Page 1

MB200

Direct Thermal Printer

OPERATOR MANUAL

PN 9001126A

Page 2

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644-1650

Technical Support Hotline: (704) 644-1660

Technical Support Fax: (707) 644-1662

E-Mail: satosales@satoamerica.com

www.satoamerica.com

All rights reserved. No part of this document may be reproduced or issued to third parties in any form

whatsoever without the express permission of SATO America, Inc. The materials in this document is

provided for general information and is subject to change without notice. SATO America, Inc. assumes no

responsibilities for any errors that may appear.

Warning: This equipment complies with the requirements in Part 15 of FCC rules for a Class B computing

device. Operation of this equipment in a residential area may cause unacceptable interference to radio

and TV reception requiring the operator to take whatever steps are necessary to correct the interference.

© Copyright 2003

SATO America, Inc.

Page 3

TABLE OF CONTENTS

INTRODUCTION

General Description 1-2

Theory Of Operation 1-2

Switches And Indicators 1-3

Connection Ports 1-3

TECHNICAL DATA

Physical Characteristics 2-1

Power 2-1

Enviromental 2-1

Print 2-1

Media 2-1

Sensing 2-2

Interface Modules 2-2

Processing 2-2

Character Font Capabilities 2-2

Barcode Capabilities 2-2

Regulatory Approvals 2-3

INTERFACE SPECIFICATIONS

Interface Types 3-1

Factory Defaults 3-1

Interface Configuration 3-1

RS232 Serial Interface 3-2

TTL Interface 3-3

Infrared Data (IrDA) Interface 3-4

ACK/NAK Protocol 3-5

Receive Buffer 3-6

CONFIGURATION

Dip Switch Complex DSW1 4-2

Dip Switch Complex DSW2 4-3

Dip Switch Complex DSW3 4-3

Configuration Modes 4-4

Normal Mode 4-5

Sleep Mode 4-6

Auto Power Off Mode 4-7

Dispenser Mode 4-8

User Test Print Mode 4-9

Default Settings Mode 4-10

Hex Dump Mode 4-11

Factory Clear Mode 4-12

Font Download Mode 4-13

Program Download Mode 4-15

TROUBLESHOOTING

Error Signals 5-1

Troubleshooting Table 5-1

RS232 Serial Interface Troubleshooting 5-2

Diagnostic Label Printing 5-3

PN 9001126A

Page 4

MAINTENANCE

Cleaning 6-1

Platen Roller 6-3

Drive Motor 6-4

Drive Gear 6-6

Feed Roller 6-7

Main Circuit Board 6-8

IrDA Sensor 6-10

Gap Sensor 6-11

Eye-Mark Sensor 6-13

Head-Open Switch 6-15

ADJUSTMENT PROCEDURES

Position Adjustments 7-1

PN 9001126A

Page 5

INTRODUCTION

This manual is laid out consistent with the product discussed and provides all of the information

required for general printer configuration, troubleshooting, and maintenance. For specialized

programming, refer to the Programming Manual located on the utility CD-ROM.

Step-by-step maintenance instructions are provided with typical problems and solutions. It is

recommended that you become familiar with each section before installing and maintaining the

printer.

This manual also incorporates the use of special information boxes. Examples of these boxes

and the type of information provided in each, are below.

WARNING: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN PERSONAL INJURY.

CAUTION: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN EQUIPMENT DAMAGE.

NOTE: Provides helpful hints to assist in performing the tasks at hand.

1

A comprehensive Table Of Contents provided at the front of this manual facilitates rapid

movement within. The contents identify the different unit sections and their respective subsections. Each references the page number of their commencement.

The pages of this manual has embedded headers and footer to assist the user in identifying his

or her exact position within the manual. The header provides the section number followed by its

name. The footer identifies the product on the left, the manual’s part number in the center, and

the page number to the right side of the page.

Page inumeration is two-part with each separated by a hyphen. The first character set references

the section number and the second identifies the page number. Page numbers begin with the

numeral (1) one at the commencement of a new section and ascends sequentially.

