E6530/E6531/E6502

1220/1222

Loudspeaker accessories

Mounting instructions

WARNING!

IMPORTANT!

CAUTION!

General Information

Mounting instructions

E6530/6531/E6502, 1220/1222 Loudspeaker accessories

Version 4.0E, 10/2000, D0020021

Copyright d&b audiotechnik AG 2000; all rights reserved.

The information presented in this document is, to the best of our

knowledge, correct. We will however not be held responsible for

the consequences of any errors or omissions. Technical

specifications, weights and dimensions can change and should

always be confirmed with d&b audiotechnik AG prior to inclusion

in any additional documentation.

d&b audiotechnik AG

Eugen-Adolff-Strasse 134, D-71522 Backnang

Telephone +49-7191-9669-0, Fax +49-7191-95 00 00

E6530/6531/E6502, 1220/1222 Loudspeaker accessories

References in the manual

This refers to a potentially dangerous situation which may lead

to personal injury.

This refers to a potentially dangerous situation which may lead to

equipment damage.

This refers to a situation which may

cause the equipment to malfunction.

Symbols on the equipment

Please refer to the information in

the operating manual.

(2.0 E) 3-8

WARNING!

WARNING!

General Safety and Installation Advice

General safety advice

d&b loudspeakers should only ever be flown or installed using

recommended d&b rigging accessories. The d&b rigging accessories

described in the d&b rigging accessories manual and the specific

mounting instructions are designed and manufactured to have a

high load safety factor for their intended role. In order to ensure

the highest safety standards, the information presented here on the

assembly and safe use of d&b rigging accessories must be carefully

understood and followed.

The installation of d&b loudspeakers using the rigging accessories

described in the d&b rigging accessories manual and the specific

mounting instructions should only ever be carried out by properly

qualified personnel in full compliance with all required safety codes

and safety standards in force at the place of installation.

(In Germany, this means compliance with the recommendations of

BGV C1 GUV 6.15)

d&b rigging accessories (components and assemblies) are supplied

exclusively for use with specific d&b loudspeakers and are not

designed or intended for use with any other loudspeakers or any

other devices. The use of d&b rigging accessories to deploy

loudspeakers and devices other than those indicated in the d&b

rigging accessories manual and the specific mounting instructions is

improper use. Improper use can compromise safety by overloading

and damaging the rigging accessories. d&b will not be held

responsible for any damage or injury resulting directly or indirectly

from the improper use of d&b rigging accessories.

d&b rigging accessories must not be modified in any way nor should

they be assembled in ways other than those indicated in the d&b

rigging accessories manual and the specific mounting instructions.

Rigging components supplied as part of a complete assembly are

non-interchangeable and must not be exchanged with the

component parts of any other assembly.

The component parts of a d&b rigging accessory must only be

assembled using the fasteners and methods of assembly

recommended in the d&b rigging accessories manual and the

specific mounting instructions. The use of fasteners and methods of

assembly not specified or approved by d&b may result in an unsafe

rigging assembly. Welding, or any other means of permanently

fixing rigging components to each other or to cabinet fixing points is

not allowed.

General installation advice

Only the screws, fasteners, plain and shakeproof washers specified

on the relevant page(s) of the d&b rigging accessories manual and

the specific mounting instructions shall be used to fasten together,

where appropriate, suitable d&b rigging components.

d&b rigging components or assemblies must only be fixed to d&b

loudspeaker cabinets using the cabinet fixing points, assembly

methods and fasteners specified on the relevant page(s) of the d&b

rigging accessories manual and the specific mounting instructions.

Any wall, floor or ceiling to which a d&b loudspeaker is fixed or

4-8 General safety and mounting instructions

WARNING!

WARNING!

WARNING!

attached using a d&b rigging accessory must be capable of safely

and securely supporting the actual load. The rigging accessory used

must be safely and securely fixed both to the loudspeaker and to

the wall, floor or ceiling.

