Page 1

A Capital Safety Company

Model Number(s):

8513158

ADVANCED SYSTEMS

UCT-300 Tripod

ENTRY/RETRIEVAL SYSTEMS

OPERATOR’S MANUAL

FORM NO: 8515531 REV: A

MAN RATED

CONFINED SPACE

CSG UCT-300 TRIPOD

© Copyright 2011, DB Industries, Inc.

Page 2

UCT-300 TRIPOD

SETUP AND WINCH INSTALLATION INSTRUCTIONS

A) Setting up the UCT-300 Tripod

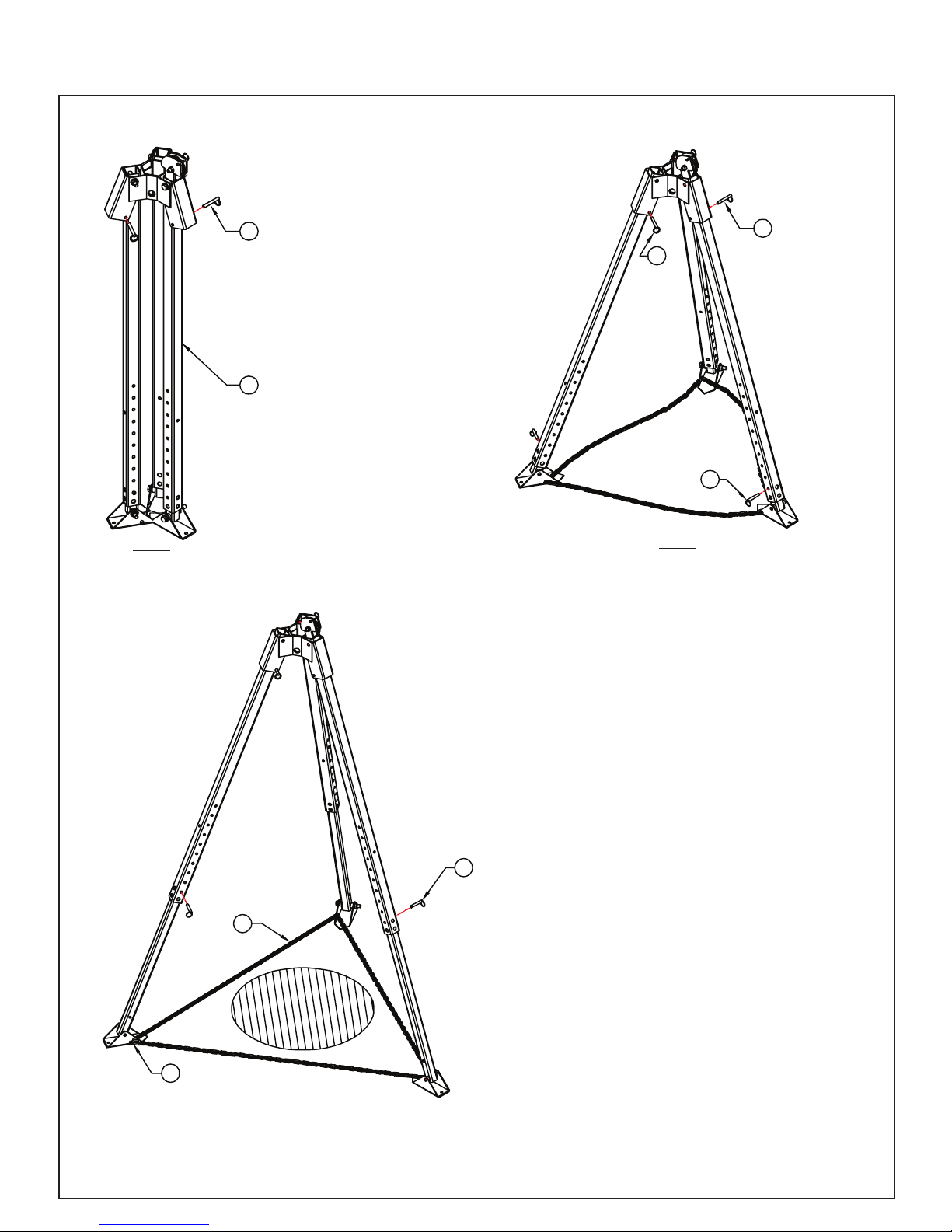

FIG 1

1. Stand collapsed Tripod[1] on oor with

2

1

feet down (See Fig. 1 ).

