Page 1

Instructions for the following series products:

SYNTHETIC ROPE HORIZONTAL LIFELINE

See the last pages for specifi c model numbers

The Ultimate in Fall Protection

User Instruction Manual Synthetic Rope

Horizontal Lifeline System

This manual is intended to be used as part of an employee training program as

required by OSHA.

Form: 5902179 Rev: C

© Copyright 2014, Capital Safety

Page 2

Page 3

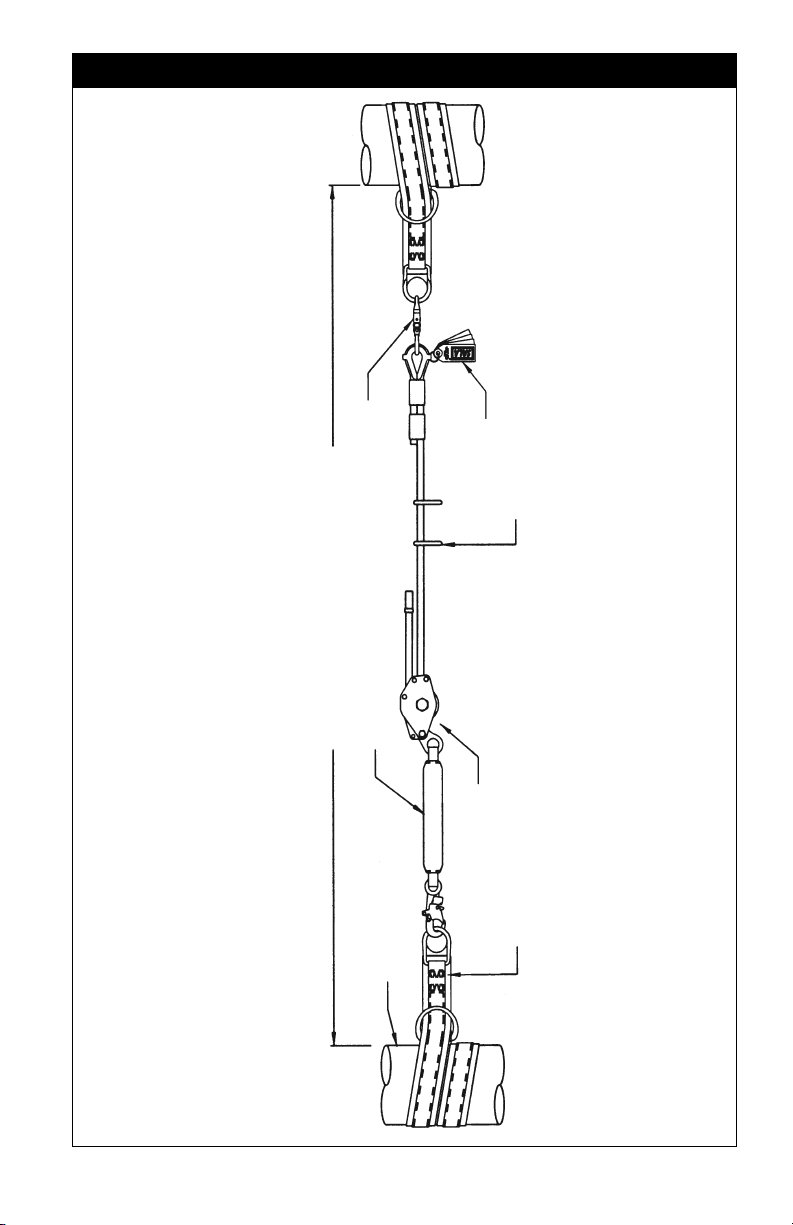

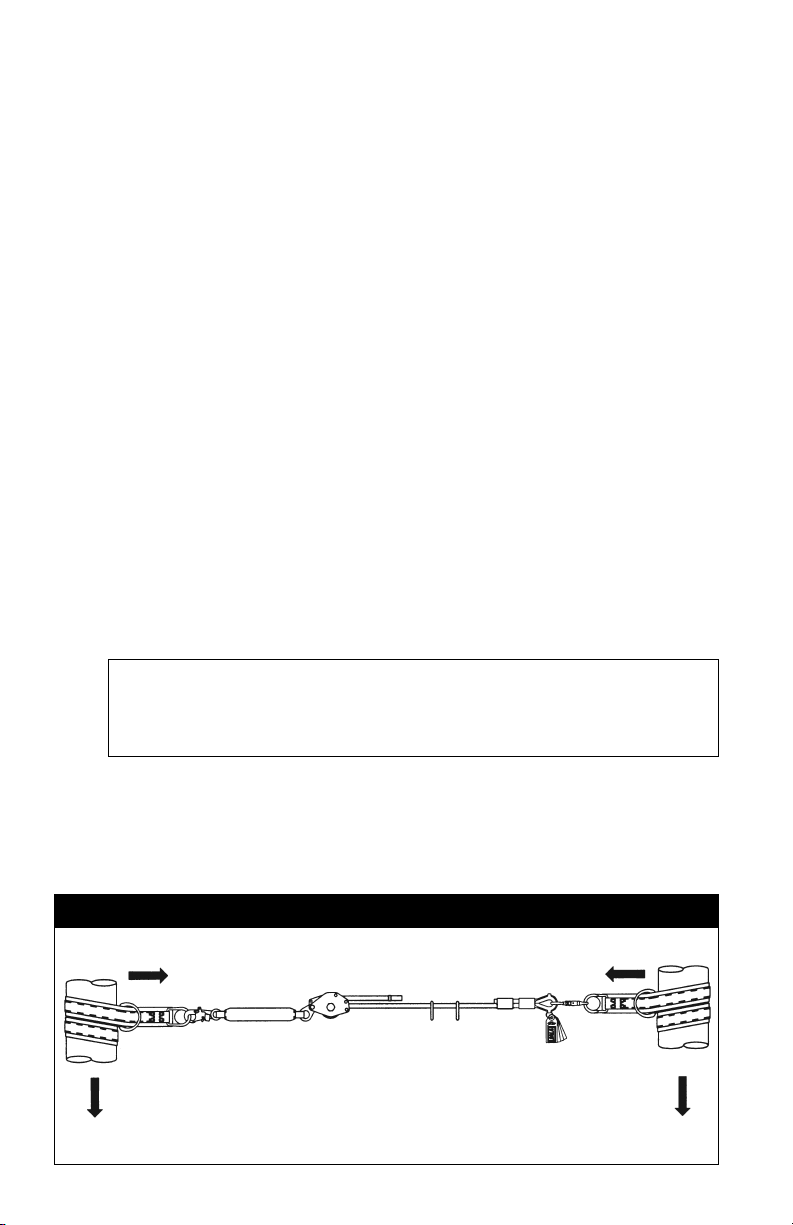

Figure 1 - Typical Installation

Snap Hook

Span length 100 ft (30.m) Max.

