Page 1

V-Series

Rigging manual (1.9 EN)

Page 2

General information

V-Series

Rigging manual

Version: 1.9 EN, 11/2014, D2702.EN .01

Copyright © 2014 by d&b audiotechnik GmbH; all rights

reserved.

Keep this manual with the product or in a safe place

so that it is available for future reference.

When reselling this product, hand over this manual to the new

customer.

If you supply d&b products, please draw the attention of your

customers to this manual. Enclose the relevant manuals with the

systems. If you require additional manuals for this purpose, you

can order them from d&b.

d&b audiotechnik GmbH

Eugen-Adolff-Strasse 134, D-71522 Backnang, Germany

T +49-7191-9669-0, F +49-7191-95 00 00

docadmin@dbaudio.com, www.dbaudio.com

Page 3

Contents

1. Safety.................................................................................... 4

1.1. Intended use............................................................................ 4

1.2. General safety......................................................................... 4

1.3. Load capacity/System safety................................................. 4

1.4. Wind loads.............................................................................. 4

1.5. d&b ArrayCalc simulation software / TI 385....................... 5

1.6. Operational safety.................................................................. 5

2. V-Series rigging concept................................................ 6

2.1.

Z5380 V Flying frame - Scope of supply.............................. 6

2.2. Z5382 V Safety chainset..................................................... 10

2.3. Z5381 V Hoist connector chain option............................... 10

2.4. Ring cotters............................................................................ 11

2.5. Locking pins........................................................................... 12

2.6. Load adapter........................................................................ 13

2.7. Suspension of the Flying frame............................................ 14

2.8. Secondary safety.................................................................. 16

2.9. Splay link of the frame.......................................................... 17

2.10. Cable pick........................................................................... 18

2.11. Cabinet rigging mechanism............................................... 19

3. V-Series arrays and assembly................................. 21

3.1.

Setup preparation................................................................. 22

3.2. Flown arrays.......................................................................... 22

3.3. V Touring cart assembly....................................................... 30

3.4. Ground stacks....................................................................... 35

4. Safety and system checks.......................................... 39

Mechanical setup................................................................. 39

4.1.

4.2. Wiring.................................................................................... 39

5. Hoisting and securing the array.............................. 40

Hoisting the array................................................................. 40

5.1.

5.2. Securing the array................................................................ 40

6. Derigging.......................................................................... 41

General................................................................................. 41

6.1.

6.2. Touring cart disassembly...................................................... 41

7. Care and maintenance / Disposal.......................... 43

Transport / Storing............................................................... 43

7.1.

7.2. Visual and functional inspection.......................................... 43

7.3. Disposal................................................................................. 44

8. Manufacturer's declaration....................................... 45

d&b V-Series Rigging manual (1.9 EN) 3

Page 4

1. Safety

1.1. Intended use

The V-Series rigging components (Flying frame, Load adapter,

Locking pins) must only be used in conjunction with d&b V-Series

loudspeakers as described in this manual.

1.2. General safety

Installation and setup should only be carried out by qualified and

authorized personnel observing the valid national Rules for the

Prevention of Accidents (RPA).

It is the responsibility of the person installing the assembly to ensure

that the suspension/fixing points are suitable for the intended use.

Always carry out a visual and functional inspection of the items

before use. In case there is any doubt as to the proper functioning

and safety of the items, these must be withdrawn from use

immediately.

Please also refer to Þ Chapter 7. "Care and maintenance /

Disposal" on page 43.

1.3. Load capacity/System safety

NOTICE!

The Z5380 V Flying frame is designed to suspend a total of 24 x

V-TOP cabinets which corresponds to a total system weight of

860 kg (1896 lb) – SWL.

The rigging components allow arrays of up to 10 x V-TOP cabinets

with a total system weight of 340 kg (750 lb) to be flown in any

vertical splay angle configuration between the cabinets.

For any other array configuration the load conditions within the

array have to be checked using the d&b ArrayCalc simulation

software.

1.4. Wind loads

WARNING!

Potential risk of personal injury and material

damage!

Flying loudspeakers overhead at wind forces higher than 6 bft

(22-27 knots, 39-49 km/h, 25-31 mph) is not recommended.

If the wind force exceeds 8 bft (34-40 knots, 62-74 km/h,

39-46 mph):

– Make sure that no person remains in the vicinity of the array.

– Lower and secure the array.

d&b V-Series Rigging manual (1.9 EN)4

Page 5

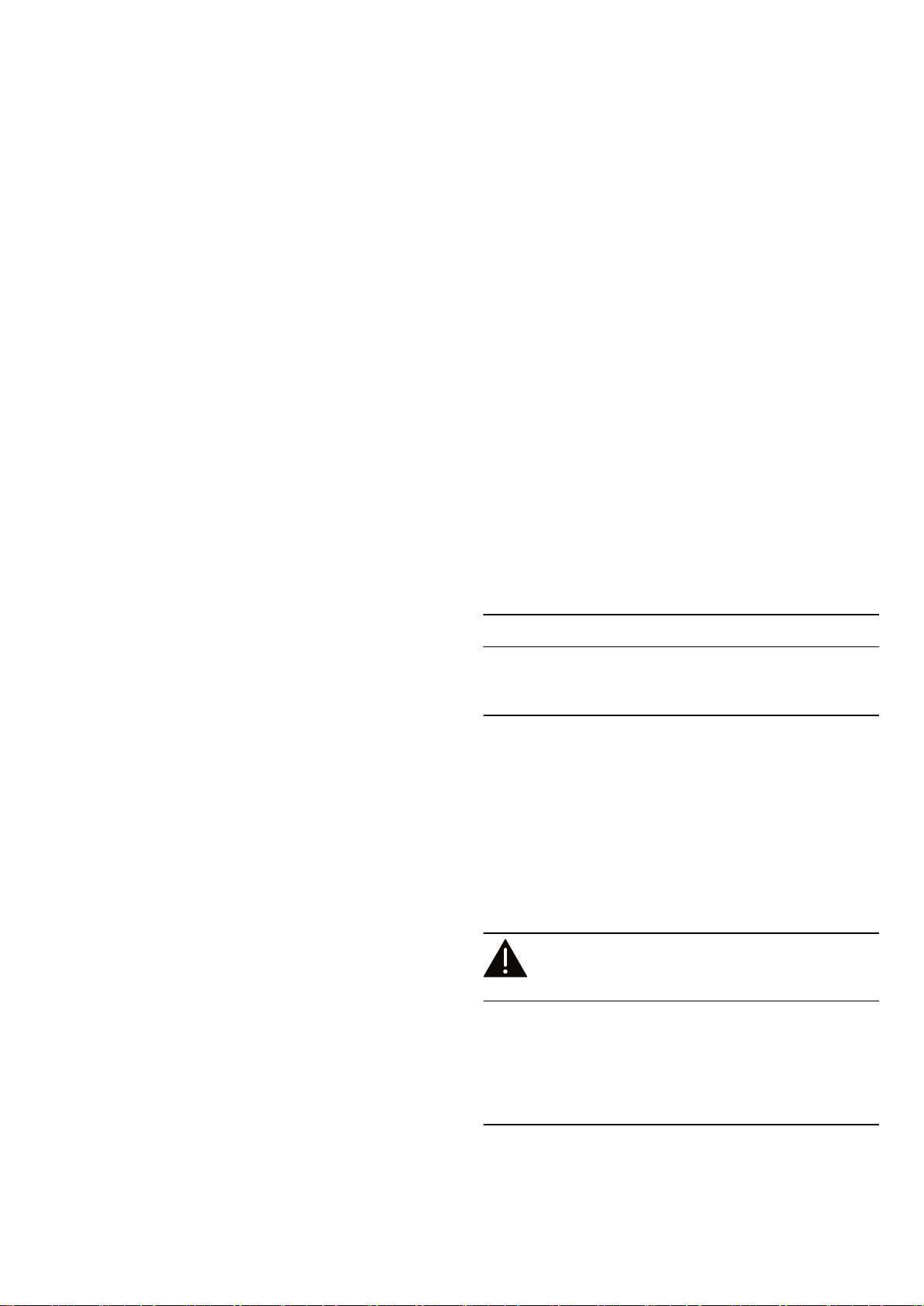

d&b ArrayCalc

1.5. d&b ArrayCalc simulation software / TI 385

For both acoustic and safety reasons d&b line arrays must be

designed using the d&b ArrayCalc simulation tool. It is available as

a native stand-alone application for both Microsoft Windows (XP

or higher) and Mac OS X (10.4.10 or higher) operating systems

and can be downloaded at www.dbaudio.com.

The use of ArrayCalc is described in "TI 385 d&b Line array

design, ArrayCalc" which is also supplied with the . This TI includes

typical array configurations within the permitted load limits.

Carefully read this TI to become familiar with the operation and

behavior of ArrayCalc and in particular with the mechanical load

conditions and limitations.

The TI can be downloaded from the d&b website at

www.dbaudio.com.

We also recommend you to attend the regularly hosted d&b Line

array training seminars. Further information regarding the d&b

seminars can be requested directly from d&b audiotechnik sales

partners.

1.6. Operational safety

The assembly should always be carried out by two persons.

During assembly pay attention to the possible risk of crushing.

Wear suitable protective clothing.

Observe all instructions given on the respective instruction labels of

the rigging components (Flying frame, Load adapters), Touring

carts and loudspeaker cabinets.

When chain hoists are in operation ensure that there is nobody

directly underneath or in the vicinity of the load.

