Page 1

REV-021504

MODEL

MEGA ARM

TM

LISTED 4P92

½ HP COMMERCIAL DUTY PARKING GATE OPERATOR

(ALSO FOR TOWER & MEGA SPRINT)

UL-325 & UL-991 LISTED

INSTALLATION AND SERVICE MANUAL

IMPORTANT INSTALLATION INSTRUCTIONS-DO NOT DISCARD

(UL-325 5

(IMPORTANT: READ AND UNDERSTAND WARRANTY PAGE FIRST)

THIS MANUAL COVERS THE NEW INTER-LOCK MEMORY FEATURES

WARNING

FAILURE TO OBSERVE SAFE OPERATING PROCEDURE, TRAIN YOUR CUSTOMER PROPERLY OR INSTALL

! CHILDREN SHOULD NEVER BE ALLOWED TO PLAY NEAR OR OPERATE AUTOMATIC GATES.

PROPER WARNING SIGNAGE MAY RESULT IN SERIOUS INJURY.

th

EDITION)

DC SOLUTIONS, INC

590 SAWGRASS CORPORATE PARKWAY

SUNRISE, FLORIDA 33325

PHONE: 954-846-9488 FAX: 954-846-9464

MEGA-ARM, MEGA-PULSE, MEGA-SENSE, MEGA SPRINT, MEGA SLIDE-UL, MEGA SWING-UL ARE TRADEMARKS OF DC SOLUTIONS, INC.

www.DCSOLUTIONSINC.com

Page 2

TABLE OF CONTENTS

INTRODUCTION

UNIT OVERVIEW.......................................................................................................... 1

INSTALLATION PROCEDURE

CONCRETE PAD.......................................................................................................... 1

ANCHORS..................................................................................................................... 1

CONDUITS............................................................................................................ 2

DIMENSIONS................................................................................................................ 12, 14

WIRING AND HOOKUP

120 VOLTS AC.............................................................................................................. 2

INPUT COMMANDS 1-8 .............................................................................................. 2

ACCESSORY AND RELAY CONNECTIONS.............................................................. 3

BATTERY INSTALLATION........................................................................................... 3

MASTER / SLAVE WIRING...........................................................................................4

REVERSING ARM DIRECTION.................................................................................... 11

TIMERS AND MODE SELECTIONS S1 & S2

MODE SELECTIONS - S1............................................................................................ 5

MODE SELECTIONS - S2 ........................................................................................... 5

CLOSE TIMER SELECTION - S2................................................................................. 5

ADJUSTMENTS

INSTANT REVERSE DEVICE (IRD)............................................................................. 6

GATE ARM LEVELING................................................................................................. 6

TROUBLE SHOOTING AND MAINTENANCE PROCEDURES

BATTERY CHECK OUT................................................................................................ 7

GATE NOT OPERATING.............................................................................................. 7

GENERAL SERVICE..................................................................................................... 7

SHEAR PIN REPLACEMENT....................................................................................... 6

SAMPLE CONFIGURATIONS

FREE EXIT OPERATION.............................................................................................. 8

ENTRY WITH ACCESS CONTROL DEVICE................................................................8

DUAL DIRECTION........................................................................................................ 8

INTERLOCK MEGA ARMS OR WITH OTHER OPERATORS..................................... 14

CONTROL BOARD LAYOUT

INPUT LOCATIONS...................................................................................................... 9

MEGA-ARM PARTS LIST

PART NUMBERS AND DESCRIPTIONS...................................................................... 10

PARTS SHIPPED......................................................................................................... 10

Page 3

INTRODUCTION

UNIT OVERVIEW

The DC SOLUTIONS model MEGA-ARM barrier style parking gate operator is unique in the

industry. Setting the MEGA-ARM apart are many features that make it the front runner in its class.

With standard

• Built in battery backup - inherent 24 VDC backup power with regulated 24VDC for accessories.

• High torque 24 volt Permanent Magnet DC motor .

• Full service controller with eight inputs and LED indicators for loops, card reader, radio, etc...

• Continuous duty operation for all applications (6k per day, SPRINT version 10k per day).

• Reversible arm direction for right or left handed operation.

• Instant Reverse Device (IRD) monitor senses obstructions going open and close.

• Automatic open of gate arm when power is lost if desired (With 15 sec. delay selection).

• Raise gate input memory will memorize multiple vehicles-ideal for barcode scanners & AVI.

• Ability to have arm STOP in close travel if tail-gating

• Anti-tail gate alarm - fires K1 relay to trigger a warning device when tail-gating

• Interlock with memory- allows Mega Arm to open a slide/swing gate first then raises arm.

• Break away mounting design for the 12 -15 foot by 3 "tubular aluminum boom arm.

• All rust proof aluminum construction with white powder coat baked on enamel.

• Molded Polyethylene UV stabilized cover never needs wax or paint

• Direct drive gear reducer eliminates many parts that might otherwise fail.

• Microprocessor (RISC) based electronics with watch dog reset timer.

• State of the art MOSFET motor drive technology, NO contactors or relays.

• Dynamic motor braking to preserve arm positioning.

• Soft start and stop in open and close travel motions.

• No limit switches to fail-uses magnetic (Hall Effect) sensors to monitor arm position.

• Maximum Run Timer for motor (MRT) with anti-tamper protection in closing direction.

• Each unit configurable as master or slave operator.

• Safe 24 VDC low voltage motor and control wiring.

• Open architecture PCB with space for OVERDRIVE CPU for future expanded options.

• LED diagnostic center for easy on-site trouble shooting.

• Closing timer adjustable from 1-33 seconds with on / off selection.

• Tranzorb diodes on all inputs for protection against transient voltage spikes.

• Capable of being powered by 120 VAC, 220 VAC or Solar power, standard.

• Duplex outlet gives convenient supply of 120 VAC for transformers and 120 VAC accessories.

• 10 year perforation warranty on cover and chassis with 2 years on electronics and mechanism.

CONCRETE PAD

The concrete pad for operator mounting should be approximately 24"x24"x24" in order to provide adequate

weight and structure to insure proper and stable operation. Pad should be 6" above finished grade or even with

top of curb if one is present. (NOTE: PAD SHOULD ALWAYS GO BELOW FROST LINE

WHERE GROUND WILL FREEZE!!)

ANCHORS (MOUNTING UNIT)

Proper anchors for fastening operator to pad will be a 1/2"x6" wedge anchor patterned to match the mounting

base of the unit. They should be installed with approximately 1.25" showing above concrete surface in order to

allow for the 1/2” thick base plate as well as washers for leveling.

features like:

is sensed at close loop.

