Enatel Motive Power Ltd.

Technical

FS3, FS5 & FS9 Series Industrial Battery Charger

Version 3

Hardware

Manual

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors exempt. Pictures

may be representative, actual products may differ.

Page | 1

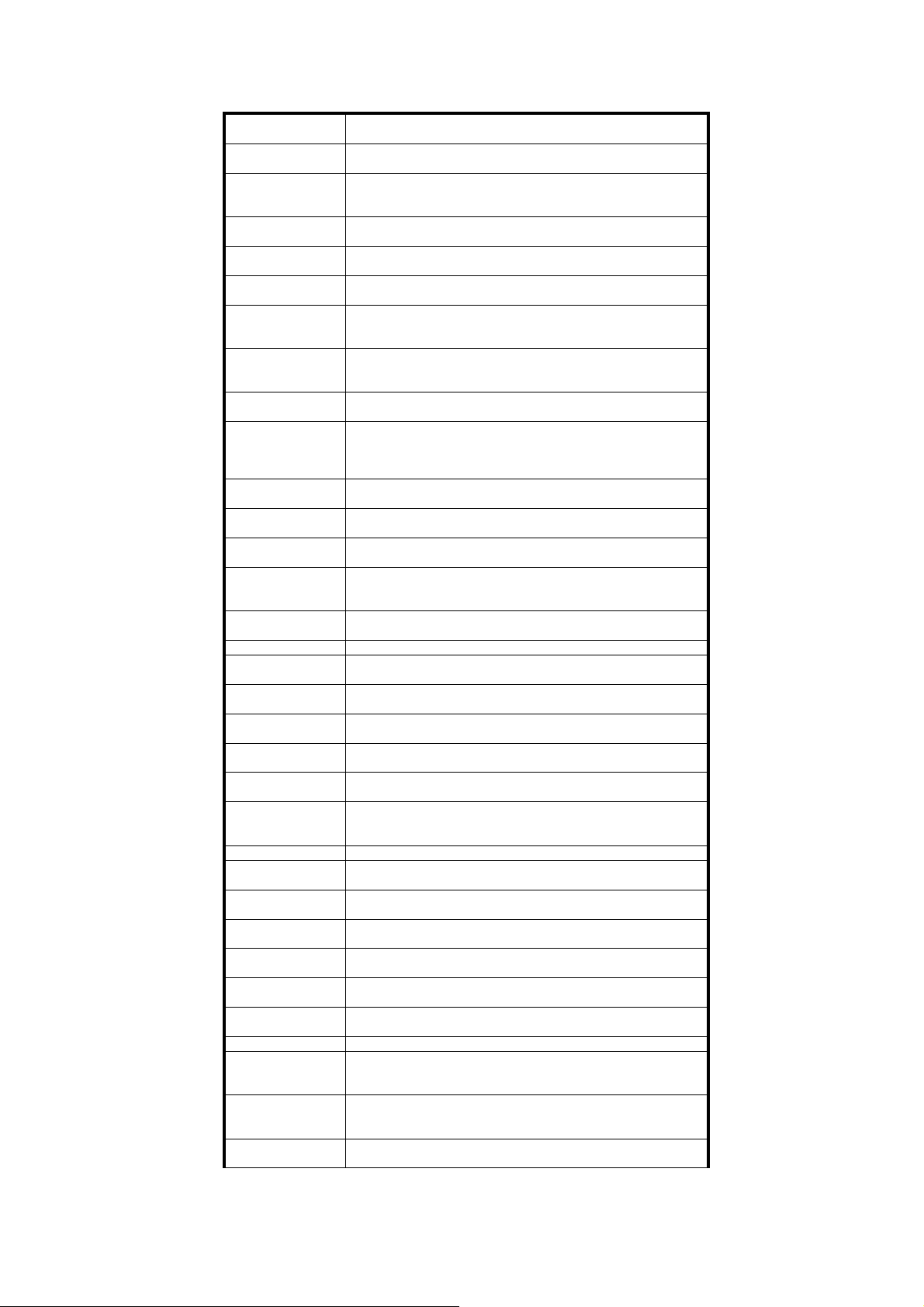

Table of Contents

1. Definition of Model Numbering ................................................................ 5

2. Introduction ............................................................................................... 6

3. Modular Charger Philosophy ................................................................... 7

Modular ........................................................................................ 7

Flexible ......................................................................................... 7

Redundancy ................................................................................. 7

4. Hardware Description ............................................................................... 8

Housing .................................................................................................... 8

FS3 ............................................................................................... 9

FS5, FS9 ...................................................................................... 9

Air Inlet Filter .......................................................................................... 10

AC Input Filter Board ............................................................................. 10

FS3LU, FS5, FS9 ....................................................................... 10

FS3LU only – Input Voltage Configuration ................................. 10

FS3xN, FS3xJ ............................................................................ 10

AC Input Terminal .................................................................................. 11

FS3xN, FS3xJ only ..................................................................... 11

Charger Module Earth and AC Supply .................................................. 11

FS3LU, FS5 & FS9 ..................................................................... 11

FS3xN ........................................................................................ 11

FS3xJ ......................................................................................... 12

DC Output Bus Bars .............................................................................. 13

FS5, FS9 .................................................................................... 13

DC Output Connector ............................................................................ 14

FS3 ............................................................................................. 14

FS9L ........................................................................................... 14

FS5, FS9H .................................................................................. 14

Auxiliary Power Supply Unit (PSU) ........................................................ 14

FS3 ............................................................................................. 14

FS5, FS9 .................................................................................... 14

Backplane .............................................................................................. 14

FS3 ............................................................................................. 14

FS5, FS9 .................................................................................... 14

MPC35 / MPC37 Charge Controller ...................................................... 16

Blank Panel – Module Bay .................................................................... 16

Blank Panel – FS5/9 DC Output Connector .......................................... 16

Mounting Bracket ................................................................................... 16

FS3 ............................................................................................. 17

FS5/9 .......................................................................................... 17

Charger Modules ................................................................................... 18

Module Types ............................................................................. 18

Charger Module Front Panel ...................................................... 18

Charger Module LED Combination States: ................................ 19

Module Installation and Removal ............................................... 19

Orientation for Installation .......................................................... 19

Module Removal ........................................................................ 19

Electrical Interconnection....................................................................... 20

FS3 ............................................................................................. 20

FS5 & FS9 .................................................................................. 20

Page | 2

MPC Controller Circuitry............................................................. 21

5. Hardware Configuration – FS3 ............................................................... 22

Introduction ............................................................................................ 22

FS3xU: AC Input & Bus Bar Connection ............................................... 22

AC Supply Configuration Table .................................................. 22

Field Wiring Connections ........................................................... 23

AC Input Configurations ............................................................. 24

FS3LN: AC Input Terminal Block Configuration .................................... 25

Single Phase (MP13x modules) ................................................. 25

Three Phase (MP33x and 3xMP13x modules) .......................... 25

FS3xJ: AC Input Terminal Block for Japan RST Mains Supply............. 25

Surge Protection of MP130 & MP133 modules ......................... 26

Earthed S-Phase Configuration ................................................. 26

Current Limiting ..................................................................................... 27

Relay Configuration for External Applications ....................................... 28

6. Hardware Configuration – FS5, FS9 ...................................................... 29

Field Wiring Connections ....................................................................... 29

AC Input Configuration .......................................................................... 29

7. Charger Display Interface ....................................................................... 30

Equalise Next Cycle Option ................................................................... 30

Service Menu ......................................................................................... 30

Service Mode ......................................................................................... 30

8. Alarm Functions ...................................................................................... 31

Charger Alarms ...................................................................................... 31

Charger Related Alarms ........................................................................ 31

Battery Related Alarms ......................................................................... 33

9. Self Test Process .................................................................................... 35

Introduction ............................................................................................ 35

Accessing Self Test ............................................................................... 35

Operating the Self Test Sequence ........................................................ 35

10. Maintenance, Service and Repair .......................................................... 37

Regular Maintenance ............................................................................. 37

Air Filter.................................................................................................. 37

Blown DC Fuse ...................................................................................... 37

Charger Module Fault ............................................................................ 37

Charger MPC Fault ................................................................................ 37

Backplane Replacement ........................................................................ 38

11. Troubleshooting ...................................................................................... 40

12. Spare Parts – Common to all models.................................................... 42

13. Spare Parts – FS3 Specific ..................................................................... 44

14. Spare Parts – FS5, FS9 Specific ............................................................ 46

15. Appendix .................................................................................................. 48

Interconnection – FS3LN/FS3HN .......................................................... 48

Interconnection – FS3LU/FS3H ............................................................. 49

AC Input Terminal Detail – FS3xN Standard ......................................... 50

AC Input Terminal Detail – FS3xJ (RST Mains) .................................... 51

Interconnection – FS5L/FS5H ............................................................... 52

Interconnection – FS9L/FS9H ............................................................... 53

Input Current by Output Current ............................................................ 54

Exploded Diagram – FS3LU .................................................................. 55

Exploded Diagram – FS5, FS9 .............................................................. 56

16. Glossary ................................................................................................... 57

Page | 3

Page | 4

1. Definition of Model Numbering

Model Number: eg. FS3LUV-532-US01

where

FS3 = Frame size, 3, 5 or 9 modules maximum

L = 24 – 65V DC output, H = 70 – 130V DC output

U = UL, N = Non-UL, J = Japan

V = branding: V=VForce, E=EcoCharge, H=Hawker

5 = Controller MPC35, 7 = MPC37

3 = module type, 1=MP130, 2=MP133, 3=MP330,

4=MP333

2 = number of modules fitted

US01 = internal manufacturer designation

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2. Introduction

This manual provides comprehensive technical information about all

aspects of the FSx series charger. It is intended for use by

technically skilled individuals responsible for second level support of

the chargers. It contains considerably more information than

required for a first level field service technician.