SATO MB200 Operator Manual PN: 9001126A Page 1-1

Page 6

Unit 1: Introduction

GENERAL DESCRIPTION

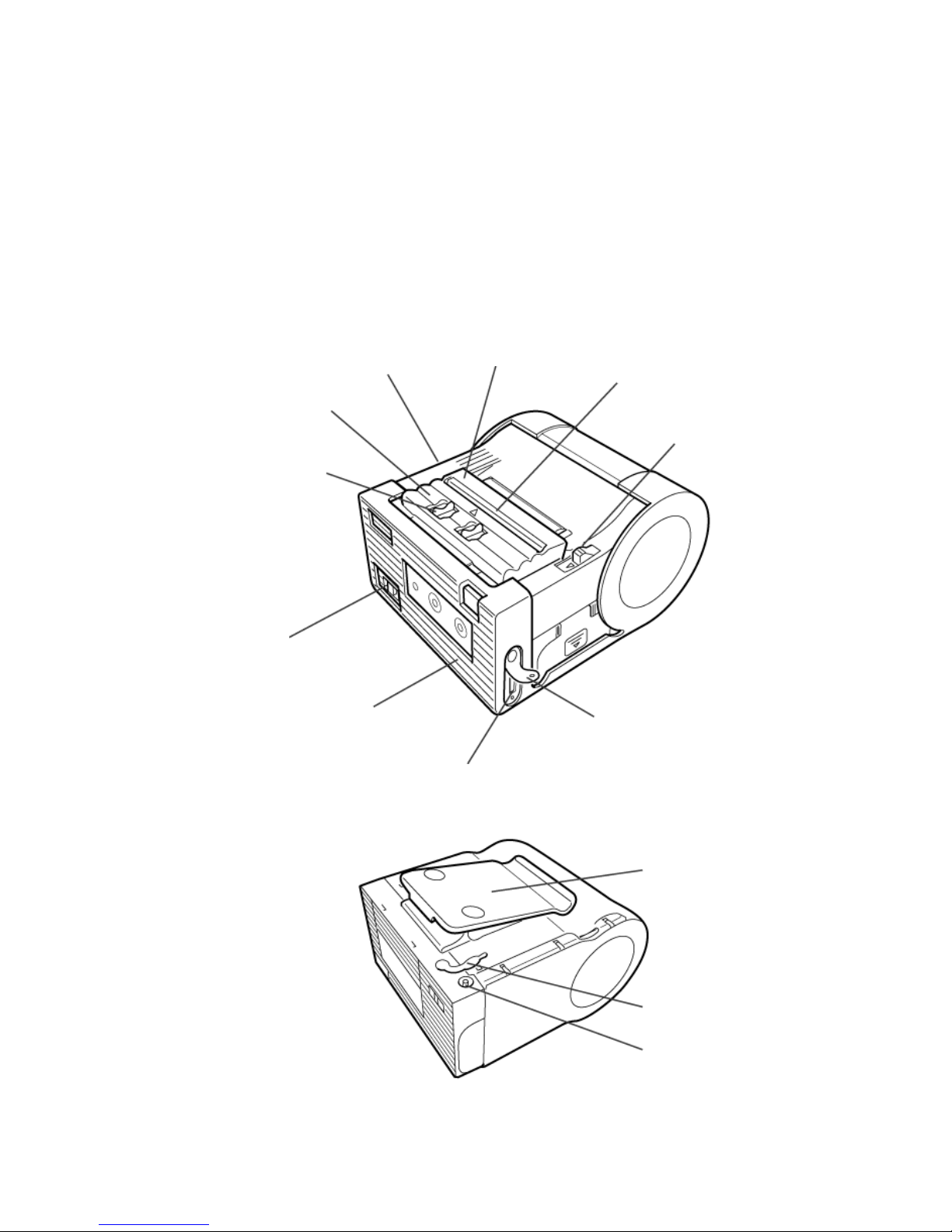

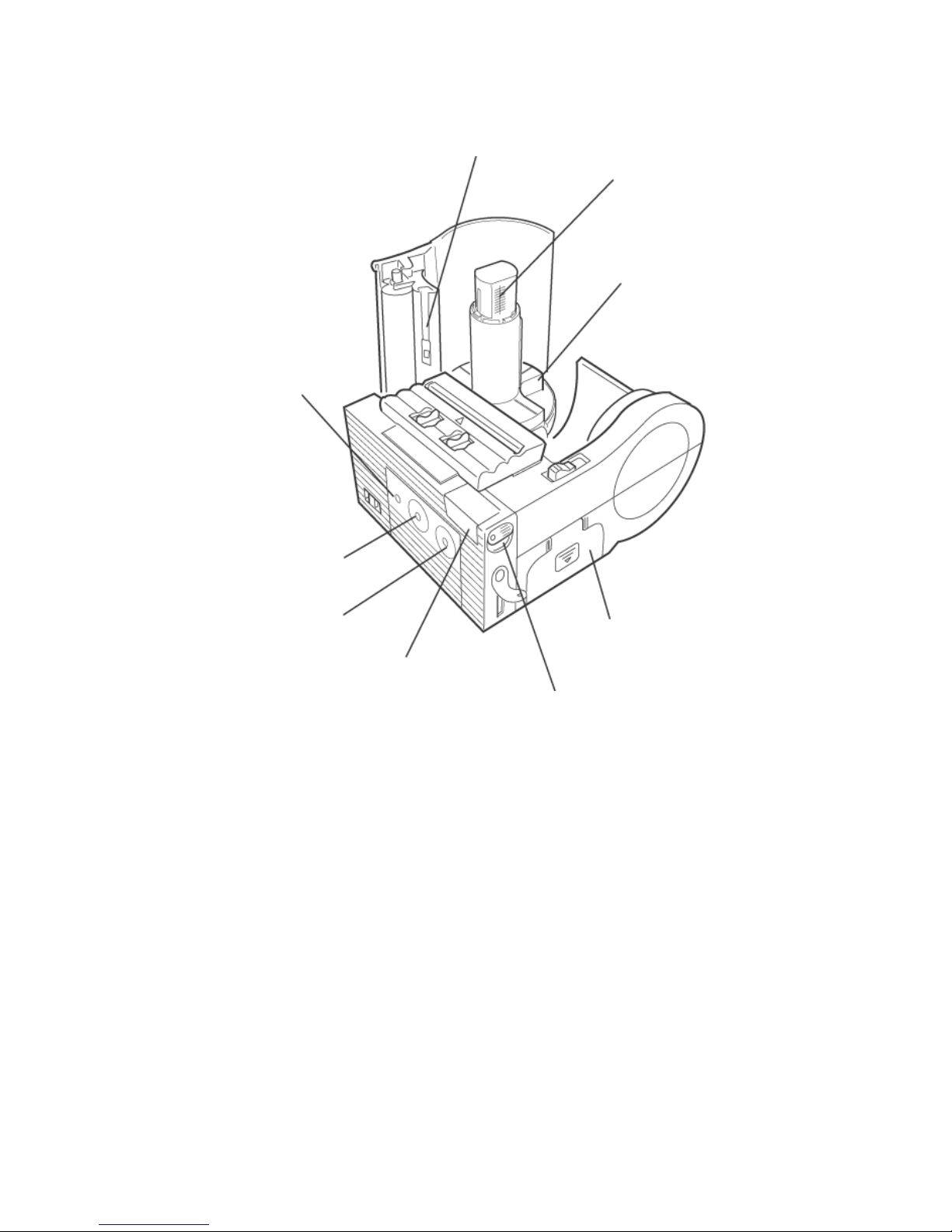

The MB400 is a compact, transportable printer designed for frequent, but intermittant use. Its

direct thermal print head not only allows high performance two-color printing, but also clear

barcode printing. It can also enlarge and print various types of fonts and Kanji characters in a free

layout.

Its ABS housing with protective rubber boots provide a durable, impact-resistant product. Oversized control buttons and shoulder strap ensures ease of use during transport. An intergrated

dispenser enables application of labels upon print. Rechargeable battery packs and a DC power

transformer ensures operation anywhere, under any conditions. An automatic power off function

turns the printer off after the last print.

Dispenser unit

Dispense /

Continuous

switch lever

Power switch

Protective case

Figure 1-1a, Primary Features & Components

Front cover

Label exit

Cutter

Cover Open/

Close lever

Interface cover

Interface connector (RS-232C)

SATO MB200 Operator Manual PN 9001126A Page 1-2

Belt hook

DC input jack cap

DC input jack

Figure 1-1b, Primary Features & Components

Page 7

Unit 1: Introduction

SWITCHES AND INDICATORS

The table below identifies and defines printer switches and indicators for operator interface. The

accompanying graphics display their locations and appearance

SWITCHES

Power Button Two position on/off switch that controls power flow to the system.

Print Button Two position on/off button that activates and deactivates print action.

Feed Button Two position on/off button that activates and deactivates feed action.

INDICATORS

Status LED Indicates the systems’ operational status.

DIP SWITCHES

1-1, 1-3 Interface settings.

1-2 Reserved.

1-4 Auto Feed function.

1-5 Head Check function.

1-6, 1-7, 1-8 Factory Clear and Error Message assignment.

POTENTIOMETERS

VR1 Eye-Mark Sensor adjustment.

VR2 Gap Sensor adjustment.

VR3 Print Position adjustment.

VR4 Print Darkness adjustment.

CONNECTION PORTS

These ports are externally accessable and permit connection of the accessories and

attachments necessary for printer programming and operation. Not listed here, are the

connection ports of circuit boards not externally accessable.

CONNECTION PORTS

DC Supply Port Connector permits 115V, 50/60 Hz supply via supplied cord.

Test Terminal For connecting the TP Test Module.

SATO MB200 Operator Manual PN 9001126A Page 1-3

Page 8

Unit 1: Introduction

Status

indicator

(LED)

Label guide (Left)

Label width scale

Label guide (Right)

