Page 1

1

Form No: 8516182 Rev: A

Page 2

2

Page 3

1 INTRODUCTION

3

Congratulations on your choice of a Unique Concepts Man Rated Confined Space Entry/Retrieval

System Winch to compliment your entry/retrieval operation. This equipment has been designed and

manufactured to comply with the requirements of OHSA 1910, ANSI Z 359.1-1992, ANSI Z117.1-1995

& CE to meet the needs of a discriminating operator for the efficient entry/or retrieval of people from a

confined space.

Safe, efficient and trouble free operation and maintenance for your component or system requires that

you or anyone else who will be operating, maintaining or inspecting the equipment, read, understand

and follow all the Safety, Installation, Operation, Maintenance and Inspection instructions contained in

this manual, and in any related manuals referenced in this manual and/or supplied with the system.

This manual covers the “Basic” Series Winches manufactured by Unique Concepts. Use the Table of

Contents or Index as a guide when searching for specific information.

Keep this manual handy for frequent reference and to pass to new operators. Establish a regular

training program for experienced and new operators per these instructions. Establish a regular

maintenance and inspection program to keep the equipment in top condition.

Modular components are labeled with the capacities and rating to which they were designed, tested,

and manufactured. The rating of any system is considered to be the rating of the lowest rated

component contained is the system.

Do not use the equipment if rating stickers are damaged or illegible. New stickers are available from

the manufacturer. When ordering replacement stickers be sure to include:

1) The part number from the bottom right hand corner of the sticker, when available.

2) The serial number of the unit.

3) The part (item) number of the component (consult the appropriate section of this

manual).

4) Any other numbers stamped on the components.

This product is a part of a Man Rated Confined

Space Entry/Retrieval System. The user must

read, understand, and follow the instructions

contained in the manual for each component or

total system before using this equipment.

Establish an appropriate training, maintenance,

and inspection program for your people and the

equipment. Failure to follow these instructions

could result in serious in

WARNING

jury or death.

Page 4

2 SAFETY

4

SAFETY ALERT SYMBOL

This Safety Alert symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert symbol identifies important

safety messages on your equipment and in the

manual. When you see this symbol, be alert to

the possibility of personal injury of death.

Follow the instructions in the safety message.

Why is SAFETY important to you?

3 Big Reasons

SIGNAL WORDS:

Note the use of the signal words

WARNING,

messages. The appropriate signal word for

each message has been selected using he

following guide-lines:

CAUTION

and

DANGER,

with the safety

Accidents Disable and Kill

Accidents Cost You Money

Accidents Can Be Avoided

DANGER -

situation that, if not avoided, will

WARNING -

CAUTION -

situation that, if not avoided, may

result in minor or moderate injury.

It may also be used to alert

against unsafe practices.

Indicates an imminently hazardous

result in death or serious injury.

This signal word is to be limited to

the most extreme situations, or for

hidden or unseen hazards.

Indicates a potentially hazardous

situation that if not avoided, could

result in death or serious injury,

and includes obvious and hidden

hazards. It may also be used to

alert against unsafe practices.

Indicates a potentially hazardous

Page 5

SAFETY

5

YOU are responsible of the SAFE

operation, maintenance and inspection of

your Unique Concepts Man Rated Confined

Space Entry/ Retrieval System Winch. YOU

must ensure that you and anyone else who

is going to operate, maintain, inspect or

work around the equipment be familiar with

the operating and maintenance procedures

and related SAFETY information contained

in this manual. This manual will take you

step-by-step through your working day and

alerts you to all good safety and operating

practices while using the equipment.

Remember, YOU are the key to safety.

Good safety practices not only protect you,

but also the people around you. Make

these practices a working part of your safety

program. Be certain that EVERYONE

operating this equipment is familiar with the

procedures recommended and follows

safety precautions. Remember, most

accidents can be prevented. Do not risk

injury or death by ignoring good safety

practices.

• Owners must give operating instructions

to operators or employees before

allowing them to use the equipment, and

at least annually thereafter.

• The most important safety device on this

equipment is a SAFE operator. It is the

operator’s responsibility to read and

understand ALL Safety and Operating

instructions in the manual and to follow

these. All accidents can be avoided.

• A person who has not read, been

trained in using and understood all

operating and safety instructions is not

qualified to operate this equipment. An

untrained operator exposes himself and

others to possible serious injury or

death.

• Do not modify the equipment in any

way. Unauthorized modification may

impair the function and/or safety and

could affect the life of the equipment.

• Think SAFETY! Work SAFELY!

2.1 GENERAL SAFETY

1. Read, understand and follow the

User Manual and all safety signs

before using, maintaining or

inspecting the equipment.

2. Refer to and follow applicable ANSI, OSHA,

CE or other Standards and local regulations.

Comply with requirements of local

regulations for your applications.

3. Establish an equipment–use training

program for experienced employees. Only

trained, competent persons shall use the

equipment. An untrained operator is not

qualified to operate the system.

4. Have a first-aid kit available for

use should the need arise and

know how to use it.

5. Provide a fire extinguisher for

use in case of an accident.

Store in a highly visible place.

6. Install and properly secure all guards

and shields before operating.

7. Wear appropriate protective gear. This

list includes but is not limited to:

- A hard hat

- Safety glasses

- Protective shoes

with slip resistant

soles

- Heavy gloves

- Protective clothing

- Face protection

8. Review and follow the Pre-Operation

Inspection before using a component in the

system or the system itself.

9. Establish a regular Maintenance and

Inspection program with your equipment and

maintain detailed records.

10. Review safety related items and operating

instructions with all personal on a regular

basis.

11. Be aware of your environmental

surroundings; be sure not to use the

equipment during an electrical storm. (this

equipment is conductive)

12. When using our winch, the noise level does

not exceed 70 d B(A).

Page 6

2.2 OPERATING SAFETY

6

1. Read, understand and follow the

Operator’s Manual and signs on the

equipment before using, maintaining or

inspecting the equipment.

2. Train all operators before allowing them

to use the equipment. An untrained

operator exposes themselves,

bystanders and workers to possible

serious injury or death.

3. Visually inspect the equipment and all

auxiliary components and equipment

before using. Correct any problems

before using the equipment.

4. Securely anchor the winch before using,

where applicable.

5. Use only certified anchor and connector

components in your system.

6. Use only an approved full body harness

for the workers.

7. Always work in teams. One person

works in the confined space and the

other one pays out the line and reels it

in.

8. Check the condition of the brake wear

each time the winch is used. When the

indicator moves into the red portion of

the scale or 1 year in service (which

ever comes first), remove from service

and return to the factory for service.

9. Do not exceed 310lbs. (141 kg) on the

line during operation.

10. Establish a regular training program for

new and experienced workers.

11. Establish a detailed inspection program

for your equipment and document the

findings. Return the equipment to the

manufacturer for rework if any problems

are found.

12. Plan your work program before starting.

Have the required people, equipment

and procedures available to do the job.