In-line Energy Absorber

Labels

Attachment O-ring for User

(Lanyard)

Typical Horizntal Lifeline Installation

Rope Tensioner

Tie-off Adapter

(Anchorage Connector)

Anchorage

3

Page 4

WARNING: This product is part of a personal fall arrest system. The

user must follow the manufacturer’s instructions for each component

of the system. These instructions must be provided to the user of this

equipment. The user must read and understand these instructions

before using this equipment. Manufacturer’s instructions must be

followed for proper use and maintenance of this equipment. Alterations

or misuse of this equipment, or failure to follow instructions, may

result in serious injury or death.

IMPORTANT: If you have questions on the use, care, or suitability of

this equipment for your application, contact DBI-SALA.

IMPORTANT: Record the product identifi cation information from the

ID label in the inspection and maintenance log in section 9.0 of this manual.

1.0 APPLICATION

1.1 PURPOSE: The Sayfl ine Synthetic Rope Horizontal Lifeline System

is designed for use as an anchoring means for one or two persons.

Use the Sayfl ine Horizontal Lifeline System where horizontal

mobility and fall protection are required.

1.2 LIMITATIONS: The following limits apply to the installation and

use of the Sayfl ine Synthetic Rope Horizontal Lifeline System.

Other limitations may apply:

IMPORTANT: OSHA regulations state that horizontal lifelines

shall be installed and used under the supervision of a qualifi ed

person (see below for defi nition) as part of a complete personal

fall arrest system that maintains a safety factor of at least two.

QUALIFIED PERSON: An individual with a recognized degree or

professional certifi cate, and extensive knowledge and experience

in the subject fi eld, who is capable of design, analysis,

evaluation, and specifi cation in the subject work, project, or

product. Refer to OSHA 1910.66, 1926.32, and 1926.502.

A. HORIZONTAL LIFELINE SPAN: The maximum span distance

is 100 feet. The span length must be reduced when clearance

is limited. See section 3.2 for clearance information.

B. ANCHORAGES: The Sayfline horizontal lifeline must be

installed on anchorages that meet the requirements specified

in section 2.4.

C. SYSTEM CAPACITY: The maximum capacity of the Sayfline

horizontal lifeline is two persons. The maximum weight of each

person, including tools and clothing, is 310 lbs. (141kg).

D. CONNECTING SUBSYSTEM: Each person’s connecting

subsystem must limit fall arrest forces to 900 lbs. (4kN) or

less. See section 2.5.

4

Page 5

E. FREE FALL: Rig and use the personal fall arrest system

such that the maximum potential free fall does not exceed

Government regulatory and subsystem manufacturer’s

requirements. See section 3.0 and subsystem manufacturer’s

Instructions for more information.

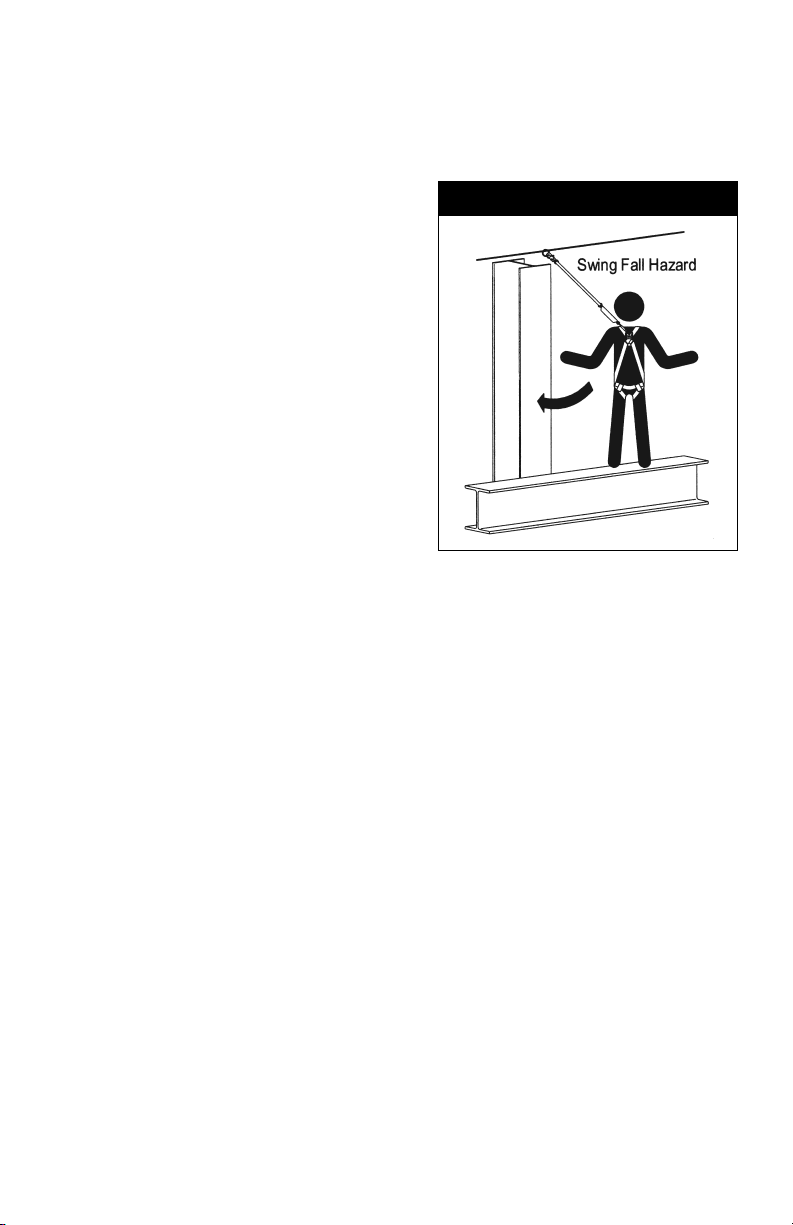

F. SWING FALLS: See Figure

2. Swing falls occur when

the anchorage point is not

directly overhead. The force

of striking an object in a

swing fall may cause serious

injury or death. Minimize

swing falls by working as

directly below the anchorage

point as possible. Do not

permit a swing fall if injury

could occur. Swing falls will

significantly increase the

clearance required when a

self retracting lifeline or other

variable length connecting

subsystem is used. If a swing

fall situation exists in your

application, contact DBI-SALA

before proceeding.

G. FALL CLEARANCE: There must be sufficient clearance below

the worker to arrest a fall before striking the lower level or

obstruction. See section 3.2 for required clearance information.

H. BODY SUPPORT: A full body harness must be used with the

Synthetic Rope Horizontal Lifeline System.

