d&b audiotechnik A1 Mainframe F-Series, M2, M1220 User Manual

A1 Mainframe

F-Series, M2, M1220

User Manual

A1 Mainframe, F-series, M2, M1220 User Manual

Version 4.0 E, 02/2001, D2100.E.04

© d&b audiotechnik 1995-2001; all rights reserved.

The information presented in this document is, to the best of our

knowledge, correct. We will however not be held responsible for

the consequences of any errors or omissions.

Technical specifications, weights and dimensions should always be

confirmed with d&b audiotechnik AG prior to inclusion in any additional documentation.

d&b audiotechnik AG

Eugen-Adolff-Strasse 134, D-71522 Backnang

Telephone +49-7191-9669-0, Fax +49-7191-95 00 00

WARNING!

CAUTION!

IMPORTANT!

References in the manual

This refers to a potentially

dangerous situation which may

lead to personal injury.

This refers to a potentially

dangerous situation which may

lead to damage to the

equipment.

This refers to a situation which

may cause the equipment to

malfunction.

Symbols on the equipment

Please refer to the information in

the operating manual.

WARNING! Dangerous voltage!

WARNING!

CAUTION!

(4.0 E) Safety precautions

Safety precautions

Before you use our products, read the manual

carefully and observe all the safety precautions.

They will protect you and help to avoid equipment

failures. Keep this manual in a safe place so that it is

available for future reference.

If you supply d&b products, please draw the

attention of your customers to these safety

guidelines. Enclose the relevant manuals with the

systems. If you require additional manuals for this

purpose, you can order them from d&b (order form

on the last page).

Information regarding use of the A1 mainframe

The mainframe complies with the electromagnetic compatibility

requirements of EN 50082-1 - residential, business and commercial

areas.

Acoustic interference and malfunctions may occur if the unit is

operated in the immediate vicinity of high-frequency transmitters

(e.g. wireless microphones, mobile phones, etc.). Damage to the

mainframe is unlikely, but cannot be excluded.

To meet the EMC requirements, use only shielded cables with

properly connected plugs for all signal terminals (INPUT, INPUT

LINK, MONO OUT).

The following information is intended to prevent fires and possible

electric shocks:

The mainframe is a protective class 1 unit. Make sure that the earth

(ground) contact is attached when the unit is in operation. A missing

earth (ground) contact may lead to dangerous voltages in the

housing and controls.

To reduce the possibility of audible hum the mainframe signal

ground (XLR pin 1) to earth (ground) connection has a high

impedance. It will prevent the unit from static charge but any

voltage applied to signal ground will pass through all connectors.

To prevent electric shock, make sure that all devices in the signal

path are grounded properly.

Never connect an amplifier output pin to any other in- or output

connector pin or earth (ground). This might damage the mainframe

or lead to electric shock.

Lay all cables to and from the unit so that they cannot be crushed

by vehicles or other equipment and that no-one can step on them.

Keep dust, moisture, water or other liquids well away from the unit.

Never operate the unit when it is open.

Always disconnect the mains power supply when replacing a

defective fuse. Only use the type of fuse listed in the specifications.

WARNING!

WARNING!

Safety precautions (4.0E)

Only carry out work specified in this manual and always disconnect

the mains power supply.

All other work should be performed by trained service staff,

especially in the following cases:

- Mains power cable or plug has been damaged

- Objects or liquids have entered the unit

- The unit is not operating normally

- The unit was dropped or the housing is damaged

Information regarding use of loudspeakers

Never stand in the immediate vicinity of loudspeakers driven at a

high level. Professional loudspeaker systems are capable of causing

a sound pressure level detrimental to human health. Seemingly

non-critical sound levels (from approx. 95 dB SPL) can cause

hearing damage if people are exposed to it over a long period.

In order to prevent accidents when deploying loudspeakers on the

ground or when flown, please take note of the following:

When setting up the loudspeakers or loudspeaker stands, make

sure they are standing on a firm surface. If you place several

systems on top of one another, use straps to secure them against

movement.

Only use accessories which have been tested and approved by

d&b for assembly and mobile deployment. Pay attention to the

correct application and maximum loading capacity of the

accessories as specified in our Rigging Accessories Manual.

Ensure that all additional hardware, fixings and fasteners used for

installation or mobile deployment are of an appropriate size and

load safety factor. Pay attention to the manufacturers instructions

and to the relevant safety guidelines.

Regularly check the loudspeaker housings and accessories for

visible signs of wear and tear, and replace them when necessary.

Regularly check all load bearing bolts in the mounting devices.

CAUTION!

(4.0 E) Safety precautions

Only use loudspeakers in the F-Series and the M2 and M1220

monitors with the A1 mainframe fitted with the correct controller

modules. The contoller monitors cone excursion and voice coil

temperature of the drivers. When loudspeakers are operated

without the correct controller, in addition to losses in tone, there is

a risk of damage to the components. Any defects arising from

operation other than those specified in this manual will be excluded

from any warranty claims.

Loudspeakers produce a static magnetic field even if they are not

connected or are not in use. Therefore make sure when erecting

and transporting loudspeakers that they are nowhere near

equipment and objects which may be impaired or damaged by an

external magnetic field. Generally speaking, a distance of 0.5 m

(1.5 ft) from magnetic data carriers (floppy disks, audio and video

tapes, bank cards, etc.) is sufficient; a distance of more than 1 m

(3 ft) may be necessary with computer and video monitors.