Other points to consider are: When mounting rigging components

on walls, floors or ceilings ensure that all fixings and fasteners used

are of an appropriate size and load rating (DIN 18800 standards

apply within Germany). Wall and ceiling claddings and the

construction and composition of walls and ceilings all need to be

taken into account when determining whether a particular fixing

arrangement can be safely employed for a particular load. Cavity

plugs or other specialist fixings, if required, must be of an

appropriate type, fitted and used in accordance with the makers

instructions.

Use only the rigging accessory fixing holes indicated on the relevant

page(s) of the d&b rigging accessories manual and the specific

mounting instructions to fix d&b rigging accessories to walls, floors

or ceilings. Where specified, the recommended maximum torque

settings for screw fasteners must be strictly complied with.

Secondary safeties

All loudspeakers flown in theatres, studios or other places of work

and entertainment must, in addition to the principle load bearing

means of suspension, be provided with an independent, properly

rated and securely attached secondary safety.

Only steel wire ropes or steel chains of an approved construction

and load rating may be used as secondary safeties. Plastic covered

steel wire ropes are not permitted for use as secondary safeties. As

recommended by BGV C1 (GUV 6.15), the secondary safety must

prevent the load from dropping more than 20 cm if the principal

means of suspension fails.

Safety inspections

All rigging components and assemblies are subject to wear and

tear, aging, corrosion etc. As safety critical components, its

imperative that, prior to each and every use or installation, all

rigging components, rigging assemblies and cabinet fixing points

are carefully inspected to ensure that they are free of defects and

that they function flawlessly. Care should be taken to identify signs

of undue wear and tear, dents, cuts, tears, splits and any

indications of corrosion. If upon inspection, damage is discovered

and there exists even the slightest doubt as to the physical integrity

and safety of the damaged item, then the damaged item must not,

under any circumstances, be deployed.

Regular, more rigorous test and inspection of rigging components

must also be carried out. Safety legislation and test and inspection

requirements will vary from country to country. In most cases,

annual independent test and inspection by a suitably approved and

qualified inspector will be required - users must ensure compliance

with all applicable safety requirements.

d&b recommends regular safety inspections and further

recommends that a logbook be kept detailing the test and inspection

history of each d&b rigging accessory.

(2.0 E) 5-8

Load safety factors

Rigging accessories are safety critical components which can, by

their failure, lead to injury or death. To maximise safety and to

reduce the risk of the possible consequences of failure, there exist

various recommendations which attempt to govern the safe design

and construction of rigging components. Unfortunately, such

recommendations vary from country to country and are frequently

adaptations of building or construction safety codes which were

never intended to specifically cover loudspeaker rigging.

A further complicating factor, frequently a result of insurance

requirements, is that different load safety factors may be demanded

for different applications. For example, the load safety factor of a

rigging component suitable for a fixed, static application may be

regarded as insufficient for a mobile application.

What exactly is a load safety factor?

It is accepted general engineering practice to design and build

components to have a minimum 1.25X load safety factor. That

means a component or assembly that can resist without breaking, a

load 25% greater than its specified safe working load (SWL).

Load safety factors are tailored to the estimated level of risk

presented by a particular application - the higher the estimated

level of risk, then the higher the load safety factor demanded.

Because of the high level of risk associated with the possible failure

of rigging, load safety factors much greater than 1.25X are

demanded. The EU Machinery Directive for example, specifies a 4X

load safety factor for shackles. This means that a shackle specified

for a SWL of 500 kg should be able to resist a 2000 kg load without

breaking.

Even more stringent load safety factors than those specified under

EU legislation can apply to applications where rigging is used. One

of the most demanding safety codes, the one used to derive the

high load safety factors for d&b rigging accessories, is the German

BGV C1 safety code.

Section §9 of Unfallverhütungsvorschrift Veranstaltungs- und

Produktionsstätten für szenische Darstellung (BGV C1 GUV 6.15)

draws a distinction between components used to rig a fixed, static

load and components used to rig a moving load. Different load

safety factors are required for otherwise similar components

depending upon whether they are used with a fixed or with a

moving load. A higher load safety factor being required for rigging

subject to the higher stress of dynamic loading.

