DCS BFGC30BGDN, BFGC30BGDL, BFGC30GL Installation Manual

The professional

Liberty collection

BFGC-30 models

Installation instructions

and User guide

US CA

A MESSAGE TO OUR CUSTOMERS

Thank you for selecting this DCS Professional “Liberty Collection” Outdoor Appliance. Because of this appliance’s

unique features we have developed this Use & Care and Installation Guide. It contains valuable information on

how to properly install, operate and maintain your new appliance for years of safe and enjoyable use.

To help serve you better, please fill out and submit your Product Registration by visiting our website at www.

dcsappliances.com and selecting “Customer Care” on the home page and then select “Product

Registration”. In addition, keep this guide handy, as it will help answer questions that may arise as you use your

new appliance.

For your convenience, product questions can be answered by a DCS Customer Care Representative at

1-888-936-7872, or email: customer.care@fisherpaykel.com.

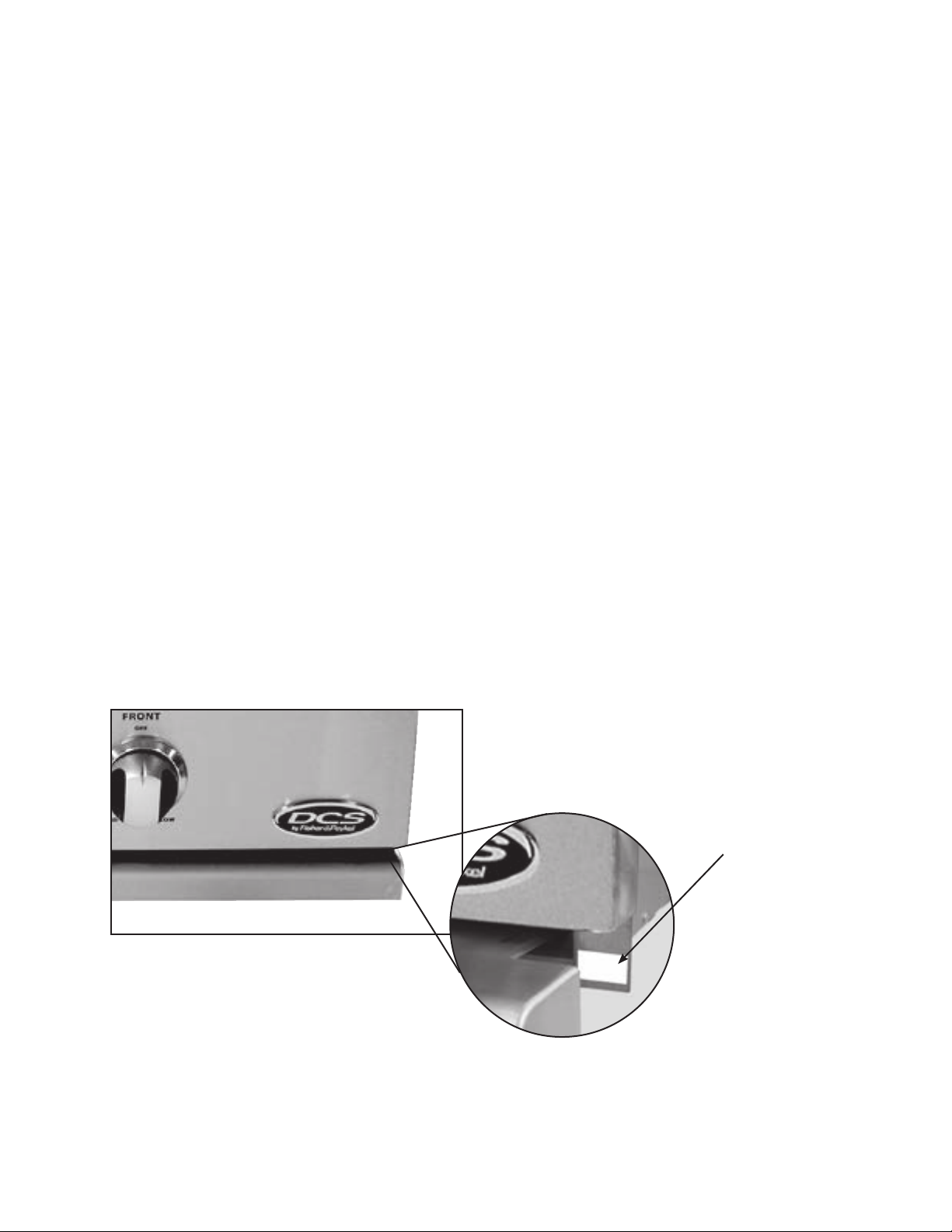

NOTE: Please write the Model, Code and Serial Numbers on this page for references (can be found on the inside,

right side panel behind the drip pan handle. See page 7.)

MODEL NUMBER CODE SERIAL NUMBER

NOTE: Inspect the product to verify that there is no shipping damage. If any damage is detected, call the shipper

and initiate a damage claim. DCS by Fisher & Paykel is not responsible for shipping damage.

DO NOT discard any packing material (box, pallet, straps) until the unit has been inspected.

WARNING!

Do not try lighting this appliance without reading the “Lighting Instructions” section of this manual.

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before

use, installing or servicing this equipment. This outdoor cooking gas appliance is not intended to be

installed in or on recreational vehicles , boats or in a non-ventilated room. For outdoor residence use

only.

WARNING

1. Do Not store or use gasoline or any other flammable vapors and liquids in the vicinity of

this or any other appliance.

2. An LP cylinder not connected for use shall not be stored in the vicinity of this or any

other appliance.

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

3. Remove any covers in place over burners/griddle.

4. If odor continues, keep away from the appliance and immediately call your gas supplier

or your fire department.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

1

CONTENTS

SAFETY PRACTICES & PRECAUTIONS 3-5

OUTDOOR APPLIANCE MODELS 6

BEFORE USING YOUR APPLIANCE 7

INSTALLATION

Locating Outdoor Appliance/Built-in Clearances 8-9

Built-in Construction Details 10

Cart Assembly Instructions 11-15

Gas Hook-up 16-19

Leak Testing 20-21

Burner Adjustment 22

Radiant Assembly 23

Sink 24

Side Shelf (optional) 25-26

Installer Checklist 26

USING THE GRILL

Lighting Instructions 27

Use of the Grill 27-28

USING THE SIDE BURNER

Lighting Instructions 29

USING THE GRIDDLE

Thermocouple 30

Before Using the Griddle for the

First Time or to Re-season 30

Use of the Griddle 30

Lighting Instructions 31

USING THE SINK 32

CARE & MAINTENANCE 33-36

TROUBLESHOOTING

Outdoor appliance 37

Side Burner 38

SERVICE 39

WARRANTY 40-41

2

SAFETY PRACTICES & PRECAUTIONS

IMPORTANT SAFETY NOTICE!

Certain Liquid Propane dealers may fill liquid propane cylinders for use in the outdoor appliance beyond cylinder

filling capacity. This “Overfilling” may create a dangerous condition.

IMPORTANT SAFETY NOTICE!

Be sure to remove covers from grill, griddle or side burners before attempting to light or use.

“Overfilled” tanks can build up excess pressure. As a safety device, the tanks pressure relief valve will vent

propane gas vapor to relieve this excess pressure. This vapor is combustible and therefore can be ignited. To

reduce this danger, you should take the following safety precautions:

1.

When you have your tank filled, be sure you tell the supplier to fill it to no more than 3/4 (75%) of its total

capacity.

2

. If you own or use a spare tank, or have a disconnected tank, you should NEVER store

it near or under the outdoor appliance/cart unit or heat box, or near any other ignition or heat source. A metallic sticker with this warning is provided with the grill

to remind you, your family and all others who may use your grill of these safety

precautions. Install this sticker close to your barbeque grill.

3. Do not store a full tank in direct sunlight.

WARNING!

Do not try lighting this appliance without reading the “LIGHTING INSTRUCTIONS”

section of this manual. This outdoor appliance is for outdoor use only.

WARNING!

Push and hold the igniter button, turn the selected burner knob to “HI” or

“SEAR”. If burner does not light in 4 to 5 seconds turn knob “OFF” and wait 5

minutes for any accumulated gas to dissipate before trying again.

n

Begin by insuring proper installation and

servicing. Follow the installation instructions

within this manual. Have your outdoor appliance installed by a qualified technician. Have

the installer show you where the gas supply

shut-off valve is located so that you know

where to shut off the gas to the outdoor appliance. If you smell gas, your installer has

not done a proper job of checking for leaks. If

the connections are not perfectly sealed, you

can have a small leak and therefore a faint gas

smell. Finding a leak is not a “do-it-yourself ”

procedure. Some leaks can only be found with

the burner control in the “ON” position and

this must be done by a qualified technician.

• Always follow lighting instructions.

• Lid must be off before lighting

the grill or side burners.

• Check for gas leaks before lighting.

• Never lean over an open grill when

lighting. Serious burns may result.

• Hot surfaces surrounding grill

grates could cause serious burns.

• Always leave at least 12" clearance

to combustibles around the grill.

• Never store a spare LP cylinder

under or near this unit.

• Never fill the tank beyond 3/4 full. A

fire causing death or serious injury

may occur.

STICKER

WARNING

n

Children should not be left alone or unattended in an area where the outdoor appliance is being used. Never

allow them to sit, stand or play on or around the outdoor appliance at any time. When in use, portions of the

outdoor appliance can get hot enough to cause severe burns.

n

Do not store items of interest to children around or below the outdoor appliance, in the cart or masonry enclo-

sure. Never allow children to crawl inside a cart or enclosure.

3

SAFETY PRACTICES & PRECAUTIONS

n

Never let clothing, pot holders or other flammable materials come in contact with or too close to any grate,

burner or hot surface until it has cooled. Fabric may ignite and result in personal injury.

n

Never attach or disconnect an LP cylinder, or move or alter gas fittings when the grill is in operation or is hot.

n

Clean and perform general maintenance on the grill twice a year. Watch for corrosion, cracks, or insect activity.

Check the regulator, hoses, burner ports, air shutter, and venturi/valve section carefully. Always turn off gas at

the source (tank or supply line) prior to inspecting parts.

n

After a period of storage or non-use (such as over the winter), the gas grill should be checked for gas leaks, dete-

rioration, proper assembly, and burner obstructions before using.

n

Do not heat unopened food containers as a build-up of pressure may cause the container to burst.

n

Always use a covered hand when taking off the lid and only do so slowly to allow heat and steam to escape.

n

Never lean over an open outdoor appliance. When lighting a burner, always pay close attention to what you are

doing.

n

After lighting burners, make sure burners are operating normally (see pages 21 and 22).

n

When using the outdoor appliance, do not touch the outdoor appliance burner grate or immediate surrounding

area as these areas become extremely hot and could cause burns.

n

Grease is flammable. Let hot grease cool before attempting to handle it. Avoid letting grease deposits collect in

the drip pan. Clean often.

For personal safety, wear proper apparel. Loose fitting garments or sleeves should never be worn while using

this appliance. Some synthetic fabrics are highly flammable and should not be worn while cooking. Only certain

types of glass, heat-proof glass ceramic, earthenware, or other glazed utensils are suitable for outdoor appliance

use. Use of some types of materials may break with sudden temperature changes. Use only on low or medium

heat settings according to the manufacturer’s directions.

