Page 1

Anchor on the Go™

Portable Roof Anchor for Metal Roofs

Part Number 762998

Patent Number 2003258383

Installation and Operating

Instructions

WARNING: This product is part of a fall protection system. Users must read and

follow instructions in this guideline for each component of the complete system.

Manufacturer’s instructions must be followed for correct care, use and maintenance

of this product. Alterations or misuse of this product, or failure to follow instructions

may result in serious injury or death. Reading this manual of itself does not

constitute competency based training in the use of fall arrest products or systems.

Page 2

CONTENTS

Topic Page

General Use Warnings 3

1.0 Introduction 3

1.1 Anchor design and application 4

1.2 Strength of supporting structures 5

1.3 Recommendations 5

1.4 Assessing Fall Hazards 6

1.5 Swing Fall 6

2.0 Installation 7

2.1 Installing Anchor on the Go™ on the roof 7

2.2 Removal of Anchor on the Go™ 10

3.0 Provision of Personal Protective Equipment 10

3.1 Types of PPE 10

4.0 Using Anchor on the Go

equipment and warnings 11

5.0 Standards Compliance 14

5.1 Inspection, care and maintenance 14

5.2 Training in the use of fall arrest systems 14

5.3 Supervision of the use of fall arrest systems 15

6.0 Schematic drawings of anchor 15

7.0 Inspection and maintenance log 17

™ with fall protection

2

Page 3

GENERAL USE WARNINGS

VISUALLY INSPECT TEMPORARY ANCHOR PRIOR TO, AND

FOLLOWING EACH USE, TO ENSURE IT IS IN A SERVICEABLE

CONDITION (refer to section 5.1). IF IN DOUBT, REMOVE FROM

SERVICE IMMEDIATELY.

INSTALLATION AND USE OF THIS PORTABLE ROOF ANCHOR

MUST BE PERFORMED BY, OR UNDER THE SUPERVISION OF A

COMPETENT PERSON.

DO NOT ATTACH OR USE TEMPORARY ROOF ANCHOR WITHOUT

FIRST READING, UNDERSTANDING & FOLLOWING THESE

INSTRUCTIONS.

DO NOT USE THE PORTABLE ANCHOR FOR ANY PURPOSE OTHER

THAN FOR WHICH IT HAS BEEN DESIGNED.

PRIOR TO COMMENCEMENT OF WORK, PLEASE ENSURE THAT

YOU HAVE READ AND COMPREHENDED THE DETAIL REFERRING

TO POSITIONING OF THE ANCHOR AND THE APPROPRIATE SAFE

WORK AREA.

THIS TEMPORARY ANCHOR POINT MUST BE SUBJECTED TO A

DOCUMENTED INSPECTION EVERY 12 MONTHS BY A COMPETENT

PERSON.

1.0 INTRODUCTION

This is a Temporary Anchorage device that has been designed as a

component of a personal fall arrest system and is for use only where

there are no other practical means of connection or work practice.

Relevant State or national legislation may impose obligations to provide

safe systems of work. To discharge these responsibilities, conduct hazard

identication and risk assessment with reference to the hierarchy of

control of risks. Refer to your local State or Federal guidelines or Code of

Practice for safe work on roofs for more details.

Anchors must be properly installed prior to the operator attaching to

them and then used according to requirements contained in this manual.

3

Page 4

1.1 Anchor Design and Application

The Anchor on the Go™ Portable Roof Anchor for Metal Roofs has been

designed and tested to 15kN and is therefore rated as a single person fall

arrest anchor under AS/NZS1891.4. It is only suitable for use on roofs

constructed with metal roof sheeting with a minimum BMT of 0.42mm

in the following proles – Custom Orb, Trimdek, Spandek and Klip-Lok

406 & Klip-Lok 700 provided ridge-capping is secured in place with roof

screws per manufacturer’s instructions.

IMPORTANT: The Anchor on the Go™ Portable Roof Anchor is NOT

suitable for tiled, shingled, aluminium sheet, asbestos or decramastic

roofs.

IMPORTANT: This anchor is designed to be attached to the opposite

side of the roof from where you intend to work. Do NOT connect to or use

the anchor on the same side of the roof where the anchor is connected.

If a second person is required to work on the roof, a second anchor

device must be used. Connecting two lines to a single anchorage device is

NOT permitted. Where two connecting devices are attached to the same

anchorage point (e.g. two snap hooks), the snap hooks may rub against

each other, causing them to be entangled or even become disengaged

from the anchorage device.

Additionally, testing has concluded that whilst this device can sustain a

load of 22kN, the roof sheeting proles most commonly used in Australia

and New Zealand will not sustain a static load greater than 15kN.

