• (D

)C

• (D

)C

03

• (D

)C

06

• (D

)C

06

• (D

)C

C

s

CO

SSO

Compressor Service & Maintenance Manual

C Series

COMPRESSOR

MPRE

erie

R

• (D)C1103

• (D)C1203

• (D)C2106

• (D)C2206

• (D)C3210

1103

12

21

22

32

Copyright © 2006 DCI. All Rights Reserved.

92311, Rev. C, 08/13

1 www.dcionline.com

www.dcionline.com

C1000 Series Service & Maintenance Manual

Compressor Service, Maintenance, and Parts Manual

Section I: INTRODUCTION

A. General Specifications

Section II: THEORY OF OPERATION

A. While Running

B. Theory of Operation While Not Running

Introduction

SECTION I

Section III: MAINTENANCE

A. Compressor Head Intake Filter

B. Coalescing Filter

C. Time Operated Purge Valve

D. Tank Drain

Section IV SERVICE REPAIR INSTRUCTIONS

A. Troubleshooting Chart

B. Electrical

1. Replacing Pressure Switch

2. Replacing Power Switch

3. Replacing Compressor Head

4. Replacing Time Operated Purge Valve

C. Pneumatic

1. Replacing Check Valve

2. Replacing Differential Filter Indicator

3. Replacing Automatic Filter Float Drain

4. Replacing Desiccant Chamber

Section V ILLUSTRATED PARTS BREAKDOWN

A. Parts Listing

B. Electrical Schematic

C. Plumbing Schematic

1.800.624.2793

1

SECTION I

Introduction

C1000 Series Service & Maintenance Manual

Introduction

This manual contains the necessary information to perform all “fi eld serviceable” aspects of the DCI Oil-less Air Compressor line.

Please take the time to read this manual and understand the proper operation and service procedures before attempting to service

this machine. Our unique dryer purge system operates much differently than conventional air compressors. Understanding the

proper operation and design will ensure years of dependable operation.

Below is a listing of the basic tools required to properly service this equipment.

Voltmeter

Screwdrivers:

Blade

Phillips

Combination

Wrenches

If you have any questions or need assistance in regards to any aspect ot the service and / or repair of this machine, please contact

the DCI Technical Support Department at:

