Page 1

OUTDOOR BEER DISPENSERS

Installation, Operation and Maintenance Instructions

DISTRIBUTEURS DE BIÈRE D’EXTÉRIEUR

Instructions d’installation, d’utilisation et d’entretien

MODELS:

MODÈLES:

RF24TR1

RF24TL1

RF24BTR1

RF24BTL1

Page 2

US

CA

CONTENTS

Contents:

Safety information ...............................................................2

Unpacking your appliance ...................................................3

Warranty registration............................................................3

Installing your appliance ......................................................4

Cabinet clearances .........................................................4

Leveling the appliance ....................................................4

Electrical connection ......................................................5

Installing the anti-tip device .................................................6

Product dimensions ............................................................8

Using your Electronic control...............................................9

Starting your appliance....................................................9

Turning your appliance "ON" or "OFF".............................9

Adjusting the temperature................................................9

Beer dispenser operation..................................................9

Alarms............................................................................9

Door ajar......................................................................9

Temperature sensor fault............................................9

High and Low temperature alarms..............................9

Alarm mute......................................................................9

Using your beer dispenser.................................................10

Tap equipment and assembly.......................................10

CO2 regulator.................................................................14

Drain kit..........................................................................15

Care and cleaning ............................................................15

Cleaning the drain sump................................................15

Keg coupler cleaning.....................................................16

Faucet cleaning ............................................................16

Front grille .....................................................................16

Cabinet.........................................................................16

Interior...........................................................................16

Long term storage / winterization .......................................17

Stainless steel maintenance ............................................19

Energy saving tips .............................................................20

Troubleshooting .................................................................21

Obtaining service .............................................................21

Warranty ............................................................................22

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situations that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operating this appliance.

Recognize Safety Symbols,

Words, and Labels.

!

WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!

CAUTION

CAUTION-Hazards or unsafe practices which could re-

sult in personal injury or property / product damage.

NOTE

NOTE-Important information to help assure a problem

free installation and operation.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals

known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals

known to the State of California to cause birth defects or

other reproductive harm.

2

Page 3

UNPACKING YOUR APPLIANCE

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

US

CA

A Message To Our Customers

Thank you for selecting this DCS Outdoor Refrigerator.

Because of this appliances’ unique features we have developed this Use and Care and Installation Guide. It contains

valuable information on how to properly install, operate and

maintain your new appliance for years of safe and enjoyable operation.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding internal components in place. The owners manual is shipped

inside the product in a plastic bag along with the warranty

registration card, and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condition. If there is damage, the packaging will be needed as

proof of damage in transit. Afterwards please dispose of all

items responsibly.

!

WARNING

WARNING - Dispose of the plastic bags which can

be a suffocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

For your convenience, product questions can be answered

by a DCS Customer Care Representative at

1-888-936-7872, or email: customer.care@sherpaykel.com

NOTE: Please write the Model, Code, and Serial Number

on this page for references (the serial plate is located on

the upper left side, inner wall).

MODEL NUMBER:

CODE:

SERIAL NUMBER:

NOTE: Inspect the product to verify that there is no shipping damage. If any damage is detected, call the shipper

and initiate a damage claim. DCS by Fisher & Paykel is not

responsible for shipping damage.

DO NOT discard any packing material (box, pallet, straps)

until the unit has been inspected.

!

WARNING

WARNING - Help Prevent Tragedies

Child entrapment and suffocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous - even if they sit out for "just a few hours".

NOTE

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

!

CAUTION

If the appliance was shipped, handled, or stored in other

than an upright position for any period of time, allow the appliance to sit upright for a period of at least 24 hours before

plugging in. This will assure oil returns to the compressor.

Plugging the appliance in immediately may cause damage

to internal parts.

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent accidents.

Before you throw away your old refrigerator or

freezer:

• Take off the doors or remove the drawers.

• Leave the shelves in place so children may not

easily climb inside.

3

Page 4

US

CA

INSTALLING YOUR APPLIANCE

Select Location

The proper location will ensure peak performance of your

appliance. We recommend a location where the unit will

be out of direct sunlight and away from heat sources. To

ensure your product performs to specications, the recommended installation location temperature range is from

55 to 115°F (13 to 46°C).

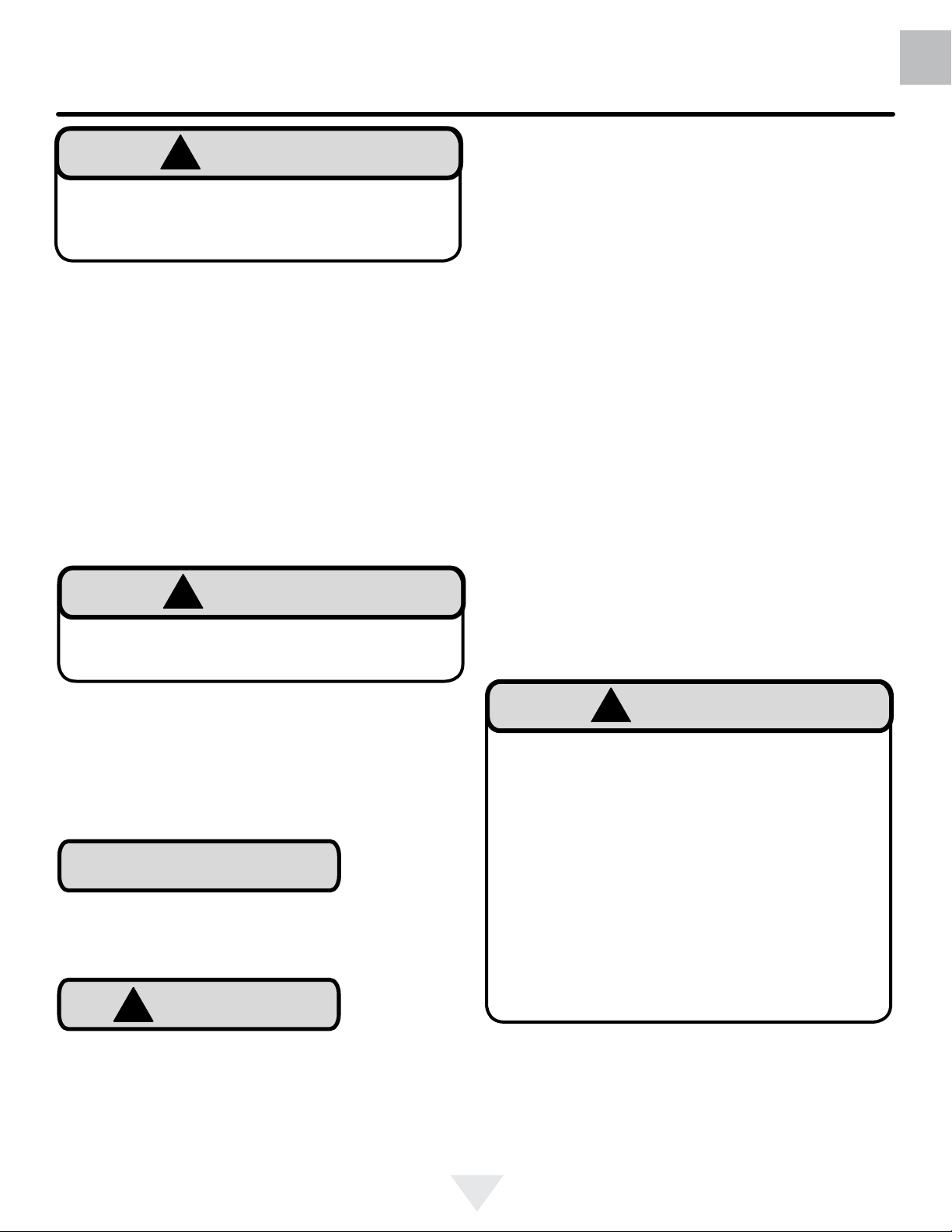

Cabinet Clearance

Ventilation is required from the bottom front of the appliance. Keep this area open and clear of any obstructions.

Adjacent cabinets and counter top can be installed around

the appliance as long as the front grille remains unobstructed.

Front Leveling

Legs

Figure 1

Front Grille,

keep this area

open.

Rear

Leveling

Legs

!

CAUTION

Front Grille

Do not obstruct the front grille. The openings within the

front grille allow air to ow through the condenser heat exchanger. Restrictions to this air ow will result in increased

energy usage and loss of cooling capacity. For this reason

it is important this area not be obstructed and the grille

openings kept clean (See Figure 1). The use of a custom

made grille is not recommended as it may restrict air ow.

Leveling Legs

Adjustable legs at the front and rear corners of the appli-

ance should be set so the unit is rmly positioned on the

oor and level from side to side and front to back. The

overall height of your appliance may be adjusted between

the minimum, 333⁄4" (85.7 cm), by turning the leveling leg in

(CW ↷) and the maximum, 343⁄4" (88.3 cm) by turning the

leveling leg out (CCW ↶).

To adjust the leveling legs, place the appliance on a solid

surface and protect the oor beneath the legs to avoid

scratching the oor. With the assistance of another person,

lean the appliance back to access the front leveling legs.

Raise or lower the legs to the required dimension by turning

the legs. Repeat this process for the rear by tilting the appliance forward using caution. On a level surface check the

appliance for levelness and adjust accordingly.

The front grille screws may be loosened and the grille adjusted to the desired height. When adjustment is complete

tighten the two front grille screws. (See Figure 2).

Front grille

Front grille screw

Figure 2

4

Page 5

INSTALLING YOUR APPLIANCE

US

CA

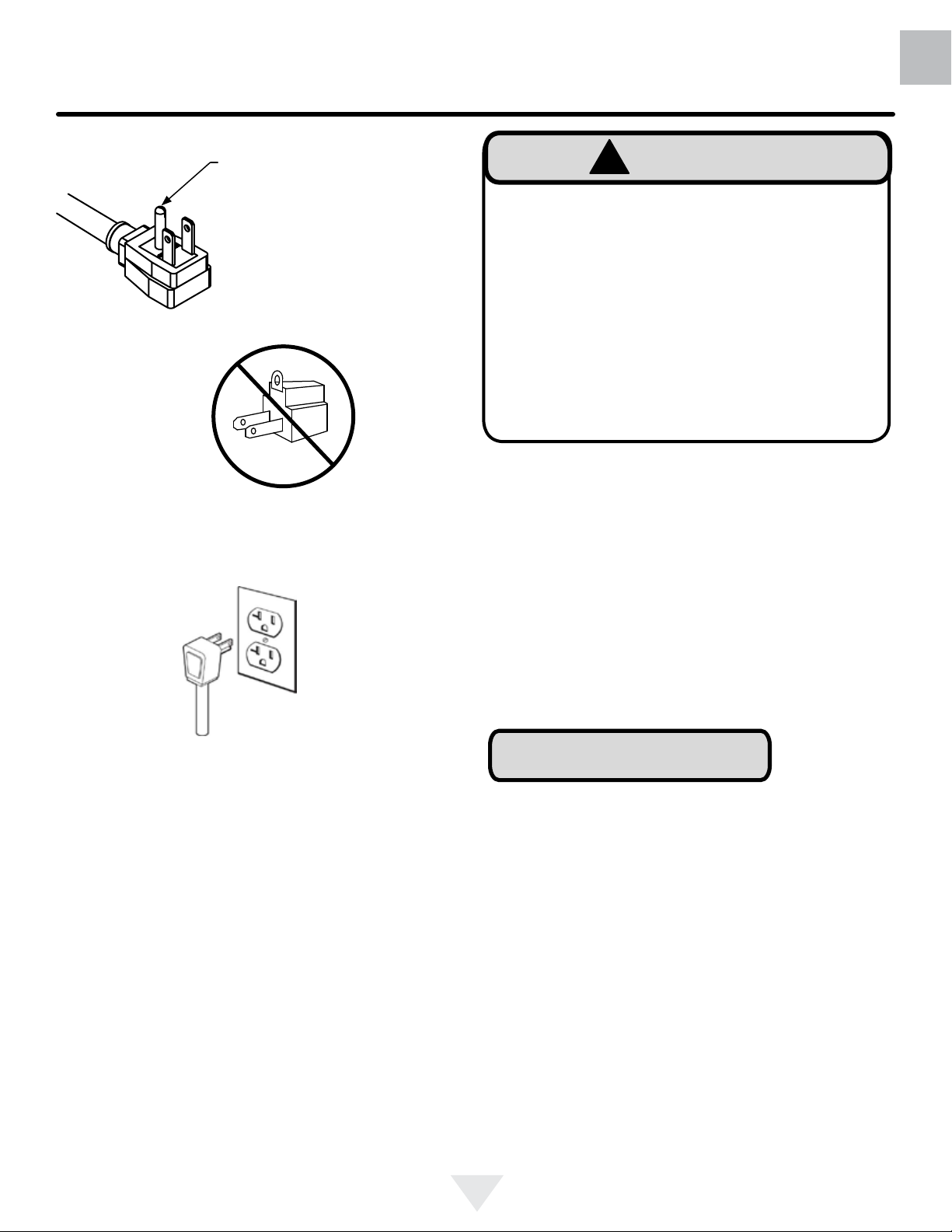

Figure 3

Do not remove

ground prong

Figure 4

!

WARNING

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any circumstances, be installed to an un-grounded electrical supply.

