ArraySight

A

Manual 1.7 en

General information

ArraySight Manual

Version: 1.7 en, 04/2019, D2735.EN .01

Copyright © 2019 by d&b audiotechnik GmbH; all rights

reserved.

Keep this document with the product or in a safe place

so that it is available for future reference.

We recommend you to regularly check the d&b website for the

latest version of this document.

When reselling this product, hand over this document to the new

owner.

If you supply d&b products, please draw the attention of your

customers to this document. Enclose the relevant documents with

the systems. If you require additional documents for this purpose,

you can order them from d&b.

d&b audiotechnik GmbH

Eugen-Adolff-Straße 134, D-71522 Backnang, Germany

T +49-7191-9669-0, F +49-7191-95 00 00

Safety precautions when using laser equipment

WARNING!

Potential risk of damage to the eyes.

Laser class 3R, 532 nm, <5 mW:

Do not suppress eye-closure reflex.

The d&b ArraySight sender unit is shipped with the following label

affixed to the top surface. Do not remove this label under any

circumstances.

The high brightness laser of the sender unit requires additional

safety considerations.

Please give careful attention to the following safety warnings

before using the d&b ArraySight inclinometer system.

NEVER look directly into the laser, even when it is switched off, as

someone may activate it without warning you.

WARN others in the venue that you are going to use a laser and

move them away from the target area before activating a laser.

ENSURE that others do not enter the target area of the laser while

it is in use.

ENSURE that the meter unit is to hand at all times so that the

beam can be switched off immediately if necessary.

ALWAYS use the laser for the minimum amount of time possible.

You can carry out most of the alignment procedure with the laser

turned off.

Disconnect the cable from the meter unit once the measurements

had been made.

ALWAYS ensure that the meter unit is disconnected when the

public have access to the venue.

NEVER leave the laser turned on while unattended.

NEVER use the laser in any other application than it is intended

for.

Operational safety

The d&b ArraySight inclinometer system is an integrated part of the

d&b rigging system and should be regarded with the same respect

as any other rigging component.

The sender unit must be safely mounted to the corresponding

Flying frame when used above 2 m (6.6 ft) from ground level using

the enclosed fixing screws.

DO NOT fix the sender unit with tape or velcro.

When making adjustments to the array with motor hoists, watch the

hoist - not the meter unit! Check the measurement only when the

hoist has finished moving.

When using the meter unit, be aware of other rigging operations

taking place around you. Always follow the appropriate safety

procedures (including wearing the appropriate personal protective

equipment).

The sender unit is weather/water resistant (IP54), enabling it to

withstand dust ingress and rain, although the limited ingress of

water may be possible. It is therefore advisable to take account of

prevailing weather and environmental conditions and take

precautions to protect the sender unit.

As with any rigging components, regular safety inspections are

obligatory.

d&b ArraySight Manual 1.7 en 3

Contents

1 d&b ArraySight..................................................................... 5

1.1 Scope of supply.......................................................................... 5

1.2 Intended use................................................................................ 5

2 Technical specifications...................................................... 7

3 Startup...................................................................................... 8

3.1 Installing the batteries................................................................. 8

3.2 Connecting the units................................................................... 8

3.3 Switching on/switching off......................................................... 9

3.4 User interface of the meter unit.................................................. 9

3.5 The menu structure.................................................................... 10

3.5.1 Home screen......................................................................... 10

3.5.2 Main menu «Menu»............................................................. 10

3.5.3 Meter settings........................................................................ 10

3.5.4 Sender settings...................................................................... 11

3.5.4.1 Editing IP and Remote ID settings..................................... 12

4 Resetting the angle (zeroing) and laser

alignment.............................................................................. 13