2. Remove leg retainer pins[2] from 3 places

in tripod head (See Fig. 1 ).

3. Fully spread all 3 legs. Install leg retainer

pins[2] in 3 places to secure legs in a spread

position (See Fig. 2).

4. Remove 3 leg adjustment pins[3] from

legs, and extend legs to fully extended

position. Install 3 leg adjustment pins to

secure leg in the fully extended position.

2

3

2

FIG 2

5. Position tripod over entry ( See Fig.3)

and ensure structure is level. Adjust lengths

of leg(s) as required by removing leg

adjustment pins and extending or retracting

leg(s) as needed. Be careful to reinstall all leg

adjustment pins once tripod is level.

6. Ensure that slack is removed from leg

chain[4] between all legs after setup and

leveling. Adjust chain by loosening quick

connect links at feet[5], and moving quick link

on chain as required.

3

4

5

FIG 3

2

Page 3

UCT-300 TRIPOD

SETUP & WINCH INSTALLATION INSTRUCTIONS

6

B) Installing the Winch to UCT-300 Tripod

Once tripod has been set up & leveled install

the winch assembly as follows.

1. Select whichever tripod leg you wish to

mount the winch on. This will be inuenced

by the location of the leg top pulley(s)[6], any

accessories being used with the tripod, and any

11

10

9

8

12

obstructions around the work area.

2. Remove winch mount pins[7], [8], [9] from

winch mount bracket[10] and position the winch

so that the cable[11 } leaves the winch as shown

(See Fig. 4 ).

3. Slide winch mount bracket[10] over leg

tube[12] (See Fig 5), and position winch where

desired. Install pin[7] through leg bracket and leg

tube using appropriate hole. Install pins[8], [9] as

shown thru bracket and behind leg tube.

See page 3

FIG 4

9

8

7

Pin #7 in any

one of these

of 3 holes.

7

FIG 5

3

Page 4

UCT-300 TRIPOD

SETUP & WINCH INSTALLATION INSTRUCTIONS

13

14

B) Installing the Winch to UCT-300 Tripod (c'ont)

4. Remove cable retainer pin[13] from top pulley

assembly[14] and route cable over pulley and

thru head as shown ( See Fig. 6 ).

5. Repeat steps 1 thru 4 as required to install

cable

any other winches and / or fall arrest devices

being used.

6. Refer to the appropriate operators manuals

for instructions on installation, use and

proper maintaince procedures for any and all

accessories being used with the tripod.

FIG 6

4

Page 5

UCT-300 TRIPOD

SETUP & WINCH INSTALLATION INSTRUCTIONS

Model includes the following

4

Item Description

1 UCT-300 7ft. (2m) Tripod

1

2

3

The CSG Safety Systems UCT-300 Tripod combines the quality

and user friendly performance of all CSG Safety equipment with

the economy of the basic tripod. Constructed of lightweight tubular

aluminum with a rugged steel head assembly, the UCT-300 tripod

can be combined with a variety of pulleys, winches and fall-arrest

devices to meet a wide range of conned space entry / retrieval

and rescue requirements. Plastic sliders between inner and outer

leg tube provide smooth adjustment and prevent inner tube from

inadvertently pulling out of outer tube. Quick release pins positively

locate components at all adjustment points for tool-less setup and

adjustment.

General specications:

Rated Capacity (working load) 450 lbs. (204 Kgs.)

@ 11:1 design factor

Max. Allowed Arresting Force

(M.A.F.) rating for retractable

devices or shock absorbers

Proof Load

Leg mounted Pro-man winch

(outside of leg)

Anchor Point 5000 lbs. (11 kN).

Weight 45 lbs. (20.5 Kgs.)

1800 lbs.(8kN)

5000lbs. (11 kN).

Accessories shown in gray but not included

2 Digital 100 Winch

3 Winch Mounting Bracket

4 Top Pulley Ass'y

DESCRIPTION

Application Restrictions:

1. Maximum allowed arresting force (M.A.F.)

rating for retractable devices or shock

absorbers is 1800 lbs. (8kN).

