DCS CE-PHFS-DW-BK-L, CE-PHFS-DW-BL-L, CE-PHFS-DW-BZ-L, CE-PHFS-DW-WT-L, CE-PHFS-DW-GN-L Use And Care Manual

...Page 1

THE PHOENIX 111 PATIO HEATER

Use and Care Guide

Models:

■

CE-PHFS-D W-BK-L

■

CE-PHFS-D W-BL-L

■

CE-PHFS-D W-BZ-L

■

CE-PHFS-D W-GN-L

■

CE-PHFS-D W-SS-L

■

CE-PHFS-D W-WT-L

D y namic Cooking S y stems , I nc .

Page 2

1

A Message To Our Customers

We are glad you selected the Phoenix III by DCS. Because this appliance contains features not found on any

other patio heater, we recommend that you read this entire booklet before your first use. Keep it in a handy

place as it has answers to questions that may occur during future use. Feel free to contact us if we can help

you. When you write please include the model number of the heater. We thank you for buying the patio

heater Made in America and wish you many years of enjoyment.

To help serve you better, please fill out and return the Ownership Registration Card and keep this guide handy,

as it will help answer questions that may arise as you use your DCS Phoenix III.

For your convenience, product questions can be answered by a DCS Customer Service

Representative by phone:1-714-372-7000, or Fax: 714-372-7003,

or by mail:

DCS

Attention Customer Service,

5800 Skylab Road, Huntington Beach, CA 92647

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result causing property damage,

personal injury or death.

PRECAUTION

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

WARNING

Improper installation, adjustment alteration, service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions thoroughly before use, installing or servicing this

equipment. For outdoor use only.

FOR YOUR SAFETY WHAT TO DO IF YOU SMELL GAS

• Shut off gas to the appliance.

• Extinguish any open flame.

• If odor continues,immediately call your gas supplier.

PLEASE RETAIN THIS MANUAL

FOR FUTURE REFERENCE.

Page 3

2

Tab le O f Contents

SAFETY PRACTICES AND PRECAUTIONS

......................................................................3

FEATURES...............................................................................................................................................4

ASSEMBLY TOOL & FASTENERS

.............................................................................................4

GAS SPECIFICATIONS

.....................................................................................................................4

ASSEMBLY INSTRUCTIONS

.....................................................................................................5-8

LP GAS HOOK-UP

................................................................................................................................9

GAS SOUNDNESS

..............................................................................................................................10

REFLECTOR SHIELD ASSEMBLY INSTRUCTIONS

...................................................11

LOCATING HEATER FOR USE

.................................................................................................12

LIGHTING INSTRUCTIONS

......................................................................................................13

STORAGE / INSECT WARNING

..............................................................................................14

BURNER REMOVAL / INSTALLATION

...............................................................................15

PILOT CLEANING

..............................................................................................................................16

TROUBLESHOOTING GUIDE

.............................................................................................17-18

PARTS LIST

.......................................................................................................................................19-20

Page 4

3

S afety P ractices & P recautions

• Read and become familiar with the entire manual.

• Do not use in an explosive atmosphere,keep heater away from areas where gasoline or other

flammable liquids or vapors are stored or used.

• Before each use check for damaged parts such as hoses,regulators, pilot or burner.

• Do not attempt to alter unit in any manner, ie: shorten post length, bypass safety valve or operate

heater without the reflector.

• Heater must always be placed on a hard and level surface.

• Always maintain proper clearance to combustible materials.(Top 19’’ sides and rear 27”),

see page 11.

• Never replace or substitute the regulator with any other regulator other than a factory suggested

replacement.

• It is imperative that the control compartment,burners, and circulating air passageways of the heater

must be kept clean. The heater should be inspected before each use, and at least annually by a

qualified service person, for the presence of spiders,webs or other insects. The burner area is a

common and desired spider haven. Spider webs can present a dangerous condition which can

damage the heater and render it unsafe for use.

CHECK THE HEATER IMMEDIATELY IF ANY OF THE FOLLOWING

CONDITIONS EXIST

1)The smell of gas in conjunction with extreme yellow tipping of the burner flames.

2)The heater does not reach temperature.

3)The heater glow is excessively uneven.

4)The burner makes popping noises during use. (a slight popping noise is normal when the

burner is extinguished).

• Installation must be carried out in accordance with local regulations in force.

• Do not clean heater with combustible or corrosive cleaners.

• Do not use if wind velocity is greater than 10 miles per hour, because of flame out possibility.

• To avoid the risk of burns or accidental clothing ignition,do not touch the heater anywhere near the

burner assembly during operation.

• Do not touch the burner assembly or reflector shield until after the heater has cooled for

approximately 20 minutes after use.

