Page 1

xA-Series

Rigging manual (1.1 EN)

Page 2

General information

xA-Series

Rigging manual

Version: 1.1 EN, 02/2012, D2962.EN .01

Copyright © 2012 by d&b audiotechnik GmbH; all rights

reserved.

Keep this manual with the product or in a safe place

so that it is available for future reference.

When reselling this product, hand over this manual to the new

customer.

d&b audiotechnik GmbH

Eugen-Adolff-Strasse 134, D-71522 Backnang, Germany

T +49-7191-9669-0, F +49-7191-95 00 00

docadmin@dbaudio.com, www.dbaudio.com

Page 3

Contents

1. System safety................................................................... 4

1.1. Intended use................................................................ 4

1.2. Load capacity.............................................................. 4

1.2.1. Approved array configurations............................... 4

1.2.2. xA-Series loudspeaker cabinet weights.................. 4

1.3. ArrayCalc / TI 385..................................................... 5

1.4. Operational safety...................................................... 5

2. Rigging concept............................................................... 6

2.1. Tool box....................................................................... 7

2.2. xA-Series rigging components.................................... 7

2.2.1. xA-Series loudspeaker cabinets.............................. 7

2.2.2. Z5413 Flying bar connector plate xA................... 7

2.2.3. Z5414 Flying bar xA............................................... 8

2.2.4. Z5415 Flying bar adapter xA................................ 9

2.2.5. Z5419 Load bar xA................................................ 9

2.2.6. Z5416 Connector plate 10A............................... 10

2.2.7. Z5417 Connector plate 10AL.............................. 10

2.2.8. Z5418 Connector plate xA-SUB.......................... 10

2.2.9. Z5421 Connector plate xA, neg. splay............... 11

2.2.10. Z5420 Load eyebolt.......................................... 11

2.3. Setting the splay angle............................................. 11

2.4. Connector plate hole grids....................................... 13

3. Suspension options...................................................... 15

3.1. Vertical arrays........................................................... 15

3.1.1. Z5415 Flying bar adapter xA.............................. 15

3.1.2. Additional suspension options.............................. 16

4. xA-Series arrays and assembly............................. 17

4.1. xA-Series array configurations................................. 17

4.2. Assembly preparations............................................. 18

4.2.1. Tools required........................................................ 18

4.2.2. Assembly area....................................................... 18

4.2.3. Orientation of the HF section................................ 18

4.3. Vertical arrays........................................................... 18

4.3.1. Horizontal assembly on the ground..................... 18

4.4. Ground stacks........................................................... 20

5. Hoisting the array........................................................ 21

5.1. Safety guidelines....................................................... 21

6. Declarations.................................................................... 22

Manufacturer's declaration...................................... 22

6.1.

6.2. Disposal..................................................................... 22

d&b xA-Series, Rigging manual (1.1 EN) 3

Page 4

1. System safety

1.1. Intended use

The xA-Series rigging components (Flying bar, Flying bar adapter,

Connector plates) must only be used in conjunction with d&b xASeries loudspeakers as described in this rigging manual.

Installation and setup should only be carried out by qualified and

authorized personnel observing the valid national Rules for the

Prevention of Accidents (RPA).

It is the responsibility of the person installing the assembly to ensure

that the suspension/fixing points are suitable for the intended use.

Always carry out a visual and functional inspection of the items

before use. In case you have any doubt as to the proper

functioning and safety of the items, these must be withdrawn from

use immediately.

1.2. Load capacity

1.2.1. Approved array configurations

The xA-Series rigging system is designed to allow the following

approved array configurations for indoor applications.

Flown arrays Ground stacks

Array configuration Number and type of cabinets

Configuration Number and type of cabinets

10AL Line array – Up to 9 x 10AL (-D) cabinets. Mixed ground stack – Up to 6 x 10AL (-D) cabinets on

top of up to 3 x 18A or 27A

subwoofers as ground support.

10A Vertical array – Up to 6 x 10A (-D) cabinets. SUB stack – Up to 4 x 18A or 27A

subwoofers.

Mixed arrays – Up to 6 x TOP cabinets

combined with up to 2 x SUB

cabinets at the top of the array.

– Up to 3 x cabinets at the top of

the array with up to 2 x SUB

cabinets in-between and up to 3

x TOP cabinets at the bottom.

SUB column – Up to 4 x 18A subwoofers.

– Up to 3 x 27A subwoofers.

1.2.2. xA-Series loudspeaker cabinet weights

Cabinet Weight in kg (lb)

10A (-D)/10AL (-D) 14 kg (31 lb)

18A-SUB 32 kg (71 lb)

27A-SUB 41 kg (90 lb)

d&b xA-Series, Rigging manual (1.1 EN)4

Page 5

1.3. ArrayCalc / TI 385

For safety reasons xA-Series arrays must be designed using the

d&b ArrayCalc simulation tool. The software is available for

download at

www.dbaudio.com.

The use of ArrayCalc is described in the technical information

TI 385 "d&b Line array design, d&b ArrayCalc", which is also

provided with this rigging manual.

Carefully read this TI to become familiar with the operation and

behavior of ArrayCalc and in particular with the mechanical load

conditions and limitations.

We also recommend you to attend the regularly hosted d&b xASeries training seminars. Further information regarding the d&b

seminars can be requested directly from the d&b audiotechnik

sales partners.

1.4. Operational safety

During assembly pay attention to the possible risk of crushing.

Wear suitable protective clothing.

Observe all instructions given on the rigging components and the

loudspeaker cabinets.

When chain hoists are in operation, ensure that there is nobody

directly underneath or in the vicinity of the load who is not involved

in the setup.

Do not under any circumstances climb on the array

d&b xA-Series, Rigging manual (1.1 EN) 5

Page 6

2. Rigging concept

d&b xA-Series, Rigging manual (1.1 EN)6

Page 7

2.1. Tool box

– Hex head socket wrench (Torque wrench) #13 mm.

– Screw driver with torx bit TX30.

– Torx socket wrench (Torque wrench) with torx bit TX45.

– Allen hex key 5 mm.

– Securing glue (such as Loctide®).

