Enatel Motive Power Ltd

Charger Interface

Software Description and User Manual

Revised October 2014

TABLE OF CONTENTS

1. INTRODUCTION TO CHARGER INTERFACE .................................................................... 3

1.1. USES .................................................................................................................... 3

1.2. SYSTEM REQUIREMENTS .............................................................................................. 3

1.3. INSTALLATION .......................................................................................................... 3

1.4. CONNECTING TO THE CHARGER ...................................................................................... 3

1.6. OPERATOR ACCESS LEVEL CONTROL................................................................................. 4

1.7. CHARGER INTERFACE READ/WRITE FUNCTIONALITY ............................................................... 4

1.8. BATTERY MODULES .................................................................................................... 4

1.9. SOFTWARE LICENSE FOR BATTERY MODULE DATA ACCESS ....................................................... 5

1.10. DIAGNOSTICS .......................................................................................................... 5

2. CHARGER INTERFACE TABS ........................................................................................ 6

2.1. TAB OVERVIEW......................................................................................................... 6

2.2. CHARGER STATUS TAB ................................................................................................ 7

2.4. CONFIGURATION TAB .................................................................................................. 8

Configuration Template ....................................................................................... 9 2.4.2.

Import CSV ........................................................................................................ 9 2.4.3.

Charger Configuration ......................................................................................... 9 2.4.4.

Print Label ....................................................................................................... 10 2.4.5.

Auto Equalise ................................................................................................... 11 2.4.7.

Auto Watering Configuration .............................................................................. 11 2.4.8.

Daily Charging Schedule .................................................................................... 11 2.4.9.

Start Time Delay ............................................................................................... 12 2.4.10.

Cool Down Period .............................................................................................. 12 2.4.11.

Real Time Clock ................................................................................................ 12 2.4.12.

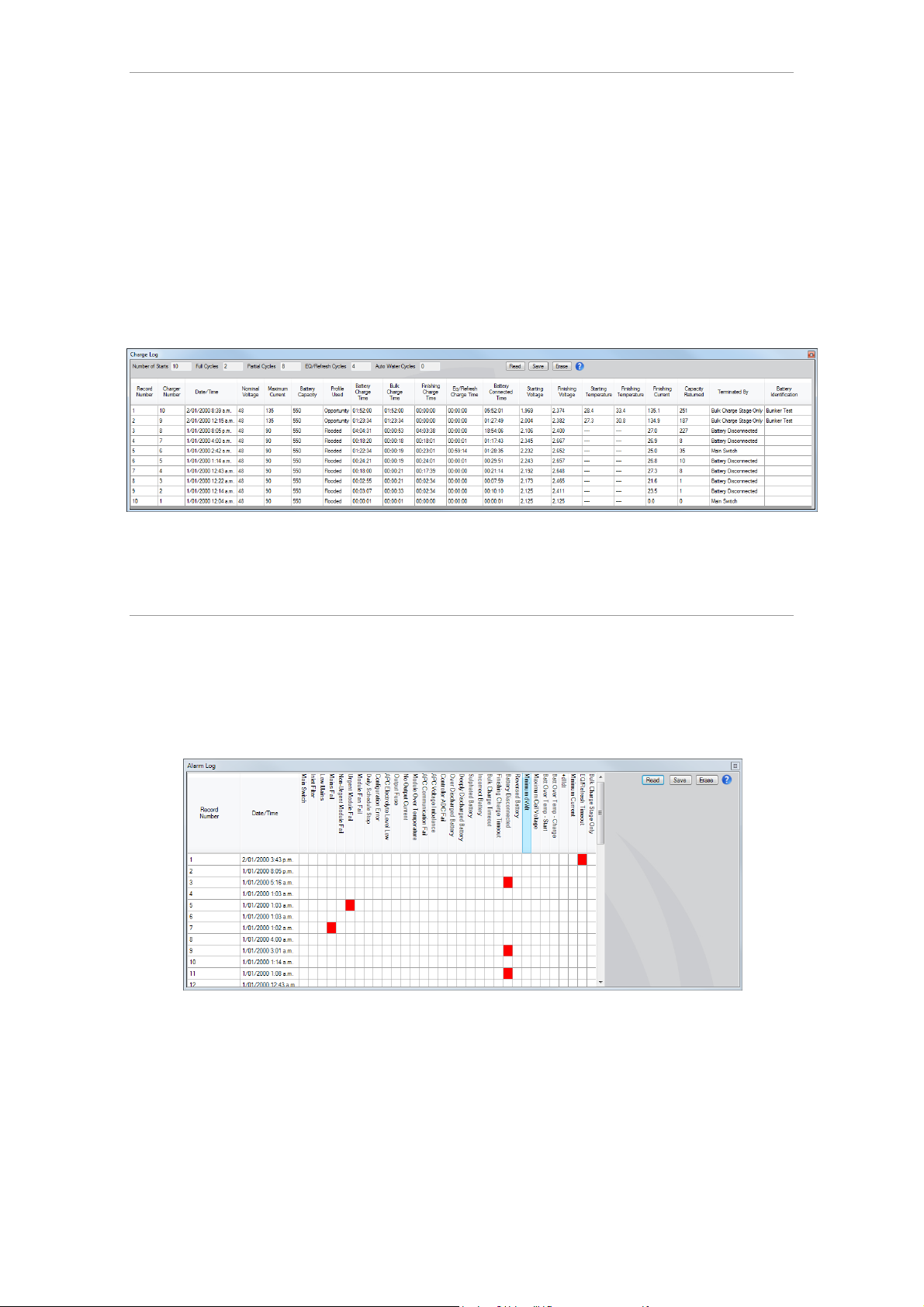

2.6. CHARGE LOG TAB .................................................................................................... 13

2.7. ALARM LOG TAB ..................................................................................................... 13

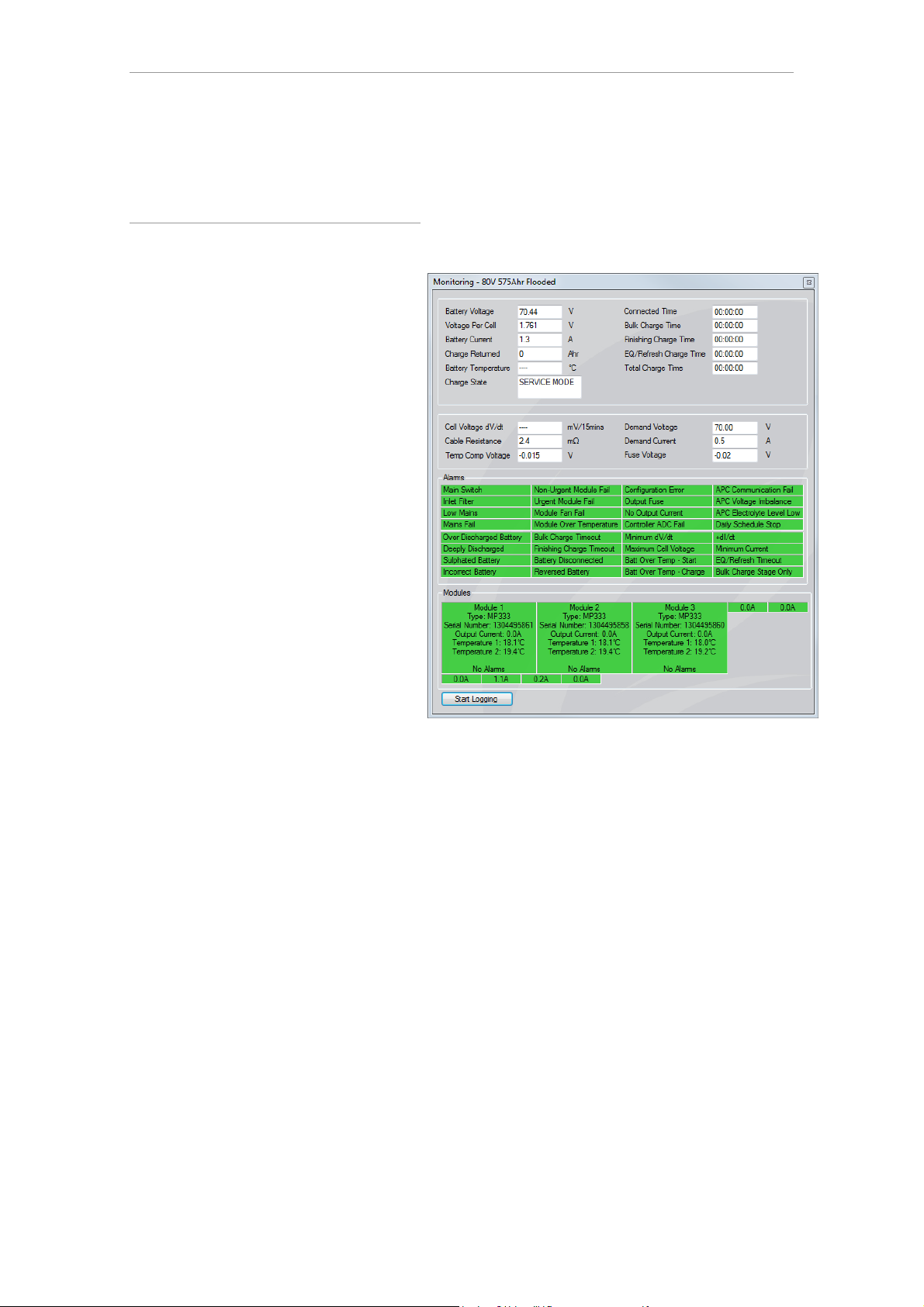

2.9. MONITORING TAB .................................................................................................... 14

2.11. CHARGE PROFILES TAB .......................................................................................... 15

2.12. BOOTLOADER TAB ................................................................................................ 17

2.13. ALARM CONFIGURATION TAB .................................................................................... 18

2.15. CONTROLLER SETTINGS TAB .................................................................................... 19

2.16. BATTERY MODULE MONITORING TAB .............................................................................. 20

2.18. BATTERY MODULE CONFIGURATION TAB .......................................................................... 21

2.19. BATTERY MODULE SETTINGS .................................................................................... 22

2.20. BMM ALARM LOG .......................................................................................... 22

2.21. BMM CHARGE LOG ......................................................................................... 22

2.22. BMM DATA LOG ..................................................................................................... 23

2.23. BMM DAILY LOG ........................................................................................... 23

3. CHARGER CONFIGURATION ...................................................................................... 24

3.1. DEDICATED PROFILE CONFIGURATION ............................................................................. 24

3.2. AUTOMATIC PROFILE CONFIGURATION ............................................................................ 24

Single and Dual Profile Charging ......................................................................... 25 3.2.1.