Do not under any circumstances climb on the array.

d&b V-Series Rigging manual (1.9 EN) 5

Page 6

2. V-Series rigging concept

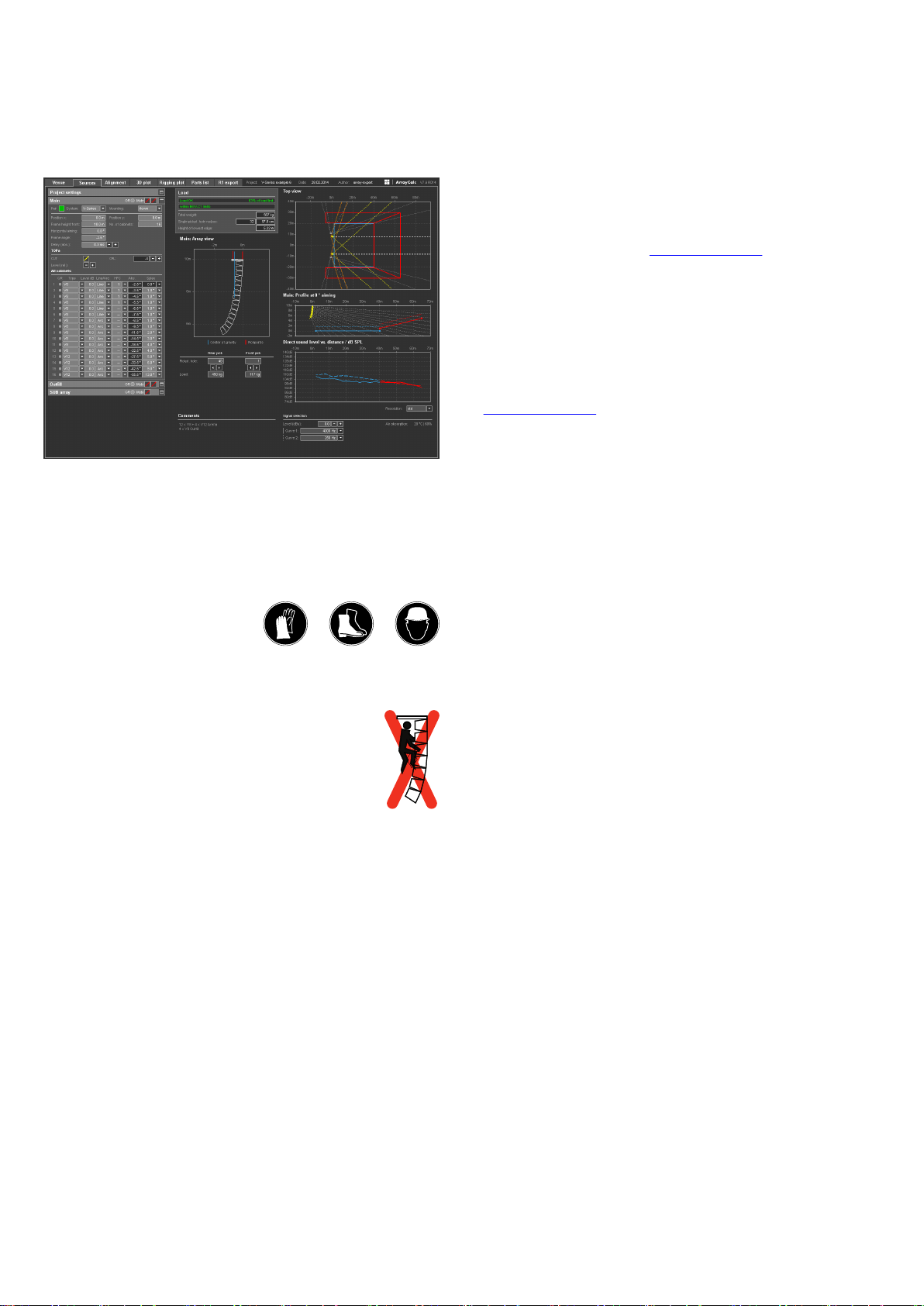

2.1. Z5380 V Flying frame - Scope of supply

Please verify the shipment for completeness and proper condition

of the items.

The Z5380 V Flying frame is equipped and supplied with the

following rigging components:

Z5380 V Flying frame top and bottom views

d&b V-Series Rigging manual (1.9 EN)6

Page 7

Pos. Component Description

[1]

Z5380 V Flying frame

[2]

Flying frame center bar

The Z5380 V Flying frame is designed to support arrays consisting of:

– Z0515/Z0516, V8/V12. Weight: 34 kg (75 lb).

– Z0518 V-SUB. Weight: 64 kg (141 lb).

The weight of the V Flying frame including all rigging components is 25.4 kg (56 lb).

[3]

Z5382 V Safety chainset

[4]

Safety point(s)

The Z5382 V Safety chainset is supplied with the Flying frame.

The Flying frame is fitted with two safety points each equipped with a 2 t shackle to attach a

secondary safety device using the enclosed V Safety chainset (refer to Þ Chapter 2.8.

"Secondary safety" on page 16).

[5] V Load adapter The Flying frame is supplied with two Load adapter to allow single or dual pickpoint

operation. Each Load adapter is supplied with a pair of Locking pins 10 mm and a 2 t shackle

(refer to Þ Chapter 2.6. "Load adapter" on page 13).

[6] V Load adapter Rota Clamp In addition, the enclosed V Load adapter Rota Clamp allows single pickpoint operation in

combination with the d&b Z5147 Rota clamp for a maximum system weight of up to 500 kg/

1100 lb (also refer to Þ Chapter 2.6. "Load adapter" on page 13).

[P] Park position During transport the Load adapters should be stored at their park positions (refer to

Þ Chapter 2.6. " Load adapter" Þ " Fixing the Load adapter at Park position" on page

13).

[7] Front link (Frame) Two additional Front links together with a pair of Locking pins 8 mm each are supplied with

the Flying frame. They are used to mount V-Series cabinets on top of the Flying frame for the

following setups:

– Mixed V-Series array with V-SUB cabinets at the top of the column (refer to

Þ Chapter 3.2.3. "Mixed array" on page 28).

– V-Series ground stack with the Flying frame as ground support (refer to Þ Chapter 3.4.

"Ground stacks" on page 35).

[8] Mounting plate An additional mounting plate is provided to accept industry standard inclinometers such as the

Teqsas LAP-TEQ line array positioning tool.

[9] Splay link (Frame) In connection with the Front links of the V-Series loudspeaker cabinets, the Splay link of the

frame is used to attach the first cabinet to the frame. By default, the Splay link of the frame is

fixed at «POSITION V8/V12». To accept V-SUB cabinets, the Splay link can be moved to

«POSITION V-SUB» (refer to Þ Chapter 2.9. "Splay link of the frame" on page 17).

During transport the Splay link should be folded back into its park position and secured by the

respective Locking pin.

[10] Cable pick An O-ring at the rear bottom of the frame slides out when releasing the respective Locking pin

to attach a cable pick (refer to Þ Chapter 2.10. "Cable pick" on page 18).

d&b V-Series Rigging manual (1.9 EN) 7

Page 8

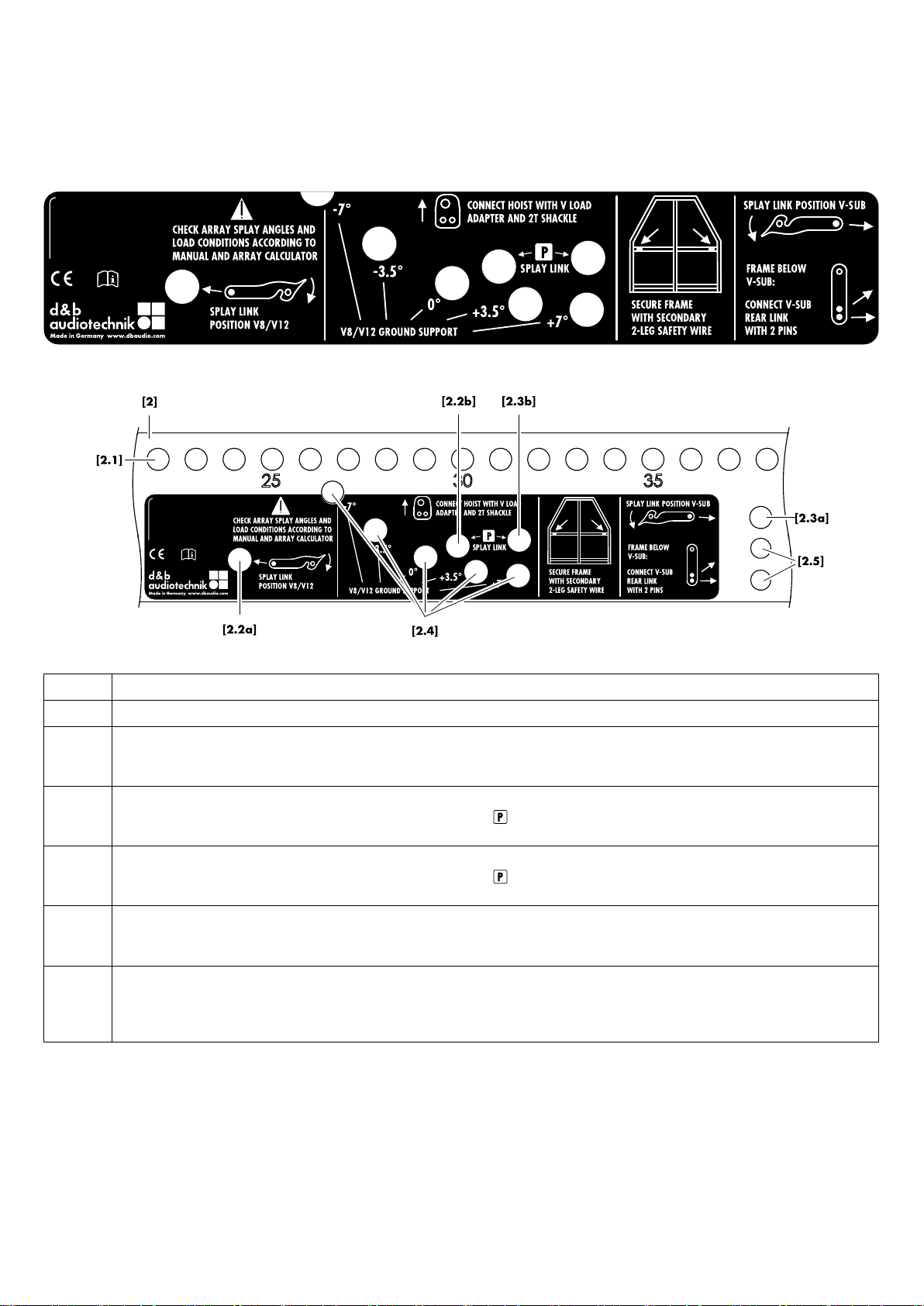

2.1.1. Flying frame instruction label

Pos. Description

[2] Center bar of the Flying frame with user instruction label.

[2.1] Main hole grid at the top of the center bar with a total of 40 holes numbered with an increment of five. Using the V Load

adapters the Flying frame can be suspended from one or two pickpoints (refer to Þ Chapter 2.6. "Load adapter" on page 13

and Þ Chapter 2.7. "Suspension of the Flying frame" on page 14).

[2.2a]

[2.2b]

Fixing point for the frame's Splay link in «POSITION V8/V12».

The additional hole is used to fix the Splay link at park position ( ) using the respective Locking pin (refer to Þ Chapter 2.9.

"Splay link of the frame" on page 17).

[2.3a]

[2.3b]

Fixing point for the frame's Splay link in «POSITION V-SUB».

The additional hole is used to fix the Splay link at park position ( ) using the respective Locking pin (refer to Þ Chapter 2.9.

"Splay link of the frame" on page 17).

[2.4] Hole grid ground stack: when V8/V12 cabinets are attached to the top of the frame, this hole grid indicates the possible settings

of –7°, –3.5°, 0°, +3.5° or +7° for the Splay link of the first (bottom) cabinet (refer to Þ Chapter 3.4. "Ground stacks"

on page 35).

