Page 1

DCE

Data Sheet 367E

(GB)

tJn

aster'

DUT NTR

UNT

RE UM

025

A

for cleaner

motor

cover

removal

--

-

Ouick-release

sealer

gear

--d

B

t

230

min

clearance

cleaned

air outlet

required for

marntenance

Terminal box

Joint line

c

I,

t

Fan chamber

Filter chamber

Cleaner motor

cover

Dust inlet spigot

(at

either side, or at rear)

e

to centre of

lnlet sprgot

Dust container

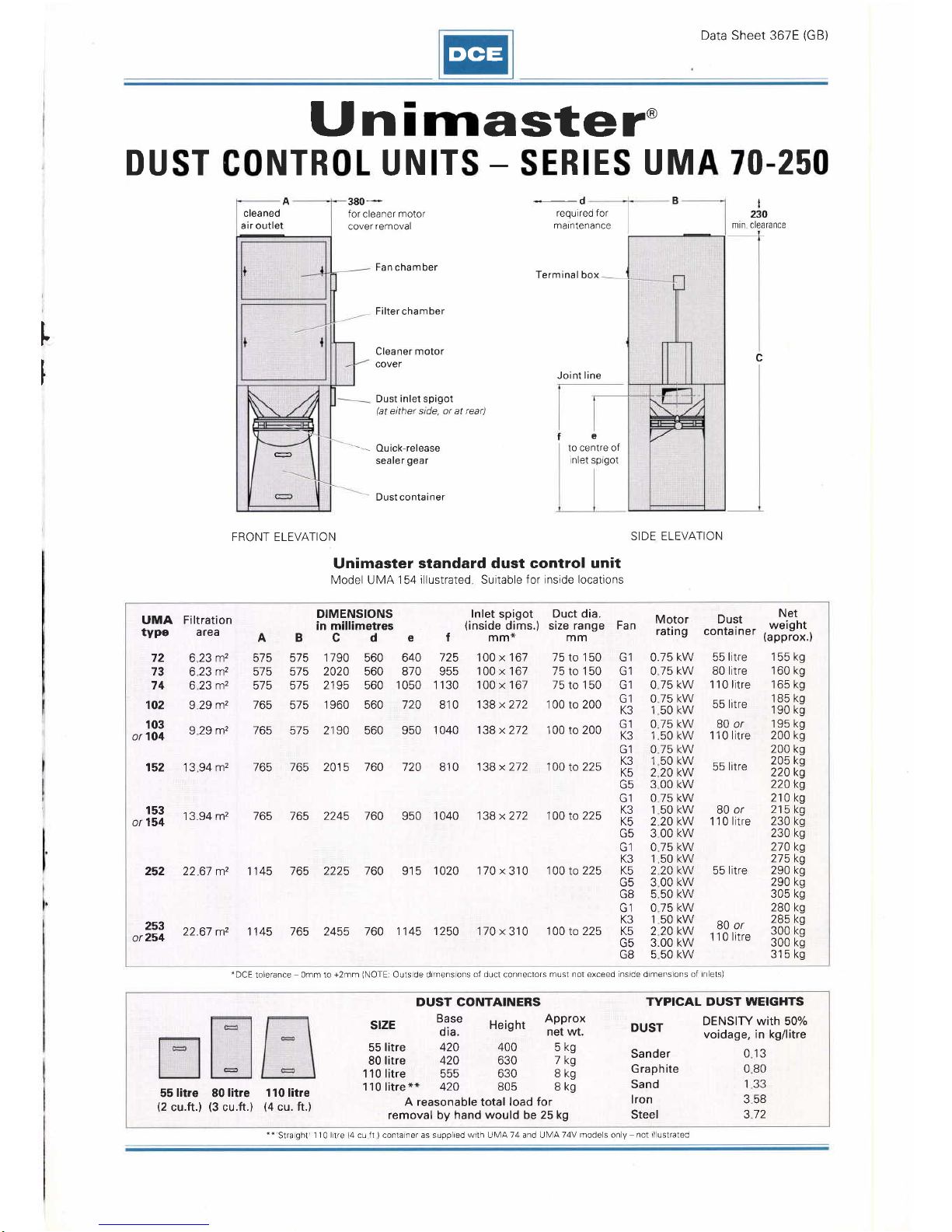

FRONT ELEVATION

SIDE ELEVATION

Unimaster

standard dust control unit

lVlodel UtVA 154 illustrated Suitable

f

or

inside locations

UMA Filtration

type

area

A

575

575

575

765

B

DIMENSIONS

in millimetres

cd

e

lnlet

spigot

(inside

dims.

f mm*

725 100

x

167

955

100

x

167

1 130 100

x

167

810 138x212

Duct dia.

)

size range Fan

mm

Motor

rating

Dust

conta iner

Net

weight

(approx.)

155 kg

160 kg

165 kg

185

kg

190

kg

19s kg

200 kg

200 kg

205 kg

220

kg

220 ks

210 kg

215

kg

230 kg

230 kg

210 kg

215 k9

290 kg

290

kg

305 kg

280 kg

285

kg

300 kg

300

ks

s15kg

72

73

74

102

103

or 1O4

623m2

623m2

623m2

929m2

575 1 790

s7s 2020

575 2195

575

1 960

560 640

560 810

560

1050

560 720

75

to

'1

50

75to150

75to150

1 00 to 200

G1

G1

G1

G1

K3

G1

K3

G1

K3

K5

AE

G1

K3

K5

G5

G1

K3

K5

G5

G8

(Jt

K3

K5

G5

GB

0.75

kw

075kw

075kw

55

litre

80 litre

1

1

0

litre

55 litre

80 or

1 1 0 litre

9

29 m2 165 515 2190 560 950

1 040 138

x

272 1 00 to 200

0

1

0

1

0

1

2

a

0

1

2

3

0

1

2

3

5

0

1

2

75 kW

50

kw

75 kw

50 kw

75 kw

50 kw

20 kw

00 kw

75 kW

50

kw

20 kw

00

kw

75 kW

50

kw

20

kw

152 13 94 m2 765

765 2015 760 720 810

138x272 100

to

225 55

litre

or

153

154

252

1 3.94 m2 765 765

2245 760

950

1 040 138

x

272 100 to

225

80

or

1

1

0

litre

22 67 m2 1145

765 2225 760 91 5 1020 1 70

x

31 0

100

to

225 55

litre

253

or254

22.67 m2 11 45 165 2455 760

1

145

1250

.1

70

x

31 0

1 00 to 225

00

50

75

50

20

KW

KW

KW

KW

80 or

1'l 0

litre

3.00

550

'DCE

toleraoce

omm to

+2mm

(NOTE:

Outs de drmens ons

of duct

conneclors

must not exceed insrde drmens ons

of rn

ets)

**Straght

110ltre(4cuft)contanerassupphedwrthU[,4A74andUNr]AT4Vmodelsony

notrlustrated

55

litre

80

litre 110 litre

(2

cu.ft.)

(3

cu.ft.)

(4

cu. ft.)

A reasonable

total

load for

removal by hand

would

be

25 kg

slzE

55

litre

80

litre

110 litre

110

litre

*r

DUST CONTAINERS

TYPICAL DUST WEIGHTS

DUST

DENSITY with 50%

voidage,

in kg/litre

013

080

133

358

312

Base

dia.

420

420

555

420

Height

400

630

630

805

Approx

net wt.

