Page 1

The Ultimate in Fall Protection

User must read and understand these instructions

before assembling or using this equipment.

BSI Product Services

P.O. Box 6221, Kitemark Court

Milton Keynes

WARNING: This product is part

of a fall arrest system. These

instructions must be provided to all

users and rescuers (see Section 7 Terminology) using this equipment.

The user must read and understand

these instructions before assembling

or using this equipment. The user

must follow the manufacturer’s

instructions for each component

of the system. Manufacturer’s

instructions must be followed for

proper use and maintenance of this

equipment. Alterations or misuse of

this equipment, or failure to follow

instructions, may result in serious

injury or death.

CE Type Test

No. 0086

Davy Avenue

MK1 9EP UK

EN795: 1996

Class B

CE Production Quality Control

No. 0086

BSI Product Services

P.O. Box 6221, Kitemark Court

Davy Avenue

Milton Keynes

MK1 9EP UK

Ladder Fall Arrest System

Model Numbers:

8517714

8517715

8517716

8517717

8517718

8517719

8530140

8530555

8530584

8530652

8530658

8530659

8530674

8530682

8530683

User Instruction Manual

8567715

8567717

8567719

IMPORTANT: Before using this

equipment record the product

identication information from

the ID label in the ‘Inspection and

Maintenance Log’ at the back of this

manual.

IMPORTANT: If you have questions

on the use, care, application, or

suitability for use of this safety

equipment, contact Capital Safety.

EMPLOYEE TRAINING: This manual is intended to meet industry standards, including OSHA, ANSI Z359.1, and CE

EN795 and should be used as part of an employee training program as required by OSHA.