[2.5] If the Flying frame is fitted below a V-SUB cabinet (Mixed V-Series array with V-SUB cabinets at the top of the column), these two

holes are used to fix the Rear link of the "last" V-SUB cabinet to the frame using the Locking pin of the respective cabinet and the

Locking pin of the Cable pick (refer to Þ Chapter 3.2.3. " Mixed array", Þ step " 2. Attach the assembly to the frame" on

page 28).

d&b V-Series Rigging manual (1.9 EN)8

Page 9

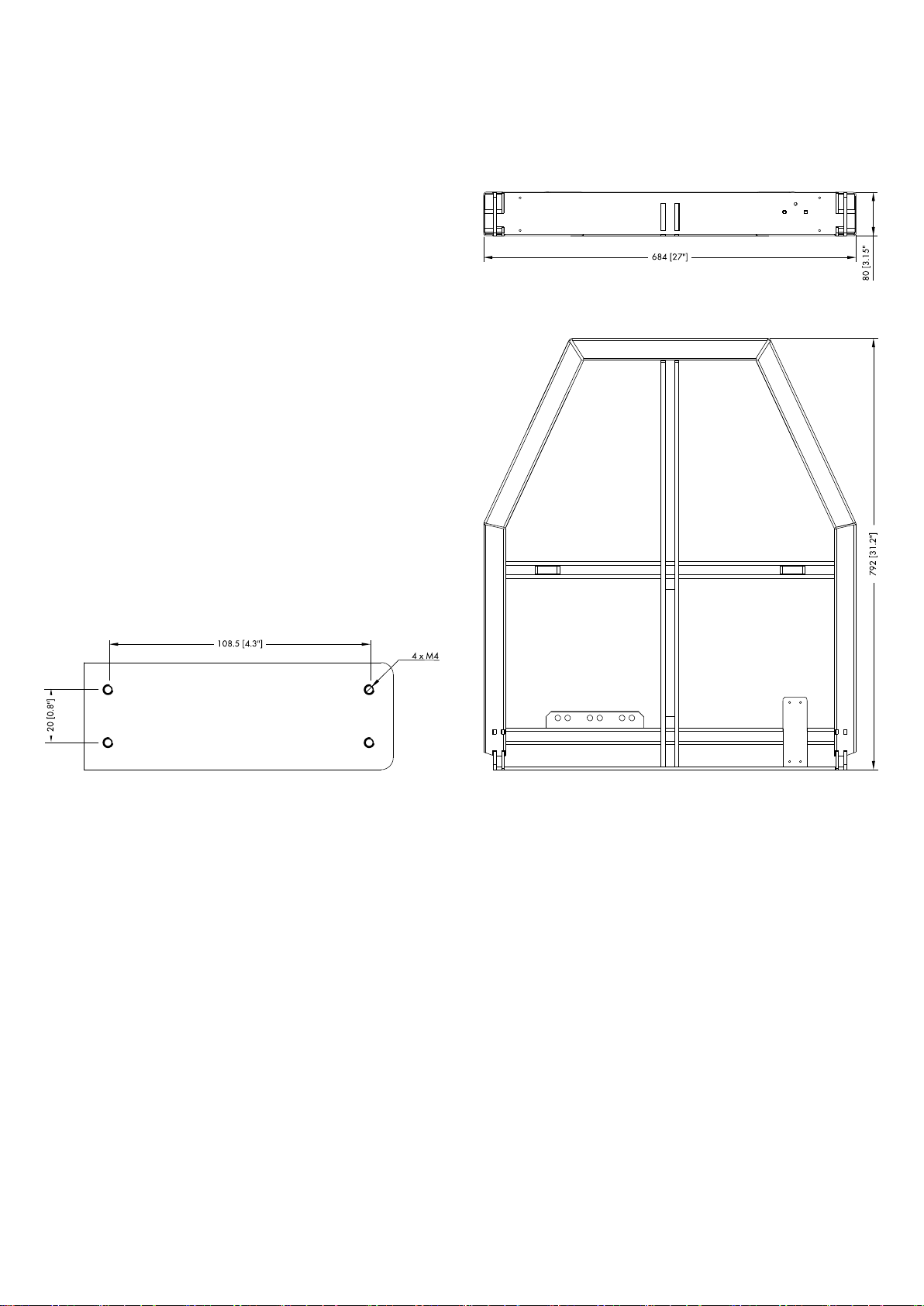

2.1.2. Dimensional drawing

Z5380 V Flying frame laser/inclinometer mounting plate [8]

dimensions in mm [inch]

Z5380 V Flying frame dimensions in mm [inch]

d&b V-Series Rigging manual (1.9 EN) 9

Page 10

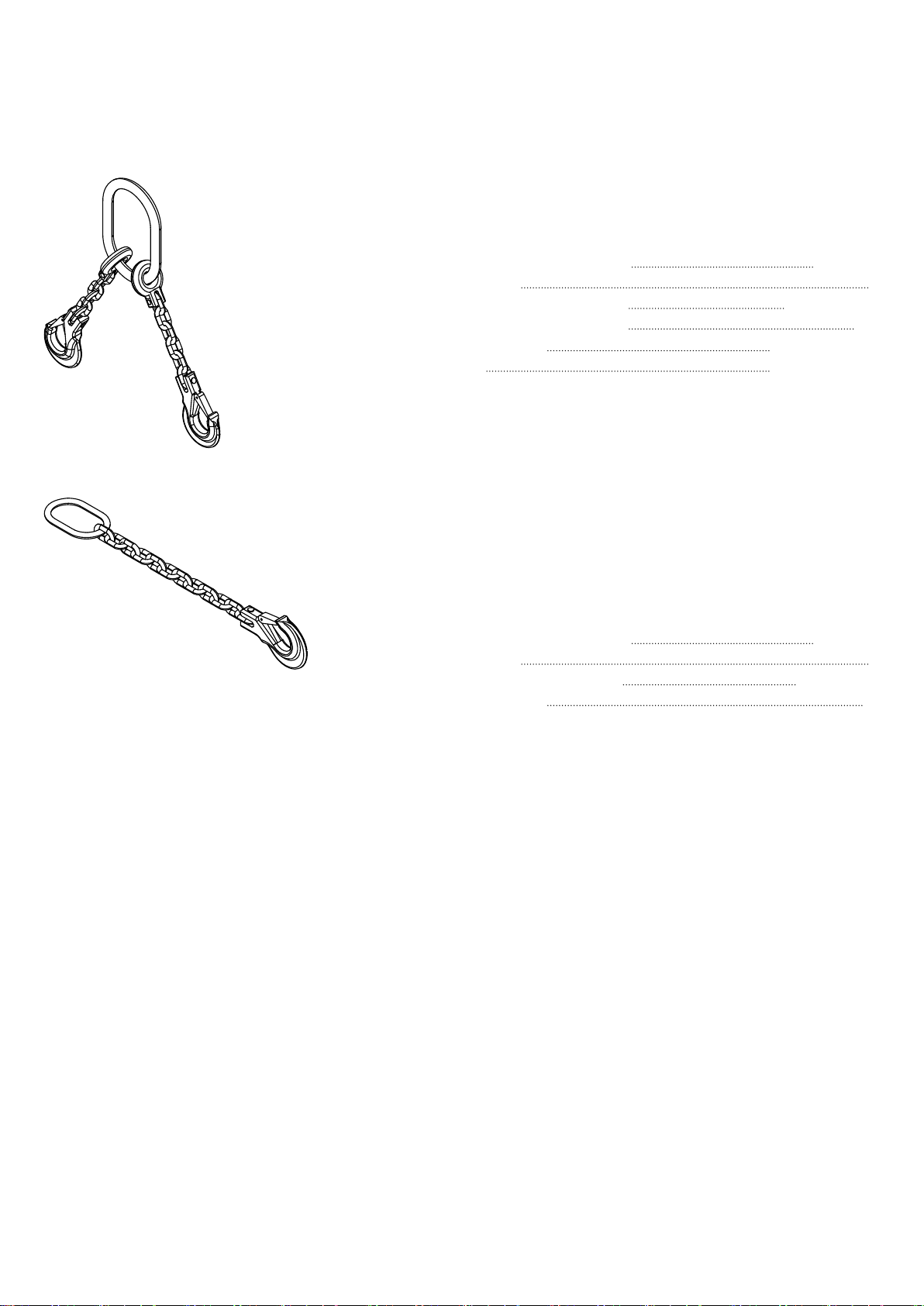

2.2. Z5382 V Safety chainset

The Z5382 V Safety chainset is supplied with the V Flying frame

and is used as a secondary safety device. Please also refer to

Þ Chapter 2.8. "Secondary safety" on page 16.

Specification

Lifting chain (DIN EN 818) 2-leg, 8 mm

Grade 8

Nominal length incl. hooks 416 mm (16.4")

Maximum sling angle b

Load rating 3.35 t (b: 0° - 45°)

Max

2.5 t (b: 46° - 60°)

60°

2.3. Z5381 V Hoist connector chain option

The Z5381 V Hoist connector chain is used to connect the lifting

motor(s) to the V Flying frame using the 2 t shackle which is

attached to the V Load adapter. Its length of 53 cm (21") allows

enough space for the hang of most 2 t motor chain containers and

avoids any impact on the vertical balance of the array when

suspended from a single pickpoint.

Specification

Lifting chain (DIN EN 818)

Grade 8

Nominal length incl. hook 535 mm (21")