Print key

Feed key

Battery cover

IrDA filter

IrDA angle lever

Figure 1-1c, Primary Features & Components

SATO MB200 Operator Manual PN 9001126A Page 1-4

Page 9

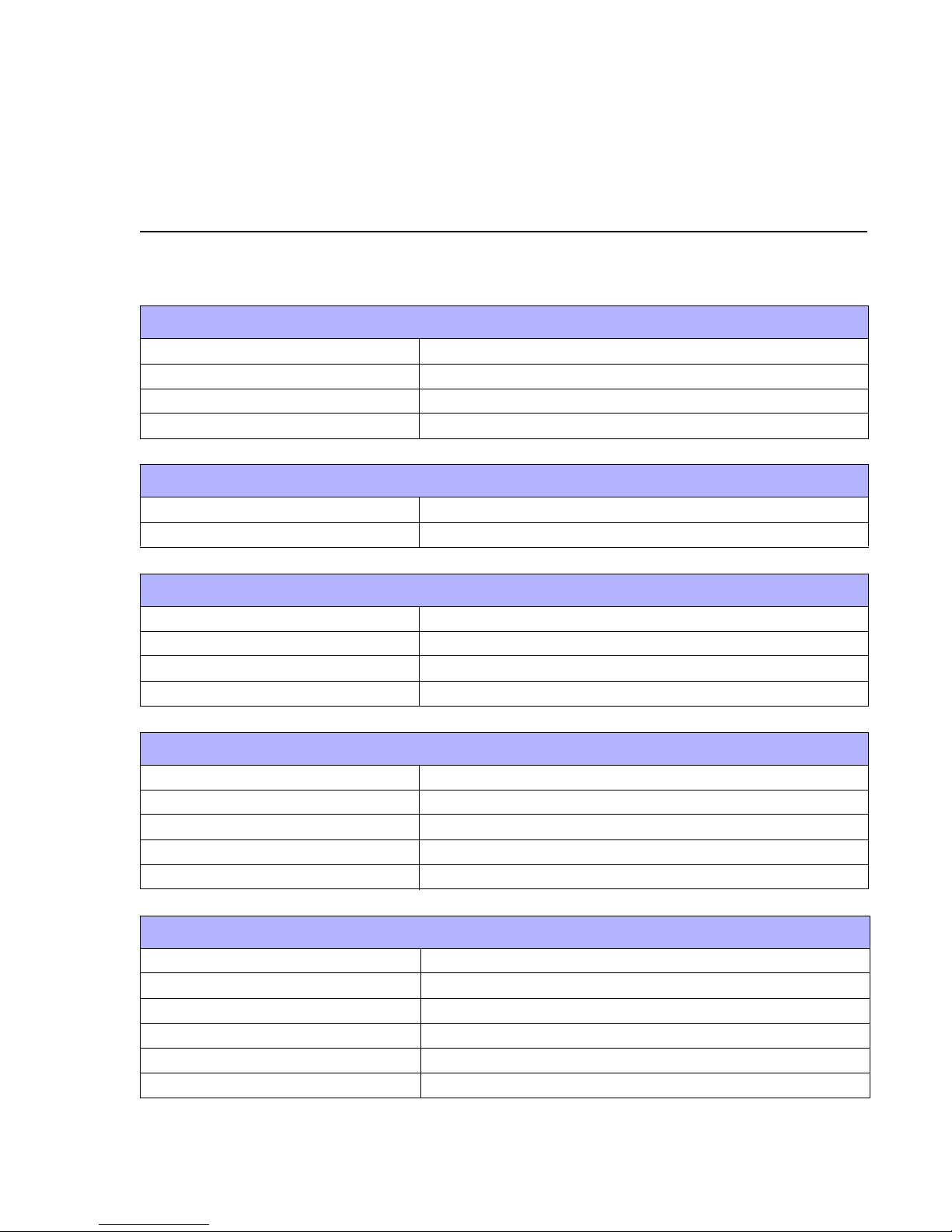

2

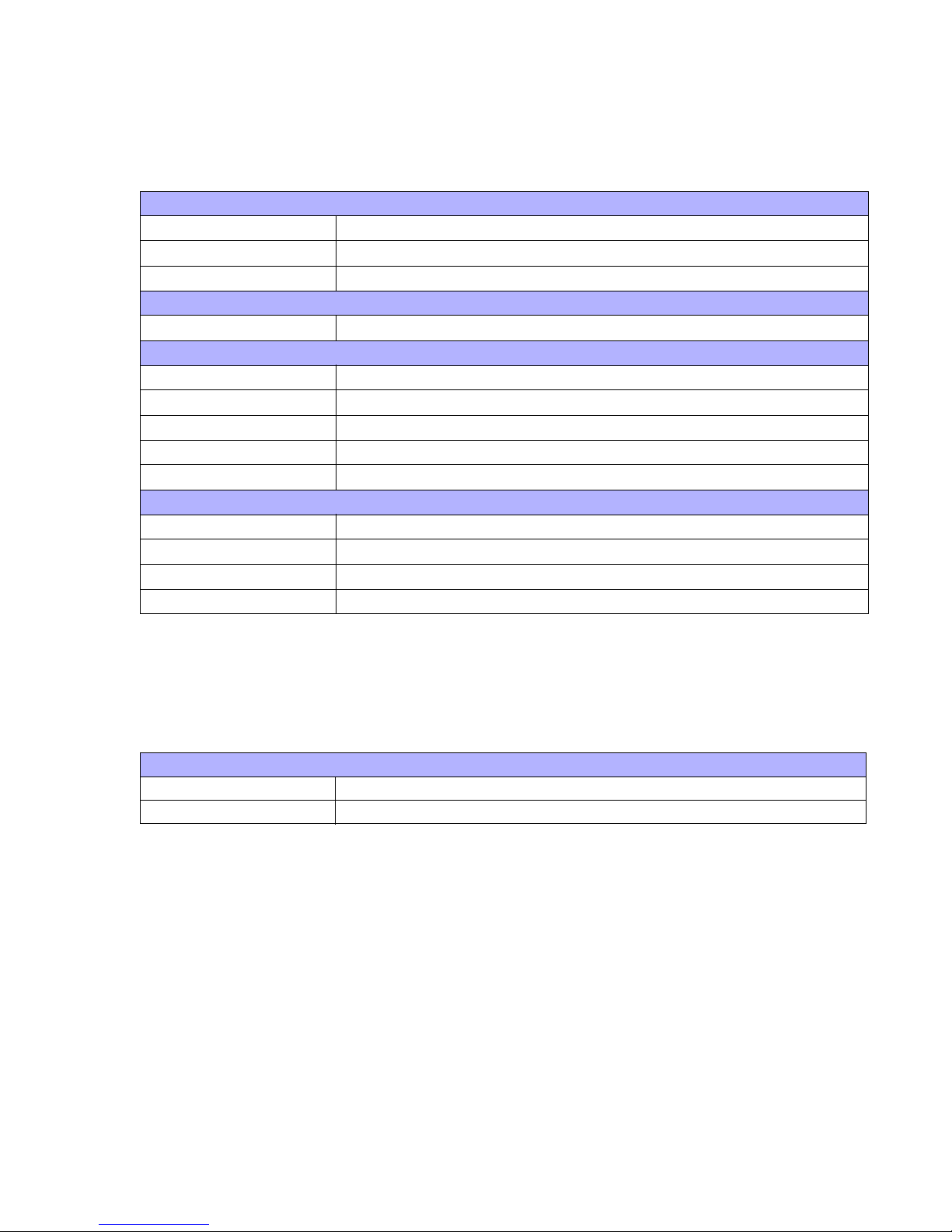

TECHNICAL DATA

All technical data deemed pertinent has been tabulated below for quick reference. Find the

relative section header and then locate the specific type of technical data in the left column.

PHYSICAL CHARACTERISTICS

Width 3.94 Inches (100 mm)

Height 2.93 Inches (74.5 mm)

Depth 5.04 Inches (128 mm)

Weight .948 Pounds (430 g)

POWER

Adapter Voltage Autoswitching 100-240 VAC, 60 Hz

Battery Supply Pack Type Lithium Ion Battery 1500mAh, 7.2v

ENVIRONMENTAL

Operating Temperature 41° to 104°Farenheit (5° to 40°C)

Storage Temperature 23° to 113°Farenheit (-5° to 45°C)

Storage Humidity 20 to 80% Non-Condensing

Operating Humidity 20 to 80% Non-Condensing

PRINT

Type Direct Thermal

Speed 2.46 Inches Per Second (62.5 mm/s)

Resolution 203 Dots Per Inch (8 d/mm)

Maximum Print Width 1.9 Inches (48 mm)

Maximum Print Length 6.3 Inches (160 mm)

MEDIA

Type Super Sensitive, Techno, Synthetic, 2-Color, Journal, Linerless

Minimum Width 1.1 Inches (28 mm)

Maximum Length 6.4 Inches (163 mm)

Maximum Width 2.3 Inches (58 mm)

Type Roll (Face out)

Maximum Caliper 0.007 Inches (0.18 mm)

SATO MB200 Operator Manual PN: 9001126A Page 2-1

Page 10

Unit 2: Technical Data

MEDIA

Maximum Roll Diameter 2.3 Inches (58 mm)

Minimum Core Diameter 1.04 Inches (26.5 mm)

INTERFACE MODULES

Serial Port RS232C/TTL (switchable)

Standard Infrared

Special RF

Special Wireless / 802.11B

PROCESSING

CPU 32 Bit RISC

FLash ROM 4 Mega-Bytes

SDRAM 16 Mega-Bytes

CHARACTER FONT CAPABILITIES

MATRIX FONTS

XB Font 48 dots W x 48 dots H

XS Font 17 dots W x 17 dots H (Universal Condensed Bold)

XM Font 24 dots W x 24 dots H (Universal Condensed Bold)

POP 80 dots W x 133 dots H

Kanji 16, 22, 24 dots W x 16, 22, 24 dots H

JIS 1 & 2 (optional)

BAR CODE CAPABILITIES

Linear Bar Codes

Two Dimensional

Ratios 1:2, 1:3, 2:5, User definable bar widths

Bar Height 4 to 999 dots, User progammable

Rotation 0, 90, 180, 270 Degrees

Sequential Numbering Sequential numbering of both numerics and bar codes

Custom Characters RAM storage for special characters

Graphics Full dot addressable graphics

EAN-8, 13

CODABAR

Code 39, 93, 128

Interleaved 2, 5

UPC-A, .E

Codabar

PDF417

QR Code

Maxicode (optional)

