Page 1

© Copyright 2003 DB Industries, Inc.

User Instruction Manual

Salalift® and Salalift® II Winches

8101000 and 8102001 Series

This manual is intended to meet industry

standards, including OSHA 1910.146 and

ANSI Z117.1, and should be used as part

of an employee training program as

required by OSHA.

WARNING: This product is to be used as part of a complete system. T he

user must follow the manufacturer's instructions for each component of the

complete system. These instructions must be provided to the user of this

equipment. Manufacturer's instructions must be followed for proper use and

maintenance of this product. Alterations or misuse of this product, or failure

to follow instructions may result in serious injury or death.

IMPORTANT: If you hav e questions on the use, care, application, or

suitability for use of this safety equipment, contact DBI/SALA.

IMPORTANT: Bef ore using this equipment record the product identification

information from the ID label on the winch in the inspection and

maintenance log in section 9.0 of this manual.

The 8101000, 8101002, 8101004, and 8101006 Salalift

Series Manually Operated Winches are classified b y Underwriters Laboratories, Inc. as to the 350 lbs. load capacity

only.

actoolsupply.com

actoolsupply.com

actoolsupply.com

Page 2

actoolsupply.com

actoolsupply.com

DBI SALA 8304000 Sealed SRL Salalift Tripod Confined Space Entry Kit

DBI SALA 8304010 Sealed SRL Salalift II Confined Space Kit

DBI SALA 8304011 Sealed SRL Salalift II Confined Space Kit

DBI SALA 8300020 Confined Space Entry Salalift II Winch Tripod 60 Ft

DBI SALA 8300030 Confined Space Entry Salalift II 60Ft Winch 7' Tripod

Page 3

3

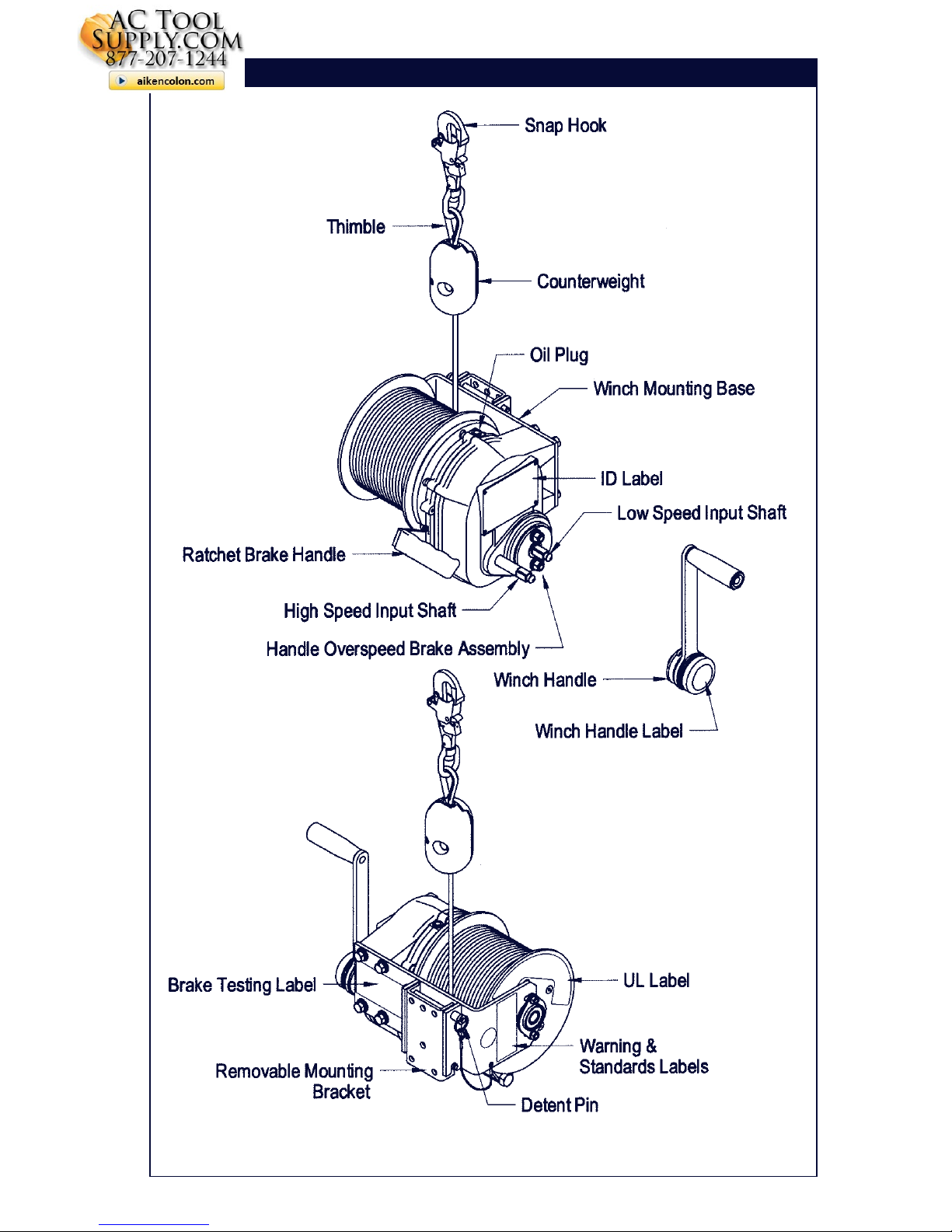

Figure 1 - 8101000 Series Parts Identification

actoolsupply.com

actoolsupply.com

Page 4

44

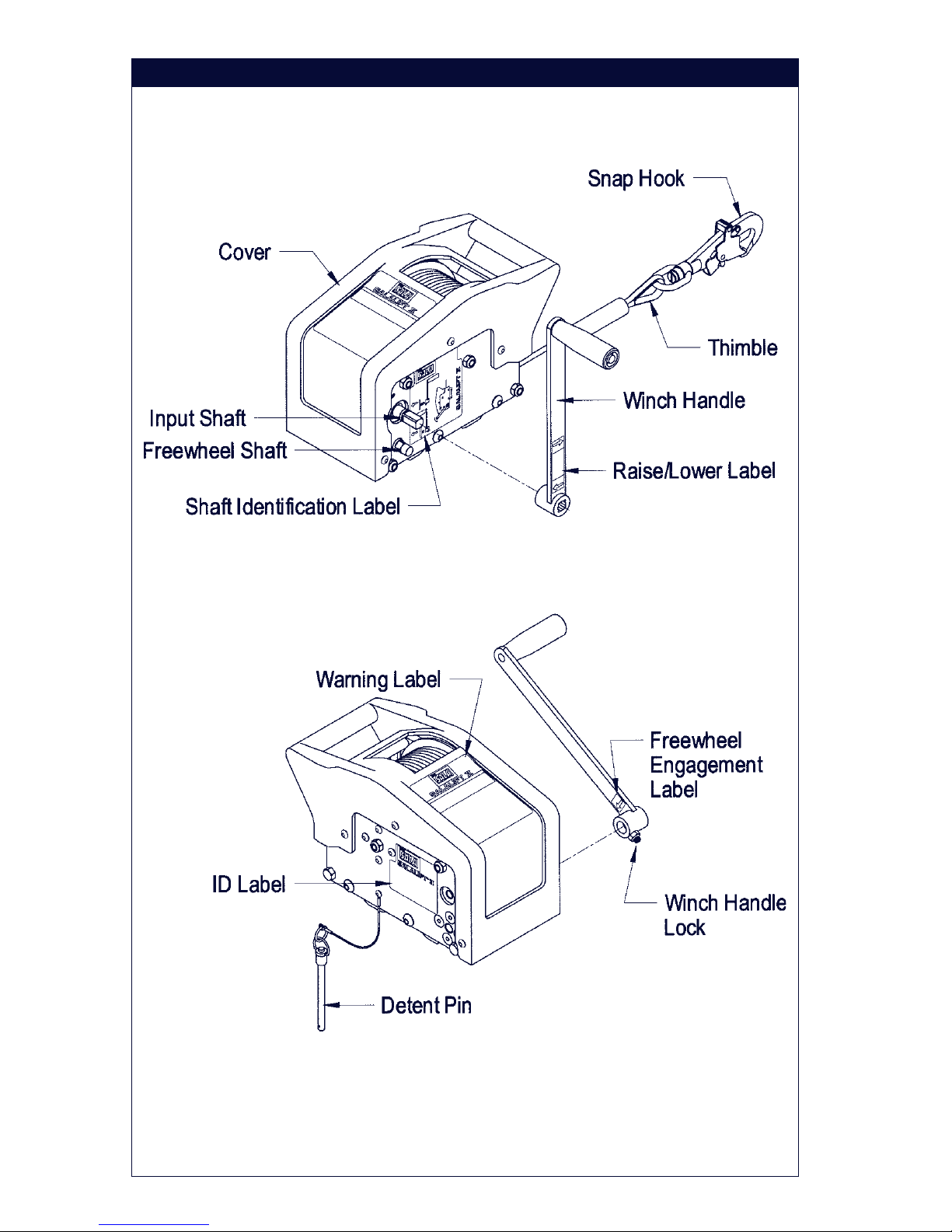

Figure 2 - 8102001 Series Parts Identification

actoolsupply.com

actoolsupply.com

Page 5

5

DESCRIPTIONS

SALALIFT® Winches:

8101000: 60 feet of 1/4 inch galvanized wire rope, carrying bag.

8101002: 60 feet of 1/4 inch stainless steel wire rope, carrying bag.

8101004: 120 feet of 1/4 inch galvanized wire rope, carrying bag.

8101006: 120 feet of 1/4 inch stainless steel wire rope, carrying bag.

8101101: 140 feet of 1/4 inch galvanized wire rope, carrying bag.

8101103: 140 feet of 1/4 inch stainless steel wire rope, carrying bag.

SALALIFT® II Winches:

8102001: 60 feet of 1/4 inch galvanized wire rope, carrying bag.

8102003: 60 feet of 1/4 inch stainless steel wire rope, carrying bag.

8102009: 90 feet of 3/16 inch galvanized wire rope, carrying bag.

8102011: 90 ft. of 3/16 inch stainless steel wire rope, carrying bag.

8102005: 120 feet of 3/16 inch galvanized wire rope, carrying bag.

8102007: 120 feet of 3/16 inch stainless steel wire rope, carrying bag.

IMPORTANT: F or special (custom) versions of this product, follo w the

