Page 1

THE PROFESSIONAL SIDE BURNER

Installation, Use and Care Guide

MODELS:

BGB131

BGB132

BGB131-BI

BGB132-BI

Page 2

Page 3

A MESSAGE TO OUR CUSTOMERS

We are glad that you selected the professional side burner by DCS. Because this appliance contains features not

ound on any other burner, we recommend that you read this entire booklet before your first use. Keep it in a

f

handy place as it has answers to questions that may occur during future use.

eel free to contact us if we can help you. When you write please include the model and serial number of the

F

Burner. We thank you for buying the professional side burner and wish you many years of enjoyment.

To help serve you better, please fill out and submit your Product Registration by visiting our website at

www.dcsappliances.com and selecting “Customer Care” on the home page and then select “Product Registration”.

For your convenience, product questions can be answered by a DCS Customer Care Representative by phone:

1-888-936-7872, or email: customer.care@fisherpaykel.com.

NOTE: Please write the Model, Code and Serial Numbers on this page for references (located on the inside of the

left side of the appliance)

MODEL NUMBER CODE SERIAL NUMBER

NOTE: Inspect the product to verify that there is no shipping damage. If any damage is detected, call the shipper

and initiate a damage claim. DCS by Fisher & Paykel is not responsible for shipping damage.

DO NOT discard any packing material (box, pallet, straps) until the unit has been inspected.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions thoroughly before installing, using or servicing this

equipment.

WARNING!

If the information in this manual is not followed exactly

personal injur

y other appliance. An LP cylinder not connected for use shall not be stored in the vicinity of this or any other

an

appliance.

y or death. Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

, a fire or explosion may result causing property damage,

WARNING!

Do not try lighting this appliance without reading the “Lighting Instructions” section of this manual. This outdoor

cooking gas appliance is not intended to be installed in or on recreational vehicles , boats or in a non-ventilated

room. For outdoor use only.

FOR YOUR SAFETY

If You Smell Gas:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

3. Open lid.

4. If odor continues, immediately call your gas supplier or your fire department

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

1

Page 4

TABLE OF CONTENTS

SAFETY PRACTICES AND PRECAUTIONS 3-4

INSTALLATION

Installation of Side Burner on 30” Grill 4-7

nstallation of Side Burner Built-in Model 8-9

I

Gas Hook-up 10-11

Leak Testing 12

Burner Adjustment 12

Installer Checklist 13

USING THE SIDE BURNER

Lighting Instructions 14

CARE AND MAINTENANCE 15

TROUBLESHOOTING 16

PARTS LIST

Single Side Burner - BGB131 & BGB131-BI 17

Double Side Burner - BGB132 & BGB132-BI 18

WIRING DIAGRAM

Single and Double Side Burner 19

SERVICE 20

WARRANTY 21-22

2

Page 5

SAFETY PRACTICES & PRECAUTIONS

Improper use or installation is dangerous. Carefully follow these instructions.

■

Always remove the cover before lighting the professional side burner. Never use the side burner if a leak is

present.

■

Do not use a flame to check for gas leaks.

■

Do not let children use the side burner.

■

Do not leave children unattended near the side burner.

■

Never let children crawl or hang on the side burner.

■

Exercise care when operating the side burner. The burner grate can get hot enough to cause burns during

operation.

■

Never leave the side burner on unattended.

■

Always wait 5 minutes before relighting the burner to allow any accumulated gas to dissipate. Should the burner

go out during use, turn off the gas valve and wait 5 minutes before attempting to relight. Always follow the

lighting instructions. Never lean over a lit burner.

■

Never cook without the drip pan in place, pushed all the way to the rear of the burner box.

■

Use only in well ventilated areas.

■

Do not use in garages, breezeways, sheds, or other such enclosed areas.

■

Keep the area surrounding the side burner clear and free from combustible materials, gasoline, other flammable

liquids or vapors, charcoal lighter fluid, and trash.

■

Do not obstruct the flow of combustion and ventilation air to the side burner. On cart mounted units, keep area

beneath the burner free of debris. If the burner is built-in, do not store gas cylinders beneath the unit without

adequate ventilation.

WARNING!

Do not store items of interest to children above or at the back of any appliance. Children could be seriously injured

if they should climb onto the appliance to reach these items.

■

Keep the side burner covered when not in use.

■

Never connect an unregulated gas line to the side burner.

f the side bur

■

I

be checked for gas leaks and obstructions in the burner.

■

Thoroughly clean the side burner on a regular basis.

■

Only use the side bur

vice versa, a factory conversion kit (see page 10 for conversion kit information) is required.

NOTE:

duct must be installed by a licensed plumber or gas fitter when installed within the Commonwealth of

o

This pr

Massachusetts.

ner has not been used for an extended period of time (over winter, for example) the unit should

e. To change from LP gas to natural, or

ner with the type of gas specified on the ra

ting pla

t

3

Page 6

SAFETY PRACTICES & PRECAUTIONS

REAR

FRONT

IGNITION

BURNER

IGNITION

10 - 5/8 "

13

"

13

"

13

"

13

"

10 - 5/8 "

12-

3/4 "

15

-3/4"

10 -1/8"

23-

3/4"

10 -1/8"

26-

3/4"

Single Side Burner

Double Side Burner

2

"

2

"

SPIDER AND INSECT WARNING!

Spiders and insects can nest in the burner(s) or orifices of this or any other gas appliance, and can block or restrict

the burner. This can cause a flash back to the control panel. This is a very dangerous condition which can cause a

fire to occur, thereby damaging the unit and making it unsafe to operate.

You must inspect the burner(s) at least once a year or immediately if any of the following conditions occur:

1. The smell of gas in conjunction with the burner flames appearing yellow.

2. The side burner(s) does not reach temperature.

3. The side burner(s) heats unevenly.

4. The burner(s) make popping noises.

■

Do not attempt to disconnect any gas connections while your burner is in use, or the gas supply is on.

■

When the side burner is stored indoors the gas supply must be disconnected and, if using an LP gas cylinder, the

cylinder must be stored outdoors in a well-ventilated area.

■

Keep any electrical supply cord away from the heated surfaces of the professional side burner.

■

On cart mounted units, never move without first allowing the side burner and/or grill to cool and ensuring that

the gas supply is turned off. Fold the side shelf down, and push; never pull the grill.

■

Never use the side burner in a windy area.

INSTALLATION

INSTALLATION OF SIDE BURNER ONTO 30” CART (BGB 131/132 MODELS ONLY)

SIDE BURNER DIMENSIONS

FRONT

REAR

SIDE

4

FRONT

REAR

SIDE

Page 7

INSTALLATION

INSTALLATION OF SIDE BURNER ON 30” CART

Important

!

Read all instructions before you begin. Do not jump ahead or skip any step. Side shelf must be removed prior

to installation.

CAUTION!

Some parts have sharp edges; care must be taken when handling the various components to avoid injury. Please,

read safety information provided in these instructions before beginning assembly. Wear gloves when handling.

GETTING STARTED

■

Remove packaging.

■

Remove side burner from inside and discard packing.

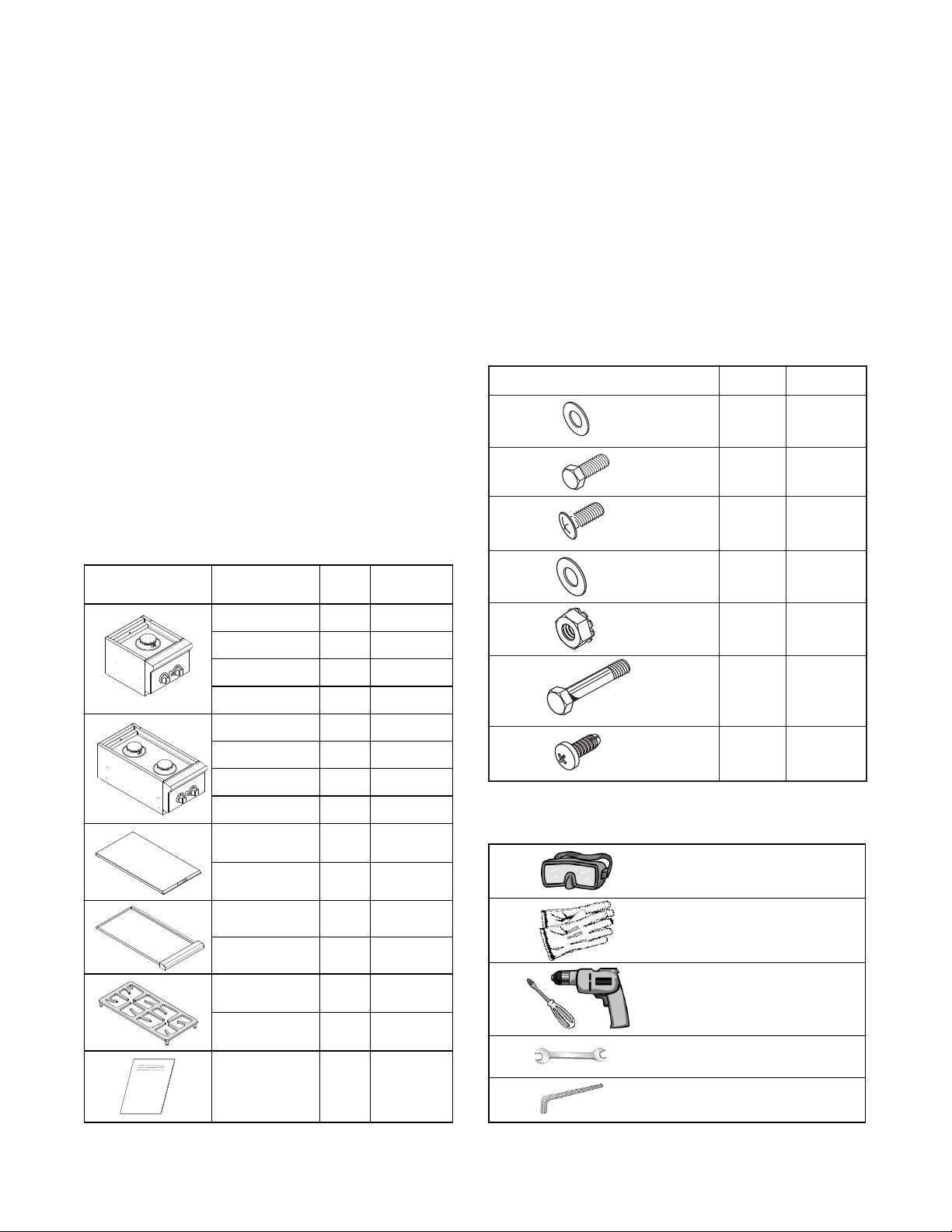

CONTENTS INCLUDED:

Your side burner is packaged in one box. The box

contains your side burner and a universal hardware kit

to be used for installation and may contain extra

hardware for your convenience.

Con

tents

Description Q

BGB131-BIL 1 70175

BGB131-BIN 1 70176

ty.

Par

t No.

Contents Qty. Part No.

