DCS DD124P5, DD224P5 Installation Manual

DISHDRAWER®

Installation Guide

MODELS:

DD124P5

DD224P5

Safety and warnings

Electrical hazard

Before installing the DishDrawer ®,remove the house fuse or open the circuit

breaker°

If permanently con!]ecting the DishDrawer ®, be sure the power is isomated

and the DishDrawer -_unp[uggedo

Failure to do so may result in electrical shock or death°

_ Cut Hazard

Take care - pane[ edges are sharp,

Failure to use caution could result [n injury or cuts°

Instatlation of this DLshDrawer_ requires basic mechanical and electrical skills°

Besure to leave these instructions with the Customer.

installation must comply with your local building and electridty regulations.

At the completion of the DishDrawer ®installation, the Instafer must perform

Final Check List on Page 29.

Remove a# packaging materials supplied with the DishDrawer®°

This dishwasher is manufactured for indoor use only.

Ensure all water connections are tumed OF£1t is the responsibility of the plumber and

electrician to ensure that each installation complies with aH Codes and Regulations.

The DishDrawer ®MUST be installed to allow for future removal from the enclosure ff service is

required.

The switched power outlet must be outside the DishDrawer ®cavity so that it is accessible after

installation.

@re should be taken when the app#ance is installed or removed to reduce the #kelihood of

damage to the power supply cot&

ff the DLshDrawer ®is to be relocated from one instaflation to another it must be kept upright to

avoid damage from water spillage°

Make sure only new hoses are used for connection (supplied with DishDrawer®)°

Old hoses should not be reused.

Failure t_ install the DishDrawer_ c_rrec_y could invalidate any warranty or liabii#y daims_

ff the product LsinstaNed in a motor vehicle, boat or similar mobile fadlity, you must bring the

vehicle, boat or mobile fadfty containing the product to the service shop at your expense or pay

the service technidan_s travel to the tocation of the product.