5kg

7kg

8kg

8ks

Sander

Graphite

Sand

lron

Steel

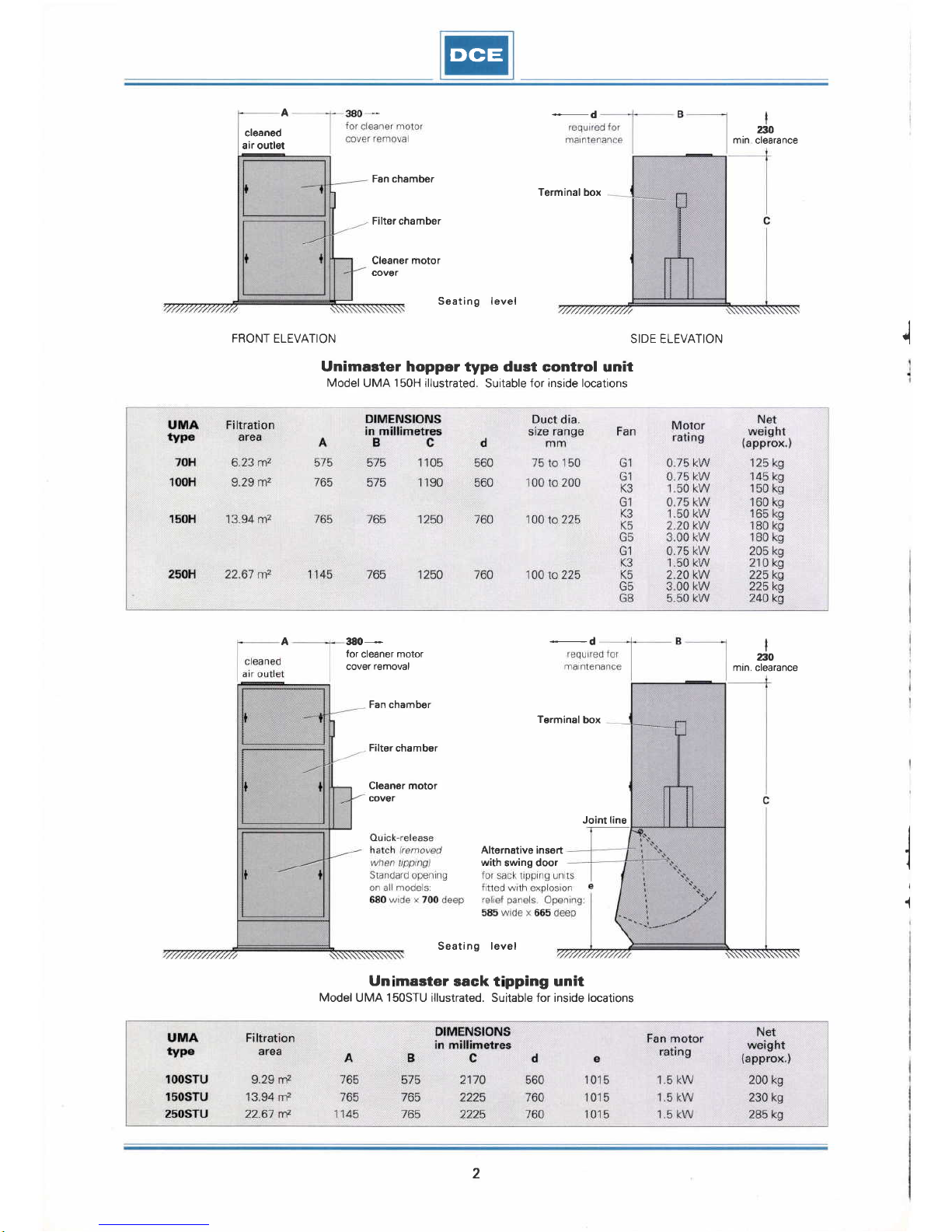

Page 2

DCE

Fan chamber

Terminal box

Filter chamber

Cleaner

motor

cover

Seating level

FRONT

ELEVATION

SIDE ELEVATION

Unimaster hopper type dust

control unit

Model UMA

150H

rllustrated.

Suitable

Jor inside locations

cleaned

air outlet

380-----

for

cleaner

motor

cover

removal

min clearance

t

ato

I

ao

min. clearance

A

A

I

-d

Fan chamber

Filter

chamber

Cl6aner motor

cover

Terminal

box

Alternative insert

with

swing door

Joint line

Seating level

Un master

sack t

pping

unit

Model

UMA

150STU

illustrated. Suitable for inside locations

I

2

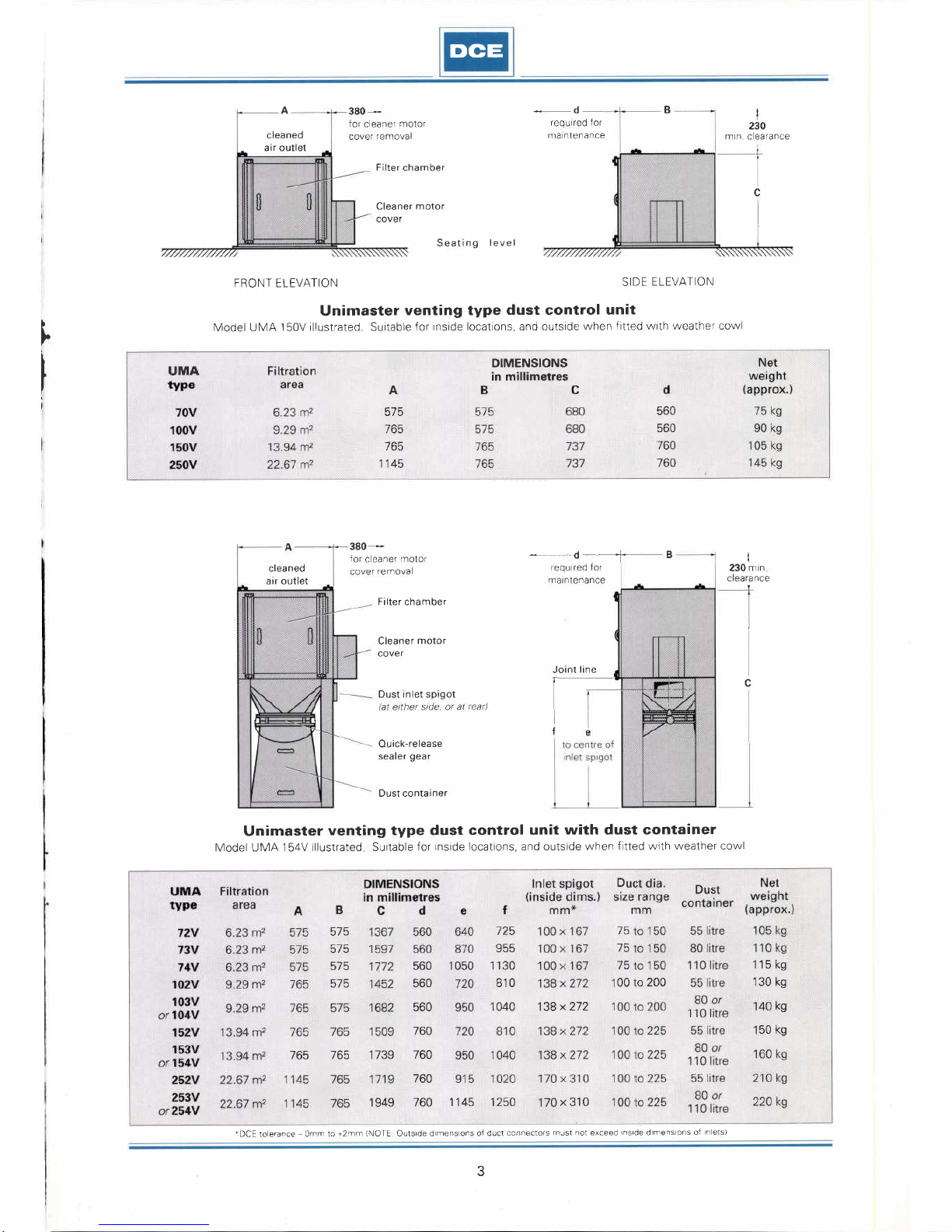

Page 3

DGE

A

cleaned

air outlet

cleaned

air outlet

380

_

for

c eaner

motor

cover

removal

Filter

chamber

Cleaner

motor

cover

380

*

for

c eaner

molor

cover

removal

-

d

requrred for

ma

ntenance

.equ

red for

marntenance

B

I

230

mrn c earance

I

230

mrn

cleara

nce

c

Seating

level

FRONT ELEVATION

SIDE

ELEVATION

Unimaster

venting type

dust control unit

lVodel UMA

150V illustrated Surtable

for rnside locatons, and outside

when fitted

wrth weather cowl

-dB

Filter chamber

Cleaner motor

cover

Joint

line

Dust inlet spigot

(at

etther stde, or at

rear)