• Do not remove the grounding prong from the power

cord. (See Figure 3).

• Do not use an adapter. (See Figure 4).

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in accordance with the National Electrical Code and applicable local codes and ordinances (see Figure 5). If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to provide the proper power

supply. The third ground prong should not, under any circumstances, be cut or removed.

Figure 5

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to nuisance tripping which will cause the appliance to shut down.

GFCI’s are generally not used on circuits with power equipment that must run unattended for long periods of time, unless required to meet local building codes and ordinances.

5

Page 6

US

CA

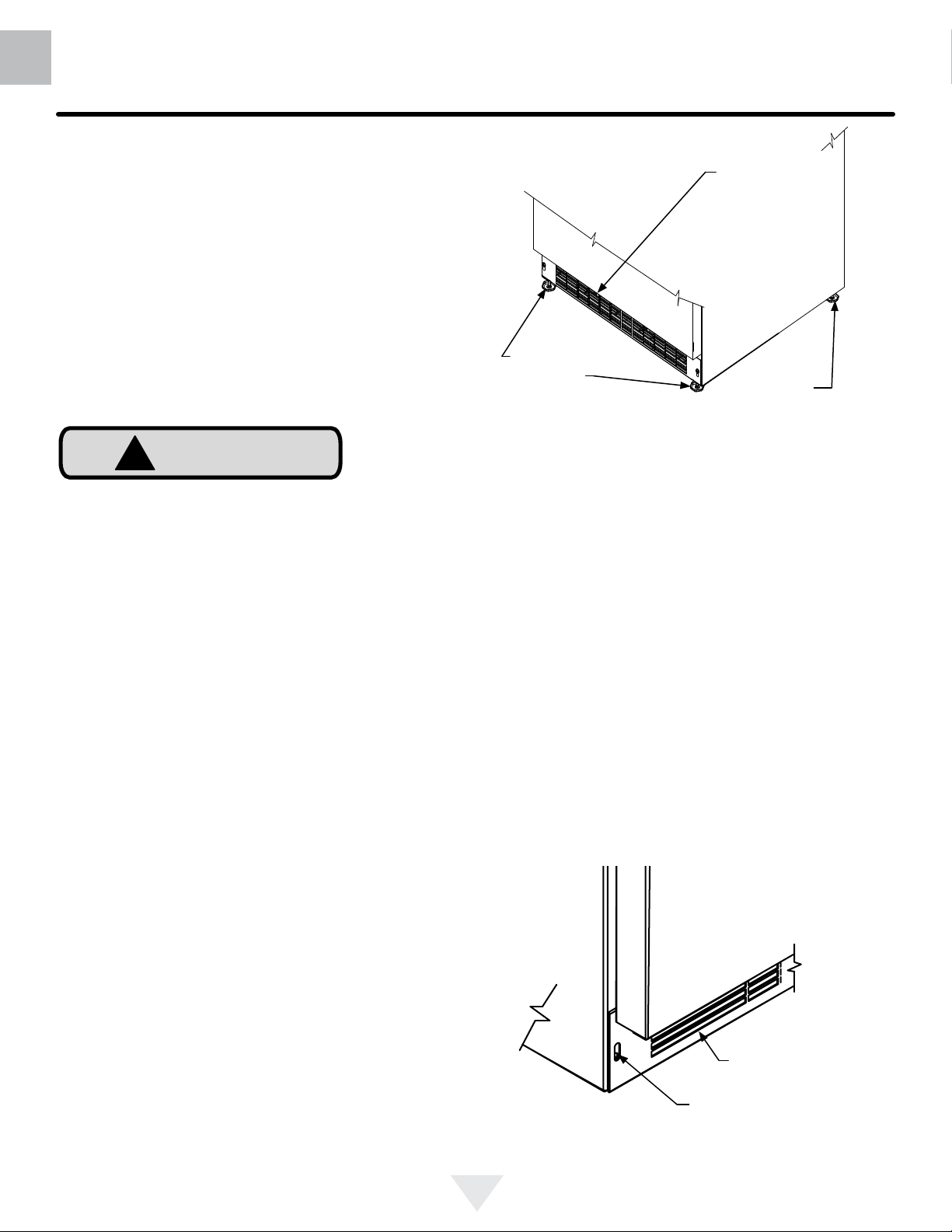

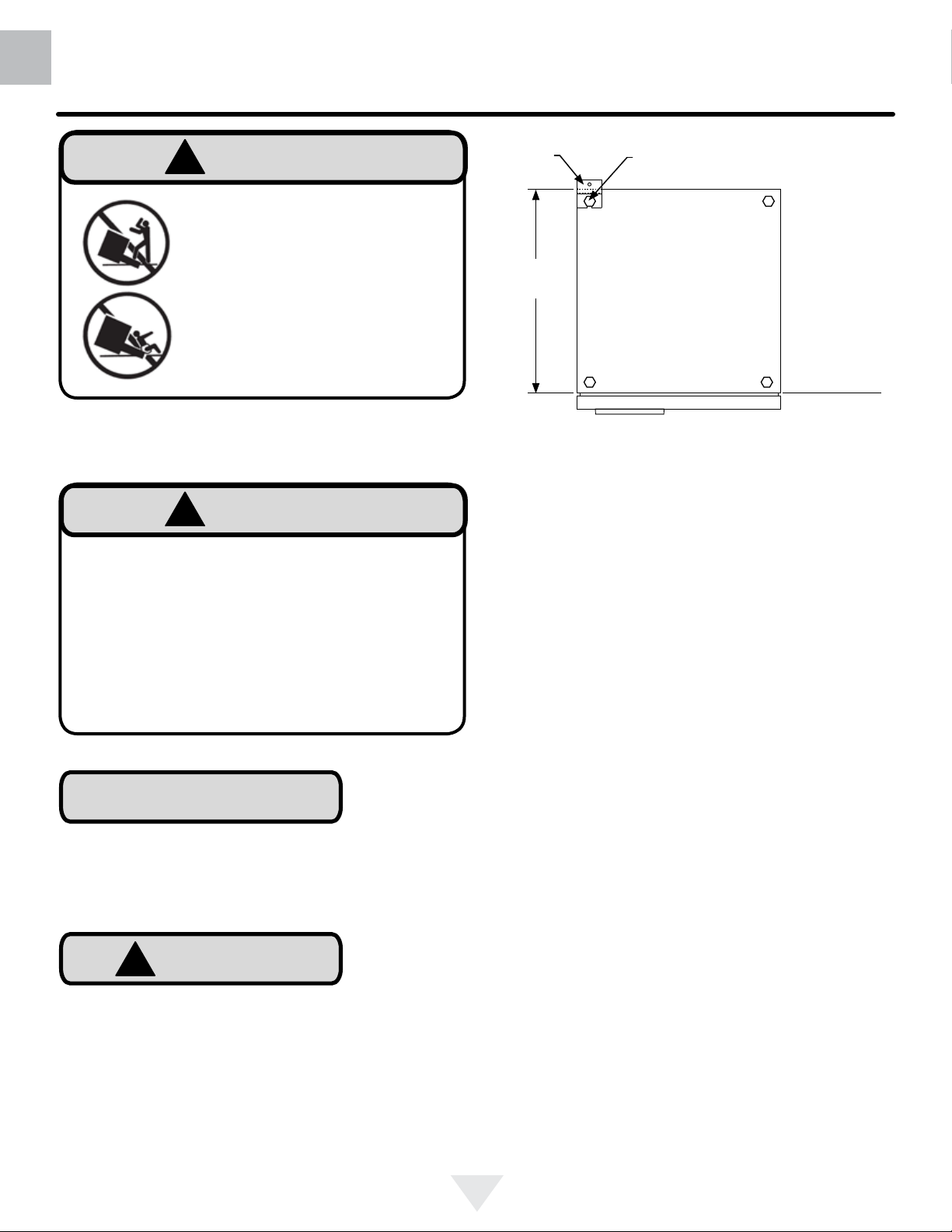

INSTALLING THE ANTI TIP DEVICE

FOR FREESTANDING INSTALLATIONS

!

WARNING

• ALL APPLIANCES CAN TIP

RESULTING IN INJURY.

Anti-Tip

Bracket

Leveling Leg

• INSTALL THE ANTI-TIP

BRACKET PACKED WITH

THE APPLIANCE.

• FOLLOW THE INSTRUCTIONS BELOW

Anti-Tip Device

!

WARNING

If your refrigerator is not located under a counter

top (free standing), you must use an anti-tip device

installed as per these instructions. If the refrigerator is

removed from its location for any reason, make sure

that the device is properly engaged with the anti-tip

bracket when you push the refrigerator back into the

original location. If the device is not properly engaged,

there is a risk of the refrigerator tipping over, with the

potential for property damage or personal injury.

211⁄2"

(54.6 cm)

Bottom View of

Beer dispenser

Front of cabinet

Figure 6

Step by step instructions for locating the

position of the bracket:

1) Decide where you want to place the beer dispenser.

Slide it into place, being careful not to damage the oor,

leaving 1" (2.5 cm) of clearance from the rear wall to allow

room for the anti-tip bracket.

2) Raise the rear leveling legs approximately 1⁄4" (6 mm) to

allow engagement with the anti-tip bracket. Level the unit

by adjusting all the leveling legs as required. Turning the

leveling leg counterclockwise will raise the unit and clockwise will lower the unit.

NOTE

If installing on a concrete oor, concrete fasteners are

required, (not included with the anti-tip kit).

!

CAUTION

Any nished ooring should be protected with appropriate

material to avoid damage when moving the unit.

Floor Mount Installation

The anti-tip bracket is to be located on the oor in the left or

right rear corner of the beer dispenser as shown in

Figure 6.

3) Make sure the beer dispenser is in the desired location,

then mark on the oor the rear and side corner of the cabinet where the anti-tip bracket will be installed. If the installation does not allow marking the rear corner of the cabinet,

then make temporary lines on the oor marking the front

corner of the cabinet, excluding the door. Slide the beer

dispenser out of the way. From the temporary line extend

the sidewall line back 211⁄2" (54.6 cm) as shown in Figure 6.

4) Align the anti-tip bracket to the marks on the oor so

the side of the bracket lines up with the side of the cabinet

mark, and the "V" notches on the anti-tip bracket line up

with the end of the 211⁄2" (54.6 cm) line (Rear of cabinet

line).

5) Fasten the anti-tip bracket to the oor using the supplied

screw. (See Figure 7).

6) Slide the cabinet back into position, making sure the rear

cabinet leveling leg slides under the anti-tip bracket engaging the slot.

6

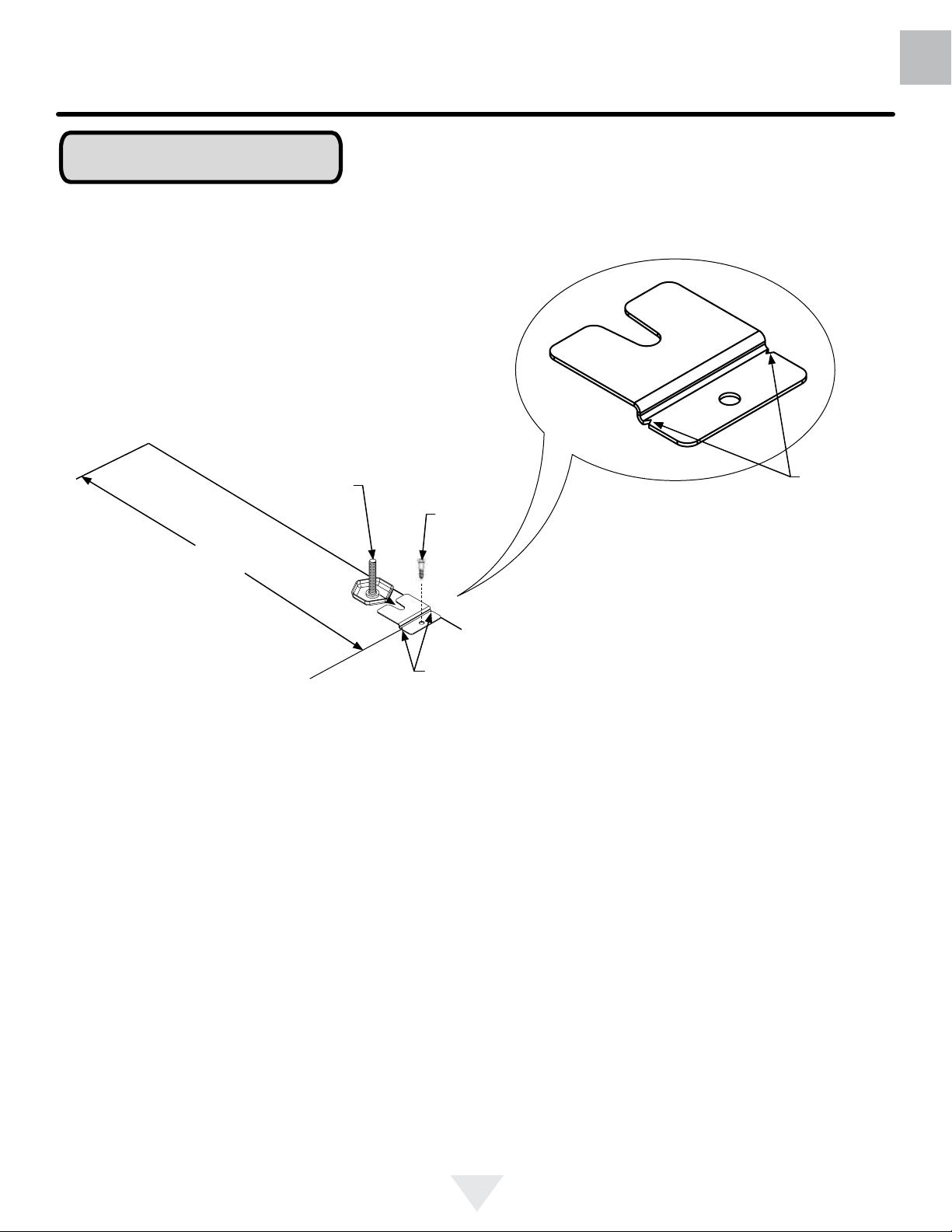

Page 7

INSTALLING THE ANTI TIP DEVICE

FOR FREESTANDING INSTALLATIONS

NOTE

When the oor mounted anti-tip bracket is used the minimum adjusted height of the cabinet is increased by

3

⁄8" (9 mm).