FORM NO: 5902345

REV: F

© Copyright 2016, Capital Safety

Page 2

Page 3

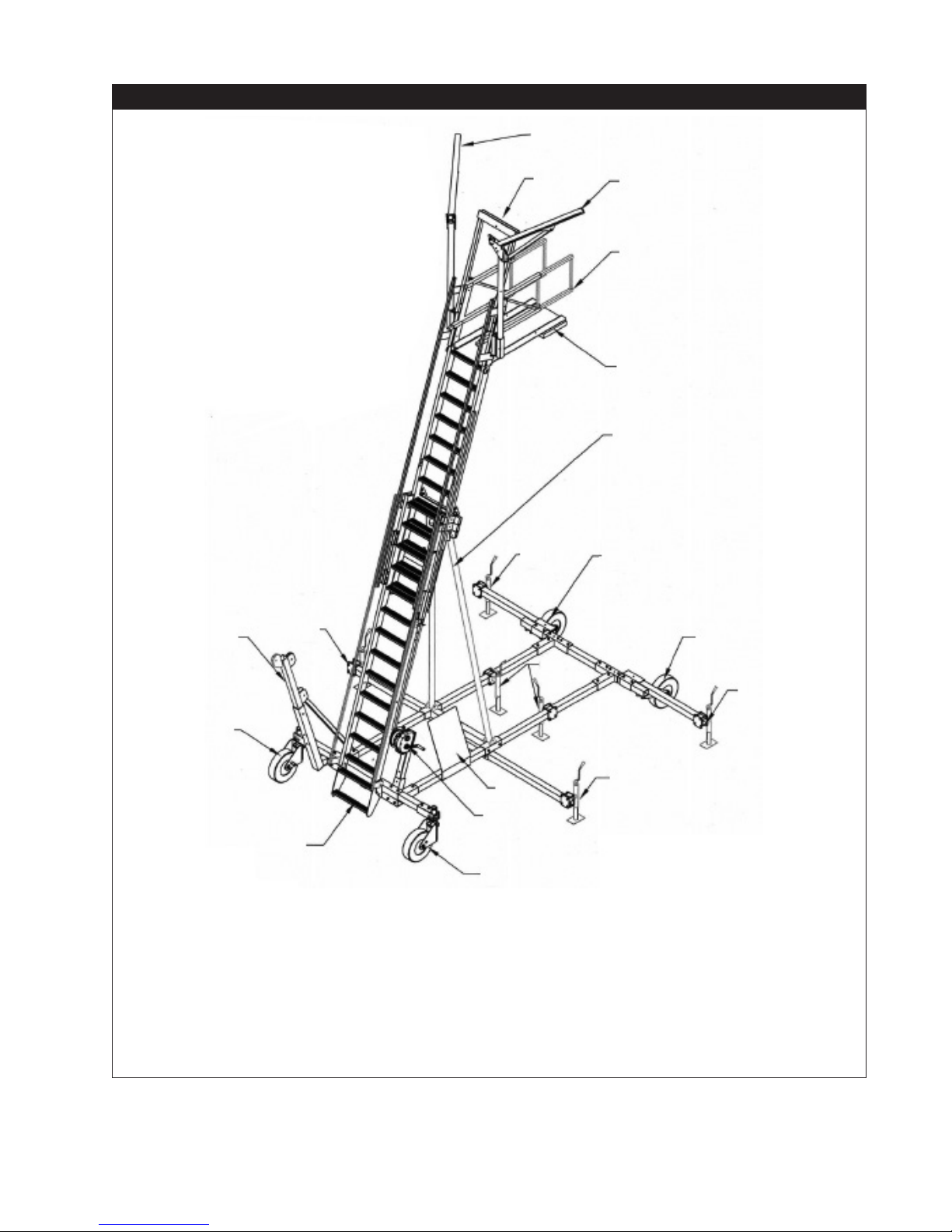

Figure 1 - Parts Identication

11

9

11

8

7

10

4

6

4

3

3

2

13

1. Inner Jacks

2. Swivel Wheel

3. Fixed Wheel

4. Outriggers and Jacks

5. Winch Post

6. Lifting Kit

7. Platform

1

4

12

4

5

2

8. Handrail (2)

9. Overhead Anchor Point Post

10. Ladder Support Tubes

11. Davit

12. Operators Setup and Use

Decal Plate

13. Step

3

Page 4

1.0 APPLICATIONS

1.1 PURPOSE: Personal Protective Equipment against falls from a height.

The adjustable Ladder Fall Arrest System (Ladder FAS) with Fall Protection

combines easy access to elevated work areas with fall protection from the ground

for the duration of the work being performed. Each unit includes two collapsible

masts. Each mast has an attachment point for the anchorage of a Personal FallArrest System (PFAS). The assembly can be moved by hand, by a forklift or towed

by a maintenance vehicle when equipped with proper accessories.

1.2 LIMITATIONS: The following application limitations must be considered before

using this product. Failure to observe product limitations could result in serious

injury or death.

A. ASSEMBLY: The ladder system must be assembled in accordance with the

requirements stated in the appropriate Instructions Manual for the product.

B. CAPACITY: The maximum working load for this product is two persons with a

combined weight of 310 lbs. (141 kg) per person (per attachment point; see

Davit, Number 12 in Figure 1).

C. PERSONAL FALL ARREST SYSTEMS: Personal fall arrest systems used with

the Ladder FAS must meet applicable state and federal regulations, or CE

regulations, and the requirements stated in Section 3.3.

D. PHYSICAL AND ENVIRONMENTAL HAZARDS: Use of this equipment in

areas with physical or environmental hazards may require that additional

precautions be taken to reduce the possibility of damage to this equipment

or injury to the user. Hazards may include, but are not limited to: high heat

(welding or metal cutting), acid or caustic chemicals, corrosive environments

such as exposure to seawater, high voltage power lines, explosive or toxic

gases, moving machinery or sharp edges. Contact DBI-SALA if you have

questions about the application of this equipment in areas where physical or

environmental hazards are present.

E. TRAINING: This equipment is to be assembled, installed and used by persons

who have been trained in its correct application and use.

1.3 STANDARDS: Refer to national standards, including the ANSI Z359 family of

standards .0, .1, .2, .3, and .4, local, state, and OSHA requirements for more

information on the application of this and associated equipment.

WARNING: Do not alter or intentionally misuse this equipment.

WARNING: It is essential for the safety of the user that if the Ladder Fall Arrest System (Ladder FAS)

is resold outside the original country of destination the reseller shall provide instructions for use,

maintenance, periodic examination and repair in the language of the country in which the product is to

be used.

MEDICAL WARNING: Working at height has inherent risks. Some risks are noted here but

are not limited to the following: falling, suspension/prolonged suspension, striking objects, and

unconsciousness. In the event of a fall arrest and/or subsequent rescue (emergency) situation, some

personal medical conditions may affect your safety. Medical conditions identied as risky for this type

of activity include but are not limited to the following: heart disease, high blood pressure, vertigo,

epilepsy, drug or alcohol dependence, psychiatric illness, impaired limb function and balance issues. We

recommend that your employer/physician determine if you are t to handle normal and emergency use

of this equipment.

4

Page 5

2.0 SYSTEM REQUIREMENTS

2.1 COMPATIBILITY OF COMPONENTS: DBI-SALA equipment is designed for use

with DBI-SALA approved components and subsystems only. Substitutions or

replacements made with non-approved components or subsystems may jeopardize

compatibility of equipment and may effect the safety and reliability of the

complete system.