WARNING!

Spiders and insects can nest in the burners of this and any other outdoor appliance, and cause the gas to flow from

the front of the burner. The gas will flow from the front of the burner into the control panel. This is a very dangerous

condition which can cause a fire to occur behind the valve panel, thereby damaging the outdoor appliance compo

-

nents and making it unsafe to operate.

WARNING!

Keep the area surrounding the outdoor appliance free from combustible materials, trash, or combustible fluids and

vapors such as gasoline or charcoal lighter fluid. Do not obstruct the flow of combustion and ventilation air.

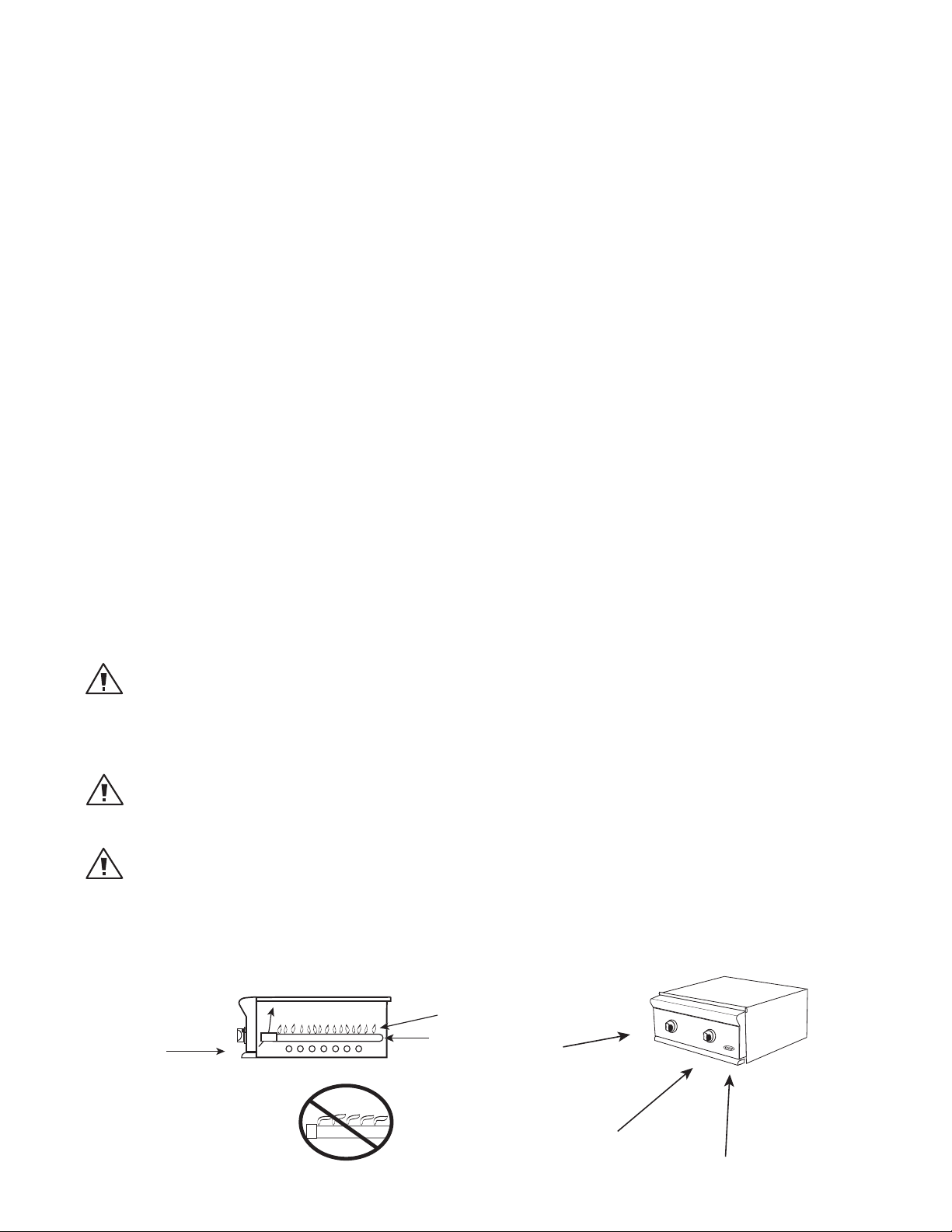

WARNING!

Never use the outdoor appliance in windy conditions. If located in a consistently windy area (oceanfront, mountaintop, etc.) a wind break will be required. Always adhere to the specified clearances listed.

OUTDOOR APPLIANCE PLACEMENT

FLAME

PREFERRED AIR FLOW

BURNER

WIND

FLAME LIFT

PRIMARY

INTAKE

AIR FLOW

WIND

4

SAFETY PRACTICES & PRECAUTIONS

n

Do not use aluminum foil to line drip pans, grates or radiants. This can severely upset combustion air flow or trap ex-

cessive heat in the control area. The result of this can be melted knobs or damaged ignition components.

n

When using the side burners always use flat bottomed pans which are large enough to cover the side burner. Adjust

the flame so that it heats only the bottom of the pan to avoid ignition of clothing. Position handles inward away from

open edges of the unit to avoid burns associated with unintentional spillovers. Hold the handle of the pan to prevent

movement of it when turning or stirring food. For proper lighting and performance of the burners, keep the ports

clean. It is necessary to clean them periodically for optimum performance.

n

Clean the outdoor appliance with caution. Avoid steam burns; do not use a wet sponge or cloth to clean the outdoor

appliance while it is hot. Some cleaners produce noxious fumes or can ignite if applied to a hot surface.

n

Be sure all outdoor appliance controls are turned off and the outdoor appliance is cool before using any type of aerosol

cleaner on or around the outdoor appliance. The chemical that produces the spraying action could, in the presence of

heat, ignite or cause metal parts to corrode.

n

Do not use the grill for cooking excessively fatty meats or products which promote flare-ups.

n

Never use outdoor appliance without the drip pan and grease tray in place and pushed all the way to the back. With-

out the grease pan, hot grease could leak downward and produce a fire or explosion hazard.

n

Do not operate the outdoor appliance under un protected combustible construction. Use only in well ventilated areas.

Do not use in buildings, garages, sheds, breezeway, covered structure or other such over head structures and enclosed

areas. This unit is for outdoor use only.

n

If a cart unit is stored indoors, ensure that it is cool, fold the optional side shelf(s) down, and never push or pull on the

side shelves. If LP, the LP cylinder must be unhooked and stored outside in a well ventilated area, out of reach of children.

n

Do not use charcoal or lighter fluid in the outdoor appliance.

n

Never use the outdoor appliance in a windy area.

n

Never use a dented or rusty LP tank. Keep the ventilation openings of the cylinder enclosure free and clear from

debris.

n

Use only dry potholders; moist or damp potholders on hot surfaces may cause burns from steam. Do not use a towel or

bulky cloth in place of potholders. Do not let potholders touch hot portions of the outdoor appliance.

n

Have an ABC rated Fire Extinguisher accessible – never attempt to extinguish a grease fire with water or ot her liquids.

n

To avoid burns when cooking, use long handled BBQ tools.

n

Do not move the appliance during its use.

n

This unit is for outdoor use only! Do not operate in enclosed areas. This could result in carbon monoxide build-up

which would result in injury or death.

n

When using the grill, be sure that all parts of the unit are firmly in place and that the grill is stable (can’t be tipped

over).

n

To put out flare-ups, adjust the controls to lower the temperature

n

CALIFORNIA PROPOSITION 65-WARNING: The burning of gas cooking fuel generates some by-products which are

on the list of substances which are known by the State of California to cause cancer or reproductive harm. California

law requires businesses to warn customers of potential exposure to such substances. To minimize exposure to these

substances, always operate this unit according to the Use and Care Guide, ensuring you provide good ventilation when

cooking with gas.

n

This outdoor cooking gas appliance is not intended to be installed in or on recreational vehicles, trailers and/or boats.

Note:

This product must be installed by a licensed plumber or gas fitter when installed within the Commonwealth of

Massachusetts.

5

OUTDOOR APPLIANCE MODELS

BFGC30G All-Grill

BFGC30BGD Double Side Burner/Griddle

BFGC30BS Double Side Burner/Sink

6

BEFORE USING YOUR APPLIANCE

1. Remove all packaging materials and labels from your appliance. If the installer has not set up your appliance,

check that you have the following items:

n BFGC-30G - All-Grill

- All-Grill cover

- Grill grates (5 pcs)

- Radiant trays to hold ceramic rods (2 pcs)

- Ceramic rods (28 pcs)

- Cover hanger (2 pcs)

n BFGC-30BGD - Side Burner/Griddle

- Covers (2 pcs)

- Griddle grease cup

- Side burner grate

- Griddle flu cover

- Cover hanger (2 pcs)

n BFGC-30BS - Side Burner/Sink

- Covers (2 pcs)

- Faucet

- Drain plug

- Side burner grate

- Cover hanger (2 pcs)

- Burner caps (2 pcs)

NOTE:

If any of the listed items are missing, contact DCS at (888) 936-7872. Please be prepared with your

Model #, Serial # and description of product you have purchased.

Tag location of

Model # and Serial #

Read all installation instructions in this manual to see if the unit has been properly installed. If not done or

done correctly, correct before using the unit.

7

INSTALLATION

LOCATING OUTDOOR APPLIANCE/BUILTIN CLEARANCES

LOCATION:

When determining a suitable location, take into account concerns such as exposure to wind (If located in a windy

area, a wind break must be provided to prevent poor burner performance or product damage.), proximity to traffic paths and keeping any gas or electrical supply lines as short as possible. Locate the outdoor appliance only in

a well ventilated area. Do not install the outdoor appliance under overhead unprotected combustible construction. Never locate the outdoor appliance in a building, garage, breezeway, shed, gazebo, lanai or other such

enclosed areas without an approved ventilation system. During heavy use, the outdoor appliance will produce a

lot of smoke and flames. Ensure there is adequate area for it to dissipate.

Important!

Gas fittings, regulator, and installer supplied shut-off valves must be used and easily accessible.

