Page 1

Z5394

Y

Rigging manual 1.1 en

Page 2

General information

Z5394 Rigging manual

Version: 1.1 en, 08/2014, D2719.EN .01

Copyright © 2014 by d&b audiotechnik GmbH; all rights

reserved.

Keep this manual with the product or in a safe place

so that it is available for future reference.

When reselling this product, hand over this manual to the new

customer.

If you supply d&b products, please draw the attention of your

customers to this manual. Enclose the relevant manuals with the

systems. If you require additional manuals for this purpose, you

can order them from d&b.

d&b audiotechnik GmbH

Eugen-Adolff-Strasse 134, D-71522 Backnang, Germany

T +49-7191-9669-0, F +49-7191-95 00 00

docadmin@dbaudio.com, www.dbaudio.com

Page 3

Contents

1. Z5394 Y Flying adapter................................................. 4

1.1. Safety....................................................................................... 4

1.1.1. Intended use......................................................................... 4

1.1.2. General safety..................................................................... 4

1.1.3. Load safety information....................................................... 4

1.2. Scope of supply...................................................................... 4

2. Assembly............................................................................. 5

2.1.

Suspension options................................................................. 5

2.2. Preparing the setup................................................................. 6

2.3. Order of assembly.................................................................. 6

2.4. Hoisting and securing the array (secondary safety)............. 9

3. Care and maintenance................................................ 10

3.1.

Transport / Storing............................................................... 10

3.2. Visual and functional inspection.......................................... 10

4. Declarations..................................................................... 11

4.1.

Manufacturer's declaration.................................................. 11

4.2. Disposal................................................................................. 11

d&b Z5394 Rigging manual 1.1 en 3

Page 4

1. Z5394 Y Flying adapter

1.1. Safety

1.1.1. Intended use

The Z5394 Y Flying adapter must only be used in conjunction with

the d&b Y-Series Y8 and Y12 loudspeakers as described in this

manual.

1.1.2. General safety

Installation and setup should only be carried out by qualified and

authorized personnel observing the valid national Rules for the

Prevention of Accidents (RPA).

It is the responsibility of the person installing the assembly to ensure

that the suspension/fixing points are suitable for the intended use.

Always carry out a visual and functional inspection of the items

before use. In case there is any doubt as to the proper functioning

and safety of the items, these must be withdrawn from use

immediately.

Please also refer to Þ Chapter 3. "Care and maintenance"

on page 10.

1.1.3. Load safety information

NOTICE!

The Z5394 Y Flying adapter is designed to suspend a total of

6 x Y8 or Y12 cabinets which corresponds to a total system weight

of 123 kg (271 lb) – SWL.