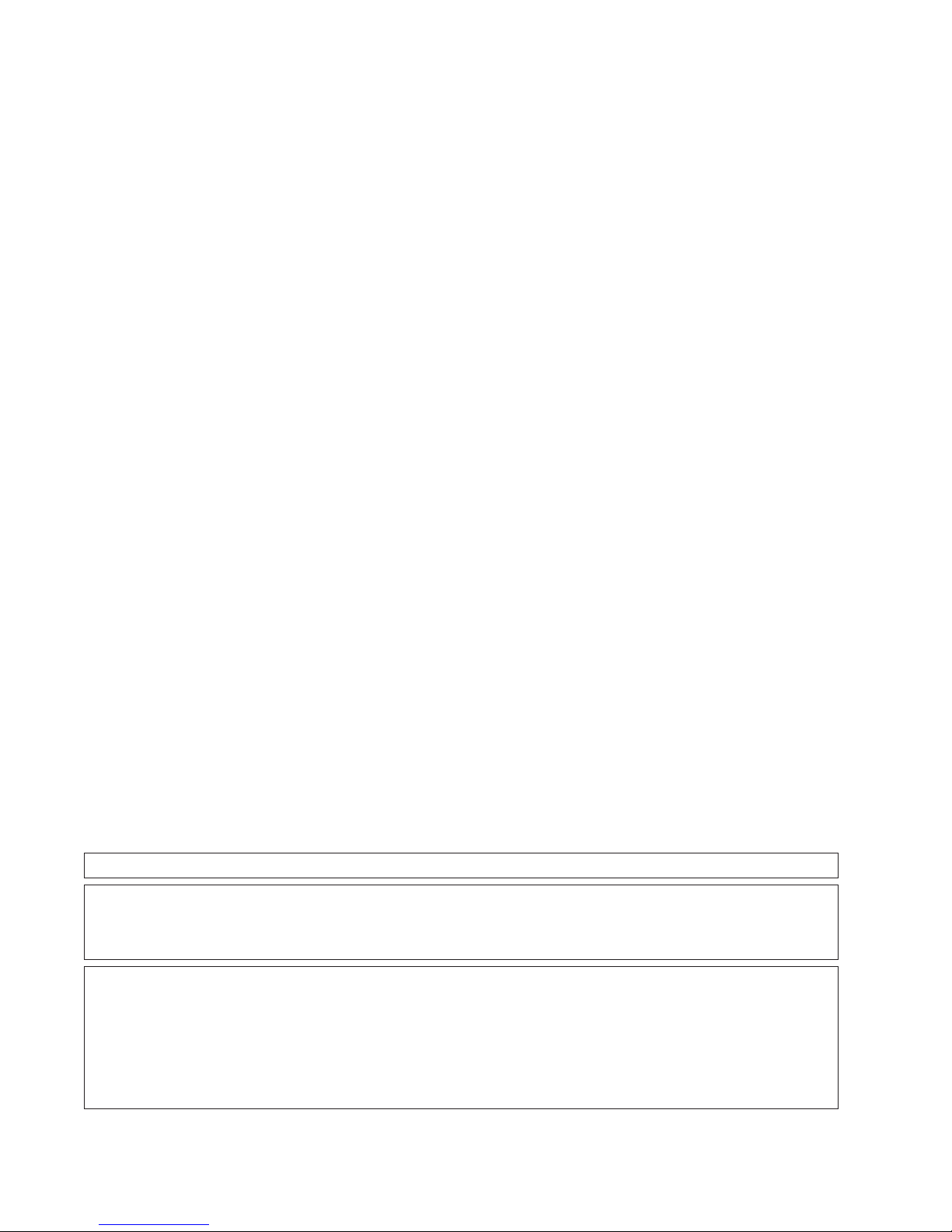

2.2 COMPATIBILITY OF CONNECTORS: Connectors are considered to be compatible

with connecting elements when they have been designed to work together in

such a way that their sizes and shapes do not cause their gate mechanisms to

inadvertently open regardless of how they become oriented. Contact DBI-SALA if

you have any questions about compatibility. Connectors (hooks, carabiners, and

D-rings) must be capable of supporting at least 5,000 lbs. (22.2kN). Connectors

must be compatible with the anchorage or other system components.

Do not use equipment that is not compatible. Non-compatible connectors may

unintentionally disengage (see Figure 2). Connectors must be compatible in size,

shape, and strength. Self-locking snap hooks and carabiners are required by CE,

ANSI Z359.1 and OSHA.

Figure 2 - Unintentional Disengagement (Roll Out)

If the connecting element that a snap hook (shown) or carabiner attaches to is

undersized or irregular in shape, a situation could occur where the connecting

element applies a force to the gate of the snap hook or carabiner. This force may

cause the gate (of either a self-locking or a non-locking snap hook) to open, allowing

the snap hook or carabiner to disengage from the connecting point.