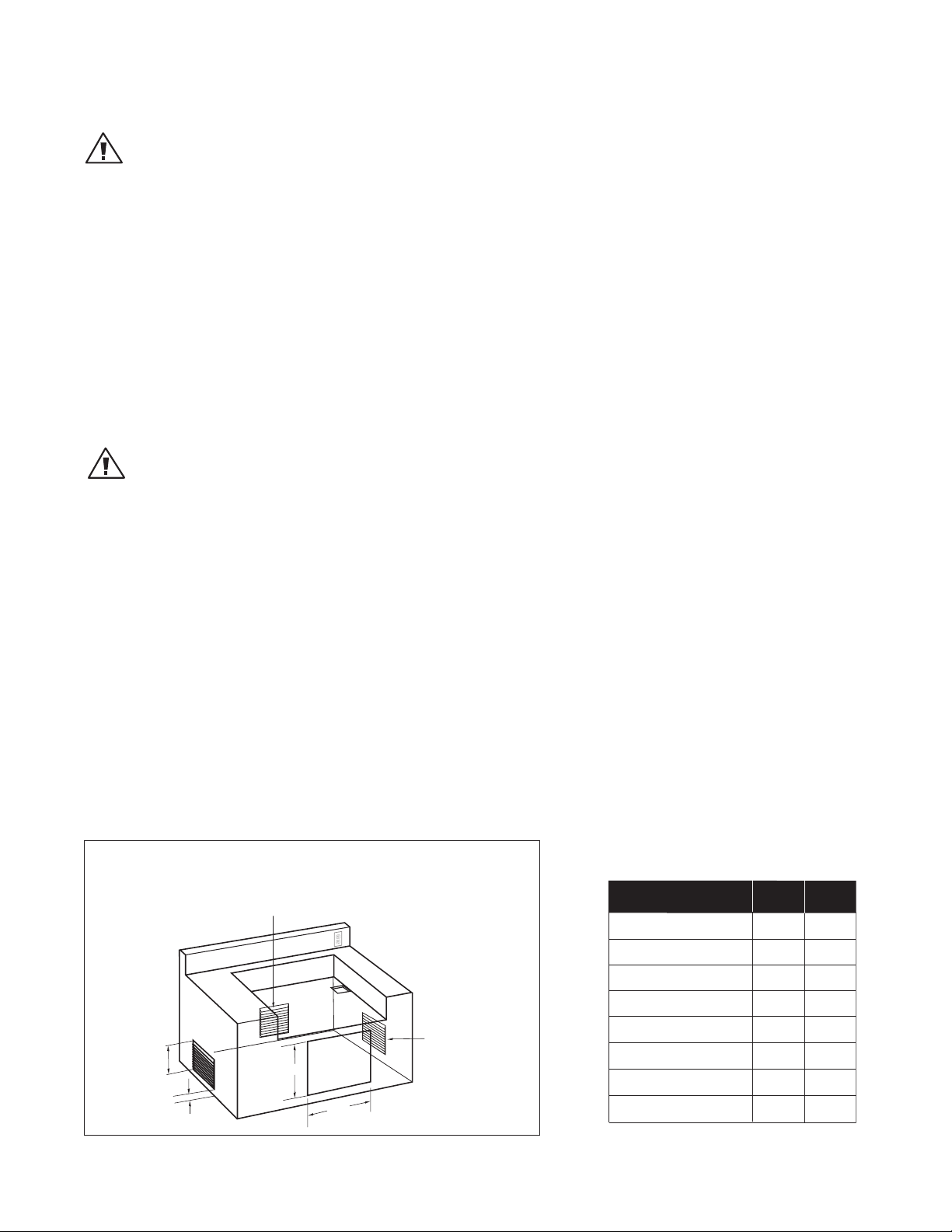

Clearances to Combustible* Construction (

see definition on page 9)

:

A minimum of 12” from the sides and a minimum of 12” from the back must be maintained from the outdoor appliance above the cooking surface to adjacent vertical combustible* construction. (Fig. 01) Do not install under

unprotected combustible* construction.

Maintain

12" from

combustible

construction

Maintain

12" from

combustible

construction

10-1/2"

2"

Bottom of

support flange

22-3/4"

25-1/2"

Maintain

12" from

combustible

construction

10 -1/16"

Fig. 01

Important!

All outdoor appliances must have an insulated jacket to combustible island construction.

Clearances to Noncombustible** Construction (

A minimum of 3” clearance from the back of the outdoor appliance to noncombustible** construction is required.

It is desirable to allow at least 6” side clearance to noncombustible** construction above the cooking surface or

counter space. The outdoor appliance can be placed directly adjacent to noncombustible** construction below

the cooking surface.

see definition on page 9)

:

WARNING!

Failure to maintain required clearances creates a fire hazard that may result in property damage or serious personal

injury.

WARNING!

If a Noncombustible** material such as metal is covering a combustible material such as wood, the minimum clearance distance needs to be held to the wood. The presence of a Noncombustible** material inside the clearance zone

does not eliminate the minimum clearance zone to combustible material.

8

INSTALLATION

AB

LOCATING BUILTIN CLEARANCES

WARNING!

The appliances are designed to function in an open area. Recommended minimum clearances should be maintained

to all surfaces (combustible* and noncombustible**) for optimum performance. Noncombustible** material within

the minimum clearance area could result in discoloration or deterioration.

*DEFINITION OF COMBUSTIBLE MATERIAL - Any materials of a building structure or decorative structure made of wood, compressed

paper, plant fibers, stucco or other materials that are capable of transferring heat or being ignited and burned. Such material shall be

considered combustible even though flame-proofed, fire-retardant treated, or painted surface or plastered.

**DEFINITION OF Noncombustible MATERIAL - Material which is not capable of being ignited and burned, such as materials consisting

entirely of, or a combination of, steel, iron, brick, tile, concrete, slate, and plaster (which is unpainted).

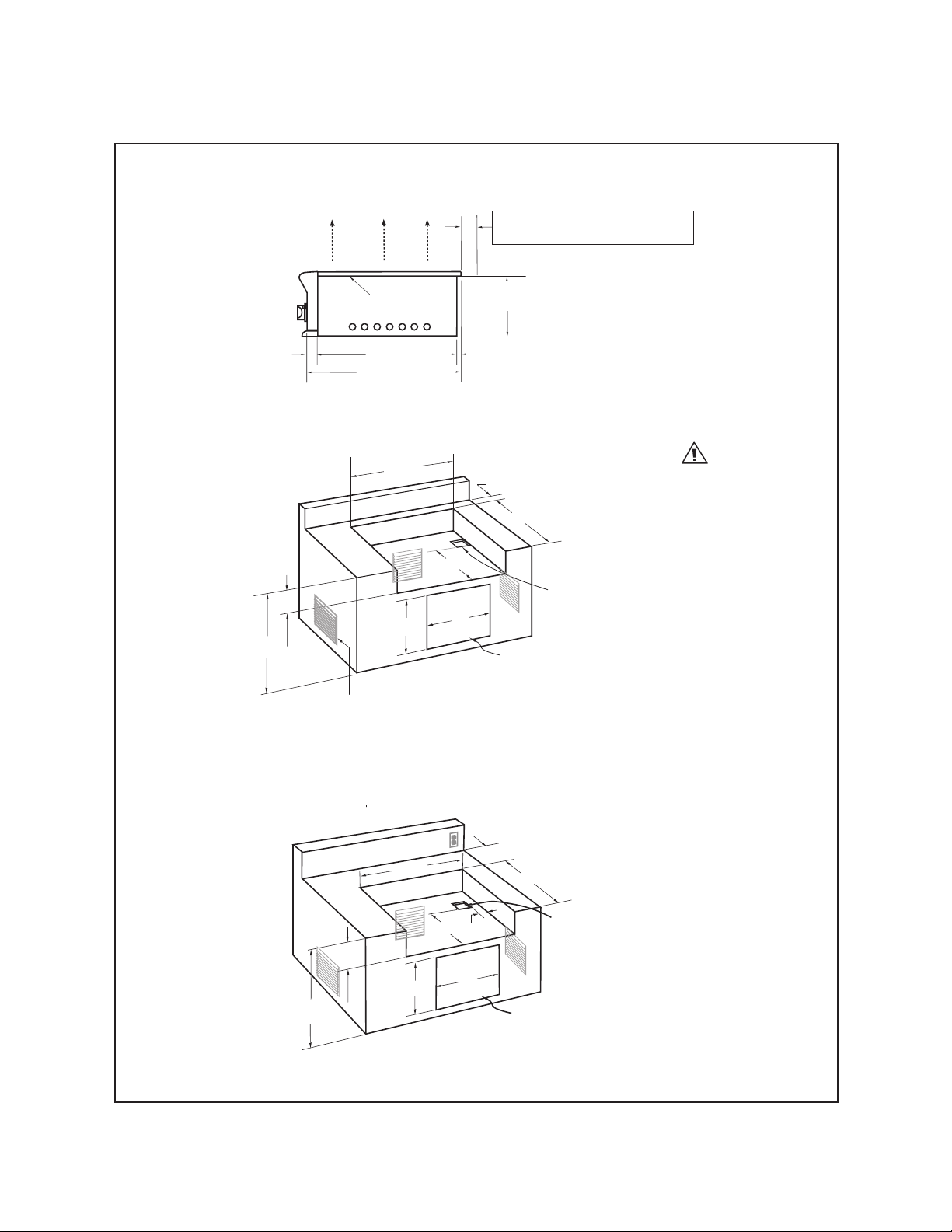

Important!

It is recommended that a minimum of 10 sq. inches of ventilation opening be provided for both the left and

right sides, as well as the back of enclosure (Fig. 02), in order to safely dissipate unburned gas vapors in the

event of a gas supply leak.

WARNING!

Note specific built-in enclosure ventilation requirements. See text and Fig. 02.

GENERAL

The outdoor appliance is designed for easy placement into masonry enclosures. For non-combustible applications the outdoor appliance drops into the opening shown in Fig. 03 and hangs from its side flanges. The deck

must be level and flat. A deck is not required to support the unit from the bottom. When using the insulated

jacket in a combustible enclosure application, see the bottom of Fig. 03. The jacket assembly must be supported

from the bottom by a ledge on each side or a solid deck beneath the entire insulated jacket.

INSULATED JACKET:

If the outdoor appliance is to be placed into a combustible enclosure, an approved insulated jacket is required

and is available from your dealer. Insulated jacket is not required for BFGC-30BS Side Burner Sink Model. Use

only the DCS insulated jacket (p/n #70859) which has specifically been designed and tested for this purpose.

Review the detail drawing shown (Fig. 03) and take into account the provisions shown for gas line hook-up clearance in the right rear corner. It is recommended that ventilation holes are provided in the enclosure to eliminate

the potential build-up of gas in the event of a gas leak. The supporting ledges or deck must be level and flat. The

counter should also be level.

10 in.2 Min. ventilation

left hand side

1" Min.

Ventilation Requirements:

2

10 in.

Min. ventilation

on the back side

B

A

Opening for

access doors/drawers

2

10 in.

Min. ventilation

on the right hand side

Note: not drawn to scale

CUTOUT DIMENSIONS OF MATCHING

ACCESS DOORS/DRAWERS:

ACCESS DOOR/

DRAWER MODELS

ADN120X24

ADN120X30

ADN120X36

ADN120X48

ADR224

ADR236

ADR230

ADR248

22"

28"

34"

46"

22"

34"

28"

46"

20"

20"

20"

20"

20"

20"

20"

20"

Fig. 02

9

INSTALLATION

BUILTIN CONSTRUCTION DETAILS

grill

exhaust

Bottom of

support flange

12" (to combustible construction)

10-1/16"

2"

22-3/4"

25-1/2"

3/4"

Standard layout for non-combustible enclosure:

28-1/2"

3"

22-3/4"

18-1/2"

4" x 4" opening

for gas supply line

opening for access doors

(see page 9 for ordering information)

35-1/2"

Max.

10-1/8"

NOTE: See page 9

for ventilation notes.

20"

28"

Layout for insulated jacket only - combustible enclosure:

WARNING!

If installing the grill

into a non-combustible

enclosure, all combustible

construction must still be

outside the 12 inch clear

ance zone. If your island

is made of stucco over the

top of wooden studs, the

wood can not be inside the

12 inch clearance zone to

combustible, even though

the stucco is what is touch

ing the grill area.

-

-

NOTE: See page 9 for insulated jacket

part ordering information.

35-1/2"

Max.

11-1/8"

34-7/8"

20"

18-1/2"

10

3-1/2"

28"

Fig. 03

12" min.

