Usage Manual

2

I. Usage Notice

II. Installation Method

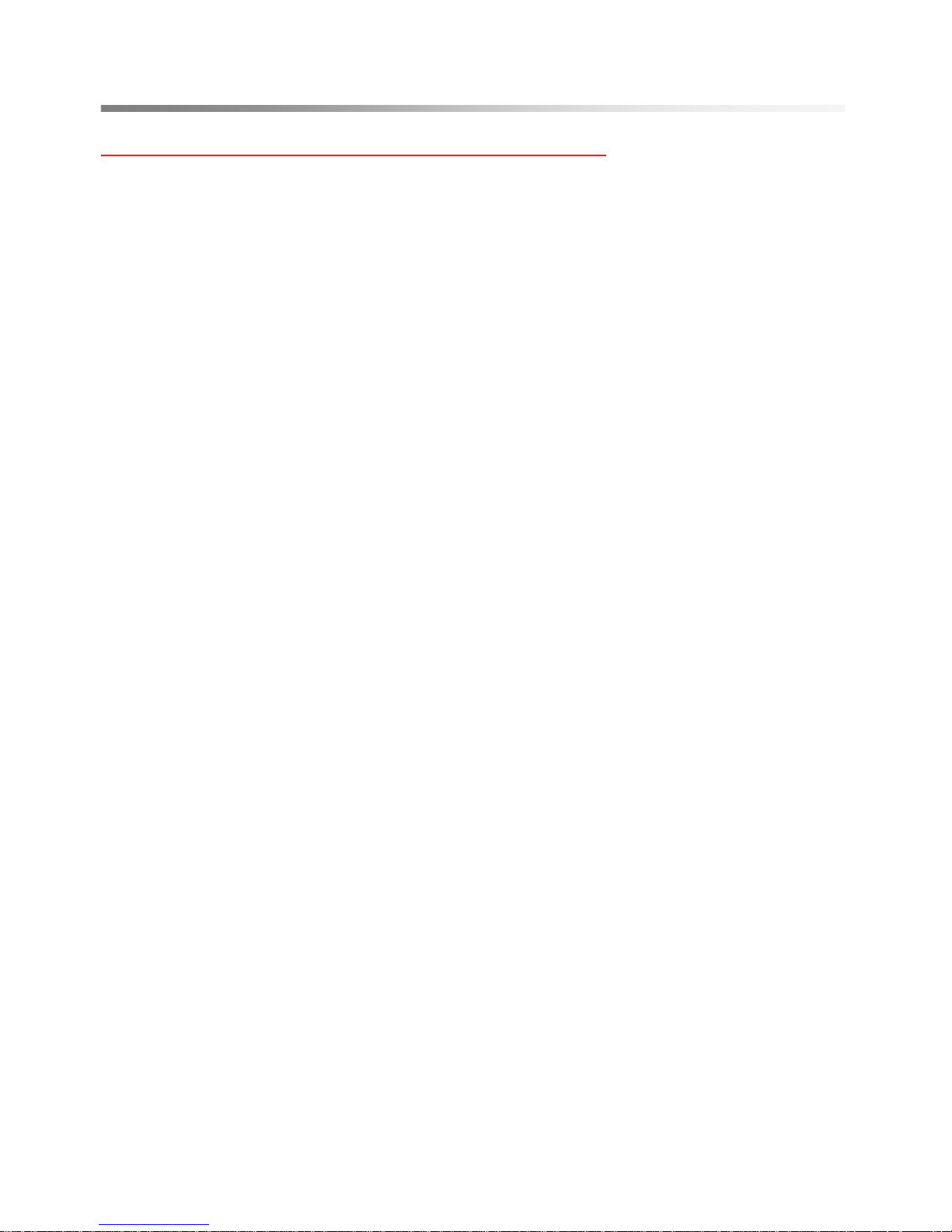

◆Name of Various Parts

◆Installation of Power Wheel

◆Installation of Power-off Brake Levers

◆SENSOR Installation

◆Installation of Console

III. Operation Instructions of Console

IV. Charging Method

◆To Charge The Console

◆To Charge The Power Wheel

V. Maintenance & Repair

◆Maintenance

◆Simple Repair Instruction

VI. Error Code (Diagnosis Message)

VII. Specification

dbRevO Usage Manual

03

04

05

06

07

08

09

12

12

13

13

14

15

3

I. Usage Notice (Foreword)

Be sure to read and abide by following instructions

then abide by traffic

rules for your driving safety. Products may be damaged to endanger personal

life safety if there is any violation.

1. Be sure to wear safety helmets when driving bicycles.

2. Power wheel may be damaged with speed deceleration due to

passengers or heavy articles.

3. Users shall prevent batteries from being affected with damp when driving

across low-lying water.

4. It is strictly prohibited to reconstruct wheel body or detach parts to avoid

reduction of products life of power wheel.