Small ring or other

non-compatibly

shaped element

1. Force is applied to

the snap hook.

2. The gate presses against

the connecting ring.

3. The gate opens allowing

the snap hook to slip off.

2.3 CONNECTIONS: Only use self-locking snap hooks and carabiners with this

equipment. Only use connectors that are suitable to each application. Ensure all

connections are compatible in size, shape and strength. Do not use equipment

that is not compatible. Ensure all connectors are fully closed and locked.

DBI-SALA connectors (snap hooks and carabiners) are designed to be used only

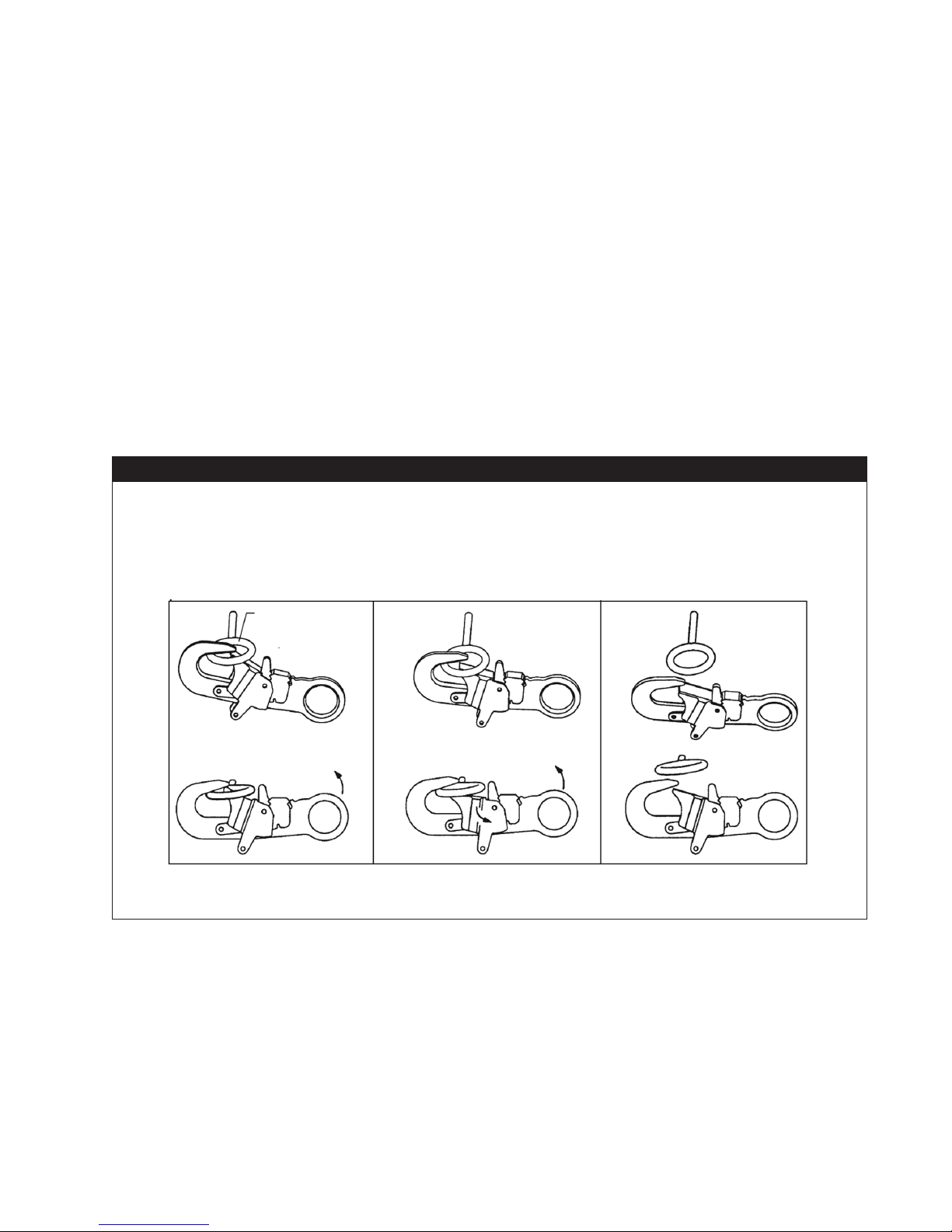

as specied in each product’s user instructions. See Figure 3 for inappropriate

connections. DBI-SALA snap hooks and carabiners should not be connected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

5

Page 6

NOTE: Large throat opening snap hooks should not be connected to standard size D-rings

or similar objects which will result in a load on the gate if the hook or D-ring twists or

rotates. Large throat snap hooks are designed for use on xed structural elements such

as rebar or cross members that are not shaped in a way that can capture the gate of the

hook.

