THE PROFESSIONAL

36/48” BGB GRILL

Use and Care Guide

MODELS:

BGB36-BQAR

BGB48-BQAR

BGB48-BQR

1

Thank you for selecting this DCS Professional “BGB” Series Grills. Because of these appliances unique

features we have developed this Use and Care Guide. It contains valuable information on how to properly

operate and maintain your new appliance for years of safe and enjoyable cooking.

To help serve you better,please fill out and submit your Ownership Registration by visiting our website at

www.dcsappliances.com and selecting “Customer Service” on the home page and then select “Ownership

Registration” or submit the enclosed Ownership Registration Card to the address below. In addition, keep

this guide handy,as it will help answer questions that may arise as you use your new appliance.

For your convenience, product questions can be answered by a DCS Customer Care Representative at

1-888-281-5698 , email:support@dcsappliances.com, or by mail:

WAR NI NG

Improper installation, adjustment alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before use, installing or servicing this

equipment. For outdoor use only.

PRECAUTION

Do Not store or use gasoline or any other flammable vapors and liquids in the

vicinity of this or any other appliance.

FOR YOUR SAFETY

IF YOU SMELL GAS:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

3. If odor continues, immediately call your gas supplier.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Fisher & Paykel Appliances,Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

www.dcsappliances.com

A MESSAGE TO OUR CUSTOMERS

2

SAFETY PRACTICES & PRECAUTIONS.......................................................................................................3-5

GRILL MODELS................................................................................................................................................................6

GAS REQUIREMENTS..............................................................................................................................................7-8

LOCATING GRILL / BUILT-IN CLEARANCES.........................................................................................9-10

BUILT-IN CONSTRUCTION DETAILS..............................................................................................................11

LEAK TESTING ...............................................................................................................................................................12

INSTALLER FINAL CHECKLIST...........................................................................................................................13

BURNER ADJUSTMENTS.......................................................................................................................................14

USING THE GRILL .................................................................................................................................................15-17

LIGHTING INSTRUCTIONS.............................................................................................................................17-18

USING THE SMOKER SYSTEM ...........................................................................................................................19

USING THE ROTISSERIE ..................................................................................................................................20-23

CARE & CLEANING.....................................................................................................................................................24

BURNER REMOVAL & CLEANING.............................................................................................................25-26

TROUBLESHOOTING................................................................................................................................................27

PA RT S LISTS

Grill Burner Assembly Parts List ..................................................................................................................28

Grill Body Parts List....................................................................................................................................29-30

Grill Burner Assembly......................................................................................................................................31

Rotisserie Assembly Parts List......................................................................................................................32

Smoker Burner Assembly Parts List ...........................................................................................................33

48 Grill Cart Parts List......................................................................................................................................34

36 Grill Cart Parts List......................................................................................................................................35

WIRING DIAGRAM

Wiring Diagram – BGB36-BQAR Models .................................................................................................36

Wiring Diagram – BGB48-BQR Models ....................................................................................................37

Wiring Diagram – BGB48-BQAR Models .................................................................................................38

SERVICE..............................................................................................................................................................................39

WAR RANT Y......................................................................................................................................................................40

TABLE OF CONTENTS

3

IMPORTANT SAFETY NOTICE:

Certain Liquid Propane dealers may fill liquid propane cylinders for use in the

grill beyond cylinder filling capacity. This “Overfilling” may create a dangerous

condition.

“Overfilled” tanks can build up excess pressure. As a safety device, the tanks pressure relief valve will

vent propane gas vapor to relieve this excess pressure. This vapor is combustible and therefore can be

ignited. To reduce this danger, you should take the following safety precautions:

1. When you have your tank filled, be sure you tell the supplier to fill it to no more than 3/4 (75%)

of its total capacity.

2. If you own or use an extra spare tank, or have a disconnected tank, you

should NEVER store it near or under the grill unit or heat box,or near any

other ignition or heat source. A metallic sticker with this warning is

attached to the grill to remind you, your family and all others who may

use your BBQ grill of these safety precautions.

Do not remove this sticker.

WAR NING:

Do not try lighting this appliance without reading the

“LIGHTING INSTRUCTIONS” section of this manual.

This Grill is for outdoor use only.

WAR NING:

Push and hold the igniter button, turn the selected burner knob to “HI”. If

burner does not light in 4 to 5 seconds turn knob “OFF” and wait 5 minutes

before trying again for any accumulated gas to dissipate.

Children should not be left alone or unattended in an area where the grill is being used. Never

allow them to sit, stand or play on or around the grill at any time. When in use, portions of the

grill get hot enough to cause severe burns.

Do not store items of interest to children around or below the grill, in the cart or masonry

enclosure. Never allow children to crawl inside a cart or enclosure.

Never let clothing, pot holders or other flammable materials come in contact with or too close

to any grate, burner or hot surface until it has cooled. Fabric may ignite and result in personal

injury.

Do not heat unopened food containers as a build-up of pressure may cause the container to

burst.

Always use a covered hand when opening the grill lid and only do so slowly to allow heat and

steam to escape.

Never lean over an open grill. When lighting a burner, always pay close attention to what you

are doing. Be certain you are pushing the ignition button when you attempt to light the grill.

When using the grill, do not touch the grill burner grate or immediate surrounding area as

these areas become extremely hot and could cause burns.

Grease is flammable. Let hot grease cool before attempting to handle it. Avoid letting grease

deposits collect in the drip pan. Clean often.