DOUBLE MODELS

Product and cabinetry dimensions

Installation

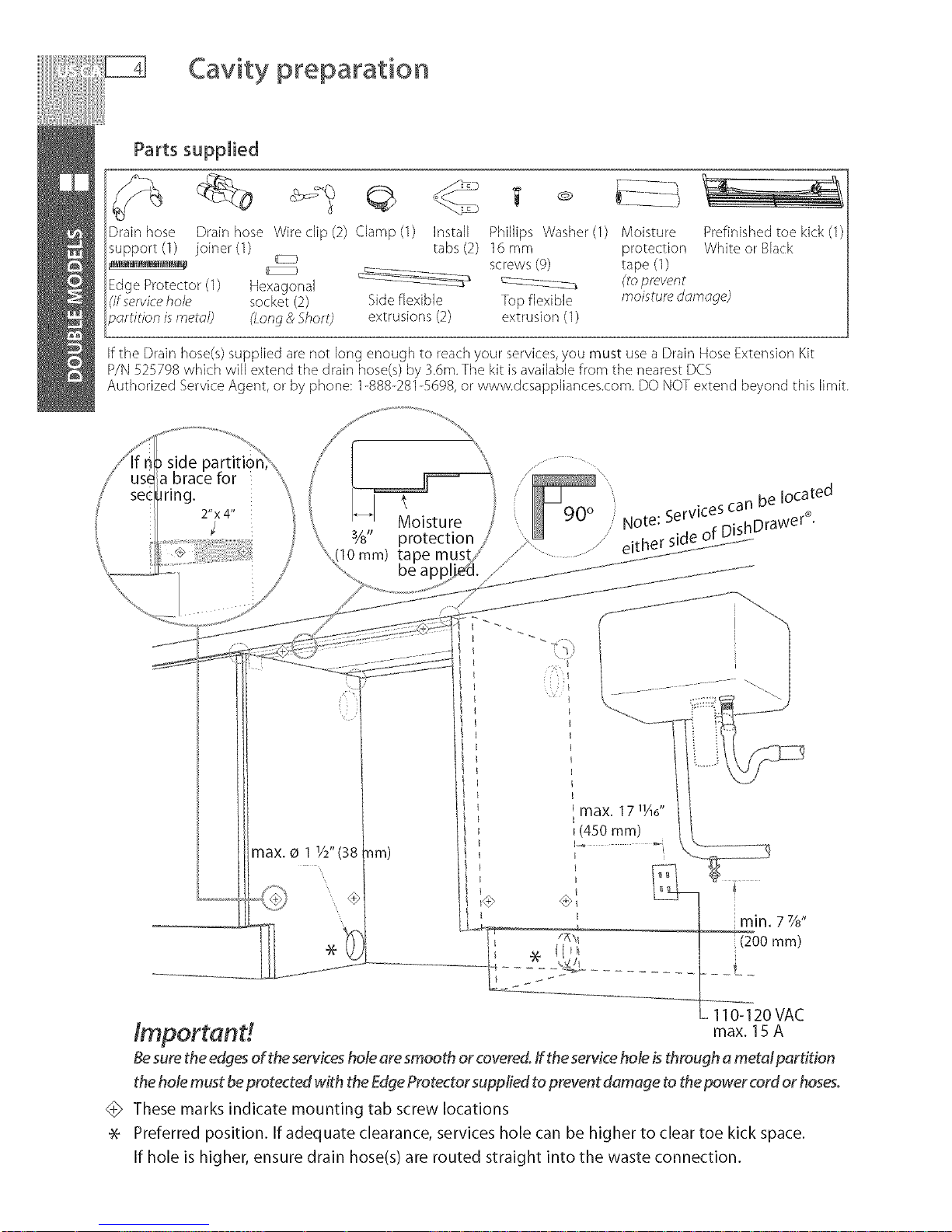

Cavity preparation

Optionally hard wiring the product

Route the hoses and move into the cavity

Removing the tub and levelling the product

Secudng the product and refitting the tub

Fitting the toekick

Plumbing and drainage oOP'T'ION1

Plumbing and drainage oOPTION 1(connection

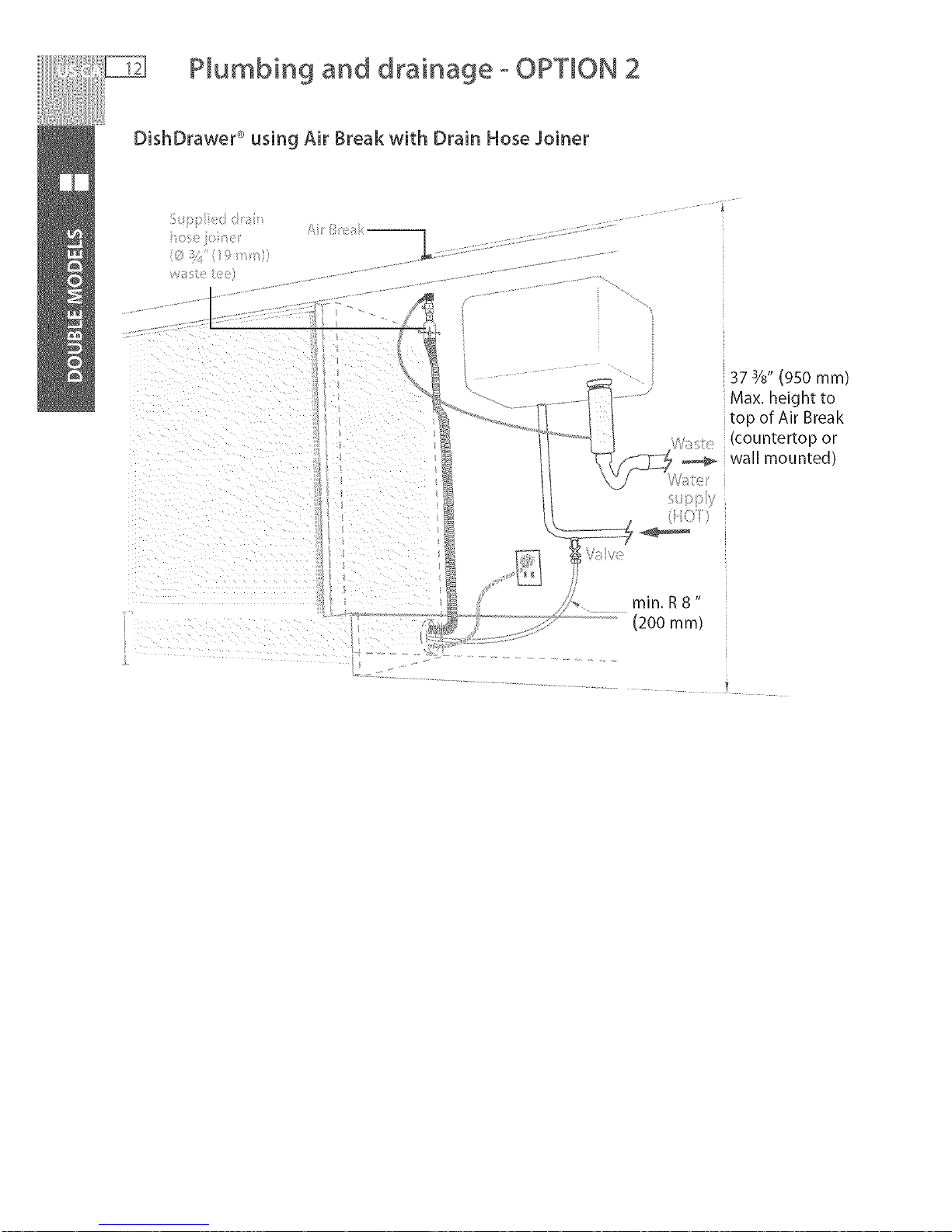

Plumbing and drainage oOP'T'IOB_2

Plumbing and drainage oOPTION 2 (connection

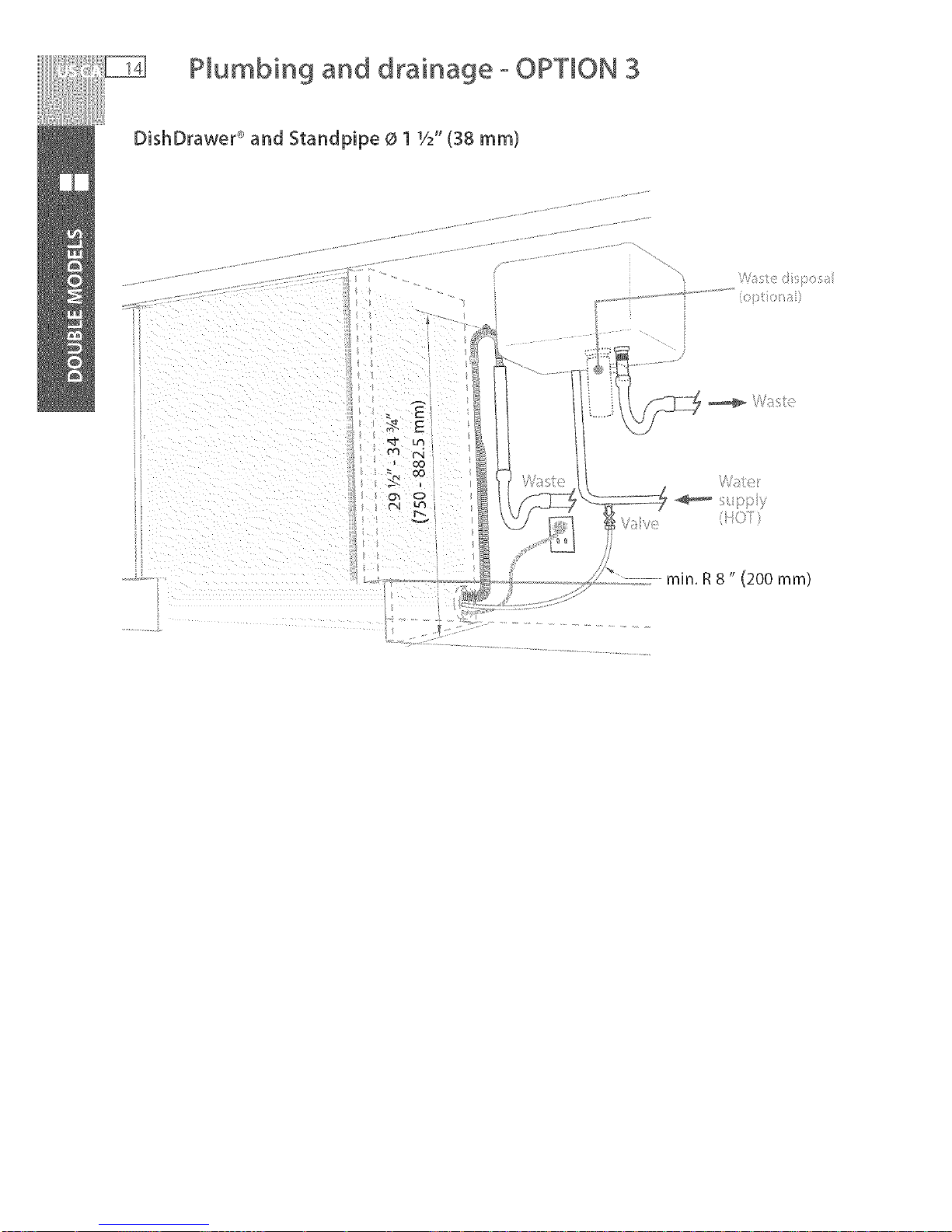

Plumbing and drainage oOPl'lOB_ 3

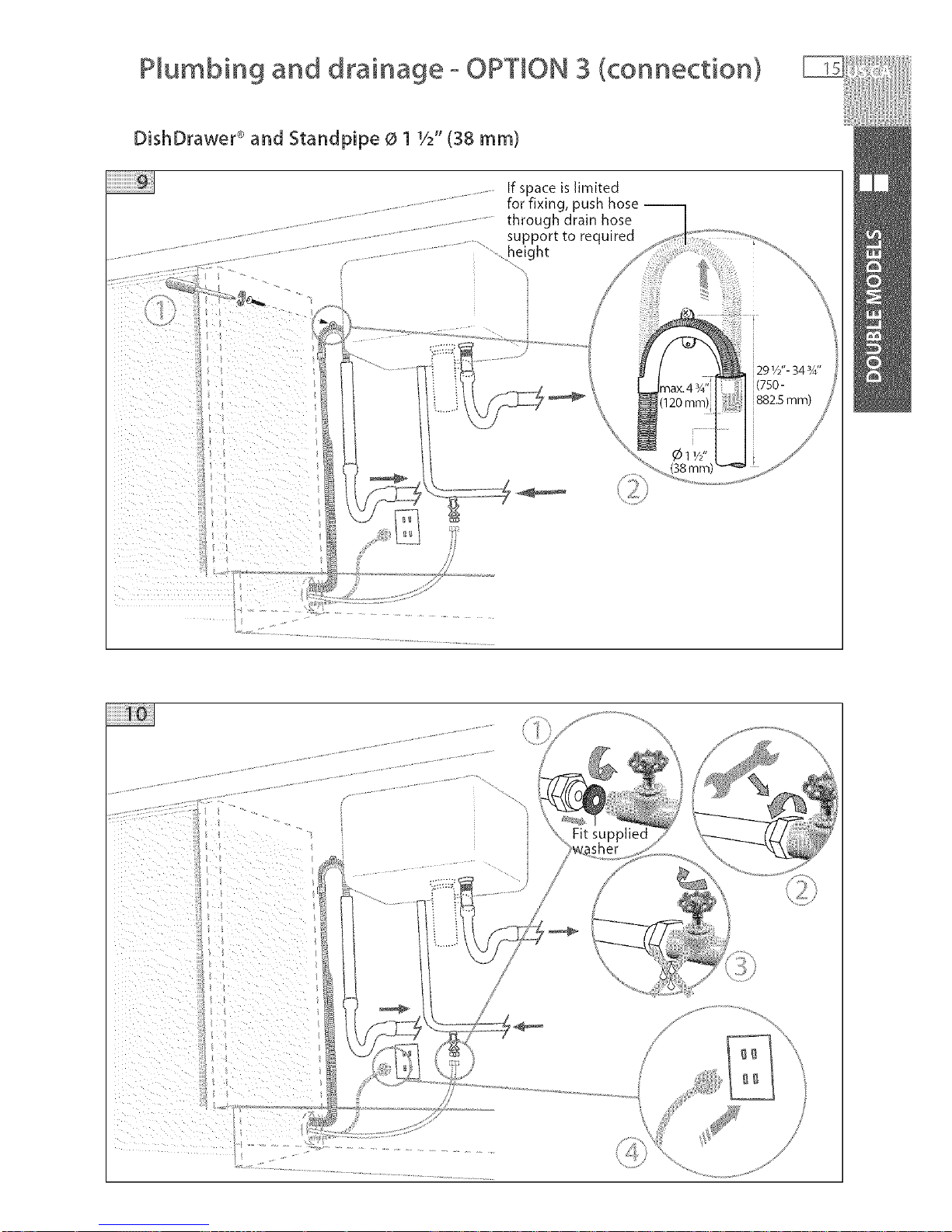

Plumbing and drainage OPl'lON 3 (connection

SINGLE MODELS

Product and cabinetry dimensions

Installation

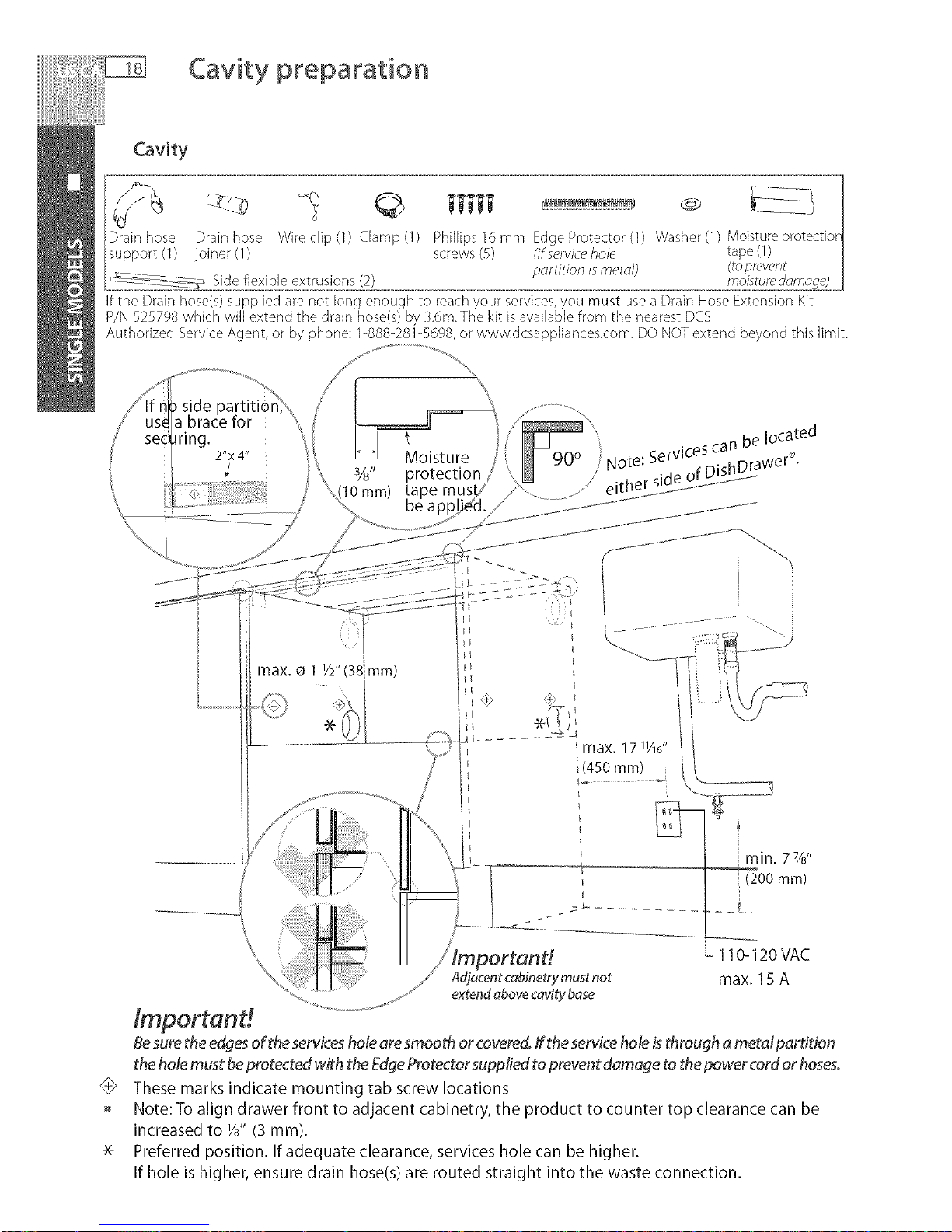

Cavity preparation

Optionally hard wiring the product

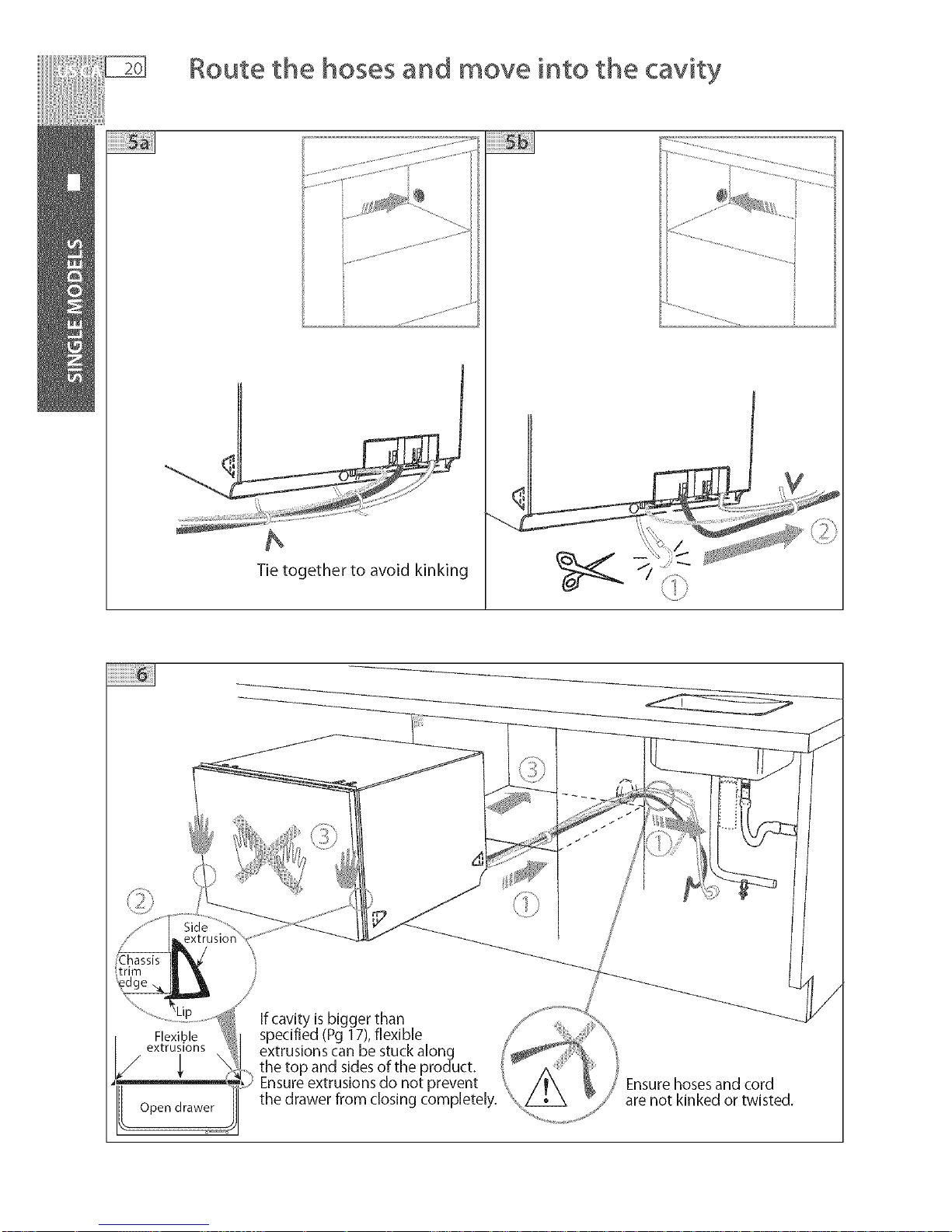

Route the hoses and move into the cavity

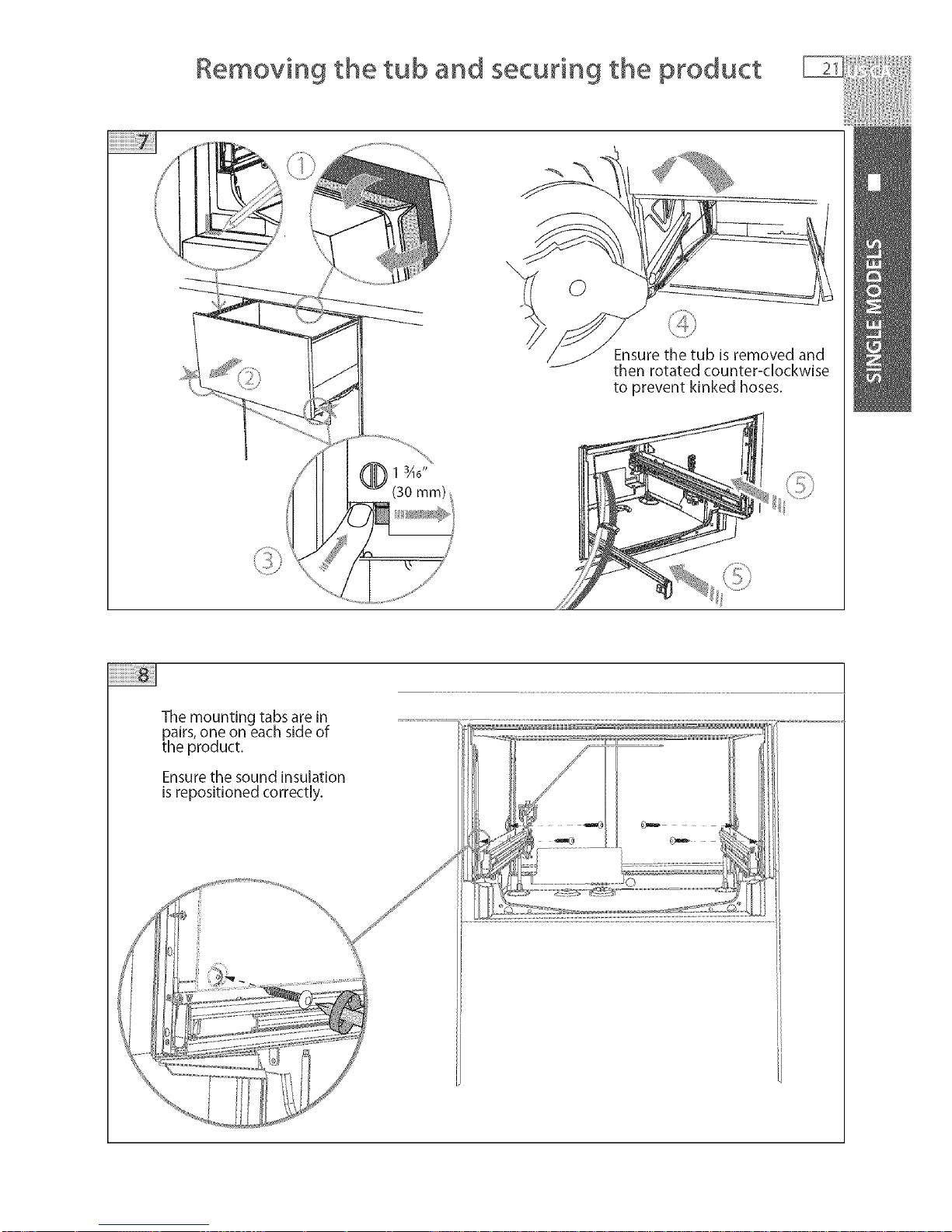

Removing the tub and securing the product

Plumbing and drainage oOP'T'IONI

Plumbing and drainage oOPTION 1(connection

Plumbing and drainage oOPl'lOB_ 2

Plumbing and drainage oOPTION 2 (connection

Plumbing and drainage oOPl'lON 3

Plumbing and drainage OPTION 3 (connection

Refitting the tub

Final checklist

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

20

21

22

23

24

25

26

27

28

29

lmportand

SAVE THESE INSTRUCTIONS

ThemodelsshowninthisUserGuidemaynotbeavailableinallmarketsandare

subjecttochangeatanytime.Forcurrantdetailsaboutmodelandspecification