Ou

ick-release

sealer

gear

Dust container

Unimaster

venting type dust

control unit

with dust container

lVodel UMA

154V rllustrated Surtable

for rnsrde locatrons, and outsrde

when

fltted wrth weather cowl

c

f

I

T

UMA

DIMENSIONS

in millimetres

A

575

765

765

1145

560

560

760

760

D

760

kg

560

560

560

760

50 kg

138

x

272

B

575

575

575

515

1 050

00 to

200

x

310

l5

75

1E

765 765

1139 760

1949 760

125

955

1 130

810

1 040

1145 1250

115 kg

130 kg

DCE to erance omm 10

+2mm

INOTE

Outsrde

d

mens

ons of duct

connectors

must

not

exceed

rnslde d mens ons ot n eIS)

3

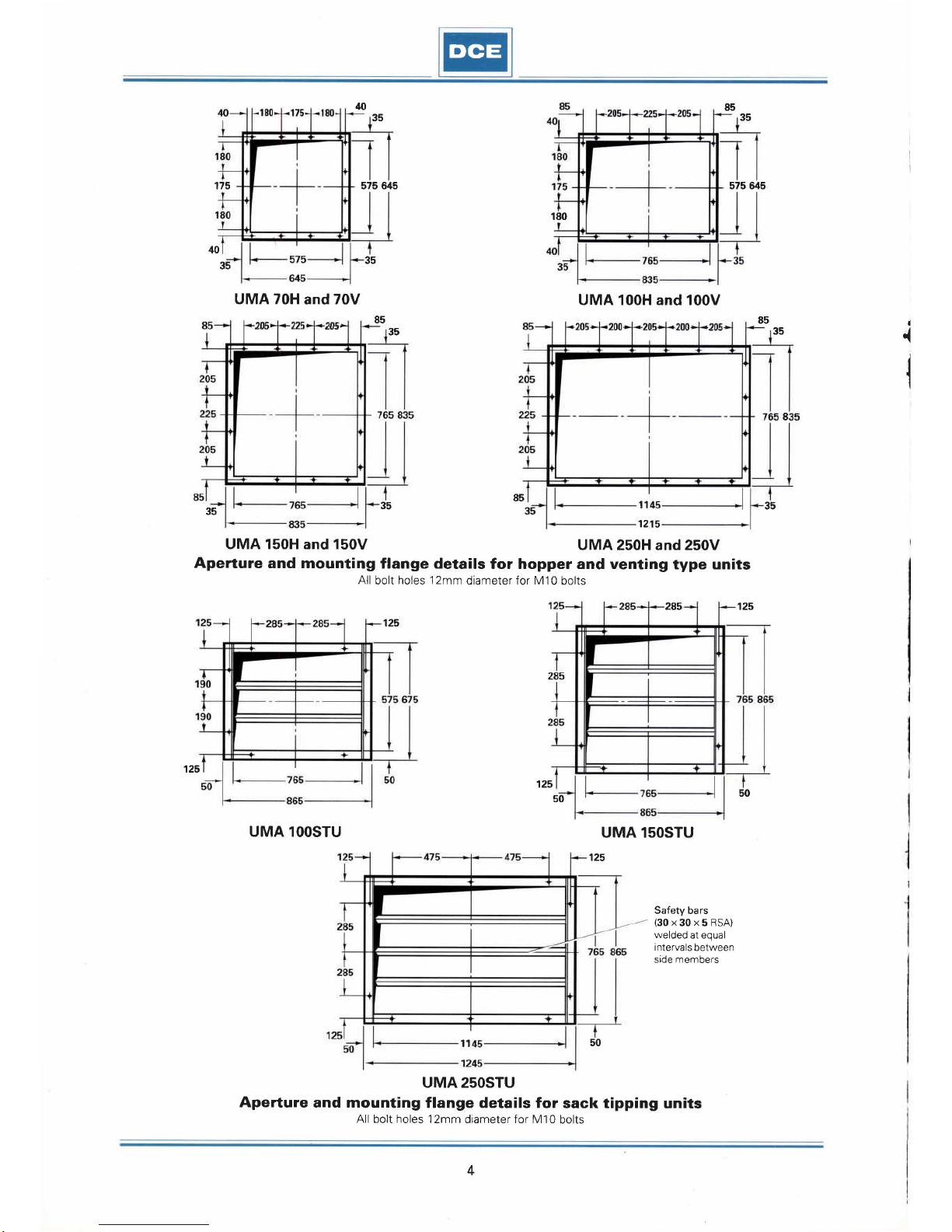

Page 4

DCE

85

tlo

35

35

575 6t15 575 645

180

40

35

35

UMA 70H

and 70V

UMA 100H and 100V

85

35

85

11

35

35

35

12

UMA 150H and 150V

UMA 250H and 250V

Aperture

and mounting

flange details

for hopper and venting

type units

All

bolt holes

12mm

diameter for M10

bolts

285 125

125

175

85

i

35

35

125

125

50

50

UMA 1OOSTU

UMA lsOSTU

125

Safety

bars

(30x30x5RSA)