Load rating 2 t

1-leg, 8 mm

d&b V-Series Rigging manual (1.9 EN)10

Page 11

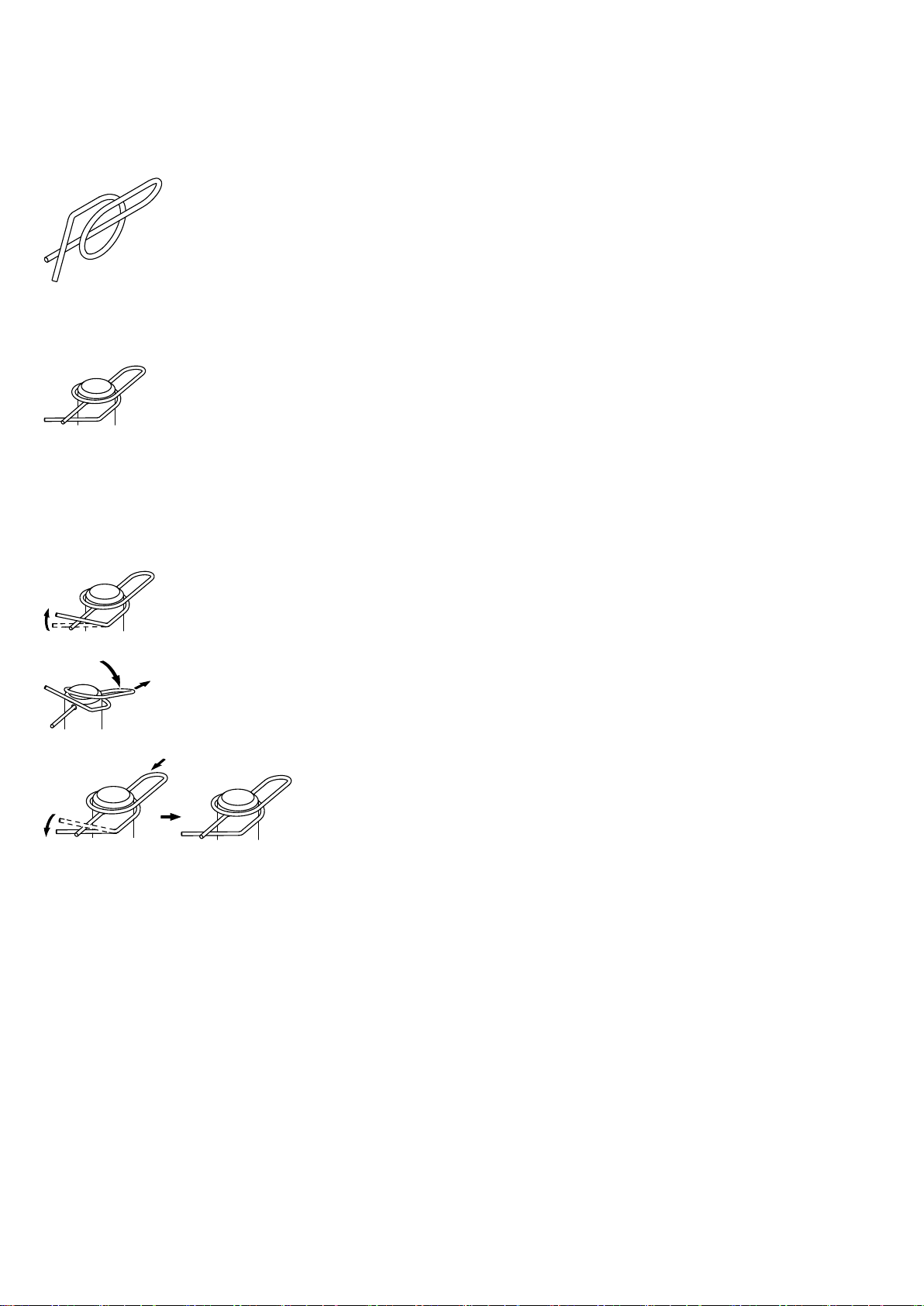

Ring cotter

Ring cotter locked

2.4. Ring cotters

In connection with the V-Series rigging system, ring cotters are used

for the following items to prevent the respective item from

slackening and/or loosening:

– Fixing bolt of the SUB cabinet's Rear link.

– Fixing bolt of the frame's Splay link and cable pick.

– Fixing bolt of the 2 t shackles attached to the Load adapters

and safety points of the Flying frame.

– Fixing bolt of the Z5147 Rota clamp.

Function of the ring cotter

By default, the ring cotters are "locked" to prevent them from

loosening.

For modification reasons such as altering the position of the frame's

Splay link or exchanging a shackle, it may be necessary to

temporarily remove the cotter and reattach it afterwards.

Note: Please also refer to Þ Chapter 7. " Care and

maintenance / Disposal", Þ section 7.2. " Visual and

functional inspection", Þ "Ring cotters" on page 43.

For this purpose proceed as follows:

1. Unlock

Unlock the ring cotter by pushing up the front wire loop over

the straight wire shaft.

2. Release and remove

Push down the rear wire loop until the ring cotter snaps over

the edge of the bolt and remove the ring cotter.

3. Refit and lock

Refit the ring cotter by pushing the straight wire shaft through

the hole and pressing the front wire loop underneath the

straight wire shaft.

d&b V-Series Rigging manual (1.9 EN) 11

Page 12

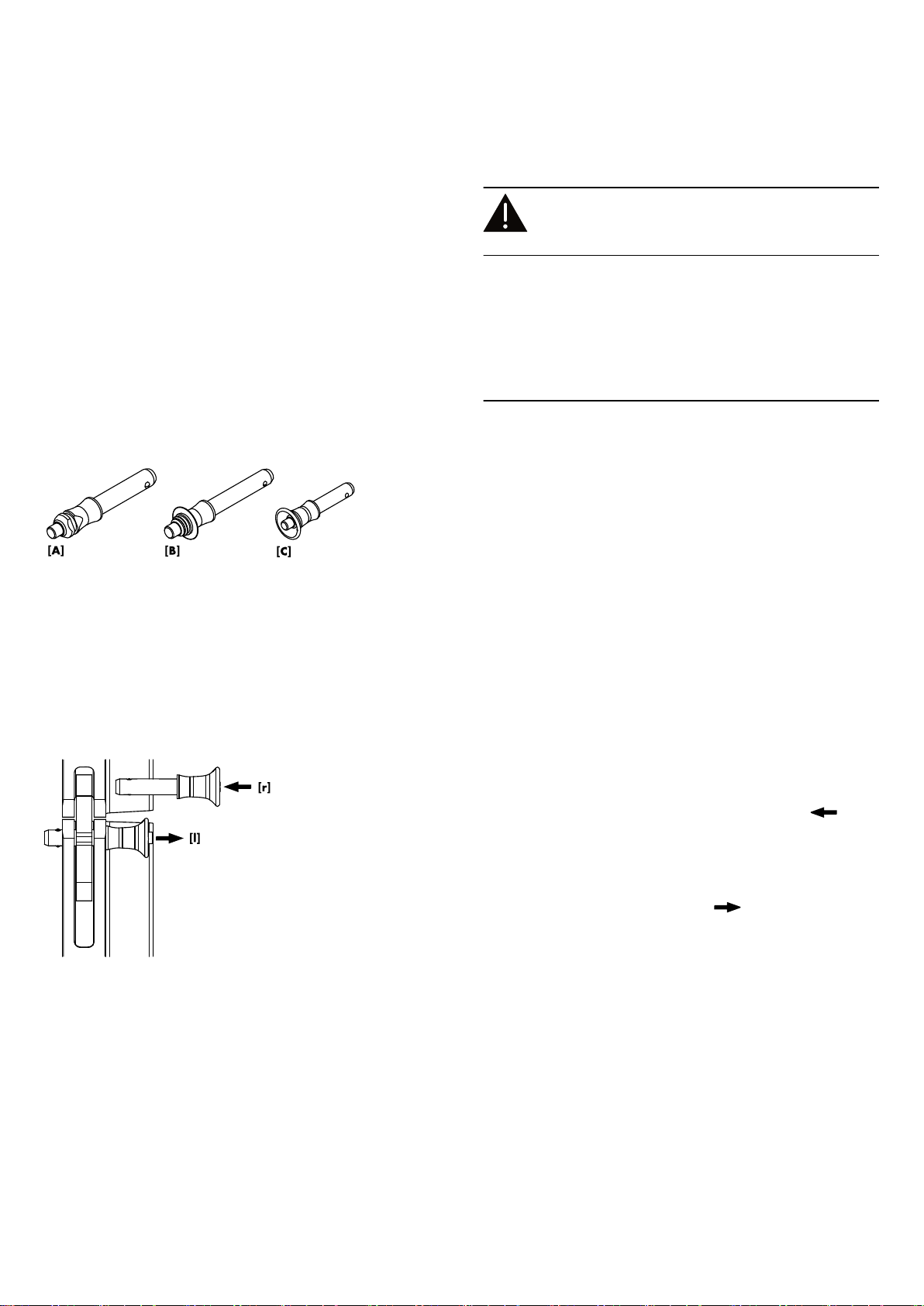

2.5. Locking pins

WARNING!

Potential risk of personal injury and/or

damage to material!

The steel wires between the Locking pins of the cabinets and

rigging components are not intended to carry any load. The

cabinet's weight must only be carried by the Front and Splay/Rear

links in conjunction with the front and rear rigging strands of the

loudspeaker cabinets and the Flying frame.

Ensure all Locking pins are fully inserted and securely locked

before lifting any load.

The V-Series loudspeaker cabinets and flying frame are equipped

with three types of Locking pins:

Locking pin assembly

Shown with pin type [C]

Type [A]

Locking pin 10 x 35 mm.

Used for the Load adapters.

Type [B] Locking pin 9 x 40 mm.

Used for the cabinets' Splay/Rear links and for the

frame's Splay link and Cable pick.

Type [C] Locking pin 8 x 23 mm.

Used for the Front links of the loudspeaker cabinets

and the frame.

Note: The Locking pins are undetachably attached to the

different rigging components on the cabinet and the frame

using steel wires.

Throughout this manual these steel wires are not shown in the

corresponding illustrations.

Functionality (Quick lock mechanism)

The quick lock mechanism applies to all types of Locking pins listed

above. Proceed as follows:

1. Press the button to release the locking mechanism ( [r]).

2. Remove the Locking pin through the respective link or socket.

3. Insert the Locking pin through the respective link or socket until

it is fixed in place.

4. Release the button to lock the pin ( [l]).

5. Recheck the Locking pin is securely locked by briefly pulling

the Locking pin towards you.