SATO MB200 Operator Manual PN 9001126A Page 2-2

Page 11

Unit 2: Technical Data

REGULATORY APPROVALS

Safety UL, CE, TUV, FCC-B

Noise VCCI-B

Electrical Resistance Level 2

SATO MB200 Operator Manual PN 9001126A Page 2-3

Page 12

INTERFACE SPECIFICATIONS

This unit presents the printer interface specifications. These specifications include detailed

information on how to properly interface the printer with the host system. The four acceptable

interface methods are:

• RS232C Asynchronous Serial

• TTL Asynchronous Serial

• IrDA Infrared

• Bluetooth Wireless

• Wireless LAN 802.11B

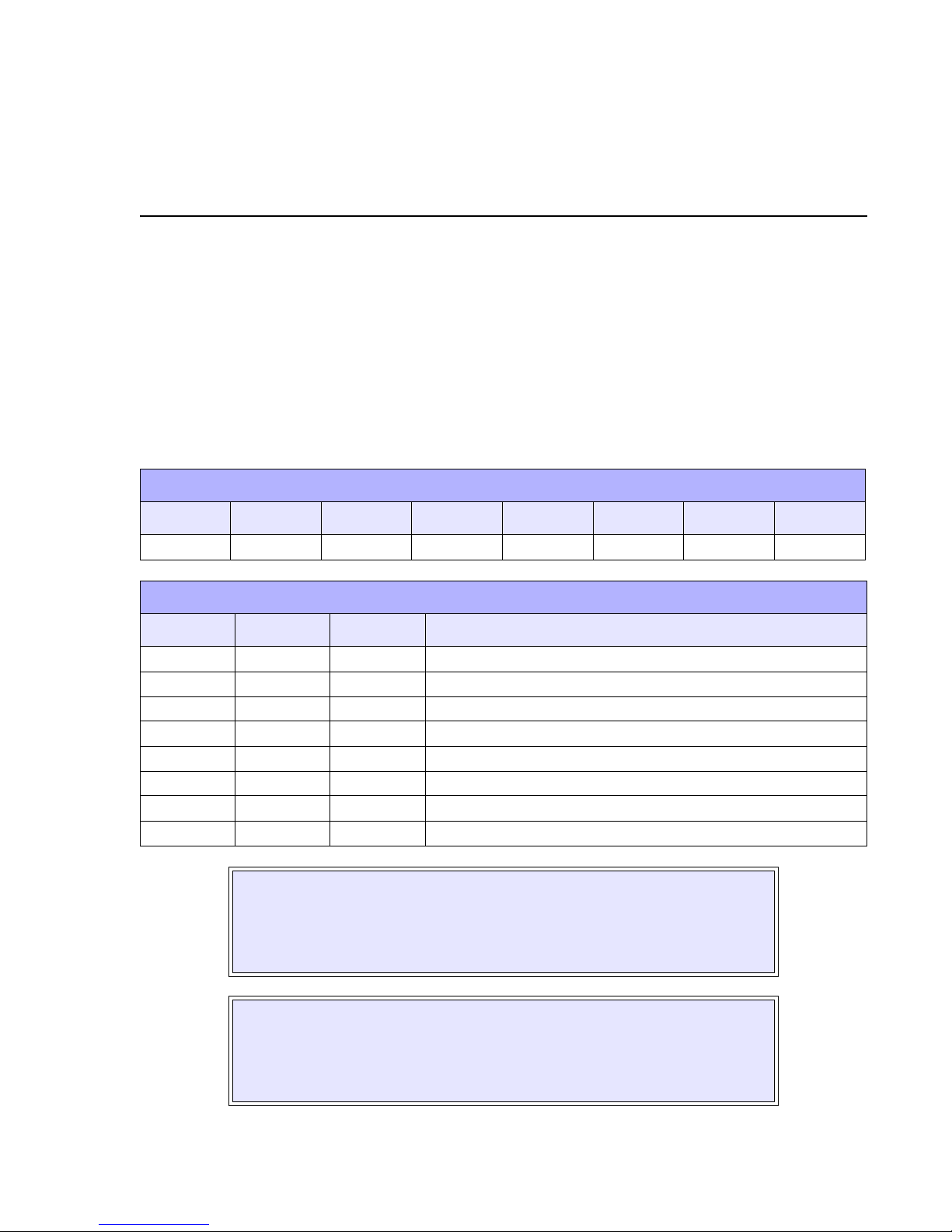

FACTORY DEFAULTS

DSW 1-1 DSW 1-2 DSW 1-3 DSW 1-4 DSW 1-5 DSW 1-6 DSW 1-7 DSW 1-8

IF Specific IF Specific IF Specific On On Off Off Off

INTERFACE CONFIGURATION

DSW 1-1 DSW 1-2 DSW 1-3 OPERATIONAL MODE

3

Off Off Off RS-232C

On Off Off TLL

Off On Off IrDA

On On Off Bluethooth (mode 1 using PIN code)

Off Off On RS-232C, IrDA

On Off On TTL, IrDA

Off On On Bluetooth (mode 2 no authentification)

On On On Wireless LAN (802.11B)

WARNING: NEVER CONNECT OR DISCONNECT INTERFACE CABLES

(OR USE A SWITCH BOX) WITH POWER APPLIED TO EITHER THE

HOST OR THE PRINTER. THIS MAY CAUSE DAMAGE TO THE

INTERFACE CIRCUITRY IN THE PRINTER/HOST AND IS NOT COVERED

BY WARRANTY.

NOTE: Some hosts monitor the Request-To-Send (RTS) signal (pin 4 of 25)

to determine if the printer is ready to receive data. Since the printer does not

generate this signal, the RTS line must be held true (high) in order to allow

communication. This can be performed by connecting the RTS pin to the

Clear-To-Send (CTS) signal (pin 5 of 25).

SATO MB200 Operator Manual PN: 9001126A Page 3-1

Page 13

Unit 3: Interface Specifications

RS232 SERIAL INTERFACE

This High Speed Serial Interface is a Plug-In Interface Module that can be connected to the

printer by the user. The only difference between this interface and the TTL is their signal levels

and cable pinouts.

RS232C SPECIFICATIONS

Asynchronous ASCII Half-duplex communication

Bi-Directional Communication

Data Transmission Rate 4800, 9600, 19200, 38400 bps

Data Length 8 bit (selectable)

Stop Bit 1 bit (fixed)

Parity Bit ODD, EVEN, NONE (selectable)

Codes Used ASC II Character Codes, JIS Kanji Codes

Control Codes STX (02H), ETX (03H), ACK (06H), NAK (15H)

Connector Special

Cable Special

Signal Levels High = +3V to +12V, Low = -3V to -12V

INTERFACE SIGNALS

PIN DIRECTION SIGNAL DEFINITION

1 Reference SG (Signal Ground)

2 To Host SD (Sending Data) - Data to the host computer from the printer.

3 To Printer RD (Receive Data) - Data to the printer from the host computer.

4 --- Reserved

5 --- Reserved

6 Reference SG (Signal Ground)

7 --- Reserved

8 --- Reserved

9 --- Reserved

10 --- Reserved

11 --- Reserved

12 Reference SG (Signal Ground)

SATO MB200 Operator Manual PN 9001126A Page 3-2

Page 14

Unit 3: Interface Specifications

TTL INTERFACE

The only difference between this interface and the RS232C is their signal levels and cable

pinouts.

TTL SPECIFICATIONS

Asynchronous ASCII Half-duplex communication

Data Transmission Rate 4800, 9600, 19200, 38400 bps

Data Length 8 bit (selectable)

Stop Bit 1 bit (fixed)

Parity Bit ODD, EVEN, NONE (selectable)

Codes Used ASC2 Character Codes, JIS Kanji Codes

Control Codes STX (02H), ETX (03H), ACK (06H), NAK (15H)

Connector Special

Cable Special

Signal Levels High = +2.0V to +3.3V Low = -0.5V to -0.8V

INTERFACE SIGNALS

PIN DIRECTION SIGNAL DEFINITION

1 Reference SG (Signal Ground)

2---Reserved

3---Reserved

4---Reserved

5---Reserved

6 Reference SG (Signal Ground)

7---Reserved

8 To Host SD (Sending Data) - Data to the host computer from the printer.

9 To Printer RD (Receive Data) - Data to the printer from the host computer.

10 --- Reserved

11 --- Reserved

12 Reference SG (Signal Ground)

WARNING: NEVER CONNECT OR DISCONNECT INTERFACE CABLES

(OR USE A SWITCH BOX) WITH POWER APPLIED TO EITHER THE

HOST OR THE PRINTER. THIS MAY CAUSE DAMAGE TO THE

INTERFACE CIRCUITRY IN THE PRINTER/HOST AND IS NOT COVERED

BY WARRANTY.