2.2. xA-Series rigging components

The xA-Series loudspeaker cabinets together with the xA-Series

rigging components allow the setup of various array

configurations, either flown or ground stacked.

The following overview provides a basic description of the

intended use of each component.

2.2.1. xA-Series loudspeaker cabinets

The cabinet side panels are equipped with integrated rigging

points to accept the corresponding xA connector plates.

To attach the connector plates, the rigging points can easily be

accessed by removing the cover plates.

Once the respective connector plates are attached to both sides of

the cabinets, the cover plates are refitted to build a solid

mechanical connection between the cabinets or to the flying bar.

2.2.2. Z5413 Flying bar connector plate xA

Intended use

The Flying bar connector plate xA is used to connect the flying bar

to the entire array. For this purpose, the connector plate is

equipped with two pairs of holes.

The lower pair is used to connect the flying bar to SUB cabinets, if

these are integrated at the top of the array.

To connect the flying bar to 10A (-D) or 10AL (-D) cabinets, either

the lower or the upper pair can be used. Using the upper pair

allows the flying bar to be connected as close as possible to the

first cabinet of the entire array.

The connector plate is equipped with an additional suspension

hole of 12.5 mm [0.5"] [S] to allow the suspension of the array

(dual pickpoint operation) using a 1t Shackle (e.g. d&b E6507)

instead of the flying bar adapter.

The connector plate can also be used to attach a second pickpoint

at the end of the array to act as a pullback anchor device, if

required.

d&b xA-Series, Rigging manual (1.1 EN) 7

Page 8

NOTICE!

Risk of damage to the rigging components.

When using the additional suspension hole of the connector plate

to suspend and/or lash the array, the Z5414 Flying bar xA must

be used as supporting device between the two connector plates.

Alternatively, the Z5419 Load bar xA can be used for this

purpose. It is recommended to attach the load bar to the rear

fixing hole of the connector plate as shown in the graphic

opposite.

A detailed description of the various suspension options is given in

Þ Chapter 3. "Suspension options" on page 15.

2.2.3. Z5414 Flying bar xA Scope of supply

Qty. d&b Code Description

1

Z5414 d&b Flying bar xA [1]

Including:

4

4

Spring washer [1.1]

Pan head bolt M8 x 18/12.9 [1.2] (torx

#T45)

Intended use

CAUTION!

Risk of damage to the rigging components.

Only use the supplied and specified pan head bolts [1.2] with a

quality grade of 12.9.

The Flying bar xA is used to suspend xA arrays with the following

options:

– Either single or dual pickpoint operation in conjunction with

the Z5415 Flying bar adapter xA. In this combination the

flying bar can be attached in two directions to provide an

extended hole grid using the flying bar adapter.

– Dual pickpoint operation in conjunction with the Z5413 Flying

bar connector plate xA.

– It can also be used to attach a second pickpoint between

adjacent cabinets in the lower part of the array or at the end

of the array acting as a pullback anchor device, if required.

– The flying bar is also used as supporting device for horizontal

array configurations in conjunction with the Q9031 M8

Safety eyebolt.

A detailed description of the various suspension options is given in

Þ Chapter 3. "Suspension options" on page 15.

d&b xA-Series, Rigging manual (1.1 EN)8

Page 9

2.2.4. Z5415 Flying bar adapter xA Scope of supply

Qty. d&b Code Description

1

Z5415 d&b Flying bar adapter xA [2]

Including:

2

2

Pan head bolt M8 x 16, torx T45 [2.1]

Self-securing nut M8 [2.2]

Intended use

The Flying bar adapter xA is used in conjunction with the Z5414

Flying bar xA and allows single or dual pickpoint operation.

It is attached to the flying bar by simply sliding it onto the bar and

fixing it at the center position using the pan head screws [2.1] and

self-securing nuts [2.2].

The flying bar also allows the attachment of two flying bar

adapters at each end of the bar, which are fixed using one pan

head screw [2.1] and self-securing nut [2.2] for each adapter.

A detailed description of the various suspension options is given in

Þ Chapter 3. "Suspension options" on page 15.

2.2.5. Z5419 Load bar xA Scope of supply

Qty. d&b Code Description

1

Z5419 d&b Load bar xA [3]

Including:

2

2

2 Q9031

Spring washer [3.1]

Pan head bolt M8 x 18, torx T45 [3.2]

M8 Safety eyebolt [3.3]

Intended use

The Z5419 Load bar xA can be used in different ways:

– as supporting device instead of using the Z5414 Flying bar

xA.

– to suspend vertical arrays in conjunction with the Z5420 Load

eye bolt.

– as supporting device for horizontal array configurations in

conjunction with the supplied Q9031 M8 Safety eyebolt.

– to attach a second pickpoint between adjacent cabinets in the

lower part of the array or at the end of the array acting as a

pullback anchor device together with the Z5420 Load eye

bolt, if required.

– to attach a second pickpoint to fix the horizontal aiming of the

array using the Q9031 M8 Safety eyebolt and appropriate

steel wire ropes.

A detailed description of the various suspension options is given in

Þ Chapter 3. "Suspension options" on page 15.

d&b xA-Series, Rigging manual (1.1 EN) 9

Page 10

2.2.6. Z5416 Connector plate 10A

The connector plate is used to interconnect 10A (-D) cabinets and

set them to different splay angles.

Splay angles between adjacent cabinets can be set in the range

from 25° to 60° in 5° steps.

Note: When setting up horizontal arrays consisting of 10A (D) cabinets, set the minimum splay angle between adjacent

cabinets to 30° to allow for the attachment of the Z5419

Load bar xA or Z5415 Flying bar adapter xA as supporting

and suspension device.

2.2.7. Z5417 Connector plate 10AL

Intended use

The connector plate is used to interconnect 10AL (-D) cabinets and

set them to different splay angles.

Splay angles between adjacent cabinets can be set to 0°, 1°, 2°,

4°, 6°, 9°, 12° or 15°.

Note: The connector plate can also be used in a mixed

vertical array when adding 10A (-D) cabinets below a SUB

cabinet.