The recommendations are met if it can be shown that:

The SWL of components such as ropes and slings used as

rigging for a fixed load does not exceed 1/10 of their

calculated ultimate stress

and

The SWL of components such as ropes and slings used as

rigging for a moving load does not exceed 1/12 of their

calculated ultimate stress ...

6-8 General safety and mounting instructions

WARNING!

Rigging component

Safety factors

Steel wire ropes

factor 5 (EN292-2, chpt. 4.1.2.5a)

Welded link chains

factor 4 (EN292-2, chpt. 4.1.2.5b)

Fabric slings

factor 7 (EN292-2, chpt. 4.1.2.5c)

Metal components

factor 4 (EN292-2, chpt. 4.1.2.5d)

A 12X load safety factor is therefore recommended for the

following components:

•

Chains

•

Steel wire ropes (for lifting and securing)

•

Shackles

•

Eyebolts etc.

In contrast, the EU Machinery Directive (EN292-2) specifies the

following load safety factors for rigging components:

The regulations enshrined in the EU directive are general

regulations - few in number and not always particularly clear or

detailed. Loudspeakers and their rigging components are not

specifically covered. The electrical and mechanical standards of

construction for lanterns are covered by a DIN standard (DIN

15560). However, there is no specific DIN or Euro standard

covering standards of construction for loudspeaker rigging

components or assemblies.

To make matters clear, at least as far as d&b rigging accessories

are concerned, we have adopted the following load safety factors:

12X load safety factor:

Chains, ropes, shackles, eyebolts, straps and hooks.

10X load safety factor:

Accessories and fixings for mobile use.

5X load safety factor:

Accessories generally employed in fixed, permanent installations.

The 12X load safety factor is derived from §9, GUV 6.15

The 10X load safety factor is likewise derived from §9 GUV 6.15. as

a basic safety standard for rigging components.

From EN292-2 chpt. 4.1.2.5d a 4X minimum load safety factor can

be derived for all metal rigging components used in fixed

installations. Our choice of a 5X minimum load safety factor for

such components provides an enhanced safety margin.

Attaching rigging to loudspeaker cabinets

d&b rigging accessories are supplied with specific mounting

instructions and must only be assembled and used in the manner

described in these instructions or as specified on the relevant

page(s) of the d&b rigging accessories manual. Failure to fully

observe specified load capacities or fitting instructions can

overload the rigging accessories or the loudspeaker cabinet fixing

points causing them to break.

The d&b rigging accessories described in the d&b rigging

accessories manual and specific mounting instructions are directly

(2.0 E) 7-8

WARNING!

attached to d&b loudspeaker cabinets and are secured using either

screws or bolts fastened to threaded inserts fitted in the

loudspeaker cabinets. For attaching rigging, d&b loudspeaker

cabinets are fitted threaded inserts.

Where provided, the supplied screws or bolts should be used to

attach rigging. Using screws or bolts other than those supplied or

specified can result in an insecure and unsafe fixing. Additionally,

using screws or bolts longer than those supplied or specified can

physically damage a cabinet by penetrating its interior and causing

an air leak.

Load ratings

d&b rigging accessories are designed and constructed to have a

load rating appropriate to their intended use. The safe working

load (SWL) for each d&b rigging accessory is specified in its

respective data sheet and on the relevant page(s) of the d&b

rigging accessories manual.

In general, d&b rigging components are designed with a 10X load

safety factor. Some components, specifically intended only for use

in fixed, permanent installations are designed with a 5X load safety

factor. Other components, for use with moving as opposed to static

loads and therefore subject to the additional wear of dynamic

loading, are designed to have a 12X safety factor.

Safety certificates

In Germany, the health and safety authority together with

industrial and professional associations has published a safety code

for stages and studios. Sound reinforcement equipment installed in

these places has to comply with the provisions of this code,

published as BGV C1 (GUV 6.15) Unfallverhütungsvorschrift

Veranstaltungs- und Produktionsstätten für szenische Darstellung.

The code provisions include:

1. Plastic load bearing components are not permitted.

2. Plastic laminated or coated steel wire ropes are not permitted.

3. Load connector parts must have a load safety factor 10X

greater than their stated SWL (Safe Working Load).