C. In a false engagement, where features that protrude from the snap hook or

carabiner catch on the anchor, and without visual conrmation seems to be

fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tieback (unless the manufacturer’s

instructions for both the lanyard and connector specically allows such a

connection).

F. To any object which is shaped or dimensioned such that the snap hook or

carabiner will not close and lock, or that roll-out could occur.

G. In a manner that does not allow the connector to align properly while under

load.

Figure 3 - Inappropriate Connections

3.0 OPERATION AND USE

WARNING: Consult DBI-SALA when using this equipment in combination with components or

subsystems other than those described in this manual. Some subsystem and component combinations

may interfere with the operation of this equipment. Use caution when using this equipment around

moving machinery, electrical hazards, chemical hazards, and sharp edges.

3.1 BEFORE EACH USE: Inspect this equipment carefully to ensure it is in good

working condition. Check for worn or damaged parts. Ensure all parts are present

and secure. Check the entire system for damage and corrosion. See Section 4.0

for further inspection details. Do not use if inspection reveals an unsafe condition.

3.2 PLANNING: Plan your system and how it will function before starting your work.

Consider all factors that affect your safety during use. Some important points to

consider when planning your system are:

A. HAZARD EVALUATION: Evaluate job site hazards prior to starting work.

Consult applicable OSHA (or CE) and industry standards for guidelines and

regulatory requirements on issues such as personal fall arrest systems (PFAS).

6

Page 7

B. WORK SITE GEOMETRY: The use of the Ladder FAS must be consistent with

the geometric requirements stated in the associated manufacturer’s instruction

manuals. Check for obstructions or sharp edges in the work path. Avoid working

where the user may swing and hit an object, or where lines may cross or tangle

with that of another worker.

C. RESCUE: A means of dealing with an accident or emergency must be planned

in advance. Response time can play an important role in the survival of

an injured worker. Users of this equipment must be trained in emergency

procedures.

The owner’s organization must provide the User Instruction Manual to any user

of this equipment or to any rescuer.

3.3 REQUIREMENTS FOR PERSONAL FALL ARREST SYSTEMS (PFAS): PFAS used

with the Ladder FAS must meet applicable OSHA and CE Fall Arrest Requirements:

OSHA Models CE Models

8517714 8517718 8530652 8530682 8567715

8517715 8517719 8530658 8530683 8567717

8517716 8530555 8530659 8567719

8517717 8530584 8530674

900 lbf (4 kN) 1350 lbf (6 kN)

• The PFAS should be rigged to minimize any potential free fall and never allow

a free fall greater than 6 ft. (1.8 m). The PFAS used with this equipment

are required to include a full body harness as the body support component.

PFAS’s that incorporate full body harnesses must maintain fall arrest forces

below 1,350 lbs. (6.0 kN) and arrest the fall within 42 in. (1.1 m). Body belts,

unless incorporated into a full body harness, are not allowed for use with this

equipment.

A typical PFAS includes a full body harness, connecting subsystem or

component (self retracting lifeline or shock absorbing lanyard), and the

necessary connectors to couple the system together.

• PFAS may only be attached to the Ladder FAS at designated locations. See

Section 3.5

WARNING: Read and follow manufacturer’s instructions for the personal fall arrest equipment

selected for use with the Ladder FAS.

IMPORTANT: Body belts are not allowed for free fall situations. Bodybelts increase the risk of

injury during fall arrest in comparison to a full body harness. Limited suspension time and the

potential for improperly wearing a body belt may result in added danger to the user’s health.

3.4 TRAINING: It is the responsibility of the user to assure they are familiar with

these instructions, and are trained in the correct care and use of this equipment.

User must also be aware of the operating characteristics, application limits, and

the consequences of improper use of this equipment.

IMPORTANT: Training must be conducted without exposing the trainee to a fall hazard. Training

should be repeated on a periodic basis.

7

Page 8

Figure 4 - Procedure for Use

9 / 10

6 in.-12 in.

(153mm-305mm

2

Locking Pin

5 Detail

6

6 in.-12 in.

(153mm-305mm

3

4

8

9 / 10

5

6

Outside Jacks

7

6

Inner Jacks

6

3

1

3.5 PROCEDURE FOR USE OF THE LADDER SYSTEM:

Step 1. Move the unit 1-3 feet (0.3-1m) away from work area/object.

Step 2. Remove 5/8 in. diameter Locking Pin.