Washer Flat

1/4x.938

Screw

1/4-20X1/2”

2

5 211323

4 211278

Screw #10

4 211371

Washer #10

4 211394

Nut #10

211375

BGB131L 1 70177

BGB131N 1 70515

BGB132-BIL 1 70178

BGB132-BIN 1 70179

BGB132L 1 70180

BGB132N 1 70604

Cover (131) 1 218614

Cover (132)

ip Pan

Dr

(131)

Drip Pan

(132)

te (131)

a

Gr

Grate (132) 1 220496

tion

nstruc

I

1

1 224826

1 237358

1 210645

1 238044

218613

Tools Required:

Shoulder Bolt

1/4-20x5/16

Screw

10-24x1/2

Pan Head

hillips -tip #2 A

P

10 mm

1

211442

2 211242

Eye Goggles

Work Gloves

Power Screwdriver or

Variable Speed Drill with

3/32” Allen Wrench

ench or S

r

W

ttachmen

ocket

t

5

Page 8

INSTALLATION

INSTALLATION OF SIDE BURNER ON 30” CART

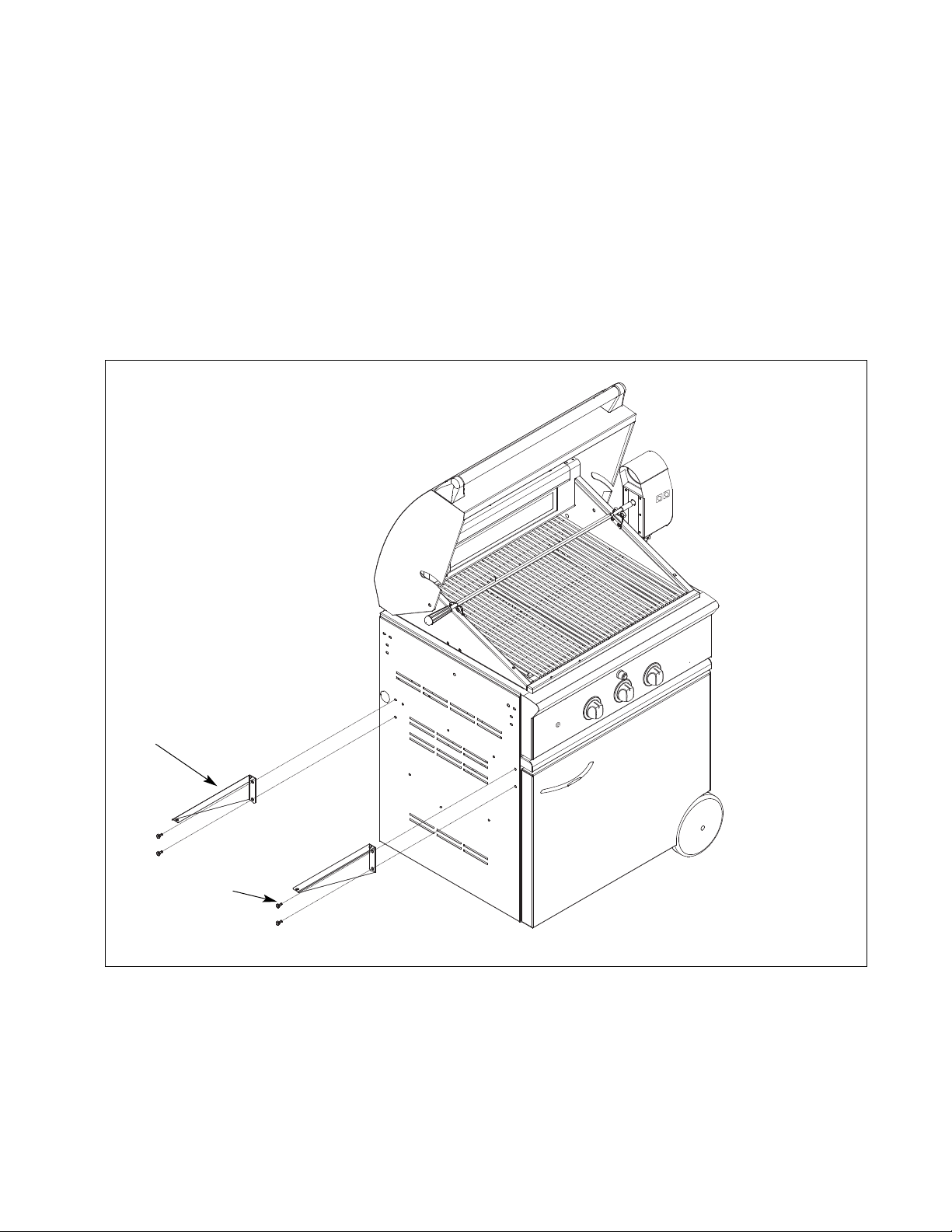

STEP 1

Remove the cover, grate, and drip pan from the side burner.

STEP 2

olt the support brackets to the grill cart side panel with (4) 1/4 x 20 bolts provided.

B

Note:

For the BGB131 side burner only, use (2) #10 sheet metal screws (211242) to bolt the back support bracket.

SUPPORT BRACKET

6

BOLT

FIG. 01

Page 9

INSTALLATION

INSTALLATION OF SIDE BURNER ON 30” CART

STEP 3

1. Bolt the side burner to the grill cart side panel from the under side of the burner assembly with a shoulder bolt

in the front and 1/4 x 20 bolt in the back as shown. Do not forget to use 1/4 flat washers. Do not tighten.

Adjust the side burner until it is level to the grill; then tighten securely.

2. Bolt the support brackets to the bottom of the side burner with (4) #10-24 machine screws, nuts and washers

provided.

3. Replace the drip pan, grate and cover.

Note:

Once the side burner is assembled, refer to the “Gas Requirements” section for proper gas hook-up requirements.

WASHER FLAT

1/4 X .938 (2PCS)

BOLT (1/4 – 20)

W #10 (4 PCS)

SCRE

ASHER #10 (4 PCS)

W

NUT#10 (4 PCS)

SIDE BURNER

Shoulder Bolt

1/4-20 x 5/16

FIG. 02

7

Page 10

INSTALLATION

COUNTER TOP

NON-COMBUSTIBLE

COMBUSTIBLE OR

6"

min.

6"

min.

6"

min.

BACK VIEW

COUNTER TOP

COUNTER TOP

NON-COMBUSTIBLE

COMBUSTIBLE OR

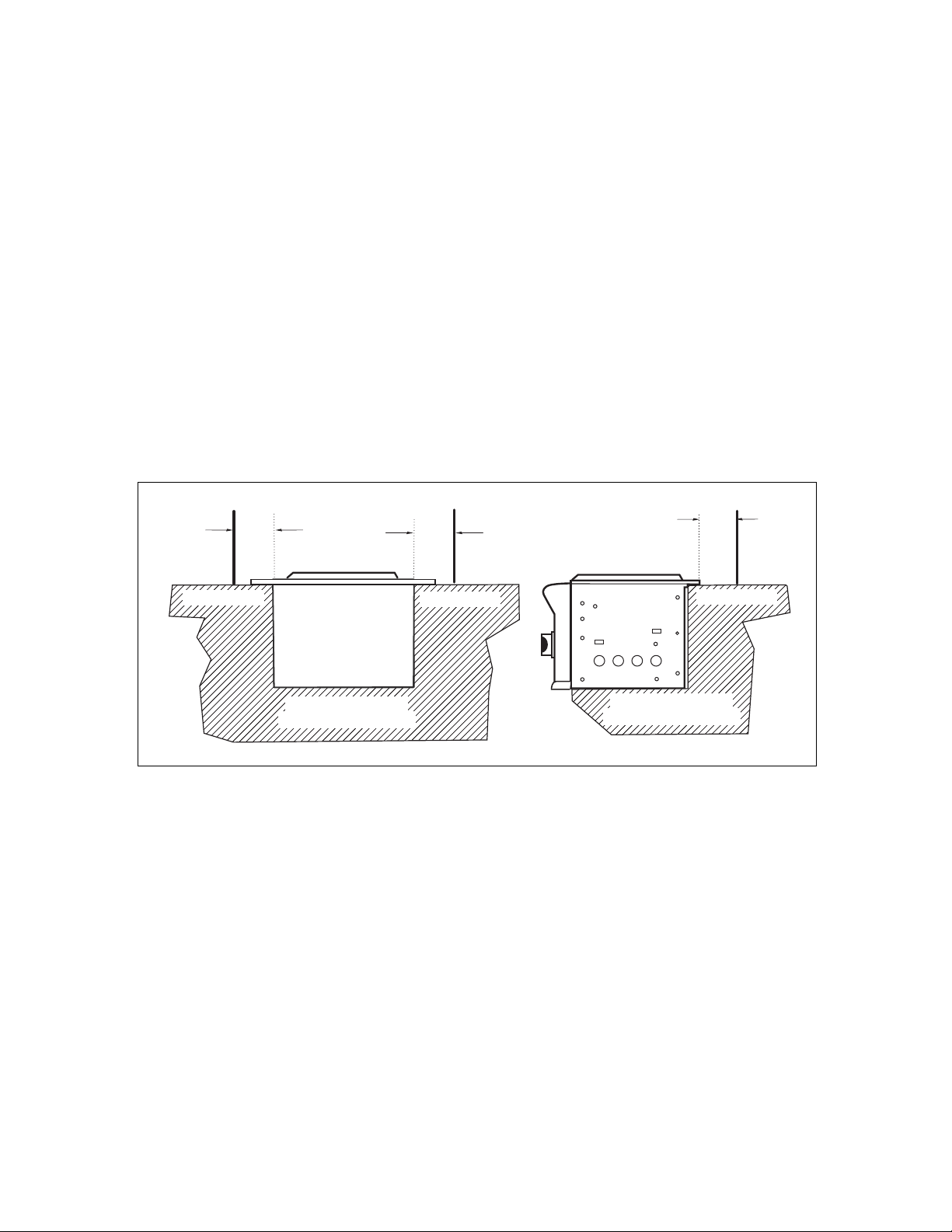

INSTALLATION OF SIDE BURNER, BUILT-IN MODEL

All BGB131-BI and BGB132-BI models can be installed into a combustible enclosure with zero clearance from

he back, side and bottom below the counter top level as shown in Fig. 03.

t

A minimum of 6” from the back and sides must be maintained from the professional side burner above the

ooking surface (see Fig. 03).

c

When determining a suitable location, take into account concerns such as exposure to wind, proximity to

traffic paths, and keeping any gas supply lines as short as possible. Locate the side burner only in a wellventilated area. Never locate the side burner in a garage, breezeway, shed, or other such enclosed areas.

It is recommended that ventilation holes are provided in the enclosure in the event of a gas leak. The counter

and supporting ledges or deck must be level and flat.

Important!

Gas fittings, regulator, and installer-supplied shut-off valves must be easily accessible.

8

FIG.03

Page 11

INSTALLATION

12"

10-

1/8"

2" X 2" opening

for gas supply line

A

MODEL A

BGB131-BI 12"

BGB132-BI 22-3/4"

note: the deck is

not required

REAR

F

RONT

I

GNITION

BURNER

IGNITION

10 - 5/8 "

10 - 5/8 "

12

"

12

"

"

14-9/16

"

14-9/16

1

11-

3/8"

2

"

16

-1/16"

10-1/8"

22-

1/8"

2

"

10-1/8"

26-

5/8"

Single Side Burner

Double Side Burner

3

-1/8"

3

-1/8"

1/2"

1/2"

2

INSTALLATION OF SIDE BURNER, BUILT-IN MODEL

SIDE BURNER DIMENSIONS

FRONT

REAR

FRONT

REAR

STANDARD CONSTRUCTION CUTOUT REQUIREMENTS

SIDE

SIDE

9

Page 12

INSTALLATION

GAS HOOK-UP

GAS REQUIREMENTS:

Verify the type of gas supply to be used, either natural or LP. Make sure the marked gas on the appliance

rating plate(s) and hook-up kit agrees with that of the supply.

IMPORTANT!

Never connect an unregulated gas line to the appliance.

An installer supplied gas shut-off valve must be installed in an easily accessible location. All installer

supplied parts must conform to local codes, or in the absence of local codes, ANSI/NFPS-770-1984.

