

As product improvement is an ongoing process at DCS, we

reserve the Hght to change specifications or design

without notice,

DCS am#liore constamment ses produits et se r#serve le

droit de modifier les sp_!cifications ou la conception de

ses produits sans aucun pr_avis.

Part No. 17431 Rev.D

Litho in USA 12/2002

Loading...

Loading...