4.1 Resetting the angle (zeroing)................................................... 13

4.2 Aligning the laser..................................................................... 14

5 Using the system................................................................ 16

5.1 Measuring the angle................................................................ 16

5.2 Measurement limits.................................................................. 16

5.3 Adjusting angles using relative values.................................... 16

5.4 Using the laser.......................................................................... 17

5.5 Application example................................................................ 17

6 OCA integration (Ethernet)............................................ 18

7 Maintenance and care.................................................... 19

7.1 Cleaning................................................................................... 19

7.2 etherCON connector socket protection.................................. 19

7.3 Calibrating the accelerometer................................................. 20

8 Manufacturer's declarations......................................... 22

8.1 EU declaration of conformity (CE symbol)............................. 22

8.2 WEEE Declaration (Disposal).................................................. 22

8.3 Licenses and Credits ................................................................ 23

9 Appendix.............................................................................. 25

9.1 Z5710.xxx d&b ArraySight sets............................................. 25

9.1.1 Z5710.001 Mounting instructions...................................... 25

9.1.2 Z5710.002 Mounting instructions...................................... 26

d&b ArraySight Manual 1.7 en4

1 d&b ArraySight

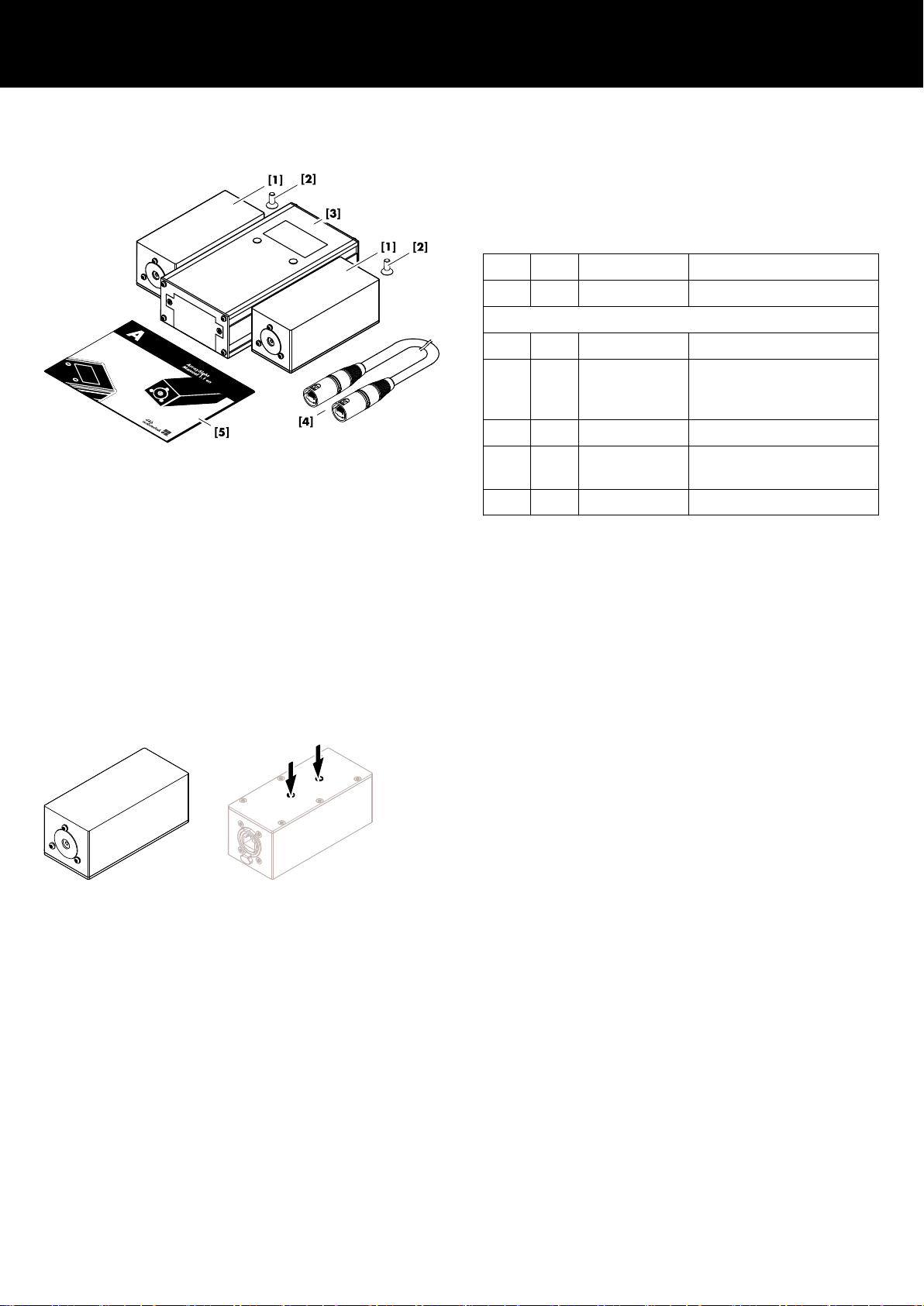

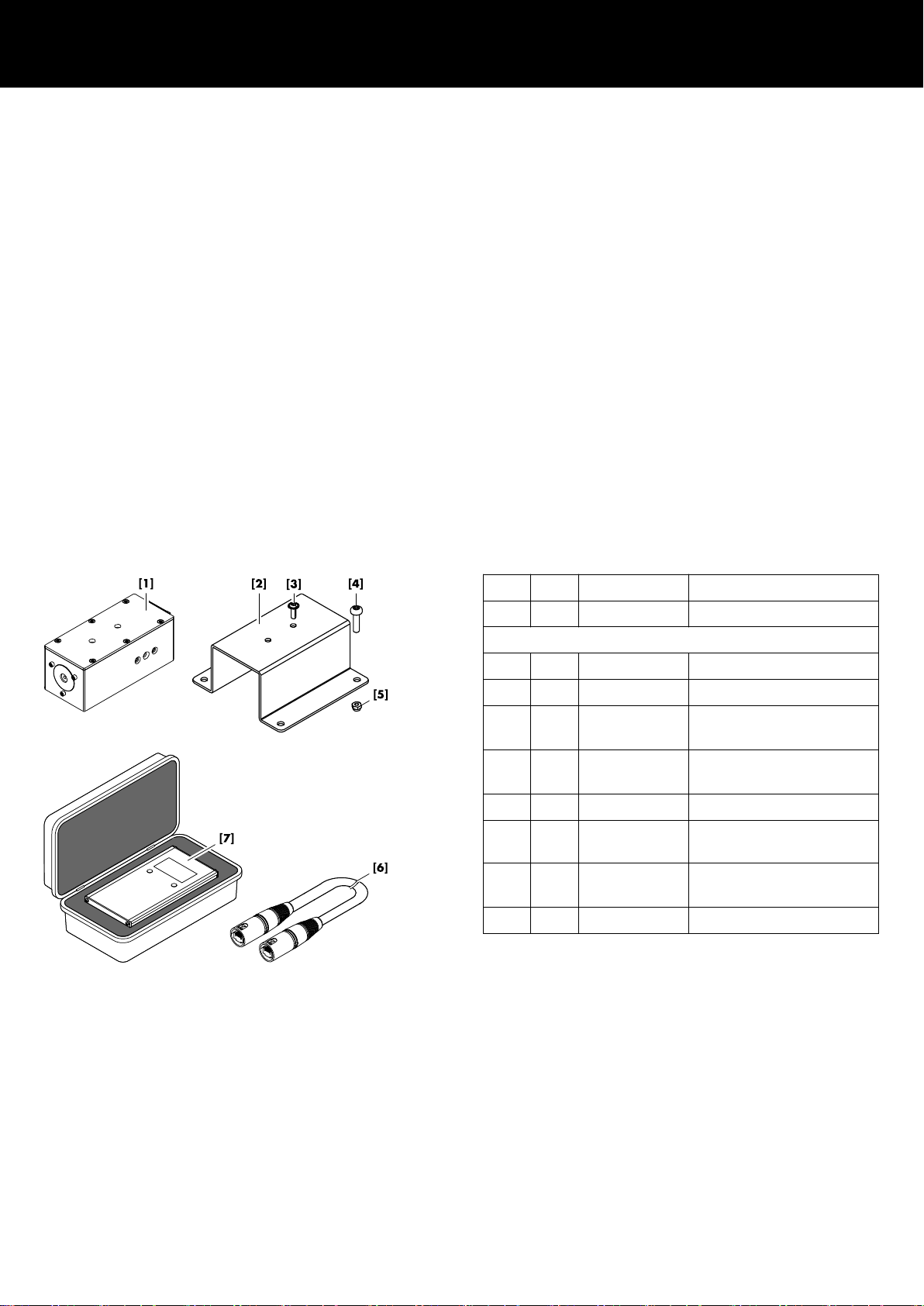

1.1 Scope of supply

Before setting up the system, please verify the shipment for

completeness and proper condition of the items.

If there is any sign of obvious damage, do not operate the units

and contact your local dealer from whom you received the system.

Pos. Qty. d&b Code Description

1 Z5710 d&b ArraySight set

Including:

[1] 2 Z5711 ArraySight sender unit

[2] 2 2 x Fixing screws for each

sender unit

(Torx T20, M4 x 14 mm).

[3] 1 Z5712 ArraySight meter unit

[4] 2 K6006.200.00 Shielded CAT5e 1:1 cable,

30 m (100 ft)

[5] 1 D2735.EN .01 ArraySight Manual

1.2 Intended use

The d&b ArraySight laser inclinometer system is intended to

vertically aim an entire array in its operating position. It provides

precision angle measurement over a wide measuring range of ±90

degrees. The sender unit uses a 3-axis MEMS accelerometer for

data acquisition. This provides accurate tilt sensing over one axis,

even when the unit is tilted on another axis. Accurate angle

measurements can be achieved, resolved to ±0.1 degrees on the

display of the meter unit.

The compact sender unit is housed in a weather resistant enclosure.

It utilizes an ultra bright green laser to provide a visible indication

for aiming the array, with a flashing mode to help locate the beam

in bright surroundings.

The sender unit can be attached to dedicated d&b Flying frames.

For this purpose, the sender unit has two threaded inserts on its

base and comes with dedicated fixing screws (Torx T20, M4 x

14 mm).

Easy calibration

Multiple sender units can be used with one meter unit. Calibration

information is stored in the sender unit using non-volatile memory,

so it remains accurate after the meter unit is disconnected. Sender

units can be reset on the fly to any angle within range, allowing

adjustment of system elevation to be made in absolute values if

required. Calibration is carried out via the meter unit’s onscreen

menu, without the need to dismantle units or use precision

hardware.

Relative angle measurement

The meter unit’s zero function means relative angle measurements

can be made via the on-screen menu and the last four readings are

stored for easy recall.

d&b ArraySight Manual 1.7 en 5

Intelligent interpolative measurement

It is possible to make accurate measurements, even before the

system has reached its final resting angle after hoist adjustment.

The meter unit automatically displays the final resting angle within

three periods of oscillation. This reduces installation time, with no

need to wait until the system comes to rest after each angle

adjustment.

Temperature and humidity measurement

In addition, the sender unit incorporates a thermo- and hygrometer

(sensor) to derive the actual onsite temperature and humidity.

Note: The sensor is calibrated by factory default and requires

no re-calibration by the user.

The thermometer covers a range from 0 to 40 °C (32 to 104 °F)

with an accuracy of ± 2 °C (± 35.6 °F) while the hygrometer

covers the range of 10 to 100 % (relative humidity) with an

accuracy of ± 5 %.

The corresponding values are displayed on the «Home» screen of

the meter unit or, when integrated into the d&b Remote network,

the values can be read out within R1.

d&b ArraySight Manual 1.7 en6

2 Technical specifications

Environmental conditions

IP rating sender unit IP54

Pollution degree 2

Temperature range 0 °C to 40 °C (32 °F to 104 °F)

Humidity (rel.) 80% up to 31 °C/87.8 °F

Linear decrease to 50% @40 °C/104 °F

Altitude max: 2000 m/6562 ft

Power supply

Meter unit 6 x AA Alkaline batteries - 9 VDC

Sender unit (single operation) Derived from meter unit - 9 VDC

Sender unit (remote operation - OCA) Power Over Ethernet (ETH/POE)

POE standard specification IEEE802.3at or IEEE802.3af

No passive injector devices or switches must be used!