2. Retractable devices or shock absorbers

MUST BE installed and used in accordance

with the manufacture's instructions.

3. All winch or block mounting hardware

MUST BE supplied or approved Capital

Safety Group Ltd.

4. Each installation MUST BE approved to

local standards by a qualied engineer.

Materials & Construction:

General Construction Aluminum / Welded Steel

Tubular Components 6061-T6 Aluminum

Head Assembly H.R. Steel

Hardware Gr.5, Gr.8 steel, zinc plated

Finish

(outer leg & head) Green & Black powder coat

(inner leg) Mill nish

Plating Specications ASTM designated B633-85

type lll, SC2

5

Page 6

T-300/T-1000 TRIPOD SYSTEM

SETUP AND WINCH INSTALLATION INSTRUCTIONS

INSTALLATION OF WINCHES, SELF-RETRACTING LIFELINES ( SRL's), WORK POSITIONING AND FALL-ARREST

DEVICES NOT MANUFACTURED BY CAPITAL SAFETY GROUP

Your T-1000 TRIPOD SYSTEM can be used as a support structure for various types of safety devices.

Some of these can mount directly to the anchor point at the top of the tripod head, while others may require an adapter

bracket available from your dealer. Any accessories being used for the hoist MUST BE installed, inspected, maintained

and operated according to the manufactures instructions. All installations MUST BE approved to local standards by a

qualied engineer.

INSPECTION OF EQUIPMENT PRIOR TO USE.

- Check all structural parts for damage: dents, cracked welds bend or crushed tubes. Minor cosmetic damage will not

affect the structural integrity of the hoist, but any seriously damaged parts MUST BE repaired or replaced before using

the hoist.

- Check all hardware ( pins, tri-screws, adjuster screws, nuts, bolts, pulleys, rollers and winch brackets) for damaged

threads, bend, damaged or missing fasteners, loose fasteners. Check all pulleys and rollers for chips, grooves and

excessive wear. Ensure that all pulleys and rollers turn freely.

- Inspect all equipment for missing, damaged or otherwise illegible warning stickers. Any damaged, missing or

otherwise illegible stickers MUST BE replaced before using hoist.

- If you are using Digital Series Winches with your hoist, inspect the winch and cable as outlined in the "maintenance

and inspection" section of the Digital Series Winch operators manual.

- Any additional winches, self-retracting lifelines (SRL's), work positioning or fall-arrest equipment being used with

your T-1000 Tripod System MUST BE installed, inspected, maintained and operated according to the manufactures

instruction.

- Report any problems with the equipment to your supervisor and DO NOT USE the equipment until it has been

repaired or replaced.

INSPECTION / MAINTENANCE SCHEDULE

DAILY ( BEFORE EACH USE) : (SEE ABOVE) INSPECTION OF EQUIPMENT PRIOR TO USE

WEEKLY: Perform a complete visual inspection of equipment as outlined in " Inspection of Equipment Prior to Use".

Clean equipment as required, to thoroughly inspect all welds, labels, pins, fasteners, pulleys, rollers, brackets and parts.

Record all ndings on a copy of the "hoist inspection log". If any problems are found with the equipment DO NOT USE

until it has been repaired.

ANNUALLY: Clean unit throuroghly, using a damp cloth and a mild soap solution. Perform a complete visual

inspection as described in section(F) " Inspection of Equipment Prior to Use" Record all ndings on a copy of the "hoist

inspection log". If any problems are found with the equipment DO NOT USE until it has been repaired.

6

Page 7

T-300/T-1000 TRIPOD SYSTEM

INSPECTION LOG BOOK

MODEL # SERIAL # MFG. DATE

HOIST INSPECTION LOG: (SAMPLE FORM - Copy to start inspection log book)

TYPE OF INSPECTION: o DAILY o WEEKLY o ANNUALLY

Date of Inspection (d / m / y)

Inspected By:

LABELS

DAMAGE

CORROSION

FASTENERS

T

R

PULLEYS

I

ROLLER

P

ANCHOR POINTS

O

D

WINCH BRACKET

SRL's BRACKET

WELDS

OTHER

COMMENTS:

FAILURE TO COMPLY AND FOLLOW REGULAR INSPECTION PROCEDURES STATED IN THIS MANUAL WILL RESULT IN VOIDING OF THE MANUFACTURES WARRANTY AND / OR

POSSIBLE SERIOUS INJURY OR DEATH TO THE OPERATOR / ENTRANT.