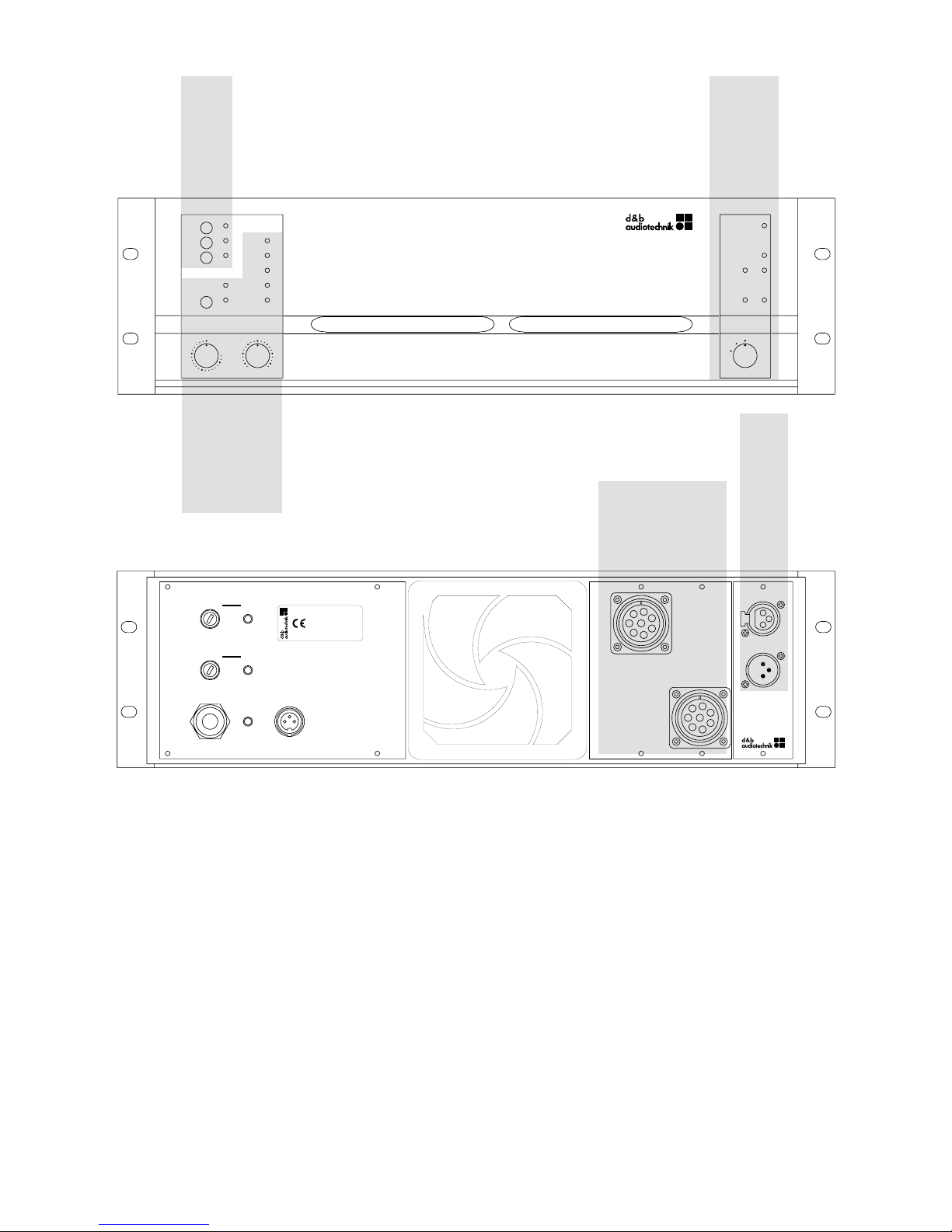

A1 mainframe front and rear views

A1

GR LO

ISP

GR HI

OV LO

OV HI

CUT

MON

LFC

MUTE

122 0- CO

0

-6

-12

-18

0

+3-3

dB HI dB

ID

OFF

ON

REM

PWR

TEMP

REM

PROT

LOCK

LO HI

INPUT

INPUT LINK

PUSH

REMOTE

CONTROL

FUSE T2A

220V-240V

∼

50-60 Hz

OVER

VOLTAGE

FUSE T8A FAIL

FAIL

PIN ASSIGNMENT

OUTPUT 2

OUTPUT 1

A LOW OU T +

B LOW OUT C SPEAKER ID

D SPEAKER ID

E SENSE DRIVE +

F SENSE DRIVE G HIGH OUT +

H HIGH OUT -

122 0

Configuration switches

These switches depend on the

type of loudspeaker. They are

described individually for each system

in the section "Loudspeakers".

Displays and controls of

controller modules

These elements are common to all

modules. They are described in the

section "Controller modules".

Displays and controls

of mainframe

These elements are described in

the section "A1 mainframe".

Output connectors

These elements are described

individually for each system

in the section "Loudspeakers".

Input connectors

These elements are described in

the section "A1 mainframe".

(4.0 E) Contents

Contents

Safety precautions

1. Introduction...................................................1-1

1.1. System concept......................................................................... 1-1

1.2. d&b active systems design...................................................... 1-2

1.3. Block diagram .......................................................................... 1-2

2. A1 mainframe ............................................... 2-1

2.1. Features..................................................................................... 2-1

2.1.1. A1 power amplifiers ................................................................2-1

2.1.2. SenseDrive ................................................................................2-1

2.1.3. SpeakerID ................................................................................. 2-2

2.1.4. Fan ............................................................................................. 2-2

2.1.5. Mains overvoltage protection................................................ 2-3

2.1.6. Mains inrush current limiter....................................................2-3

2.1.7. Fuses .......................................................................................... 2-3

2.1.8. Remote control & monitoring ................................................2-3

2.2. A1 controls & indicators..........................................................2-5

2.3. Connections .............................................................................. 2-6

2.4. Mainframe installation ............................................................ 2-7

2.5. Power consumption and power loss...................................... 2-8

2.6. Technical specifications ...........................................................2-9

3. Controller modules........................................3-1

3.1. Features..................................................................................... 3-1

3.2. Controls & indicators............................................................... 3-2

3.3. Module exchange and replacement......................................3-3

4. Loudspeaker systems .................................... 4-1

4.1. Connections .............................................................................. 4-2

4.2. Data sheets for the loudspeakers ..........................................4-3

F1220

F1222

M1220

M2

F2

B1-SUB

B2-SUB

5. System operation ..........................................5-1

5.1. Setting up/stacking the loudspeakers ...................................5-1

5.1.1. Vertical coverage ....................................................................5-1

5.1.2. Arraying mid/high cabinets ................................................... 5-1

5.1.3. Stacking subwoofers................................................................5-2

5.2. Wiring .......................................................................................5-3

5.3. Level setting for mixed systems..............................................5-4

6. Troubleshooting ............................................ 6-1

7. Publications list.............................................. 7-1

8. EU declaration of conformity (CE symbol) .....8-1

(4.0 E) 1-1

1. Introduction

This user manual describes the facilities, functions and operation of

d&b active controller loudspeaker systems and covers the operation of the A1 mainframe, controller modules and loudspeakers used

in these systems.

d&b publishes additional application and technical information notes (TI). A d&b publications list and order form is appended to this

manual and we will gladly send you any of the listed publications

on request.

This user manual should provide the information you need in order

to get the best performance out of the system. If you have any

comments on the information presented, or feel that something is

inadequately explained or not covered, then please tell us using

the comments section of the publication order form.

1.1. System concept

All d&b loudspeaker systems are designed to meet the following

criteria :

- Consistent neutral sound over the full working dynamic range

- Ease of operation

- Simple set up and wiring

- Safe and reliable operation

- Compact design

In order to satisfy these demands d&b developed a complete

system concept incorporating the loudspeaker, the loudspeaker

specific control electronics (the controller) and the power amplifier.

Fundamental to the performance of the loudspeaker is the care

taken in the development of individual components resulting in well

controlled dispersion, high efficiency and excellent dynamic

response.

The controller creates the optimum mix of output level capability,

operating reliability and longevity, and pure sound quality.

Protective circuits continuously model the loudspeaker load through

simulation of cone displacement and voice coil temperature

ensuring signal level is only reduced when necessary to prevent

driver damage. No signal compression takes place within the

systems normal operating range and there is no dynamic

manipulation of system frequency response enabling most

applications and acoustic environments to require no additional

signal processing.

The power amplifier and control for each loudspeaker are housed

within the A1 and P1200A mainframes or the E-PAC power

amplifier controller. All systems are compatible, easily combined

and complementary, and can be accessed using the d&b remote

control system to allow overview and control over the most

complex applications.