d&b V-Series Rigging manual (1.9 EN)12

Page 13

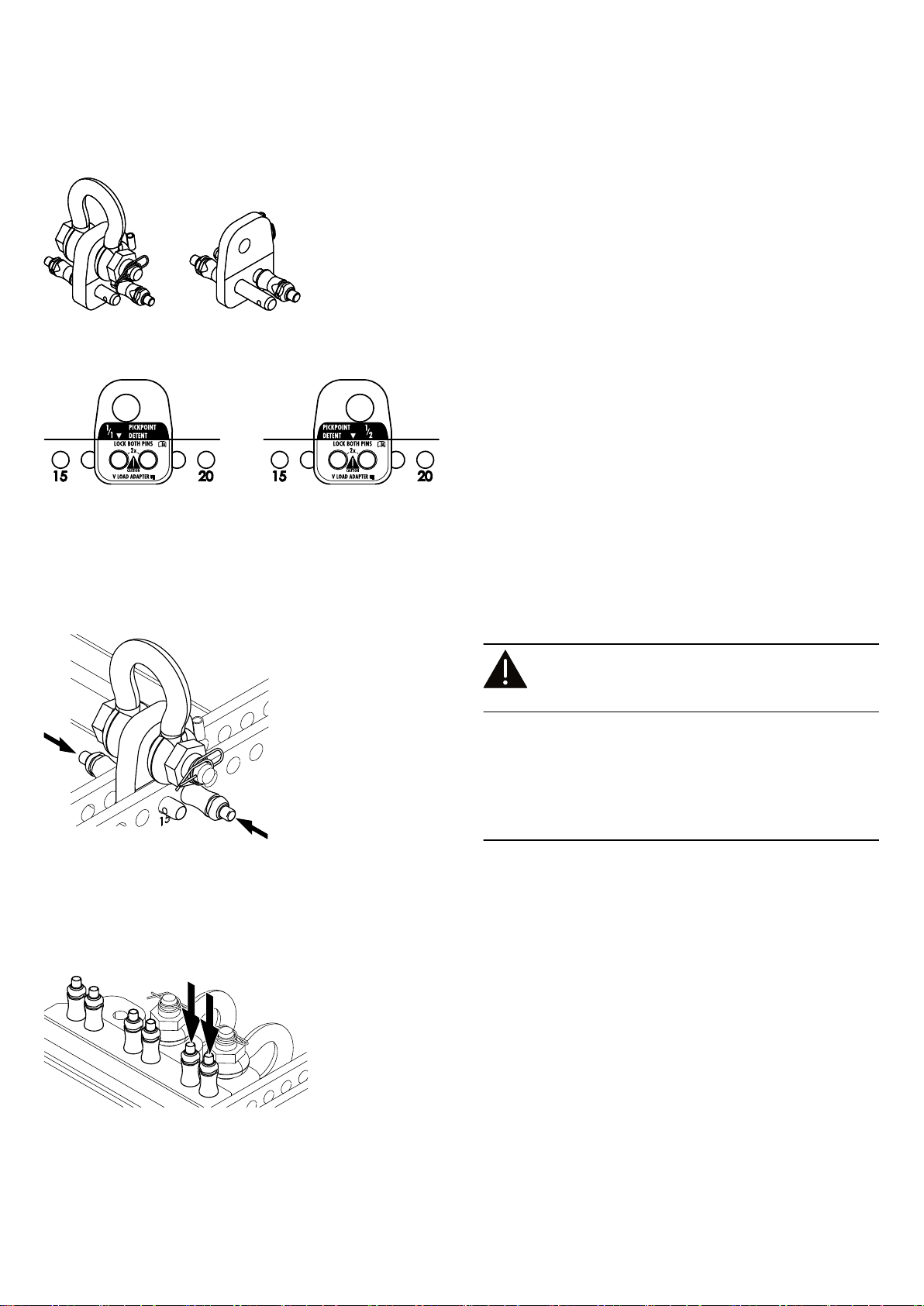

V-Series Load adapter

Y-Series Load adapter

Type 1/Type 2

Type 1/Type 2

2.6. Load adapter

The Flying frame is supplied with two different types of load

adapters:

Type 1: 2 x V Load adapter, allowing either single or dual

pickpoint operation.

Type 2: 1 x V Load adapter Rota Clamp, allowing single

pickpoint operation in combination with the d&b

Z5147 Rota clamp for a maximum system weight of

up to 500 kg /1100 lb.

Both types allow for a full grid (1/1 PICKPOINT DETENT) or a half

grid (½ PICKPOINT DETENT) setting depending on the direction of

attachment to the frame's center bar.

The frame's hole index marked on one side of the center bar is the

reference for the direction of the Load adapter.

Direction of the Load adapter for:

Left: Full grid (1/1 PICKPOINT DETENT), shown: Hole 17

Right: Half grid (½ PICKPOINT DETENT), shown: Hole 17.5

As an example, the graphics opposite show hole positions 17 and

17.5 in connection with the V Load adapter.

As an example, the graphics opposite show hole positions 17 and

17.5 in connection with the Y Load adapter.

Note: The same applies to the V Load adapter Rota Clamp.

Attaching the Load adapter to the Flying frame

WARNING!

Potential risk of personal injury and/or

damage to material!

Before attaching the Load adapter, check the 2 t. shackle is

properly fitted to the Load adapter and secured with a locked ring

cotter.

Ensure the Load adapter is properly attached to the center bar of

the frame and both Locking pins are inserted and locked securely

before lifting the array.

The Load adapter is attached to the center bar of the Flying frame

and fixed using its two Locking pins 10 mm.

Note: It is advisable to insert the Locking pins opposite each

other as shown in the graphic opposite.

Fixing the Load adapter at Park position

During transport the Load adapters should be stored at their park

positions [P].

For this purpose, insert both Locking pins of each Load adapter in

the same direction from the top, as shown in the graphic opposite.

d&b V-Series Rigging manual (1.9 EN) 13

Page 14

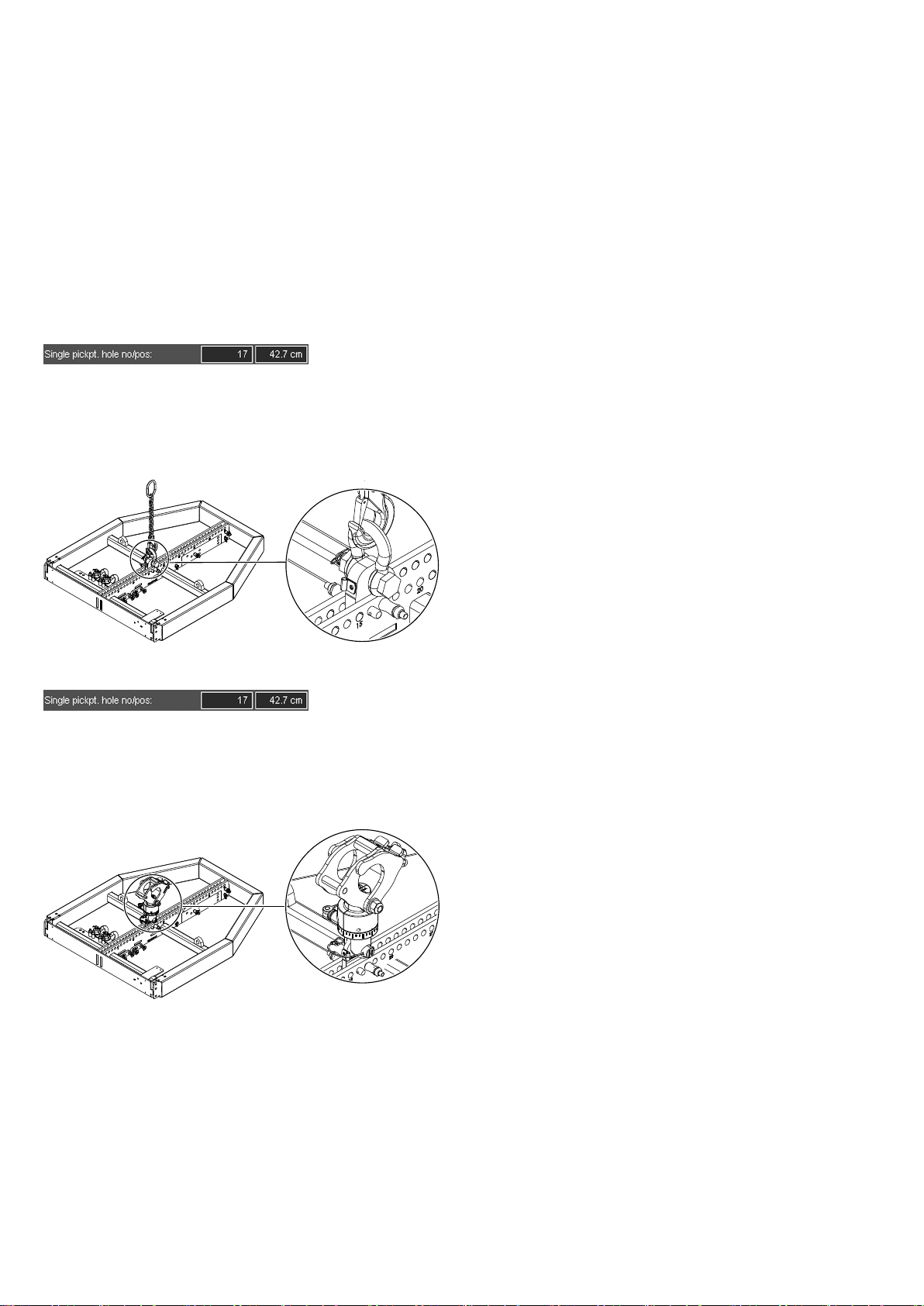

ArrayCalc Single pickpoint

2.7. Suspension of the Flying frame

The suspension of the V Flying frame is carried out using one or

two V Load adapter(s), depending on the chosen type of

suspension (Single or Dual pickpoint operation).

The Load adapters are attached to the center bar of the Flying

frame and fixed using the two Locking pins of each adapter as

described in the previous section Þ 2.6. Load adapter

Þ Attaching the Load adapter to the Flying frame on page 13.

2.7.1. Single pickpoint operation

With "Single pickpoint operation" the position of the V Load

adapter defines the vertical aiming of the entire array.

The corresponding hole position is calculated using ArrayCalc.

Note: The target angle of the entire array is achieved when

the array is fully set up and hoisted as intended.

Attachment

1. Choose the appropriate hole position on the center bar

according to the ArrayCalc calculation and attach the Load

adapter correspondingly.

If ArrayCalc displays a half numbered hole setting (half

Þ

grid) turn the Load adapter correspondingly.

2. Attach the Hoist connector chain or motor hook to the shackle

of the Load adapter.

ArrayCalc Single pickpoint

2.7.2. Z5147 Rota clamp option

Alternatively, a V-Series array with a total system weight of up to

500 kg (1100 lb) can be suspended and horizontally aligned

from a single flying point using the d&b Z5147 Rota clamp. The

clamp allows the load to be attached to overhead bars or truss

with a tube diameter of up to 51 mm (2”).

The corresponding hole position is calculated using ArrayCalc.

Attachment

1. Choose the appropriate hole position on the center bar

according to the ArrayCalc calculation and attach the Load

adapter Rota clamp correspondingly.

If ArrayCalc displays a half numbered hole setting (half

Þ

grid) turn the Load adapter correspondingly.

2. Attach the Rota clamp to the Load adapter.

Note: Please observe the relevant mounting instructions

which are enclosed with the Rota clamp.

d&b V-Series Rigging manual (1.9 EN)14

Page 15

ArrayCalc Dual pickpoint

2.7.3. Dual pickpoint operation

With "Dual pickpoint operation" the vertical aiming of the array is

set by trimming the hoist motors after the array has been fully

assembled and lifted to its operating position.

The corresponding hole positions are calculated using ArrayCalc.

Attachment

1. Choose the appropriate hole positions for the Front and

Rearpick on the Flying frame center bar according to the

ArrayCalc calculation and attach the Load adapters

correspondingly (Direction: Full grid 1/1 pickpoint Detent).

2. Connect the Hoist connector chains or motor hooks to the

shackles of the Load adapters.

d&b V-Series Rigging manual (1.9 EN) 15

Page 16

2.8. Secondary safety

WARNING!

Potential risk of personal injury and/or

damage to material!

The secondary safety suspension must be independent of the

primary suspension points and capable of carrying the total system

weight.

The additional safety device must be mounted in a way that the

array is caught by the safety device without any drop and swing in

the event that the primary suspension fails.

The Z5380 V Flying frame is equipped with two safety points [4]

fitted with two 2 t shackles to accept a secondary safety device.

We recommend the use of the d&b Z5382 V Safety chainset

which is supplied with the Flying frame.

Assembly

The two legs of the V Safety chainset and the distance [d]

between the two safety points [4] of the frame's tie bar form an

equilateral triangle maintaining the maximum sling angle (b

Max

) of

60°.

1. Before attaching the safety device ensure the two 2 t shackles

[S] are properly fitted to the frame's safety points [4] and

secured against loosening using a locked ring cotter [C] as

shown in the graphic opposite.

2. Attach the Safety chain and ensure the chains are not twisted

and the hooks [H] are in the right direction as shown in the

graphic opposite.

d&b V-Series Rigging manual (1.9 EN)16

Page 17

2.9. Splay link of the frame

Splay link position

By factory default the Splay link is attached and parked to

«POSITION V8/V12».