• Carefully monitor young children in the vicinity of any operating heater.

• Never connect an unregulated gas supply.

• Always ensure that there is ample fresh air ventilation.this unit is for outdoor use only.

• Do not hang clothing or any other flammable materials from,on, or near the heater.

• A minimum inlet pressure must not exceed 100 psi.

• The heater is shipped from the factory for LP use. never substitute gases without first converting the

heater with a factory supplied conversion kit.

•A minimum supply pressure of 37 mbar is required for the purpose of input adjustment.

• Do not paint either the emitter screen, valve panel or reflector.

•All leak tests should be done with a soap solution.

• Matches should never be used for this purpose.

•The LP tank should be turned off when the heater is not in use.

• Do not install unit in basements or below ground level.

•Avoid twisting the flexible tube. Regularly check the gas supply hose for wear, replace as necessary.

• Ser vicing must be carried out by a qualified technician.

Page 5

4

Features

• W eatherproof • All High Heat Parts Made Of Stainless Steel

• Uniform Heat Pattern • Flame Out Protection Safety Control Valve

• Durable Non-Slip Wheels • Weighted Base For Stability / Low Maintenance

• Piezo Spark Ignition • Easy Access Door With A Positive Latch

• Heats (16’-20’) Diameter Area • Large Stainless Steel Emitter Grid

• Uses 13 kg LP Tank

(not included) • Easy Access Door With A Positive Latch

TOOLS NEEDED

• Phillips Head Screwdriver • Channel Lock Pliers (Min.2” Capacity)