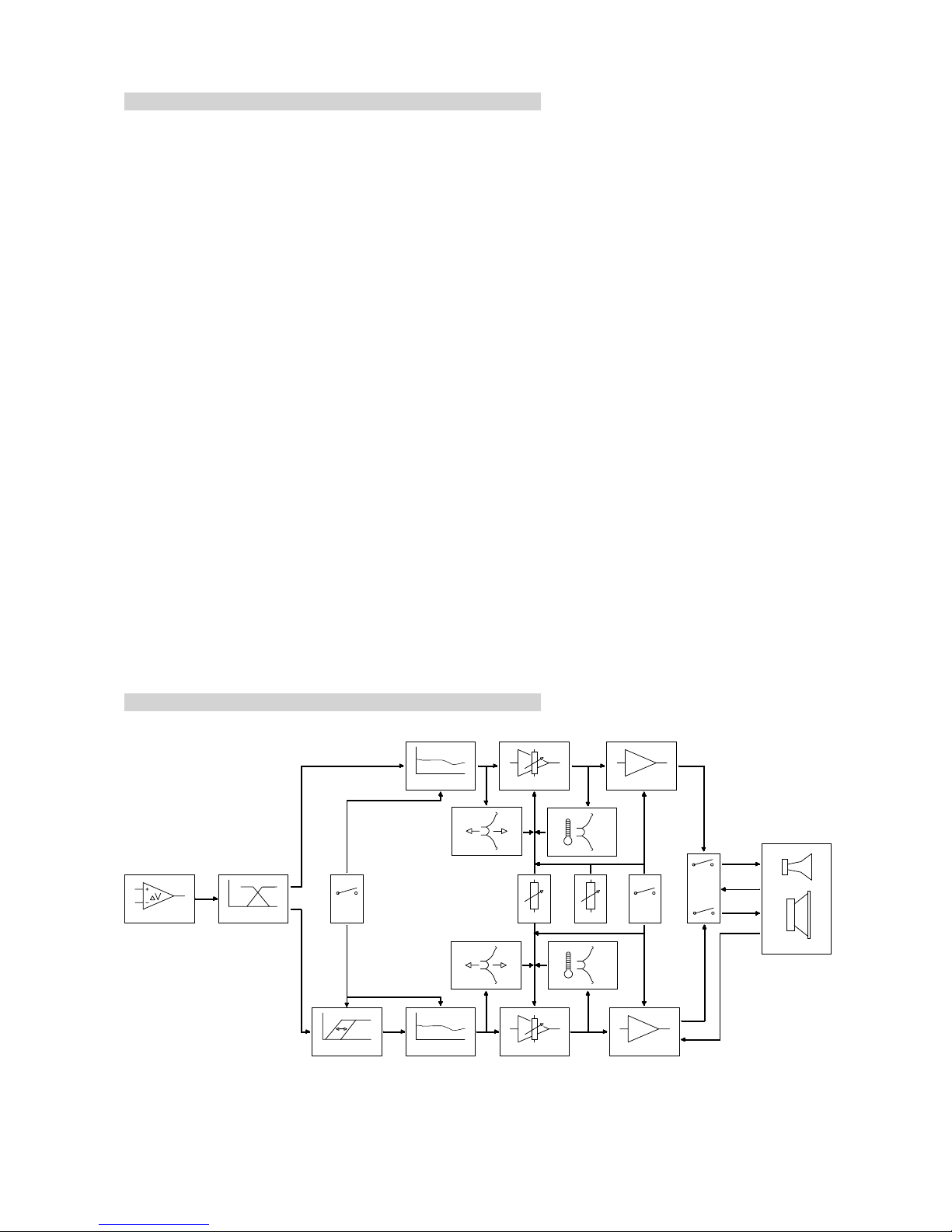

Block diagram - full range active system

Highpass

switchable

2-way box

with Speaker ID

and SenseDrive

Configuration

Level

Mute

Displacement

Temperature

Input Stage

HF-Protect

EQ VCA

Power Amplifier

Cross Over

EQ VCA

Power Amplifier

HF Level

ID

Sense

Drive

Displacement

Temperature

1-2 A1 User Manual

1.2. d&b active systems design

Their are two types of d&b active loudspeaker system - active subwoofers and full range, 2 way, active loudspeakers. Each type of

active system is driven by an A1 mainframe fitted with a single,

loudspeaker specific controller module.

The different loudspeaker controller modules house the signal processing electronics, connectors, controls & indicators appropriate to

the different types of loudspeaker.

As well as the controller module, the A1 mainframe houses two separate power amplifiers - a 1200 W / 4 Ohm low frequency amplifier and a 350 W / 4 Ohm high frequency amplifier. In the case

of the full range 1220 System, a single A1 fitted with a 1220 controller module can drive two 1220 cabinets. With the higher output

full-range F2 System, each F2 cabinet needs to be driven by its

own A1/F2 controller module combination.

The full range systems can of course be supplemented with B1 or

B2 subwoofers. Each active subwoofer cabinet is driven by its own

A1/controller module combination - the mainframe HF amplifier

being unused.

The modular nature of mainframe based systems allows later reconfiguration. Simply changing the type of controller module fitted

to a mainframe alters the mode of mainframe operation without

the need for any internal changes to the mainframe itself.

The A1 mainframe incorporates an interface for remote control

and monitoring of all controller module and mainframe functions.

Active full range systems may also be used with Series 02 subwoofers - e.g. the F2 System and C4-SUBs. Series 02 systems use the

d&b 1200A mainframe.

1.3. Block diagram

(4.0 E) 2-1

2. A1 mainframe

The A1 mainframe is housed in a 3 rack unit high, 353 mm (13.9")

deep, 19" rack mount enclosure. The A1 is designed to accept a single d&b active system controller module and includes power supplies,

separate LF and HF power amplifiers, protection circuits with their indicators and a remote control interface.

All mainframe facilities and functions and those of the controller

modules can be remotely interrogated and altered via the d&b

Remote Interface Bridge (RIB).

2.1. Features

2.1.1. A1 power amplifiers

The two power amplifiers fitted to the A1 can, respectively, deliver

700 W +200 W continuous sine wave power into an 8 ohm load - increasing to 1200 W + 350 W continuous sine wave power into a

4 ohms load. These output ratings are valid for at least 30 minutes of

operation at an ambient temperature not exceeding 24° C.

Continuous sine wave power rating represents an extreme of operation not normally encountered when reproducing typical speech and

music signals - both complex waveforms with average power levels

usually well below their peak power level. Even when driving a d&b

active system with highly compressed music (2:1 crest factor), the A1

will operate indefinitely - provided of course that the amplifier cooling

system has sufficient cool airflow.

2.1.2. SenseDrive

The accuracy of a loudspeakers signal reproduction, both level and

transient response, is influenced by dynamic damping factor - the ratio of the load to source impedance.

Especially at low frequencies, the impedance of a loudspeaker will vary markedly with frequency. This impedance variation will significantly

affect the system response. Whilst amplifier source impedance remains

constant the impedance of the cables and connectors will largely depend upon the length and type of cable used - longer cables produce

greater signal losses.

d&b SenseDrive compensates for the electrical properties of the loudspeaker cable. Two sense wires connect the signal from the LF driver

back to the amplifier where it is compared and corrected to compensate for the cable losses. Signal reproduction is enhanced by delivering the correct signal to the loudspeaker terminals irrespective of the

cable losses.

The SenseDrive technique is not used for driving the loudspeaker HF

driver since external interference from souces such as adjacent lighting wiring could interfere with the operation of the Sense-Drive circuits. The relatively high impedance of HF drivers also tends to swamp

any increase in load impedance due to longer speaker cables.

The A1 SenseDrive circuit is gain limited and whilst this imposes a ceiling on damping factor improvement, it guarantees stable operation

with no cable length restriction using speaker multicores such as d&b

MC8.

IMPORTANT!

2-2 A1 User Manual

2.1.3. SpeakerID

A built-in SpeakerID circuit ensures that signal can only be connected to a loudspeaker if it matches the controller module fitted to

the mainframe. When the SpeakerID circuit senses that the correct

loudspeaker is connected to the mainframe output then the internal

power amplifier outputs are fed to the mainframe speaker output

connector(s) and the green ID LED on the controller module front

panel illuminates.

With no cabinet connected, the ID LED remains unlit. If the wrong

type of cabinet is connected the ID LED will flash and the power

amplifier outputs are internally isolated from the mainframe speaker output connector(s).