Figure 2 - Swing Fall

I. ENVIRONMENTAL HAZARDS: Use of this equipment in areas

with environmental hazards may require additional precautions

to reduce the possibility of injury to the user or damage to the

equipment. Hazards may include, but are not limited to; heat,

chemicals, corrosive environments, high voltage power lines,

gases, moving machinery, and sharp edges. Contact DBI–

SALA if you have questions about using this equipment where

environmental hazards exist.

J. TRAINING: This equipment must be installed and used by

persons trained in its correct application and use. See section 4.0.

1.3 APPLICABLE STANDARDS: Refer to national standards, including

ANSI Z359.1, local, state, and federal (OSHA 1910.66 and

1926.502) requirements for more information on personal fall

arrest systems and associated components. In Canada, see the

Z259 group of CSA standards.

5

Page 6

2.0 SYSTEM REQUIREMENTS

2.1 PERSONAL FALL ARREST SYSTEM COMPONENTS: The

Sayfl ine horizontal lifeline must be used with DBI-SALA approved

components and subsystems. Non-approved components may

be incompatible, and could affect the safety and reliability of the

complete system. Personal fall arrest components used with this

system must meet all applicable OSHA and ANSI requirements. A

full body harness must be used with this system.

2.2 PERSONAL FALL ARREST SYSTEM CONNECTORS: Connectors

used to attach to the attachment O-ring on the horizontal lifeline

(hooks, carabiners, D-rings) must support at least 5,000 lbs.

Connectors and attachment elements must be compatible in

size, shape, and strength. Non-compatible connectors may

unintentionally disengage (roll-out). Do not use non-locking

connectors with this system.

2.3 ANCHORAGE CONNECTORS: Connectors used to attach the

horizontal lifeline to end anchors must be compatible with the

connection point. The connection must be positive; and, with

connecting elements, capable of sustaining a 5,000 lbs. (22.2kN)

load without failure.

2.4 STRUCTURE LOAD: Structural anchorage points must be rigid,

and capable of supporting at least 3,600 lbs. (16kN) along the axis

of the horizontal lifeline. Anchorages must also support at least

3,600 lbs. (16kN) applied in all potential directions of fall arrest that

are perpendicular to the axis of the horizontal lifeline. See Figure 3.

WARNING: Anchorages must be rigid. Large deformations of

the anchorage will affect system performance, and may increase

the required fall clearance below the system, which could result

in serious injury or death.

2.5 CONNECTING SUBSYSTEM: The connecting subsystem is the

portion of the personal fall arrest system that is used to connect

between the horizontal lifeline subsystem and harness fall arrest

attachment element. The connecting subsystem must limit forces

applied to the horizontal lifeline to 900 lbs. (4kN) or less.

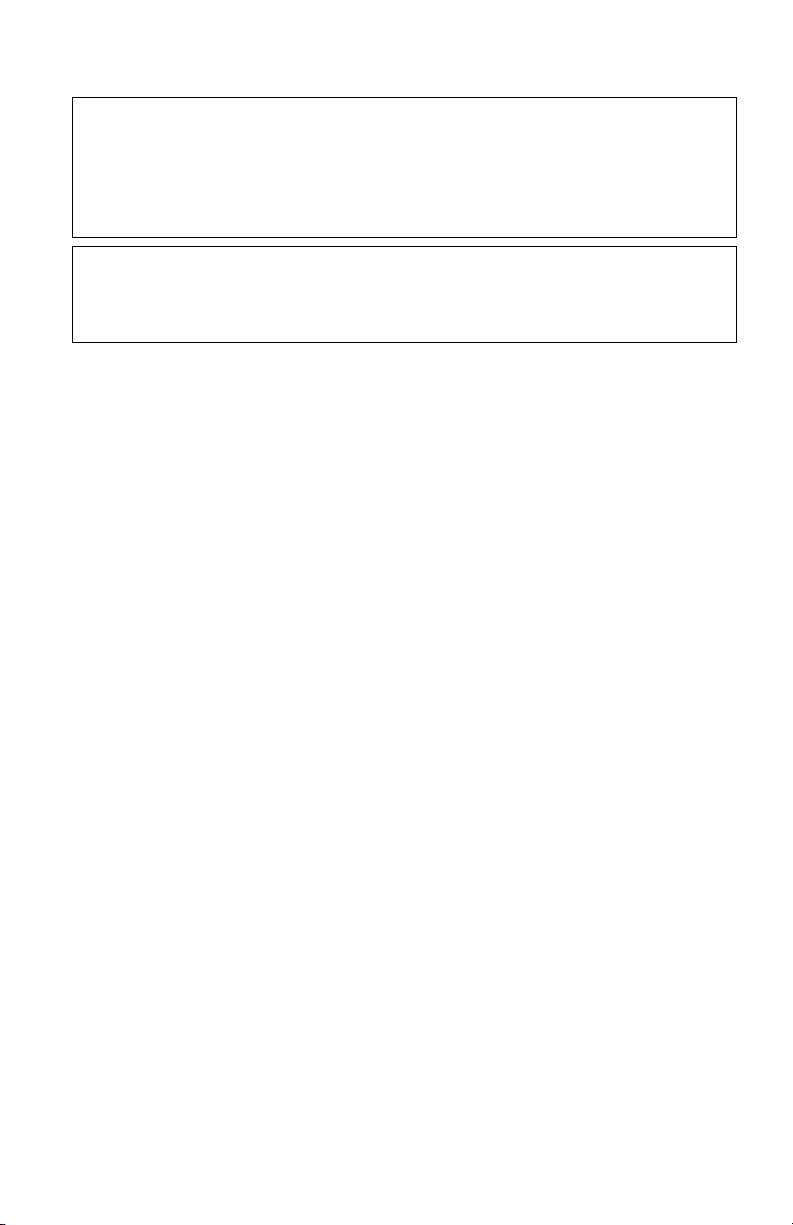

Figure 3 - Strength Requirements

Anchorage Strength Requirements

3,600 lbs (16kN) Minimum 3,600 lbs (16kN) Minimum

3,600 lbs (16kN) Minimum in all potential directions of fall

arrest that are perendicular to the axis of the lifeline

6

Page 7

3.0 OPERATION AND USE

WARNING: Do not alter or intentionally misuse this equipment. Consult

DBI-SALA when using this equipment in combination with components or

subsystems other than those described in this manual. Some subsystem

and component combinations may interfere with the operation of this

equipment. Use caution when using this equipment around moving

machinery, electrical hazards, chemical hazards, and sharp edges.

WARNING: Consult your doctor if there is reason to doubt your

fi tness to absorb the impact from a fall arrest. Age and fi tness can

affect your ability to withstand fall arrest forces. Pregnant women and

minors must not use this system.

