Page 1

Compressor Installation Guide

C Series

COMPRESSOR

• C1103

• C1203

• C2106

• C2206

• C3210

Copyright © 2006 DCI. All Rights Reserved.

92094, Rev. D, 08/13

Page 2

1 www.dcionline.com

www.dcionline.com

Page 3

C - Series

Compressor

C Series Installation Guide

Compressor Model Specification

Oil-Less

# Heads

Tank

Power

Power

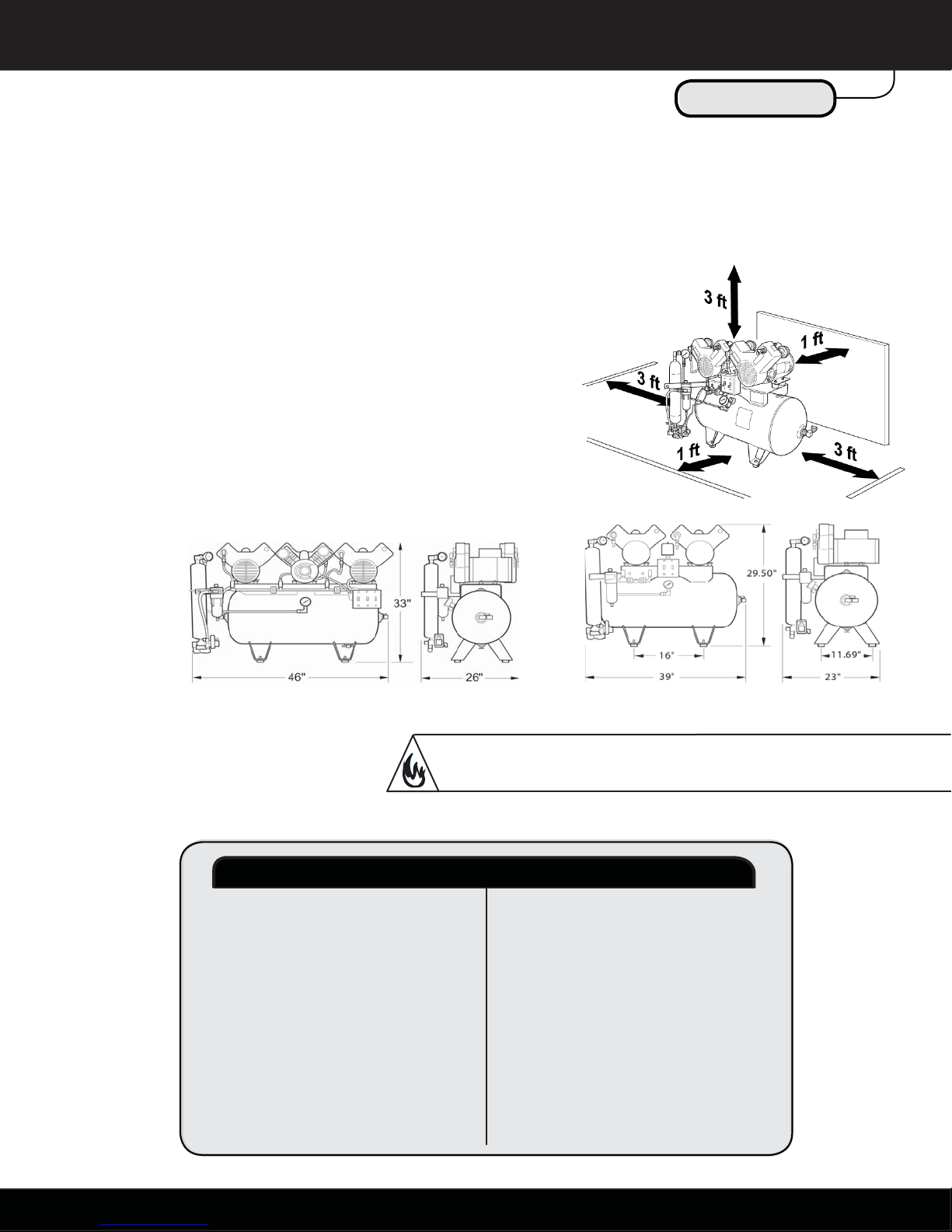

Model # # of Heads Tank Size Voltage Breaker Size Amps

C1103 1 Horizontal 20 gal. 115 20 Amps 13.4

C1203 1 Horizontal 20 gal. 230V 20 Amps 6.7

C2106 2 Horizontal 20 gal. 115V 30 Amps 26.8

C2206 2 Horizontal 20 gal. 230V 20 Amps 13.4

C3210 3 Horizontal 30 gal. 230V 30 Amps 20.1

All Voltage Ratings ± 5%.