SpeakerID not only prevents loudspeaker damage it also prevents

hazardous voltages appearing on the exposed pins of the speaker

output connector(s).

Where a mainframe, such as the 1220 System, has two speaker

output connectors these are independently monitored and separately switched. However, to alert the user, connecting just one

wrong cabinet will mute both output connectors.

2.1.4. Fan

A fan draws in air through a filter behind the rear panel air intake.

The fan speed is governed by the temperature of the output

module heat sink and the momentary output level. This

arrangement ensures a minimum of fan noise since the fan

operates at minimum speed when power demand is low.

The level controlled fan allows greater cooling during louder

passages, thereby allowing fan speed to be reduced still further

during quiet passages preventing background noise interference.

We advise frequent cleaning of the fan filter to ensure good

airflow through the unit. If the filter is visibly dirty, then it should be

cleaned or replaced. Never operate the A1 without a filter. Dust

deposits, especially combined with damp conditions, could cause

the mainframe to malfunction.

When setting up the mainframe, do not block or cover the rear

panel air intake or the vents on the front panel of the mainframe.

See also section 2.4. (Mainframe installation).

A1 mains input and fuses

REMOTE

CONTROL

FUSE T2A

220V-240V

∼

50-60 Hz

OVER

VOLTAGE

FUSE T8A FAIL

FAIL

(4.0 E) 2-3

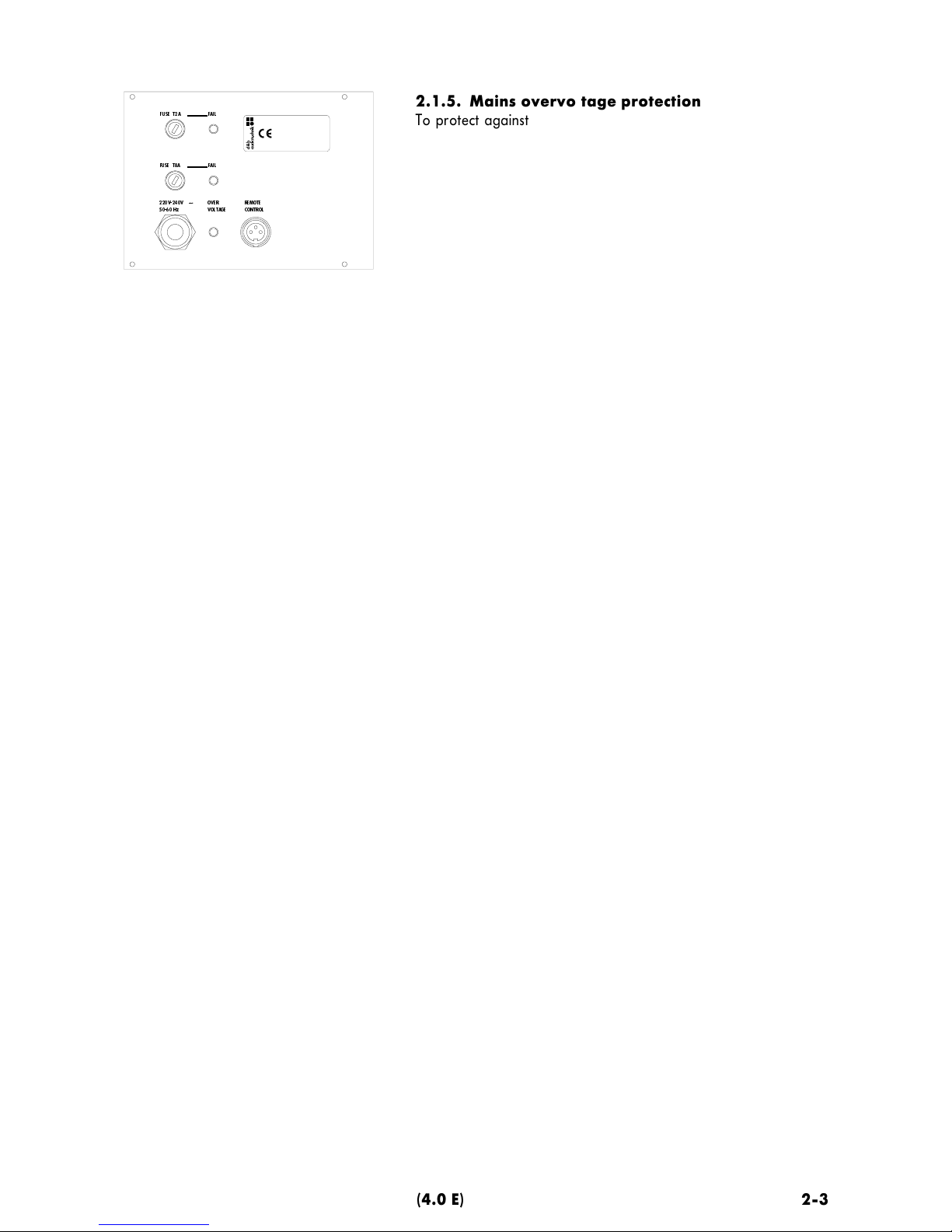

2.1.5. Mains overvoltage protection

To protect against mains overvoltage damage the A1 is fitted with

an efficient, self-resetting mains overvoltage protection circuit.

As soon as the mains supply voltage exceeds 265 V (115 V for the

100 V supply version) the overvoltage protection circuit responds

and isolates the mainframe power supply from the mains supply

leaving only a supervisory circuit active to monitor the mains supply voltage. The green POWER LED on the mainframe front panel

goes out and the OVER VOLTAGE LED on the mainframe rear panel comes on.

Only if the mains voltage drops below 255 V (111 V) is the mainframe automatically reconnected to the mains supply and normal

operation resumed. This 10 V difference in the protection circuit

switching levels (switching hysteresis) prevents the mainframe from

cycling on and off with a fluctuating mains supply voltage.

The protection circuit will operate with any mains overvoltage up

to 400 V; allowing the A1 to survive connection across two phases

of a three phase supply.

2.1.6. Mains inrush current limiter

The mains inrush current limiter ensures a slow "start-up" for the

mainframe and allows several mainframes connected to the same

mains supply circuit to be switched on together without temporarily

overloading the supply circuit and causing a breaker to trip. The

inrush current at switch on is limited to 5 A (230 V version).

Note that repeatedly and rapidly switching a mainframe on and

off will overheat and stress the inrush current limiter circuit - a rear

panel fuse protects the circuit from damage.

2.1.7. Fuses

Two 20 mm delay fuses are fitted on the mainframe rear panel an 8 A fuse for the mainframe power supply and a 2 A fuse protecting the mains inrush current limiter. If either fuse should blow

then the red LED (FAIL) indicator next to the respective fuseholder

will light.

2.1.8. Remote control & monitoring

The A1 is fitted with a twin wire remote interface for various levels

of remote control and system supervision of the mainframe and its

controller module. The remote interface connection is opto-isolated

and floating.

Basic Remote

The Basic Remote is the simplest way to implement a remote control

system. A mainframe can be remotely powered on by simply applying an 18 - 28 VDC control voltage to the terminals of its remote interface connector. Connecting a simple detector circuit to

the remote interface of a mainframe also allows remote warning of

a mainframe fault. Details of basic circuits for remote power control and fault display are published in d&b technical information

bulletin TI 212.

2-4 A1 User Manual

Remote operation using the d&b Remote Interface

Bridge (RIB)

The d&b RIB is housed in a 1 RU high, 19 rack mount enclosure.