13. Do not use the equipment around

physical or environmental hazards. This

list includes but is not limited to:

a. Corrosion that may affect the structural

integrity of the life line or other

components .

b. Chemicals which can degrade

components and not be visible.

c. Toxic gases: Rescuers or workers can

be killed in toxic environments.

d. Heat or elevated temperatures.

e. Moving machinery: Workers or

auxiliary equipment can be contacted

by or pulled into moving components.

f. Sharp edges: Workers or the

equipment can be injured or damaged

by sharp edges or components.

g. Electrical hazards: Stay away from

power lines or components carrying

electrical power.

h. Overload: Do not exceed 310 lbs. (141

kg) during operation.

Follow confined space regulations in

i.

Standards.

Noise: wear appropriate noise

j.

protection where necessary.

Environmental hazards: do not operate

k.

equipment during electrical storms.

2.3 MAINTAINANCE/

INSPECTION SAFETY

1. Read, understand and follow the User

Manual and signs on the equipment

before using, maintaining or inspecting

the equipment.

2. ANSI, OSHA & CE requires a regular

inspection program for all Confined

Space Entry/Retrieval Equipment and to

maintain documented results of these

inspections. Follow the inspection

procedure contained in this manual and

use the inspection form to document the

results.

3. Keep instructional and safety signs

clean and legible at all times. Clean or

replace as required.

4. Lubricate winch as per instructions in

Section 4 of this manual.

5. Remove the equipment from service if a

problem is found during the inspection.

Return to an authorized repair depot or

the factory for service.

Page 7

3 OPERATING, NEW

7

OPERATOR OR OWNERS

The “Basic” Series Winch is designed to

attach to a person (entrant) and allow them

to enter a confined space and assist in

exiting if required. Every new operator must

read, understand and follow the instructions

in all applicable manuals. No one should be

allowed to use the equipment without

training. The training should be reviewed

with experienced operators on a regular

basis. At regular intervals perform a

detailed inspection of the equipment and

document the results. Remove from service

if deficiencies are found. Alterations or

misuse of this equipment or failure to follow

instructions, may result in serious injury of

death.

It is the responsibility of the owner’s

organization or operator to read this

manual and to train all other operators

before they start working with the

equipment. Follow all safety instructions

exactly. Safety is everyone’s business.

By following recommended procedures,

a safe working environment is provided

for the operator, bystanders and the area

around the work site. Untrained

operators are not qualified to operate the

equipment.

Many features incorporated into this

equipment are the result of suggestions

made by customers like you. Read this

manual carefully to learn how to operate the

equipment safely and how to set it to

perform as intended. By following the

operating instructions in conjunction with a

good maintenance program, and diligence

in annual re-certification your equipment will

provide many years of trouble-free service.

Page 8

OPERATING SAFETY

8

1. Read, understand and follow the User

Manual and signs on the equipment

before using, maintaining or inspecting

the equipment.

2. Train all operators before allowing them

to use the equipment. An untrained

operator exposes themselves,

bystanders and workers to possible

serious injury or death.

3. Visually inspect the equipment and all

auxiliary components and equipment

before using. Correct any problems

before using the equipment.

4. Securely anchor the winch before using.

5. Use only certified anchor and connector

components in your system.

6. All anchor points, or mounting/setup

locations for permanent or portable

systems must be approved to local

standards by a qualified engineer.

7. Use only an approved body harness for

the workers.

8. Always work in teams. One person

works in the confined space and the

other one pays out the line and reels it

in.

9. Do not use the equipment when the

winch brake wear indicators display in

the red or 1 year in service (which ever

comes first). Return equipment to

manufacturer for service.

10. Do not exceed 310lbs. (141 kg) on the

personal man rated lifeline during

operation.

11. Use only retractable lifelines or shock

absorber with a maximum arrest force

(MAF) equal to or lower than the lowest

rated component of your system.

12. Establish a regular training program for

new and experienced workers.

13. Establish a detailed inspection program

for your equipment and document the

findings. Return the equipment to the

manufacturer for rework if any problems

are found.

14. Plan your work program before

starting. Have the required people,

equipment and procedures available to

do the job.

15.

Do not use the equipment around

physical or environmental hazards. This

list includes but is not limited to:

a. Corrosion that may affect the

structural integrity of the life line or

other components.

b. Chemicals which can degrade

components and not be visible.

c. Toxic gases: Rescuers or workers

can be killed in toxic environments.

d. Heat or elevated temperatures.

e. Moving machinery: Workers or

auxiliary equipment can be

contacted by or pulled into moving

components.

f. Sharp edges: Workers or the

rescue equipment can be injured

by or damaged by sharp edges or

components.

g. Electrical hazards: Stay away from

power lines or components carrying

electrical power.

h. Overload: Do not exceed a

personal load capacity of 310 lbs.

(141 kg) or material load capacity

of 620lbs. (282 kg) during

operation.

i. Follow confined space regulations

in Standards.

j. Noise: wear appropriate noise

protection where necessary.

k. Environmental hazards: do not

operate equipment during electrical

storms.

Page 9

9

3.1 PRINCIPLE COMPONENTS

The “Basic” Series Winch is designed to

extend and retract a lifeline from a drum for

attaching to a person who is entering or

exiting a confined space. It is designed with

a double redundant braking system to hold

the line in any position. Line extending or

retracting is controlled by the crank handle

attached to the 5.1:1 driving shaft.

The winch frame back plate mates to a

mounting system that attaches to various

structures. Secure the winch to the

mounting system with the hand tightened

bolt before using the winch. Maximum of 70

feet line can be installed on the drum and a

red marker is located 10 feet from the fixed

end to alert the user not to pay out more

line. This prevents the line from being

wrapped backward on the spool and

ensures effective protection during Load

Limiter Clutch activation. Line extension

must occur when the handle is turned

counter-clockwise and clockwise for

retraction to have the internal brakes

properly engaged.

To prevent accidental reversal of the cable

on the drum, the cable is installed and

conforms to the proper cable direction on

the drum. Spooling the cable entirely off the

drum is forbidden in case of accidentally

spooling the cable in the reverse on the

drum. Spooling the cable on the drum in

reverse will cause freewheeling of the

drum and cable and may cause serious

injury or death.

C

M

D

H

E

F

C

A Crank Arm

B Crank Handle

C Cover

D Brake Indicator

E Drum

F Cable

G Load Indicator Snap

L

A

B

H Pressure Bar

I Cable Retainer Spring

J Load Limiter Window

K Load Limiter Tear Strip

L Annual Recertification

Date

K

J

A

F

H C

Figure 1 Winch Components

Page 10

10

3.2 PRE-OPERATION

INSPECTION

It is necessary to perform a detailed visual

inspection prior to using the winch. If

deficiencies are found, remove the winch

from service and return to Unique Concepts

Ltd. or authorized service center for rework.

This checklist should be used as a guide to

determine whether the equipment is in good

operating condition prior to using.

Equipment that is not in good condition can

endanger the safety of the entrant during

use.

The visual inspection must include but is not

limited to the following items:

1. Check that the winch has no structural

defects.

2. Be sure the winch is clean and the

labels are legible.

3. Be sure the crank handle moves freely.

4. Functional check:

a. Pull on cable and turn the crank

counterclockwise to extend cable.

b. Release the crank and pull hard on

the cable.

c. Pull on cable and turn handle

clockwise to retract cable.

d. Be sure that cable is threaded

through the structure pulleys and

rollers as per instructions in

applicable structure manual.