4. Load bearing chains must have a load safety factor 0.5X

greater than the dynamic value specified by the manufacturer

- equivalent to a load safety factor 12X the specified SWL.

Provision #4 needs some explanation. High tensile chains and

related components conforming to EN 818, grade 8 are specified

with a load safety factor 4X their SWL. To comply with the 12X

load safety factor required for load bearing chains under BGV C1

(GUV6.15), the specified SWL for DIN certified chains must be

derated by a factor of three.

d&b audiotechnik AG, Eugen-Adolff-Str. 134, D-71522 Backnang, Germany, Phone +49-7191-9669-0, Fax +49-7191-95 00 00

60° Angle bracket (E6502)

Ring & Screw fittings for detented

rigging tracks (E6530/E6531)

WARNING!

(4.0E) 1220/1222

1220/1222 Accessories

1220/1222 loudspeakers are fitted with detented rigging tracks at

the top, bottom and rear of the cabinet. Two types of fitting can be

used with these tracks.

E6530 Ancra ring fitting

The ring fittings allow single 1220/1222 loudspeakers or two cabinet

1220/1222 clusters to be flown at a precisely defined vertical angle

without the need for additional stabilising guylines. Preset flying

angles between +48° and -12° are obtained by using the ring fittings

in certain positions in the detented tracks.