Combinations of 1 to 12 mainframes (A1 or P1200A) up to 500 m

away can be directly connected to a RIB I/O port by a twin wire

bi-directional serial link.

From the front panel of the RIB each mainframe can then be remotely powered on and off and its power and error status monitored.

A group of mainframes can be switched directly by the RIB front

panel MASTER ON/OFF switch or remotely via a connection to an

opto-isolated input port on the rear panel of the RIB. Remote indication of the error status of a mainframe group can also be relayed by the RIB.

Computer/MIDI control

The RIB can be controlled by a computer (RS232, RS422 or MIDI interface) running suitable control software or by a MIDI control device. Under computer control, the following remote control and display options become available:

Remote control

−

Power On/Off switching of mainframe

−

Level control from +0 to -63.5 dB in 0.5 dB steps.

−

MUTE switching

−

Configuration switching e.g. CUT, MON, etc.

Remote status information

−

Configuration switch status

−

Mute switch status

−

Level control setting

−

Front panel indicator status (ISP, GR, OVL etc.)

−

SPEAKER ID status

−

Protect status (DC protect, short circuit protect, thermal protect)

−

Heatsink temperature in °C

−

Available headroom (pre-limiter)

−

Gain reduction (due to limiter operation)

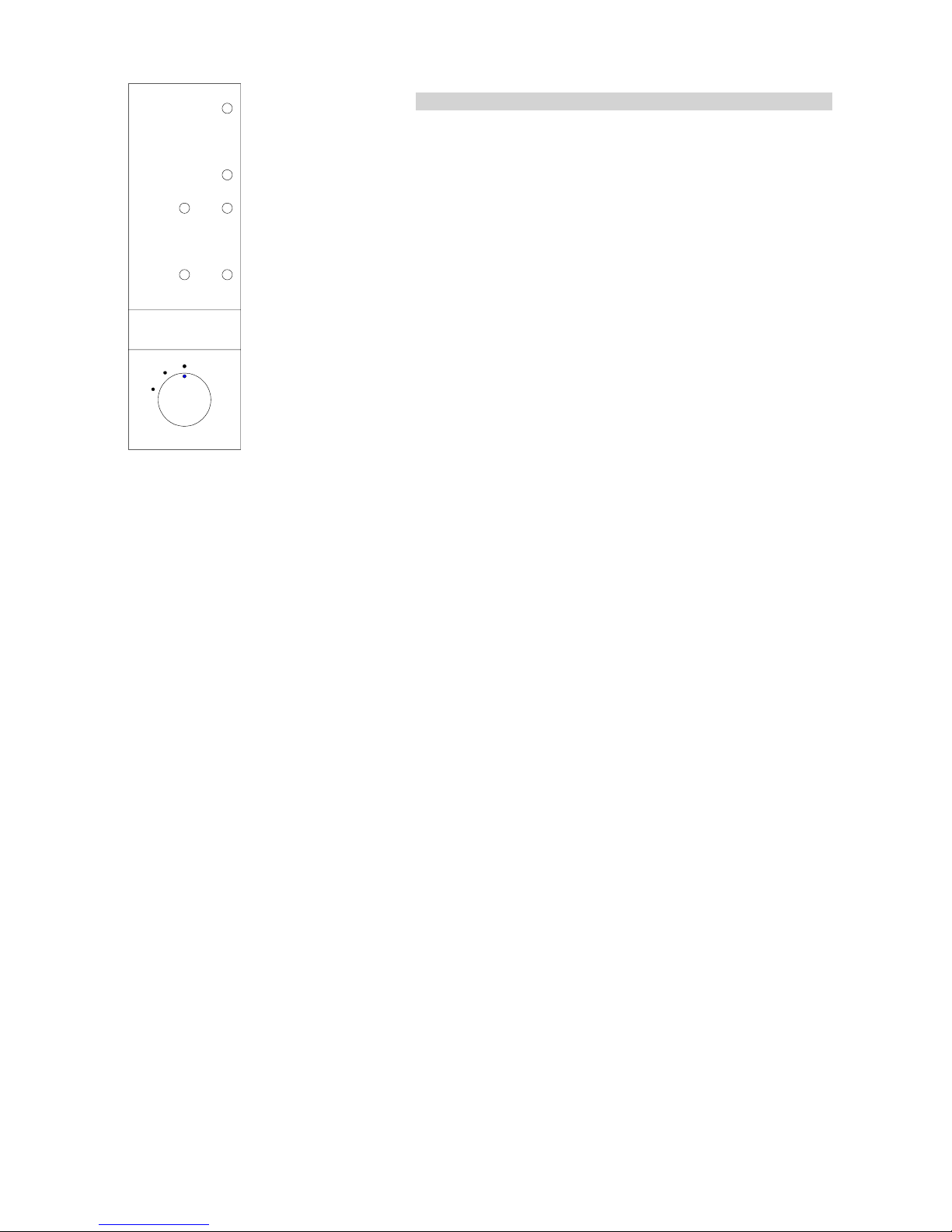

A1 front panel

OFF

ON

REM

PWR

TEMP

REM

PROT

LOCK

LO HI

(4.0 E) 2-5

2.2. A1 controls & indicators

PWR - Power (green)

−

On

. when the mainframe is connected to the mains supply, swit-

ched on and ready for use.

−

Off

. The mainframe is not connected to or powered from the

mains supply. The mains overvoltage protection has triggered

(see above) or the mainframe is not switched on.

−

Flashes

during the initial power-up cycle for about 2 seconds

and also when the mains overvoltage protection circuit is triggered by an external fault (see also PROT below).

TEMP - Temperature (red)

−

Flashes

. The mainframe has switched off because the maximum

permissable operating temperature has been exceeded. This occurs if the power amplifier heatsink temperature exceeds 83° C or

if the mains power transformer temperature exceeds 120° C.

PROT - Protect (red)

As the two mainframe power amplifier channels operate independently there are separate PROT indicators for LO and HI channel.

−

On

. An internal fault has been detected on the mainframe channel concerned and that channel has been disconnected (e.g. DC

voltage fault in the output stage).

−

On and the PWR LED also flashes

. An external fault has

switched off the affected power amplifier channel. Typical faults

producing this indication are shorted speaker cables or a load

impedance which is too low for the amplifier to drive. Once the

cause of the fault has been identified and removed, either muting

and un-muting the controller module, or powering the mainframe

off and on again, will reset the mainframe fault protection circuits

and allow normal operation to resume.

REM - Remote (green)

−

On

. The mainframe is connected to the d&b RIB and ready for

communication.

LOCK (yellow)

−

On

. The mainframe has been placed in a locked condition by a

remote control system. This means that all the mainframe and

controller module controls with the exception of the mains switch

are inactive (locked out).

−

Off

. The A1 mainframe is set to local operation, i.e. may be operated using the front panel controls.

OFF/REM/ON (power switch)

−

OFF

. With the exception of the mains overvoltage protection cir-

cuit, the mainframe is isolated from the mains supply.

−

REM

. The mainframe is set to remote operation. If no remote

control system is connected this setting is equivalent to the power

switch OFF position.

−

ON

. The mainframe is switched on. In this switch position, the remote control system can monitor and display the operational status of the mainframe but cannot change any settings.