instructions herein. See supplemental instructions, if included, for additional

instructions on custom equipment.

1.0 APPLICATIONS

1.1 PURPOSE: DBI/SALA Salalift winches are to be used for work

positioning (8101000 series only), personnel riding, material handling,

climbing protection, or rescue and ev acuation. These winch models are

to be used with a DBI/SALA tripod, davit arm, or other support

structure, and may be used in situations where personnel or materials

need to be raised or lowered 60-140 feet.

1.2 WINCH APPLICA TION TYPES:

A. WORK POSITIONING: The Salalift winch (8101000 series only) is

used to suspend the worker in a work position, acting as the primary

means of support. Applications include suspending a worker in a

work seat or harness. A back-up personal fall arrest system must be

attached to the suspended employee.

NOTE: OSHA requires that manual or pow ered winches be independently

evaluated and classified for use as a single point suspension system. See

OSHA regulation 29 CFR 1926.451, and 29 CFR 1910.28.

B. PERSONNEL RIDING: The Salalift or Salalift II winch is used to r aise

or lower a worker to a work level. At the work level the worker is no

longer supported by the winch. It is recommended that the w orker be

connected to a back-up arrest system while being raised or lowered.

actoolsupply.com

actoolsupply.com

Page 6

6

C. RESCUE AND EV A CUATION: The Salalift or Salalift II winch is used

to raise or lower an endangered or injured work er, or rescue

personnel. Applications include permit and non-permit confined

space entry work.

D. CLIMBING PRO TECTION: The Salalift or Salalift II winch is used to

protect a worker ascending or descending a fixed ladder or similar

structure. It is recommended that this use of the winch be restricted

to structures where other means of climbing protection; such as

permanently installed ladder safety systems or personal fall arrest

systems are infeasible. For this application, the following conditions

must be met:

1. Ladder or steps are in good condition and allows for a straight,

continuous climb .

2. The worker climbing the ladder is wearing a full body harness and

the winch line is connected to the dorsal (back) D-ring of the

harness.

3. The winch operator is trained and competent in the operation of

the winch.

4. No slack line is allowed to develop when the worker moves up or

down the ladder .

5. DBI/SALA recommends , for the 8101000 series winches only,

that an energy absorbing lanyard be connected between the

harness dorsal D-ring and the winch line.

1.3 LIMITATIONS: The following application limitations must be considered

before using this product. F ailure to observe product limitations could

result in serious injury or death.

A. INSTALLATION: The winch must be installed in accordance with the

requirements stated in section 3.0 of this manual.