• Pipe Wrench ( 2” or larger) • Open End (7/16”,3/4”,7/8”, and 15 /16” Wrenches

GAS SPECIFICATIONS

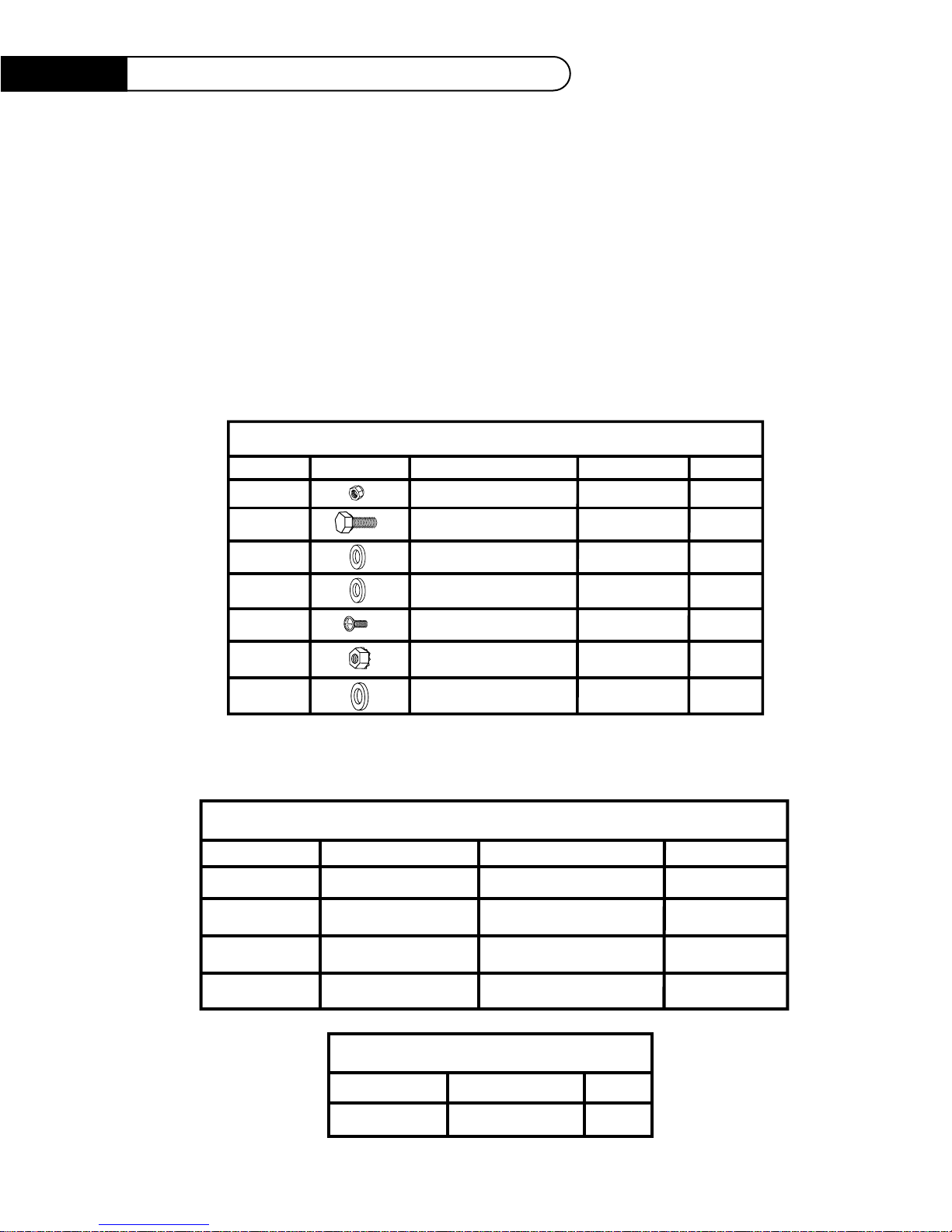

FASTENER DIRECTORY

ITEM

1

2

3

4

5

6

7

SPECIFIED CATEGORY AND DELIVERY PRESSURES:

GAS CATEGORY

1 3P

1 3P

PICTORIAL

1/4-20 ACORN NUT

WASHER - FLAT - SS

WASHER - SPLIT - SS

NYLON WASHER

OPERATING PRESSURE

37 m

bar

50 m

bar

DESCRIPTION

1/4-20 BOLT

no. 10 - 24 X 1/2

S/S SCREWS

1/4-20 KEPS NUT

GB, IE, FR, BE, P

15005-08

COUNTRY

T

N

L

, E

S

PART NUMBER

15019-02

15003-06

15005-15

15005-10

15001-26

15021-09

, E

S

, CH

QTY.

4

8

12

4

3

12

8

INJECTOR SIZE

50 DMS

52 DMS

1 3B/

P

1 3B/P

30 m

bar

50 mbar

UNIT GROSS INPUT RATING

G31 PROPANE

G

30 BUT

A

N

E

43,000 Btu / hr

43,000 Btu / hr

DK, SE, FI, N

FR, D

E

, CH, A

L

T

12.6 Kw

12.6 Kw

50 DMS

53 DMS

Page 6

5

As semb ly I ns tructions

NOTE: Assembly of this heater requires basic mechanical skills. Proper assembly is the responsibility of

the installer.