US

CA

Front of cabinet line

Side of cabinet line

211⁄2"

(54.6 cm)

Figure 7

Rear Leveling leg

Rear of cabinet line

Screw

"V" notches

in bracket

Figure 7a

"V" notches

in bracket

7

Page 8

US

CA

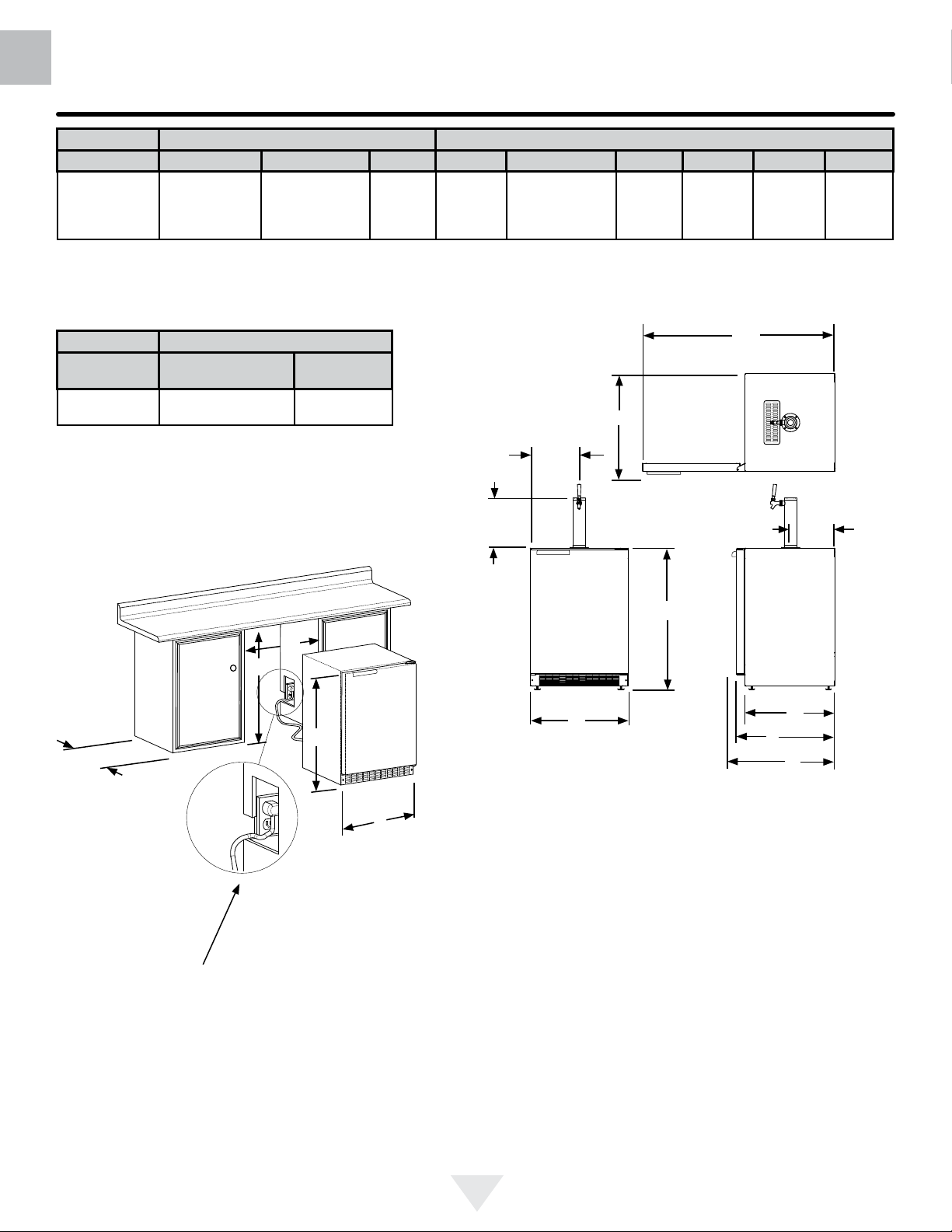

PRODUCT DIMENSIONS

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

MODEL "A" "B" "C" "D" "E" "F" "G" "H" "J"

1

24

All Models

⁄4" (61.6 cm)

24 ½" (62 cm)

(with optional DCS

side trim kit)

**34" to 35"

(86.4 to 88.9 cm)

*

237⁄8"

(60.7 cm)

333⁄4" to 343⁄4"

(85.7 to 88.3 cm)

2323⁄32"

(60.2 cm)

261⁄4"

(66.7 cm)

4613⁄32"

(117.9 cm)

(66.7 cm)

261⁄4"

PRODUCT DATA

MODEL

All Models 115V/60Hz/15A

"C"

ELECTRICAL

REQUIREMENTS***

"B"

"A"

PRODUCT

WEIGHT

140 lbs

(63.6 kg)

"E"

1115⁄16"

(30.3 cm)

121⁄4"

(31.1 cm)

"D"

"J"

"E"

Figure 9

"H"

11"

(27.9 cm)

211⁄2"

(54.6 cm)

"F"

"G"

"D"

Figure 8

Figure 8a

If necessary to gain clearance inside the rough-in

opening a hole can be cut through the adjacent cabinet and the power cord routed through this hole to a

power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

* Depth dimension of rough-in opening may vary depending on each individual installation. To recess entire door "F"

dimension plus 1" (2.5 cm) for thickness of power cord plug

is required.

** Minimum rough-in opening required is to be larger than

the adjusted height of the cabinet.

*** A grounded 15 amp dedicated circuit is required. Follow

all local building codes when installing electrical and appliance.

8

Page 9

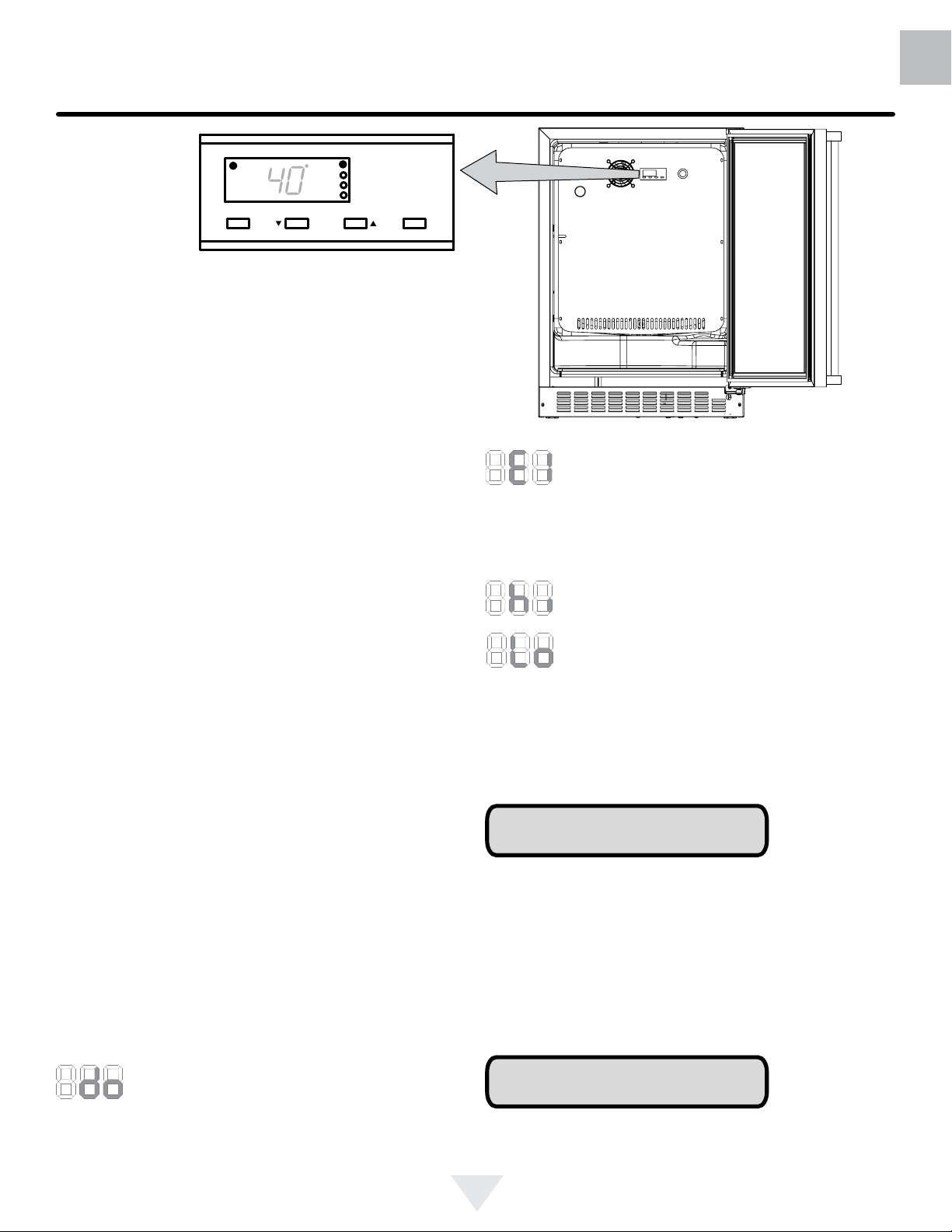

USING YOUR ELECTRONIC CONTROL

Alarm

F

Figure 10

close-up of control

Set

Press and Hold Press and Hold

Starting your beer dispenser

Plug the beer dispenser power cord into a wall outlet. Your

beer dispenser will begin cooling after power is applied.

If your beer dispenser does not start, check that the beer dispenser is turned on and the set temperature is cold enough.

Colder Warmer

ON/OFF

US

CA

Turning your beer dispenser ON or OFF

If the beer dispenser is on, the beer dispenser temperature

will be shown on the display. To turn the beer dispenser

off, press and hold the "ON/OFF" button for three seconds.

"OFF" will appear on the display.

If the beer dispenser is not on, "OFF" will be shown on the

display. To turn the beer dispenser on, press and hold the

"ON/OFF" button for three seconds. The beer dispenser

temperature will be shown on the display.

Set temperature

To set the beer dispenser temperature, press and hold

the "SET" button. When the "SET" button is pressed, the

display will show the set temperature. While holding the

"SET" button, press the "WARMER" or "COLDER" buttons

to adjust set temperature.

Beer dispenser operation

The available temperature range of the beer dispenser is

34 to 46°F (1 to 8°C).

It may take up to 24 hours for your beer dispenser to reach

desired temperature. This will depend on amount of content

loaded and number of door opening and closings.

For best results allow beer dispenser to "pull down" to

desired set temperature before loading. Once contents are

loaded, allow at least 48 hours for temperature to stabilize

before making any adjustments to the set temperature.

Alarms

Your digital display function will monitor beer dispenser

function and alert you with a series of audible and

visual alarms.

panel will ash "do" and the Alarm LED located at the top

left of the display below the word "Alarm" will be illuminated. This will stop as soon as the door is closed.

• Door Ajar Alarm: If the door has been left

open for over ve minutes, the alarm will

sound in one second intervals. The display

Figure 11

• Temperature Sensor Fault: If the control-

ler detects that the temperature sensor is not

properly functioning, a temperature sensor

alarm will sound in one (1) second intervals. "E1" will ash

on the display panel and the Alarm LED located at the top

left of the display below the word "Alarm" will be illuminated.

• High and Low Temperature Alarm: If your

unit reaches an unacceptable temperature

outside of your set-point, the alarm will sound

in (1) second intervals. The display panel will

ash either "Hi" or "Lo" depending upon the

condition and the Alarm LED light at the top

left of the display below the word "Alarm" will be illuminated. These alarms indicate that the compartment temperature has moved 10° or more from the set point for more

than 1 hour duration. The alarm will remain active until the

condition is corrected.

NOTE

During initial appliance start-up, the high temperature alarm

may sound until the interior temperature reaches set point.

The high temperature alarm can also occur if the door remains open during an extended period of time (i.e. cleaning

or door ajar alarm condition), high usage or loading with

warm product. After a high temperature alarm condition check

all perishables to ensure they are safe for consumption.

Alarm Mute

Press any key to mute the audible portion of an alarm.