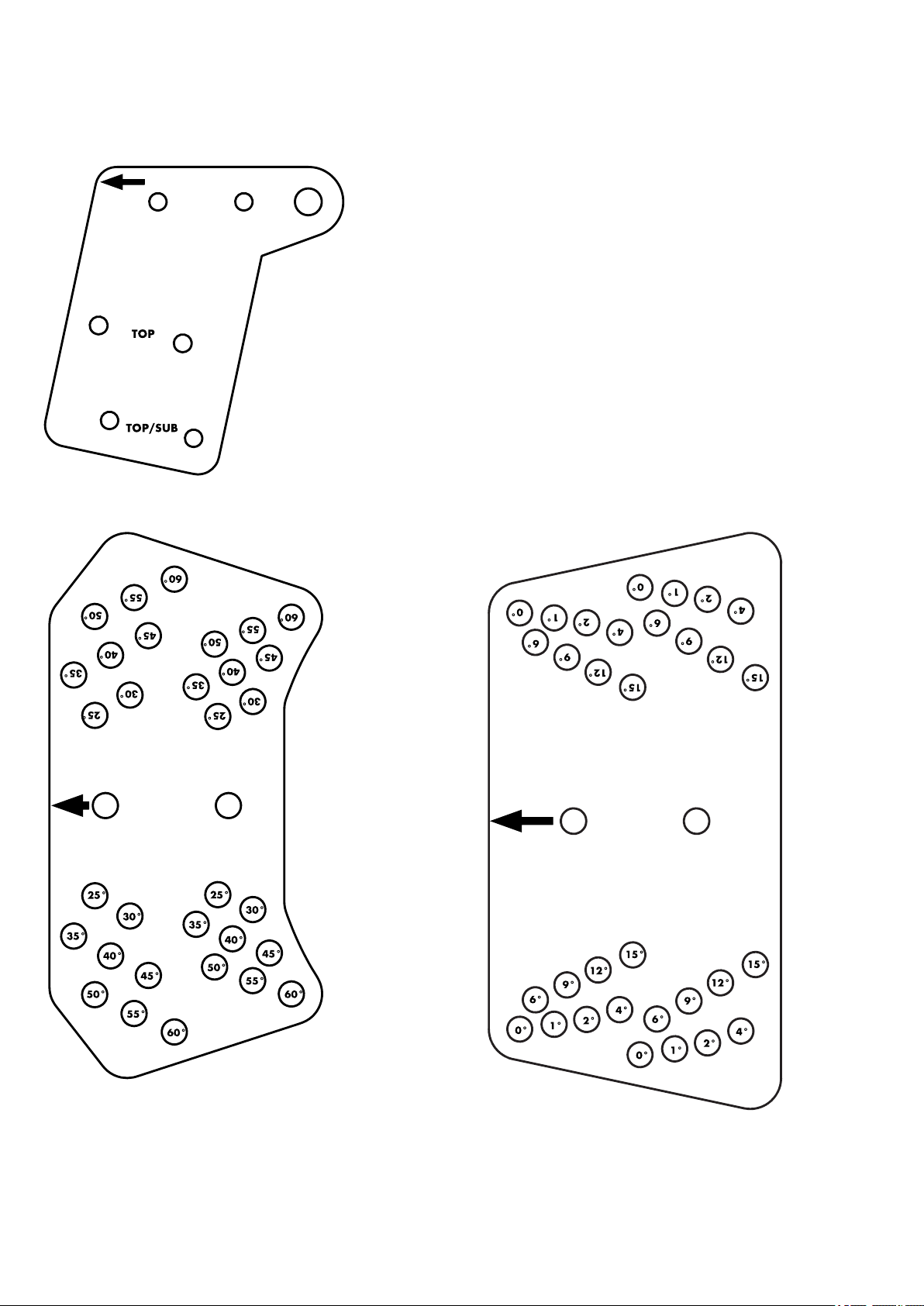

2.2.8. Z5418 Connector plate xA-SUB

Intended use

The connector plate is used to interconnect xA-SUB cabinets and

allows splay angle settings between adjacent SUB cabinets of 0°,

2.5° or 5°.

d&b xA-Series, Rigging manual (1.1 EN)10

Page 11

2.2.9. Z5421 Connector plate xA, neg. splay

Intended use

The connector plate is used in ground stack setups to apply a

downtilt (negative splay) to the first TOP cabinet.

The connector plate can also be used in mixed vertical arrays to

apply either an uptilt to the first TOP cabinet below a SUB cabinet

or a downtilt to the first TOP cabinet above a SUB cabinet.

Angles can be set to 0°, 1°, 2°, 4°, 6° or 9°.

2.2.10. Z5420 Load eyebolt

Intended use

The Z5420 Load eye bolt is rotatably supported and is used to

suspend the array in conjunction with the Z5413 Flying bar

connector plate xA and the Z5419 Load bar xA.

It can also be used to attach a second pickpoint between adjacent

cabinets in the lower part of the array or at the end of the array

acting as a pullback anchor device together with the Z5419 Load

bar xA, if required.

Assembly

CAUTION!

Potential risk of loosening of the fixing screw.

The integrated fixing screw of the eyebolt is rotatably supported

and therefore cannot be secured against loosening using a spring

or lock washer. To prevent the screw from loosening, an

appropriate securing glue such as "Loctide®" must be used.

When attaching the eyebolt, handtighten the screw using a 5 mm

Allen hex key. Do not use any extension tool as this might apply

too much torque and cause an overload on the fixing screw.

2.3. Setting the splay angle

The procedure of setting the splay angles between adjacent

cabinets (TOP or SUB cabinets) is the same for all connector plates

of the xA-Series. For this purpose, the connector plates are

equipped with a hole grid at each end.

To set the desired splay angle, use the respective pair of holes on

the connector plate for the upper and for the lower cabinet.

A correspondingly labeled diagram of the connector plate's hole

grids and possible angle settings is provided in the following

section (Þ Chapter 2.4. "Connector plate hole grids"

on page 13.