welded

at equal

intervals

between

side members

11

50

UMA 25OSTU

Aperture

and mounting

flange details for

sack tipping

units

All bolt holes

I 2mm diameter f or M 1 0 bolts

I

4

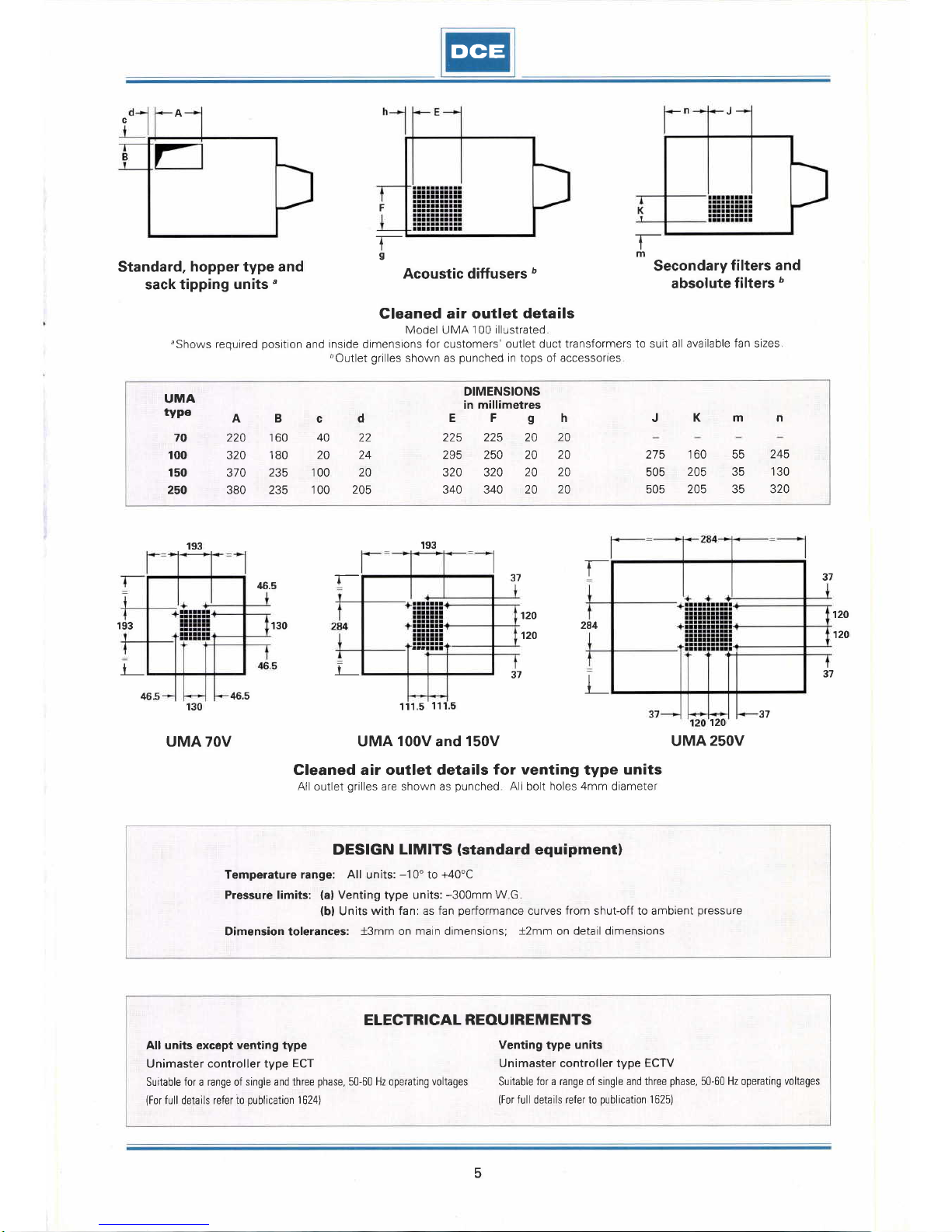

Page 5

DCE

A

J

Secondary

filters

and

absolute

filters

b

c

F

K

T-

s

r

m

Standard,

hopper type and

sack tipping

units'

193

Acoustic diffusers

b

Cleaned air outlet

details

Model UMA

100 illustrated

,Shows

required

position

and inside dimensions

for

customers'outlet

duct transformers to suit

all available fan sizes

bOutlet

grilles

shown as

punched

in tops of accessofles

45.5

T-

37

120

120

193

193

r

t_

37

130

t

37

46.5

130

111.5

11 .5

120

UMA 7OV

UMA 100V and 150V UMA

25OV

Gleaned air outlet details

for venting

type

units

All

outlet

grilles

are shown as

punched

All bolt

holes 4mm

diameter

DESIGN

LIMITS

(standard

equipmentl

Temperature range:

All

units:

-1

0'

to

+40'C

Pressure limits:

(al

Venting type units:

-300mm

W G

(bl

Units

with fan: as fan

performance

curves

from

shut-off to ambient

pressure

Dimension tolerances:

+3mm

on main dimensions;

+2mm

on

detail dimensions

ELECTRICAL

REOU IREM ENTS

All units exc6pt

venting type

Unimaster controller type

ECT

Suitable for a range of

single and three

phase,

50-60 Hz operating voltages

(For

full details refer

io

publication

1

624)

Venting

type

units

Unimaster controller type

ECTV

Suitable

for a range of single and three

phase,

50-60 Hz operating

voltages

(For

full

details

refer to

publication

1 625)

284

120

120

37

t

465

37

UMA

type

DIMENSIONS

in millimetres

A

220

320

370

380

B

160

180

235

235

c

40

20

100

100

d E

225

295

320

340

Fgh

225 20

20

250 20

20

320

20 20

340 20

20

JKm

n

70

100

150

250

22

24

20

205

275

505

505

160

205

205

trtr

atr

35

245

130

320

5

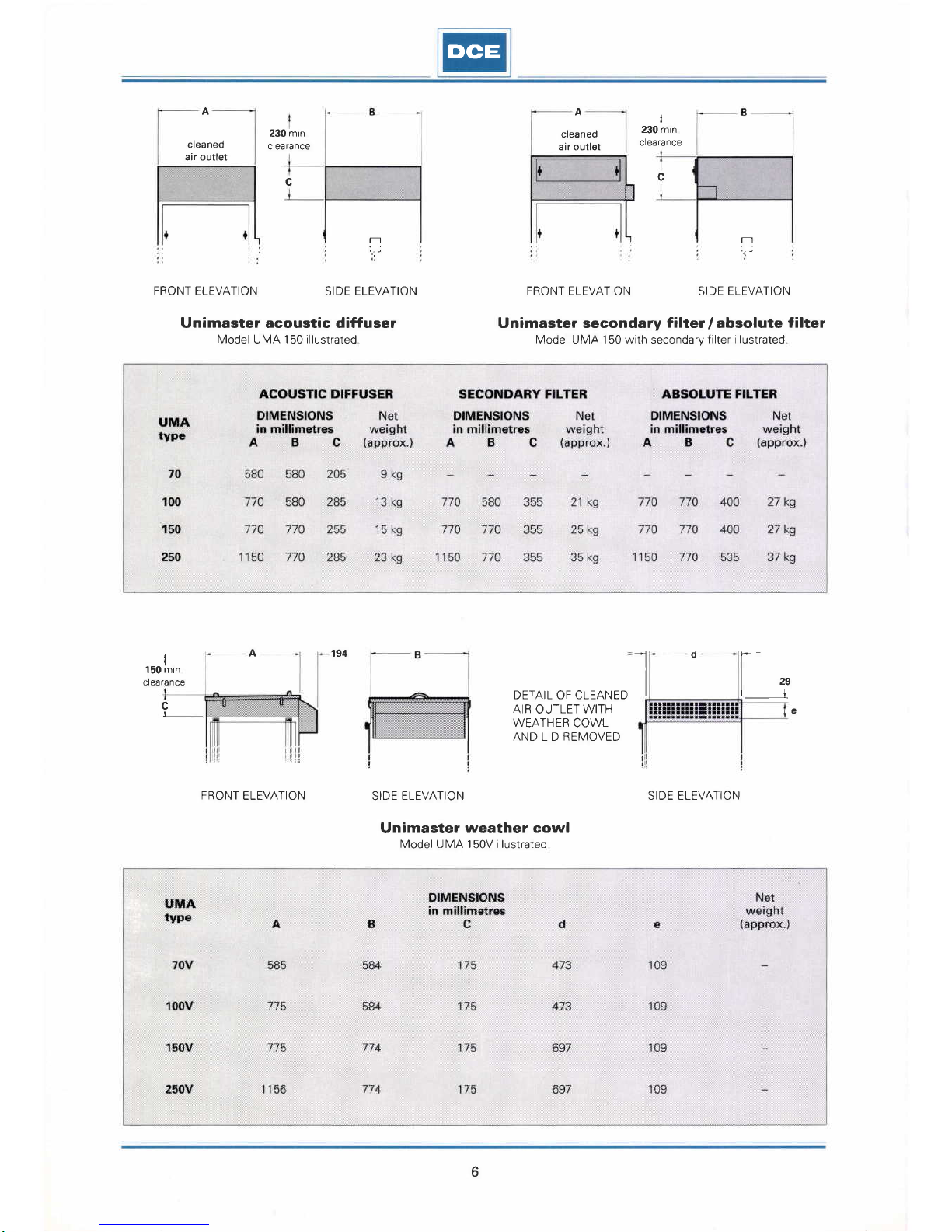

Page 6

DCE

A

A

DETAIL OF CLEANED

AIB

OUTLET

WITH

WEATHER

COWL

AND

LID

REIVIOVED

cleaned

air outlet

FBONT ELEVATION

SIDE ELEVATION

Unimaster acoustic diffuser

Model

Ult/lA

150 illustrated

I

150 mrn

clearance

A

194

cleaned

air outlet

c

FRONT

ELEVATION SIDE ELEVATION

Unimaster secondary

tilf.er

labsolute

filter

Model

UMA

150 with secondary filter

illustrated

230

mtn

clea rance

,rolrn,n

clearance

c

T--]

rr

l

d

L"

c

e

I

FRONT

ELEVATION

SIDE

ELEVATION

Unimaster

weather cowl

Model UMA 150V rllustrated

SIDE ELEVATION

6

Page 7

DGE

I

'MEtvIBREX'