INSTALLATION PROCEDURE

is sensed.

IN REGIONS

PAGE 1

Page 4

NOTE 1: MAXIMUM AMBIENT TEMPERATURE FOR INSTALLATION, 104 F.

NOTE 2: FOR AUTOMOTIVE USE ONLY, NO MOTORCYCLES, BICYCLES OR PEDESTRIANS.

NOTE 3: HEATER OPTION MUST BE USED IF TEMP IS (15F) OR BELOW TEMPERATURES.

CONDUITS

Conduits should be restricted to fit the 3.5"x3.5" opening in pedestal base. Location on pad should be

centered and spaced approximately 6" from edge of pad on drive way side ( in order to get the most reach out

of arm ). Conduits to be included should be 120 VAC main power, low voltage control wiring and one or two

extra for loop sensor leads. Conduit size should be limited to .5" when possible to reduce crowding if more

than four are needed. All conduits must be U.L. approved.

WIRING AND HOOKUP (Only by a qualified electrician/installer!)

120 VAC

Be sure your main power (120vac) is OFF before attempting hookup. The 120 volts AC supply should be

terminated to the wires in top of the 4"x4" tube at the top of the chassis. Connect the 120 VAC to BLACK wire,

Neutral to the WHITE wire and Ground the GREEN wire. Warning- Do not connect any 120 VAC wires

directly to the terminal strips on the electronic control board. Only U.L. approved 14 AWG ( or larger)

600 volt insulated wire should be used. A separate UL approved 10 amp circuit breaker should be used for

each MEGA-ARM operator. BATTERIES MUST BE INSTALLED AFTER 120VAC POWER IS TURNED ON.

See BATTERY at page 3 and 120 VAC wiring on page 4.

INPUT COMMANDS

Control wire connections at low voltage terminal strip will be at the top of the electronic control board. Make

connections to the appropriate points for the desired operation. Wires should be U.L. approved 600 volt rated

and at least 18 awg. They are to be routed through the upper grommet in chassis to avoid chafing. All external

control devices must have normally open dry contacts. DO NOT CONNECT ANY DEVICE WHICH WOULD

DELIVER ANY VOLTAGE OF ANY KIND TO THESE TERMINALS.

Terminals 9, 10, 11, 12 are the commons (0 VDC) used to activate the following inputs.

1, 2, 3 OPEN- These inputs will trigger gate open when pulsed or hold gate open with maintained contact.

When released gate will close if closing timer is on or if close input is given.

4, AUXILIARY OPEN - Same as 1,2 and 3 with S2 switch 6 off. With S2 switch 6 on, this input will memorize

multiple vehicles and not allow gate to close until the final vehicle in memory crosses the close loop. Use with

laser scanners or card readers and (transmitters with timed anti-pass back). With S1 switch 5 on, this input

becomes a momentary pulse open, pulse close.

NOTE: Insert a jumper across the JP2 terminal to allow the interlock feature (see page 5 & 14) to work with the

multiple vehicle memory count selection, use the K1 relay to open the interlocked gate (S1-5 off, S2-6 on,

jumper across JP2). This allows gate to store input counts via J5 #4 but not raise the arm until the interlocked

slide or swing gate has fully opened.

5, SAFETY- This input is generally not used with the MEGA-ARM. If used its function is to make gate reverse

and go back to the open position if it was closing. Input is disabled when gate is closed.

6, CLOSE- When used with a vehicle detector, it is recommended that the presence contacts (N.O. & C.) be

used for the close input. This input will close gate after input is applied and then removed. It will stop the open

cycle and reverse gate to close. (Example: Car crosses over close loop before arm reaches full open positiongate will reverse and close). (Note: The close input also acts as a safety-stop in that if gate is closing and a

tailgater is sensed at the close input, the gate WILL STOP its closing motion and not continue to close until the

close input is removed or gate is re-opened).

PAGE 2

Page 5

INPUT COMMANDS (Continued)

7, BACK-AWAY (FREE EXIT INPUT) This input is used as a free exit input to open gate. When input

is active, gate will open and close immediately once input is removed. (EXAMPLE: Car pulls up to

exit loop, gate opens; car "backs-away" from exit loop and gate closes).

8, SHAD- INTERLOCK (REDEFINED INPUT!!!) Used to monitor an auxiliary open limit switch of

another operator in the same lane. Interlock with memory feature (v5.20 or higher) see page 13.

9, 10, 11,12- COMMON- These are the commons (0 VDC) to be used to activate above inputs.

Note: Above inputs are tied to LED indicators to show input command activity.

ACCESSORY CONNECTIONS

These terminals will provide battery backed power to 24 VDC devices and are located at the bottom

of the electronic control board at terminals 1 and 2. Terminal 1 is 24 VDC (+) and number 2 is 0 VDC

(-). Peripheral CLASS 2 low voltage devices that require 24 VDC power maybe connected here (500

ma. maximum). EXAMPLE: Vehicle detector, radio receiver.

RELAY OUTPUT K1- (OPTION)

S1-6 off, S1-8 off

S1-6 on S1-8 off, relay will fire when arm is pushed up off of limit switch (use with slip clutch option).

and fires relay when a tail-gate is detected by the close loop -ANTI TAIL-GATE ALARM

S1-6 off S1-8 on relay will pulse relay when arm reaches full open position.

S1-6 on S1-8 on relay will only pulse when input is given to J5 1,2,3 inputs. (see page 14).

, relay will fire (latch) when gate is not closed.