NOTE: 1) All machines are of the 3 wire grounded system type.

2) Minimum Breaker size 30 amp & larger wire size #10 supply connection.

29.50"

33"

16"

39"

11.69"

23"

NOTE: Installation of this product should be undertaken only

If the product does not function as described in the start-up and

test procedures in this manual, call the number below for assistance.

NOTE: Air fl ow rates in excess of compressor ratings will result

Space Requirements

by qualifi ed service technicians.

This product has been factory-tested prior to shipment.

Technical Support: 1-800-624-2793

in reduced performance and possible overheating.

1.800.624.2793

46"

26"

1

Page 4

C Series Installation Guide

Installation Kit

Compressor Installation Kit

Installation Kit

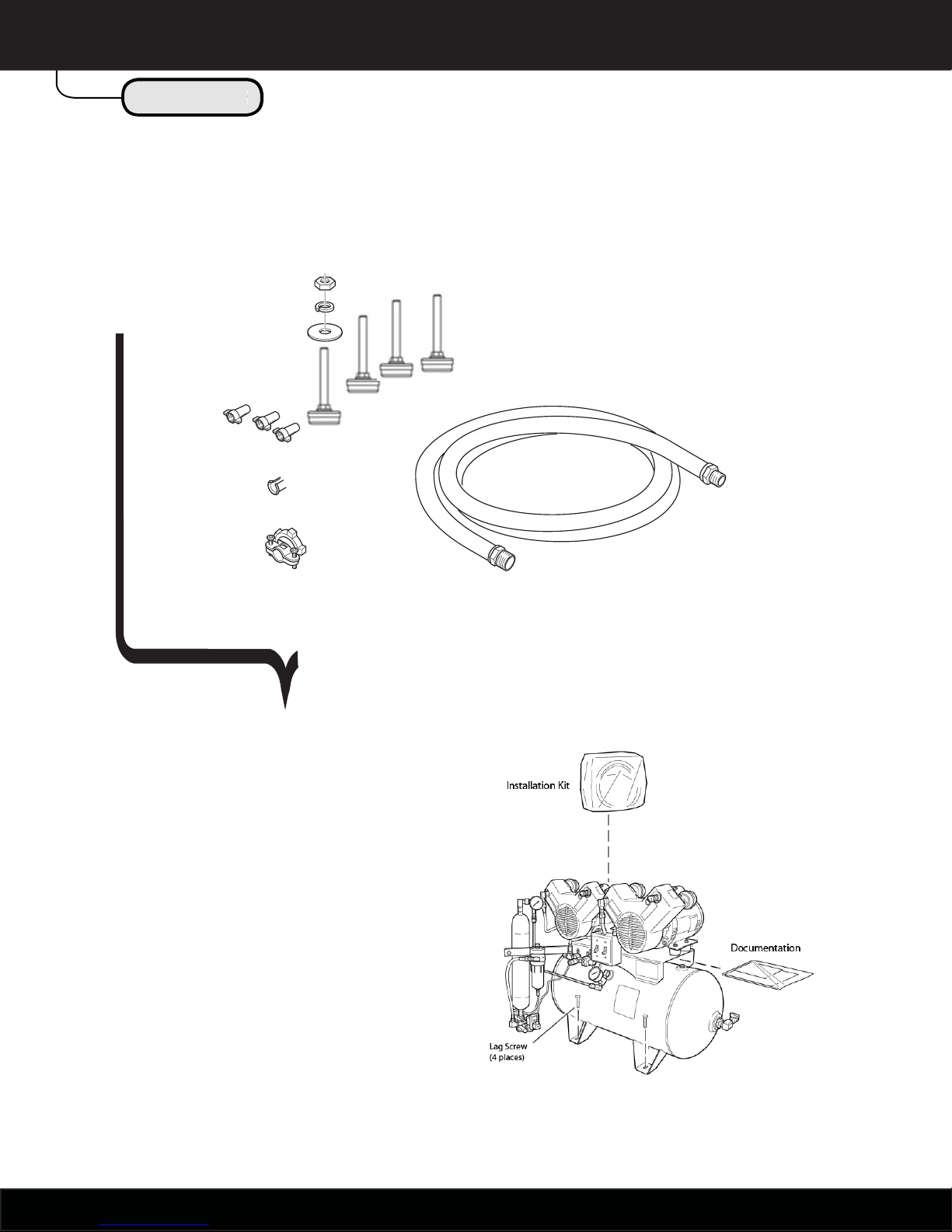

The C - Series is shipped with the following:

Lock Washer

Flat Washer

Antivibration Foot

Wire Nuts

Nut

Split Bushing

Conduit Connector

You must provide:

Fittings and bushings as required to connect the

•

fl exible hose to the on-site piping (the hose-end

is 3/8 in. NPT “male”).

Earthquake restraints for securing the equipment

•

if required by local codes.

6 ft. Hose

2

www.dcionline.com

Page 5

C Series Installation Guide

Site Requirements

Clearance Site Requirements

Adequate clearance as shown below for servicing and air circulation — room

•

temperature should be maintained between 40°F and 100°F when the motors

are running.

A fl at, level fl oor that provides stable support.

•

Protection from the weather and direct sunlight.

•

A power source within 3 ft. of back-center that provides a dedicated,

•

breaker-protected circuit.

Compressor Site Requirements

WARNING! Fire Hazard! Running motors generate heat. Do not store fl ammable

liquids or objects such as clothing, mops, or brooms near or above the unit.

PLUMBING REQUIREMENTS

1. 1/2 in I.D. minimum pipe size.

2. Pipe connection is to be located within 3 ft of

center back of compressor.