Laser specification

Complies with 21 CFR 1040 with deviations pursuant to Laser Notice 50,

and with IEC/EN 60825-1 (2001)

Laser Class 3R laser product

Wavelength 532 nm

Max power: less than 5 mW

Dimensions and weights

Meter unit W x H x D: 85 x 45 x 160 mm / 405 g (0.9 lb)

Sender unit W x H x D: 48 x 44 x 120 mm / 295 g (0.65 lb)

Inclinometer system

Measuring range ±45° @ ±0.1° (full accuracy)

±90° @ ±1° (reduced accuracy)

Thermometer/Hygrometer (Sensor)

Range/Accuracy 0 to 40 °C (32 to 104 °F) / ± 2 °C (35.6 °F)

10 ... 100% (rel.) / ± 5 %

Connections

Meter unit etherCON (RS232 - 19.2 kB/s)

Sender unit POE enabled etherCON (RS232/Ethernet)

RS232: 19.2 kB/s

Ethernet (OCA): 100 Mbit/Half-duplex

Cable type Shielded CAT5e 1:1 cable

Cable length RS232: Up to 30 m (100 ft)

Ethernet (OCA): Up to 100 m (328 ft)

Controls and indicators (Meter unit)

2 x Soft keys Switch on/off, access MENU and LASER

Display Graphical LC display with backlight

d&b ArraySight Manual 1.7 en 7

3 Startup

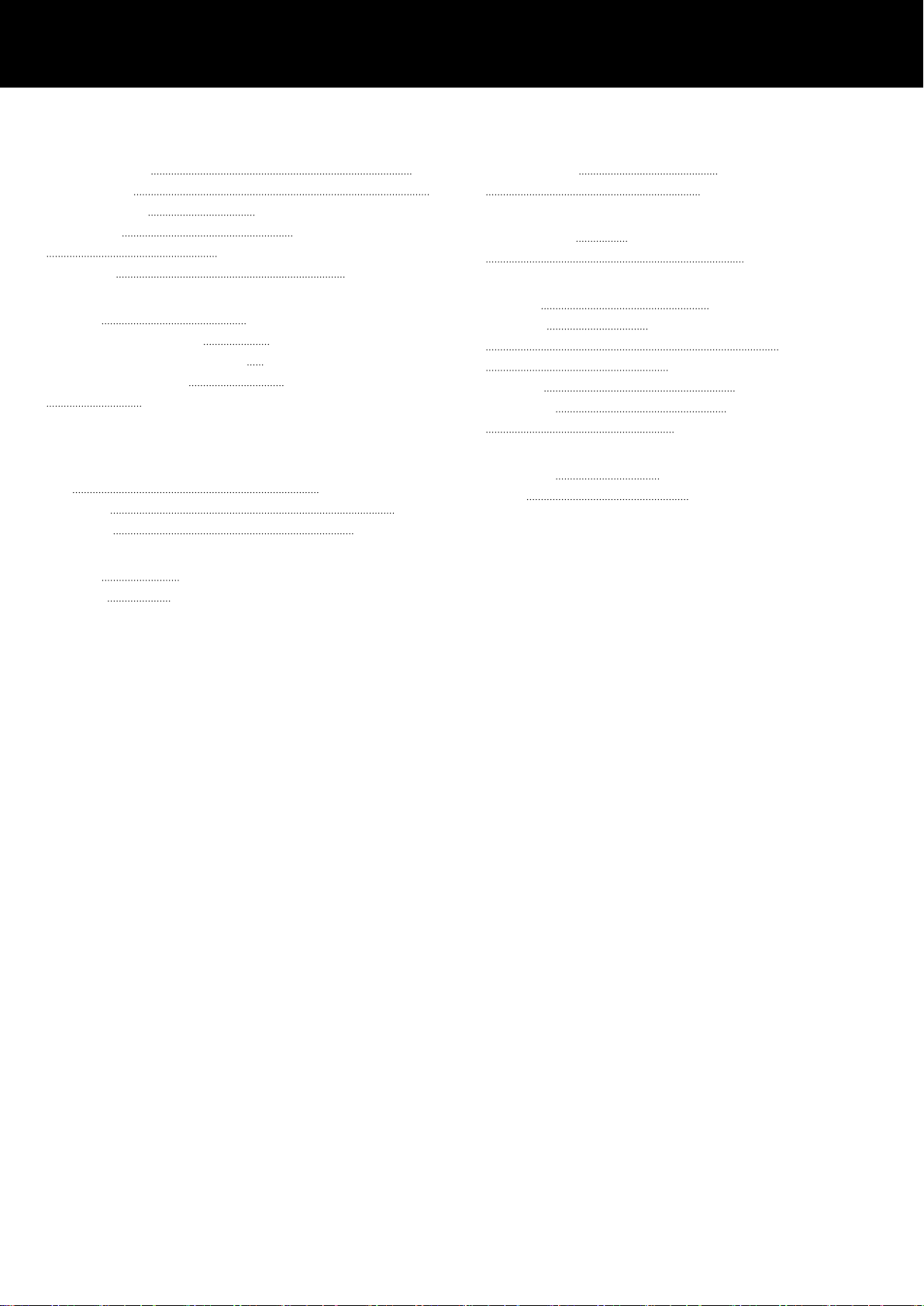

3.1 Installing the batteries

NOTICE!

To power the ArraySight inclinometer system, professional high

power Alkaline batteries (6 x AA - 1.5 VDC) must be used.

1. To insert and remove the batteries, undo the two M3 screws

on the end of the meter unit and slide out the battery holder.

↳

Observe the correct polarity.

2. Reinsert the battery holder and redo the screws.

To conserve battery life, the meter unit is set to power down after

one minute of inactivity by factory default. This can be adjusted in

the Þ «Auto power» menu.

Note: Once the battery voltage drops below 7.75 V

(approx. 24%) , the laser unit will be switched off and is no

more accessible. The battery icon on the display will be

crossed out Þ

.

However, the meter unit remains operating and angle

measurements are still possible.