5. Inspect the cable:

a. Check cable for kinking, cuts, wear

and fraying.

b. Check that the thimble and cable

crimps are in good condition.

c. Check that the snap lock is in good

condition. Be sure the gate will not

open unless the lock is released to

prevent rollout. Be sure the load

activation indicator snap reads green

according to Section 4.2.2.

6. Check brake wear indicator. Remove

from service if indicator displays in the

red and return winch to the factory for

service.

7. Check the Annual Re-Certification date

stamped into the crank handle. Remove

from service if stamped date exceeds

the current date of operation and return

winch to factory for service. Refer to

winch inspection log for details on winch

servicing.

8. If the winch is not in good condition,

remove from service and tag for

shipment to an authorized repair depot

or the factory for rework. Using a winch

that is not in good condition can lead to

a hazardous condition for entrant(s).

9. Go through the detailed inspection

procedure on a regular basis (at least

annually) per the Inspection Section of

this manual. Document the results

using the sample form and retain for

your files.

10. A detailed inspection is required after 6

months of periodic use and records

kept.

Page 11

11

3.3 APPLICATIONS

1. General

The Unique Concepts “Basic” Series

Man Rated Confined Entry/Retrieval

System Winch is designed to be used in

work support or rescue. It extends and

retracts a line as the handle is turned.

When the handle is not being turned, an

internal brake holds the spool and the

line will not extend or retract.

2. Scope

The winch works well in both vertical

and horizontal applications. However,

different mounting, anchoring and

support systems are required for each

type of application. The user has the

responsibility of reading and

following the instructions for the

other systems in addition to the

winch. Misuse or abuse of any

component can create hazards for

personnel.

3. Work Support

The winch works well for supporting

workers in a boatswains chair or a full

body harness (single point suspension).

In some applications, a back-up fall

arrest system is also used. In these

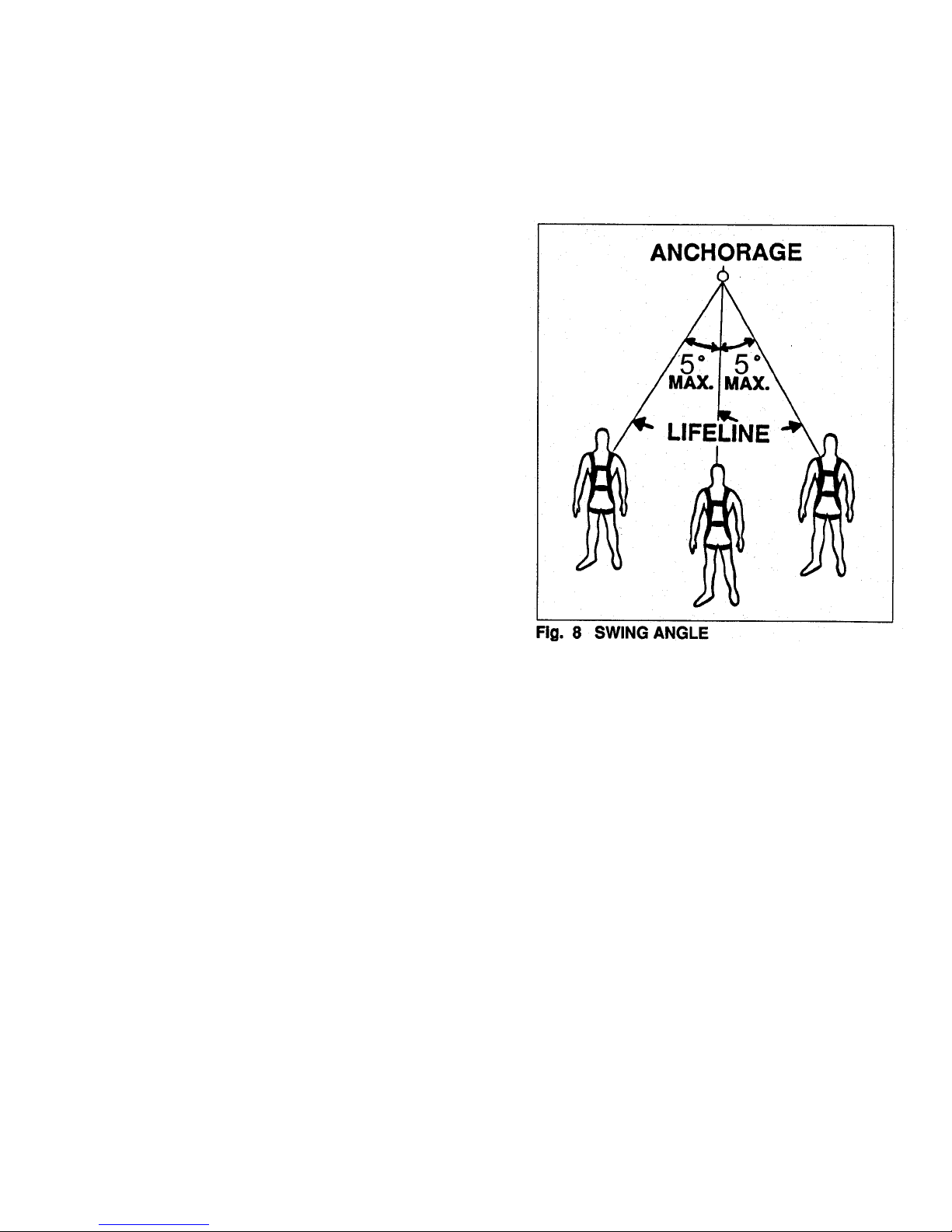

applications, a swing angle of less than

5° is recommended. Use only an

approved mounting or anchoring system

at all times. Use only approved

connectors that are equipped with an

anti rollout device.

4. Emergency Rescue

In emergency situations, use the winch

to remove personnel from a hazardous

or an unsafe environment. In these

situations, a back-up fall arrest system

is generally not required. Be sure to use

the proper mounting and anchoring

system for the winch. Use only a fullbody harness for personnel. Always be

aware of the system limitations and

follow the instructions.

5. Limitations

Operators must be aware of several

limitations on the use of the winch

whenever it is used and plan their work

accordingly. Limitations include but are

not limited to:

a. Corrosion:

Do not keep the winch in an area

that has a corrosive atmosphere.

Corrosive vapors can be released

by sewage plants or in fertilizer

plants. Sea water or spray can also

cause corrosion to the case, lifeline

or other components. Long term

exposure to these types of

environment will require more

frequent inspections to insure that

the function of the unit has not been

effected.

b. Chemical or Toxic Environments:

Work environments that contain

strong acids, bases or other

corrosive chemicals in solutions,

sprays or vapors may damage the

winch or auxiliary components.

Inspect the unit frequently to detect

any damage. Chemical damage

may be difficult to detect visually and

periodic lifeline replacement is

recommend to insure safety.

c. Electrical Hazards:

Stay away from power lines or other

components carrying electrical

power. The metal lifeline can

conduct electricity if it gets close to

or contacts a power line or electrified

component. Remember electricity

can jump across an air gap and

electrocute personnel using the

winch. Contact your local utility to

remove or disconnect the power

before working around these

components. Contact Unique

Concepts for synthetic rope options

for reduced conductivity.