F2-CO loudspeaker output

PIN ASSIGNMENT

OUTPUT

A LOW OUT +

B LOW OUT C SPEAKER ID

D SPEAKER ID

E SENSE DRIVE +

F SENSE DRIVE G HIGH OUT +

H HIGH OUT -

F2

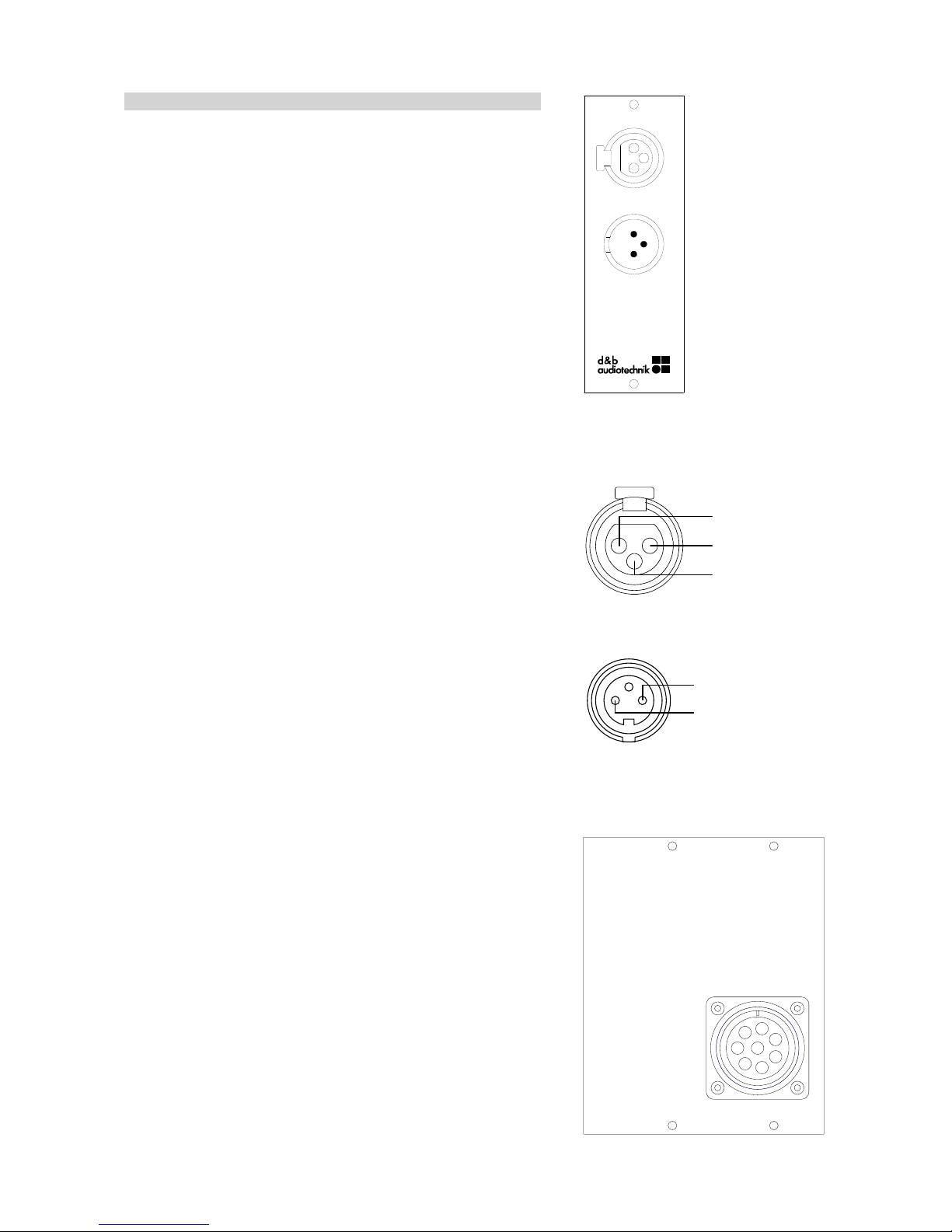

A1 input signal connectors

INPUT

INPUT LINK

Pin assignment for remote

control

Pin 3 (+)

Pin 1 (–)

Pin 1 (GND)

Pin 2 (pos. signal)

Pin 3 (neg. signal)

Pin assignments on P1200A signal inputs

2-6 A1 User Manual

2.3. Connections

INPUT and INPUT LINK

The mainframe has a 3 pin XLR female input connector. Beneath

and wired in parallel is a 3 pin male XLR connector to provide an

input link - sometimes called a pass-through connector - used to

feed the input of the next device in the system signal chain.

Transformer balanced input (option)

To prevent system ground loops, the P1200A can be supplied with

transformer balanced inputs. The transformers used are studio

quality torroidal transformers able to handle signal levels up to

+28 dBu without degrading the systems low frequency response.

The input balancing transformer gives electrical isolation between

the source output (e.g. mixing console) and controller inputs and

therefore prevents ground loops. A 22 kohms coupling resistor

prevents electrostatic loading of the mainframe.

REMOTE CONTROL

The A1 is fitted with a two-wire serial remote control interface. The

3 pin female DIN remote control connector is located on the left of

the A1 rear panel. The connector is opto-coupled.

The remote functions are detailed in section 2.6. (Remote control &

monitoring).

OUTPUT (loudspeaker outputs)

The speaker output(s) are also located on the mainframe rear panel. Both power amplifier outputs (LF & HF), SENSE DRIVE and

SPEAKER ID connections all terminate on a single 8-pin CA-COM

connector. The CA-COM is a particularly robust and reliable bayonet fit (locking) connector.

Different controller modules have different output connector pin

assignments which are printed on the panel next to the connector(s). Each controller module speaker output panel is described in

the later sections of this manual along with the different active

loudspeakers and their controller modules.