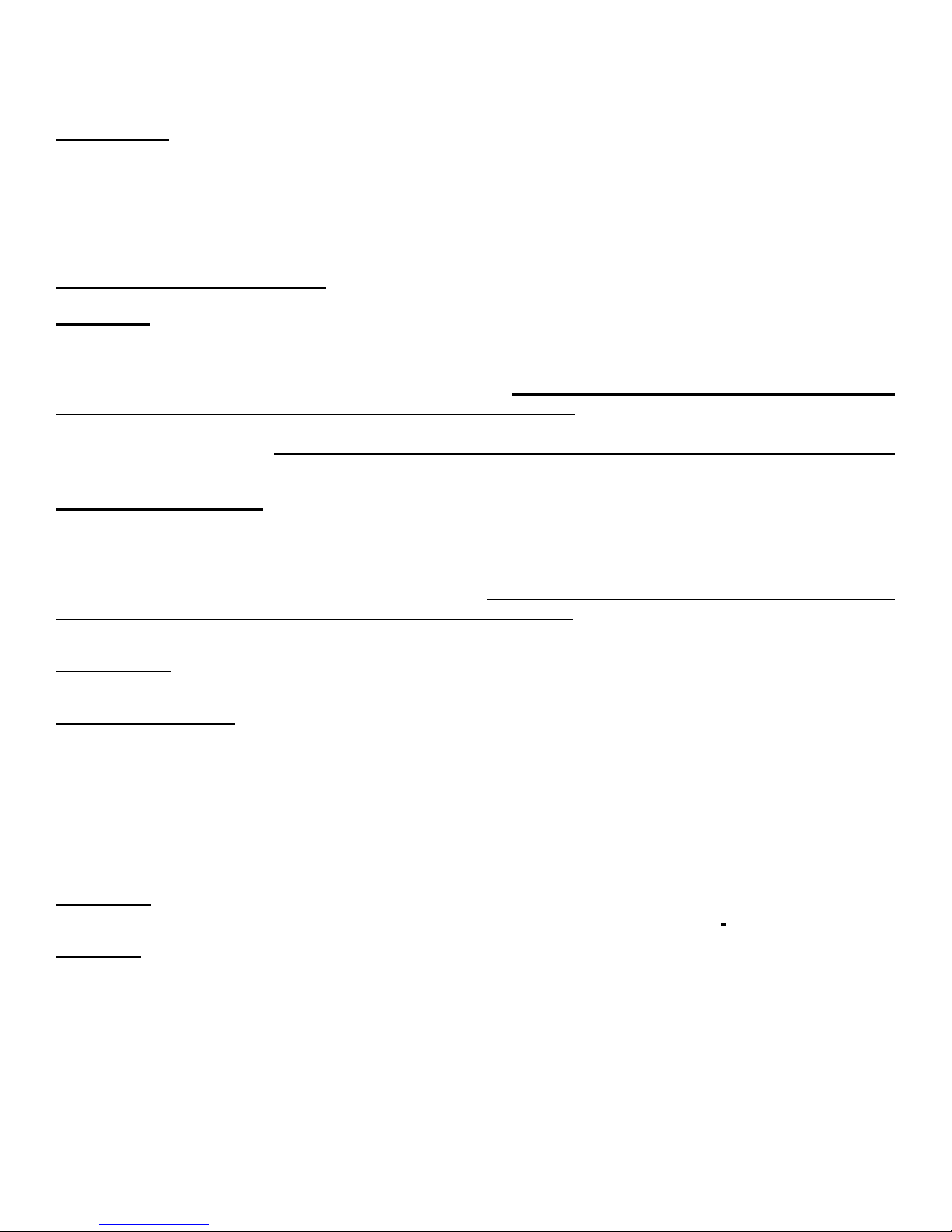

BATTERY INSTALLATION

HOOKING UP BATTERY LEADS- ALWAYS HOOKUP AND TURN ON AC POWER

BEFORE INSTALLING BATTERIES. After turning on AC power, install two new, fully charged 12

volt DC batteries on shelf next to motor. Connect red lead from operator to the positive (RED +)

terminal of one battery and black lead from the operator to the (BLACK-) terminal of the OTHER

battery. Place the supplied jumper between the remaining terminals of each battery if one is not

already in place. See diagram. (USE YUASA BRAND PN#NP7-12)

WARNING-DO NOT RUN OPERATOR WITHOUT INSTALLING THE BATTERIES

BLACK LEAD

-

12 VDC BATTERY

12 VDC BATTERY

Failure to install batteries correctly WILL cause damage and WILL not be covered by warranty.

+

JUMPER

-

RED LEAD

+

PAGE 3

Page 6

5

V

E

120 VAC POWER CONNECTION

120 VAC (BLACK)

GROUND

(GREEN)

NEUTRAL

(WHITE)

TOP END OF

4"x4" TUBE

120 VAC CONNECTIONS ARE TO BE MADE

IN TOP OF 4"x4" TUBE (POST). ONLY

USE UL-LISTED 600 V WIRE INSIDE TUBE.

