Page 1

PROFESSIONAL GRILL

36 & 48" BH1 models

LE GRIL PROFESSIONNEL

Modèles 36 et 48" BH1

INSTALLATION GUIDE/USER GUIDE

GUIDE D’INSTALLATION/GUIDE D’UTILISATION

US CA

Page 2

!

WARNING!

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

y Do not try to light any appliance.

y Do not touch any electrical switch.

y Do not use any phone in your building.

y Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

y If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

Page 3

CONTENTS

Safety and warnings 3

Grill models 6

Product dimensions 7

Installation

Locating grill / built-in clearances 8

Built-in construction details 12

Gas hook-up 14

Leak testing 17

Burner adjustment 18

Radiant assembly 19

Installer checklist 20

Using the grill

Lighting instructions 21

Grilling 23

Using the smoker system 29

Using the rotisserie 30

Care & maintenance 34

Troubleshooting 37

Service 38

EN

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this user guide may not be available in all markets and are subject to change at any time. For current details

about model and specification availability in your country, please visit our website listed on the back cover or contact your Fisher

& Paykel dealer.

1

Page 4

A MESSAGE TO OUR CUSTOMERS

Thank you for selecting this DCS Professional BH1 Series Grill. This installation and user guide

contains valuable information on how to properly install, operate and maintain your new appliance

for years of safe and enjoyable cooking.

Please fill out and submit your Product Registration by visiting our website at

www.dcsappliances.com and selecting “Support” on the home page and then selecting “Product

Registration”.

For your convenience, product questions can be answered by a DCS Customer Care Representative

at www.dcsappliances.com, or email: customer.care@fisherpaykel.com.

Please write the model, code, and serial numbers on this page for reference (can be found on the

inside, right side panel behind the drip pan handle. See page 20).

MODEL NUMBER CODE SERIAL NUMBER

IMPORTANT!

DO NOT discard any packing material (box, pallet, straps) until the unit has been inspected.

Inspect the product to verify that there is no shipping damage. If any damage is detected, call

the shipper and initiate a damage claim. DCS by Fisher & Paykel is not responsible for shipping

damage.

2

Page 5

SAFETY AND WARNINGS

To reduce the risk of fire, electrical shock, injury to persons, or damage when using the appliance,

follow the important safety instructions listed below:

!

WARNING!

Hot Surface Hazard

Accessible parts may become hot during use.

Do not touch surface units or areas near units of the grill.

Hood must be opened before lighting the grill.

Never let clothing or other flammable materials come in contact with or get too close

to any grate, burner or hot surface until it has cooled. Fabric may ignite and result in

fire or personal injury.

Never lean over an open grill. When lighting a burner, always pay close attention to

what you are doing. Be certain you are pushing the burner knob when you attempt to

light the grill.

When using the grill, do not touch the grill burner, grate, or immediate surrounding

area as these areas become extremely hot and could cause burns.

Grease is flammable. Never operate the grill without a grease tray. Let hot grease cool

before attempting to handle it. Avoid letting grease deposits collect in the drip pan.

Clean the grill with caution. Avoid steam burns; do not use a wet sponge or cloth to

clean the grill while it is hot. Some cleaners produce noxious fumes or can ignite if

applied to a hot surface.

Use only dry potholders; moist or damp potholders on hot surfaces may cause burns

from steam. Do not use a towel or bulky cloth in place of potholders. Do not let

potholders touch hot portions of the grill or burner grate.

To avoid burns when cooking, use long handled BBQ tools.

Failure to follow this advice may result in burns and scalds or serious injury.

EN

!

WARNING!

Explosion Hazard

If you smell gas, do not use the appliance.

Do not use water on grease fires, a violent steam explosion may result. Turn all burners

off, then smother fire or flame or use dry chemical or foam-type extinguisher.

Do not heat unopened food containers such as cans – build-up of pressure may cause

container to burst and result in injury.

Failure to follow this advice may result in injury or death.

!

WARNING!

Fire Hazard

Do not operate the grill under un protected combustible construction. Use only in

well ventilated areas. Do not use in buildings, garages, sheds, breezeways, covered

structures or other such enclosed areas. This unit is for outdoor use only.

Never leave the grill unattended when in use.

Never store a spare LP cylinder under or near this unit.

Never fill the tank beyond

Do not store a full tank in direct sunlight.

Failure to follow this advice may result in death or serious injury.

Electrical Shock Hazard

This appliance (rotisserie motor) is equipped with a three-prong or four-prong

grounding plug for your protection against shock hazard and should be plugged

directly into a properly grounded power outlet. Do not under any circumstances cut or

remove the grounding prong from this plug.

Failure to follow this advice may result in death or electrical shock.

full.

¾

!

WARNING!

3

Page 6

SAFETY AND WARNINGS

IMPORTANT SAFETY INSTRUCTIONS!

y Children should not be left alone or unattended in an area where the grill is being used. Never allow

them to sit, stand or play on or around the grill at any time. When in use, portions of the grill get hot

enough to cause severe burns.

y Do not store items of interest to children around or below the grill, in the cart or masonry enclosure.

Never allow children to crawl inside a cart or enclosure.

y After a period of storage or non-use (such as over the winter), the gas grill should be checked for

gas leaks, deterioration, proper assembly, and burner obstructions before using.

y Do not heat unopened food containers as a build-up of pressure may cause the container to burst.

y Always use a covered hand when opening the grill lid and only do so slowly to allow heat and steam

to escape.

y Do not try lighting this appliance without reading the “LIGHTING INSTRUCTIONS” section of this

manual (page 21).

y After lighting burners, make sure burners are operating normally (see page 18).

y Do not use aluminum foil to line drip pans or grill grates or radiants. This can severely upset

combustion air flow or trap excessive heat in the control area. The result of this can be melted knobs

or damaged ignition components.

y Do not operate with a damaged cord or plug or after the appliance malfunctions or has been

damaged in any manner. Contact the manufacturer for repair.

y Do not let the rotisserie cord hang over the edge of a table or touch hot surfaces.

y Do not use an outdoor cooking appliance for purposes other than intended.

y For personal safety, wear proper apparel. Loose fitting garments or sleeves should never be worn

while using this appliance. Some synthetic fabrics are highly flammable and should not be worn

while cooking. Only certain types of glass, heat-proof glass ceramic, earthenware, or other glazed

utensils are suitable for grill use. These types of materials may break with sudden temperature

changes. Use only on low or medium heat settings according to the manufacturer’s directions.

y Spiders and insects can nest in the grill burners, causing gas not to flow through the burner. The gas

will flow from the front of the burner into the control panel. This is a very dangerous condition which

can cause a fire to occur behind the valve panel, thereby damaging the grill components and making

it unsafe to operate.

y Keep the area surrounding the grill free from combustible materials, trash, or combustible fluids

and vapors such as gasoline, charcoal or lighter fluid. Do not obstruct the flow of combustion and

ventilation air.

y Never use the grill in windy conditions. If located in a consistently windy area (oceanfront,

mountaintop, etc.) a wind break will be required. Always adhere to the specified clearances as

defined in the “INSTALLATION” section of this manual. Refer to the “Grill Placement” section for

details if fitting a wind break.

y CALIFORNIA PROPOSITION 65-WARNING: The burning of gas cooking fuel generates some

by-products which are on the list of substances which are known by the State of California to cause

cancer or reproductive harm. California law requires businesses to warn customers of potential

exposure to such substances. To minimize exposure to these substances, always operate this unit

according to the manual, ensuring you provide good ventilation when cooking with gas.

y This outdoor cooking gas appliance is not intended to be installed in or on recreational vehicles,

trailers and/or boats.

y Note: this product must be installed by a licensed plumber or gas fitter when installed within the

Commonwealth of Massachusetts.

y When using the side burners always use flat bottomed pans which are large enough to cover

the side burner. Adjust the flame so that it heats only the bottom of the pan to avoid ignition of

clothing. Position handles inward away from open edges of the unit to avoid burns associated

with unintentional spillovers. Hold the handle of the pan to prevent movement of it when turning

or stirring food. For proper lighting and performance of the burners keep the ports clean. It is

necessary to clean periodically for optimum performance.

4

Page 7

SAFETY AND WARNINGS

IMPORTANT SAFETY INSTRUCTIONS!

y Be sure all grill controls are turned off and the grill is cool before using any type of aerosol cleaner

on or around the grill. The chemical that produces the spraying action could, in the presence of heat,

ignite or cause metal parts to corrode.

y Never grill without the drip pan and grease tray in place and pushed all the way to the back of the

grill. Without it hot grease could leak downward and produce a fire or explosion hazard.

y Do not place griddle plates (some models only) side by side on the grill or on top of the Infrared

Hybrid Burner.

y Do not use the Infrared Hybrid Burner on BGB-36” or BGB-48” models. Use on BH1-36” & BH1-48”

models only.

y If a cart unit is stored indoors, ensure that it is cool, fold the side shelf down, then push the grill,

never pull. Never push or pull on the side shelves. If LP, the cylinder must be unhooked and the LP

cylinder stored outside in a well ventilated area, out of reach of children.

y Never use the grill in a windy area.

y Do not locate, store or operate the grill on an inclined plane. Make sure you lock the castor wheels

before operating the grill.

y Do not use charcoal or lighter fluid in the outdoor grill.

y Keep any electrical supply cord, or the rotisserie motor cord away from the heated areas of the grill

and water (pools, fountains, puddles).

y Never use a dented or rusty LP tank. Keep the ventilation openings of the cylinder enclosure free and

clear from debris.

y Do not move the appliance during its use.

y This unit is for outdoor use only. Do not operate in enclosed areas. This could result in carbon

monoxide build-up which would result in injury or death.

y When using a grill, be sure that all parts of the unit are firmly in place and that the grill is stable

(can’t be tipped over).

y To put out flare-ups, adjust the controls to lower the temperature

y Never attach or disconnect an LP cylinder, or move or alter gas fittings when the grill is in operation

or is hot.

y Clean and perform general maintenance on the grill twice a year. Watch for corrosion, cracks,

or insect activity. Check the regulator, hoses, burner ports, air shutter, and venturi/valve section

carefully. Always turn off gas at the source (tank or supply line) prior to inspecting parts.

y If you own or use a spare tank, or have a disconnected tank, you should NEVER store it near or under

the grill/cart unit or heat box, or near any other ignition or heat source. A metallic sticker with this

warning is provided with the grill to remind you, your family and all others who may use your BBQ

grill of these safety precautions. Install this sticker close to your barbeque grill.