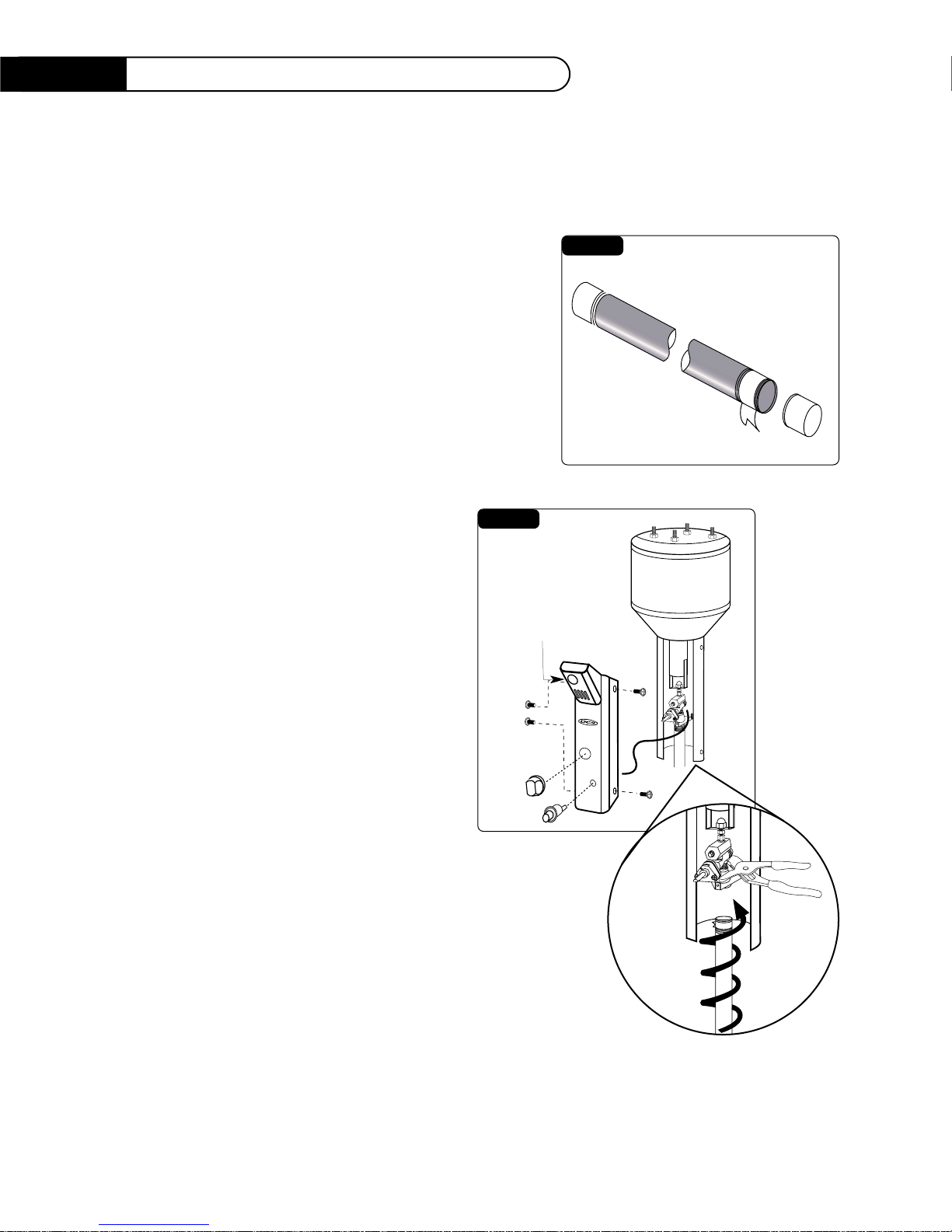

STEP 1

Remove all individual components from all cartons.Dispose

of the remaining packaging.

STEP 2

Remove one protective end cap from the intake pipe, make

certain pipe threads remain wrapped with white teflon tape.

• Do not tape over the first two threads at the of the intake

pipe (fig.01)

STEP 3

Locate the heater head assembly. Place the head

assembly on a stable horizontal surface. Please

allow for the entire length of the patio heater

when establishing a work area (i.e.workbench,

floor). Remove valve panel by removing the knob

then the (4) screws. Be careful when removing

valve panel so as not to tug on igniter wire that is

still attached. Carefully remove wire,(attached

with a push/pull connection).

Firmly holding the safety valve with channel lock

pliers,thread the intake pipe clockwise into safety

valve until tight. Reattach the valve panel and

continue to step 4 to attach the post assembly.

FIG.01

D

y

n

a

m

i

c

C

o

o

k

i

n

g

S

y

s

t

e

m

s

,

I

n

c

.

FIG.02

Match

Light Cover

Page 7

6

As s emb ly I ns tructions

STEP 4

Remove the protective endcap at the bottom of the intake pipe.Make certain that the threads remain

bare.Locate the reducer fitting and thread it onto the open end of the intake pipe. Hold the intake

pipe above the threads with your channel lock pliers and tighten the reducer fitting clockwise onto the

intake pipe.

HARDWARE USED

1) P/N 18159 Reducer Fitting (1)

FIG.03

STEP 4

INTAKE PIPE

CHANNEL LOCK

PLIERS

INSTALL REDUCER

FITTING

Page 8

As semb ly I ns tructions

7

STEP 5

Locate the post assembly. Carefully insert the

intake pipe through the top of the post assembly

being careful not to allow the head assembly to

slide too far down the post as undue scraping may

occur. Align the screw holes on the panel of the

burner head and the post assembly.Fasten the

burner and post with the #10 screws.

HARDWARE USED

1) P/N 15001-26 #10 Machine Screws (3)

STEP 4

STEP 5

POST

BASE COVER

Page 9

As semb ly I ns tructions

8

STEP 6

To join the post assembly with base cabinet

you will need to place the base upright on the

floor and lift the post assembly and place it

onto the cabinet with the burner panel facing

the same side as the door. Tighten the (8)

nuts and bolts at the bottom of post assembly

to the top of the cabinet base. Replace valve

panel utilizing step 2 in the reverse order.

HARDWARE USED

1) P/N 15003-05 1/4-20 Bolts (8)

2) P/N 15005-08 Washers Nylon (8)

(Painted Models Only)

3) P/N 15021-09 1/4-20 Keps Nuts (8)

STEP 7

Hold the reducer fitting with a 15/16” wrench

and tighten the hose / regulator assembly onto

the reducer fitting.(Not included)

STEP 8

Do not attach the reflector shield until all

leak testing has been completed. This unit is

tippable once the post assembly is fastened to the cabinet base and could damage or misshapen

the reflector shield prior to use.

FIG.06

FIG.05

3

2

1

HIGH

PRESSURE HOSE

Page 10

LP Gas Hook-Up

9

The heater comes equipped with a regulator/hose assembly for connection to a standard 13kg

gas tank

(not included) and 18” tank strap to secure the tank within the base. A dented or rusty LP

tank may be hazardous and should be checked by your LP supplier.