Page 12

12

d. Load Capacity:

Do not exceed the winch capacity of

310 lbs. (141 kg) (includes people,

harness, tools etc). Do not carry

more than one person at a time on

the lifeline. Overloading the winch

can exceed the design safety factors

and could create hazards.

e. Training:

Do not allow anyone to use this

winch unless they are trained in its

limitations and use. Untrained

operators can expose themselves

and others to hazards. Train new

operators before using the unit.

Review operating procedures on a

regular basis with experienced

personnel.

3.4 SYSTEM REQUIREMENTS

The Unique Concepts “Basic” Series Winch

is a component in a Confined Space

Entry/Retrieval System. The winch and all

auxiliary components must be compatible to

prevent creating unexpected hazards. A list

of system compatibility requirements

includes but is not limited to:

a. Anchorage

The winch is designed to be attached to

a mounting and support system that

provides the required anchorage

strength.

Anchorage strength requirements are

defined by ANSI and OSHA Standards

or local regulations and must be met to

insure the safety of the entrant. If

Unique Concepts has reviewed and

approved the mounting or anchorage

system, it has sufficient strength to fulfill

the ANSI and OSHA requirements. If

the winch will be used with a non-factory

approved mounting or anchorage

system, a qualified person must review

and approved the application prior to

use.

b. Connectors

Use only approved connectors with

sufficient capacity that have an anti

rollout device designed into the snap.

Non-approved connectors can open

during use and create unexpected

hazards. Do not use them.

c. Personnel Harness

Use only an approved full body harness.

Do not use a single belt or strap system.

Only a full body harness can provide the

required support for the body to prevent

injury.

Page 13

3.5 FIELD OPERATION

13

1. Read, understand and follow the User

Manual and signs on the equipment

before using, maintaining or inspecting

the equipment.

2. Train all operators before allowing them

to use the equipment. An untrained

operator exposes themselves,

bystanders and workers to possible

serious injury or death.

3. Visually inspect the equipment and all

auxiliary components and equipment

before using. Correct any problems

before using the equipment.

4. Securely anchor the winch before using.

5. Use only certified anchor and connector

components in your system.

6. All anchor points, or mounting/setup

locations for permanent or portable

systems must be approved to local

standards by a qualified engineer.

7. Use only an approved body harness for

the workers.

8. Always work in teams. One person

works in the confined space and the

other one pays out the line and reels it

in.

9. Do not use the equipment when the

winch brake wear indicators display in

the red or 1 year in service (which ever

comes first). Return equipment to

manufacturer for service.

10. Do not exceed 310lbs. (141 kg) on the

personal man rated lifeline during

operation.

11. Use only retractable lifelines or shock

absorber with a maximum arrest force

(MAF) equal to or lower than the lowest

rated component of your system.

OPERATING SAFETY

12. Establish a regular training program for

new and experienced workers.

13. Establish a detailed inspection program

for your equipment and document the

findings. Return the equipment to the

manufacturer for rework if any problems

are found.

14. Plan your work program before

starting. Have the required people,

equipment and procedures available to

do the job.

15.

Do not use the equipment around

physical or environmental hazards. This

list includes but is not limited to:

a. Corrosion that may affect the

structural integrity of the life line or

other components .

b. Chemicals which can degrade

components and not be visible.

c. Toxic gases: Rescuers or workers

can be killed in toxic environments.

d. Heat or elevated temperatures.

e. Moving machinery: Workers or

auxiliary equipment can be

contacted by or pulled into moving

components.

f. Sharp edges: Workers or the

rescue equipment can be injured

by or damaged by sharp edges or

components.

g. Electrical hazards: Stay away from

power lines or components carrying

electrical power.

l. Overload: Do not exceed a

personal load capacity of 310 lbs.

(141 kg) or material load capacity

of 620lbs. (282 kg) during

operation.

m. Follow confined space regulations

in Standards.

Page 14

14

The Unique Concepts “Basic” Series Winch

is designed for use in many applications

including but not limited to work positioning,

personnel riding, rescue or confined space

entry/retrieval. It is the responsibility of the

operator to be familiar with and follow all

applicable OSHA and industry standards on

operating guidelines for your project. If you

have any questions, consult with a qualified

person or call the factory.

When using the winch, follow this

procedure:

1. Review and follow the Pre-Operation

Inspection (Refer to Section 3.3).

2. Inspect the unit prior to each use.

Visually check each component to be

sure that there is no damaged or

missing parts. Check that all systems

and components function as intended.

Do not use the equipment if any

problems are found.

3. Working Planning

Plan your entire work project before

starting. Consider all the equipment and

system requirements and comply with

these requirements before starting.

Anticipate the needs before, during and

after the project is being done and

prepare for these needs. Be prepared

for the unexpected by planning in

advance. Your advance planning list

includes but is not limited to:

a. Anchorage

We recommend mounting the winch

to only approved supporting

components and systems to be sure

that the anchorage has sufficient

strength. All support and mounting

systems must be designed to ANSI

and OSHA Standards. Refer to

Structural manual for specific

strengths.

b. Connectors

Connectors if used should be

equipped with an anti-rollout device

to prevent accidental

disengagement. Roll-out can occur

when there is interference between

the connector and load that causes

the gate or keeper to accidentally

open or release. Do not take a

chance with safety. Only use

approved components.

c. Hazards

Stay away from mechanical,

chemical and electrical hazards.

Moving machinery, sharp edges and

other mechanical hazards can injure

personnel, damage equipment or

interfere with the work procedure,

chemical, corrosive or toxic

environments can damage

equipment or affect the well-being or

personnel. Electrical power can

follow through the equipment and

electrocute personnel even if there is

no direct contact. Plan your work or

rescue procedures to consider these

factors and allow for them. Advance

planning will allow the equipment to

be used safely in a variety of

conditions.

d. Cable Path

Body parts, clothing, tools or other

items can get snagged when going

around a corner or over obstacles

during the retrieval procedure.

Corners or sharp edges can also

damage the lifeline as it goes by. Be

prepared to do an entry rescue to

assist in the retrieval of a down

entrant.

e. Vertical Applications

For vertical applications, keep the

swing-fall angle less than 5°.

Serious injuries to personnel can

occur if they swing into a solid

object. Try to keep the entrant

directly below the winch attachment

point at all times. Two people are

required at all times: the entrant and

winch operator. Always maintain

communication to be sure the lifeline

is kept taut and that the entrant is

not encountering problems.

Page 15

15

f. Emergency

During rescue or emergency

procedures, the winch anchorage

must be capable of supporting at

least 1500 lbs. Always use a fullbody harness when moving people.

People can be seriously injured

during rescue or in an emergency

situation if they are not supported in

an approved full body harness.

However quick response is required

in any emergency or rescue

operation.

4. Personal Fall Arrest System

In some entry/retrieval applications,

OSHA and ANSI Standards require that

the entrant be connected to a Personal

Fall Arrest System. It is the

responsibility of the operator to be

aware of these requirements and follow

them. Always use a full body harness

on the entrant when attached to a PFAS

to minimize potential injury to the

entrant. Application limitations for the

winch also apply to a PFAS.

5. Installation/Removal

The “Basic” Series Winch can be

equipped with a universal mounting

base that can mate with mounting

hardware for any support or anchorage

system.

A. Installing

a. Secure attaching hardware to

the universal mounting base.