SAFETY PRACTICES & PRECAUTIONS

4

For personal safety,wear proper apparel. Loose fitting garments or sleeves should never be worn while

using this appliance. Some synthetic fabrics are highly flammable and should not be worn while cooking. Only certain types of glass, heat-proof glass ceramic, earthenware,or other glazed utensils are suitable for grill use. These types of materials may break with sudden temperature changes. Use only on

low or medium heat settings according to the manufacturer’s directions.

WAR NING:

Spiders and insects can nest in the burners of this and any other grill, and cause

the gas to flow from the front of the burner. This is a very dangerous condition

which can cause a fire to occur behind the valve panel, thereby damaging the

grill components and making it unsafe to operate.

WAR NING:

Keep the area surrounding the grill free from combustible materials, trash, or

combustible fluids and vapors such as gasoline or charcoal lighter fluid. Do

not obstruct the flow of combustion and ventilation air.

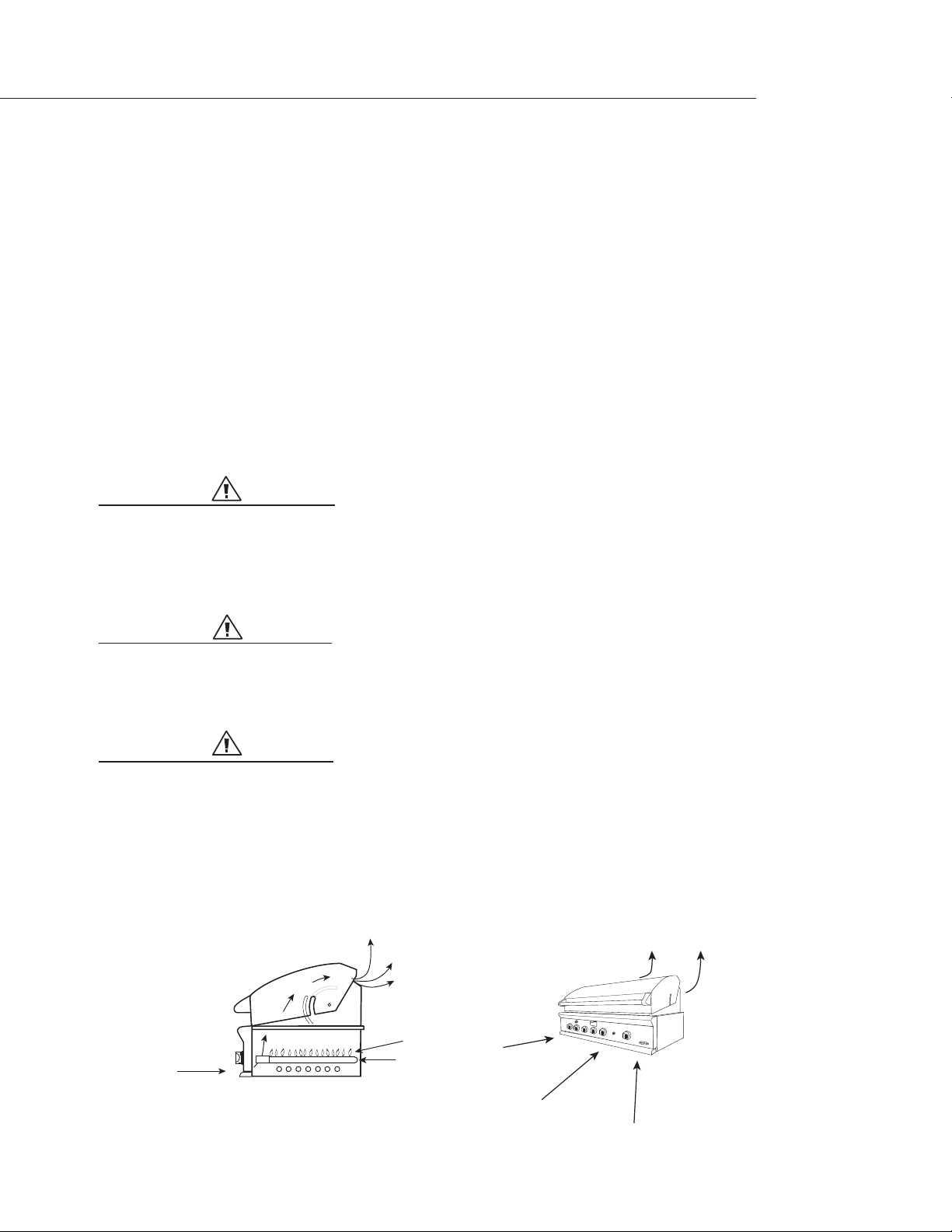

WAR NING:

Never use the grill in windy conditions. If located in a consistently windy area

(oceanfront, mountaintop, etc.) a wind break will be required. Always adhere

to the specified clearances listed.

PREFERRED AIR FLOW

GRILL EXHAUST

EXHAUST

FLAME

BURNER

WIND

WIND

PRIMARY

INTAKE

AIR FLOW

EXHAUST VENT FLOW

GRILL PLACEMENT

Do not use aluminum foil to line drip pans or grill racks. This can severely upset combustion air

flow or trap excessive heat in the control area. The result of this can be melted knobs or ignition

buttons.

Begin by insuring proper installation and servicing. Follow the installation instructions

provided with this product. Have your grill installed by a qualified technician. Have the installer

show you where the gas supply shut off valve is located so that you know where to shut off the

gas to the grill. If you smell gas, your installer has not done a proper job of checking for leaks.

If the connections are not perfectly sealed, you can have a small leak and therefore a faint gas

smell. Finding a leak is not a “do-it-yourself ”procedure. Some leaks can only be found with the

burner control in the “ON”position and this must be done by a qualified technician.