Distribution of this manual is to be restricted as the information

contained is not suitable for individuals who do not already have

some knowledge of the correct method to charge forklift batteries.

This information is commercial in confidence and is not to be

distributed to a third party without the express permission of Enatel

Motive Power.

An Operator/Installer manual is available for each charger and is

suitable for distribution to a wider audience.

A software manual is also available covering use of the Charger

Interface software to configure, troubleshoot and customize

operation of the FSx series charger.

It is expected that an individual responsible for the support of the

FSx series chargers will read and understand both the hardware

manual and the companion software manual.

Page | 6

3. Modular Charger Philosophy

The modular charger concept represents a fundamentally different

approach to the way in which a forklift battery charger is designed.

Historically battery chargers have been designed to match a

specific battery type and rating. These uncontrolled chargers need

to be very closely matched to the intended battery. Due to the large

number of combinations of voltage, amp-hours, cell type and

recharge times, this results in a wide range of charger models being

required.

Modular

The modular charger is based on the deployment of paralleled, high

frequency charger modules with microprocessor oversight

controlling the charge parameters. Modules can be easily added or

removed as required and the controller is configured via PC

software to set the charger’s particular rating.

Flexible

The modular charger series is capable of charging batteries of any

nominal voltage in the range of 24V - 80V and offer the choice to

operate on AC supply ranges of 208V single phase through to 480V

three phase. The modules can be paralleled to a maximum of three,

five or nine depending on the charger model.

Redundancy

Using parallel-connected charger modules also introduces the

capability to offer redundancy, which is a unique and desirable

feature for a forklift battery charger. Redundancy offers the

capability to complete a charge with backup modules should an

issue arise, albeit at a slower rate

Page | 7

4. Hardware Description

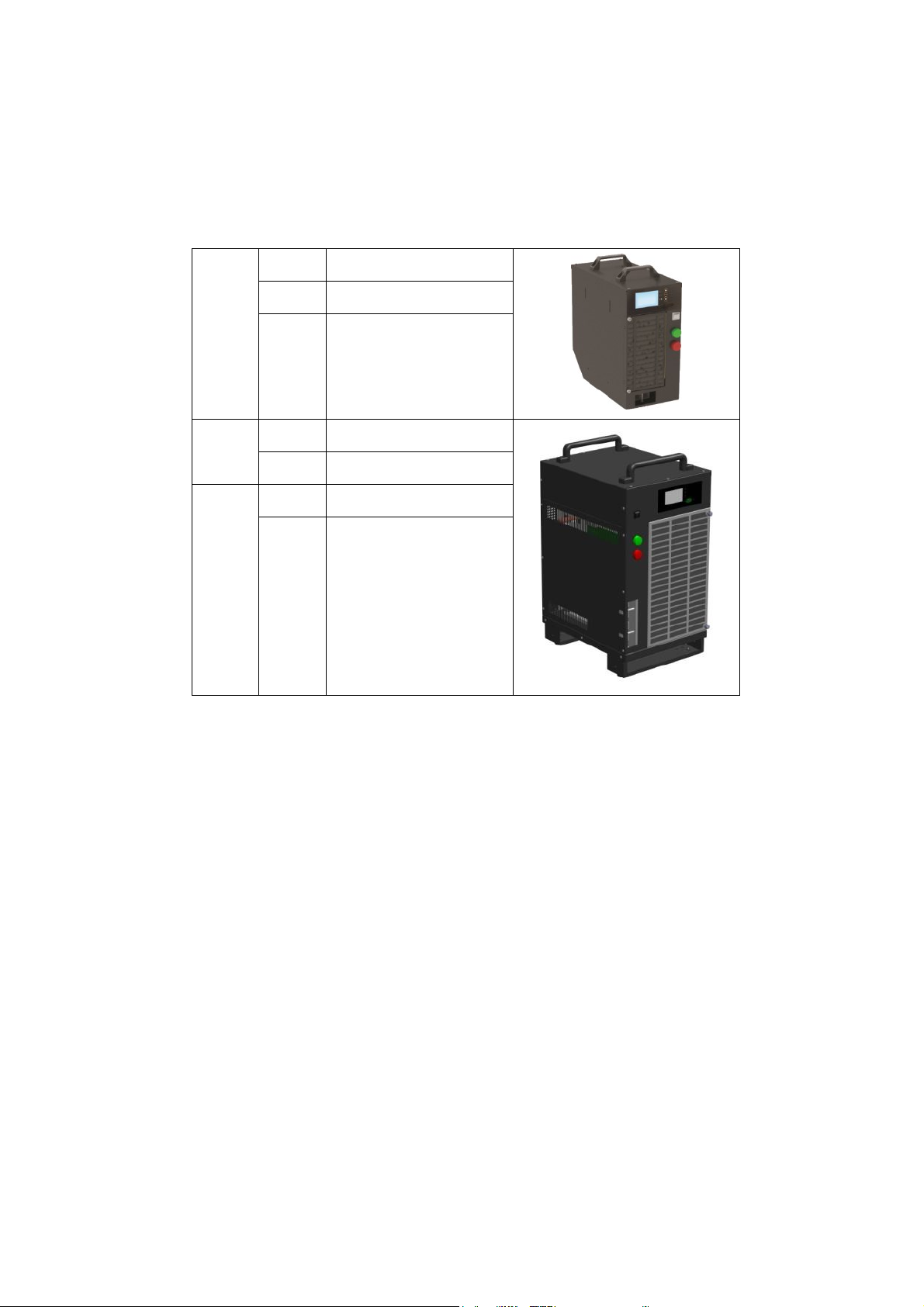

FS3

FS3LU

Low voltage, UL Listed

FS3LN

Low voltage, Non-UL

FS3HN

High voltage, Non-UL

FS5

FS5LU

Low voltage, UL Listed

FS5HN

High voltage, Non-UL

FS9

FS9LU

Low voltage, UL Listed

FS9HN

High voltage, Non-UL

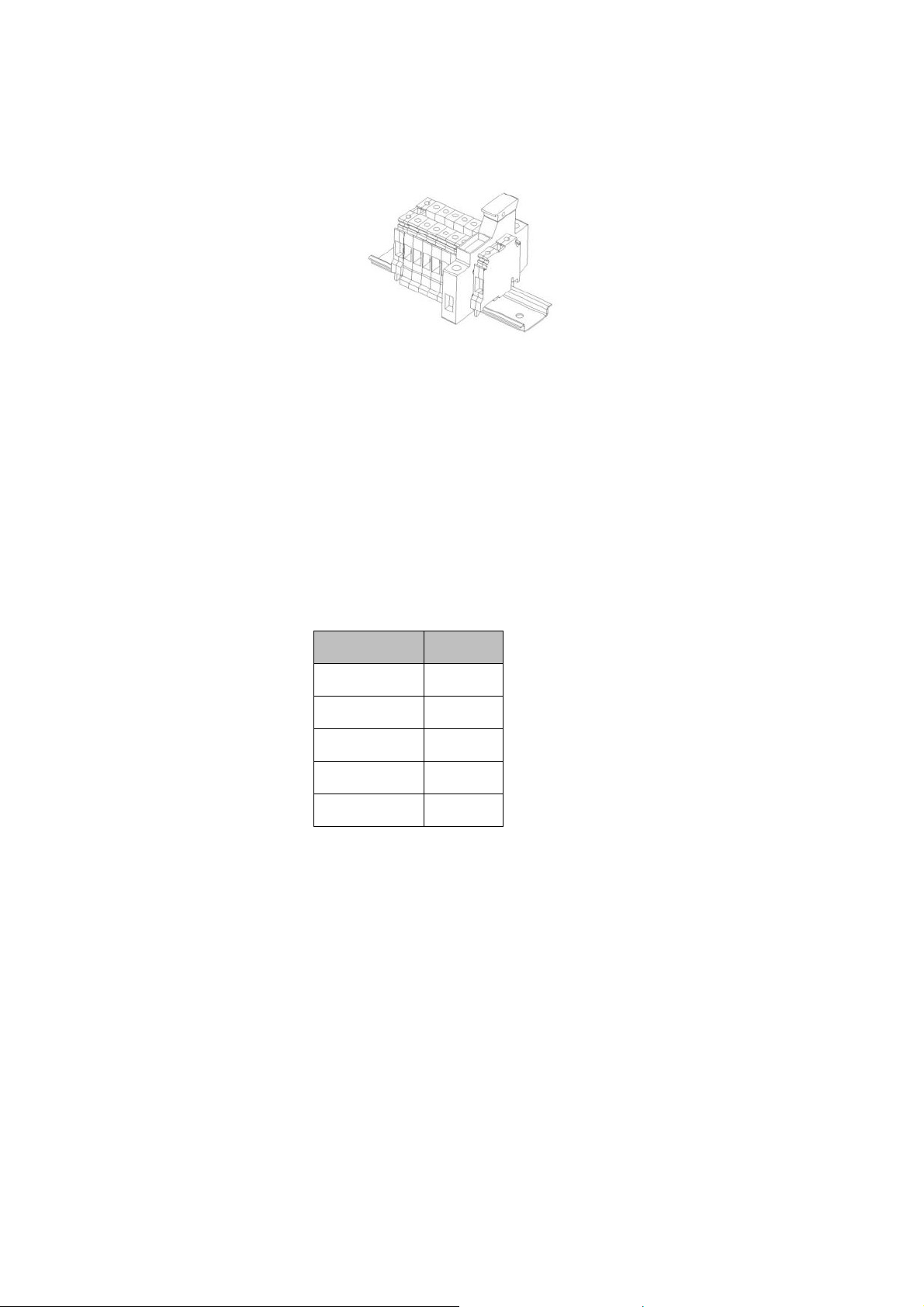

Three base models make up the FSx modular charger series. For

each of the FS3, FS5 and FS9, a low and high output voltage model

cover the battery voltage range. Logical model name modifiers

allow differentiation, shown in the table below.