Refer to appropriate Structure

Manual for bracket mounting

details.

b. Pin crank handle into position by

lining up the holes and pin. Make

sure in is pinned secure before

operating.

c. Refer to Structure Manual for

mounting of winches.

Figure 2 Universal Mounting Base

Figure 3 Crank Handle in collapsed position

Page 16

16

d. Pull on the cable with at least 10

lbs. Force and turn the crank

arm counterclockwise to extend

cable.

Refer to applicable Structure

Manual(s) for cable threading

instructions.

e. Be sure the cable crimps,

thimble, swivel and snap-lock

connector are in good condition

and functioning as intended.

f. Attach the snap hook to the

entrants full body harness.

Figure 4 Cable Extended (Typical)

Figure 5 Snap-lock Connector

Page 17

17

B. Removal:

a. Disconnect the snap hook from

harness. Maintain at least a 10

lb. load on the cable to keep the

cable tight on the spool.

b. Turn the crank handle clockwise

to retract the cable through the

pulley and rollers of the structure

(if applicable) while maintaining

a 10 lb. pull on the cable. See

appropriate structure manual.

c. Retract until copper crimps and

thimble just rolls loosely onto

drum.

d. Remove from mount or

anchorage. Refer to structure

manual for details.

6. Load Attachment

The entrant must be attached to the

winch using the snap hook on the end of

the lifeline. This, and any other

connector, must be equipped with an

anti-rollout device on the gate. When

attaching the entrant, follow this

procedure:

a. Pull on the snap hook with at least

10 lbs. pull while extending the

lifeline until there is sufficient slack

to attach to the entrant.

b. Use two hands when attaching to

the entrant.

c. Use one hand to apply a steady pull

on the lifeline and to steady the snap

hook.

d. Use the other hand to depress the

lock and open the gate.

e. Insert the harness D-ring into the

hook.

IMPORTANT

Always use a full body harness for

personnel and attach to the dorsal

“D” ring.

f. Close gate and be sure the lock

clicks into its locked position.

g. Tighten the lifeline.

h. Reverse the above procedure when

unhooking from the entrant.

Figure 6 Maintaining 10 lbs. on Cable

Figure 7 Snap-lock Connector

Page 18

18

7. System-Integrity

The entrant should always verify the

intergrity of the attachment and system

before entering a confined space. To verify

the integrity of the system, follow this

procedure:

a. Connect the snap hook to the dorsal

ring of the full body harness.

b. Snug up the lifeline.

c. The entrant should slowly lift their feet

off the ground and transfer all the weight

to the lifeline.

d. Be sure the winch holds you in a

stationary position.

e. Be sure the full body harness is

comfortable and does not pinch, chafe

or bind. Adjust for comfort before

starting.

f. Do not enter confined space unless

connectors, brakes, winch and harness

are functioning properly.

8. Crew Personnel

A working crew requires the use of at

least 2 people at all times. The entrant

who is attached to the end of the lifeline

and the attendant who turns the winch

crank and guides the lifeline. Each must

be properly trained in the use of the

equipment and for their task. As the

entrant enters the confined space, the

entrant should maintain communication

with the attendant operating the winch.

Heavy gloves should be worn by the

attendant when guiding the cable. The

two people must work as a team to get

the job done safely and efficiently.

Do not test system

over confined entry.

WARNING

Page 19

19

9. Entering Confined Space

When entering confined space, follow

this procedure:

a. The entrant should move slowly and

smoothly into the confined space

(either vertical or horizontal).

b. The attendant should turn the winch

handle counter-clockwise to pay out

the lifeline.

IMPORTANT

Do not use the winch if turning the

handle clockwise pays out the lifeline.

The internal brakes are engaged only

when the handle operating direction

retrieves the lifeline when the handle is

turned clockwise. The reverse cable

protector should prevent backwards

winding of cable.

c. Wearing gloves, place one hand on

the lifeline to guide it as it extends.

Use your hand to maintain a slight

pull on the cable at all times.

d. For a vertical entry, maintain the swing angle at less than 5

while working. The entrant can be seriously injured if the

swing angle exceeds 5°.

e. If the entrant is not suspended and there is no chance of a

fall, pay out sufficient line (2 ft. max.) so it is slack and the

entrant can work. Hold the lifeline so there is a slight pull

on it at all times.

f. Extend or retract the lifeline as required to keep the line

snug.

g. Maintain communication between the entrant and

attendant at all times. Be sure each knows what the other

is doing.

h. Do not go around corners when entering a confined

space. Body parts, clothing, tools or other items can get

snagged when going around a corner and over obstacles

during retrieval procedure. Corners or sharp edges can

also damage the lifeline as it goes by. Be prepared to do

an entry rescue to assist in the retrieval of a down entrant.

Page 20

prep

i. If the lifeline becomes tight or slack

20

during entry, communicate with the

entrant to determine whether there is a

problem. Correct the problem before

proceeding.

j. The last 10 feet of the lifeline has a

red marker and should not be

unwound from the drum. This

length provide the required wrap on

the drum to properly anchor the

lifeline and insures that the lifeline

wrap direction is correct. Stop

extending the lifeline when you see

the red marker.

10. Retrieving From Confined Space

When exiting from confined space, follow

this procedure:

a. Turn the winch crank arm clockwise to

retract the lifeline and retrieve the

entrant from the confined space.

IMPORTANT

Do not use the winch if turning the

handle counterclockwise retrieves

the lifeline. The internal brakes are

engaged only when the handle

operating direction retrieves the

lifeline when the handle is turned

clockwise.

b. Maintain communication with entrant

when preparing to retrieve and during

the retrieval process.

c. Turn the handle smoothly to maintain an

even retrieval rate.

Figure 9 Cable Marker

d. If the winch handle turning load

increases suddenly, stop and

investigate. Determine the cause and

correct before continuing the retrieval.

Usually this occurrence is caused by the

load catching or snagging on something.

Release the snag before continuing. It

may be necessary to extend the line

slightly to release the snag.

e. Support the entrant or load after

retrieval and disconnect snap hook.

Should the entrant become caught

around a corner or get snagged or

tangled, it may be necessary to enter the

confined space and assist the original

entrant. This should be considered a

new entry or rescue and all regulations

apply to the new entrant. E.g. Lifeline.

Be

CAUTION

ared for a rescue.

Page 21

11. Load Limiter Clutch

21

The winch is designed with a load limiter

clutch that activates when a short free fall

has occurred and while brakes are

engaged. The clutch will slow the fall

gradually until it comes to a complete stop.

There must be at least 10 feet of cable on

the drum at all times for this clutch to be

effective.

When activation of the load limiter clutch

occurs, the operator can still extend or

retract the cable from its stopped position by

turning the crank. When the entrant is out,

remove the winch from service and return to

the factory for rework.

12. Rescue or Emergencies

The winch is designed for entry and retrieval

of people from confined spaces in rescue or

emergency applications. Although fast

response is crucial for saving lives, it is still

necessary to be aware of and follow all

safety and operating procedures. Do not

take chances with shortcuts. Peoples lives

are at stake. Use only trained competent

people who know the equipment and can

safely rescue people from an emergency

situation.