5. Be sure to inspect and maintain periodically to reduce failures.

6. It is strictly prohibited to drive on excessively instable pavement to avoid

damaging power wheel.

7. It is strictly prohibited to use assistance power for slope section to avoid

danger.

8. Motor will stop power supply automatically. if super-high motor

temperature is caused by continuous climbing. Climbing slope is limited

to 13°

9. Users shall pay attention to pits, stones on roads and rails, etc which may

deviate from driving direction at any time during driving.

10. Users shall stop driving if driving safety is influenced by damaged parts

during driving.

11. It is suggested to use parts of original manufacturer according to

replacement demand.

12. Power wheel is originally designed for urban usage. It is strictly prohibited

to use in following locations such as cross-country, athletics or instable

pavement to avoid personal injury or bicycle damage.

13. Users shall stop driving and take care of it as soon as possible if there is

noise or sound under abnormal conditions.

14. It is strictly prohibited to use solvent or other chemical medicine on

battery cell. It can be wiped by dipping cloth by water.

15. Note! Users can not reconstruct power wheel easily.

4

II. Installation Method

◆Name Of Various Parts:

A Power wheel G Screw capx2

B

Truss headhexagon screws

(M4,M5,M6)

H Power-off brake levers

C Sleeve (M4,M5,M6) I Disc brake +Screw x 6 (optional)

D Console J Magnetic disc for sensor

E Front fork fixation piece K sensor

F

Washer x 7

(Users shall install the washer

according to the space between

front fork)

L

Axle center fixation sheet iron

(NT-2881)