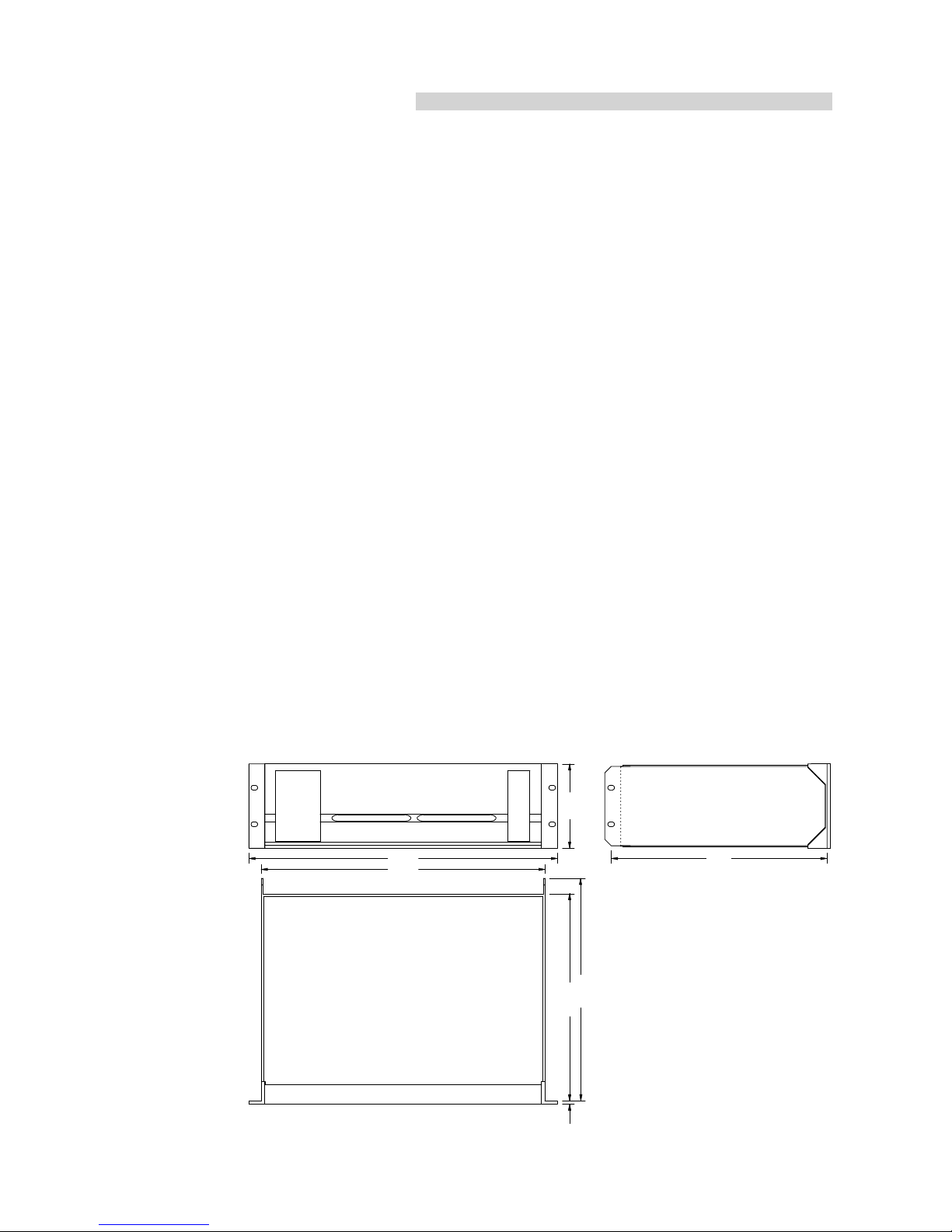

483

443

348

132

338

5

323

A1 enclosure dimensions

(4.0 E) 2-7

2.4. Mainframe installation

P1200A mainframe enclosures are designed to fit a standard 19"

equipment rack or cabinet.

The front panel vent slot serves as a useful handle for lifting and

moving mainframes in and out of racks. The front panel switches

are flush-fitted and the level control(s) and mainframe power

switch are recessed to protect them from accidental damage and

unintentional adjustment.

When specifying a rack, be sure to allow extra depth (10 cm is

usually sufficient) to accommodate the cables and connectors at the

rear of the mainframe(s).

When mounting mainframes into a 19" rack cabinet, provide

additional support using shelves fixed to the inner sides of the

cabinet or the mounting holes provided on the mainframe rearmounted rack ears - do not just rely on fixing and supporting

mainframes by their front panels. This advice is particularly

important if mainframes are being racked-up for touring use.

Since the P1200A power amplifiers can generate a lot of heat,

please ensure, whatever the mounting or racking arrangement,

that adequate cool airflow is provided to avoid a build-up of hot

air inside the rack leading to overheating. The P1200A air intake is

on the rear panel and the air outlets are set into the front panel.

To maintain good airflow through mainframes we recommend

frequent cleaning of the fan filters. If mainframes are installed in

cabinets so that direct access to the rear panel filters is not

possible, we recommend using additional fan modules with frontmounted filters which can be easily replaced without opening the

sealed cabinets. We will gladly advise on the choice of suitable fan

modules.

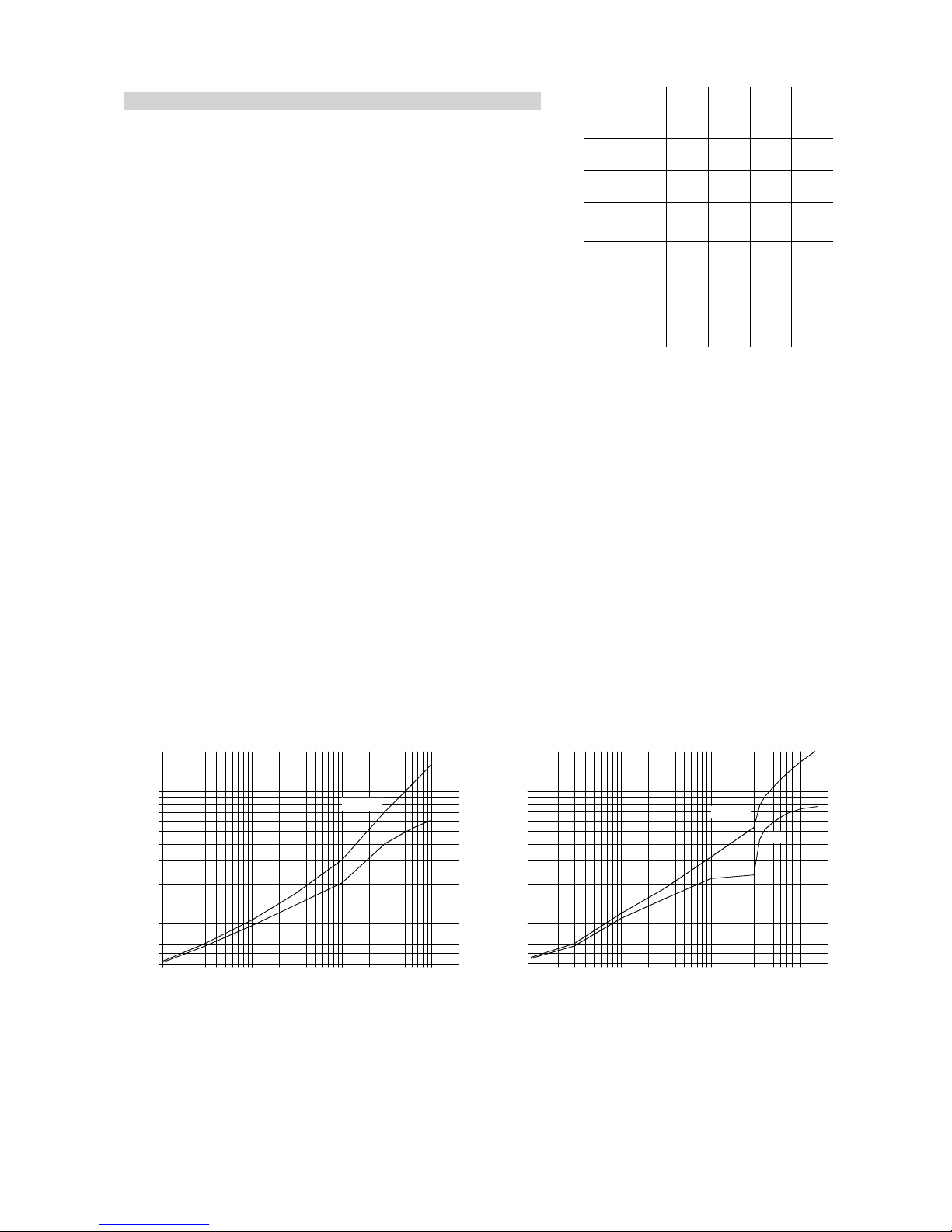

Signal

waveform

CF

P

out

[W]

P

in

[W]

P

loss

[W]

Square wave

1

2150

2900

750

Sine wave

1,4

1400

2130

730

Pink noise, compressed music

3,5

200

500

300

Music with medium dynamic

range

5

100

300

200

Speech, music

with wide dynamic range

840200

160

CF : Crest factor

P

out

: Maximum average outputpo-

wer (sum of both channels)

P

in

: Power input

P

loss

: Power loss

A1 Power balance

Average power consumption and loss of A1 as a factor of

output power with pink noise signal

(load impedance 4 / 8 ohms, both channels driven, sum of

output power of both channels)

Average power consumption and loss of A1 as a factor of

output power with sine wave signal

(load impedance 4 / 8 ohms, both channels driven, sum of

output power of both channels)

2000

1000

100

50

1 10 100 1000 2000

power [W]

average output power [W]

loss

consumption

2000

1000

100

50

1 10 100 1000 2000

power [W]

average output power [W]

loss

consumption

2-8 A1 User Manual

2.5. Power consumption and power loss

The power required from the mains supply and the waste heat

produced by the amplifiers power loss are variable figures

depending on the load impedance and the signal levels and

characteristics (e.g. speech, music).