The FS5 and FS9 utilize a common larger chassis - only internal

components differ between the two - while the FS3 takes a more

compact form, suited to single-person handling.

The principal components of the FSx series comprise a number of

paralleled charger modules each monitored and controlled by a

system level microprocessor. The charger output characteristics are

controlled depending on the charge requirements, battery type and

state of charge.

The following sections describe the primary and auxiliary

components of the FSx series, including where relevant, detail on

model-specific features.

Housing

The FSx charger housings are 1.2 mm electro galvanized and

powder coated steel. An internal chassis provides support for

charger modules as well as primary and auxiliary circuitry. The

housing front contains the charger display, status LEDs, pushbuttons, and air filter assembly.

Access to internal charger circuitry for service is gained by

removing exterior panels.

Note: Before exterior housing panels are removed the charger

must be isolated from both the AC supply and battery.

Page | 8

FS3

The front of the FS3 housing takes up to three charger modules in

a vertical, side-by-side orientation. Top and side covers allow

access to the main serviceable internal areas of the FS3,

removable in that order.

FS5, FS9

These models share a common frame and external housing, the 5/9

designation is determined by internal hardware and circuitry with

the FS5 and FS9 supporting an operating maximum of five and nine

modules respectively.

Access to the module bays is via the air filter assembly on the front

face of the housing. Installed in the module bays, each charger

module is supported in a horizontal orientation by the internal

chassis.

The FS5 and some FS9 models require a single rather than double

DC output connectors. These models are fitted with a steel blanking

plate in place of the DC connector location.

Page | 9

Air Inlet Filter

A stainless steel grille incorporating an electrostatic particulate air

filter ensures cooling air drawn through the charger modules is free

of dust and particulate matter.

The filter assembly is fastened to the front of the housing with

thumbscrews.

The Maintenance section of this document covers the air filter

cleaning procedure.

AC Input Filter Board

FS3LU, FS5, FS9

The AC Filter Board distributes AC supply to the modules and

auxiliary power supply while providing protection to these

components from surges in the supply voltage.

AC input cables are terminated onto the AC filter board input

terminal via a five way terminal strip.

FS3LU only – Input Voltage Configuration

Configuration possible for single and three phase, 208V-480V

supplies. Configurable bus bars provide AC input type selection and

two headers allow either 240V or 480V connection to the auxiliary

power supply.

FS3xN, FS3xJ

See AC Input Terminal

Page | 10

AC Input Terminal

Colour

Notation

Red

L1

White

L2

Blue

L3

Black*

N*

Yellow/Green

E

FS3xN, FS3xJ only

FS3 chargers not fitted with an AC input filter board instead utilize

an input terminal block providing AC supply to the charger modules

and the auxiliary power supply via their respective looms.

The terminal block is configurable for single and three phase supply

via jumpers fitted to the terminal block. Refer to the Hardware

Configuration section for details on terminal block configuration.

Charger Module Earth and AC Supply

AC is delivered to the backplane via the AC Loom consisting of

2.5mm² cable for each phase and neutral*.

*FS3 option only

FS3LU, FS5 & FS9

Earth connections are grouped together, bolted to the chassis and

fed to the charger modules via the AC Loom. The chassis is

connected to the mains earth via a ground trace on the AC Filter

Board PCB, where a mounting screw provides connection.

FS3xN

Earth connections are grouped together, bolted to the chassis and

fed to the charger modules via the AC Loom. The chassis is

connected to the mains earth via 2.5mm² cable to the Input

Terminal earth block. See

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

FS3xJ

The FS3LJ and FS3HJ models are earthed the same as the FS3xN,

however, some models (Toyota specific) wired for Japan’s RST

mains feature an earthed S-Phase at the AC Input Terminal Block.

See the Appendix for wiring diagrams.

Page | 12

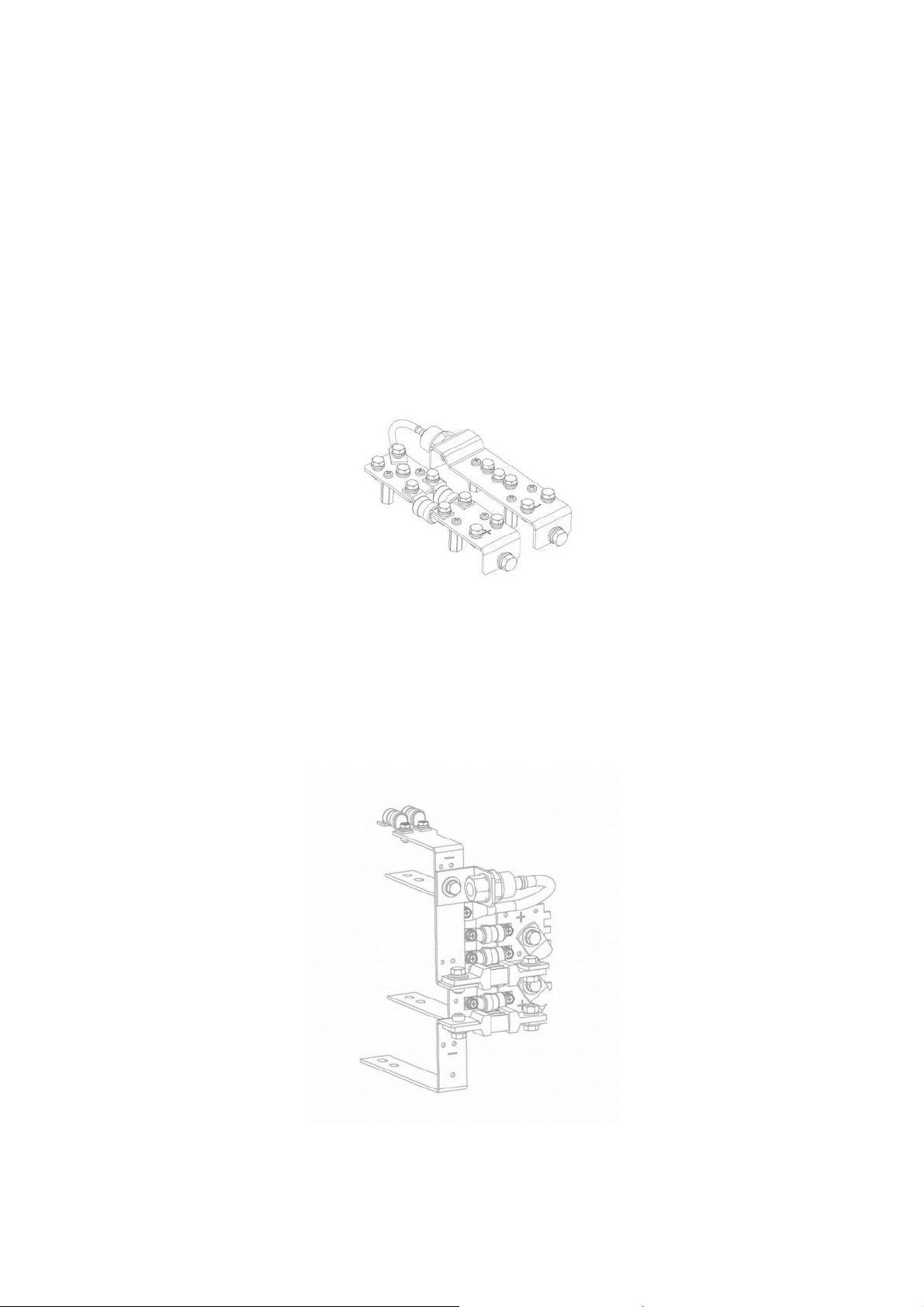

DC Output Bus Bars

The DC output bus bars are solid copper bars mounted inside the

charger on the internal chassis frame. The bus bars provide DC

connectivity from the backplane to the output connector(s) at the

front of the charger.

Mounted on the bars are several key components of the charger

self-protection features. In all models, a crowbar diode and high

current fuses provide protection for the charger modules in the

event that a reverse polarity battery is connected to the charger.

Fuse status is monitored by the MPC controller using voltage sense

looms attached to the bus bars either side of the fuses.

FS3

FS5, FS9

Calibrated current shunts fitted to the output circuit allow

accurate current measurement at high amperages. These

shunts are fitted with voltage sense looms monitored by the

MPC controller.

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

DC Output Connector

The DC output connector fitted to the FSx series is a high current

SB350 connector designed for low resistance connections.

FS3

A single SB350 connector mounted horizontally. Special

applications may require an SB175 connector fitted in place of the

SB350.

FS9L

Frame allows for two connectors to manage large output currents.

FS5, FS9H

A single DC output connector is fitted.

All models provide for fixing of the connecting battery cable by way

of the supplied threaded screws fastened through the cable

connector into the internal chassis.

Auxiliary Power Supply Unit (PSU)

The FSx series chargers contain a power supply unit to provide a

DC supply to the charger controller. A feed from this supply also

holds the charger modules in a default “standby” state, ready to

commence charging.