Power switch

Charging hole

Software updating

location

5

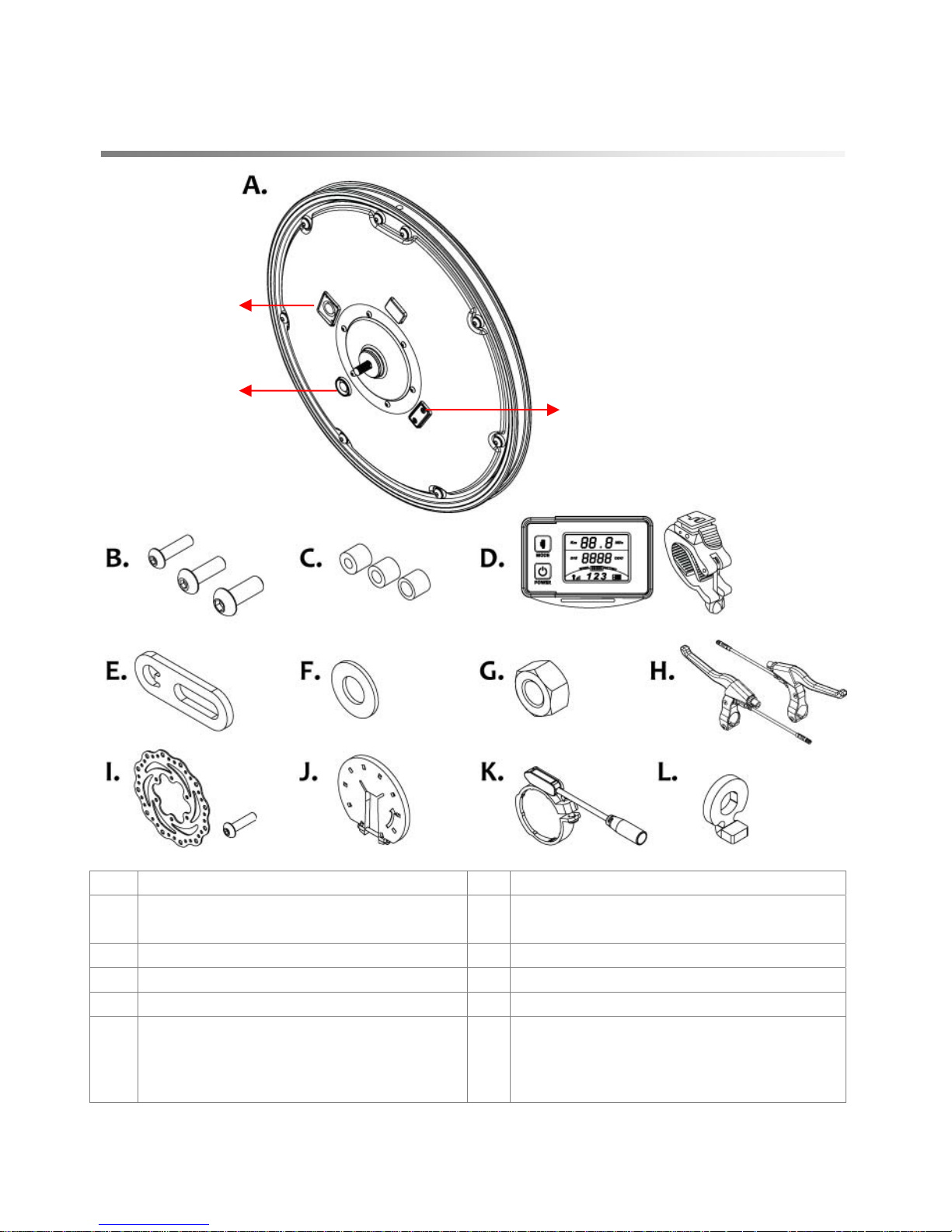

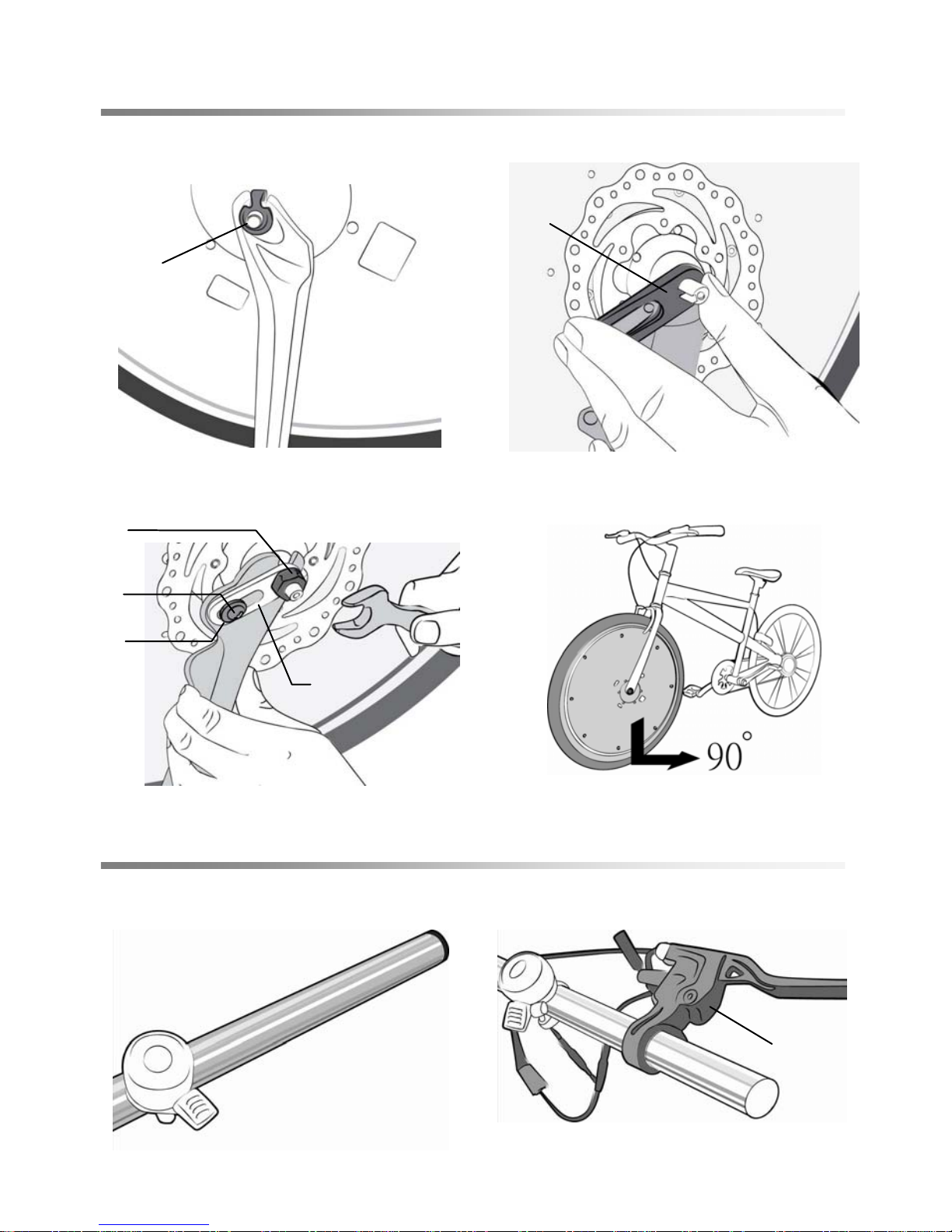

◆Installation Of Power Wheel:

1. To detach front wheel brake wire

of general bicycle and front wheel.

(Be sure to detach the entire brake

for installation of optional disc

brake.)

2. To lock alignment position of disk

brake by screw properly. (Disc brake is

optional.)

3. To invert the bicycle and place

power hole of power wheel in right

side then place (optional) disk brake

in left side into front fork.

4. To align center of power wheel to

front fork connector.

Front fork

I.