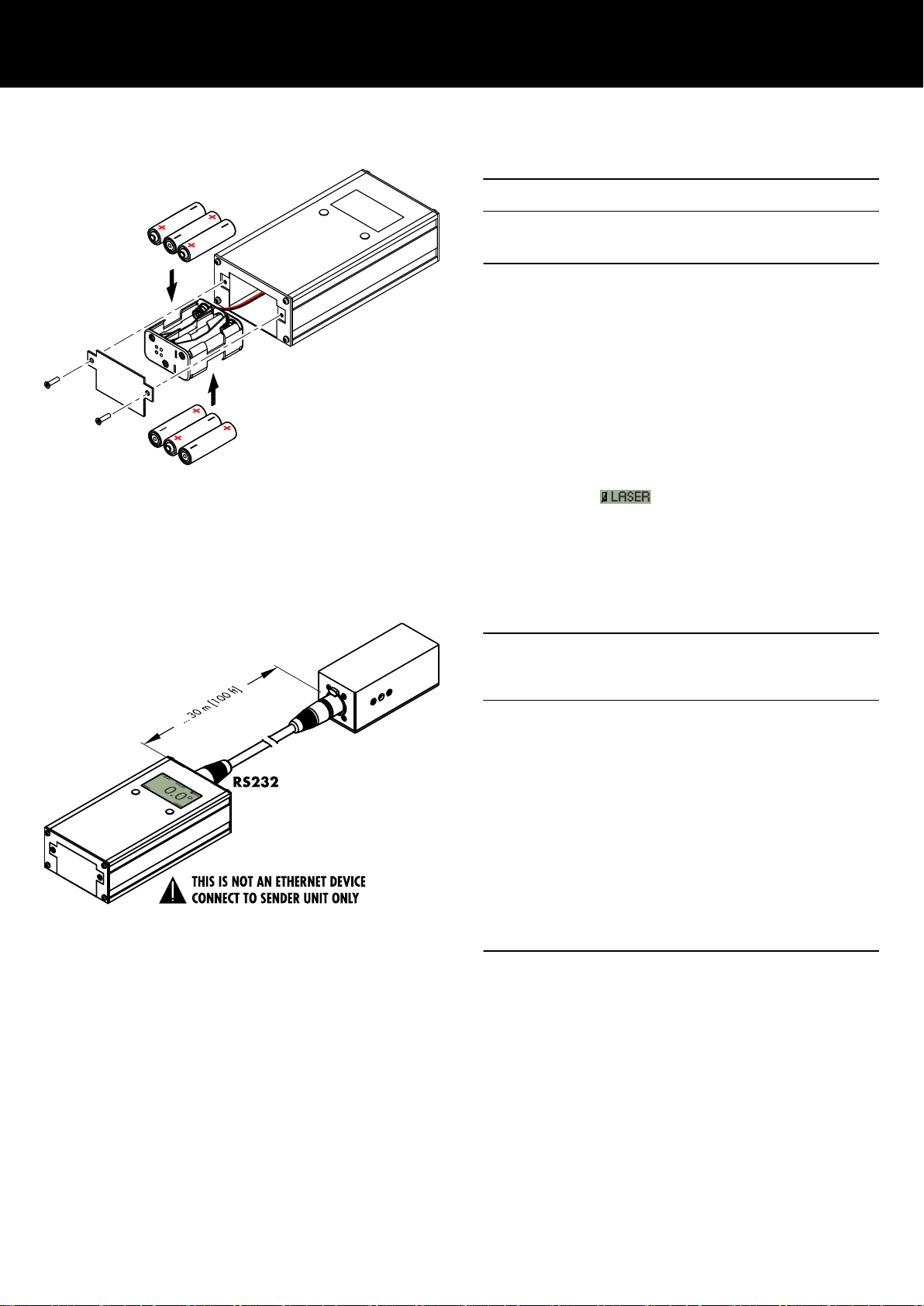

3.2 Connecting the units

NOTICE!

Potential risk of malfunction and/or damaging to

components!

The meter unit is not an Ethernet device!

DO NOT connect the meter unit to any Ethernet port or device

such as Ethernet switches.

The meter unit is equipped with an RS232 interface and provides

the power supply and communication for the direct connection of a

single sender unit for read out.

Connect the sender unit to the meter unit using the enclosed,

shielded CAT5e 1:1 cable with etherCON connectors.

For this purpose, the meter and sender units are equipped with

corresponding etherCON connector sockets.

Cable lengths of up to 30 m (100 ft) are allowed.

DO NOT use any cables other than specified above.

d&b ArraySight Manual 1.7 en8

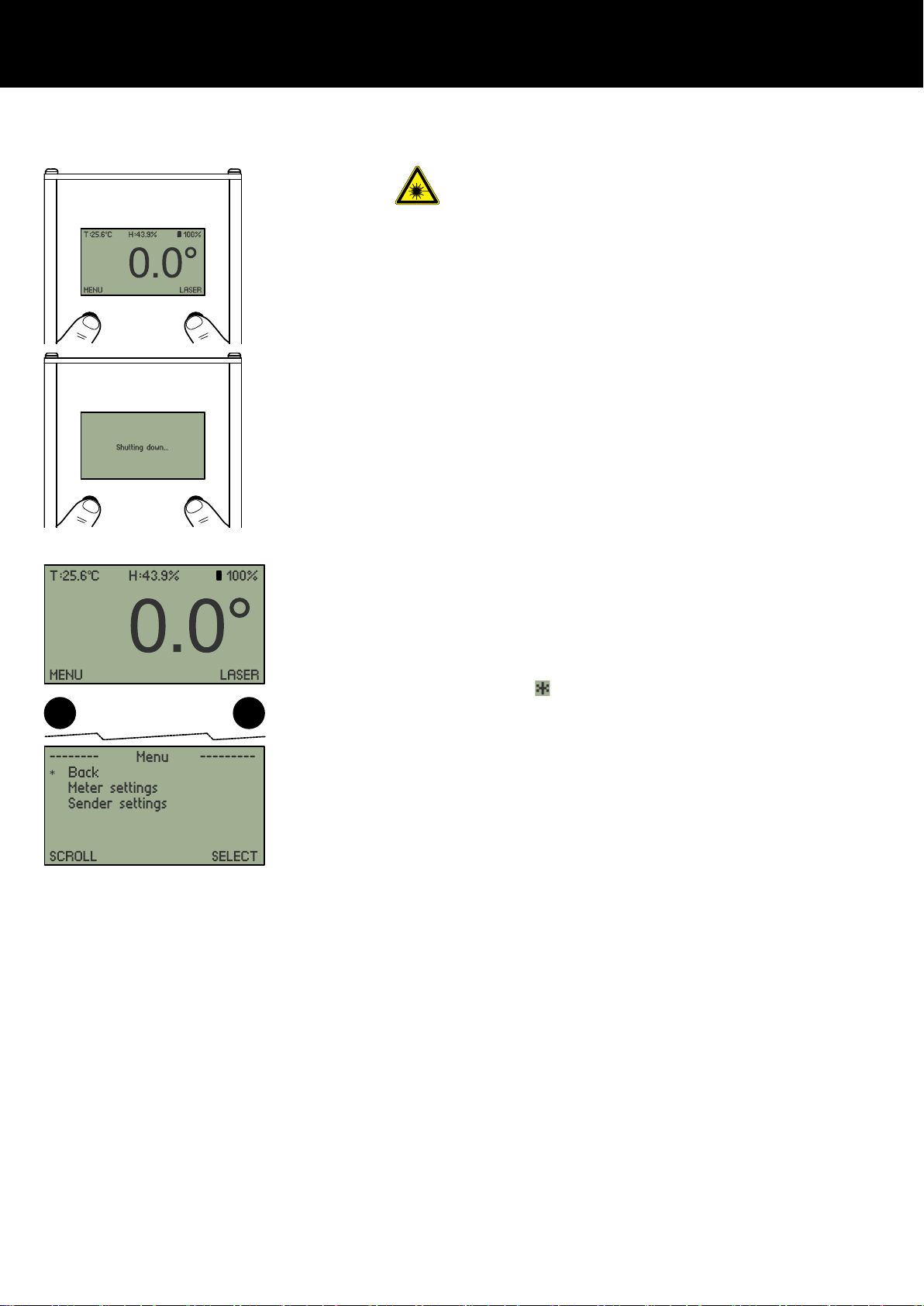

3.3 Switching on/switching off Please observe the "Safety precautions when using

laser equipment!"

1. To switch on the meter unit, hold down both buttons below the

screen.

↳

The menu screen will illuminate and initially display the d&b

logo. The unit will then switch to the «Home» screen and

display the current angle readout.

2. Release both buttons.

3. To power down the meter unit (and the connected sender

unit), proceed in the same manner until the «Shutting down»

message is displayed.

3.4 User interface of the meter unit

The meter unit features a detailed graphical display with an

intuitive on-screen menu system.

Navigation through the menus is by two buttons below the display.

Within the main menu and the submenus, the left-hand button is

generally used to scroll down through the menu items

Þ «SCROLL». The corresponding menu items are marked by an

asterisk (

).

The right-hand button is used to select a function Þ «SELECT».

Apart from that, the buttons have different functions within the

various submenus. The current function is always indicated above

each button (e.g. «BACK», SET, «CANCEL», «INC»...)