3.1 BEFORE EACH USE inspect this equipment according to section

5.0. Do not use this equipment if inspection reveals an unsafe or

defective condition. Plan your use of the fall protection system

prior to exposing workers to dangerous situations. Consider all

factors affecting your safety before using this system.

A. Read and understand all manufacturer’s instructions for each

component of the personal fall arrest system. All DBI-SALA

harnesses and connecting subsystems are supplied with separate

user instructions. Keep all instructions for future reference.

B.

Review sections 1.0 and 2.0 to ensure system limitations and

other requirements have been adhered to. Review applicable

information regarding system clearance criteria, and ensure

changes have not been made to the system installation (i.e.

length) or occurred at the job site that could affect the required

fall clearance. Do not use the system if changes are required.

3.2 SYSTEM INSTALLATION: Figure 1 shows a typical Sayfl ine

horizontal lifeline installation. When using an energy absorbing

lanyard to connect to the system, the end anchorages must be

located at a height which will limit the free fall to 6 feet (1.8m).

When using a self retracting lifeline (SRL) to connect to the

system, the end anchorages must be located above the user. The

SRL, when fully retracted, must be above the harness attachment

level. The horizontal lifeline system should be positioned at a

level that will minimize free fall while allowing ease of use. The

horizontal lifeline should be positioned near the work location to

minimize swing fall hazards. The connecting subsystem length

should be kept as short as possible to reduce the potential free

fall and required clearance distance. Both anchorages must

be installed at approximately the same elevation, so that the

horizontal lifeline system is not sloped more than 5°.

Step 1. Determine the locations of the end anchorages and

evaluate their strengths in accordance with section 2.4.

Determine the span length and evaluate the required

clearance using Figures 4, 5, or 6 and Tables 1, 2 or 3.

7

Page 8

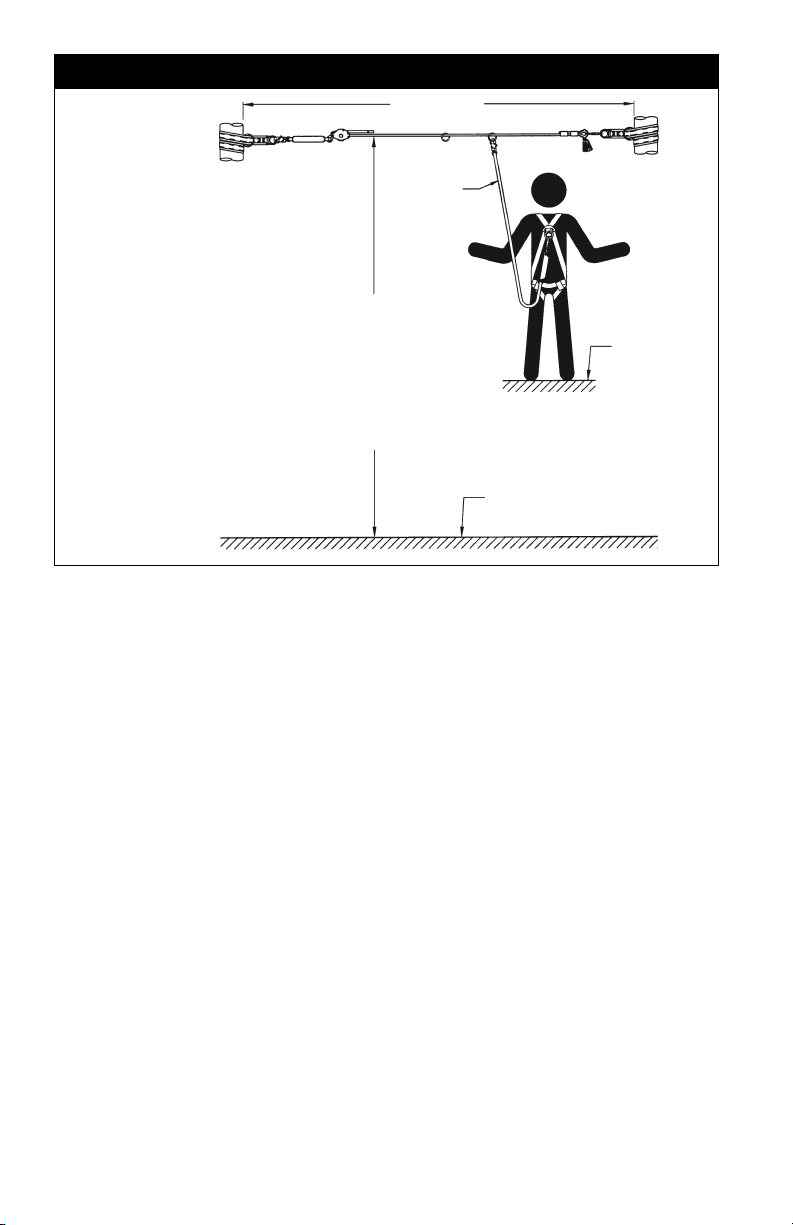

Figure 4 - Clearance: Single Worker with Energy Absorbing Lanyard

Span Length

Energy

Absorbing

Clearance Evaluation for One

Worker Connected to the HLL with a

DBI-SALA Energy Absorbing Lanyard

Required clearance from nearest lower level or

obstruction to HLL system height

1) Find your system span length in the rows of

Table 1.

2) Find your lanyard length in the columns of

Table 1.

3) The requied clearance is where the span

length row and lanyard length column intersect.

Lanyard

Lower Level or

Obstruction

Working Level

8

Page 9

Table 1 - Required Clearance for One Worker Connected to the System

with a DBI-SALA Energy Absorbing Lanyard (See Figure 4)

Span length

in feet

0-10

(0-3.05)

10-15

(3.05-4.57)

15-20

(4.57-6.10)

20-25

(6.10-7.62)

25-30

(7.62-9.14)

30-35

(9.14-10.67)

35-40

(10.67-12.19)

40-45

(12.19-13.72)

45-50

(13.72-15.24)

50-55

(15.2-16.76)

55-60

(16.76-18.29)

60-65

(18.29-19.81)

65-70

(19.81-21.34)

70-75

(21.34-22.86)

75-80

(22.86-24.38)

80-85

(24.38-25.91)

85-90

(25.91-27.43)

90-95

(27.43-28.96)

95-100

(28.96-30.48)

3

(.91)4 (1.22)5 (1.52)6 (1.83)7 (2.13)8 (2.44)9 (2.74)

16’-1”

(4.90)

16’-3”

(4.95)

16’-5”

(5.00)

16’-7”

(5.06)

16’-9”

(5.11)

17’-6”

(5.33)

18’-3”

(5.56)

18’-11”

(5.77)

19’-6”

(5.94)

20’-2”

(6.15)

20’-10”

(6.35)

21’-5”

(6.53)

22’-1”

(6.73)

22’-8”