Technical Support

1-800-624-2793

2

www.dcionline.com

C1000 Series Service & Maintenance Manual

Introduction

Introduction

INTRODUCTION

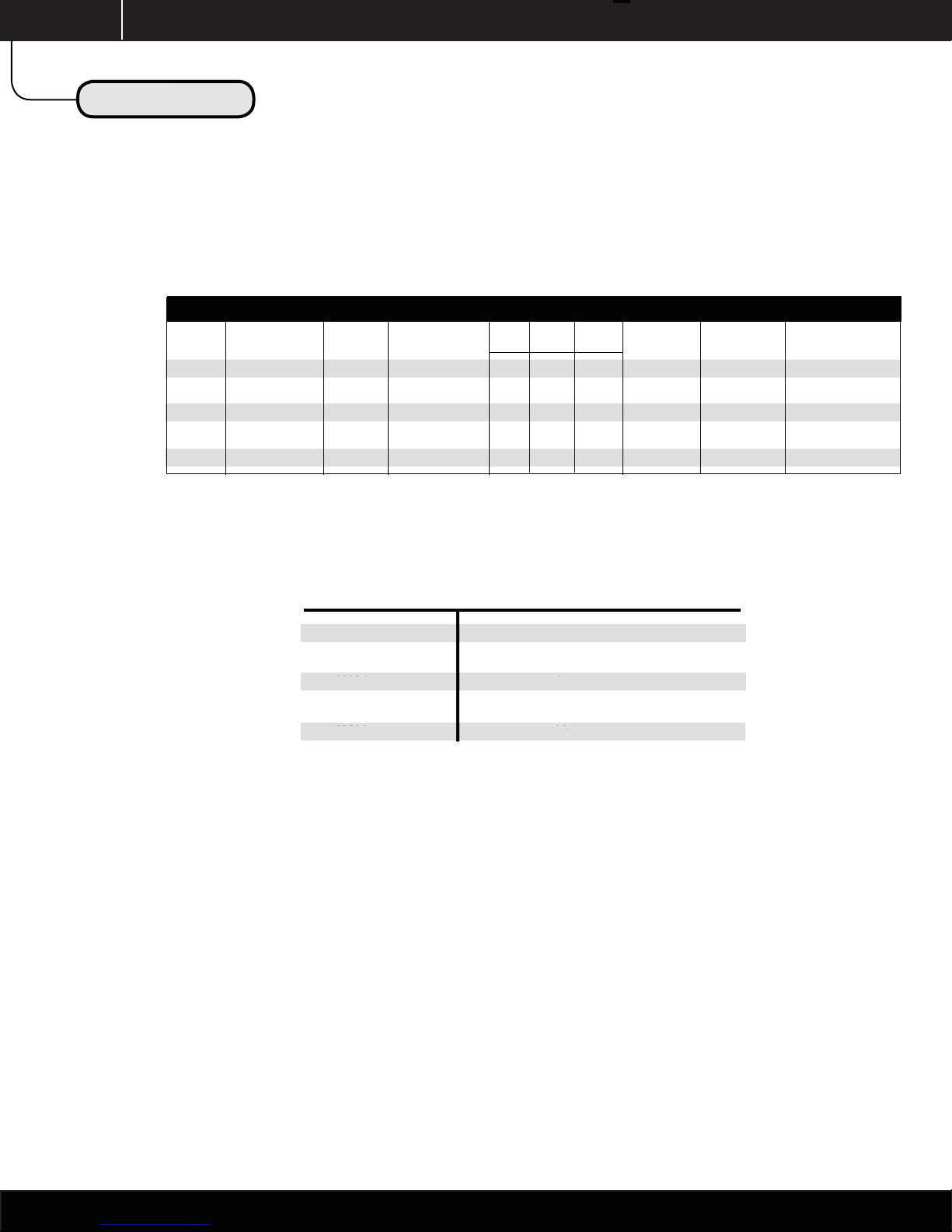

This manual contains the necessary instructions for the maintenance and/or service of the DCI air compressors.

There are 3 basic confi gurations available; single and dual head available in 115V and 230V, and the triple head available in 230V.

NOTE: ALL VOLTAGES +/- 5%

Confi gurations

1. Single 1 horsepower compressor head on 20 gal. Horizontal tank. (See Fig. A)

2. Dual 1 horsepower compressor heads on 20 gal. Horizontal tank. (See Fig. B)

3. Dual 1 horsepower heads on 30 gal. horizontal tank. (Not Shown)

SECTION I

Fig. A Fig. B

Picture of Single

Horizontal Compressor

Model #C1103 & #C1203

Picture of Dual

Horizontal Compressor

Model # C2106 & #C2206

Picture of Triple

Horizontal Compressor

Model # C3210

1.800.624.2793

3

g

3

SECTION I

Unpackin

Model Specifi cations

C1000 Series Service & Maintenance Manual

Introduction

MODEL SPECIFICATIONS

Model CFM @ 80PSI Total HP Tank Capacity Dimensions (inches) Voltage Amps Circuit Breaker

L D H

C1103 3.95 1 20 34 24 29.5 115 13.4 15

C1203 3.95 1 20 34 24 29.5 230 6.7 10

C2106 7.95 2 20 34 24 29.5 115 26.8 30

C2206 7.95 2 20 34 24 29.5 230 13.4 15

C3210 11.85 3 30 46 26 36 230 21.1 30

NOTE: ALL VOLTAGES ARE +/- 5%

MODEL NUMBER MAXIMUM SIMULTANEOUS USERS

C1103 3

1103

C1203 3

C2106 6

C2206 6

C3210 10

NOTE: Number of users based on 1.5cfm @ 80psi per user. Additional equipment such as air abrasion units, blow-guns, and lab equipment should

be factored into the system requirements.

Site Requirement Templates and additional technical information available through our Technical Service Department.

4

1 www.dcionline.com

www.dcionline.com

C1000 Series Service & Maintenance Manual

Theory of Operation

Theory of Operation

THEORY OF OPERATION

While Running

To start the compressor, the user shall activate the compressor head or heads with the power switches located on the front center

of the machine. The selected motors will then begin to run and build pressure in the tank and piping system.