B. CAPACITY: The maximum working load for this product is 350 lbs.

(160 kg).

C. PERSONAL F ALL ARREST SYSTEMS: P ersonal fall arrest

systems used with the Salalift or Salalift II winch must meet

applicable state and federal regulations and the requirements stated

in section 3.3.

D. PHYSICAL AND ENVIRONMENT AL HAZARDS: Use of this

equipment in areas with physical or environmental hazards may

actoolsupply.com

actoolsupply.com

Page 7

7

require that additional precautions be taken to reduce the possibility

of damage to this equipment or injury to the user. Hazards ma y

include, but are not limited to; high heat (welding or metal cutting),

acid or caustic chemicals, corrosive environments such as

exposure to sea water , high v oltage po wer lines , e xplosive or to xic

gases, moving machinery or sharp edges. Contact DBI/SALA if you

have questions about the application of this equipment in areas

where physical or environmental hazards are present.

E. TRAINING: This equipment is to be installed and used by persons

who have been trained in its correct application and use.

1.4 Refer to national standards, including; ANSI Z117.1, local, state, and

OSHA requirements (26 CFR 1910.146), for more information on the

application of this and associated equipment.

2.0 SYSTEM REQUIREMENTS

2.1 COMP ATIBILITY OF COMPONENTS: DBI/SALA equipment is

designed for use with DBI/SALA approved components and

subsystems only. Substitutions or replacements made with nonapproved components or subsystems may jeopardize compatibility of

equipment and may effect the safety and reliability of the complete

system.

2.2 COMP A TIBILITY OF CONNECT ORS: Connectors are considered to be

compatible with connecting elements when they have been designed to

work together in such a way that their sizes and shapes do not cause

their gate mechanisms to inadvertently open regardless of how they

become oriented. Contact DBI/SALA if you have any questions about

compatibility.

Connectors ( hooks, carabiners, and D-rings) must be capable of

supporting at least 5,000 lbs. (22kN). Connectors must be compatible

with the anchorage or other system components. Do not use equipment

that is not compatible. Non-compatible connectors may unintentionally

disengage. See Figure 3. Connectors must be compatible in size,

shape, and strength. Self locking snap hooks and carabiners are

required by ANSI Z359.1 and OSHA.

2.3 Making Connections: Only use self-locking snap hooks and carabiners

with this equipment. Only use connectors that are suitable to each

application. Ensure all connections are compatible in size, shape and

strength. Do not use equipment that is not compatible. Ensure all

connectors are fully closed and locked.

actoolsupply.com

actoolsupply.com

Page 8

8

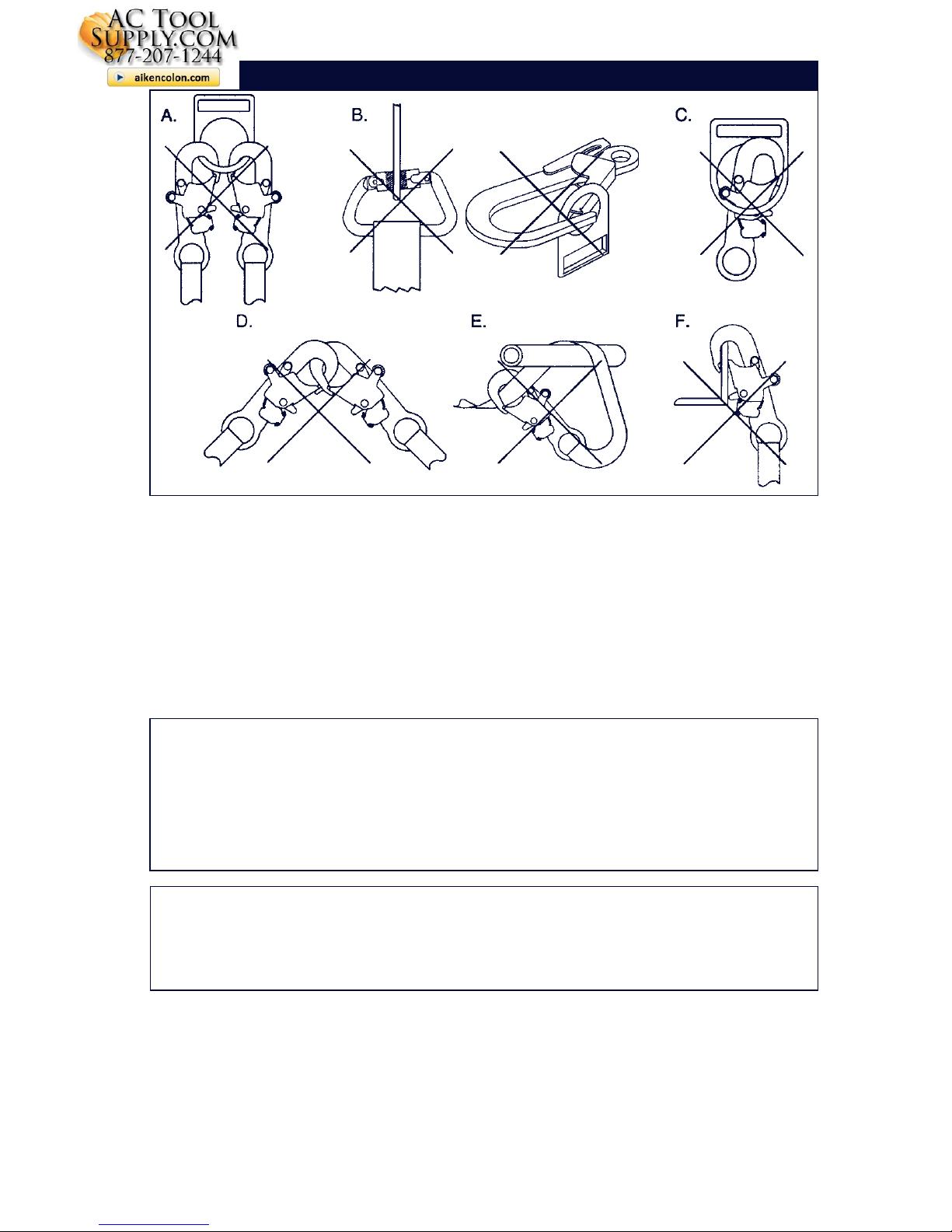

DBI/SALA connectors (snap hooks and carabiners) are designed to be

used only as specified in each product’s user’s instructions. See Figure

4 for inappropriate connections. DBI/SALA snap hooks and carabiners

should not be connected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

NOTE: Large throat opening snap hooks should not be connected to

standard size D-rings or similar objects which will result in a load on the gate

if the hook or D-ring twists or rotates. Large throat snap hooks are designed

for use on fixed structural elements such as rebar or cross members that are

not shaped in a way that can capture the gate of the hook.