(6.91)

23’-4”

(7.11)

24’-0”

(7.32)

24’-7”

(7.49)

25’-3”

(7.70)

25’-10”

(7.87)

Length of Enerrgy Absorbing Lanyard in feet

17’-1”

(5.20)

17’-3”

(5.26)

17’-5”

(5.31)

17’-7”

(5.36)

17’-9”

(5.41)

18’-6”

(5.64)

19’-3”

(5.87)

19’-11”

(6.07)

20’-6”

(6.25)

21’-2”

(6.45)

21’-10”

(6.66)

22’-5”

(6.83)

23’-1”

(7.04)

23’-8”

(7.21)

24’-4”

(7.42)

25’-0”

(7.62)

25’-7”

(7.80)

26’-3”

(8.00)

26’-10”

(8.18)

18’-1”

(5.51)

18’-3”

(5.56)

18’-5”

(5.61)

18’-7”

(5.66)

18’-9”

(5.72)

19’-6”

(5.94)

20’-3”

(6.17)

20’-11”

(6.38)

21’-6”

(6.55)

22’-2”

(6.76)

22’-10”

(6.96)

23’-5”

(7.14)

24’-1”

(7.34)

24’-8”

(7.52)

25’-4”

(7.72)

26’-0”

(7.93)

26’-7”

(8.10)

27’-3”

(8.31)

27’-10”

(8.48)

19’-1”

(5.82)

19’-3”

(5.87)

19’-5”

(5.92)

19’-7”

(5.97)

19’-9”

(5.97)

20’-6”

(6.25)

21’-3”

(6.48)

21’-11”

(6.68)

22’-6”

(6.86)

23’-2”

(7.06)

23’-10”

(7.26)

24’-5”

(7.44)

25’-1”

(7.65)

25’-8”

(7.82)

26’-4”

(8.03)

27’-0”

(8.23)

27’-7”

(8.41)

28’-3”

(8.61)

28’-10”

(8.79)

20’-1”

(6.12)

20’-3”

(6.12)

20’-5”

(6.27)

20’-7”

(6.27)

20’-9”

(6.33)

21’-6”

(6.55)

22’-3”

(6.78)

22’-11”

(6.99)

23’-6”

(7.16)

24’-2”

(7.37)

24’-10”

(7.57)

25’-5”

(7.75)

26’-1”

(7.95)

26’-8”

(8.13)

27’-4”

(8.33)

28’-0”

(8.53)

28’-7”

(8.71)

29’-3”

(8.92)

29’-10”

(9.09)

Meters are shown in parenthesis

21’-1”

(6.43)

21’-3”

(6.48)

21’-5”

(6.53)

21’-7”

(6.58)

21’-9”

(6.63)

22’-6”

(6.86)

23’-3”

(7.09)

23’-11”

(7.29)

24’-6”

(7.47)

25’-2”

(7.67)

25’-10”

(7.87)

26’-5”

(8.05)

27’-1”

(8.26)

27’-8”

(8.43)

28’-4”

(8.64)

29’-0”

(8.84)

29’-7”

(9.02)

30’-3”

(9.22)

30’-10”

(9.40)

22’-1”

(6.73)

22’-3”

(6.78)

22’-5”

(6.83)

22’-7”

(6.88)

22’-9”

(6.93)

23’-6”

(7.16)

24’-3”

(7.39)

24’-11”

(7.60)

25’-6”

(7.77)

26’-2”

(7.98)

26’-10”

(8.18)

27’-5”

(8.36)

28’-1”

(8.56)

28’-8”

(8.74)

29’-4”

(8.94)

30’-0”

(9.14)

30’-7”

(9.32)

31’-3”

(9.53)

31’-10”

(9.70)

10

(3.1)

23’-1”

(7.04)

23’-3”

(7.09)

23’-5”

(7.14)

23’-7”

(7.19)

23’-9”

(7.24)

24’-6”

(7.47)

25’-3”

(7.70)

25’-11”

(7.90)

26’-6”

(8.08)

27’-2”

(8.28)

27’-10”

(8.48)

28’-5”

(8.66)

29’-1”

(8.87)

29’-8”

(9.04)

30’-4”

(9.25)

31’-0”

(9.45)

31’-7”

(9.63)

32’-3”

(9.83)

32’-10”

(10.01)

9

Page 10

Figure 5 - Clearance: Two Workers with Energy Absorbing Lanyards

Span Length

Energy Absorbing

Lanyard

Required clearance from nearest lower level or

obstruction to HLL system height

1) Find your system span length in the rows of

Table 2.

2) Find your lanyard length in the columns of

Table 2.

3) The requied clearance is where the span

length row and lanyard length column intersect.

Clearance Evaluation for One or Two

Workers Connected to the HLL with a

DBI-SALA Energy Absorbing Lanyard

Working

Level

Lower Level or

Obstruction

10

Page 11

Table 2 - Required Clearance for Two Workers Connected to the System

with a DBI-SALA Energy Absorbing Lanyard (See Figure 5)

Span

in

length

feet

0-10

(0-3.05)

10-15

(3.05-4.57)

15-20

(4.57-6.10)

20-25

(6.10-7.62)

25-30

(7.62-9.14)

30-35

(9.14-10.67)

35-40

(10.67-12.19)

40-45

(12.19-13.72)

45-50

(13.72-15.24)

50-55

(15.2-16.76)

55-60

(16.76-18.29)

60-65

(18.29-19.81)

65-70

(19.81-21.34)

70-75

(21.34-22.86)

75-80

(22.86-24.38)

80-85

(24.38-25.91)

85-90

(25.91-27.43)

90-95

(27.43-28.96)

95-100

(28.96-30.48)

3

(.91)4 (1.22)5 (1.52)6 (1.83)7 (2.13)8 (2.44)9 (2.74)

16’-5”

(5.00)

17’-5”

(5.31)

18’-5”

(5.61)

19’-4”

(5.89)

20’-4”

(6.20)

21’-7”

(6.58)

22’-9”

(6.93)

23’-10”

(7.26)

24’-11”

(7.60)

26’-0”

(7.93)

27’-2”

(8.28)

28’-3”

(8.61)

29’-4”

(8.94)

30’-5”

(9.27)

31’-6”

(9.60)

32’-7”

(9.93)

33’-8”

(10.26)

34’-9”

(10.59)

35’-10”

(10.92)

Length of Enerrgy Absorbing Lanyard in feet

17’-5”

(5.31)

18’-5”

(5.61)

19’-5”

(5.92)

20’-4”

(6.20)

21’-4”

(6.50)

22’-7”

(6.88)

23’-9”

(7.24)

24’-10”

(7.57)

25’-11”

(7.90)

27’-0”

(8.23)

28’-2”

(8.59

29’-3”

(8.92)

30’-4”

(9.25)