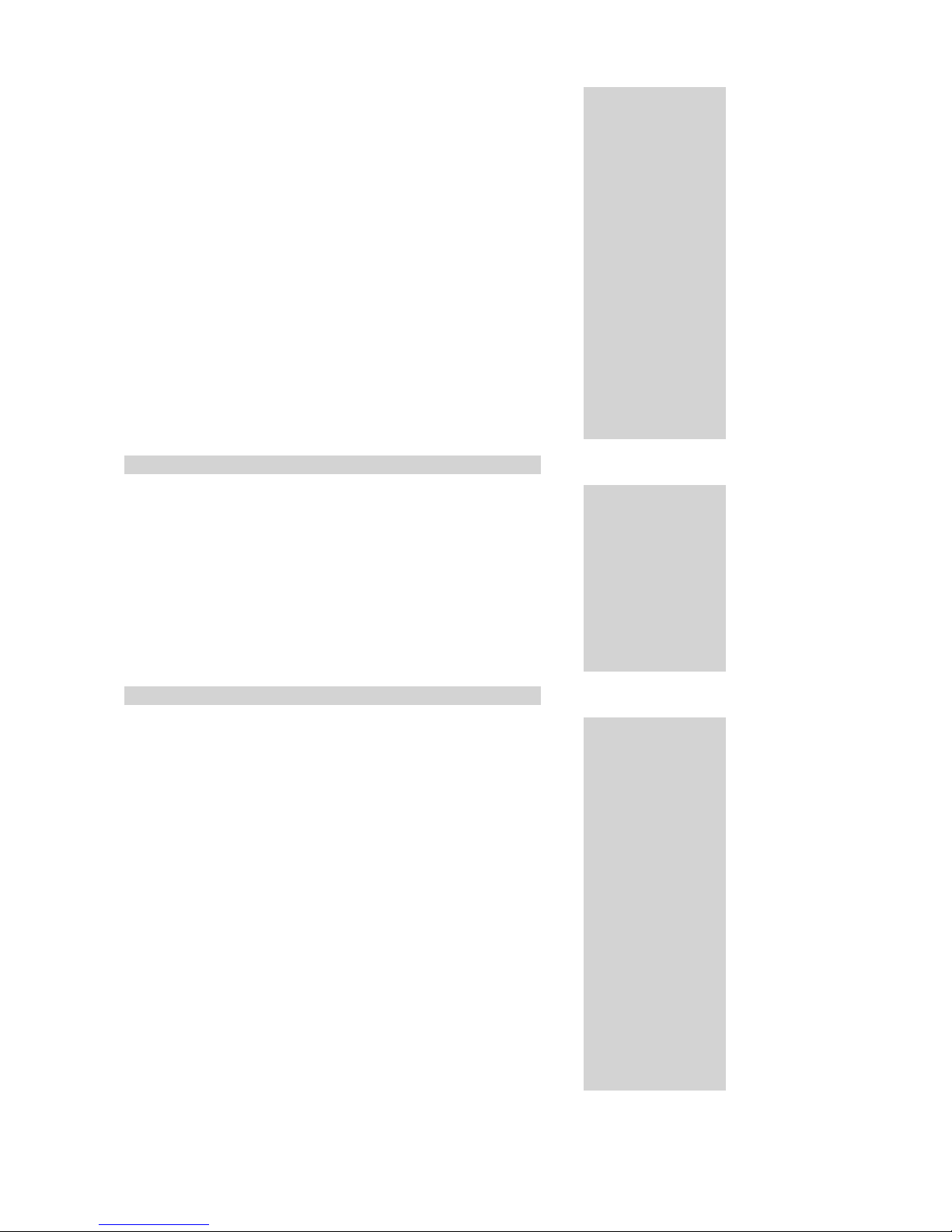

The table below shows the resulting vertical flying angles using a

pick-up (flying) point on the cabinet top or upper rear detented

track. Column A gives the flying angles for single loudspeakers, whilst

column B gives the angles for two cabinet clusters.

A single ring fitting will support the weight of a single 1220/1222

loudspeaker with a 12x load safety factor.

E6531 Ancra stud fitting

The screw fitting is for use with detented rigging tracks and has a 3/

8 threaded stud fitted with a flange nut. The screw fitting is used to

attach the E6502 60° Angle bracket.