C. In a false engagement, where features that protrude from the snap

hook or carabiner catch on the anchor and without visual

confirmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the

manufacturer’ s instructions for both the lan yard and connector

specifically allows such a connection).

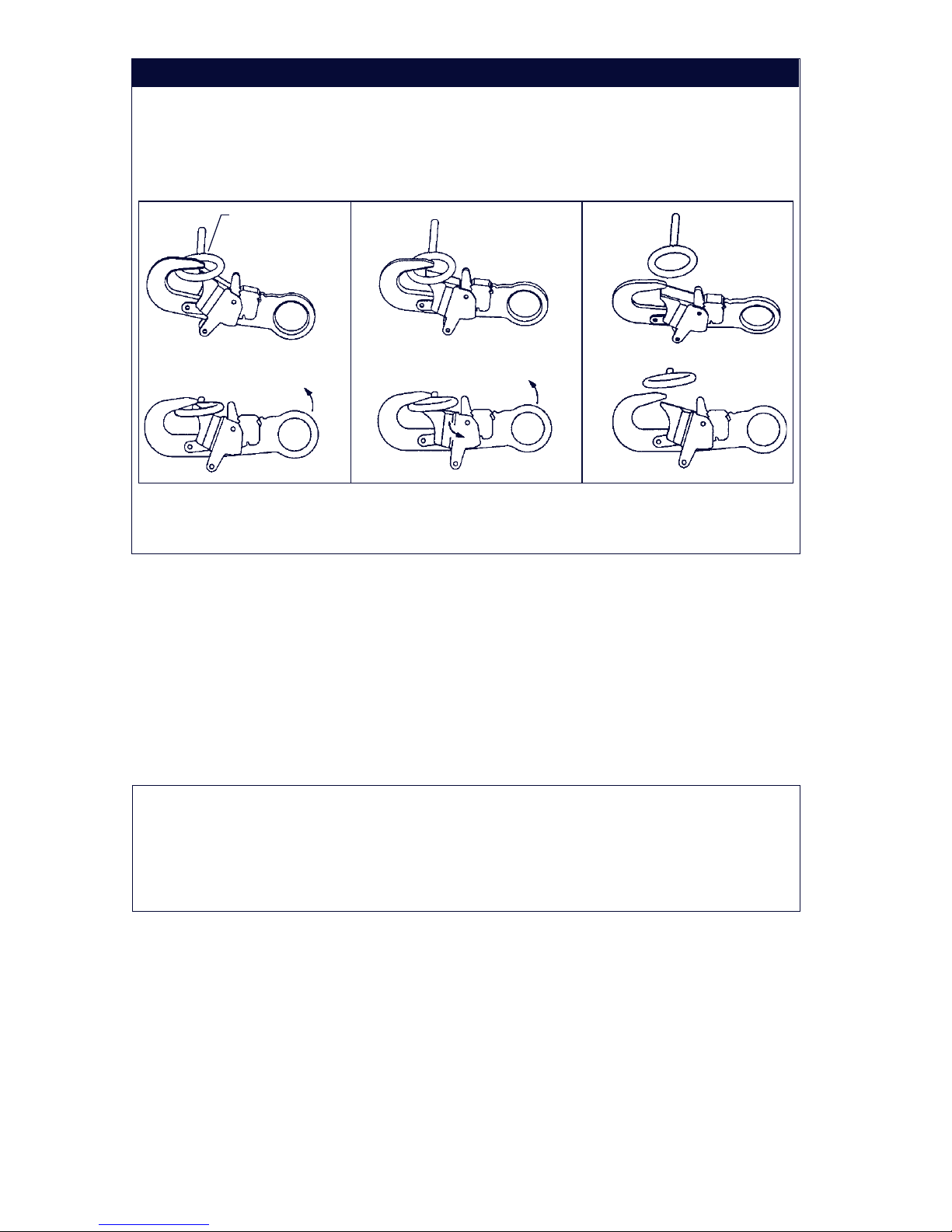

Figure 3 - Unintentional Disengagement (Roll-out)

If the connecting element that a snap hook (shown) or carabiner attaches to is

undersized or irregular in shape, a situation could occur where the connecting

element applies a force to the gate of the snap hook or carabiner. This force may

cause the gate (of either a self-locking or a non-locking snap hook) to open,

allowing the snap hook or carabiner to disengage from the connecting point.

1. Force is applied to

the snap hook.

2. The gate presses against

the connecting ring.

3. The gate opens

allowing the snap

hook to slip off.

Small ring or other

non-compatibly

shaped element

actoolsupply.com

actoolsupply.com

Page 9

9

F. To any object which is shaped or dimensioned such that the snap

hook or carabiner will not close and lock, or that roll-out could occur .

2.4 SUPPORT STRUCTURE STRENGTH: The support structure to which

the winch is installed must meet minimum strength requirements stated

in section 3.4

3.0 OPERATION AND USE

W ARNING: Do not alter or intentionally misuse this equipment. Consult

DBI/SALA when using this equipment in combination with components or

subsystems other than those described in this manual. Some subsystem

and component combinations may interfere with the operation of this

equipment. Use caution when using this equipment around moving

machinery , electrical hazards, chemical hazards, and sharp edges.

WARNING: Consult your doctor if there is reason to doubt your fitness to

safely absorb the shock from a fall arrest. Age and fitness seriously affect a

worker's ability to withstand falls. Pregnant women or minors must not use a

DBI/SALA winch, unless for unavoidable emergency use situations.

3.1 BEFORE EACH USE: Before each use of this equipment carefully

inspect it to ensure it is in good working condition. Check for worn or

damaged parts. Ensure all parts are present and secure. Chec k

operation of winch; ensure that it will lift, lower , and hold the load under

normal operation. Check winch and entire system for damage and

corrosion. See section 5.0 f or further inspection details. Do not use if

inspection reveals an unsafe condition.

Figure 4 - Inappropriate Connections

actoolsupply.com

actoolsupply.com

Page 10

10

3.2 PLANNING: Plan your system and how it will function bef ore starting

your work. Consider all factors that affect your safety during use. Some

important points to consider when planning your system are:

A. HAZARD EV ALU A TION: Ev aluate job site hazards prior to starting

work. Consult applicable OSHA and industry standards for

guidelines and regulatory requirements on issues such as confined

space entry , personal f all arrest systems (PFAS), and single point

adjustable suspended scaffolds.