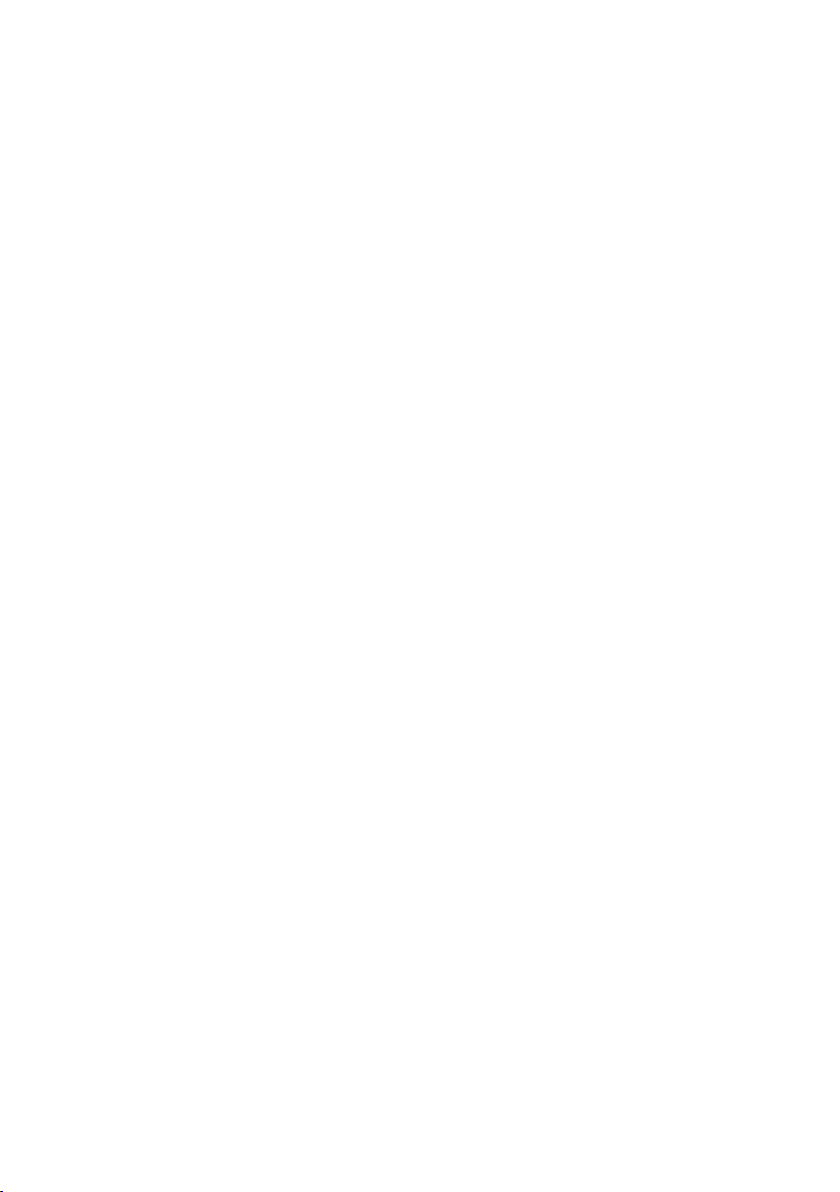

IMPORTANT: Do NOT work outside an arc of 30 degrees either side of

the centre line of the anchorage location to reduce the danger of swing

fall hazards - refer to Figure One over the page.

The user of this Anchor on the Go™ Portable Roof Anchor shall be

trained and ensure that care is taken to adjust the safety line length so

that he/she will not be able to fall off the ends of the roof.

IMPORTANT: Anchor on the Go™ Portable Roof Anchor is NOT suitable

for use as an anchorage device for a Temporary Horizontal Life Line.

4

Page 5

Figure One

1.2 Strength of Supporting Structures

If it is unclear to the operator or competent person that the roof sheeting

or structure is adequate, the roof sheeting or structure shall be assessed

by an engineer. It is NOT SAFE to climb onto the roof on the same side

as you have attached the anchor or use it when connected to the same

side.

The supporting structure/ roof sheeting should be capable of sustaining

an ultimate load equal to 15kN for single point connection as per

AS/NZS1891.4.

1.3 Recommendations

Employers, Supervisors and Operators should ensure that:

• Locations of anchors comply with the requirements for safe use, safe

access, the pendulum effect, as stipulated in AS/NZS 1891.4 clause

3.2.

• Structural supports for anchors are assessed separately by a suitably

qualied engineer (as stipulated in AS/NZS 1891.4, clause 3.1.2.)

or by a competent person, as appropriate, and the assessment

documented.