31’-5”

(9.58)

32’-6”

(9.91)

33’-7”

(10.24)

34’-8”

(10.57)

35’-9”

(10.90)

36’-10”

(11.23)

18’-5”

(5.61)

19’-5”

(5.92)

20’-5”

(6.27)

21’-4”

(6.50)

22’-4”

(6.81)

23’-7”

(7.19)

24’-9”

(7.54)

25’-10”

(7.87)

26’-11”

(8.20)

28’-0”

(8.53)

29’-2”

(8.89

30’-3”

(9.22)

31’-4”

(9.55)

32’-5”

(9.88)

33’-6”

(10.21)

34’-7”

(10.54)

35’-8”

(10.87)

36’-9”

(11.20)

37’-10”

(11.54)

19’-5”

(5.92)

20’-5”

(6.27)

21’-5”

(6.53)

22’-4”

(6.81)

23’-4”

(7.11)

24’-7”

(7.49)

25’-9”

(7.85)

26’-10”

(8.18)

27’-11”

(8.51)

29’-0”

(8.84)

30’-2”

(9.20

31’-3”

(9.53)

32’-4”

(9.86)

33’-5”

(10.19)

34’-6”

(10.52)

35’-7”

(10.85)

36’-8”

(11.18)

37’-9”

(11.51)

38’-10”

(11.84)

20’-5”

(6.27)

21’-5”

(6.53)

22’-5”

(6.83)

23’-4”

(7.11)

24’-4”

(7.42)

25’-7”

(7.80)

26’-9”

(8.15)

27’-10”

(8.48)

28’-11”

(8.81)

30’-0”

(9.14)

31’-2”

(9.50

32’-3”

(9.83)

33’-4”

(10.16)

34’-5”

(10.49)

35’-6”

(10.82)

36’-7”

(11.15)

37’-8”

(11.48)

38’-9”

(11.81)

39’-10”

(12.14)

Meters are shown in parenthesis

21’-5”

(6.53)

22’-5”

(6.83)

23’-5”

(7.14)

24’-4”

(7.42)

25’-4”

(7.72)

26’-7”

(8.10)

27’-9”

(8.46)

28’-10”

(8.79)

29’-11”

(9.12)

31’-0”

(9.45)

32’-2”

(9.80

33’-3”

(10.14

34’-4”

(10.47)

35’-5”

(10.80)

36’-6”

(11.13)

37’-7”

(11.46)

38’-8”

(11.79)

39’-9”

(12.12)

40’-10”

(12.45)

22’-5”

(6.83)

23’-5”

(7.14)

24’-5”

(7.44)

25’-4”

(7.72)

26’-4”

(8.03)

27’-7”

(8.41)

28’-9”

(8.76)

29’-10”

(9.09)

30’-11”

(9.42)

32’-0”

(9.75)

33’-2”

(10.11

34’-3”

(10.44

35’-4”

(10.77)

36’-5”

(11.10)

37’-6”

(11.43)

38’-7”

(11.76)

39’-8”

(12.09)

40’-9”

(12.42)

41’-10”

(12.75)

10 (3.1)

23’-5”

(7.14)

24’-5”

(7.44)

25’-5”

(7.75)

26’-4”

(8.03)

27’-4”

(8.33)

28’-7”

(8.71)

29’-9”

(9.07)

30’-10”

(9.40)

31’-11”

(9.73)

33’-0”

(10.06)

34’-2”

(10.41

35’-3”

(10.74

36’-4”

(11.07)

37’-5”

(11.41)

38’-6”

(11.74)

39’-7”

(12.07)

40’-8”

(12.40)

41’-9”

(12.73)

42’-10”

(13.06)

11

Page 12

Figure 6 - Clearance: One or Two Workers with SRLs

Span Length

Self Retracting

Lifeline

Required clearance from nearest lower level or

obstruction to working level

1) Find your system span length in the rows of

Table 3.

2) Find the number of workers to be connected to

the system in the columns of Table 3.

3) The requied clearance is where the span length

row and number of workers column intersect.

Clearance Evaluation for One

or Two Workers Connected to

the HLL with a DBI-SALA Self

Retracting Lifeline

WARNING: This information only applies

when the SRL is directly overhead and above

the level of the harness attachment point and

the user is standing.

Lower Level or

Obstruction

Working Level

12

Page 13

Table 3 - Required Clearance for One or Two Workers Connected to the

System with a DBI-SALA Self Retracting Lifeline (See Figure 6).

Span Lenght

in feet

0-10

(0-3.05)

10-15

(3.05-4.57)

15-20

(4.57-6.10)

20-25

(6.10-7.62)

25-30

(7.62-9.14)

30-35

(9.14-10.67)

35-40

(10.67-12.19)

40-45

(12.19-13.72)

45-50

(13.72-15.24)

50-55

(15.2-16.76)

55-60

(16.76-18.29)

60-65

(18.29-19.81)

65-70

(19.81-21.34)

70-75

(21.34-22.86)

75-80

(22.86-24.38)

80-85

(24.38-25.91)

85-90

(25.91-27.43)

90-95

(27.43-28.96)

95-100

(28.96-30.48)

Required Clearance Below

Working Level for One Worker

7’-11”

(2.41)

8’-2”

(2.49)

8’-5”

(2.57)

8’-8”

(2.64)

8’-10”

(2.69)

9’-1”

(2.77)

9’-4”

(2.84)

10’-3”

(3.12)

11’-3”

(3.43)

12’-2”

(3.71)

13’-2”

(4.01)

14’-2”

(4.32)

15’-1”

(4.60)

16’-1”

(4.90)

17’-0”

(5.18)

18’-0”

(5.49)

19’-0”

(5.79)

19’-11”

(6.07)

20’-11”

(6.38)

Meters are shown in parenthesis

Required Clearance Below

Working Level for Two Workers

8’-11”

(2.72)

9’-7”

(2.92)

10’-3”

(3.12)

10’-10”

(3.30)

11’-6”

(3.51)

12’-2”

(3.71)

12’-9”

(3.89)

14’-2”

(4.32)

15’-6”

(4.72)

16’-11”

(5.16)

18’-3”

(5.56)

19’-8”

(5.99)

21’-0”

(6.40)

22’-5”

(6.83)

23’-9”

(7.24)

25’-2”

(7.76)

26’-6”

(8.08)

27’-11”

(8.51)

29’-3”

(8.92)

13

Page 14

Step 2. Install the

anchorage

connectors.

Some

Figure 7 - Tie-off Adapter

Installing Tie-Off Adaptor to Vertical

or Sloped Anchorage Structure.

Sayfl ine

horizontal

lifeline

systems

include

Vertical or Sloped

Anchorage Structure

Tie-Off Adaptor

two tie-off

adaptor

anchorage

Wrap Tie-Off Adaptor twice

around Anchorage Structure

connectors.