Dual Profile Charge Example .............................................................................. 26 3.2.3.

3.3. AUTO EQUALISE/REFRESH .......................................................................................... 26

4. BATTERY MODULE CONFIGURATION .......................................................................... 27

4.1. SINGLE PROFILE ..................................................................................................... 27

4.3. DUAL PROFILE ........................................................................................................ 28

4.5. BACKUP AND DUPLICATE A MODULE ............................................................................... 29

4.6. ELECTROLYTE LEVEL MONITORING ................................................................................. 29

4.7. CELL IMBALANCE MONITORING ..................................................................................... 30

5. FIRMWARE BOOTLOADING ....................................................................................... 31

6. ALARMS ................................................................................................................. 33

6.1. CHARGER RELATED ALARMS ........................................................................................ 33

6.3. BATTERY RELATED ALARMS ........................................................................................ 34

1

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

6.5. BMM ALARMS ........................................................................................................ 35

7. APPENDIX .............................................................................................................. 36

7.1. CHARGE PROFILE TYPES ............................................................................................ 36

IUIa ................................................................................................................ 367.1.1.

IUa ................................................................................................................. 387.1.2.

IUUa ............................................................................................................... 407.1.4.

Ia ................................................................................................................... 427.1.6.

7.3. CHARGE PROFILE DEFAULT PARAMETERS .......................................................................... 43

7.4. GLOSSARY ............................................................................................................ 46

2

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

1. Introduction to Charger Interface

1.1. Uses

The Charger Interface software allows configuration of any FSx series charger

by PC connectivity via the charger’s front panel USB port.

Common uses for Charger Interface include:

Configuring a charger or battery module for first use.

Retrieving charge and alarm logs from a charger or battery module.

Reconfiguring a charger for a different battery type.

Adjusting charge profile parameters.

Upgrading charger or battery module firmware (bootloading).

1.2. System Requirements

Charger Interface has the following minimum system requirements:

Microsoft Windows XP(SP3)/Windows Vista/Windows 7/Windows 8

Microsoft .NET Framework

USB 1.0/1.1/2.0

Administrator privileges on the PC for installation.

1.3. Installation

Ensure the minimum system

requirements are met before

installing Charger Interface.

The software installer may be

supplied on a CD, USB flash drive

or other distribution method.

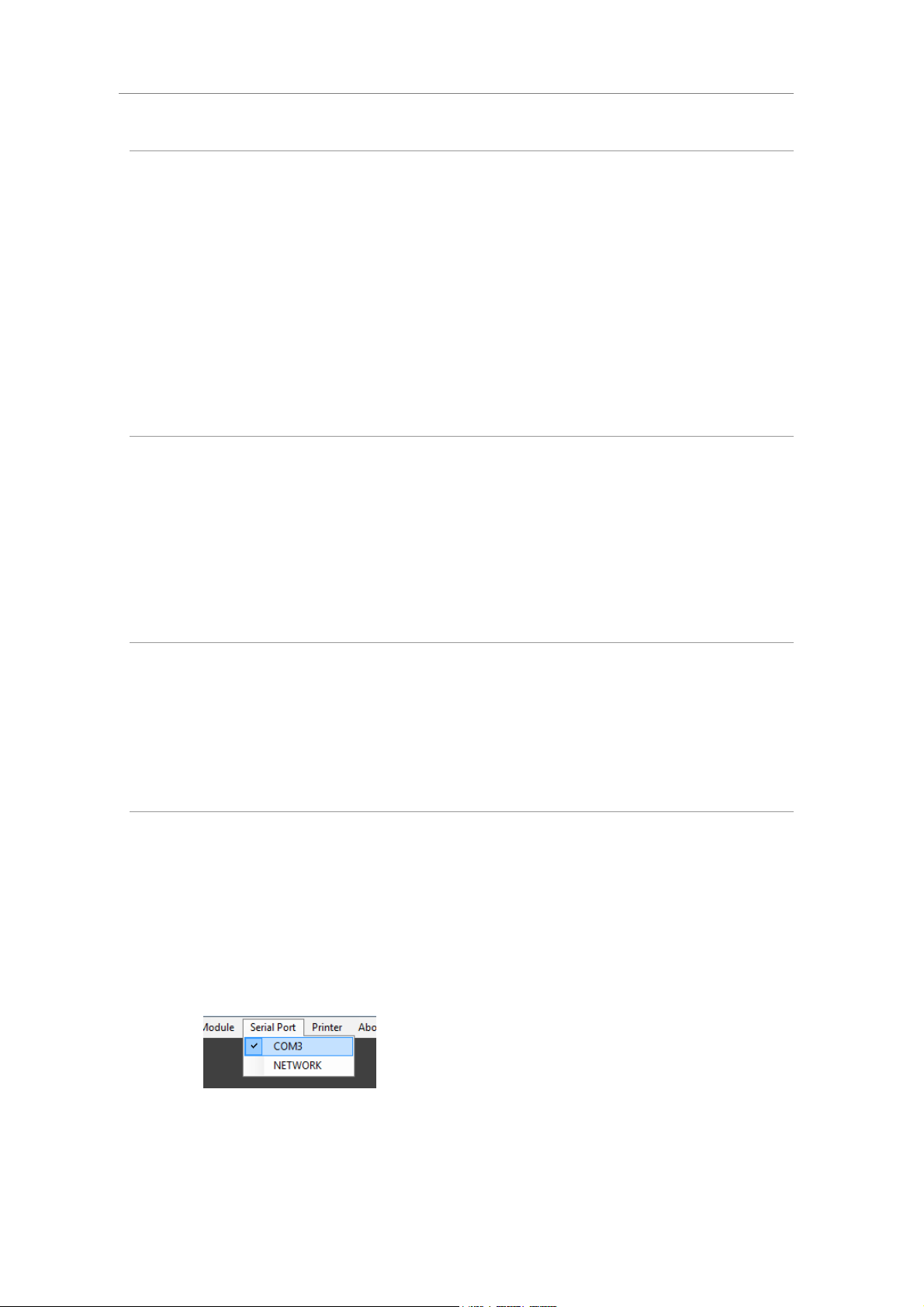

1.4. Connecting to the Charger

Power on the charger and connect

the charger to the PC with a USB

cable.

Ensure the Charger Interface

software is installed before

connecting the charger via USB.

Locate and run the software

installer file. Follow the installer

prompts to complete the install.

The installer will create a desktop

shortcut to run Charger Interface.

A successful USB connection

can be confirmed by the

charger serial number and

firmware version displaying in

the window title bar.

For example:

“(Charger: MPC35 0123456789 V51)”.

If a connection is not made

within 30 seconds, ensure the

correct COM port is selected

from the Serial Port menu

(Figure 1). If connectivity is

still not established, remove

and reinsert the USB cable.

3

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

1.6. Operator Access Level Control

An incorrectly configured charger can cause irreversible damage to batteries.

For this reason Charger Interface employs a three-level access control

system to limit access to advanced features and parameters. The default

level is Read Only.

To access levels beyond Read Only, a password is required (supplied by the

distributor). This can be entered in the About Charger Interface box from

the About menu.

Read Only Access

Read charger status, chargerbattery configuration, start and

delay times, and alarm and charger

logs from the charger. Viewing the

configuration of an attached

battery module is also possible.

Configuration Access

User can modify battery

configuration settings on the

charger and any connected battery

module using pre-defined template

settings only.

Advanced Access ( )

Allows advanced control over the

charger and battery module

functions. Access to view and edit

charge profiles, advanced control

over charger controller and charger

module settings is possible

including charger firmware

bootloading and relay

configuration.

1.7. Charger Interface Read/Write Functionality

Charger Interface can read a charger or module configuration and display on

screen and, depending on access levels, write any changes back to the

charger.

Live Feed

It should be noted that only the

Monitoring tabs for charger and

battery modules provide a “live”

feed of updating information.

Read/Write

In all operations involving

modifying a charger or module

configuration, the “Read” or

“Refresh” buttons should be used

first to ensure the visible

parameters and settings accurately

reflect the current configuration in

the device.

Similarly, any modifications or

adjustments should always be

followed by clicking the appropriate

“Write” button ensuring the

parameters are written back to the

charger.

1.8. Battery Modules

A battery module generally describes a device installed on a battery to

provide varying levels of functionality depending on the module model. Some

features of the Charger Interface software discussed in this manual may only

apply to certain battery module types.

Unless otherwise stated, reference to a battery module is assumed to be the

APC/BMID module.

APC/BMID Module

APC (Automatic Profile

Configuration) Module and BMID

(Battery Monitoring and

Identification) provide identification

to the charger of battery type and

required charge profile as well as

basic battery status including

temperature, electrolyte level, and

voltage imbalance monitoring.

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

BMM/BMID ‘Current Sensing’

BMM (Battery Monitoring Module)

provides the functionality of the

APC/BMID module, as well as

charge/discharge current

monitoring and data logging

features.