A. The air is taken in through the intake fi lters, located on the rear of each compressor cylinder. The dirt and dust is fi ltered out

of the intake fi lter to 5 microns in this process.

SECTION II

B. The air is then compressed with the pistons in each cylinder, and then travels through the after-cooler (copper) tubing, which

cools the air to help condense any moisture “humidity” taken in during the process of compression.

C. The wet / dirty compressed air and condensed moisture then travel through a coalescing fi lter assembly. This fi lter allows the

condensed moisture to fall to the bottom of the fi lter bowl via gravity, where it will be automatically expelled via the fl oat

drain contained in the bottom of the fi lter bowl. The compressed air also travels through the coalescing fi lter element, which

removes 99.998% of all particles down to 0.01 microns. A fi lter change indicator located on the top of the fi lter housing

shows the condition of the element, and alerts the operator as to when the element is in need of replacement. GREEN

indicates the element has more useful life, while RED indicates the element is in need of replacement.

NOTE: The indicator only functions while compressed air is traveling through the fi lter with compressor running. The indicator

will ALWAYS read “GREEN” with compressors not running.

D. The compressed air then travels through the bottom of the desiccant “drying chamber”, where the remaining contained

moisture is reduced to a pressure dewpoint of -100°F, and then travels into the main storage tank for use in the dental

operatory.

E. When reaching its cut-off pressure of 100psi, the pressure switch will open and the compressor motors will stop.

NOTE: The time operated dryer purge valve DOES NOT open and purge when compressor stops, as it does on most competitive

brands. See Theory of Operation “While Not Running” for more information as to the proper operation of our purge valve.

1.800.624.2793

5

SECTION II

Theory of Operation

While Not Running

A. When the motors stop after reaching the cut-out pressure of 100psi, the user will have clean / dry air ready for use in

the dental operatory. The compressor will remain in this “idle” state until the tank pressure drops to 80 psi, at which time

the compressor motors will turn on and return the running mode of operation.

B. The “Time Operated” dryer purge valve operates on a time basis instead of a “single cycle” basis used on most other

types of dental air compressors. Two timers, “located on the front of the valve assembly”, control how often and the

duration of each purge cycle.

C1000 Series Service & Maintenance Manual

Theory of Oporation

THEORY OF OPERATION

NOTE: The compressor does not purge when the

compressor cycles off!

C. The “Left” timer knob on the purge valve, controls the

duration of the purge cycles. This timer is factory preset

and should not be adjusted. The factory setting is at the

maximum of 10 seconds.

D. The “Right” timer knob on the purge valve controls how

often the compressor purges moisture from the drying

chamber. The factory setting is 7 minutes, and should NOT

be adjusted.

E. A “TEST” button is located between the two timer knobs

to allow a technician to verify that the valve is operating

correctly.

By purging the drying chamber on a time basis, the DCI air

compressors ensure the drying chamber desiccant remains dry,

even during heavy usages, for consistent air quality.

Aftercooling

Tubing

Coalescing

Filter

Condensate

Drain

Left

Motor

Check

Valve

Flow/Check

Drying Chamber

Strainer

Shutoff

Valve

Right

Motor

Check

Valve

Dryer Bypass

Ball Valve

Drying System

Pressure Gauge

To

Storage

Tank

6

1 www.dcionline.com

Time Purge

Valve

Plumbing Schematic

www.dcionline.com

While Not Running

Electrical Schematic

C1000 Series Service & Maintenance Manual

THEORY OF OPERATION

Theory of Oporation

SECTION II

Theory of Operation

1.800.624.2793

7

g

SECTION III

Unpackin

Maintenance

COMPRESSOR MAINTENANCE SCHEDULE

Maintenance Item Frequency

Intake Filter Elements Every Six Months (semi-annually)

Coalescing Filter Element Every 90 Days

Time Operated Purge Valve Every 60 Days

Tank Drain Every 90 Days

A. Compressor Head Intake Filter Elements

Dirty intake fi lter elements reduce the amount of air the compressor can take in. This

reduces air output and increases the load of the motors. Every six months, remove

the intake fi lter cover as shown in (Fig. D), to check for excessive dirt or discoloration.