B. WORK SITE GEOMETR Y : The installation and use of the support

structure (tripod, davit arm and base) must be consistent with the

geometric requirements stated in the associated manufacturer's

instruction manuals. When suspending working lines from the

support structure, check for obstructions or sharp edges in the work

path. Av oid working where the user may s wing and hit an object, or

where lines may cross or tangle with that of another worker .

C. SECONDAR Y OR BA CK-UP F ALL ARREST SYSTEM: When using

the Salalift winch (8101000 series) as a support for w ork positioning,

a secondary or back-up fall arrest system is required. See OSHA 29

CFR 1910.28 and 1926.451. The DBI/SALA tripod and davit arm has

provisions for connection of a secondary or back-up PFAS. See

sections 3.3 and 3.5 (A).

D. RESCUE: A means of dealing with an accident or emergency must

be planned in advance. Response time can pla y an important role in

the survival of an injured worker . Users of this equipment must be

trained in emergency procedures.

3.3 REQUIREMENTS FOR PERSONAL F ALL ARREST SYSTEMS: PFAS

used with the Salalift or Salalift II winch and support structure must

meet applicable OSHA requirements.

• The PFAS should be rigged to minimize any potential free fall and

never allow a free fall greater than 6 feet. It is recommended that the

PFAS used with this equipment include a full body harness as the

body support component. PFAS's that incorporate full body

harnesses must maintain fall arrest forces below 1,800 lbs. and arrest

the fall within 42 inches. Body belts, unless incorporated into a full

body harness, are not recommended for use with this equipment. A

typical PFAS includes a full body harness, connecting subsystem or

component (self retracting lifeline or lifeline and rope grab), and the

necessary connectors to couple the system together.

• Anchorages selected for PFAS must sustain static loads, applied in

the directions permitted by the PFAS, of at least; (A) 3,600 lbs.

actoolsupply.com

actoolsupply.com

Page 11

11

(16kN) when certification exists (see ANSI Z359.1 for certification

definition), or (B) 5,000 lbs. (22kN) in the absence of certification.

When more than one PFAS is attached to an anchorage, the

anchorage strengths set forth in (A) and (B) must be multiplied by the

number of PFAS attached to the anchorage. Per OSHA 1926.500 and

1910.66: Anchorages used for attachment of a PFAS shall be

independent of any anchorage being used to support or suspend

platforms, and must support at least 5,000 lbs. (22kN) per user

attached, or be designed, installed, and used as part of a complete

PFAS which maintains a safety factor of at least two, and is

supervised by a qualified person.

W ARNING: Read and f ollow manufacturer's instructions f or the personal fall

arrest equipment selected for use with the winch and support structure.

IMPORTANT: Body belts are not allowed f or free fall situations. Body belts

increase the risk of injury during fall arrest in comparison to a full body

harness. Limited suspension time and the potential for improperly wearing a

body belt may result in added danger to the user’ s health.

3.4 INST ALLA TION OF WINCH T O SUPPORT STRUCTURE:

A. MOUNTING BRACKET: These winches incorporate a “quick-mount”

style brack et for attachment to the support structure. DBI/SALA

tripods, davit arms, and other support structures supplied by

DBI/SALA, include a bracket that mates with the winch quick-mount

bracket. All DBI/SALA winches include the quick-mount bracket.

When using the 8102001 series winch with the 8004176 W all Mount

Bracket, a mounting adapter kit is required. Contact DBI/SALA for

more information.

B. LOAD REQ UIREMENTS: Figure 5 illustrates mounting the winch to

the support structure and the load requirements. The mounting

bracket m ust support the loads shown in Figure 5.

C. GEOMETRIC REQUIREMENTS: Refer to the support structure

manufacturer's instructions for geometric requirements. Installations

of the winch to support structures other than those provided by

DBI/SALA must meet the geometric requirements shown in

Figure 5. P osition the support structure so the load and the lifeline of

the winch can be directed over the work area when installed. For

personnel use, do not position the support structure where the

worker will hav e to swing under the support structure to reach the

work area. Avoid positioning the support structure where the working

line may abrade against sharp edges.

actoolsupply.com

actoolsupply.com

Page 12

12

IMPORTANT: P osition the winch and support structure in a location which

allows the operator to safely use the winch.

D. QUICK-MOUNT INST ALLA TION: See Figure 6. Mount the winch

using the quick-mount bracket as follows:

Step 1. Pull out the locking detent pin by depressing the button on end

of the pin. Lift the winch into place and position the slot in the

bracket o v er the fixed pin on the support structure bracket.

Step 2. Push the top of winch in toward the support structure while the

bottom rotates on the fixed pin. Align the holes and push the

detent pin through until it stops. Ensure the pin locks in place.

Figure 5 - Load/Geometric Requirements

actoolsupply.com

actoolsupply.com

Page 13

13

Step 3. Slowly pull out the winch line. Route the line o v er the support

structure pulley system. See the support structure

manufacturer's instructions for details.

E. WELDED INST ALLATIONS: If w elding the mounting bracket to a

support structure it is recommended that the welding be done by a

certified welder. P ortions of the mounting brack et that have been

exposed due to welding should be painted or otherwise protected

from corrosion.

Figure 6 - Quick-Mount Installation

3.5 OPERA TION OF WINCH:

A. CONNECTING WINCH LINE TO LOAD: See Figure 7. For

applications that do not require a secondary PFAS , the winch line

should be connected to the worker's harness back D-ring. For

applications requiring a secondary PFAS, the winch line should be

connected to a Y-type lanyard and this lany ard should be attached to

the worker's harness shoulder D-rings. The secondary lifeline should

be connected to the worker's harness back D-ring. For material

handling applications, connect the winch line to the load using a tieoff adapter or other anchoring device.

B. SALALIFT WINCH (8101000 Series): Attach the winch to the

support structure as described in section 3.4 (D). Install the winch

crank handle onto the high or low speed shaft by aligning the handle

with the shaft and pushing firmly inward until the handle snaps in

place. To release the handle from the shaft, depress the handle

release and pull the handle off the shaft. Pull the ratchet lever

downward and feed the line off the drum by rotating the crank handle

in the “lower” direction. Route the line ov er the support structure

pulley system.

actoolsupply.com

actoolsupply.com

Page 14

14

TO RAISE A LO AD: Rotate the winch crank handle clockwise when

using the low speed shaft and counterclockwise when using the high

speed shaft. For work er safety, the crank handle incorporates an

overload clutch which limits the winch lifting force on the high speed

shaft to approximately 250 lbs. and 500 lbs. on the low speed shaft,

thus reducing the possibility of injury should a worker become

entangled during retrieval. Do not exceed the rated capacity of 350

lbs.