Never use an LP tank with a damaged valve. The LP tank must be arranged to provide for vapor

withdrawal from the operating cylinder.

Never connect an unregulated LP tank to the heater. The heater is shipped from the factory for LP

use, never substitute gases without first converting the heater with a factory supplied conversion kit.

Conversion kits are available through customer service.

LP GAS CONNECTION-REFERENCE

The heater is designed to house a 13 Kg.gas cylinder in the base assembly. Open the door,and

place the cylinder into the housing. The regulator can then be screwed into the cylinder. The regulator

and the tank have right-handed threads (clockwise to tighten no teflon tape is required). When

tightening be careful not to put too much force on the cylinder valve.

CHECK THE FOLLOWING CONNECTIONS

1) Regulator to gas cylinder.

2) All connections on the hose/regulator assembly.

3)The reducer fitting and the intake pipe.

4) Intake pipe fitting at base of safety valve. The remaining connections are to be tested after the

heater has been lit. (See lighting instructions on page 12).

5) Pilot tubing to safety valve.

6) Orifice fitting and Safety valve.

7) Pilot tubing and the pilot. Once leak tested, close the door and replace the valve panel.

NOTE: Gas connections on the heater head assembly

are leak tested at the factory prior to

shipment.

FIG.07

GAS CYLINDER

(NOT INCLUDED)

2

1

3

Page 11

10

PRECAUTIONS

• Periodically check the whole gas system for leaks

or immediately check if the smell of gas is

detected.

• Extinguish all open flames

• Never leak test while smoking. If you can not

stop a leak,turn off the cylinder valve and call

the dealer you purchased the heater from or

customer service.

• Do not use heater until all connections have

been leak tested and do not leak.

• When leak testing, refer to the connections

diagrams below.

• Only those parts recommended by the

manufacturer should be used.

• Substitution of parts can

void warranty.

LEAK TEST

Make a soap solution of one part liquid detergent,and one

part water. The soap solution can be applied with a spray

bottle, brush or rag,soap bubbles will appear where a leak

is present. Make sure the safety valve control knob is in

the “OFF” position. Turn the gas supply on check for

leaks at leak point. If a leak is present,turn off supply,

tighten any leaking fittings,turn gas on and recheck.