Depending on the type of cabinet (V8/V12 or V-SUB) to be

attached to the Flying frame the position of the frame's Splay link

needs to be changed as described in the following section

Þ Changing the Splay link position.

Splay link of the frame – «POSITION V8/V12»

Splay link at park position – «POSITION V8/V12»

Splay link of the frame – «POSITION V-SUB»

Splay link park position

During transport the Splay link can be folded into its park position

and fixed using its Locking pin.

Splay link at park position – «POSITION V-SUB»

Changing the Splay link position

WARNING!

Potential risk of personal injury and/or

damage to material!

The fixing bolt [B] of the frame's Splay link bears the full load of

the array.

It is essential that the bolt is fitted correctly and secured by a

locked ring cotter [C].

To change the Splay link position, proceed as follows:

d&b V-Series Rigging manual (1.9 EN) 17

Page 18

1. Release and remove the Locking pin of the Splay link at park

position and fold out the Splay link.

2. Unlock and remove the ring cotter of the fixing bolt.

3. Pull out the fixing bolt and remove the Splay link.

4. Attach the Splay link to its new position and insert the fixing

bolt.

5. Secure the fixing bolt using the ring cotter and ensure the ring

cotter is properly locked.

2.10. Cable pick

The Flying frame is equipped with an O-ring to allow the

attachment of a cable pick. To prepare the attachment of the cable

pick, proceed as follows:

1. Release the Locking pin holding the O-ring at park position.

2. Pull out the O-ring and reinsert the Locking pin.

Cable pick

d&b V-Series Rigging manual (1.9 EN)18

Page 19

2.11. Cabinet rigging mechanism

V-Series cabinets are mechanically connected to the V Flying frame

and subsequent loudspeakers using the Front links attached to both

sides of the cabinet front and the central Splay/Rear link at the

rear of the cabinet.

All necessary rigging components are mounted to the cabinet and

slide out when needed.

In principle, the Front link mechanism applies to both the V8/V12

and V-SUB cabinets.

2.11.1. Front link mechanism

V8/V12

1. Release both Locking pins and slide out the Front link.

2. Insert and lock one Locking pin to the upper hole to fix the link

in place.

V8/V12 Front link mechanism

V-SUB Front link mechanism

V-SUB

The Front link mechanism of the SUB cabinets provides four

different settings:

a. SUB to Frame (Þ Fig. 1)

b. SUB to SUB with 0° splay between the cabinets (Þ Fig. 2).

c. SUB to SUB with 2.5° splay (free Þ Fig. 3) between the

cabinets.

d. SUB to SUB with 2.5° splay (blocked Þ Fig. 4) between the

cabinets.

This setting is used to prevent the cabinets from folding up.

Fig. 1: SUB to Frame

d&b V-Series Rigging manual (1.9 EN) 19

Fig. 2: SUB to SUB, 0° splay

Fig. 3: SUB to SUB, 2.5° splay,

free

Fig. 4: SUB to SUB, 2.5° splay,

blocked

Page 20

Splay/Rear link mechanism

2.11.2. Splay/Rear link mechanism

Release the respective Locking pin(s) and fold out the Splay/Rear

link.

2.11.3. Preset splay angles on V8/V12 cabinets

The splay angles between adjacent cabinets can be set in the

range from 0° to 14° in 1° steps. The splay angles are set at the

central rear rigging strands of the cabinets.

– Insert and lock the Locking pin to the respective hole.

Preset splay angle (e.g. 7°)

Park position V8/V12 Splay link

2.11.4. Park position V8/V12 Splay link

The Splay link of the last cabinet of an array may be kept in its

park position.

Note: In this case, the lowest cabinet can be set to the

following splay angles: 3°, 5° and 7° to 14°.

d&b V-Series Rigging manual (1.9 EN)20

Page 21

3. V-Series arrays and assembly

V8 Line array 8-deep,

dual pickpoint operation,

shown with:

Z5381 V Hoist connector chain

Z5382 V Safety chainset

Refer to

V8/V12 Ground stack

Refer to

V-SUB column shown with 2.5°

splay between the cabinets

Refer to

Mixed array with

V-SUB at the top of the array

Refer to

V-SUB Ground stack

Refer to

Mixed ground stack

Refer to Þ Chapter 3.4.3. "Mixed

ground stack" on page 38

V Touring cart assembly

Refer to Þ Chapter 3.3. "V Touring cart

assembly" on page 30

d&b V-Series Rigging manual (1.9 EN) 21

Page 22

3.1. Setup preparation

Check the acoustical and mechanical setup using ArrayCalc and

prepare enough printouts for each array.

The plan enables the riggers to set up the suspension points, the

securing points and the chain hoists.

When on site first:

– Clear the working areas and ensure there is enough space to

set up and lift the array.

– Check that the hoists are exactly in the specified position.

– Ensure the chains are not twisted.

Inspections before setup

Before setup carry out a visual inspection of all system components

for faults. This also includes the loudspeakers and in particular the

rigging parts of the cabinets (Front and Splay/Rear links).

Damaged components must be withdrawn from use immediately.

Please follow the instructions given in Þ Chapter 7. "Care and

maintenance / Disposal" on page 43.

3.2. Flown arrays

Flown arrays are suspended using the Z5380 V Flying frame.

1. Suspend the Flying frame according to the chosen type of

suspension as described in Þ Chapter 2.7. "Suspension of the

Flying frame" on page 14.

2. At this point we recommend you to attach the secondary

safety device using the Z5382 V Safety chainset as described

in Þ Chapter 2.8. "Secondary safety" on page 16.

3. Prepare the cables and link cables according to the number of

amplifier channels and cabinets used.

d&b V-Series Rigging manual (1.9 EN)22

Page 23

Splay link of the frame – «POSITION V8/V12»

3.2.1. V8/V12 Array

Preparations

For this type of setup the Splay link of the frame must be attached

to «POSITION V8/V12». Check the position and alter it if

necessary as described in Þ Chapter 2.9. " Splay link of the

frame" Þ " Changing the Splay link position" on page 17.

1. Prepare the first cabinet

Prepare the Front and Splay links of the first cabinet as described

in Þ Chapter 2.11. " Cabinet rigging mechanism" on page 19.

2. Attach the Flying frame to the first cabinet

1. Lower the frame onto the cabinet until the Front links fit into the

slots at the front of the frame.

2. Insert and lock the second Locking pins of the cabinet's Front

links on both sides.

3. Release the Locking pin that keeps the frame's Splay link in its

park position.

4. Fold out the Splay link and reinsert the Locking pin.

5. On the rear rigging strand of the cabinet, insert and lock the

first Locking pin of the cabinet in the [0°] hole.

6. Slightly lower the frame and fold in the Splay link.

7. Lift the frame until the hook of the Splay link hooks into the

preset Locking pin.

8. Insert the second Locking pin (Safety pin) to secure the frame's

Splay link in place.

d&b V-Series Rigging manual (1.9 EN) 23

Page 24

3. Add further cabinets

1. Prepare the Front and Splay links of the next cabinet as

described in Þ Chapter 2.11. " Cabinet rigging mechanism"

on page 19.

2. Preselect the splay angle according to your ArrayCalc

simulation.

3. Lift the frame to a suitable working height.

4. Attach the prepared cabinet to the corresponding slots on the

front of the upper cabinet.

5. Insert and lock the second Locking pins of the cabinet's Front

links on both sides.

6. Raise the bottom cabinet until the Splay link of the upper

cabinet has hooked into the preset Locking pin.

7. Release the cabinet and insert the second Locking pin (Safety

pin) to secure the Splay link.

To add further cabinets proceed in the same manner until the

assembly is completed.

4. Rig the cabling

1. Connect the flying cables and link cables according to the

number of amplifier channels and cabinets used.

2. Attach the cable pick.

5. Check the assembly

Before hoisting the array to its operating position recheck the

actual status of the entire assembly according to the checklist given

in Þ Chapter 4. "Safety and system checks" on page 39.

d&b V-Series Rigging manual (1.9 EN)24

Page 25

Splay link of the frame – «POSITION V-SUB»

3.2.2. V-SUB Column

Preparations

For this type of setup the Splay link of the frame must be attached

to «POSITION V-SUB». Check the position and alter it if necessary

as described in Þ Chapter 2.9. " Splay link of the frame"

Þ " Changing the Splay link position" on page 17.

1. Prepare the first cabinet

Prepare the Front links of the first cabinet as described in section

Þ Chapter 2.11. " Cabinet rigging mechanism" on page 19.

2. Attach the Flying frame to the first cabinet

1. Lower the frame onto the cabinet until the Front links fit into the

slots at the front of the frame.

2. Insert the second Locking pins of the cabinet's Front links on

both sides.

3. On the rear rigging strand of the cabinet, release both Locking

pins.

4. Fold the Splay link into the rigging strand and reinsert the

Locking pins.

d&b V-Series Rigging manual (1.9 EN) 25

Page 26

3. Add further cabinets

1. Prepare the Front links of the next cabinet as described in

section Þ Chapter 2.11. " Cabinet rigging mechanism" on

page 19.

2. Lift the current assembly to a suitable working height.

3. Position the next cabinet below the assembly.

4. Lower the assembly onto the cabinet until the Front links of the

bottom cabinet fit into the slots of the upper cabinet.

5. Insert the second Locking pins of the cabinet's Front links on

both sides.

6. On the rear rigging strand, release the Locking pins of both

cabinets.

7. Fold out the Rear link of the upper cabinet.

8. Reinsert the Locking pin on the upper cabinet.

9. Fold the Rear link into the rigging strand of the bottom cabinet.

10. Reinsert the two Locking pins on the bottom cabinet.

SUB to SUB, 2.5° splay, free

To add further cabinets, proceed in the same manner until the

assembly is completed.

Splay option

The Front links of the SUB cabinets allow for a splay angle of 2.5°

between adjacent SUB cabinets. Before hoisting the array, the

angle can be set in two ways:

free

The second Locking pin of the cabinet's Front link is

inserted in the top hole of the front rigging strand as

shown in the graphic opposite. This can be done for

all cabinets in one step.

The angle opens itself as soon as the array is

hoisted.

blocked

The second Locking pin of each cabinet's Front link

is inserted in the second hole cabinet by cabinet

during hoisting as shown in the graphic opposite.

Due to the design of the Front link mechanism, the

Locking pin can be inserted free of load.

SUB to SUB, 2.5° splay, blocked

d&b V-Series Rigging manual (1.9 EN)26

Page 27

4. Rig the cabling

1. Connect the flying cables and link cables according to the

number of amplifier channels and cabinets used.

2. Attach the cable pick.

5. Check the assembly

Before hoisting the array to its operating position recheck the

actual status of the entire assembly according to the checklist given

in Þ Chapter 4. "Safety and system checks" on page 39.

d&b V-Series Rigging manual (1.9 EN) 27

Page 28

3.2.3. Mixed array

NOTICE!