All pipe sealants must be an approved type and resistant to the actions of LP gases. Never use pipe sealant

on flare fittings.

All gas connections should be made by a qualified technician and in accordance with local codes and

ordinances. In the absence of local codes, the installation must comply with the National Fuel Gas Code ANSI

Z223.1.

Gas conversion kits are available from the factory. When ordering, have the model number, and the type of

gas (natural or LP) which you need.

Total gas consumption of the professional side burner with burner(s) on “HIGH” – Table 1 below.

TABLE 1

MODEL Btu/hr

BGB131

17,000

BGB132 34,000

BGB131-BI 17,000

BGB132-BI 34,000

The appliance and its individual shut-off valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 PSIG (3.5kPa.).

The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2

PSIG (3.5 kPa.).

The installation of this appliance must conform with local codes or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1. Installation in Canada must be in accordance with the Standard

CAN1-b149 and/or .2 (installation code for gas burning appliances and equipment) and local codes.

NATURAL GAS HOOK-UP:

CONNECTION: 1/2” NPT male with 3/8” flare adapter.

OPERATING PRESSURE: 4.0” W.C.

SUPPLY PRESSURE: 5” to 14” W.C. If in excess of 14”W.C., a step down regulator is required.

ompan

Check with your local gas utilit

Be sure to check on type and size of run, and how deep to bury the line. If the gas line is too small, the

professional side burner will not function properly.

10

y c

y or with local c

odes for instructions on installing gas supply lines.

Page 13

INSTALLATION

O

pen Top

M

anifold

Bottomof

1

31 &132 Burner

1/2" Coupling

1

/2" NPT x 2.0”

Nipple

1

/2" NPT to 3/8"

FlareAdapter

R

egulator

T

o Gas Supply

1

/2" NPT x 2.0”

Nipple

GAS HOOK-UP

NATURAL GAS HOOK-UP (continued)

To hook-up the fittings supplied with the side burner, assemble as shown in Fig.04. Use joint compound on

male threads only.

o not use joint compound on the flare end of the 1/2” NPT

D

to 3/8” flare adapter. Ensure that the regulator arrow points

in the direction of gas flow-towards the unit, away from the

supply.

Do not forget to place the installer-supplied gas valve in an

accessible location.

LP GAS HOOK-UP

CONNECTION: 1/2” NPT male with 3/8” flare adapter

(included). Use 90º elbow 1/2” NPT with 3/8” flare

(P/N 212394) for side mount models only when installing on

the cart. Use sealer on 1/2” NPT threads only.

OPER

ATING PRESSURE: 10.0” W.C. side burner uses the LP

regulator from adjoining grill.

SUPPLY PRESSURE: 11” to 14” W.C.

FIG. 04 Natural Gas

Apply joint compound to the threaded end of the side burner gas

inlet and tighten the adapter to the pipe. Assemble the 24” and 30” hoses to the 3/8” flare tee, as shown in

Fig.05. Tighten the regulator hose to the remaining fitting of the 3/8” flare tee.

LP TANK REQUIREMENTS

■

A dented or rusty LP gas cylinder may be hazardous and

should be checked by your LP supplier. Never use a cylinder

with a damaged valve.

■

The LP gas cylinder must be constructed and marked in

accordance with the specifications for LP gas cylinders of the

U.S. Department of Transportation (DOT) and designed for

use with a Type 1 system only.

■

Do not change the regulator/hose assembly from that

empt to use a Type 1 equipped

ed out

or

tt

doors in a w

ell ventila

ed area

t

FIG. 05 LP G

as

supplied with the unit or a

regulator/hose assembly with a standard 510 POL tank/valve

assembly. The cylinder must be provided with a shut-off

alve terminating in an LP gas supply cylinder valve outlet

v

specified, as applicable, for connection Type 1.

■

If the appliance is stored indoors, the cylinder must be

disconnect

ylinders must be st

■

C

ed and removed from the appliance.

out of the reach of children.

■

Gas cylinder supply must be turned off when not in use.

11

Page 14

INSTALLATION

LEAK TESTING

WARNING!

Do not smoke while leak testing. Extinguish all open flames.

Make a soap solution of one part liquid detergent, and one part

water. Never test for leaks with an open flame. For LP units, check

with a full cylinder. Make sure all control valves are in the “OFF”

position. Turn the gas supply “ON”. Check all connections from the

supply line (Fig. 04), or LP cylinder(Fig. 05) up to the manifold pipe

assembly (Fig. 06). Apply the soap solution around the connection

with a spray bottle, brush, or rag. Soap bubbles will appear where

leak is present. If a leak is present, turn off gas supply, tighten any

leaking fittings, turn gas on, and recheck.

WARNING: IMPORTANT!

Inspect the gas supply piping or hose prior to turning the gas “ON”. If

there is evidence of cuts, wear or abrasion, it must be replaced prior to

use. Do not use the side burner if the odor of gas is present. Turn the

control knob to “OFF”, then turn off the gas supply. If using LP, is there gas in the tank? Always keep your face

and body as far away from the burner as possible when lighting.

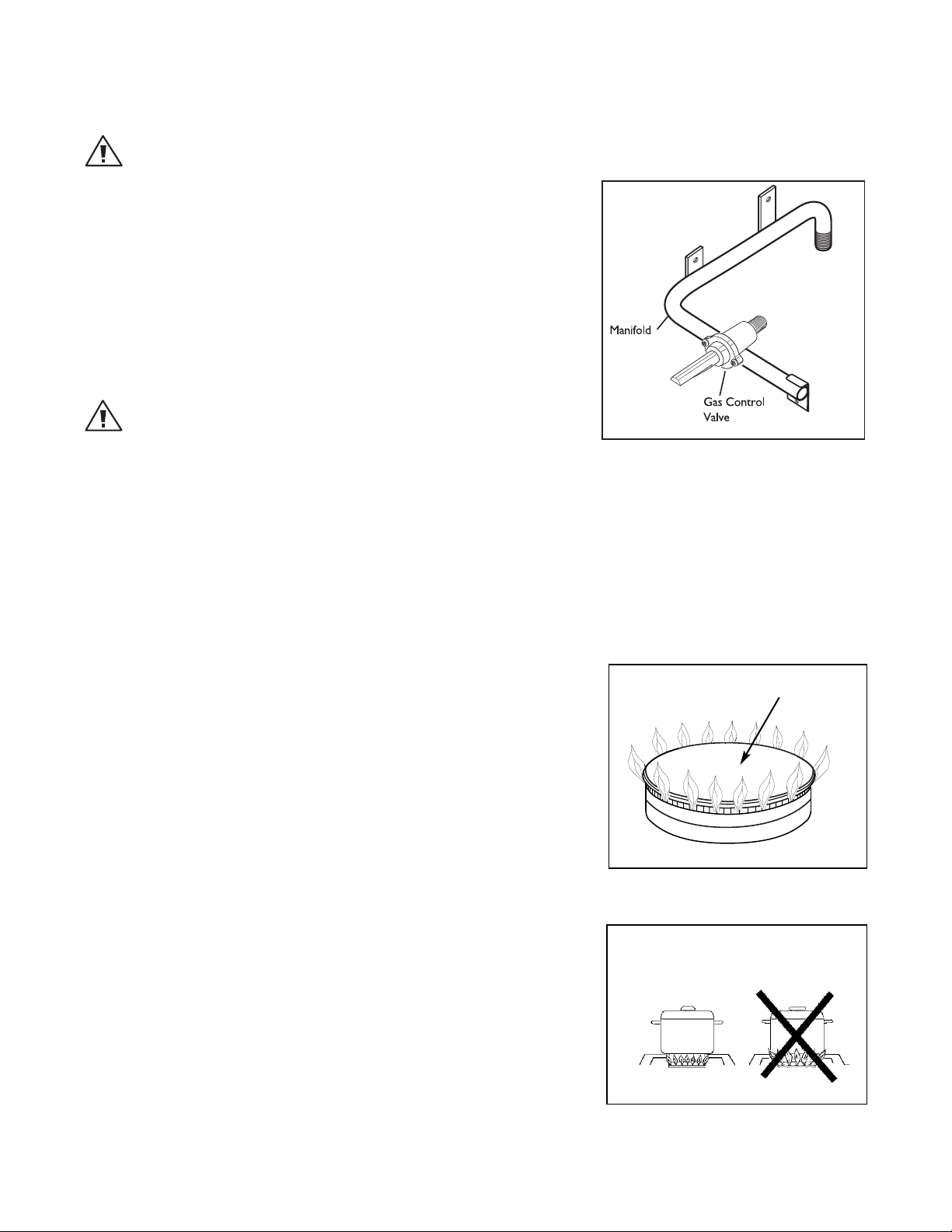

FIG. 06

BURNER ADJUSTMENT

BURNERS

Your new side burner is equipped with burners typical of those used in

restaurants (Fig. 07). These burners are designed for maximum

cleanability and controlability. The burner should never be operated if

the cap is not in place.

BURNER EFFICIENCY AND FLAME CHARACTERISTICS

It is necessary to keep the burner ports and the igniters clean for

proper lighting and efficient performance of the burners. The burner

flame should burn completely around the burner with no excessive

noise or lif

yellow tips. During initial use, foreign particles in the gas line, or dust

in the air around the appliance may cause an orange flame. This will

disappear with use

FLAME HEIGHT

he c

T

bottom of the cooking utensil, the material of the cooking utensil, the

amount and type of food and the amount of liquid in the utensil. The

ollo

f

■

For safety reasons the flame must never extend beyond the

bott

the side of the pan (see F

ting. The flame should be blue in color and stable with no

.

ect height of the flame mainly depends on the size of the

r

or

wing ar

om of the c

e some basic rules f

ooking utensil. Never allow flames to curl up

or selecting flame height.

.08).

ig

Cap

FIG. 07

PROPER FLAME HEIGHT

■

Utensils which conduct heat slowly (such as glass-ceramic)

should be used with medium t

large amount of liquid

12

, a sligh

tly lar

w flames

o lo

ger flame can be used

. If you are cooking with a

.

FIG. 08

Page 15

INSTALLATION

INSTALLER CHECKLIST

■

Specified clearances maintained to combustibles.

■

Side burner is properly mounted.

■

All internal packaging removed.

■

Burner is seated properly and does not rock.

■

Each burner lights satisfactorily, individually or with adjacent burner lit.

■

Knob(s) turn freely. Bezel(s) centered.

■

Flame adjusted.

■

Pressure regulator connected and set for 4.0"W.C. Natural, 11.2"W.C. LP gas.

■

Manual shut-off valve installed and accessible.

■

Unit tested and free of leaks.

■

User informed of gas supply shut-off valve location.

■

Battery installed in module properly and generates ignition spark when activated.

PLEASE LEAVE THESE INSTRUCTIONS WITH THE USER.

USER, PLEASE RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE.