EN

Sticker

5

Page 8

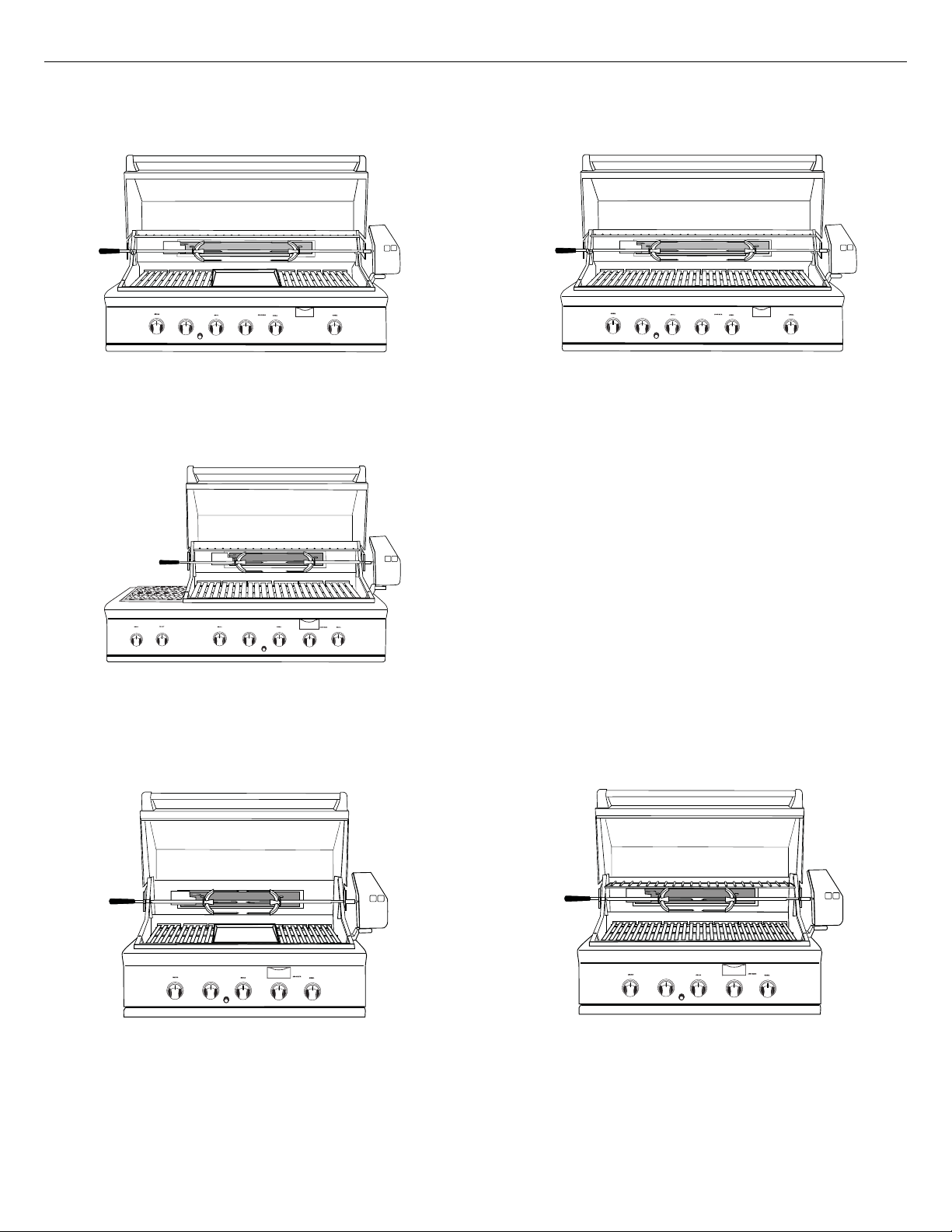

GRILL MODELS

BH1-48RBH1-48RGI

BH1-48RS

BH1-36RGI

BH1-36R

6

Page 9

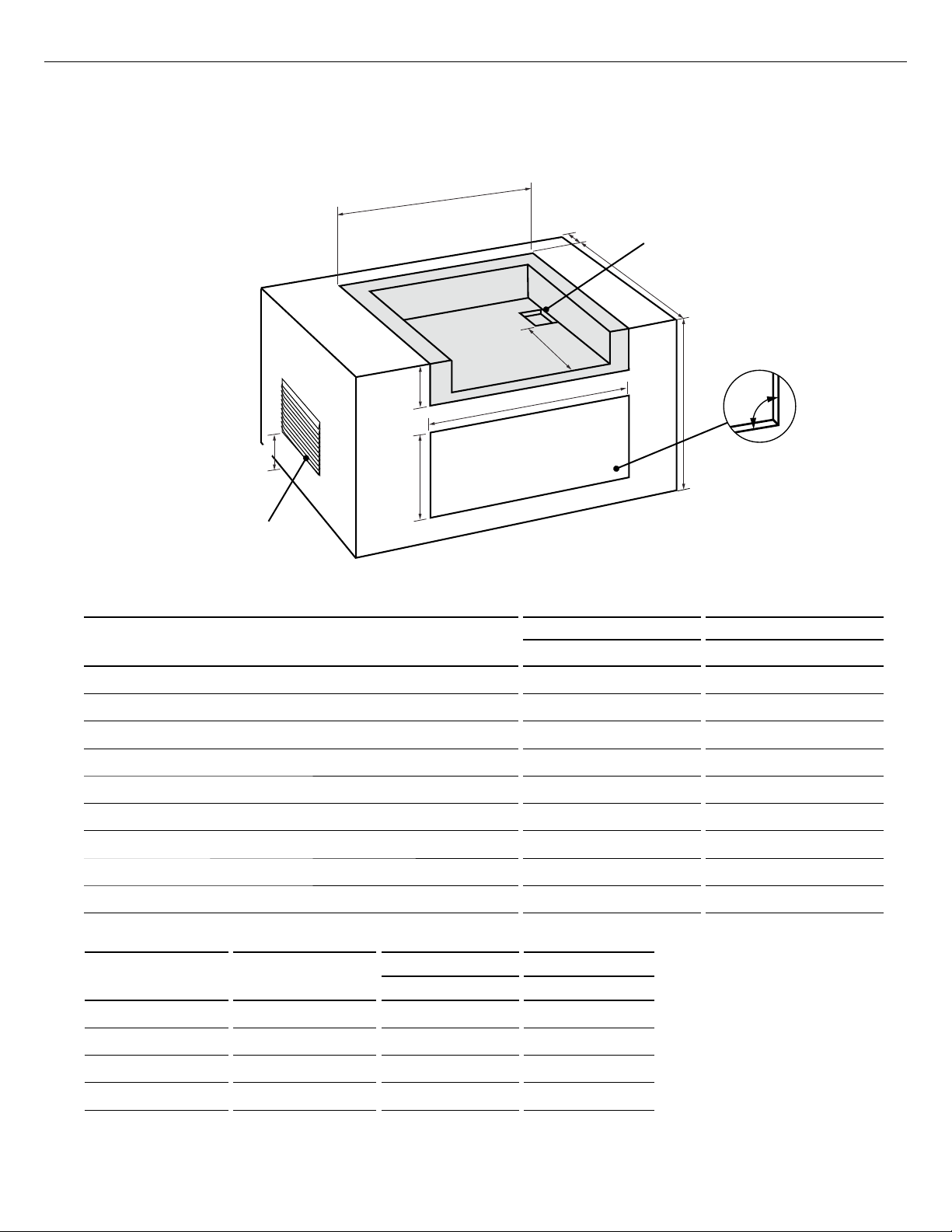

A

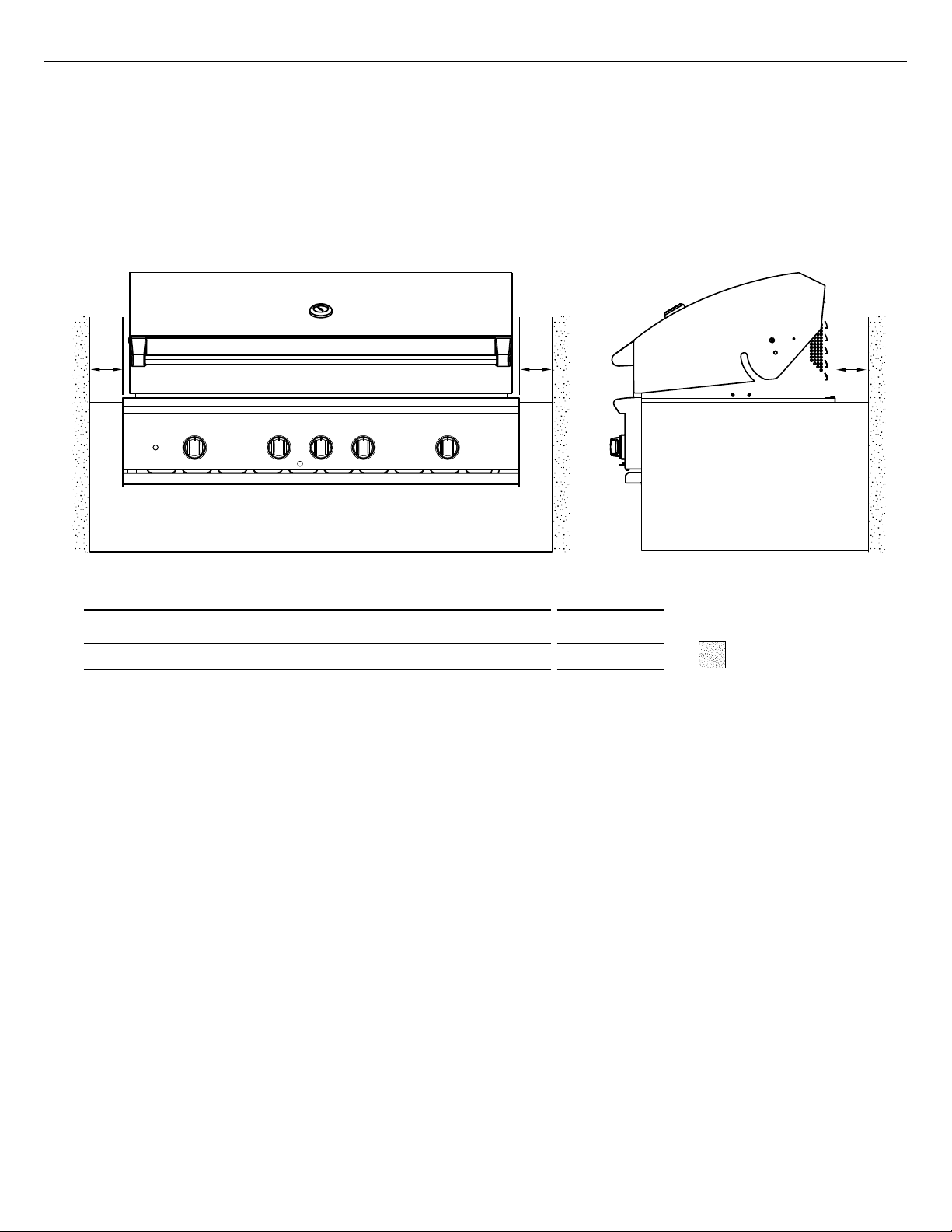

PRODUCT DIMENSIONS

B

EN

f

e

d

c

PRODUCT DIMENSIONS

A

B

C

Overall height of grill

Overall width of grill

Overall depth of grill

(excluding handle and dials)

D

E

f

G

Depth of chassis

Height of chassis

Height of hood

Overall width of grill with

rotisserie motor mounted

BH1-48RGI Model Illustrated

G

BH1-48RS BH1-48/RGI BH1-36/RGI

INCHES (MM) INCHES (MM) INCHES (MM)

24 ¼ (616) 24 ¼ (616) 24 ¼ (616)

47 ⅞ (1216) 47 ⅞ (1216) 35 ⅞ (911)

26 ⅝ 676 26 ⅝ 676 26 ⅝ 676

22 ⁄ (567) 22 ⁄ (567) 22 ⁄ (567)

10 (254) 10 (254) 10 (254)

13 ¾ (349) 13 ¾ (349) 13 ¾ (349)

53 ⁄ (1357) 53 ¼ (1352) 41 ⅝ (1057)

7

Page 10

INSTALLATION

Locating Grill/Built-in Clearances

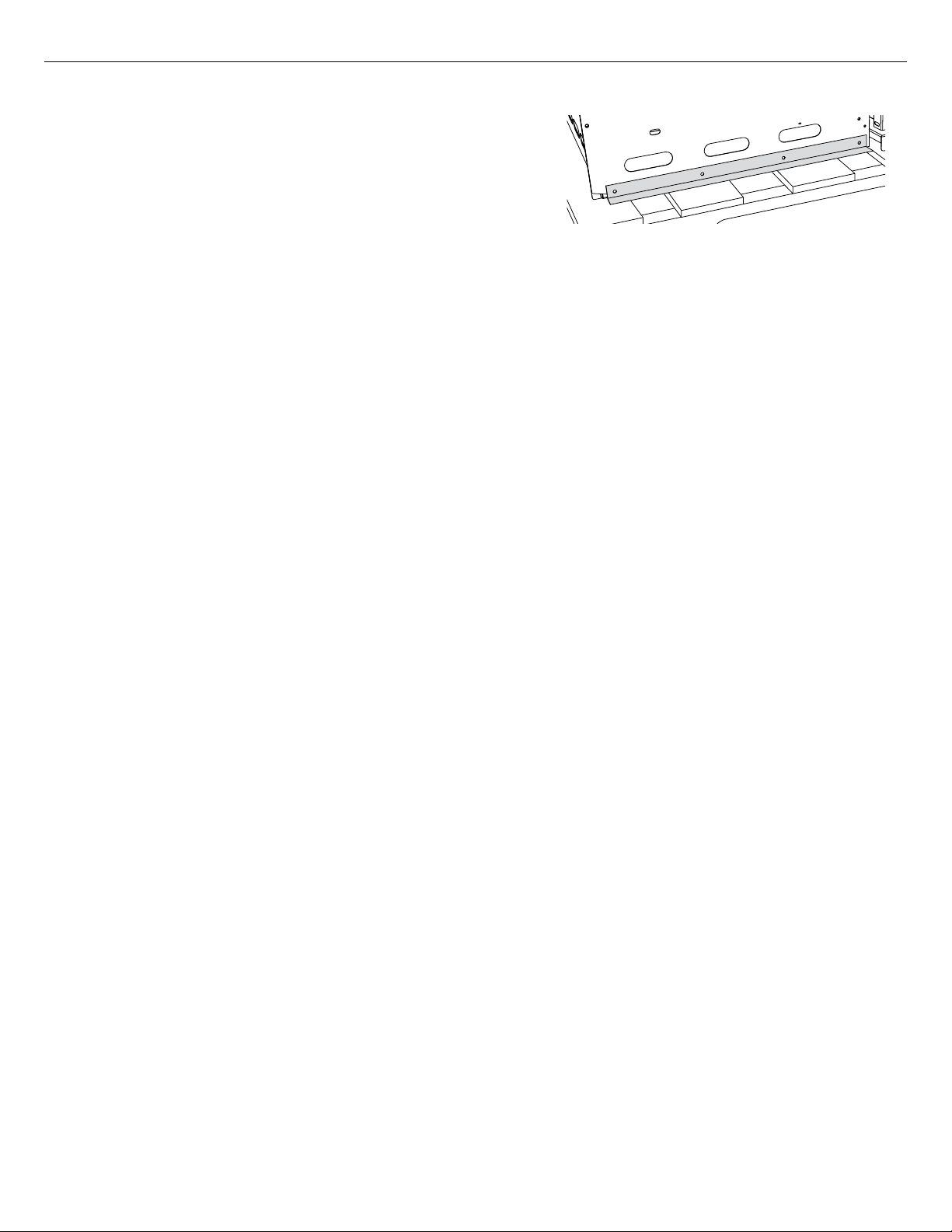

IMPORTANT!

Before installation, remove shipping brackets from the grill.

Loosen the four screws. Slide the shipping bracket off and

re-tighten the screws.

Location

When determining a suitable location, take into account concerns such as exposure to wind,

proximity to traffic paths and keeping any gas or electrical supply lines as short as possible and

away from heat sources. Locate the grill only in a well ventilated area. Do not build the grill under

overhead unprotected combustible construction. Never locate the grill in a building, garage,

breezeway, shed or other such enclosed areas. During heavy use, the grill will produce a lot of heat

and smoke. Ensure that the grill is used in a well ventilated area.

If locating the grill in a windy area, try to locate the grill so the prevailing wind will blow air at the

front of the grill as shown in Fig. 01b. This will assist the grill in venting hot air through the back of

the grill. In addition, this will help keep any smoke from blowing at someone who is cooking on the

grill. If you have to locate the grill in a windy area where the prevailing wind is at the rear of the

grill (Fig. 01a), a windscreen must be installed. The windscreen

wind from entering the exhaust vent in the rear of the unit as shown in Fig. 01c. Location of the

windscreen relative to rear of the grill must adhere to the clearances specified for combustible or

non-combustible construction as defined in these instructions. Refer to following pages.

should be set-up so that it blocks

As a high-performance gas appliance, your grill requires significant amounts of air to support the

combustion process. Your grill is designed to take air in through the valve panel area, and send the

exhaust products out through the exhaust gap at the rear of the hood. Using your grill in windy

conditions can disrupt the proper flow of air though your grill, leading to reduced performance, or in

certain severe cases, causing heat buildup in the valve panel area. This can lead to problems such as

having the knobs melt, or burn hazards when the valve panel surfaces become too hot to touch.

Please note that damage to your grill resulting from use in windy conditions, such as melted knobs or

igniter wires, or valve panel discoloration from heat build-up, are excluded from warranty coverage.

8

Page 11

INSTALLATION

Locating Built-in Clearances

IMPORTANT!

Gas fittings, regulator, and installer supplied shut-off valves must be easily accessible.

EN

GRILL EXHAUST

EXHAUST

FLAME LIFT

EXHAUST

FIG. 01a FIG. 01b

WIND

DIRECTION

PREFERRED

AIR FLOW

Wind hitting the grill while in use, (especially wind blowing into or across the hood gap) can cause

poor performance and in some cases can cause the control panel to get dangerously hot.