Gas Sounding Test

FIG.09

TEST POINTS

FIG.08

ORIFICE FITTING &

SAFETY VALVE

PILOT ASSEMBLY

&

PILOT TUBING

PILOT TUBING

TO SAFETY VALVE

5

6

7

4

INTAKE

PIPE FITTING

Page 12

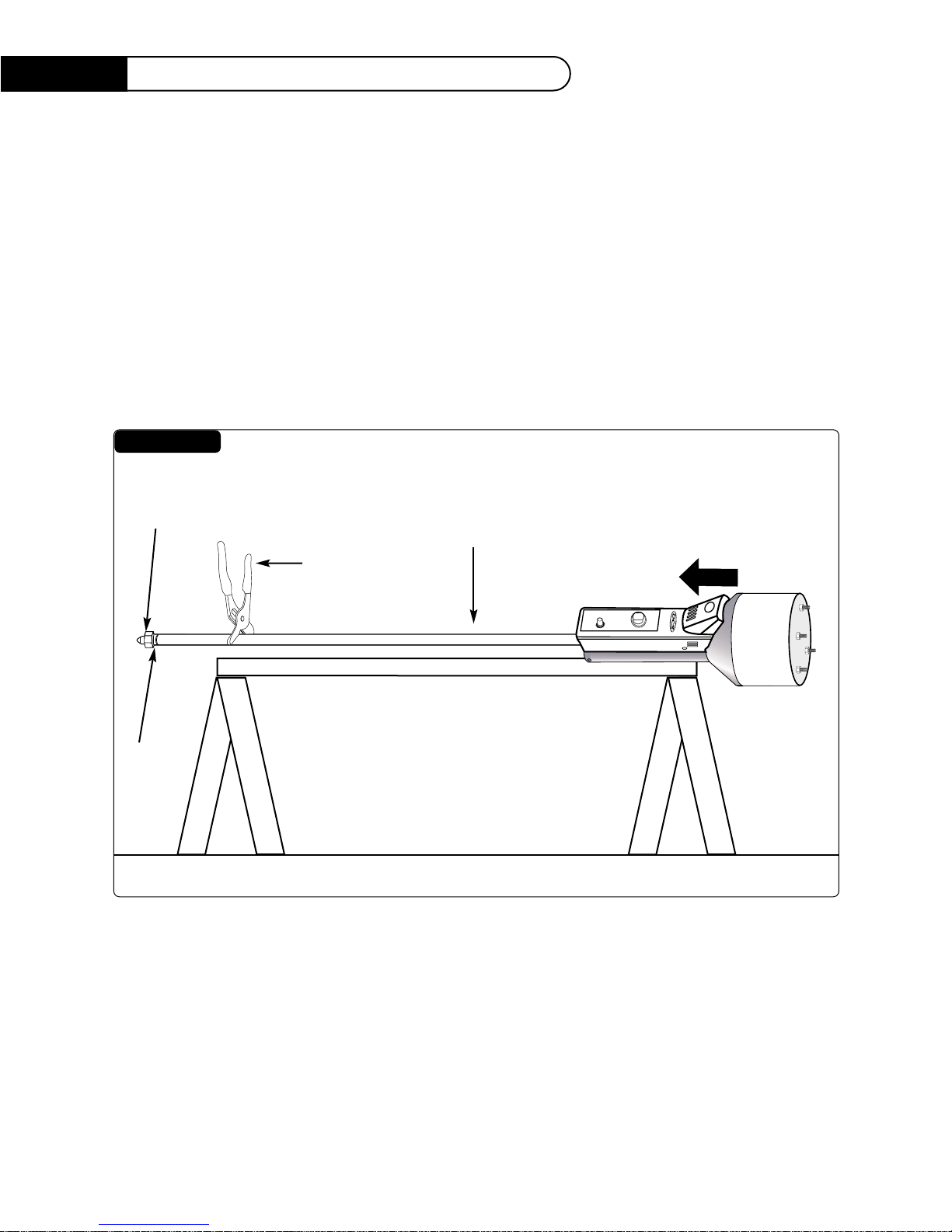

STEP 9

Locate the cap nuts,washers (4 ea.) and

reflector shield. Tip the heater backwards and

support it with stable horizontal surface (i.e.

sawhorse,workbench step ladder).

Install the reflector shield with the cap nuts

and washers.

Use caution not to over-tighten

or damage the reflector.

Return the unit to

its upright position and continue to the next

section for recommended locations and

usage.

HARDWARE USED

1) P/N 15005-15 Washers - Flat (4)

2) P/N 15019-07 1/4 Cap Acorn Nuts (4)

3) P/N 15005-10 Washers - Split (4)

11

As semb ly I ns tructions

FIG.11

FIG.10

REFLECTOR

ACORN NUT

SPLIT WASHER

FLAT WASHER

BURNER HEAD

Page 13

This outdoor heater is primarily for temporary

heating of outdoor patios,decks,spas, pool, and

work areas.

This heater is not intended for indoor use or

enclosed area use.

Always ensure that adequate fresh air ventilation is

provided.

The minimum clearances to combustible

construction shown here must be maintained at all

times.

The installation must conform to local codes,or in

the absence of local codes,with the standard for

the storage and handling of liquefied petroleum

gases.

CAUTION: The heater must be placed on

level,firm ground.

WARNING: Never operate in an explosive

atmosphere keep away from

areas where gasoline or other

flammable liquids or vapors are

stored or used. Heater will

engage the ground and start

to roll once a minimum angle

from center is established.

12

Locating Heater For Us e

FIG.12

WALL / COMBUSTIBLES

COMBUSTIBLES

19” MINIMUM

27”

Page 14

L ig hting And S hutdown

13

BEFORE TURNING THE GAS SUPPL Y “ON”

Visually inspect the hose assembly for evidence of excessive abrasion, cuts or wear. If the hose leaks it

must be replaced prior to use. The replacement hose assembly shall be that specified by the manufacturer. Make sure the surrounding areas are free of combustible materials,gasoline and other flammable

vapors or liquids.

BEFORE LIGHTING

For your safety, if relighting a hot heater,always wait 5 minutes. The heater should be inspected

(emitter screen,gas hookup, pilot assembly) before each use,and at least annually by a qualified

service person.

To light:

1) Open door.

2) Make sure regulator hose is connected to the heater intake pipe and regulator is connected to the

LP tank with both connections tight and leakproof.

3)Turn supply tank valve in a counter-clockwise direction. Check for leaks by applying soapy water to

the tank and hose connections.

4)Turn control knob counter clockwise to the pilot position.

5) Depress and hold in the control knob to begin pilot gas flow, hold in the control knob for (3)

minutes on new installations or cylinder changes to purge air from the lines,or (5) seconds for

regular relight.

6)While depressing knob, depress the igniter button which will snap indicating it has produced a spark

which should light the pilot.If not,depress control again and depress the igniter until lit or match

light. The pilot is located behind the match hole cover.Rotate the disc upward from the hole for

match lighting or viewing (see figure 2 on page 5).