HELIEF I.4EI\,48BANE

ilPLOSION

20

UMA

70 explosaon relief flange

Prtch

centresr

140mm vertrcally; 130mm horzontally

708

40

581

501

40

74

20

UMA 150 explosion relief

flange

Prtch centres. 150mm vertrcally; l30mm

horizontally

NOTE

1t04

UMA 250 explosion relief

flange

Pitch

centres

130mm vertrcally, 135mm horrzontally

40

40

668

20

40

40

20

40

534

40

44

4

520

574

51

5

492

20

75.5*

to

lornt

lrne

455

27

20

14

74

20 20

UMA

100

explosion

relief flange

P

tch centres:

140mm vertically, 130mm horizontally

66.5'to

lornt

lrne

20

75.5* to

lornl

ne

20

44

20

20

541

458

74

74

20

99.5+ to

loint

ine

Explosion

relief flange mounting

details

Alvertrcai

holesdrilledl0mmdiameterforlVSbolts Alhorzonta hoesthreadedtoacceptttulSbolts

*lncrease

dimensron by 38

for ventrng

type unrt

wrthout

bottom assembly

N4ountrng f lange

prolects

1O0mm beyond

rear

of

f lter

K3 sound

leves

taken

at

typcal

arvoume of 1000 mr/h K5 sound

leves

taken al a

typcal

a

r

voume of

1500 m3/h

*Secondary

friter and absolute

frter.ot

suppl ed wth Gl

tan

I

I

,MEIUBREX'UPLOSION

SELIEF

IVEMBRANE

+ +

All

readings were

taken

in

sem

andl 5metresabove

WEIGHTED SOUND

PBESSURE LEVELS

Unit only

With

acoustic diffuser

With secondary filter

With absolute filter

7

Page 8

DCE

400

350

300

250

200

150

100

50

a

=

E

E

F

L!

I

z

F

ul

CC

l

U)

ct)

L!

t

o-

(_)

F

F

(./)

15{t0

2000 2500 3000

AIR VOLUME

(m3lh)

These curves were obtained f rom volume and

pressure

readings taken at unit rnlet with the

filter

clean.

Standard and Hopper type units

To

select the

most

suitable unit

for

a

given

application:

1 Determine the

air

volume, in m3/h, needed

to entrain the dust.

2 Estimate

pressure

drop through

connected system

-

i.e. between

point

of

entrainment and unit inlet.

3

Assess

pressure

drop across

filter

prior

to

shaking, usually 50-1 00mm

W

G

4 The

sum of 2 and 3 = W.G.

required

5 Consult

graph

for fan

performances

available.

Sack Tipping Units have K3

(1

5 kW)

fans

with modified

outlet to ensure adequate

face

velocities at the tipping hatch under normal

operating conditions

Typically, the exhaust

rate for the

UIVA

250STU is 1275m3/h

(750

cfm)

0593

0

500

1000

3500 4000

Unit

performance

curves

DCE

LIMITED

Thurmaston

LEICESTER LE4 8HP England TEL LEICESTER

(0533)696161

FAX

(0533)

693028

rELEx342409 DUST G

THE DCE

GROUP OF COMPANIES

@)

DCE Ltd, Leicester

@)

DCE DEUTSCHLAND GmbH, Dusseldorf

@)

DCE BENELUX BV, Wormerveer

G)

DCE SA, Paris

G)

DCE IBERICA SA, Barcelona

@)

DCE SCANDINAVIA

^y'S,

Copenhagen

@)

DCE,

lnc

,

Jelfersonrown,

Ky

GD

DCEVOKES(Pty)Ltd,Springs,Tvl

(ND

ACCO,Calcuua(DCElicensee)

@

HUYCKDCEKK,Yokohama

@)

DCE VOKES fty Ltd, Sydney, Vtelbourne & Brisbane

6>

DCE FILTERS Ltd, Auckland

Fepresented in

principal

countries throughout

the world

DATA SHEET 367E

(GB)

dust control equipment for industry

Unimastero

quality

dust control units Dalamatico automatic reverse

jet

filters Sintamatic'' advanced technology dust filtration

DCE reserve

the

right

to alter design without notice Freedom from

patenl

restrictions must

not

be assumed

Page 9

lrla

@

T LL

TY

T9, 12, 23 30

FUNCTION

This controller

ensures the efficient

cleaning

of

the

filter

mattress

on initiation of a cleaning

rycle

after

each

dutycycle of

the

Unimaster dust control

unit.

To

protect

the Unimaster filter fabric, the

controller

is interlocked so.that the fan motor

cannot

be

restarted during the operation of the cleaner

motor.

SPECIFICATION

The equipment is housed

in

a

rigid

H/C box

designed

to

lP65

protection,

with

cable entries

at top

and

bottom.

Functioning

as a dual direct-on-line

starter,

it

comprises

(1)

a double-wound transformer

with

a

selection of input tappings for the

incoming supply,

gMng

an

output of 24Y AC;

(2)two

contactors

labelled

K1 and K2

(electrically

interlocked to

prevent

simultaneous operation) to control the

fan and cleaner

motors;

(3)

a thermal overload

relay with

single

phase protection

for the fan motor

(no

protection

being

supplied for

the cleaner

motor except

where

required

by national

regulations,

as

in France);

(4)

a

pre-set

electronic

timer

module controlling

the

'fan

rundown' and'cleaning'

periods.

These components

are all

mounted

on a baseplate

within the box.

Timer

ambient temperature

range is

-5"C

to

+40'C.

For temperatures

outside these

limits

please

refer

to DCE.

!NSTALI.ATION

Mount

the controller

independently of the Unimaster

dust control unit on a vertical surface

free of

vibration.

Bring

the

incoming

mains

via

a

switch-fuse

unit

(preferably

'on-load'

typelto the terminal

block,

{see

Table

1

for the fuse rating). Seal all

joints

at conduit

entry

holes

to

prevent

dust entering

the box.

Publication

16244

(GB)

OVERLOAD

SETIING

IMPORTANT

Before start-up,

the overload

relay

calibration

lever must be set

at the value

given

by

motor

full load current

in Table

2.

OPERANNG

RANGE

The controlldr

is.suitable

for use on a

range of

3-phase,

50

-

60

Hz operating

voltages,

with fan

motors

rated up to and

including some

at 11 kW.

A

stardelta

(Y/A)

controller,

type

ECT SD, is available

for other

11 kW fans. S6e

Table

2.

A variance

of t10o/o is

allowable on transformer

input tappings.

OPERATION

1. START

(average

operating

period

for fan, 4 hours)

Press

'START'

button:

o Fan

contactor K1

is

energized;

timer

module

sets

and

fan motor runs.

2. CLEAN

Press'CLEAN' button:

o Fan

contactor

K1 is de+nergized

and the

timer

energized.

O After

approximately 90

seconds

cleaner

motor

contactor

K2 is energized;

cleaner motor

now

runs

for approximately

45 seconds.

o Cleaner

motor

contactor

is

decnergized

and

the

timer

resumes inactive state.

Before

a cleaning

cycle can be

initiated

by

pressing

the

'CLEAN'

button,

thefan

contactor

K1 must

have

remained

energized

for at least

30 seconds.