23-3/4"

4" x 4" opening

for gas supply line

opening for access doors/drawers

(see page 9 for ordering information)

INSTALLATION

CART ASSEMBLY INSTRUCTIONS

IMPORTANT:

Read all instructions before you begin. Do not jump ahead or skip any step.

CAUTION:

Some parts have sharp edges; care must be taken when handling the various components to

avoid injury. Please read safety information provided in these instructions before beginning

assembly. Wear gloves when handling.

Two or more people should work together to assemble the cart and All-Grill, Double Side Burner/

Sink, or Double Side Burner/Griddle.

NOTE: Avoid using optional side shelf to move cart. Push or pull cart by grasping corners of head.

LOCATING THE CART

For proper use, this product should be installed/positioned on a flat ground or patio. Unevenness such as

bumps, cracks and protrusions should be 1/4” or less. Refer to Fig. 04 for required flat area dimensions.

TOP VIEW (with drawers open)

CAD 30 = 30”

Getting Started

n Remove packaging.

CAD 36 = 36”

CAD 48 = 48”

Contents Included:

Your cart is packaged in one box. The box contains your 30” cart and a

universal hardware kit to be used for head installation and may contain

extra hardware for your convenience.

Contents Qty.

Tools Required:

1

30” Cart

Machined Phillips

screws

10-24X1/2”

Bracket, Tab

Bolt Hex

1/4-20-1/2”

13

2

2

4 feet

Fig. 04

Eye Goggles

Work Gloves

Power Screwdriver or Vari-

able Speed Drill with Phillips

- tip #2 Attachment

5/32” Allen Wrench

Washer

.313 x .750

Nut Hex

1/4-20

4

2

11

3/16” Allen Wrench

3/32” Allen Wrench

INSTALLATION

CART ASSEMBLY INSTRUCTIONS

Step 1

Link Carts Together (optional)

(To link two or more CAD carts, the following instructions must be done first, using

the hardware provided, before installing the top modules.)

1. To link your carts together - hand tighten 2 bolts, 4 washers, and 2 nuts on the front and back sides of the carts as

shown in Fig. 04. Carefully wrench tighten fasteners once carts are aligned with each other.

CAUTION:

Once the carts are linked, they cannot be moved. Moving the carts once linked could damage the carts.

Head of bolt with washer

End of bolt with nut and washer

Fig. 05

Head of bolt with washer

End of bolt with nut and washer

12

INSTALLATION

CART ASSEMBLY INSTRUCTIONS

Step 2

Outdoor Appliance Head Preparation

1. First you will need to remove the angle brackets from the side

of the unit and replace them with cart mount brackets

(Fig. 06). Unit is shipped prepared for island installation.

2. Install the bracket tab on both sides of the appliance head

using 8 of the 10-24 x 1/2” screws. Install each bracket with 4

screws on each side of the outdoor appliance head

(Fig. 07 and 08).

SCREWS

Fig. 06

SCREWS

Fig. 07

Fig. 08

Step 3

Head Placement onto Cart (2 Persons Required)

1. Remove drip tray/pan (Fig. 09) and other removable components

(to lighten the load) such as grates, top burner caps and

components, and griddle flue cover, radiant tray and grill burner

for easier handling.

2. Two persons required to lift head (sink module shown).

Placing head on cart, place rear of head over the rear of the cart

first (Fig. 10). Then allow the rear side tabs to first locate in

the slots on the top of the cart sides. The other tabs will locate in

the middle and front slots as the head is lowered into position on

the cart (Fig. 11).

Fig. 09

3. Position tabs on side bracket to fit into slots on the cart (be aware

of pinch points)(Fig. 11 -13). When complete, the leading ledge should sit flush on the top of the cart (no gap).

4. Secure the head to rear of cart (Fig. 14) with (2) Phillips-head screws provided (10-24 x 1/2”)(p/n 211242).

Fig. 10

13

TABS

Fig. 11

INSTALLATION

CART ASSEMBLY INSTRUCTIONS

3. Position tabs on side bracket to fit into slots on the cart (be aware of pinch points)(Fig. 12-13). When complete,

the leading ledge should sit flush on the top of the cart (no gap)(Fig. 14).

PINCH POINT

Fig. 12

4. Secure the head to rear of cart (Fig. 15) with (2) Phillips-head screws provided (10-24 x 1/2”).

5. Install remaining (3) screws (10-24 x 1/2”) into the front of head to the cart (Fig. 16).

6. Slide drip tray/pan back into place and reinstall parts removed in Step 3, #1.

Fig. 15

Fig. 13

Fig. 16

Fig. 14

14

INSTALLATION

CART ASSEMBLY INSTRUCTIONS

Step 4

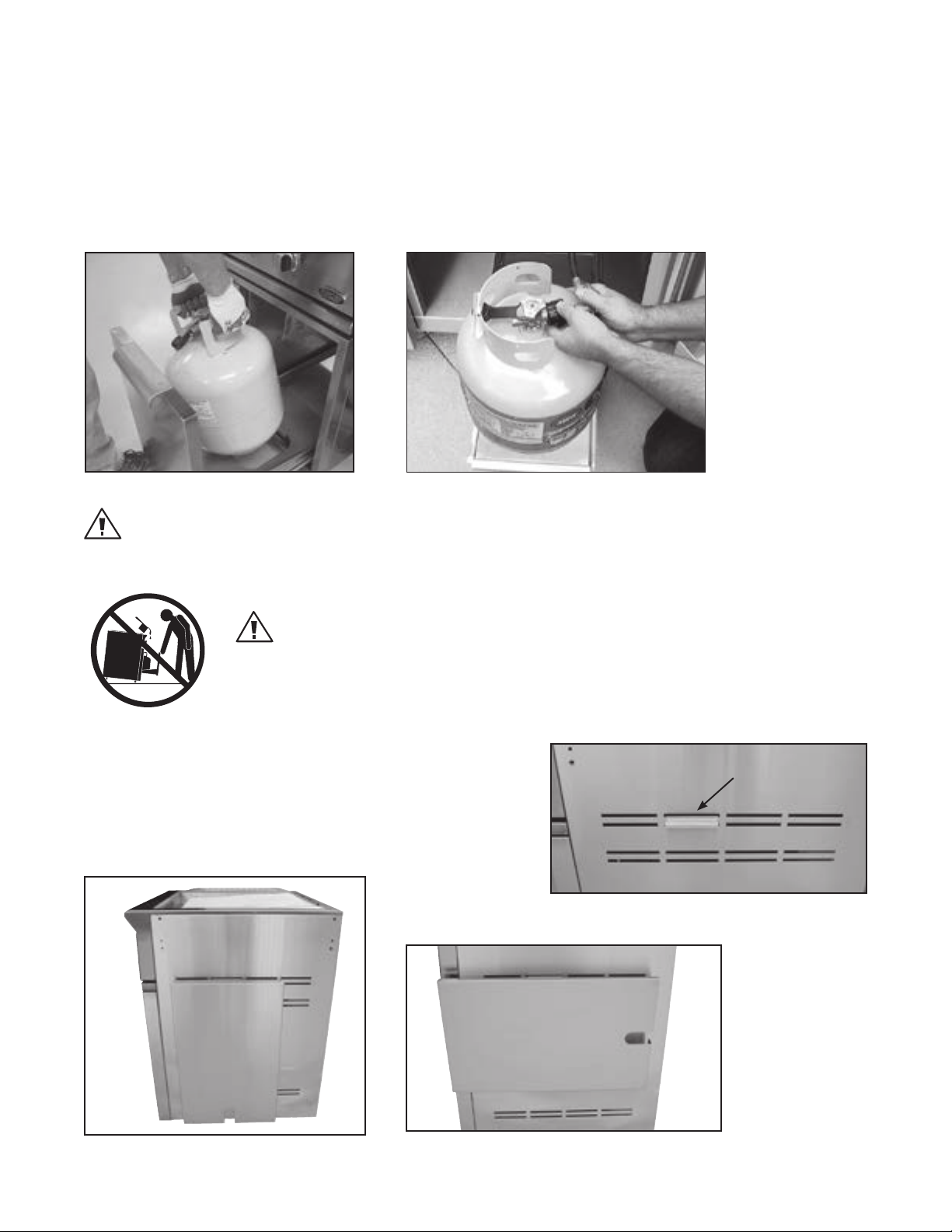

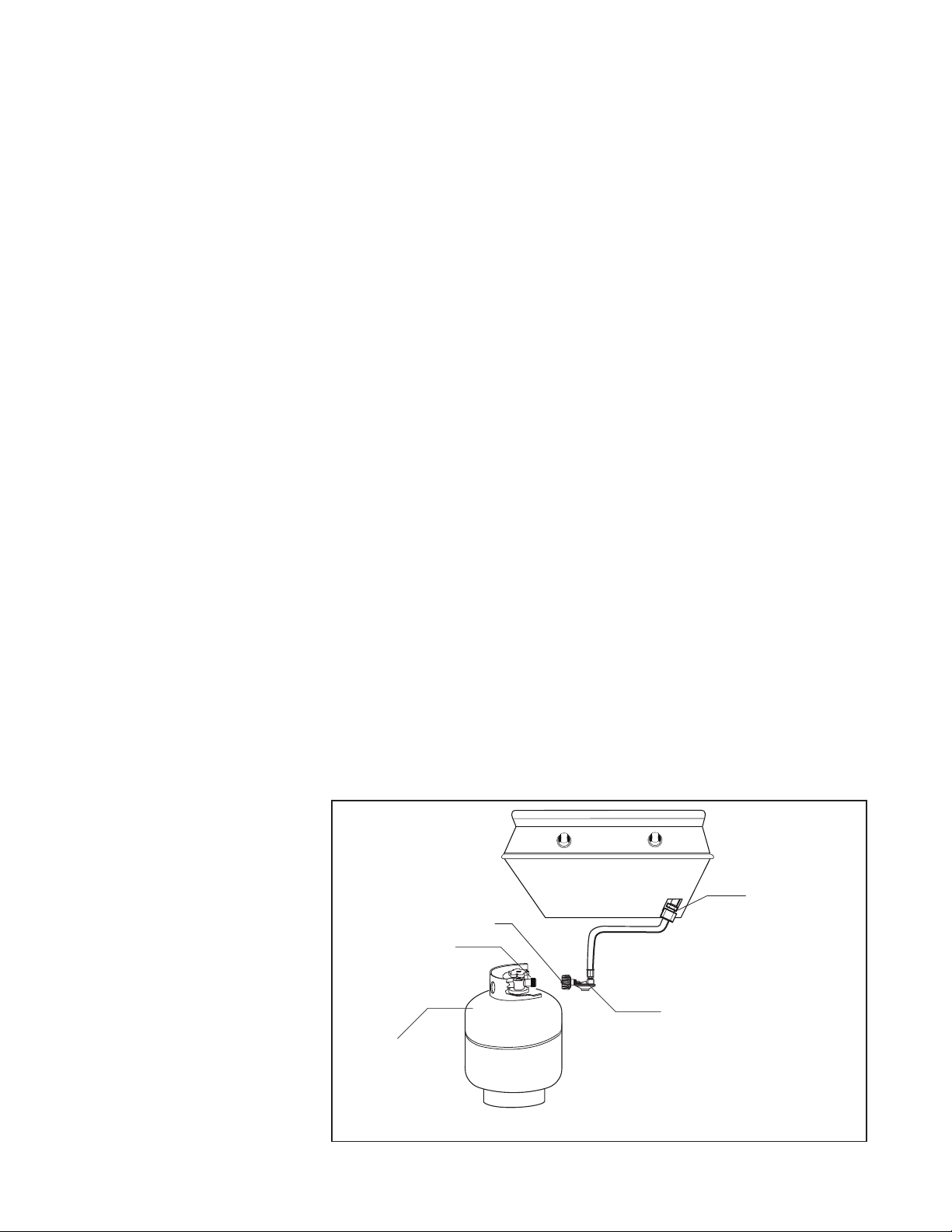

Gas Hookup - LP

Make sure the cart assembly is stable. Open the tank drawer. Place the LP tank into location as shown in Fig. 17.