13

Page 16

USING THE SIDE BURNER

LIGHTING INSTRUCTIONS

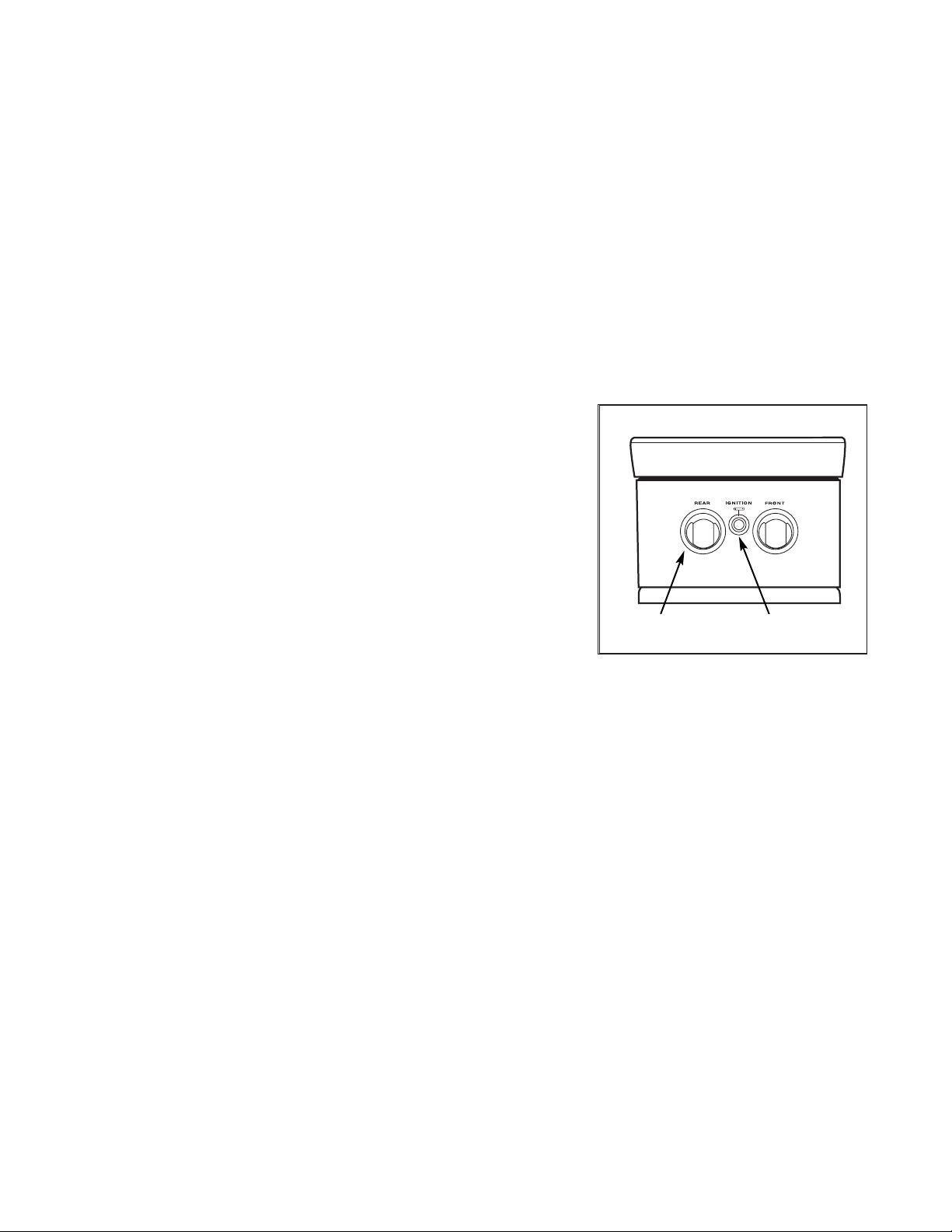

First remove the burner cover and any cooking utensils from the burner grate. Push and hold the ignition

utton, turn the control knob to the “HI” position until the burner is lit or 4 seconds pass. If the burner doesn’t

b

ignite, wait 5 minutes for any accumulated gas to dissipate then try again. If the burner will not light after

several attempts, check the troubleshooting instructions on page 16.

MATCH LIGHTING

Hold a lit fireplace match near the burner ports, turn the control knob counterclockwise to “HI”. Rotate the knob

immediately once the burner is lit to the desired setting.

Note:

If you are using propane gas, a slight pop or flash may occur at the burner ports a few seconds after the burner has been

turned “off”. This “extinction pop” is normal for propane gas.

Control

Knob

FIG. 09 BGB132 Shown

Ignition

Button

14

Page 17

CARE AND MAINTENANCE

The side burner will give you years of trouble free service if properly maintained. The body panels and front

alve panel and burner hanger are made from non-rusting high grade stainless steel. The burner is heavy duty

v

cast iron and brass. The venturi tube is brass.

STAINLESS STEEL

There are many different stainless steel cleaners available. Always use the mildest cleaning procedure first,

scrubbing in the direction of the grain. Do not use steel wool as it will scratch the surface. To touch up

noticeable scratches in the stainless steel, sand very lightly with Bear-Tex (p/n 25032).

SIDE BURNER GRATE

The side burner grate is porcelain enamel over cast iron for durability. To avoid burns, do not clean a hot grate.

They may be wiped while in place with hot, soapy water, rinsed and wiped dry thoroughly. Never immerse a hot

grate in water. Due to rapid temperature changes the porcelain may pop off the edges of the grates. If the

grates develop chips, do not be concerned as the base metal, cast iron, soon darkens to blend with the porcelain

enamel. Use care when wiping areas where the enamel has popped off, the edges may be sharp. If cleaning

necessitates grate removal, care should be taken in lifting them. They are very heavy. Be sure to place them on

a protected surface.

DRIP TRAY

A stainless steel aeration pan and drip tray with a

stainless steel handle is located under the burner.

It collects any boil-overs or spills. Pull forward to

remove. Spills should be washed off as soon as

possible to prevent baked on soil.

BURNERS

For proper lighting and performance, keep the

burners clean. It is necessary to clean the burners if

they do not light even though the igniter clicks, if

there has been a severe boil over, or when the flame

does not burn blue. Be certain all burner knobs are

in the off position before attempting to clean the

burners. The burners have been designed for ease of

cleaning. When the grate and burners are cool,

remove the grate. The burner cap and the brass port

ring can easily be lifted off. Wash these parts in hot

soapy water, rinse and dry thoroughly. The burner

caps are porcelain enamel, follow the directions on

the previous page that were given for the burner

grates. A bristle brush can be used to clean out the

toothed burner ports, if necessary. After cleaning, it

is important to make sure the location pins on the

bott

om side of the port ring are properly aligned

with the corresponding holes in the base. Incorrect

alignment will produce a potentially dangerous flame

and poor bur

ner performance (see Fig. 10).

Brass Ring Locating

Pins

Locating Notch

Electrode

oca

L

ting Holes

FIG. 10

Electrode (keep clean)

Cap

Main

Burner

Port Ring

Burner

Base

enturi

V

ELECTRODES

er dampened cotton swab. Be careful not to damage

t

ipe with a w

W

the electrode (see Fig. 11)

a

FIG. 11

15

Page 18

TROUBLESHOOTING

PROBLEM WHAT TO DO

Burner won’t light when the

ignition is pushed.

Burner flame is yellow or

orange, in conjunction with the

odor of gas.

Remove the burner grate. With the control knob in the

“OFF” position, listen to the electrode while engaging

he ignition. There should be a spark from the

t

electrode. When the spark jumps, it makes a ticking

sound.

If there is no spark........

Could be a dead battery. Try replacing the battery.

Or the air gap between an electrode tip and a contact

metal is too far (gap should be 1/8”) or dirty.

If there is a spark... is there gas supplied to the unit and

is the line purged of air? See Fig. 04 and Fig. 05.

Does the other burner of a dual burner model

operate?

Check the orifice or venturi for blockage.

Check the burner for obstructions or dirt. See page 15.

Check for proper gas supply or wrong gas type.

Is the side burner in a dusty area? Move to less dusty

area if possible.

Low heat with knob in “HI”

position.

Is the fuel hose bent or kinked? See Fig. 04 and

Fig. 05.

Is there adequate gas supply available? If it is only one

burner of the dual burner unit that appears low, does

the burner need cleaning? See Fig. 10 and

Fig. 11.

If using LP gas, check for empty tank or low fill level.

16

Page 19

PARTS LIST

SINGLE SIDE BURNER - BGB131 & BGB131-BI

1

5

6

28

27

3

2

15

24

21

17

14

25

26

16

4

23

22

20

19

18

13

11

7

8

9

29

30

31

10

12

NOTE: Part list typical for BGB131 & BGB131-BI models. Illustration shows BGB131-BI model.

DESCRIPTION

ITEM

1 BURNER COVER 214430

PULL HANDLE 212278

2

3 RUBBER BUMPER 212359

TE BK 210645

A

OP GR

T

4

5 D BURNER CAP 210608

6 PORT RING ASSEMBLY 210644

VENTURI

7

8 BASE D BURNER 210639

9 PLATE SUPPORT BURNER 224833

PLATE SUPPORT BURNER (BGB131-BI) 224930

10 BURNER HANGER 224834

11 JET HOLDER LP 210543

JET HOLDER NA

T

12 DRIP PAN ST. STL (BGA131-BI MODEL) 214165

DRIP PAN ST. STL (BGB131 MODEL) 224825

AN HANDLE DBI (BGA131-BI MODEL)

DRIP P

13

DRIP PAN HANDLE 131/132 (BGB131 MODEL) 214428

14 1.5VDC BATTERY AA 221154

PART NO.

210643

210536

214366

ITEM DESCRIPTION PART NO.

15 BEZEL 210935

16 CONTROL KNOB 211188

17 IGNITION MODULE 211872

WIRE BLACK W/ TERMINALS 8” 211823

18

19 WIRE BLACK W/ TERMINALS 10” 211826

20

TUBING 5/16” (9”

LENGTH) 212399

21 ELBOW 1/8NPT X 5/16 T.O.D. 212396

22 FERRULE 5/16 212313

NUT M22 JET HOLDER

23

24 NUT 1/2-24UNF 212312

25 MANIFOLD (BGB131-BI MODEL) 212297

MANIFOLD (BGB131 MODEL) 221924

26 MANUAL GAS VALVE 220575

27 VALVE PANEL (BGA131-BI MODEL) 224854

VE PANEL (BGB131 MODEL) 224839

AL

V

28 VALVE PANEL SCREWS (BGB131-B1) 211300

29 ELECTRODE 210562

SPRING ELEC

30

TRODE

31 CLIP ELECTRODE 210578

210468

210577

17

Page 20

PARTS LIST

DOUBLE SIDE BURNER - BGB132 & BGB132-BI

4

5

6

2

16

29

1

3

25

24

26

20

23

27

28

15

17

14

22

21

19

18

13

7

8

9

10

11

30

31

32

12

NOTE: Part list typical for BGB132 & BGB132-BI models. Illustration shows BGB132-BI model.

ITEM DESCRIPTION PART NO.

1 BURNER COVER 214425

2 PULL HANDLE 212278

3 RUBBER BUMPER 212359

4 TOP GRATE BK 220496

5 D BURNER CAP 210608

6 PORT RING ASSEMBLY 210644

7 VENTURI 210643

BASE D BURNER 210639

8

9 PLATE SUPPORT BURNER 214424

URNER (BGB132-BI) 224931

TE SUPPOR

PLA

URNER HANGER (BGB132 MODEL)

B

10

T B

224817

11 JET HOLDER LP 210543

JET HOLDER NAT

210536

12 DRIP PAN ST. STL (BGA132-BI MODEL) 214164

DRIP PAN ST. STL (BGB132 MODEL) 214427

13 DRIP PAN HANDLE (BGA132-BI MODEL) 214366

DRIP PAN HANDLE 131/132 (BGB132 MODEL) 214428

14 1.5VDC BATTERY AA 221154

15 BEZEL

210935

ITEM DESCRIPTION PART NO.