EXHAUST VENT FLOW

WIND

15” (381 mm) min.

WIND

PRIMARY INTAKE

AIR FLOW

WIND

FIG. 01c

3” (76 mm) min. for

non-combustibles

18” (457 mm) min.

for combustibles

If wind is an issue, a windscreen should be added. The windscreen should be higher than the top of

the opening in the back of the grill, with a minimum clearance of 3” (76mm) for non-combustibles,

or 18” (457mm) for combustibles, from the back of the grill.

9

Page 12

INSTALLATION

Locating Built-in Clearances

Clearances to non-combustible construction*

A minimum of 3” clearance from the back of the grill to non-combustible construction is required

for the purpose of allowing the lid to open fully. It is desirable to allow at least 6” rear and side

clearance to non-combustible construction above the cooking surface for counter space. If you’ll

be using the rotisserie option, the space is essential for motor and skewer clearance. The grill can

be placed directly adjacent to non-combustible construction below the cooking surface (Fig. 02).

A A A

FIG. 02

PRODUCT DIMENSIONS INCHES (MM)

NON-COMBUSTIBLE

A

Minimum distance from non-combustible surface to grill

3

(76)

=

SURFACE

*DEFINITION OF NON-COMBUSTIBLE MATERIAL - Material which is not capable of being ignited and

burned, such as materials consisting entirely of, or a combination of, steel, iron, brick tile, concrete,

slate, and plaster.

IMPORTANT!

y Failure to maintain required clearances creates a fire hazard that may result in property damage or

serious personal injury.

y The grill is designed to function in an open area. Recommended minimum clearances should be

maintained to all surfaces (combustible and non-combustible) for optimum performance. Noncombustible material within the minimum clearance area could result in discoloration or deterioration.

y If a non-combustible material such as stucco is covering a combustible material such as wood, the

minimum clearance distance needs to be considered for wood. The presence of a non-combustible

material inside the clearance zone does not eliminate the minimum clearance zone to combustible

material.

General

The grill is designed for easy placement into built-in masonry enclosures. For non-combustible

applications the grill drops into the opening shown in Fig. 04 and hangs from its side flanges. A

deck is not required to support it from the bottom. When using the insulated jacket in a combustible

enclosure application, see the Fig. 05. The insulation jacket assembly must be supported from the

bottom by a ledge on each side and back or a solid deck.

A spirit level should be used to ensure that the unit is level both front-to-back and side-to-side. If

it is not level, burner combustion may be erratic or the unit may not function efficiently for grease

flow. If the floor is uneven, re-leveling may be required whenever a freestanding unit is moved.

10

Page 13

INSTALLATION

Locating Built-in Clearances

Clearances to combustible construction**

Minimum of 18” (457 mm) from the sides and rear of grill must be maintained to adjacent vertical

combustible construction, above the counter top level. You should take in account that there is a

large volume of heat, and smoke will exhaust from the rear of the grill. This may discolor or damage

unprotected areas. Do not install under unprotected combustible construction without using a fire

safe ventilation system.

A 18” (457mm) minimum clearance must be maintained under the counter top to combustible

construction. The clearance can be modified by a use of an insulated jacket.

AA A

EN

FIG. 03

PRODUCT DIMENSIONS INCHES (MM)

COMBUSTIBLE

A

Minimum distance from combustible surface to grill

18 (457)

=

SURFACE

**DEFINITION OF COMBUSTIBLE MATERIAL - Any materials of a building structure or decorative

structure made of wood, compressed paper, plant fibers, vinyl/plastic or other materials that

are capable of transferring heat or being ignited and burned. Such material shall be considered

combustible even though flame-proofed, fire-retardant treated or surface-painted, or plastered.

IMPORTANT!

It is required that a minimum of three 10x10” (645 x 645mm) of ventilation opening be provided for

both the left and right sides, as well as the back of enclosure (Fig. 04), in order to safely dissipate

unburned gas vapors in the event of a gas supply leak.

Insulated jacket

If the grill is to be placed into a combustible enclosure, an approved insulated jacket is necessary.

Insulated jackets are available from your dealer. Use only the DCS insulated jacket which has

specifically been designed and tested for this purpose. Review the detail drawing shown (Fig. 05)

and take into account the provisions shown for gas line hook-up clearance in the right rear corner.

It is required that ventilation holes are provided in the enclosure to eliminate the potential build-up

of gas in the event of a gas leak. The supporting ledges or deck must be level and flat and strong

enough to support the grill and insulated jacket. The counter should also be level.

IMPORTANT!

Installing this product into a combustible enclosure without an insulated jacket could result in fire,

property damage and personal injury.

11

Page 14

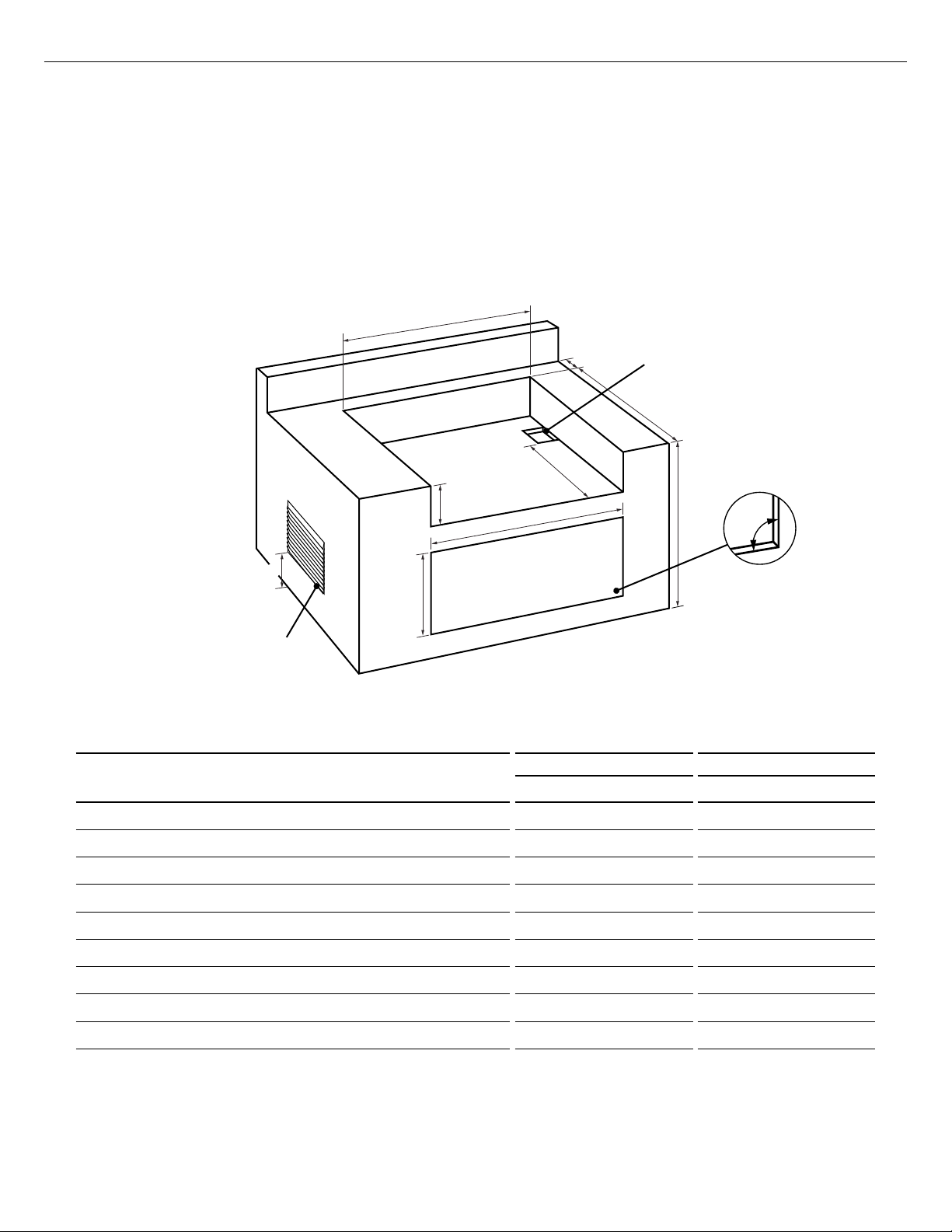

INSTALLATION

Built-in Construction Details

Standard layout for non-combustible cavity

IMPORTANT!

If installing the grill into a non-combustible enclosure, all combustible construction must still be

outside the 18" (457mm) clearance zone. If your island is made of stucco over the top of wooden

studs, the wood can not be inside the 18 inch clearance zone to combustible, even though the

stucco is what is touching the grill area.

D

G

H

Note: vents are to be located at the

left, right and rear of the enclosure.

Minimum size of all vents is 10x10"

(645mm x 645mm).

CAVITY DIMENSIONS

A

Maximum height of enclosure shell

B

Depth of enclosure shell

C

Minimum depth for hood swing

D

Width of enclosure cavity

E

Height of enclosure cavity

f

Depth to gas supply opening

G

Height to base of vents (min)

H

Height of opening for access doors/drawers

I

Width of opening for access doors/drawers

E

FIG. 04

I

F

C

Note: 4x4” (102 x 102mm)

opening for gas supply

line.

B

A

Note: the cut-out of

each corner should be a

90°angle in order for the

access doors/drawers to

fit properly.

BH1-48R BH1-36R

Inches (mm) Inches (mm)

35 ½ (902) 35 ½ (902)

22 ¾ (578) 22 ¾ (578)

3 ¾ (95) 3 ¾ (95)

45 ¾ (1162) 34 ½ (876)

10 ⅛ (257) 10 ⅛ (257)

18 ½ (464) 18 ½ (464)

1 (25) 1 (25)

20 (508) 20 (508)

46 (1168) 34 (864)

12

Page 15

INSTALLATION

A

Built-in Construction Details

Standard layout for cavity including insulated jacket

D

EN

E

G

H

Note: vents are to be located at the

left, right and rear of the enclosure.

Minimum size of all vents is 10x10"

(645mm x 645mm).

CAVITY DIMENSIONS

A

Maximum height of enclosure shell

B

Depth of enclosure shell

C

Minimum depth for hood swing

D

Width of enclosure cavity

E

Height of enclosure cavity

f

Depth to gas supply opening

G

Height to base of vents (min)

H

Height of opening for access doors/drawers

I

Width of opening for access doors/drawers

FIG. 05

I

F

C

Note: 4x4” (102mm x 102mm)

opening for gas supply line.

B

Note: the cut-out of

each corner should be a

90°angle in order for the

access doors/drawers to

fit properly.

BH1-48R BH1-36R

Inches (mm) Inches (mm)

35 ½ (902) 35 ½ (902)

23 ¾ (603)

18 ¾ (476)

23 ¾ (603)

18 ¾ (476)

51 ⅝ (1318) 40 ½ (1029)

11 ⅛ (283) 11 ⅛ (283)

18 ½ (464) 18 ½ (464)

1 (25) 1 (25)

20 (508) 20 (508)

46 (1168) 34 (864)

ACCESS DOORS

MODEL NUMBER

ACCESS DRAWERS

MODEL NUMBER

CAVITY WIDTH CAVITY HEIGHT

Inches (mm) Inches (mm)

ADN1-20x48 ADR2-48 46 (1168) 20 (508)

ADN1-20x36 ADR2-36 34 (864) 20 (508)

ADN1-20x30 ADR2-30 28 (711) 20 (508)

ADN1-20x24 ADR2-24 22 (559) 20 (508)

To order access drawers or doors, please visit www.dcsappliances.com for further details.

13

Page 16

INSTALLATION

Gas Hook-up

Gas requirements

Verify the type of gas supply to be used, either natural or LP, and make sure the marking on the

appliance rating plate agrees with that of the supply. The rating plate is located on the underside

of the drip tray. Never connect an unregulated gas line to the appliance. You must use the gas

regulator provided with the unit, even if the supply is controlled.

An installer-supplied gas shut-off valve must be installed in an easily accessible location. All installer

supplied parts must conform to local codes, or in the absence of local codes, with the National

Electrical Code, ANSI/NFPA 70 or the Canadian Electrical Code, CSA C22.1, and the National

Fuel Gas Code, ANSI Z223.1 or CSA-B149.1 Natural Gas Installation Code or CSA-B149.2 Propane

Installation Code.

All pipe sealants must be an ap proved type and resistant to the actions of LP gases. Never use

pipe sealant on flare fittings. All gas connections should be made by a qualified technician and

in accordance with local codes and ordinances. In the absence of local codes, the installation

must comply with the National Fuel Gas Code ANSI Z223.1. Gas conversion kits are available from

Customer care. When ordering gas conversion kits, have the model number, and the type of gas

(natural or LP) from your grill.

Total gas consumption of the grill with all burners on HI

BH1-48RS - 126,500 Btu/hr or 133.5MJ/h BH1-48R/BH1-48RGI - 121,500 Btu/hr or 128.2 MJ/h

BH1-36R/BH1-36RGI - 92,500 Btu/hr or 97.5 MJ/h.

The appliance and its individual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 PSIG (3.5 kPa.)

The appliance must be isolated from the gas supply piping system by closing its individual manual

shut-off valve during any pressure testing of the gas supply piping system at test pressures equal to

or less than 1/2 PSIG (3.5 kPa.). The installation of this appliance must conform with local codes or,

in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54. Installation in

Can ada must be in accordance with Natural Gas and Propane Installation Code, CSA B149.1, and/or

Propane Storage and Handling Code, B149.2 and local codes.

Natural gas built-in hook-up

(This should be performed by a technician only)

Connection: 1/2” NPT female with 3/8” flare adapter

Operating pressure: 4.0” W.C. Supply pressure:

5” to 14” WC. If in excess of 14” W.C., a step down

regulator is required. Check with your local gas utility

company or local codes for instructions on installing

gas supply lines. Be sure to check on type and size

of run, and how deep to bury the line. If the gas line

is too small, the grill will not function properly. Any

joint sealant used must be an approved type and be

resistive to the actions of LP gases.