Winch

Handle

8

Page 9

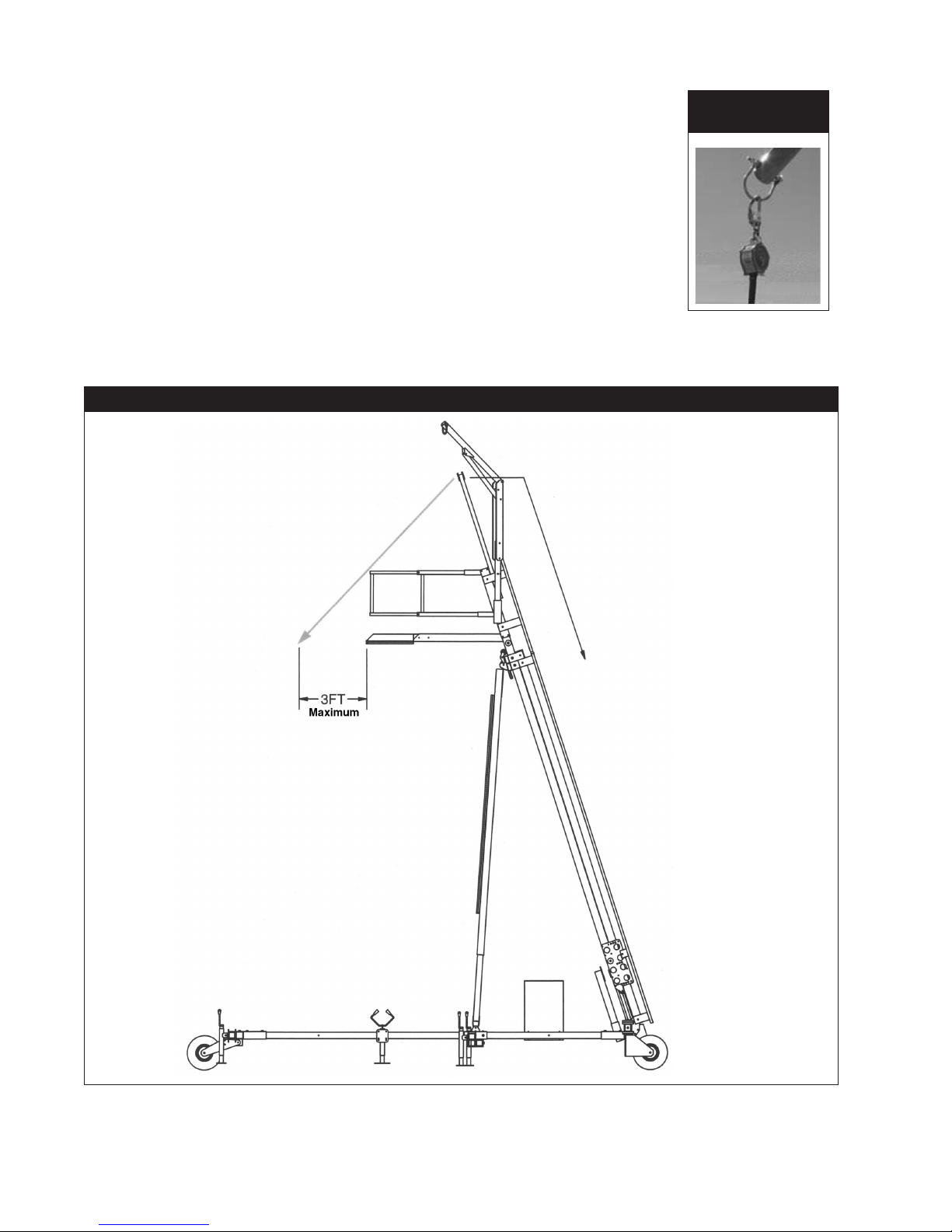

3 Ft (1m)

maximum safe

work radius from

the leading edge

of the platform

Figure 5 - Safe Work Radius

6 Ft (2m) maximum safe

work radius from anchor

point MAXIMUM 10 ft

(3 m) SRL

Optional

Scissor Jack

6 Ft (2m) maximum safe

work radius from anchor point

MAXIMUM 10 ft (3 m) SRL

WARNING: Do not work outside of outrigger “footprint.” Loss of stability

of the Free Standing Portable Access Ladder System could result.

Step 3. Adjust ladder height 6 in. to 12 in. (150-300 mm) above the work area by

cranking the winch crank handle in a clockwise direction.

Step 4. Insert the 5/8 in. diameter Locking Pin into the ladder locking mechanism tube

to the rst, closest hole to prevent accidental ladder movement.

Step 5. Push the unit to position the platform 6 in. to 12 in. (150-300 mm) away from

the work area/object for safe access. Wheels and jacks must be positioned

over a stable, level surface, or leveled with blocks.

Step 6. Extend the outriggers to maximum length, rotate jacks down and apply

approximate pressure of 3 to 5 revolutions after initial contact with surface.