7

Page 8

LIMITED LIFETIME WARRANTY

ISO

Warranty to End User: D B Industries, Inc., dba CAPITAL SAFETY USA (“CAPITAL SAFETY”) warrants to the

original end user (“End User”) that its products are free from defects in materials and workmanship under

normal use and service. This warranty extends for the lifetime of the product from the date the product is

purchased by the End User, in new and unused condition, from a CAPITAL SAFETY authorized distributor.

CAPITAL SAFETY’S entire liability to End User and End User’s exclusive remedy under this warranty is limited

to the repair or replacement in kind of any defective product within its lifetime (as CAPITAL SAFETY in its sole

discretion determines and deems appropriate). No oral or written information or advice given by CAPITAL

SAFETY, its distributors, directors, ofcers, agents or employees shall create any different or additional

warranties or in any way increase the scope of this warranty. CAPITAL SAFETY will not accept liability for defects

that are the result of product abuse, misuse, alteration or modication, or for defects that are due to a failure to

install, maintain, or use the product in accordance with the manufacturer’s instructions.

CAPITAL SAFETY’S WARRANTY APPLIES ONLY TO THE END USER. THIS WARRANTY IS THE ONLY WARRANTY

APPLICABLE TO OUR PRODUCTS AND IS IN LIEU OF ALL OTHER WARRANTIES AND LIABILITIES, EXPRESSED

OR IMPLIED. CAPITAL SAFETY EXPRESSLY EXCLUDES AND DISCLAIMS ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND SHALL NOT BE LIABLE FOR INCIDENTAL,

PUNITIVE OR CONSEQUENTIAL DAMAGES OF ANY NATURE, INCLUDING WITHOUT LIMITATION, LOST PROFITS,

REVENUES, OR PRODUCTIVITY, OR FOR BODILY INJURY OR DEATH OR LOSS OR DAMAGE TO PROPERTY, UNDER

ANY THEORY OF LIABILITY, INCLUDING WITHOUT LIMITATION, CONTRACT, WARRANTY, STRICT LIABILITY, TORT

(INCLUDING NEGLIGENCE) OR OTHER LEGAL OR EQUITABLE THEORY.

CSG USA & Latin America

3833 SALA Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

solutions@capitalsafety.com

CSG EMEA

(Europe, Middle East, Africa)

Le Broc Center

Z.I. 1ère Avenue

5600 M B.P. 15 06511

Carros

Le Broc Cedex

France

Phone: + 33 4 97 10 00 10

Fax: + 33 4 93 08 79 70

information@capitalsafety.com

A Capital Safety Company

CSG Canada

260 Export Boulevard

Mississauga, ON L5S 1Y9

Phone: 905.795.9333

Toll-Free: 800.387.7484

Fax: 888.387.7484

info.ca@capitalsafety.com

CSG Australia & New Zealand

95 Derby Street

Silverwater

Sydney NSW 2128

AUSTRALIA

Phone: +(61) 2 8753 7600

Toll-Free : 1 800 245 002 (AUS)

Toll-Free : 0800 212 505 (NZ)

Fax: +(61) 2 87853 7603

sales@capitalsafety.com.au

www.capitalsafety.com

CSG Northern Europe

Unit 7 Christleton Court

Manor Park

Runcorn

Cheshire, WA7 1ST

Phone: + 44 (0)1928 571324

Fax: + 44 (0)1928 571325

csgne@capitalsafety.com

CSG Asia

Singapore:

16S, Enterprise Road

Singapore 627666

Phone: +65 - 65587758

Fax: +65 - 65587058

inquiry@capitalsafety.com

Shanghai:

Rm 1406, China Venturetech Plaza

819 Nan Jing Xi Rd,

Shanghai 200041, P R China

Phone: +86 21 62539050

Fax: +86 21 62539060

9001

Certificate No. FM 39709

Loading...

Loading...