Page 1

MODEL

4078

SINGLE-CHANNEL

AC STRAIN GAGE

INSTRUMENT

SB.2

INSTRUCTION MANUAL

4000

Instrument Series

Page 2

Copyright © 1996, Daytronic Corporation. All rights reserved.

No part of this document may be reprinted, reproduced, or used in any form or by

any electronic, mechanical, or other means, including photocopying and recording,

or in any information storage and retrieval system, without permission in writing

from Daytronic Corporation. All specifications are subject to change without notice.

Page 3

Model 4078 Instruction Manual, v. SB.2

Pub. No. 4078.2, Issued 10/96

MODEL

4078

SINGLE-CHANNEL

AC STRAIN GAGE INSTRUMENT

INSTRUCTION MANUAL

Part No. 91630

Daytronic Corporation

Dayton, OH 45439-1521

www.daytronic.com

Page 4

Page 5

1. Introduction

a. Description and Specifications ............................................. 1.1

b. Physical Layout .................................................................... 1.5

c. Panel Mounting .................................................................... 1.7

d. Standard Channel Configuration ..........................................1.8

e. Standard Logic Configuration .............................................. 1.9

f. Using the Front-Panel Setup Buttons ................................. 1.11

g. Low Battery Warning ..........................................................1.17

2. Setup

a. Transducer Cabling ............................................................. 2.1

b. Powerup .............................................................................. 2.5

c. Adjusting LCD Viewing Angle .............................................. 2.7

d. Selecting a Channel for Display .......................................... 2.8

e. Channel Calibration ............................................................. 2.9

f. Setting Channel Filter ........................................................ 2.12

g. Scaling the Bargraph Display ............................................ 2.13

h. Defining Limit Zones .......................................................... 2.15

i. Logic I/O Connections ....................................................... 2.16

j. Analog Output Connections ............................................... 2.18

3. Operation: Use of Front Panel Buttons ................................. 3.1

Appendix A: Complete Standard Configuration ......................... A.1

Appendix B: 4078/Computer RS-232-C Connections ............... B.1

Appendix C: Legend and Indicator Annunciation ....................... C.1

Appendix D: Modifying the Input Range .................................... D.1

Appendix E: Phase/Symmetry Adjustment for a

Lebow 1800 Series Transducer ................................................. E.1

Appendix F: "Simulated" Calibration ........................................... F.1

Appendix G: Changing the Battery ............................................ G.1

i

Contents

Section

Page

Page 6

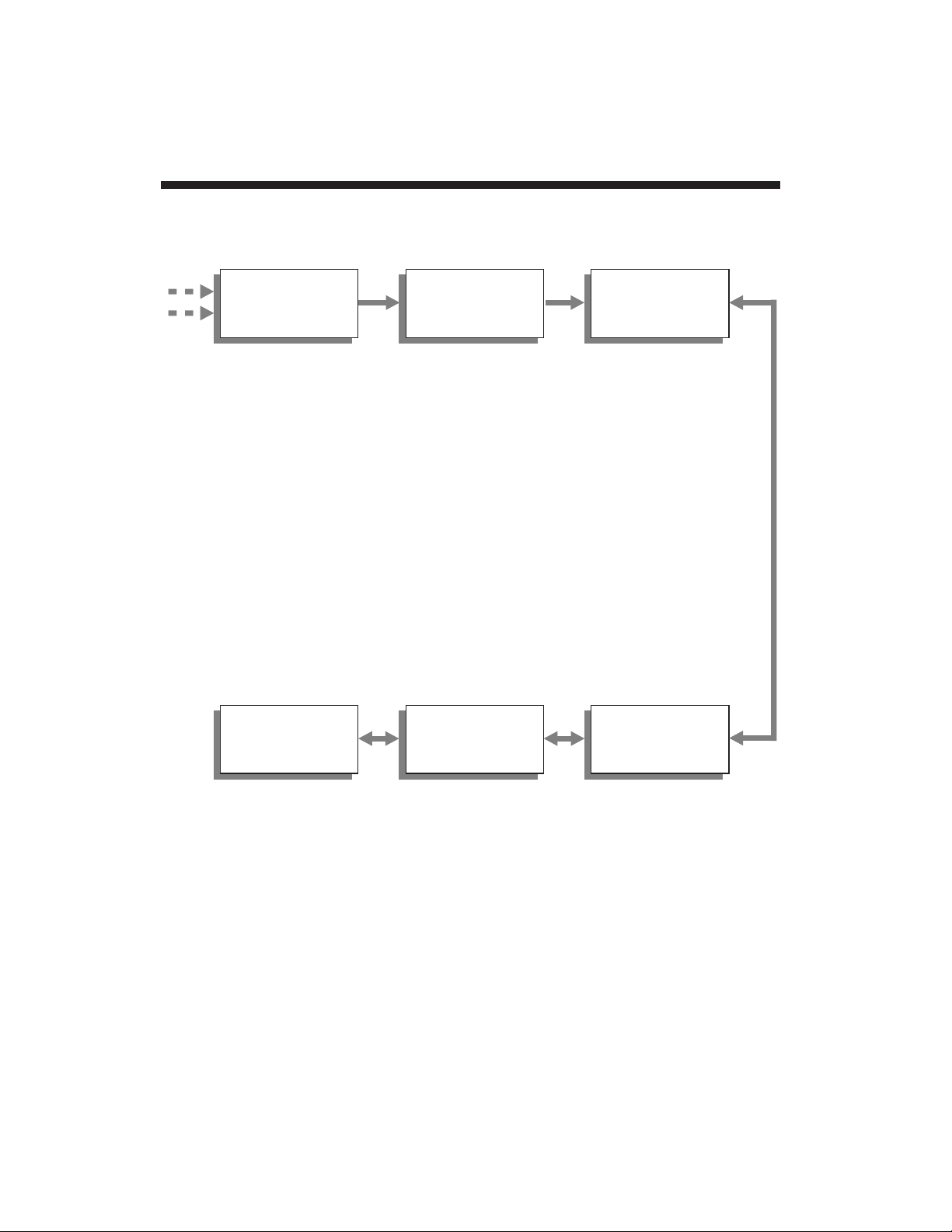

1.a Model 4078 Description and Specifications

1.1

A to D

Conversion

Real-Time

Math

Processing

Signal

Conditioning

Communi-

cations &

Memory

Process

Control

Displays &

Buttons

Transducer

Input(s)

General 4078 Features

• + – x ÷ √

• Digital Max/Min

• Constants

• Limits (7 zones,

including "Safety"; can

be used to generate

logic control outputs or

to trigger predefined

command sequences

automatically)

• Tare offset

• Scalable 51-segment

bargraph with endpoint indication

• Backlit 0.6-inch LCD

with adjustable viewing

angle and limittriggered flashing

• Independently settable

dual-limit displays

• RS-232-C I/O

• Port for optional

keyboard

• Simple step-through

configuration setup

and review via front

panel

• Battery-backed data

and configuration

storage

• Scalable 10-V analog

output for strip-chart

recording, etc.

• 8 TTL-level logic I/O's

for annunciation,

process control, and

automatic command

execution

• 16-bit (±32000 count)

• Optional internal

linearization (up to 15

variable-length

segments)

• Excitation

• "y = mx + b" scaling

• Analog and digital

filtering

Page 7

The Model 4078 is a single-channel conditioner of

phase-sensitive

carrier-amplifier

design (rather than a fully DC instrument). Intended for

applications involving transformer-coupling to the transducer bridge (as

with rotary-transformer torque sensors), it can also be used when high

sensitivity is required or where the electrical environment is especially

noisy. Responding only to the modulated carrier frequency, the 4078

rejects extraneous voltages that can cause errors in DC systems,

particularly when there is a need to "blow up" a portion of the transducer range.

A "tare" function is preprogrammed for the strain gage input, and may

be activated by a front-panel push button. Via front-panel buttons, you

can also display and reset MAXIMUM, MINIMUM, and "MAX minus

MIN" values for the "tared" analog input.

Unless otherwise specified at the time of order, your Model 4078 has

been set, prior to shipment, to a

standard configuration

. THIS

CONFIGURATION IS FULLY ADEQUATE FOR MOST APPLICATIONS, AND LETS YOU CONTROL BASIC INSTRUMENT SETUP

AND OPERATION SOLELY BY MEANS OF THE SIX FRONT-PANEL

PUSH BUTTONS. A full listing of your 4078's standard configuration is

given in Appendix A.

Like all 4000 Series instruments, however, the 4078 can be rapidly and

easily reprogrammed in the field, to provide a variety of unique

application solutions. For such reprogramming you can use either

• an optional Model 10P80D Extended Keyboard that plugs directly

into the rear of the 4078 unit, or

• the optional StartPAC 100 Software (Model GS-SP100).* This

software applies to ALL Daytronic RS-485 networkable instruments, and offers a number of valuable utilities for terminal

emulation, node configuration, network monitoring, data display

and logging, etc. IT IS SUPPLIED FREE OF CHARGE WITH ALL

4000 SERIES MODELS. For details on the installation and

operation of StartPAC 100, see the

StartPAC 100 Instruction

Manual

.

StartPAC 100 lets a connected computer serve as a "dumb" terminal

for entry of the specific MNEMONIC COMMANDS required to repro-

1.2

Model 4078 Description and Specifications 1.a

* Alternatively, you can use any of a number of commercially available

terminal emulation programs

to issue commands directly to the 4078.

Page 8

gram the 4078. These commands may also be issued directly to the

4078 via the optional Extended Keyboard. Commands which are

common to all 4000 Series models are described in detail in the

optional 4000 Series

System Instruction Manual

. IT IS RECOM-

MENDED THAT YOU STUDY THE

SYSTEM INSTRUCTION

MANUAL

BEFORE YOU ATTEMPT ANY RECONFIGURATION OF

YOUR MODEL 4078 BEYOND THAT DISCUSSED IN THE

APPENDICES OF THE PRESENT MANUAL.

See Appendix B of the present manual for direct RS-232-C connections

between the 4078 and a computer or printer.

Unless otherwise specified, every 4078 comes with the standard

engineering-unit legends

and

button-function indicators

shown in Fig. 1.

Different legend/indicator films may be optionally obtained. Via optional

keyboard or computer, you can instruct the 4078 to light any one or a

combination of given legends and indicators. See Appendix C for

"Legend and Indicator Annunciation." Note that under the "standard

configuration," the "F1" indicator will

always

be on when the 4078 is in

"RUN-TIME" mode.