Replace with DCI Part Number 2012 if needed. The fi lters are located on the rear of each

compressor cylinder.

C1000 Series Service & Maintenance Manual

Maintenance

MAINTENANCE

B. Coalescing Filter Element

The coalescing fi lter element should be checked with the compressor motors running. If

the indicator located on the top of the fi lter housing remains GREEN, the fi lter element has

additional useful life. However, if the indicator turns RED, the element should be changed.

To change the element, fi rst turn off the compressor motor switches. Then turn off the

Dryer bypass valve as shown in (Fig. E). With dryer bypass valve in OFF position, press the

TEST button on the time operated purge valve to bleed pressure off of the drying system.

Depressurization of the drying system can be confi rmed by reading the drying system

pressure gauge located on top of the drying chamber.

WARNING: DO NOT ATTEMPT TO SERVICE WITH SYSTEM PRESSURIZED.

Unscrew the fi lter bowl by turning counter-clockwise. Lower the fi lter bowl to access the

fi lter element contained inside. The fi lter element is held in place with an O-ring and

internal ridges located in the bowl. Replace with DCI Part Number 2006, and reassemble

the fi lter bowl. Turn the dryer bypass valve to the ON position and check compressor for

proper operation by turning the power switches on.

Fig. D

OFF

ON

NOTE: A “popping” relief valve indicates a clogged coalesing element OR

the Dryer Bypass valve is closed.

8

1 www.dcionline.com

Fig. E

www.dcionline.com

C1000 Series Service & Maintenance Manual

g

Maintenance

Unpackin

Maintenance

SECTION III

MAINTENANCE

C. Time Operated Purge Valve

The time operated purge valve should be checked for proper operation every 60 days. To test, press the TEST button located between the

two timer adjustment knobs (see Fig. F). If air escapes from the valve, it is working properly. If no air is expelled, verify that the fi lter /

strainer valve is in the ON position “parallel with fl oor”. Check the fi lter screen inside the fi lter / strainer valve as shown in Fig. G. If the

strainer / shutoff valve is on and the screen is not clogged, replace the Time Operated Purge Valve with DCI part Number 2011 for 230 volt

models, or DCI Part number 2848 for 115 volt models.

Fig. F

D. Tank Drain

The tank drain “petcock” should be opened to check for moisture in the storage tank every 90 days. The tank drain is located at the bottom

right hand side of the storage tank. (See Fig. H) If no moisture is present, the drying system is working properly. If moisture is present, refer

to the Time Operated Purge Valve section above.

Fig. H

Fig. G

1.800.624.2793

9

”

”

g

SECTION IV

Unpackin

Troubleshooting Chart

SYMPTOMS CAUSES POSSIBLE REMEDY

C1000 Series Service & Maintenance Manual

Service and Repair

TROUBLESHOOTING CHART

Compressor Will Not Run

Compressor Will Not Start, “hums”

ompressor Will Not Start, “hums

Motor Overheats

No Power

Improper Line Voltage

Tripped Overload

Pressure Switch

System Already at Pressure

Improper Line Voltage

Open Start Capacitor

Open Start Winding

Improper Voltage

Ambient Temperature Too High

Too Many Starts Per Hour

Cycle Time Too Long

Check circuit breaker.

Ensure that supply voltage matches equipment ratings.

Check for loose wiring.

Check contact points and adjust or replace.

Bleed pressure from system to ensure proper starting.

Ensure supply voltage matches equipment ratings.

Replace Start Capacitor.

Replace Compressor Head.

Ensure supply voltage matches equipment ratings.

Improve ventilation; add a fan.

Check for air leaks and repair; add additional compressor.

Check for air leaks and repair; add additional compressor.

High System Pressure

igh System Pressure

Low System Pressure

Relief Valve “popping”

elief Valve “popping

Clogged Intake Filter

Pressure Switch

Pressure Switch

System Undersized

Clogged Coalescing Filter Element

Dryer Bypass Valve Is Closed

Faulty Relief Valve

Replace intake Filter.

Improperly set or defective pressure switch.

Improperly set or defective pressure switch.

Additional or larger compressor required.

Replace coalescing fi lter element.