SATO MB200 Operator Manual PN 9001126A Page 3-3

Page 15

Unit 3: Interface Specifications

INFRARED DATA (IRDA) INTERFACE

Infrared communications is based on technology which is similar to entertainment remote control

devices used in homes today. This technology offers a convient, interoperable, low power, and

reliable way to connect computer and printer without the use of cables. The half duplex, serial

data interconnection capabilities supports walk up point to point use.

The infrared transmission of print data is transferred from the terminal to the printer in four

phases: (1) Connection, (2) Printer Status Check, (3) Data Transfer, (4) Disconnection.

IRDA SPECIFICATIONS

Asynchronous ASCII Half-duplex communication

Ready/Busy Hardware Flow Control

Pin 20, DTR Control

Pin 4, RTS Error Condition

X-On/X-Off Software Flow Control

Bi-Directional Communication

Data Transmission Rate 9600, 19200, 38400, 57600 bps

Data Length 8 bit (selectable)

Stop Bit 1 bit (fixed)

Parity Bit NONE

Codes Used ASC2 Character Codes, JIS Kanji Codes

Control Codes STX (02H), SYN (16H), EXT (03H), DLE (10H)

Communication Time Time-Out: 5 seconds, Retry: over 500 milliseconds.

Receiving Type Single item.

Signal Levels

Compliance HP-SIR Type of IrDA Standard IrSIR version 1.2. Upper levels are

not implemented.

CONTROL CODE - DLE must be added just prior to SYN, STX, or ETX. DLE should also be

added if the same code with DLE is included in the transferred message. With these two

methods, any control code can be used in the transferred message.

FORMAT - All transferred messages from phase 1 to phase 4 take the following format to form

the BCC calculation area. BCC is a 2-byte 16 bit SUM and the lower byte is placed at the head.

The calculation of BCC is the sum of the header and data parts.

HEADER - The Header includes the type of transferred message (cmd) and packet number (cnt).

However, some headers do not have a packet number.

Cmd is a single byte code that represents the type of packet. Cnt is only added when the packet

is any of Data Response, Data Transmission Complete, or Transmission Termination Response,

and represents the data packet number. The number begins from 1 and increments by one,

every time the terminal receives a new packet. The printer responds wit the Response packet by

putting the received number in it. Confirm the number matches with the terminal side.

Also, specify the total number of transferred packet for the Data Transmission Complete/

Transmission Complete Response packets.

SATO MB200 Operator Manual PN 9001126A Page 3-4

Page 16

Unit 3: Interface Specifications

MESSAGE FORMATS

SSS, YYT, NNX Header, variable length Data, variable length EXT BB, CC, CC, Ih

HEADER PACKETS

Connection Request/Connection Response packet 40H

Printer Status Inquiry/Printer Status Response packet 14H

Data Header/Response packet 03H

Data/Data Response packet 15H

Data Transmission Complete/Transmission Complete Response packet 17H

Disconnection Request/Disconnection Response packet 41H

DATA ITEMS

SPACE(13) Dummy data.

null(4) Dummy data.

size(4) Data size.

len(2) Data block length (maximum 256 bytes).

block Data block (maximum 256 bytes).

status(4) Status

id(6) Printer ID (ASC2 specification).

flag Packet status flag

ACK/NAK PROTOCOL

Bi-Directional ACK/NAK protocol is used for error control. In a normal transmission sequence

when the transmission is received, the printer will return an ACK (06H) signifying that it was

received without a transmission error. After the transmission command structure has been

analyzed, a status byte is returned to the host. This status byte informs the host of the validity of

the command structure.

If the command structure is error free, the printer proceeds with the print operation. When the

print operation is completed, a Printer Status message is returned to the host. If an error was

detected during the initial transmission sequence, a NAK (15H) will be returned signalling to the

host that the received transmission contained errors and must be resent. If the returned Status

byte indicates a command structure error, the error must then be corrected before the print data

is resent to the printer.

A valid transmission to the printer must be bounded by an STX/ETX pair, with the STX (02H)

signifying the start of the Print Data and ending with an ETX (03H) signifying the end.

SATO MB200 Operator Manual PN 9001126A Page 3-5

Page 17

Unit 3: Interface Specifications

RECEIVE BUFFER

The data stream is received from the host to the printer one job at a time. This allows the

software program to maintain control of the job print queue so that it can move a high priority job

in front of ones of lesser importance.

The printer receives and prints one job at a time. If a print job exceeds the buffer size,

transmission will be rejected by the printer. Flow control protocols to throttle transmission are not

used. Error conditions that occur during the Print Data transmission will cause the printer to

return a NAK.

SATO MB200 Operator Manual PN 9001126A Page 3-6

Page 18

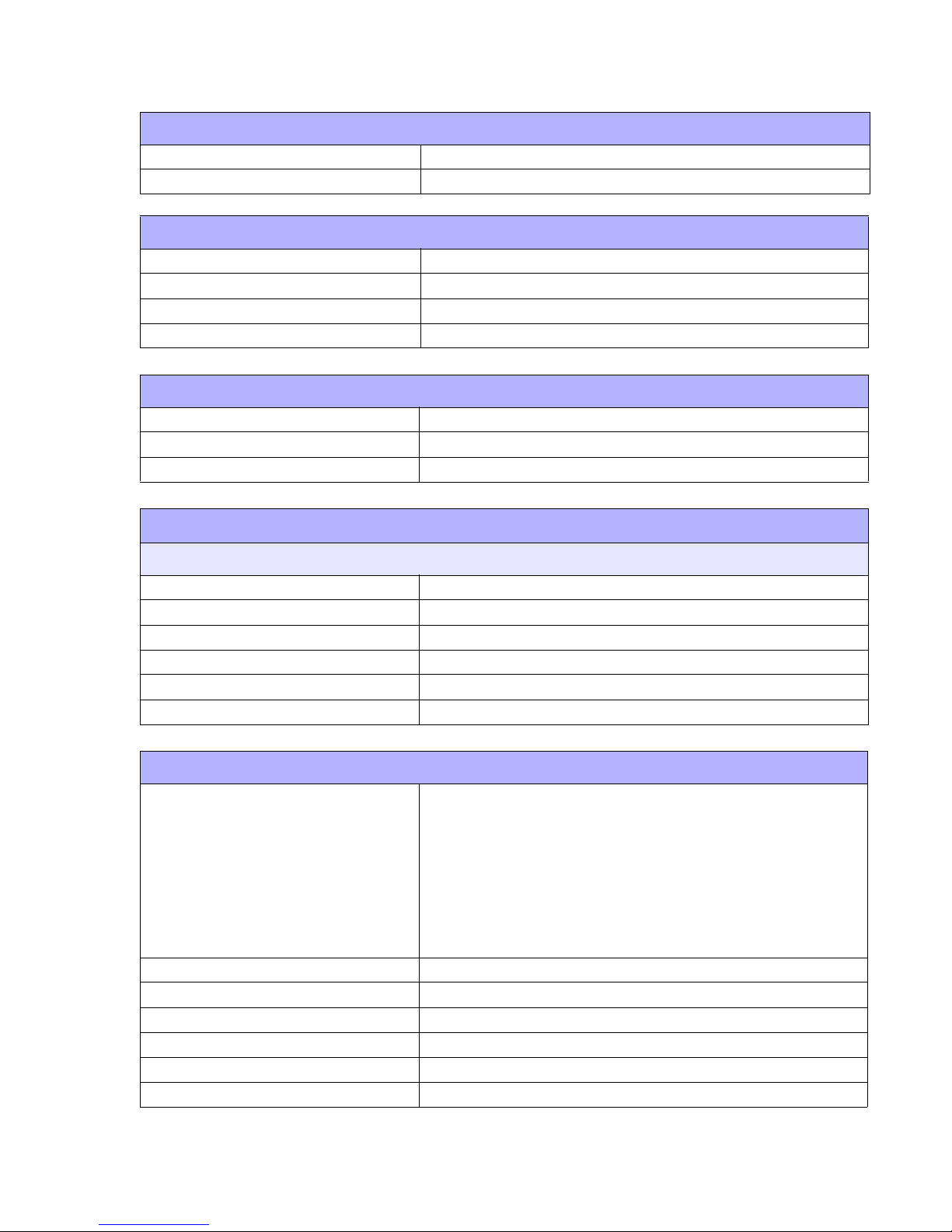

PRINTER CONFIGURATION

The printer may be configured for specific jobs via the operator and interface panels. The

operator panel is located on the face of the front housing cover and is comprised of a power

switch, Print button, Feed button, and a Status LED.