The display is backlit for viewing in all light conditions.

d&b ArraySight Manual 1.7 en 9

3.5 The menu structure

3.5.1 Home screen

The Home screen is split into three sections:

Header Indicates the actual onsite temperature («T») and

humidity («H») as well as the battery status in

gaphic form and as a percentage value.

Read out The current angle readout in degrees, relative to the

last calibration of the unit.

Footer From the Home screen, the following functions are

accessible:

MENU Left-hand button to enter the Þ Main menu

«Menu».

LASER Please observe the "Safety precautions

when using laser equipment"!

The right-hand button provides access to the laser

function with the following options:

On Þ Flash mode Þ Off

Please also refer to Þ Chapter 5.4 "Using the

laser" on page 17.

3.5.2 Main menu «Menu» The main menu screen provides direct access to the:

Þ Meter settings

Þ Sender settings

3.5.3 Meter settings

History

Displays the last four readings of the inclinometer.

The readings are saved every time the unit is

powered off, or when the sender unit is

disconnected.

Auto

power

Temp. unit

Defines the auto power-off timer between 1 min.

(default), 2 min. and 5 min.

Defines the temperature units.

°C/°F

Version Displays the currently installed firmware version

of both the meter and the sender units.

If the sender unit is not connected, «Offline» will

be displayed instead.

d&b ArraySight Manual 1.7 en10

3.5.4 Sender settings

IP

settings

Defines the required IP settings such as the IP

address Þ «IP», the Subnet Þ «SN», the Gateway

Þ «GW» and the IP mode Þ «Mode».

By factory default, the IP mode is set to «Auto» and

is recommended for a network with a DHCP server

present Þ DHCP+LL (Link Local).

The IP mode can be set to «Manual» if required.

RemoteIDDefines the required «Remote ID» settings in

connection with d&b R1.

The «Remote ID» menu comprises two items, the

«Subnet» and the «Device ID».

Within an d&b OCA network, up to 100 subnets

can be defined (values 0 to 99).

Using the two digit Device ID for each subnet, you

can define a total of 63 devices (values 1 to 63).

Reset

angle

(zeroing)

Saves an angle offset in the sender unit for relative

measurements. When performed, the meter displays

zero, when the sender unit is in its current position.

The reset angle function is also used to ensure that

the sender unit is correctly aligned to the flying

frame (refer to Þ Chapter 4.1 "Resetting the angle

(zeroing)" on page 13).

Calibrate By factory default, the sender unit is already

calibrated.

However, for maintenance reasons it might be

necessary to re-calibrate the sender unit’s

accelerometer.

For this purpose, selecting «Calibrate» starts the

calibration procedure for the connected sender unit

as described in Þ Chapter 7.3 "Calibrating the

accelerometer" on page 20.

d&b ArraySight Manual 1.7 en 11

3.5.4.1 Editing IP and Remote ID settings

Editing the IP and the Remote ID settings is performed in the same

manner.

To edit the IP settings, proceed as follows:

1. Ensure the sender unit is connected.

↳

If the connection of the sender unit has been accidently

interrupted, this will be detected by the meter unit within 5

seconds.

The meter unit will then switch to the «Home» screen and a

corresponding message will be issued.

The «LASER» button and the sender settings menu will no

longer be accessible.

After the interruption has been resolved, the meter unit will

return to the Home screen.

The «LASER» button and the sender settings menu will

become accessible again.

2. Within the «Sender settings» menu, select the «IP settings» item

to enter the «IP settings» menu.

3. Scroll to the desired item (e.g. IP) and press the «SELECT»

button.

↳

The «Set IP» menu opens and the first digit is flashing.

4. Use the «SCROLL» button to move through the digits. When a

digit is marked, it starts flashing.

Use the «INC» button to increment the selected digit by one.

5. Once the last digit is selected, the left-hand button changes

from «SCROLL» to «SET».

6. Press the button to confirm your changes.

↳

The meter unit switches back to the «IP settings» menu.

If no changes have been made, the meter unit switches

directly back to the «IP settings» menu as soon as you scroll

to the last digit.

d&b ArraySight Manual 1.7 en12

4 Resetting the angle (zeroing) and laser alignment

4.1 Resetting the angle (zeroing)

Preparation

1. With the flying frame resting on a solid, stable and flat

surface, check the sender unit is correctly aligned.

2. Place a good quality spirit level, or calibrated digital level on

the top edge of the flying frame as shown in the graphic

opposite. You need to check that the top of the flying frame is

truly horizontally [x] and vertically [z] leveled.

3. Fix the flying frame at the front or rear as required to ensure

that it is perfectly aligned.

↳

Once this is achieved, you can reset the angle of the

sender unit as follows:

Resetting the angle

1. Switch on the connected meter unit and confirm that the initial

display is showing 0.0°.

2. Select "«MENU» Þ «Sender settings» Þ «Reset angle»".

3. Press «SET» to confirm the reset.

↳

The angle displayed, will be set to zero (0.0°) and the

offset value is stored in the sender unit, even when it is

disconnected from the meter unit.

Note: The angle needs to be reset for each sender unit in

use. If you have sender units attached to a left and right array,

when you plug the second sender unit in, you will need to

reset this to zero, but if subsequently you reconnect the meter

unit to the first sender unit at this location, the offset value

stored in the sender unit is still valid.

d&b ArraySight Manual 1.7 en 13

4.2 Aligning the laser Take precautions to prevent anyone from looking

directly into the laser beam.

Wear appropriate eye protection.

In normal use, the initial factory setup can be relied on, but if the

unit is dropped or exposed to extreme temperatures, the laser may

be realigned.

Correct alignment of the laser means the beam is emitted precisely

on a central axis in relation to the case of the sender unit in both,

the horizontal and vertical orientations.

Note: It is recommended that you label the sender unit with

the date and name of the person conducting the work so a

record of the laser alignment is maintained.

Small errors in alignment will multiply the further the laser is

projected. It is therefore important to check the laser alignment

from time to time and adjust it where necessary.

This procedure should be carried out at base in a workshop,

not on site.

It is essential for the sender unit to be accurately in position during

the alignment procedure, both vertically and horizontally. To

achieve this, place the Flying frame on a solid, stable and flat

surface with a known level surface as described in the previous

section (Þ Chapter 4.1 "Resetting the angle (zeroing)"

on page 13).

1. Connect the sender unit to the meter unit so the laser can be

operated.

2. You also require a vertical surface to project the laser onto,

positioned at a distance of 10 m (33 ft) from the sender unit.

Alignment Procedure

Tools required: Torx wrench #T10

1. Switch on the laser and check where the laser dot falls on the

vertical target surface.

2. Adjust the alignment of the laser using the three M3 machine

screws around the circumference of the laser bezel.

↳

The adjustment is quite sensitive, so make small adjustments

to each in turn and make sure that any of the screws are

not tightened completely.

The required accuracy is ± 5 mm (± 0.2" hor./vert.) which

leads to a maximum deviation of 10 cm/100 m

(3.94"/328 ft).

3. Adjust the screws until the laser dot aligns precisely.

4. Switch the laser off and disconnect the sender unit.

d&b ArraySight Manual 1.7 en14

5. Once alignment is complete, place a drop of thread-locking

fluid on each of the screw heads to prevent loosening.

d&b ArraySight Manual 1.7 en 15

5 Using the system

5.1 Measuring the angle

Once the array has been hoisted to its working height, ArraySight

uses intelligent interpolating algorithms to determine the resting

point of the array, while it is still moving after motor adjustment.

This is important because it means you can make accurate

measurements without waiting for the system to come to a

complete rest after adjustment. It typically takes around three

periods of oscillation, or pendulum swings of the array for the

sender unit to achieve an accurate measurement of the angle.

As a guideline, the angle display has the following accuracy:

Cycles Accuracy

1 period of swing ±1.0

2 periods of swing ±0.5

3 periods of swing ±0.1

Clearly, the measurement cannot be relied upon when the motor

hoists are actually in operation. Once the hoist(s) have stopped,

the meter unit quickly resolves the measurement. A usable value for

the resting angle is normally displayed within a few seconds.