A

'fail-safe'feature ensures that

if the

power

supply

fails

while the timer

is

performing

a cycle,

then

re-

applying

the

power

will not cause

the cycle

to be

completed.

I nstead, the controller

will

automatically

re-set

ready for the fan to

be restarted.

KW

0.18

0.50

0.55

0.75

1.10

1,50

2.20

3.00

4.00

5.50

7.50

11.00

1.28

1.65

2.30

3.22

4.32

5.70

7.40

9.80

13.80

19.30

'1.26

1.60

2.20

3.15

4.20

5.40

7.00

9.20

13.00

18.20

Single Phase

110v

220v

240v

4.4

7.4

9.7

14.0

20.0

Table2-MotorCurtents

Three

Phase

200v

220v 380v

415v 440v

1.40 1.20 0.75 0.69

0.65

2.2 2.2

3.3

3.3

4.t 4.7

6.5 6.5

,r_

r:

2.50

2.40 1.40

3.30 3.10

1.80

4.60 4.30

2.50

6.47 6.05

3.50

8.70 8.13

4.70

11.7810.72 6.20

15.4014.00

8.10

20.3018.5010.70

28.50 25.90

15.00

39.90 36.30

21.00

Figwes

in-amps lor

motds

o,

otlrcrSrlcY-

Spaces

marted

le, not suitablo

to.

application

FLC

Amps

0.00

-

0.45

-

0.95

-

1.51

-

4.00

-

Tablel-FuseRadng

HRC'Amp

Rating

Fuse Wire

Amp Rating

6

8

'12

16

30

o.M

0.94

1.50

3.90

6.25

2

4

6

10

16

20

25

32

40

50

63

6.26

7.76

10.01

12.21

17.2'.1

21.61

7.75

10.00

12.20

17.20

21.60

29.00

T

Fuse

\Nire

not

recommended

'HRC.

High rupturing capacity.

HRC Fusas: BS

88

Pan 2 1975

Class

0l l.E.C. 21 69:2

Fuse

wiro

sire basod

upon

sir

times

full load

curent

Page 10

DCE

TERMINAL

STRIP

T

Lg

S

Lz

R

Lr

l

KT

xl

A2

,a

69

TERM

INAL

BOX

l-

,

I

\

SFIAKER

ttt

,/

-

11-

('

\/

FAN

r-l

It,

I

Standard

Wiring

Diagram

for Types

ECT 9

& ECT 12

(3-wire

supply)

lf

controller

differs from

this, refer

to diagram in

lid

TERMINAL

STRIP

T

La

S

Lz

R

Lr

I

-(

j

I

M

5-

HAKER

S

FAN

l-l_l

ly',

\/

I

)'

l

\

I

UNIMASTER

CONTROLLER,

Type Ecr

9 & Ecr 12

(3-wire

suppty, with

two

overtoads)

DCE

LIMITED

Thurmaston

LEICESTER

LE4

8HP

England

TEL

LEICESTER

(05331

6961

61 FAx

(0533)

69302g

TELEX

342409 DUST G

llJ

J

f

o

o

=

IE

IIJ

=

F

AT

t

t3

K2

START

,Q

R

CI.EAN

t

13

21

START

2

,a.

LlJ

J

f

o

o

=

E

UJ

=

tr

Publication

16244

(GB)

0691

Page 11

Publication 85B

Cleaned air

outlet

Fan

chamber

access

panel

Fan

motor

Four captive

wing-nuts

secunng

filter

assembly

Slide

in

guides

Filter assembly

Filter chamber

access

panel

Cleaner motor

Shaker bar

Filter bag

showing wire

mesh insert

lnlet

duct

connector

bt either side

I /or at rear)

Ouick-release

sealing

gear

Dust

container

Locating

stops

When ordering spares or

accessories

PLEASE

OUOTE SERIAL

NUMBER OF UNIT

IN FULL

(See

plate

adjacent

to shaker motor cover)

DCE

This

dust control unit has been

carefully

designed to

give

efficient trouble-free service

provided

the following instructions

are adhered

to:

a

Explosion relief

panels,

if fitted,

should

be vented

to a safe area, Any

relief duct must be straight, as

short as

possible

(3

metres

max.

)

and strong

enough

to withstand the

pressure

of an

explosion.

a

Do

not

start

the fan if access

panel(s),

filter

assembly or dust container are

not in

place

and

fastened.

a

Clean the

filter at least twice in a working day

(see

OPERATION

below).

a

Do not overfill the

dust container or allow it to

become too heavy for removal and emptying.

NOTE _ ALWAYS ISOLATE

THE ELECTRICAL

CONTROLS BEFORE SERVICING

OPERATION

The START button on

the

Unimaster

FE controller

operates the

fan motor. Dust-laden air

is

drawn into

the

unit beneath the

filter assembly as shown in the

illustration,

heavy

particles

falling directly

into

the dust container.

As

the air

passes

through the

filter the finer dust is deposited

on

the

outer surfaces

of the filter fabric.

The fan handles

cleaned air only, discharging

it through the outlet at the

top of the unit.

The

CLEAN

button switches off the

fan motor and

automatically starts the two-part

cleaning cycle. First,

there is

a

'dwell' period

of approximately 90 seconds to

allow the fan

to

run down;

secondly, the cleaner motor is

activated for about 45 seconds, imparting

a

vigorous

shaking action to

the filter to dislodge accumulated dust.

lf air were drawn through

the filter while it was being

shaken,

the dust, instead of being dislodged, would

become deeply embedded in the

fabric

and cause serious

@

OPERAT ON

ET

MA NTENANCE NSTRUCT

ONS

loss of suction. The two motors are therefore

interlocked

by the controller so that the

fan

cannot

be restarted until

the

cycle has been completed. Following a

power

failure

the timer automatically

resets itself so that the Unimaster

can only be operated again by

pressing

the START

button.

Full

details

of

the

controller

are

given

in Publication

110.

DUST DISPOSAL

(for

models with container and

quick-

release sealing

gear,

as illustrated).

a Release container f ully by

raising

sealing

gear

handle.

b

Remove

and empty

the container.

c

To replace, slide container back to the

locating stops.

d Lower the sealing

gear

handle.

TO REMOVE FILTER ASSEMBLY

a lsolate electrical controls and

remove both access

panels.

b

Fully

slacken

the four

captive

wing-nuts located in the

fan chamber.

c Withdraw complete

filter

assembly

through front of

filter chamber.

d Remove wire mesh

inserts from individual filter bags.

e Detach filter bag assembly from supporting

frame.

TO REPLACE

FILTER

ASSEMBLY

a

Fit filter bag assembly into supporting frame, feeding

individual

filter

bags between

locating bars, and fold

collar over

peripheral

sealing flange.

b Replace wire mesh inserts in filter bags.

c Slide

filter

assembly

into the

guides

until bottom

corners of filter bags make contact with the shaker bar.

d

Locate individual filter bags in shaker bar.

e Slide

filter

assembly

fully home and tighten wing-nuts

to form air-tight seal.

f Replace and fasten access

panels.

INADEOUATE

SUCTION CAN

BE

CAUSED

BY:

1

Motor

running

the wrong

way. Check with anow show-

ing direction of rotation, situated on the motor base.

2 Access

panels,

filter

assembly or

dust container not

properly

sealed.

3 Choked

filter.

4 Dust container overfilled.

5 A restriction in the suction ducting or cleaned air outlet.

REGULAR SERVICING Every 1,000

working hours

(approximately

6 months at

zl0

hours

per

week) the filter fabric,

shaker mechanism and all dust seals should be

checked and any defective

parts

replaced. Please ask for details

of the

DCE Maintenance Service Scheme, which is in

operation throughout mainland England,

Scotland

and Wales.