The interface panel is located under the hinged cover beneath the operator panel. The interface

panel is comprised of three eight dip switch complexes, three potentiometers, and an interface

connector located to the right.

4

Print & Feed Buttons

LED

Power Switch

Potentiometers

DSW1 (eight switch complex)

RS232 Interface Connector

Figure 4-1, Interface Panel

SATO MB200 Operator Manual PN: 9001126A Page 4-1

Page 19

Unit 4: Configuration

DIP SWITCH COMPLEX DSW1

The following tables provide guidance on the enabling/disabling of various functions and

features. This chapter deals solely with dip switch complex DSW1.

FACTORY DEFAULTS

DSW 1-1 DSW 1-2 DSW 1-3 DSW 1-4 DSW 1-5 DSW 1-6 DSW 1-7 DSW 1-8

IF Specific IF Specific IF Specific On On Off Off Off

INTERFACE CONFIGURATION

DSW 1-1 DSW 1-2 DSW 1-3 OPERATIONAL MODE

Off Off Off RS-232C

On Off Off TLL

Off On Off IrDA

On On Off Bluetooth (mode 1 using PIN code)

Off Off On RS232C, IrDA

On Off On TTL, IrDA

Off On On Bluetooth (mode 2 no authentification)

On On On Wireless LAN (802.11B)

AUTOFEED & HEAD CHECK CONFIGURATION

DSW 1-4

DSW 1-5

Off: Manual Feed or Factory Offset / On: Auto Feed or Print Darkness adjustment

Head Check - Off: Disabled / On: Enabled

MODE CONFIGURATION

DSW 1-6 DSW 1-7 DSW 1-8 OPERATIONAL MODE

Off Off Off Factory Clear Mode w/o counter clear

On Off Off Factory Clear Mode w/ head counter clear

Off On Off Factory Clear Mode w/ head counter & factory counter clear

On On Off Reserved

Off Off On Dispenser Operation

On Off On Hex Dump Mode

Off On On Font Download

On On On Program Download

NOTE: Some button/key combinations are required when altering

some dip switches. Refer to the relative mode in the Configuration

Modes chapter to follow for guidance.

SATO MB200 Operator Manual PN 9001126A Page 4-2

Page 20

Unit 4: Configuration

DIP SWITCH COMPLEX DSW2

The DSW2 dip switch complex is used for configuring the IrDA Interface. For instructions on this

configuration, contact SATO Technical Support for guidance. The factory defaults are provided

below in case of accidental alteration of their settings.

CAUTION: DO NOT CHANGE THE DEFAULT SETTINGS

UNLESS DIRECTED OTHERWISE.

NOTE: The IrDA Interface for this unit is not compatible with LPT or

COM.

FACTORY DEFAULTS

DSW 2-1 DSW 2-2 DSW 2-3 DSW 2-4 DSW 2-5 DSW 2-6 DSW 2-7 DSW 2-8

Off Off Off Off Off Off Off Off

DIP SWITCH COMPLEX DSW3

Dip switch complex DSW3 allows the specification of a Bluetooth interface frequency. For

instructions on this configuration, contact SATO Technical Support for guidance. The factory

defaults are provided below in case of accidental alteration of their settings.

CAUTION: DO NOT CHANGE THE DEFAULT SETTINGS

UNLESS DIRECTED OTHERWISE.

FACTORY DEFAULTS

DSW 3-1 DSW 3-2 DSW 3-3 DSW 3-4 DSW 3-5 DSW 3-6 DSW 3-7 DSW 3-8

On On On On On On On On

SATO MB200 Operator Manual PN 9001126A Page 4-3

Page 21

Unit 4: Configuration

CONFIGURATION MODES

This section provides an overview of the various configuration modes of the operation menu. Refer to Figure 5-2 for initial activity and then advance to its relative section that follows.

Refer to

POWER

Normal Mode

Normal Mode

Section

Figure 5-3

STATUS LED

flashes red,

illuminates

green

STATUS LED

blinks green

FEED + POWER

Cover Open

+ PRINT

+ POWER

DSW1-6 = ON

DSW1-7 = OFF

DSW1-8 = ON

POWER

Sleep Mode

Auto Power Off Mode

Dispenser Mode

User Test Print

Mode

Default Setting

Mode

Hex Dump

Mode

Refer to

Sleep Mode

Section

Figure 5-4

Refer to

Auto Power

Off Mode

Figure 5-5

Refer to

Dispenser

Mode

Section 5-6

Refer to

Test Print

Mode

Figure 5-7

Refer to

Default

Setting Mode

Figure 5-8

Refer to Hex

Dump Mode

Figure 5-9

SATO MB200 Operator Manual PN 9001126A Page 4-4

DSW1-6

DSW1-7

DSW1-8

Cover Open

PRINT + FEED + POWER

DSW1-6 = OFF

DSW1-7 = ON

DSW1-8 = ON

POWER

DSW1-6 = ON

DSW1-6 = On

DSW1-7 = ON

DSW1-7 = On

DSW1-8 = ON

DSW1-8 = On

POWER

POWER

Figure 4-2, Configuration Modes

Factory Clear

Mode

Font Download

Mode

Program Download

Mode

Refer to

Factory Clear

Mode

Figure 5-10

Refer to Font

Download

Figure 5-11

Refer to

Program

Download

Figure 5-12

Page 22

Unit 4: Configuration

NORMAL MODE

Figure 5-3 provides the specific sequence of events required by the operator, the printer, and the

printer’s software for normal mode congiguration.

POWER

STATUS LED

flashes red,

flashes green

STATUS LED

blinks green

PRINT

STATUS LED

illuminates

green

Prints then

positions for the

next label.

Online

Offline Status/

Journal Printing

FEED

One label is

printed

Offline

STATUS LED

turns off

PRINT

STATUS LED

illuminates green

Online

SATO MB200 Operator Manual PN 9001126A Page 4-5

Print Pause

Status – printing

resumes when

data

is received

STATUS LED

turns off

Figure 4-3, Normal Mode Configuration

Page 23

Unit 4: Configuration

SLEEP MODE

Figure 5-4 provides the specific sequence of events required by the operator, the printer, and the

printer’s software for sleep mode to be activated.

Printer left

untouched for 5

seconds. Or 30

seconds after an

error occurs

Sleep Mode

STATUS LED

blinks green

Press any key,

open cover, or

receive data

Normal Mode

STATUS

turns off

Figure 4-4, Sleep Mode

LED

SATO MB200 Operator Manual PN 9001126A Page 4-6

Page 24

Unit 4: Configuration

AUTO POWER OFF MODE

Figure 5-5 provides the specific sequence of events required by the operator, the printer, and the

printer’s software for the auto power-off mode to be activated.

Sleep Mode

STATUS LED

blinks green

with 2 second

interval

Printer left

untouched for 5

minutes

Auto Power Off Mode

STATUS LED

turns off

Figure 4-5, Auto Power Off Mode

SATO MB200 Operator Manual PN 9001126A Page 4-7

Page 25

Unit 4: Configuration

DISPENSER MODE

Figure 5-6 provides the specific sequence of events required by the operator, the printer, and the

printer’s software for dispenser mode to be activated.