• Anchors are inspected for compliance with the requirements in

AS/NZS 1891.4 clause 9.3.3 and the inspection documented. The

5

Page 6

documentation should specify any ongoing requirement to carry out

testing of anchor points.

• Anchors are properly labelled and instructions for safe use and

appropriate installation plans are supplied to the user.

• ALL operators must be competently trained for safe work at height

prior to commencing any activities as per AS/NZS 1891.4.

1.4 Assessing Fall Hazards

Employers must ensure that any task an employee is required to

undertake on a roof, that any potential fall hazard is identied, such as:

• from an unprotected edge;

• from an unsecured or inappropriately xed ladder or scaffold;

• slipping on a wet or steep pitched roof(caused by inclement weather

or inappropriate footwear);

• accessing varying roof levels;

• through a fragile roof;

• through a ceiling, skylight or vent;

• being blown or knocked over the edge of a roof.

All such hazards should be identied in the risk assessment process and

documented with relevant precautions to be taken to avoid personal

injury in advance of any work taking place.

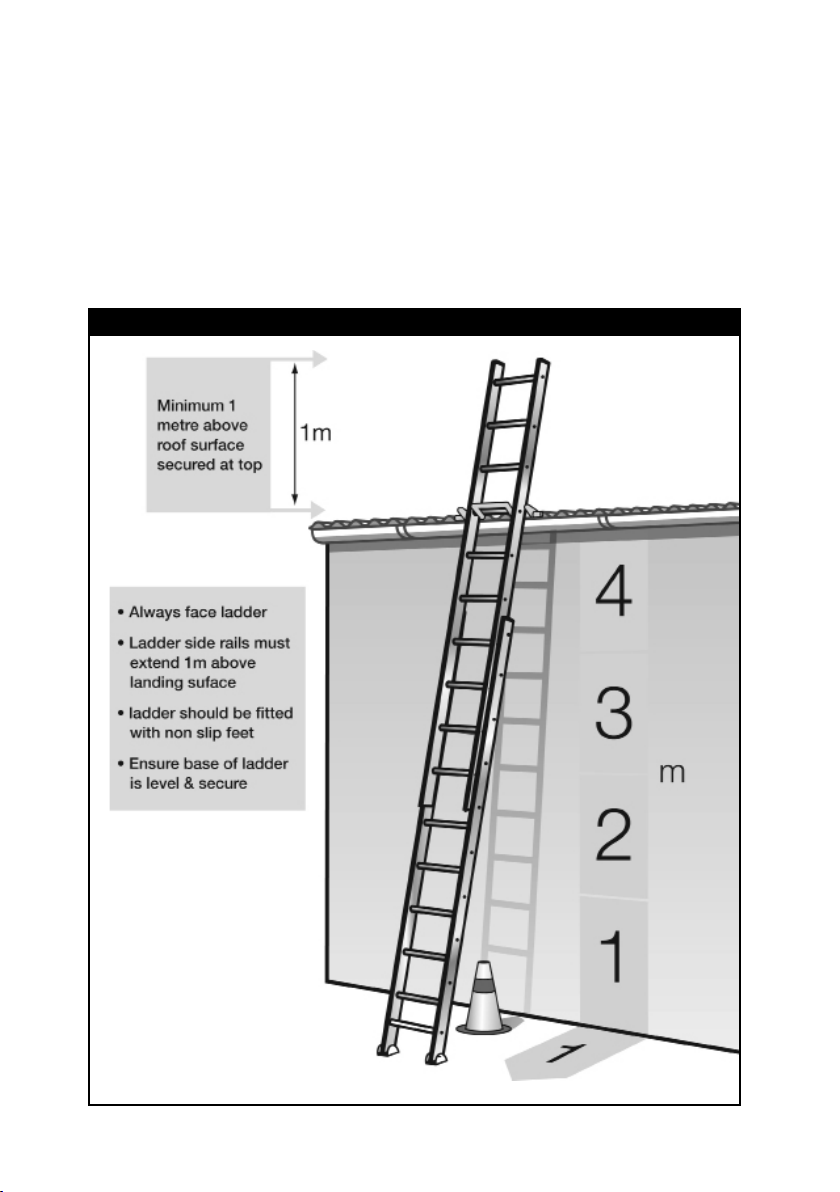

1.5 Swing Fall

Figure Two

Operators should ensure they

do not subject themselves to a

common hazard known as swing

fall, refer to Figure Two. Precautions

to avoid this hazard include

removing working slack from the

rope working line, using restraint

techniques and ensuring the person

does not approach a leading edge

such they may be subjected to an

unplanned fall.

6

Page 7

2.0 INSTALLATION

2.1 Installing Anchor on the Go™ on the roof

Step 1: Plan and prepare for the work to be undertaken. Complete a risk

analysis of the site to determine all the potential hazards. Consideration

should be given to work method statements, safe access, roof structure/

sheeting integrity, rescue procedure and so on.