Your 4078 is initially configured for a full-scale transducer range of

3.00 mV/V

(excitation for the 4078 is

fixed

at 3 V-AC RMS). If you

require a range setting of 0.75 or 1.50 mV/V, see Appendix D. Appendix F explains an alternative "simulated calibration" technique that uses

an internal shunt resistor and requires the entry of special mnemonic

commands to open and close the shunt (via computer or keyboard).

NOTE: EXCEPT FOR APPENDICES C, D, AND F—AND ALSO THE

PHASE AND SYMMETRY ADJUSTMENT

PROCEDURES GIVEN IN

SECTION 2.e AND APPENDIX E—THE PRESENT MANUAL WILL

ONLY TREAT PROCEDURES AND CONSIDERATIONS WHICH ARE

RELEVANT TO THE 4078 "STANDARD CONFIGURATION" AND

WHICH DO NOT REQUIRE A CONNECTED COMPUTER OR

KEYBOARD. FOR INFORMATION ON THE FULL FUNCTIONALITY

OF YOUR MODEL 4078, SEE THE OPTIONAL

SYSTEM

INSTRUCTION MANUAL

.

MODEL 4078 SPECIFICATIONS (for general 4000 Series Physical,

Electrical, and Environmental specifications—including Logic

1.a Model 4078 Description and Specifications

1.3

Page 9

I/O—see Appendix A of the 4000 Series

System Instruction

Manual)

:

Transducer Types and Ranges: The 4078 accepts a force-

measurement signal from a conventional strain gage transducer

with 4-arm bridge of nominal 350 ohms or higher, and a full scale

range of 0.75, 1.50, or 3.00 mV/V.

Excitation: Regulated 3 V-AC (rms) at 3280 Hz; 75 mA (rms),

maximum

Amplifier: AC-coupled demodulator with user-settable phase and

symmetry controls

Normal-Mode Range: ±12 mV rms, operating; ±8 V-DC without

instrument damage

Common-Mode Range: ±0.8 V-DC operating; ±8 V-DC without

instrument damage

Common-Mode Rejection Ratio: DC: infinite; at 60 Hz: infinite; at 1

kHz: -80 dB; at 3 kHz: -60 dB

Input Impedance (Differential and Common-Mode): 10 megohms

Offset: Initial: ±3% of full scale; vs. temperature: ±0.005% f.s./°C; vs.

time: ±0.002% f.s./month

Gain Accuracy*: ±0.025% of full scale

typical

, following calibration

Gain Stability: vs. temperature: ±50 ppm/°C; vs. time: ±20

ppm/month

Filter: 3-pole modified Butterworth; 3 dB down at 7.5 Hz; 60 dB down at

60 Hz

Step Response Settling Time (Full-Scale Output):

To 1% of final value: 300 msec

To 0.1% of final value: 450 msec

To 0.02% of final value: 600 msec

Analog Output: ±10 V, microprocessor driven and scaled, ±1 mV

resolution

Accuracy: 0.05% of current voltage reading ± 2 mV

Output Bandwidth: 40 Hz maximum

* Initial (uncalibrated) inaccuracy may be as great as ±3% of full scale.

Maximum error that could occur upon replacement of a Model 4078

not followed by calibration

is ±6% of full scale.

1.4

Model 4078 Description and Specifications 1.a

Page 10

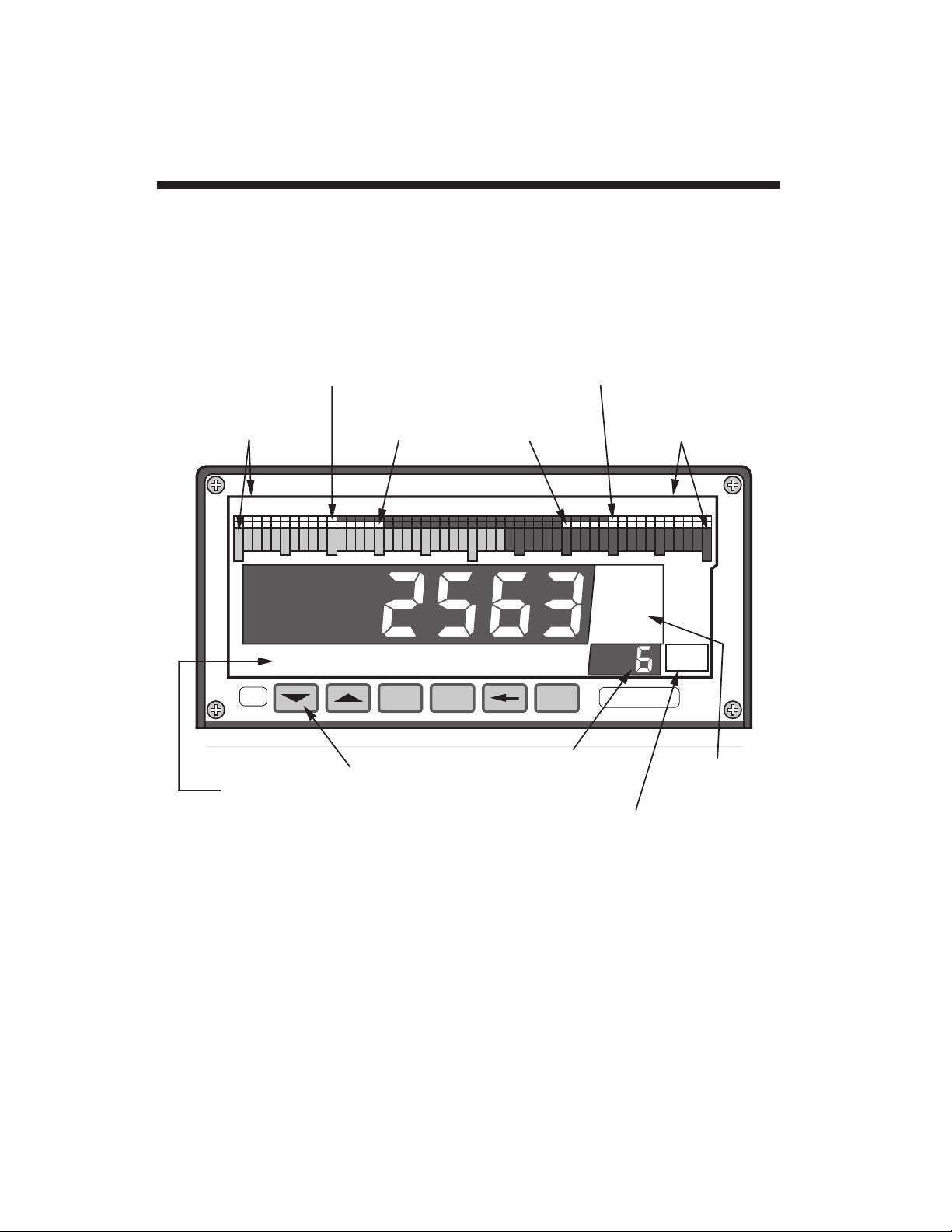

Study the following diagrams to acquaint yourself with your 4078's most

important front and rear elements.

1.b Physical Layout

1.5

psi

lb-ft

Bargraph

Low Endpoint

(LEP)

"Low-Low" Limit

(LLL)

Setup and Special

Function Buttons

Engineering-

Unit Legends*

Channel No.

and

Mnemonic

Display

lbs

SET

UP

Bargraph

High Endpoint

(HEP)

"High-High" Limit

(HHL)

"Low" Limit

(LOL)

"High" Limit

(HIL)

Button

"RUN-TIME

FUNCTION"

Indicators*

Button Activity

Indicator

ON

LINE

F1 F2 F4

SET

UP

F3 F5

* Standard film shown.

(F1 = LIVE DISPLAY

F2 = [NOT USED]

F3 = TARE

F4 = MAX/MIN/MAX-MIN STEP

F5 = MAX/MIN RESET

—see Section 3)

CHAN STEP

44000

Fig. 1 4078 Front Panel

Page 11

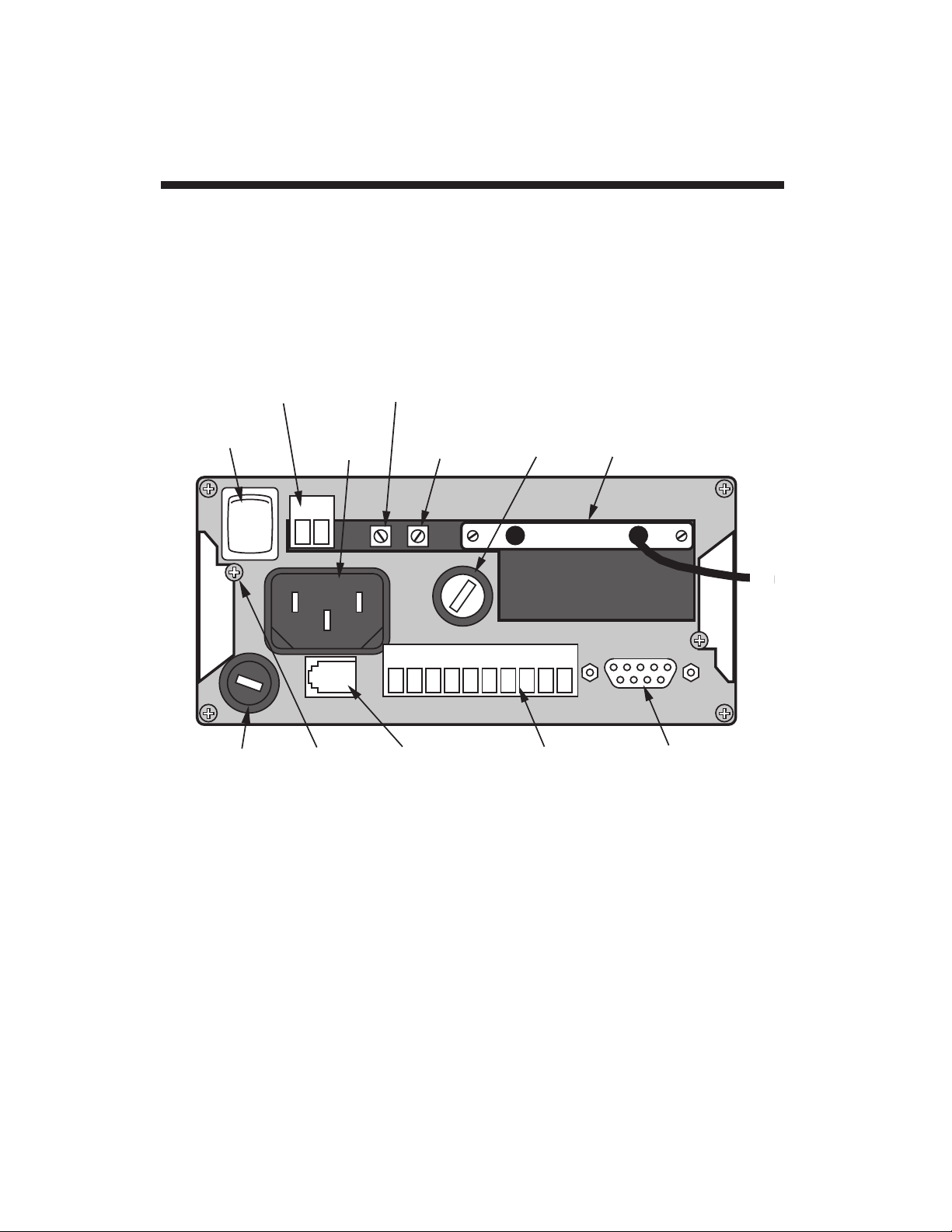

Physical Layout 1.b

1.6

Analog

Output

Connector

(see Fig. 10)