ONTROL KNOB 211188

C

16

17 IGNITION MODULE 211872

TERMINALS 10” 211826

CK W/

WIRE BLA

18

19 WIRE BLACK W/ TERMINALS 18” 221058

20 TUBING 5/16” (21” LENGTH) 221956

21 ELBOW 1/8NPT X 5/16 T.O.D. 212396

22 TUBING 5/16” (9” LENGTH) 212399

23 NUT M22 JET HOLDER 210468

24 FERRULE 5/16 212313

NUT 1/2-24UNF 212312

25

ANIFOLD (BGB132-BI MODEL) 212296

M

26

ANIFOLD (BGB132 MODEL)

M

27 MANUAL GAS VALVE 220575

ANEL (BGA132-BI MODEL)

VE P

AL

V

28

VALVE PANEL (BGB132 MODEL) 214426

29 VALVE PANEL SCREWS (BGB132-B1) 211300

TRODE

ELEC

30

31 SPRING ELECTRODE 210577

32 CLIP ELECTRODE 210578

212387

214436

210562

18

Page 21

WIRING DIAGRAM

SINGLE & DOUBLE SIDE BURNER

SINGLE SIDE BURNER

GND

SPARK ELECTRODE

(P/N 210562)

(Switch is built into module)

TERMINAL

1.5 VOLT

ALKALINE

BATTERY

(P/N 221154)

IGNITION MODULE

ARK ELEC

SP

(P/N 210562)

BATTERY

(P/N 211872)

TRODE

DOUBLE SIDE BURNER

SPARK ELECTRODE

(P/N 210562)

(Switch is built into

module)

TE: HIGH VOLTAGE AT TERMINALS

NO

TERMINAL

TTERY

BA

IGNITION MODULE

(P/N 211872)

19

Page 22

SERVICE

HOW TO OBTAIN SERVICE:

For warranty service, please contact your local service provider or DCS Customer Care at (888) 936-7872. Before

you call, please have the following information ready:

■ Model Number (located on the inside of the left side of the appliance)

■ Serial Number (located on the inside of the left side of the appliance)

■ Code (located on the inside of the left side of the appliance)

■ Gas Type

■ Date of installation

■ A brief description of the problem

Your satisfaction is of the utmost importance to us. If a problem cannot be resolved to your satisfaction, please

write or email us at:

Write:

Fisher & Paykel Appliances, Inc.

Attention: DCS Customer Care

5900 Skylab Road

Huntington Beach, CA 92647

Email: customer.care@fisherpaykel.com

BEFORE YOU CALL FOR SERVICE:

1.

Check troubleshooting on page 16.

2.

Is the gas turned on?

3.

Is there a dead battery in the ignition module?

20

Page 23

WARRANTY

LIMITED WARRANTY

When you purchase a new DCS Side Burner, you automatically receive a One Year Limited Warranty covering

parts and labor for the entire product, and a Five Year Limited Warranty on the structural integrity of the exterior

and interior body parts for servicing within the 48 mainland United States, Hawaii, Washington D.C. and Canada.

n Alaska, the Limited Warranty is the same except that you must pay to ship the Product to the service shop or

I

the service technician’s travel to your home. Products for use in Canada must be purchased through the

Canadian distribution channel to ensure regulatory compliance. Should corrosion occur to the degree of

non-performance, replacement parts will be furnished. This does not apply if the unit was subjected to other

than normal residential use.

FISHER & PAYKEL UNDERTAKES TO:

Repair without cost to the owner either for material or labor any part of the Product, the serial number of which

appears on the Product, which is found to be defective. In Alaska, you must pay to ship the Product to the

service shop or for the service technician’s travel to your home.

If we are unable to repair a defective part of the Product after a reasonable number of attempts, at our option

we may replace the part or the Product, or we may provide you a full refund of the purchase price of the Product

(not including installation or other charges).

This warranty extends to the original purchaser and any succeeding owner of the Product for products

purchased for ordinary single-family home use. All service under this Limited Warranty shall be provided by

Fisher & Paykel Appliances Inc. or its Authorized Service Agent during normal business hours.

HOW LONG DOES THIS LIMITED WARRANTY LAST?

Our liability under this Limited Warranty for the entire product expires ONE YEAR from the date of purchase of

the Product by the first consumer. Our liability under this Limited Warranty for the structural integrity of the

exterior and interior body parts expires FIVE YEARS from the date of purchase of the Product by the first

consumer.

Our liability under any implied warranties, including the implied warranty of merchantability (an unwritten

warranty that the Product is fit for ordinary use) also expires ONE YEAR (or such longer period as required by

applicable law) from the date of purchase of the Product by the first consumer. Some states do not allow

limitations on how long an implied warranty lasts, so this limit on implied warranties may not apply to you.

THIS WARRANTY DOES NOT COVER:

A. Service calls that are not related to any defect in the Product. The cost of a service call will be charged if the

problem is not found to be a defect of the Product. For example:

1. Correct faulty installation of the Product.

2. Instruct you how to use the Product.

e house fuses

eplac

3. R

4. Correct fault(s) caused by the user.

5. Change the set

ed modifica

6. Unauthor

7. Noise or vibration that is considered normal, for example, drain/fan sounds, regeneration noises or user

warning beeps.

8. Correcting damage caused by pests, for example, rats, cockroaches etc.

B. Defects caused by factors other than:

iz

, reset circuit breakers, correct house wiring or plumbing, or replace light bulbs.

-up of the P

roduct.

tions of the P

oduc

r

t.

1. Normal domestic use or

2. Use in accordance with the Product’s Use and Care Guide.

21

Page 24

WARRANTY (continued)

C. Defects to the Product caused by accident, neglect, misuse, fire, flood or Act of God.

D. The cost of repairs carried out by non-authorized repairers or the cost of correcting such unauthorized repairs.

E. Travel Fees and associated charges incurred when the product is installed in a location with limited or restricted

access (i.e. airplane flights, ferry charges, isolated geographic areas).

F. Normal recommended maintenance as set forth in the Product’s Use and Care Guide.

If you have an installation problem, contact your dealer or installer. You are responsible for providing adequate

electrical, exhausting and other connection facilities. We are not responsible for consequential or incidental

damages (the cost of repairing or replacing other property damaged if the Product is defective or any of your

expenses caused if the Product is defective). Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

HOW TO GET SERVICE

Please read your Use and Care Guide. If you then have any questions about operating the Product, need the

name of your local DCS Authorized Service Agent, or believe the Product is defective and wish service under this

Limited Warranty, please contact your dealer or call us at:

TOLL FREE 1-888-936-7872 or contact us through our web site: www.dcsappliances.com

You may be required to provide reasonable proof of the date of purchase of the Product before the Product will

be serviced under this Limited Warranty.

COMMERCIAL USE

This warranty applies to appliances used in residential applications; it does not cover their use in commercial

situations.

NO OTHER WARRANTIES

This Limited Warranty is the complete and exclusive agreement between you and Fisher & Paykel Appliances Inc.

regarding any defect in the Product. None of our employees (or our Authorized Service Agents) are authorized to

make any addition or modification to this Limited Warranty.

Warrantor: Fisher & Paykel Appliances, Inc.

If you need further help concerning this Limited Warranty, please call us at the above number, or write to:

isher & Paykel Appliances, Inc.

F

Attention: DCS Customer Care

5900 Skylab Road, Huntington Beach, CA 92647

This Limited Warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

Fisher & Paykel Appliances Inc. is a leading manufacturer of premium quality cooking and specialty appliances

under the Fisher & Pa

ykel and DCS brands.

22

Page 25

NOTES

23

Page 26

NOTES

24

Page 27

LE BRÛLEUR LATÉRAL PROFESSIONNEL

Manuel d'utilisation et d'entretien et installation

MODÈLES :

BGB131

BGB132

BGB131-BI

BGB132-BI

Page 28

À L'INTENTION DE NOS CLIENTS

Nous sommes heureux que vous ayez choisi le brûleur latéral professionnel de DCS. Étant donné que cet appareil

st doté de caractéristiques que l'on ne trouve pas dans d'autres brûleurs, nous vous recommandons de lire

e

intégralement ce manuel avant la première utilisation. Gardez-le à portée de main car vous y trouverez des

réponses à des questions susceptibles de surgir à l'avenir.

N'hésitez pas à nous contacter si vous avez besoin d'aide.Si vous nous écrivez, n'oubliez pas d'inclure le numéro

de modèle et de série du brûleur. Nous vous remercions de l'acquisition du brûleur latéral professionnel, et vous

souhaitons des années de plaisir en l'utilisant.

Aidez-nous à mieux vous servir en remplissant l'enregistrement de produit et en nous la soumettant depuis

notre site Web à www.dcsappliances.com. Sélectionnez « Customer Care » sur la page d'accueil puis « Product

Registration ».

Si vous avez des questions au sujet de notre produit, communiquez avec un représentant du centre de service à

la clientèle DCS par téléphone :1-888-936-7872, ou par courriel : customer.care@fisherpaykel.com.

REMARQUE : Veuillez noter les numéros de modèle et de série sur cette page pour information (situé à

l'intérieur, sur le côté gauche de l'appareil)

NUMÉRO DE MODÈLE CODE NUMÉRO DE SÉRIE

REMARQUE : Inspecter le produit pour vérifier qu’il n’a pas été endommagé pendant l’expédition. En cas de

dommages, contacter le transporteur et entamer une déclaration pour dommage. DCS by Fisher & Paykel n’est en

aucun cas responsable des dommages pendant l’expédition.

Ne pas jeter le matériau d’emballage (boîte, palette, sangles) avant d’avoir inspecté l’unité.

AVERTISSEMENT!

N'essayez pas d'allumer l'appareil sans avoir lu la section « Instructions d'allumage » de ce manuel. Toute installation, ajust

euillez lire soigneusement ces instructions d'installation, d'utilisation et d'entretien avant d'utiliser, installer ou

V

effectuer l'entretien de cet appareil. Cet appareil de cuisson à gaz pour l'extérieur n'est pas conçu pour être installé

sur des véhicules récréatifs, des bateaux ou des pièces sans aération. Pour usage en plein air uniquement.

ement, altération ou entretien incorrect peut causer des dommages matériels, des blessures ou la mort.

AVERTISSEMENT!

1. Évitez de stocker ou d'utiliser de l'essence ou tous autres liquides et vapeurs inflammables à proximité de cet

appareil ou de tout autre appareil électroménager.

ez de ranger une bouteille de gaz propane (qui n'est pas connectée car non utilisée) à proximité de cet

vit

É

2.

.

appareil électr

oménager ou de tout autr

e

POUR VOTRE SÉCURITÉ

OUS SENTEZ UNE ODEUR DE GA

V

SI

■

Fermez l'alimentation en gaz de l'appareil.

oute flamme vive.

nez t

eig

t

■

É

■

■

ez le couvercle s'il est mis

Enlev

Si l'odeur persiste, appelez immédiatement votre fournisseur de gaz.

Z :

.

Toute installation ou service doit être confié à un installateur qualifié, un organisme de service ou le fournisseur de

gaz.

VEUILLEZ CONSERVER CE M

1

ANUEL À TITRE DE RÉFÉRENCE.

Page 29

TABLE DES MATIÈRES

MESURES DE SÉCURITÉ ET DE PRÉCAUTION 3-4

INSTALLATION

Installation du drûleur latéral BGB131/132 à gril 30 po 4-7

Installation du drûleur latéral - modèle encastré 8-9

Branchement du gaz 10-11

Test de détection des fuites 12

Réglage des brûleur 12

Liste de contrôle 13

UTILISATION DU DRÛLEUR LATÉRAL

Instructions d'allumage 14

NETTOYAGE GÉNÉRAL 15

DÉPANNAGE 16

LISTE DES PIÈCES

Brûleur latéral simple modèles BGB131 ET BGB131-BI 17

Brûleur latéral double modèles BGB132 ET BGB132-BI 18

SCHÉMA DE CÂBLAGE

Brûleur latéral simple et double 19

SERVICE 20

GARANTIE 21-22

2

Page 30

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

Toute mauvaise utilisation ou installation est dangereuse. Respectez soigneusement les instructions

i-dessous.

c

■

Retirez toujours le couvercle avant d'allumer l'appareil. N'utilisez jamais l'appareil en cas de fuite.