7) Once the pilot is lit,continue to hold in the control knob for 30 seconds or until the pilot remains

lit after knob is released.

8)The burner may now be turned on to the full on position (all the way counter-clockwise) and then

reduce to the desired heat range.

9) Close door.

Relighting:

1)Turn control knob to off position.

2)Wait (5) minutes before attempting to relight pilot.

3) Repeat steps beginning with step (4) above.

Shut down instructions:

1)Turn control knob clockwise to the off position,the burner will make a slight popping sound when

extinguished. This is a normal condition.

2)Turn LP-tank gas valve clockwise to“OFF” position when heater is not in use.

Page 15

Storage And Insect Warning

14

NOTE: When storing the heater,the connection between the LP c ylinder and the heater must be

disconnected and the LP cylinder removed and stored outdoors in a well ventilated area

SPIDER & INSECT WARNING:

Spiders or insects can nest in the burners or orifices of this or any outdoor gas appliance. This is a very

dangerous condition which can damage the heater and render it unsafe for use. You must inspect the

burner at least once a year or immediately if any of the following conditions occur:

1)The smell of gas in conjunction with extreme yellow tipping of burner.

2)The heater does not reach temperature.

3)The heater glow is excessively uneven.

4)The burner makes popping noises.

If blockage exists,clean the burner immediately (see page 14).

CLEANING:

Cleaning must be done when the heater is COLD. Your heater will last longer if maintained properly.

It is important that the flow or combustion air must never be obstructed. Orifices and air openings

must be kept free of dirt and spiderwebs.

NEVER use a cleaning agent which is flammable or

corrosive.

DCS recommends on painted models that the heater body components;below the stainless steel

burner head (post,door, and cabinet base) are periodically protected with a coat of automobile wax. If

repainting is necessary,paint only the post/base assembly. Do not paint the safety valve cylinder,valve

panel or instruction plate.

The ports of the burner head must remain clear so that the gas flow is unrestricted. The air inlet of

the venturi tube must also be kept clear for combustion air supply. If the heater is not performing

properly it may be necessary to clean the burner. See the next section for burner removal.

Page 16

NOTE: Unit must be cold before removal

BURNER REMOVAL

1) Remove reflector and emitter assembly by

removing the screws that fasten the

emitter assembly to the lower screen

cone.

2) Remove valve panel;avoid tugging the

ignition wire attached to backside of the

valve panel at the igniter.

3) Remove the 1/4 NPT nut (using a 7/8 open

end wrench) which holds the burner head

to the orifice fitting. Remove the burner.

Any debris in the opening of the burner

assembly can be cleared with a straightened

piece of coat hanger. Any rust can be

removed with a wire brush. Never use wood

or plastic objects to clear ports, wood or plastic can break and block the ports.

BURNER INSTALLATION

Install the burner assembly by reversing the

(4) steps used for disassembly making certain

the burner assembly stands centered when

complete. After reassembly,the heater should

be tested observe the burner flame. It should

be as shown with the flame being blue with

slight yellow tipping.

Burner Removal And I ns tallation

15

FIG.13

Emitter assembly

LOWER

SCREEN CONE

1/4 NPT NUT

VALVE PANEL ASSEMBLY

PIEZO

IGNITER

FIG.14

Page 17

P ilot Cleaning

When storing the heater the connection

between the LP cylinder and the heater must

be disconnected and the LP cylinder removed

and stored outdoors in a well ventilated area.

1) Removing the valve panel to gain access

to the pilot.(see figure 2 on page 5).

2) Remove the screw which fastens the pilot

to the lower screen cone.

3) Hold the pilot with pliers,loosen and

remove the nut at the base of the pilot.

4) Inspect the pilot and tubing for blockage,

you should be able to see through the

pilot.If obstructed by debris clear with a

piece of wire.

5)The cap-like pilot orifice can be cleaned

with a sewing needle.Use the needle gently

on inside of the orifice to clear debris.

Never enlarge the opening of the pilot orifice.

The pilot burner provides a flame to light the main burner. It also heats a

thermocouple which must be hot before allowing the main burner to come

on. If the pilot is blocked (by debris,spider webs, etc);the pilot flame may

be small and the thermocouple may not heat up enough for the main burner

to come on. If this occurs it will be necessary to clean the pilot.

16

FIG.15

FIG.16

THERMOCOUPLE

PILOT

IGNITER

PILOT

ORIFICE

PILOT

TUBING

Page 18

Troub les hooting

17

Can you Match light the

pilot?

PROBLEM:

Pilot does not light

using the piezo

lighter.

YES

NO

Piezo igniter problem. Is there a spark at the pilot

when the piezo is pressed?

Is there adequate gas supply

available?