SAFETY PRACTICES & PRECAUTIONS

5

When using the open top burners always use flat bottomed utensils which are large enough to

cover the burner. Adjust the flame so that it heats only the bottom of the pan to avoid ignition

of clothing. Position handles inward away from open edges of the unit to avoid burns

associated with unintentional spillovers. Hold the handle of the pan to prevent movement of

the utensil when turning or stirring food. For proper lighting and performance of the burners

keep the ports clean. It is necessary to clean them periodically for optimum performance.

Clean the grill with caution. Avoid steam burns; do not use a wet sponge or cloth to clean the

grill while it is hot. Some cleaners produce noxious fumes or can ignite if applied to a hot

surface.

Be sure all grill controls are turned off and the grill is cool before using any type of aerosol

cleaner on or around the grill. The chemical that produces the spraying action could, in the

presence of heat, ignite or cause metal parts to corrode.

Do not use the grill for cooking excessively fatty meats or products which promote flare-ups.

Never grill without the drip pan and grease tray in place and pushed all the way to the back of

the grill. Without it hot grease could leak downward and produce a fire or explosion hazard.

Do not operate the grill under unprotected combustible construction. Use only in well

ventilated areas. Do not use in buildings, garages, sheds, breezeway or other such enclosed

areas. This unit is for outdoor use only.

If a cart unit is stored indoors ensure that it is cool, fold the side shelf down, then push, never

pull, the grill. If LP, the cylinder must be unhooked and the LP cylinder stored outside in a well

ventilated area, out of reach of children.

Do not use charcoal in the grill. Never use the grill in a windy area. Keep any electrical supply

cord, or the rotisserie motor cord away from the heated areas of the grill.

Never use a dented or rusty LP tank. Keep the ventilation openings of the cylinder enclosure

free and clear from debris.

Use only dry potholders; moist or damp potholders on hot surfaces may cause burns from

steam. Do not use a towel or bulky cloth in place of potholders. Do not let potholders touch

hot portions of the grill or burner grate.

CALIFORNIA PROPOSITION 65-WARNING: The Burning of gas cooking fuel generates some

by-products which are on the list of substances which are known by the State of California to

cause cancer or reproductive harm. California law requires businesses to warn customers of

potential exposure to such substances. To minimize exposure to these substances always

operate this unit according to the Use and Care Manual,ensuring you provide good ventilation

when cooking with gas.