If SUB cabinets are included in the array, these must always be

positioned at the top of the column.

Remarks

For a mixed setup two Flying frames are required. One frame is

used for suspension and the second frame acts as an adapter to

add V8/V12 cabinets below the SUB cabinets.

Since the first part of the setup is similar to the setup of a flown

SUB column as described in , this section only describes the

assembly of the second Flying frame below the SUB cabinets.

Preparations

For this type of setup the Splay link of the second frame must be

attached to «POSITION V8/V12». Check the position and alter it

if necessary as described in Þ Chapter 2.9. " Splay link of the

frame" Þ " Changing the Splay link position" on page 17.

Splay link of the frame – «POSITION V8/V12»

1. Prepare the second Flying frame

To attach the second frame below the SUB cabinets, the two

additional Front links of the frame are needed.

1. Remove the additional Front links together with their Locking

pins from their park positions on the frame.

2. Attach the additional Front links at the top of the front tracks of

the frame and fix them with one Locking pin each.

Note:

Observe the direction of attachment as shown in the

graphic opposite.

2. Attach the assembly to the frame

1. Lift the assembly to allow the second frame to be positioned

below the assembly.

2. Position the frame below the assembly.

3. Fold out the Rear link of the SUB cabinet.

d&b V-Series Rigging manual (1.9 EN)28

Page 29

4. Lower the assembly onto the frame until

the Front links fit into the slots at the front of the frame

and the Rear link fits into the track of the frame's center bar.

5. Insert the second Locking pins of the Front links on both sides.

6. On the rear rigging strand of the cabinet, insert the (first)

Locking pin of the cabinet's Rear link to the fixing hole of the

frame's center bar.

7. Release the Locking pin of the cable pick and insert it to the

second fixing hole of the frame's center bar.

3. Add V8/V12 cabinets below the SUBs

Adding V8/V12 cabinets below the SUBs is similar to the setup of

a flown V8/V12 array as described in .

4. Rig the cabling

1. Connect the flying cables and link cables according to the

number of amplifier channels and cabinets used.

2. Attach the cable pick.

5. Check the assembly

Before hoisting the array to its operating position recheck the

actual status of the entire assembly according to the checklist given

in Þ Chapter 4. "Safety and system checks" on page 39.

d&b V-Series Rigging manual (1.9 EN) 29

Page 30

3.3. V Touring cart assembly

The V Touring cart allows for a quick and easy setup of arrays as

the entire cabinet assembly stored in the cart can be directly

connected to the V Flying frame or mounted below already

suspended V8/V12 or V-SUB cabinets.

This type of setup is also very efficient when working space is

restricted.

3.3.1. Assembly

Remarks

For the assembly the same general preparations are made as

described in .

The setup should always be carried out by two persons.

The rigging procedure described below applies to both touring

cart options.

Splay link of the frame

For this type of setup, the Splay link of the frame must be attached

to «POSITION V8/V12». Check the position and alter it if

necessary as described in Þ Chapter 2.9. " Splay link of the

frame" Þ " Changing the Splay link position" on page 17.

Splay link of the frame – «POSITION V8/V12»

3.3.1.1. Cabinet assembly to Flying frame

1. Prepare the touring cart

1. Move the cart to its assembly position.

2. Unlock the four fasteners (CamLocks) on the top lid and take

off the lid.

3. Unlock the four fasteners (CamLocks) on the bottom tray and

remove the connecting poles.

d&b V-Series Rigging manual (1.9 EN)30

Page 31

2. Prepare the cabinets

1. On the rear first remove all Locking pins.

2. Preset the splay angles of all cabinets based on your

ArrayCalc simulation.

Note: If the cabinet assembly is connected directly to the

Flying frame, the splay angle of the first (top) cabinet must be

set to [0°].

3. On the top cabinet, release both Locking pins and slide out the

Front link.

4. Insert and lock one Locking pin to fix the link in place.

3. Attach the Flying frame

1. Lower the frame onto the first cabinet of the assembly until the

Front links fit into the slots at the front of the frame.

2. Insert and lock the second Locking pins of the cabinet's Front

links on both sides.

3. Release the Locking pin that keeps the frame's Splay link in its

park position.

4. Fold out the Splay link and reinsert the Locking pin.

d&b V-Series Rigging manual (1.9 EN) 31

Page 32

5. On the rear rigging strand of the first cabinet, check the splay

angle is set to [0°].

6. Slightly lower the frame and fold in the Splay link into the

strand.

7. Lift the frame until the Splay link hooks into the preset Locking

pin.

8. Insert and lock the second Locking pin (Safety pin) to secure

the Splay link in place.

4. Apply and fix the preset splay angles

The Splay links will be engaged automatically while lifting the

assembly.

1. Slowly lift the cabinet assembly out of the cart until all Splay

links have hooked into the preset Locking pins.

2. Stop lifting and insert and lock the second Locking pins (Safety

pins) to secure the Splay links in place.

Note: In certain cases, the Splay links may not be engaged

automatically. In this case, the Splay angles of the cabinets

should be applied and fixed in the cart before the assembly is

connected to the array. For this purpose, proceed as follows:

4a. Apply and fix the preset splay angles manually

1. Raise the back of the cabinet until the Splay link has hooked

into the preset Locking pin of the bottom cabinet.

2. Hold the cabinet in place and insert the second Locking pin

(Safety pin) to fix the Splay link.

To apply and fix the splay angles of further cabinets, proceed in

the same manner.

d&b V-Series Rigging manual (1.9 EN)32

Page 33

3.3.1.2. Cabinet assembly below V8/V12 cabinets

Preparations

To mount the cabinet assembly below already suspended V8/V12

cabinets, prepare the respective cabinet assembly in the same

manner as described in the previous section Þ 3.3.1.1. " Cabinet

assembly to Flying frame", Þ "2. Prepare the cabinets"

on page 30.

1. Attach the assembly to the array

1. Lower the array until the Front links of the top cabinet in the

cart fit into the slots at the front of the bottom cabinet in the

array while a second person secures the cart against moving

and tipping over.

2. Insert and lock the second Locking pins of the cabinet's Front

links on both sides.

2. Apply and fix the preset splay angles

1. Slowly lift the cabinet assembly out of the cart until all Splay

links have hooked into the preset Locking pins.

2. Stop lifting and insert and lock the second Locking pins (Safety

pins) to secure the Splay links in place.

Note:

If the Splay links are not engaged automatically,

proceed in the same manner as described in the pervious

section Þ 3.3.1.1. " Cabinet assembly to Flying frame"

Þ " 4a. Apply and fix the preset splay angles manually" on

page 32.

3. Connect the bottom assembly to the Splay link of

the upper assembly

1. With two persons raise the entire assembly until the Splay link

of the array's bottom cabinet hooks into the preset Locking pin.

2. Slightly lower the assembly to allow the second Locking pin

(Safety pin) to be inserted.

3. Insert and lock the second Locking pin (Safety pin) to secure

the Splay link in place.

4. Rig the cabling

Connect the flying cables and link cables according to the number

of amplifier channels and cabinets used.

5. Check the assembly

Before hoisting the array to its operating position recheck the

actual status of the entire assembly according to the checklist given

in Þ Chapter 4. "Safety and system checks" on page 39.

d&b V-Series Rigging manual (1.9 EN) 33

Page 34

3.3.1.3. Cabinet assembly below V-SUB cabinets

Mounting the cabinet assembly below already suspended V-SUB

cabinets is similar to the procedure described in the previous

section Þ Chapter 3.3.1.2. "Cabinet assembly below V8/V12

cabinets" on page 33.

However, due to the possible size and weight of the suspended

SUB assembly, carry out the assembly very carefully and

considerably.

We recommend you to apply and fix the splay angles of the TOP

cabinets in the cart manually, before attaching the SUB assembly.

For this purpose proceed as follwos:

Apply and fix the preset splay angles manually

1. Raise the back of the cabinet until the Splay link has hooked

into the preset Locking pin of the bottom cabinet.

2. Hold the cabinet in place and insert the second Locking pin

(Safety pin) to fix the Splay link.

To apply and fix the splay angles of further cabinets, proceed in

the same manner.

3.3.1.4. Cart storage

The most space-saving way to store the carts during an event is to

place the connecting poles into the bottom tray and attach the top

lid to the bottom tray.

The conical connectors of the bottom tray will keep the top lid fixed

in place.

d&b V-Series Rigging manual (1.9 EN)34

Page 35

Splay link removed and Cable pick attached to hole 35.

3.4. Ground stacks

WARNING!

Potential risk of personal injury and/or

damage to material!

Always secure ground stacked setups against movement and

possible tipping over.

Observe the maximum number of cabinets permitted. This is

particularly important when setting up mixed ground stacks.

3.4.1. V8/V12 ground stack

Limitations

A maximum of 8 x TOP cabinets with the V Flying frame serving as

ground support are allowed to be set up as ground stack.

Preparations

In this type of setup the V Flying frame is used as ground support.

For this purpose, the Splay link of the frame must be removed and

stored in a safe place.

The Locking pin of the Cable pick will be used to fix the vertical

aiming of the first TOP cabinet on the Flying frame at a later stage.

For this reason, the Cable pick assembly (O-ring) must be attached

to hole 35 of the Frame's hole grid.

Proceed as follows:

1. Prepare the Flying frame

To attach the TOP cabinets to the Flying frame, the two additional

Front links of the frame are required.

1. Remove the additional Front links together with their Locking

pins from the park position on the frame.

2. Attach the additional Front links at the top of the front tracks of

the frame and fix them using one Locking pin.

Þ Observe the direction of attachment as shown in the

graphic opposite.

d&b V-Series Rigging manual (1.9 EN) 35

Page 36

2. Change the position of the Cable pick

1. Release and remove the Locking pin of the Cable pick.

2. Unlock and remove the ring cotter of the fixing bolt.

3. Pull out the fixing bolt and take off the O-ring.

4. Attach the O-ring to its new position (hole 35) and insert the

fixing bolt.

5. Reinsert the ring cotter to secure the fixing bolt and ensure the

ring cotter is properly locked.

3. Attach the first cabinet to the frame

1. Place the cabinet onto the frame until the additional Front links

fit into the slots at the front of the cabinet.

2. Insert the second Locking pins of the additional Front links on

both sides.

4. Set the vertical aiming of the first cabinet

The hole grid on the Flying frame allows the first cabinet to be set

to a fixed vertical angle of –7°, –3.5°, 0°, +3.5° or +7°. The

hole (drill) of the cabinet's Splay link is used for this purpose. It

supports the cabinet and defines the angle setting.

1. Release the Locking pins of the cabinet's Splay link.

2. Fold out and insert the Splay link into the track of the center

bar of the frame and align the hole of the link with the desired

hole of the frame.

3. Fix the angle of the cabinet using the Locking pin of the Cable

pick.

5. Add further cabinets

1. Release the Locking pins of the Front links of the first cabinet.

2. Slide out the Front links and insert one Locking pin each to fix

them in place.