4

1.9. Software License for Battery Module Data Access

In order to retrieve the full range of BMM and Current Sensing BMID data,

Charger Interface requires activation by the purchase of a software license.

Purchase will result in supply of a license file. See below for instructions to

activate the Charger Interface for BMM.

Charger Interface allows as standard access to the BMM Data Log. The

addition of the Software License provides access to the following logs by

enabling tabs dedicated to each:

BMM Alarm Log

BMM Charge Log

BMM Daily Log

See Section 2 for details and use of each of these tabs.

Activating the Battery Module License

1. Click Software Licensing under the About menu.

2. Click Import License File and select the supplied license file.

A valid license file will display the licensing details,

including Name, Company in the Current License area.

1.10. Diagnostics

Troubleshooting issues may be aided by saving a diagnostic file for review by

an expert. The file contains the full configuration as read by Charger

Interface and allows the charger configuration to be loaded and viewed on a

separate PC.

Create Diagnostics File

1. Click the About option in

the menu bar.

2. Click Prepare Diagnostic

File.

A prompt requests

confirmation to include

battery module data (if

connected). Battery module

data can take up to 1 hour to

fully download. If the issue

does not involve a battery

module, click No.

The diagnostic file is prepared

and saved in the default

Documents folder of the

currently logged in user. The

file name incorporates the

charger serial and current

date in an XML file.

5

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2. Charger Interface Tabs

2.1. Tab Overview

Charger Interface displays the various charger data in a series of tabs within

the main window. Tabs may be closed from view or reopened using the

Charger and Battery Module menus in the main window title bar.

Depending on the user access level, some tabs may not be available.

Indicates a tab accessible only at the Advanced Access level.

Indicates a tab available with additional Software License purchase.

Some tabs such as the Monitoring Tab are undocked by default. These tabs

may be docked to the main window by double-clicking the tab title bar.

Charger Tabs

Charger Status

View recent charge cycles for

insight into the health and usage of

the battery. If the charger is used

to charge multiple batteries, the

battery ID can be selected. Also

available on this tab is the ten

most recent alarms recorded.

Configuration

View the current configuration of

the charger, including battery type,

equalise, scheduled start, and start

delay options. Changing these

options requires Configuration

access.

Charge Log

Displays the charge cycle log for

saving to PC. Useful for

determining usage trends, battery

health.

Alarm Log

Displays all recorded charger and

battery alarms for analysis and

saving to PC.

Monitoring

A live display of the current charge

cycle parameters including battery,

charger module and alarm status.

Charge Profiles

View and edit charge profiles for

each battery and charge type.

Bootloader

Update the charger and battery

module firmware.

Alarm Configuration

Configure or re-define alarms

according to urgent/non-urgent

status. On-board relays to activate

according to specified alarm states.

Controller Settings

Advanced control of the charger

low-level control functions,

including setting service mode,

temperature compensation, fast

charge, auto water and battery

module enable.

Battery Module Tabs

Battery Module Monitoring

Monitor battery status via a battery

module.

Battery Module Configuration

Configure battery module for

battery type and ratings as well as

set charge profile types and

sequences for a battery module.

Battery Module Settings

Additional module settings and

functionality control.

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

BMM Alarm Log

View and save the alarm log from a

BMM battery module.

BMM Charge Log

View and save the charge log from

a BMM battery module.

BMM Data Log

View and save the data log from a

BMM battery module.

BMM Daily Log

View daily summaries of battery

activity.

6

2.2. Charger Status Tab

Gain a quick overview of the most recent charge cycles, the charger

configuration and recent alarms.

7

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.4. Configuration Tab

The Configuration tab allows the charger configuration to be viewed, modified

and saved back to the charger.

Uses:

View or edit charger configuration depending on access level.

Print charger rating label using configuration parameters.

Configure Auto Equalise, Daily Charging Schedule, Start Time Delay, Cool Down

Timer. Set charger internal clock.

Section Overview:

Configuration Template

Select battery, charger model and

AC supply type to generate the

charger configuration

automatically. A CSV file with the

appropriate parameters must first

be loaded using the Import CSV

button.

Charger Configuration

View the current configuration of

the charger, print a rating label.

Changing these options requires

Configuration access.

Print Label

Print a rating label once the

charger is configured. Options for

what parameters to print and print

designation are available.

Auto Equalise Settings

Set the charger to perform equalise

charges according to defined rules:

profile, cycle or time based.

Requires Configuration access.

Auto Watering Settings

Set duration and number of charge

cycles per watering event. Auto

Water activation is via Relay 2 by

default.

Daily Charging Schedule

Daily lockout periods can be set by

dragging three bars horizontally.

Green and red sections indicate go

and no-go periods respectively.

Start Time Delay

Set a delay in hours:minutes to

delay charging after the charger

switch is set to Start. Charger

displays a count-down timer to

charge.

Real-Time Clock

Read or set the charger’s internal

clock. An internal cell battery

maintains the RTC in the event of a

power outage.

8

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

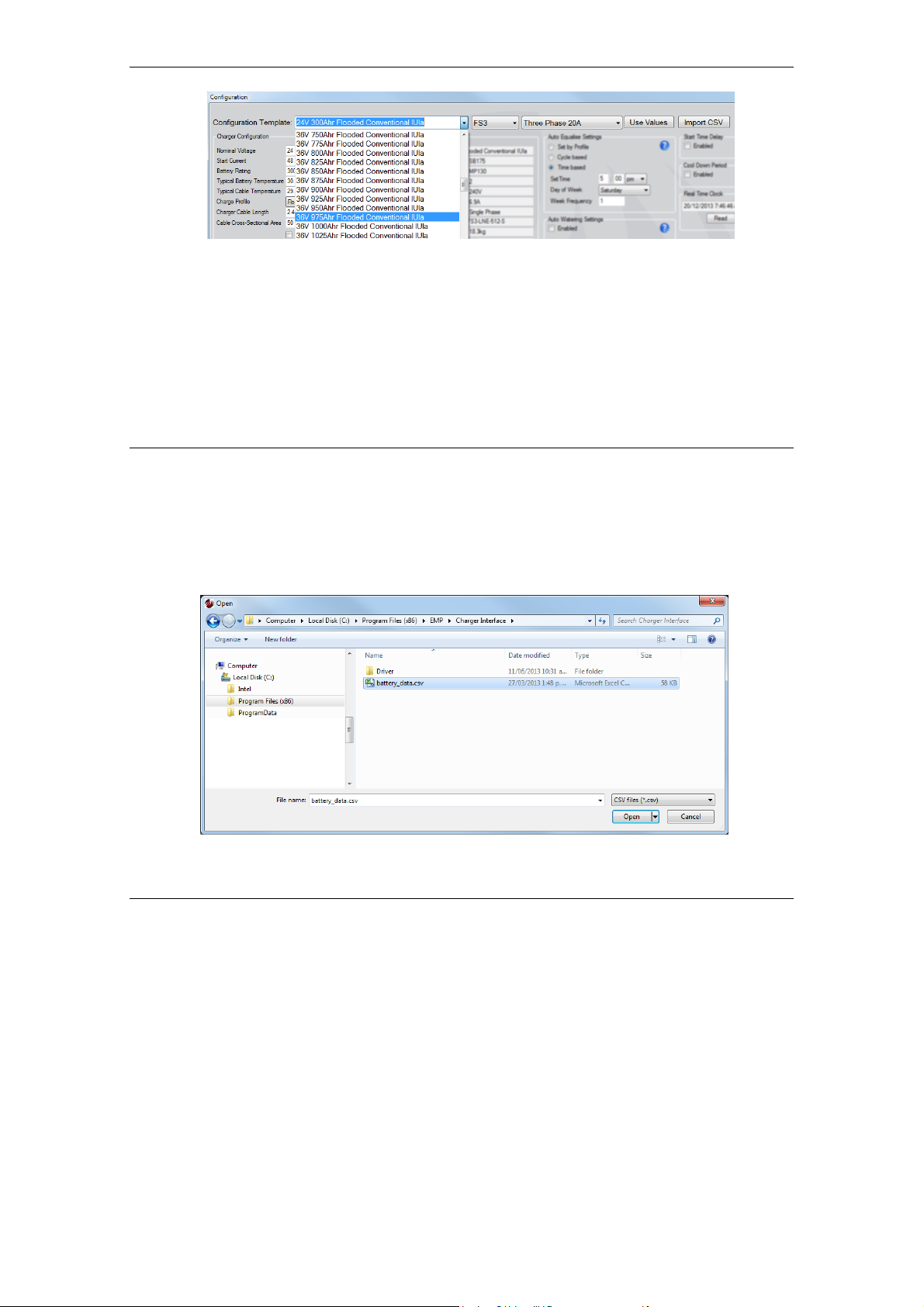

Configuration Template2.4.2.

Configuration templates simplify

charger configuration and allow for

accurate configurations with

minimal user input. The templates

are pre-set configurations that may

be selected for certain battery

types. A template may be used asis (Configuration Access) or loaded

Import CSV 2.4.3.

Charger Interface software

packages ship with a Configuration

Template CSV file included. The

CSV file contains the ratings and

related charge configuration data

for known battery types.

and details fine tuned (Advanced

Access required to adjust

parameters).

Template data is contained in a

CSV formatted file that needs to be

imported into Charger Interface

when using a template for the first

time.

To import a CSV, click Import CSV

and locate the CSV file. Typically a

dealer-supplied CSV file is located

in the Charger Interface installation

folder within the Program Files

folder.