'allumez pas de flamme pour vérifier s'il y a des fuites de gaz.

■

N

■

Ne laissez pas les enfants utiliser l'appareil.

■

Ne laissez pas les enfants près de l'appareil sans surveillance.

■

Ne laissez jamais les enfants monter sur l'appareil ou s'y accrocher.

■

Faites preuve de prudence lorsque vous utilisez l'appareil. La grille du brûleur peut être suffisamment chaude

pour causer une brûlure.

■

Ne laissez jamais le brûleur latéral sans surveillance une fois allumé.

■

Attendez toujours 5 minutes que le gaz accumulé se soit dissipé avant de rallumer le brûleur. Si le brûleur

s'éteint en cours d'utilisation, fermez la valve à gaz et attendez 5 minutes avant de rallumer. Suivez toujours les

instructions d'allumage. Ne vous penchez jamais au-dessus d'un brûleur allumé.

■

Ne cuisinez jamais sans que le ramasse-gouttes ne soit mis et enfoncé jusqu'au fond de la boîte du brûleur.

■

Utilisez l'appareil uniquement dans des endroits bien ventilés.

■

N'utilisez pas l'appareil à l'intérieur de garages, abris, passages couverts ou autres lieux clos.

■

Gardez la zone entourant l'appareil dégagée et exempte de matériaux combustibles, d'essence et autres vapeurs

ou liquides inflammables, de liquide d'allumage pour charbon de bois ou de déchets.

■

Évitez d'obstruer le flot d'air de combustion et de ventilation dirigé vers l'appareil. Si l'appareil est monté sur un

chariot, gardez la zone en-dessous du brûleur exempte de débris. Si le brûleur est encastré, évitez de ranger les

bouteilles de gaz sous l'appareil sans ventilation adéquate.

AVERTISSEMENT!

Évitez de ranger sur l'appareil ou à l'arrière des articles pouvant attirer les enfants. Les enfants peuvent être blessés

sérieusement s'ils grimpent sur l'appareil pour atteindre ces articles.

■

Couvrez l'appareil quand il n'est pas utilisé.

■

Ne connectez jamais un tuyau à gaz non régulé à l'appareil.

■

Si l'appareil n'a pas été utilisé pendant une longue période (durant l'hiver, par exemple), vérifiez qu'il ne

présente pas de fuite de gaz ni aucune obstruction.

■

Nettoyez soigneusement l'appareil de façon régulière.

vec le type de gaz spécifié sur la plaque signalétique. Pour convertir l'appareil du

tilisez l'appar

■

U

gaz propane au gaz naturel ou inversement, vous aurez besoin d'un kit de conversion fourni par le fabricant (voir

la page 10 pour des informations à ce sujet).

eil seulemen

t a

Remarque :

Ce produit doit être installé par un plombier ou ajusteur d'appareils à gaz agréé si l'installation a lieu au sein du

Commonwealth du Massachusetts.

3

Page 31

MESURES DE SÉCURITÉ ET DE PRÉCAUTION

REAR

FRONT

IGNITION

BURNER

IGNITION

33,02 cm/

13 po

26,99 cm/

10 -5/8 po

32,38 cm/

12-

3/4 po

40 cm/

15

-3/4 po

60,33 cm/23-

3/4 po

88 cm/26-

3/4 po

5,08 cm/

2 po

33,02 cm/

13 po

33,02 cm/

13 po

33,02 cm/

13 po

26,99 cm/

10 -5/8 po

25,72 cm/

10 -1/8 po

25,72 cm/

10 -1/8 po

5,08 cm/

2 po

AVERTISSEMENT CONCERNANT LES ARAIGNÉES ET LES INSECTES!

Les araignées et les insectes peuvent se loger dans les brûleurs ou orifices de cet appareil ou d'autres appareils à

gaz, et bloquer ou restreindre le brûleur. Ceci peut causer un retour de flamme vers le panneau de contrôle. Cela est

très dangereux et peut provoquer un incendie, ce qui endommagerait l'appareil et rendrait son utilisation

dangereuse.

Vous devez inspecter le(s) brûleur(s) au moins une fois l'an, ou sans retard dans les circonstances suivantes :

1. Présence d'une odeur de gaz alors que les flammes du brûleur sont d'apparence jaunâtre.

2. L'appareil n'atteint pas la température désirée.

3. L'appareil chauffe de façon inégale.

4. Le(s) brûleur(s) émet(tent) des bruits secs.

■

Ne tentez pas de débrancher les connexions de gaz pendant l'utilisation du brûleur ou lorsque l'alimentation en

gaz est ouverte.

■

Lorsque l'appareil est rangé à l'intérieur, l'alimentation en gaz doit être déconnectée et, si vous utilisez une

bouteille de gaz propane, rangez celle-ci à l'extérieur.

■

■

■

Gardez tout cordon électrique à l'écart des parties chaudes de l'appareil.

Si l'appareil est monté sur un chariot, ne le déplacez jamais avant que le brûleur latéral ou le gril ait refroidi et

prenez soin de couper l'alimentation en gaz. Rabattez la tablette latérale, puis poussez; ne tirez jamais le gril.

N'utilisez jamais l'appareil dans un endroit venteux.

INSTALLATION

BRÛLEUR LATÉRAL BGB131/132 UNIQUEMENT À CHARIOT 30 PO

DIMENSIONS

BRÛLEUR LATÉRAL SIMPLE

vue de face

BRÛLEUR LATÉRAL DOUBLE

vue arrière

vue latérale

vue de face

vue arrière

vue latérale

4

Page 32

INSTALLATION

BRÛLEUR LATÉRAL BGB131/132 À CHARIOT 30 PO

Important!

Lisez toutes les instructions avant de commencer. Évitez de sauter des étapes. Retirez la tablette latérale

avant l'installation.

MISE EN GARDE!

Certaines pièces ont des bords coupants; faites attention lorsque vous manipulez les différents composants pour

éviter de vous blesser. Veuillez lire les consignes de sécurité de ce manuel avant de commencer l'assemblage.

Portez des gants.

POUR COMMENCER

■

Retirez l'emballage.

■

Retirez le brûleur latéral de l'intérieur et jetez

l'emballage.

CONTENU :

Le brûleur latéral est emballé dans une seule boîte.

Celle-ci contient le brûleur latéral et un kit de matériel

universel destiné à l'installation qui comprend du

matériel supplémentaire pour votre commodité.

tenu

Con

Description Qté.

BGB131-BIL 1 70175

BGB131-BIN 1 70176

BGB131L 1 70177

BGB131N 1 70515

BGB132-BIL 1 70178

BGB132-BIN 1 70179

BGB132L 1 70180

Réf.

Contenu Qté. Réf.

Rondelle plate

1/4x.938

Vis

1/4-20X1/2”

2

5 211323

211375

4 211278

Vis #10

4 211371

Rondelle #10

4 211394

Écrou #10

Boulon à

épaulement

1/4-20x5/16

Vis

10-24x1/2

Tête cylindrique large

1

2 211242

211442

BGB132N 1 70604

Couvercle (131)

C

ouvercle (132)

Ramasse-

gouttes (131)

amasse-

R

gouttes (132)

Grille (131)

Grille (132)

Instructions

5

1 218614

1

1 224826

1 237358

1 210645

1 220496

1 238044

218613

Outils requis :

Lunettes de sécurité

Gants de travail

ournevis mécanique ou

T

perceuse à vitesse variable

avec embout Phillips no. 2

Clé ou douille 10 mm

Clé Allen 3/32 po

Page 33

INSTALLATION

BRÛLEUR LATÉRAL BGB131/132 À CHARIOT 30 PO

ÉTAPE 1

Retirez le couvercle, la grille et le ramasse-gouttes du brûleur latéral.

ÉTAPE 2

Fixez les supports au panneau latéral du chariot de gril à l'aide de quatre (4) boulons 1/4 x 20 fournis.

Remarque :

Pour le brûleur latéral BGB131 uniquement, utilisez deux (2) vis à tôle no. 10 (211242) pour fixer le support arrière.

Support

Boulon

FIG. 01

6

Page 34

INSTALLATION

BRÛLEUR LATÉRAL BGB131/132 À CHARIOT 30 PO

ÉTAPE 3

. Fixez le brûleur latéral au panneau latéral du chariot de gril par dessous l'ensemble du brûleur à l'aide d'un

1

boulon à épaulement à l'avant et d'un boulon 1/4 x 20 à l'arrière tel qu'indiqué. N'oubliez pas d'utiliser les

rondelles plates 1/4. Évitez de serrer. Ajuster le brûleur latéral jusqu'à ce qu'il soit de niveau par rapport au

gril; serrez ensuite.

2. Fixez les supports à la partie inférieure du brûleur latéral à l'aide de quatre (4) vis à métaux no. 10-24, d'écrous

et de rondelles (fournis).

3. Replacez le ramasse-gouttes, la grille et le couvercle.

Remarque :

Une fois le brûleur latéral assemblé, reportez-vous à la section « Exigences concernant le gaz » pour les exigences à

respecter pour le branchement du gaz.

RONDELLE PLATE

1/4 X 0,938 (2)

BOULON (1/4 – 20)

. 10 (4)

VIS no

RONDELLE no. 10 (4)

ÉCROU no

. 10 (4)

BRÛLEUR LATÉRAL

BOULON À ÉPAULEMENT

1/4–20 x 5/16

FIG. 02

7

Page 35

INSTALLATION

COUNTER TOP

NON-COMBUSTIBLE

COMBUSTIBLE OR

15,24

cm

6 po

min.

VUE ARRIÈRE

COUNTER TOP

COUNTER TOP

NON-COMBUSTIBLE

COMBUSTIBLE OR

15,24

cm

6 po

min.

15,24

cm

6 po

min.

INSTALLATION DU BRÛLEUR LATÉRAL - MODÈLE ENCASTRÉ

Tous les modèles BGB131-BI et BGB132-BI peuvent être installés dans une enceinte combustible avec

dégagement nul à l'arrière, sur le côté et au bas au dessous du premier niveau opposé selon la fig. 03.

Prévoyez une distance de 15,2 cm (6 po) minimum sur les côtés et l'arrière de l'appareil, au-dessus de la

surface de cuisson (voir Fig. 03).

Pour déterminer un emplacement approprié, vous devez tenir compte de plusieurs éléments : exposition au

vent, proximité de chemins de circulation, nécessité de garder les conduites d'alimentation en gaz le plus

court possible. Placez l'appareil dans un lieu bien aéré. Ne placez jamais l'appareil à l'intérieur d'un garage,

abri, passage couvert ou autre lieu clos.

Il est recommandé de prévoir des trous de ventilation dans l'enceinte au cas où une fuite de gaz se produirait.

Le comptoir et les pièces d'appui ou la base de support doivent être de niveau et plats.

Important!

Les raccords de gaz, le régulateur et le robinet d'arrêt fournis par l'installateur doivent être facilement accessibles.