3. Install per all Local and State plumbing codes.

ELECTRICAL REQUIREMENTS

1. 3 wire single phase 115 vac or 230 vac. All

voltage ratings ± 5%.

2. Green Wire is to be grounded to a suitable

system ground.

3. Power supply must be on a dedicated circuit.

4. See data tag for appropriate breaker size.

5. Power supply connection is to be located

within 3 ft of center back of compressor.

6. Install per all local and State electrical codes.

1.800.624.2793

3

Page 6

C Series Installation Guide

Unpacking

n-

Unpacking

Step One:

Unbolt the crate from the pallet

and remove crate intact.

NOTE: Returns must be in the original packaging. Retain the packaging until

installation and test are complete.

Step Two:

Remove the four bolts that

secure the C - Series to the

pallet and put them with the

other packaging.

Step Three:

Mount the four rubber feet.

4

1 www.dcionline.com

www.dcionline.com

Page 7

Step Four:

Grasp the C - Series by the tank and

move it into position.

C Series Installation Guide

Unpacking

Unpacking

NOTE: Returns must be in the original packaging. Retain the packaging until

installation and test are complete.

1.800.624.2793

5

Page 8

C Series Installation Guide

Installation

n-

Installation

Electrical

Step One:

Make sure the power supply is turned off and matches the voltage rating of the motors.

Note: Appropriate Breaker size is listed on the machine data tag.

Step Two:

Connect the power, making sure to adhere to all local and state codes.

Connect the “Green” Ground wire to an earth ground.

Note: 3 wire system.

Step Three:

Attach the fl exible piping and connect to on-site piping.

Install appropriate over current protection; i.e., circuit breaker.

Note:

Model # Breaker Size

C 1103 20 Amps

C 1203 20 Amps

C 2106 30 Amps

C 2206 20 Amps

C 3210 30 Amps

WARNING! Do not connect rigid pipe directly to the compressor. Motor vibration

loosens fi ttings, causing leaks. Use the fl exible pipe provided or a similar substitute.