6

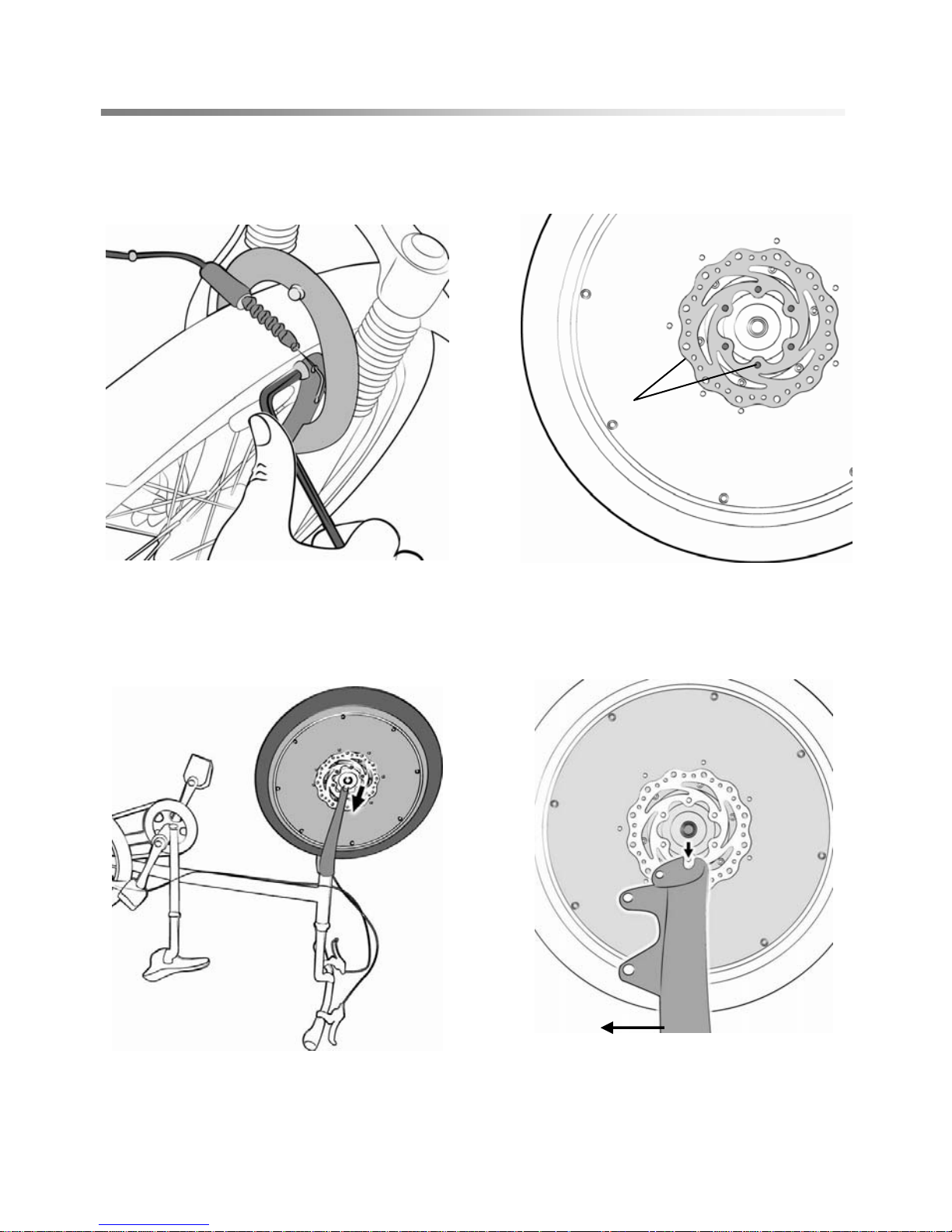

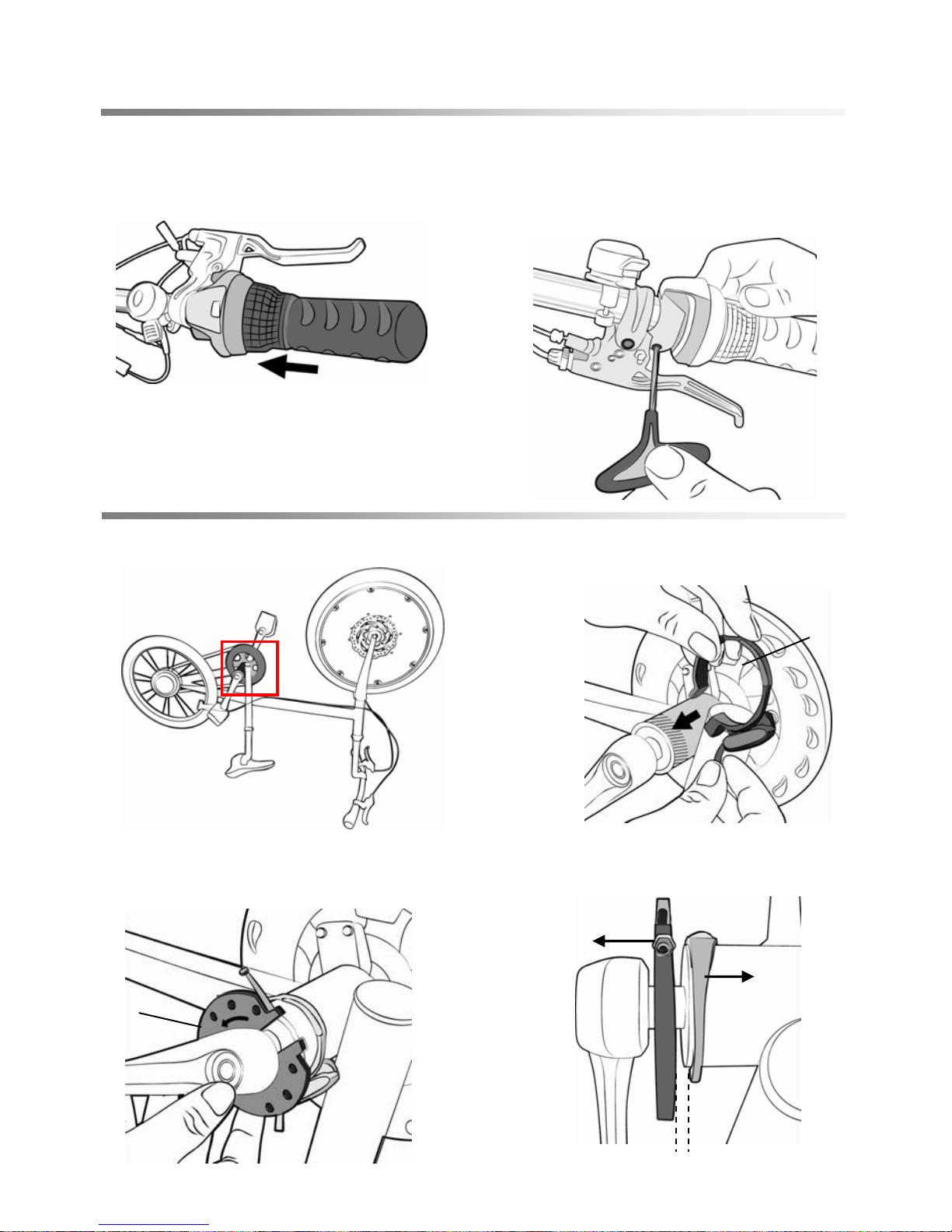

◆Installation Of Power Wheel:

◆Installation Of power-off Brake Levers:

B.

E.

G.

F.

10. To install H. and connect brake

wires.

9. To detach handlebar grips, original

brake levers and gearshift lever by

tools.

6. To align E. to axle center.5. To align L. into groove and place

into axle center (in charging side)

for lockin

g

.

H.

8. To check if tyre is perpendicular to

ground or not.

L.

E.

7.To install B. onto F. and place into E.

for lock (according to B.C. conditions).

To install axle center onto G. then lock.

7

Magnetic

disc

sensor

2-3mm

◆Installation of power failure handle:

◆SENSOR installation:

11. To install back the gearshift

lever and handlebar grips.

12. To adjust power-off brake levers

and gearshift lever for proper angle

then lock. To fix brake wires then test

brake repeatedly to see if it functions

well.

14. To place K outward and lock at the

part highlighted with oblique line shown

in the photo.

13. To invert the bicycle for sensor

installation.

15. Place magnetic disc into it and

arrow direction on magnetic disk must

be consistent with

p

edal movement

16. The peoper gap between

magnetic disc and sensor is 2-3mm.

Tighten the magnetic disc by nut.

K.

J.

8

◆Installation Of Console:

17. Install the bracket on the

handlebar.