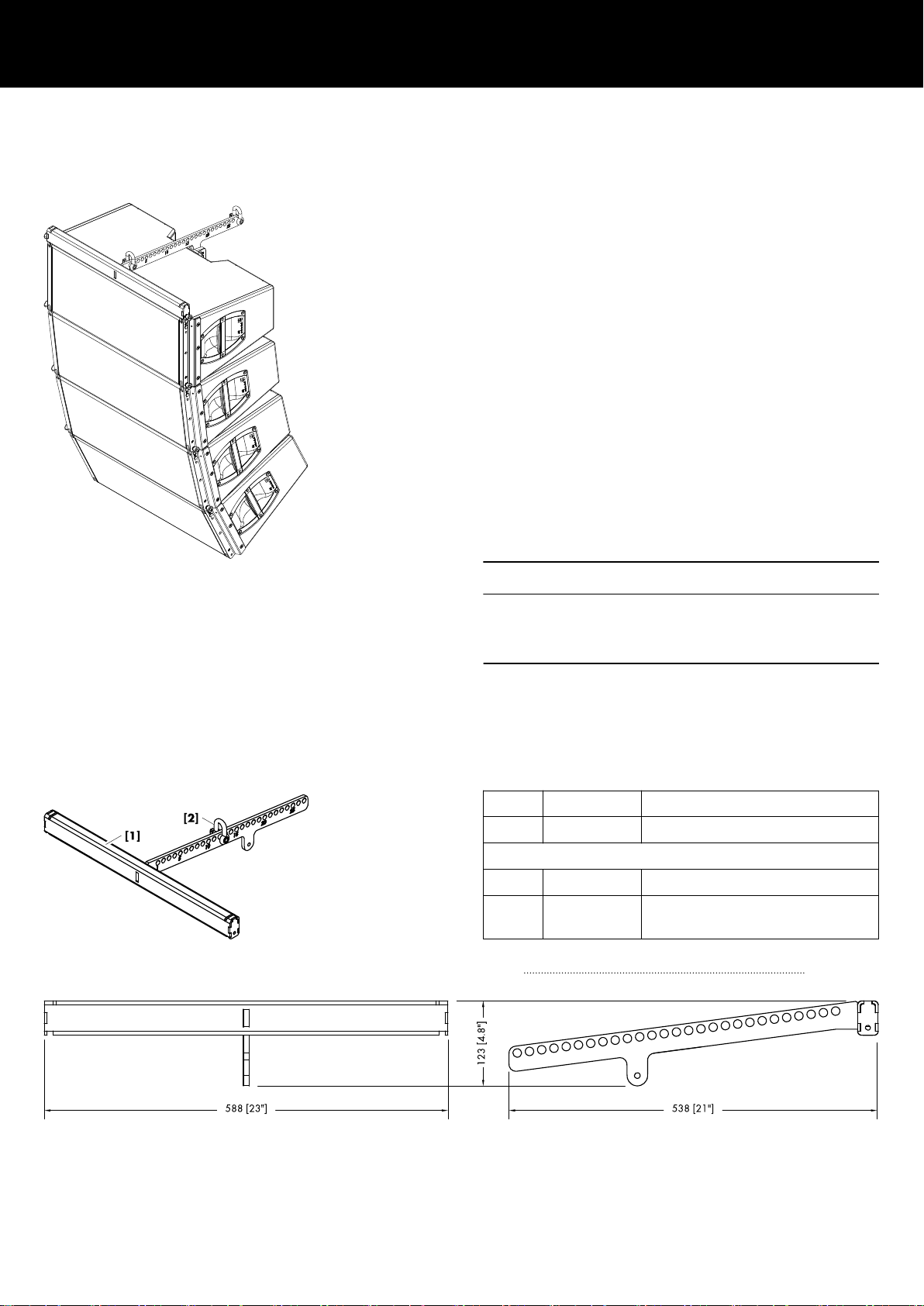

1.2. Scope of supply

Please verify the shipment for completeness and proper condition

of the items.

Qty.

d&b Code Description

1 Z5394 d&b Y Flying adapter [1]

Including:

1 E6507 1t shackle [2]

1 D2719.EN .01Z5394 Rigging manual

Weight 3.6 kg / 8 lb

Z5394 Y Flying adapter dimensions in mm [inch]

d&b Z5394 Rigging manual 1.1 en4

Page 5

2. Assembly

2.1. Suspension options

The center bar of the adapter is equipped with a total of 27 holes

to allow the suspension of the array and the setting of different

vertical angles.

The holes are numbered with an increment of five.

Single or dual pick point operation

The array can be suspended using one or two E6507 1t shackle(s)

and appropriate lifting devices or steel wire ropes.

With "Dual pick point operation", the vertical aiming of the entire

array is set by trimming the respective lifting devices.

With "Single pickpoint operation", the overall vertical aiming of the

entire array is defined by using a particular hole of the hole index

of the center bar.

The corresponding hole position is calculated using the d&b

ArrayCalc simulation software. For this purpose, ArrayCalc can be

downloaded at www.dbaudio.com.

Note: The use of ArrayCalc is described in "TI 385 d&b Line

array design, ArrayCalc" which is included in the ArrayCalc

software. The TI can also be downloaded at

www.dbaudio.com.

In ArrayCalc, the closest pickpoint hole and the exact distance in

cm/inch are displayed in the «Main» array section Þ

«Pickpoints and load» (last entry) on the «Rigging plot» page,

provided the corresponding array is selected on this page.

Z5147 Rota clamp option

Alternatively, the array can be suspended and horizontally aligned

from a single pickpoint using the d&b Z5147 Rota clamp. The

clamp allows the load to be attached to overhead bars or truss

with a tube diameter of up to 51 mm (2”).

Attachment

Choose the appropriate hole position in the center bar according

to the ArrayCalc calculation and attach the Rota clamp

correspondingly.

Note: Please observe the relevant mounting instructions

which are enclosed with the Rota clamp.

d&b Z5394 Rigging manual 1.1 en 5

Page 6

2.2. Preparing the setup

General

Check the acoustical and mechanical setup using ArrayCalc and

prepare enough printouts for each array.

The plan enables the riggers to set up the suspension points, the

securing points and the chain hoists.

When on site first:

– Clear the working areas and ensure there is enough space to

set up and lift the array.

– Check that the hoists are exactly in the specified position.

– Ensure the chains are not twisted.

– Prepare the cables and link cables according to the number of

amplifier channels and cabinets used.

Inspections before setup

Before setup carry out a visual inspection of all system components

for faults. This also includes the loudspeakers and in particular the

rigging parts of the cabinets (Front and Splay/Rear links).

Damaged components must be withdrawn from use immediately.

Please follow the instructions given in Þ Chapter 3. "Care and

maintenance" on page 10.

2.3. Order of assembly

Due to the compact size of the Y-Series TOP cabinets and the

maximum number of six cabinets that can be flown, the assembly

may be carried out either suspended or on the ground. The

following description refers to the suspended assembly.

1. Prepare the first cabinet

1. At the front release the Locking pins of the Front links.

Þ The Front links will slide out automatically.

2. On the rear release both Locking pins and fold out the Splay

link.

d&b Z5394 Rigging manual 1.1 en6

Page 7

2. Attach the Flying adapter

1. Attach the Flying adapter on top of the cabinet until the Front

links of the cabinet fit into the slots at the front of the adapter.