To ensure

the tie-off adaptor does not slide down a vertical or

sloped anchorage, the tie-off adaptor must be wrapped

twice around the structure as shown in Figure 7.

Refer to the tie-off adaptor instructions for complete

installation information. The horizontal lifeline may be

secured directly to the anchorage when the anchorage

incorporates a compatible attachment

element that

meets the requirements specifi ed in section 2.3.

Step 3. Secure each end of the horizontal lifeline to the

anchorage connectors with the snap hook or carabiner.

Loosen and reposition the rope tensioner as required.

Step 4. Remove the slack from the horizontal lifeline by pulling

the rope through the tensioner by hand. To tension

the horizontal lifeline, use a pointed bar or a 1 1/8 in.

wrench and turn the tensioning nut clockwise until the

tensioner slips. Do not modify the rope tensioner to

achieve greater lifeline tension. See Figure 8. The fi nal

tension will be 300 to 450 lbs. (1.3 to 2.0 kN).

Figure 8 - Tensioning the Horizintal Lifeline

Tensioning the

Horizontal Lifeline

Pointed Bar

Rope Tensioner

Tensioning Nut

14

Page 15

3.3 OPERATION:

A. PERSONAL FALL ARREST SYSTEM COMPONENTS: Inspect

and don the full body harness according to manufacturer’s

instructions. Attach the connecting subsystem (energy

absorbing lanyard or SRL) to the dorsal connection on the

harness.

B. CONNECTING TO THE HORIZONTAL LIFELINE SYSTEM:

Approach the work area using the appropriate access

equipment. Connect your personal fall arrest system to one of

the attachment O-rings on the horizontal lifeline. Connectors

must meet all compatibility and strength requirements.

C. HAZARDOUS SITUATIONS: Do not take unnecessary risks,

such as jumping or reaching too far from the edge of the

working surface. Do not allow the connecting subsystem

to pass under arms or between feet. To avoid inadequate

clearance, do not climb above the horizontal lifeline. To avoid

swing fall hazards, do not work too far from either side of the

horizontal lifeline.

D. TWO (2) PERSONS CONNECTED TO THE HLL: When a

person falls while connected to the horizontal lifeline, the

system will deflect. If two (2) persons are connected to

the same horizontal lifeline, and one (1) person falls, the

second person may be pulled off the working surface due to

deflection. The potential for the second person falling increases

as the horizontal lifeline span length increases. The use of

independent horizontal lifeline systems for each person, or

shorter span length, is recommended to minimize the potential

of the second person falling.

E. FREE FALL: The personal fall arrest system must be rigged to

limit free falls to 6 feet (1.8m) or less when using an energy

absorbing lanyard, or such that the SRL is overhead without

slack, according to OSHA requirements.

F. SHARP EDGES: Avoid working where the connecting

subsystem or other system components will be in contact with,

or abrade against, unprotected sharp edges. If working around

sharp edges is unavoidable, a protective cover must be used to

prevent cutting of the personal fall arrest system components.

G. IN THE EVENT OF A FALL: The responsible party must have

a rescue plan and the ability to implement a rescue. Tolerable

suspension time in a full body harness is limited, so a prompt

rescue is critical.

H. RESCUE: With the number of potential scenarios for a

worker requiring rescue, an on-site rescue team is beneficial.

The rescue team is given the tools, both in equipment and

technique, to perform a successful rescue. Training should be

provided on a periodic basis to ensure rescuers’ proficiency.

15

Page 16

Figure 9 - Releasing Tension from the Horizontal Lifeline

Pointed Bar

Releasing Tension on

the Horizontal Lifeline

Locking Lever

Rope Tensioner

Tensioning Nut

3.4 SYSTEM REMOVAL: When no longer required, the horizontal

lifeline system should be removed from the job site.

A. RELEASE TENSION ON THE HORIZONTAL LIFELINE:

Step 1. Lift the locking lever and position the pointed bar under

the locking lever as shown in Figure 9.

Step 2. Push the pointed bar in a upward motion to unlock the

lever.

Step 3. Loosen the tensioning nut by inserting the pointed bar

through the hole in the nut, or use a 1 3/16 in (30 mm)

wrench, and turn the tensioning nut counterclockwise.

Step 4. Remove all knots and kinks in the rope before storage.

4.0 TRAINING

4.1 It is the responsibility of all users of this equipment to understand

these instructions, and to be trained in the correct installation,

use, and maintenance of this equipment. These individuals must

be aware of the consequences of improper installation or use

of this equipment. This user manual is not a substitute for a

comprehensive training program. Training must be provided on a

periodic basis to ensure profi ciency of the users.

5.0 INSPECTION

5.1 INSPECTION FREQUENCY: The Sayfl ine Synthetic Rope

Horizontal Lifeline System shall be inspected by the user before

each use and, additionally, by a competent person1 other than the

user after installation and at intervals of no more than one year2.

Results of the Competent Person inspection should be recorded in

the “Inspection and Maintenance Log” at the back of this manual.

1 Competent Person: One who is capable of identifying existing and predictable hazards in the

surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who

has authorization to take prompt corrective measures to eliminate them.

2 Inspection Frequency: Extreme working conditions (harsh environments, prolonged use, etc.) may

require increasing the frequency of competent person inspections.

16

Page 17

5.2 INSPECTION STEPS:

Step 1. Inspect all metal components (hooks, O-rings, rope

tensioner, etc.) for cracks, deformities, corrosion,

or other damage that may affect their strength or

operation.

Step 2. Inspect rope for concentrated wear; especially those

portions of the rope that contact the Rope Tensioner.

Material must be free of frayed strands, broken yarns,

cuts, abrasions, burns, and discoloration. The rope

must be free of knots, excessive soiling, paint build-up,

and rust staining. Inspect ferrules for cracks or other

damage. Thimble must be held fi rmly by the ferrule.

Check for chemical or heat damage; indicated by brown,

discolored, or brittle areas. Check for ultraviolet damage;

indicated by discoloration, splinters, and slivers along

the rope surface. All of the above factors are known to

reduce rope strength.

ROPE CORE: Concentrated wear, cuts,

abrasion, or burns may expose the white inner

core of the rope. Any time the white inner core

of the rope is visible, excluding the cut ends

of the rope, the rope shall be removed from

service and no longer used. If the braided

black cover must be pulled, spread apart, or

separated by hand to expose the white core,

the rope is still acceptable for use. Frayed or

broken strands that give the rope a “fuzzy”

appearance are acceptable, provided the white

inner core is not visible.

Acceptable:

White inner core

is not exposed.

Unacceptable:

White inner core

is exposed.

Step 3. Inspect system labels. The labels must be present and

fully legible. See section 8.0.