18. Insert console into bracket.

19. Connect wires to finish the

installation.

Detachment method is opposite to above steps.

Note! Users shall store detached power wheel properly for best

condition.

9

III. Operation Instructions Of Console

◆Istructions of data readout on console

(a) Speed:

Display the speed per hour of the bike by KM/H(Mile), speed range: 0~99.9.

Note: The speed shown by KM/H or Mile has been pre-set up.

(b)DIS/ODO:

Positive number—Distance counting is set to 0.

Distance increases from 0000 to 9999 by 1km/h(mile). When the distance is

over 9999, the system will automatically reset and record from 0.

Assistant

driving force

levels

Power

switch

Indicator of

battery

capacity for

Power wheel

2.4G wireless

transmission signal

Indicator of battery

capacity for console

assistance

level

selection

Mileage

Speed

10

◆Operation Instructions Of Console

(c)

Indicator of battery capacity for Power wheel

Energy column will display full number (namely, 5 BARs) when power volume is

full. BAR will flicker (with frequency of once every second) if there are only 2 BARs.

It will begin to flicker and alarm to notify users of charging need.

The battery indicator will display full 5 BARs when fully charged. BAR will flicker

(with frequency of once every second) if there are only 2 BARs It will begin to

flicker and as an alarm to notify users of charging need.