Connect the regulator assembly to the tank connection with all appliances valves in the “OFF” position. Open the

tank valve and test for gas leaks (Fig. 18).

Fig. 17

Fig. 18

FOR YOUR SAFETY

To prevent personal injury or damage to the drawers, do not overload them. The maximum rating of each drawer is

35 pounds.

WARNING!

Do not push down on the top of the drawers. The unit could tip forward.

COVER HANGER

To use the cover hangers provided, first place the cover hanger

into the slot on the side or rear of your Cart (Fig. 19). Then hang

the cover in either direction. (Fig. 20 or 21).

Note:

Do not move the cart while the covers are hung. This could cause

the covers to fall off the hangers and damage the covers.

Cover hanger

Fig. 19

Fig. 20

Fig. 21

15

INSTALLATION

GAS HOOKUP

GAS REQUIREMENT

Verify the type of gas supply to be used, either natural or LP, and make sure the marking on the appliance rating

plate agrees with that of the supply. The rating plate is located on the bottom of the outdoor appliance. Never

connect an unregulated gas line to the appliance. You must use the gas regulator provided with the unit even if

the supply is controlled.

An installer-supplied gas shut-off valve must be installed in an easily accessible location. All installer supplied

parts must conform to local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA

70 or the Canadian Electrical Code, CSA C22.1, and the National Fuel Gas Code, ANSI Z223.1 or CSA B149.1 Natural

Gas Installation Code or CSA B149.2 Propane Installation Code.

All pipe sealants must be an ap proved type and resistant to the actions of LP gases. Never use pipe sealant on

flare fittings. All gas connections should be made by a qualified technician and in accordance with local codes

and ordinances. In the absence of local codes, the installation must comply with the National Fuel Gas Code,

ANSI Z223.1. Gas conversion kits are available from the factory. When ordering gas conversion kits, have the

model number, and the type of gas (natural or LP) from your outdoor appliance.

TOTAL GAS CONSUMPTION OF THE OUTDOOR APPLIANCE WITH ALL BURNERS ON HI/

SEAR:

BFGC-30G - 50,000 Btu/hr BFGC-30BGD - 49,000 Btu/hr BFGC-30BS - 34,000 Btu/hr

The appliance and its individual shut-off valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 PSIG (3.5 kPa.) The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 PSIG (3.5 kPa.). The installation of

this appliance must conform with local codes or, in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1. Installation in Can ada must be in accordance with the Standard Can1-b149.1 and/or .2 (installation

code for gas burning appliances and equipment) and

local codes.

NATURAL GAS HOOK UP: THIS TYPE OF

CONNECTION SHOULD BE PERFORMED BY A

CERTIFIED OR LICENSED TECHNICIAN ONLY.

Connection: 1/2” NPT male with 3/8” flare adapter.

Operating pressure: 4.0” W.C. Supply pressure: 5”

to 14” water column. If in excess of 14” W.C., a stepdown regulator is required. Check with your local

Threading compound

must be resistant to LP gas

gas utility company or local codes for instructions on

installing gas supply lines. Be sure to check on type

and size of run, and how deep to bury the line. If the

gas line is too small, the outdoor appliance will not

1/2” NPT x 5.0”

Nipple

function properly. Any joint sealant used must be

an approved type and be resistive to the actions of

natural gases.

Installer supplied shut-off

valve must be easily

accessible*

TO HOOKUP THE FITTINGS SUPPLIED

WITH THE OUTDOOR APPLIANCE:

Assemble as shown (Fig. 22). Use threading compound on male threads only. Do not use threading

compound on the male end of the 1/2” NPT to 3/8

flare adapter. Use a second pipe wrench to hold the

outdoor appliance inlet pipe to avoid shifting any

internal gas lines of the outdoor appliance. Ensure

that the regulator arrow points in the direction of gas

flow towards the unit, away from the supply. Do not forget to place the installer-supplied gas valve in an accessible location.

16

Bottom of unit

Coupling

1/2” NPT x

2.0”

Nipple

Regulator

4.0" W.C.

Adapter 1/2” NPT

to 3/8” flare fitting

Do not put threading

compound on these

threads

*Installation must conform with local

codes or with the National Fuel Gas Code

ANSI Z223.1 or the CSA B149.2 Propane

Installation Code

Fig. 22 Natural Gas

T

INSTALLATION

GAS HOOKUP

LP GAS HOOK UP TYPE 1 OR QCC1 REGULATOR:

All outdoor appliances orificed for use with LP gas come equipped with a high capacity hose/regulator assem bly

for connection to a standard 20 lb. LP cylinder (Type 1). The LP tank is not included.

Connection: 1/2” NPT male with a 3/8” Flare adapter (included). LP Hose with a quick disconnect and fittings are

included. Operating pressure: 11.0” W.C.

CAUTION!

Before connecting LP tank to regulator, check that all burners are in the “OFF” position and the lid has been removed.

To connect the LP regulator/hose assembly to the tank/valve assembly, first make sure the main valve on the tank

is completely closed. Although the flow of gas is stopped when the Type 1 system is disconnected as part of its

safety feature, you should always turn off the LP tank main valve (Fig. 23) after each use and during transport of

the tank or unit. Insert the regulator inlet into the tank valve and turn the black coupler clockwise until the coupler tightens up. Do not overtighten the coupler. Turn the main tank valve on, push and turn the burner control

valves on the unit to the “HI” position for about 20 seconds to allow the air in the system to purge, turn valves off

and wait 5 minutes before attempting to light the burners.

To disconnect the coupler, first make sure the main tank valve is turned off. Grasp the coupler and turn counter

clockwise. The inlet will then disengage. Remove the inlet from the tank valve opening if it has not already done

so when it disengaged. Your local LP filling station should be equipped with the proper equipment to fill your

tank.

LP TANK REQUIREMENTS:

A dented or rusty LP tank may be hazardous and should be checked by your LP supplier. The cylinder that is

used must have a collar to protect the cylinder valve. Never use a cylinder with a damaged valve. Always check

for leaks after every LP tank change. The LP gas cylinder must be constructed and marked in accordance with the

specifications for LP gas cylinders of the U.S. Department of Transportation (DOT or CAN/CSA-B339) and designed

for use with a Type 1 system only. Do not change the regulator/hose assembly from that supplied with the unit

or attempt to use a Type 1 equipped regulator/hose assembly with a standard 510 POL tank/valve assembly. The

cylinder must be provided with a shut-off valve terminating in a LP gas supply cylinder valve outlet specified, as

applicable, for connection Type 1. If the appliance is stored indoors, the cylinder must be disconnected and

removed from the appliance. Cylinders must be stored outdoors in a well-ventilated area out of the reach of

children.

Note:

When an LP unit is directly attached

into an LP house system, the stepdown regulator MUST be used to

reduce the supply pressure to a max.

14” W.C. and min. 11” W.C. to the

outdoor appliance regulator.

hreading

compound must be

resistant to LP gas

Type 1 Regulator

Main Tank Valve

Type 1 Tank

Bottom of unit

LP Regulator hose

assembly 11" W.C.

(installed on unit)

1/2” female

NPT x 3/8” male f lare

(installed on unit)

Note: Do not put

threading compound

on male threads of f lare

f itting

17

*Installation must conform with

local codes or with the National

Fuel Gas Code ANSI Z223.1 or the

CSA B149.2 Propane Installation

Code

Fig. 23 LP Gas

INSTALLATION

GAS HOOKUP

LP TANK RESTRAINT FOR BUILTIN INSTALLATION

If the grill is to be installed in a Built-in application, then the grill must be installed in accordance with the

Built–in installation guidelines.

If you intend to operate your Built-in grill on LP gas utilizing a 20 lb Type 1 cylinder, then the Built-in LP tank

restraint must be installed prior to initial use of the grill. If you do not have one please contact DCS Customer Care

at (888) 936-7872 for information on obtaining one.

The following steps will illustrate how to properly locate and install the LP tank restraint within the Built-in enclosure.

NOTE:

The grill comes with the LP Regulator/Hose assembly installed at the factory. The assembly, along with the entire grill

system, is leak tested.

Do not remove the Regulator/Hose assembly from the grill during installation.

The maximum distance from the center

of the manifold cut out to the center of

the tank restraint is 18 inches.

Tank Restraint can be placed

within this area without causing

stress on the LP regulator hose

connection.

Center of manifold cut

out projected to floor

of the island.

18” max.

Fig. 24

18

INSTALLATION

GAS HOOKUP

STEP 1

Place the tank restraint in the island (Fig. 25).

STEP 2

Locate the tank restraint in the island within the recommended area

(Fig. 24 and 26).

STEP 3

Once located, secure to the bottom of the island using all eight hole

locations provided on the restraint. Wood screws can be used for

wooden floors or 1/4 inch diameter anchor screws or bolts may be

used if the floor is concrete or masonry (Fig. 27).

STEP 4

When secure, place the LP cylinder into the tank restraint making

sure to seat the tank all the way down, securely affixing the tank in

the restraint (Fig. 28).

STEP 5

Attach the regulator hose assembly and operate the grill normally as

described in the Use and Care manual (Fig. 29).

Fig. 25

Fig. 26

Fig. 27

Fig. 28

Fig. 29

19

INSTALLATION

LEAK TESTING GRILL/GRIDDLE UNIT

GENERAL:

Although all gas connections on the outdoor appliance are leak tested at the factory prior to shipment, a complete gas tightness check must be performed at the installation site due to possible mishandling in shipment, or

excessive pressure unknowingly being applied to the unit. Periodically check the whole system for leaks, or immediately check if the smell of gas is detected.

Before Testing:

Do not smoke while leak testing. Extinguish all open flames. Never leak test with an open flame. Make a soap

solution of one part liquid detergent and one part water. You will need a spray bottle, brush, or rag to apply the

solution to the fittings. For LP units, check with a full cylinder. The valve panel must be removed to check the

valves and fittings. Remove the knobs, then remove the 2 screws which fasten the valve panel to the unit (you

will need a Phillips screw driver for this). Pull the valve panel outward and unplug the wires from the ignition

module.

To Test:

Make sure all control valves are in the “OFF” position. Turn the gas supply “on”. Check all connections from the

supply line, or LP cylinder up to and including the manifold pipe assembly. Apply the soap solution around the

connection, valve, tubing and end of the manifold. Soap bubbles will appear where a leak is present. If a leak is

present, immediately turn off gas supply, tighten any leaking connections, turn gas on, and recheck. Check all

the gas connections at the base of the control valves where they screw into the manifold pipe.

If you cannot stop a gas leak, turn off the gas supply and call your local gas utility, or the dealer you purchased

the appliance from. Only those parts recommended by the manufacturer should be used on the outdoor appliance. Substitution can void the warranty.