availabilityinyourcountry,pleasegotoourwc,bsitewww.dcsappliances.comor

contact your iota/DCS Customer (?are Representative.

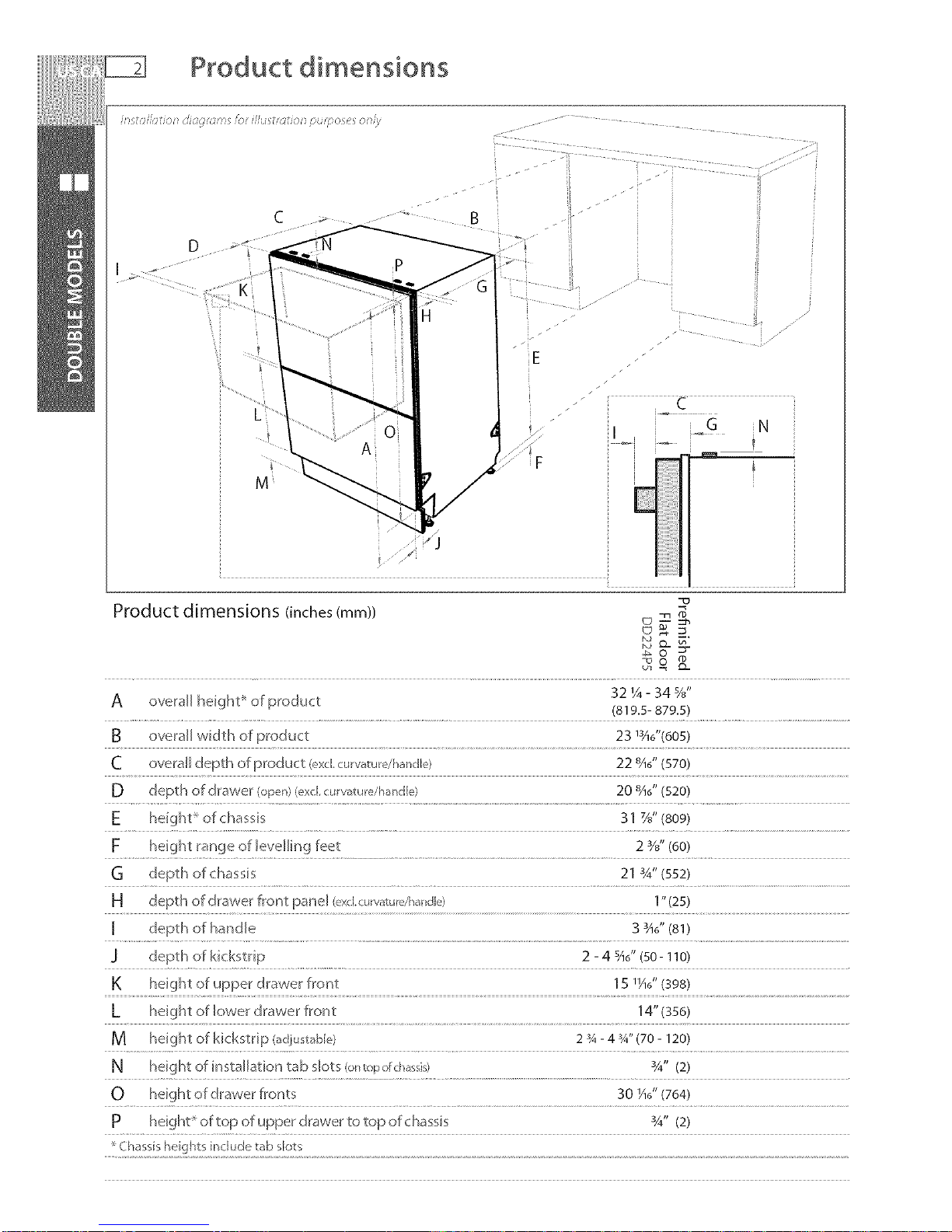

Product dimensions

hlst'Jii'J_io_ f£,grc,£'is _orii _istl_¢io_ oii_;>osus o_i

Product dimensions (inches (mm)) _ _-

32 _4- 34 s/d'

A overall height _ of product (819.5- 879.5)

B overall width of product 23 SA6"(605)

C overall depth of product (exd d rva ure/ha_dle) 22 sad'(570)

D depth of drawer (opt,9 (_xd curva ure/handk_) 20 8A6"(520)

E height" of chassis 31 7/d'(809)

F height range of levelling feet 2 3/8"(60)

G depth of chassis 21 3_,,(552)

H depth of drawer front panel (e×(l.culvature/hande) 1" (25)

[ depth of handle 3 3A6"(81)

J depth of kickstrip 2 - 4 sad' (50- 110)

K height of uppe_ drawer front 15 11A6"(398)

L height of lower drawer front 14"(356)

M heightofkickstrip(adjut hie) 2 34-4 34"(70 - 120)

N height of instdhtion tab slots (_r topof_ _asi9 SA" (2)

0 height of drawer fronts 30 ¼6" (764)

P height'_oftop ofupperdrawerto topofchassis s4" (2)

Chasss heights ncudetab slots

Cabinetry dimensions

D A

E

Cabinetry dimensions (inches (ram)) __

_4o_d

_o__

32 sA0- 34 3_,,

A inside height o[: cavity (820- 882.5)

B in ide width ofcavity 24"(610)

C inside depth of cavity (nsid_) 22 7/8"(580)

D height of adjacent cabinetry 28 3/8"(720)

E heigh_ of kickstrip 23/4-43/4"(70-120)

Minimum clearances (inches(mm))

3/811

mm)

Moisture

protection

// ............... \

....i_ 90 ° .ces can be locatedote: SerVl _ _n wer ®.