1

O

CONDITIONER

CONNECTOR

—attaches to 4078

Analog Input Board

(see Figs. 5-7)

Logic I/O

Connector

(see Figs. 4, 9)

ON-OFF

Switch

Fuse

AC Power

Connector

Connector

for Optional

Keyboard

Voltage

Selector

Switch

RS-232-C

Interface

Connector

(see App. B)

PanelMount

Clamp

Screw

PHASE

ADJUSTMENT

CONTROL

SYMMETRY

ADJUSTMENT

CONTROL

Fig. 2 4078 Rear Panel

Page 12

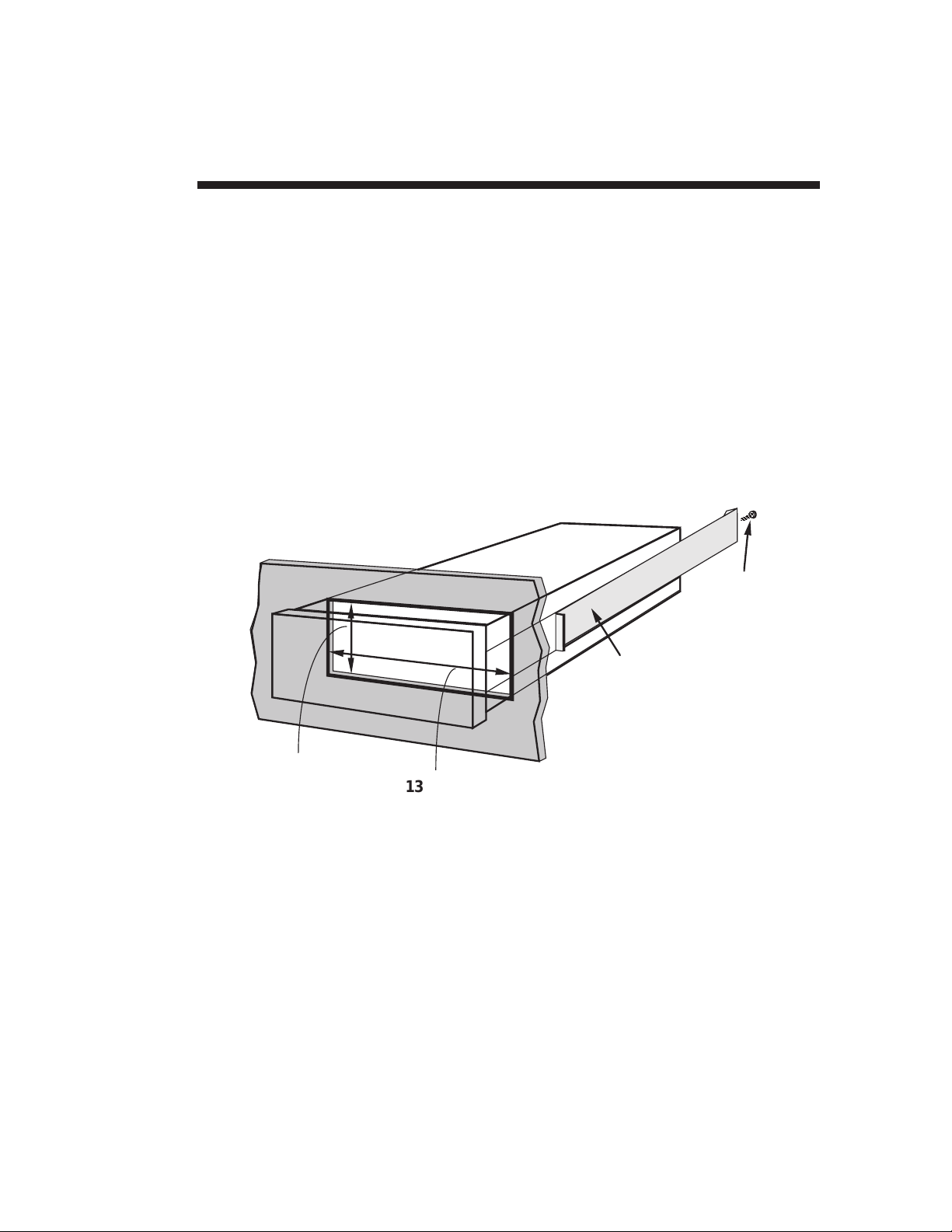

You can easily mount a Model 4078 in your own precut panel. Cutout

dimensions for a

panel-mounted

unit are standard DIN (see Fig. 3);

panel thickness should not exceed 6 mm (0.24 in).

When mounting a 4078,

DO NOT REMOVE THE FRONT BEZEL.

Simply unscrew the two rear-panel CLAMP SCREWS and slide the

CLAMP SLIDES rearwards out of their grooves. Insert the 4078 unit

through the panel cutout,

from the front of the panel

(if the unit has

rubber feet, these will have to be removed). Then reinstall the CLAMP

SLIDES, and tighten the CLAMP SCREWS until the instrument is

securely mounted.

1.7

1.c Panel Mounting

138 ± 1.0 mm

(5.43 ± 0.04 in)

68 ± 0.7 mm

(2.68 ± 0.03 in)

CLAMP SLIDE

CLAMP

SCREW

Fig. 3

4078 Panel Mounting

Page 13

Channel No. Channel Function

1 "LIVE" INPUT CHANNEL

This channel represents the 4078's

conditioned analog

input

. Sensor calibration is performed on this channel, as

explained in Section 2.e and Appendix F.

2 THIS CHANNEL IS NOT T

O BE USED FOR THE 4078

5 "LIVE" INPUT WITH TARE

This channel represents the value of Channel 1

minus

the current "tare" offset for the input

(that is, the value of

Channel 1 that existed when the front-panel "TARE"

button was last pressed). Active control limits will

normally operate on the basis of this channel—see

Section 1.e.

6 "MAXIMUM" VALUE OF CHN. 5

This channel represents the

most positive

value of

Channel 5 since "MAX" measurement was last reset via

the front-panel "MAX/MIN RESET" button.

7 "MINIMUM" VALUE OF CHN. 5

This channel represents the

least positive

value of

Channel 5 since "MIN" measurement was last reset via

the front-panel "MAX/MIN RESET" button.

8 "MAX minus MIN" VALUE OF CHN. 5

This channel represents the existing

net difference

between Channel 6 and Channel 7.

19 ANALOG OUTPUT

This channel represents Channel 5 ("tared" analog input),

scaled to a full range of ± 10 V-DC. It may be used for

strip-chart recording, input to other systems, or generalpurpose signal monitoring. For rescaling and connection

of the analog output, see Section 2.j.

The 4078's Channel Nos. 4 and 14-16 are used as intermediate result

registers or reference channels, and will not normally be displayed.

The remaining scanned channels (Nos. 2, 3, 9-13, 17, and 18) are not

used in the standard 4078 configuration. CHANNEL 2 CANNOT BE

USED IN

ANY

4078 CONFIGURATION.

Standard Channel Configuration 1.d

1.8

Page 14

Your 4078 provides eight logic input/output bits in

open-collector,

negative-true

form, where the "Logic 1" state is defined as nominal

0

V-DC

and "Logic 0" as nominal

+5 V-DC.

The standard logic I/O

configuration is shown in Fig. 4, below, with reference to the 10-terminal

Logic I/O Connector on the rear of the 4078. For recommended logic

interconnections, see Section 2.i.

You can use the seven logic control outputs to actuate solenoid valves,

illuminate panel displays, sound alarms, start and stop motors or

pumps, initiate and control safety shut-down sequences, and perform

many other automation tasks that require "intelligent" switching, even of

substantial amounts of power. These are

nonlatching

outputs; each

terminal will return to

Logic 0

as soon as the corresponding limit

violation ceases to occur. For "Defining Limit Zones," see Section 2.h.