Step 2: Inspect all equipment (Anchor on the Go™, Harness and any

associated Safety Equipment) prior to use to ensure it is within operating

period and is t for purpose, free of damage etc. This process should

include a thorough inspection of structure to which the Anchor on the

Go™ will be installed. Refer to section 5.1 for inspection, care and

maintenance details.

Step 3: A safe means to access the intended temporary anchor installation

shall be provided.

Access to the roof will generally be by scaffold or ladder systems.

Scaffolding may only be erected, moved or disassembled by a competent

person and fall protection principles must be followed in those processes.

Further information can be obtained from AS/NZS 4576 Guidelines for

Scaffolding.

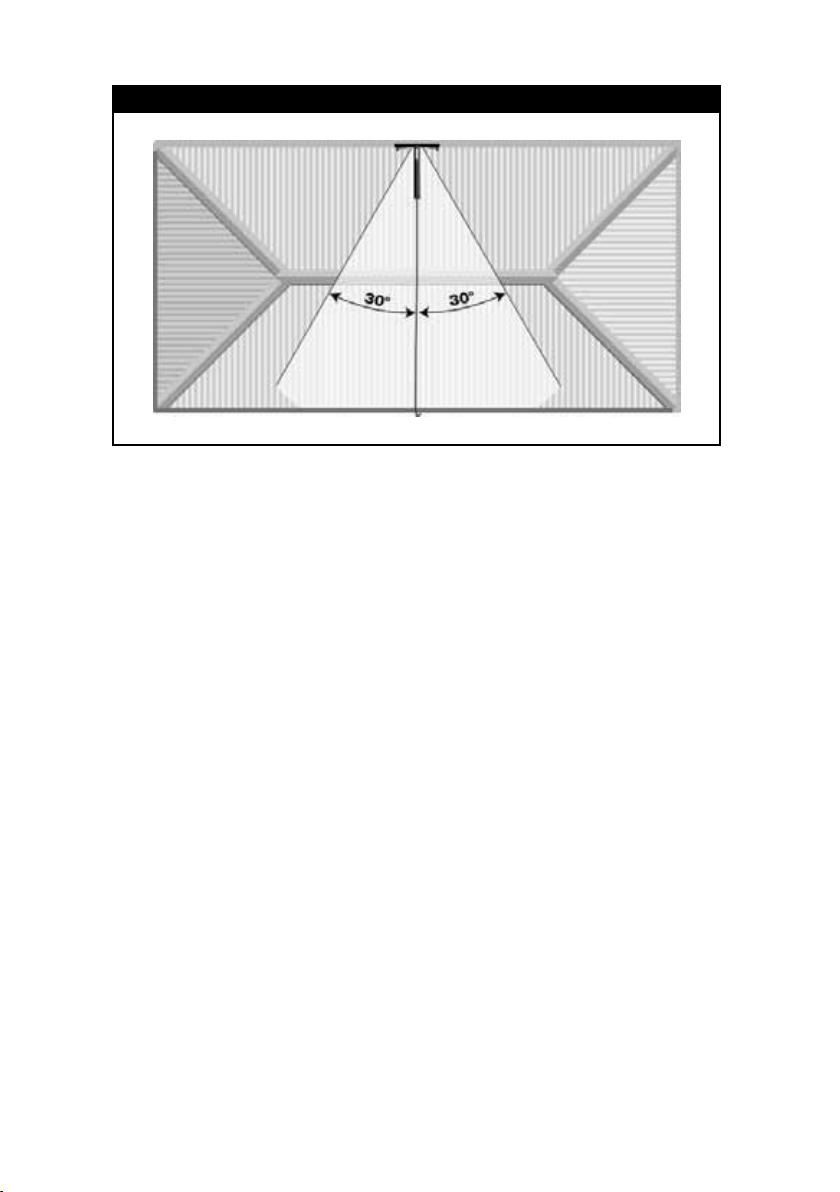

Where access is by ladder systems, the following items should be

checked:

• Inspect the ladder rungs and rails for any defects, cracks or corrosion.

• Never use a ladder with split or missing rungs or with oil or other

slippery material on the rungs.

• The ladder should be tted with non slip feet.

• Place the ladder at a slope of 4 to 1, and secure at both the top and

bottom.

• Ascend and descend facing the ladder with both hands free to hold

the ladder.

• Always keep the area near the top and bottom of the ladder clear.

• Ladder side rails must extend 1m above the landing surface and be

7

Page 8

secured at the top to prevent slipping.

Further information can be obtained from AS/NZS 1892.1 Portable

Ladders Part 5: Selection, Safe Use and Care.