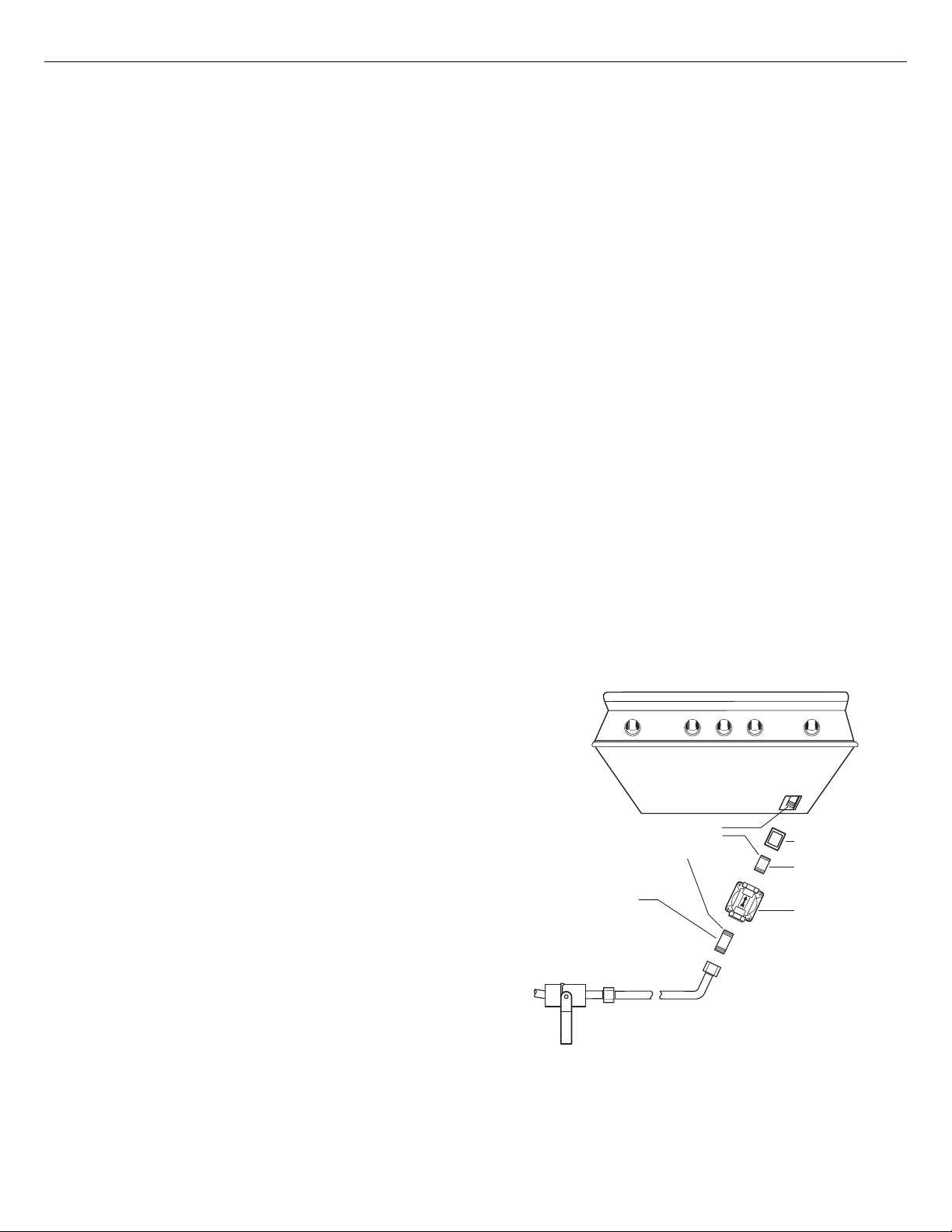

To hook-up the fittings supplied with the grill

Assemble as shown (Fig. 06). Use threading

compound on male threads only. Do not use threading

compound on the male end of the 1/2 NPT to 3/8 flare

adapter. Use a second pipe wrench to hold the grill

inlet pipe to avoid shifting any internal gas lines of

the grill. Ensure that the regulator arrow points in the

direction of gas flow towards the unit, away from the

supply. Do not forget to place the installer-supplied

gas valve in an accessible location.

LP Gas Hook Up (Type 1 or QCC1 regulator)

Grills orificed for use with LP gas come equipped

with a high capacity hose/regulator assem bly for

connection to a standard 20 lb. LP cylinder (Type 1).

The LP tank is not included.

14

Threading compounds

(Must be resistant to

LP gas)

1/2” NPT x

5.0" Nipple

Installer supplied

shut-off valve must be

easily accessible*

*Installation must conform

with local codes or with the

National Fuel Gas Code ANSI

Z223.1 or the CSA-B149.2

Propane Installation Code

Bottom of unit

Coupling

1/2” NPT

x 2.0”

NIpple

Regulator

4.0" W.C.

FIG. 06 Natural Gas

Page 17

INSTALLATION

Gas Hook-up

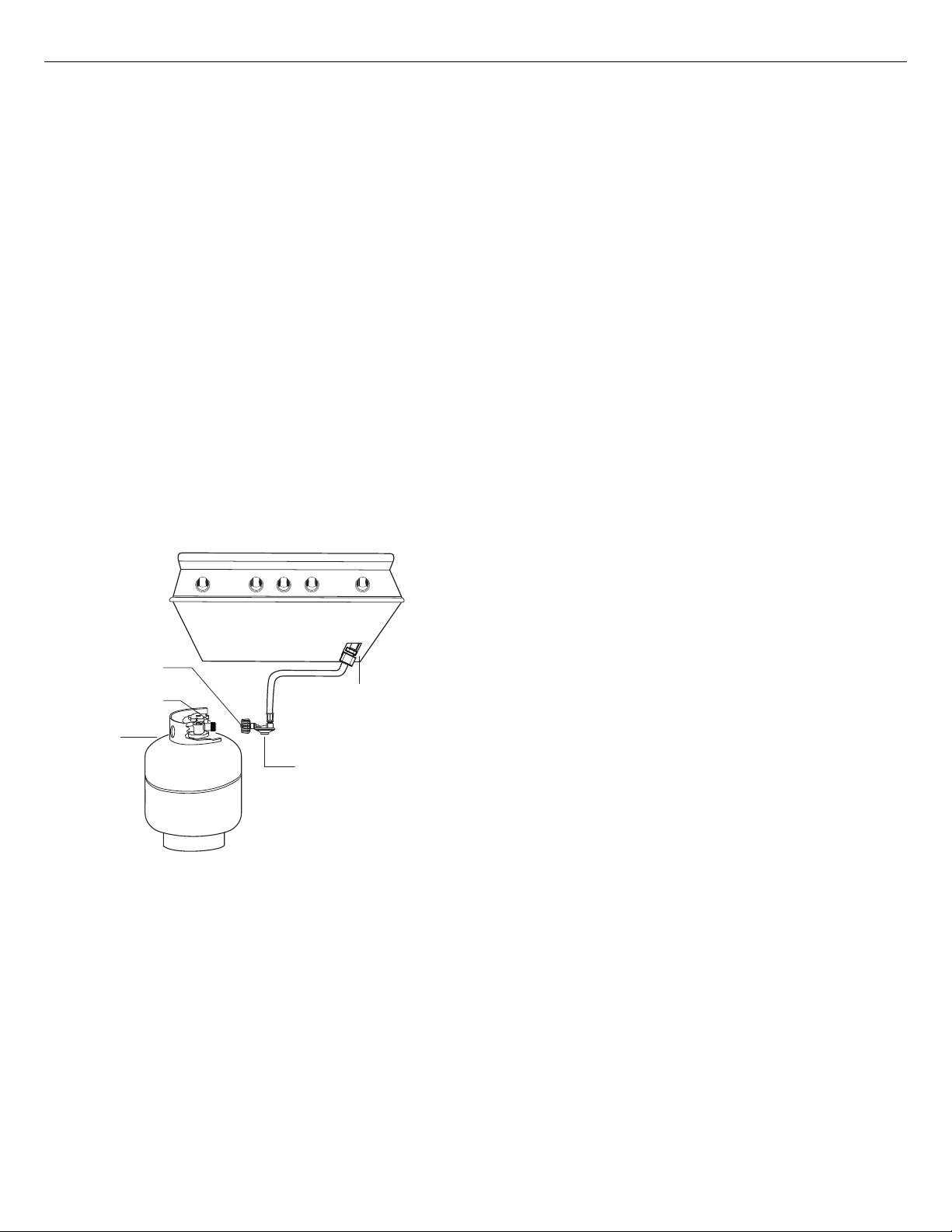

LP cart hook-up

Grills orificed for use with LP gas come equipped with a high capacity hose/regulator assem bly for

connection to a standard 20 lb. LP cylinder (Type 1). The LP tank is not included.

leak tested, do not remove the Regulator/Hose assembly from the grill during cart installation.

Connection: LP Hose with a Type 1 quick disconnect and regulator is included. Operating pressure:

11.0” W.C. Note: all gas piping and connectors must conform to the Standard for Connectors for

Outdoor Gas Appliances and Manufactured Homes, ANSI Z21.75/CSA 6.27.

To connect the LP regulator/hose assembly to the tank/valve assembly, first make sure the main

valve on the tank is completely closed. Although the flow of gas is stopped when the Type 1 system

is disconnected as part of of its safety feature, you should always turn off the LP tank main valve

(Fig. 07) after each use and during transport of the tank or unit. Insert the regulator inlet into the

tank valve and turn to the black coupler clockwise until the coupler tightens up. Do not overtighten

the coupler. Turn the main tank valve on and turn the burner control valves on the unit to the “HI”

position for about 20 seconds to allow the air in the system to purge. Turn valves off and wait 5

minutes before attempting to light the burners.

To disconnect the coupler, first make sure the main tank valve is turned off. Grasp the coupler and

turn counter clockwise. The inlet will then disengage. Remove the inlet from the tank valve opening

if it has not already done so when it disengaged. Your local LP filling station should be equipped

with the proper equipment to fill your tank.

The grill system is

EN

IMPORTANT!

y Before connecting LP tank to regulator, check

Bottom of unit

Type 1 Regulator

Main Tank Valve

20 lb.

LP Tank

FIG. 07 LP Gas - Cart

Elbow 45°

1/2” female

NPT x 3/8” male flare

(installed on the unit)

LP Regulator hose

assembly 11" W.C.

*Installation must conform

with local codes or with the

National Fuel Gas Code ANSI

Z223.1 or the CSA-B149.2

Propane Installation Code

LP tank requirements

A dented or rusty LP tank may be hazardous and should be checked by your LP supplier. The

cylinder that is used must have a collar to protect the cylinder valve. Never use a cylinder with

a damaged valve. Always check for leaks after every LP tank change. The LP gas cylinder must

be constructed and marked in accordance with the specifications for LP gas cylinders of the U.S.

Department of Transportation (DOT or CAN/CSA-B339) and designed for use with a Type 1 system

only. Do not change the regulator/hose assembly from that supplied with the unit or attempt to

use a Type 1 equipped regulator/hose assembly with a standard 510 POL tank/valve assembly. The

cylinder must be provided with a shut-off valve terminating in an LP gas supply cylinder valve outlet

specified, as applicable, for connection Type 1. If the appliance is stored indoors, the cylinder must

be disconnected and removed from the appliance. Cylinders must be stored outdoors in a wellventilated area out of the reach of children.

that all grill burners and rotisserie valves are in

the OFF position and open grill hood.

y Do not place the Grill directly on the ground or

any other flat surface without support. This will

prevent damaging the regulator/hose assembly

by the weight of the grill.

y Check the hose, regulator and connectors for

damage. Look for cracks, abrasions, brittleness,

holes, dents and nicks.

y Do not attempt to remove, repair, or replace the

regulator/hose assembly by yourself. It must be

done by a qualified licensed technician only.

15

Page 18

INSTALLATION

Gas Hook-up

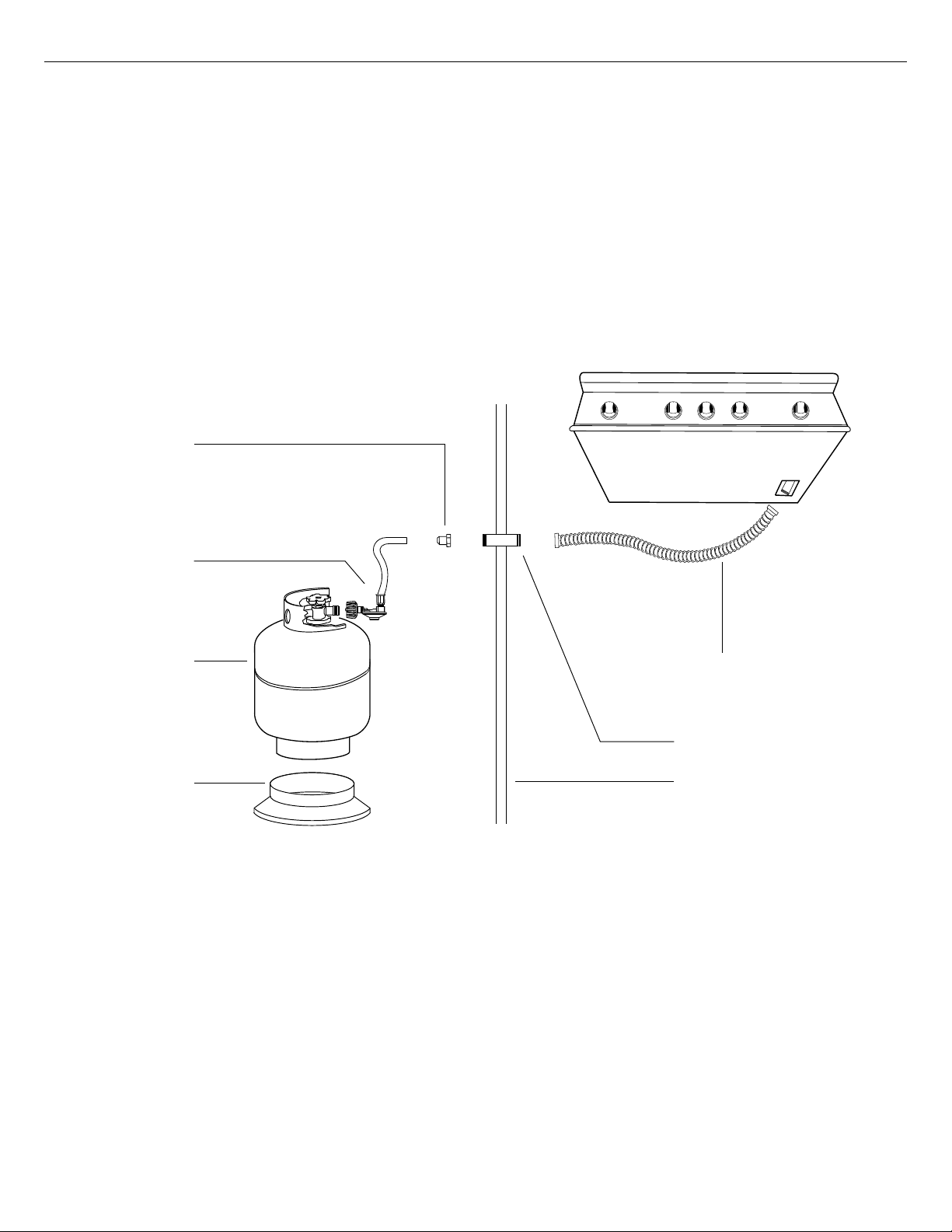

LP built-in hook-up

If the grill is to be installed in a built-in application, then the grill must be installed in accordance with

the built–in installation guidelines and

product

.