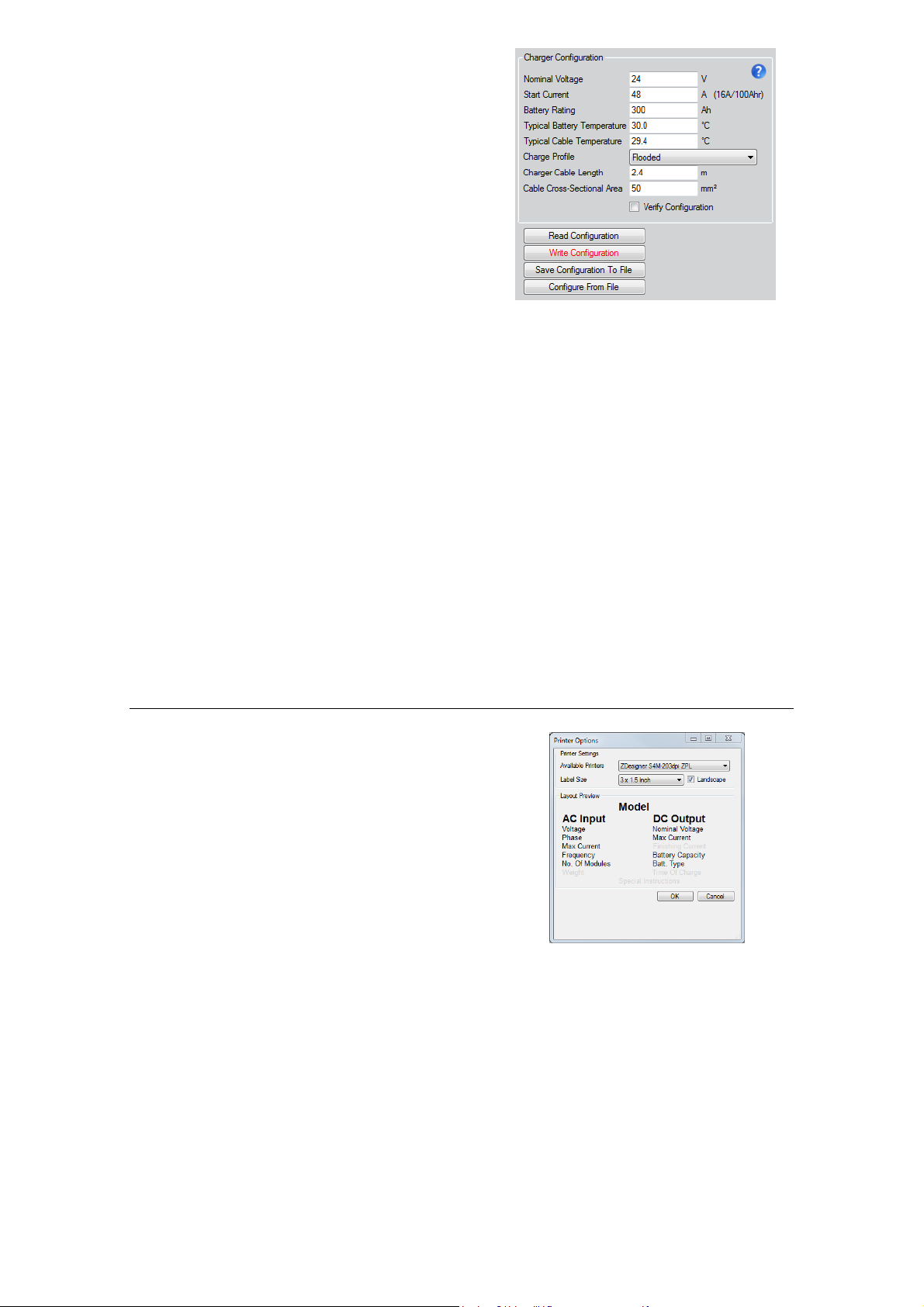

Charger Configuration 2.4.4.

The Charger Configuration section

displays the set parameters for a

charger configured for a single

battery type. See Section 3:

Charger Configuration for a

description of the various

charger/battery module

configuration options, and step-bystep example configurations.

The Charger Configuration section

displays the fundamental charge

parameters of the charger as

determined by the battery it is

configured for. Modifying these

parameters requires Advanced

9

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

Access.

Click Read Configuration to

retrieve current values from

the charger.

Always click Write

Configuration to save these

settings to the charger. Failure

to do so will leave the charger

with the previous settings.

Nominal Voltage

As defined by the battery, typically

24V/36V/48V

Start Current

Defines the maximum current

delivered in the first stage of the

charge, as recommended by the

battery manufacturer.

Battery Rating

Capacity of the battery, measured

by discharge rate x discharge time.

Typical motive batteries are

measured at a 5 hour (“C5”) rate,

e.g. a 500Ah battery can be

discharged for 5 hours at 100A.

Typical Battery Temperature

An indicative value of the battery

temperature that assists in

managing parameters during a

charge.

Typical Cable Temperature

An indicative value of the battery

cable temperature that assists in

managing parameters during a

charge.

Charge Profile

Profile as selected according to the

battery type and requirements.

Profiles are defined in the Charge

Profiles tab.

Charger Cable Length

Length of cable from charger to

battery. An indicative value used to

manage parameters while

charging.

Cable Cross-Sectional Area

Gauge of cable from charger to

battery. An indicative value used to

manage parameters while

charging.

Verify Configuration

When enabled during Write

Configuration the charger checks

that the installed modules can

meet the requirements of the

chosen configuration.

Should the required configuration

exceed the capacity of the installed

modules, install further modules or

a larger capacity charger is

required.

Print Label2.4.5.

Label printing options include

printer selection, label size and

orientation selections. A layout

preview allows selection or removal

of fields from the resulting printout.

A grey field indicates a field that

will not be printed.

10

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

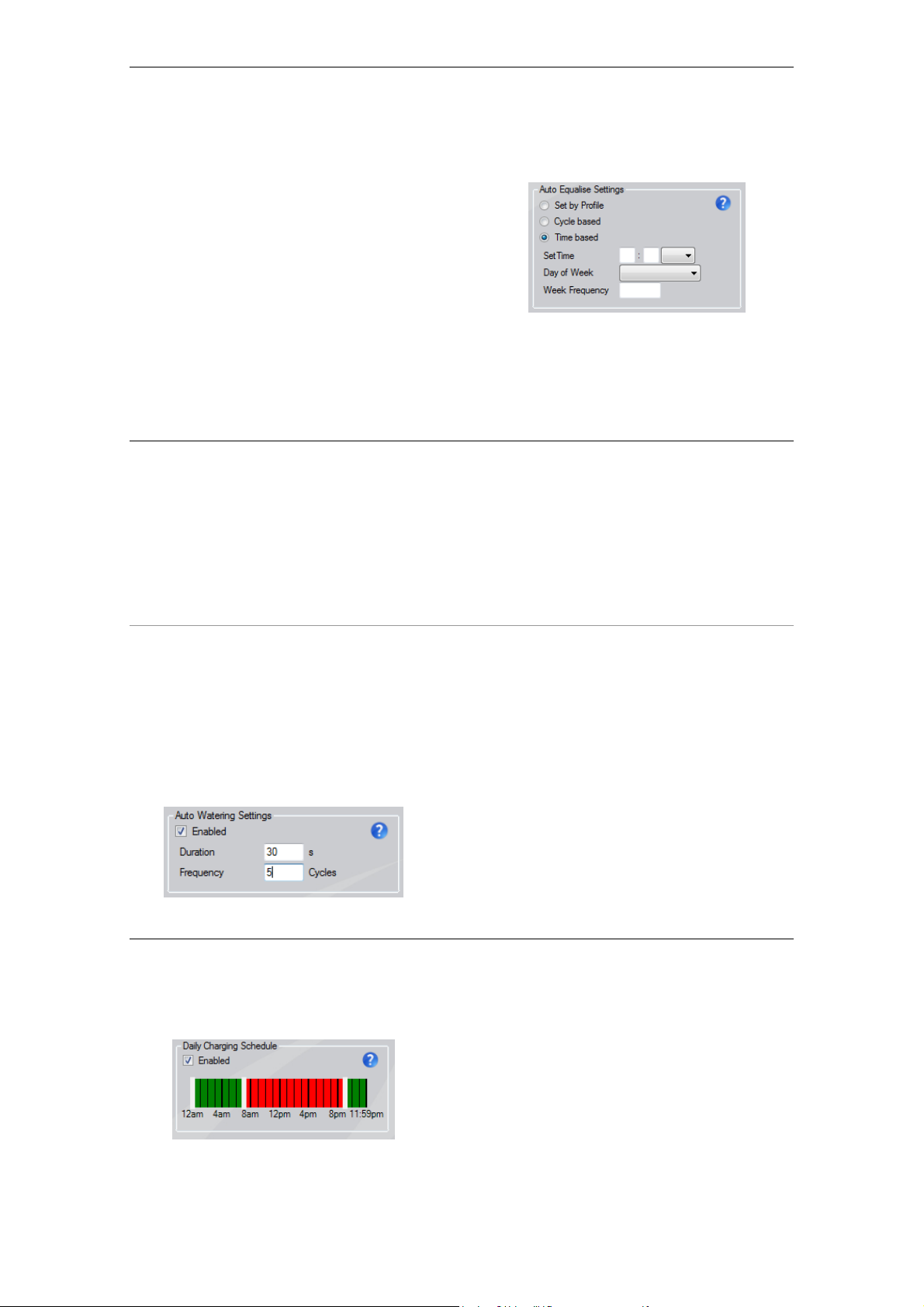

Auto Equalise 2.4.7.

An automatic equalise charge can

be programmed to begin

automatically according to defined

parameters: Profile, Cycle or Time

based.

Set By Profile

Any equalise settings are controlled

within the set charge profile,

configurable in the Charge Profile

tab. See Section 2.11.

Cycle Based

Cycle based equalise parameters

apply to a charger configured with

a dedicated profile, as the number

of charge cycles that charger

performs.

Auto Watering Configuration 2.4.8.

Auto watering functions are

triggered primarily by a charge

cycle frequency count configured

on the Configuration tab.