NOTE

This action will only mute the alarm. If the condition that

caused the alarm continues, the alarm code will continue to

ash and will sound for 20 seconds every 60 minutes.

9

Page 10

US

CA

This beer dispensing unit will support

rel. The double draft tower units can support two sixth (1⁄6)

barrels of beer. See chart below for quantity of beer in each

barrel size.

1/6 barrel 1/4 Barrel 1/2 Barrel

5

23

Height

Diameter

Gallons 5.16 7.75 15.5

#12 ounce

Glasses

Keg Size

5 gallon Corny 15 to 22

1/6 barrel 14 to 21

1/4 Barrel 10 to 14

1/2 Barrel 5 to 7

⁄16"

(59.2 cm)

1

9

⁄4"

(23.5 cm)

60 82 163

Table A

USING YOUR BEER DISPENSER

1

⁄2 barrel or 1⁄4 bar-

Barrel Sizes

1413⁄16"

(37.6 cm)

17"

(43.2 cm)

#of kegs per

5 pound CO2 Tank

235⁄16"

(59.2 cm)

17" to 171⁄4"

(43.2 to 43 cm)

Tools required for installation:

Flat bladed screwdriver

Phillips screwdriver

Pliers

Adjustable wrench or a 11⁄8" open end wrench

1⁄2" open end wrench

!

WARNING

CO2 can be dangerous. If it becomes difcult to

breathe and/or your head starts to ache, a high

concentration of carbon dioxide may be present.

Leave the area immediately.

• The CO2 tank must always be connected to the

regulator. Never connect the tank to the keg.

• The CO2 tank must be securely mounted in the

upright position. Secure it with the chain provided.

• Never drop or throw the CO2 tank.

• Keep the CO2 tank away from heat.

• Ventilate the area after a CO2 leak.

Table B

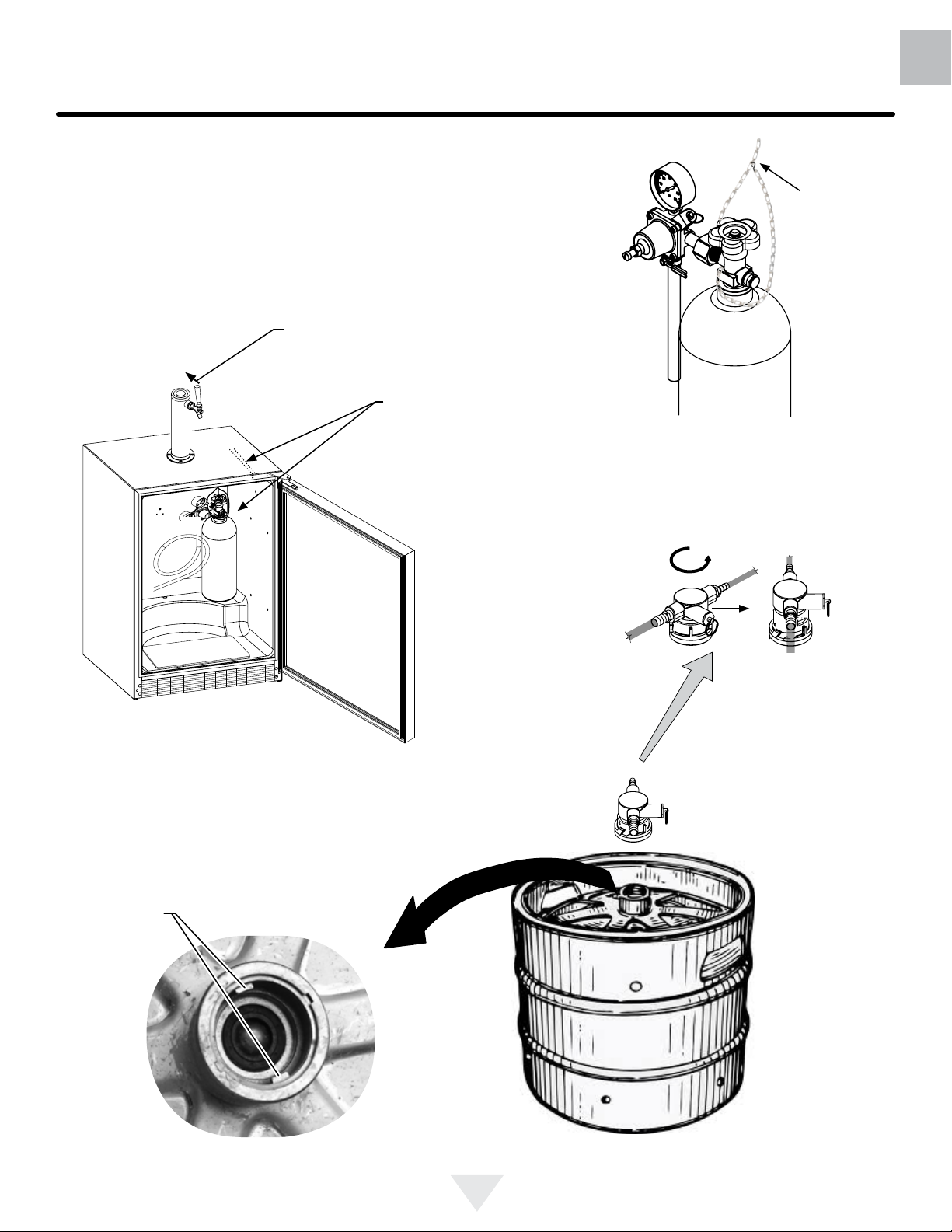

Tap Equipment and Assembly

Your dispensing kit includes the following parts:

Polished stainless steel tower with clear beer line (single

or double dispense)

Tower Gasket

Phillips oval head screws

Knob for Tower (Faucet Handle)

Keg coupler(s)

CO2 regulator with red gas line(s) attached

Empty 5 pound CO2 tank

Plastic clamp(s) large and small

Faucet wrench

1. Remove shelving and packaged components from the

interior of the refrigerator before beginning the assembly process.

2. Take your empty 5 pound CO2 tank to your local gas

supply dealer to be lled. You can usually nd them in

your "yellow pages" under "Welding Supply" or "Fire

Protection". One 5 pound tank can process many kegs

(see table "B") Your dealer should supply you with a

new plastic washer every time the tank is lled. This

washer is used at the regulator to tank connection. See

Figure 15 and 22 on page 11. Replace the old washer

with the new one whenever the tank is relled.

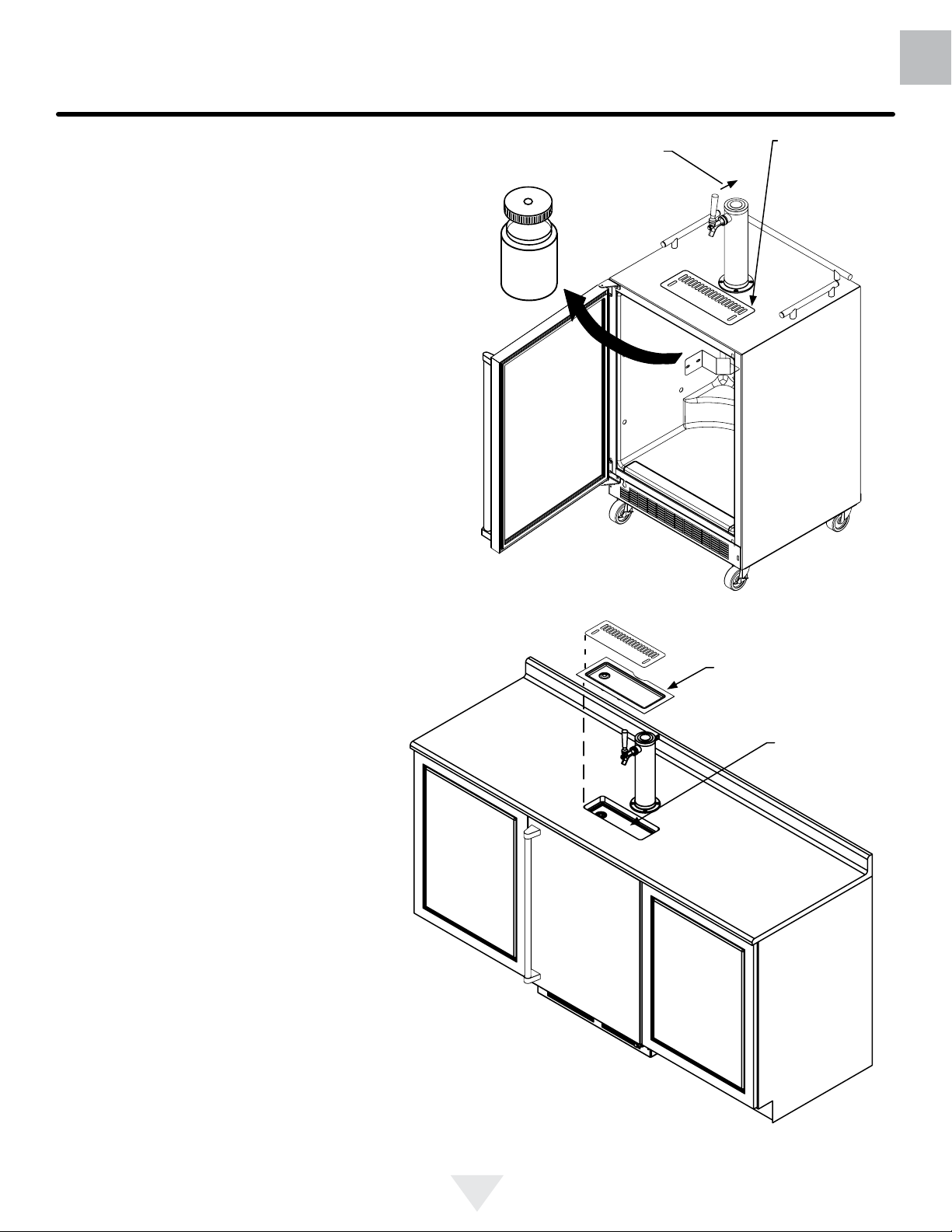

3. Tower mounting (if you are installing the unit under a

counter skip to step 4). If you are mounting the tower

directly to the top of the refrigerator, rst remove the

four screws from the top of the refrigerator. Remove the

foam plug from the large hole in the top of the refrigerator. Feed the clear beer line through the tower gasket

and the large hole in the refrigerator top. Align the 4

holes in the tower with the 4 holes in the refrigerator

top and secure the tower with the 4 screws removed

previously. Skip to step 5.