Connection: LP Hose with a Type 1 quick disconnect and regulator is included. Operating pressure:

11.0” W.C. All gas piping and connectors must conform to the Standard for Connectors for Outdoor

Gas Appliances and Manufactured Homes, ANSI Z21.75/CSA 6.27.

If you intend to operate your built-in grill on LP gas utilizing a 20v lb type 1 cylinder, then a builtin LP tank restraint must be installed prior to initial use of the grill. The Installer must supply ½” ID

Flex hose and fixed pipe and a flare adaptor as indicated in Fig. 08.

Adapter 3/8”

flare fitting

1/2” NPT female

(not supplied)

the LP regulator/hose assembly must be removed from the

Bottom of unit

LP regulator/

hose assembly

20 lb

LP Tank

(not supplied)

Tank retention

device (not

supplied)

Note:

when an LP unit is being directly connected to an LP house system, you must follow the natural

FIG. 08 LP Gas - Built-in

1/2” ID flex hose with

1/2” NPT fittings

(not supplied)

1/2” NPT fixed pipe

(not supplied)

Enclosure wall

gas hook up guidelines.

The installer must provide the proper gas regulator to reduce the gas pressure to 11” W.C.

IMPORTANT!

Gas piping and connectors must be clamped within the the enclosure to avoid contact with moving

parts and hot surfaces. Where the gas piping passes through an opening in the enclosure, the

piping must be protected for a distance of at least 2” (50mm) either side of the opening.

16

Page 19

INSTALLATION

Leak Testing

IMPORTANT!

Gas leak testing must be carried out by a qualified technician.

General

Although all gas connections on the grill are leak tested at the factory prior to shipment, a

complete gas tightness check must be performed at the installation site due to possible mishandling

in shipment, or excessive pressure unknowingly being applied to the unit. Periodically check the

whole system for leaks, or immediately check if the smell of gas is detected.

Before Testing

Do not smoke while leak testing. Extinguish all open flames. Never leak test with an open flame.

Make a soap solution of one part liquid detergent and one part water. You will need a spray bottle,

brush, or rag to apply the solution to the fittings. For LP units, check with a full cylinder. The valve

panel must be removed to check the valves and fittings. Remove the knobs and the safety valve

knob, then remove the 2 screws which fasten the valve panel to the unit (you will need a Philips

screw driver for this). Pull the valve panel outward and unplug the wires from the ignition module.

In the back of the unit remove the screws which hold the service panel in place. Remove the service

panel.

To Te st

Make sure all control valves are in the “OFF” position. Turn the gas supply “ON”. Check all

connections from the supply line, or LP cylinder up to and including the manifold pipe assembly.

Apply the soap solution around the connection, valve, tubing and end of the manifold. Avoid

getting the soap solution on or in the valve switches. Soap bubbles will appear where a leak is

present. If a leak is present, immediately turn off gas supply, tighten any leaking connections, turn

gas on, and recheck. Check all the gas connections at the base of the control valves where they

screw into the manifold pipe.

EN

To check rotisserie burner and safety valve the burner must be lit, then leak test the connections

located behind the service panel. If you cannot stop a gas leak turn off the gas supply and call your

local gas utility, or the dealer you purchased the appliance from. Only those parts recommended by

the manufacturer should be used on the grill. Substitution can void the warranty.

IMPORTANT!

y Do not use the grill until all connections have been checked and do not leak.

y Check all gas supply fittings for leaks before each use. Keep a spray bottle of soapy water near the

gas supply shut-off valve. Spray all the fittings, bubbles indicate leaks.

BOTTOM OF UNIT

LEAK TEST POINTS

LEAK TEST POINTS

BOTTOM OF UNIT

CHECK HOSES

FOR SIGNS OF

CRACKS, LEAKS

OR ABRASIONS

LEAK TEST POINTS

BOTTOM OF UNIT

CHECK HOSES

FOR SIGNS OF

CRACKS, LEAKS

OR ABRASIONS

FIG. 10 LP Gas - CartFIG. 09 Nat. Gas FIG. 11 LP Gas - built-in

17

Page 20

INSTALLATION

Burner Adjustment

IMPORTANT!

Before lighting, inspect the gas supply piping or hose prior to turning the gas “on”. If there is evidence

of cuts, wear, or abrasion, it must be replaced prior to use.

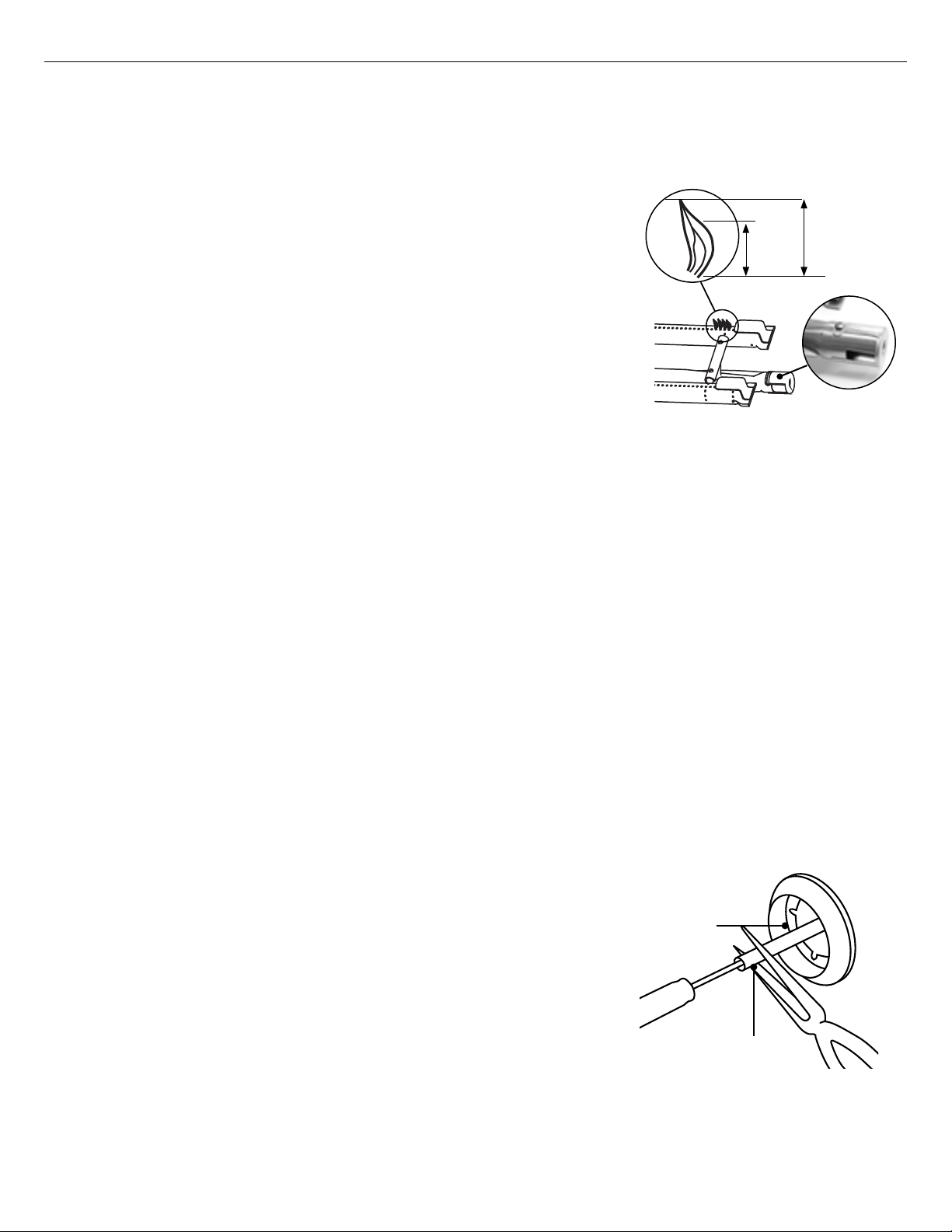

Grill burner air adjustment

Each grill burner is tested and adjusted at the factory prior to

shipment; however, variations in the local gas supply or a conversion

from one gas to another may make it necessary to adjust the burners.

The flames of the burners (except the rotisserie burner) should be

(10mm)

visually checked and compared to that of the drawing in Fig.12.

Flames should be blue and stable with no yellow tips (LP units may

have some yellow tipping), excessive noise or lifting. If any of these

conditions exist, check if the air shutter or burner ports are blocked

by dirt, debris, spider webs, etc. Proceed with air shutter adjustment.

The amount of air which enters a burner is governed by a metal cup

at the inlet of the burner called an air shutter. It is locked in place

by a screw which must be loosened prior to lighting the burner for

adjustment.

FIG. 12

Grill burner flame height

Before beginning, ensure the grill is off and cool. To access the grill burner air shutters, first remove

the grates and radiants from the firebox, then remove the grill burner using instructions shown on

page 35. With a screw driver, loosen the lock screw on the face of the air shutter slightly so that the

air shutter can be adjusted.

⅜ "

1 ½ "

(38mm)

To adjust

1 Be careful as the burner may be very hot.

2 If the flame is yellow, indicating insufficient air, turn the air shutter counter-clockwise to allow more air

to the burner.

3 If the flame is noisy and tends to lift away from the burner, indicating too much air, turn the air shutter

clockwise.

Note: reinstall the U-burner, ensuring the burner is level. Light the burner and check the flame.

If the color of the flame is blue and the height is stable, remove the burner and tighten the air

shutter screw. If the flames show instability or an inconsistent color, repeat the above procedure to

readjust the air shutter.

Low flame setting adjustment

The valves on the grill feature an adjustable low setting. Due to fluctuations in gas pressure, heating

value or gas conversion, you may feel it necessary to increase or decrease gas flow in the low

position. We do not recommend adjusting the infrared rotisserie burner.

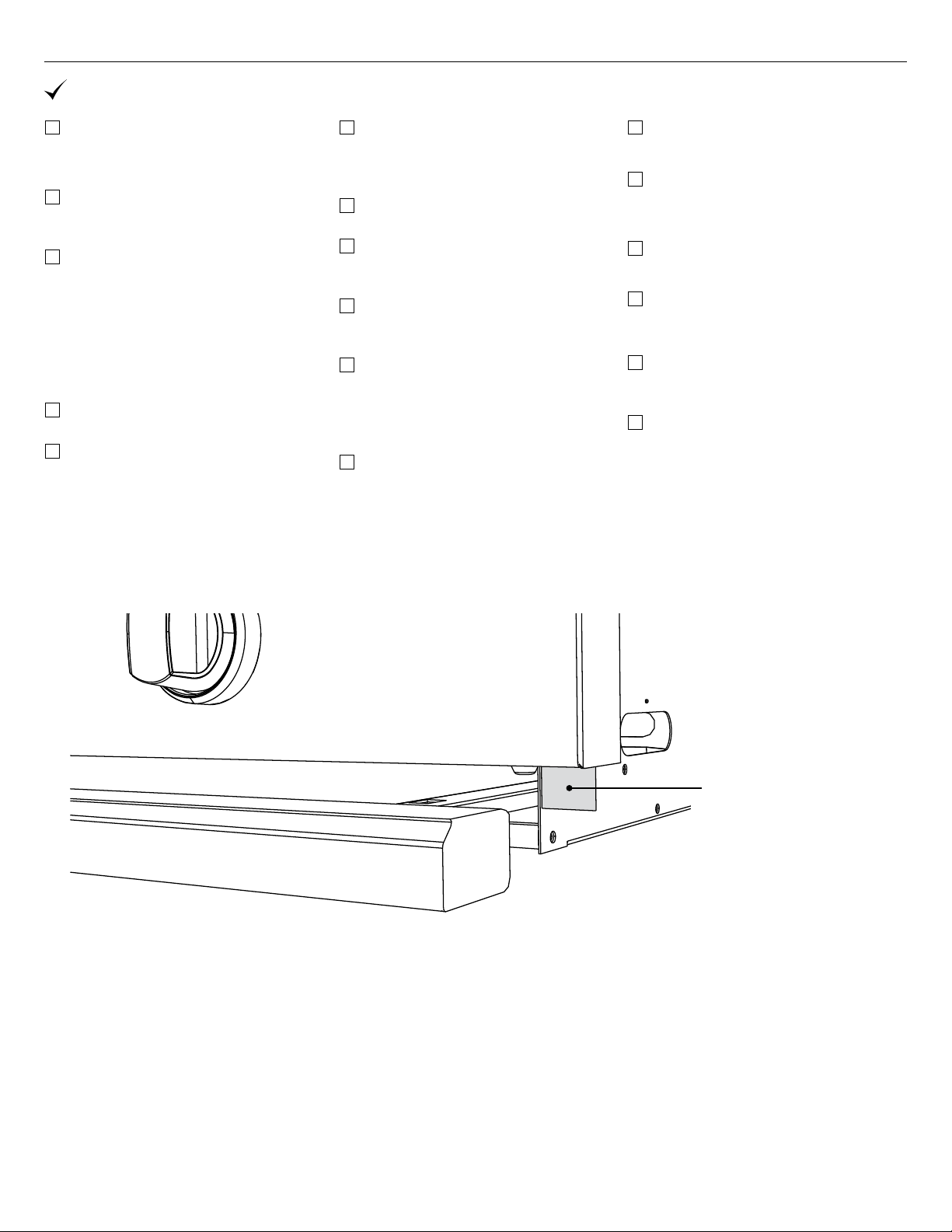

To adjust

1 Light the burner.

2 Turn the control knob to the lowest setting (counter-clockwise).

3 Remove the knob.

BEZEL

4 While holding the valve shaft with pliers, insert a thin, flat tipped

screwdriver into the shaft and while viewing the burner adjust to a

minimum stable flame.