...._ /, N _ uisu_,ra

max. o 11/2"(38 nm)

_mpor_nt_ max. 15 A

Besure the edges of the services hole are smooth or covered. If the service hole isthrough a metal partition

the hole must beprotected with the EdgeProtector supplied to prevent damage to thepower cord or hoses.

<_> These marks indicate mounting tab screw locations

* Preferred position. If adequate clearance, services hole can be higher to clear toe kick space.

If hole is higher, ensure drain hose(s) are routed straight into the waste connection.

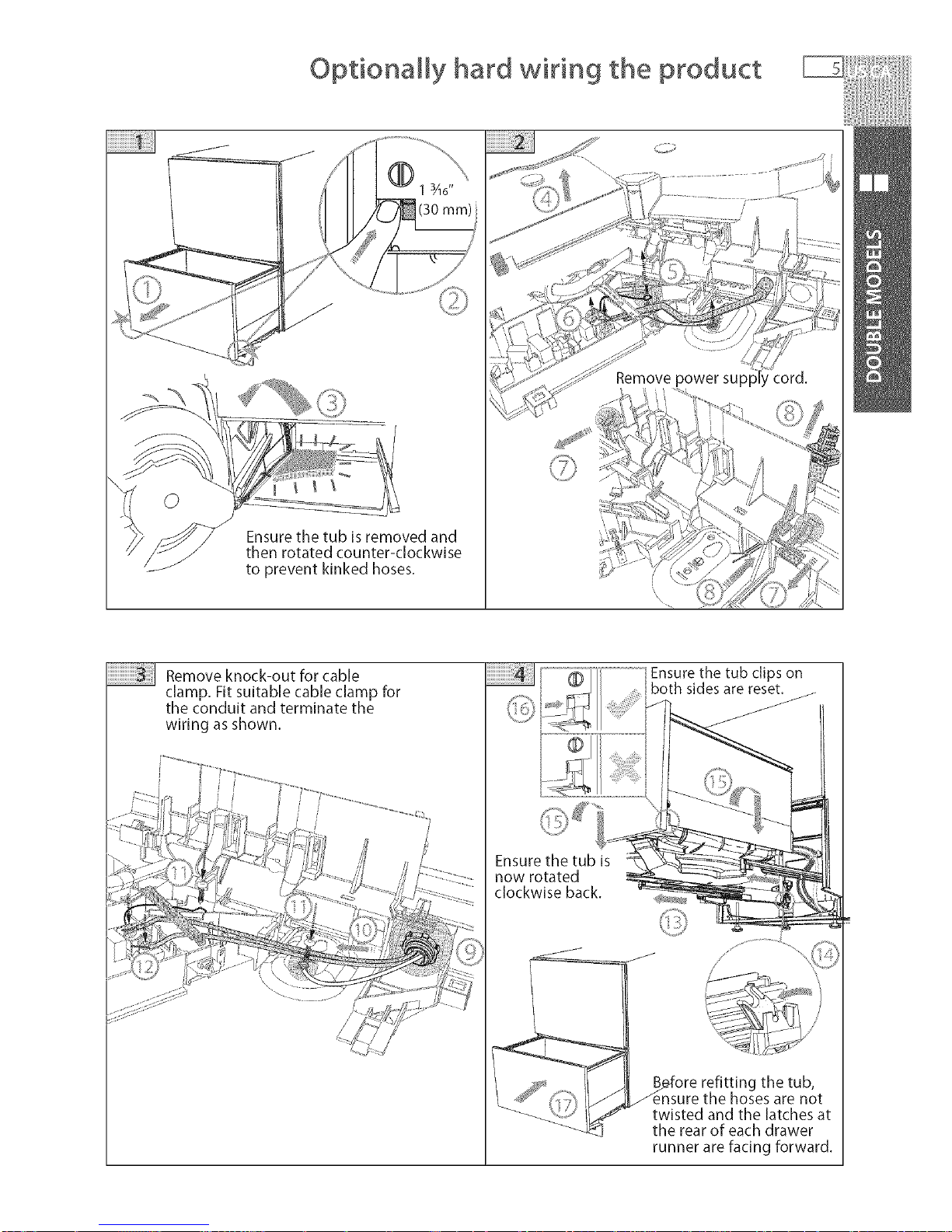

Optionally hard wiring the product

Ensure the tub is removed and

then rotated counter-clockwise

to prevent kinked hoses.

Remove knock-out for cable

clamp. Fit suitable cable clamp for

the conduit and terminate the

wiring as shown.

0 Ensure the tub clips on

both sides are reset.

Ensure the tub is

now rotated

clockwise back.

g the tub,

the hoses are not

twisted and the latches at

the rear of each drawer

runner are facing forward.

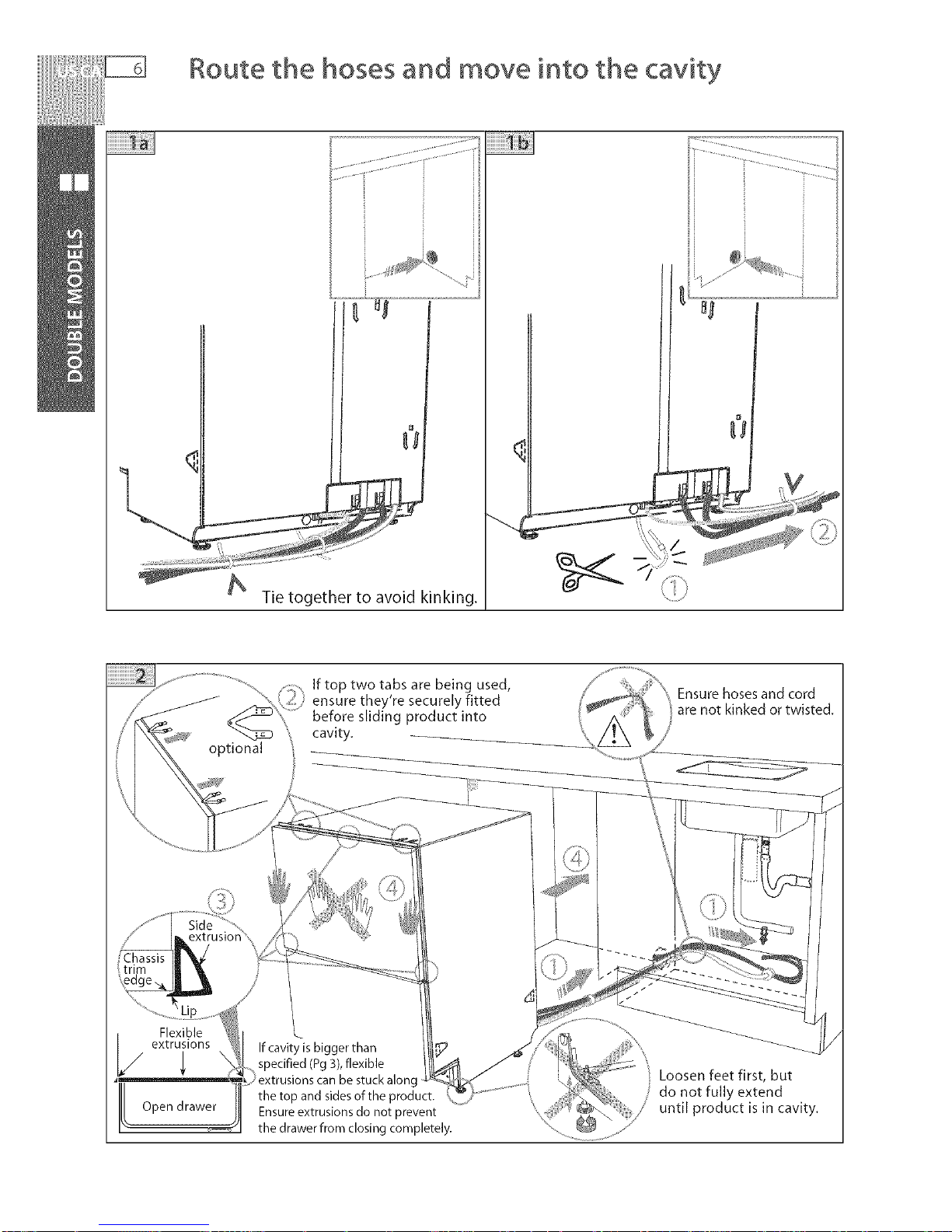

Route the hoses and move into the cavity

1

........................................,J: If top two tabs are being used,

..... "',, 2)

they're securely fitted

_ ,(ii(i:: ensure

before sliding product into

cavity.

optional

Ensurehosesand cord

are not kinked or twisted.

Flexible

_ extrusions Ifcavity is bigger than

specified (Pg 3),

flexible

extrusions can be stuck along

the top and sides of the product.

Open drawer Ensure extrusions do not prevent

the drawer from closing completely.

Loosen feet first, but

do not fully extend

until product is in cavity.