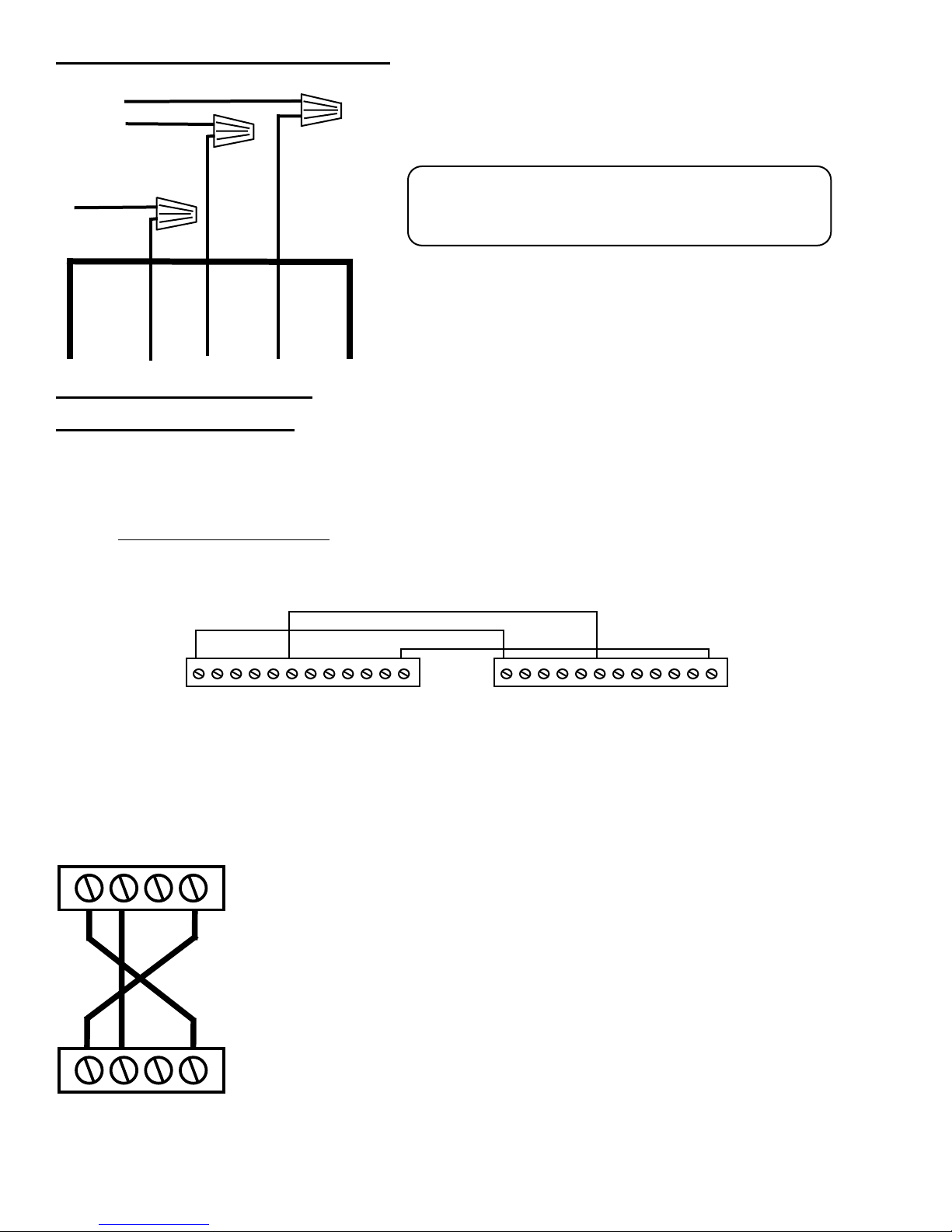

MASTER SLAVE WIRING

Master-slave wire hook up.

STEP 1- In a master/slave configuration, either unit can be the master. Choose one unit to be the master and

then direct all control wiring to it (also install vehicle detector and receivers in it).

STEP 2- At the MASTER, any input (at J5) with control (detectors, receivers, keypads, timers, etc...) wires to it

must also be run to the same terminals of the slave. Along with these control wires, both operators MUST

share a common ground connection

terminal #12 to slave gate J5 terminal #12)

EXAMPLE: If only open and close are used at master then three wires will run between gates.

OPEN

from chassis to chassis (or from common to common , i.e. master gate J5

CLOSE

COMMON

EXAMPLE:

1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12

MASTER- J5 SLAVE-J

STEP 3- If it is required that if one gate senses an obstruction, the other reverses also, then 3 additional wires

must be run between the master J3 and slave J3 as shown below. These connections are for transmitting IRD

(obstruction signals) between both units. This will allow the master or slave to inform the other that a closing

obstruction has occurred and for it to also reverse and open. SET switches on S2, 1-8 the same on both gates

RX GND TX

1 2 3 4

MASTER - J3

IRD - OBSTRUCTION SIGNAL CONNECTIONS

TERMINAL 1 OF MASTER MUST

GO TO TERMINAL 4 OF SLAVE AND TERMINAL 1 OF SLA

GO TO TERMINAL 4 OF MASTER. TERMINAL 2 OF MAST

GO TO TERMINAL 2 OF SLAVE.

1 2 3 4

SLAVE - J3

RX GND TX

Page 4

Page 7

TIMERS AND MODE SECTIONS-(S1 and S2)

FULL SPEED RUN TIMER- SWITCH PACK S1 (1-4) With all switches off the default is

approximately 1.5 seconds. Changing settings will adjust fast run timer by 1/8 second increments.

(Example: #2 on equals .25 seconds, #4 on equals 1 second. #2 and #4 on equals 1.25 seconds)

1/8ths SECONDS 1 2 4 8

S1

1 2 3 4 5 6 7 8

SHOWS DEFAULT SETTINGS

FAST RUN TIMER 1-4 | MODE SELECTION 5-8

MODE SELECTIONS- SWITCH PACK S1 (5-8)

SWITCH - 5. ON -Will allow J5 input #4 to operate as a pulse open/pulse close function.

SWITCH - 6

. ON -Will fire relay if gate is pushed UP from closed limit, used with clutch option. Also

ANTI TAIL-GATE ALARM, if tail gating is detected by close loop, K1 relay will fire. When using clutch

option, turning on S1-6 & S2-7, gate will close by timer whenever forced up.

SWITCH - 7. USED TO ENABLE ARM TO WORK IN REVERSE DIRECTION, SEE PAGE 11.

SWITCH - 8.Off will make K1 relay activate during open cycle (use with buzzers, counters, etc..) On

will pulse K1 relay when OPEN LIMIT (OLS) is reached (activates a swing or slide gate its lane).

(SEE ALSO PAGE 3 -

RELAY OUTPUT-K1.

CLOSE TIMER- SWITCH PACK S2 (1-5)

On the MEGA-ARM the switches 1-5 on S2 are for the closing time delay to select the period of time

that the gate stays open after the obstruction sensor has reversed and re-opened the arm or if the

S2-7 timer to close is turned on. The default will keep the gate up for 4 seconds to allow the vehicle

to be moved from the gate arm path. Changing settings 1 - 5 will increase or decrease this hold open

time. The default of

SECONDS-------- 1 2 4 8 16

3 ON and 1,2,4,5 OFF will provide a 4 second close time delay .

S2

1 2 3 4 5 6 7 8

CLOSE TIMER 1-5 | MODE SELECTION 6-8

MODE SELECTIONS- SWITCH PACK S2 (6-8)

SWITCH - 6. INPUT MEMORY. Activates multiple vehicle memory at aux input terminal #4 on J5.

SWITCH - 7 AUTO CLOSE TIMER. Default is OFF. On will close gate by timer when all inputs are

cleared. Time is set by using S2 1-5 switches (WARNING-Special care should be used to avoid arm

from closing on cars. Use safety loops, stop loops, photo beams and a long enough time delay)

(Note: Can be used with multiple vehicle memory buffer to allow gate to close and reset count

memory to zero. When using clutch option, turning on S1-6 & S2-7, gate will close by timer whenever

forced up.

SWITCH - 8 AUTO OPEN ON POWER FAILURE. When switch number 8 is in the ON position, the

operator will automatically open the gate approximately 15 seconds after the loss of power. Once

power is restored the operator will resume normal operation after the first car passes closing loop or if

close timer S2-7 in turned on (It is recommended to allow the gate to close by loop, not by timer).

SHOWS DEFAULT SETTINGS

PAGE 5

Page 8

ADJUSTMENTS

INSTANT REVERSE DEVICE (IRD)

The reverse device is an internal circuit that continuously monitors the motors current for increased

draw. Turning the IRD1 right (CW more sensitive), or left (CCW less sensitive) in small increments

will allow sensitivity adjustments (IF ARM DOES NOT REVERSE, DO NOT CONTINUE TO FORCE).

The obstruction that you apply should STOP the arm. Adjust sensitivity so that consistent reversal

occurs . If the gate stops while opening then the

way may be needed in order that the gate only reverses when obstructed. If gate is obstructed while

closing, gate will reverse to the open position, time out (using the time delay set at S-2 switches 1-5)

and then close. If gate is opening when obstructed, gate will stop its open travel, then will time out

and close using the same delay set at S-2. If S-2 switch number 8 is off (you have programmed the

unit to

NOT AUTO RAISE when power fails) then recheck your adjustments with AC power off to be

sure proper operation will be maintained.