5.2 Measurement limits

ArraySight has a usable range of ±45° with full accuracy. The

sender unit sensor is capable of measuring angles up to ±90°, but

with reduced accuracy of ±1°. The additional range is available to

you to use, but it should be used with caution.

5.3 Adjusting angles using relative values

The angle of the flying frame can be re-adjusted to a new angle,

relative to its original angle. This is achieved by resetting the

sender unit to zero while in situ at the original angle as described

in Þ Chapter 4.1 "Resetting the angle (zeroing)" on page 13. The

array can then be tilted on the hoists, reading the value off the

adjustment on the meter unit, relative to the original position.

Note: When the sender unit has been reset in this way, its

true horizontal position will no longer display 0.00°. This is

why we recommend checking the horizontal position at the

start of each sender unit installation.

d&b ArraySight Manual 1.7 en16

5.4 Using the laser Take precautions to prevent anyone from looking

directly into the laser beam.

Wear appropriate eye protection.

The sender unit features a powerful laser to assist angle

adjustment. The laser is used to confirm that the upper margin of

the PA system dispersion reaches the design target - for example

the seating at the rear of an auditorium.

1. On the «Home» screen, «LASER» is displayed at the bottom

right.

2. Press the right-hand button once to switch the laser on.

↳

Pressing the button a second time will put the laser into

flashing mode, which can be useful for locating the beam in

a bright location. Pressing the button a third time turns the

laser off.

The on/off and flashing mode statuses are indicated by a

corresponding permanent or flashing laser icon to the left

of the «LASER» item Þ

.

5.5 Application example

To take an example: ArrayCalc indicates a frame angle of –3.6°

from vertical.

1. Using ArraySight to measure this angle, you raise the first

array to its operating height and then check the meter unit

screen.

2. The figures displayed settle as the meter compensates for the

swing of the array. If the settled display shows +0.5°, you

then use the hoists to lift the rear or lower the front of the

array. Make small adjustments and allow the meter unit to

calculate the new angle. Continue to make adjustments until

you achieve the angle of –3.6°.

3. Once the first array is complete, disconnect the meter unit from

the first sender unit and reconnect it to the sender unit of the

second array.

4. Repeat the procedure, starting with resetting the angle to zero

for the second sender unit. Raise the second array, check the

angle and adjust the angle as necessary.

5. If subsequent re-adjustment of the first array is required the

meter unit can be re-connected to the first sender unit and the

correct offset will be recalled.

d&b ArraySight Manual 1.7 en 17

6 OCA integration (Ethernet)

NOTICE!

Potential risk of malfunction and/or damage to the

device!

Only use POE injector devices and/or switches which comply with

the POE standards IEEE802.3at or IEEE802.3af.

DO NOT use passive injector devices or switches.

The data transmission rate is fixed @ 100 Mbit/Half-duplex.

Therefore ensure that you use compatible switches.

In standard operation, the sender unit is directly connected to the

meter unit which provides power supply and communication via its

RS232 interface.

However, the sender unit also supports the d&b OCA/AES70

protocol and therefore directly integrates into the d&b workflow in

connection with the d&b ArrayCalc simulation and R1 Remote

control software. This allows multiple sender units to be read out

within R1.

By factory default, the sender unit comes with the following

ethernet and remote settings:

IP mode:

IP address:

Subnet:

Gateway:

Remote ID:

Auto Þ DHCP+LL (Link Local)

192.168.0.111

255.255.255.0

192.168.0.1

0.01

d&b ArraySight Manual 1.7 en18

7 Maintenance and care

7.1 Cleaning

During normal operation, the units provide maintenance-free

service.

If the units require cleaning ...:

▪ Use a soft cloth only.

▪ Do not use any solvent cleaners.

▪ Do not spray directly on the LC display or laser.

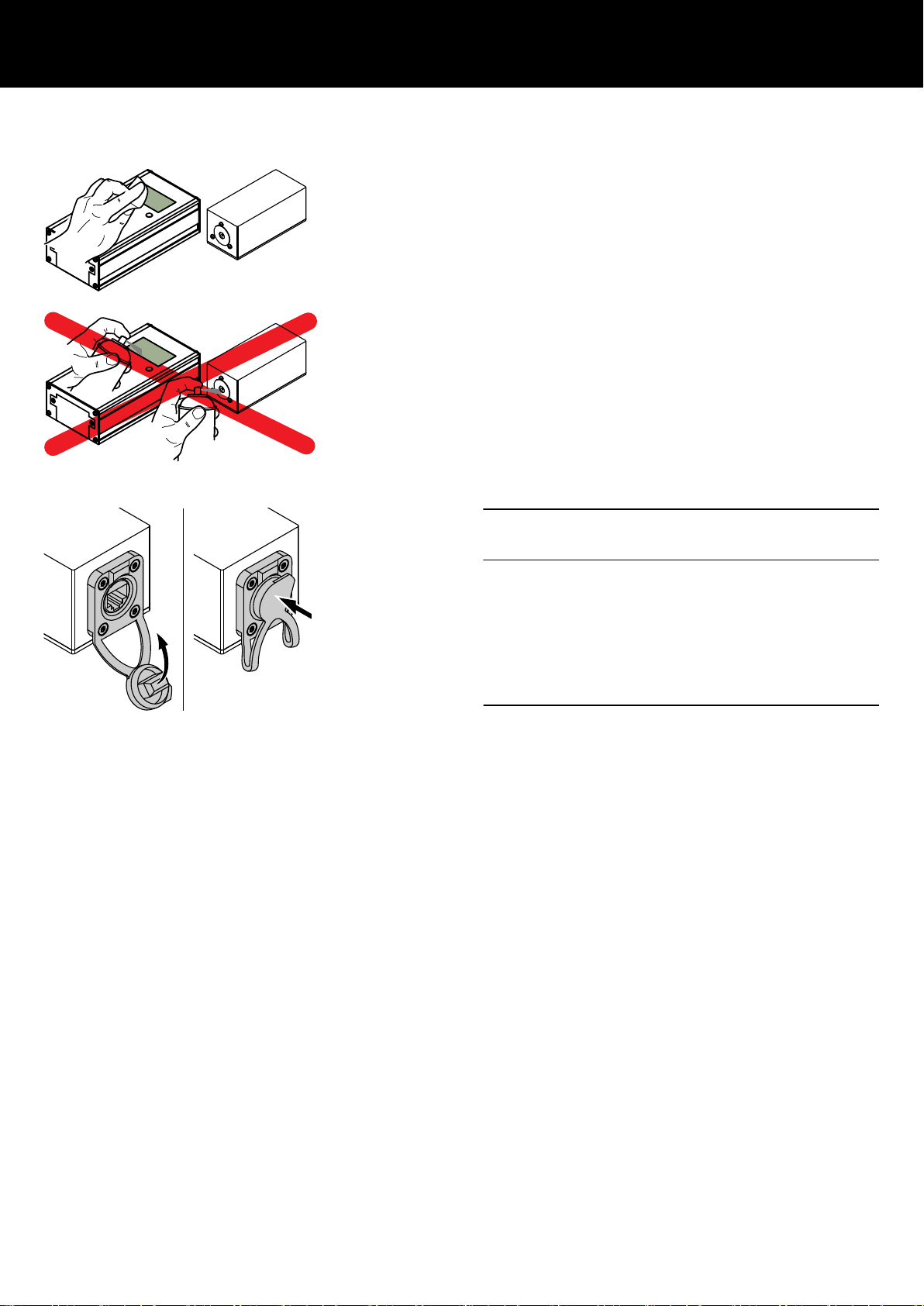

7.2 etherCON connector socket protection

NOTICE!

Possible risk of damage to the device!

Always make sure the dust cap of the etherCON connector socket

is properly attached (closed) during transport or when it is not in

use, as shown in the graphic opposite.