Safely position a portable ladder close to the roof location where the

temporary anchor is to be located. Ensure the ladder is securely fastened

to the building to remove the risk of a fall from the ladder - refer to

Figure Three.

Figure Three

8

Page 9

WARNING: If it is unclear to the operator or competent person that the

supporting structure, roof sheeting or anchor is structurally inadequate,

they must be assessed by an engineer.

Step 4: Once you have safely ascended the ladder, slide the bottom

angle iron of the portable roof anchor under the roof sheeting. The

cylindrical support post must rest in the pan of the roof sheeting. Both

locking cam levers must also be located within the roof sheeting pans.

If they do not t within the pan, reposition the locking cams into an

alternative adjustment position along the L-angle until they do. Note:

When adjusting the position of the locking levers, ensure left and right

levers are correctly installed. Refer to section 6, Figure Eight a & b for

correct orientation.

Figure Four

Step 5: Securely push down

locking cam levers onto roof

sheeting to achieve a solid

connection. Once the anchor is

attached and your anchorage

line is secured to the anchor

point, throw the rope over

to the other side of the roof

such that the anchor line is

accessible without climbing

onto the roof. Refer to Figure

Five.

Figure Five

9

Page 10

Step 6: Return to the ground and walk to the other side of the roof and

connect the rope grab on the anchorage line to the fall arrest connection

point on your full body harness. Capital Safety always recommends that

a shock absorber be used between the rope grab and the connection

point to reduce the risk of injury in a fall.

NOTE: A second Anchor on the Go™ device can be installed on the

opposite side of the roof to enable the operator to work on both sides of

the roof and be connected between them with two separate rope lines.

This is called Restraint Technique.

2.2 Removal of Anchor on the Go™

After descending the roof from the access side and disconnecting from

the anchor line, then climb the ladder you have placed (safely) close to

the temporarily installed anchor and simply reverse the process used for

installation.

3.0 PROVISION OF PPE

Before commencing work on roofs, the contractors doing the work should

assess all foreseeable conditions likely to affect the health and safety of

the employees or themselves, as identied during the risk assessment

procedure, and arrange for the provision and use of appropriate Personal

Protective Equipment (PPE). If alternative means of access can be

arranged safely without the need for PPE, these methods should be

adopted rst if deemed practical.

3.1 Types of PPE

The following are examples of PPE often associated with roof work.

Appropriate PPE, whether listed below or not, should be provided when

required:

• Fall arrest equipment should be selected to protect the wearer and

allow them access to the areas they need to work, maintaining

freedom of movement and be comfortable;

• Footwear to reduce the risk of falls resulting from slips - rubber soled

shoes with herring bone or similar nonslip tread pattern are commonly

selected;

• Eye protection to reduce the risk of eye injury - eye protection

10

Page 11

complying with AS1337 Eye protectors for industrial applications

should be provided and used;

• Protection from sun, workers should be protected from sunlight/UV

radiation by using a sunscreen with a sun protection factor (SPF)

rating of at least 30+ and by wearing hats, shirts with long sleeves

and long trousers.

4.0 USING THE ANCHOR ON THE GO™ WITH FALL

ARREST EQUIPMENT.

The anchor should be tted in accordance with the manufacturer’s

instructions (Section 2.0) at the edge of the non working side of the roof.

Step 1: The operator should inspect and don a fall arrest rated harness

tted with a frontal fall arrest point and adjust it to ensure it is correctly

tted and comfortable. Capital Safety always recommends that a shock

absorber be used between the rope grab and the connection point to

reduce the risk of injury in a fall. The rear (dorsal) fall arrest connection

point is also deemed an appropriate connection point however its

selection/use will depend on the type of work being completed.

Step 2: Once the Anchor on the Go™ is installed as per instructions in

Section 2.0, ensure the rope is of sufcient length to hang two metres

past the proposed connection point on the alternative side of the roof

in order to facilitate attachment to a fall arrest attachment point prior

to leaving the ladder or scaffold. The rope should be pulled tight and

tensioned to ensure all slack has been taken up before connection. If the

rope grab is already on the rope, ensure it is positioned at the free end.

Step 3: The roof should then be accessed from the working side, the

operator connecting the rope grab to the rope (or accessing the rope

grab permanently attached to the rope) and the shock absorber to the

rope grab before moving from the ladder or scaffold onto the roof.

Step 4: To minimise the fall distance resulting from any slip or fall, it is

important to have the least amount of slack on the line at any point in

time. This means regular and small adjustments of the rope grab up and

down the rope in line with the required movement on the roof. Refer to

Figure Six over the page.