If a battery module is installed with

an electrolyte sensor, the module

can be configured to monitor

A charger set as APC Enabled uses

the battery module charge cycle

count to determine a battery’s

need for an equalise charge.

Time based

The equalise charge can be set to

occur at a specific time, weekday

and at a week-based interval.

electrolyte levels, triggering an

auto watering cycle if required.

See your auto watering kit

installation manual for full

hardware and software

configuration.

Auto Water Activation

1. Connect to the charger and

select the Configuration

tab.

2. Check the Auto Watering

Enable option and enter the

required values for Duration

and Frequency and click

Write to program the

settings into the charger.

Daily Charging Schedule 2.4.9.

The charging schedule provides a

graphical representation of a 24

hour period, with markers at 1 and

4 hour intervals.

Duration (seconds)

determines the length of time

the auto watering circuit is

open and providing water to

the battery.

Frequency (cycles)

determines the number of

charge cycles per watering

activation.

Dragging the three white vertical

bars allows setting of lockout

periods (red) preventing charging.

This is useful where power

providers offer discounted power

pricing during off-peak demand

periods.

If a battery is connected and

the start/stop switch activated

during a lockout period, a

Start Time Delay counter on

the charger display will count

11

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

down to the charge start.

If a charge is interrupted by a

lockout period, the Daily

Schedule Stop alarm is

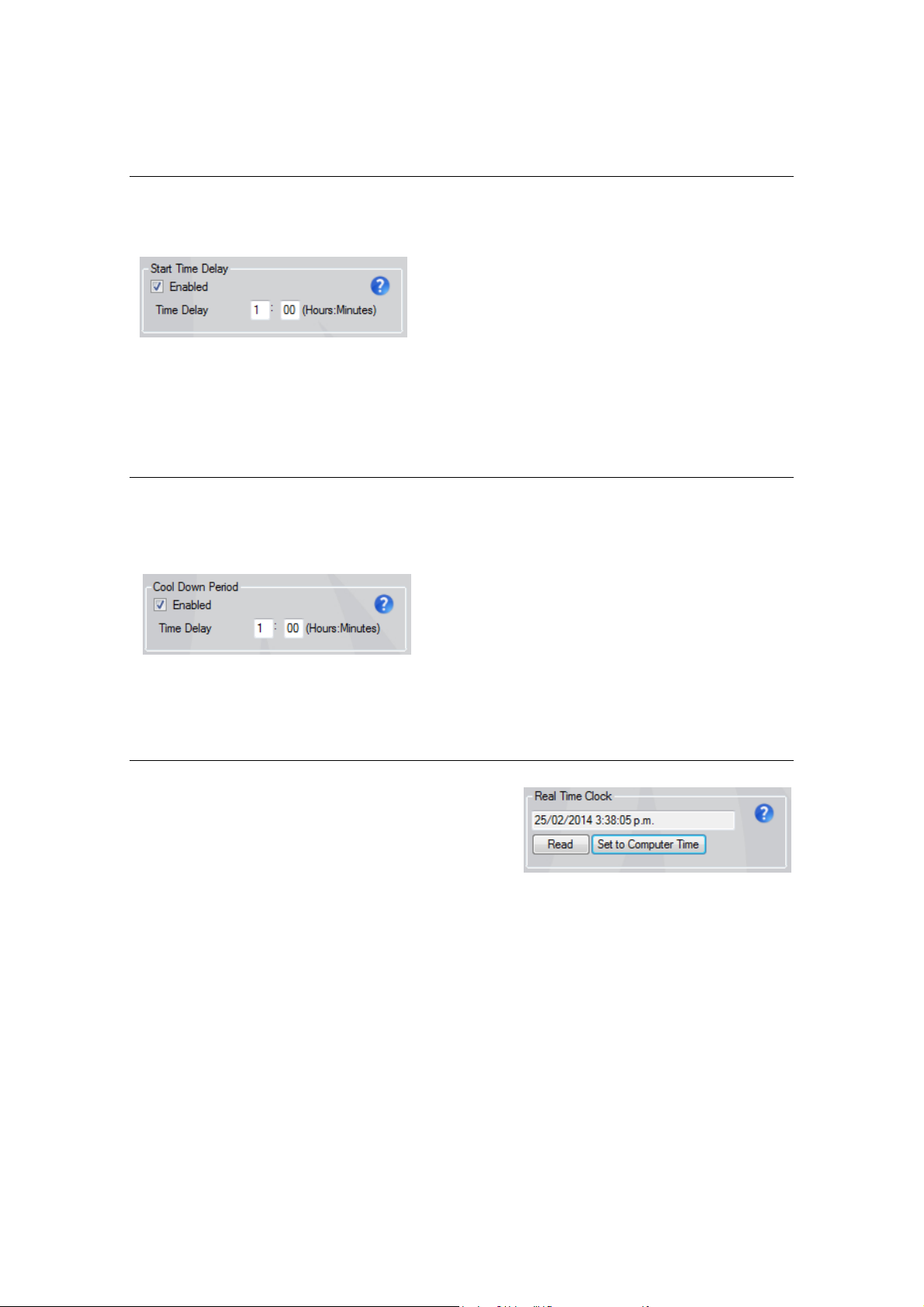

Start Time Delay 2.4.10.

flagged and the charge will

resume at the end of the

lockout period.

A start time delay may be set in

hours:minutes to start the charge

after the specified delay.

Cool Down Period 2.4.11.

A period following a charge may be

set to allow the battery to cool

before the charger indicates charge

completion.

A start delay is typically used to

allow heavily used batteries to cool

before charging begins.

The charger Start/Stop switch must

be activated to begin the delay

timer.

A user may over-ride the Start Time

Delay by holding the Enter button

on the front panel for approximately

10 seconds. The delayed charge will

begin immediately.

If enabled, the cool down period

begins at the end of the charge,

with the charger display counting

down the specified cool down time

in Hours:Minutes. The front panel

green LED alternates on/off during

this period.

When the cool down period is

complete, the green LED remains

steady on, and the charger display

counter indicates the total time the

battery has cooled.

Real Time Clock 2.4.12.

The charger’s internal clock allows

charge and alarm logs to accurately

timestamp records as well as the

Daily Charging Schedule and other

features to perform as required.

It is important that the Real Time

Clock is accurately set for the local

time zone.

The date format is dd/MM/yyyy

The time format is hh:mm:ss

Ensure the connected PC has the

correct local time and click Set To

Computer Time.

Click Read to confirm the charger’s

clock is now set accurately.

The real time clock will display in

12hr format regardless of the PC’s

12/24hr setting.

12

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.6. Charge Log Tab

The Charge Log tab displays a

number of details for each charge

cycle for analysis and

troubleshooting. Records can be

viewed in the tab by clicking Read,

and downloaded to a PC in CSV or

XML formats using the Save

button. Erase will clear all records

currently stored on the charger.

Each charge cycle is recorded with

profile type, durations of the

various charge phases, start and

finishing voltages, as well as

charge returned.

Charge logs are retained in the

charger memory by an internal

battery and are not subject to

erasure due to power loss.

When the 2400 charge cycle record

maximum is reached, the charger

retains only the most recent

records. Logs should be retrieved

from the charger regularly to

maintain charge cycle records.

2.7. Alarm Log Tab

The Alarm Log tab displays the last

200 alarms recorded during the

operation of the charger. Records

can be viewed in the tab by clicking

Read and downloaded to a PC in

CSV or XML formats using the

Save button. Erase will clear all

records currently stored on the

charger.

Refer to Section 6: Alarms for

charger alarm definitions.

13

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.9. Monitoring Tab

The monitoring tab provides realtime updates on the parameters of

the charge, charger alarm states

and per-module status indicators

Sections

Charge Status

View current charge parameters as

delivered to the battery and

elapsed times. Charge parameters

reflect all variables entered into the

Configuration tab including cable

and battery variables.

Alarms

Real-time view of alarm states –

green indicates clear state, red

indicates alarm state is currently

triggered.

Charger Modules

Click on a module label to view

individual module reports

displaying current, input and

output air temperatures per

charger module. Green indicates

charging state, red indicates alarm

or failure, grey indicates module

deactivated or not in use.

for the charge in progress. Detailed

logging directly to the file on the

connected PC is available.

Charge Detail Log

The Start Logging button initiates

collection of detailed charging data

directly to a connected PC. Sample

rate, log filename and location and

log start time can be customised.

14

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.11. Charge Profiles Tab

“Bulk”

“Finishing”

Profile Type

Stage 1

Stage 2

Stage 3

Description

Unused

A profile configured as Unused allows that profile to be rendered

non-functional and is ignored by the charger.

IUIa

Constant

Current

Constant

Voltage

Constant

Current

Standard three stage charge

profile for flooded cells.

Ia

Constant Current

Useful for commissioning or

de-sulphating batteries.

Normal charger min/max

voltage operation parameters

apply.

IUUa

Constant

Current

Constant

Voltage

Constant

Voltage

Useful for infrequent charging

of AGM traction batteries.

IUa

Constant

Current

Constant Voltage

Charging reserve batteries or

using as a power supply.

The charge profile used during

charging is selected in the

Configuration tab, (if using a

battery module, thecharge profile is

selected in the Battery Module

Configuration tab), however the

Charge Profiles tab is used to

adjust the thresholds that define a

profile and to create all new

profiles.

The charger is programmed with

eight default charge profiles

covering the most common battery

chemistries and can store up to 16

additional customized charge

profiles.

Each stage of the charge cycle has

thresholds, timeouts and durations

which may be adjusted to suit

specific batteries and charge rates.

A graphical representation of the

profile is provided reflecting the

threshold values.

Profile Type

The Profile Type drop-down list allows the basic structure of the profile to be selected.

Descriptions of available profile types are listed below.

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

15

Auto Equalise/Refresh Options

Equalise charges may be

configured as a part of a profile.