Repeat for all four outside jacks. Optional Scissors Jack setup will not require

rotation.

Step 7. Rotate inner jacks down and apply light pressure by just contacting the

surface.

Step 8. You will need a tag line to access the self retracting lifeline (SRL) attached to

the Overhead Anchor Point Post.

9

Page 10

Step 9. When you reach the platform at the top, you may

need a tag line to reach the davit SRLs. You must

Figure 6 - SRL

Connections

remain connected to at least one SRL while transferring

connections from the Overhead Anchor Point Post to the

Davit SRL. Do not remain connected to more than one SRL

while working.

Step 10. A maximum of two operators can be attached to the unit

using the individual davits. No more than one person can

be attached to a davit at any time.

Step 11. Adjust the handrails to appropriate length for comfortable step up and down

to and from the platform.

Figure 7 - Ladder Access and Egress Anchor Point

Ladder Access and

Egress Anchor Point

MAXIMUM 50 ft SRL

10

Page 11

4.0 INSPECTION

4.1 VISUAL INSPECTION:

A complete visual inspection should be performed on the Ladder FAS equipment

you are using prior to the operation. The following items should be checked, and

the results recorded on the “Inspection and Maintenance Log” sheet at the back of

this manual.

A. Labels: Check that all labels are clean and legible. Clean the labels if any are

dirty using a mild soap and a damp cloth. Replace if any are illegible (Refer to

Section 5 for a listing of all labels).

B. Fasteners: Check that all ladder screws and other fasteners are tight. Tighten

ladder fasteners hand tight only.

Base fasteners must be checked using 15 ft. lbs (2.1 kg.m) of torque. If any are

loose, tighten to 20 ft. lbs (2.8 kg.m). Refer to assembly instructions.

Contact your local dealer or DBI-SALA for any replacement fasteners that may

be required.

C. Components: Check the components for cracks, dents, bends, or breaks.

Minor cosmetic damage in the component body will not affect the function

of the Ladder FAS. However, if there are major dents or any other structural

damage, the unit should be removed from service and returned to the

manufacturer for service.

D. Corrosion: Check all components for damage from corrosion. Although all

components resist corrosion, working in corrosive environments can lead

to damage. Inspect all structural components and fasteners for signs of

damage. If corrosion damage is found, remove from service and return to the

manufacturer for service.

4.2 Maintenance: At regular intervals perform a detailed inspection of the equipment

and document the results. An ‘Inspection nd Maintenance Log’ is included in this

manual. Remove the equipment from service if deciencies are found.

WARNING: Do not make alterations or additions to this equipment without prior written

consent from DBI-SALA. (Only the equipment manufacturer, or persons or entities authorized

in writing by the manufacturer, can make repairs to the equipment.)

A. Periodically clean the ladder system using mild detergent and a damp cloth.

B. Clean labels and replace as needed.

C. Lubricate the winch according to the instructions in the Winch Operator’s

Manual.

11

Page 12

4.3 Functional Inspection

A functional check should be performed on the Ladder FAS prior to every use.

The following functional tests should be done; and the results recorded on the

“Inspection and Maintenance Log” at the back of this manual.

A. System Operation and Adjustments: The Ladder FAS contains operational

parts that may include pulleys and or rollers. These parts must be carefully

checked for chips, cracks, or worn areas that can cause malfunction during

operation of the system.

Make sure that all the adjustment points are in full functional condition. This

may include parts that contain pins, bolts, tri-screws, and adjusting screws.

There are also mechanical adjustments which may include, adjustable legs,

sleeves, adjustable sliding blocks, and brackets. These areas must be kept

clean from debris and corrosion for proper functional use. If any part of the

system that includes all listed items above becomes damaged contact DBI-SALA

for parts and/or service.

B. SRL and other Accessory Inspection: Refer to the manufacturer’s operator’s

manual or instructional material for proper functional inspection procedures for

SRL’s and accessories not covered by this manual.

WARNING: If the ladder system has been subjected to impact forces from fall arrest, it must be

immediately removed from service and inspected. If the ladder system fails to pass the inspection,

do not use. The equipment must be sent to an authorized service center for repair.

IMPORTANT: Extreme working conditions (harsh environment, prolonged use, etc.) may require

increasing the frequency of inspections.

5.0 WARNING LABELS

The following labels must be securely attached to the Ladder FAS and fully legible.

Proper maintenance of the labels must be established by the operator/entrant to keep

system use safe. If labels are damaged, the operator/entrant must enforce a lockout/

tagout procedure. New labels are available from the local dealer or manufacturer.

9509349 Rev. A

(CE Only)

12

Page 13

6.0 SPECIFICATIONS

• Working Load: Maximum of two persons with a combined weight of 310 lbs. (141

kg) per person.