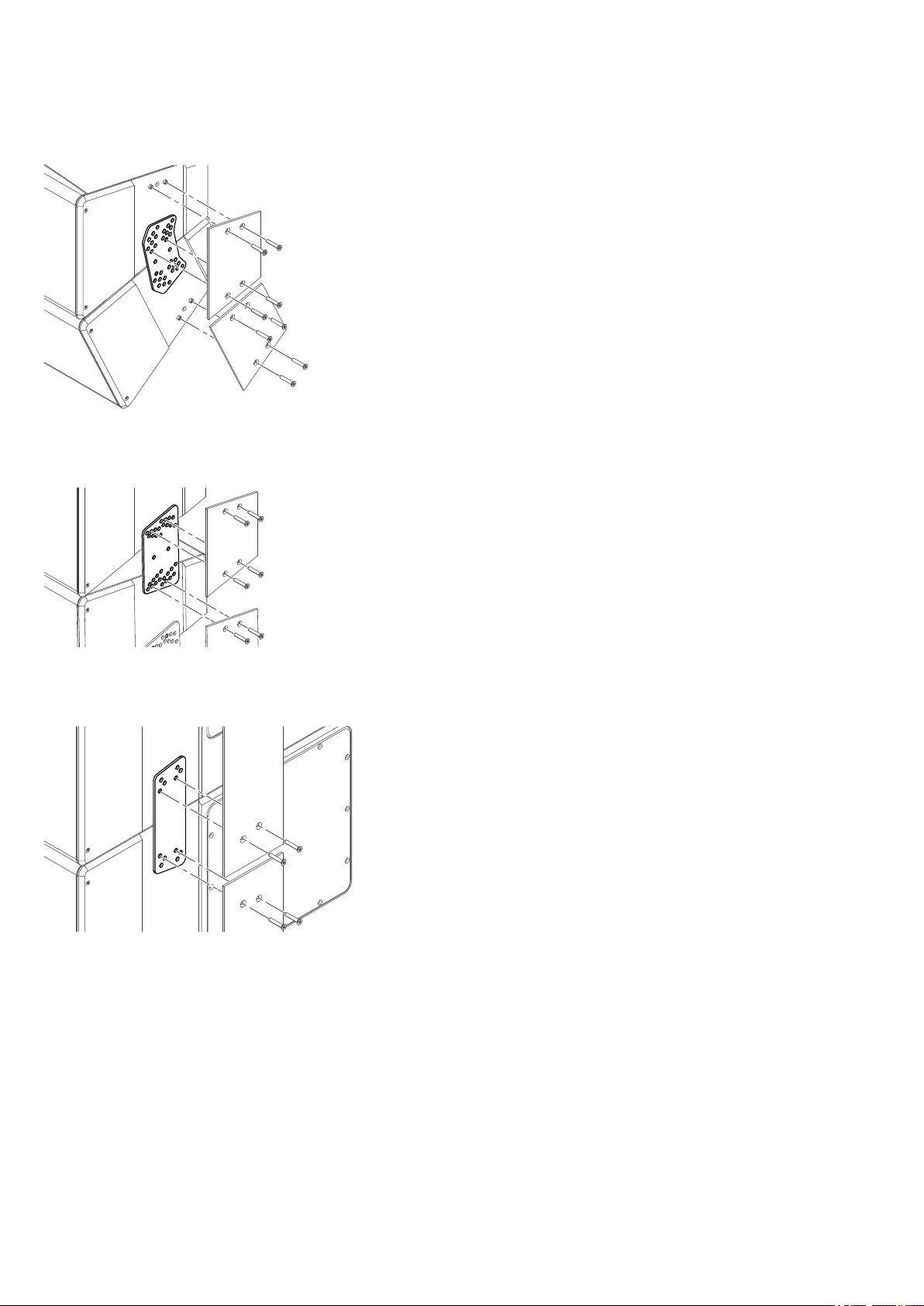

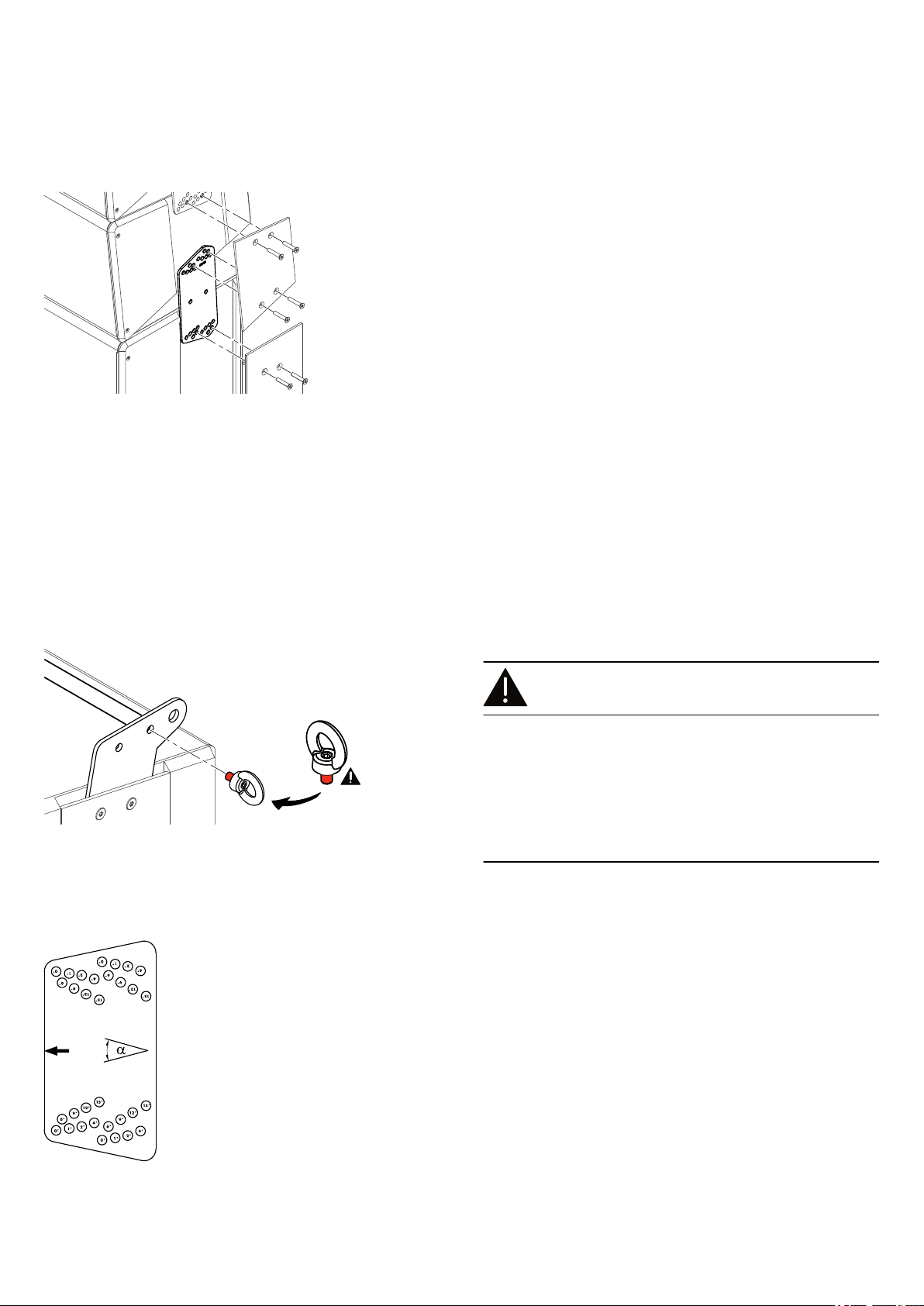

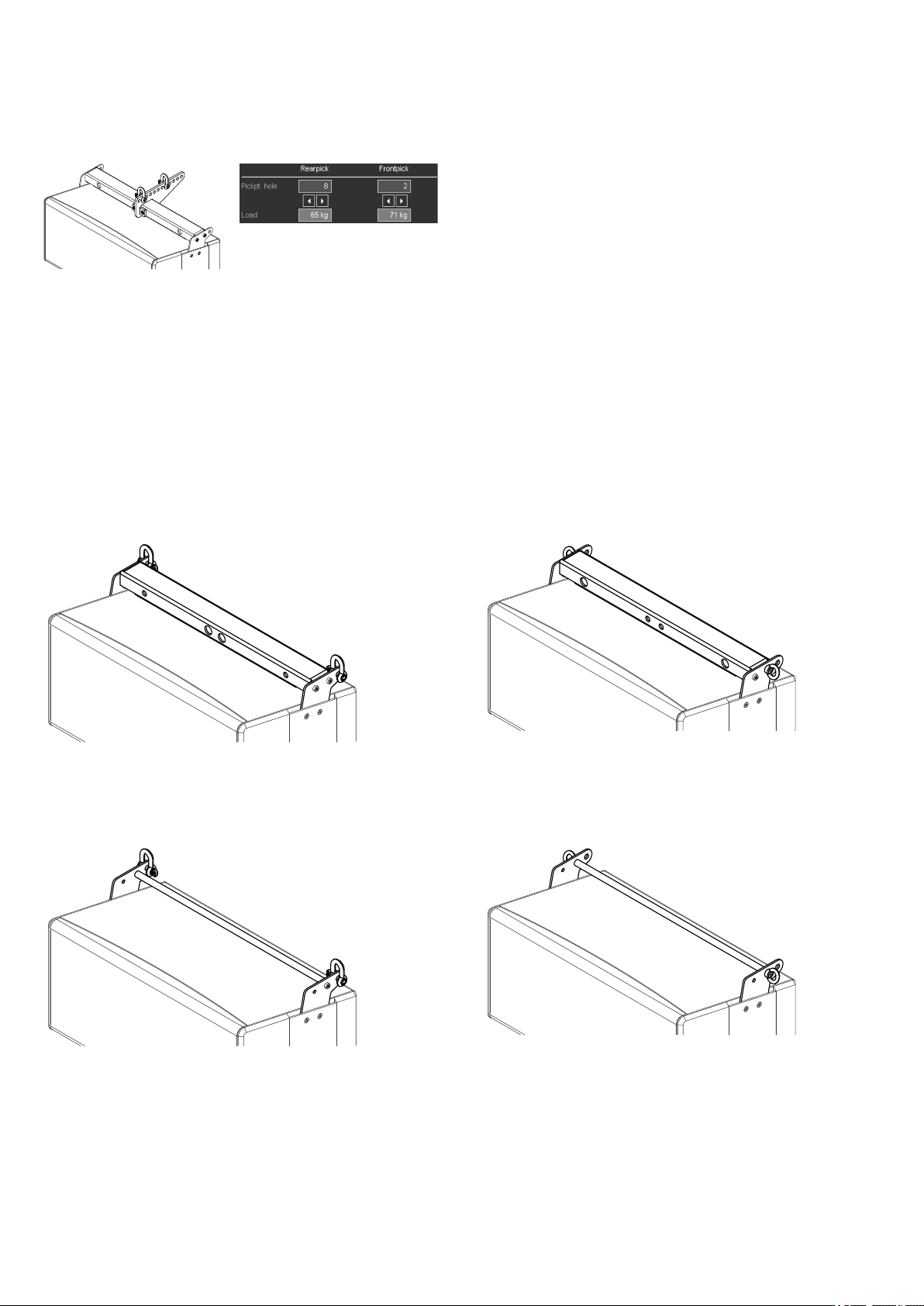

The following graphics show example settings for each of the

connector plates, indicating the holes to be used and the set splay

angles.