FS3

The auxiliary PSU is integrated into the backplane PCB and can be

configured at the AC filter board (UL models) or Input Terminal

block (Standard models) for 208VAC or 480VAC input voltages.

The FS3 PSU outputs a nominal 24VDC.

FS5, FS9

The auxiliary PSU is located on a dedicated PCB assembly

mounted on the side of the internal chassis frame above the

controller and bus bars.

The FS5-9 PSU provides a regulated 54VDC output from a 480VAC

supply.

Backplane

At the rear of the FSx housing is the backplane PCB providing

connectivity to the charger modules. The backplane features a

multi-pin connector in each supported module bay for connection

with an installed charger module. The connector passes AC from

the AC Loom and DC output into the backplane. The connectors

also contain a pin for communications between the modules and

the MPC controller.

FS3

The backplane also incorporates the auxiliary PSU circuitry and

three module connectors.

FS5, FS9

Backplanes each support five and nine module connectors

respectively.

Page | 14

Page | 15

MPC35

MPC37

Operating Voltage

12-65VDC

65-150VDC

Module Compatibility

MP130/MP330

MP133/MP333

MPC35 / MPC37 Charge Controller

The MPC controller provides the monitoring and control functions of

the charger.

Operating on a 12-65VDC supply, the MPC35 controls the low

voltage MP130 & MP330 range of modules while the MPC37

operates at 65-150VDC controlling the high voltage MP133 &

MP333 modules.

The MPC allows the charger to be configured easily to charge

different battery types. The MPC can also be set to automatically

reconfigure when connected to a battery fitted with a battery module

(Automatic Profile Configuration – APC).

The MPC also features configurable relays for operation of optional

accessories such as battery auto-watering systems.

The MPC indicates the charger configuration and status on an LCD

display, LED status lights, push button controls and a mini-USB port

located on the front panel of the charger.

Blank Panel – Module Bay

Unused charger module positions should be fitted with a blank

panel fixed to the housing metalwork. The blank panel prevents

high temperature exhaust air recirculating inside the charger

enclosure to the module air intake, ensuring the modules receive

cool externally-sourced air.

To fasten to the chassis, two self-tapping screws are required per

blank panel.

Blank Panel – FS5/9 DC Output Connector

The FS5-9 Output Blank Panel covers the lower output connector

opening in models where a second connector is not fitted.

The blank panel is fastened to the charger chassis with two M5

captured washer hex-head bolts.

Mounting Bracket

The charger mounting bracket enables the charger to be secured at

an elevated position and is recommended to protect the charger

against accidental physical damage from vehicles or other hazards.

Bracket fasteners should be appropriate for the wall construction

and material, and the wall should be capable of supporting the

weight of the charger.

Page | 16

FS3

The optional FS3 mounting bracket allows the charger to be fixed to

a surface via the base, rear or left side.

The bracket can be mounted to an appropriate surface suitable for

the particular configuration of the charger.

An FS3 with three modules can weigh up to 21kg.

The charger incorporates two slots for locating the bracket and two

captured thumbscrews then secure the charger to the bracket.

FS5/9

The FS5/9 wall mounting bracket requires eight fasteners to secure

it to the supporting wall.

An FS9 with nine modules can weigh up to 90kg.

The charger can be positioned on and fixed to the bracket using M5

machine screws fastening into the charger base frame. The same

base mounting points may be used for a standard shelf, rack or

table-top. The base mounting measurements are as follows:

FS5-9 base screw spacing (mm, c-c): 333W x 275D

Page | 17

Charger Modules

Low Voltage Output

High Voltage Output

MP130

MP330

MP133

MP333

Supply

Phase

Single or 3

Phase

3 Phase only

Single or 3

Phase

3 Phase only

Input Voltage

Range

208 - 240

380 - 480

208 - 240

380 - 480

Output

Voltage

Range

25 - 65

70 - 143

Nominal

Battery

Voltages

24 / 36 / 48

72 / 80

Faceplate

Color

Yellow/Black

Green

Blue/Black

Blue/Green

Charger

Compatibility

FS3L

FS3L, FS5L,

FS9L

FS3H

FS3H, FS5H,

FS9H

RED

AMBER

GREEN

No Output

Current Limit

Charging

The primary function of the charger modules is to rectify AC mains

into DC suitable for battery charging.

Module Types

There are four module types available depending on the input and

output requirements of the charger. The module variants are

detailed in the table below.

Charger Module Front Panel

Charger modules have a front panel with three LEDs to indicate

their basic operating state. The charger front panel display and LED

indicators typically provide any charger status information, however

the charger module LEDs are useful for understanding and

troubleshooting charger issues.

The module front panel LED indicators are as follows:

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

Charger Module LED Combination States:

Charger State

LED State

AC Power OFF

Battery Disconnected

No LEDs illuminated

AC Power ON

Battery Disconnected

No LEDs illuminated

AC Power ON

Battery Connected

Red LEDs illuminated

AC Power OFF

Battery Connected

Red LEDs illuminated

Charge Cycle Stage:

Constant Current

Green & amber LEDs illuminated

Charge Cycle Stage:

Constant Voltage

Green LEDs illuminated

Charge complete

Battery connected

Red LEDs illuminated

NOTE: Charger alarm indicators are reset if the battery is

disconnected.

Module Installation and Removal

Ensure the charger is removed from AC supply before

installing or removing modules.

Modules are installed through the front of the charger housing. The

air filter assembly must first be removed to gain access to the

module bays.

Only a small amount of force is required to have the module

connect with the charger backplane. Once the module is fully

inserted, engage the locking tabs at each side of the module front

panel. A module removal tool is available combining the module

locking and removal requirements into one tool. A small pair of

needle-nosed pliers is a good alternative.

Orientation for Installation

It is important the module orientation be correct before installing a

module.

FS5, FS9

The module must be oriented horizontally with the front panel type

identification up-right and readable.

FS3

The modules must be installed vertically so that the rear blue

connector is at the top.

Module Removal

To remove a module, first unlock the green locking tabs and, using

either the module removal tool or needle-nosed pliers on the

module grille, draw the module forward from the housing.

Page | 19

Electrical Interconnection

FS3

The FS3 electrical interconnection differs at the AC input stage of

the charger depending on the model. UL listed models feature the

AC Filter Board, while the standard non-UL models distribute AC

via a terminal block.

Aside from the AC supply filtering and distribution, the two variants

share the same internal circuitry.

FS5 & FS9 AC Filter Boards are non-configurable.

FS3xU AC Input: AC Filter Board - UL models only

Each phase of the AC input supply is connected to the charger

module bays via the AC Filter board, the AC Loom and a connector

on the backplane. Incoming earth is connected to the internal

chassis via a mounting screw on the AC Filter board.

The FS3 AC Filter board allows for re-configuration of the incoming

phases to allow for a number of AC input types, explained in detail

in the Hardware Configuration section.

The auxiliary power supply is connected via the AC Loom from

either J5 or J6 on the AC Filter board depending on the mains

supply configuration of the charger.

FS3xN, FS3xJ AC Input: Input Terminal Block –

Standard models only

Non-UL models distribute the AC phase and neutral to each of the

three module bays via a din rail mounted terminal block. The Input

Terminal Block also provides an AC supply to the Auxiliary Power

Supply Unit. Jumpers are required to be fitted correctly depending

on the AC supply type. See the Hardware Configuration section.

Incoming earth is tied to the earth stud on the internal chassis.

FS3 DC Output Circuitry: All Models

Individual DC outputs from each charger module are connected in

parallel with 9 mm² cables to the output bus bars. Fuses and a

crowbar diode mounted on the bus bar assembly provide reverse

polarity protection. Two voltage-sensing PCBs fitted either side of

the fuses enable the MPC to determine if the fuses are blown.

The final internal connections to the SB350 output connector are via

short lengths of 50 mm² cable.

FS5 & FS9

The FS5/9 input circuitry consists of a non-configurable AC Filter

board distributing each AC phase via dedicated looms to each of

the backplane and auxiliary power supply. No neutral is supplied to

the backplane.

Incoming earth is connected to the internal chassis via a mounting

screw on the AC Filter board ground plane, and the backplane loom

earth wires are all tied to a stud on the internal chassis.

DC output circuitry consists of copper bus bars carrying DC current

via fuses, current shunts and 70mm2 cable to the output

connector(s). Models with output capability exceeding 300A utilize

parallel output circuits terminating with two output connectors.

Fuses fitted in-line with the bus bars are each 180A and provide

reverse polarity protection with a 300A crowbar diode fitted across

the output.

Page | 20

Up to two copper current measuring shunts are fitted in the DC

output line, with current sense PCBs fitted to each shunt to allow

sensing by the MPC.

FS5 and FS9H models: single bus bar, current shunt and DC

output connector.

FS9L models: dual bus bars, current shunts and DC output

connectors.

The FS5/9 Auxiliary PSU provides a nominal 54VDC. This is

supplied to the backplane via J4 enabling module-MPC

communications, and from J8 on the backplane via an RJ45 cable,

providing a power supply to the MPC.

MPC Controller Circuitry

With the exception of current sensing in FS5 & 9 models, chargerMPC interconnections are fundamentally the same for all models of

MPC and charger.

The MPC has a number of connections on the main board to allow

control and monitoring functions. Digital signals to and from the

charger modules are via the RJ45 cable connected at J101.

Charger module shutdown control (RSD) is also via the RJ45

communications cable.

The Auxiliary power supply is fed to the MPC from the backplane

via J102 and J109. The large front panel mounted LEDs are

connected to J109 and the rocker switch input signals to J102.