SAFETY PRACTICES & PRECAUTIONS

6

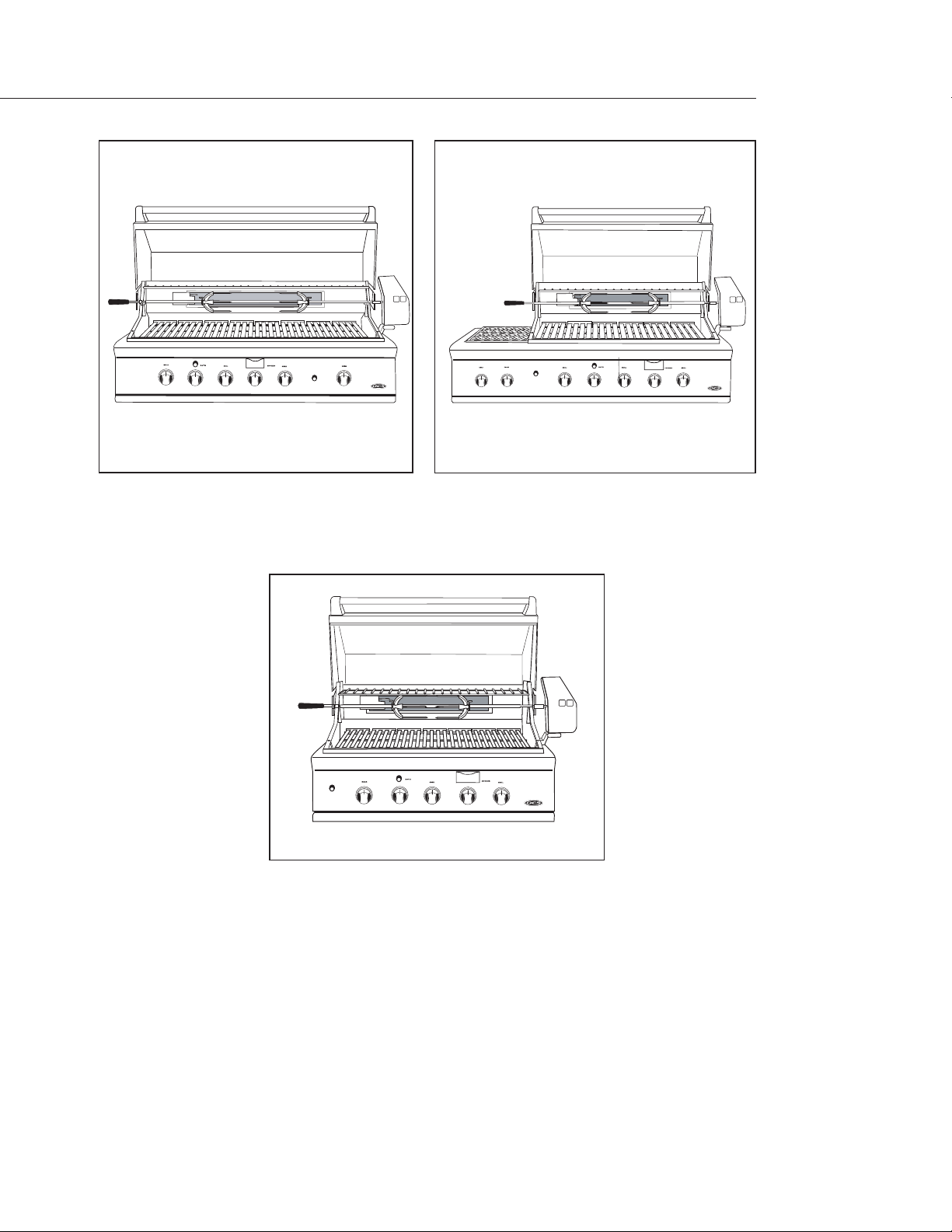

IGNITION

IGNITION

BGB48-BQAR

BGB48-BQR

BGB36-BQAR

GRILL MODELS

7

Verify the type of gas supply to be used,

either natural or LP, and make sure the

marking on the appliance rating plate

agrees with that of the supply. The rating

plate is located on the outside of the back

wall of the Grill. Never connect an

unregulated gas line to the appliance.

An installer supplied gas shut-off valve

must be installed in an easily accessible

location. All installer supplied parts must

conform to local codes,or in the absence of

local codes, with the National Electrical

Code, ANSI/NFPA 70-1990, and the

National Fuel Gas Code,ANSI Z223.1.

All pipe sealants must be an approved type

and resistant to the actions of LP gases.

Never use pipe sealant on flare fittings. All

gas connections should be made by a

qualified technician and in accordance

with local codes and ordinances. In the absence of local codes, the installation must comply with the

national fuel gas code ANSI Z223.1. Gas conversion kits are available from the factory. When ordering

gas conversion kits have the model number, and the type of gas (natural or LP) from your grill.

TOTAL GAS CONSUMPTION OF THE GRILL WITH ALL BURNERS ON HI:

BGB48-BQR - 122,500 Btu/hr BGB48-BQAR - 121,500 Btu/hr BGB36-BQAR - 92,500 Btu/hr

The appliance and its individual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 PSIG (3.5 kPa.) The

appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than 1/2 PSIG (3.5 kPa.). The installation of this appliance must conform with local codes or, in the

absence of local codes, with the national fuel gas code, ANSI Z223.1. Installation in Canada must be in

accordance with the Standard Can1-b149.1 and/or .2 (installation code for gas burning appliances and

equipment) and local codes.

NATURAL GAS HOOK UP:

Connection: 1/2" NPT male with 3/8" flare adapter. Operating pressure: 4.0" W.C.

Supply pressure: 5" to 14" water column. If in excess of 14" W.C. a step down regulator is required.

Check with your local gas utility company or with local codes for instructions on installing gas supply

lines. Be sure to check on type and size of run, and how deep to bury the line. If the gas line is too

small, the grill will not function properly. Any joint sealant used must be an approved type and be

resistive to the actions of LP gases.