When moving up the roof, the manual rope grab should be opened and

11

Page 12

slid up the rope as much as an arm’s

length. It should immediately be

Figure Six

released to lock the rope grab onto

the rope. The worker should climb

towards the rope grab and repeat the

movement until the work position has

been reached.

When moving down the roof, the

worker should move down until the

rope is taught, then release and

move the rope grab towards the

body, releasing it to again provide an

anchor. When the work position has

been reached, the rope grab should be

released and run up the rope toward

the roof ridge to remove as much

slack as possible.

By removing the working slack from the system, the person reduces the

risk of swing fall, lessens overall fall distance and reduces possible fall

distance in the event the roof surface gives way, allowing the person to

fall through.

GENERAL OPERATIONAL WARNINGS – SAFE WORK AREA

When traversing the roof, the same procedure should be followed

and should be set up such that the system operator will be

prevented from reaching an unprotected edge.

The operator of the Anchor on the Go™ Portable Roof Anchor

shall be trained and ensure that care is taken to adjust the safety

line length so that he/she will not be able to fall off the ends of

the roof.

The maximum number of operators connected at a time shall not

exceed one.

Do not climb onto the same side of roof that the anchor is installed

on. If work is required on both sides of the roof, install two

separate Anchor on the Go™ anchors and rope lines on opposite

sides.

12

Page 13

The Anchor on the Go™ Portable Roof Anchor should never be

installed on the ridge line or ridge capping of a roof.

Do not work outside an arc of 30 degrees either side of the centre

line on the Anchor on the Go™ to reduce the danger of swing fall

hazards. Always work a minimum of 2m from unprotected edge

(refer to Figure Seven below).

Figure Seven

13

Page 14

5.0 STANDARDS COMPLIANCE

The Anchor on the Go™ has been manufactured in accordance with AS/

NZS 1891.4 and meets its requirements when used in accordance with

the operator’s manual.

5.1 Inspection, Care and Maintenance

Before rst use, ensure product identication details have been recorded

in this manual and that it is stored safely for future reference, along with

the recording of annual inspections by a competent person. Alternatively,

store the records of inspections separately and securely, including the

product identication number attached to the individual components

purchased. The instruction label on the Anchor on the Go™ also has

room for recording inspection dates if required. Alternatively, an i-Safe™

tag can be retrotted to the device to assist with product identication.

Before and after each use of the Anchor on the Go™, carefully inspect it

to ensure it is in serviceable condition. Check for worn or damaged parts.

Inspect for sharp edges, burrs, cracks or corrosion. Inspect all other

fall protection equipment used along with this system in accordance to

manufacturer’s instructions. Check that all components are currently

within the inspection period. If in doubt, do not use the equipment and

refer to a competent person for inspection and certication.

5.2 Training in the use of fall arrest systems

The use of this product must be accompanied by competency based

training in fall arrest systems – reading this manual alone will not

be sufcient for all people – particularly those with no training in fall

protection equipment or with prior experience at working at height. The

training and instruction given should cover at least:

• How to complete a risk assessment of a work area and prepare work

instructions and work method statements to be put into place for a

safer working environment;

• The method to be used in carrying out the specied work task. This

should include access and the attachment method;

• The correct use, care and storage of individual fall arrest equipment

and temporary fall arrest systems;

14

Page 15

• Inspection and maintenance of fall arrest equipment and recording

information on a log card; and

• The procedure to be adopted in the event of an accident or injury

(i.e. rescue and recovery).

5.3 Supervision of the use of fall arrest systems

The employer must ensure that:

• Only employees who have received training and instruction in

relation to the system of work are authorised to carry out the work;

• That adequate occupational safety and health systems are in place

and functional and that safe work practices have been adopted and

are used. This should include the use of fall arrest systems and

devices.