See Auto Equalise/Refresh in

Section 3.3.

Dual profile operation is enabled by

configuring a Primary Profile as

either:

Profile Management

Details of a profile may be viewed or changed by selecting the desired profile from the

list of available charge profiles. Thresholds and values for each stage is shown,

alongside a graphical representation of the charge profile.

Maintenance Profile

Bulk Charge Only, Full Charge on

Equalise

Or

Bulk Charge Only, Full Charge after

Delay

Engaging the Maintenance Profile provides a cycle of top-up charging to take place

following completion of any charge profiles, and until the charger is switched off or the

battery is disconnected.

The maintenance profile manages the battery based on voltage and time thresholds.

Any desired changes must be saved to the charger using the Write Profile button.

Front Panel Desulphation Profile (V52 firmware and later)

This feature allows designation of a profile for access and selection via the Service

Menu on the charger front panel. Typically used for a one-off desulphation charge, the

charger will return to the standard profile once complete.

1. To configure, select the listed profile under Front Panel Desulphation Profile.

2. Enter the profile details in the Profile Management area. Profile Type is required

to be set for the profile to be valid for use.

The profile may be configured as any other profile and may be

configured for desulphation by default, depending on the charger’s

factory configuration.

3. Click Write Profile to save the details into the Front Panel Desulphation Profile

location.

The profile may be enabled at the charger front panel by holding both up

and down buttons for 16 seconds to enter the Service Menu, and using

the up or down button to select the Desulphation option. Use the OK and

up/down buttons to enable then store the change. The profile will take

affect for the next charge only.

16

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.12. Bootloader Tab

The Bootloader tab may be used to update the embedded firmware in both the

charger and battery module.

See Section 5: Firmware Bootloading for more information.

17

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.13. Alarm Configuration Tab

Requires Advanced Access.

The various charger alarms are, by

default, organised into Urgent and

Non-Urgent levels. The level of

the alarm determines the charger’s

response to that alarm. In addition

to alarm levels, alarms can also be

configured to activate one of two

relays, or activate the in-charger

audible beep.

Read/Write

Click Read to view each of the lists

stored in the charger, Write to

save any changes to a list back to

the charger.

Lists

Six lists allow addition and removal

of alarms from each category as

labelled at the top of each list.

Right-clicking in a list allows a new

alarm to be added to that list.

Right-clicking on a selected alarm

in a list allows the option to remove

that alarm from the list.

Refer to Section 6: Alarms for a list

of the default alarm lists.

Alarm Configuration Lists:

Alarm Log

Alarms listed here will appear in

the alarm log.

Urgent Alarm

Alarms categorized as Urgent

terminate the charge cycle and

alarm and charge logs are flagged

with the event. Notification is by a

front panel display message and

alternate flashing Ready and

Charging LEDs.

Non-Urgent Alarm

Alarms categorized as Non-Urgent

allow the charge cycle to continue.

Flags alarm log. Notification is by

front panel display and flashing red

Charging LED.

Alarm Relays 1 & 2

Alarms selected to activate an onboard relay for external

accessories.

Buzzer

Alarms selected to produce an

audible tone from the charger when

triggered, until the alarm condition

is cleared or the charge cycle is

complete.

18

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.15. Controller Settings Tab

Provides full control over advanced charger settings and parameters.

Settings:

Voltage Regulation

Regulate voltage at charger level

instead of module level. Default:

Enabled

Monitor Current Share

Regulate current at charger level

instead of module level. Default:

Enabled.

Current Shunt Measurement

Measure current output using FS5 & 9

charger shunt(s). Default: Enabled

Minimum Module Voltage

Minimum nominal voltage the charger

can be set to. Default: 25V

Maximum Module Voltage

Maximum nominal voltage charger can

be configured to. Default: 66V

Maximum Module Current

Maximum current per charger module.

Default: 66V

Urgent Module Fail Count

Number of failed modules required

before an urgent alarm is triggered,

stopping the current charge cycle.

Default: 2

Automatic Module Shutdown

Intelligently disable modules to ensure

charger operates at the highest

efficiency or to optimise power factor.

Fuse Blown Threshold

Maximum Voltage allowed across the

DC fuses before the output fuse alarm

is set Default: 0.7V

Cable Resistivity

DC cable resistance value. Default:

20nΩ.m

Configuration Alarm Threshold

Percentage of nominal current that

must be achieved by the charger within

a given time, before the charger

triggers the configuration error alarm.

Default: 95%

Zero Current Threshold

Minimum amount of current possible

before an urgent alarm is triggered and

charge terminated. Default: 0.4A

Start-up Battery Temp Limit

Charger will not start if this value is

exceeded at start-up. Default:

55°C/131°F

Charging Battery Temp Limit

Charger will trigger an urgent alarm

and terminate charge if this value is

exceeded. Default: 60°C/131°F

dI/dt Threshold

Maximum allowable increase in current

during the finishing charge. Default:

20A

Temperature Compensation

Temperature compensation when an

external temp sensor or battery

module is fitted. Default: Disabled

APC Mode/BMID Mode

Force charger into APC mode: Single,

Dual or Disabled. Default: Disabled

Battery Status Indicator

Dedicate two relays to triggering a

remote charge status indicator (relays

1&3).

Relay Alarm Mode

Dedicate two relays to an alarm

trigger. Specify the alarm type and

relay in the Alarm Configuration tab.

Desulphation Minimum Voltage

19

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

Specify minimum voltage limit during

desulphation charge.

Desulphation Maximum Voltage

Specify maximum voltage limit during

desulphation charge.

Network Identifier

Optional unique identifier for large

networked charger installations.

Keypad Beep

Enable or disable audible feedback on

front panel buttons.

Backlight Brightness

Set minimum and maximum values for

LCD backlight. Default Min:0, Default

Max: 255

Display Contrast

Charger Serial Number

Service Mode

Refresh All

2.16. Battery Module Monitoring Tab

View real-time and accumulated data from a connected battery module.

Availability of battery current data depends on the model of battery module.

Adjust readability of LCD. Default: 350

Read or change the serial number of

the charger.

Allows manual specification of charge

parameters. Charger operation is

possible at a defined voltage, current

and duration.

CAUTION: Normal charger selfprotection features are disabled in this

mode.

Read all visible values from the

charger.

Status

Critical, real-time battery data.

Active Alarms

Alarms reported by the module as

currently active.

Counters

Battery charge, discharge and other

battery condition data as accumulated

by the battery module.

Right-click on the Counters

section to adjust the reporting

parameters.

20

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.18. Battery Module Configuration Tab

Use the Battery Module

Configuration Tab to read the

battery module configuration or

configure a new battery module.

The Configuration Template

simplifies configuration by choosing

a predefined configuration

appropriate for the battery type.

First time use of the template

option requires a template file to be

loaded using Import CSV button on

the Configuration Tab.

Modifying individual configuration

values and other settings requires

Advanced Access.

Battery Ratings

Parameters from the battery rating

plate, Single or Dual Profile

selection.

Dual Profile operation allows two

distinct profiles to be stored in the

battery module. Chargers may be

configured to use the Primary,

Secondary or both profiles in

sequence.

Primary/Secondary Profile

Set start current and basic profile

type for the Primary Profile and if

utilising Dual Profiles, the

Secondary Profile. The A/100Ahr

rate for the start current value is

shown.

Settings

Set a module identifier for quick

reference in logs and other data.

Installed Date is populated

automatically based on the PC’s

clock.

Other optional battery module

configurations may be set

depending on the installation. Swap

Current Direction may be used

where a BMM is reporting reversed

current flow.

Save/Configure Battery Module

to/from File

See Section 4.3 for battery module

backup operations.

Save Lifetime Counters to File

Save a summary of battery lifetime

status counters to CSV file.

21

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.19. Battery Module Settings

Some battery module alarms

trigger at predefined thresholds.

Setting thresholds involves

adjusting the value and clicking

Write.

2.20. BMM Alarm Log

A BMM can store more than 8000 alarm occurrences. These can be read and

saved to file (CSV or XML), or erased from the module.

If the maximum number of

entries is reached, the log

will purge the oldest entries

first to allowing the most

recent entries to be

recorded.

2.21. BMM Charge Log

A BMM can store more than 4000 charge log entries. These can be read and

saved to file (CSV or XML) or erased from the module.

The log records Charging, Discharging and Idle states, with start and end

times, battery voltages, temperatures and state of charge and capacity

values for each state change.

If the maximum number of entries is reached, the log purges the oldest

entries first, allowing the most recent entries to be recorded.

22

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2.22. BMM Data Log

The BMM automatically logs voltage, current (charge and discharge) and

temperature as measured on the battery. The log keeps the last 18 days of

activity, logging an entry once per minute. BMM Data Logs can be saved to

file (CSV or XML) or erased from the BMM.

The resulting data is represented in the multiple-variable plot. Each data

point is displayed in a scrolling table. Selecting a data point in the table also

highlights that point on the plot.

Note: The BMM Data Log can contain more than 20,000 records and

download times may exceed 20 minutes. Ensure the PC has adequate battery

or AC supply during the Read process.

2.23. BMM Daily Log

The Daily Log allows a monthly overview of a daily summary of the battery

status.

Each day displays total charge and discharge plot, and total charge time and

average battery temperature for each 24 hour period. A specific month can

be viewed using the month and year selectors.

Alarms active on any given day are indicated by the alert symbol.

Click on the day of interest to view the specific alarm(s) for that

day.

23

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

3. Charger Configuration

The FSx series charger can be operated in a number of different ways, depending on

the configuration of the charger and battery modules.

Dedicated Profile Configuration

This is the standard single battery-type

configuration (voltage, capacity and

chemistry) and default configuration

for the charger. The charger is

manually configured for use with a

single battery configuration and any

battery may be charged provided the

rating matches that of the charger

configuration.