E6502 60° Angle bracket

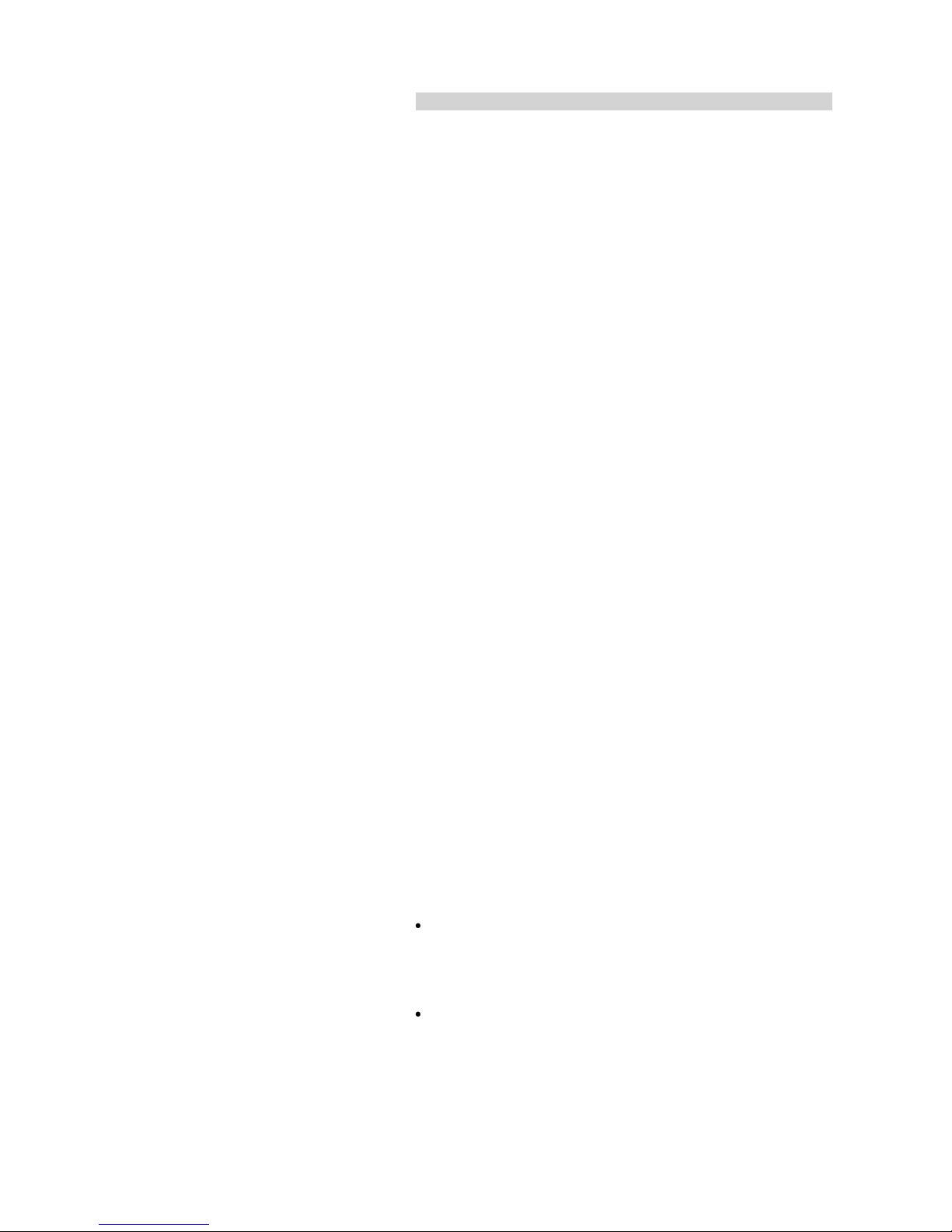

The 60° Angle bracket is used, as shown below, to precisely align two

1220/1222 loudspeakers next to each other. The resulting two

cabinet cluster has a 120° dispersion angle.

The bracket is fixed to the 1220/1222 loudspeaker rear panel

detented rigging tracks with two E6531 Ancra stud fittings. We

recommend using two brackets, one attached to the upper rear

panel tracks and the other to the lower tracks.

The hole in the centre of the Angle bracket is for use only to attach a

stabilising guyline if needed. The cluster itself must be flown using

E6530 Ancra ring fittings attached to the upper flying tracks.

Under no circumstances should you fly a speaker

cluster using the Angle bracket as a suspension

(flying) point!

d&b audiotechnik AG, Eugen-Adolff-Str. 134, D-71522 Backnang, Germany, Phone +49-7191-9669-0, Fax +49-7191-95 00 00

1220/1222 Vertical flying angles

Application example

d&b audiotechnik AG, Eugen-Adolff-Str. 134, D-71522 Backnang, Germany, Phone +49-7191-9669-0, Fax +49-7191-95 00 00

Declaration of Conformity to BGV C1

This declaration applies to the following components described in this Rigging

Accessories Manual :

Z5024 Loudspeaker stand adapter

Z5010 TV spigot with fixing plate (shipped after 27/11/97)

Z5012 Pipe clamp for TV spigot

Z0127 T bar adapter

Z5020 02 Flying adapter

Z5025 03 Flying adapter

Z5015 02 TV spigot

Z5021 02 Flying frame, 90° (shipped after 12/2/98)

Z5022 02 Flying frame, 60° (shipped after 3/4/98)

Z5023 02 Flying bracket (shipped after 27/8/97)

Rigging accessories C4/C7/F2/B1/MAX

Z5042 Flying plate

Z5080 Flying bar

Z5090 Single bar

Z5016 Heavy duty Pipe clamp

Z5017 Heavy duty TV spigot

Z0124 E1 Vertical bracket

Z0126 E1 Horizontal bracket

Z5033 E3 Ball joint adapter

Z5029 TV spigot for E3 ball joint adapter

Z5027 E3 Ball joint wall bracket

Z5031 E3 Standard bracket

Z5030 E3 x 2 Angle bracket

Z5032 E3 Swivel bracket

Z5028 E3 Horizontal bracket

Z5007 1220 Frame

Z5008 1220 Stand adapter

Z5043 MAX Horizontal bracket

Z5044 MAX Bracket connector

We hereby declare that the above listed products supplied by

d&b audiotechnik AG comply with the relevant requirements of

BGV C1(GUV 6.15).

d&b audiotechnik AG of Backnang accepts responsibility for

this declaration.

d&b audiotechnik AG, Eugen-Adolff-Str. 134, D-71522 Backnang, Germany, Phone +49-7191-9669-0, Fax +49-7191-95 00 00

Loading...

Loading...