IMPORTANT: If this equipment is subjected to the forces of a

fall arrest, it must be removed from service and destroyed, or

returned to DBI-SALA for inspection or repair.

5.3 If inspection reveals an unsafe or defective condition, remove unit

from service and destroy, or contact DBI-SALA for possible repair.

IMPORTANT: Only DBI-SALA or parties authorized in writing

may make repairs to this equipment.

5.4 USER EQUIPMENT: Inspect harness and energy absorbing

lanyard or SRL according to manufacturer’s instructions.

5.5 i-Safe™ RFID TAG: If your equipment

has an i-Safe Radio Frequency

Figure 10 - RFID

Identifi cation (RFID) tag (Figure 10),

the RFID tag can be used with a reading

device to simplify inspection and provide

records for your equipment. Contact

Capital Safety or see the Capital Safety

website (http://www.capitalsafety.com/

en-us/Pages/i-Safe.aspx).

17

Page 18

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 CLEANING AND MAINTENANCE: Clean the horizontal lifeline

system with water and a mild detergent. Wipe dry with a clean,

dry cloth and hang to air dry. Do not force dry with heat. An

excessive build-up of dirt, paint, etc. may prevent the system

from working properly, and in severe cases, weaken the rope. A

lubricant may be applied to the moving parts of the rope tensioner.

Do not allow lubricant to contact the rope tensioner teeth.

6.2 STORAGE: Store this horizontal lifeline system in a clean, dry

environment, out of direct sunlight. Avoid areas where chemical

vapors are present. Thoroughly inspect the system after extended

storage.

6.3 USER EQUIPMENT: Maintain, service, and store user equipment

according to manufacturer’s instructions.

7.0 SPECIFICATIONS

7.1 MATERIALS:

• Rope Tensioner: Steel, plated

• O-rings: Alloy steel, plated

• Lifeline Rope: 11/16 in. nylon, static kernmantle, breaking

strength: 12,000 lb.

• Rope Tensioner Strap: Polyester/Nylon

• Snap Hooks: Alloy steel, plated

• Carabiners: High tensile alloy steel, plated

• Tie-off Adaptor: Polyester web, plated alloy steel hardware

18

Page 19

8.0 LABELING

8.1 The following labels must be present and fully legible:

WARNING

19

Page 20

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 21

INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER:

MODEL NUMBER:

DATE PURCHASED: DATE OF FIRST USE:

INSPECTION DATE INSPECTION ITEMS

NOTED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

CORRECTIVE ACTION MAINTENANCE

PERFORMED

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Page 22

Page 23

This instruction applies to the following models:

5908549

7600008

7600009

7600501

7600502

Additional model numbers may appear on the next printing of these instructions

7600503

7600504

7600505

7600506

7600507

7600508

7600509

7600510

7600511

7600512

7600513

7600514

7600515

7600516

7600517

7600518

7600519

7600520

7600521

7611904

Page 24

LIMITED LIFETIME WARRANTY

Warranty to End User: D B Industries, Inc., dba CAPITAL SAFETY USA (“CAPITAL SAFETY”)

warrants to the original end user (“End User”) that its products are free from defects in materials

and workmanship under normal use and service. This warranty extends for the lifetime of the

product from the date the product is purchased by the End User, in new and unused condition, from

a CAPITAL SAFETY authorized distributor. CAPITAL SAFETY’S entire liability to End User and End

User’s exclusive remedy under this warranty is limited to the repair or replacement in kind of any

defective product within its lifetime (as CAPITAL SAFETY in its sole discretion determines and deems

appropriate). No oral or written information or advice given by CAPITAL SAFETY, its distributors,

directors, offi cers, agents or employees shall create any different or additional warranties or in any

way increase the scope of this warranty. CAPITAL SAFETY will not accept liability for defects that are

the result of product abuse, misuse, alteration or modifi cation, or for defects that are due to a failure

to install, maintain, or use the product in accordance with the manufacturer’s instructions.

CAPITAL SAFETY’S WARRANTY APPLIES ONLY TO THE END USER. THIS WARRANTY IS THE ONLY

WARRANTY APPLICABLE TO OUR PRODUCTS AND IS IN LIEU OF ALL OTHER WARRANTIES AND

LIABILITIES, EXPRESSED OR IMPLIED. CAPITAL SAFETY EXPRESSLY EXCLUDES AND DISCLAIMS

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

AND SHALL NOT BE LIABLE FOR INCIDENTAL, PUNITIVE OR CONSEQUENTIAL DAMAGES OF ANY

NATURE, INCLUDING WITHOUT LIMITATION, LOST PROFITS, REVENUES, OR PRODUCTIVITY, OR FOR

BODILY INJURY OR DEATH OR LOSS OR DAMAGE TO PROPERTY, UNDER ANY THEORY OF LIABILITY,

INCLUDING WITHOUT LIMITATION, CONTRACT, WARRANTY, STRICT LIABILITY, TORT (INCLUDING

NEGLIGENCE) OR OTHER LEGAL OR EQUITABLE THEORY.

CSG USA & Latin America

3833 SALA Way

Red Wing, MN 55066-5005

Toll Free: 800.328.6146

Phone: 651.388.8282

Fax: 651.388.5065

solutions@capitalsafety.com

CSG EMEA

(Europe, Middle East, Africa)

Le Broc Center

Z.I. 1ère Avenue

5600 M B.P. 15 06511

Carros

Le Broc Cedex

France

Phone: + 33 4 97 10 00 10

Fax: + 33 4 93 08 79 70

information@capitalsafety.com

The Ultimate in Fall Protection

CSG Canada

260 Export Boulevard

Mississauga, ON L5S 1Y9

Phone: 905.795.9333

Toll-Free: 800.387.7484

Fax: 888.387.7484

info.ca@capitalsafety.com

CSG Australia & New Zealand

95 Derby Street

Silverwater

Sydney NSW 2128

AUSTRALIA

Phone: +(61) 2 8753 7600

Toll-Free : 1 800 245 002 (AUS)

Toll-Free : 0800 212 505 (NZ)

Fax: +(61) 2 87853 7603

sales@capitalsafety.com.au

www.capitalsafety.com

ISO

9001

CSG Northern Europe

5a Merse Road

North Moons, Moat

Reditch, Worcestershire, UK

B98 9HL

Phone: + 44 (0)1527 548 000

Fax: + 44 (0)1527 591 000

csgne@capitalsafety.com

CSG Asia

Singapore:

16S, Enterprise Road

Singapore 627666

Phone: +65 - 65587758

Fax: +65 - 65587058

inquiry@capitalsafety.com

Shanghai:

Rm 1406, China Venturetech Plaza

819 Nan Jing Xi Rd,

Shanghai 200041, P R China

Phone: +86 21 62539050

Fax: +86 21 62539060

Loading...

Loading...