(d)

Battery volume display of electronic watch

Energy column will display full number (namely, 5 BARs) when power volume is

full. BAR will flicker (with frequency of once every second) if there are only 2 BARs.

It will begin to flicker and alarm to notify users of charging need.

The battery indicator will display full 5 BARs when fully charged. BAR will flicker

(with frequency of once every second) if there are only 2 BARs It will begin to

flicker and as an alarm to notify users of charging need.

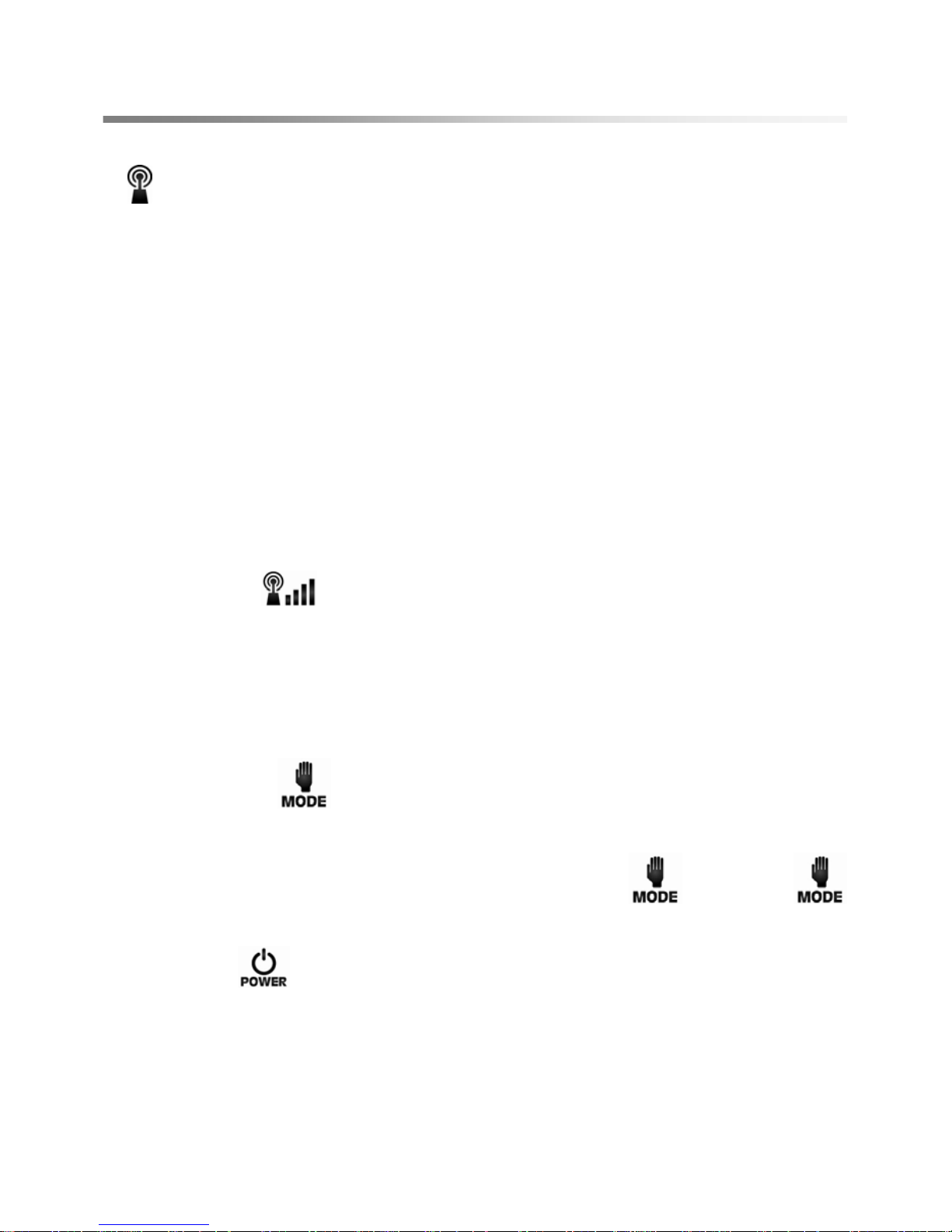

(e)

2.4G wireless transmission signal display

Full signal (of 4 BARs) refers to strong transmission signal and no signal (of 0 BAR)

means the transmission stops.

(f)

Power switch

Power switch function of console: Press to turn on the console with blue

backlight; press again to turn off the console.

(g)

Auxiliary power set key

● Press to select the assisted power level from none, level 1, level 2 and level 3.

● Console only displays SPEED and DISODO when selecting no assisted power.

● The assisted power will supply according to the selected level (from level 1 to

level 3) when users start pedaling.

● Controller shall supply assisted power instantly when receiving the signal from

speed sensor. It will cut off power supply instantly when speed reaches 24.5KM.