DCE L M TED

Thurmaston

LEICESTER LE48HP England

O,

Leicester

(0533)696161

Fax

(0533)

693028 Telex 342409 DUSTG

Page 12

EDE

Issue

9

Page

1

of 8

Unimaster

UMA 70-250

*gA

*98

*9C

*9D

*gE

*9F

*gG

*9H

*1

0A

*1

0A

*1

0B

*1

0B

*1

0c

*1

0c

*1

0D

*'l0D

*7F

*7G

*7H

1A

1B

1C

1D

1E

*74

*78

*7C

*7D

*7E

27572-579

27572-590

27572-596

27572-607

27572-617

44824-921

44824-922

44824-923

M824-924

44824-928

44824-929

44824-930

44824-931

44824-005

44824-006

44824-007

44824-008

44824-305

4r'.824-306

44824-307

44824-308

42772-502

42772-502

42773-502

42773-502

42772-503

42772-503

42773-501

42773-501

1HP

MOTOR

TEFC

O.75KW

sOHZ & 6OHZ

MOTOR

ONLY

2.2KW

gOL

FRAME

sOHZ & 6OHZ

4HP MOTOR

3KW lOOL

FRAME

sOHZ

& 6OHZ

5.5HP MOTOR

4KW

112M FRAME

sOHZ &

6OHZ

7.5 HP MOTOR

5.5 KW 132

FRAME

TOP FRAME,BAG,INSERT

AND

EDGINGS

COMPLETE

COTTON

UMATO

TOP FRAME,BAG,INSERTAND

EDGINGS

COMPLETE

COTTON

UMA1OO

TOP FRAME,BAG,INSERT

AND

EDGINGS

COMPLETE

COTTON

UMAl50

TOP

FRAME,BAG.INSEBTAND

EDGINGS

COMPLETE

COTTON

UMA25O

TOP FRAME,BAG,INSERT

AND

EDGINGS

COMPLETE

POLYPROPYLENE

UMATO

TOP

FRAME,BAG,INSERT

AND

EDGINGS

COMPLETE

POLYPROPYLENE

UMAlOO

TOP FRAME,BAG,INSERT

AND

EDGINGS

COMPLETE

POLYPROPYLENE

UMAl50

TOP

FRAME,BAG,INSERT

AND

EDGINGS

COMPLETE

POLYPROPYLENE

UMA25O

MULTIPLE

FILTER

BAG

COTTON

UMATO

MULTIPLE

FILTER

BAG

COTTON

UMA1OO

MULTIPLE

FILTER

BAG

COTTON

UMA]50

MULTIPLE

FILTER

BAG

COTTON

UMA25O

MULTIPLE

FILTER

BAG POLYPROPYLENE

UMATO

MULTIPLE

FILTER

BAG POLYPROPYLENE

UMA1OO

MULTIPLE

FILTER

BAG POLYPROPYLENE

UMA150

MULTIPLE

FILTER

BAG POLYPROPYLENE

UMA25O

COTTON

INSERT

EDGINGS

FOR

UMATO

COTTON

INSERT

EDGINGS

FOR

UMA1OO

COTTON

INSERT

EDGINGS

FOR

UMA150

COTTON

INSERT

EDGINGS

FOR

UMA2sO

POLYPROPYLENE

INSERT

EDGINGS

FOR

UMATO

POLYPROPYLENE

INSERT

EDGINGS

FOR

UMA1OO

POLYPROPYLENE

INSERT

EDGINGS

FOR

UMA150

POLYPROPYLENE

INSERT

EDGINGS

FOR

UMA2sO

1

1

1

1

18

18

12

1

1

29

I

1

I

29

1

1

1

1

1

'l

1

1

2

Item no.

Description

Part

number

The above items

are always

stocked and readily

available.

For items

not

listed contact

DCE

Spares

departmerit

for

availability

DCE

L

M TED

Thurmaston

LEICESTER

LE4

8HP England

TEL

LEICESTER

(0533)

696161

FAx

(0533)

693028

TELEX

342409

DUST

Page 13

ED

The above items

are always stocked

and readily

available. For items not listed

contact DCE

Spares department

for

availability.

DCE

L M

TED

Thurmaston

LEICESTER LE48HP

England rEL

LEICESTER

(0533)696161

FAx

(0533)693028

rELEx342409

DUST

lssue 9

Unimaster

UMA

70-250

11A

11B

12

13

144

148

14C

14D

15

178

17C

24

24

16

174

41

353-026

41353-027

27572-541

41157-103

44571-002

44571-009

44572-002

44571-016

18165-223

3531

1-519

18165470

18165-481

18165-481

41121-112

41121-139

*Multiple

filter

bags

and lnsert edgings other than

Cotton

or Polypropylene

are available to order,

e.g. Nylon

and

Terylene.

BAG TNSERT

UMA70

(12)&

UMA1oo

(18)

BAG INSERTS

UMA150

(18)&

UMA2sO

(29)

SHAKER MOTOR

O.18KW

3PH SOHZ

BIN

SEALING

GEAR

TV/O

CU.FT. BIN

THREE

CU.FT. BIN

FOUR

CU.FT. BIN

FOUR

CU.FT. BIN

UMATO ONLY

RUBBER

SEAL

25MM

X 12.5MM X l4OOMIV

Length 1400mm

BIN

CANVAS

SLEEVE

DOOR

SEALING RUBBER

22MM X

8MM

UNIT FAN

CHAMBER

STU BASE

U|VA7O

1850mm

UMA100

2450mm

29O0mm

UMA150

2450mm

2900mm

UMA250

3200mm

2900mm

DOOR

SEALING

RUBBER

VENTING

UNIT DOORS

UN/A70V

2150mm

UMA100V

2600mm

UMA150V

2750mm

UMA250V

3500mm

DOOH

SEALING RUBBER

FILTER

MATTRESS

DOORS

UMATO

2,I5OMM

UMA1OO

26OOMM

UMA150

275OMM

UMA2sO

3sOOMM

COMPLETE

SET

OF

DOOR FASTENER

PARTS

lncluding:

Handle,

washe(l/32)

",

washer(3/32)",

cam,

binx nut

M6, and

washer

M6

FASTENER

PARTS FOR

EXPLN

DOORS

(OUTER)

1

1

1

1

1

1

1

1

1

1

Item

no.

Description

Part

number

Page 14

DE

The

above items are always

stocked

and

readily

available.

For

items not listed

contact DCE Spares

department

for availability

DCE

L M TED

Thurmaston LEICESTER

LE4

8HP England TEL

LEICESTER

(0533)

696161 FAx

(0533)

693028

TELEX

342409 DUST

Unimaster

UMA 70-250

31

36E

60A

608

60c

60D

53

54

55

35C

35D

36C

36D

36F

36G

39B

464

468

46C

65A

658

65C

65D

41121-140

41 1

55-023

41155-024

43141-113

43141-114

43141-112

43141-111

43143-517

43143-518

43171-013

43171-014

43171-015

42332-508

640-B-43

42335-51

0

640-3339

640-334'l

640-3344

640-3346

42321-511

42331-510

42331-510

42347-022

FASTENER

PARTS

FOR

VENTING DOORS

lncluding:

M10

x 50

setscrew, M'10

nut,

M10 wing nut,

(3/8)"

UNC

wing nut,

M10

washer,

stud

plate.