Replace relief valve.

Open Valve.

1 www.dcionline.com

10

www.dcionline.com

C1000 Series Service & Maintenance Manual

M

s

g

Troubleshooting Chart

TROUBLESHOOTING CHART

SYMPTOMS CAUSES POSSIBLE REMEDY

Service and Repair

Unpackin

SECTION IV

Compressor Overheats

Moisture In Air Lines

oisture In Air Line

Clogged Air Intake Filter

Exhaust Valve

Too Much Run Time

Ambient Temperature Too High

Time Operated Purge Valve

Timers Incorrectly Set

Strainer Valve Off or Clogged

Coalescing Filter Auto-Drain

Desiccant Failure

Compressor Undersized

Faulty Dental Unit Diaphragm

Clean or replace intake fi lter element.

Clean & Replace valve-plate.

Air leaks; compressor too small to meet demand.

Add ventilation and \ or cooling to equipment room.

Clean or replace solenoid valve assembly.

Left Timer knob “duration of purge” set at 10 seconds.

Right Timer knob “purge interval” set at 7 minutes.

Clean strainer and ensure valve is on.

Clean or replace as needed.

Replace drying chamber assembly.

Additional or larger compressor to met demand requirements.

Check Master shut-off and water relay diaphragms.

1.800.624.2793

11

SECTION IV

Electrical

A. Electrical Components

1. Pressure Switch: Turns on or off the power supplied to the

individual compressor motor switches. The pressure switch is preset

to run the compressors to 100psi and then open, therefore stopping

the motor(s). When the system pressure drops to 80psi, the switch

closes, running the compressor motors to 100psi again.

To test the switch, bleed all pressure from the tank. Remove the

pressure switch top cover with a 3/8” wrench. With an AC voltmeter,

place the test leads on the outer terminals as shown in Fig. I. The

voltage indicated should agree with the machine data plate, either 115

or 230 volt AC. If no voltage is present, check the circuit breaker.

C1000 Series Service & Maintenance Manual

Service and Repair

ELECTRICAL

Fig. I

If the proper voltage is present on the outer terminals, move the voltmeter test leads to the inner terminals of the pressure switch as shown in

Fig. J. If NO voltage is present, the pressure switch is defective. If voltage is present, proceed to the next step.

Turn the machine power on, and wait for compressor to reach 100psi

and stop running. The 3/8” adjusting screw may be turned clockwise

to increase the cutoff pressure or counter-clockwise to decrease the

cutoff pressure. The maximum pressure cutoff should not exceed

100psi. If the compressor will not cut off at the desired preset

pressure, or will not stop under any condition, the pressure switch is

defective.

12

1 www.dcionline.com

Fig. J

www.dcionline.com

2. Power Switches: The toggle switches located on the front center of the

compressor control the individual compressor motors. If the pressure

switch is operating correctly, remove the motor terminal cover on the back

of the desired compressor motor. With the power switch in the on “up”

position, check for voltage to the compressor motor as shown in Fig. K. If

the proper voltage is present, the power switch is good. If no voltage is

present at the motor, replace the corresponding power switch.

C1000 Series Service & Maintenance Manual

Service and Repair

Electrical

SECTION IV

Fig.K

3. Compressor Motor (head): The compressor motor turns the compressor crankshaft to generate airfl ow to the system. If the correct

voltage is present on the L1 and L2 terminals as described in the testing procedure listed above, but the compressor hums and does not

start, the start capacitor is defective. If the correct voltage is present but nothing happens, the head is defective.

To replace the motor, it is not required to cut the spade terminals from the wiring (see Figures L and M) for proper disassembly without

cutting factory wiring.

After removing the wiring from the compressor motor, the motor may be removed by unscrewing the air discharge hose on the front left

cylinder, and removing the four ½” nuts securing the head to the vibration isolation mounts.

Fig. L Fig. M

1.800.624.2793

13

SECTION IV

Electrical

To Replace the Time Operated Purge Valve

1. Remove the Philips head screw that holds the electrical connector in place, and pull the electrical connector off of the timer assembly.

2. Turn “OFF” the strainer / shutoff valve in Fig. N.

3. Remove the valve and replace with DCI Part Number 2011 for 230 volt machines OR DCI Part Number 2848 for 115 volt models.