11

◆Operation Instructions Of Console

Other operation supplementation instructions:

1. flickers when user brake the power-off brake.

2. Integrated energy-saving technology will power off the system if the bike

stopped for more than 15 minutes. To re-start the system, user has to

switch off the power for 3 to 5 seconds before to power on again.

3.The console and controller will communicate through 2.4G wireless

transmission when use dbRevO wheel for the 1

st

time.

4. Users shall power on the wheel before power on the console. After the

console and controller communicate through 2.4G wireless transmission,

user will see

which means the communication is successful. If to

power on the console before to power on the wheel, error code E-0 will

flicker on the console screen.

5. Wheel size setup

● User shall press

key for 10 seconds to enter into wheel size setup

under standby mode, when not braking the power-off brake. .

● To select the wheel size from 16-30 inch by pressing

key. Press

once to increase 2 inch each time.

● Then, press

key to save the setup and return to standby mode

12

IV. Charging Method

◆To Charge The Console:

z Charging time is about 3-4 hours. Be sure to charge the console for 12

hours before using the battery for the 1

st

time.

z Suitable ambient temperature for charging is 0~45℃.

z Users shall charge the battery immediately after using, and to charge at

least once every month for better maintenance.

z Meanings of the LED colors on console charger.

Orange LED Red LED Orange LED

Standby:

Power supply

In charging Full charged

◆To Charge The Power Wheel:

z Charging time is about 4-6 hours. Be sure to charge the console for 12

hours before using the battery for the 1

st

time.

z Users shall use the charger provided by the original manufacturer. It is

strictly prohibited to use charger from other manufacturers randomly.

z Suitable ambient temperature for charging is 0~45℃.

z Users shall charge the battery immediately after using, and to charge at

least once every month for better maintenance.

z Meanings of the LED colors on dbRevO Wheel charger.

Green LED Orange LED Green LED

Standby:

Power supply

In charging Full charged

13

V. Maintenance and Repair

◆Maintenance:

1. To check if there’s any rusty part or leaks carefully. Leaks may be eroded

to accelerate damage and enlarge the leaks itself.

2. To clean dbRevO wheel periodically and keep away from all corrosive

materials such as salt.

3. Do not polish, drill or carve on wheel surface. Leaks may be caused by

large scratch, chisel hole or nick.

4. Users shall pay attention to find out noise source if any, and try to solve

the problems as soon as possible.

5. It is strictly prohibited to wash the wheel by strong spout to avoid

damaging the battery. Users shall clean the wheel by clean mop.

6. Users shall use neutral or soft detergent to avoid damaging the wheel

housing.

7. It is strictly prohibited to clean the wheel by sea water or salty water. Users

shall use cold water to avoid corrosion problems.

8. It is suggested to park the bicycle indoor or at cool places to avoid being

exposed to the sun and rain. Users shall keep the wheel dry to avoid rusty

problems. .

9. It is strictly prohibited to drop or to dash against the wheel. Huge external

force may cause the deformation and damage the internal electrical parts,

which is dangerous for users safety.

◆Simple Repair Instruction

1. To inspect the safety mark on the tire and to replace new tire instantly if

abrasion exceeds the mark.

2. To inspect the front and rear brakes and parts of the bike to see if any

operation fails, wire disconnection, or damage problems.

3. To keep the tire pressure within the marked scope on the tire because tire

may be burst when driving.

4. To check if there is chapping, damage or abnormal abrasion on tire or not.

Users shall replace a new tire instantly if it is damaged severely.

5. To check if there is excessive abrasion for brake pad or not. It shall be

replaced to avoid inflexible brake.