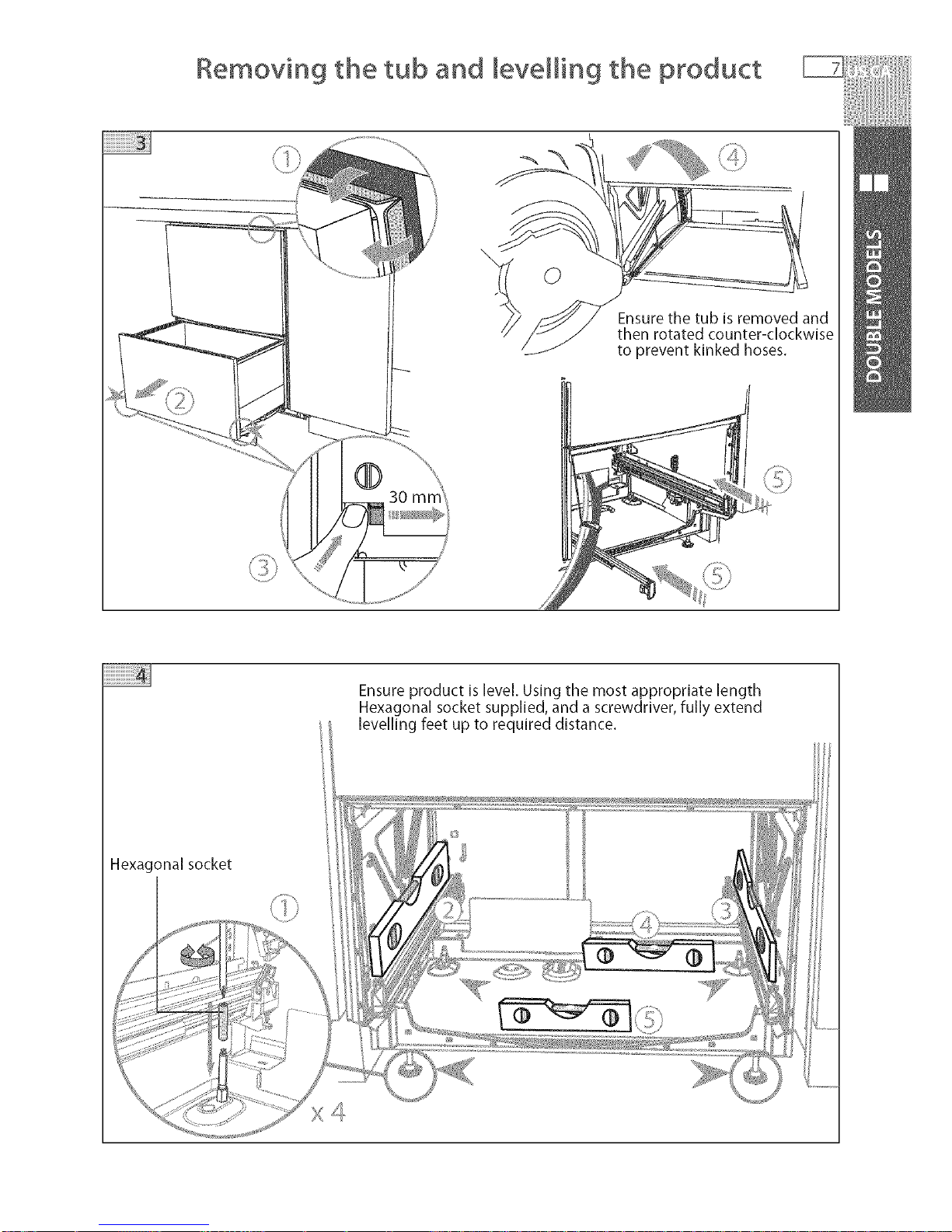

Removing the tub and levelling the product

// Ensure the tub is removed and

"/ then rotated counter-clockwise

to prevent kinked hoses.

Ensure product is level. Using the most appropriate length

Hexagonal socket supplied, and a screwdriver, fully extend

levelling feet up to required distance.

Hexagonal socket

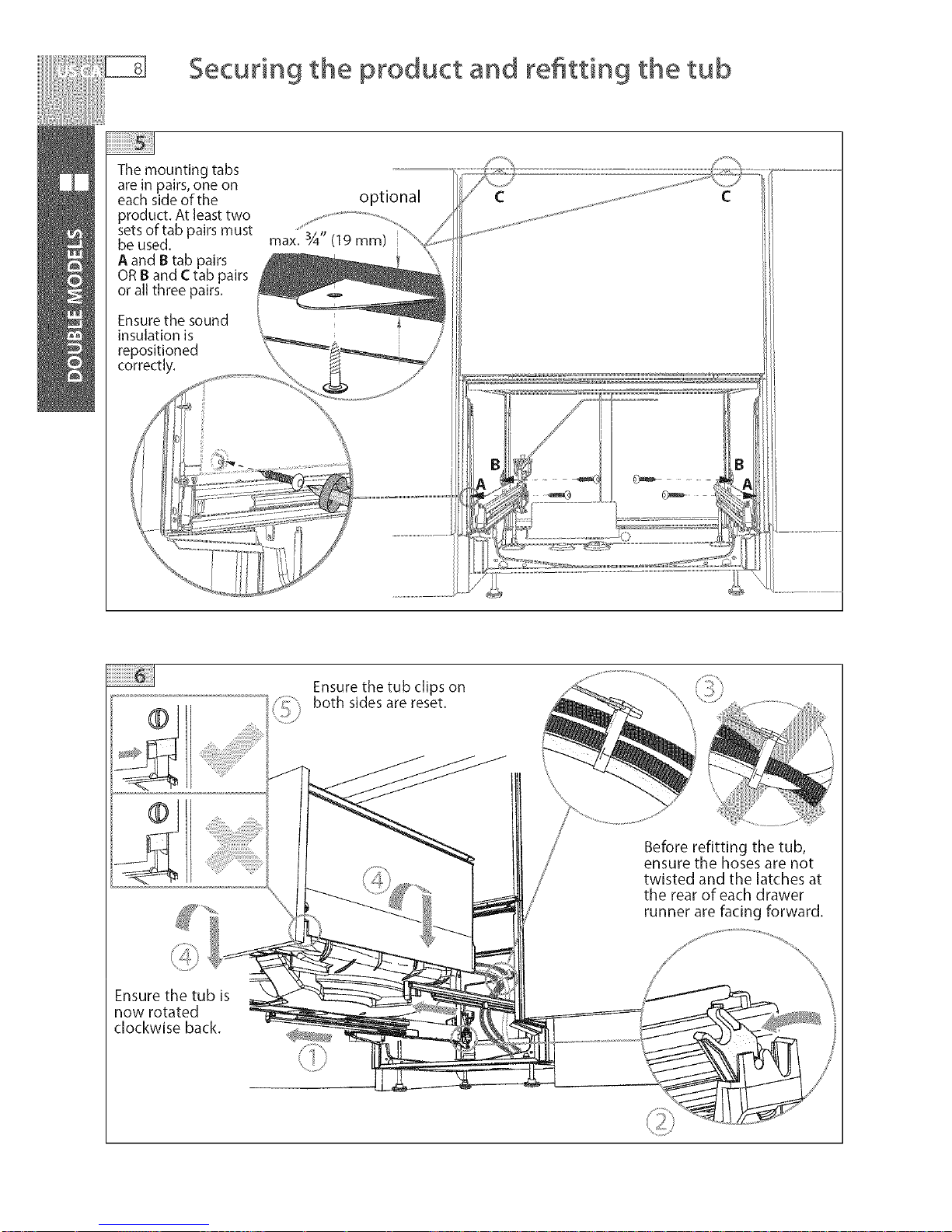

Securing the product and refitting the tub

The mounting tabs

are in pairs,one on

each side of the optional C C

product. At leasttwo _,,_..............

setsof tab pairs must 3/,',

beused, max. Y4 (]gmm)

A and B tab pairs

ORB and Ctab pairs

or all three pairs.

Ensurethe sound

insulation is

repositioned

correctly.

I

Ensure the tub clips on

(_'::_ both sides are reset.

% !

.....J

Before refitting the tub,

ensure the hoses are not

twisted and the latches at

the rear of each drawer

runner are facing forward.

Ensure the tub is

now rotated

clockwise back.

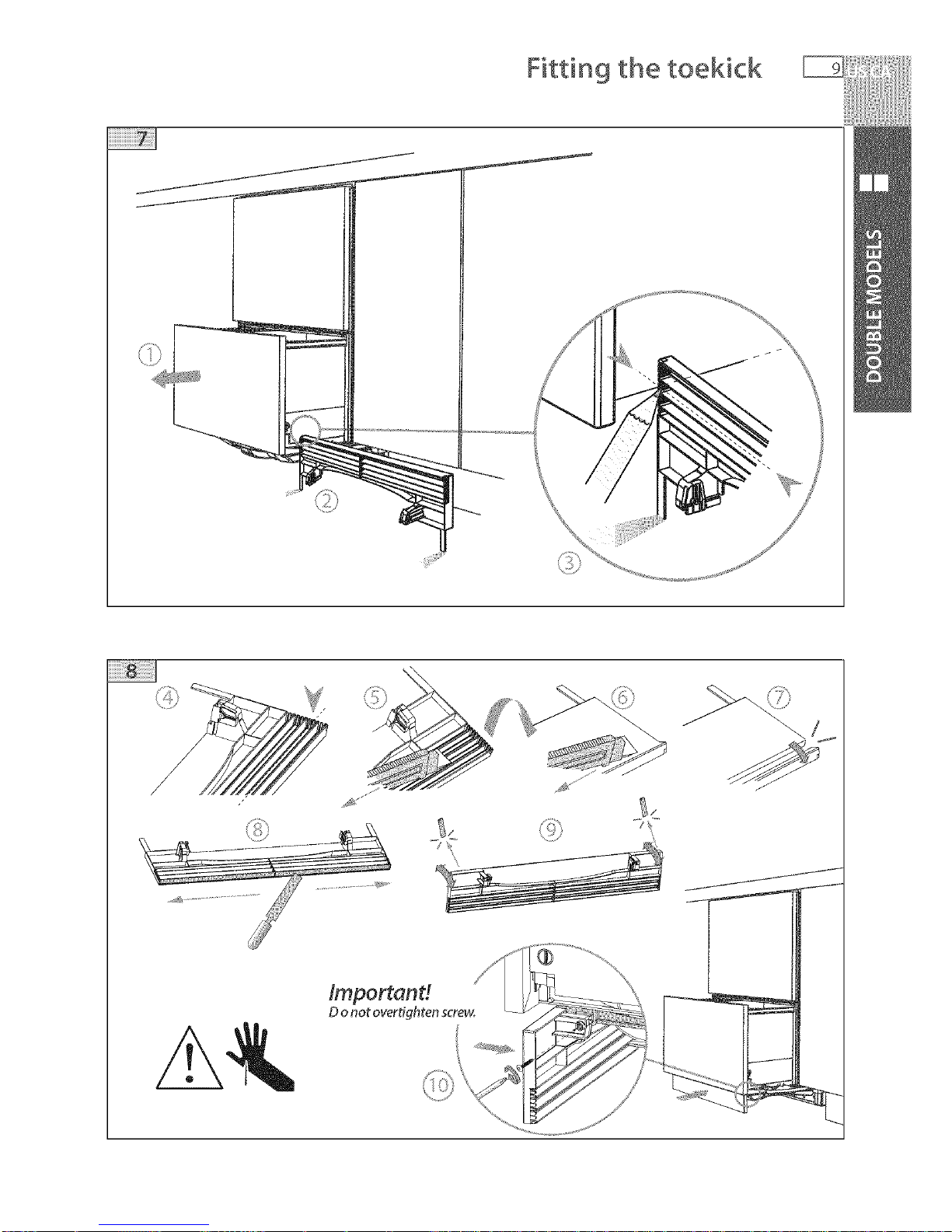

Fittin 9 the toekick

/ _7¸¸ x ...................

7: ......................................................