3. Attach the next cabinet to the Front links and insert the second

Locking pins on both sides.

d&b V-Series Rigging manual (1.9 EN)36

Page 37

4. At the rear, release both Locking pins of the upper cabinet's

Splay link.

5. Preset the desired splay angle on the rear rigging strand of the

bottom cabinet using one Locking pin.

6. Fold the Splay link of the upper cabinet into the rigging strand

of the bottom cabinet.

7. Raise the upper cabinet until the hook of the Splay link hooks

into the preset Locking pin.

8. Hold the cabinet in place and insert the second Locking pin

(Safety pin) to fix the Splay link in place.

To add further cabinets, proceed in the same manner until the

assembly is completed.

6. Rig the cabling

Connect the flying cables and link cables according to the number

of amplifier channels and cabinets used.

7. Check the assembly

Recheck the actual status of the entire assembly according to the

checklist given in Þ Chapter 4. "Safety and system checks"

on page 39.

3.4.2. V-SUB stack

Limitations

A maximum of 8 x SUB cabinets are allowed to be set up as SUB

stack.

1. Assembly

Stack the SUB cabinets and interconnect them with their Front and

Rear links.

2. Rig the cabling

Connect the flying cables and link cables according to the number

of amplifier channels and cabinets used.

3. Check the assembly

Recheck the actual status of the entire assembly according to the

checklist given in Þ Chapter 4. "Safety and system checks"

on page 39.

d&b V-Series Rigging manual (1.9 EN) 37

Page 38

3.4.3. Mixed ground stack

Limitations

A combination of 8 x TOP/SUB cabinets at maximum are allowed

to be set up as mixed ground stack.

Preparations

For this type of setup the Splay link of the frame must be attached

to «POSITION V-SUB». Check the position and alter it if necessary

as described in Þ Chapter 2.9. " Splay link of the frame"

Þ " Changing the Splay link position" on page 17.

Splay link of the frame –

«POSITION V-SUB»

1. Assembly

1. Stack the SUB cabinets and interconnect them using their Front

and Rear links.

2. Prepare the Front links of the upper SUB cabinet as described

in Þ Chapter 2.11.1. "Front link mechanism" on page 19.

3. Place the frame onto the cabinet until the Front links fit into the

slots at the front of the frame.

4. Insert the second Locking pins of the cabinet's Front links on

both sides.

5. On the rear rigging strand of the cabinet, release both Locking

pins.

6. Fold the frame's Splay link into the rigging strand and reinsert

the Locking pins.

The assembly of the V8/V12 cabinets on top of the frame is

carried out in the same manner as described in the previous

section Þ Chapter 3.4.1. "V8/V12 ground stack" on page 35.

2. Rig the cabling

Connect the flying cables and link cables according to the number

of amplifier channels and cabinets used.

3. Check the assembly

Recheck the actual status of the entire assembly according to the

checklist given in Þ Chapter 4. "Safety and system checks"

on page 39.

d&b V-Series Rigging manual (1.9 EN)38

Page 39

4. Safety and system checks

Before hoisting the array to its operating position recheck the

actual status of the assembly as follows:

Note: When applicable, the same system and safety checks

also apply to ground stack assemblies.

4.1. Mechanical setup

– Check the attachment of the Load adapter(s) to the Flying

frame and ensure all Locking pins are properly inserted and

locked.

– Check the attachment of the secondary safety device at the

Flying frame (refer to section Þ Chapter 2.8. "Secondary

safety" on page 16).

– Check the attachment of the Flying frame(s) to the cabinets

and ensure all Locking pins are properly inserted and locked.

– Check the attachment of all Front links on both sides of the

cabinets and ensure all Locking pins are properly inserted and

locked.

– Check the splay angles and the attachment of the Splay/Rear

links on the rear of the cabinets and ensure all Locking pins

are properly inserted and locked.

– In "Single pickpoint operation" check the desired total vertical

aiming of the entire array using an inclinometer.

4.2. Wiring

– Check the wiring.

If the amplifiers are already wired and powered on, use their

System check functions or Channel mute switches and a test

signal to check the correct operation and routing of all

channels and cabinets.

d&b V-Series Rigging manual (1.9 EN) 39

Page 40

5. Hoisting and securing the array

5.1. Hoisting the array

WARNING!

Potential risk of personal injury and/or

damage to material!

Always ensure that each of the hoists is able to carry the total

weight of the array.

When hoisting the array, unpredictable dynamic forces as well as

swinging of the array must be taken into account. This may lead to

personal injury and/or damage to the rigging components and

loudspeaker cabinets.

Ensure that there is nobody directly underneath or in the vicinity of

the load who is not involved in the setup.

When all the mechanical adjustments, system checks and safety

checks have been made, the array can be hoisted up to its

operating position.

When hoisting the array, ensure that the loudspeaker cables do

not get caught anywhere. The cables can be strapped together

with the motor cable to form a loom while the system is hoisted.

The chain hoist motors must raise the system slowly and evenly so

that it does not swing or move from side to side during hoisting.

5.2. Securing the array

When the array is in its final operating position the secondary

safety must be applied. A detailed description is given in

Þ Chapter 2.8. "Secondary safety" on page 16.

d&b V-Series Rigging manual (1.9 EN)40

Page 41

6. Derigging

6.1. General

To dismantle any of the assemblies described above, follow the

corresponding assembly instructions in reverse order.

The same safety instructions apply.

6.2. Touring cart disassembly

With respect to the touring carts the following procedure is strongly

recommended.

CAUTION!

Potential risk of personal injury and/or

damage to material!

In particular make sure that when lowering the array nobody is

directly underneath or in the vicinity of the array.

When lowering the array onto the cart avoid diagonal pull.

This could lead to the potential risk of the array tipping over

towards the front.

Depending on the type of surface (arena floor/outdoor field) the

cart could suddenly slide out of position and could cause a

potentially dangerous situation which may lead to personal injury.

1. Dismantle the first cabinet assembly

1. Lower the array to a suitable working height.

2. Release the Safety pin of the Splay link on the lowest cabinet

of the upper assembly.

3. With two persons raise the bottom assembly and fold out the

Splay link of the upper assembly.

4. Carefully lower the bottom assembly.

5. Release all Safety pins of the bottom assembly.

Note: To prevent the Safety pins from getting jammed while

the assembly is lowered onto the cart, reinsert the Safety pins

in one of the remaining holes in the rear rigging strands of the

cabinets.

d&b V-Series Rigging manual (1.9 EN) 41

Page 42

6. Lower the array slowly and evenly onto the cart until the Front

links are load-free.

7. Release the Locking pins of the Front links on the top cabinet of

the assembly while a second person renders support to

prevent the upper suspended assembly from unpredictable

swing.

8. Slowly lift the remaining assembly to allow the cart to be

turned or moved aside.

Proceed in the same manner until the array is completely

dismantled.

2. Reassembling the cart

1. Slide in the Front links of the top cabinet and reinsert the two

Locking pins.

2. Attach the connecting poles to the bottom tray and lock all

fasteners (CamLocks).

3. Attach the top lid and lock all fasteners (CamLocks).

Note: The top lids of the touring carts are equipped with

additional guiding tracks to fix the cabinet assemblies in place.

In conjunction with the E7463 V Touring cart 4 x V8/V12

observe the direction of attachment as shown in the graphic

below.

d&b V-Series Rigging manual (1.9 EN)42

Page 43

7. Care and maintenance / Disposal

7.1. Transport / Storing

During transport ensure the rigging components are not stressed or

damaged by mechanical forces. Use suitable transport cases.

We recommend the use of the d&b E7463 or E7464 V Touring

cart for this purpose.

Due to their surface treatment the rigging components are

temporarily protected against moisture. However, ensure the

components are in a dry state while stored or during transport and

use.

7.2. Visual and functional inspection

WARNING!

Potential risk of personal injury and/or

damage to material

To eliminate the potential risk of accident due to malfunctioning of

a component, regularly inspect all system components.

Cabinet enclosure

– Visual inspection of all fitting plates for obvious damage (e.g.

cracks or corrosion).

– Visual inspection of the rear rigging strand for obvious

damage (e.g. cracks, deformation or corrosion) including all

drilled holes of the component.

– Inspection of all fitting plates including front grills to ensure

they are securely attached.

– Regularly lubricate the sockets using WD-40® or a similar

product.

Front and Splay (Rear) links

Visual inspection regarding deformation and damage (e.g. cracks

and corrosion) including all drilled holes of the component.

Locking pins

– Visual inspection for deformation, cracks and corrosion of the

component.

– Inspection for missing ball bearings and damage.

– Functional inspection of the release mechanism to ensure it

operates properly.

– Regularly lubricate the Locking pins using WD-40® or a similar

product.

d&b V-Series Rigging manual (1.9 EN) 43

Page 44

Condition of the ring cotter

[a]: Ring cotter OK

[b]: Exchange the ring cotter

Ring cotters

– Visual inspection for obvious damage and deformation.

– Functional test of the locking mechanism as described in

Þ Chapter 2.4. "Ring cotters" on page 11.

If a ring cotter can no longer be properly fitted to the fixing

bolt and locked, it must be exchanged.

Z5380 V Flying frame

– Visual inspection regarding deformation and damage (e.g.

cracks and corrosion) including all drilled holes of the

component.

– Regularly check the flatness of the Flying frame. For this

purpose position the Flying frame on a flat surface and visually

check the frame for deformation and/or torsion. For obvious

deformation and/or torsion contact d&b audiotechnik for

further advice on how to proceed.

Z5381 V Hoist connector chain / Z5382 V Safety chain

Inspection according to the appropriate regulations for lifting

devices (EN 818-6:2000). Regularly inspect within a 12 months

period. Regularly inspect for cracks within a 36 months period.

7.3. Disposal

When out of use the rigging components must be disposed of in

accordance with the national environmental regulations.

Ensure that damaged rigging components are disposed of in a

way that they cannot be used again.

d&b V-Series Rigging manual (1.9 EN)44

Page 45

8. Manufacturer's declaration

We hereby declare that the equipment designated below is

designed and built in the version sold by us in such a way as to

comply with the relevant fundamental safety and health criteria of

the applicable EC Directive(s). This declaration shall cease to be

valid if alterations are made to the equipment without our prior

agreement.

This declaration covers:

d&b V-Series loudspeaker cabinets

(With integrated rigging components.)

– Z0515 V8

– Z0516 V12

– Z0518 V-SUB

d&b V-Series rigging components

(Including all additional components such as Load adapter, Front

links frame, shackles.)

– Z5380 V Flying frame

– Z5381 V Hoist connector chain

– Z5382 V Safety chainset

National standards and technical specifications

applied:

DIN EN ISO 12 100, DIN EN 1050, BGV C1.

Backnang, -2014-08

Frank Bothe,

Head of R&D

d&b audiotechnik GmbH

d&b V-Series Rigging manual (1.9 EN) 45

Page 46

D2702.EN .01, 11/2014 © d&b audiotechnik GmbH

www.dbaudio.com

Loading...

Loading...