NOTE- INSTANT REVERSE DEVICE (IRD) SHOULD BE TESTED MONTHLY TO INSURE

PROPER OPERATION. IF ADJUSTMENTS ARE REQUIRED, REFER TO ABOVE PARAGRAPH.

ADJUSTMENTS TO BE DONE BY QUALIFIED SERVICE PERSONS ONLY.

GATE ARM INSTALLATION AND LEVELING

Install arm in gate arm bracket by lining up holes in arm with the slotted holes in bracket. Insert the

bolts through the arm and through the bracket. Next install the flat washers then the nylon nuts. (It is

recommended the only nylon nuts be used to attach arms). The magnetic limit cam is pre-adjusted

for near proper arm travel, however if leveling of the arm is required this can be done through

adjustment to the magnetic cam arm. Note that during these adjustments the arm only travels

approximately 85 to 89 degrees for its full motion. Always adjust for a level arm in the

POSITION. There is a small set screw in the side of the cam arm which can be loosened to allow the

cam arm magnet to reach the close limit sensor (located on back of controller, H2) earlier or later in

its travel. Continue to open and close the gate while adjusting until a satisfactory horizontal stopping

point can be maintained. Afterwards re-secure set screw in cam arm. (Note: In some cases additional

adjustments may be required after the belt wears in). When stopping in the open position, the arm will

stop just before the full vertical position.

NOTICE: TO PREVENT ENTRAPMENT, ALLOW FOR TWO (2) FEET MINIMUM CLEARANCE

PAST END OF ARM WHEN IN DOWN POSITION.

SHEAR PIN REPLACEMENT

If

gate arm is vandalized and the tapered pin in the output shaft has been sheared, it must be

replaced correctly and with the right pin type. Replacement must be done by always punching out the

pin (or pieces) from the small end only. If drilling is required, DO NOT DAMAGE THE SHAFT, use a

drill bit smaller than the small hole size of the pin. (Correct pin is a 2" pin with a number 6 taper only)

NEVER USE A BOLT AS A TEMPORARY FIX, THIS WILL DAMAGE THE SHAFT AND COLLAR

1) Use S-3 to rotate bracket to up position 6) Lightly oil the new pin then insert into collar

2) Turn off AC power and disconnect batteries small end first.

3) Remove gate arm bracket and pieces in collar 7) Fully seat pin in shaft by taping on large end

4) Drive out pin pieces with hammer and punch 8) Reinstall the arm if required

(Solid sharp blows are better than light ones)

5) Reinstall gate arm bracket 10) Turn off S-3 to put gate into operation

IRD is TOO sensitive. Some slight adjustment either

HORIZONTAL

9) Turn on AC power and connect batteries

PAGE 6

Page 9

TROUBLE SHOOTING AND MAINTENANCE PROCEDURES

WARNING - DISCONNECT BATTERIES AND AC POWER BEFORE

BATTERY CHECKOUT- . When the batteries become weak the gate will begin to run noticeably

slower. (Note: Batteries should only be checked when you are sure they have had adequate time to

fully charge). Turn off the AC power and run gate for 5 to 10 cycles while observing low battery

indicator LED D12. If LED 12 comes ON, batteries are too weak to function properly. If LED 12 does

not light, then voltage should be checked as they still maybe near failure. Correct voltage is

approximately 24.5VDC. (Note: If LED D12 does light, gate will open to conserve batteries in this test

or in a real power loss, even if mode switch 8 on S2 is off). Return of AC power will clear low battery

indicator. Correct charge voltage is 27.5 VDC with batteries not connected (adjustment is at R63).

GATE WILL NOT CLOSE

1)

Check for any active inputs, AC power loss, AC power switch is off or weak batteries.

2) Check that batteries are connected properly.

3) Is switch S-3 in on position (this is manual open switch).

4) Check for S-2 switch number 8 is in on position and if AC power is lost, see LED D14.

5) Check LED D12, if lit and AC power is off, then batteries needs to be charged or replaced.

GATE WILL NOT OPEN

1) Check for AC power loss at D14 (check AC power switch) and that batteries are fully charged.

2) Check fuses and if inputs are wired correctly, test S-3 manual open switch.

GATE DEAD, NO OPERATION

1) Check LED D14 for AC power indication and check AC power switch is on.

2) Check LED D11 for Heart Beat pulses, if none and D14 (AC) & D5 (Brake) are on, then gate

has repeatedly sensed obstructions. Clear obstruction then clear with next new input.

3) IRD (D2) LED is flashing, MRT has expired. H1, H2 (Hall sensors) and clearance to magnet

on cam

(MRT is

Reset the AC and battery power to clear this once you have rectified the problem.

FUSE(S) ARE BLOWN, F-3 (10 AMP AC) AND / OR F-4 (15 AMP DC)

Check for shorts in wiring. If F-3 AC fuse is blown then batteries may also be weak or dead.

1)

GATE CLOSES THEN REVERSES

1) See page 6 for IRD adjustments also check for obstacles in gate travel, trees etc......

2) Charge voltage to batteries too low, adjust at R63. With batteries disconnected set to 27.5.

IRD OBSTRUCTION SIGNAL TO OTHER GATE NOT WORKING CORRECTLY

1) Remove connector at J3, obstruct arm, LED D13 should go off for a few seconds. This indicates

signal was transmitted. Be sure gates share a common ground (See master slave pg. 4)

GENERAL SERVICE

1) Belt loose or needs replacement, adjust with 4 bolts that support motor to allow 1/4 inch play.

2) Charge voltage for batteries should be 27.5 VDC with batteries disconnected. (set at R63)

3) Replace batteries with Yuasa, pn# NP7-12, 7 amp hour 12vdc sealed lead / acid type.

SERVICING ANY MECHANICAL OR MOVING COMPONENTS!!!!

MUST be check for intermittent activation, failure to rectify may result in malfunctions.

Maximum Run Timer that disables the gate if the magnet does not reach H1or H2).

"Warning- For Continued Protection Against Fire,

Replace Only With The Same Type And Rating Of Fuse".

PAGE 7

Page 10

SAMPLE CONFIGURATIONS

FREE EXIT ON VEHICLE APPROACH:

CLOSE

LOOP

BACK AWAY

LOOP

(FREE EXIT)

GATE WILL OPEN WHEN SENSED BY

EXIT LOOP AND THEN CLOSE ONCE

THE CLOSE LOOP IS CLEARED. IF THE

VEHICLE PULLS UP TO THE EXIT LOOP

AND THEN BACKS AWAY IT WILL CLOSE.