Figure 10 Load Limiter Clutch Indicator Window

Page 22

13. Operating Hints

22

a. Follow all applicable OHSA and ANSI

Standards and local regulations when

using this equipment.

b. Train all new operators before allowing

them to use the equipment. Conduct

regular refresher training sessions with

all experienced operators.

c. Inspect and maintain the equipment on

a regular basis. Remove defective

equipment from service. Keep

inspection and maintenance records.

d. It is recommended that the winch be

used in conjunction with other approved

components and systems. Approved

components and systems have the

required function, strength and

compatibility for all applications.

e. Review and follow the limitations for the

equipment. Do not use in corrosive

conditions, toxic atmosphere or around

mechanical or electrical hazards without

taking special precautions.

f. Plan your project before starting to work.

Anticipate all the normal and

unexpected needs relating to equipment

and procedures and have them at hand

before starting. Advance planning can

save time and lives.

g. An entrant and attendant must work as

a team. Maintain communication at

all times.

h. Check the condition of the brake wear

each time the winch is used. When the

indicator moves into the red portion of

the scale or 1 year in service (which

ever comes first), remove from service

and return to the factory for service.

i. Use Loctite 262 (or equivalent thread

locker) to secure crank handle anchor

bolts if required, Figure 11. Secure

them if they come loose during use.

Brake Wear Indicator Window

Expiration Date, has to be recertified

Figure 11 Winch Safety Features

Figure 12 Handle Anchor Bolts

Page 23

3.6 STORAGE

23

Prior to storage, the winch should be

thoroughly inspected and maintained.

Return winch for repair or replacement

of any worn or damaged components to

prevent any unnecessary down time at

the next use. Follow this procedure:

1. Thoroughly clean the winch using

mild soap on the body and labels.

Be sure the labels are legible.

2. Use a neutralizing solution to clean

lifeline. This is particularly important

if the unit had been used in corrosive

or toxic environments.

3. Perform a complete inspection of the

unit and document the results.

4. Touch up all nicks and scratches to

prevent corrosion.

5. Store in a cool dry place.

Page 24

24

9. Entering Confined Space

When entering confined space, follow

this procedure:

a. The entrant should move slowly and

smoothly into the confined space

(either vertical or horizontal).

b. The attendant should turn the winch

handle counter-clockwise to pay out

the lifeline.

IMPORTANT

Do not use the winch if turning the

handle clockwise pays out the lifeline.

The internal brakes are engaged only

when the handle operating direction

retrieves the lifeline when the handle is

turned clockwise. The reverse cable

protector should prevent backwards

winding of cable.

c. Wearing gloves, place one hand on

the lifeline to guide it as it extends.

Use your hand to maintain a slight

pull on the cable at all times.

d. For a vertical entry, maintain the swing angle at less than 5

while working. The entrant can be seriously injured if the

swing angle exceeds 5°.

e. If the entrant is not suspended and there is no chance of a

fall, pay out sufficient line (2 ft. max.) so it is slack and the

entrant can work. Hold the lifeline so there is a slight pull

on it at all times.

f. Extend or retract the lifeline as required to keep the line

snug.

g. Maintain communication between the entrant and

attendant at all times. Be sure each knows what the other

is doing.

h. Do not go around corners when entering a confined

space. Body parts, clothing, tools or other items can get

snagged when going around a corner and over obstacles

during retrieval procedure. Corners or sharp edges can

also damage the lifeline as it goes by. Be prepared to do

an entry rescue to assist in the retrieval of a down entrant.

Page 25

25

Weekly

1. Functional Inspection

Perform a functional inspection. Refer to

Section 4.2.2. Record results and keep

documentation.

AS REQUIRED

A) Lubricate the Cable

Use a light oil to lubricate the cable.

Lubricating oil should only be applied to

a clean dry cable. Use a stiff bristled

brush to remove contaminants from the

cable if it is dirty. Allow the oil to

penetrate into the cable to reduce

internal friction. Wipe the cable dry with

a clean cloth as it is being retracted into

the winch.

B) Clean Winch

Use a damp cloth and mild soap to

clean the body components and labels

of dirt and residue. Be sure labels are

legible.

C) Complete Inspection

Perform a complete inspection. Refer to

Section 4.2.3. Record results and keep

documentation.

Annually

This winch must be returned to the

manufacturer annually to be re-certified for

continued use.

All risk of personal injury, death or property

damage occurring after the expiration date

shown shall be completely assumed by the

user, and the user releases Unique Concepts

Ltd., its employees and agents, from all liability

for any such personal injury, death or property

damage occurring after the expiration date

shown.

Expiration date is indicated on the winch crank

arm.

Figure 14 Cable Oiling

Page 26

26

4.2 INSPECTION

4.2.1 Visual Inspection

A complete visual inspection should be

performed on the system you are using prior to

the operation. The following items should be

checked; and the results recorded on the

“Inspection Log” sheet (see Section 4.2.5).

1. Labels

Check that all labels are clean and legible.

Clean the labels if any are dirty using a mild

soap and a damp cloth. Replace if any are

illegible (Refer to Section 5 for a listing of all

labels).

2. Fasteners

Check that all screws and other fasteners

are tight. If any are loose or missing,

contact your local dealer or the

manufacturer.

3. Structural Components

Check the components for cracks, dents,

bends, or breaks. Minor cosmetic damage

in the component body will not affect the

function of the davit system. However if

there are major dents or any other structural

damage, the unit should be removed form

service and returned to the manufacturer for

service.

4. Corrosion

Check all components for damage from

corrosion. Although all components resist

corrosion, working in corrosive

environments can lead to damage. Inspect

all structural components and fasteners for

signs of damage. If damage found, remove

from service and return to the manufacturer

for service.

Figure 15 Labels

Instruction Plate Side

Crank / Cover Side

Page 27

27

5. Crank Arm

Check that each handle on the crank arm is

tight. Use Loctite 262 (or equivalent thread

locker) on the anchor screw if required to deep

them tight. Check that the crank arm slides

easily into each drive pocket and that it locks

securely in place. If the crank arm is bent,

damaged or does not fit and lock into the drive

pockets, remove arm and replace. Do not use

crank arm unless it is fully functional.

6. Connectors

Check the cable collar and clamp for signs of

wear, distortion or cable fraying. Remove from

service and return to the factory for service if

any problems are found. Check the gate and

gate lock on the snap hook. Both must open

and close easily. If they do not, remove from

service and return to the factory for service.

7. Brake Indicator and Expiration

Check the condition of the brake indicator and

annual re-certification date. The indicator

should be in the green. If the window shows in

the red or a combination of green/red, remove

from service and return to the factory for

service. If the expiration date exceeds 1 year in

service, remove form service and return to the

factory for service.

Figure 16 Handle Anchor Bolts

Figure 17 Snap-lock Connector

Brake Wear Indicator Window

Expiration Date, has to be recertified

Figure 18 Winch Safety Features

Page 28

4.2.2 Functional Inspection

28

A functional check should be performed on

the winch prior to every use. The following

functional tests should be done:

1. Winch Crank Rotation Direction

The winch crank must turn in the

clockwise direction to retract the lifeline

and counterclockwise to extend for the

internal brakes to engage properly. If

the crank direction is reversed, the

lifeline must be extended completely

(including the last 10 feet past the

plastic coated red mark) to remove all

the cable from the spool. In this

procedure, turning the crank clockwise

will extend the cable. Always keep a 10

lb. pull on the cable clockwise until the

cable stops extending and starts

retracting. Maintain the 10 lb. tension

on the line until the cable is completely

retracted. If the cable has been

reversed on the spool, the cable may

have been damaged. Inspect the cable

as in Section 4.2.3.