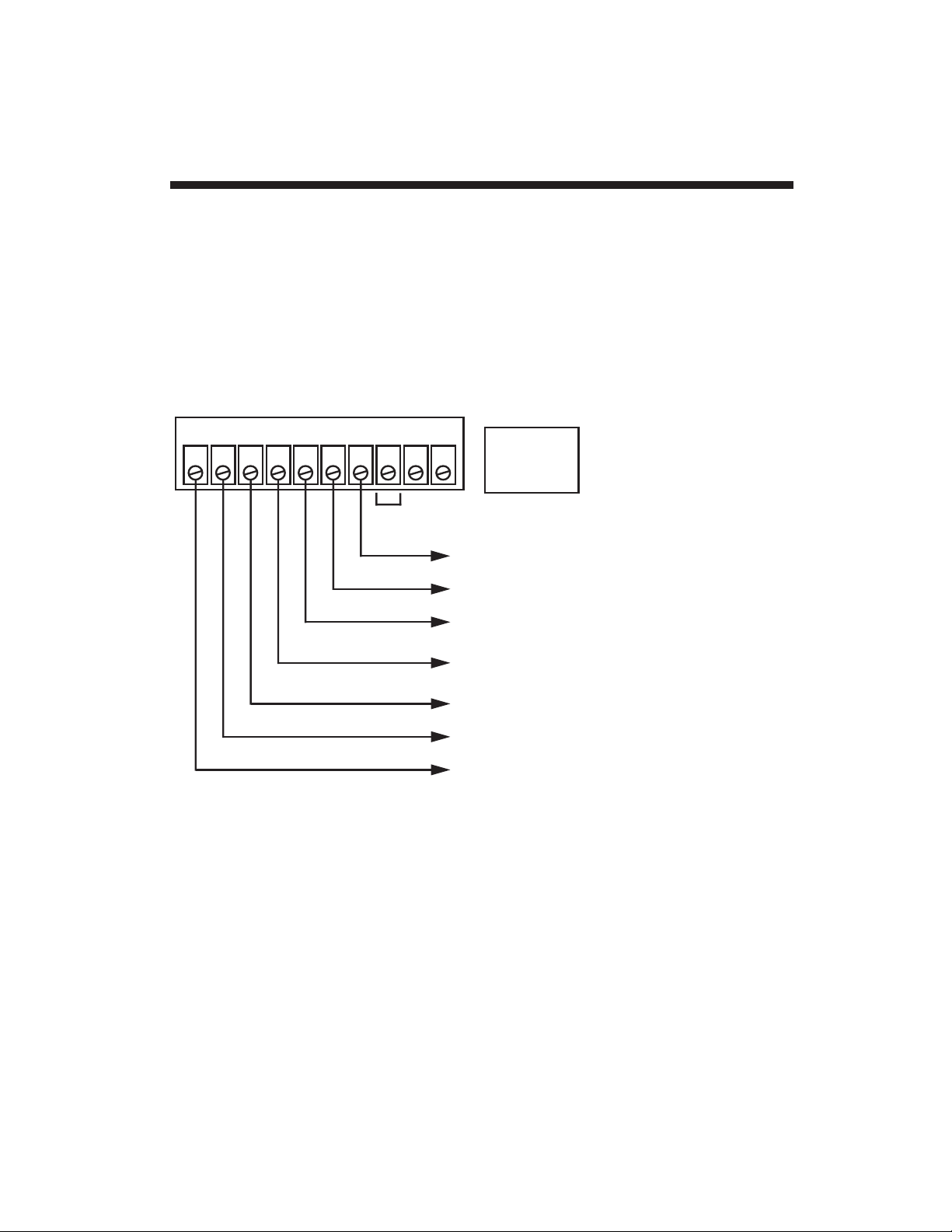

1.e Standard Logic Configuration

1.9

0 1 2 3 4 5 6 7 +5 GD

LOGIC LOW

TO ENABLE

(see Fig. 9)

Unassigned

CHN. 5 IN "ABOVE BARGRAPH" ZONE

CHN. 5 IN UPPER "DANGER" ZONE

CHN. 5 IN UPPER "CAUTION" ZONE

Logic Outputs:

CHN. 5 IN SAFETY (NO VIO) ZONE

CHN. 5 IN LOWER "CAUTION" ZONE

CHN. 5 IN LOWER "DANGER" ZONE

CHN. 5 IN "BELOW BARGRAPH" ZONE

Fig. 4 4078 Standard Logic Outputs

Page 15

Bit No. Logic Function

0 "BELOW BARGRAPH" VIOLATION OUTPUT

Terminal 0 will be at a

Logic 1

(0 V-DC) level whenever

the reading of Channel 5 is less than the current "LEP"

value for that channel.

1 "LOW LOW" VIOLATION OUTPUT

Terminal 1 will be at a

Logic 1

(0 V-DC) level whenever

the reading of Channel 5 is less than the current "LLL"

value for that channel and greater than or equal to the

current "LEP" value.

2 "LOW" VIOLATION OUTPUT

Terminal 2 will be at a

Logic 1

(0 V-DC) level whenever

the reading of Channel 5 is less than the current "LOL"

value for that channel and greater than or equal to the

current "LLL" value.

3 "OK" (NO VIOLATION) OUTPUT

Terminal 3 will be at a

Logic 1

(0 V-DC) level whenever

the reading of Channel 5 is greater than or equal to the

current "LOL" limit value and less than or equal to the

current "HIL" limit value for that channel.

4 "HIGH" VIOLATION OUTPUT

Terminal 4 will be at a

Logic 1

(0 V-DC) level whenever

the reading of Channel 5 is greater than the current "HIL"

value for that channel and less than or equal to the

current "HHH" value.

5 "HIGH HIGH" VIOLATION OUTPUT

Terminal 5 will be at a

Logic 1

(0 V-DC) level whenever

the reading of Channel 5 is greater than the current

"HHH" value for that channel and less than or equal to

the current "HEP" value.

6 "ABOVE BARGRAPH" VIOLATION OUTPUT

Terminal 6 will be at a

Logic 1

(0 V-DC) level whenever

the reading of Channel 5 is greater than the current

"HEP" value for that channel.

1.10

Standard Logic Configuration 1.e

Page 16

Study this manual section carefully to familiarize yourself with the

general operation of your 4078's front-panel buttons when they are in

"SETUP" mode. Specific setup parameters—such as "HIGH ENDPOINT (HEP)", "FILTER (FIL)," "LCD," etc.—are explained in detail in

Section 2.

The 4078 provides

instant visual feedback

for its front-panel buttons.

Thus, pressing any button will light the green ON LINE indicator. This

indicator is located in the lower right-hand corner of the 4078 front

panel (see Fig. 1). It will remain lit as long as the button is pressed.

The 4078's six front-panel buttons greatly simplify the basic setup

procedure. With them you can quickly review in sequence the existing

numeric "configuration parameters"

of any selected channel. At the

same time you can easily reset any displayed parameter to any

allowable value. The LEFT ARROW button lets you select a displayed

digit

or

decimal-point location.

The UP ARROW and DOWN ARROW

buttons let you change as desired the numeric value of the parameter,

its polarity, and/or (if it is a calibration value) its decimal-point location.

The new number goes into effect as soon as you exit "SETUP," and is

automatically stored in battery-backed memory.

1. Entering "Setup" Mode

To enter "SETUP" mode,

PRESS THE BUTTON

WARNING!

DO NOT USE A SHARP OR POINTED OBJECT TO

DEPRESS THE FRONT-PANEL BUTTONS.

SERIOUS INSTRUMENT DAMAGE COULD RESULT.

ALSO, DO NOT SPLASH LIQUID ON THE FRONT

OF THE UNIT. THIS CAN CAUSE THE BUTTON

SWITCHES TO SHORT OUT.

1.f Using the Front-Panel Setup Buttons

1.11

SET

UP

Page 17

Each of the six buttons will now assume its "SETUP" function, as

designated by the actual button label (for each button's "RUNTIME" function, see Section 3.) The small mnemonic display under

the 4078's unit legends will alternately read "DIS" and the number

of the channel that was on display when you pushed the SETUP

button. The main LCD display will read the number of the currently

selected channel. The rightmost digit of the main LCD display will

now flash, indicating that it is the "active" digit. NOTE: the smaller

display will continue to read the number of the

initially selected

channel—even though you may call one or more other channels to

the main display during the setup procedure—and will alternate

this number with the

mnemonic

of the parameter presently under

consideration. On exiting "SETUP," the smaller display will show

the number of the channel currently displayed by the main LCD.

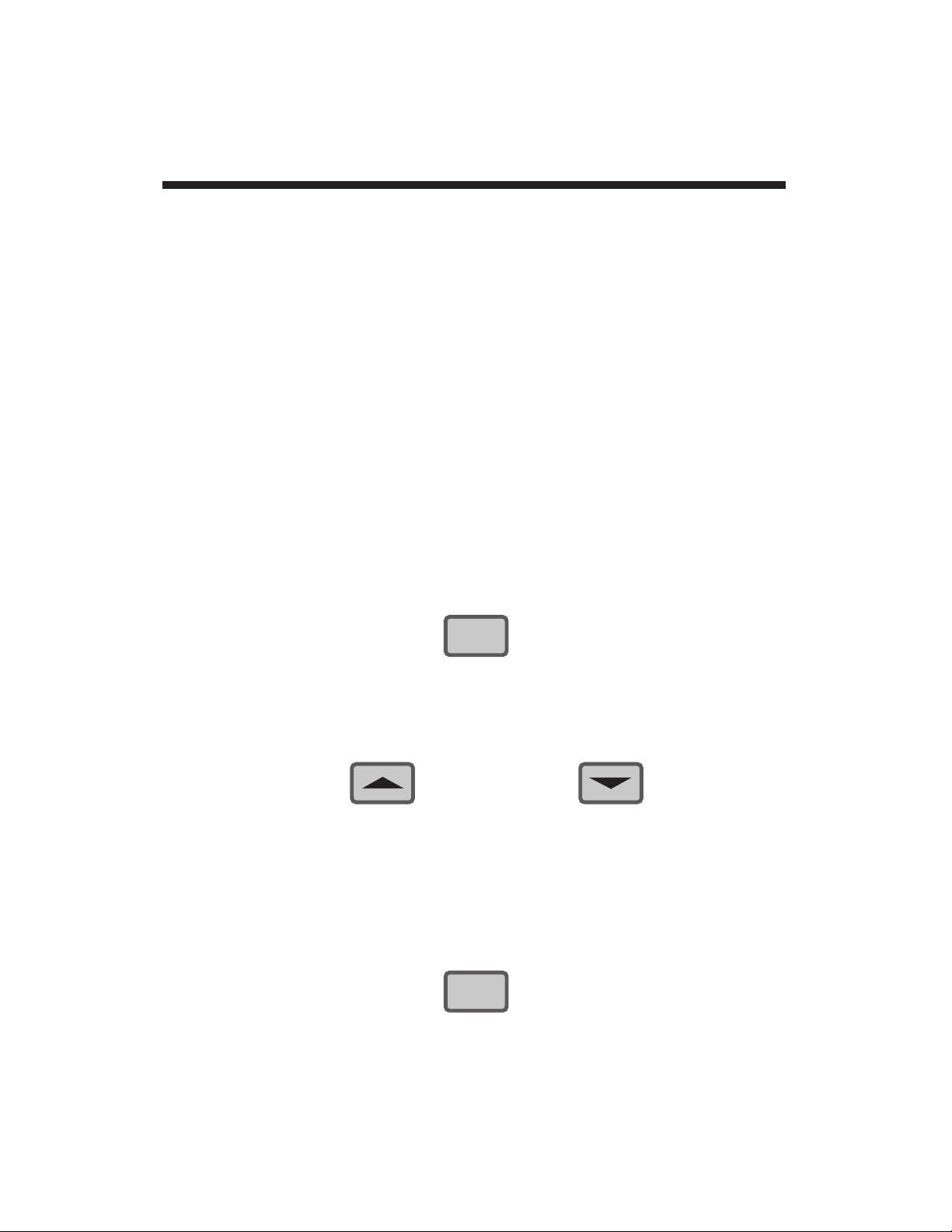

2. Selecting a Channel for Setup and/or Review

If, after pressing SETUP, you wish to review and/or reconfigure the

channel whose number is now being displayed,

PRESS THE BUTTON

This will invoke the channel's actual "parameter list," beginning

with "LCT."