d&b xA-Series, Rigging manual (1.1 EN) 11

Page 12

Fig. 1: Z5416 Connector plate 10A, angle setting

Fig. 3: Z5418 Connector plate xA-SUB, angle setting

Fig. 2: Z5417 Connector plate 10AL, angle setting

Fig. 4: Z5421 Connector plate xA, neg. splay, angle setting

d&b xA-Series, Rigging manual (1.1 EN)12

Page 13

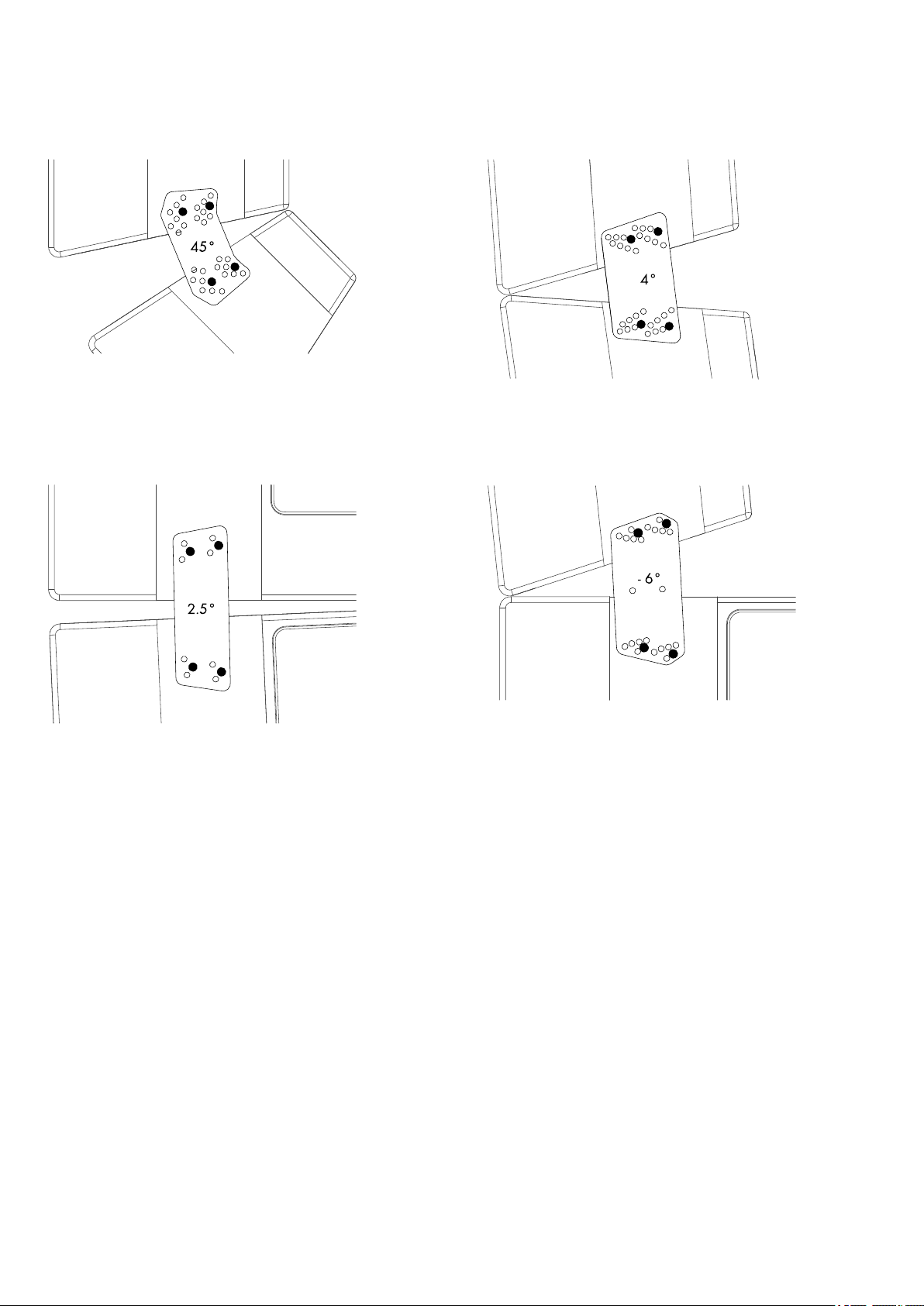

Fig. 5: Z5413 Flying bar connector plate xA

2.4. Connector plate hole grids

In the following, the hole grids of the xA connector plates are

labeled with the corresponding angle settings.

Note:

– The graphics are not to scale.

– The arrow indicates the mounting direction of the

connector plate toward the front of the respective cabinet.

Fig. 6: Z5416 Connector plate 10A

Fig. 7: Z5417 Connector plate 10AL

d&b xA-Series, Rigging manual (1.1 EN) 13

Page 14

Fig. 8: Z5418 Connector plate xA-SUB

Fig. 9: Z5421 Connector plate xA, neg. splay

d&b xA-Series, Rigging manual (1.1 EN)14

Page 15

3. Suspension options

The xA-Series rigging system provides several options to suspend

xA-Series arrays depending on the various requirements on-site.

WARNING!

The array must be suspended using appropriate steel wires or

hoisting chains or using the d&b Z5147 Rota clamp (single

pickpoint operation). Any other type of suspension of the array is

not allowed.

The working load limits of the steel wires or chain hoists and their

suspension points must be high enough to carry the total system

weight.

Each of the suspension points must be able to carry the total system

weight.

3.1. Vertical arrays

Vertical xA-Series arrays may consist of 10AL (-D) or 10A (-D)

cabinets in combination with 18A or 27A subwoofers. This section

describes the suspension options for 10AL (-D) line arrays planned

using ArrayCalc.

3.1.1. Z5415 Flying bar adapter xA

The array is suspended using the Z5414 Flying bar xA together

with the Z5415 Flying bar adapter xA. Single or dual pickpoint

operation is possible.

On the upper edge of the flying bar adapter twelve 12.5 mm

[0.5"] holes are provided to accept:

– 1t Shackle (e.g. d&b E6507)

– d&b Z5147 Rota clamp

Þ single pickpoint operation to allow the attachment to

overhead bars or truss with a tube diameter of up to 51 mm

(2").

The adapter can be aligned in two directions (rearward [R] or

forward [F]) by simply turning the flying bar through 180°.

The corresponding hole positions for either single or dual pickpoint

operation are calculated using ArrayCalc.

Note: The calculated hole positions also apply when two

flying bar adapters are attached to the flying bar.

Single pickpoint operation

In single pickpoint operation, the position of the chosen hole

defines the overall vertical aiming of the entire array.