YES

NO

See lighting

instructions

Remove valve panel, make sure

igniter wire is attached to piezo

igniter. Touch valve panel to safe-

ty valve cylinder to ground, and

try again. Is there a spark?

NO

Has the igniter wire insulation been

pinched, cut, or burnt away?

YES

NO

Call customer service

for replacement pilot

assembly.

Replace piezo igniter.

call customer service for

replacement

YES

NO

Is supply hose bent

or kinked?

Is gas cylinder full?

Are lighting instruc-

tions being followed?

Straighten

hose

YES

NO

Check pilot for blockage.

See page 15

YES

Page 19

Troub les hooting

18

Is there adequate

gas supply?

PROBLEM:

Burner flame is

low.

YES

Fill LP cylinder

NO

Is the supply hose bent or kinked?

YES

Straighten hose

YES

Is the control knob in the full “on”

position? (all the way counter clock-

wise)?

Check the burner and orifices for

blockage, see page 15

Is there adequate

gas supply?

PROBLEM:

Emitter glow is

uneven.

Note: It is normal for the bottom 1/2”to 1”of the emitter not to glow.

In addition, the section of the emitter above the valve panel may

also glow less than the rest of the emitter.

YES

Is the heater level?

Fill LP cylinder

NO

YES

Is the lower screen cone tilted?

Loosen but don’t remove screws at top of

safety valve cylinder, level, retighten

Level heater

Clean burner

see page 15.

NO

NO

NO

YES

Page 20

Parts List

19

ITEM PART NO. DESCRIPTION

1. 15019-07 1/4-20 Acorn Nut

2. 15005-10 Split Washer

2.b 15005-15 Flat Washer

3. 23002-SP Reflector

4. 15021-09 1/4-20 Keps Nut

5. 23018-01 Emitter Assembly

6. 15003-15 Bolt 1/4-20 x 3/4

7. 15001-26 Screw #10-24 x 1/2

8. 12015 Burner Head

9. 23083 Burner Assembly

10. 15077 Nut 1/4 NPT

11. 15005-23 Internal TH.Washer, 08

12. 23024 Match Hole Cover

13. 15001-26 Screws 10-24 x 1/2

14. 23064 Valve Panel Assembly

15. 16025-4 Piezo Igniter

16. 23080 LowerScreenConeAssy.

17. 13025-XX Orifice LP Gas (refer gas

spec. table pg.4)

18. 15005-25 Flat Washer

19. 13024 Orifice Fitting

20. 13066 Safety Valve

21. 13231-01 LP PilotWeldAssembly

22. 13028-10 Pilot Orifice LP Gas

23. 13027 1/4 Tubing Ferrule

24. 13229 Thermocouple

25. 23094 Pilot Tubing

26. 18018-03 Intake Pipe

27. 18184 900Elbow

28. 13226 Test Point

29. 18181 Valve Block

30. 14154-01 Knob

31. 23065 Valve Support Bracket

1

2

3

4

5

6

7

8

9

16

10

11

12

13

14

15

17

18

19

29

23

21

22

24

26

27

28

20

30

31

2b

25

D

y

n

a

m

i

c

C

o

o

k

i

n

g

S

y

s

t

e

m

s

,

I

n

c

.

Page 21

Parts List

20

ITEM PART NO. DESCRIPTION

1. 23121-XX Post Assembly (1)

2. 23096-XX Base Assembly (1)

3. 23106-XX Door (1)

4. 17314 Manual (1)

5. 15003-15 1/4-20 Bolt (8)

6. 15005-8 Nylon Washer (8)

7. 23112 Tank Retainer

8. 18159 Reducer Fitting (1)

9. 18290 Rubber Foot (4)

10. 23122 Rubber Collar (1)

11. 18143 6” Wheel (2)

12. 23112 Axle (1)

13. 18023 Cap Nuts (2)

14. 18024-03 Door Handle (1)

15. 23119 SS Spring (1)

16. 23108 Latch Bracket (1)

17. 15021-09 1/4-20 Hex Nut (8)

18. 23114 18” Tank Strap (1)

19. 14088 Grommet (1)

Note : Please specify your model color when reordering

post, base assembly, or door (items 1-3).

1

2

3

4

18

6

5

8

9

17

11

12

13

15

10

19

14

7

Page 22

Part No.17379 Rev.B

Litho in USA 08/2001

As product improvement is an

ongoing process at DCS,we

reserve the right to change

specifications or design without

notice.

5800 Skylab Road, Huntington Beach, CA 92647 Tel: (714) 372-7000

Fax: (714) 372-7001 Customer Service: (888) 281-5698

www.dcsappliances.com

Loading...

Loading...