If this is

not

the channel you wish to review and/or reconfigure,

PRESS THE BUTTON OR THE BUTTON

one or more times until you arrive at the desired channel. Then

press the STEP button to invoke its parameter list. When you exit

"SETUP" mode, the last channel to have been thus selected will

continue to be displayed.

At any time during the setup procedure, you can move back up to

the "DIS" parameter of the channel currently on display. Simply

PRESS THE BUTTON

1.12

Using the Front-Panel Setup Buttons 1.f

STEP

CHAN

Page 18

—at which point you can, if desired, move to any other channel via

the UP/DOWN ARROW buttons, as above.

3. Stepping Through a Channel's Parameter List

A given channel's configuration sequence includes the parameters

listed on the next page. These will appear as mnemonics under

the unit-legend display. Their respective

numeric values

will

appear on the main LCD digital display. ONLY THE PARAMETERS PRINTED IN BOLDFACE ARE TREATED IN THIS

MANUAL. For the remaining parameters, see the optional

System

Instruction Manual.

Channel Configuration Parameters

DIS (DISPLAY) (Section 2.d)

LCT (LOCATE)

LNS (LINEARIZATION SEGMENTS)

F0 (FIRST CALIBRATION POINT) (Section 2.e)

F1* (SECOND CALIBRATION POINT) (Section 2.e)

LEP (LOW ENDPOINT) (Section 2.g)

LLL (LOW LOW LIMIT) (Section 2.h)

LOL (LOW LIMIT) (Section 2.h)

HIL (HIGH LIMIT) (Section 2.h)

HHL (HIGH HIGH LIMIT) (Section 2.h)

HEP (HIGH ENDPOINT) (Section 2.g)

ASN (ASSIGN SATELLITE NUMBER)

FIL (FILTER) (Section 2.f)

BAU (BAUD RATE)

DBS (DATA BITS)

SBS (STOP BITS)

PAR (PARITY)

LCD (LCD VIEWING ANGLE) (Section 2.c)

REL (4000 SOFTWARE RELEASE DATE)

1.f Using the Front-Panel Setup Buttons

* Applicable only to 4078 Channel 1.

1.13

Page 19

To move to the next parameter in sequence,

PRESS THE BUTTON

As each parameter appears, you have the option of leaving it as it

is and stepping to the next one by again pressing STEP, or of

modifying its value by means of the "ARROW" buttons. You

cannot backstep through the parameter sequence; you can only

start it over again, via the CHAN button, or continue stepping

forward until you come back around to the desired parameter.

4. Moving the "Active" Digit

As each parameter value appears on the LCD display, its least

significant digit will be

flashing

, to signify that this is the currently

"active" (changeable) digit. You have the option of changing the

value of the "active" digit, as explained in Step 5, or of "activating"

the next digit to the left. To move the "active" digit one digit to the

left,

PRESS THE BUTTON

For "activation" of

decimal points

, see Step 7, below.

NOTE: You cannot move the active digit to the right. If you want to

return to a digit you have already passed, you must continue

moving leftward until you come back around to the desired digit.

5. Modifying the "Active" Digit

To increase the value of the active digit by "1"—that is, to add "+1"

to that number, regardless of its algebraic sign—

PRESS THE BUTTON

To decrease the value of the active digit by "1"—that is, to add "-1"

to that number, regardless of its sign—

PRESS THE BUTTON

1.14

Using the Front-Panel Setup Buttons 1.f

STEP

Page 20

In the negative realm

, these buttons seem at first glance to function

backwards. Thus, if the displayed parameter is preceded by a

minus sign, then "increasing" the active digit by "1"—as a result of

pressing the UP ARROW button—means

decreasing

that digit's

absolute value

by "1." Similarly, by pressing the DOWN ARROW

button you will cause the absolute value of a negative active digit

to

increase

by "1." When dealing with negative parameters, just

remember that the UP ARROW button brings you UP the number

scale towards zero, through progressively "lower" (more positive)

negative numbers, while the DOWN ARROW takes you DOWN the

scale through progressively "higher" negative numbers.

You can cycle a given active digit—positive or negative—in either

direction. With the completion of every "upward" cycle (either a

positive

active digit going from"9" back to "0" or a

negative

one

going from "0" back to "9"), "+1" will be added to that digit, with

appropriate adjustment of higher-placed digits. For example, if the

originally displayed number is "99

0" (the active digit being the

second from the right), and the UP ARROW button is pressed

once, the resulting number will be "100

0." Note that the original

active digit will continue to flash until you press the LEFT ARROW

button.

Similarly, after every "downward" cycle (either a

positive

active digit

going from"0" back to "9" or a

negative

one going from "9" back to

"0"), "-1" will be added to that digit, with appropriate adjustment of

higher-placed digits (e.g., "-19

20" becomes "-2020" when the

active digit is the third from the right and the DOWN ARROW is

pressed once).

6. Modifying the Polarity of the Displayed Value

To change the polarity of the presently displayed number, press the

LEFT ARROW button repeatedly until the

leftmost

digit (the "most

significant digit") is active. Cycle this digit once

through zero

and

back to its original numeric value. If you're changing the number

from

positive to negative

, you will cycle "downwards" through zero

via the DOWN ARROW button; if you're changing from

negative

to positive

, you will cycle "upwards" through zero via the UP

ARROW button. The number's sign will change as the most

significant digit passes through zero.

1.f Using the Front-Panel Setup Buttons

1.15

Page 21

NOTE: The above procedure

will change the original values of

one or more digits to the right of the most significant digit

, except in

the case where they are all originally zero. Therefore, you will

most likely have to go back and

reset

these digits, using the LEFT

ARROW and UP/DOWN ARROW buttons as explained in Step 5.

7. Adding a Decimal Point or Modifying the Decimal-Point

Location

NOTE: You can only add or modify a decimal point for an "F0" or

"F1" entry (see Section 2.e). Decimal points may appear in the

limit-zone parameters ("LEP," "LLL," "LOL," etc.) following

calibration, but

these cannot then be modified

.

To add a decimal point to an existing integral "F0" or "F1" value,

press the LEFT ARROW button repeatedly until five flashing

decimal points appear. Then press the UP ARROW button

repeatedly until a single flashing decimal point appears in the

desired position (the DOWN ARROW button can here be used to

move the decimal point to the right, if necessary).

To change the position of an existing decimal point, press the

LEFT ARROW button repeatedly until the present decimal point is

"active." To move it to the left, press the UP ARROW button; to

move it to the right, press the DOWN ARROW button.

NOTE: Decimal-point modification of the "F0" setting will not be

effective until the "F1" setting has been similarly modified. If the

"F1" decimal point is initially in the desired location, it is still

necessary to "relocate" it. Move the "F1" decimal point first to

some other location, and then back to its original location.

8. Exiting "Setup" Mode

To exit "SETUP" mode at any time during the above procedure,

PRESS THE BUTTON

All configuration changes will be saved, and all front-panel buttons

will resume the normal "RUN-TIME" functions described in Section

3.

1.16

Using the Front-Panel Setup Buttons 1.f

SET

UP

Page 22

The 4078 is equipped with an internal 3-V lithium battery. This battery

is necessary to maintain the instrument's DATA RAM and to retain

factory-entered analog alignment values required for accurate

calibration. Data retention is guaranteed down to a battery level of 2.2

V-DC. Under normal usage, the battery should last about five years.

The 4078 will check its battery every time the unit is turned on. If on

powerup, the battery is found to be below 3.0 V-DC, the front-panel

LCD will display a warning of "LO bat." Note that at this level the

battery will still be good for weeks or even months. You are advised,

however, to

change the battery

as soon as possible after the warning

first appears. Detailed instructions for this procedure are given in

Appendix G of this manual.

To acknowledge the "LO bat" warning and resume the normal display,

simply press any one of the front-panel buttons.

1.17

1.g Low Battery Warning

Page 23

The Model 4078's Analog Input Board mates with Daytronic CONDITIONER CONNECTOR No. 60322, which allows direct

solder-terminal

attachment of cable leads. The connector's internal solder terminals

are labelled 1 through 10 and A through L. The connector is "keyed" by

small plastic inserts embedded between certain terminal-pin pairs, each

of which matches a slot in the 4078's rear Analog Input Board. This

prevents the connector from being inadvertently attached upside-down.

Open the connector housing by removing the four screws that hold it

together. Secure all cables by means of the internal clamp bars.

4-wire strain gage cabling (Fig. 5(a)) is to be used when the cable is

under 20 feet in length.

The 4078 is equipped with an internal 59-KΩ, 0.1%

calibration resistor

for the standard "shunt" calibration technique described in Appendix F.

If you wish to use your own external shunt resistor, it should be tied

between Pin 5 of the CONDITIONER CONNECTOR and the transducer's +SIGNAL line, as shown in Fig. 6. In this case, "CAL SENSE"

(Pin 4) is not used.

With cabling under 20 feet in length, the +SENSE and –SENSE lines

are tied to the corresponding EXCITATION lines

at the CONDITIONER

CONNECTOR.

Also, the CALIBRATION SENSE line from Pin 4—or

2.1

Transducer Cabling 2.a

---------- IMPORTANT----------

CABLE SIGNAL WIRES SHOULD ALWAYS BE PROPERLY

SHIELDED

, AS INDICATED IN THE DIAGRAMS BELOW. THIS

WILL MINIMIZE THE PRODUCTION OF UNWANTED ELECTRICAL NOISE FROM CAPACITIVE AND INDUCTIVE EFFECTS.

THE "SHIELD" WIRE OF EACH TRANSDUCER CABLE

SHOULD BE SOLDERED TO THE EXPOSED TERMINAL OF

THE L-SHAPED GROUND LUG LOCATED UNDER THE HEAD

OF ONE OF THE CONNECTOR'S TWO CAPTIVE MOUNTING

SCREWS. THIS WILL ENSURE DIRECT SHIELD CONTACT

WITH THE 4078 CASE.

Page 24

the optional external SHUNT RESISTOR line from Pin 5—is tied to the

+SIGNAL line

at the CONDITIONER CONNECTOR.

