Page 1

Z5147

Rota Clamp

Mounting instructions (2.2 EN)

Page 2

Contents

1. Product description..............................................................................................3

2. Scope of supply....................................................................................................3

3. Load safety information.....................................................................................3

4. Weight/Installation height.................................................................................3

5. Assembly................................................................................................................3

6. Installation..............................................................................................................4

7. Operation/Adjustments.....................................................................................6

8. Maintenance and care.......................................................................................7

9. Disposal/Environmental protection.................................................................7

10. Manufacturrer's declaration..........................................................................8

General information

Z5147 Rota Clamp

Mounting instructions

Version 2.2 EN, 03/2013, D2970.EN .02

Copyright © 2013 d&b audiotechnik GmbH; alll rights reserved.

Keep this manual with the product or in a safe place

so that it is available for future reference.

d&b audiotechnik GmbH

Eugen-Adolff-Strasse 134, D-71522 Backnang

Telefon: +49-7191-9669-0, Fax: +49-7191-95 00 00

E-mail: docadmin@dbaudio.com, Internet: www.dbaudio.com

Page 3

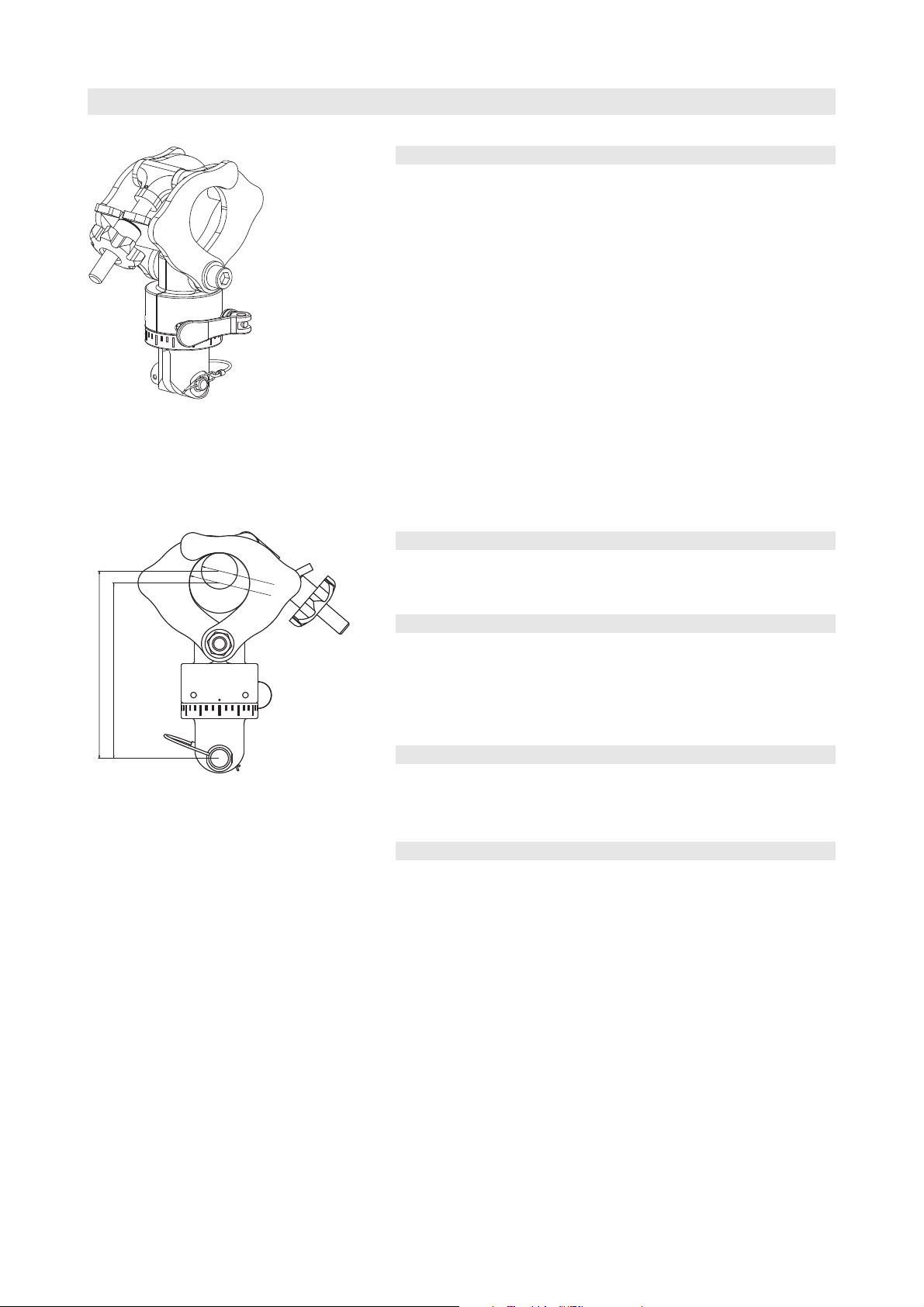

Z5147 Rota Clamp

Ø

30

Ø

50

1. Product description

Using the Z5147 Rota Clamp loudspeaker arrays or single cabinets can

be suspended and horizontally aligned from a single flying point. The

Rota Clamp allows the load to be attached to overhead bars or truss

with a tube diameter up to 51 mm (2”). It can be used in combination

with the following d&b rigging accessories:

Z5020 Flying adapter 02

Z5121/22 Flying frame 02 90°/60°

Z5044 Bracket connector

Z5145 Ci Mounting frame

Fig. 1: Z5147 Rota Clamp

Fig. 2: Z5147 Rota Clamp

Installation height

Z5054 Ci Flying adapter

Z5156 Q Flying adapter

Z5159 Q Flying frame

Observe the maximum permitted load of the respective accessories as

stated in their respective manuals/mounting instructions.

2. Scope of supply

The Z5147 Rota Clamp is pre assembled and supplied together with this

mounting instructions.

3. Load safety information

The maximum permitted load of the Z5147 Rota Clamp

is 500 kg/1100 lb according to the German standard

BGV C1. No additional loads must be added.

Never fit the clamp at an angle other than straight down.

4. Weight/Installation height

Weight..............................................................................................................2.2 kg/4.9 lb