This prevents the sender unit from damage due to:

▪ Ingression of moisture or liquids (e.g. water from rain) through

the etherCON connector socket,

▪ corrosion of the connector socket's spring contacts.

d&b ArraySight Manual 1.7 en 19

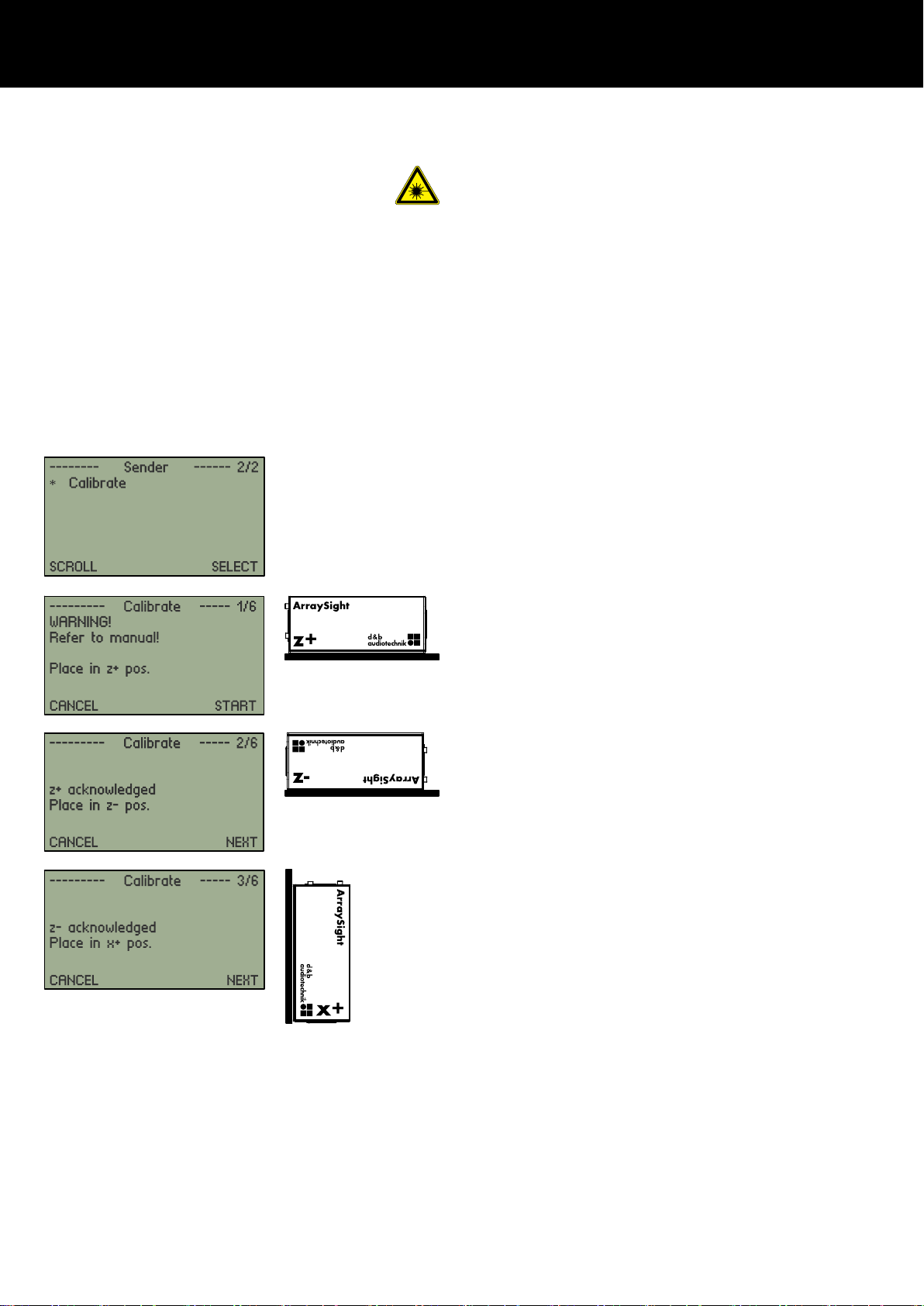

7.3 Calibrating the accelerometer ENSURE the laser is switched off throughout this

procedure.

The ArraySight sender units are calibrated in the factory using

precision calibration jigs. If this process is attempted without a level

surface and a true 90° angle, then calibration information could

be incorrect. Only attempt this process if you have the appropriate

facilities to ensure accuracy.

Calibration is performed using gravity as a reference.

Note: If you are interrupted during any of the following steps,

or the display shows anything other than indicated, you will

need to start the procedure again. Errors can occur if the unit

'times out' or if a button is inadvertently pressed twice.

The calibration procedure can be canceled at any time by

pressing the left-hand «CANCEL» button.

1. Place the sender on a known level surface with a block or side

fence positioned at exactly 90°, so the unit can be registered

accurately both vertically and horizontally.

2. Connect the sender unit to the meter unit and power it up.

3. Select "«MENU» Þ «Sender settings» Þ «Calibrate»".

You’ll then need to follow a six step procedure:

1. First, the meter screen will prompt you to place the sender in

the z+ position.

z+ is the sender unit’s "normal" orientation, sat flat on the

table top.

Select «START»…

2. When «z+ acknowledged » is displayed, place the unit in the

z– position, i.e. upside down on the table top, so the base of

the unit is facing upwards.

Select «NEXT»…

3. When «z– acknowledged» is displayed, you are next

prompted to place the unit in the x+ position.

In the x+ position, the unit points upwards, with the laser

aperture at the top. This requires holding the unit with the base

against a vertical surface.

Select «NEXT»…

d&b ArraySight Manual 1.7 en20

4. When «x+ acknowledged» is displayed, place the unit in the

x– position by turning the unit 180 degrees.

The laser aperture should now point downwards and the top

of the unit should rest against the vertical surface.

Select «NEXT»…

5. When «x– acknowledged» is displayed, you are next

prompted to place the unit in the y+ position.

Turn the unit on its side, in a clockwise direction so when the

unit is viewed from the front, the brass screw nearest the top

surface is now at 9 o’clock, and the base of the unit rests

against the side fence. This is y+.

Select «NEXT»…

6. When «y+ acknowledged» is displayed, you are prompted to

place the unit in the y– position.

Turn the unit through 180 degrees.

The brass screw has moved from 9 o’clock to 3 o’clock.

Select «NEXT»…

When «y– acknowledged» is displayed on the screen, the sender

unit will process the measurements and calibration will be

complete. This data is stored in the non-volatile EEPROM in the

sender unit.

When «y– acknowledged» is displayed on the screen, the sender

unit will process the measurements and calibration will be

complete. This data is stored in the non-volatile EEPROM in the

sender unit.

Correctly calibrated, the sender unit will provide accurate angle

measurements in all orientations.

d&b ArraySight Manual 1.7 en 21

8 Manufacturer's declarations

8.1 EU declaration of conformity (CE symbol)

This declaration applies to:

d&b Z5710 ArraySight set

Including:

▪ Z5711 ArraySight sender unit

▪ Z5712 ArraySight meter unit

Provided they correspond to the original technical version and

have not been subject to any later design or electro mechanical

modifications.

▪ General Product Safety Directive 2001/95/EC

rd

▪ IEC 61010-1:2010 (3

Edition) Safety requirements for

electrical measurement, control and laboratory use.

▪ IEC/EN 60825-1:2014 Safety of laser products.

▪ IEC 60529/A2:2013 Degrees of protection provided by

enclosure (IP code).

▪ Electromagnetic Compatibility (EMC) Directive) 2014/30/EU

▪ EN61326-2-1:2013 (EN 61326-1:2013) & FCC CFR 47

parts 15, 107 & 15.109 and ICES-003 Issue 6 (EMC).

▪ Restriction of Hazardous Substances 2011/65/EU

We herewith declare that said products are in conformity with the

provisions of the respective EC directives and Standards including

all applicable amendments.