MATTRESS

FRAME

SEALING RUBBER

UMA

150

MATTRESS

FRAME

SEALING RUBBER

UMA 250

Eccenteric

parts

-

Assembly

C

ECCENTRIC PARTS

FOR

AEI BK22O6

MOTOR

UMA15OI25O

ECCENTRIC

PARTS

FOR ASEA,

LEROY

SOMER 71

OR

SIEMENS UMA15OI25O

ECCENTRIC

PARTS

FOR

ASEA, LEROY

SOMER 71

OR

SIEMENS

UMATO/IOO

ECCENTRIC

PARTS FOR

AEI BK22O6

MOTOR

UMATO/IOO

CONNECTING

ROD

PARTS FOR

AEI BK22O6

MOTOR

CONNECTING

ROD

PARTS FOR

ASEA, LEROY

SOMER

71

OR SIEMENS

SHAKER ROD

ASSEMBLY

UMATO

SHAKER ROD ASSEMBLY

UMA1 OO &

UMA150

SHAKER ROD

ASSEMBLY

UMA25O

Sack

tipper base doors

(Not

illustrated)

SACK TIPPING

BASE

DOOR LIFT

OFF

SACK TIP BASE

DOOR HINGED

UMA 1OOI15OI25O

SACK TIPPING

BASE

DOOR HINGED

LID ASSY

COMPLETE

UMATOV

LID ASSY

COMPLETE

UMAlOOV

LID

ASSY

COMPLETE

UMA1sOV

LID ASSY

COMPLETE

UMA25OV

*

Doortype

1:

Standard door

Door type

2: Explosion

door

Door

type

3: Strapped

door

venting.

UMATO FAN DOOR

TYPE 1

51sMM X 41OMM

Fastener

Fig. 3

UMA l

OO AND

UMA 150 FAN

DOOR TYPE

1 7O5MM

X 495MM

Fastener

Fig.

3

UMA 1OO

AND

UMA 150 FAN DOOR TYPE

1 7O5MM

X 495MM

Fastener

Flg.

3

UMA

250 FAN DOOR

TYPE 1 1O85MM X 495MM

Fastener

Fig.

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Item no.

Description

Part

number

Page 15

E,E

The above

items are always stocked and

readily

available.

For items not listed contact

DCE Spares

department

for

availability.

DCE L M

TED

Thurmaston LEICESTER

LE4

8HP England

TEL

LEICESTER

(0533)

6961 61 FAx

(0533)

693028 TELEX

342409

DUST

lssue 9Page 4

of 8

Unimaster UMA 70-250

61A

618

61C

61D

624

628

62C

62D

62E

63A

638

63C

63D

63E

63F

644

42324-506

42331-508

42331-509

42347-021

42322-519

42332-518

42332-518

42348-017

42348-021

42322-520

42332-519

42332-520

42348-018

42332-522

42348-020

42325-511

UMATO

MATTRESS DOOR TYPE

1

515MM

X 56OMM

Fastener Fig.

3

UMA1OO MATTRESS DOOR

TYPE 1 7O5MM X 56OMM

Fastener Fig.

3

UMA150 MATTRESS DOOR

TYPE 1 7O5MM X 62OMM

Fastener

Fig.

3

UMA2sO MATTRESS

DOOR TYPE 1

1O85MM X 62OMM

Fastener Fig. 3

UMATO

FAN EXPLOSION DOOR

TYPE

2 51 sMM

X 41OMM X 76MM

Fastener

Fig. 6

UMA1

OO & UMAl50

FAN EXPLOSION

DOOR TYP 2

7OsIVIIVX495MMX76MM

Fastener Fig. 6

UMA1 OO & UMA150 FAN EXPLOSION

DOOR TYP 2

7O5MMX495MMX76MM

Fastener

Fig.

6

UMA2sO FAN EXPLOSION DOOR

TYPE 2

1O85MM

X 495MM X 76MM

Fastener Fig.

6

UMA 250

FAN

EXPLOSION

DOOR TYP

2

1O85MMX495MX4OMM

Fastener Fig.

6

UMATO MATTRESS EXPLOSION

DOOR

TYP

2

51sMMX56OMMX76MM

Fastener Fig. 6

UMAlOO MATTRESS EXPLOSION

DOOR

TYP 2

7O5MMX56OMMX76MM

Fastener Fig.

6

UMA150

MATTRESS EXPLOSION

DOOR

TYP 2

7O5MMX62OMMX76MM

Fastener Fig.

6

UMA25O

MATTRESS

EXPLOSION

DOOR

TYP 2

1O85MMX62OMMX76MM

Fastener

Fig. 6

UMA150 MATTRESS EXPLOSION

DOOR

TYP 2

7O5MMX62OMMX4OMM

Fastener Fig. 6

UMA2sO MATTRESS

EXPLOSION

DOOR TP 2

1O85MMX62OMMX4OMM

Fastener

Fig. 6

UMATOV DOOR

TYPE

3 51sMM

X

56OMM

X

SOMM

Fastener Fig.

6

,l

'l

1

1

1

1

1

1

1

1

1

1

1

1

1

1

hem no DescriptionPart number

Page 16

DCE

The

above items

are always

stocked

and readily

available.

For

items not

listed contact

DCE

Spares

depaftment

for

availability

DCE

L

M TED

Thurmaston

LEICESTER

LE4

8HP

England

TEL

LEICESTER

(0533)

696161 FAx

(0533)

693028

TELEX

342409

DUST

lssue

9

Page

5

of 8

Unimaster

UMA 7O-25O

648

64C

64D

64E

64F

64G

64H

64J

64K

64L

42332-007

42332-017

42332-503

42332-521

42348-004

42348-019

42332-018

42332-019

42332-524

42332-525

UMA1OOV

DOOR

TYPE

3 14'STBAP,

7O5MM

X 56OMM

X 175MM

Fastener

Fig.

6

UMA1OOV

DOOR

TYPE

3

23.5'STRAP,

7O5MM

X

56OMM

X 55MM

Fastener

Fig.

6

UMA1SOV

DOOR

ryPE

3 14'STRAP,

7O5MM

X

62OMM

X 175MM

Fastener

Fig.

6

UIVA1sOV

DOOR

TYPE

3 23.5"

STRAP,

7O5MM

X

62OMM

X 55MM

Fastener

Fig.

6

UMA25OV

DOOR

TYPE

3

14'STRAP,

1O85MM

X 62OMM

X 185MM

Fastener

Fig.

6

UMA2SOV

DOOR

TYPE

3 19.25"

STRAP, 1O85MM

X 62OMM

X

55MM

Fastener

Fig.

6

UMATOV

DOOR

TYPE

3 51sMM

X

56OMM X

SOMM

Fastener

Fig.

7

UMA1OOV

DOOR

TYPE

3 7O5MM

X 56OMM

X

55MM

Fastener

Fig.7

UMA1sOV

DOOR

TYPE

3

7O5MM

X

62OIVM

X

55MM

Fastener

Fig

.7

UMA2sOV

DOOR

TYPE

3

1O85MM

X 62OMM

X

55MM

Fastener

Fig .7

1

1

1

1

Description

Item

no.

Part number

Page 17

\

/

DE

60

24

17

6l

t7

l6

2

3

4

5

7

I

9

t2

Shaker

Mechanism

1t

l3

r0

66

2

3

4

6

t5

t4

67

68

69

17

7

8

9

35

12

Shaker

Mechanism

24

ll lo

267-9

Page 18

DCE

DOOR

FASTENERS

Fig2

-'

3lB

l8

l9

22

Fis 6

27

30

3rc

IA

11

Fig

4

Fig 1

9

Fis 5

Fig 3

Fis

7

32

33

32

33

34

,

5

K

s0 I

SHAKER

MECHANISMS

I

44

4

42

Assembly

C

39

NOIE:-

Shaker Mechanism

rAssembly

Ct was

introduced

July 1978

16

36

5l

Assembly

B

44

13

37

17

40

l

I

E

AssemblyA

1t

38

267-9

Page 19

DCE

I

Standard

fan door

Standard

maftress

door

DOOR TYPE

1 DOOR

TYPE

2

DOOR TYPE 3

Explosion

fan door

or

venting

mattress

door

Venting

unit

door

267-9

Loading...

Loading...