(SPACE BETWEEN LOOPS WILL BE 4' TO 10')

MEGA-ARM

ENTRY WITH ACCESS CONTROL DEVICE:

CLOSE

LOOP

CARD READER

TELE-ENTRY

RADIO CONTROL

MEGA-ARM

DUAL DIRECTION AS ENTRY OR FREE EXIT:

TERMINAL # 7 IS BACKAWAY (FREE EXIT).

TERMINAL # 6 IS CLOSE INPUT.

GATE WILL OPEN WHEN ACTIVATED BY AN

ACCESS CONTOL DEVICE. WHEN VEHICLE

PASSES AND CLEARS CLOSE LOOP, GATE

WILL CLOSE.

NOTE: IF A SECOND VEHICLE TAIL-GATES

AND IS SENSED AT THE CLOSE LOOP, GATE

WILL STOP ITS CLOSING MOTION UNTIL

LOOP IS CLEARED AGAIN.

TERMINAL # 6 IS CLOSE INPUT.

TERMINAL # 1,2,3 ARE OPEN INPUTS.

BACK AWAY

LOOP

CLOSE

LOOP

(FREE EXIT)

MEGA-ARM

CARD READER

TELE-ENTRY

RADIO CONTROL

RECOMMENDATION 1: If vehicle detectors are used to open or close the gate, use of the presence contacts are

recommended. Using the pulse contacts will REDUCE the gates safe operation.

RECOMMENDATION 2: If closing timer is to be used, use ONLY on a dedicated free exit.

RECOMMENDATION 3: Close loop must be centered under gate arm.

DUAL DIRECTION IS A COMBONATION OF

BOTH OF THE ABOVE CONFIGURATIONS

TO PROVIDE THE ABILITY FOR TRAFFIC

TO ENTER OR EXIT IN THE SAME LANE.

(SPACE BETWEEN LOOPS WILL BE 4' TO 10')

PAGE 8

Page 11

CONTROL BOARD LAYOUT

BOARD REV 2.0 (2/98)

OPEN GATE INPUTS-READER, PUSH BUTTON

AUX OPEN INPUT-WITH MEMORY BUFFER

SAFETY INPUT

CLOSE GATE INPUT-CLOSE LOOP

BACK AWAY-FREE EXIT LOOP

INTERLOCK MEMORY

COMMONS - 0VDC

(EXTERNAL LIMIT INPUTS)

MASTER/SLAVE

S3-MANUAL

OPEN

J5

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8

U5

CPU

IRD1

AC OK

_

F1

1 AMP-DC

F4

F3

_

+

BLK RED YEL YEL BLU ORG

15 AMPS

10 AMP

R63

BATTERY CHARGE

Q6

Q5

MOSFETS

Q4

Q3

HEAT SINK

MODE 5-8

FAST RUN 1-4

CLOSE TIMER 1-5

MODE 6-8

OPEN LIMIT SENSOR

OPEN DRIVERS ON

MOTOR BRAKE ON

CLOSE DRIVERS ON

CLOSE LIMIT SENSOR

OBSTRUCTION SENSE

(IRD AND MRT)

RELAY INDICATOR

RELAY (OPTIONAL)

TX

J2 J3

S 1

D7

D6

D5

D4

D3

D2

D1

K-1

J1

U3

OVER

DRIVE

CPU

BATTERY LOW

H BEAT

D13

S 2

I/O INTERFACE PORT

D11 D12 D14

ACC. POWER BATTERY AC XFMR MOTOR

+

K-1 RELAY

TERMINALS

1-C, 2-NC, 3-NO, 4-24VDC+ {REGULATED}

24VDC

{REQULATED}

ACCESSORY POWER IS 24VDC REGULATED RATED AT 500 ma. [1/2 AMP]

{POWER AT ACCESSORY+ AND AT RELAY PIN-4+ IS FUSED AT F1 WITH A 1 AMP FAST-BLO FUSE}

NOTE: J5 #8 IS NOW THE INTERLOCK WITH MEMORY INPUT (SEE PAGE 13)

D11- HEART BEAT- SHOWS THAT PROCESSOR AND PROGRAM ROUTINE ARE RUNNING PROPERLY

D12- BATTERY STATUS- SEE DIAGNOSTIC PROCEDURES

D14- AC POWER INDICATOR- SHOWS THAT AC POWER IS PRESENT

S3- MANUAL OPEN- TO ALLOW GATE TO BE OPENED OR CLOSED DURING SERVICE OF UNIT.

F1- 1 AMP FAST BLO FUSE (5mmX20mm). MAXIMUM CONTINUOUS DRAW IS 1/2 AMP. (U.L. FUSE ONLY)

F3- 10 AMP ATO TYPE FUSE FOR 24VAC INPUT POWER. (U.L. LISTED FUSE ONLY)

F4- 15 AMP ATO TYPE FUSE FOR 24VDC BATTERY INPUT POWER. (U.L. LISTED FUSE ONLY)

PAGE 9

Page 12

MEGA-ARM PARTS LIST

10

13

5

12

11

2021

2

18

1

8

7

9

18

19

15

3

14

4

6

16

ITEM PN DESCRIPTION

1 MA-001 CONTROLLER-CPU

2 MA-002 REMOVABLE CONNECTOR

3 MA-003 DC MOTOR - 24 VDC

4 MA-004 12VDC 7AH BATTERY-2 REQUIRED (NOT INCLUDED)

5 MA-005 GEAR REDUCER 60:1

6 MA-006 ALUMINUM CHASSIS

7 MA-007 DRIVE BELT

8 MA-008 REDUCER PULLEY

9 MA-009 MOTOR PULLEY

10 MA-010 GATE ARM BRACKET

11 MA-011 MAGNET

12 MA-012 CAM ARM

13 MA-013 SHEAR PIN

14 MA-014 BOLT & NUT (4) MOTOR

15 MA-015 TRANSFORMER (110 / 220 VAC-24VAC)

16 MA-016 MAIN POWER CONNECTION BOX

17 MA-017 BOLT & NUT (4) REDUCER

18 MA-018 GROMMET (2)

19 MA-019 117 VAC ON-OFF SWITCH

* MA-020 UNIT COVER

* MA-021 NYLON ARM NUTS (2)

* MA-022 ARM BOLTS (2)