Dispense

Auto/Manual

DSW1-6 = Off

DSW1-7 = Off

DSW1-8 = Off

Advance Dispenser

DSW1-6 = Off

DSW1-7 = Off

DSW1-8 = On

Retract Dispenser

Auto Dispense

Mode

Manual Dispense

Mode

One Label

Printed

Pause Mode

One Label

Printed each

time label

removed

SATO MB200 Operator Manual PN 9001126A Page 4-8

FEED

One label

printed for

each time

pressed.

Figure 4-6, Dispenser Mode

Page 26

Unit 4: Configuration

USER TEST PRINT MODE

Figure 5-7 provides the specific sequence of events required by the operator, the printer, and the

printer’s software for the user test print mode to be activated.

FEED + POWER

STATUS LED

flashes red,

Illuminates

green

Online

STATUS LED

blinks green

FEED

Test Print Mode

STATUS LED

illuminates and

printer prints

Print/Pause

Print/Stop

FEED

STATUS LED

blinks green and

printer pauses

FEED

Test Print Mode

STATUS LED

illuminates and

printer prints

SATO MB200 Operator Manual PN 9001126A Page 4-9

POWER

Figure 4-7, User Test Print Mode

Page 27

Unit 4: Configuration

DEFAULT SETTING MODE

Figure 5-8 provides the specific sequence of events required by the operator, the printer, and the

printer’s software for default setting mode to be activated.

Open Cover

PRINT + POWER

Default Settings Mode

STATUS LED

flashes orange,

blinks green to

begin process

STATUS LED

terminates when

process complete

Sleep Mode

STATUS LED

blinks at 2 second

intervals when in

sleep mode.

Auto

Power

Off

SATO MB200 Operator Manual PN 9001126A Page 4-10

Figure 4-8, Default Setting Mode

Page 28

Unit 4: Configuration

HEX DUMP MODE

Figure 5-9 provides the specific sequence of events required by the operator, the printer, and the

printer’s software for hex dump mode to be activated.

DSW1-6 = ON

DSW1-7 = OFF

DSW1-8 = ON

POWER

STATUS LED

flashes red,

blinks green

Hex Dump Mode

STATUS LED

illuminates green

when

Receiving Data

Hex Dump

Print

STATUS LED

blinks green

when complete

SATO MB200 Operator Manual PN 9001126A Page 4-11

POWER

DSW1-6 = Reset

DSW1-7 = Reset

DSW1-8 = Reset

Figure 4-9, Hex Dump Mode

Page 29

Unit 4: Configuration

FACTORY CLEAR MODE

Figure 5-10 provides the specific sequence of events required by the operator, the printer, and

the printer’s software for factory clear mode to be activated.

Which Factory

Clear option

NO COUNTER CLEAR

DSW1-6 = OFF

DSW1-7 = OFF

DSW1-8 = OFF

Open Cover

Close Cover

STATUS LED

blinks green

HEAD & FACTORY COUNTER CLEAR

DSW1-6 = OFF

DSW1-7 = ON

DSW1-8 = OFF

Open Cover

PRINT + FEED + POWER

STATUS LED

blinks red

Factory Clear Mode

HEAD COUNTER CLEAR

DSW1-6 = ON

DSW1-7 = OFF

DSW1-8 = OFF

Open Cover

STATUS LED

blinks green

Stops printing

labels

SATO MB200 Operator Manual PN 9001126A Page 4-12

Press FEED key

STATUS LED

Illuminates green

Test Printing of

Labels

FEED

Pause/Print/

Exit

Figure 4-10, Factory Clear Mode

POWER

DSW1-6 = Reset

DSW1-7 = Reset

DSW1-8 = Reset

Page 30

Unit 4: Configuration

FONT DOWNLOAD MODE

A Flash ROM is used to internally store and delete font data and custom designed character

data. The storage capacity for custom designed characters is a maximum of 95 for each type of

16 x 16, 22 x 22, and 24 x 24 dots.

There are four transmission protocols for font download: (1) Download Font Storage, (2)

Download Font Deletion, (3) Download Font Information Aquisition, (4) Storage CustomDesigned Character. The return status from the printer is set between STX (02H) and ETX (03H),

and transferred in 3 bytes. Note that the return status for the font data transfer when storing font

is 1 byte of ACK (06H). All status data transferred from the host are set between STX (02H) and

ETX (03H), and transferred in 3 bytes.

Wiring on the computer side may require a CTS (pin 5) and RTS (pin 4) cable connection.

Confirm the host settings before downloading.

Figure 5-11 provides the specific sequence of events required by the operator, the printer, and

the printer’s software for font download mode to be activated.

DSW1-6 = OFF

DSW1-7 = ON

DSW1-8 = ON

Connect printer RS232C

interface with download

source

POWER

STATUS LED

flashes red,

Illuminates green

STATUS LED

blinks green

Waiting for Data

Font Download Mode

Has

storage area been

used before?

STATUS LED

illuminates green

while

downloading

STATUS LED

illuminates red,

then orange, then

green when writing

to Flash ROM

STATUS LED

blinks green

Waiting for Data

Execute Downloading

SATO MB200 Operator Manual PN 9001126A Page 4-13

POWER

DSW1-6 = Reset

DSW1-7 = Reset

DSW1-8 = Reset

Figure 4-11, Font Download Mode

Page 31

Unit 4: Configuration

DOWNLOAD FONT REGISTRATION

STATUS DESCRIPTION ACSII HEX TRANSFER

Not Already Stored A 41 Printer to Host

Already Stored B 42 Printer to Host

Storage Area NG N 4E Printer to Host

Store Font 0 30 Host to Printer

Do Not Store Font 1 31 Host to Printer

Ready For Storage Status O 4F Printer to Host

Font Storage Completed Normally E 45 Printer to Host

Font Storage Cancelled S 53 Printer to Host

Font Storage Completed Abnormally Z 5A Printer to Host

DOWNLOAD FONT DELETION

STATUS DESCRIPTION ACSII HEX TRANSFER

Not Already Stored A 41 Printer to Host

Already Stored B 42 Printer to Host

Delete Font 0 30 Host to Printer

Do Not Delete Font 1 31 Host to Printer

Font Deletion Completed Normally E 45 Printer to Host

Font Deletion Cancelled S 53 Printer to Host

Font Storage Completed Abnormally Z 5A Printer to Host

DOWNLOAD FONT INFORMATION AQUISTION

STATUS DESCRIPTION ACSII HEX TRANSFER

Not Already Stored A 41 Printer to Host

Already Stored B 42 Printer to Host

Font Information Transferred OK 0 30 Host to Printer

Number of Transferred Data 000000-

999999

Font Information Font Info Data + Font

6 bytes w/

Data Info

Printer to Host

30-39

Printer to Host

STORAGE OF CUSTOM DESIGNED CHARACTER

STATUS DESCRIPTION ACSII HEX TRANSFER

Storage Ready Status O 4F Printer to Host

Storage Completed Normally E 45 Printer to Host

Storage Completed Abnormally Z 5A Host to Printer

SATO MB200 Operator Manual PN 9001126A Page 4-14

Page 32

Unit 4: Configuration

PROGRAM DOWNLOAD MODE

Figure 5-12 provides the specific sequence of events required by the operator, the printer, and

the printer’s software for program download mode to be activated.

DSW1-6 = ON

DSW1-7 = ON

DSW1-8 = ON

Connect printer RS232C

interface with download

source

POWER

STATUS LED

flashes red,

Illuminates green

Program Download Mode

STATUS LED

Is not illuminated

when

Waiting for Data

POWER

DSW1-6 = Reset

DSW1-7 = Reset

DSW1-8 = Reset

Has

storage area been

used before?

STATUS LED

illuminates green

while

downloading

STATUS LED

illuminates red,

then orange, then

green when writing

to Flash ROM

STATUS LED

Is not illuminated

when

Waiting for Data

Execute Downloading

SATO MB200 Operator Manual PN 9001126A Page 4-15

Figure 4-12, Program Download Mode

Page 33

TROUBLESHOOTING

This unit is provides assistance in identifying the route cause of inadequate performance or

complete failure. Whereas simple instructions may be provided here for problem correction, their

indepth procedures will most likely be found in the Adjustment Procdures or Replacement

Procedures sections of this manual.