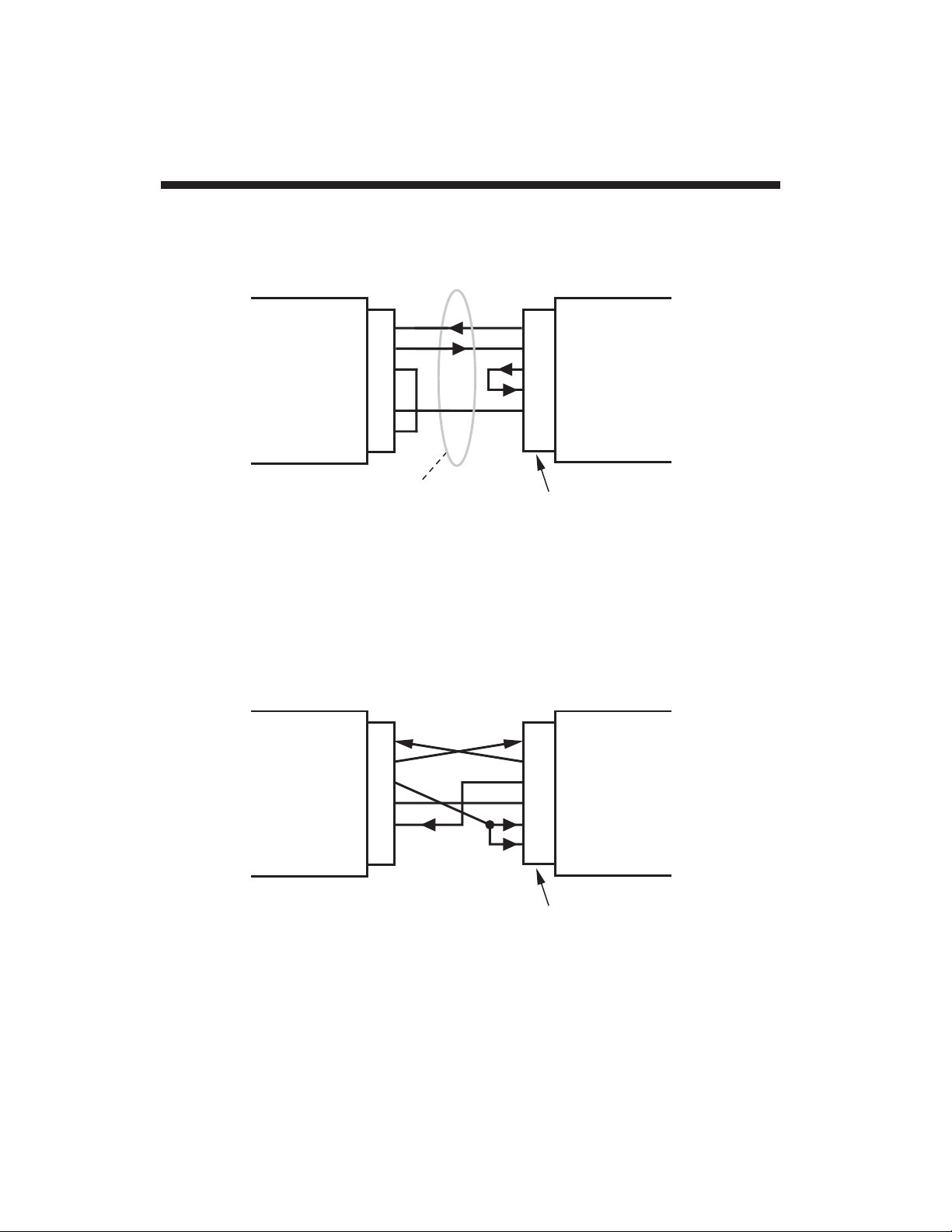

8-wire strain gage cabling (Fig. 5(b)) is to be used when the cable is 20

feet or longer.* As before, you can install your own shunt calibration

resistor between Pin 5 and the +SIGNAL line, in which case Pin 4 is not

used.

With cabling of 20 feet or over, the +SENSE and –SENSE lines are tied

to the corresponding EXCITATION lines

at the transducer

. Also, the

CALIBRATION SENSE line from Pin 4—or the optional external

SHUNT RESISTOR line from Pin 5—is tied to the +SIGNAL line

at the

transducer

. Note the wire connected to the –SIGNAL line at the trans-

ducer, but left

unconnected

at the 4078. This wire is to be paired with

the CAL SENSE or SHUNT RESISTOR line for shielding purposes.

Special 8-wire cabling (shown in Fig. 7) is required for connecting a

Model 4078 to a Lebow 1600 Series Transducer. The cable should

2.a Transducer Cabling

* NOTE: This cabling is to be used when connecting a Model 4078 to a Lebow

1800 Series Transducer.

2.2

A

B

C

D

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

+SIGNAL

CONDITIONER CONNECTOR

(No. 60322)

–EXCITATION

+EXCITATION

–SIGNAL

–SENSE

+SENSE

CAL SENSE

SHIELD

Connector pins shown as viewed

from rear (cable) side of connector.

Ground Lug

Fig. 5(a)

Model 4078

Transducer Cabling:

4-Wire Strain Gage Cabling

(under 20 ft. in length)

Page 25

2.3

Transducer Cabling 2.a

A

B

C

D

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

CONDITIONER CONNECTOR

(No. 60322)

–SENSE

+SENSE

SHIELD

External

SHUNT

CALIBRATION

RESISTOR

(UserSupplied)

+SIGNAL

Fig. 6

Model 4078

Transducer Cabling:

Installation of User's

External Shunt

Calibration Resistor

A

B

C

D

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

CONDITIONER CONNECTOR

(No. 60322)

+EXCITATION

+SENSE

SHIELD

Connector pins shown as viewed

from rear (cable) side of connector.

Ground Lug

+SIGNAL

–EXCITATION

–SIGNAL

–SENSE

CAL SENSE

Unconnected wire

(Paired with "CAL SENSE")

Fig. 5(b)

Model 4078 Transducer

Cabling: 8-Wire Strain

Gage Cabling (20 ft. or

longer)

Page 26

be shielded in four pairs, as shown in the figure, with the shield open at

the transducer end. Also note that

• SENSE and EXCITATION lines should be tied

at the transducer

.

• The 4078's Pin 5 ("LEBOW CAL") is to be connected to the "CAL"

pin on the Lebow sensor (Pin 4 is not used in this case).

• Leave the last (extra) wire unconnected at both ends, and pair it

with the "LEBOW CAL" line for the fourth shield.

• THE MODEL 4078 MUST BE INTERNALLY SET TO "SIGNAL

COMMON" MODE. CONTACT THE FACTORY FOR PRECISE

INSTRUCTIONS.

2.a Transducer Cabling

2.4

A

B

C

D

E

F

H

J

K

L

1

2

3

4

5

6

7

8

9

10

CONDITIONER CONNECTOR

(No. 60322)

+EXCITATION

+SENSE

SHIELD

Connector pins shown as viewed

from rear (cable) side of connector.

Ground Lug

+SIGNAL

–EXCITATION

–SIGNAL

–SENSE

A

D

C

B

CAL

(E)

Unconnected wire

(Paired with "LEBOW CAL")

LEBOW CAL

Fig. 7

Model 4078 Transducer Cabling:

8-Wire Cabling to LEBOW 1600 SERIES TRANSDUCER (ONLY)

Page 27

A 4078 can operate from a line voltage of either 90-135 or 180-270 VAC (47-63 Hz; 35 W maximum). The VOLTAGE SELECTOR SWITCH

is located on the rear panel (see Fig. 2).

If you change the voltage-level setting, YOU MUST ALSO CHANGE

THE 4078'S BUSS FUSE (again, see Fig. 2): nominal 110 V-AC takes a

0.5-amp fuse; nominal 220 V-AC takes a 0.25-amp fuse.

To change the fuse after changing the voltage setting—or after the

existing fuse has "blown" for some reason—use a screwdriver to turn

the fuse slot counterclockwise, and the fuse will spring out.

IN THE EVENT OF AN APPARENT POWER-SUPPLY FAILURE,

FIRST CHECK THE FUSE. WHEN REPLACING A "BLOWN" FUSE,

ALWAYS INVESTIGATE THE CAUSE OF OVERLOAD BEFORE

REACTIVATING THE INSTRUMENT.

The 7.5-foot, three-conductor power cord supplied with the 4078 plugs

into the rear AC POWER CONNECTOR. The offset pin on the power

Powerup 2.b

2.5

---------- PLEASE NOTE ----------

EVERY TIME YOU POWERUP YOUR MODEL 4078, ALLOW A

NOMINAL 15 SECONDS FOR VALID DATA AND SETUP

VALUES TO BE ESTABLISHED.

ALSO NOTE: Since setup entries are automatically saved to

nonvolatile memory, your 4078 will always powerup to the

same setup and display configuration that existed when it was

last powered down.

---------- IMPORTANT ----------

Before powering up your 4078, make sure that the VOLTAGE

SELECTOR SWITCH is set to the proper nominal AC line

voltage (110 or 220).

Page 28

connector is ground. THE INSTRUMENT MUST BE PROPERLY

GROUNDED. To safely operate from a

two-contact

outlet, use a 3prong-to-2-prong adaptor and connect the green pigtail on the adaptor

to earth ground.

Since the presence of

electrical noise

can affect the ultimate integrity of

your data, the noise level should be suppressed as much as possible.

In particular, care should be taken to avoid utility-line problems that can

interfere with or possibly even damage sensitive microprocessor-based

equipment. Such noise can also be generated by electrical motors,

relays, and motor control devices.

While your 4078 has internal circuitry to protect it from overvoltage

transients and mild EMI, a clean line is still very desirable. No

protection is provided against dropout longer than 8 milliseconds or

brownout below 90 volts. Depending on your line conditions, a number

of protective devices are available (isolators, regulators, uninterruptible

power supplies, etc.).

2.6

2.b Powerup

Page 29

You can easily optimize your 4078's LCD DIGITAL DISPLAY for your

particular

viewing angle

.

1. Following the procedure given in Section 1.f, above, press the

instrument's front-panel SETUP key, and then "step" to the "LCD"

parameter (the letters "LCd" should appear in the digital display, to

indicate that the instrument is in "LCD adjustment" mode).