14

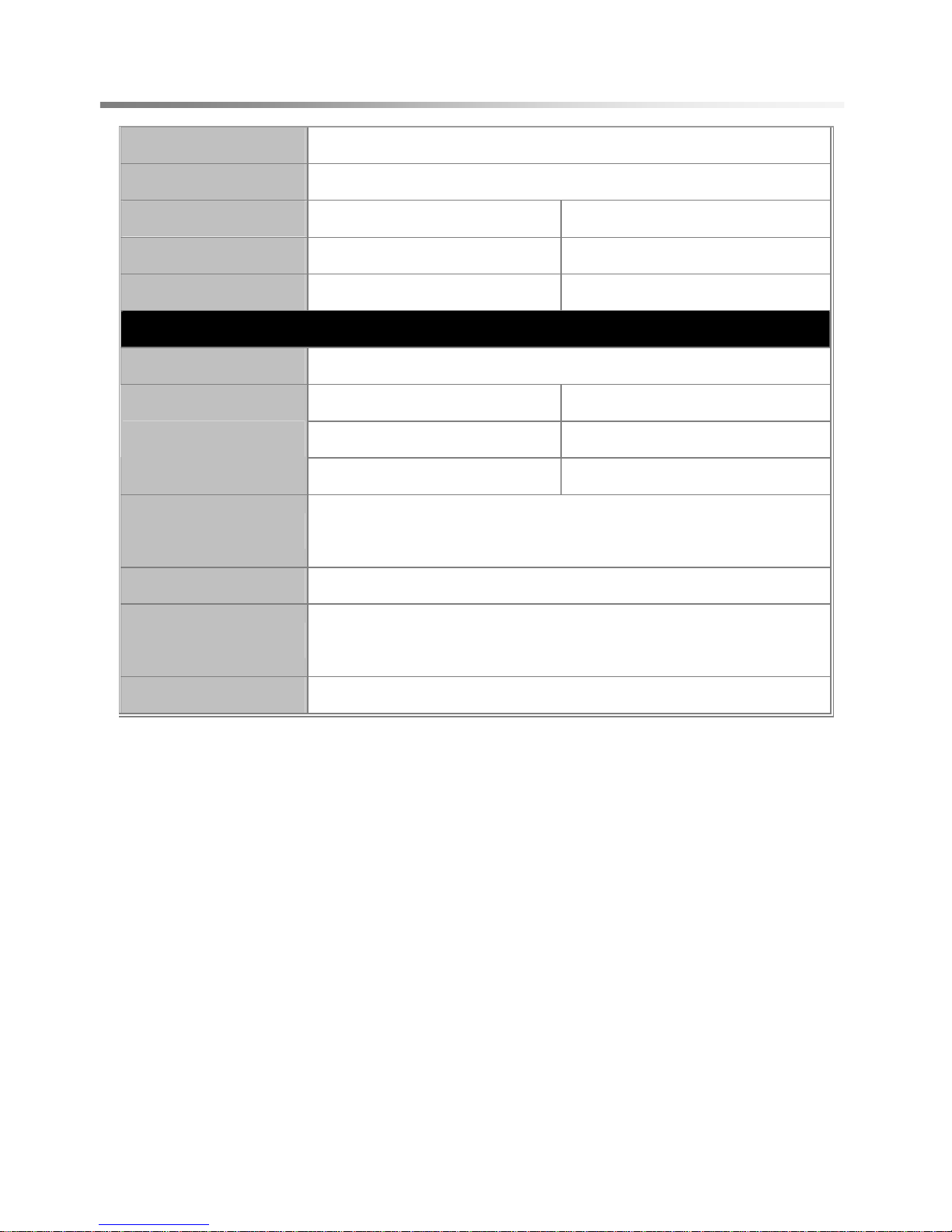

VI. Error Code

Error Code will flicker when control system is under abnormal conditions.

The console will be powered off automatically after Error Code flickers for 10

seconds.

Troubles And Troubleshooting

Trouble

code

Trouble Description Troubleshooting

1. To check if motor signal wire is disconnected.

E1

No speed signal from

motor during driving.

2. To replace motor.

E3

Controller fails when

motor operates

1. To replace control board.

E4

Controller fails when

motor operates.

1. To replace control board.

1. To check if Torque Sensor zeroing voltage setting is correct.

2. To check if Torque Sensor signal wire is disconnected.

E7

Torque Sensor voltage

is abnormal or out of

the scope of standard.

3. To replace Torque Sensor.

1. To check if motor signal wire is disconnected.

2. To replace motor.

E-8

UVW wire is

disconnected when

motor operates.

3. To replace lower controller.

1. To replace motor.

E-9

Short-circuit after

motor start-up

2. To replace lower controller.

1. To check if motor signal wire is disconnected.

2. To replace motor.

E-A Motor cannot operate

3. To replace lower controller.

E-B

Controller current is

over the scope of

standard.

1. To replace motor.

1. To power on the console after the battery is placed well and

switch on for 3-5 seconds.

As the console and controller are checking the battery

capacity after the battery is switched on. To power on the

console within 3-5 seconds, E-0 will flickers on the console.

2. To check if battery voltage is lower than 16V or not. If yes, to

charge the battery to full.

E-0

Battery voltage is

lower than the scope

of standard

3. To replace console

●Users shall contact with local dealers if troubles still cannot be solved under

above situations!

15

VII. Dimension Form

Color Many options

Battery Housing Specification

Wheel rim 26" Alu-alloy 20'' Alu-alloy

Tire 26''X1.95 20''X1.95

G.W. 26'':8.6 kgs 20'':6.4 kgs

Power System Specification

Motor 24V250W DC Brushless

26'' 20''

24V8Ah Lithium Battery 24V6.6Ah Lithium Battery

Battery

Optional 11A Optional 8.8A

Charger

24V2A charger for battery &

5V500mA USB charger for console

Display LCD Console (Quick-released, wireless)

Sensor Device

Speed Sensor Inside Motor or

Wireless Speed Sensor for pedelec

Power-Off Brake Easy-installed Power-off Brake

2011/4/11 V1.0

Loading...

Loading...