10

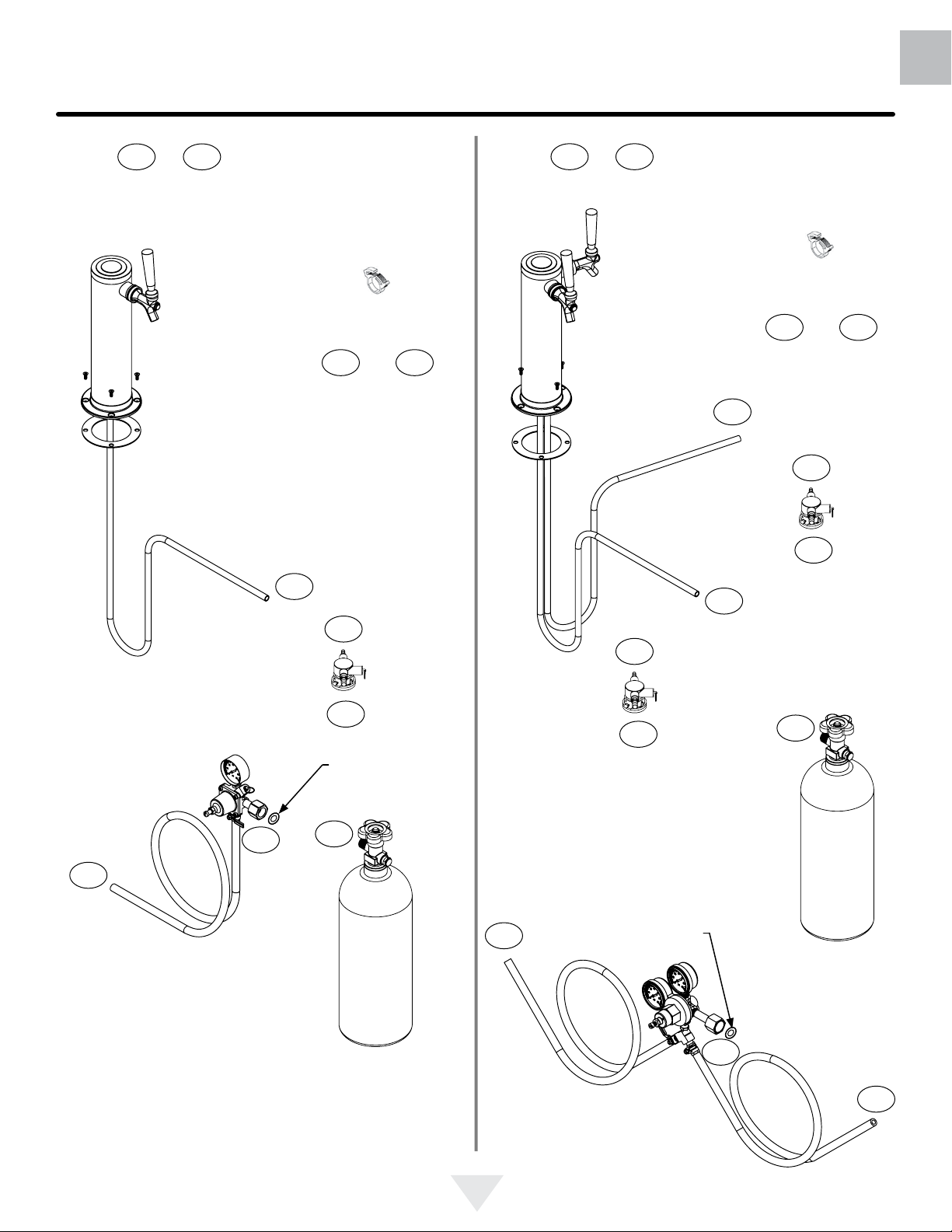

Page 11

USING YOUR BEER DISPENSER

US

CA

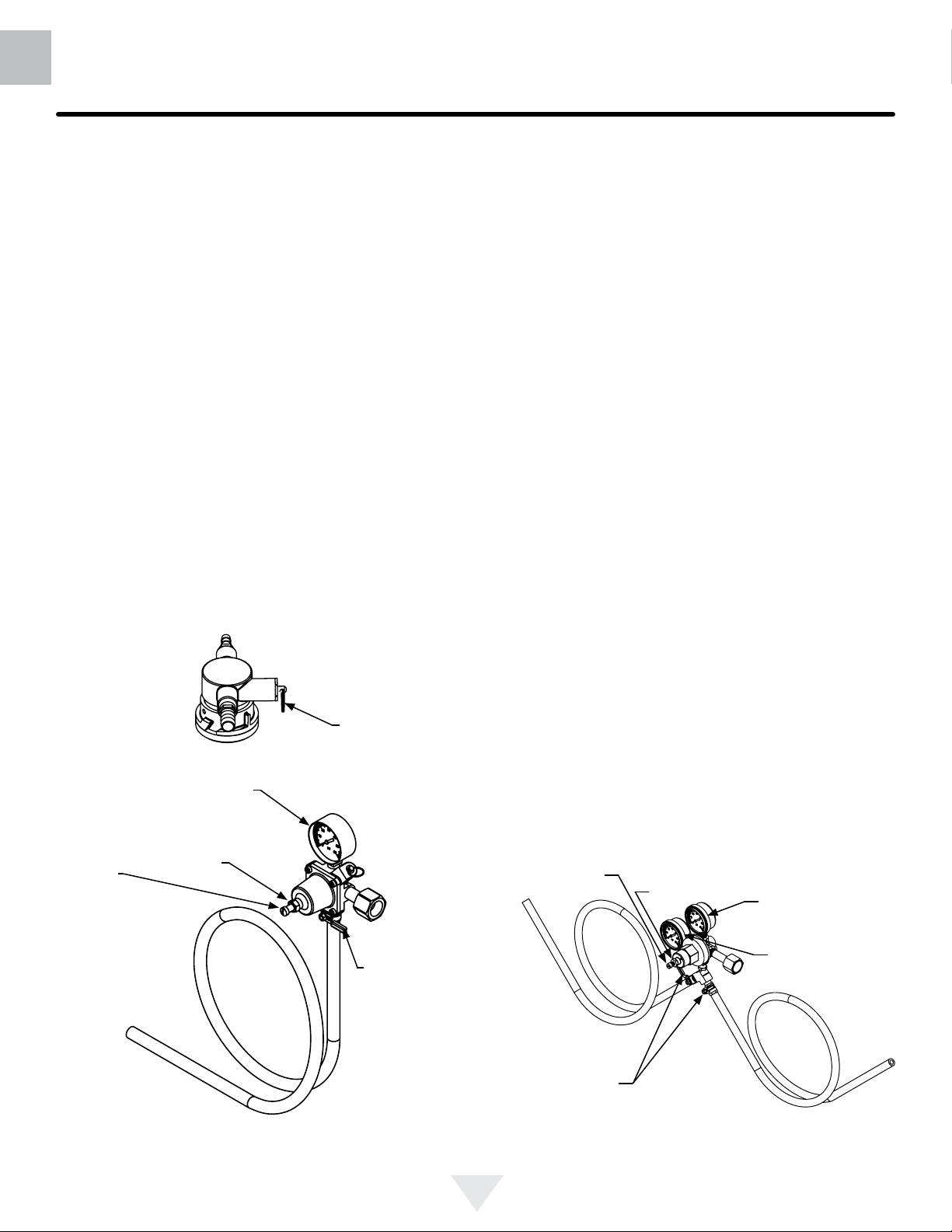

Single Dispense Tower Kit

Connect to ,etc........

A A

Single

Dispense

Tower

Figure 12

Figure 13

Hose clamps

use for connections

A

and

A

C

Double Dispense Tower Kit

Connect to ,etc........

A A

Figure 17

Double

Dispense

Tower

Figure 18

Hose clamps

use for connections

A

A

A

C

Figure 19

A

and

C

Keg

Coupler

C

Regulator

Figure 15

with red

airline

B

A

Figure 14

Keg

Coupler

C

New plastic

washer

B

5 Pound

CO2 Tank

Figure 16

C

Regulator

with red

airline

A

C

New plastic

washer

Figure 22

Keg

Coupler

Figure 20

B

B

5 Pound

CO2 Tank

Figure 21

C

11

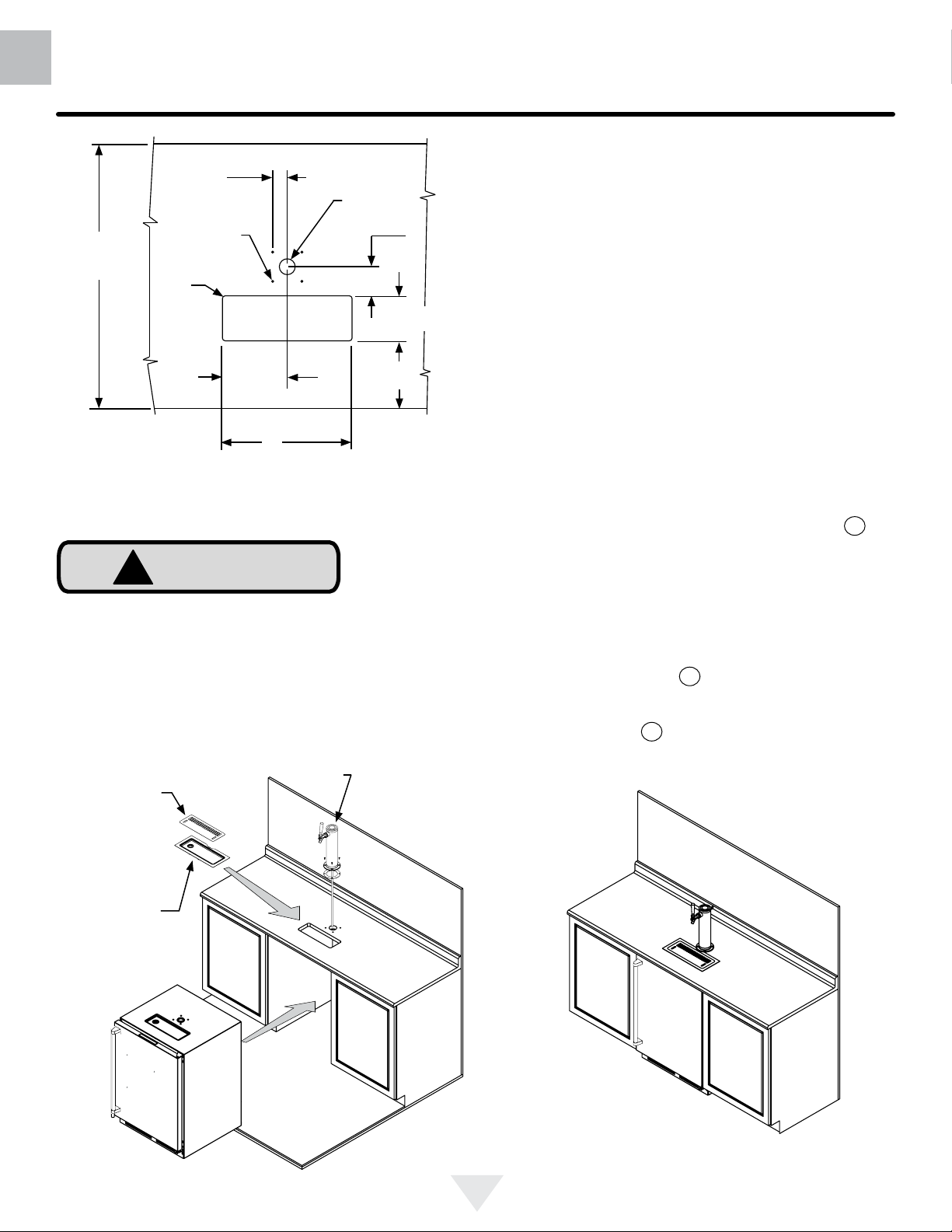

Page 12

US

CA

USING YOUR BEER DISPENSER

Rear of counter top

3

⁄8"

1

counter

top depth

5

25

⁄16"

(64.3 cm)

Diameter

1

⁄4" (6 mm)

radii,

typical

(3.5 cm)

typical

to suit

(15.6 cm)

1

6

⁄8"

1

12

⁄4"

(31.1 cm)

1

1

⁄2" (38 mm)

Diameter

(16.2 cm)

7

2

⁄38"

(7.3 cm)

41⁄4"

(10.8 cm)

3

6

⁄8"

Figure 23

!

CAUTION

The cutout dimensions shown in Figure 23 are based on

a 255⁄16" (64.3 cm) deep counter top. Your counter top may

be different than this and require other front to back dimensioning. Refer to the product dimensions on page 8 when

determining the required dimensions.

4. If you are installing your keg refrigerator under a

counter you will need to drill 5 holes in the counter top

to mount the tower. The rst hole is a 11⁄2" diameter

hole located at the center of the tower for the beer

line, locate approximately 131⁄2" (34.3 cm) from the

front edge of the counter top (based on a counter top

depth of 255⁄16"). Next drill the 4 tower mounting holes

per the dimensions in Figure 23. The hole diameter

is dependent on the counter top material and if screw

anchors are required. The screws supplied are in the

literature pack and are a #10 x 1" type AB stainless

steel screw. Mark and cut the rectangular cutout for

the drain sump. After the holes are drilled and the

keg refrigerator is in place under the counter top feed

the beer line through the tower gasket, the 11⁄2" hole

in the counter top and the hole in the top of the keg

refrigerator. Mount the tower to the counter top with the

4 screws provided. Place the counter top drain sump,

from the literature pack, in the rectangular hole with the

radius cutout to the rear around the tower and place

the grate in the sump.

5. Mount the regulator to the CO

2 tank (connection

B

)

use the new plastic washer you received from the gas

supply company. Note that the regulator has left hand

threads and has to be turned counterclockwise to

tighten. Tighten with the adjustable wrench or the 11⁄8"

open end wrench.

6. Connect the red air line(s) from the regulator to the

large air line tting on the keg coupler with a large

hose clamp (connection C).

7. Connect the clear beer line from the tower to the small

air line tting on the keg coupler with a small hose

clamp (connection A).

Grate from top of

beer dispenser

Counter top

sump from

literature pack

Tower

Figure 25

Figure 24

12

Page 13

USING YOUR BEER DISPENSER

US

CA

8. Locate the CO

shown in Figure 26 and secure with the chain. Close

the faucet handle on the tower.

9. Hooking up the keg coupler to the keg: Verify the coupler is in the "OFF" position (see Figure 27a).Align the

lugs on the keg with the corresponding openings on the

keg coupler and turn clockwise until the coupler stops

(about 90°). Push down and twist the top of the coupler

clockwise to allow gas to enter the keg.

2 tank in the corner of the refrigerator as

Push faucet handle back toward

tower to close the faucet

Chain-The chain is fastened

and taped to the top of the

interior liner. Remove the tape

and secure the CO

place in the back right corner.

Loop chain around top of tank

and connect with "S" hook.

Connect with

"S" hook

Figure 26a

2 tank in

Rotate the top of the coupler counter clockwise to extend the coupler

to the to the "OFF"position.

Lugs

on keg

Figure 26

Figure 27a

Coupler

extended

Figure 27b

Figure 27

13

Page 14

US

CA

USING YOUR BEER DISPENSER

CO2 Regulator (Single Dispense Tower)

Your beer dispenser comes equipped with a 5 pound CO2

tank and a single gauge regulator. The gauge reads the

pressure being supplied to the beer keg. Follow the procedure below to adjust the pressure to 12 - 14 psi (0.8 to

1 bar) for lager beer or 9 - 12 psi (0.6 to 0.8 bar) for ale's.

To adjust the pressure (Single Gauge):

1. Close the shutoff valve at the bottom of the regulator.

2. Be sure the faucet handle is closed on the tower (see

Figure 26).

3. Loosen the lock nut by turning ↶ counterclockwise using the

adjustment of the pressure adjustment screw.

4. With the at bladed screwdriver turn the adjustment

screw ↷ clockwise to increase the pressure or ↶ counterclockwise to decrease the pressure.

5. Open the shutoff valve on the bottom of the regulator. The gauge reading may drop but will return very

quickly.