A 10-way ribbon cable provides connectivity for the charger front

panel display, LEDs and push buttons, as well as USB

communications with a connected PC.

A communications transformer is fitted to the output circuit of the

FSx range and connects to J103, allowing communication with a

battery module (if fitted).

The MPC also features six available relay contacts to provide

switching for external functions such as auto watering systems.

Page | 21

5. Hardware Configuration – FS3

Headers for aux power supply

voltage selection. 240V – J5

480V – J6

Mounting posts for mains-select

bus bars

208-240V single phase

208-240V three phase

480V three phase

Introduction

The FS3 can be configured for a number of different AC supply

voltages and phase configurations.

FS3 UL models (FS3xU) feature an AC Input PCB with

configurable link bars for various supply phases and

voltages.

Standard FS3 models (FS3xN) are configured with

jumper bars fitted to the AC input terminal block.

FS3xU: AC Input & Bus Bar Connection

Before AC is connected, the AC-select bus bars and auxiliary PSU

supply must be configured for the type of AC supply to be

connected.

Bus Bar Options

Unused bars are bolted to the internal chassis near the AC input

field wiring terminal inside the FS3 frame.

Bus bar screws should be torqued to 21in-lb (2.4 N.m) minimum.

AC Supply Configuration Table

The table below provides AC-configuration options for the various

AC supply and module configurations.

Page | 22

* In single phase mode the output power will reduce

L1 L2 L3 Neutral Earth

to maintain maximum AC current draw.

** In three phase mode the adding of the third

charger module reduces the AC current draw to

achieve the same DC output as for two modules.

Field Wiring Connections

Field wiring connections should be made by a qualified

electrician.

A field wiring terminal strip on the input side of the AC Filter PCB

allows the connection of AC supply wiring to the unit.

Access into the frame should be gained through one of three

knockouts in the rear panel.

A minimum of 2.5mm² multi strand cable per connection

should be used and cable-tied to the strain relief mount

provided.

Wiring color should conform to standard practice for the

region of installation.

Page | 23

AC Input Configurations

The figures below show common industrial AC supply types and the

appropriate wire connections to the input terminal strip.

Should connection to another type of supply be required, contact

the local distributor before connecting.

Note: It is common in the US that a fourth wire (neutral) be used in

a three phase circuit. If present, it should be attached to the “E”

(ground) terminal.

Page | 24

FS3LN: AC Input Terminal Block Configuration

2-pole jumper location

3-pole jumper location

2-pole jumper location

Standard FS3 models may be configured for single or three phase

input, depending on the type and number of charger modules

installed.

Single Phase (MP13x modules)

One 3-pole jumper and one 2-pole jumper required, fitted as shown.

Alternatively, two 2-pole jumpers may be used in place of the 3pole.

Three Phase (MP33x and 3xMP13x modules)

One 2-pole jumper required, fitted as shown:

FS3xJ: AC Input Terminal Block for Japan RST

Mains Supply

The RST configuration does not require jumpers. Input wiring colour

standards vary across Japan, therefore input wiring colours shown

are indication only. See below for important surge protection

information for MP130 and MP133 modules.

Page | 25

Surge Protection of MP130 & MP133 modules

Models fitted with 2 or more MP130 or MP133 charger modules

must be fitted with MOVs across phases as follows:

3 modules: 625VAC MOV fitted across S&T and T&R.

2 modules: 625VAC MOV fitted across S&T.

1 module: No MOV required.

MOVs may be fitted to the terminal blocks in conjunction with the

backplane loom wiring. MOV legs must be sufficient to

Earthed S-Phase Configuration

Some RST models required Earthed S phase, where an addition

earth link is made from the E terminal to the input S terminal.

Page | 26

Current Limiting

J119 and J120

current limiting

jumpers on the

MPC35

Default setting

A current limit may be required where the mains supply or input

cable has reduced current capacity. Jumpers on the MPC controller

enable the limiting of input current drawn by the charger.

A charger with current limit applied causes the Charger Interface

software to reject any configuration requiring more current than the

set limit. The software will alert the operator to any configuration

exceeding the current limit during the Charger Interface charger

configuration stage.

A position combination of jumpers J119 and J120 will limit the input

current to 10A,15A or 30A depending on the current limit

requirements.

Page | 27

Relay Configuration for External Applications

Relay

Function

Notes

1

Charge

complete

BSI option must be enabled in

Controller Settings

2

Auto Watering

Auto Watering must be enabled in

Configuration tab

3

Charge Active

BSI option must be enabled in

Controller Settings

4

Alarm 1

Relay Alarm mode must be enabled in

Controller Settings

5

Alarm 2

Relay Alarm mode must be enabled in

Controller Settings

The on-board relays fitted to the MPC controller allow control of

external devices such as lights, indicators or Auto Watering.

Jumpers for each relay allow setting of the default state, NO

(Normally Open) or NC (Normally Closed).

Page | 28

6. Hardware Configuration – FS5,

FS9

The FS5 and FS9 require connection to a three phase 480V AC

supply.

AC supply wiring should meet or exceed the current draw

requirements of the specific charger model. See the rating label on

the charger for the input current requirements.

Field Wiring Connections

Field wiring connections should be made by a qualified

electrician.

A field wiring terminal strip on the input side of the AC Filter PCB

allows the connection of AC supply wiring to the unit. Access into

the frame should be gained through one of the two knockouts in the

rear panel.

Provision for securing the input cable jacket to the chassis with a

cable tie is located near the cable entry point.

Wiring color should conform to standard practice for the region of

installation.

FS5: Copper conductors required.

FS9: Copper conductors rated 75°C minimum required.

AC Input Configuration

Configuration No. 4 – 480V Three Phase

Note: It is common in the US that a fourth wire (neutral) be used in

a three phase circuit. If present, it should be attached to the “E”

(ground) terminal.

Page | 29

7. Charger Display Interface

By default the charger display provides the basic charge profile

information and charger firmware version. The top of the display

indicates the current status of the charger.

Equalise Next Cycle Option

From the default menu, pressing either the

arrow buttons shows the Eq. Next Cycle

option to have the charger perform an equalize

charge following the next successful charge

completion.

Press Enter to adjust the option, use the arrow

buttons to select Enabled. The option will

reset to Disabled once an equalize charge is

achieved.

Service Menu

A service menu can be accessed by holding down together up and

down buttons on the charger front panel for a minimum of 16

seconds. The top of the display shows the first item in the Service

Menu: “Service Mode”.

The following items are available from the Service Menu:

Service Mode Allows the charger to operate at a

specified voltage current and duration.

Self-Test Executes a self-test of the charger’s

internal and external components.

Requires user input when prompted to

advance through each step.

Relay Test Manually activate each of the 6 relays on

the MPC mainboard.

APC Mode Enable or disable the charger to use

Automatic Profile Configuration when

connected to a battery fitted with a

battery module.

Desulphation Advanced battery service option. When

enabled the charger will perform a

desulphation service charge on a battery if

the voltage is measured to be below

1.5V/cell.

Service Mode

To access Service Mode from the Service Menu, press the Enter

button. Within the Service Mode menu, use the up or down buttons

to specify current, voltage and duration. Within each menu press

Enter to select the value, up or down to change the value. Press

Enter again and choose “Store” to save the value.

Page | 30

8. Alarm Functions

The FSx series charger includes comprehensive fault protection

and alarm monitoring. Charger alarms are graded into urgent and

non-urgent alarms.

Urgent alarms indicate a serious condition, and the charger

will stop the charge cycle.

Non-urgent alarms are indicated on the front panel and

recorded in the alarm log, but will not interrupt a charge cycle.

Non-urgent alarms can be expected to occur from time to time due

to the varying charge characteristics of batteries. Should non-urgent

alarms consistently arise, further investigation should be made.

If an urgent alarm occurs mid-charge cycle the charger stops,

illuminates the red Alarm LED on the front panel display and

indicates an urgent alarm event by alternating both large green and

red LED lamps.

If a non-urgent alarm occurs mid-charge cycle amber Alarm LED on

the front panel display illuminates and the large red LED lamp

flashes.

In both cases the alarm is logged into the memory of the MPC in

the form of an alarm log that can be downloaded at a later date to

aid fault diagnosis. In the PC application the relevant alarm name

highlight changes from green to red.

Charger Alarms

Charger Related Alarms

Main Switch - Urgent

Shows the status of the front panel start/stop toggle switch.

Inlet Filter - Non-urgent

Provides a warning as to when the inlet filter needs

servicing. Not enabled by default.

Low Mains - Non-urgent

Gives an indication of variation in the input mains voltage

without actually affecting the ability of the charger to provide

rated output. Can also indicate that a charger module is

being overloaded.

Mains Fail – Urgent

A mains loss situation and the charge cannot proceed.

Non-Urgent Rectifier Fail - Non-urgent

Page | 31

Charger is still operating but a charger module is not

providing output. Redundancy has been lost and reduced

power output and longer charge time will result.

Urgent Rectifier Fail – Urgent

If the number of charger modules not providing output

equals or exceeds the setting for urgent module count in

the PC application monitor tab then the charger will stop. If

the urgent module count is set to one then the charger is

configured without redundancy and a single fault will stop

the charge.

Rectifier Over Temperature – Urgent

Normally related to a blocked filter, restricted exhaust air or

installation in an inappropriate location.

Configuration Error - Urgent

The charger cannot meet the target current required by the

controller even with all fitted charger modules operating.

The configuration does not meet the limits set for a 10A or

15A mains input hardware limited charger.