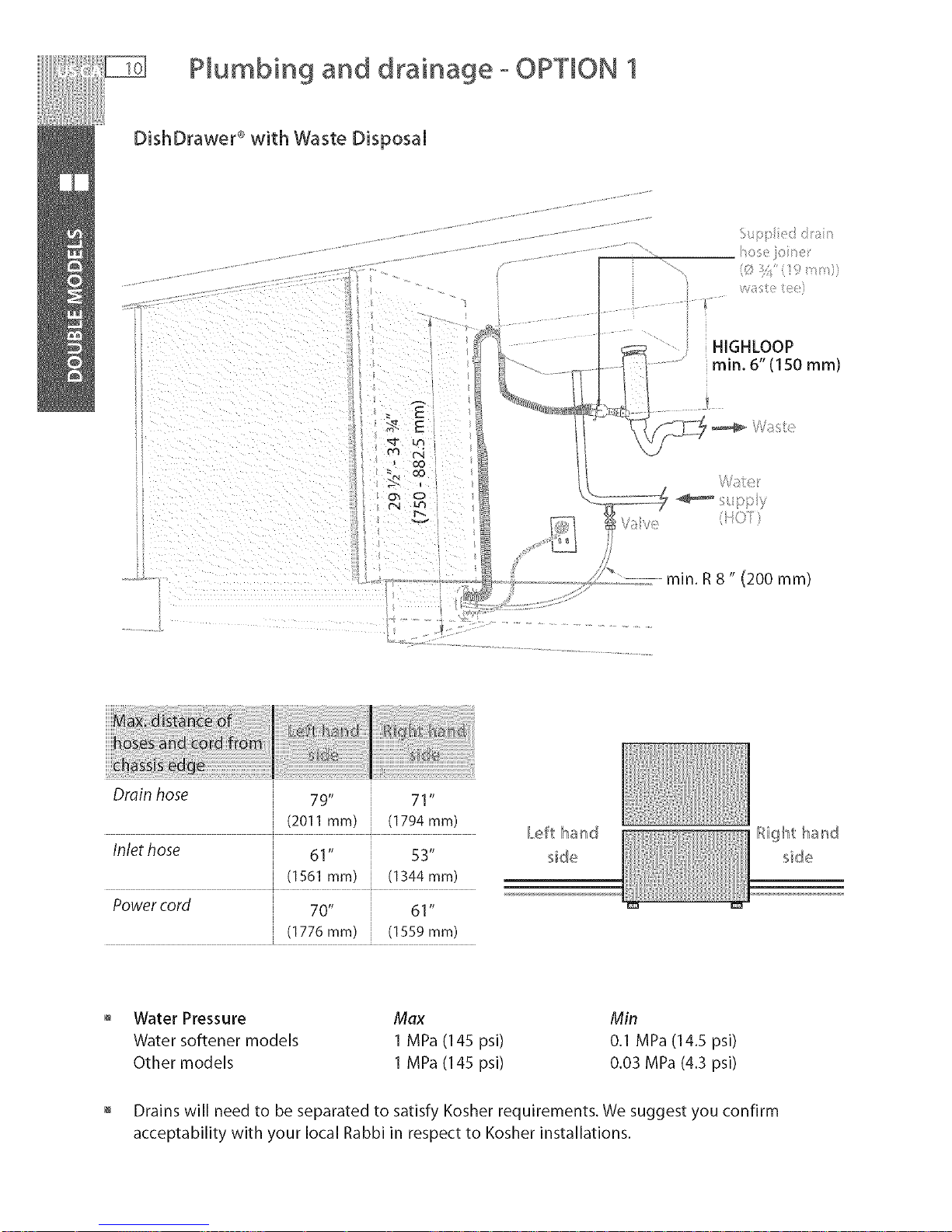

Drain hose 79" 71"

(2011 mm) (1794 ram)

Inlet hose 61" 53"

(1561 mm) (1344 mm)

Power cord 70" 61"

(1776 mm) (1559 mm)

ILefthand

side

Water Pressure Max Min

Water softener models 1 MPa (145 psi) 0,1 MPa (14.5 psi)

Other models 1 MPa (145 psi) 0,03 MPa (4.3 psi)

Drains will need to be separated to satisfy Kosher requirements. We suggest you confirm

acceptability with your local Rabbi in respect to Kosher installations.

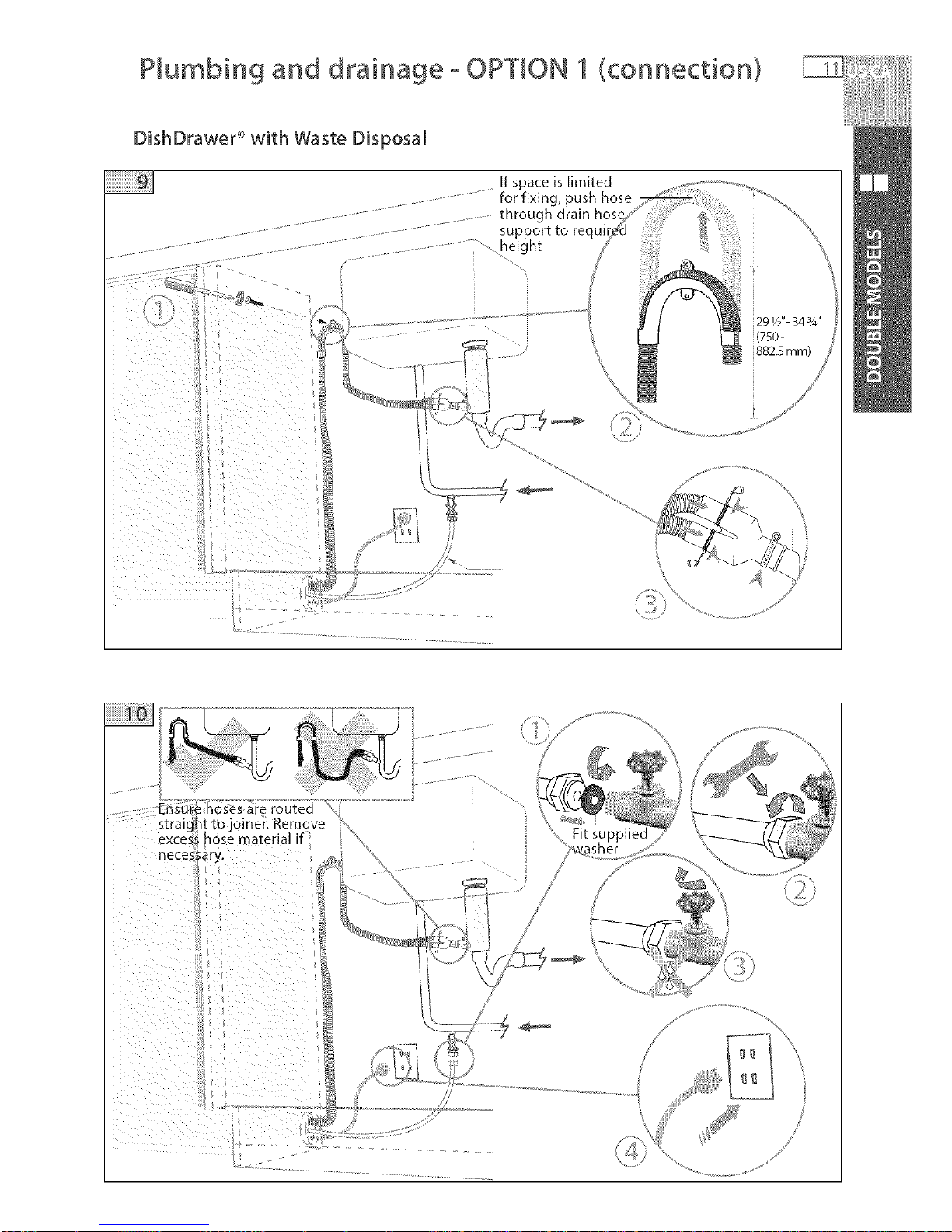

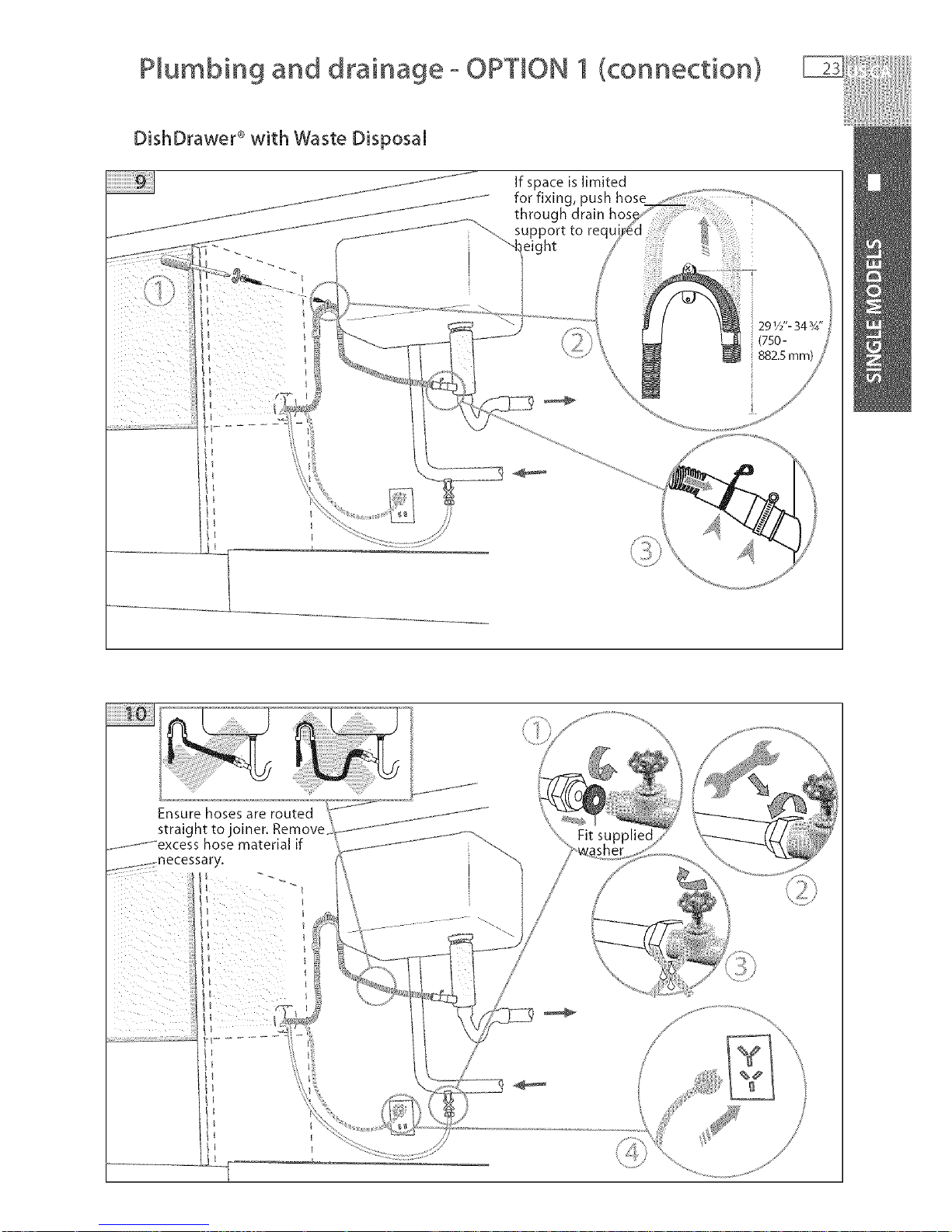

Plumbing and drainage - OPTION 1 (connection)

DishDrawer ®with Waste Disposal

If space is limited

.....................................................................................for fixing, push hose

through drain hos

................................................................................................support to requi

: tb joiner. Remove

_Osematerial if

!r).