WARNING!

Do not use the outdoor appliance until all connections have been checked and do not leak.

Check all gas supply fittings for leaks before each use. Keep a spray bottle of soapy water near the gas supply

shut-off valve. Spray all the fittings. Bubbles indicate leaks.

Bottom of unit

Bottom of unit

LEAK TEST POINTS

CHECK HOSE FOR

LP TANK

SIGNS OF ABRASIONS,

CRACKS, OR LEAKS

LEAK TEST POINTS

Fig. 30 LP Gas

Fig. 31 Nat. Gas

20

INSTALLATION

LEAK TESTING SIDE BURNER

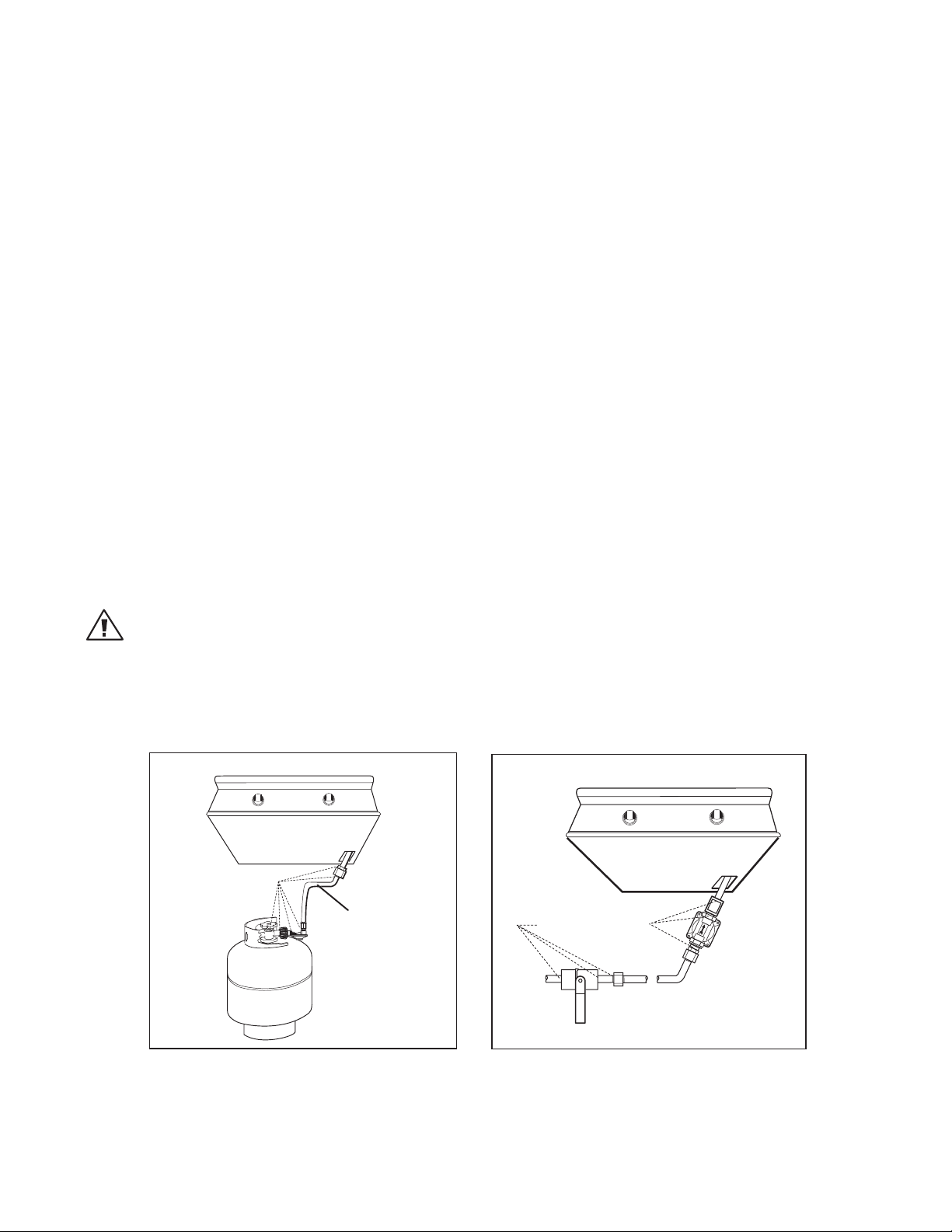

WARNING!

Do not smoke while leak testing. Extinguish all open flames.

Make a soap solution of one part liquid detergent, and one part

water. Never test for leaks with an open flame. For LP units, check

with a full cylinder. Make sure all control valves are in the “OFF”

position. Turn the gas supply “ON”. Check all connections from the

supply line (Fig. 31), or LP cylinder (Fig. 30) up to the manifold pipe

assembly (Fig. 32). Apply the soap solution around the connection

with a spray bottle, brush, or rag. Soap bubbles will appear where

leak is present. If a leak is present, turn off gas supply, tighten any

leaking fittings, turn gas on, and recheck.

WARNING: IMPORTANT!

Inspect the gas supply piping or hose prior to turning the gas “ON”.

If there is evidence of cuts, wear or abrasion, it must be replaced prior to

use. Do not use the side burner if the odor of gas is present. Turn the control knob to “OFF”, then turn off the gas

supply. If using LP, is there gas in the tank? Always keep your face and body as far away from the burner as pos

sible when lighting.

Fig. 32

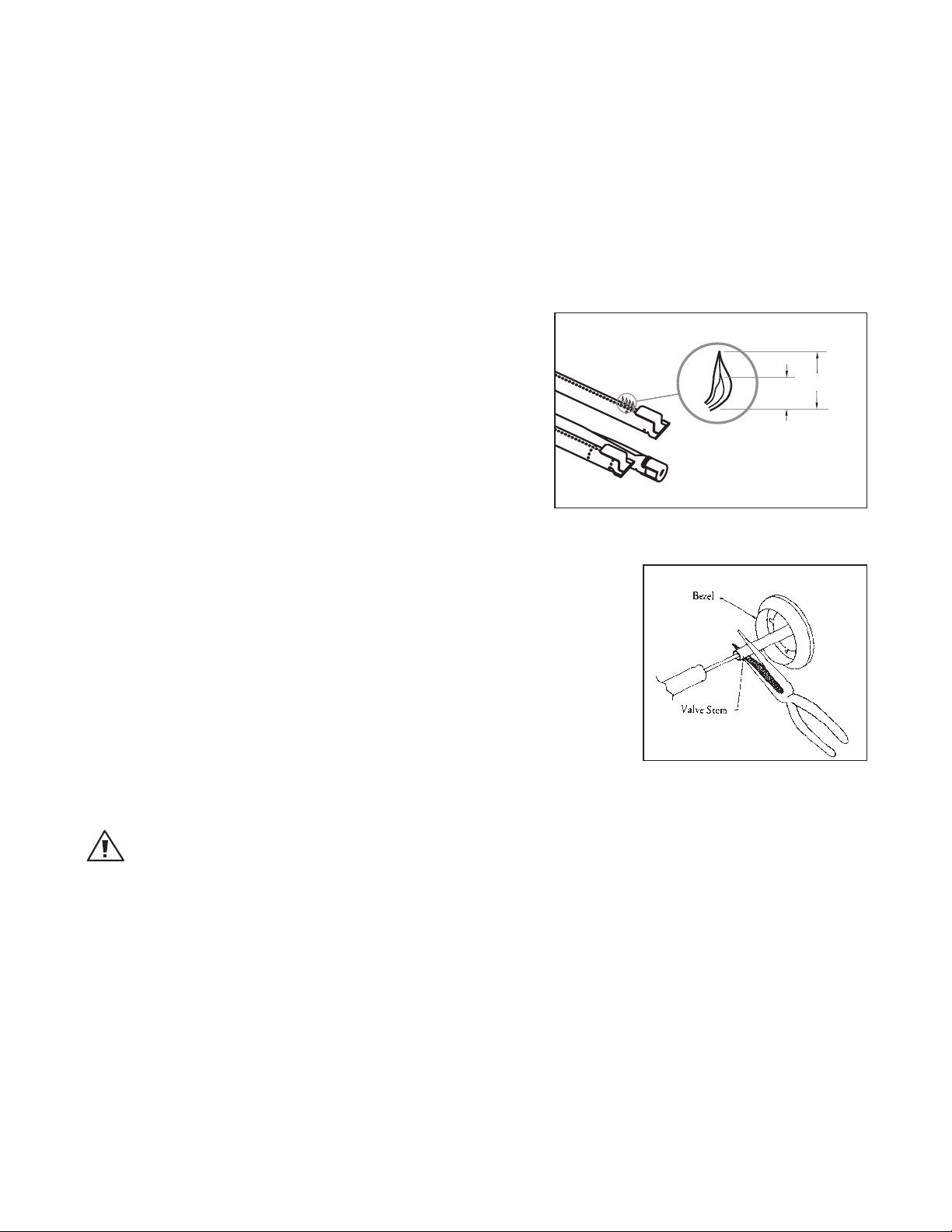

BURNER ADJUSTMENT - SIDE BURNER

Your new side burner is equipped with burners typical of those used

in restaurants (Fig. 33). These burners are designed for maximum

cleanability and controlability. The burner should never be operated if the cap is not in place.

BURNER EFFICIENCY AND FLAME CHARACTERISTICS

It is necessary to keep the burner ports and the igniters clean for

proper lighting and efficient performance of the burners. The

burner flame should burn completely around the burner with no excessive noise or lifting. The flame should be blue in color and stable

with no yellow tips. During initial use, foreign particles in the gas

line, or dust in the air around the appliance may cause an orange

flame. This will disappear with use.

FLAME HEIGHT

The correct height of the flame mainly depends on the size of the

bottom of the cooking utensil, the material of the cooking utensil,

the amount and type of food and the amount of liquid in the utensil.

The following are some basic rules for selecting flame height.

Fig. 33

PROPER FLAME HEIGHT

Cap

-

n

For safety reasons the flame must never extend beyond the

bottom of the cooking utensil. Never allow flames to curl up the

side of the pan (see Fig. 34).

n

Utensils which conduct heat slowly (such as glass-ceramic)

should be used with medium to low flames. If you are cooking with

a large amount of liquid, a slightly larger flame can be used.