FIG. 03

8

Page 36

INSTALLATION

30,5 cm/

12 po

25,72 cm/

10-1/8 po

Ouverture de 5,08 x

5,08 cm (2 x 2 po) pour

la conduite

d'alimentation en gaz

A

MODÈLE A

BGB131-BI 30,5 cm/

12po

BGB132-BI 57,79 cm/

22-3/4 po

remarque : base de

support sous le brûleur

latéral illustrée; non

requise

2

R

EAR

FRONT

I

GNITION

B

URNER

IGNITION

30,48 cm/

12 po

36,98 cm/

14-9/16 po

3

28,89 cm/

11-

3/8 po

5

40,8 cm/16

-1/16

po

56,20 cm/22-

1/8 po

67,63 cm/26-

5/8 po

7,94 cm/3

-1/8 po

1,27 cm/

1/2 po

5,08 cm/

2 po

5,08 cm/

2 po

26,99 cm/

10 -5/8 po

26,99 cm/

10 -5/8 po

25,72 cm/

10 -1/8 po

25,72 cm/

10 -1/8 po

1,27 cm/

1/2 po

7,94 cm/

3

-1/8 po

30,48 cm/

12 po

36,98 cm/

14-9/16 po

INSTALLATION DU BRÛLEUR LATÉRAL - MODÈLE ENCASTRÉ

DIMENSIONS

BRÛLEUR LATÉRAL SIMPLE

vue de face

vue arrière

BRÛLEUR LATÉRAL DOUBLE

vue de face

vue arrière

CONSTRUCTION STANDARD

vue latérale

vue latérale

9

Page 37

INSTALLATION

BRANCHEMENT DU GAZ

EXIGENCES CONCERNANT LE GAZ :

Vérifiez le type d'alimentation en gaz qui sera utilisé (gaz naturel ou propane). Assurez-vous que les indications

de gaz figurant sur la plaque signalétique de l'appareil et le kit de branchement sont conformes à ceux de

l'alimentation.

IMPORTANT!

Ne connectez jamais un tuyau à gaz non régulé à l'appareil.

Un robinet d'arrêt fourni par l'installateur doit être installé dans un endroit facilement accessible. Toutes les

pièces fournies par l'installateur doivent être conformes aux codes en vigueur ou, en l'absence de tels codes, à

la norme ANSI/NFPS-770-1984.

Tous les produits d'étanchéité utilisés doivent être approuvés et résister aux effets du propane. N'utilisez jamais

ces produits sur des raccords évasés.

Toutes les connexions de gaz doivent être effectuées par un technicien qualifié conformément aux codes et

règlements en vigueur. En l'absence de codes locaux, l'installation doit être conforme à la norme ANSI Z223.1 du

National Fuel Gas Code.

Les kits de conversion au gaz sont disponibles auprès de l'usine. Au moment de commander un kit, ayez sous la

main le numéro de modèle et le type de gaz (naturel ou propane) de votre appareil.

Consommation totale de gaz de l'appareil, les brûleurs étant tous sur « HIGH » – Tableau 1 ci-dessous.

TABLEAU 1

MODÈLE BTUH

BGB131 17 000

BGB132 34 000

BGB131-BI 17 000

BGB132-BI 34 000

L'appareil et son robinet d'arrêt doivent être déconnectés du système d'alimentation en gaz durant les tests de

pression lorsque celle-ci est supérieure à 3,5 kPa (1/2 PSIG).

Isolez l'appareil du système d'alimentation en gaz en fermant son robinet d'arrêt durant les tests de pression si

celle-ci est inférieure ou égale à 3,5 kPa (1/2 PSIG).

L'installation de cet appareil doit être conforme aux codes en vigueur ou, en l'absence de tels codes, à la norme

ANSI Z223.1 du National Fuel Gas Code. L'installation au Canada doit être conforme aux normes Standard CAN1b149 ou .2 (code d'installation pour les appareils et équipements à gaz) et aux codes en vigueur.

BRANCHEMENT DU GAZ NATUREL :

CONNEXION : Raccord mâle 1/2 po NPT avec adaptateur évasé 3/8 po.

PRESSION UTILE : 4.0 po C.E.

PRESSION D'ALIMENTATION : 5 à 14 po C.E. Si la pression dépasse 14 po C.E., un régulateur est requis pour

diminuer la pression.

Renseignez-vous auprès de votre service de distribution de gaz local ou consultez les codes en vigueur au sujet

de l'installation de conduites d'alimentation en gaz. Vérifiez en particulier le type et les dimensions de la

conduite et de sa profondeur d'enfouissement. L'appareil risque de ne pas fonctionner correctement si la

conduite de gaz est trop courte.

10

Page 38

INSTALLATION

Collecteur

supérieur ouvert

Partieinférieuredu

b

rûleurlatéral 131 et 132

Raccord1/2 po

R

accord

1

/2 po NPT x

2

.0 po

Raccord1/2 po NPT

avecadaptateurévasé 3/8 po

Régulateur

V

ers l'alimentation en gaz

R

accord

1

/2 po NPT x

2

.0 po

Partie inférieure du

brûleur latéral 131 et 132

Collecteur

supérieur ouvert

Tuyau de gaz 30 po

Tuyau de gaz 24 po

Pièce évasée 3/8 po à 3/8 po

Raccord en T évasé 3/8 po

Raccord 1/2 po NPT avec adaptateur

évasé 3/8 po ou pièce 212394 pour

montage latéral seulement

Vers le collecteur du gril

24 po

En provenance du réservoir

de propane à régulator

BRANCHEMENT DU GAZ

Pour connecter les raccords fournis avec l'appareil, effectuez

l'assemblage tel qu'indiqué à la Figure 04. Utilisez le composé à

oint sur les filetages mâles uniquement.

j

N'en mettez pas sur l'extrémité évasée du raccord 1/2 po NPT avec

adaptateur évasé 3/8 po. Assurez-vous que la flèche du régulateur

pointe en direction du débit de gaz, vers l'appareil, dans le sens

opposé à l'alimentation de gaz.

N'oubliez pas de placer le robinet d'arrêt fourni par l'installateur

dans un endroit facilement accessible.

BRANCHEMENT DU GAZ PROPANE

CONNEXION : Raccord mâle 1/2 po NPT avec adaptateur évasé

3/8 po (inclus). U

adaptateur évasé 3/8 po avec coude de 90º (réf. 18523) pour les

modèles à montage latéral seulemen, dans le cas d'une installation

sur chariot. Utilisez le produit d'étanchéité sur les filetages 1/2 po

NPT seulement.

PRESSION UTILE : 10 po C.E. Le brûleur latéral utilise le régulateur

de propane du gril adjacent.

tilisez un raccord mâle 1/2 po NPT avec

FIG. 04 Gaz Naturel

PRESSION D'ALIMENTATION : 11 à 14 po C.E.

Appliquez le composé à joint à l'extrémité filetée de l'admission de gaz du brûleur latéral et serrez l'adaptateur sur le tube. Fixez les tuyaux de 24 et 30 pouces au raccord en T 3/8 po évasé, tel qu'indiqué à la Figure

05. Serrez le tuyau du régulateur sur le raccord restant du raccord en T.

EXIGENCES CONCERNANT LA BOUTEILLE DE PROPANE

■

Une bouteille de gaz propane bosselée ou rouillée peut

constituer un danger. Faites-la examiner par votre four

nisseur de gaz. N'utilisez jamais une bouteille dont la

valve est endommagée.

■

La bouteille de propane doit être fabriquée et marquée

onformément aux spécifications relatives aux bouteilles

c

de propane publiées par le « U.S. Department of Trans

portation » (DOT) et porter la mention limitant leur

utilisation aux systèmes de Type 1.

■

Ne changez pas l'ensemble régulateur/tuyau fourni avec

l'appareil et n'essayez pas d'utiliser un ensemble

eur/tuy

égulat

r

510 POL standard. La bouteille doit posséder un robinet

d'arrêt terminé par une sortie de valve spécifiée, selon le

, pour une c

cas

■

Si l'appareil est rangé à l'intérieur, débranchez la

bouteille et retirez-la de l'appareil.

■

Les bouteilles doiv

■

Si l'appareil n'est pas utilisé, le gaz doit être fermé au niveau de l'arrivée de gaz de la bouteille.

lieu bien aéré, hors de portée des enfants.

11

au de Type 1 avec une valve de bouteille

onnexion de Type 1.

angées à l'extérieur dans un

e r

t êtr

en

FIG. 05 Gaz Propane

Page 39

INSTALLATION

Collecteur

Valve de

réglage de gaz

TEST DE DÉTECTION DES FUITES

AVERTISSEMENT!

Ne fumez pas pendant le test. Éteignez toute flamme vive.

Préparez une solution savonneuse composée à moitié de détergent

liquide et à moitié d'eau. Ne vérifiez jamais la présence de fuites près

d'une flamme vive. Pour les appareils à propane, effectuez la vérification

avec une bouteille pleine. Assurez-vous que les valves de réglage sont

en position « OFF » (fermé). Ouvrez l'alimentation en gaz « ON ». Vérifiez

toutes les connexions, de la conduite d'alimentation (Fig. 04) ou la

bouteille de propane (Fig. 05) au tube du collecteur (Fig. 06). Appliquez

la solution savonneuse autour des connexions à l'aide d'un vaporisateur,

d'une brosse ou d'un chiffon. Des bulles de savon apparaîtront en cas de

fuite. Si c'est le cas, fermez le gaz, serrez tous les raccords qui fuient,

ouvrez le gaz et vérifiez de nouveau.

AVERTISSEMENT : IMPORTANT!

Inspectez le tube ou tuyau d'alimentation avant d'ouvrir le gaz (« ON »). S'il porte des signes de coupures, usure ou

abrasion, remplacez-le avant l'utilisation. N'utilisez pas l'appareil si vous sentez une odeur de gaz. Tournez le

bouton de réglage à la position « OFF », puis fermez le gaz. Si vous utilisez du propane, y-a-t-il du gaz dans la

bouteille? Éloignez toujours le visage et le corps le plus possible du brûleur lorsque vous allumez celui-ci.

FIG. 06

RÉGLAGE DES BRÛLEUR

Capuchon

BRÛLEURS

Votre nouvel appareil est équipé de brûleurs similaires à ceux que l'on utilise

dans les restaurants (Fig. 07). Ces brûleurs sont conçus pour être extrêmement

faciles à nettoyer et régler. Ne faites jamais fonctionner le brûleur sans son

capuchon.

EFFICACITÉ DES BRÛLEURS ET CARACTÉRISTIQUES DE LA

FLAMME

Il est nécessaire de maintenir les ports des brûleurs et les allumeurs dans un

état de propreté afin d'assurer l'allumage correct et le rendement optimal

des brûleurs. La flamme doit encercler complètement le brûleur sans bruit

ou élévation excessive. Les flammes doivent être bleues et stables, sans

pointe jaune. Durant l'utilisation initiale, la présence de particules

étrangères dans la conduite de gaz ou de poussière dans l'air à proximité de

l'appareil peut produire une flamme orange. Ceci disparaît avec l'usage.

HAUTEUR CORRECTE

DE LA FLAMME

FIG. 07

HAUTEUR DE LA FLAMME

La hauteur correcte de la flamme dépend essentiellement des dimensions du

fond de l'ustensile de cuisson, du matériau de l'ustensile, de la quantité et

du type de nourriture, et de la quantité de liquide dans l'ustensile. Voici

quelques règles de base pour sélectionner la hauteur de flamme.

■

Pour des raisons de sécurité, la flamme ne doit jamais dépasser le fond du récipient. Ne laissez jamais les

flammes lécher les parois de l'ustensile de cuisson (voir Fig. 08).

FIG. 08

■

Les ustensiles qui conduisent lentement la chaleur (tels que ceux en vit rocéramique) doivent être utilisés avec

un feu doux ou moyen. Vous pou vez augmenter légèrement le feu si le volume de liquide est important.

12

Page 40

INSTALLATION

LISTE DE CONTRÔLE

■

Dégagements spécifiés respectés pour les combustibles.