i/ / /

i i /

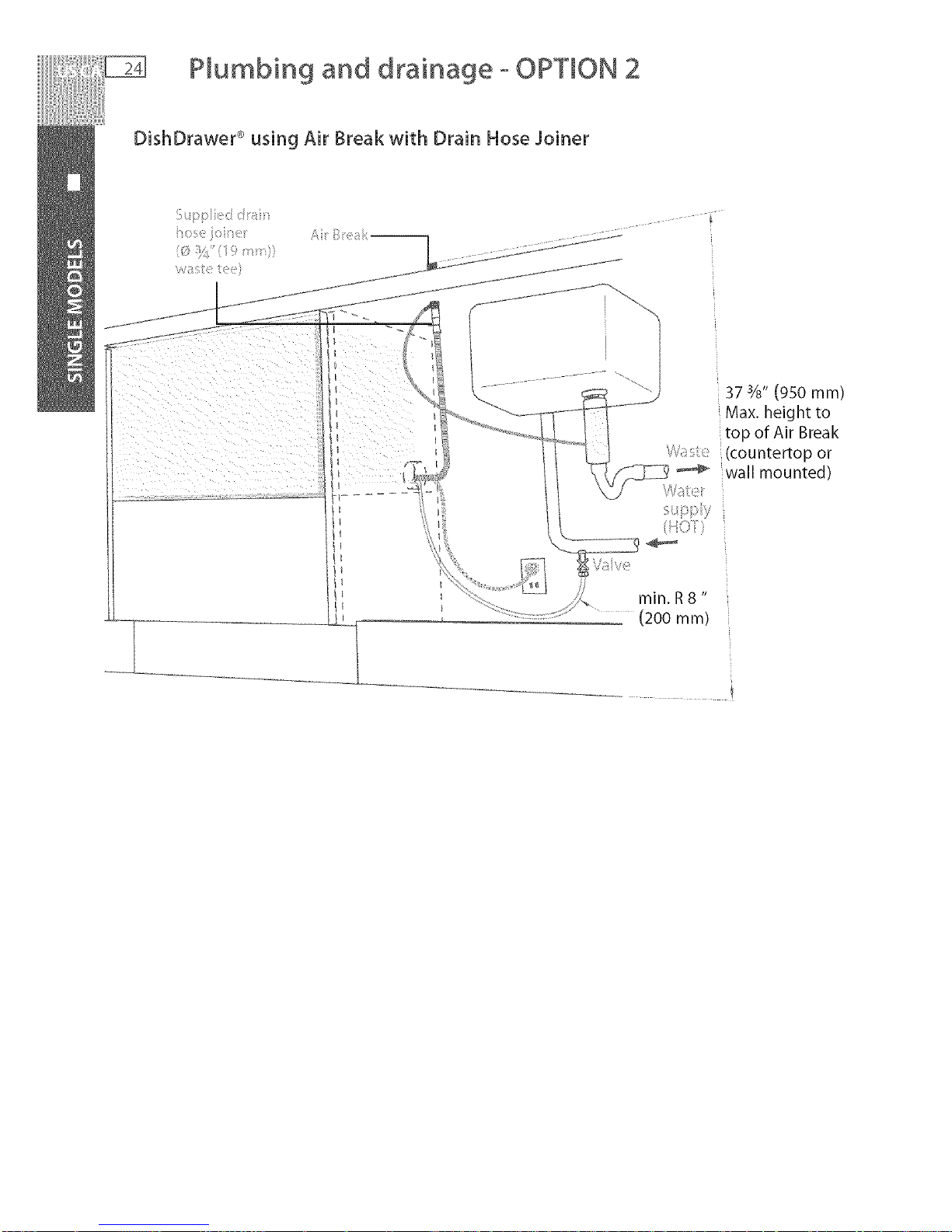

Plumbing and drainage ,oOPTION 2

i DishDrawer ®using Air Break with Drain Hose Joiner

'_ top of Air Break

_j_:::_ (countertop or

wallmounted)

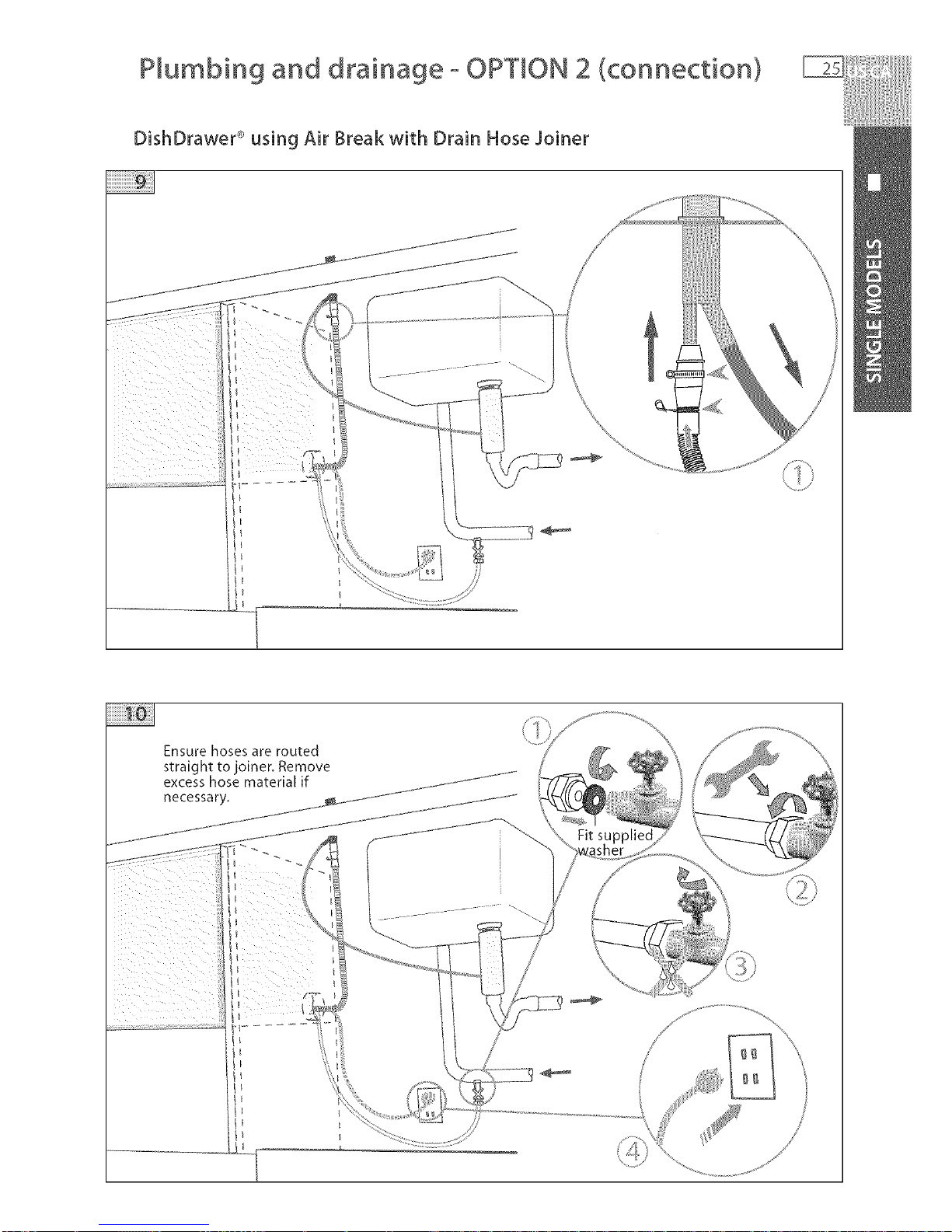

Plumbing and drainage - OPTION 2 (connection)

DishDrawer ®using Air Break with Drain Hose Joiner

Ensure hoses are routed

straight to joiner. Remove

excess hose material if

/ ..............................................................................................................

o

p

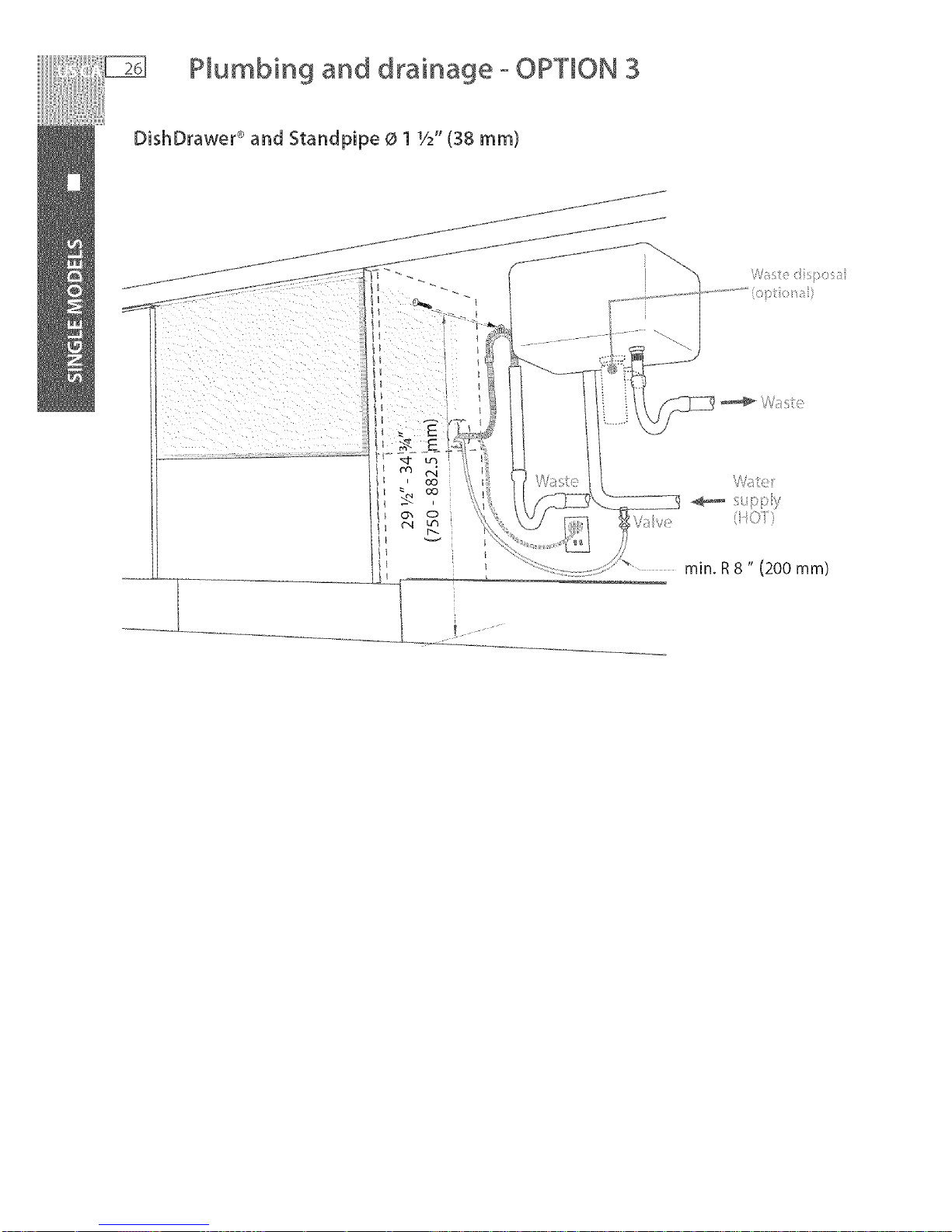

Plumbing and drainage - OPTION 3 (connection)

DishDrawer ®and Standpipe D1 1/I' (38 ram)