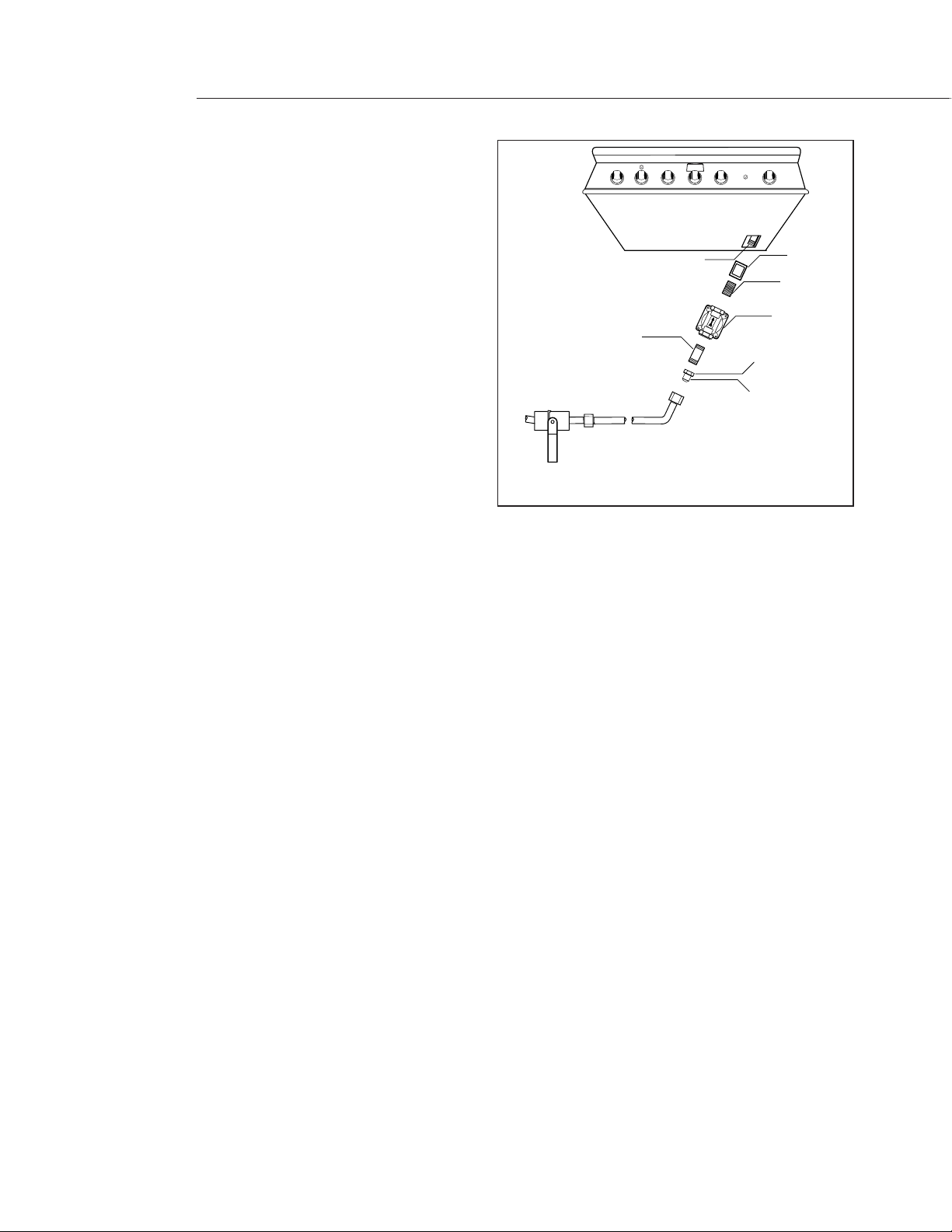

TO HOOK-UP THE FITTINGS SUPPLIED WITH THE GRILL:

Assemble as shown (Fig.01). Use threading compound on male threads only. Do not use threading

compound on the male end of the 1/2 NPT to 3/8 flare adapter. Use a second pipe wrench to hold the

grill inlet pipe to avoid shifting any internal gas lines of the grill. Ensure that the regulator arrow points

in the direction of gas flow towards the unit,away from the supply. Do not forget to place the installer

supplied gas valve in an accessible location.

FIG.01 Natural Gas

GAS REQUIREMENTS

Threading compound

must be resistant to LP gas

Installer supplied shut-off

valve must be easily

accessible*

1/2 x 5" NPT

Close

NIpple

*Installation must conform with

local codes or with the National

Fuel Gas Code ANSI Z223.1

Bottom of unit

Coupling

1/2 NPT

Close

NIpple

Regulator

4.0" W.C.

Adapter 1/2 NPT

to 3/8 flare fitting

Do not put threading

compound on these

threads

8

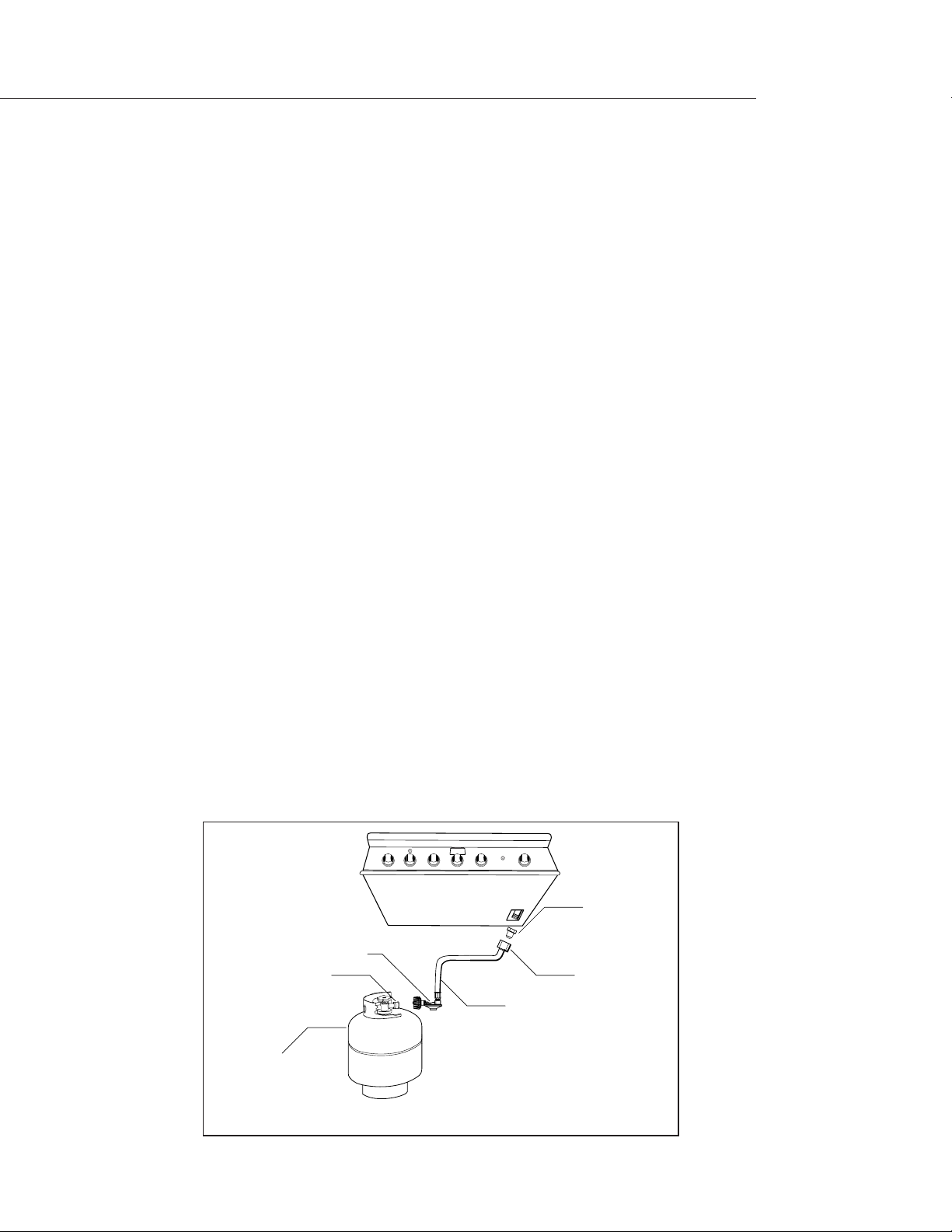

LP GAS HOOK UP (TYPE 1 OR QCC1 REGULATOR):

Grills orificed for use with LP gas come equipped with a high capacity hose/regulator assembly for

connection to a standard 20 lb. LP cylinder (Type 1). The LP tank is not included.