ERROR SIGNALS

STATUS LED MODE RESOLUTION GUIDE

Illuminated Red After Power Input Program or flash ROM error. Replace flash ROM or reload

program.

Illuminated Orange All Modes Low battery. Recharge or replace.

Blinking Red On-Line Ensure cover is locked and the cover open switch is

operational.

5

Blinking Red/Orange

Alternately

Blinking Orange On-Line Damaged print head. Replace.

Blinking Orange/Green

Alternately

Blinking Green Printing/Recieving The buffer is near full. Pause the data transmission and

TROUBLESHOOTING TABLE

IMAGE VOIDS

Poor label quality. Use high quality label stock.

Damaged print head. Replace print head.

Damaged platen. Replace platen.

LIGHT PRINT IMAGE

Poor label quality. Use high quality direct thermal label stock.

Low print head energy/darkness. Adjust darkness level.

On-Line Received data is larger than buffer. Incorrect protocol

setting.

All Modes Print head protection feature that activates when the head

rises above 131° F and deactivates when it cools down to

122° F (55°C - 50°C).

allow the buffer to empty before retrying.

Foriegn material on print head. Clean print head and platen roller.

Poor head alignment. Align print head as required.

Excessive print speed. Reduce print speed setting.

SATO MB200 Operator Manual PN: 9001126A Page 5-1

Page 34

Unit 5: Troubleshooting

SMEARED PRINT IMAGE

Poor label quality. Use high quality direct thermal label stock.

Foreign material on print head and platen

roller.

Foreign material on labels. Use high quality label stock.

Excessive print head energy. Adjust darkness control.

Excessive print speed. Adjust speed as required.

Clean print head and platen roller.

FUZZY PRINT IMAGE

Heat too high. Adjust as required.

NO LABEL MOVEMENT

Loose or broken platen drive gears. Adjust or replace platen drive gears as required.

Incorrect label pitch sensor selected. Select the correct label sensor type.

NO PRINTED IMAGE

Print head is disconnected. Ensure that print head wiring harness is connected on each

end.

Low voltage output. Test power supply voltage and replace as necessary.

Damaged print head. Replace print head.

Damaged electronics. Replace circuit board.

POWER LED NOT ILLUMINATED

AC power cable disconnected. Ensure the cable is connected at each end.

Defective power supply. Test with meter and replace as required.

WILL NOT GO ON-LINE

Defective power supply cord. Ensure proper function or replace.

House power supply discontinued. Test receptacle.

Battery pack power depleted. Recharge or replace.

RS232 SERIAL INTERFACE TROUBLESHOOTING

• Ensure the serial cable is thoroughly connected to the PC and the printer.

CAUTION: NEVER CONNECT OR DISCONNECT INTERFACE CABLES

(OR USE A SWITCH BOX) WITH POWER APPLIED TO EITHER THE

PRINTER OR THE HOST. THIS MAY CAUSE DAMAGE TO THE INTERFACE CIRCUITRY AND IS NOT COVERED BY WARRANTY.

• Ensure the serial cable is not defective and that it is manufactured to specifications.

• Ensure the RS232 Interface Module is properly installed.

SATO MB200 Operator Manual PN 9001126A Page 5-2

Page 35

Unit 5: Troubleshooting

• Ensure the data stream is correct (all letters of command codes are in upper case and

without spaces).

• Ensure the Baud rate, Parity, Data Bits, and Stop Bits are consistent with that of computer.

Print a Configuration Test Label to determine the RS232 settings.

• Ensure the printer is recieving from the computer using the Hex Dump Mode. Refer to that

procedure for instructions. The printer will print (only once) a hexadecimal dump of everything

it has received from the host computer. Each hexadecimal character represents a character

the printer received. Analyze and troubleshoot the data stream.

NOTE: A small label may produce a large amount of data when printed in

Hex Dump.

While checking the hex dump printout, look for OD

h OAh (carriage return and line feed)

characters throughout. The command string should be continuous. CR or LF charcters are

not allowed between the start command (<ESC>A) and the stop command (<ESC>Z). If

Basic is being used, it may be adding these characters automatically as the line wraps.

Adding a width statement to your program can help suppress these extra OD

H OAH

characters by expanding the line length up to 255 characters.

If not programming in BASIC, check to see if the equivalent statement in language exists to

suppress extra carriage returns and line feeds from data being sent to the printer. The data

stream must be one complete line going to the printer.

PRINT TEST LABEL

The contents of the Print Buffer can be examined using the Hex Dump mode. In the left column,

each line of data received is numbered. The center column provides the data in hexadecimal

format. And in the right column, the same data is provided in the ASC II format. Follow the

instructions below for guidance.

1 Power off the printer (if on).

2 Place the DSW1-6 switch in the ON position.

3 Place the DSW1-7 switch in the OFF position.

4 Place the DSW1-8 switch in the ON position.

5 Power on the printer.

6 Print a diagnostic label.

7 Turn the printer off and then back on to return to the normal print mode.

8 Return switch DSW1-8 to the OFF position.

9 Return switch DSW1-7 to the ON position.

10 Return switch DSW1-6 to the OFF position.

SATO MB200 Operator Manual PN 9001126A Page 5-3

Page 36

MAINTENANCE

This unit includes all of the operator approved maintenance activities.

CLEANING PROCEDURES

Cleaning of the printer is a necessary maintenance activity to ensure print quality and long printer

life. There are two basic types of cleaning involved; the removal of loose debris and the removal

of residue.

Use a soft cloth and/or a pneumatic blower (pressurized air) to remove debris from the printer.

This process should be performed prior to the removal of residue. To remove residue, apply

SATO Solvent or isopropryl alcohol to a clean cotton swab and gently wipe the entire surface of

the print head and platen roller until clean.

WARNING: ALLOW THE PRINT HEAD TO COOL TO ROOM

TEMPERATURE PRIOR TO CLEANING.

PLATEN ROLLER REPLACEMENT

The platen roller is considered to be a high wear component due to its treading against the print

media. This treading contact will eventually wear grooves into the rubber material and negatively

effect print output.

6

1 Switch off the printer and disconnect the power supply.

2 Remove protective rubber from printer’s exterior, open top housing cover (1, Figure 7-1).

NOTE: The top housing cover is removed from Figure 7-1 to optimize viewing

of relative components.

3 Detach dispenser bar (2) from top housing cover (1).

NOTE: The dispenser bar snaps free from the left end as viewed in the

illustration, then withdraw the right end.

4 Detach worn platen roller assembly (3) from top housing cover (1).

5 Snap replacement platen roller assembly (3) into top housing cover.

NOTE: Insert the geared end of replacement platen roller assembly into

place first followed by opposite end. Ensure the gear of the replacment platen

roller assembly meshes with those of the dive train.

6 Snap dispenser bar (2) into top housing cover (1).

SATO MB200 Operator Manual PN: 9001126A Page 6-1

Page 37

Unit 6: Maintenance

3

1

2

Figure 7-1, Platen Roller Replacement

SATO MB200 Operator Manual PN 9001126A Page 6-2

Page 38

ADJUSTMENT PROCEDURES

This section of the manual provides instruction of all printer operational adjustments.

Adjustments for the MB200 printer are minimal. Almost all adjustments are electrical in nature

due to self aligning and balancing design features.

POSITION ADJUSTMENTS

Adjustment Method Adjustment Description

Factory Offset Switch DSW1-4 to the Off

position, then adjust the VR3

potentiometer.

7

Printer Setting Commands Use the <PG> programming

Base Point Offset

Pitch Offset

Dispense Offset

Tear-Off Offset

Base Point Offset Use the <A3> programming

Pitch Offset Use the <PO3> programming

Dispense Offset Use the <PO1> programming

Tear-Off Offset Use the <PO2> programming

command.

command.

command.

command.

command.

Saves the values to the Flash ROM.

Takes effect after specified and the

value is cleared once the power is

turned off.

Takes effect after specified and the

value is cleared once the power is

turned off.

Takes effect after specified and the

value is cleared once the power is

turned off.

Takes effect after specified and the

value is cleared once the power is

turned off.

SATO MB200 Operator Manual PN: 9001126A Page 7-1

Loading...

Loading...