If space is limited

for fixing, r

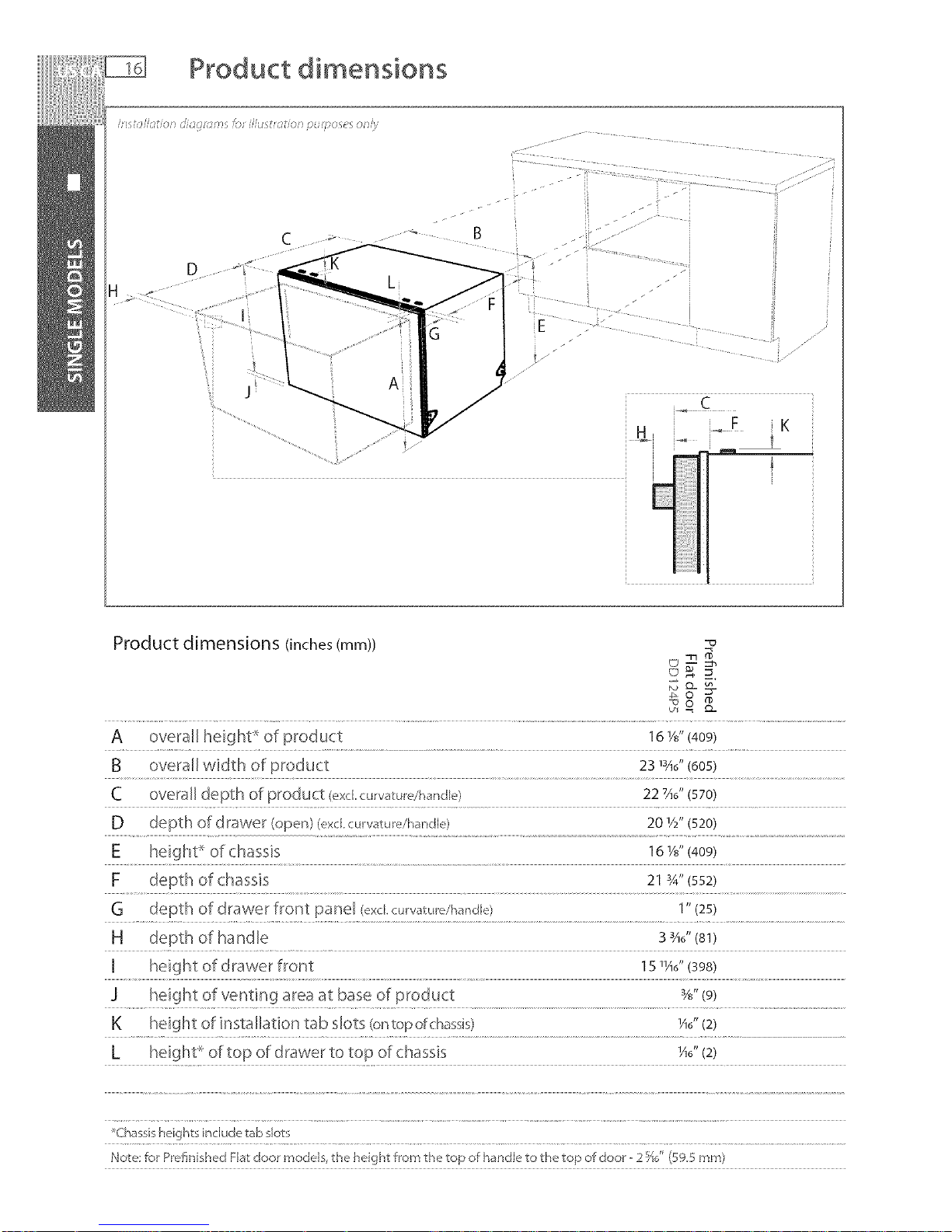

-7 Product dimensions

hlst'JiJoFio; rio:ton% "oI ii usFmFio; bii¢;_osus o; J

Product dimensions (inches (mm))

A overall height _ of product 16ys"(409)

B overall width of product 23 l+Ad'(605)

C overall depth of product (exd+curvature/hande) 22 TAd'(570)

D depth of drawer (open) (exc curvature/handle) 201/2"(520)

E height _+of chassis 16ys"(409)

F depth of chassis 21 3_,,(552)

G depth of drawer front pane[ (exc[.CLrvatLre/handle) 1" (25)

H depth of handle 3 346"(81)

I height of d rawer front 151¼6"(398)

J height of venting area at base of product 3/s"(9)

K height of installation tab slots (ontopdchass+s) ¼6"(2)

L height :_of top of d rawer to top of chassis ¼6"(2)

++Chassisheights include tab s[ots

Note: for Prefin shed Flat door modeB, the height flora the top of handle to die top oFdoor - 2 _," (595 rnm)

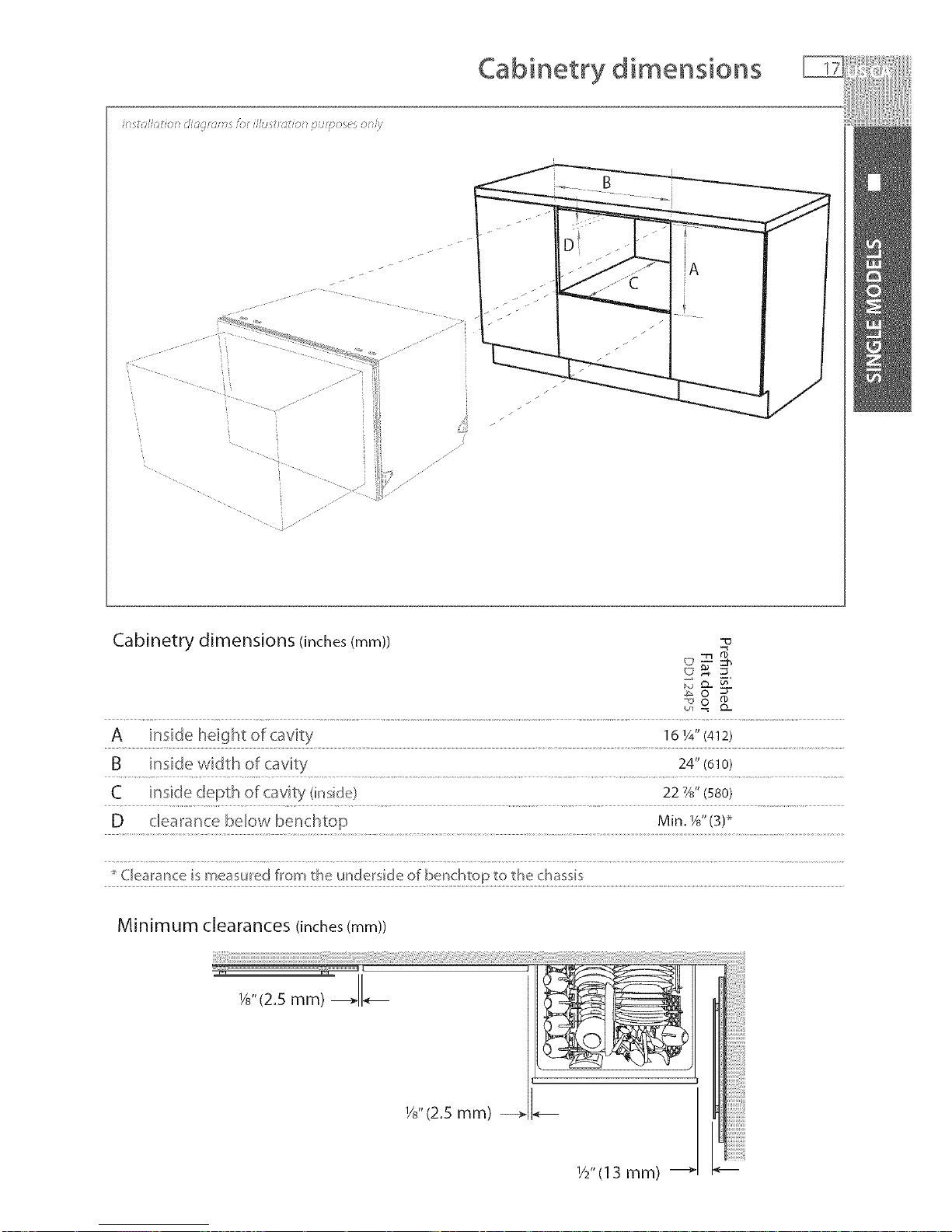

Cabinetry dimensions

Cabinetry dimensions (inches (ram))

¢_ 0

A inside height of cavity 161A'(412)

B inside width of cavity 24"(610)

C inside depth of cavity (inside) 22 Ys"(580)

D clearance below benchtop Min,Ys"(3)_

Clearance is measured from the underside of benchtop to the chassis

Minimum clearances (inches(mm))

÷

min. 7Ys"

t

I (200 mm)

110-120VAC

Adjacentcabinetrymustnot max. 15A

extend above cavity base

lmportand

Besuretheedgesoftheservicesholearesmoothorcovered,if theserviceholeisthroughametalpartition

theholemustbeprotectedwith theEdgeProtectorsuppliedtopreventdamageto thepowercord orhoses.

These marks indicate mounting tab screw locations

Note: Toalign drawer front to adjacent cabinetry, the product to counter top clearance can be

increased to 1/s"(3 ram).

Preferred position. Ifadequate clearance, serviceshole can be higher.

If hole is higher, ensure drain hose(s)are routed straight into the waste connection.

Optionally hard wiring the product

Ensure the tub is removed and

then rotated counter-clockwise

to prevent kinked hoses.

Remove knock-out for cable

clamp. Fit suitable cable clamp for

the conduit and terminate the

wiring as shown.

Ensure the tub clips on

both sides are reset.

now rotated

clockwise back.

Before refitting the tub, ensure the hoses are

not twisted and the latches at the rear of each

drawer runner are facing forward.

Route the hoses and move into the cavity

.....................i

Tie together to avoid kinking

Flexible

extrusions

Open drawer

If cavity is bigger than

specified (Pg 17),flexible

extrusions can be stuck along

the top and sides of the product.

Ensure extrusions do not prevent

the drawer from closing completely.

Ensure hosesand cord

are not kinked or twisted.

Removing the tub and securing the product

Ensure the tub is removed and

then rotated counter-clockwise

to prevent kinked hoses.

@ ] 3_6"

(30 mm)

The mounting tabs are in

pairs, one on each side of

the product.

Ensurethe sound insulation

is repositioned correctly.

:HIGHLOOP

rain. 6"(150 ram)

rain. R8" (200 ram)

Drain hose 79" 71"

(2011 ram) (1794 ram)

Inlet hose 37" 53"

(1561 ram) (1344 ram)

Power cord 61" 28"

(936 ram) (719 ram)

ILeft hand

side

side

Water Pressure Max Min

Water softener models 1MPa (145 psi) 0,1 MPa (14.5psi)

Other models 1MPa (145 psi) 0.03 MPa(4.3psi)

P[umbin 9 and drainage - OPTION 1 (connection)

DishDrawer ®with Waste Disposal

29 V2"- 34 ¾"

(750-

882,5 mm)

hose material if

i!

i

37 3/8" (950 ram)

Max. height to

(top of Air Break

W;_se (countertop or

_ wall mounted)

W_te_

min. R8 "

(200 mm)

PJumbin9 and drainage - OPTION 2 (connection)

DishDrawer ®using Air Break with Drain Hose Joiner

iill __ii_II_ i_Ii_:ii_iii

ii: kkl i i _

t

Ensure hoses are routed

straight to joiner. Remove

excess hose material if

necessary.

min. R8 " (200 mm)

Loading...

Loading...