2. Insert and lock the Locking pins of the cabinet's Front links on

both sides.

3. On the rear align the Flying adapter with the [0°] hole of the

rear rigging strand.

4. Insert and lock one Locking pin in the [0°] hole.

Note: The second Locking pin is not needed and can be

stored in one of the remaining holes.

3. Prepare the next cabinet

1. Prepare the Front and Splay links of the next cabinet.

4. Preset the splay angle

The splay angles between adjacent cabinets are set at the central

rear rigging strands of the cabinets and can be set in the range

from 0° to 14° in 1° steps.

Þ

Preselect the splay angle according to your ArrayCalc

simulation and insert and lock one Locking pin in the

appropriate hole.

d&b Z5394 Rigging manual 1.1 en 7

Page 8

5. Attach the next cabinet

1. Suspend the assembly according to the desired suspension

option.

2. Lift the assembly to a suitable working height.

3. Attach the prepared cabinet to the corresponding slots on the

front of the upper cabinet.

4. Insert and lock the Locking pins of the cabinet's Front links on

both sides.

5. Raise the bottom cabinet until the hook of the Splay link of the

upper cabinet has hooked into the preset Locking pin.

6. Release the cabinet and insert the second Locking pin (Safety

pin) to secure the Splay link.

To add further cabinets, proceed in the same manner until the

assembly is completed.

6. Splay link of the last cabinet

The Splay link of the last cabinet can be kept in its park position.

Note: In this case, the lowest cabinet can be set to the

following splay angles: 3°, 5° and 7° to 14°.

7. Rig the cabling

Connect the flying cables and link cables according to the number

of amplifier channels and cabinets used.

8. Check the assembly

Before hoisting the array to its operating position recheck the

actual status of the entire assembly.

– Check the attachment of the shackles or Rota clamp to the

Flying adapter.

– Check the attachment of the Flying adapter to the first cabinet

and ensure all Locking pins are properly inserted and locked.

– Check all Front links on both sides of the cabinets and ensure

all Locking pins are properly inserted and locked.

– Check the splay angle settings and the Splay links on the rear

of the cabinets and ensure all Locking pins are properly

inserted and locked.

– In "Single pick point operation" check the desired total vertical

aiming of the entire array using an inclinometer.

d&b Z5394 Rigging manual 1.1 en8

Page 9

2.4. Hoisting and securing the array (secondary safety)

When all the mechanical adjustments, system checks and safety

checks have been made, the array can be hoisted up to its

operating position.

When hoisting the array, ensure that the loudspeaker cables do

not get caught anywhere. The cables can be strapped together

with the motor cable to form a loom while the system is hoisted.

The chain hoist motors must raise the system slowly and evenly so

that it does not swing or move from side to side during hoisting.

When the array is in its final operating position the secondary

safety must be applied.

d&b Z5394 Rigging manual 1.1 en 9

Page 10

3. Care and maintenance

3.1. Transport / Storing

During transport ensure the rigging components are not stressed or

damaged by mechanical forces. Use suitable transport cases.

Due to their surface treatment the rigging components are

temporarily protected against moisture. However, ensure the

components are in a dry state while stored or during transport and

use.

3.2. Visual and functional inspection

WARNING!

Potential risk of personal injury and/or

damage to material

To eliminate the potential risk of accident due to malfunctioning of

a component, regularly inspect all system components.

Cabinet enclosure

– Visual inspection of all fitting plates for obvious damage (e.g.

cracks or corrosion).

– Visual inspection of the rear rigging strand for obvious

damage (e.g. cracks, deformation or corrosion) including all

drilled holes of the component.

– Inspection of all fitting plates including front grills to ensure

they are securely attached.

– Regularly lubricate the sockets using WD-40® or a similar

product.

Front and Splay links

Visual inspection regarding deformation and damage (e.g. cracks

and corrosion) including all drilled holes of the component.

Locking pins

– Visual inspection for deformation, cracks and corrosion of the

component.

– Inspection for missing ball bearings and damage.

– Functional inspection of the release mechanism to ensure it

operates properly.

– Regularly lubricate the Locking pins using WD-40® or a similar

product.

Z5394 Y Flying adapter

Visual inspection regarding deformation and damage (e.g. cracks

and corrosion) including all drilled holes of the component.

d&b Z5394 Rigging manual 1.1 en10

Page 11

4. Declarations

4.1. Manufacturer's declaration

This declaration covers:

– d&b Z5394 Y Flying adapter.

National standards and technical specifications

applied:

DIN 18 800, DIN 1055, BGV C1.

Backnang, 2014-06-30

Frank Bothe,

Head of R&D

d&b audiotechnik GmbH

4.2. Disposal

When out of use the rigging components must be disposed of in

accordance with the national environmental regulations.

Ensure that damaged rigging components are disposed of in a

way that they cannot be used again.

d&b Z5394 Rigging manual 1.1 en 11

Page 12

Page 13

D2719.EN .01, 08/2014 © d&b audiotechnik GmbH

www.dbaudio.com

Loading...

Loading...