6. Pull the ring on the keg coupler to allow the gas to ow

momentarily.

7. Make any ne adjustments if necessary with the adjustment screw.

8. Tighten the locknut with the 1⁄2" open end wrench by

turning clockwise ↷.

1

⁄2" open end wrench until loose, this will allow

Ring on keg

Figure 28

coupler

CO2 Regulator (Double Dispense Tower)

Your beer dispenser comes equipped with a 5 pound CO2

tank and a dual gauge regulator. The lower gauge should

be reading approximately 750 psi (52 bar) when the tank is

properly lled and the tank is not in the refrigerator (at room

temperature). The tank will read less when chilled. Use this

lower gauge as an indicator of how much CO2 you have left

in the tank.

The upper gauge reads the pressure being supplied to the

beer keg. Follow the procedure below to adjust the pressure to 12 - 14 psi (0.8 to 1 bar) for lager beer or 9 - 12 psi

(0.6 to 0.8 bar) for ale's.

To adjust the pressure (Upper Gauge):

1. Close the shutoff valves at the bottom of the regulator.

2. Be sure the faucet handle is closed on the tower (see

Figure 29).

3. Loosen the lock nut by turning ↶ counterclockwise using the

adjustment of the pressure adjustment screw.

4. With the at bladed screwdriver turn the adjustment

screw ↷ clockwise to increase the pressure or ↶ counterclockwise to decrease the pressure.

5. Open the shutoff valve on the bottom of the regulator. The gauge reading may drop but will return very

quickly.

6. Pull the ring on the keg coupler to allow the gas to ow

momentarily.

7. Make any ne adjustments if necessary with the adjustment screw.

8. Tighten the locknut with the 1⁄2" open end wrench by

turning clockwise ↷.

1

⁄2" open end wrench until loose, this will allow

Pressure Gauge

Pressure

Adjustment

Screw

Figure 29 (Regulator for

Single Dispense Tower)

Lock Nut

shutoff valve

(closed position shown)

position shown)

14

Pressure

Adjustment

Screw

(2) shutoff

valves (closed

Figure 30 (Regulator for

Double Dispense Tower)

Lock Nut

Upper Gauge

Lower Gauge

Page 15

USING YOUR BEER DISPENSER AND CARE AND CLEANING

US

CA

Drain kit (All Models): The drain kit is shipped in

place and ready to use. To empty: Pull drain hose out of

bottle cap, remove bottle from unit, unscrew cap and discard waste and rinse bottle. Reinstall bottle in unit.

Cleaning the drain sump:

On a free standing beer dispenser remove the grate from

in front of the tower, clean with soap and water and dry

before reinstalling. Clean the sump area with soapy water

and dry. (See gure 31).

On a built in beer dispenser remove the grate and counter top sump, clean with soap and water and dry before

reinstalling. Clean the sump area with soapy water and dry.

(See Figure 32).

Push faucet handle back toward

tower to close the faucet

Unscrew

cap

Figure 31

Removable

grate for cleaning sump area

Counter top

sump

Clean and dry

sump area

15

Figure 32

Page 16

US

CA

CARE AND CLEANING

Cleaning and Maintaining Dispensing System

The dispensing system needs to be cleaned between

usage to prevent spoilage and/or foul taste in your beer.

Cleaning

Remove the keg coupler from the keg if necessary. Close the

gas valve(s) below the regulator, remove both the red gas

line(s) and clear beer line(s) from the keg coupler(s) by removing the plastic hose clamps (See Figure 33). Soak and brush

the keg coupler in hot water or a sanitizing solution. Rinse

thoroughly with clean water. Dry all parts and reassemble.

Hose clamps can be

released by a lateral

movement to the head.

Figure 33

Figure 34

After removing the

handle the shaft will

slide out the back of the

faucet

Figure 36

Soak all faucet parts in hot water or a solution of hot water

and a sanitizing solution. Do not use soap. Rinse thoroughly with clean water.

Reassemble faucet, assemble faucet to tower (be sure

faucet is in off position), and turn on gas valve.

Unscrew knurled

cap on faucet body

and remove handle

assembly

Front Grille

Be sure that nothing obstructs the required air ow openings

in front of the cabinet. At least once or twice a year, brush or

vacuum lint and dirt from the front grille area (see page 4).

Faucet Cleaning

Turn off the gas supply with the shutoff valve(s) under the

regulator (see Figure 29 or 30) and open the faucet to relieve the pressure. To remove the faucet from the tower use

the spanner wrench provided. Place the pin on the wrench

into the hole on the faucet collar and turn clockwise ↷ to

remove the faucet. (See Figure 35).

Remove the knurled cap from the faucet body just below

the handle and pull the handle assembly from the faucet.

This will allow the shaft to be removed from the back of the

faucet, see Figure 36.

Place pin on

wrench into hole

in faucet collar.

Figure 35

!

CAUTION

SHOCK HAZARD: Disconnect electrical power from the

appliance before cleaning with soap and water.

Cabinet

The stainless steel cabinet can be washed with either a

mild soap and water and thoroughly rinsed with clear water.

NEVER use abrasive scouring cleaners. Dry thoroughly

with a terry towel.

Interior

Wash interior compartment with mild soap and water. Do

NOT use an abrasive cleaner, solvent, polish cleaner or

undiluted detergent.

Care of Appliance

1. Avoid leaning on the door, you may bend the door

hinges or tip the appliance.

2. Exercise caution when sweeping, vacuuming or mop-

ping near the front of the appliance. Damage to the

grille can occur.

3. Periodically clean the interior of the appliance as needed.

In the Event of a Power Failure

If a power failure occurs, try to correct it as soon as possible. Minimize the number of door openings while the

power is off so as not to adversely affect the appliance's

temperature.

16

Page 17

CARE AND CLEANING

Long term storage / winterization:

1. Time to Winterize, when the daily low ambient temperature is at or below 38°F (3.3°C).

!

CAUTION

Operating of the unit at ambient temperatures below the

recommended Winterization temperature will void your warranty.

2. Turn unit off, (see page 9).

3. Remove all contents.

4. If necessary, move the unit so you can gain access to

the rear of the product.

5. Unplug the unit from the power outlet.

6. It is also recommended that the power to the outlet be

turned-off if the circuit is not required for other items

during the Winter season.

7. Shut-off CO2 tank valve.

8. Drain beer line(s)

Figure 37

US

CA

Front grille

Front grille screw

a. Remove keg coupler (sankey tap), (see

page 16).

b. Remove faucet on tower, (see page 16).

c. Beer lines will gravity drain.

d. Clean beer line tubing.

9. Disassemble faucet and clean, (see page 16).

10. Soak and clean Sankey Low-Boy tap, (see page 16).

11. When cleaning unit pay particular attention to any

cracks and crevices that may have accumulated dirt

and debris.

12. Remove the front toe-grille, (see Figures 37 and 38),

and use a brush and vacuum to clean dirt and debris

from beneath the unit.

13. Thoroughly clean the toe-grille and re-install on the

unit.

14. Remove the rear access cover, (see Figure 39), and

use a brush and vacuum to clean dirt and debris from

the machine compartment.

• If the plastic defrost drain pan located

under the compressor contains water,

use a sponge to remove as much

water as possible

15. Thoroughly clean the rear access cover and re-install

on the unit.

16. Wipe down all interior surfaces with anti-bacterial

cleaner to be followed with clean rinse water to remove

any residual chemicals which could cause staining. Do

not use any abrasive cleaners or scouring pads.

• Remove plastic oor protector and

stainless steel lower edge guard to

clean underneath.

Figure 38a

Clean out

behind

grille

Figure 38

Floor protector

Remove oor

protector and

edge guard

and clean

Spacer

Edge

guard

Grille

17

Page 18

US

CA

Figure 39

CARE AND CLEANING

17. Leave door open and allow to completely dry out before closing door.

18. Thoroughly clean the door gasket with anti-bacterial

cleaner to be followed with clean rinse water to remove

any residual chemicals.

19. Thoroughly clean the exterior with a cleaner approved

for stainless steel . Do not use any abrasive cleaners

or scouring pads.

20. Any mounting hardware / fasteners that are showing

signs of corrosion should be replaced.

21. Once the exterior has been thoroughly cleaned, you

may want to apply a coating of car wax to help protect

Remove 11

screws from

around the

perimeter of the

access cover

with a 5⁄16" nut

driver.

against spotting from moisture, dirt, and debris that

may accumulate on the surfaces during the Winterization period.

After completion of the above, you may choose to store the

unit indoors, although this is not required.

Figure 40

Remove the power

cord from the grommet

in the access cover.

Soak up water

from plastic

drain pan if

necessary

Start-Up After Long-Term Storage:

1. Connect the unit to electrical power.

2. If stored outside, it is recommended that the unit again

be thoroughly inspected per the storage instructions

above to address any dirt or debris from the weather

and/or animals/insects.

3. Turn unit on and conrm your desired control settings.

4. Allow 24-hrs for the unit to stabilize before loading

contents.

Clean out

debris

18

Page 19

STAINLESS STEEL MAINTENANCE

US

CA

Background

Stainless steel does not stain, corrode, or rust as easily as

ordinary steel, but it is not stain or corrosion proof. Stainless steels can discolor or corrode if not maintained properly.

Stainless steels differ from ordinary carbon steels by the

amount of chromium present. It is this chromium that

provides an invisible protective lm on the surface called

chrome-oxide. This protective chrome-oxide lm on the

surface can be damaged or contaminated, which may

result in discoloration, staining, or corrosion of the base

metal.

Care & Cleaning

Routine cleaning of the stainless steel surfaces will serve to

greatly extend the life of your product by removing contaminants. This is especially important in coastal areas which

can expose the stainless to severe contaminants such as

halide salts, (sodium chloride).

It is strongly recommended to periodically inspect and thoroughly clean crevices, weld points, under gaskets, rivets,

bolt heads, and any locations where small amounts of liquid

could collect, become stagnant, and concentrate contaminates. Additionally, any mounting hardware that is showing

signs of corrosion should be replaced.

Note: Stainless steel products should never be installed, or

stored in close proximity to chlorine chemicals.

Whichever cleaning product you chose, it should be used

in strict accordance with the instructions of the cleaner

manufacturer.

Frequency of cleaning will depend upon the installation

location, environmental, and usage conditions.

Choosing a Cleaning Product

The choice of a proper cleaning product is ultimately that

of the consumer, and there are many products from which

to choose. Depending upon the type of cleaning and the

degree of contamination, some products are better than

others.

Typically the most effective and efcient means for routine

cleaning of most stainless steel products is to give the surfaces a brisk rubbing with a soft cloth soaked in warm water

and a gentle detergent, or mild mixture of ammonia. Rubbing should, to the extent possible, follow the polish lines of

the steel, and always insure thorough rinsing after cleaning.

Although some products are called "stainless steel cleaners," some may contain abrasives which could scratch the

surface, (compromising the protective chrome-oxide lm),

and some many contain chlorine bleach which will dull,

tarnish or discolor the surface if not completely removed.

After the stainless surfaces have been thoroughly cleaned,

a good quality car wax may be applied to help maintain the

nish.

19

Page 20

US

CA

ENERGY SAVING TIPS

The following suggestions will minimize the

cost of operating your refrigeration appliance.

1. Do not install your appliance next to a hot appliance

(cooker, dishwasher, etc.), heating air duct, or other

heat sources.

2. Install product out of direct sunlight.

3. Ensure the front grille vents at front of appliance beneath door are not obstructed and kept clean to allow

ventilation for the refrigeration system to expel heat.

4. Plug your appliance into a dedicated power circuit. (Not

shared with other appliances).

5. When initially loading your new product, or whenever

large quantities of warm contents are placed within

refrigerated storage compartment, minimize door

openings for the next 12 hours to allow contents to pull

down to compartment set temperature.

6. Maintaining a relatively full storage compartment will

require less appliance run time than an empty compartment.

7. Ensure door closing is not obstructed by contents

stored in your appliance.

8. Allow hot items to reach room temperature before placing in product.

9. Minimize door openings and duration of door openings.

10. Use the warmest temperature control set temperature

that meets your personal preference and provides the

proper storage for your stored contents.

11. When on vacation or away from home for extended pe-

riods, set the appliance to warmest acceptable tem perature for the stored contents.

12. Set the control to the “off” position if cleaning the

appliance requires the door to be open for an extended

period of time.

20

Page 21

TROUBLESHOOTING AND OBTAINING SERVICE

US

CA

Before You Call for Service

If the appliance appears to be malfunctioning, read through

this manual rst. If the problem persists, check the troubleshooting guide below. Locate the problem in the guide and

refer to the cause and its remedy before calling for service.

The problem may be something very simple that can be

solved without a service call. However, it may be required

to contact your dealer or a qualied service technician.

!

WARNING

Electrocution Hazard

• Never attempt to repair or perform maintenance on

the appliance until the main electrical power has been

disconnected. Turning the appliance control "OFF"

does not remove electrical power from the unit's wiring.

• Replace all parts and panels before operating.

How to Obtain Service:

For warranty service, please contact your local service

provider or DCS Customer Care at (888) 936-7872. Before

you call, please have the following information ready:

• Model Number (the serial plate is located on the upper

left side, inner wall).

• Serial Number (the serial plate is located on the upper left

side, inner wall).

• Code (the serial plate is located on the upper left side,

inner wall).