Output Fuse - Urgent

A blown fuse in nearly all cases is caused by connecting a

reverse polarity battery to the charger. When a fuse is

blown check all cells for a reversed cable connection, a

common problem with first charge of shift batteries that

have not been previously tested in a lift truck. After

replacing a battery or charger cable always check the

polarity before plugging the battery into the charger.

No Output Current – Urgent

The charger is not providing the expected output current.

Generally related to a premature disconnection of the

battery, but also could be an incorrectly inserted charger

module.

Monitor ADC Fail - Urgent

The internal watchdog of the MPC micro-controller is

indicating a major fault and potential unpredictable behavior

if the charger is left running.

APC Communications Fail - Urgent

The battery module has failed to communicate with the

charger.

APC Incorrect Voltage - Urgent

The charger cannot produce the voltage required by the

battery module.

APC Unknown Charger - Urgent

The charger cannot find the required profile required by

battery module.

APC Water Level Low - Non-Urgent

For battery module equipped batteries, indicates the

electrolyte sensor has detected a low level of electrolyte.

APC Voltage Imbalance - Non-Urgent

Page | 32

For battery module equipped batteries, indicates the

midpoint voltage varies from nominal by more than 0.5V.

Battery module will schedule an equalize charge to rectify

this variation.

Battery Related Alarms

Over Discharged Battery - Urgent

The battery is still under 1.9Vpc after 30 seconds of charge

and indicates a faulty battery that needs investigation.

Deeply Discharge Battery - Non-urgent

The battery initially is under 1.9Vpc but recovers within 30

seconds of the charge cycle start, this alarm normally

comes up when a battery is unplugged from the lift truck

and immediately plugged into the charger.

Sulphated Battery – Urgent

The battery fails to complete a de-sulphation profile applied

by the charger correctly and generally means that the

battery requires attention.

Incorrect Battery - Urgent

The battery is inappropriate for the configuration of the

charger and cannot be charged without reconfiguring the

charger to suit the battery.

Bulk Charge Timeout - Urgent

The battery has exceeded the maximum time allowed for

the initial constant current bulk charge phase. Could

indicate a faulty battery or the charger configuration is not

correct for the size of battery to be charged. May need

additional charger modules added to the charger.

Finishing Charge Timeout - Non-urgent

The battery has exceeded the maximum time allowed for

the finishing part of the charge cycle. Generally not a

problem and indicates the battery did not quite perform as

expected. Not uncommon with new batteries that are still

cycling up to full capacity (allow 10 cycles) however if the

alarm is a regular occurrence it needs investigation and

possible adjustment of the charger or service of the battery.

Battery Disconnected - Urgent

The battery has been unplugged before charge cycle has

complete. This can damage the battery connector and

increase risks of battery explosions as sparks around

batteries at their top of charge whilst gassing can be very

dangerous. If the battery needs to be disconnected mid

cycle, the toggle switch must be first set to STOP. This will

stop the charge and log a partial cycle in the charge log but

allows safe disconnection of the battery.

Reversed Battery – Urgent

A battery with its positive and negative cables reversed has

been connected to the charger. Generally this will also

cause an output fuse alarm and the need to replace the

chargers DC output fuse(s). Such a situation is not covered

by warranty as new batteries should always first be

Page | 33

checked for correct polarity BEFORE plugging onto the lift

truck or a charger.

Minimum dV/dt - Non-urgent

Details the change in battery voltage over time. The alarm

occurs when the change in voltage exceeds the value set in

the profile settings. This alarm also indicates the

termination of a successful charge.

Maximum Cell Voltage - Non-urgent

Occurs when the voltage per cell exceeds the value set in

the profile settings. Typically 2.7V per cell for lead acid

batteries.

Batt Over Temp – Start - Urgent

Occurs when the battery temperature measured before a

charge profile starts exceeds the value set in the controller

settings. This alarm will not allow the charge profile to

continue.

Batt Over Temp – Charge - Non-urgent

Occurs when the battery temperature measured during a

charge profile exceeds the value set in the controller

settings. This alarm will allow the charge profile to

complete.

+dI/dt - Urgent

Occurs when the measured current in the constant voltage

stage is rising instead of falling. This alarm will terminate

the charge profile.

Minimum Current - Non-urgent

Occurs when using a IU profile and the current in the

constant voltage stage falls below the value set in the

profile settings. This alarm will not stop a profile and is

considered normal for some types of batteries.

EQ/Refresh Timeout - Non-urgent

Occurs when the time in a given stage of the equalize

profile exceeds the value set for that stage of the profile.

This alarm will terminate the equalize charge but is not

considered an urgent alarm.

Page | 34

9. Self Test Process

Connect Battery

48V

Flooded

1000AHr

V29

100A

Test Mode

Disabled

Self Test

Disabled

Self Test

Disabled

Self Test

Enabled

Cancel

Store

Cancel

Store

Self Test

Switch Test

Toggle Switch

Self Test

Red Led Test

ON - Push UP

OFF - Push DOWN

Introduction

The self test process verifies the basic functions of the charger. A

combination of button presses on the charger front panel allows

access to the charger’s Service Mode menu. The self test can then

be selected from the menu.

Self test checks the ability to store data, start/stop switch function,

charge status indicators, audible buzzer test, charger module startup as well as the MPC controller’s internal real time clock and

memory.

At least one charger module is required to be fitted for the

self test to complete.

Accessing Self Test

With mains power only applied to the charger ensure that the

LCD displays the start-up screen

Hold down the UP and DOWN buttons simultaneously for 10

seconds until “Test Mode” is displayed as below.

Press the down button to get to the Self-Test option, then press

the ENTER button.

Press the UP button to enable Self Test and press the ENTER

button. In the Cancel/Store menu press the ENTER button to

select Store.

Operating the Self Test Sequence

Press ENTER and in the Switch Test menu Toggle the On/Off

switch. Ensure that the Red Charging lamp in illuminated and

the display reads Red Led Test. Press the UP button to pass

the test.

Page | 35

In Green Led Test menu ensure that the Green Ready lamp is

Self Test

Green Led Test

ON - Push UP

OFF - Push DOWN

Self Test

Buzzer Test

ON - Push UP

OFF - Push DOWN

Self Test

RTC Test

Self Test

Rectifier Test

Self Test

Memory Test

Self Test

Test Succeeded

(Enter to Exit)

illuminated and the display reads Green Led Test. Press the

button to pass the test.

In the Buzzer Test menu ensure the buzzer is sounding, press

the UP button to pass the test. The next 3 tests are automated

and require no user intervention.

On completion of the test “Test Succeeded” should be

displayed. If a fault occurs the test will stop at the point of

failure. Cycling the power returns the charger to normal

operation mode.

Page | 36

10. Maintenance, Service and Repair

Regular Maintenance

Cleaning the charger air filter is the only regular maintenance

recommended.

The air filter should be inspected for dust accumulation at a 6 month

interval, more frequently if the charger is in a particularly dusty

environment.

Air Filter

The air filter may be cleaned with compressed air from the reverse

side after removal from the charger. Extremely soiled filter material

can be washed with clean soapy water and allowed to fully air dry

before refitting to the charger.

Failure to ensure the air filter is clean can lead to excessive fan

operation in order to maintain the charger module cooling during

operation. If left to operate in this way for an extended period the

risk of module fan wear increases, and charging ability is reduced

as the charger modules may de-rate output to avoid overheating.

Modules damaged by overheating due to lack of filter maintenance

will not be covered by warranty.

Blown DC Fuse

A reverse connected battery will blow the DC output fuse(s) in the

charger. A fuse blown alarm will be indicated on the front panel

display and the charger alarm logs. Fuses should be replaced only

with the same fuse as specified in the Spare Parts list.

Fuse Replacement

1. Remove the charger side panel (FS5, FS9 also remove rear

grille) and identify fuses.

FS3: Two fuses on the positive output bus bar.

FS5: Two fuses on the rear bus bar, two on the

side bus bar.

FS9: Same as FS5, with an additional two fuses

on the side bus bar

2. Remove each fuse and check for continuity.

3. Replace any open circuit fuses with the same fuse type.

Charger Module Fault

Charger modules found to be faulty should be removed from the

housing and returned to the Distributor for factory repair. Never

attempt to open a charger module, there are no user serviceable

parts inside and any warranty will be voided.

Charger MPC Fault

If the MPC is found to be faulty or damaged, it should be removed

from the housing and returned via the Distributor for factory repair.

A replacement controller can be factory configured with the

installation site information (battery type, capacity and voltage),

taken to site and fitted.

Page | 37

FS5, FS9: Replacement MPC boards for these models require

Current Shunt Measurement to be enabled. Advanced User access

to Charger Interface is required to make this configuration.

Backplane Replacement

Should a fault or damage be traced to the backplane, the option to

remove and replace the backplane is available.

A scorpion connector pin removal tool is required to remove

the AC Loom from the back plane.

FS3

Removal

1. Remove any charger modules from the charger, and

remove the side panel.

2. Disconnect the two secondary circuit connectors from the

lower backplane. (RJ45 and Molex connectors)

3. Remove the backplane AC supply

4. Remove the AC Loom chassis earth nut, and rear panel

earth connector nut.

5. Remove the 4 nuts fastening the backplane bracket to the

chassis.

6. Remove the backplane bracket assembly from the chassis.

7. Using the connector pin tool, release the AC loom pins from

the three backplane connectors.

8. Cut any cable ties securing the loom to the backplane

bracket.

9. Remove 11 screws fastening the backplane to the

backplane bracket.

Refit

Refit new backplane assembly following the above steps in

reverse, re-securing wires with cable ties where

appropriate.