Side burner flame height

The correct height of the flame mainly depends on the size of the

bottom of the cooking utensil, the material of the cooking utensil,

the amount and type of food and the amount of liquid in the

utensil. Following are some basic rules for selecting flame height.

VALVE STEM

FIG. 13

y For safety reasons the flame must never extend beyond the bottom of the cooking utensil. Never allow

flames to curl up the side of the pan.

y Utensils which conduct heat slowly (such as glass-ceramic) should be used with medium to low flames. If

you are cooking with a large amount of liquid, a slightly larger flame can be used.

18

Page 21

INSTALLATION

Radiant Assembly

IMPORTANT!

Before assembling the radiant, check that the radiant trays have not moved during transit. They

should sit securely on their locating pins in the base of the grill.

EN

1 Locate the radiant in the unit. 3 Unlock radiant end cap

4 Place the 18 ceramic rods

onto the radiant.

If a ceramic rod breaks

1 Unlock radiant end cap by pushing it up with two fingers.

2 Replace broken ceramic rod.

3 Lock radiant end cap.

2 Unpack ceramic rods and

remove radiant from the unit.

5 Lock radiant end cap. 6 Place the assembled

by pushing it up with two

fingers.

radiant into the unit.

To order a replacement ceramic rod, please visit www.dcsappliances.com.

Note: for BH1-48RGI and BH1-36RGI models see the Quick Start Guide for information on installing

the griddle and Infrared Hybrid Burner.

19

Page 22

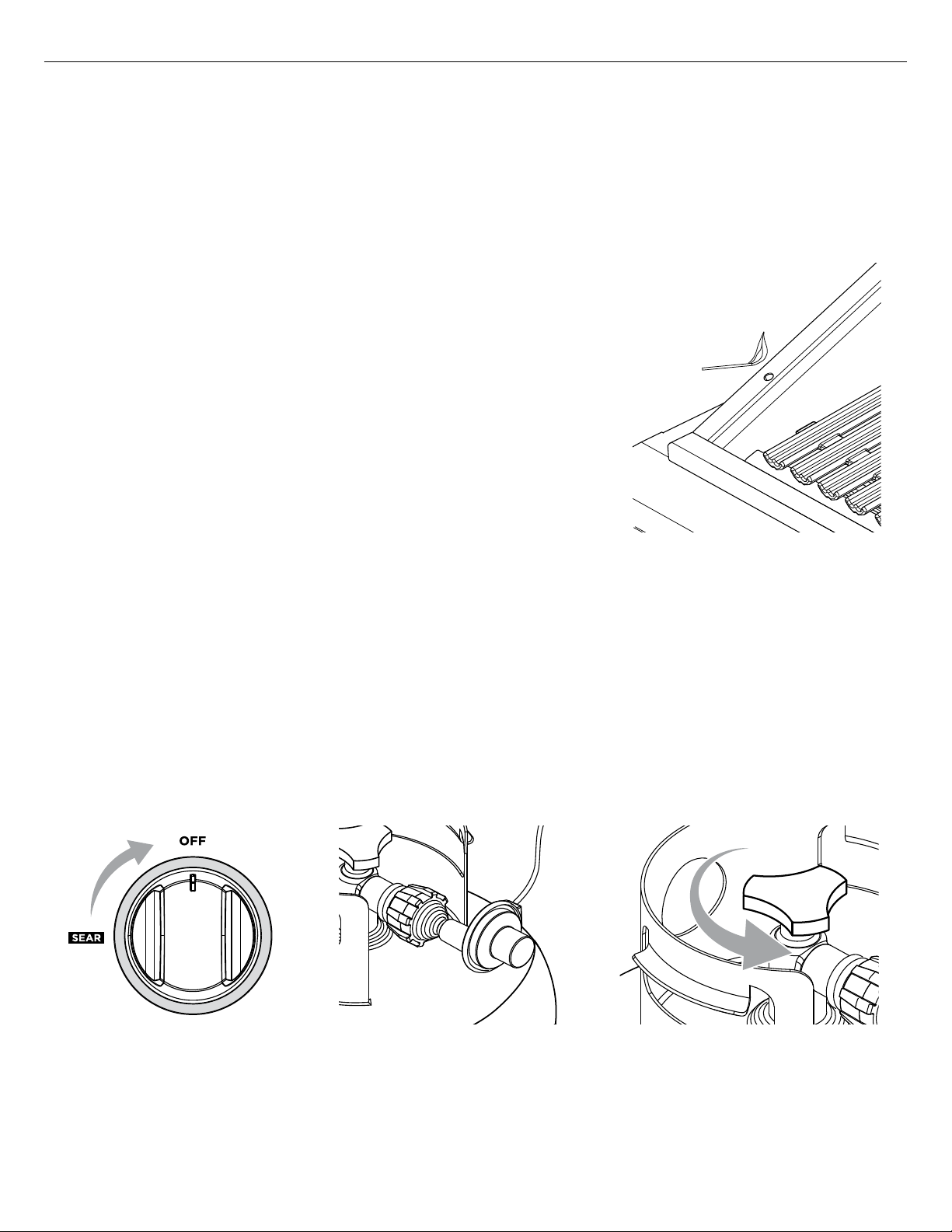

Installer Checklist

INSTALLATION

Specified clearances

maintained to

combustibles.

Verified proper enclosure

ventilation.

All internal packaging

and any adhesive residue

removed. To remove

stubborn residue, use

rubbing alcohol or a

commercially available

adhesive remover.

Removed shipping bracket.

Knobs turn freely, bezels

centered.

Contact DCS at www.dcsappliances.com if any of the listed items are missing. Please be prepared

with your model #, serial # and description of item(s) that are missing.

Each burner lights

satisfactorily - individually

or with adjacent burner lit.

Air shutters adjusted.

Low flame setting

satisfactory.

Drip pan in place properly

and sliding freely.

Pressure regulator

connected and set for 4.0”

C.E. Natural, 11.0” C.E. LP

gas.

Manual shut-off valve

installed and accessible.

Unit tested and free of

leaks.

User informed of gas

supply shut-off valve

location.

All radiant trays are

assembled and put in place.

Check match lighting.

Please leave these

instructions with the user.

User, please retain these

instructions for future

reference.

Tag location of

model # and serial #

IMPORTANT!

Read all installation instructions in this manual to see if the unit has been correctly installed. Ensure

that installation has been completed correctly before use.

20

Page 23

USING THE GRILL

Lighting Instructions

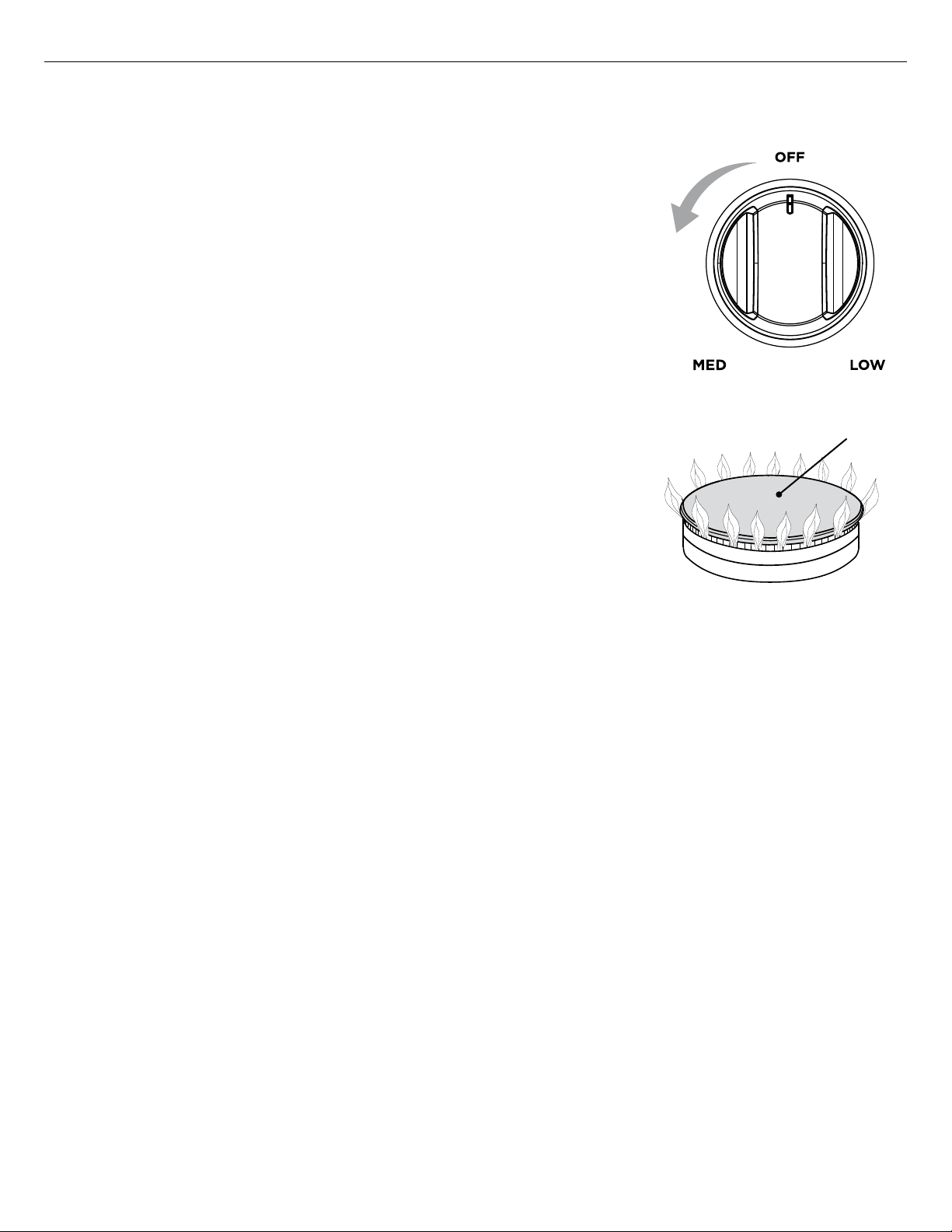

Grill lighting instructions

IMPORTANT!

Open the grill lid and/or remove the top grate cover from side burner (for BH1-48RS) before lighting.

Turn all knobs to “OFF”. Turn the main gas supply on. If you smell gas, shut-off gas supply and call for

customer care.

Grill lighting instructions

The grill knob is connected to the electronic ignition module.

Pushing in on the burner knob will activate the ignition module to

get a spark. Push in and turn the selected burner knob to HI/SEAR

position. Release the knob when the burner lights. If burner does

not light in four to five seconds, turn knob “OFF” and wait five

minutes before trying again so any accumulated gas may dissipate.

Grill Match Lighting

If the burner will not light after several attempts, then the burner

can be match lit. If you’ve just attempted to light the burner

with the ignition, allow five minutes for any accumulated gas to

dissipate. Keep your face as far away from the outdoor appliance

as possible and hold a paper book match over the hole located

on the top left for burner on the left, or the right hole for the

right burner (Fig. 13). Push in and turn the control knob which is

centered on the burner where the lit match is located, to “SEAR”.

If the burner does not light in four seconds, turn the knob off, wait

five minutes and try again.

FIG. 14

EN

IMPORTANT!

Improper lighting procedures can cause the LP tank flow control to activate, resulting in reduced

heat output. If this is suspected the flow control will need to be reset. For BH1-48RGI and BH1-36RGI

models see the Quick Start Guide for how to use the griddle and Infrared Hybrid Burner.

Resetting the flow control

IMPORTANT!

Failure to follow the steps in the order shown may cause the Flow Limiting Device to activate resulting

in extremely low gas flow and irregular operation.

1 All knobs must be in the

OFF position.

2 Attach regulator hose

assembly to the tank.

3 Open the LP tank valve.

(Two full turns min).

21

Page 24

USING THE GRILL

Lighting Instructions

To Light Dual Side Burners (48BQR Models only)

IMPORTANT!

The side burner cover may be hot if the grill burners are in operation.

Side Burners Lighting Instructions

First remove the burner cover and any cooking utensils from the

burner grate. The control knob is connected to the electronic

ignition module. Pushing in on the control knob will activate the

ignition module to get a spark. Push the control knob in and turn to

“HI”. If burner does not light in four to five seconds, turn knob “OFF”

and wait five minutes before trying again for any accumulated gas

to dissipate. If the burner will not light after several attempts, check

the trouble shooting instructions on page 37.

Side Burners Match Lighting

Hold a lit paper book match near the burner ports, turn the control

knob counterclockwise to “HI”. Move your hand immediately once

the burner is lit. Rotate the control knob to the desired setting.

Note: if you are using propane gas, a slight pop or flash may occur

at the burner ports a few seconds after the burner has been turned

“OFF”. This “extinction pop” is normal for propane gas.

HI

FIG. 15

Cap

Side burners

Your side burner is equipped with burners typical of those used in

restaurants. These burners are designed for maximum cleanability

and controlability. The burner should never be operated if the cap is

not in place (Fig. 16).

FIG. 16

22

Page 25

USING THE GRILL

Grilling

Grill

Each grill section consists of a large stainless steel burner, stainless

steel heat baffles, a series of ceramic rods encased in a stainless

steel radiant, and a stainless steel heat retaining grate. Each burner

is rated at 25,000 Btu/hr or 26,5MJ/h. Below the burners there is a

stainless steel heat baffle which reflects usable heat upward into the

cooking area and reduces temperatures of the drip pan below. Above

the burners are stainless steel radiants which encase the ceramic rods

and protect the grill burner ports from blockage (Fig. 17).

The grill is supplied with radiant ceramic rods. Because of the porosity of ceramic rods,

performance is superior in the rods’ ability to capture heat as it rises from the grill burners. They

also possess the thermal mass needed for even cooking performance. Flare ups are controlled

because the radiant ceramic rods keeps grease from getting to the flames and igniting. The intense

heat produced by this system produces true grilled flavor as fats and juices are brought to the

surface of the food and caramelized. Discoloration of the grates is normal after use.