TO LO WER A LO AD: Rotate the winch crank handle in the “raise”

direction until the ratchet brake lever can be pulled down, then rotate

the crank handle in the “lo wer” direction. When a load is suspended

from the winch, use caution when the ratchet brake lever is pulled

down since the load will be transf erred to the winch crank handle. To

prevent loss of control of the load, do not bloc k or r e strict the ratchet

lever from engaging the teeth on the drum, except by normal manual

operation. If the operator fatigues, or for any reason desires to “hold”

the load, allow the ratchet brake to engage and support the load.

The Salalift® I winch is designed and typically used for manual

operation. Certain situations where the speed of the rescue, coupled

with fatigue experienced by operator during long lifts, may

necessitate the need for a powered drive operation. Contact DBI/

SALA for more information.

C. SALALIFT II WINCH (8102001 Series): Attach the winch to the

support structure as described in section 3.4 (D). Install winch crank

handle onto the input shaft by aligning the hub of the crank handle

with the square drive marked "winch shaft" and pushing firmly

inward until handle snaps in place (the grip on the handle should

Figure 7 - Connection

actoolsupply.com

actoolsupply.com

Page 15

15

face outward). To release the crank handle from the shaft, pull the

handle off the shaft. Feed the line off the winch drum by rotating the

crank handle in the lowering direction (counterclockwise). Apply

slight tension to the line while feeding it off the drum. F ree-wheel

mode may also be used, see section 3.5 (C). Route the line over the

support structure pulley system.

TO RAISE A LO AD: Rotate the winch crank handle in the raise

direction (clockwise). To hold or momentarily suspend the load, stop

cranking. The automatic clutch/brak e will hold the load if handle is

released. The winch incorporates an overload clutch limiting the

lifting force to approximately 700 lbs., reducing the chance of injury

if a worker becomes entangled during retrieval. Do not exceed the

rated capacity of 350 lbs.

TO LO WER A LO AD: Rotate the winch crank handle in the lower

direction (counterclockwise). When low ering line without a load,

maintain slight tension on the line to aid payout.

FREE-WHEEL MODE: Remove the crank handle from the raise/lower

input shaft. Reverse the crank handle and install it onto the square

drive marked "freewheel shaft" by aligning the handle hub with the

shaft. See Figure 8. To engage free-wheel mode, rotate the crank

handle counterclockwise until it stops and hold. The line can now be

freely pulled off of the winch drum. T o a v oid build-up of slack line on

the drum, pull the line off the drum smoothly , remo ve slack on the

drum by releasing the crank handle and pulling on the line. If the line

pays out too rapidly, an ov er speed br ak e will activate and lock,

stopping the line. If this happens, return to the winch mode and

rotate the crank handle clockwise two turns to unlock the over

speed brake. Do not engage free-wheel mode with load on the lifting

line, remove load on the line before engaging free-wheel mode.

When using the Salalift II for climbing protection applications, freewheel mode is not recommended. The oper ator must be attentive to

slack line; paying out and reeling in line as needed.

D. IMP A CT INDICA T OR AND CABLE RESERVE: The Salalift II winch

is supplied with a connecting swiveling hook that incorporates a load

indicator . This indicator functions if the winch is sev erely impact

loaded or if the lifting capacity is exceeded by a preset amount. See

section 5.0 for inspection of load indicator . The Salalift II

incorporates a reserve cable retention feature on the cable drum.

With the drum near empty (single layer of cable remaining), the

shear pin is visible. See Figure 10. The reserve cab le ensures that

the shock absorbing feature is available throughout the working

range of the winch. If the winch is shock loaded at the reserve point

actoolsupply.com

actoolsupply.com

Page 16

16

of cable pay out, the shear pin will shear , allowing the shoc k

absorber to function normally . If the shear pin has been sheared, the

unit must be returned for inspection and repair . See section 5.0 for

inspection details.

IMPORTANT: Do not use winch f or lifting or lowering of more than one

person, except for emergency situations. In this case, if using the 8101000

series, the low speed shaft must be used to pre vent handle slippage. The

maximum lifting force is approximately 500 lbs.

W ARNING: If the cr anking tension eases during lowering, the person or

material being lowered has reached a work level or obstruction. Do not

continue cranking without communicating with the person or checking the

material being lowered. Always keep the cable tension firm. Slack cable

could cause a free fall.

WARNING: A minimum of four wraps of line must remain on the drum at all

times on the 8101000 series. One complete layer of line must remain on the

8102001 series. Do not attempt to reverse wind the line onto the drum. Line

must wind onto the drum by turning the crank handle in the "raise" direction

only . Check periodically to see that the line is winding ev enly on the drum.

Use gloves when handling line.

4.0 TRAINING

4.1 It is the responsibility of the user to assure they are familiar with these

instructions, and are trained in the correct care and use of this equipment.

Figure 8 - Free-Wheel Mode

actoolsupply.com

actoolsupply.com

Page 17

17

User must also be aware of the operating characteristics, application

limits, and the consequences of improper use of this equipment.

IMPORTANT: T raining m ust be conducted without exposing the trainee to a

fall hazard. T raining should be repeated on a periodic basis.

5.0 INSPECTION

5.1 FREQUENCY :

• Before Each Use: Visually inspect per steps listed in sections 5.2

and 5.3.

• Monthly: A formal inspection of the winch should be done by a

competent person other than the user. See sections 5.2 and 5.3 for

guidelines. Record results in the inspection and maintenance log in

section 9.0.

• Annual: It is recommended that the winch be serviced by a factory

authorized service center or the manufacturer. Extreme working

conditions may require increasing the frequency of inspections.

Annual servicing shall include, but not be limited to, an intensive

inspection and cleaning of all internal and external components.

Failure to provide proper service may shorten product life and could

endanger performance.

• After An Impact: Inspect entire winch according to section 5.2.

W ARNING: If the winch has been subjected to impact forces, it must be

immediately removed from service and inspected. If the winch fails to pass

the inspection, do not use. The equipment must be sent to an authorized

service center for repair .

IMPORTANT: Extreme working conditions (harsh environment, prolonged

use, etc.) may require increasing the frequency of inspections.