C1000 Series Service & Maintenance Manual

Service and Repair

Time Operated Purge Valve

4. Return the strainer / shutoff valve to the On position.

NOTE: Make sure the coil voltage matches that of the machine data tag.

14

1 www.dcionline.com

Fig. N

www.dcionline.com

C1000 Series Service & Maintenance Manual

Service and Repair

SECTION IV

Electrical

PNEUMATIC

WARNING: HIGH SYSTEM PRESSURES MAY CAUSE SERIOUS INJURY.

ALWAYS DEPRESSURIZE THE ENTIRE SYSTEM BEFORE ATTEMPTING TO SERVICE PNEUMATIC COMPONENTS.

1. Replacing the check valves. If a check valve failure occurs, the symptom will be air escaping through one of the compressor

heads with the compressor NOT running. To replace a defective check valve, unscrew “counterclockwise” the air discharge hose fi tting

from the appropriate compressor head. Once the air discharge hose is disconnected from the compressor head, the check valve,

along with the discharge hose, may be removed from the discharge manifold by unscrewing the check valve ”counterclockwise”, and

replaced with a new check valve. Reverse this process to reassemble the check valve / discharge hose assembly.

2. Replacing the Differential Filter Indicator. If the differential indicator becomes stuck in either the red OR green

indicating position, the indicator needs replacement. Replace the differential fi lter indicator by unscrewing the entire assembly

“counterclockwise” with a 15/16” - 6 point / box end wrench. Install the new indicator in the reverse order.

3. Automatic Filter Float Drain. Unscrew the coalescing fi lter bowl from the fi lter head. Using a 9/16 wrench, unscrew the

retaining nut on the bottom of the fi lter bowl. With the retaining nut removed, the automatic fl oat drain will be removed from the

fi lter bowl. Replace in the reverse order.

4. Replacing Desiccant Chamber. To replace the desiccant chamber, remove the rigid stainless steel tubing from the dryer

bypass valve at the compression fi tting, located at the dryer bypass valve. Remove the top plumbing manifold assembly from the top

of the desiccant chamber, by turning counterclockwise. Remove the electrical cord from the dryer purge valve by removing the Philips

head retaining screw, and pulling the cable away from the valve timer block. Next, remove the fl exible discharge hose from the

discharge side of the coalescing fi lter, and then unscrew the bottom manifold assembly from the bottom of the desiccant chamber.

Replace the desiccant chamber and reassemble in the reverse order.

1.800.624.2793

15

g

SECTION V

Unpackin

Parts Call-Out

C1000 Series Service & Maintenance Manual

Illustrated Parts Breakdown

2856

Pressure Gauge

2005

Pressure

Switch

2013

Relief Valve

2012

Intake Element

2135

Check Valve

2014

Drying Chamber

Assembly

2002

1 hp Head

Data Tag

Outlet Ball Valve

2856

Pressure Gauge

2859

Petcock Valve

Bypass Valve

2009

Strainer Shut O

16

2008 Indicator

2135 Check Valve

2003 Coalescing Filter

2006 Coalescing Element

2007 Float Drain

2011 Automatic Purge Valve (230 Volt)

OR 2848 Automatic Puge Valve (115 Volt)

www.dcionline.com

C1000 Series Service & Maintenance Manual

g

Illustrated Parts Breakdown

Unpackin

Electrical Schematic

SECTION V

1.800.624.2793

17

SECTION V

g

Unpackin

Plumbing Schematic

C1000 Series Service & Maintenance Manual

Illustrated Parts Breakdown

Aftercooling

Tubing

Coalescing

Filter

Condensate

Drain

Left

Motor

Check

Valve

Flow/Check

Drying Chamber

Strainer

Shutoff

Valve

Right

Motor

Check

Valve

Dryer Bypass

Ball Valve

Drying System

Pressure Gauge

To

Storage

Tank

18

1 www.dcionline.com

Time Purge

Valve

www.dcionline.com

1.800.624.2793

19

305 N. Springbrook Road

Newberg, Oregon 97132 USA

503.538.8343

800.624.2793

www.dcionline.com

Loading...

Loading...