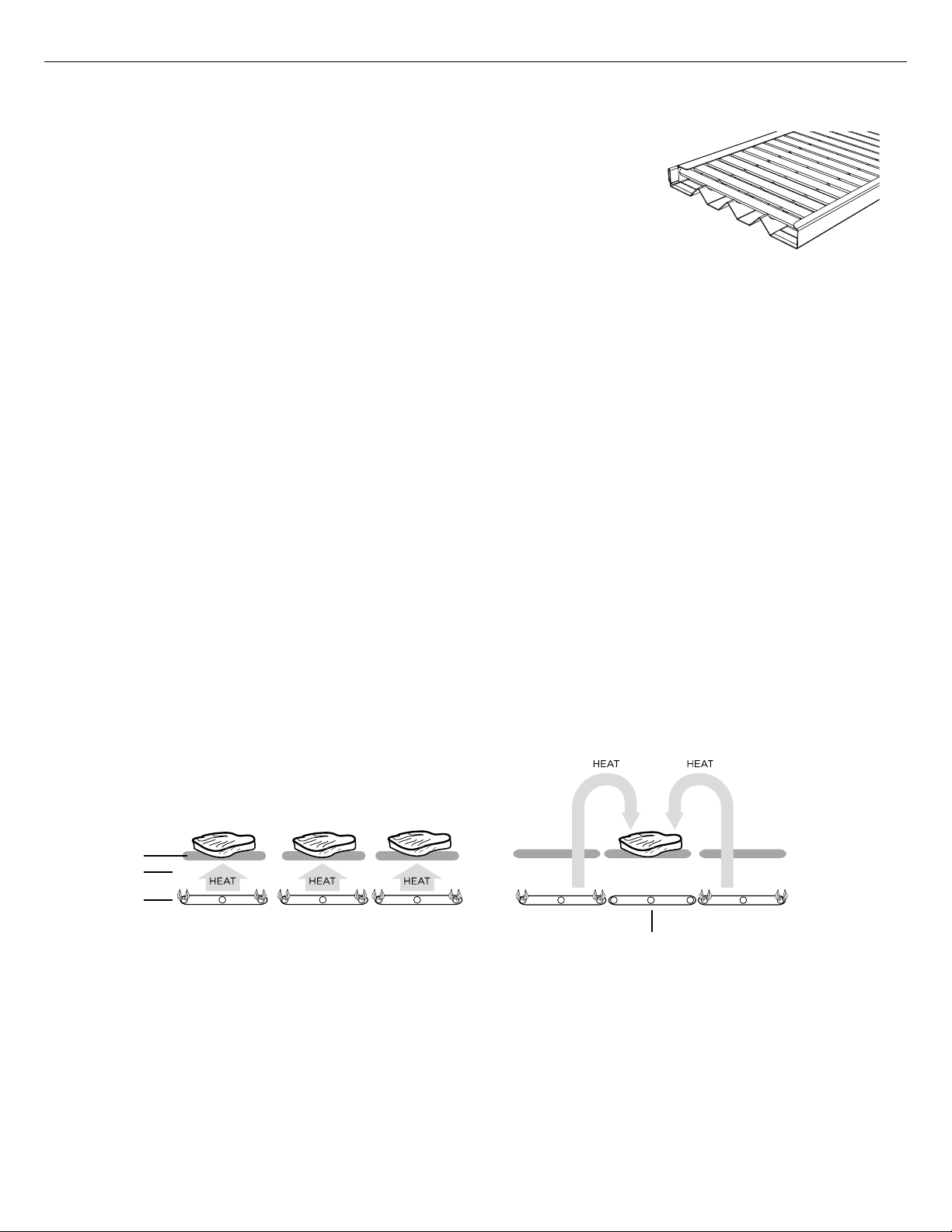

Direct/indirect cooking notes

Direct cooking involves placing food on grates over lighted burners. Use this method for foods that

take less than 20 minutes to cook or to sear larger items at the start of the cooking process that

will then be indirectly cooked to finish. Place items on the preheated surface and leave until they

no longer stick. Turning too soon and too often is one of the most common grilling mistakes. Never

spray water on the grill or into grease. The patented Grease Management System™ reduces flare-ups

by channeling grease away from the flame. Use a meat thermometer to achieve desired doneness

and remove items one degree below how you would like to enjoy them, as the resting period before

carving or consuming will raise the temperature.

FIG. 17

EN

Indirect cooking method is a popular alternative to direct heat grilling. Indirect cooking uses heat

from adjacent burners to cook food and, in many cases, reduces the possibility of overcooked or

overly browned food. Foods most appropriate for indirect grilling included breads, thicker pieces of

chicken or steaks. Indirect cooking involves placing the food on grates where the burners below are

not lit and then closing the grill top to create an oven effect. All the items you usually oven-roast

can be grilled to perfection using indirect heating. Preheat the burners surrounding the food to be

cooked. Use your basting pan to hold food and add water or chicken broth to the pan to prevent

the natural juices from burning or evaporating.

Direct Heat Grilling Indirect Heat Grilling

FOOD

GRILL RACK

BURNER

BURNER OFF

IMPORTANT!

y Season your grates before first use and then periodically to protect the grate surface from corrosion,

and to stop food sticking. See 'Care and Maintenance'. To season the grates, pour a tablespoon of

vegetable oil on a soft cloth and rub on both sides of the grates. Only a light coating is needed and

some smoke may be visible during the preheating.

y Grilling requires high heat for searing and proper browning. Most foods are cooked at the “MEDIUM”

to “LOW” heat setting for the entire cooking time. However, when grilling large pieces of meat or

poultry, it may be necessary to turn the heat to a lower setting after the initial browning. This cooks

the food through without burning the outside. Foods cooked for a long time or basted with a sugary

marinade may need a lower heat setting near the end of the cooking time.

23

Page 26

USING THE GRILL

Grilling

1 Ensure that the drip pan and grease tray are in place.

2 Light the grill burners following the lighting instructions.

3 Once you have verified the burners are lit, put the hood down to preheat for five to 10 minutes.

4 Place the food on the grill and cook to the desired doneness. Adjust heat setting, if necessary. The

control knob may be set to any position between “SEAR” and “LOW".

5 When you have finished using the grill, turn the control knobs to “OFF” and shut off the main gas supply.

6 Allow the grill to cool and clean the grates, drip pan and grease tray after each use.

Note: if using LP gas, your preheat time may be shorter than recommended. To prevent overcooking or

burning, you may want to lower the heat settings.

Using the temperature gauge

When preheating the grill, use the temperature gauge in the hood to check if the grill has reached

the desired heat setting.

Note: the temperature gauge only indicates air temperature inside the grill. For food safety and

optimal cooking performance, use a meat probe to check the temperature of meat while cooking and

to ensure desired internal temperatures are reached.

Dual-sided grates

Whether you or your guests crave seafood, steak or veggies, the double-sided grates provide

varying surfaces for varying textures. The “W”-shaped side creates nice sear lines for steaks, chicken

and chops and routes oil and grease away from the food. The opposite “radius” side offers more

surface area for support and handling of delicate items like scallops (see below for a sample list of

which foods to cook on which side of the grate).

"W" SHAPED GRATE RADIUS GRATE

y Chicken (bone-in and boneless cuts)

y Steaks

y Chops

y Burgers

y Ribs

y Kabobs

y Steak cuts of fish like tuna and swordfish

y Whole fish

y Game

y Oysters

y Large slices of whole vegetables

y Fruit

y Bread

y Sausages

y Delicate fish fillets

y Lobster meat

y Shrimp

y Scallops

y Clams

y Mussels

y Suckling pig

y Turkey legs

y Indirect cooking and smoking

y Potatoes

y Smaller vegetables or slices

y Roasted peppers

y Roasted whole garlic

y Pizza dough and flat breads

24

y Hot dogs

y Crab cakes

Page 27

USING THE GRILL

Grilling hints

The doneness of meat, whether rare, medium or well done, can depend on the thickness of the

cut. The cooking time of meat is dependent on the kind of meat, size, shape and cut along with

the temperature of the meat when cooking begins. Expert chefs say it is impossible to have a rare

doneness with a thin cut of meat. When defrosting meats, it is recommended to defrost overnight

in a refrigerator as opposed to a microwave. This will ensure meat retains it juices. Use a spatula

instead of tongs or a fork to turn the meat, as a spatula will not puncture the meat and let the juices

run out. To get the juiciest meats, add seasoning or salt after the cooking is finished and turn the

meat only once (juices are lost when the meat is turned several times). Turn the meat just after the

juices begin to bubble to the surface. Trim any excess fat from the meat before cooking. To prevent

steaks or chops from curling during cooking, slit the fat around the edges at two-inch intervals.

The cuts, temperatures, weights and grilling times in the following charts are meant to serve as a

guideline. Environmental factors such as wind, outside temperature and altitude can affect cooking

times, so should be taken into consideration. The USDA's definition of medium doneness is used

for the cooking times of beef and lamb, unless otherwise stated. Before carving, let roasts and

other large cuts of meat (including thick steaks) rest for 5 to 10 minutes after cooking. The internal

temperature will increase slightly during this time.

For indirect cooking, we suggest placing the meat in the secondary cooking area in the lower or

upper position depending on size and desired temperature.

EN

Cooking Chart - Main Grill

BEEF:

FOOD TYPE THICKNESS WEIGHT METHOD

New York

Strip

Steak

Ground Beef Patty 5 oz Direct Low-Medium Heat 10-14 min

Fajitas 3/4" Thick 3 lb Direct Low-Medium Heat 20 min

Finger Rib 2 lb Direct/Indirect Low-Medium Heat 1-2 hours

Brisket 3-5 lb Direct/Indirect Low Heat 2-3 hours

LAMB:

FOOD TYPE THICKNESS WEIGHT METHOD

Chop 1" Thick Direct High Heat 4-8 min

Leg of Lamb Roast 3-7 lb Direct/Indirect Low 2-3 hours

Rack of Lamb 1-2 lb Direct/Indirect Low-Medium Heat 15-20 min

Porterhouse 1" Thick Direct High Heat 6-8 min

Rib-Eye 1" Thick Direct High Heat 6-8 min

T-Bone 1" Thick Direct High Heat 6-8 min

1" Thick Direct High Heat 4-8 min

TEMP CONTROL

DIAL

TEMP CONTROL

DIAL

APPROX TIME

(HRS/MINS)

APPROX TIME

(HRS/MINS)

PORK:

FOOD TYPE THICKNESS WEIGHT METHOD

Hot Dog 2-4 oz Direct/Indirect Low Heat 5 min

Bratwurst 4 oz Link Direct/Indirect Low Heat 10-15 min

Ribs: Baby Back 3-5 lb Direct/Indirect Low Heat 3-4 hours

Spare Ribs 3-5 lb Direct/Indirect Low Heat 4-6 hours

Boston Butt/Shoulder 3-7 lb Direct/Indirect Low Heat 4-6 hours

TEMP CONTROL

DIAL

APPROX TIME

(HRS/MINS)

25

Page 28

USING THE GRILL

Grilling

Cooking Chart - Main Grill

POULTRY:

FOOD TYPE THICKNESS WEIGHT METHOD

Chicken Breast Boneless 6 -7 oz Direct/Indirect Low-Medium Heat 10-12 min

Chicken Thigh Boneless 3-5 oz Direct/Indirect Low-Medium Heat 10-12 min

Chicken Whole 3-5 lb Indirect/Rotisserie Medium Heat 1-2 hours

Duck Whole 3-5 lb Indirect/Rotisserie Medium Heat 1-2 hours

Turkey Whole 10-12 lb Indirect/Rotisserie Medium Heat 2-3 hours

SEAFOOD:

FOOD TYPE THICKNESS WEIGHT METHOD

Halibut ½ -1" Thick Direct Medium Heat 6-10 min

Snapper ½ -1" Thick Direct Medium Heat 6-10 min

Salmon ½ -1" Thick Direct Medium Heat 6-10 min

Fish Fillet/Steak:

Shrimp 2-4 oz Direct Medium Heat 4-5 min

Fish Whole 3-5 lb Indirect Low-Medium Heat 20-30 min

Sea Bass ½ -1" Thick Direct Medium Heat 6-10 min

Swordfish ½ -1" Thick Direct Medium Heat 6-10 min

Tuna ½ -1" Thick Direct Medium Heat 6-10 min

Trout ½ -1" Thick Direct Medium Heat 6-10 min

TEMP CONTROL

DIAL

TEMP CONTROL

DIAL

APPROX TIME

(HRS/MINS)

APPROX TIME

(HRS/MINS)

VEGETABLES:

FOOD TYPE THICKNESS WEIGHT METHOD

Aubergine 1" Thick Slices Direct Low Heat 4-6 min

Asparagus ½" Stem

Diameter

Corn on the Cob Whole Direct/Indirect Low Heat 20-25 min

Mushroom - Portobello Whole Direct Low Heat 8-10 min

Onion ½" Thick Slices Direct Low Heat 10-12 min

Peppers Halved Direct Low Heat 8-10 min

Potato ½" Thick Slices Direct Low Heat 10-15 min

Tomato Halved Direct Low Heat 4-6 min

Zucchini

Sweet Potato

FRUIT:

FOOD TYPE THICKNESS WEIGHT METHOD

Bananas Halved Direct Low Heat 5-6 min

Peaches

Apricots Halved Direct Low Heat 6-8 min

Nectarines Halved Direct Low Heat

Pineapple ½" Thick Slices Direct Low Heat

1" Thick Slices Direct Low Heat

1" Thick Slices Direct Low Heat

Halved

Direct Low Heat 4-6 min

Direct Low Heat 6-8 min

TEMP CONTROL

DIAL

TEMP CONTROL

DIAL

APPROX TIME

(HRS/MINS)

4-6 min

10-12 min

APPROX TIME

(HRS/MINS)

6-8 min

5-6 min

* Slow cooking of some meat cuts may require surfaces to be seared over direct high heat prior to indirect cooking.