• Date of installation

• A brief description of the problem

Your satisfaction is of the utmost importance to us. If a

problem cannot be resolved to your satisfaction, please

write or email us at:

Write:

Fisher & Paykel and DCS

Appliances Inc

695 Town Centre Drive, Suite #180 Costa Mesa

CA 92626-1902

USA

Email:

customer.care@sherpaykel.com

Problem Possible Cause Remedy

Appliance not cold enough

(See “Adjusting the temperature" on

page 9)

Appliance too cold

(See “Adjusting the Temperature” on

page 9)

Noise or Vibration • Appliance not level

Appliance will not run. • Appliance turned off

• Control set too warm

• Content temperature not stabilized.

• Excessive usage or prolonged

door openings.

• Airow to front grille blocked.

• Door gasket not sealing properly.

• Control set too cold

• Door gasket not sealing properly.

• Fan hitting tube obstruction.

• Power cord not plugged in.

• No power at outlet.

• Adjust temperature colder. Allow 24 hours for temperature to

stabilize.

• Allow temperature to stabilize for

at least 24 hours.

• Airow must not be obstructed to

front grille. See “clearances” on

page 4.

• Replace door gasket.

• Adjust temperature warmer.

Allow 24 hours for temperature to

stabilize.

• Replace door gasket.

• Level appliance, see “Leveling

Legs” on page 4.

• Contact a qualied service technician.

• Turn appliance on. See “Starting

your appliance” on page 9.

• Plug in power cord.

• Check house circuit.

21

Page 22

US

CA

WARRANTY

Limited Warranty

When you purchase any new DCS Refrigeration Product,

you automatically receive a Two Year Limited Warranty

covering parts and labor for servicing within the 48

mainland United States, Hawaii, Washington, D.C. and

Canada. In Alaska the Limited Warranty is the same

except that you must pay to ship the Product to the service

shop or for the service technician’s travel to your home.

Products for use in Canada must be purchased through

the authorized Canadian distribution channel to ensure

regulatory compliance.

You receive an additional Three Year Limited Warranty

(for a total of Five Years) covering parts for the sealed

refrigeration system (compressor, evaporator, condenser,

lter dryer, and connecting tubing) within the 48 mainland

United States, Hawaii, Washington, D.C. and Canada. In

Alaska the Limited Warranty for the sealed refrigeration

system is the same except that you must pay to ship the

Product to the service shop or the service technician’s

travel to your home.

If the product is installed in a motor vehicle, boat or similar

mobile facility, you receive the same two year warranty, but

you must bring the vehicle, boat or mobile facility containing

the product to the service shop at your expense, or pay the

service technicians to travel to the location of the product.

Fisher & Paykel Undertakes to:

Repair without cost, with limited expectations described

herein, to the owner either for material or labor any part

of the Product, the serial number of which appears on the

Product, which is found to be defective. In Alaska, you

must pay to ship the Product to the service shop or for the

service technician’s travel to your home.

If we are unable to repair a defective part of the Product after a reasonable number of attempts, at our option we may

replace the part or the Product, or we may provide you a

full refund of the purchase price of the Product (not including installation or other charges).

This warranty extends to the original purchaser and any

succeeding owner of the Product during the term of warranty, for products purchased for ordinary single-family

home use.

Limited Warranty

How Long Does this Limited Warranty Last?

Our liability under this Limited Warranty expires Two

Years from the date of purchase of the Product by the

rst consumer.

Our liability for repair of defects in any sealed refrigeration

system (compressor, evaporator, condenser, lter dryer,

and connecting tubing) extends an additional Three Years,

for a total of Five Years from the date of purchase of the

Product by the rst consumer.

Our liability under any implied warranties, including the

implied warranty of merchantability (an unwritten warranty

that the Product is t for ordinary use) also expires Two

Years (or such longer period as required by applicable law)

from the date of purchase of the Product by the rst consumer. Some states do not allow limitations on how long

an implied warranty lasts, so this limit on implied warranties

may not apply to you.

Fisher & Paykel will honor any warranty required by the

law of the particular country or state in which the product

is sold.

This Warranty Does Not Cover

A.

Service calls that are not related to any defect

in the Product. The cost of a service call will

be charged if the problem is not found to be a

defect of the Product. For example:

1. Correct faulty installation of the Product.

2. Instruct you how to use the Product.

3. Replace house fuses, reset circuit breakers, correct

house wiring or plumbing, or replace light bulbs.

4. Correct fault(s) caused by the user.

5. Change the set-up of the Product.

6. Unauthorized modications of the Product.

7. Noise and vibration that is considered normal e.g.

drain sounds, regeneration noises and user warning

beeps.

8. Correcting damage caused by pests e.g. rats, cockroaches etc.

9. Used in commercial applications.

All service under this Limited Warranty shall be provided

by Fisher & Paykel Appliances Inc. or its Authorized DCS

Service Agent during normal business hours.

There is no warranty for commercial purchase or use.

Defects caused by factors other than:

B.

1. Normal domestic use or

2. Use in accordance with the Product’s Use and Care

Guide.

22

Page 23

C.

Defects to the Product caused by accident,

neglect, misuses, re, ood or Act of God.

D.

The cost of repairs carried out by non-authorized repairers or the cost of correcting such

unauthorized repairs.

E.

Travel Fees and associated charges incurred

when the product is installed in a location

with limited or restricted access.(i.e. airplane

ights, ferry charges, isolated geographic

areas).

F.

Normal recommended maintenance as set

forth in the Product’s Use and Care Guide.

If you have an installation problem contact

your dealer or installer. You are responsible

for providing adequate electrical, exhausting

and other connection facilities.

This product has been designed for use in a

normal domestic (residential) environment.

This product is not designed for commercial

use (whatsoever). Any commercial use by a

customer will terminate/affect this products

limited warranty.

We are not responsible for consequential or

incidental damages (including without limitation the cost of repairing or replacing other

property damaged if the Product is defective

or any of your expenses caused if the Product

is defective). Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

WARRANTY

Commercial use

This warranty applies to appliances used in residential applications; it does not cover their use in commercial situations.

No other warranties

This Limited Warranty is the complete and exclusive agreement between you and Fisher & Paykel Appliances Inc.

regarding any defect in the Product and no other express

warranty has been made or will be made on behalf of

Fisher & Paykel. None of our employees (or our Authorized

Service Agents) are authorized to make any addition or

modication to this Limited Warranty.

Warrantor: Fisher & Paykel Appliances, Inc.

If you need further help concerning this Limited Warranty,

or to make a claim under this warranty, please call us at the

above number, or write to:

Fisher & Paykel and DCS

Appliances Inc

695 Town Centre Drive, Suite #180 Costa Mesa

CA 92626-1902

USA

This Limited Warranty gives you specic legal rights, and

you may also have other rights which vary from country to

country and from state to state.

Fisher & Paykel Appliances Inc. is a leading manufacturer

of premium quality cooking and specialty appliances under

the Fisher & Paykel and DCS brands.

US

CA

How to get service

Please read this Use and Care Guide. If you then have any

questions about operating the Product, need the name of

your local DCS Authorized Service Agent, or believe the

Product is defective and wish service under this Limited

Warranty, please contact your dealer or call us at:

TOLL FREE 1-888-936-7872 or contact us through our web

site: www.dcsappliances.com

You may be required to provide reasonable proof of the

date of purchase of the Product before the Product will be

serviced under this Limited Warranty.

23

Page 24

US

CA

(FR)

TABLE DES MATIÈRES

Table des matières :

Informations de sécurité ........................................................24

Déballage de votre appareil ...................................................25

Enregistrement de la garantie ................................................25

Installation de votre appareil ..................................................26

Dégagement requis pour l’appareil ...................................26

Mise à niveau de l’appareil ................................................26

Raccordement électrique ..................................................27

Installation du dispositif antibasculement ..............................28

Dimensions du produit ............................................................30

Utilisation de votre commande électronique...........................31

Démarrage de votre appareil .............................................31

Mise en « MARCHE » ou « ARRÊT » de votre appareil ....31

Réglage de la température .................................................31

Fonctionnement du distributeur de bière ............................31

Alarmes ..............................................................................31

Porte entrouverte ...........................................................31

Défaillance du capteur de température ..........................31

Alarme de température élevée ou basse .......................31

Mise en sourdine de l’alarme .............................................31

Utilisation de votre distributeur de bière .................................32

Équipement de robinet et assemblage ...............................32

Régulateur de CO2 ............................................................36

Ensemble d’évacuation ......................................................37

Entretien et nettoyage ...........................................................37

Nettoyage du drain d’évacuation ........................................37

Nettoyage du coupleur de fût à bière .................................38

Nettoyage du robinet .........................................................38

Grille frontale .....................................................................38

Bâti .....................................................................................38

Intérieur ..............................................................................38

Rangement de longue durée / hivernage ..............................39

Entretien de l’acier inoxydable .............................................41

Conseils d’économie d’énergie ..............................................42

Dépannage ............................................................................43

Obtention de service ..............................................................43

Garantie .................................................................................44

Consignes de sécurité importantes

Les consignes de sécurité et avertissements contenus

dans ce guide ne couvrent pas de façon exhaustive toutes

les conditions et situations possibles. Soyez prudents et

agissez avec précaution et attention lors de l’installation,

l’entretien ou l’utilisation de cet appareil.

Portez attention aux symboles,

indications et étiquettes de sécurité.

!

MISE EN GARDE

AVERTISSEMENT – Vous risquez de subir des

blessures graves, voire mortelles, si vous ne respectez

pas ces instructions.

!

ATTENTION

MISE EN GARDE – Risques ou manipulations dange-

reuses susceptibles d’entraîner des blessures et des dommages matériels / au produit.

REMARQUE

REMARQUE – Informations importantes visant à assurer

une installation et une utilisation sans problème.

État de la Californie – Avertissements de la Proposition 65 :

AVERTISSEMENT : Cet appareil contient un ou plusieurs

produits chimiques reconnus par l’État de la Californie comme

étant cancérigènes.

AVERTISSEMENT : Cet appareil contient un ou plusieurs

produits chimiques reconnus par l’État de la Californie

comme étant sources d’anomalies congénitales ou nuisibles

à la reproduction.

24

Page 25

DÉBALLAGE DE VOTRE APPAREIL

!

MISE EN GARDE

RISQUE DE POIDS EXCESSIF

Assurez-vous d’être au moins deux personnes

pour déplacer le produit. Le non-respect de cette

consigne peut entraîner des blessures.

Retirez l’emballage intérieur

Votre appareil a été emballé en veillant à ce que toutes

les pièces risquant d’être endommagées lors du transport

soient xées solidement. Retirez tous les matériaux d’emballage intérieurs et tous les rubans adhésifs qui maintiennent les

composants internes en place. Le manuel du propriétaire est

inclus à l’intérieur du produit, dans un sac de plastique avec la

carte d’enregistrement de garantie et les autres accessoires.

Important

Conservez la boîte et les matériaux d’emballage jusqu’à ce

que vous terminiez l’inspection minutieuse de votre appareil

pour vous assurer qu’il est en bon état. En cas de dommage,

l’emballage sera requis comme preuve d’endommagement

causé lors du transport. Veuillez ensuite mettre au rebut de

manière responsable tous les éléments d’emballage.

US

CA

(FR)

Un message à l’intention de nos clients

Nous vous remercions d’avoir choisi ce réfrigérateur d’extérieur DCS. Nous avons élaboré ce Guide d’installation,

d’utilisation et d’entretien dans le but d’expliquer les fonctions

uniques de cet appareil. Ce guide contient des informations

très utiles sur la façon adéquate d’installer, de faire fonctionner et d’effectuer l’entretien de votre nouvel appareil

an de pouvoir en proter en toute sécurité pendant de

nombreuses années.

Si vous avez des questions au sujet de ce produit, communiquez avec un représentant du service à la clientèle DCS

par téléphone :

1-888-936-7872, ou par courriel :

customer.care@sherpaykel.com

REMARQUE : Veuillez noter le numéro de modèle, le code

et le numéro de série sur cette page pour référence ultérieure

(la plaque signalétique se trouve sur la paroi interne, dans

la partie supérieure gauche).

NUMÉRO DE MODÈLE :

CODE :

NUMÉRO DE SÉRIE :

!

MISE EN GARDE

AVERTISSEMENT – Jetez les sacs de plastique

qui peuvent représenter un risque de suffocation.

Remarque à l’intention du client

Cette marchandise a été soigneusement emballée et

inspectée avant de quitter notre usine. Le détaillant assume

la responsabilité de la livraison au moment de l’acceptation

de la marchandise. Toute réclamation pour perte ou dommage

encouru lors du transport doit être présentée au détaillant.

REMARQUE

NE RENVOYEZ AUCUNE MARCHANDISE ENDOMMAGÉE AU FABRICANT – DÉPOSEZ VOTRE RÉCLAMATION

AUPRÈS DU DÉTAILLANT.

!

ATTENTION

REMARQUE : Inspectez le produit pour vous assurer

qu’aucun dommage n’a été causé lors de l’expédition. En cas

de dommage, communiquez avec l’expéditeur pour effectuer

une demande d’indemnisation. DCS par Fisher & Paykel n’est

pas responsable des dommages causés lors de l’expédition.

NE METTEZ PAS au rebut les matériaux d’emballage

(boîte, palette, sangles) avant d’avoir terminé l’inspection

de l’appareil.