* MA-023 GATE ARM-12 FT

20 MA-036 COLLAR

21 MA-037 NYLON WASHER ( * ) PARTS NOT SHOWN

PARTS SHIPPED

1 MEGA-ARM OPERATOR

1 CONTROLLER CPU

1 UNIT COVER

1 INSTALLATION AND SERVICE MANUAL

2 ARM BOLTS WITH WASHERS

10 NYLON NUTS

UNIT ALSO REQUIRES (2) SEALED 12 VDC 7 AMP HR BATTERIES- NOT INCLUDED

17

PAGE 10

Page 13

REVERSING ARM DIRECTION

THE MEGA ARM ALLOWS FOR THE "HANDING" OR REVERSING OF THE ARMS DIRECTION OF MOVEMENT

IN RELATION TO THE UNITS NORMAL OPERATION. THIS ALLOWS FOR MOUNTING IN TIGHT PLACES OR WHEN

IT IS DESIRED TO HAVE THE ARM , WHEN ACROSS THE DRIVE WAY, TO BE IN FRONT OF THE UNIT OR BEHIND

THE UNIT WHEN VIEWED FROM THE TRAFFIC FLOW DIRECTION.

WARNING- POWER MUST BE OFF AND NO ARM INSTALLED BEFORE MAKING THESE CHANGES

STEP 1) ONLY UNITS WITH SOFTWARE VERSIONS v4.14 OR HIGHER HAVE THIS CAPABILITY.

BEFORE POWER UP SWITCH BANK S1 SWITCH #7 MUST BE ON.

STEP 2) NEXT THE MOTOR WIRES ON THE CONTROL BOARD MUST BE REVERSED. AT J4 ON THE BOTTOM

OF PCB, THE LAST 2 WIRES ON THE RIGHT (J4-7, J4-8) NORMALLY ARE BLUE THEN ORANGE. THEY

MUST BE REVERSE TO BE (J4-7) ORANGE

STEP 3) AFTER COMPLETING THE STEPS ABOVE, THE CAM ARM WHICH ADJUSTS THE LIMITING POINTS OF

THE ARMS TRAVEL MUST BE TURNED 90 DEGREES TO THE LEFT WHEN VIEWED WHILE STANDING

IN FRONT OF THE CONTROL BOARD (CAM ARM NOW POINTS IN THE DIRECTION OF THE ARM AND

IS LEVEL WITH MOUNT BRACKET, NOTE THE SMALL LIMIT SENSORS ON THE BACK OF THE PCB).

STEP 4) NOW CHECK TO MAKE SURE THAT S1 #7 IS ON, MOTOR WIRES ARE REVERSED, THE CAM IS

ADJUSTED AND THAT THE MANUAL OPEN CLOSE SWITCH (S3) IS SET TO CLOSE

THE AC POWER AND CONNECT THE BATTERIES. NOW RUN THE GATE OPEN AND CLOSE WITH THE

S3 MANUAL SWITCH MAKING SURE THAT THE MECHANISM TRAVELS IN THE PROPER 90 DEGREES

DESIRED. ONCE YOU ARE TOTALLY SURE YOU HAVE THE CORRECT OPERATION YOU CAN

INSTALL THE ARM.

INSTALLATION NOTE: ARMS LONGER THAN 12 FEET MUST USE THE PROPER COUNTER WEIGHT

THEN (J4-8) BLUE.

. NEXT TURN ON

ARM SHOWN IN REVERSED DIRECTION

BATTERY

ACC+ ACC- BLACK RED

7

S1

XFMR MOTOR

YELLOW

CAM ARM

OUT PUT SHAFT OF GEAR BOX

BLUE

ORANGE

S1, #7 TO BE TURNED ON BEFORE POWER UP

TO ENABLE REVERSE OF ARM

PAGE 11

Page 14

ADDENDUM 1

UNIT DIMENSIONS (MEASURMENTS ARE IN INCHES)

20.25

15.75

17.5

5.

9.0

4.

41.5

20.25

21.5

PAD (24x24)

13.5

8.0

3.5

34.75

41.5

36.5

CENTER LINE

THESE DIMENSIONS WILL CENTER

THE OPERATOR ON THE PAD

12.0

12.0

8.0

INSIDE POST

9.0

5.5

3.5

3.5

5.5

6.0

2.0

8.0

3.25

FOOT PRINT OF BASE ON PAD

PAGE 12

Page 15

ADDENDUM 2 (TOWER CABINET DIAGRAM)

UNIT DIMENSIONS (MEASURMENTS ARE IN INCHES)

14.20

PAD (24x24X24)

GATE ARM BRACKET

7.125 7.125

42.0

13.50

24.0

13.50

SIDE VIEW

3.5

42.0

36.5

3.50

10.25

OPEN AREA IN BASE

9.90

8.25

FOR CONDUIT

13.50

24.0

12.20

DOOR

14.20

FOOT PRINT OF BASE ON PAD

PAGE 13

Page 16

INTERLOCK WITH MEMORY FEATURE

INTERLOCK WITH OTHER OPERATORS: (REQUIRES THE K1 RELAY OPTION)

VERSIONS 5.20 OR GREATER NOW HAVE THE ABILITY TO ALLOW THE MEGA-ARM TO MONITOR FOR THE FULL OPEN

POSITION OF A SLIDE, SWING, VERTICAL PIVOT, ROLL UP OR OVERHEAD OPERATOR AS WELL AS THE DOWN POSITION

OF MOTORIZED TRAFFIC TEETH (MTC-31) AND RAISE THE ARM ONCE FULLY OPEN.

This new feature will allow a logical interface between the MEGA ARM barrier gate and a swing, slide, etc... gate operator (or MTC-31).

All that is required is 4 wires between the Mega Arm barrier gate and the other operator. It will be necessary to have one set of

dedicated/isolated dry contacts-{C. & N.C.} COMMON & NORMALLY CLOSED be available at the other operators OPEN LIMIT

SWITCH. Most units will require that this EXTRA limit switch be added to their open limit switch assembly.

OPERATION

the other operator causing it to open, however, the MEGA ARM's boom will not raise yet. When the other operator reaches its full open

limit switch, this will open the COMMON & NORMALLY CLOSED contact on the EXTRA open limit switch. This will allow the original

signal from your access control device (that was stored in memory) to now raise the gate arm. As long as the other operator is in the full

open position, any additional open pulse sent will in turn energize the MEGA ARM's K1 relay to send another open signal to the other

operator as well as cause the arm to raise again if it has closed via a car crossing the MEGA ARM's close loop.