6

1 www.dcionline.com

www.dcionline.com

Page 9

g

Step One:

Turn off the switches on the front of the compressor.

Step Two:

Ensure that the dryer by-pass shut-off valve is open.

Step Three:

Ensure that strainer shut-off valve is open.

Step Four:

Close outlet valve on the compressor tank.

Step Five:

Apply power to system — the purge valve my emit a hissing sound as the purge timer resets.

Step Six:

C Series Installation Guide

Start-Up & Test

Unpackin

Start-Up & Test

Switch on the motors. If you hear the popping sound of air escaping the relief valve, the dryer by-pass valve is closed.

1.800.624.2793

7

Page 10

g

C Series Installation Guide

Start-Up & Test

Unpackin

Start-Up & Test

Step Seven:

As the tank pressurizes, watch the

pressure gauge. If the pressure switch

is functioning normally, the motors will

shut off at approximately 100 PSI.

Wait fi ve minutes and watch the gauge

to ensure there are no leaks in the

C Series. The system should lose

no more than one PSI per minute.

Step Eight:

Test the purge valve by pressing the

TEST button. If the valve is functioning

normally, you will hear the hiss of air

escaping for approximately ten seconds.

150

BAR

100xkPa

psi

12

180

15

21

18

210

0

0

3

2

4

0

27

0

0

2

1

0

9

9

6

0

6

3

3

0

0

0

8

1 www.dcionline.com

Do not adjust the timer dials on the purge valve.

NOTE!

If the purge timing needs adjustment, call technical support.

www.dcionline.com

Page 11

g

Step Nine:

C Series Installation Guide

Start-Up & Test

Unpackin

Start-Up & Test

150

180

0

2

1

0

9

6

0

6

3

3

0

0

0

210

12

9

BAR

100xkPa

psi

2

15

4

0

18

21

270

0

0

3

Release air using the purge-valve

TEST button and watch the pressure

gauge to see when the motors start.

The motors should start when the

pressure drops to approximately 80 PSI.

You may have to push the TEST button

several times before enough air is

released to lower the pressure to 80 PSI.

Step Ten:

Open the outlet valve on the tank to

pressurize the piping and wait until the

tank is fully pressurized and the motors

stop running.

Step Eleven:

Ensure that no equipment is drawing

pressure from the tank. When no equip-

Loses less than 1 psi per min?

NO LEAKS!

150

18

0

8

100

9

BAR

100xkPa

BAR

100xkPa

psi

0

210

1

2

12

6

0

2

15

40

8

0

18

4

10

1

21

11

270

0

0

6

30

1

psi

0

2

0

1

6

0

9

0

4

4

6

0

2

6

0

3

2

3

0

0

0

0

ment is drawing on the tank, pressure

should drop no more than 1 PSI per

minute.

Watch the pressure gauge. If pressure

drops faster than 1 PSI per minute, an

air leak is indicated somewhere in the

system. Repair as necessary.

1.800.624.2793

9

Page 12

2856

Pressure Gauge

2005

Pressure

Switch

2013

Relief Valve

2012

Intake Element

2135

Check Valve

2014

Drying Chamber

Assembly

2002

1 hp Head

Data Tag

Outlet Ball Valve

2856

Pressure Gauge

2859

Petcock Valve

Bypass Valve

2009

Strainer Shut O

2008 Indicator

2135 Check Valve

2003 Coalescing Filter

2006 Coalescing Element

2007 Float Drain

2011 Automatic Purge Valve (230 Volt)

OR 2848 Automatic Puge Valve (115 Volt)