In practice, the theoretical peak power consumption of a system

will only be sustained for a short period of time. Basing mains

current and air conditioning plant requirements on the peak power

consumption of the sound system would result in a generously

over-specified installation. The key factor in power consumption

calculations is the crest factor of the music signal or speech signal the ratio of peak to sustainable RMS voltage of the signal.

The table on the right gives power figures for various types of

signal waveforms. The figures were measured on a A1 mainframe

driving a 4 and 8 ohms load (LO and HI channel) to the clipping

point of both mainframe power amplifiers.

Power input and thermal power loss as a function of average

output power for sine wave and pink noise signal waveforms can

also be derived from the two graphs shown below (Note that pink

noise signal reaches the clipping point of the amplifiers at approx.

200 W average output power).

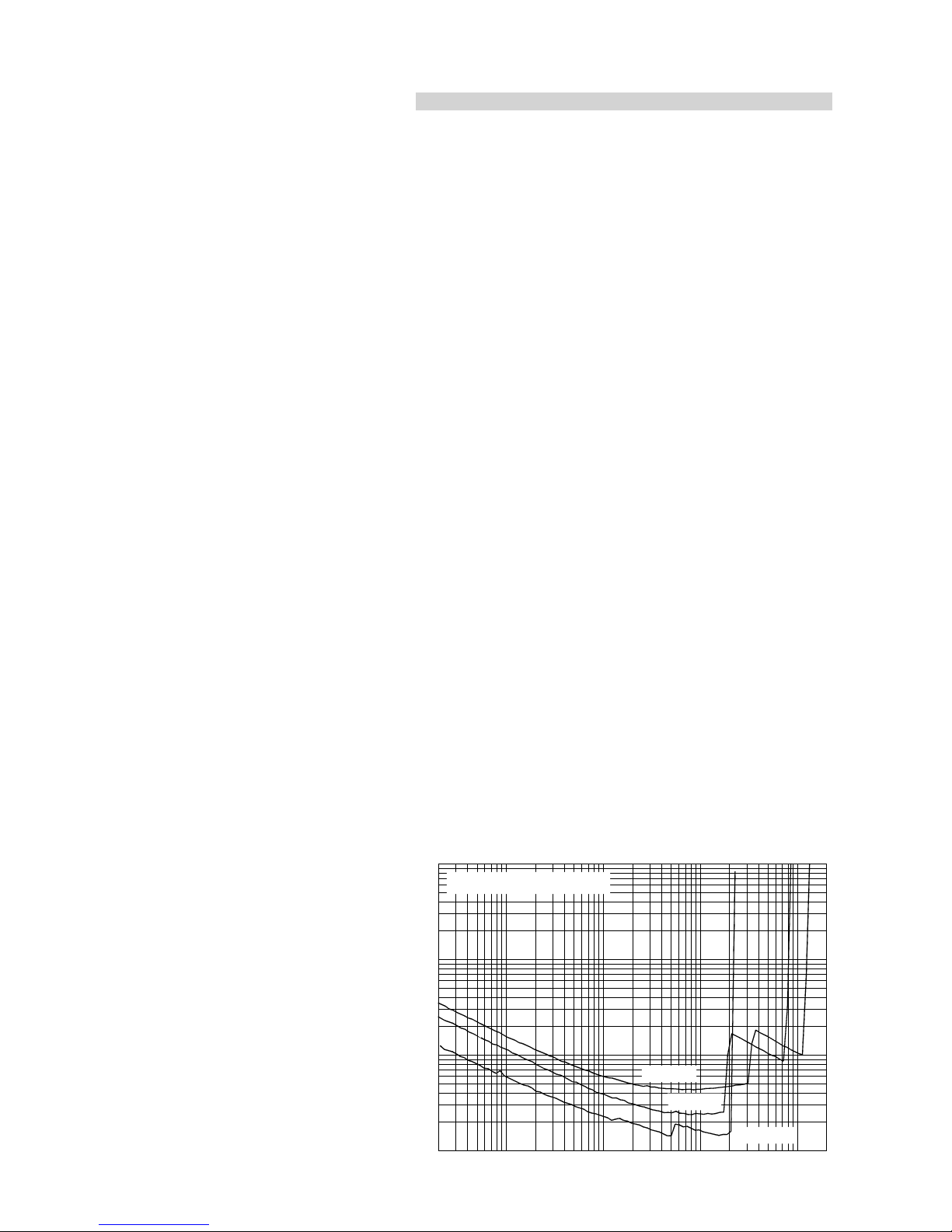

1

0.001

0.010

0.1

0.2 1

10 100

1k

2k

Low 4 ohms

Low 8 ohms

THD + Noise (%) vs Output Level (W)

High 8 ohms

(4.0 E) 2-9

2.6. Technical specifications

Nominal output power

............................................... 700 / 200 watts - 8 ohms

(THD+N < 0.1%, both channels driven)..........................1200 / 350 watts - 4 ohms

Frequency response

(1 dB)............................................................. 20 Hz - 50 Hz

measured at rated output power, both channels driven

Harmonic distortion

(THD+N)................................................ < 0.05 % / 0.03 %

from 0.1 W to rated output power, 20 Hz - 20 kHz

Intermodulation distortion

(SMPTE).................................. < 0.06 % / 0.02 %

from 0.1 W to rated output power

Residual noise

............................................................................... > 112 dB / 114 dB

below rated output power, 22 Hz - 22 kHz, unweighted, RMS

Damping factor

at loudspeaker output ................................................ > 50 / 100

20 Hz - 20 kHz, 4 ohms load

Crosstalk

.............................................................................................................< 55 dBr

Protection circuits

Mains inrush current limiter ............................................................................................ 5 A

Switch-on delay .............................................................................................................. < 2 s

Overvoltage, DC output, overtemperature and short circuits

INPUT

.........................................................................................................XLR 3-pin female

Input impedance......................................................................................................44 kohms

electronically or transformer balanced (optional)

INPUT LINK

................................................................................................XLR 3-pin male

parallel to input

C4-OUT

(B2-CO only)..............................................................................XLR 3-pin. male

balanced, output load impedance .................................................................≥ 600 ohms

OUTPUT

...........................................................................................8-pin CA-COM, male

Pin assignments depend on type of loudspeaker

General

Height x width x depth ...................... 3 rack unit x 483 mm (19") x 353 mm (13.9")

Weight with module fitted........................................................................ 22 kg (48.5 lbs)

Mains voltage (min/nominal/max) ........................ 195 /230 /265 V / 50 - 60 Hz

.................. (additionally with 115/230 V version: 98 / 115 / 132 V / 50 - 60 Hz)

............................................................(100 V version: 85 / 100 / 115 V / 50 - 60 Hz)

Fuses ............................................................1 x 2 A Time Lag (T), 1 x 8 A Time Lag (T)

.......................................................................(115/230 V version: 2 x 8 A Time Lag (T))

....................................(100 V version: 1 x 5 A Time Lag (T), 1 x 16 A Time Lag (T))

Loading...

Loading...