Installation height.........155.4 mm/6", related to a tube diameter of 30 mm/1.2"

..........................................145.4 mm/5.7", related to a tube diameter of 50 mm/2"

5. Assembly

Safety precautions

The Z5147 Rota Clamp must only be used to suspend d&b loudspeaker

cabinets from a single suspension point in conjunction with the

recommended d&b rigging accessories.

Installation should only be carried out by fully trained personnel. There

are certain rules for installation that must be complied with.

It is the responsibility of the person installing the assembly to ensure that

the structure being attached to is suitable for the intended use.

All system components must be inspected for faults before use. Please

pay attention to section 8. Maintenance and care on page 7. Damaged

components must be withdrawn from use immediately.

Z5147 Mounting instructions (2.2 EN) Page 3 of 8

Page 4

Preparations

Release Remove/

Fit

Snap in Lock

[1 b ]

[1 a]

[1 a ]

The desired position in the rigg as well as the total vertical angle of the

assembly should be defined in advance. The total vertical angle can be

set via the holes grid of the respective adapter or frame.

Function of the securing pin (Rue ring cotter)

Fig. 3: Function of the Rue ring cotter (schematic diagram)

Fitting to Flying adapter/Flying frame

1. Unlock and remove the ring cotter [1a] of the fixing bolt and

remove the fixing bolt [1b].

2. Attach the Rota Clamp to the respective hole of the flying adapter

or flying frame.

Fig. 4: Z5147 Rota Clamp assembly with

Z5156 Q Flying adapter

Fig. 5: Fixing bolt secured

CAUTION!

3. Insert the fixing bolt [1b] and secure the bolt with the ring cotter

[1a].

4. Recheck your work and ensure the ring cotter [1a] is properly fitted

to the fixing bolt - Fig. 5.

6. Installation

Installation must only be to horizontal tubes. Never fit

the clamp at an angle other than straight down.

With the Rota Clamp fitted to the assembly as described above, the

assembled unit is now ready to install.

Proceed as follows:

Z5147 Mounting instructions (2.2 EN) Page 4 of 8

Page 5

[2]

Fig. 6: Installation - Step 1

[U]

[2]

Fig. 7: Installation - Step 2/3

1 First release the hand wheel [2] of the clamping lever until its end-

position.

2. Fold out the clamping lever.

3. With the support clamp open, the assembly can now be lifted into

position.

4. Close The two halves of the clamp around the bar.

Fig. 8: Installation - Step 4

Fig. 9: Installation - Step 5/6

Fig. 10: Installation - Step 7

5. Pull back the U-washer [U] of the clamping lever to the hand wheel

[2].

6. Fold back the clamping lever.

7. Hand-tighten the hand wheel [2].

Safety precaution!

No other adjustments should be attempted until the

hand wheel has been tightened.

A safety wire (secondary safety) should now be fitted to

secure the assembly before carrying out either positional

or directional adjustments.