FS5, FS9

Removal

1. Remove any charger modules from the charger, and

remove the rear grille, and top and side panels.

2. Disconnect the two secondary circuit connectors from top of

the backplane. (RJ45 and Molex connectors)

3. Cut the cable ties securing the secondary circuit wires to

the backplane bracket

4. Release the AC Loom from the AC Filter terminal blocks.

5. Remove the AC Loom chassis earth nut, and rear panel

earth connector nut.

6. Remove bolts securing the backplane to the output bus

circuit.

7. Remove the 5 bolts fastening the backplane bracket to the

chassis.

8. Remove the backplane bracket assembly from the chassis.

9. Using the connector pin tool, release the AC loom pins from

the backplane connectors.

10. Cut any cable ties securing the loom to the backplane

bracket.

Page | 38

11. Remove 11 screws fastening the backplane to the

backplane bracket.

Refit

Refit new backplane assembly following the above steps in

reverse, re-securing wires with cable ties where

appropriate.

Page | 39

11. Troubleshooting

Problem

Possible Cause

Remedy

Main Switch

Alarm

Front panel switch in

the STOP position

Charge will start when the

switch is set to START

Inlet Filter Alarm

Air inlet filter blocked

Clean the filter

Low Mains

Alarm

AC mains supply is low

or charger modules

may be overloaded

Check configuration of the

charger suits the application

Non-Urgent

Rectifier Fail

Alarm

charger module not

providing output, there

is capacity to charge at

a reduced rate

Replace the faulty charger

module(s)

Urgent Rectifier

Fail Alarm

Faulty charger

modules are affecting

the ability of the

charger to charge the

battery

Replace the faulty charger

module(s)

Rectifier Fan

Fail

Faulty charger module

fan

Replace charger module

Rectifier Over

Temperature

Charger module is

overheating

Check air inlet filter is not

blocked, check the charger is

installed without any

obstructions to air inlet and

outlet

Configuration

Error

Charger cannot

provide the target

output current

Check the controller

configuration matches the

quantity of Charger modules

installed, add charger

modules if necessary

Output Fuse

Blown output fuse

Check battery polarity,

replace blown fuse

No Output

Current

Battery unplugged

during charge.

Charge profile allows

current to fall below

0.7A.

Ensure battery has not been

unplugged before charge

completion.

Check that the charge profile

is appropriate for the battery

type.

Monitor ADC

Fail

Faulty MPC35

controller module

Replace the MPC35

controller module ensuring

the replacement is correctly

configured

Low Output

Current

Only one battery cable

connected (FS9).

Ensure two battery cables

are connected to the FS9.

Page | 40

Over Discharged

Battery

Battery is <1.9Vpc at

connection but

recovers within 30

seconds of charge

Typically due to the battery

being quickly unplugged from

the truck and plugged onto

the charger without allowing

the battery to recover.

Regular occurrences might

need investigation of work

practices

Deeply

Discharged

Battery

Battery is still <1.9Vpc

after 30 seconds of

charge

Check battery for faults

Incorrect Battery

Charger voltage does

not match battery.

Check the configuration

matches the battery, check

the operator is not trying to

plug an incorrect battery type

onto the charger

Bulk Charge

Timeout

The bulk charge part of

the cycle is longer than

expected

Check the charger

configuration matches the

battery, check the battery for

problems

Finishing

Charge Timeout

The finishing charge

part of the cycle is

longer than expected

Check that the configuration

matches the battery, regular

timeouts may indicate a

problem with the battery

Battery

Disconnected

Battery has been

disconnected mid

charge cycle

Remind the operator if there

is a need to disconnect the

battery mid charge cycle they

must first set the front panel

toggle switch to STOP

Reversed

Battery

A reverse polarity

battery has been

connected to the

charger

Correct the incorrect battery

wiring and replace the blown

charger output fuse(s)

Inability to set a

36V

configuration to

greater than 46A

or a 48V config

greater than 35A

Charger is connected

to a 10 Amp mains

supply, current limit

configuration is in

place.

Upgrade the AC input circuit

and remove the hardware AC

current limit function

Page | 41

12. Spare Parts – Common to all

Image

Description

MP130 Module

MP330 Module

MP133 Module

MP333 Module

DC Output plug

retaining screw

USB Hole Plug

MPC35/37 Large

Display Assembly

Voltage Sense Tab

MPC35 Main Board

Assembly

MPC37 Main Board

Assembly

Fuse HRC180A

150VDC 240VAC

Front Control Panel

Membrane

Specify branding

Front Panel Green

Indicator

models

Page | 42

Front Panel Red

Indicator

Front Panel Rocker

Switch

Module Bay

Blanking Plate

Page | 43

13. Spare Parts – FS3 Specific

Image

Description

FS3 Cabinet

Mounting Bracket

Backplane Assembly

AC Filter and Voltage

Selection Assembly

FS3LU models

AC Input Terminal Block

FS3xN models

AC Input Terminal Jumper Set

– 1x 2 pole, 1x 3 pole

FS3xN models

Stud Diode 150A 300V

Carry Handle

Case Foot

FS3 Lid

FS3 Side Panel

DC Output Loom

Blanking Plate Conduit

Page | 44

Upper Gland Plate

Lower Gland Plate

Two Piece Filter Assembly

Filter Element

Page | 45

14. Spare Parts – FS5, FS9 Specific

Image

Description

300A Current Shunt

Current Sense Loom

FS5/9 AC Filter

Auxiliary PSU

Stud Diode 240A 400V

FS5/9 Cabinet

Welded Filter Assembly

Filter Element

Backplane Assembly – FS5

Backplane Assembly – FS9

Page | 46

Top Cover

Side Panel

DC Output Loom

Handle

Lower Gland Plate

Page | 47

15. Appendix

R1

W1

B1

Module 1

Module 2

Module 3

Mains Input

Housing

Chassis

Internal

Module

Fusing

Output Fuse x2

180A or 160A

CP17x27 UR2

Reverse Polarity

Diode

SKN240

+Ve -Ve

4K7

Output Connector SB350

Backplane

MP301PB9

J4

J102

Red Green

Rocker Switch

ON/OFF

J109

J111

Display,

Pushbuttons

&USB

MPC35/37 Monitor

TFF-FS9COMMS-00

RJ45 Cable

J101

ESM31DSL

J8

Fuse Monitor +Ve

Fuse Monitor -Ve

J103

Internal

Module

Fusing

2x

70mm

2

Each

J124 J123

4K7

J10

Line 1

Line 3

RY6

NC

NO

RY5

NC

NO

RY4

NC

NO

RY3

NC

NO

RY2

NC

NO

RY1

NC

NO

J107J105

J100 J110

J7

Menu Enable

(NC)

MP130/330

MP133/333

MP130/330

MP133/333

MP130/330

MP133/333

Chassis

E

N

L3

L2

L1

R2

W2

B2

R3

W3

B3

N1

N2

N3

E1

E2

E3

Jumper

7x2 Terminal block

White

Red

Black

Option 1

(3 phase)

Option 2

(Single phase)

OR

Jumper

Jumper

Interconnection – FS3LN/FS3HN

Page | 48

Interconnection – FS3LU/FS3H

A

B

C

N

A

B

C

N

A

B

C

N

FS3 AC Filter

Module 1

Module 2

Module 3

L1

L2

L3

N

E

Mains Input

Terminals

Housing Chassis

J5/J6

Line 1

Line 3

Internal

Module

Fusing

Output Fuse x2 180A

or 160A CP17x27

UR2

Reverse Polarity

Diode

SKN240

+Ve -Ve

4K7

Output Connector SB350

Backplane

MP301PB9

J4

J102

Red Green

Rocker Switch

ON/OFF

J109

J111

Display,

Pushbuttons &USB

MPC35/37 Monitor

TFF-FS9COMMS-00

RJ45 Cable

J101

ESM31DSL

J8

Fuse Monitor +Ve

Fuse Monitor -Ve

J103

Internal

Module

Fusing

2x

70mm

2

Each

J124 J123

4K7

J10

Line 1

Line 3

RY6

NC

NO

RY5

NC

NO

RY4

NC

NO

RY3

NC

NO

RY2

NC

NO

RY1

NC

NO

J107J105

J100 J110

J7

Menu Enable (NC)

MP130/330

MP133/333

MP130/330

MP133/333

MP130/330

MP133/333

J5 – 240V AC supply

J6 – 480V AC supply

Chassis

FH1 Fuse

1A/500V

Page | 49

AC Input Terminal Detail – FS3xN Standard

Page | 50

AC Input Terminal Detail – FS3xJ (RST Mains)

Page | 51

Interconnection – FS5L/FS5H

Housing

J20

Line 1

Line 3

Output Fuse x2 180A or

160A CP17x27 UR2

Reverse Polarity

Diode

SKN240

4K7

4K7 4K7

Output Connector SB350

Backplane

MP301PB9

J4

J102

Red Green

J100

Rocker Switch

ON/OFF

J101

J109

J103

Display, Pushbuttons

&USB

MPC35/37 Monitor

Auxiliary PSU

RJ45 Cable

J101

ESM31DSL

J8

Shunt 300A 50mV

Fuse Monitor +Ve

Fuse Monitor -Ve

J103

2x 70mm

2

Each

J124 J123

4K7

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

Module 1

Module 2

Module 3

Module 4

Module 5

L1

L2

L3

N

E

Mains Input

Terminals

Internal

Module

Fusing

+Ve -Ve

Internal

Module

Fusing

4K7

Output Fuse x2 180A or

160A CP17x27 UR2

TFF-FS9COMMS-00

MP330/333

MP330/333

MP330/333

MP330/333

MP330/333

FS5 AC Filter

Page | 52

Interconnection – FS9L/FS9H

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

A

B

C

N

E

FS9 AC Filter

Module 1

Module 2

Module 3

Module 4

Module 5

Module 6

Module 7

Module 8

Module 9

L1

L2

L3

N

E

Mains Input

Terminals

Housing

J20

Line 1

Line 3

Internal

Module

Fusing

Output Fuse x4 180A or

160A CP17x27 UR2

Reverse Polarity

Diode

SKN240

+Ve -Ve

4K7

4K7 4K7

4K7

4K7

Output Connectors SB350 (x2)