Alternate battery types cannot be

charged without reconfiguring the

charger appropriately.

Automatic Profile Configuration

3.1. Dedicated Profile Configuration

Configure a charger for use with

a single battery type.

1. Select the Charger

Configuration tab.

2. Select the correct battery

type, voltage and capacity

from the drop-down template

menu.

If no battery types are

available, click Import CSV to

populate the drop-down

menu from a CSV file.

3. Select the charger size and

AC supply type from the two

adjacent drop-down menus,

click Use Values. The

battery charging parameters

will populate in the Charger

4. Ensure the values are

5. Use the Verify

6. The charger front panel will

7. To print a rating label, click

Any battery module-fitted battery

within the voltage and current

capabilities of the charger can be

connected and charged appropriately.

The battery module provides the

necessary profile information to the

charger once the battery is connected.

Configuration section.

appropriate for the charging

configuration and write the

new configuration to the

charger by clicking Write

Configuration.

Configuration option to

force check the installed

hardware for suitability for

the configuration.

display the new rating

details.

Read Configuration and

then Print Label.

3.2. Automatic Profile Configuration

Configure a charger for

Automatic Profile Configuration

(APC). A battery fitted with a

battery module is required to

utilise an APC configured

charger.

1. From the Configuration tab,

select APC Enabled (Single

Profile) or from the dropdown menu.

2. For dual profile charging

select APC Enabled (Dual

Profile Capable).

3. Select the charger size and

AC supply type from the two

adjacent drop-down menus,

24

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

click Use Values. The

battery charging parameters

will populate in the Charger

Configuration section.

4. Check that the values are

appropriate for the charging

configuration and write the

new configuration to the

charger by clicking Write

Configuration.

5. The charger front panel will

display APC Enabled.

6. Connecting a battery fitted

with a battery module will

automatically configure the

charger for that battery.

Single and Dual Profile Charging 3.2.1.

Module Configuration

Single Profile

Dual Profile

Charger APC

Configuration

Single Profile

Primary Profile Only

Secondary Profile Only

Dual Profile

Capable

Primary Profile Only

Primary Profile

Then

Secondary Profile*

A charger may be connected to a battery module that is configured for either

a Single or Dual Profile operation. The charger behaviour depends on both

the module and charger configurations.

The charger must be APC Enabled to one of two types:

APC Enabled (Single Profile)

A charger set to APC Enabled (Single

Profile) and connected to a battery

module will perform a single profile

charge.

Single Profile module:

Charges using the module’s single

Primary Profile

Dual Profile module:

Charges using the module’s Secondary

Profile, ignoring the Primary Profile.

Single and Dual Profile Operation Summary

The table below shows the various configurations of module and charger

configuration and the resulting profile that is used.

APC Enabled (Dual Profile Capable)

A charger set to APC Enabled (Dual

Profile Capable) and connected to a

battery module will perform as follows.

Single Profile module:

Charges using the module’s single

Primary Profile

Dual Profile module:

Charges first using the Primary Profile

followed by the Secondary Profile. The

Primary Profile must be correctly

configured to engage the secondary

profile.

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

* The Primary Profile in this case must be correctly configured to initiate the

Secondary Profile.

25

exempt. Pictures may be representative, actual products may differ.

Dual Profile Charge Example 3.2.3.

A Dual Profile allows a battery to

be charged with either of two

profiles depending on how the

charger is configured and how

the profiles are set up.

An example would be a high

demand battery requiring

opportunity (bulk stage) charging

from a high rate charger during a

shift and a full charge (bulk

charge with finishing stage)

when connected to a standard

charger.

In this scenario, the following

configuration details must be in

place:

1. The battery module is set for

dual profile and the primary

profile appropriately set with

criteria for starting the

secondary profile charge.

(See Battery Module

3.3. Auto Equalise/Refresh

Configuration, Section 4)

2. The high rate charger must

be set for APC Enabled

(Dual Profile Capable)

from the Charger

Configuration tab.

3. The standard charger must

be set for APC Enabled

(Single Profile) from the

Charger Configuration Tab.

4. Alternatively, the high rate

charger may also provide the

secondary profile charge if

left connected following a

primary charge. The charger

will provide a bulk charge

based on the primary profile,

and follow with the

secondary profile depending

on the selected criteria eg. a

time delay.

The Set by Profile option for Auto Equalise requires a number of steps to

configure correctly.

Set by Profile

1. Select Set by Profile in the

Configuration tab.

2. In the Charge Profiles tab,

choose the active charge

profile to modify and use the

Auto EQ/Refresh Options

button to select Profile Auto

Equalise Enable.

3. Check the EQ/Refresh

Current, Duration, and Max

Cell Voltage values are

appropriate.

4. Click Write Profile. The

charger will now perform an

equalise charge according

the EQ/Refresh values saved

in the profile.

Auto EQ/Refresh After allows

a cool down period before autoinitiated equalise charges. This

includes Set by Profile, Cycle,

Time or battery module based

initiation.

EQ/Refresh Lockout enforces

a period of no equalise following

a standard charge completion.

This is a global setting that

applies to manual and any autoinitialised equalise charges.

Manual Equalise

The charger may be set to perform a one-time equalise charge on a

connected battery.

1. Ensure the battery is

connected. If currently

charging, the charge cycle

can remain in progress.

26

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

2. Hold the Enter button on the

charger front panel until the

display confirms an equalise

charge has been set.

4. Battery Module Configuration

Single Profile Configuration

A Single Profile Configuration provides

the profile details to the charger, and

the charge is completed as per the

Primary Profile. Typically this would be a

conventional rate charge profile with

appropriate finishing stages to ensure a

healthy battery.

4.1. Single Profile

1. Select the Battery Module

Configuration tab and

choose the correct battery

from the Configuration

Template drop-down menu.

Click Use Values.

2. Check the values populated

below in the Battery

Ratings section are correct

and select Single Profile.

3. Set the Primary Profile Start

Current (typically 16% of the

rated battery capacity).

4. Set the Charge Profile

appropriate for the battery

and usage application.

5. Enter a battery Identifier

and check the electrolyte and

midpoint voltage probe

options if applicable.

Dual Profile Configuration

A Dual Profile Configuration allows a

battery to be charged with either of two

profiles depending on how the charger

is configured and how the module

profiles are set up.

Typical use is a high-rate primary

profile, followed by a conventional rate

charge with finishing stages as a

secondary profile.

The secondary profile starts only once

criteria in the primary profile are met,

such as after a time delay.

6. Check the Primary Profile

parameters to ensure the

profile is correct per the

battery manufacturer

recommendations.

7. Set any EQ/Refresh options

desired.

8. Auto Equalise control is a

charger-based setting, set on

the Charger Configuration

tab, and must be set to Set

by Profile in order to use

the battery module profile EQ

parameters. Otherwise, the

profile EQ settings are

ignored.

9. Click Write Configuration

to save the configuration to

the battery module.

27

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

4.3. Dual Profile

A battery module may be configured to

perform a primary profile charge such

as a high rate opportunity charge, and

follow with a secondary profile charge

after some elapsed time or cycle count.

Alternatively, the battery may

Configure a Battery Module for Dual Profile Operation

1. Ensure the battery module is

configured for the battery

ratings as per the Single

Profile instructions above.

2. Select Dual Profile in the

Battery Ratings section.

3. A new section will appear

below called Secondary

Profile.

4. In the Primary Profile and

Secondary Profile sections,

enter the required Start

Current and Charge Profile

for each Profile.

5. Select Primary Profile in the

Profile Parameters section,

and select the desired Profile

Type.

6. Ensure the stage threshold

values are appropriate for

the battery and charge

profile type. Select the Auto

EQ/Refresh Options select

box and choose the required

Dual Profile behaviour:

be connected to a second

charger configured just to

charge a single profile - APC

Enabled (Single Profile), in

which case the secondary profile

is used.

Bulk Charge Only, Full

Bulk Charge Only, Full

Secondary Profile after

Charge on Equalise

occurs according to the

Auto Equalise Settings

on the charger

(Configuration tab).

Charge after Delay

occurs according the delay

specified in the Auto

EQ/Refresh After

parameter.

Delay allows the

secondary profile to begin

after the delay specified in

the primary profile.

28

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

4.5. Backup and Duplicate a Module

Using the appropriate buttons in the Battery Module Configuration tab, a module

configuration may be saved to file and loaded back from file. This process may be used to

easily duplicate configurations across multiple modules. Configuration Access is required to

save to and configure from file.

Save Battery Module Configuration To File

1. Connect the battery to the

charger and ensure the

software is communicating

with the battery module.

Select the Battery Module

Configuration tab.

2. Confirm the module is

communicating by clicking

Configure Battery Module From File

1. Connect the battery to the

charger and ensure the

software is communicating

with the battery module.

Select the Battery Module

Configuration tab.

2. Click Configure Battery

Module From File and

4.6. Electrolyte Level Monitoring

1. Select the Module

Configuration tab and click

Read Configuration.

Read Configuration to

display the module’s current

parameters.

3. Click Save Battery Module

Configuration to File

4. The software will prompt for

a save location and file

name.

select the desired MPC file

containing battery module

configuration.

3. Once the configuration is

complete, click Read

Configuration to confirm

the module has the new

configuration.

2. Check the Electrolyte

Sensor Fitted option and

click Write to program the

settings into the charger.

When the module

determines the electrolyte

level is low, an Electrolyte

Level Low Alarm will be

raised and an auto

watering-enabled charger

will receive an instruction

to initiate a watering cycle,

if connected to the battery.

29

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

4.7. Cell Imbalance Monitoring

The Midpoint Voltage Sensor allows the battery module to detect voltage

imbalance across the battery cells. The module flags a Cell Imbalance Alarm

which, instructs the charger to perform an equalise charge at the next

opportunity.