2. If you wish to

raise

the viewing angle—that is, to make the display

more readable from

above

the instrument—press the "UP

ARROW" key until the desired display of the word "LCd" is produced (note that the extreme setting in this direction will cause the

display to disappear, and you will then have to lower the angle

somewhat (Step 3)). Also note that it usually takes about three

seconds before you see any real change in the display.

3. If you wish to

lower

the viewing angle—that is, to make the display

more readable from

below

the instrument—press the "DOWN

ARROW" key until the desired display of the word "LCd" is

produced (note that the extreme setting in this direction will cause

all segments of the display to be clearly visible when the instrument is viewed from any angle except approximately 30% below

the level of the display).

4. To return the display to "normal" mode, press the SETUP key once

again. The 4078 should subsequently powerup with the LCD angle

to which you have just set it.

2.7

Adjusting LCD Viewing Angle 2.c

Page 30

Your 4078's "Standard Channel Configuration" was given in Section

1.d, above. To cause the current "live" reading of any channel—either

"scanned" or "unscanned"—to be displayed on both the DIGITAL and

BARGRAPH displays, you need only

1.

PRESS THE BUTTON

2.

PRESS THE BUTTON OR THE BUTTON

repeatedly until the number of the desired channel appears in the

main

LCD display (the original channel number will continue to

flash in the small mnemonic display under the engineering

legends).

3. Again

PRESS THE BUTTON

The number of the displayed channel should now appear in the

mnemonic display, with the "live" reading of this channel in the

main LCD display.

NOTE: As explained in Section 3, you can always use the LIVE

DISPLAY button—when not in "SETUP MODE"—to call to display your

4078's Channel 5 ("tared" analog input). You can also use the

MAX/MIN/MAX-MIN STEP button to cycle sequentially through

Channel 5 through 8.

2.d Selecting a Channel for Display

2.8

SET

UP

SET

UP

Page 31

IMPORTANT: FOR THE MOST ACCURATE CALIBRATION, YOU

SHOULD ALLOW THE 4078 TO WARM UP FOR AT LEAST 30

MINUTES BEFORE CALIBRATING.

Under "standard" 4078 operating conditions, the only channel you need

to calibrate is Channel 1 ("LIVE" ANALOG INPUT). All other channels

derive their readings from Channel 1.

Of the two calibration methods possible with the 4078, the "TWOPOINT (DEADWEIGHT)" method described in this section can be

accomplished solely via the front-panel buttons. For "SIMULATED

(SHUNT)" calibration, see Appendix F. For use of the 4078's internal

LINEARIZATION TABLES (for a

nonlinear

input), and for a discussion

of "y = mx + b" calibration theory, see the optional 4000 Series

System

Instruction Manual

.

Before you calibrate your 4078 for the first time, you should perform the

following PHASE AND SYMMETRY ADJUSTMENT procedure.* Once

set for your transducer, this adjustment need not be repeated unless a

significant change in cable length or capacitance is required. NOTE:

THIS PROCEDURE REQUIRES THAT A MODEL 10P80D EXTENDED

KEYBOARD BE PLUGGED INTO THE REAR OF YOUR 4078.

1. Display the 4078's Channel No. 1 (this is the "live" input

channel—see Section 2.d for "Selecting a Channel for Display").

2. Load the transducer in the positive direction with a convenient

"deadweight" value which is greater than one-half of full scale.

Adjust the rear-panel PHASE control until a

maximum reading

is

obtained for Channel 1.

3. Remove the transducer load.

4. To zero the reading of Channel 1, use the keyboard to enter a

command of

ZRO 1 = 0 [CR]

2.9

Channel Calibration 2.e

* NOTE: WHEN USING THE MODEL 4078 WITH A LEBOW 1800 SERIES

TRANSDUCER, YOU SHOULD FOLLOW THE SPECIAL PHASE/

SYMMETRY ADJUSTMENT PROCEDURE OUTLINED IN APPENDIX E.

Page 32

(where [CR] is the CARRIAGE RETURN that terminates the

command).

5. Now switch in the internal shunt resistor for a

positive

up-scale

reading of Channel 1 by entering a SHUNT CALIBRATE—

POSITIVE command of

SHP 1 = ON [CR]

6. Record the reading you get.

7. Disconnect the positive shunt and switch in the resistor for a

negative

reading by entering a SHUNT CALIBRATE—NEGATIVE

command of

SHN 1 = ON [CR]

8. Now adjust the SYMMETRY control until the

negative

value of the

reading you recorded in Step 6 appears.

9. Disconnect the negative shunt by entering a command of

SHN 1 = OFF [CR]

You are now ready to calibrate Channel No. 1. In general terms, you

will do so by commanding the 4078's microprocessor to compute and

store two constant values: a ZERO OFFSET (based on setup entry

"F0") and a SCALING FACTOR (based on entry "F1").

10. Display Channel 1 (see Section 2.d).

11. Following the general procedure explained in Section 1.f, enter

"SETUP" mode and step to Channel 1's "F0" parameter.

12. Apply an

accurately known

value of input loading to the source

transducer—a value (positive or negative) less than 50% of the

nominal full-scale rating. If it is possible to remove all load from the

transducer, thus establishing a true

zero input

for Channel 1, you

should do so.

13. Using the "ARROW" buttons, enter the numerical value of the

known input, with appropriate polarity (in the "zero input" case, of

course, you will enter "0"). Then press the STEP button to display

Channel 1's "F1" parameter.

2.10

2.e Channel Calibration

Page 33

Channel Calibration 2.e

14. Apply a second

accurately known

value of input loading—a value

(positive or negative) from 80% to 100% of the transducer's

nominal full-scale rating.

15. Now enter the numerical value of the second known input, with

appropriate polarity. This "forces" the channel's data reading to

equal this value, thereby determining the SCALING FACTOR to be

applied to all subsequent channel readings.

NOTE: This entry also sets the desired

precision

for Channel 1. If,

for example, you're measuring "pounds," and enter an "F1" of

"100," then all subsequent readings will be rounded to the nearest

pound. If "F1" is "100.0," then all readings will be rounded to the

nearest

tenth

of a pound. This same precision will be automatically reflected in Channel 1's "limit-zone" parameters: "LEP,"

"LLL," "LOL," "HIL", "HHL," and "HEP" (see Section 2.h).

16. Now Exit "SETUP" mode by pressing the SETUP button.

2.11

Page 34

2.12

2.f Setting Channel Filter

In addition to the normal-mode analog filtering applied to the Model

4078's "live" input channel (No. 2),

digital filtering

is also provided, with

smoothing constants selectable via the front panel. The effect of the

digital filter is to remove small unwanted dynamic signal components,

while allowing large-scale fluctuations to pass unaffected.

To set the digital filter for Channel 1,

1. Display the channel (see Section 2.d).

2. Following the general procedure explained in Section 1.f, enter

"SETUP" mode and step to the "FIL" parameter.

3. Enter a number from 0 through 10. These "filter constants" signify

increasing amounts of automatic digital filtering. Channel 1 is

normally preset to a filter setting of "4."

4. Exit "SETUP" mode by pressing the SETUP button.

Page 35

After calibrating your 4078's "live" input channel (No. 2), you should set

the high and low endpoints for the individual BARGRAPH display of

Channel 5 ("LIVE" INPUT WITH TARE), using the procedure given

below. This same procedure may be used to scale the bargraph display of any of the other 4078 data channels listed in Section 1.d. For

the relation of BARGRAPH endpoint values to the other four limit-zonedefining parameters, see Fig. 8 in the next section.

1. Display Channel 5 (see Section 2.d).

2. Following the general procedure explained in Section 1.f, enter

"SETUP" mode and step to the "LEP" (LOW ENDPOINT)

parameter.

The initial "LEP" setting for Channel 5 is normally "-20000." THIS

WILL HAVE BEEN AUTOMATICALLY SCALED, HOWEVER, SO

THAT ITS DECIMAL-POINT LOCATION MATCHES THAT OF THE

SCALING FACTOR ("F1") YOU ENTERED WHEN YOU CALIBRATED CHANNEL 1 IN SECTION 2.e. If, for example, your "F1"

value for Channel 1 was "XXX.X" (where "X" is any number), the

displayed "LEP" value for Channel 5 will be "-2000.0." The

decimal-point position will always be the same for all six limit-zone

parameters ("LEP," "LLL," "LOL," "HIL," "HHL," and "HEP").

As mentioned in Section 1.f,

this position cannot be changed

, since

it depends directly on the precision of the last "F1" entry.

3. Using the "ARROW" buttons as explained in Section 1.f, enter the

desired LOW ENDPOINT value for the bargraph display of Channel 5, as expressed in the engineering units selected for that

channel.

4. Press the STEP button five times. The "HEP" parameter should

now be displayed. Enter the desired HIGH ENDPOINT value for

the bargraph display of Channel 5 (again, as expressed in the

engineering units selected for that channel). The initial "HEP"

setting for Channel 5 is normally "20000."

The "LEP" and "HEP" values for a given channel may be any numeric

constants from -32768 through 32767, provided that the "LEP" value is

Scaling the Bargraph Display 2.g

2.13

Page 36

less than the "HEP" value. At least 51 units (absolute count) must

separate the HEP and LEP values.

NOTE, however, that the 4078's front panel furnishes a "truncated"

numeric display of the two endpoint values of the currently displayed

bargraph (see Fig. 1). That is, the endpoint numbers will appear with

all but the first two significant digits converted to "0."

THE RESULTING

PRECISION OF THE DISPLAYED "LEP" AND "HEP" VALUES DOES

NOT REFLECT THE PRECISION OF THE ACTUAL BARGRAPH

ENDPOINTS CURRENTLY IN EFFECT. If, for example, a "HEP" of

"3495.0" is entered, this value is still in effect,

to that precision

, even

though it is displayed as "3400." In order to update the decimal-point

position in the numeric HEP and LEP displays after rescaling the bargraph, it is necessary to "recall" the channel— i.e., to display another

channel and then return to the original one.

2.g Scaling the Bargraph Display

2.14

Page 37

Once you have set the endpoints of the respective bargraph display for

Channel 5, you can define seven discrete

limit zones

for the bargraph,

as shown in Fig. 8: "BELOW BARGRAPH" ZONE (less than LEP);

LOWER "DANGER" ZONE (LEP to LLL); LOWER "CAUTION" ZONE

(LLL to LOL); SAFETY (NO VIOLATION) ZONE (LOL to HIL); UPPER

"CAUTION" ZONE (HIL to HHL); UPPER "DANGER" ZONE (HHL to

HEP); and "ABOVE BARGRAPH" ZONE (greater than HEP). These

limit zones are represented by pairs of smaller bars that light up above

the main bargraph. The upper and lower "CAUTION" ZONES are

indicated by the YELLOW bars; and the upper and lower "DANGER"

ZONES by the RED ones.