21

Fig. 34

INSTALLATION

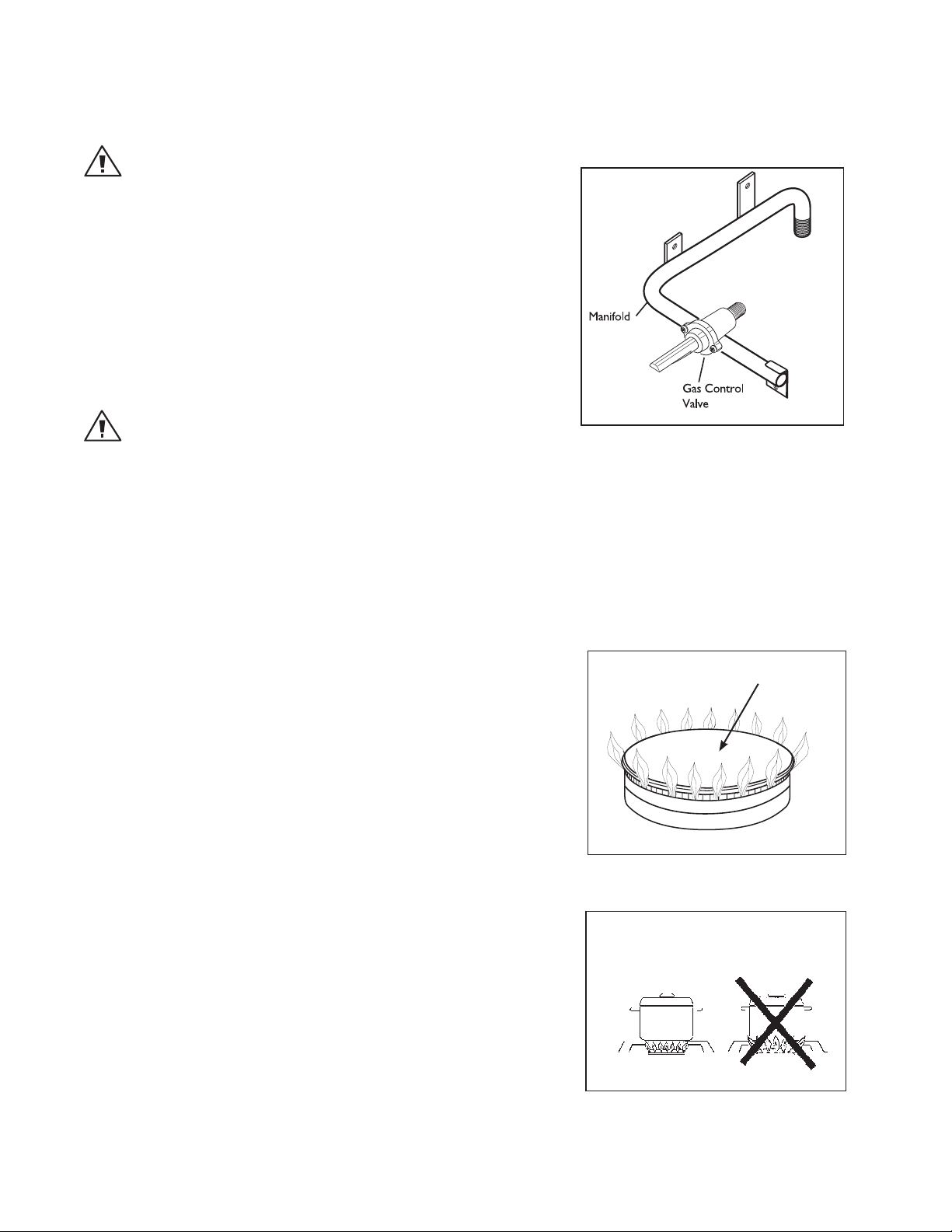

BURNER ADJUSTMENT GRILL/GRIDDLE UNIT

Each outdoor appliance burner is tested and adjusted at the factory prior to shipment; however, variations in the

local gas supply or a conversion from one gas type to another may make it necessary to adjust the burners. The

flames of the burners should be visually checked and compared to that of the drawing in Fig. 35. Flames should

be blue and stable with no yellow tips, excessive noise or lifting. If any of these conditions exist, check if the air

shutter or burner ports are blocked by dirt, debris, spider webs, etc. Proceed with air shutter adjustment. The

amount of air which enters a burner is governed by a sheet metal cup at the inlet of the burner called an air shutter. It is locked in place by a screw which must be loosened prior to lighting the burner for adjustment.

OUTDOOR APPLIANCE BURNER FLAME HEIGHT:

To access the outdoor appliance burner air shutters, first remove

the valve panel by removing it the same way as described on page

20, section “Before Testing”. With a screw driver, loosen the lockscrew on the face of the air shutter. Light the burner and adjust

according to the directions (Fig. 35).

To Adjust:

1.

Be careful as the burner may be very hot.

2.

If the flame is yellow, indicating insufficient air, turn the air shutter

counterclockwise to allow more air to the burner.

3.

If the flame is noisy and tends to lift away from the burner, indi-

cating too much air, turn the air shutter clockwise.

Fig. 35 Burner Flame Height

3/8"

1-1/2"

4.

Once adjusted turn the burner off and reverse steps to reassemble.

LOW SETTING ADJUSTMENT:

The valves on the outdoor appliance feature an adjustable low setting. Due

to fluctuations in gas pressure, heating value or gas conversion, you may feel

it necessary to increase or decrease gas flow in the low position.

To Adjust:

1.

Light the burner.

2.

Turn the control knob to the lowest setting (all the way counter-clockwise).

3.

Remove the knob.

4.

While holding the valve shaft with pliers, insert a thin, flat tipped screwdriver

into the shaft and while viewing the burner adjust to a minimum stable flame (Fig. 36).

Fig. 36 Low Setting Adjustment

WARNING: IMPORTANT!

Before lighting, inspect the gas supply piping or hose prior to turning the gas “on”. If there is evidence of cuts, wear,

or abrasion, it must be replaced prior to use.

22

INSTALLATION

RADIANT ASSEMBLY

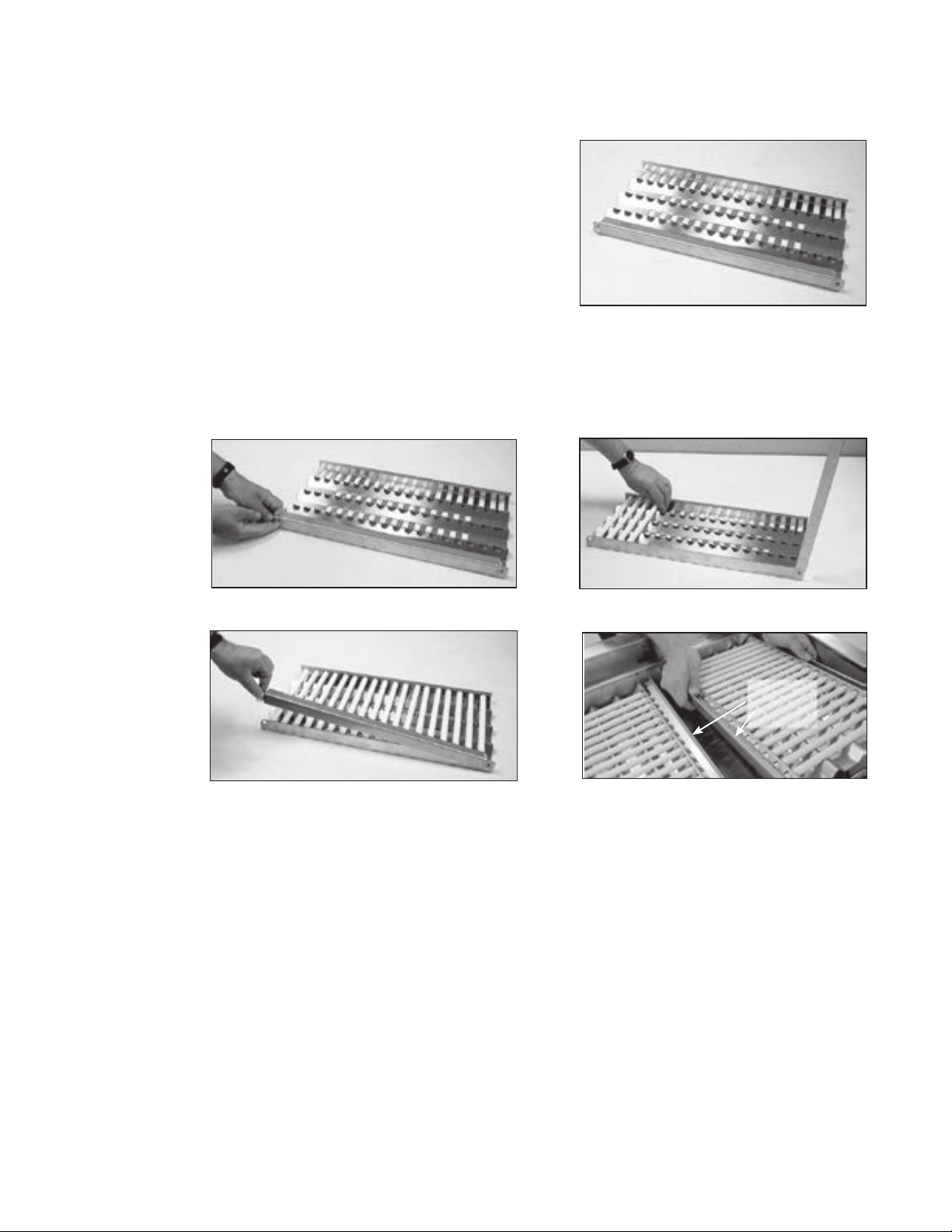

RADIANT ASSEMBLY INSTALLATION:

1.

Unpack ceramic rods and remove radiant (Fig.37) from the unit.

2.

Unlock radiant end cap by pushing it up with two fingers

(Fig. 38).

3.

Place 18 ceramic rods on the radiant (Fig. 39).

4.

Lock radiant end cap (Fig. 40).

5.

Place the assembled radiant in the unit (Fig. 41).

Fig. 37

IMPORTANT:

Placement of the trays in the grill are critical to ensure even cooking performance. Lock radiant end caps must be in

the middle of the grill. See Figure 41.

Fig. 38

Fig. 40

Fig. 39

Fig. 41

Note:

In case a ceramic rod breaks:

a) Unlock radiant end cap by pushing it up with two fingers (Fig. 38) or pliers may be used.

b) Replace broken ceramic rod.

c) Lock radiant end cap.