A charger may also be configured to provide an equalise charger according to

a number of different rules. See Section 3.3 for more on charger-controlled

equalise charges.

See Section 6.5 for details on the Cell Imbalance Alarm.

1. Select the Module

Configuration tab and click

Read Configuration.

2. Check the Midpoint Voltage

Probe Fitted option.

3. Click Write to program the

settings into the charger.

The battery module will now

monitor the battery for cell

imbalance, flagging the Cell

Imbalance Alarm.

See the battery module

documentation for Midpoint

Voltage Sensor installation

guidelines.

30

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

5. Firmware Bootloading

Updated firmware (embedded

software) for either charger or

battery module may be made

available to address issues or add

features. New firmware is loaded

from PC to the device in a process

called bootloading.

Bootloading requires Advanced

Access.

Irreversible damage to the charger

controller may occur if the bootload

process is interrupted once

underway. Bootloading should be

performed with a reliable AC supply

Bootload Process – Charger or Battery Module

1. Connect to the charger USB

port and confirm PC

communication with the

charger has been

established. Open the

Bootloader tab.

2. Click Read Controller or

Read Battery Module to

confirm the current target

serial number and firmware

version.

3. Click Open File to select the

supplied HEX firmware file

from the PC.

4. The software reads the

selected firmware file and

determines the appropriate

target – charger or battery

for both PC and charger. Ensure

any automatic sleep or shutdown

settings are disabled during

bootloading.

Bootloading a Battery Module

Bootloading a battery module

requires that the associated battery

is connected to the charger. In this

way the charger acts as a host to

communicate with the battery

module. Otherwise the process to

bootload a module is the same as

for that of a charger, as below.

module.

5. Click Program to begin the

bootloading process. Do not

interrupt the power supply or

connectivity to the charger,

battery module or PC during

this operation.

6. The display window will

indicate a single line

“SUCCESS” once the

bootload is complete”.

If bootloading a charger,

the bootload should be

checked by cycling the AC

supply and confirming

operation of the front

panel display.

Additional Options

Reset Profiles

This option clears any profiles in

the charger to the factory profiles

included with the firmware.

Load Settings From File

As a part of the bootload process,

the charger settings are

automatically saved to the PC, and

31

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

loaded back to the charger before

displaying “SUCCESS”. This option

allows manual selection of the

settings file.

Save Settings To File

Charger settings can be manually

saved to file for backup purposes.

Battery module settings can be saved

and loaded from the Battery Module

Configuration tab.

32

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

6. Alarms

6.1. Charger Related Alarms

Main Switch

Shows the status of the front panel

start/stop switch. Default: Urgent

Inlet Filter

Can give a warning as to when the

inlet filter needs servicing.

Default:Disabled

Low Mains

Indicates non-critical variation in the

input mains voltage. May also indicate

an overloaded charger module.

Default:Non-Urgent

Mains Fail

A mains supply loss situation and the

charge cannot proceed. Default:

Urgent

Non-Urgent Rectifier Fail

The charger is operating but a charger

module has stopped, causing

redundancy to be lost. Reduced power

output and longer charge time as a

result. Default:Non-Urgent

Urgent Rectifier Fail

If the number of power modules not

providing output equals or exceeds the

setting for urgent module count in

Charger Interface monitor tab then the

charger will stop. If the urgent module

count is set to one then the charger is

configured without redundancy and a

single fault will stop the charge.

Default: Urgent

Module Over Temperature

Normally related to a blocked filter,

restricted exhaust air or installation in

an inappropriate location. Default:

Urgent

Configuration Error

Charger cannot meet the target current

required by the controller even with all

fitted power modules operating. The

configuration does not meet the limits

set for a 10A or 15A mains input

hardware limited charger. Default:

Urgent

Output Fuse

Typically blown output fuses caused by

connecting a reverse polarity battery to

the charger. Check all cells for a

reversed cable connection. After

replacing a battery or charger cable

always check the polarity before

plugging the battery into the charger.

Default: Urgent

No Output Current

Charger is not providing the expected

output current. Generally related to a

premature disconnection of the

battery, but also could be an

incorrectly inserted power module.

Default: Urgent

Monitor ADC Fail

Internal checks on the MPC board

indicate potential problems. MPC board

should be tested and/or replaced.

Default: Urgent

APC Communications Fail

The battery module has failed to

communicate with the charger.

Default: Urgent

APC Incorrect Voltage

Charger cannot produce the voltage

required by the battery module.

Default: Urgent

APC Unknown Charger

Charger cannot find the required profile

required by the battery module.

Default: Urgent

APC Water Level Low

For battery module equipped batteries,

indicates the Electrolyte Sensor has

detected a low level of electrolyte.

Default:Non-Urgent

APC Voltage Imbalance

For battery module equipped batteries,

indicates the midpoint voltage varies

from nominal by more than 0.5V.

Battery module will schedule an

equalize charge to rectify this

variation. Default:Non-Urgent

33

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

6.3. Battery Related Alarms

Over Discharged Battery

Battery is still under 1.9Vpc after 30

seconds of charge. Indicates a faulty

battery that needs investigation.

Default: Urgent

Deeply Discharged Battery

Battery initially is under 1.9Vpc but

recovers within 30 seconds of the

charge cycle start. This alarm normally

occurs when a battery is unplugged

from the lift truck and immediately

plugged into the charger. Default:NonUrgent

Sulphated Battery

Battery fails to complete a desulphation profile applied by the

charger correctly and generally means

that the battery requires attention.

Default: Urgent

Incorrect Battery

Battery is inappropriate for the

configuration of the charger and cannot

be charged without reconfiguring the

charger to suit the battery. Default:

Urgent

Bulk Charge Timeout

Battery has exceeded the maximum

time allowed for the initial constant

current bulk charge phase. Could

indicate a faulty battery or the charger

configuration is not correct for the size

of battery. May need additional charger

modules added to the charger. Default:

Urgent

Finishing Charge Timeout

Battery has exceeded the maximum

time allowed for the finishing part of

the charge cycle. Common with new

batteries with less than 10 charge

cycles. If the alarm occurs regularly,

investigation is advised and possible

adjustment of the charger or service of

the battery. Default:Non-Urgent

Battery Disconnected

Battery has been unplugged before

charge cycle has completed. This can

damage the battery connector and

increase risks of ignition of battery

charge gasses. If the battery needs to

be disconnected mid cycle, the charger

must be first set to STOP. A partial

charge cycle will be logged. Default:

Urgent

Reversed Battery

A battery with positive and negative

cables reversed has been connected to

the charger. Generally this will also

cause an output fuse alarm and the

need to replace the charger output

fuse(s). Batteries should always first

be checked for correct polarity BEFORE

plugging onto the lift truck or a

charger. Default: Urgent

Minimum dV/dt

Change in battery voltage over time.

Alarm occurs when the change in

voltage exceeds the value set in the

profile settings. This alarm also

indicates the termination of a

successful charge. Default:Non-Urgent

Maximum Cell Voltage

Occurs when the voltage per cell

exceeds the value set in the profile

settings. Typically 2.7V per cell for lead

acid batteries. Default:Non-Urgent

Batt Over Temp – Start

Occurs when the battery temperature

measured before a charge profile starts

exceeds the value set in the controller

settings. This alarm will not allow the

charge profile to continue. Default:

Urgent

Batt Over Temp - Charge

Occurs when the battery temperature

measured during a charge profile

exceeds the value set in the controller

settings. This alarm will allow the

charge profile to complete.

Default:Non-Urgent

+dI/dt

Occurs when the measured current in

the constant voltage stage is rising

instead of falling. This alarm will

terminate the charge profile. Default:

Urgent

Minimum Current

Occurs when using a IU profile and the

current in the constant voltage stage

falls below the value set in the profile

settings. This alarm will not stop a

profile and is considered normal for

some types of batteries. Default:NonUrgent

EQ/Refresh Timeout

Occurs when the time threshold in a

given stage of the equalize profile has

been exceeded. This alarm will

terminate the equalize charge but is

not considered an urgent alarm.

Default:Non-Urgent

34

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

6.5. BMM Alarms

EEPROM Fail

The module has detected an

unrecoverable internal error which may

cause functionality and logging

failures. Module should be replaced as

soon as possible.

State of Charge Low

Battery charge is at or below the

defined threshold. Thresholds are set

in the Battery Module Settings tab.

Default threshold is 20% of the rated

capacity.

State of Health Low

Battery State of Health is calculated

from the change in State of Charge

over the expected number of charge

cycles for the life of the battery.

Default threshold is 20%.

Temperature Low

Battery temperature has reached the

minimum threshold. Thresholds are set

in the Battery Module Settings tab.

Default threshold is 5°C/41°F.

Temperature High

Battery temperature has reached the

maximum threshold. Thresholds are

set in the Battery Module Settings tab.

Default threshold is 55°C/131°F.

Cell Imbalance

Voltage difference between each half of

the battery (positive post to midpoint

and midpoint to negative post) must

be below the set threshold. Thresholds

are set in the Battery Module Settings

tab. Default threshold is 0.5V.

Electrolyte Level

The electrolyte sensor (if fitted) has

detected a low electrolyte level. This

alarm can flag the battery to receive a

top-up from an auto watering kit if

fitted.

35

© 2014 Enatel Motive Power Ltd. Specifications subject to change without prior notice. Errors

exempt. Pictures may be representative, actual products may differ.

7. Appendix

7.1. Charge Profile Types

This section describes in detail each stage threshold that defines a charge profile type.

A charge profile type determines the number of stages and the type of current vs. voltage

delivery for that stage.

IUIa 7.1.1.

Most commonly used for charging

flooded traction batteries, the bulk

charge portion of the IUIa is also used

for Opportunity Charging which can be

initiated from the .csv file when

configuring the charger.

The general shape of the IUIa profile is

shown below. The first “I” stage,

constant current, is commonly referred