Connection: 1/2" NPT male with a 3/8" Flare adapter (included). LP Hose with a quick disconnect and

fittings are included. Operating pressure: 10.0" W.C.

To connect the LP regulator/hose assembly to the tank/valve assembly, first make sure the main valve

on the tank is completely closed. Although the flow of gas is stopped when the Type 1 system is

disconnected as part of of its safety feature, you should always turn off the LP tank main valve (Fig.02)

after each use and during transport of the tank or unit. Insert the regulator inlet into the tank valve

and turn to the black coupler clockwise until the coupler tightens up. Do not overtighten the coupler.

Turn the main tank valve on and turn the burner control valves on the unit to the “HI”position for about

20 seconds to allow the air in the system to purge before attempting to light the burners.

To disconnect the coupler, first make sure the main tank valve is turned off. Grasp the coupler and turn

counter clockwise. The inlet will then disengage, remove the inlet from the tank valve opening if it has

not already done so when it disengaged. Your local LP filling station should be equipped with the

proper equipment to fill your tank.

LP TANK REQUIREMENTS:

A dented or rusty LP tank may be hazardous and should be checked by your LP supplier. Never use a

cylinder with a damaged valve. Always check for leaks after every LP tank change. The LP gas cylinder must

be constructed and marked in accordance with the specifications for LP gas cylinders of the U.S.

Department of Transportation (DOT) and designed for use with a Type 1 system only. Do not change the

regulator/hose assembly from that supplied with the unit or attempt to use a Type 1 equipped

regulator/hose assembly with a standard 510 POL tank/valve assembly. The cylinder must be provided with

a shut-off valve terminating in an LP gas supply cylinder valve outlet specified,as applicable, for connection

Type 1. If the appliance is stored indoors, the cylinder must be disconnected and removed from the

appliance. Cylinders must be stored outdoors in a well-ventilated area out of the reach of children.

NOTE:When an LP unit is directly attached into an LP house system, the step down regulator MUST

be used to reduce the supply pressure to a max. 14”W.C. and min. 11” W.C. to the grill regulator.

FIG.02 LP Gas

GAS REQUIREMENTS

Threading compound

must be resistant to LP

gas

Type 1 Regulator

Main Valve

Bottom of unit

LP Regulator hose

assembly 10" W.C.

Adapter 1/2 NPT

to 3/8 flare

fitting

Do not put threading

compound on these

threads

Type 1 Tank

*Installation must conform

with local codes or with the

National Fuel Gas Code ANSI

Z223.1

9

INSULATED JACKET:

Do not build the Grill under overhead unprotected combustible construction. If the Grill is to be

placed into a combustible enclosure, an approved insulated jacket is necessary and is available from

your dealer. Use only the DCS insulated jacket which has specifically been designed and tested for this

purpose.

Location:

When determining a suitable location take into account concerns such as exposure to wind,proximity

to traffic paths and keeping any gas or electrical supply lines as short as possible. Locate the grill only

in a well ventilated area. Never locate the grill in a building, garage, breezeway, shed or other such

enclosed areas without an approved ventilation system. During heavy use, the grill will produce a lot

of smoke. Ensure there is adequate area for it to dissipate.

IMPORTANT :

Gas fittings, regulator, and installer supplied shut-off valves must be easily

accessible.