Z5147 Mounting instructions (2.2 EN) Page 5 of 8

Page 6

7. Operation/Adjustments

[2]

[3]

0° 10°10°20° 20°30° ...... 30°

WARNING!

Fig. 11: Horizontal position

CAUTION!

Carry out positional and directional adjustments one at a

time. Never try to make more than one adjustment

without the others being firmly locked off.

Vertical alignment

The vertical tilt of the load must not be adjusted by

turning the Rota Clamp against the supporting tube. The

desired total vertical angle is to be set via the holes grid

of the respective adapter or frame in advance as

described above in section 'Assembly'.

Positional adjustment (Horizontal position)

If an adjustment of the position on the bar is necessary proceed as

follows:

1. Release the locking hand wheel [2] only enough to release the grip

on the bar.

2. While supporting the weight of the assembly, the positional

adjustment can now be made. Observe that you do not damage the

tube (notching).

3. Always re-tighten the hand wheel after any adjustments.

Horizontal alignment

Fig. 12: Z5147 Rota Clamp Horizontal

alignment

Horizontal adjustments can be carried out via the rotatable unit of the

clamp. Proceed as follows:

1. Release the excentric lever [3] of the clamp-

2. Set the desired horizontal angle.

The angle can be read from the scale releated to the mark (point) of

the clamp.

The scale's increment is 10° for every graduation mark. The taller

mark displays an increment of 30°.

3. Close the excentric lever [3].

Z5147 Mounting instructions (2.2 EN) Page 6 of 8

Page 7

[4]

[3]

[2]

[1b]

[1a]

Fig. 13:Z5147 Rota Clamp

[4a]

[4]

Maintenance and care

8. Maintenance and care

Cleaning

Regularly clean and lubricate the Rota Clamp with WD-40®or a similar

product.

Inspections

To eliminate the potential risk of accident because of malfunction of a

component regularly inspection according to the appropriate

regulations for lifting device of all system components is essential.

Test recommendations

1. Visual inspection of the Rota Clamp regarding obvious deformation

and damage (e.g. cracks and corrosion) of the components including

all holes of the components.

2. Visual inspection of the fixing bolt [1b] regarding deformation

(notching) and damage (e.g. cracks and corrosion).

3. Visual inspection of the fasting lever and hand wheel [2] regarding

deformation and damage (e.g. cracks and corrosion) and inspection

of proper function.

4. Functional inspection of the excentric lever and rotation device

(swivel mechanism for horizontal adjustment) of the clamp [3].

5. The connection between the clamp and the rotation device [4] is

adjusted for proper function by the manufacturer. A visual inspection

of the self-locking nut for correct function and an inspection of the

clamp mechanism should be carried out regularly. In the case of

damage or no proper function (e.g. twisted clamps or rough running

mechanism of the clamp) the Rota Clamp should only be repaired by

d&b audiotechnik.

Fig. 14:Z5147 Rota Clamp Deformation of

the outer clamp

Ring cotter o.k. Change the ring cotter

Fig. 15: Condition of the Rue ring cotter [1a]

6. Open the clamp mechanism and check the outer clamps for obvious

deformation - Fig. 14. In the case of damage or no proper function

(e.g. twisted clamps or rough running mechanism of the clamp) the

Rota Clamp should only be repaired by d&b audiotechnik.

7. Visual inspection of the Rue ring cotter [1a] for obvious damage and

deformation. Also carry out a functional test of the locking

mechanism. If the ring cotter can no more be properly fitted to the

fixing bolt and locked it must be exchanged - Fig. 15.

9. Disposal/Environmental protection

The product must be disposed in accordance to the national

environmental regulations.

Z5147 Mounting instructions (2.2 EN) Page 7 of 8

Page 8

Manufacturer's declaration

_______

10. Manufacturrer's declaration

We hereby declare that the equipment designated below is designed and built in the version sold by us in such a way as

to comply with the relevant fundamental safety and health criteria of the applicable EC Directive(s). This declaration shall

cease to be valid if alterations are made to the equipment without our prior agreement.

This declarations covers:

•••• Z5147 Rota Clamp

To be used as described in this mounting instructions

National standards and technical specifications applied, in particular:

DIN 18800-1, DIN EN 1050, DIN EN ISO 12100

Backnang, 2013-03-27

D2970.EN .02, 03/2013 d&b audiotechnik GmbH

(Frank Bothe, Head of R&D)

d&b audiotechnik GmbH, Eugen-Adolff-Str. 134, D-71522 Backnang, Germany, Phone +49-7191-9669-0, Fax +49-7191-95 00 00

Loading...

Loading...