■

Appareil installé correctement.

■

Emballage interne retiré.

■

Le brûleur est de niveau et ne balance pas.

■

Chaque brûleur s'allume correctement, que ce soit seul ou avec le brûleur adjacent allumé.

■

Les boutons tournent librement. Cadran(s) centré(s).

■

Flamme ajustée.

■

Régulateur de pression connecté et réglé pour 4,0 po C.E. (gaz naturel) ou 11,2 C.E. (gaz propane).

■

Robinet d'arrêt manuel installé et accessible.

■

Appareil testé et exempt de fuites.

■

Utilisateur informé de l'emplacement du robinet d'arrêt de l'alimentation de gaz.

■

Pile installée correctement dans le module; produit une étincelle d'allumage lorsqu'activée.

VEUILLEZ LAISSER CES INSTRUCTIONS À L'UTILISATEUR.

UTILISATEUR, VEUILLEZ CONSERVER CES INSTRUCTIONS À TITRE DE RÉFÉRENCE.

13

Page 41

UTILISATION DU DRÛLEUR LATÉRAL

INSTRUCTIONS D'ALLUMAGE

Commencez par retirer le couvercle du brûleur et les ustensiles de cuisson de la grille du brûleur. Enfoncez le

outon d'allumage et tournez le bouton de réglage à la position « HI », jusqu'à ce que le brûleur s'allume ou que

b

4 secondes s'écoulent. Si le brûleur ne s'allume pas, patientez 5 minutes avant d'essayer de nouveau, afin de

laisser le temps au gaz accumulé de se dissiper. Si le brûleur ne s'allume pas après plusieurs tentatives, consultez

la section de dépannage à la page 16.

ALLUMAGE À L'ALLUMETTE

Tenez une allumette près des ports du brûleur et tournez le bouton de réglage dans le sens antihoraire pour le

mettre sur « HI ». Retirez la main dès que le brûleur s'allume. Mettez le bouton de réglage sur le niveau désiré.

Remarque :

Il se peut qu'un léger crépitement ou flash se produise au niveau des ports de brûleur quelques secondes après que le

brûleur soit éteint. Ce bruit d'extinction est normal dans le cas du gaz propane.

Bouton de

réglage

FIG. 09 Modèle BGB132

Allumage

14

Page 42

NETTOYAGE GÉNÉRAL

Le brûleur latéral professionnel vous assurera des années de bon fonctionnement si vous en prenez bien soin.

es panneaux du corps, le panneau des valves avant et le support de brûleur sont en acier inoxydable de haute

L

qualité. Le brûleur est en fonte robuste et en laiton. Le venturi est en laiton.

ACIER INOXYDABLE

On trouve toute sorte de nettoyants pour acier inoxydable sur le marché. Employez toujours la méthode de

nettoyage la plus douce au début, en frottant dans le sens du grain. N'utilisez pas de laine d'acier car elle peut

égratigner la surface. Pour réparer des égratignures visibles à l'œil nu, frottez très légèrement avec du Bear-Tex

(réf. 25032).

GRILLE DU BRÛLEUR LATÉRAL

La grille du brûleur latéral est faite d'émail de porcelaine sur fonte très durable. Pour éviter de vous brûler, ne la

nettoyez pas quand elle est chaude. Vous pouvez la nettoyer à l'eau savonneuse chaude, la rincer puis l'essuyer

jusqu'à bien la sécher. Ne plongez jamais une grille chaude dans de l'eau. À cause des changements de

température rapides, la porcelaine pourrait éclater en morceaux des bords de la grille. Ne vous inquiétez pas car

le métal de base, en fonte, devient foncé en peu de temps et se fond à l'émail de porcelaine. Essuyez avec

précaution les endroits où l'émail a éclaté de crainte que les bords ne soient tranchants. Faites attention si vous

devez retirer les grilles pour le nettoyage, car elles sont très lourdes. Prenez soin de les placer sur une surface

protégée.

RÉCIPIENT À GRAISSE

Panneau d'aération en acier inoxydable et un récipient

à graisse à poignée en acier inoxydable se trouvent

sous le brûleur. Ils servent à recueillir les

débordements ou déversements. Tirez pour l'enlever.

Broches de position de couronne

en laiton

Nettoyez immédiatement tout déversement pour

éviter que les salissures ne « cuisent » sur place.

BRÛLEURS

Pour assurer un bon allumage et une bonne

performance des brûleurs, gardez-les dans un état

propre. Vous devez nettoyer les brûleurs s'ils ne

s'allument pas même si l'allumeur clique, après chaque

débordement important ou si la flamme ne devient

pas bleue. Assurez-vous que tous les boutons des

brûleurs sont en position « OFF » avant d'essayer de

nettoyer les brûleurs. Les brûleurs ont été conçus pour

être faciles à nettoyer. Une fois la grille et les brûleurs

refroidis, retirez la grille. Le capuchon de brûleur et la

couronne en laiton peuvent être facilement enlevés.

Lavez ces pièces dans de l'eau savonneuse chaude,

rincez et séchez soigneusement. Les capuchons de

brûleur son

t en émail de porcelaine; suivez les

instructions données à la page précédente

concernant les grilles des brûleurs. Utilisez au besoin

une br

osse en soies pour nettoyer les ports dentés

des brûleurs. Après le nettoyage, il est important de

vous assurer que les broches de position au bas de la

c

ouronne sont correctement alignées avec les trous correspondants de

la base. Un mauvais alignement produira une flamme potentiellement

dangereuse et entraînera un mauvais fonctionnement du brûleur (voir

Fig. 10).

Électrode

ous de positionnemen

r

T

Encoche de position

t

FIG. 10

UMEUR (DOIT Ê

ALL

Capuchon

Couronne

de brûleur

principale

Base de

brûleur

Venturi

TRE GARDÉ PROPRE)

ALLUMEURS

on-tige imbibé d'

Essuyez à l'aide d'un c

ot

endommager l'allumeur (voir Fig. 11).

15 15

eau. Faites attention de ne pas

FIG. 11

Page 43

DÉPANNAGE

PROBLÈME SOLUTION

Le brûleur ne s'allume pas

lorsqu'on enfonce le bouton

'allumage.

d

La flamme du brûleur est jaune

ou orange, et il y a une odeur

de gaz.

Retirez la grille du brûleur. Le bouton de réglage

étant sur « OFF », écoutez l'électrode tout en

nfonçant le bouton d'allumage. Vous devriez

e

entendre une étincelle jaillir à l'intérieur du

capuchon de l'électrode. Quand cela se produit,

l'étincelle fait comme un son de tic-tac.

S'il n'y a pas d'étincelle........

La pile pourrait être à plat.

Ou l'espace entre l'extrémité de l'électrode et un

contact métallique est trop grand (l'espace doit être

de 3,2°mm [1/8 po]) ou sale.

S'il y a une étincelle... vérifiez l'alimentation en gaz et

purgez l'air qui pourrait se trouver dans la conduite.

Voir les Figures 03 et 04.

L'autre brûleur (dans le cas d'un brûleur double)

fonctionne-t-il?

Vérifiez si l'orifice ou le venturi est bouché.

Vérifiez si le brûleur est obstrué ou sale. Voir page 15.

Vérifiez que l'alimentation et le type de gaz sont

corrects.

Chaleur faible avec bouton en

position « HI ».

L'appareil se trouve-t-il dans un lieu poussiéreux?

Déplacez-le, si possible, dans un endroit moins

poussiéreux.

Le tuyau de carburant est-il plié ou tordu? Voir les

Figures 04 et 05.

'alimentation en gaz est-elle suffisante? Si un seul

L

brûleur (du brûleur double) semble faible, faut-il le

nettoyer? Voir les Figures 10 et 11.

Si vous utilisez du propane, vérifiez si la bouteille est

vide ou si son niveau est bas.

16

Page 44

LISTE DES PIÈCES

BRÛLEUR LATÉRAL SIMPLE MODÈLES BGB131 ET BGB131-BI

1

5

6

28

27

3

2

15

24

21

17

14

25

26

16

4

23

22

20

19

18

13

11

7

8

9

29

30

31

10

12

17

REMARQUE : Liste de pièces typique pour les modèles BGB131 et BGB131-BI. L'illustration montre le

modèle BGB131-BI.

DESCRIPTION RÉF.

.

NO

1 COUVERCLE DU BRÛLEUR 214430

POIGNÉE 212278

2

3 BUTÉE DE CAOUTCHOUC 212359

GRILLE SUPÉRIEURE 210645

4

5 CAPUCHON DE BRÛLEUR D. 210608

6 ENSEMBLE DE COURONNE 210644

VENTURI

7

210643

8 BASE, BRÛLEUR D. 210639

9 PLAQUE DE SUPPORT 224833

PLAQUE DE SUPPORT (BGB131-BI) 224930

10 SUPPORT DE BRÛLEUR 224834

11 SUPPORT DE BUSE, GAZ PROP. 210543

USE, GAZ NAT. 210536

T DE B

SUPPOR

12 RAMASSE-GOUTTES, ACIER INOX.(MOD. BGA131-BI) 214165

RAMASSE-GOUTTES, ACIER INOX. (MOD. BGB141) 224825

TES, POIGNÉE (MOD. BGA131-BI) 214366

GOUT

ASSE-

M

A

R

13

RAMASSE-GOUTTES, POIGNÉE 131/132 (MOD. BGB131) 214428

14 PILE AA 1,5 V C.C. 221154

NO. DESCRIPTION RÉF.

15 CADRAN 210935

16 BOUTON DE RÉGLAGE 211188

17 MODULE D'ALLUMAGE 211872

FIL NOIR AVEC BORNES 8°PO 211823

18

19 FIL NOIR AVEC BORNES 10°PO 211826

TUBE 5/16°PO (9°PO DE LONG.)

20

21 COUDE NPT 1/8 X 5/16 DIAM. EXT. TOT. 212396

22 FERRULE 5/16 212313

USE 210468

23

ÉCROU M22, SUPP

. DE B

24 ÉCROU 1/2-24 UNF 212312

25 COLLECTEUR (MOD. BGB131-BI) 212297

COLLECTEUR (MOD. BGB131) 221924

26 VALVE À GAZ MANUELLE 220575

27 PANNEAU DES VALVES (MODÈLE BGA131-BI) 224854

U DES VALVES (MODÈLE BGB131) 224839

ANNEA

P

28 PANNEAU DES VALVES, VIS (BGB131-B1) 211300

29 ALLUMEUR 210562

MEUR, RESSOR

U

ALL

30

T

31 ALLUMEUR, CLIP 210578

212399

210577

Page 45

LISTE DES PIÈCES

BRÛLEUR LATÉRAL DOUBLE MODÈLES BGB132 ET BGB132-BI

4

5

6

7

8

9

10

11

30

31

32

12

16

1

3

25

20

24

23

22

13

2

27

28

29

15

26

21

19

18

17

14

REMARQUE : Liste de pièces typique pour les modèles BGB132 et BGB132-BI. L'illustration montre le

modèle BGB132-BI.

NO. DESCRIPTION RÉF.

1 COUVERCLE DU BRÛLEUR 214425

2 POIGNÉE 212278

3 BUTÉE DE CAOUTCHOUC 212359

4 GRILLE SUPÉRIEURE 220496

5 CAPUCHON DE BRÛLEUR D. 210608

6 ENSEMBLE DE COURONNE 210644

7 VENTURI 210643

BASE, BRÛLEUR D. 210639

8

9 PLAQUE DE SUPPORT 214424

QUE DE SUPP

PLA

. DE BRÛLEUR (MOD

SUPP

10

. (BGB132-BI)