Backplane

MP301PB9

J4

J102

Red Green

J100

Rocker Switch

ON/OFF

J101

J109

J103

Display,

Pushbuttons &USB

EMPC35/37 Monitor

Auxiliary PSU

TFF-FS9COMMS-00

RJ45 Cable

J101

ESM31DSL

J8

Shunt 300A 50mV

Shunt

300A

50mV

Fuse Monitor +Ve

Fuse Monitor -Ve

J103

Internal

Module

Fusing

4x

70mm

2

Each

J124 J123

4K7

MP330/333

MP330/333

MP330/333

MP330/333

MP330/333

MP330/333

MP330/333

MP330/333

MP330/333

Page | 53

Input Current by Output Current

Page | 54

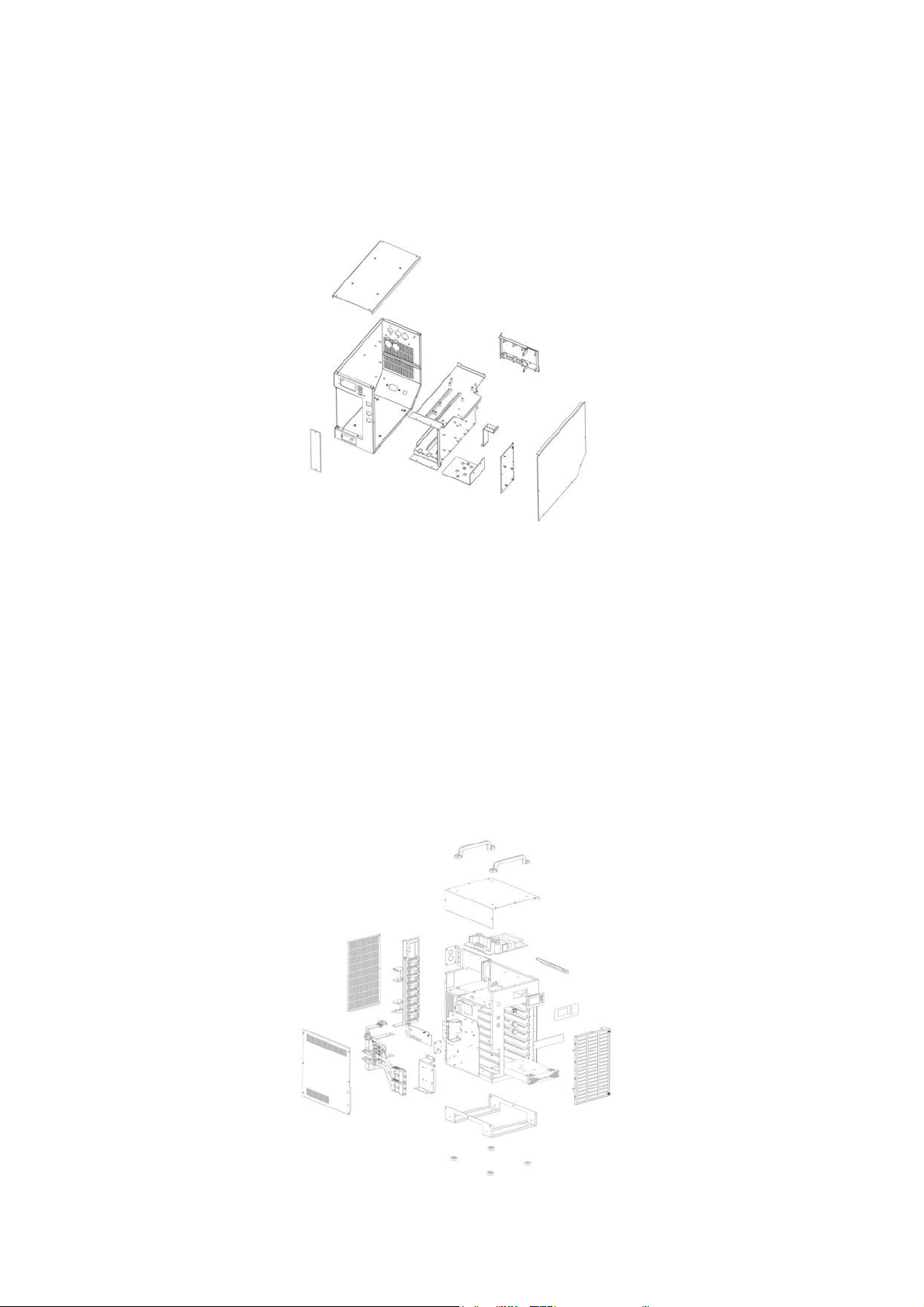

Exploded Diagram – FS3LU

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

Exploded Diagram – FS5, FS9

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

16. Glossary

ADC

Analogue to Digital Converter, internal controller hardware to

convert measurements into digital signals for processing

APC

Automatic Profile Configuration, a charger state where the

charge profile is read from a battery module.

APC Module

Battery module providing battery ID, charge profile, electrolyte,

temperature and voltage imbalance monitoring. Also known as

BMID.

Aux TX

Auxiliary transformer used to provide power to the MPC35

controller when no battery is connected to the charger

backplane

Printed circuit board with connectors and components to

connect the charger modules to the charger housing

battery module

A battery mounted module for battery-to-charger charge profile

identification and other functions. See APC, BMM, BMID.

BMID

Battery Monitoring Identification Device. Provides battery ID,

charge profile, electrolyte, temperature and voltage imbalance

monitoring. Also known as APC Module.

BMM

Battery Monitoring Module, provides same functions as

BMID/APC with additional discharge current monitoring and

logging features.

bootload

Setting a microprocessor in a condition where you can load or

update its firmware

bulk charge

The first stage of a charge cycle where the charging outputting

maximum current to recharge to battery as quickly as possible,

must stop when the voltage reaches a certain point which

generally equates to 75-80% state of charge

Charger Interface

PC software application required to communicate with the

MPC35/37 controller

charger module

The core module that converts AC power into DC power

suitable for charging a battery

configuration

Setting the necessary adjustments of the MPC35 Controller to

suit the battery and charging application

Data.csv

CSV file containing the information for configuring the charger

to suit a battery, must be in the same directory as the MMPC

Interface application

din rail

Clip on mounting method for fixing electrical components to

metalwork

diode

Electronic component that only passes current in no direction

DOD

Depth of discharge, measure of the battery discharge

condition, 100% is totally discharged

dv/dt

Rate of change of voltage, slope of the change in voltage

against time

efficiency

Ratio of output power to input power of an electrical device,

the higher the efficiency the less energy is lost as heat

equalize

Maintenance function using a low constant current charge to

ensure all cells in the battery have similar voltages

equalize lockout

Timer to prevent an equalize charge starting after a normal

charge until the battery has had time to cool down

finishing charge

The stage(s) that follow the bulk charge to return the battery

from 80 to 100% state of charge which must be done more

slowly than the bulk charge stage

firmware

Computer code that is embedded in a microprocessor

flash

Process where the firmware is written into the

microprocessor’s FLASH memory

flooded cell

Batteries that have liquid electrolyte that can freely vent, also

referred to as wet batteries

FS3

FS3 Frame Size 3 modular charger that can accommodate up

to 3 charger modules

FS5

FS5 Frame Size 5 modular charger that can accommodate up

to 5 charger modules

FS9

FS9 Frame Size 9 modular charger that can accommodate up

to 9 charger modules

fuse

Easily replaced device that internally melts during an electrical

fault to prevent damage to other components

FW

FW Abbreviation for Firmware

GEL

Battery that the electrolyte is trapped in a silica gel, fitted with

a pressure relief value so it only vents under unusual

circumstances

harmonics

Higher frequency components being multiple of the 50hz AC

power that may damage or degrade the performance of

electrical equipment

HF

High frequency, a generic term for switch mode battery

chargers used in motive power applications

Page | 57

LED

Light emitting diode, a solid state light source that does not

wear out

micro controller

Computer in a single chip

motive

Battery application used in moving plant and being regularly

used and then recharged by connecting to a battery charger

MP130 – MP330

3kW Motive low voltage charger modules

MP133 – MP333

3kW high voltage charger modules

MPC35/37

Motive Power Controller type 35/37

neutral

The fifth wire in a three phase supply

PCB

Printed circuit board used to mount and connect together

electronic components

phase

Identification of the 3 lines of electrical power that make a

3phase supply, referred to as A,B,C or 1,2,3

power factor

A measure of the effectiveness of an electrical device to

convert volt-amperes to watts, PF=1 is best

charger module

The core module that converts AC power into DC power

suitable for charging a battery

rectifier

Another name for the charger module

reserve

Battery application where the batteries are generally on float

charge, only being discharged during AC power outages

reversed battery

Battery/charger must be connected positive/positive and

negative/negative, reversed connection will blow the fuses

RJ45

8 pin modular connector used for the control cabling between

the MPC31 controller and the backplane

SB350/SC350

350A Anderson Power connector type SB/SC

SOC