!

MISE EN GARDE

AVERTISSEMENT – Aidez à prévenir

les accidents

Les risques d’emprisonnement et de suffocation

des enfants sont des problèmes toujours présents.

Les réfrigérateurs mis au rebut ou abandonnés sont

toujours dangereux, même s’ils sont laissés sans

surveillance pendant quelques heures seulement.

Si vous devez mettre au rebut votre ancien réfrigérateur,

veuillez suivre les instructions ci-dessous pour éviter

les accidents.

Si l’appareil a été expédié, déplacé ou entreposé dans une

position autre que verticale pendant une durée quelconque,

laissez l’appareil en position verticale pendant au moins

24 heures avant de le brancher. Cela permettra à l’huile

de retourner au compresseur. Le fait de brancher l’appareil

immédiatement pourrait endommager les pièces internes.

Avant de mettre au rebut votre ancien réfrigérateur

ou congélateur :

• Retirez les portes ou les tiroirs.

• Laissez les tablettes en place an d’éviter que

les enfants puissent facilement pénétrer à l’intérieur.

25

Page 26

US

CA

(FR)

INSTALLATION DE VOTRE APPAREIL

Sélection de l’emplacement

Un emplacement adéquat permet d’assurer le fonctionnement

optimal de votre appareil. Nous recommandons un emplacement éloigné des sources de chaleur, où l’appareil ne sera pas

exposé à un ensoleillement direct. Pour assurer le fonction-

nement de votre produit selon les spécications, la plage de

température recommandée à l’emplacement d’installation est

de 55 à 115 °F (13 à 46 °C).

Dégagement requis pour l’appareil

La partie avant inférieure de l’appareil nécessite une ventilation adéquate. Gardez cette zone ouverte et libre de toute

obstruction. Les armoires adjacentes et le comptoir peuvent

être installés autour de l’appareil, à condition que la grille frontale ne soit pas obstruée.

Pattes de

nivellement

avant

Figure 1

Grille frontale –

gardez cette

zone dégagée.

Pattes de

nivellement

arrière

!

ATTENTION

Grille frontale

N’obstruez pas la grille frontale. Les ouvertures de la grille

frontale permettent à l’air de circuler dans l’échangeur de

chaleur du condensateur. Toute obstruction de cette circulation d’air entraînerait une utilisation d’énergie accrue et une

perte de puissance du système de refroidissement. Pour cette

raison, il est important que cette zone ne soit pas obstruée

et que les ouvertures de la grille demeurent propres (voir

Figure 1). L’utilisation d’une grille fabriquée sur mesure n’est

pas recommandée, car cela pourrait limiter la circulation d’air.

Pattes de nivellement

Les pattes de nivellement dans les coins avant et arrière de

l’appareil doivent être réglées de manière à ce que l’appareil repose fermement au sol, en étant au niveau de droite à

gauche et d’avant en arrière. La hauteur hors tout de votre

appareil peut être ajustée entre la hauteur minimum, 333⁄4 po

(85,7 cm), en vissant la patte de nivellement (sens horaire ↷),

et la hauteur maximum, 343⁄4 po (88,3 cm) en dévissant

la patte de nivellement (sens antihoraire ↶).

Pour régler les pattes de nivellement, placez l’appareil sur une

surface solide et protégez le plancher pour éviter de causer

des égratignures sous les pattes. Avec l’aide d’une autre

personne, inclinez l’appareil vers l’arrière pour accéder aux

pattes de nivellement avant. Élevez ou abaissez les pattes à

la hauteur requise en les tournant. Répétez cette procédure à

l’arrière en inclinant l’appareil vers l’avant, en faisant preuve

de prudence. Sur une surface de niveau, vériez si l’appareil

est bien de niveau et ajustez-le si nécessaire.

Il est possible de desserrer les vis de la grille frontale an

d’ajuster cette dernière à la hauteur souhaitée. Une fois

l’ajustement terminé, serrez les deux vis de la grille frontale. (Voir Figure 2).

26

Grille frontale

Vis de grille frontale

Figure 2

Page 27

INSTALLATION DE VOTRE APPAREIL

US

CA

(FR)

Figure 3

Ne retirez pas

la broche de

mise à la terre

Figure 4

!

MISE EN GARDE

Risque de choc électrique

• N’utilisez aucune rallonge avec cet appareil. Cela

peut s’avérer dangereux et risque de compromettre

le fonctionnement du produit.

• Cet appareil ne doit en aucun cas être raccordé à une

alimentation électrique qui n’est pas mise à la terre.

• Ne retirez pas la broche de mise à la terre du cordon

d’alimentation. (Voir Figure 3).

• N’utilisez aucun adaptateur. (Voir Figure 4).

• N’éclaboussez ou n’arrosez pas l’appareil avec

un boyau. Cela pourrait causer un choc électrique

risquant d’entraîner des blessures graves ou mortelles.

Raccordement électrique

Un circuit dédié de 115 volts, 15 ampères avec mise à la terre

est requis.

Ce produit est équipé en usine d’un cordon d’alimenta-

tion muni d’une che à trois broches avec mise à la terre.

Cette che doit être branchée dans une prise avec mise

à la terre de type correspondant et conforme au Code

national de l’électricité, ainsi qu’aux codes et règlements

locaux en vigueur (voir Figure 5). Si le circuit ne comporte

pas de prise avec mise à la terre, le client a la responsabilité et l’obligation de faire installer une prise d’alimentation

adéquate. La broche de mise à la terre ne doit en aucun

cas être coupée ou retirée.

Figure 5

REMARQUE

Les disjoncteurs différentiels de fuite à la terre (DDFT)

sont sujets aux déclenchements indésirables entraînant

une mise en arrêt de l’appareil. Les DDFT ne sont généralement pas utilisés sur les circuits avec des équipements

devant fonctionner sans surveillance pendant de longues

périodes, à moins que cela ne soit nécessaire pour assurer la conformité aux codes de construction et règlements

locaux.

27

Page 28

US

CA

(FR)

INSTALLATION DU DISPOSITIF ANTIBASCULEMENT

POUR LES INSTALLATIONS NON ENCASTRÉES

!

MISE EN GARDE

• TOUS LES APPAREILS

PEUVENT BASCULER ET AINSI

CAUSER DES BLESSURES.

• INSTALLEZ LA PIÈCE DE

FIXATION ANTIBASCULEMENT

FOUNIE AVEC L’APPAREIL.

• SUIVEZ LES INSTRUCTIONS

CI-DESSOUS.

Pièce de xation

antibasculement

211⁄2 po

(54,6 cm)

Patte de nivellement

Vue de dessous

du distributeur

de bière

Devant de

l’appareil

Dispositif antibasculement

!

MISE EN GARDE

Si votre réfrigérateur n’est pas installé sous un comptoir

(non encastré), vous devez utiliser un dispositif antibasculement installé conformément à ces instructions. Si

le réfrigérateur est déplacé de son emplacement pour

une raison quelconque, assurez-vous que le dispositif

s’emboîte correctement avec la pièce de xation antibasculement lorsque vous réinstallez le réfrigérateur à

son emplacement initial. Si le dispositif n’est pas correctement emboîté, le réfrigérateur risque de basculer et

d’entraîner des dommages matériels ou des blessures.

REMARQUE

Lors de l’installation sur un plancher en béton, des xations

pour béton sont requises (non comprises avec l’ensemble

antibasculement).

Figure 6

Instructions étape par étape pour localiser

la position de la pièce de xation :

1) Choisissez l’endroit où vous souhaitez placer le distributeur

de bière. Glissez-le en place, en veillant à ne pas endommager le plancher et en laissant un dégagement de 1 po

(2,5 cm) à partir du mur arrière an de laisser de l’espace pour

la pièce de xation antibasculement.

2) Élevez les pattes de nivellement arrière d’environ

(6 mm) an de permettre l’emboîtement avec la pièce de xation antibasculement. Mettez l’appareil de niveau en réglant

toutes les pattes de nivellement, au besoin. Tournez la patte

de nivellement dans le sens des aiguilles d’une montre pour

abaisser l’appareil, ou dans le sens inverse pour l’élever.

3) Assurez-vous de placer le distributeur de bière à l’endroit

souhaité, puis marquez sur le plancher le coin correspondant aux parties arrière et latérale de l’appareil, à l’endroit où

la pièce de xation antibasculement sera installée. Si l’installation ne permet pas de marquer le coin arrière de l’appareil,

tracez des lignes temporaires sur le plancher pour marquer le

coin avant de l’appareil, en excluant la porte. Glissez le distributeur de bière hors de son emplacement. À partir de la ligne

temporaire, prolongez la ligne de paroi latérale de 211⁄2 po

(54,6 cm) vers l’arrière, comme illustré dans la

1

⁄4 po

Figure 6.

!

ATTENTION

Les revêtements de sol doivent être protégés à l’aide de matériaux appropriés pour éviter les dommages lors du déplacement de l’appareil.

Installation avec xation au plancher

La pièce de xation antibasculement doit être située sur

le plancher, dans le coin arrière gauche ou droit du distributeur

de bière, comme illustré dans la

Figure 6.

4) Alignez la pièce de xation antibasculement sur les marques

tracées sur le plancher, de manière à ce que le côté de la pièce

de xation soit aligné avec le côté de la marque de l’appareil et

que les encoches en « V » sur la pièce de xation antibascu-

lement soient alignées avec l’extrémité de la ligne de 211⁄2 po

(54,6 cm) (ligne correspondant à l’arrière de l’appareil).

5) Fixez la pièce de xation antibasculement au plancher en

utilisant la vis fournie. (Voir

6) Replacez l’appareil sur son emplacement, en vous assurant

que la patte de nivellement arrière glisse sous la pièce de

xation antibasculement qui s’emboîte dans la fente.

Figure 7).

28

Page 29

INSTALLATION DU DISPOSITIF ANTIBASCULEMENT

POUR LES INSTALLATIONS NON ENCASTRÉES

REMARQUE

Lorsque la pièce de xation antibasculement montée

au plancher est utilisée, la hauteur d’ajustement minimum

de l’appareil augmente de 3⁄8 po (9 mm).

US

CA

(FR)

Ligne du devant de l’appareil

211⁄2 po

(54,6 cm)

Figure 7

Ligne du côté de l’appareil

Ligne de l’arrière de l’appareil

Patte de

nivellement

arrière

Vis

Encoches en « V »

dans la pièce de xation

Figure 7a

Encoches

en « V »

dans la pièce

de xation

29

Page 30

US

CA

(FR)

DIMENSIONS DU PRODUIT

DIMENSIONS DE L’OUVERTURE DIMENSIONS DE L’APPAREIL

MODÈLE « A » « B » « C » « D » « E » « F » « G » « H » « J »

24 ¼ po (61,6 cm)

Tous

les modèles

24 ½ po (62 cm)

(avec ensemble de

garnitures latérales

DCS en option)

**34 po à 35 po

(86,4 à 88,9 cm)

*

237⁄8 po

(60,7 cm)

333⁄4 po à 343⁄4 po

(85,7 à 88,3 cm)

2323⁄32 po

(60,2 cm)

261⁄4 po

(66,7 cm)

4613⁄32 po

(117,9 cm)

261⁄4 po

(66,7 cm)

MODÈLE

Tous

les modèles

« C »

DONNÉES DU PRODUIT

ALIMENTATION

REQUISE***

115 V/60 Hz/15 A

« A »

« B »

POIDS DU

PRODUIT

140 lb

(63,6 kg)

« E »

1115⁄16 po

(30,3 cm)

121⁄4 po

(31,1 cm)

« D »

« J »

« E »

Figure 9

« H »

11 po

(27,9 cm)

211⁄2 po

(54,6 cm)

« F »

« G »

« D »

Figure 8

Figure 8a

S’il est nécessaire de gagner de l’espace à l’intérieur de

l’ouverture, vous pouvez découper un trou dans l’armoire

adjacente an d’y passer le cordon d’alimentation pour

l’acheminer à une prise de courant. Une autre façon

d’augmenter la profondeur d’ouverture disponible est

d’encastrer la prise de courant dans le mur arrière an

de récupérer l’épaisseur de la che du cordon d’alimen-

tation.

* La profondeur de l’ouverture peut varier selon chaque installation. Pour encastrer la totalité de la porte, la dimension « F »

avec 1 po (2,5 cm) supplémentaire est requise pour l’épais-

seur de la che du cordon d’alimentation.

** L’ouverture minimale requise doit être supérieure à

la hauteur ajustée de l’appareil.

*** Un circuit dédié de 15 ampères avec mise à la terre est

requis. Respectez tous les codes locaux du bâtiment lors

de l’installation du raccordement électrique et de l’appareil.

30

Page 31

UTILISATION DE VOTRE COMMANDE ÉLECTRONIQUE

Alarm

F

Figure 10

Gros plan de

la commande

Set

Press and Hold Press and Hold

Démarrage de votre distributeur de bière

Branchez le cordon d’alimentation du distributeur de bière dans

une prise de courant. Votre distributeur de bière commencera à

refroidir après sa mise sous tension.

Si votre distributeur de bière ne démarre pas, vériez s’il est mis en

marche et si la température réglée est sufsamment froide.

Colder Warmer

ON/OFF

US

CA

(FR)

Mise en MARCHE ou ARRÊT de votre distributeur de bière