• Materials and Construction:

General Construction: Welded Steel/Aluminum

Finish (Aluminum): Yellow Powder Coat

Hardware Material: Zinc Plated

7.0 TERMINOLOGY

Authorized Person: A person assigned by the employer to perform duties at a

location where the person will be exposed to a fall hazard (otherwise referred to as

“user” for the purpose of these instructions).

Rescuer: Person or persons other than the rescue subject acting to perform an

assisted rescue by operation of a rescue system.

Certied Anchorage: An anchorage for fall arrest, positioning, restraint, or rescue

systems that a qualied person certies to be capable of supporting the potential fall

forces that could be encountered during a fall or that meet the criteria for a certied

anchorage prescribed in this standard.

Qualied Person: A person with a recognized degree or professional certicate and

with extensive knowledge, training, and experience in the fall protection and rescue

eld who is capable of designing, analyzing, evaluating and specifying fall protection

and rescue systems to the extent required by this standard.

Competent Person: One who is capable of identifying existing and predictable

hazards in the surroundings or working conditions which are unsanitary, hazardous,

or dangerous to employees, and who has authorization to take prompt corrective

measures to eliminate them.

13

Page 14

14

Page 15

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 16

ISO

USA

3833 SALA Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

solutions@capitalsafety.com

Brazil

Rua Anne Frank, 2621

Boqueirão Curitiba PR

81650-020

Brazil

Phone: 0800-942-2300

brasil@capitalsafety.com

Mexico

Calle Norte 35, 895-E

Col. Industrial Vallejo

C.P. 02300 Azcapotzalco

Mexico D.F.

Phone: (55) 57194820

mexico@capitalsafety.com

Colombia

Compañía Latinoamericana de Seguridad S.A.S.

Carrera 106 #15-25 Interior 105 Manzana 15

Zona Franca - Bogotá, Colombia

Phone: 57 1 6014777

servicioalcliente@capitalsafety.com

LIMITED LIFETIME WARRANTY

liability for defects that are the result of product abuse, misuse, alteration or modifi cation, or for defects

FR

Warranty to End User: CAPITAL SAFETY warrants to the original end user (“End User”) that its

products are free from defects in materials and workmanship under normal use and service. This

warranty extends for the lifetime of the product from the date the product is purchased by the End

User, in new and unused condition, from a CAPITAL SAFETY authorised distributor. CAPITAL SAFETY’S

entire liability to End User and End User’s exclusive remedy under this warranty is limited to the

repair or replacement in kind of any defective product within its lifetime (as CAPITAL SAFETY in its

sole discretion determines and deems appropriate). No oral or written information or advice given by

CAPITAL SAFETY, its distributors, directors, offi cers, agents or employees shall create any different or

additional warranties or in any way increase the scope of this warranty. CAPITAL SAFETY will not accept

that are due to a failure to install, maintain, or use the product in accordance with the manufacturer’s

instructions. THIS WARRANTY IS THE ONLY WARRANTY APPLICABLE TO OUR PRODUCTS AND IS IN

LIEU OF ALL OTHER WARRANTIES AND LIABILITIES, EXPRESSED OR IMPLIED.

Canada

260 Export Boulevard

Mississauga, ON L5S 1Y9

Phone: 905.795.9333

Toll-Free: 800.387.7484

Fax: 888.387.7484

info.ca@capitalsafety.com

EMEA (Europe, Middle East, Africa)

EMEA Headquarters:

5a Merse Road

North Moons Moat

Redditch, Worcestershire

B98 9HL UK

Phone: + 44 (0)1527 548 000

Fax: + 44 (0)1527 591 000

csgne@capitalsafety.com

France:

Le Broc Center

Z.I. 1re Avenue - BP15

06511 Carros Le Broc Cedex

France

Phone: + 33 04 97 10 00 10

Fax: + 33 04 93 08 79 70

information@capitalsafety.com

www.capitalsafety.com

9001

Australia & New Zealand

95 Derby Street

Silverwater

Sydney NSW 2128

Australia

Phone: +(61) 2 8753 7600

Toll-Free : 1800 245 002 (AUS)

Toll-Free : 0800 212 505 (NZ)

Fax: +(61) 2 8753 7603

sales@capitalsafety.com.au

Asia

Singapore:

69, Ubi Road 1, #05-20

Oxley Bizhub

Singapore 408731

Phone: +65 - 65587758

Fax: +65 - 65587058

inquiry@capitalsafety.com

Shanghai:

Rm 1406, China Venturetech Plaza

819 Nan Jing Xi Rd,

Shanghai 200041, P R China

Phone: +86 21 62539050

Fax: +86 21 62539060

inquiry@capitalsafety.cn

Loading...

Loading...