5.2 GENERAL INSPECTION STEPS FOR ALL WINCH MODELS:

Step 1. Inspect all screws, bolts and nuts. Ensure they are securely

attached and tight. Check to see if any bolts, nuts or other

parts are missing, or have been substituted or altered in any

wa y. Inspect covers, housings, guards, etc. Ensure they are

free of cracks, dents, or other damage.

Step 2. Crank handle must lock positively onto the shaft and be free of

cracks, bends, or other damage.

actoolsupply.com

actoolsupply.com

Page 18

18

Step 3. Connecting hook must not be damaged, broken, distorted, or

have an y sharp edges, burrs, crac ks, worn parts, or corrosion.

Ensure the connecting hook works properly . Hook gate must

move freely and loc k upon closing. Hook must swivel freely.

Step 4. Wire Rope: Inspect entire length of wire rope assembly starting

at the hook. Always wear protective gloves when inspecting

wire rope.

A. Inspect for broken wires by passing the wire rope through gloved

hands, flexing it every few inches to expose breaks. Broken wires

can be removed b y bending the wire back and f orth parallel to the

rope length. Do not attempt to pull wires out of rope. Inspect for

kinks, cuts, crushed burned areas, or other damage. Wire rope with

serious damage must be removed from service.

B. The wire rope assembly must be replaced by an authorized service

center if there are six or more randomly distributed broken wires in

one lay, or three or more broken wires in one strand in one la y. Note:

A “lay” of wire rope is the length of wire rope that it takes for a

strand (the larger groups of wires) to complete one revolution or

twist along the rope.

C. The wire rope assembly must be replaced by an authorized service

center if there are any broken wires within one inch of the metal

compression sleev es at either end of the assembly. Note: To inspect

wire rope area near compression sleeves on hook end, remove

counterweight (8101000 series) or slide rubber hook bumper up on

wire rope (8102001 series).

D. Inspect entire length of wire rope for signs of corrosion. Severely

corroded wire rope must be replaced.

Synthetic Rope: Inspect for the following if the winch uses synthetic rope:

A. Inspect for concentrated wear, frayed strands , brok en yarns, cuts,

and abrasions. The line must be free of knots, e xcessiv e soiling,

heavy paint buildup, and rust staining throughout its length.

B. The line must be free of chemical or heat damage, indicated by

brown, discolored, or brittle areas.

C. The line must be free of ultraviolet damage, indicated by discoloration

and the presence of splinters and slivers on the rope surface.

D. All of the above factors are known to reduce rope strength. As a rule

of thumb, rope strength is reduced proportional to the cross

actoolsupply.com

actoolsupply.com

Page 19

19

sectional area of the rope damaged. Damaged or questionable rope

should be replaced by an authorized service center.

Step 5. Inspect all identification and warning labels, ensuring that they

are legible and securely attached. See Figure 1 (8101000

series), Figure 2 (8102001 series) and section 8.0.

Step 6. Inspect each system component (support structure, back-up

fall arrest system, body support, connectors, etc.) according to

manufacturer's instructions.

Step 7. See additional inspection steps for the winch in sections 5.3,

5.4, and 5.5.

5.3 INSPECTION OF SALALIFT WINCH (8101000 SERIES): The f ollowing

steps are additional inspection procedures to those in section 5.2 that

must be performed on the 8101000 series winch. See Figure 1.

Step 1. Check operation of the winch in high and low speed positions; it

must crank up and down freely. Stiff or rough operation ma y

indicate a worn gear or bearing.

Step 2. Inspect the ratchet brake . With the brak e engaged, the drum

should be prev ented from paying off cab le. The spring must be

in place and undamaged. The ratchet brak e lev er must fully

engage the teeth on the drum, the drum teeth must be in good

condition.

Step 3. Inspect for oil in the gearbox by removing plug on top and tilting

unit so oil can be seen through hole. Inspect for oil leaks.

Step 4. Check operation of the handle over speed brake as follows:

A. Over le v el ground set up support structure and winch as it will be

used.

B. By raising or lowering the winch cable, position the lifting hook to

approximately chest height.

C. Remove the winch crank handle and have someone hold the ratchet

brake lever in its disengaged position, such as when lowering a

load.

D. Pull down sharply on the lifting hook to engage the over speed

brake.

actoolsupply.com

actoolsupply.com

Page 20

20

E. If the brake fails to engage or noticeable brake slippage occurs,

remove from service and return to an authorized service center for

repair.

Step 5. Check operation of the drum over speed brake as follows, see

Figure 9:

A. To test the drum over speed br ake, remov e the handle ov er speed

brake assembly. Using a snap ring pliers, remo ve the ring that

retains the handle over speed brake assembly on the low speed

shaft. Remov e the brak e assemb ly, taking care not to damage the

pawl springs on the back side of the brake. Note: If damage exists

on the shaft such as a nick or corrosion, repair the damaged area

using a file or emery cloth before removing the brake assemb ly.

B. With the handle over speed brake removed, on level ground, set up

the support structure and winch as it will be used. To test the drum

over speed brake, remove the crank handle and disengage the ratchet

brake, then pull down sharply on the winch cable to engage brake.

C. If the brake fails to engage or slippage of more than one inch occurs

(a small amount of brake slippage is normal), remove the winch

Figure 9 - Inspecting level wind 8101000

actoolsupply.com

actoolsupply.com

Page 21

21

from service immediately and return to an authorized service center

for repair .

D. If the brake functions properly, reassemble the handle ov er speed

brake. Ensure the pawls are in place and the “A” side is showing on

each pawl. Reinstall the retaining ring onto the shaft. Test the handle

over speed brake for proper operation using the method given in

step 4.

Step 6. See Figure 9. Inspect the level wind assuring that it moves

freely and applies pressure against the line. If the plastic wear

pad needs to be replaced, return the winch to an authorized

service center.

5.4 INSPECTION OF SALALIFT II WINCH (8102001 SERIES): The

following steps are additional inspection procedures to those in section

5.2 that must be performed on the 8102001 series winch. See Figure 2.

Step 1. Check operation of the free-wheel mode and the drum over

speed brake as follows:

A. Engage free-wheel mode by connecting the crank handle to the

free-wheel shaft and rotating the handle counterclockwise. The

winch line should pay out freely. Pull down sharply on the winch line

with the winch in the free-wheel mode to engage the brake.

B. The brake must lock and hold. If the brake fails to engage or

slippage of more than one inch occurs (a small amount of brake

slippage is normal), remove the winch from service immediately and

return to an authorized service center for repair .

Step 2. See Figure 10.

Inspect the shear

pin. The shear pin

should retain one

complete wrap of

line on the drum. If

the shear pin is

broken or missing

the unit must be

returned to an

authorized service

center for repair .