Within ArrayCalc the orientation of the adapter changes

according to the center of gravity of the array. If both orientations

are possible, the rearward orientation [R] is chosen. The direction

in which the holes are counted changes correspondingly.

d&b xA-Series, Rigging manual (1.1 EN) 15

Page 16

Dual pickpoint operation

With dual pickpoint operation the overall vertical aiming of the

entire array is set by trimming the hoist motors after the array has

been fully assembled and lifted to its operating position.

3.1.2. Additional suspension options

In addition to the standard suspension option using the Flying bar

xA together with the Flying bar adapter xA, vertical arrays can be

suspended using one of the following options.

Note: All these options require a second pickpoint acting as

a pullback anchor device to set the overall vertical aiming of

the entire array. This second pickpoint is attached in the lower

part of the array between adjacent cabinets or at the end of

the entire array. Refer to .

Option 1: Suspension of the array using the Z5414 Flying bar

xA together with 2 x 1t shackle, e.g. d&b E6507.

Option 3: Suspension of the array using the Z5419 Load bar

xA together with 2 x 1t shackle, e.g. d&b E6507.

Option 2: Suspension of the array using the Z5419 Load bar

xA together with 2 x Z5420 Load eye bolt.

Option 4: Suspension of the array using the Z5419 Load bar

xA together with 2 x Z5420 Load eye bolt.

d&b xA-Series, Rigging manual (1.1 EN)16

Page 17

4. xA-Series arrays and assembly

4.1. xA-Series array configurations

xA-Series arrays can be assembled in the following ways.

Fig. 10: 10AL line array 9-deep Fig. 11: xA-Series mixed array,

type 1

Fig. 12: xA-Series mixed array,

type 2

Fig. 13: xA-SUB column

Fig. 14: 10A array 3-deep Fig. 15: xA-Series ground stack

d&b xA-Series, Rigging manual (1.1 EN) 17

Page 18

4.2. Assembly preparations

xA-Series arrays are mainly assembled horizontally on the ground.

Assembly may be carried out by a single person. However, as

during assembly the array needs to be rotated through 180° and

depending on the size of the array, a second person should assist

in the work.

4.2.1. Tools required

– Screw driver with torx bit TX30.

– Torx socket wrench (Torque wrench) with torx bit TX45.

– 13 mm hex head socket wrench.

4.2.2. Assembly area

To carry out the assembly on the ground, make sure:

– the surface is flat and clean.

– there is enough space for the overall dimensions of the array.

– to provide an additional protective underlay for assembly to

prevent the cabinets from scratching or other damage during

assembly.

4.2.3. Orientation of the HF section

Before starting to assemble the array, you must define the

orientation of the HF section of the TOP cabinets.

The xA-Series TOP cabinets have a biaxial design. In default

orientation, the HF waveguide is located to the left, viewed from

the audience side. To enable a symmetrical setup for stereo

systems, the cabinet orientation may be reversed.

The cabinet's connector plate at the rear may serve to indicate the

orientation of the HF section, as shown in the graphic opposite.

4.3. Vertical arrays

4.3.1. Horizontal assembly on the ground

This section describes the assembly of a mixed 10AL line array.

The same procedure applies to the assembly of 10A arrays. SUB

columns may, most appropriately, be assembled vertically.

d&b xA-Series, Rigging manual (1.1 EN)18

Page 19

4.3.1.1. Assembly procedure Joining the cabinets together

The procedure applies to both sides of the cabinets.

1. Place the cabinets with their side panels next to each other in

the right order and with the right orientation of the HF sections.

2. Remove the cover panels.

3. Attach the respective connector plates and set the desired

splay angles.

4. Refit the cover panels and tighten the screws to a torque of

12 N·m.

5. Recheck your work.

6. Carefully turn the array through 180°.

Þ Depending on the size (length) of the array, a second

person should assist you.

7. Complete the assembly by proceeding in the same manner.

8. Carefully turn the array over onto the front of the cabinets.

9. Recheck all your work:

– Check the splay angles.

– Ensure all screws are properly tightened.

The array is now ready for the attachment of the desired

Þ

suspension device.

d&b xA-Series, Rigging manual (1.1 EN) 19

Page 20

Attaching the suspension device

Depending on the suspension option chosen, attach the suspension

device correspondingly.

NOTICE!

Observe all safety instructions applicable for the respective

suspension option given in Þ Chapter 3. "Suspension options"

on page 15.

Before hoisting the array to its operating position, recheck all your

work. In particular, make sure that all screws are properly

tightened.

Hoisting the array

When all the mechanical adjustments, system checks and safety

checks have been performed, the array can be hoisted up to its

operating position.

Depending on the total system weight and overall size (length) of

the array, adequate precautions must be taken during the hoisting

procedure. For this purpose, refer to Þ Chapter 5. "Hoisting the

array" on page 21.