2. Snap Hook

Manually check that the swivel on the

top of the snap hook turns easily without

sticking or binding. Also check that the

gate locks and the gate opens and

closes easily without binding and

sticking. If any component sticks or

binds, lubricate with a light oil. If

sticking or binding persists, remove

winch from service and return to the

factory for service.

3. Brake Engagement

The internal brake must hold the cable

from extending or retracting unless the

crank arm is turned. To functionally

check this required feature, extend the

cable in 10 foot increments by turning

the crank counterclockwise. Then pull

sharply on the cable to be sure the

brakes hold securely. If they do not

hold, remove the winch from service and

return to the factory for service.

4. Brake Ratchet Mechanism

The winch is designed with an internal

ratchet that engages the brake

continuously when the crank arm is

turned. The ratchet should be making a

clicking sound when the crank is turned.

This ensures the spring-loaded pawls

are continuously engaging the ratchet. If

ratchet clicking is not heard when the

crank is turned, remove from service

and return to the factory for service.

A

B

a Retrieval Clockwise

b Extension Counter-Clockwise

Figure 19 Crank Rotation

Page 29

3.con’t

29

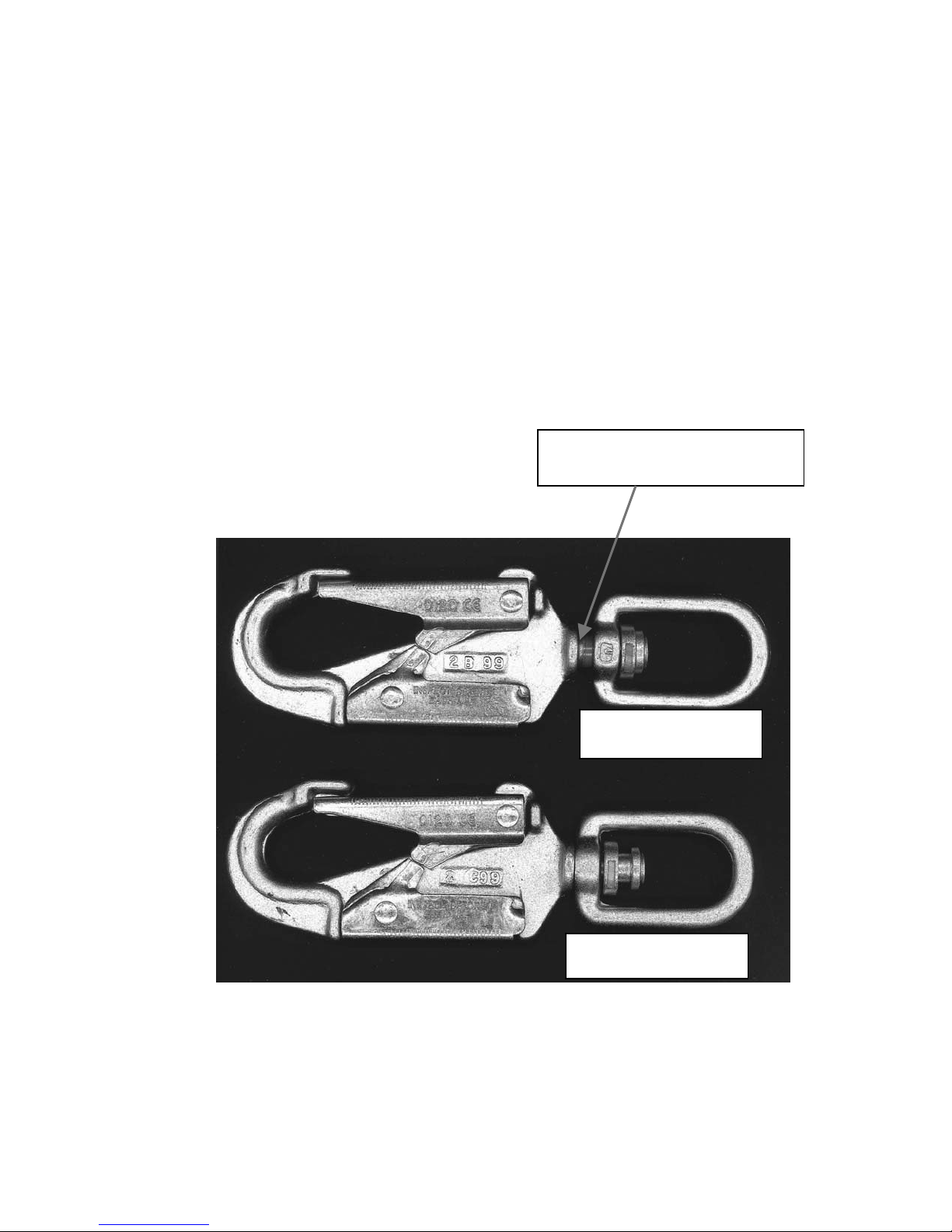

Starting in September of 2000, new

UCL Safety Systems Lifeline assemblies will

incorporate a double-locking swivel snap with a

built in overload indicator. These snaps are

designed to visually identify lifeline assemblies

that have been subjected to loading in excess

of double the winch’s rated working load limit of

310 lbs.

Any winch on which the overload indicator has

been activated must be removed from service

immediately and inspection, repair, and recertification.

All warranties and liabilities shall be void for

winches on which the overload indicator has

been activated.

Exposed Red Overload

Indicator

Activated Snap

Indicator

Un-Activated Snap

Indicator

Figure 20 Load Indicator Double Locking Snap

Page 30

4.2.3 Detailed Inspection

30

A detailed inspection should be done at

the manufacturers winch factory on the

winch every year. The inspection must

include the following, results logged on

the sample inspection form and retained

in your files should anyone ask to see

them. Refer to Section 4.2.6 for a

sample inspection form.

The detailed inspection should include:

1. Visual Inspection

Refer to Section 4.2.1 for a listing of all

times that should be checked visually.

Log the results on the inspection form.

2. Functional Inspection

Refer to Section 4.2.2 for listing of all

items that should be functionally

checked. Log the results on the

inspection form.

3. Detailed Inspection

a. Cable Fittings/Snap Hook

Check the cable fittings on the end

of the lifeline. Be sure that it is not

cracked, distorted, bent, corroded,

worn, loose or cutting into the cable.

Be sure that the cable clamp is tight

without signs of wear of corrosion.

Be sure the cable and strands are

not frayed or broken.

Check the snap hook. Be sure it is

not bent, distorted, cracked or worn.

Be sure the swivel turns freely and

the gate locks and the gate opens

and closes easily.

Note results on inspection log.

b. Cable Inspection

The cable must be inspected over its

full length and the results recorded

in the inspection log. Always wear

heavy gloves to prevent cuts and

slivers while handling the cable. If

any strands are broken, remove

from service.

Figure 21 Cable Fittings/Snap Hook

Figure 22 Cable Definitions

Page 31

i. Check for broken wires

31

Pull the cable out in small segments

and flex to check for broken wires.