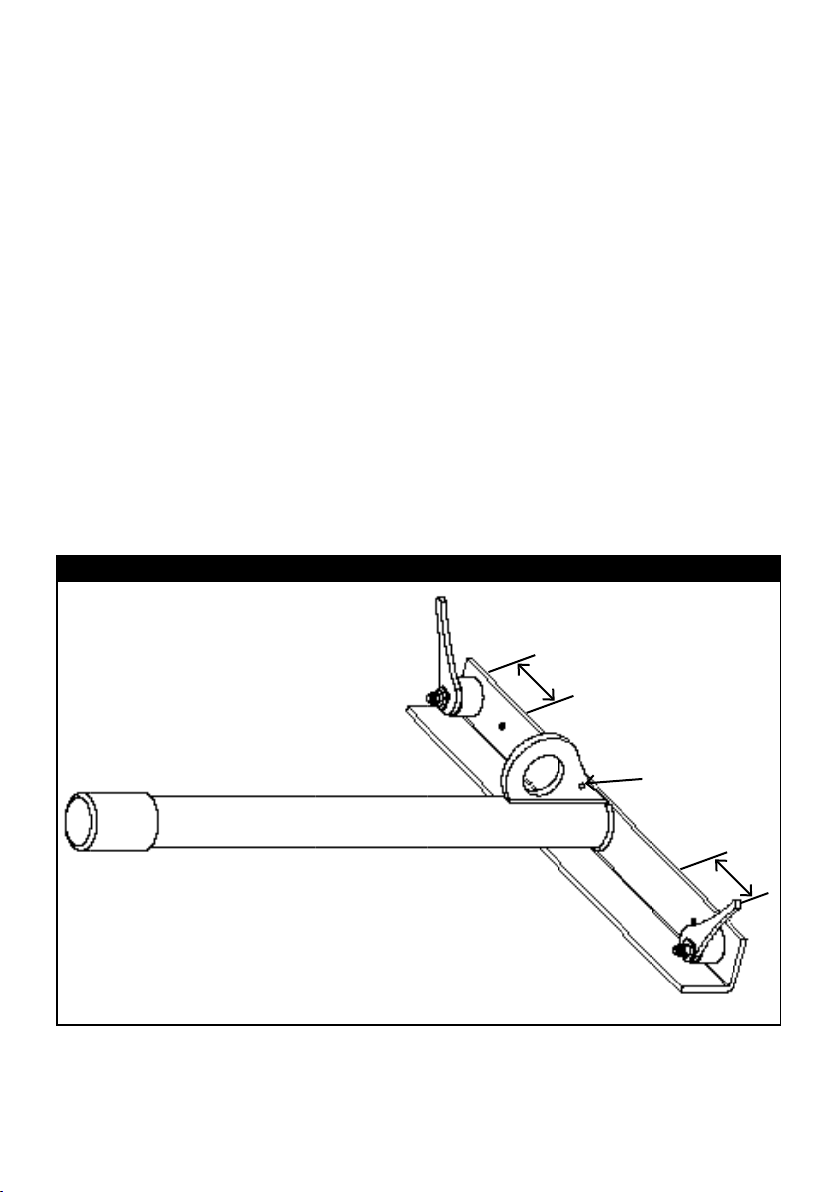

6.0 ANCHOR SCHEMATIC DRAWINGS

Figure Eight a

Adjusts to suit

roof prole

R

Location for

i-Safe™ tag

if required

L

WARNING: Levers are separately marked ‘L’ and ‘R’. Ensure anchor

cam levers are re-installed in the correct location and locked down to

ensure safe connection.

15

Page 16

Figure Eight b

Left lever

(marked ‘L’)

Right lever

(marked ‘R’)