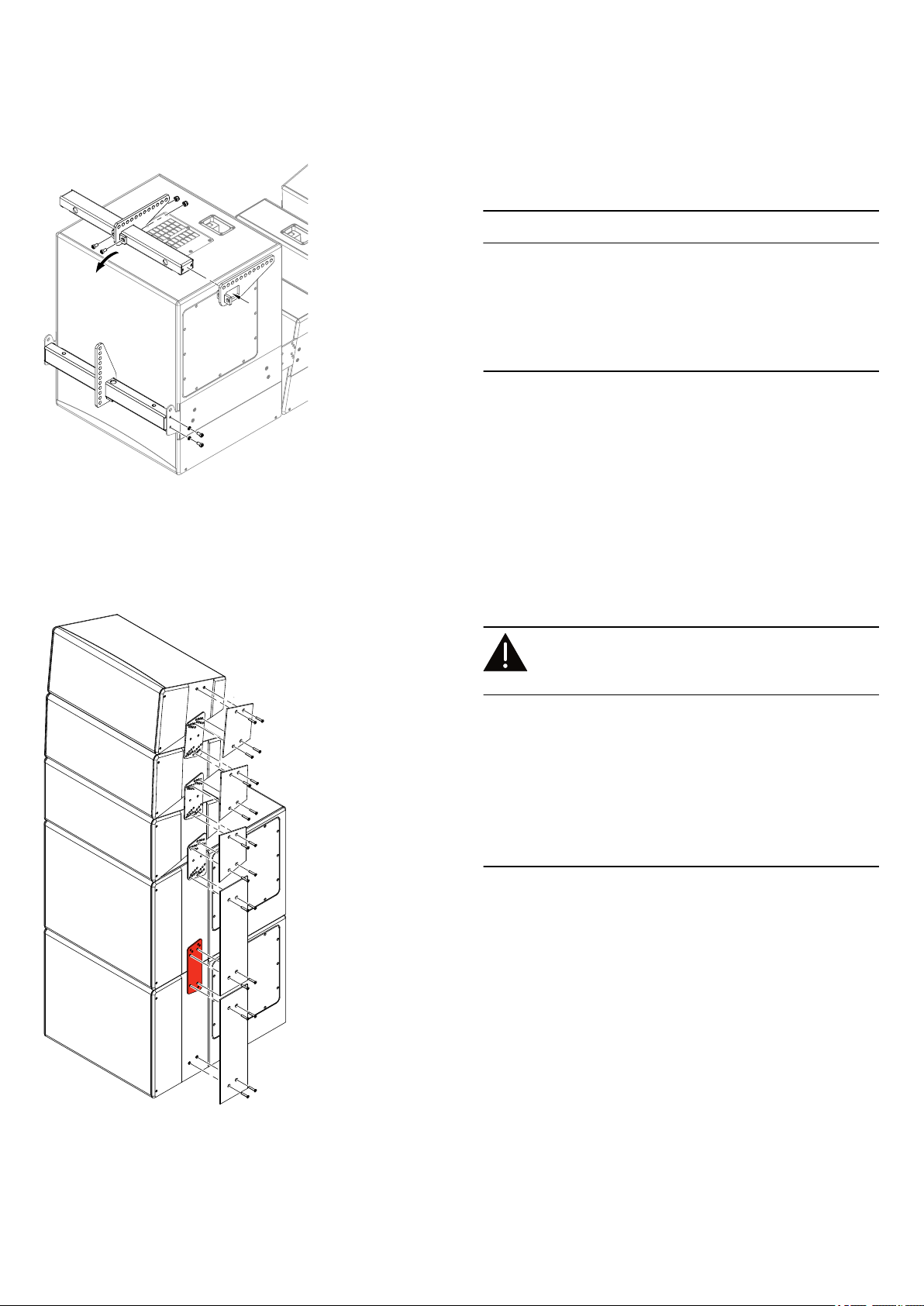

4.4. Ground stacks

WARNING!

Potential risk of personal injury and/or

damage to material!

Always secure ground stacked setups against movement and

possible tipping over.

When xA-Series subwoofers 18A- and 27A-SUB are stacked, the

cabinets must be interconnected on both sides using the Z5418

Connector plate xA-SUB.

It is also recommended to place the entire ground stack onto an

appropriate additional non-slip mat to prevent the ground stack

from moving.

Assembly

When assembling mixed ground stacks, the same requirements

regarding the assembling area, orientation of the HF section and

safety precautions apply as described in Þ Chapter 4.2.

"Assembly preparations" on page 18.

The assembly of mixed ground stacks is carried out in the same

manner as described in Þ Chapter 4.3.1. "Horizontal assembly

on the ground" on page 18.

SUB stacks may be assembled in vertical order.

d&b xA-Series, Rigging manual (1.1 EN)20

Page 21

5. Hoisting the array

Due to the various array configurations and on-site conditions an

applicable hoisting procedure is not possible in general.

Depending on the array configuration, system weight and on-site

conditions the persons hoisting the array must review the on-site

situation and decide an applicable hoisting procedure respectively.

In addition observe the following safety guidelines.

5.1. Safety guidelines

CAUTION!

Unpredictable dynamic forces and swing.

When hoisting the array, unpredictable dynamic forces as well as

swinging of the array must be taken into account. This may lead to

personal injury and/or damage to the rigging components and

loudspeaker cabinets.

Ensure that there is nobody directly underneath or in the vicinity of

the load who is not involved in the setup.

xA-Series arrays with a total system weight of up to 140 kg

(309 lb) may be lifted directly from their horizontal assembly

position (i.e. the arrays were assembled horizontally on the

ground).

– Before starting to hoist the array, make sure to prevent the

cabinets from scratching or other possible damage.

– Ensure the array's pickpoint is in line with the rigging point and

hoisting devices.

– When changing over from horizontal to vertical position,

observe the following (depending on the size (length) and

weight of the array):

– Two persons, one on each side of the array, should support

you to prevent unpredictable lateral tensile forces from

acting on the array.

– It is advisable that all persons involved in hoisting the array

are in close proximity so that you will be able to give

instructions, if necessary.

– When the array is about to leave the ground, make sure there

is enough support to prevent the array from unpredictable

movement and swinging.

– During the further hoisting procedure raise the array slowly

and evenly so that it does not swing or move from side to side.

d&b xA-Series, Rigging manual (1.1 EN) 21

Page 22

6. Declarations

6.1. Manufacturer's declaration

This declaration covers:

d&b xA-Series loudspeaker cabinets

– Z1555/56, 10A/10A-D

– Z1557/58, 10AL/10AL-D

– Z1571, 18A-SUB

– Z1581, 27A-SUB

d&b xA-Series rigging components

– Z5413 Flying bar connector plate xA

– Z5414 Flying bar xA

– Z5415 Flying bar adapter xA

– Z5416 Connector plate 10A

– Z5417 Connector plate 10AL

– Z5418 Connector plate xA-SUB

– Z5419 Load bar xA

– Z5420 Load eye bolt

– Z5421 Connector plate xA, neg. splay

National standards and technical specifications

applied:

DIN 18 800, DIN 1055, BGV C1, BGI 810-3.

Backnang, 2012-02-03

Frank Bothe,

Managing Director

d&b audiotechnik GmbH

6.2. Disposal

When out of use the rigging components must be disposed of in

accordance with the national environmental regulations.

Ensure that damaged rigging components are disposed of in a

way that they cannot be used again.

d&b xA-Series, Rigging manual (1.1 EN)22

Page 23

D2962.EN .01, 02/2012 © d&b audiotechnik GmbH

www.dbaudio.com

Loading...

Loading...