Radiant End

Caps

23

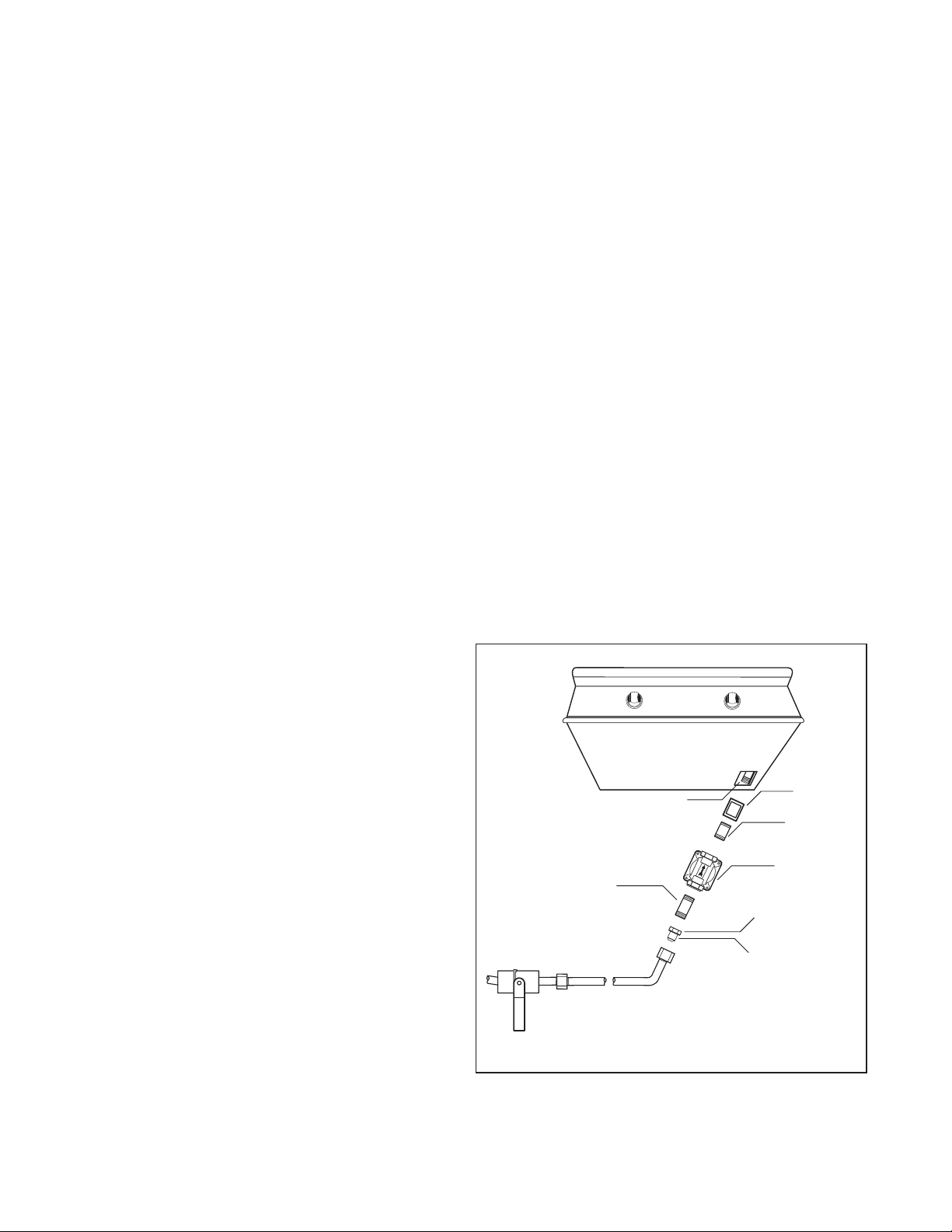

INSTALLATION

SINK

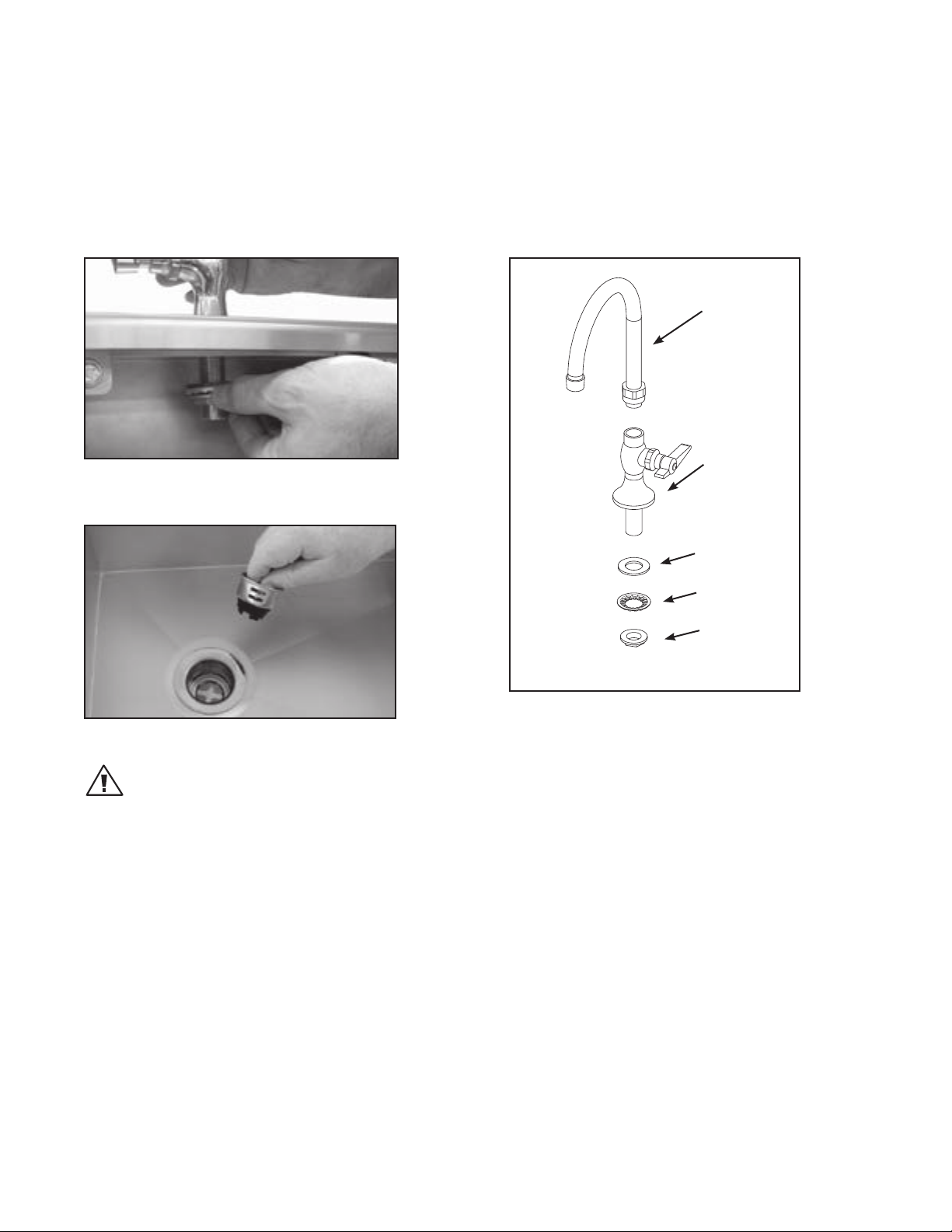

FAUCET INSTALLATION

1. Attach the faucet to the sink as shown in Fig. 42 and 42a.

CAUTION:

Finger tight first, then use a 1” wrench.

Fig. 42

2. Insert drain plug into the drain hole Fig. 43.

Faucet stem

Valve

Rubber gasket

Lock washer

Nut

Fig. 42a

Fig. 43

WARNING!

The sink is intended for hand washing and cleaning activities. The sink should not be used for potable water or food

preparation activities unless installed by a certified plumber and per local codes.

SINK INSTALLATION

Permanent Water/Drain Installation (Island Installation)

Use a certified plumber to connect and install water supply and drain system per local code requirements.

Make sure you have the drain connections in accordance with local codes.

Sink water inlet connection is 1/2 male NPS. .

Sink water drain connection is 1-1/2 male NPS.

Sink Water Installation on Cart CAD-30

An optional Sink Drain Accessory Kit Model #70855 is available from your local dealer.

1. Set the burner box securely on a table and attach (installer provided) water supply hose through the hole at the

bottom of the burner box, and attach it to the faucet using a wrench.

24

INSTALLATION

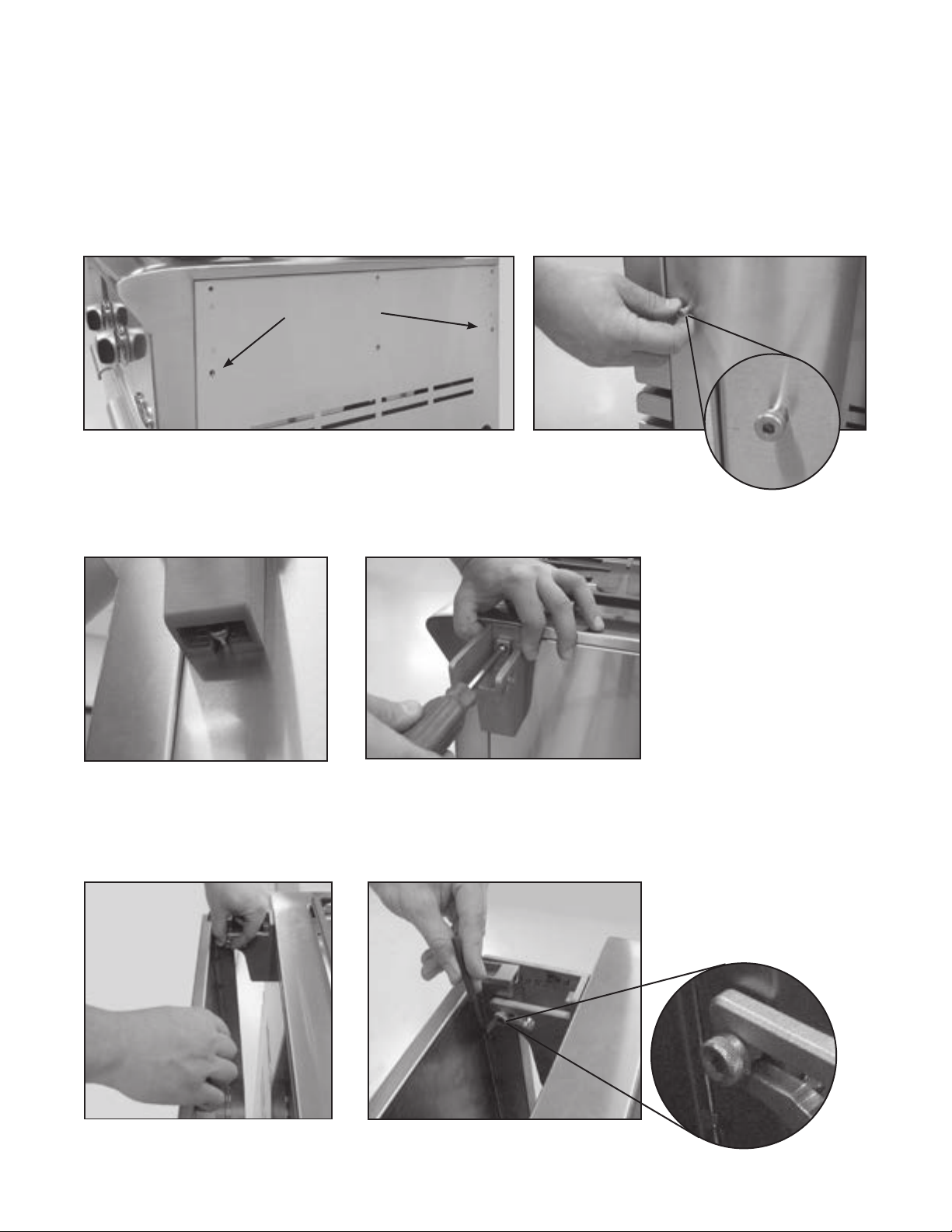

SIDE SHELF Optional accessory)

Attach Side Shelf Accessory on Either Side. Side shelf Model CAD-SK can be installed with the head already on

the cart.

1. Screw shoulder bolts (2) into the bottom screw holes on the side of the cart only (Fig. 44 and 45). Tighten with

5/32 Allen wrench.

SHOULDER BOLT

SCREW HOLES

Fig. 44

2. Slide left and right side shelf brackets over the shoulder bolt (Fig. 46) and install top screw attaching the side shelf

brackets onto the cart (Fig. 47). Tighten with Phillips screwdriver.

Fig. 46 Fig. 47

3. Holding the side shelf, install 2 shoulder bolts into the slot and screw into the side shelf tray (Fig. 48). Tighten

witha 3/16 Allen wrench (Fig. 49).

Fig. 45

Fig. 48

Fig. 49

25

Loading...

Loading...