26

Page 29

USING THE GRILL

Grilling

Cooking Chart - Smoking

BEEF:

FOOD TYPE THICKNESS WEIGHT METHOD

Brisket 4-6 lb Indirect Low Heat 6-8 hours

LAMB:

FOOD TYPE THICKNESS WEIGHT METHOD

Leg of Lamb Roast 3-7 lb Direct/Indirect Low Heat 2-3 hours

PORK:

FOOD TYPE THICKNESS WEIGHT METHOD

Ribs: Baby Back 3-5 lb Indirect Low Heat 4-5 hours

Spare Ribs 3-5 lb Indirect Low Heat 5-6 hours

Boston Butt/Shoulder 3-7 lb Indirect Low Heat 6-8 hours

TEMP CONTROL

DIAL

TEMP CONTROL

DIAL

TEMP CONTROL

DIAL

APPROX TIME

(HRS/MINS)

APPROX TIME

(HRS/MINS)

APPROX TIME

(HRS/MINS)

EN

POULTRY:

FOOD TYPE THICKNESS WEIGHT METHOD

Chicken Whole 3-5 lb Indirect Low Heat 2-4 hours

Duck Whole 3-5 lb Indirect Low Heat 2-4 hours

Turkey Whole 10-12 lb Indirect Low Heat 8-10 hours

SEAFOOD:

FOOD TYPE THICKNESS WEIGHT METHOD

Salmon ½ -1" Thick Indirect Low Heat 1 hour

Swordfish ½ -1" Thick Indirect Low Heat 1 hour

Fish Fillet/Steak:

Shrimp 2-4 oz Indirect Low Heat 1 hour

Fish Whole 3-5 lb Indirect Low Heat 3-4 hours

VEGETABLES:

FOOD TYPE THICKNESS WEIGHT METHOD

Aubergine 1" Thick Slices Indirect

Corn on the Cob Whole Indirect

Mushroom - Portobello Whole Indirect

Onion Whole/halved Indirect

Peppers Whole/halved Indirect

Potato Whole/halved Indirect

Tomato Whole/halved Indirect

Zucchini

Sweet Potato

Tuna ½ -1" Thick Indirect Low Heat 1 hour

Trout ½ -1" Thick Indirect Low Heat 1 hour

Mackerel ½ -1" Thick Indirect Low Heat 1 hour

Halved

lengthwise

Whole/halved Indirect

Indirect

TEMP CONTROL

DIAL

TEMP CONTROL

DIAL

TEMP CONTROL

DIAL

Low Heat

Low Heat

Low Heat

Low Heat

Low Heat

Low Heat

Low Heat

Low Heat

Low Heat

APPROX TIME

(HRS/MINS)

APPROX TIME

(HRS/MINS)

APPROX TIME

(HRS/MINS)

1 hour

1 ½ hours

1 ½ hours

2 hours

1 ½ hours

2 hours

45 minutes

1 hour

2 hours

27

Page 30

USING THE GRILL

Grilling

Meat Temperatures

The “Remove” temperature on the left is the target temperature to remove from heat source. The “Ideal”

temperature on the right is the ideal internal temperature after resting. These temperatures are all

Fahrenheit.Note, these are not USDA Recommendations. The USDA temperatures are conservatively 10

– 15

°

higher because of food safety however most professional chefs will not cook a medium-rare steak to

150

°F

.

FOOD TYPE RARE MEDIUM-RARE MEDIUM MEDIUM-WELL

°

EN

REMOVE IDEAL REMOVE

Beef Steaks

Beef Roasts

Lamb Chops

Lamb Roast

Pork Chops

Pork Roasts

Veal Chops

Veal Roasts

FOOD TYPE RESTING TIME REMOVE IDEAL INTERNAL TEMPERATURE

Whole Chicken - Roasted 5 minutes

Whole Turkey - Roasted*

125° 130° 130° 135° 140° 145° 155° 160°

120° 125° 125° 130° 135° 145° 150° 160°

125° 130° 130° 135° 135° 145° 155° 160°

120° 130° 125° 130° 135° 145° 150° 160°

125° 130° 135° 140° 145° 150°

125° 130° 135° 140° 145° 150°

130° 135° 140° 145° 155° 160°

125° 130° 135° 145° 150° 160°

20-60 minutes 150° - 170°

IDEAL

160° - 165°

REMOVE IDEAL REMOVE

165°- 170°

165° - 170°

IDEAL

* A large Turkey can take 60 minutes of resting with a temperature shift of 20° or more

28

Page 31

USING THE SMOKER SYSTEM

The smoker system on each grill consists of a stainless steel slide out tray which is positioned

above a 3,500 Btu/hr or 3.7 MJ/h burner. The burner is controlled by a precision brass valve which

is capable of being turned down to very low heat levels. The system may be used alone for low

temperature roasting and smoking or in conjunction with any combination of other burners. When

using the smoker system in conjunction with the optional infrared rotisserie burner, you’ll find it

helpful to use the low setting of the smoker burner to minimize the heat rising up to the rotisserie

basting pan. Staggering the meat away from the smoker burner also helps.

To minimize burn potential do not completely remove the smoker tray when hot.

To light the smoker burner

Open the lid and remove the smoker tray. Locate the

burner visually by looking through the cut-out in the valve

panel. Push in the burner knob and turn to the “HI” position

until the burner is lit. If the burner doesn’t ignite, wait five

minutes for any accumulated gas to dissipate, then try again.

If the burner will not light after several attempts, wait five

minutes, then match light using a paper book match through

the cut-out in the valve panel. Once lit, fill the smoker tray

and replace.

Wood chips

There are many wood chips available for purchase and

selection is based on personal taste. The most common

wood chips used are mesquite or hickory. Mesquite has

a sweeter taste and is commonly used with poultry and

seafood. Hickory is best suited for red meats. Use of oak,

cherry, maple, aspen or apple is also common while aromatic

herbs like sage, bay leaves, thyme or basil may also be

used. Soaking the chips in water before using them will help

ensure the wood chips smoke and do not flame up. To start,

you may want to use the “HI” position to start the chips

smoking, then reduce the heat to a lower level to prevent

them from drying out and flaming. If the wood chips do

flame up, add a small amount of water to extinguish the

flame. This should be done carefully through the top in the

grill area, or by pulling the tray out slightly. Use caution

when adding water to a hot tray to avoid steam burns, and

never completely remove a hot tray. When smoking, the lid

should remain closed as much as possible to maximize the

effect. During extended roasting periods it is normal to add

fresh wood chips to the tray several times.

FIG. 18

EN

Your smoker tray comes with a removable smoker lid. For

best results we recommend using the smoker lid.

FIG. 19

29

Page 32

USING THE ROTISSERIE

The grill rotisserie system is designed to cook items from the

back using infrared heat. The location of the burner allows the

placement of the rotisserie basting pan (included) beneath

the food to collect juices and drippings for basting and gravy.

To flavor the contents of the basting pan, you can add herbs,

onion, garlic, or spices. Hams are especially good with the

addition of pineapple slices and brown sugar to the basting

pan. The rotisserie burner is an infrared type which provides

intense searing radiant heat. Preferred by chefs over other

methods, this intense heat is magnificent for searing in the

natural juices and nutrients found in quality cuts of meat.

Once lit, the rotisserie burner will reach cooking temperatures

in about one minute. The orange/red glow will even out in

about five minutes. The rotisserie motor is equipped with metal

gears and is capable of turning up to a 50 lb. cut of meat or

poultry. The rotisserie motor on the grills is secured down to

a cast rotisserie block with two black screw-down knobs. The

rotisserie block is in turn bolted to the right side panel. The

rod for the rotisserie is assembled into the motor assembly by

placing the pointed end into the motor, and resting the handle

end on the support at the left side of the grill. With the rod

pushed as far as possible into the motor, the round end of the

rod should rest on the rollers.

FIG. 20

The motor is equipped with a halogen bulb to provide light

when other sources of light are not sufficient. Use only a 50W

(or its equivalent) Max. Halogen Narrow Flood replacement

bulb.

IMPORTANT!

Halogen lamps are constructed of a glass bulb with a

pressurized internal filament tube that operates at high

temperatures and could unexpectedly shatter. Should the outer

bulb break, particles of extremely hot glass could be discharged

into the fixture enclosure and/or surrounding environment,

thereby creating a risk of personal injury or fire. When replacing

the bulb, let the bulb cool, and assure that power to the light

has been turned off. Never allow the hot bulb to come into

contact with water. DO NOT TOUCH the light bulb when in use.

It may be hot enough to cause injury.

FIG. 21

MOTOR

LIGHT

30

FIG. 22

Page 33

USING THE ROTISSERIE

IMPORTANT!

Do not use the grill burners when the rotisserie burner is on. It will burn your meat and make it very

dry. Use only one section at a time, grill or rotisserie.

Preparation

Recommended: dental floss or butcher string, scissors, broiler pan (bottom only), pliers, meat

probe, foil, and hot pads.

Working area

Allow enough space to accommodate food and rotisserie rod assembly in a clean environment.

Meat preparation

Tie meat with butcher string or dental floss in three areas. Purchase a roast that is equally balanced

from top to bottom in size to ensure meat will cook evenly while on the rotisserie. For poultry, tie

wings and legs to the body using dental floss or butcher string to prevent flopping around while

turning.

EN

1 Determine the center placement for the food,

put first prong on the rod, turn “L”-shaped

screw to tighten.

3 Pick up the rod, rotate it to check for balance.

If unbalanced, adjust prongs and food. Take

pliers and tighten the “L”-shaped screws on

both prongs.

2 Center tied meat/poultry on the rod, place

second prong, turn “L”-shaped screw to

tighten.

4 Remove grates and top rack on the grill. Place

bottom portion of basting pan on ceramic rods

so meat drippings can be caught in pan.

31

Page 34

USING THE ROTISSERIE

To light the rotisserie burner before cooking

The location of the rotisserie burner makes it more susceptible to strong wind conditions, more so

than the protected grill burners. For this reason you should avoid operating the rotisserie during

windy conditions. As an added safety feature we’ve equipped the burner with an automatic safety

valve which will not allow gas to flow to the rotisserie burner unless the following conditions are

present with the knob on:

1 The safety valve button is pressed, and held down.

2 The safety valve thermocouple has been sufficientlyheated to keep safety valve open.

Open the lid. Push in and hold the burner knob. You’ll hear a snapping sound. Turn the burner knob

to “HI”. Engage the safety valve button and continue to hold until the burner is lit. Once lit, turn

burner knob to desired setting. If the burner does not light within four to five seconds, release the

safety valve button and turn the burner knob to “OFF” and wait five minutes before trying again.

y If relighting a hot burner, wait five minutes.

y Never leave the control knob on if rotisserie is not in use.

y Never light the grill burners under the rotisserie while the rear rotisserie burner is lit.

Manual lighting

To manually light the rotisserie, place a butane lighter

near the tip of the thermocouple as shown in Fig. 23. Turn

the burner knob to “HI”. Hold the safety valve button in

for about four to five seconds or until the burner remains

lit. Once lit, turn burner knob to desired setting. If the

burner does not light within four or five seconds, release

the safety valve button and turn the burner knob to “OFF”

and wait five minutes before trying again.

IMPORTANT!

Keep hands and face away from front of burner! Stand to

the side when lighting. Once lit move hand away quickly.

FIG. 23

IMPORTANT!

Electrical Grounding Instructions: this appliance (rotisserie motor) is equipped with a three-prong

(grounding) plug for your protection against shock hazard and should be plugged directly into

a properly grounded three-prong receptacle or a three-prong grounded extension cord rated for

the power of the rotisserie motor and approved for outdoor use with a W-A marking. Do not cut

or remove the grounding prong from this plug. Use only a ground fault interrupter (GFI) protected

circuit.

The rotisserie motor must be electrically grounded in accordance with local codes or, in the absence

of local codes, with the National Electrical Code, ANSI/NFPA 70. Keep the rotisserie motor electric

cord away from the heated surfaces of the grill. When not in use, remove and store the motor

in a dry location. To protect against electric shock, do not immerse the cord or plug in water or

other liquid. Unplug rotisserie unit from the outlet when not in use and before cleaning. Allow the

rotisserie to cool before putting on or taking off parts.

32

Page 35

Cooking on the rotisserie

USING THE ROTISSERIE

EN

1 Place prepared rod into motor, lay across

and into the rollers on other side.

3 To check temperature of the meat, turn off

motor and turn temperature to low while

using a meat probe.

2 Once placement has been verified, ignite

burner and start rotisserie motor. Turn the

burner knob to the desired setting.

4 Once finished, turn the motor and rotisserie

knob to “OFF”. If you have finished using the

appliance altogether, turn the main gas supply

off too.

5 Remove the rod and place meat or poultry on

pan then remove prongs. Take care as the rod

will be hot.

IMPORTANT!

The prongs are very sharp. Keep hands

away from tips when removing the food.

Note: cover with foil for a 15 to 20 minute

waiting time. Meat will carve better and

juices will go back into the meat.

33

Page 36

CARE AND MAINTENANCE

Battery replacement

IMPORTANT!

Battery condition should be checked at least once a year.

1 Remove drip pan.

2 Open cart door (on cart model only).

3 Pull battery downwards (this may require use of pliers).

4 Re-install upward and push to snap (polarity shown in Fig. 24).

Regulator and hose replacement

The pressure regulator and hose assembly supplied with the unit must be used. If replacements are

needed, contact Customer Care at www.dcsappliances.com. Do not use the grill if the odor of gas

is present. If the unit is LP, screw the regulator into the tank and leak check the hose and regulator

connections with a soap and water solution before operating the grill. Turn all knobs to “OFF” then

turn on the gas supply. If LP, check that there is gas in the tank.

FIG. 24

IMPORTANT!

y Always keep your face and body as far away from the grill as possible when lighting.

y DO NOT leave the grill unattended while cooking.

y Keep a spray bottle of soapy water near the gas supply valve and check connections before each use.

y Do not attempt to light the grill if the odor of gas is present.

y Wait five minutes before relighting a hot grill.

Grill grates

Method 1

Turn on “HI” for 15-20 minutes to burn any remaining food particles. After turning the grill “OFF”,

use a bristle barbeque brush to remove any remaining food particles or ash.

Method 2

The easiest way to clean the grill is immediately after cooking is completed and after turning off the

flame. Wear a barbeque mitt to protect your hand from the heat and steam. Dip a soft brass bristle

barbeque brush in a mixture of 2 cups of tap water and 1/2 cup of vinegar and scrub the hot grill.

Dip the brush frequently in the bowl of water and vinegar. Steam, created as water contacts the hot