Figure 10 - Inspecting shear pin

actoolsupply.com

actoolsupply.com

Page 22

22

Step 3. See Figure 11. Inspect the impact indicator on the snap hook. If

the hook is in the indicated mode, return the winch to an

authorized service center for repair .

Step 4. See Figure 12. Inspect the level wind assuring that it moves

freely and applies pressure against the line. If the plastic wear

pad needs to be replaced return the winch to an authorized

service center.

5.5 If inspection or operation reveals a defective condition, remove the

winch from service immediately and contact an authorized service

center for repair .

NOTE:

Only DBI/SALA or parties authorized in writing may mak e repairs to

this equipment.

6.0 MAINTENANCE, SERVICING, STORAGE

6.1 P eriodically clean the exterior of the winch using water and a mild

detergent solution. Clean labels as required. At least twice a year , clean

and lubricate the wire rope. Do not use solvents to clean the wire rope

as they will remove internal lubrication. Lubricate wire rope using a cloth

(wearing gloves) and a light machine oil.

6.2 LUBRICA TION OF SALALIFT WINCH;

• For the 8101000 series Salalift winch, the gear box contains eight

ounces of high quality gear oil, SAE 80 or 90. The oil does not require

changing unless there is evidence of contaminants in the oil. See

section 5.3, step 3. If the oil is contaminated or leaking contact DBI/

SALA for repair.

Figure 12 - Inspection level wind 8102000

Figure 11 - Impact Indicator

actoolsupply.com

actoolsupply.com

Page 23

23

daoLgnikroWdetaR.sbl053

epyTepoReriW

,leetssselniatsrodezinavlag73x6,retemaidhcni4/1

leetssselniatsrodezinavlag91x7,retemaidhcni61/3

epyTepoRcitehtnyS retseylopdiarbnodiarbeporcitehtnysretemaidhcni8/3

yticapaCmurD

teef041:elbachcni4/1:seireS0001018

teef58:elbachcni4/1:seireS1002018

teef051:elbachcni61/3

thgieW

.sbl26:0001018

.sbl17:4001018

.sbl63:1002018

.sbl53:9002018

.sbl73:5002018

raeG/deepSgnirewoLrognitfiL*

oitaR

oitar1:6.6/egareva.nim/tf2.31:deepSwoLseireS0001018

oitar1:3.3/egareva.nim/tf8.62:deepShgiHseireS0001018

oitar1:6/egareva.nim/tf5.21:seireS1002018

lairetaM

,leetsdetalpcnizdna,munimulayltnanimoderP

)ylnoseireS1002018(enelyhteyloP

• For the 8102001 series Salalift winch, lubrication should be applied

periodically to the winch drum gear. Maintain a light film of grease on

the drum gear teeth at all times. Apply grease to the drum gear teeth

as required. Do not over lubricate.

6.3 Replacement parts, as well as additional maintenance and servicing

procedures, must be completed b y a factory authorized service center.

An authorization and a return number must be issued by DBI/SALA.

6.4 Store this equipment in a cool, dry , clean environment out of direct

sunlight. A v oid areas where chemical v apors e xist. Inspect after any

period of extended storage.

6.5 Clean and store body support, support structure, and associated

system components according to separate instructions provided with

that equipment.

7.0 SPECIFICATIONS

* Note: Speeds given assume 60 rpm cranking rate. Actual rates may

vary depending on cranking speed and the amount of rope on the

drum.

• The 8101000, 8101002, 8101004, and 8101006 manually operated

winches are classified by Underwriters Laboratories, Inc. as to the

350 lbs. load capacity only.

actoolsupply.com

actoolsupply.com

Page 24

24

8101000 Series ID Label

8101000 Series UL Label

8101000 Series Brake T esting Label

8.0 LABELING

8.1 The following labels must be present and fully legible:

actoolsupply.com

actoolsupply.com

Page 25

25

8101000 Series W arning Label

8101000 Series Standards Label

8101000 Series Winch Handle Label

8102001 Series W arning Label

8.1 Labeling, continued:

actoolsupply.com

actoolsupply.com

Page 26

26

8102001 Series

Raise/Lower Label

8102001 Series

Free wheel

Engagement Label

8102001 Series Shaft Identification Label

8102001 Series ID Label

8.1 Labeling, continued:

actoolsupply.com

actoolsupply.com

Page 27

27

9.0 INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER: ____________________________________________

MODEL NUMBER: ____________________________________________

DATE PURCHASED: __________________________________________

ETADNOITCEPSNISMETINOITCEPSNI

DETON

NOITCAEVITCERROCECNANETNIAM

DEMROFREP

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

actoolsupply.com

actoolsupply.com

Page 28

28

9.0 INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER: ____________________________________________

MODEL NUMBER: ____________________________________________

DATE PURCHASED: __________________________________________

ETADNOITCEPSNISMETINOITCEPSNI

DETON

NOITCAEVITCERROCECNANETNIAM

DEMROFREP

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

actoolsupply.com

actoolsupply.com

Page 29

29

9.0 INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER: ____________________________________________

MODEL NUMBER: ____________________________________________

DATE PURCHASED: __________________________________________

ETADNOITCEPSNISMETINOITCEPSNI

DETON

NOITCAEVITCERROCECNANETNIAM

DEMROFREP

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

actoolsupply.com

actoolsupply.com

Page 30

9.0 INSPECTION AND MAINTENANCE LOG

SERIAL NUMBER: ____________________________________________

MODEL NUMBER: ____________________________________________

DATE PURCHASED: __________________________________________

ETADNOITCEPSNISMETINOITCEPSNI

DETON

NOITCAEVITCERROCECNANETNIAM

DEMROFREP

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

:yBdevorppA

30

actoolsupply.com

actoolsupply.com

Page 31

Equipment offered by DBI/SALA is warranted against factory defects in

workmanship and materials for a period of two years from date of installation

or use by the owner , pro vided that this period shall not exceed two y ears

from date of shipment. Upon notice in writing, DBI/SALA will promptly

repair or replace all defective items. DBI/SALA reserves the right to elect

to have any defective item returned to its plant for inspection before making

a repair or replacement. This warranty does not co ver equipment damages

resulting from abuse, damage in transit, or other damage beyond the control

of DBI/SALA. This w arranty applies only to the original purchaser and is

the only one applicable to our products, and is in lieu of all other warranties,

expressed or implied.

WARRANTY

actoolsupply.com

actoolsupply.com

Loading...

Loading...