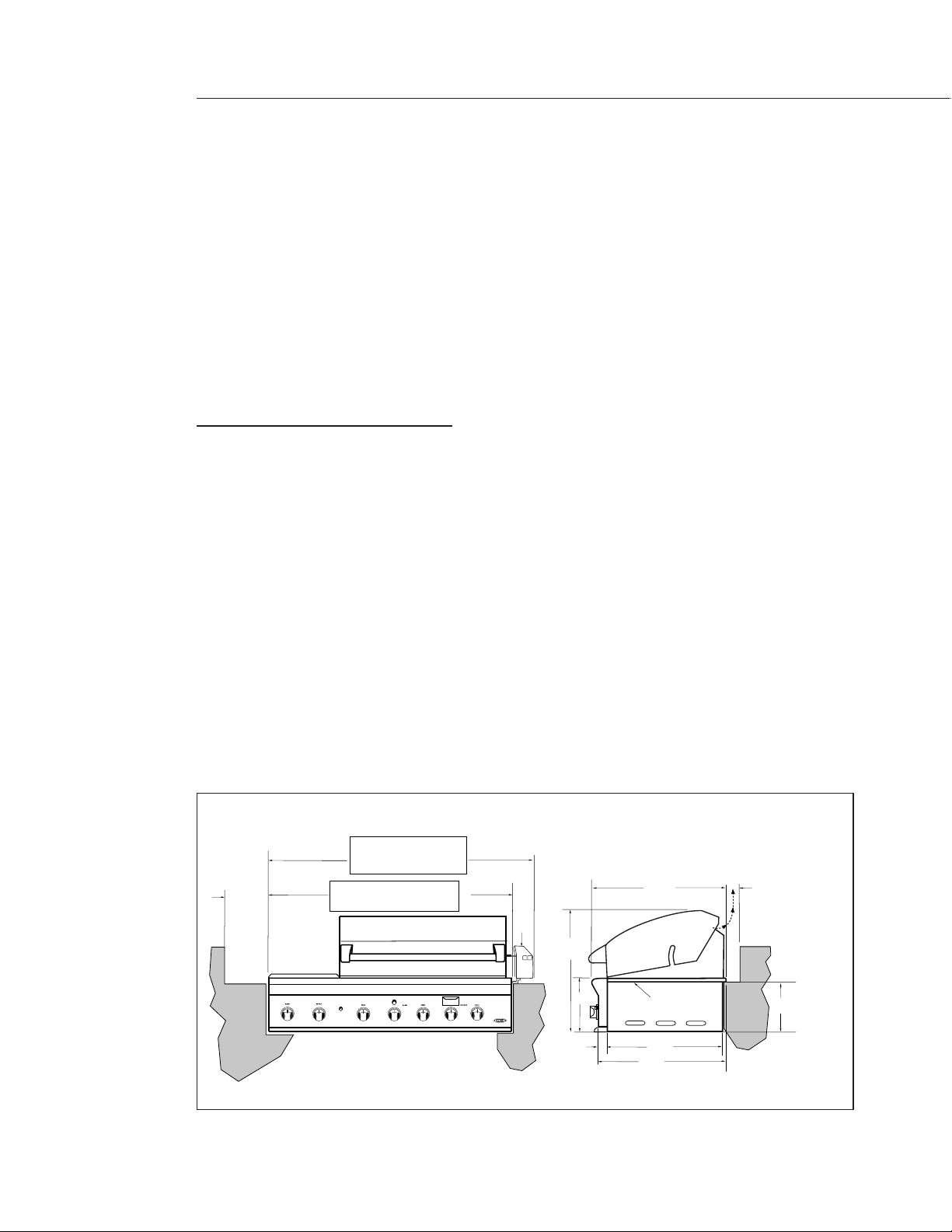

CLEARANCES TO COMBUSTIBLE CONSTRUCTION:

A Minimum of 12" from the sides and a minimum of 12" from the back must be maintained from the

Grill above and below the cooking surface to adjacent vertical combustible construction. (Fig. 03)

Clearances to Non-Combustible Construction:

A minimum of 3" clearance from the back of the grill to non-combustible construction is required for

the purpose of allowing the lid to open fully. It is desirable to allow at least 6" side clearance to noncombustible construction above the cooking surface for counter space. If you’ll be using the rotisserie

option, the space is essential for motor and skewer clearance. The Grill can be placed directly adjacent

to non-combustible construction below the cooking surface. (Fig. 03)

LOCATING GRILL/BUILT-IN CLEARANCES

FIG.03

48 BQAR = 53-1/4"

48 BQR = 53-7/16"

36 BQAR = 41-5/8"

12"

(to left

and right

side of

grill to

combustible

construction)

(with rotisserie motor mounted)

48" Models = 47-7/8"

36" Models = 35-7/8"

(without rotisserie motor mounted)

rotisserie

motor

24-1/4"

10-1/2"

26-1/2"

Bottom of

support flange

grill

exhaust

3" (to non-combustible

construction / minimum

lid clearance)

12" (to combustible

construction)

10 "

2"

22"

25-1/2"

10

General

The Grill is designed for easy placement into masonry enclosures. For non-combustible applications

the grill drops into the opening shown in (Fig. 04) and hangs from its side flanges. A deck is not

required to support it from the bottom. When using the insulated jacket in a combustible enclosure

application, see the bottom of Fig. 04. The jacket assembly must be supported from the bottom by a

ledge on each side or a solid deck beneath the entire grill or insulated jacket.

Review the detail drawing shown (Fig. 04) and take into account the provisions shown for gas line

hook-up clearance in the right rear corner. It is recommended that ventilation holes are provided in

the enclosure in the event of a gas leak. The supporting ledges or deck must be level and flat. The

counter should also be level.

LOCATING GRILL/BUILT-IN CLEARANCES

11

BUILT–IN CONSTRUCTION DETAILS

FIG.04

grill

exhaust

3" (to non-combustible construction /

minimum lid clearance)

12" (to combustible construction)

13-3/4"

Bottom of

support flange

10"

2"

Standard layout for non-combustible enclosure:

2

10 in.

Min. ventilation

on the back side

10 in.2 Min. ventilation

left hand side

10-1/8"

35-1/2"

Max.

1" Min.

Layout for insulated jacket only - combustible enclosure:

NOTE: See page 28, #29 for insulated

jacket part ordering information.

2

Min. ventilation

10 in.

on the back side

22"

25-1/2"

48" Models = 45-3/4"

36" Models = 34-1/2"

20"

48" Models = 46"

36" Models = 34"

48" Models = 51-5/8"

36" Models = 40-1/2"

18-1/2"

1-1/2"

NOTE: If using a backguard apron or rear

wall, locate electrical service on the right

hand side for rotisserie motor connection

3" Min. for Lid

Clearance

22-3/4"

4" x 4" opening

for gas supply line

2

10 in.

Min. ventilation

on the right hand side

opening for access doors

NOTE: If using a backguard apron or rear

wall, locate electrical service on the right

hand side for rotisserie motor connection

3" Min. for Lid

Clearance

10 in.2 Min. ventilation

left hand side

11-1/8"

35-1/2"

Max.

1" Min.

20"

18-1/2"

48" Models = 46"

36" Models = 34"

23-3/4"

4" x 4" opening

for gas supply line

3"

2

10 in.