1 www.dcionline.com

10

www.dcionline.com

Page 13

C Series Installation Guide

g

Unpackin

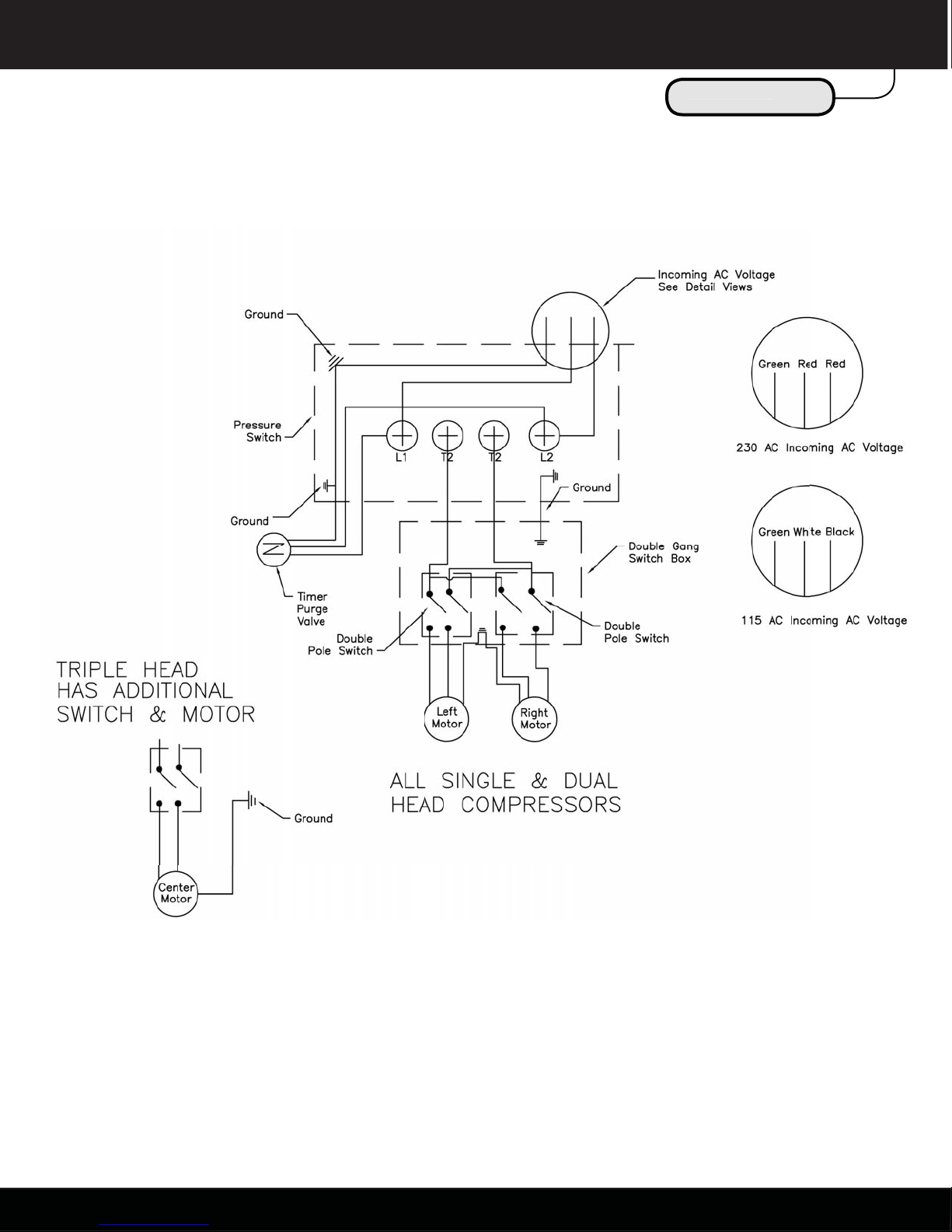

Electrical Schematic

Electrical Schematic

1.800.624.2793

11

Page 14

g

C Series Installation Guide

Plumbing Schematic

Unpackin

Plumbing Schematic

Aftercooling

Tubing

Coalescing

Filter

Condensate

Drain

Left

Motor

Check

Valve

Flow/Check

Drying Chamber

Strainer

Shutoff

Valve

Right

Motor

Check

Valve

Dryer Bypass

Ball Valve

Drying System

Pressure Gauge

To

Storage

Tank

12

1 www.dcionline.com

Time Purge

Valve

www.dcionline.com

Page 15

1.800.624.2793

Page 16

305 N. Springbrook Road

Newberg, Oregon 97132 USA

503.538.8343

800.624.2793

www.dcionline.com

Loading...

Loading...