16

Page 17

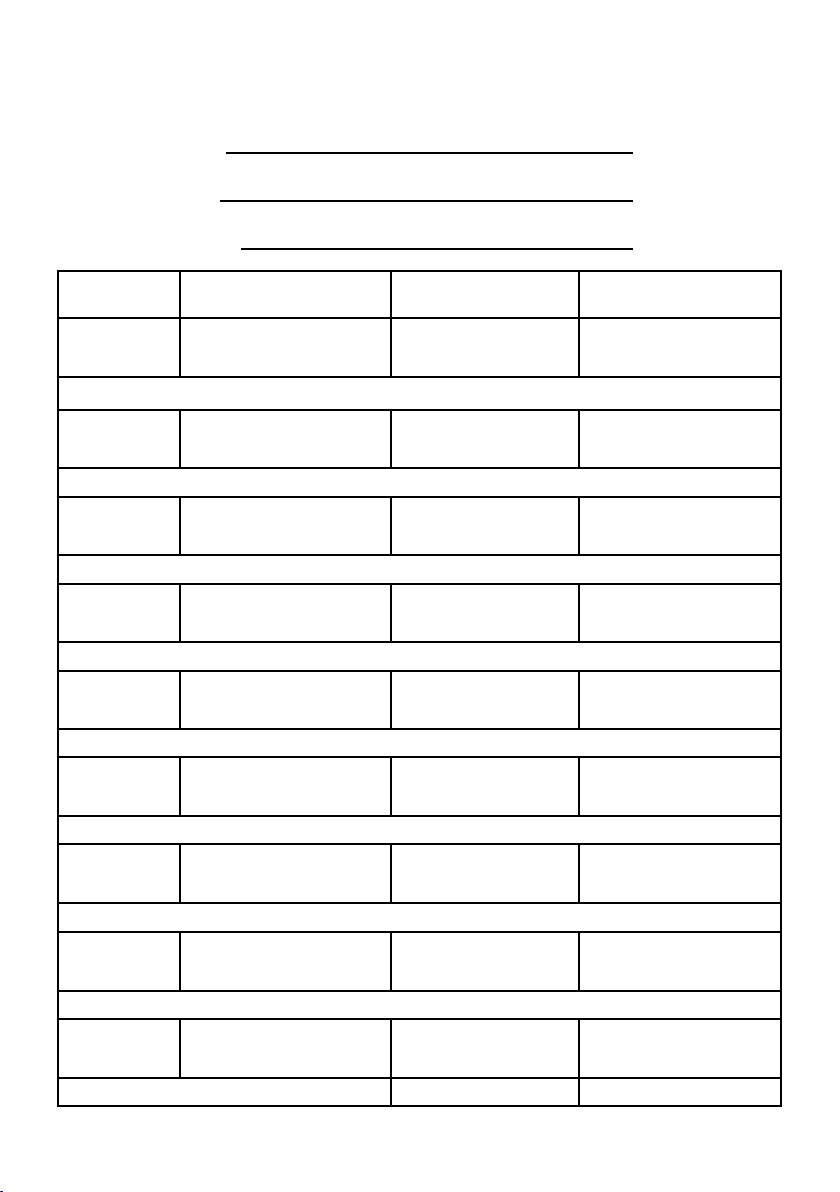

INSPECTION AND MAINTENANCE LOG

Serial Number:

Model Number

Date Purchased:

Inspection

Date

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Inspection Items

Noted

Corrective

Action

Maintenance

Performed

Approved By:

Approved By:

Approved By:

17

Page 18

INSPECTION AND MAINTENANCE LOG

Serial Number:

Model Number

Date Purchased:

Inspection

Date

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Inspection Items

Noted

Corrective

Action

Maintenance

Performed

Approved By:

Approved By:

Approved By:

18

Page 19

INSPECTION AND MAINTENANCE LOG

Serial Number:

Model Number

Date Purchased:

Inspection

Date

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Inspection Items

Noted

Corrective

Action

Maintenance

Performed

Approved By:

Approved By:

Approved By:

19

Page 20

Limited Lifetime Warranty Statement

ISO 9001

Warranty to End User: CAPITAL SAFETY GROUP AUSTRALIA PTY LTD and SKYHOOK

AUSTRALIA PTY LTD (“CAPITAL SAFETY”) warrants to the original end user (“End

User”) that its products are free from defects in materials and workmanship under

normal use and service. This warranty extends for the lifetime of the product from

the date the product is purchased by the End User, in new and unused condition,

from a CAPITAL SAFETY authorised distributor. CAPITAL SAFETY’S entire liability

to End User and End User’s exclusive remedy under this warranty is limited to

the repair or replacement in kind of any defective product within its lifetime (as

CAPITAL SAFETY in its sole discretion determines and deems appropriate). No

oral or written information or advice given by CAPITAL SAFETY, its distributors,

directors, ofcers, agents or employees shall create any different or additional

warranties or in any way increase the scope of this warranty. CAPITAL SAFETY

will not accept liability for defects that are the result of product abuse, misuse,

alteration or modication, or for defects that are due to a failure to install,

maintain, or use the product in accordance with the manufacturer’s instructions.

CAPITAL SAFETY’S WARRANTY APPLIES ONLY TO THE END USER. THIS WARRANTY IS

THE ONLY WARRANTY APPLICABLE TO OUR PRODUCTS AND IS IN LIEU OF ALL OTHER

WARRANTIES AND LIABILITIES, EXPRESSED OR IMPLIED. CAPITAL SAFETY EXPRESSLY

EXCLUDES AND DISCLAIMS ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, AND SHALL NOT BE LIABLE FOR INCIDENTAL,

PUNITIVE OR CONSEQUENTIAL DAMAGES OF ANY NATURE, INCLUDING WITHOUT

LIMITATION, LOST PROFITS, REVENUES, OR PRODUCTIVITY, OR FOR BODILY INJURY

OR DEATH OR LOSS OR DAMAGE TO PROPERTY, UNDER ANY THEORY OF LIABILITY,

INCLUDING WITHOUT LIMITATION, CONTRACT, WARRANTY, STRICT LIABILITY,

TORT (INCLUDING NEGLIGENCE) OR OTHER LEGAL OR EQUITABLE THEORY.

95 Derby Street Silverwater NSW 2128 Australia

Phone: (02) 8753 7600 Fax: (02) 8753 7603

Email: sales@capitalsafety.com.au www.capitalsafety.com.au

Call 1800 245 002 (AUS) 0800 212 505 (NZ)

DBI-SALA is a registered Trademark of Capital Safety Part Number: A024 DEC 2010

© 201 0, Capit al Safet y (Austra lia)

DBI-SALA is a brand of Capital Safety

Quality

20

Loading...

Loading...