NOTE

The inspection of the cable is all

based on the definition of a lay, core,

strand and wire. A lay is where a

strand makes one complete

revolution around the core. The

core is the center of the cable itself.

A strand is the bundle of wires that

move around the core. A wire is a

single filament that makes up a

strand.

Start the inspection at the cable

clamp to check for broken wires or

strands. Pull out a short segment of

cable and turn it while flexing to

check for broken wires.

IMPORTMANT

Review the cable inspection log to

determine the location of previously

found broken wires or other defects.

These previously found defects

combined with those found during

this inspection may require that the

winch be removed from service.

Inspect the entire length of the cable

logging the results on the inspection

form.

When a broken wire is found,

remove the protruding end by flexing

it back and forth along the length of

the cable. The wire will normally

break off inside the cable so there

are no exposed ends to damage

adjacent strands. Do not pull on an

end or wire with pliers. It can pull

the broken end out to expose it.

Figure 23 Broken Wire

Page 32

Use the previous inspection logs to

32

determine the total number of

broken wires in a lay. Remove the

cable and winch from service when:

• There are three or more

randomly distributed broken

wires in one cable lay.

• There are two or more broken

wires in one strand in one lay.

• There are any broken wires

within 1.0 inches (25 mm) of the

cable clamps next to the thimble.

Return the winch to the factory for

cable replacement if any of these

conditions are met or exceeded.

ii. Worn or Abraded Wires

Check for worn or abraded wires.

Worn or abraded wires are caused

by friction and rubbing against

adjacent components and are

usually brighter in appearance.

Remove from service if any surface

wires in one area are worn by 1/3 or

more of their diameter.

Figure 24 Cable Inspection

iii. Bulges or Reduction in

Diameter

Check for bulges or a reduction of

the cable diameter. When these

conditions occur, it indicates serious

internal cable damage. Remove the

unit from service when the cable

diameter increases or decreases by

0.05 inches (1.3 mm).

Figure 25 Cable Diameter

ASSESS

Page 33

33

iv. Corrosion:

Check for corrosion. Corrosion can

be seen as a discoloration of the

wires in most cases. Although there

is no simple sure way to tell when

corrosion has excessively weakened

the cable, the inspection personnel

must keep in mind that corrosion

normally develops on the inside of

the cable before it becomes visible

on the outside. Have a qualified

person assess the damage and

determine whether the unit should

be removed from service. Pitting is

a particularly serious sign of

advanced corrosion. Rust along

with broken wires in a given area is

sufficient reason to remove the unit

from service.

v. Insufficient Lubrication

Check for insufficient lubrication of

the cable. Generally this is caused

by a build-up of contamination

between the strands of cable.

Packed grease, dirt, paint or other

contaminants prevents the lubricant

from getting inside the cable to

prevent internal friction and

corrosion. If contaminants have

filled the grooves, remove from

service.

vi. Snagged Wires and

Crushed or Flattened

Strands

Check for snagged wires and

crushed or flattened strands. These

conditions appear when the cable

has been pulled around corners or

caught between two heavy objects.

Remove from service and return to

the factory for rework.

Figure 26 Crushed Cable

Page 34

vii. Unlaying and Bird-Caging

34

Check for unlaying and bird-caging

of strands. This condition appears

as the formation of gaps, loops and

excessive clearance between

strands. If this appears, remove the

unit from service and return to the

factory for rework.

viii. Kinks and Bends

Check for kinks and bends in the

cable. Kinks and bends are created

when a loop forms in a slack cable

and then it is pulled tight without the

loop uncoiling. Remove from

service if kinks or bends are formed

in the cable.

ix. Heat Damage, Torch Burns

or Electric Arcs

Check for examples of heat damage,

torch burns or electric arc strikes.

Localized discoloration, fusing or

melting indicate this type of damage.

If this is found, remove the unit from

service and return to the factory for

service.

Figure 27 Cable Separation

Figure 28 Cable Damage

Page 35

35

4.2.5 Inspection Log

4.2.5.1 Winch Inspection Log

Sample form. Copy page to start inspection log record book. Fill out using ball point pen.

Model No.: Serial No.: Annual Re-Certification Date:

Date of Inspection

Counter Number

Inspector

FUNCTION

WINCH BODY

SNAP HOOK

Extension (CCW)

Retraction (CW)

Brakes

Fasteners

Labels

Brake Pointer

Damage

Corrosion

Cable Collars

Handle(s)

Damage/Wear

Corrosion

Swivel

Gate Lock

Gate

Cable Clamp

Note: If the brake indicator points into the red or the winch is in service for 1 year, (which ever comes first),

return to manufacturer for inspection and service.

Page 36

36

4.2.5 INSPECTION LOG (con't)

4.2.5.2 WINCH CABLE INSPECTION LOG

Sample Form. Copy page to start inspection log record book. Fill out using ball point pen.

Model No. Serial No. Mfg. Date:

Cable

Location*

Measured

Diameter

Broken Wires At Fittings

In 1 Strand

In 1 Lay

of 1 Lay

Corrosion

Excess

Wear

Broken

Wires Corrosion

Lubrication

* Note: Measure location from snap hook.

Page 37

5 LABELS

37

5.1 Warning Labels

The types of labels and locations on the

equipment are shown in the illustration

below. Good safety requires that you

familiarize yourself with the various

LABELS, the type of warning and the area,

or particular function related to that area,

that requires you SAFETY AWARENESS.

Think SAFETY! Work SAFELY!

Instruction Plate Side

Crank / Cover Side

Figure 29 Labels

Page 38

38

Page 39

39

Page 40

Certificate No. FM 39709

ISO

9001

A Capital Safety Company

40

CSG USA & Latin America

3833 SALA Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

solutions@capitalsafety.com

CSG EMEA

(Europe, Middle East, Africa)

Le Broc Center

Z.I. 1ère Avenue

5600 M B.P. 15 06511

Carros

Le Broc Cedex

France

Phone: + 33 4 97 10 00 10

Fax: + 33 4 93 08 79 70

information@capitalsafety.com

CSG Canada

260 Export Boulevard

Mississauga, ON L5S 1Y9

Phone: 905.795.9333

Toll-Free: 800.387.7484

Fax: 888.387.7484

info.ca@capitalsafety.com

CSG Australia & New Zealand

20 Fariola Street

Silverwater

Sydney NSW 2128

AUSTRALIA

Phone: +(61) 2 9748 0335

Toll-Free : 1 800 245 002 (AUS)

Toll-Free : 0800 212 505 (NZ)

Fax: +(61) 2 9748 0336

sales@capitalsafety.com.au

www.capitalsafety.com

CSG Northern Europe

Unit 7 Christleton Court

Manor Park

Runcorn

Cheshire, WA7 1ST

Phone: + 44 (0)1928 571324

Fax: + 44 (0)1928 571325

csgne@capitalsafety.com

CSG Asia

Singapore:

16S, Enterprise Road

Singapore 627666

Phone: +65 - 65587758

Fax: +65 - 65587058

inquiry@capitalsafety.com

Shanghai:

Rm 1406, China Venturetech Plaza

819 Nan Jing Xi Rd,

Shanghai 200041, P R China

Phone: +86 21 62539050

Fax: +86 21 62539060

Loading...

Loading...