8.2 WEEE Declaration (Disposal)

Electrical and electronic equipment must be disposed of separately

from normal waste at the end of its operational lifetime.

Please dispose of this product according to the respective national

regulations or contractual agreements. If there are any further

questions concerning the disposal of this product, please contact

d&b audiotechnik.

d&b ArraySight Manual 1.7 en22

FreeRTOS

Permission is hereby granted, free of

charge, to any person obtaining a copy of

this software and associated

ocumentation files (the "Software"), to

deal in the Software without restriction,

including without limitation the rights

to use, copy, modify, merge, publish,

distribute, sublicense, and/or sell

copies of the Software, and to permit

persons to whom the Software is furnished

to do so, subject to the following

conditions:

The above copyright notice and this

permission notice shall be included in

all copies or substantial portions of the

Software.

8.3 Licenses and Credits

This product uses a number of third-party libraries to provide

certain features. These libraries are supplied along with the

product.

THE SOFTWARE IS PROVIDED "AS IS", WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO THE

WARRANTIES OF MERCHANTABILITY, FITNESS

FOR A PARTICULAR PURPOSE AND

NONINFRINGEMENT. IN NO EVENT SHALL THE

AUTHORS OR COPYRIGHT HOLDERS BE LIABLE

FOR ANY CLAIM, DAMAGES OR OTHER

LIABILITY, WHETHER IN AN ACTION OF

CONTRACT, TORT OR OTHERWISE, ARISING

FROM, OUT OF OR IN CONNECTION WITH THE

SOFTWARE OR THE USE OR OTHER DEALINGS IN

THE SOFTWARE.

lwIP

lwIP is licensed under the BSD license:

Copyright (c) 2001-2004 Swedish Institute

of Computer Science. All rights reserved.

1. Redistributions of source code must

retain the above copyright notice,

this list of conditions and the following

disclaimer.

2. Redistributions in binary form must

reproduce the above copyright notice,

this list of conditions and the following

disclaimer in the documentation

and/or other materials provided with the

distribution.

3. The name of the author may not be used

to endorse or promote products

derived from this software without

specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE AUTHOR

AS IS AND ANY EXPRESS OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED

TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE DISCLAIMED. IN NO

EVENT SHALL THE AUTHOR BE LIABLE FOR ANY

DIRECT, INDIRECT, INCIDENTAL, SPECIAL,

EXEMPLARY, OR CONSEQUENTIAL DAMAGES

(INCLUDING, BUT NOT LIMITED TO,

PROCUREMENT OF SUBSTITUTE GOODS OR

SERVICES; LOSS OF USE, DATA, OR PROFITS;

OR BUSINESS INTERRUPTION) HOWEVER CAUSED

AND ON ANY THEORY OF LIABILITY, WHETHER

IN CONTRACT, STRICT LIABILITY, OR TORT

(INCLUDING NEGLIGENCE OR OTHERWISE)

ARISING IN ANY WAY OUT OF THE USE OF THIS

SOFTWARE, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGE.

d&b ArraySight Manual 1.7 en 23

edeca/Electronics graphics library

Copyright (c) 2010-2015, David Cannings

All rights reserved.

Redistribution and use in source and

binary forms, with or without

modification, are permitted provided that

the following conditions are met:

* Redistributions of source code must

retain the above copyright notice, this

list of conditions and the following

disclaimer.

* Redistributions in binary form must

reproduce the above copyright notice,

this list of conditions and the following

disclaimer in the documentation and/or

other materials provided with the

distribution.

* Neither the name of the author nor the

names of contributors may be used to

endorse or promote products derived from

this software without specific prior

written permission.

THIS SOFTWARE IS PROVIDED BY THE

COPYRIGHT HOLDERS AND CONTRIBUTORS "AS

IS" AND ANY EXPRESS OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED

TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE DISCLAIMED.

IN NO EVENT SHALL THE COPYRIGHT HOLDER OR

CONTRIBUTORS BE LIABLE FOR ANY DIRECT,

INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY,

OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT

NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE

GOODS OR SERVICES; LOSS OF USE, DATA, OR

PROFITS; OR BUSINESS INTERRUPTION)

HOWEVER CAUSED AND ON ANY THEORY OF

LIABILITY, WHETHER IN CONTRACT, STRICT

LIABILITY, OR TORT (INCLUDING NEGLIGENCE

OR OTHERWISE) ARISING IN ANY WAY OUT OF

THE USE OF THIS SOFTWARE, EVEN IF ADVISED

OF THE POSSIBILITY OF SUCH DAMAGE.

d&b ArraySight Manual 1.7 en24

9 Appendix

9.1 Z5710.xxx d&b ArraySight sets

In connection with d&b flying frames other than the SL-Series flying

frames, d&b also provides additional ArraySight sets including

dedicated flying frame adapter to allow the d&b ArraySight

sender unit to be mounted to the corresponding flying frame.

The following sets are covered by this manual

(Mounting instructions):

▪ Z5710.001: d&b ArraySight set J-Series

▪ Z5710.002: d&b ArraySight set V-Series

Apart from any other items, each ArraySight set includes the

mechanical components (flying frame adapter) for two flying

frames.

Please verify the shipment for completeness and proper condition

of the items.

Tools required

▪ Torx screw driver T20

▪ Torx screw driver T25

▪ Socket wrench SW8

9.1.1 Z5710.001 Mounting instructions

Scope of supply

Pos.

Qty. d&b Code Description

1 Z5710.001 d&b ArraySight set J-Series

Including:

[1] 2 Z5711 ArraySight sender unit

[2] 2 J Flying frame adapter

[3] 4 Panhead screw (Torx T20)

M4 x 12

[4] 8 Panhead screw (Torx T25)

M5 x 18

[5] 8 Self securing nut M5

[6] 2 K6006.200.00 Shielded CAT5e 1:1 cable,

30 m (100 ft)

[7] 1 Z5712 ArraySight meter unit

within transport case

1 D2735.EN .01 ArraySight Manual

d&b ArraySight Manual 1.7 en 25

Assembly

1. First attach the ArraySight sender unit [1] to the flying frame

adapter [2].

2. Fix the sender unit with the two panhead screws (M4 x 12)

[3].

3. As the sender unit assembly is mounted from the bottom of the

J flying frame, turn frame by 180°.

4. Position the frame onto an appropriate and flat surface.

5. Attach the sender unit assembly to the mounting plate of the

frame with the laser unit facing towards the front of the frame.

6. Fix the sender unit assembly using the four panhead screws

(M5 x 18) [4] and the self securing nuts (M5) [5].

7. Recheck your work and ensure all screws are properly

tightened.

9.1.2 Z5710.002 Mounting instructions

Scope of supply

Pos.

Qty. d&b Code Description

1 Z5710.002 d&b ArraySight set V-Series

Including:

[1] 2 Z5711 ArraySight sender unit

[2] 2 V Flying frame adapter

[3] 12 Panhead screw (Torx T20)

M4 x 12

[4] 2 K6006.200.00 Shielded CAT5e 1:1 cable,

30 m (100 ft)

[5] 1 Z5712 ArraySight meter unit

within transport case

1 D2735.EN .01 ArraySight Manual

d&b ArraySight Manual 1.7 en26

Assembly

1. First attach the ArraySight sender unit [1] to the flying frame

adapter [2].

2. Fix the sender unit using two panhead screws (M4 x 12) [3].

3. Position the V flying frame onto an appropriate and flat

surface.

4. Attach the sender unit assembly to the mounting plate of the

frame with the laser unit facing towards the front of the frame.

5. Fix the sender unit assembly using four panhead screws

(M4 x 12) [3].

6. Recheck your work and ensure all screws are properly

tightened.

d&b ArraySight Manual 1.7 en 27

D2735.EN .01, 04/2019 © d&b audiotechnik GmbH

www.dbaudio.com

Loading...

Loading...