Min. ventilation

on the right hand side

opening for access doors

12

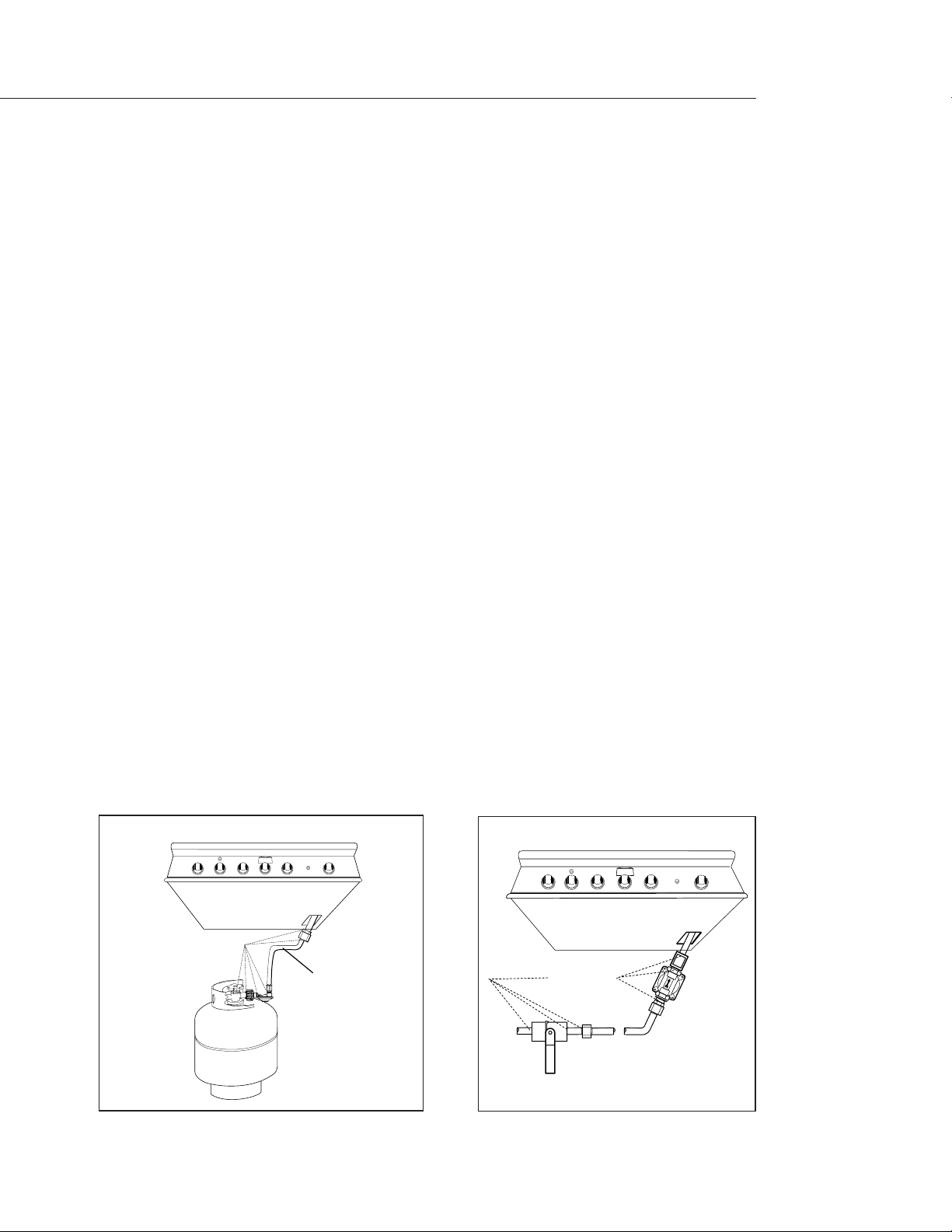

GENERAL:

Although all gas connections on the grill are leak tested at the factory prior to shipment, a complete

gas tightness check must be performed at the installation site due to possible mishandling in

shipment, or excessive pressure unknowingly being applied to the unit. Periodically check the whole

system for leaks, or immediately check if the smell of gas is detected.

Before Te sting:

Do not smoke while leak testing. Extinguish all open flames. Never leak test with an open flame.

Make a soap solution of one part liquid detergent and one part water. You will need a spray bottle,

brush,or rag to apply the solution to the fittings. For LP units,check with a full cylinder. The valve panel

must be removed to check the valves and fittings. Remove the knobs and the safety valve knob, then

remove the 2 screws which fasten the valve panel to the unit (you will need a Philips head for this). Pull

the valve panel outward and unplug the wires from the ignition module and the back of the ignition

button. Remove the screws which hold the service panel in place. Remove the service panel.

To Test:

Make sure all control valves are in the“OFF” position. Turn the gas supply“ON”. Check all connections

from the supply line, or LP cylinder up to and including the manifold pipe assembly. Apply the soap

solution around the connection, valve, tubing and end of the manifold. Soap bubbles will appear

where a leak is present. If a leak is present, immediately turn off gas supply, tighten any leaking

connections, turn gas on, and recheck. Check all the gas connections at the base of the control valves

where they screw into the manifold pipe.

To check rotis burner and safety valve the burner must be lit, then leak test the connections located

behind the service panel. If you cannot stop a gas leak turn off the gas supply and call your local gas

utility, or the dealer you purchased the appliance from. Only those parts recommended by the

manufacturer should be used on the Grill. Substitution can void the warranty.

Do not use the grill until all connections have been checked and do not leak.

Check all gas supply fittings for leaks before each use. It is handy to keep a spray bottle of soapy water near

the shut-off valve of the gas supply valve. Spray all the fittings. Bubbles indicate leaks. (Fig. 05 & 06)

LEAK TESTING

FIG.05 LP Gas

FIG.06 Nat. Gas

Bottom of unit

Bottom of unit

LEAK TEST POINTS

LP TANK

CHECK HOSE FOR

SIGNS OF ABRASIONS,

CRACKS, OR LEAKS

LEAK TEST POINTS

Loading...

Loading...