WIRING: Run 2 wires from the other operators isolated common & normally closed contacts of its open limit switch to the MEGA

ARM J5#8 and one of the commons J5 , #9-12. Next run 2 wires from the MEGA ARMs K1 relay (common & normally open) to the

other operators common and open input. (WARNING: max of 30 VOLTS @ .5 AMPS THROUGH RELAY). J5 #8 was the unused

SHADOW LOOP input on the MEGA ARM. Note: A separate open device (24 hour timer, toggle switch) can be run to the other operator

to control it without raising the gate arm. Tampering with the other operators safety loops, safety edges and reverse sensors WILL NOT

cause the arm to raise if one tripped. The arm will only raise if an intended open signal was sent to the MEGA ARM.

NOTE: FOR MOTORIZED TEETH, VERTICAL PIVOT OR OVERHEAD OPERATOR, LEAVE S1-6, S1-8 OFF (THIS WILL KEEP THE

K1 RELAY LATCHED

LOCKED OPEN

SENSES AN IMPACT, THE K1 RELAY WILL STAY ENERGIZED HOLDING OPEN

UNTIL THE ARM TIMES OUT AND CLOSES.

: A one second pulse from access control device to the MEGA ARM will energize its K1 relay sending an open signal to

UNTIL THE ARM REACHES THE DOWN POSITION. THIS WILL KEEP THE OTHER GATE OPERATOR

OR TEETH LOCKED DOWN UNTIL THE ARM CLOSES COMPLETELY). NOTE: IN THIS MODE IF THE ARM

(OR TEETH DOWN) THE OTHER OPERATOR

MEGA ARM

OTHER OPERATOR

(slide/swing/teeth/etc...)

K1 RELAY

C

OPEN INPUT

N.O.

C

NC

ACCESS

DEVICE

J5 #11

J5 #8

EXTRA OPEN LIMIT

J5 #1

SWITCH

J5 #12

S1, 6 &8 (ON) = K1 RELAY PULSE

ONLY. S1, 6 & 8 (OFF) = K1 RELAY LATCH ONLY.

INTER-LOCK TWO MEGA ARMS WITH "MEMORY": REQUIRES THE K1 RELAY OPTION

NOTE: (5.20 or greater) can be used when you have two entry gates that you want to INTER-LOCK with each other. This is when you

can only have ONE

priority, while if the other gets an open signal, it will be HELD IN MEMORY

gate has a telephone entry unit or access device (AVI ,prox , etc...). Connect the K1 relay C & N.O. of each gate to the SHADOW

LOOP J5 #8 input & common of the other . (Leave S1-6 & 8 OFF to allow relay to stay latched).

VISITOR LANE

TELE-ENTRY

gate raised at a time (bottle neck or gates at a cross street). In this case, which ever one raises first will get first

, then raise once the first gate closes. This will work if either

MEGA ARM

K1 RELAY

C.

N.O.

J5 #1

J5 #9

J5 #11

J5 #8

MEGA ARM

J5 #11

J5 #8

J5 #1

J5 #9

C.

RESIDENT LANE

READER, ETC.

K1 RELAY

N.O.

PAGE 14

Page 17

(You must

read, understand and agree with all items in the limited warranty)

LIMITED WARRANTY

DC SOLUTIONS, INC. Warrants the MEGA ARM-UL to be free of defects in workmanship and materials for

a period of 2 years for electronics & mechanical components and includes a 10 year corrosion perforation

warranty on the cover and chassis. Warranty will begin from the date of purchase.

DC Solutions, inc. reserves the right of final determination as to the existence and causes of any defect or

failure. Any part or parts found to be defective and are returned to DC Solutions within the warranty period,

shall at our option be repaired or replaced free of charge F.O.B. the factory. Freight is not included at any time

on gate arms & chassis. ONLY UPS ground freight is included during the first year of warranty.

The warranty will not apply the following circumstances which are considered beyond our control.

Mis-use, vandalism, accident, neglect, unauthorized repairs or modifications, acts of God (lightning, floods,

insect damage, etc...), power surges, units subjected to corrosive environments, incorrect installation or

application, the batteries or incorrect battery installation, operation without or failure to use correct battery type,

damage to arm bracket and / or gear reducer due to use of incorrect arm.

The warranty set forth above is entirely exclusive and no other warranty whether written or oral, is expressed

or implied. DC Solutions, inc. specifically disclaims any and all implied warranties, merchantability or fitness for

a particular purpose. It is the purchasers sole and exclusive responsibility to determine whether or not the

equipment will be suitable for a particular purpose. In no event shall DC Solutions, inc. be held liable for direct,

indirect, incidental, special, consequential damages or loss of profits whether based on contract, tort, or any

other legal theory during the course of the warranty or at any time there after. The installer and/or end user

agree to assume all

liability.

MEGA ARM NOT FOR USE WITH MOTOR CYCLES, BICYCLES OR PEDESTRIANS.

YOU MUST

IN ORDER TO INSTALL AND USE THE MEGA ARM, YOU MUST UNDERSTAND AND BE IN FULL UNCONDITIONAL AGREEMENT

WITH ALL

IF OPERATOR IS

AGREEMENT WITH ALL OF THE ABOVE STIPULATIONS.

NEVER

STIPULATIONS OUTLINED ABOVE. IF YOU ARE NOT IN FULL AGREEMENT, DO NOT PUT UNIT INTO OPERATION.

Materials, components, features and specifications are subject to change without notice.

________________________________________________________________________________

NAME OF INSTALLING DEALER_____________________________________________________

NAME OF CUSTOMER____________________________________________________________

ADDRESS_____________________________________________________________________

CITY__________________________________STATE_______ZIP CODE____________________

MODEL______________________________SERIAL NUMBER____________________________

EXPECTED CYCLES PER DAY _____ NUMBER OF HOMES OR APARTMENTS_______

CONFIGURED AS A 1) VISITOR ENTRANCE______ 2) RESIDENT ENTRANCE______

3) MAIN ENTRANCE ____ 4) EXIT______ 5) OTHER_____ (EXPLAIN)______________________

responsibility for all liability in use of this product, releasing DC SOLUTIONS, INC of all

WARNING!

PROVIDE APPROPRIATE SIGNAGE BEFORE ACTIVATING THE UNIT.

ALLOW CHILDREN TO PLAY NEAR OR OPERATE AUTOMATIC GATES.

PUT INTO OPERATION THIS WILL BE CONFIRMATION THAT YOU ARE IN FULL UNCONDITIONAL

WARANTY REGISTRATION

MAIL OR FAX THIS PORTION TO DC SOLUTIONS TO CONFIRM YOUR WARRANTY

Loading...

Loading...