Using the same "SETUP" button techniques as before, enter desired

values for these parameters for Channel 5:

"LLL" ("LOW LOW LIMIT")—initially set to "-10000"

"LOL" ("LOW LIMIT")—initially set to "-5000"

"HIL" ("HIGH LIMIT")—initially set to "5000"

"HHL" ("HIGH HIGH LIMIT")—initially set to "10000"

As with the "LEP" and "HEP" entries (Section 2.g), each value should

be expressed in the engineering units selected for the channel, and

each can be any constant from -32768 through 32767, provided that

"LLL" is less than "HHL" and that "LOL" is less than "HIL."

As mentioned in Section 1.e, a separate TTL-level

control output

will be

automatically issued from Terminal 0 of the 4078's rear Logic I/O

Connector whenever the "live" reading of Channel 5 lies

below

the

current "LEP" value for that channel (i.e., within the "BELOW BAR-

Defining Limit Zones 2.h

2.15

"BELOW

BARGRAPH"

ZONE

LOWER

"DANGER"

ZONE

LOWER

"CAUTION"

ZONE

SAFETY

(NO VIOLATION)

ZONE

UPPER

"CAUTION"

ZONE

UPPER

"DANGER"

ZONE

"ABOVE

BARGRAPH"

ZONE

RED LIMIT BARS

YELLOW LIMIT BARS

LEP LLL LOL HIL HHL HEP

Fig. 8 Per-Channel Limit Zones

Page 38

2.16

2.h Defining Limit Zones

GRAPH" ZONE). Similarly, a logic output will be issued from Terminal 1

when Channel 5 is in the current LOWER "DANGER" ZONE; from

Terminal 2 when it is in the current LOWER "CAUTION" ZONE; from

Terminal 3 when it is in the current SAFETY (NO VIOLATION) ZONE;

from Terminal 4 when it is in the current UPPER "CAUTION" ZONE;

from Terminal 5 when it is in the current UPPER "DANGER" ZONE; and

from Terminal 6 when it is in the current "ABOVE BARGRAPH" ZONE.

2.i Logic I/O Connections

As shown in Fig. 4, the 4078's rear Logic I/O Connector has eight

numbered LOGIC I/O terminals, plus a +5-V (LOGIC REFERENCE)

terminal and a "GD" (GROUND) terminal. The "standard" 4078

configuration calls for logic OUTPUTS from Terminals 0 through 6. It

does not call for any logic INPUTS, but the initially unassigned Terminal

7 can be used for this purpose, if the application requires. Fig. 9 shows

how to wire

1. negative-true logic INPUT to a given terminal ("N") from an active

TTL logic system;

2. negative-true logic INPUT to Terminal "N" from external switch

contacts;

3. open-collector logic OUTPUT from Terminal "N" to an active TTL

logic system; and

4. open-collector logic OUTPUT from Terminal "N" to drive an external

relay or TRIAC controller (including the Model 9398 and 9399

Solid State Relays).

Page 39

For full LOGIC I/O SPECIFICATIONS, see the optional 4000 Series

System Instruction Manual

.

2.17

Logic I/O Connections 2.i

Fig. 9 (a) Input from External TTL Logic

+ 5

TTL

Logic I/O

Connector

N

+ 5

GD

(0-7)

Logic I/O Connector

OPEN = LOGIC 0

CLOSED = LOGIC 1

N

+ 5

GD

(0-7)

4

3

2

1

Model 9398/9399

Coil Resistance > 500

N

+ 5

GD

(0-7)

Logic I/O Connector

Fig. 9(c) Output to

External TTL Logic

Fig. 9(d) Output to

External Relay

+ 5

TTL

Logic I/O

Connector

N

+ 5

GD

(0-7)

Fig. 9(b) Input from

External Switch

Page 40

Under the "standard" configuration, the 4078's Channel 19 is an analog

output that corresponds to the "LIVE" INPUT WITH TARE (Channel 5)

with a full range of ±10 V-DC and a maximum resolution of ±1 mV. This

output is initially scaled for

1 mV of output per count for the current

reading of Channel 5

.

It can be rescaled by entering a new value for the scaling factor "m" of

the ANALOG OUTPUT (ANO) expression that defines Channel 19:

ANO 19 = m(CHN5) + 0 [CR]

An appropriate "m" can be determined by dividing the desired full-scale

analog output range in

millivolts

(up to the allowable maximum of 10000

mV) by the actual force reading (in lbs, kg, ft-lbs, etc.) which you want

the full-scale output to represent. The "m" value should reflect the

precision that currently applies to Channel 5 (this is initially the nearest

integral unit

).

For example, if you want a reading of 500 lbs to output the full +10000

mV, you need only enter a command of

ANO19 = 20(CHN5) + 0 [CR]

since (10000/500) = 20. If, however, you want 500 lbs to produce an

output of +5000 mV, you would enter

ANO19 = 10(CHN5) + 0 [CR]

since (5000/500) = 10.

Fig. 10 shows how an

external device connects to

the two-terminal Analog

Output Connector on the rear

of the 4078. The output is

single-ended, and returns to

"SIGNAL COMMON" (this is

the negative Analog Output

terminal).

2.j Analog Output Connections

–+

EXTERNAL

DEVICE

+

–

Signal

Common

Signal

Shield

ANALOG

OUTPUT

Fig. 10

Analog Output

Connections

2.18

Page 41

The "SETUP" functions of the 4078's six front panel buttons have been

described in Section 1.f. These are the functions labelled on the

buttons themselves. The "RUN-TIME" button functions are as follows:

BUTTON No. 1 ("LIVE DISPLAY"):

Each Push

: Calls Channel 5 ("LIVE" INPUT WITH TARE) to digital

and bargraph display. Under the "standard configuration," the "F1"

indicator will

always

be on when the 4078 is in "RUN-TIME" mode.

BUTTON No. 2 [NOT ASSIGNED]:

This button has no assigned "run-time" function in the "standard"

4078 configuration.

BUTTON No. 3 ("TARE"):

Each Push

: Zeroes Channel 5 ("LIVE" INPUT WITH TARE) so that

subsequent readings of Channel 5 will represent the value of

Channel 1 ("LIVE" INPUT)

minus the existing value of Channel 1

(now stored as a constant "tare" offset).

BUTTON No. 4 ("MAX/MIN/MAX-MIN STEP"):

Each Push

:

If Channel 5 is currently on display, displays Channel 6 ("MAXI-

MUM" VALUE OF CHANNEL 5) and lights the "F3" indicator.

If Channel 6 is currently on display, displays Channel 7 ("MINI-

MUM" VALUE OF CHANNEL 5) and lights the "F4" indicator.

If Channel 7 is currently on display, displays Channel 8 ("MAX

minus MIN" VALUE OF CHANNEL 5) and lights the "F5" indicator.

If Channel 8 is currently on display, displays Channel 5 ("LIVE"

INPUT WITH TARE) and lights the "F2" indicator.

BUTTON No. 5 ("MAX/MIN RESET"):

Each Push

: Resets the "MAX"- and "MIN-" measuring functions of

Channels 6 and 7, respectively, momentarily setting each of these

channels equal to the current "live" reading of Channel 5.

BUTTON No. 6 ("SETUP")

First Push

: Enables "SETUP MODE" for the selected channel (see

Section 1.f). Causes the "SETUP" indicator to light.

Second Push

: Disables "SETUP MODE" for the selected channel

(see Section 1.f). Turns off the "SETUP" indicator.

3.1

Use of Front-Panel Buttons 3

Page 42

Page 43

For a full explanation of the parameters listed in this section, see the

optional 4000 Series

System Instruction Manual

.

CHANNEL CONFIGURATION

Channel

No. TYP LCT EMM BEE FIL RNG LNS

1 00* 1* 20000 0 4 3M [mV/V] 1

2 00* 2* 32000 0 4 32000 [Hz] 1

3 00 1 20000 0 N/A N/A N/A

4 F6 1 1 0 N/A N/A N/A

5 F1 1 1 0 N/A N/A N/A

6 FA 1 1 0 N/A N/A N/A

7 FB 1 1 0 N/A N/A N/A

8 F1 1 1 0 N/A N/A N/A

9 00 1 20000 0 N/A N/A N/A

10 00 1 20000 0 N/A N/A N/A

11 00 1 20000 0 N/A N/A N/A

12 00 1 20000 0 N/A N/A N/A

13 00 1 20000 0 N/A N/A N/A

14 F6 1 1 0 N/A N/A N/A

15 F6 1 1 0 N/A N/A N/A

16 F6 1 1 0 N/A N/A N/A

17 00 1 1 0 N/A N/A N/A

18 00 1 1 0 N/A N/A N/A

19 E0 1 1 0 N/A N/A N/A

CHANNEL LIMIT VALUES

Channel

No. LEP LLL LOL HIL HHL HEP

1 - 13 -20000 -10000 -5000 5000 10000 20000

14 001122

15 002233

16 003344

17 -20000 -10000 -5000 5000 10000 20000

18 - 19 -10000 -7500 -5000 5000 7500 10000

A.1

Complete Standard Configuration App. A

* IMPORTANT: NEVER CHANGE THESE INITIAL TYP AND

LCT SETTINGS FOR THE 4078'S CHANNELS 1 AND 2.

Page 44

CHANNEL LIMIT LOGIC

Channel

No. BLE BLL LLT LBT LGT BHH BHE

1 - 4 N/A N/A N/A N/A N/A N/A N/A

50123456

6 - 13 N/A N/A N/A N/A N/A N/A N/A

14 N/A N/A N/A 13 N/A N/A N/A

15 N/A N/A N/A 14 N/A N/A N/A

16 N/A N/A N/A N/A 15 N/A N/A

17 - 19 N/A N/A N/A N/A N/A N/A N/A

CALCULATION CHANNELS

Channel

No. CLC

4 1(CHN4)+0

5 1(CHN1-CHN4)+0

6 1(MAX CHN5)+0

7 1(MIN CHN5)+0

8 1(CHN6–CHN7)+0

14 1(CHN14)+0

15 1(CHN14)+0

16 1(CHN14)+0

ANALOG OUTPUT

Channel

No. ANO

19 1(CHN5)+0

EXECUTES

Bit

Number EXU EXU/

0 - 12 N/A N/A

13 ANN3=1 ANN3=0:ANN4=1

14 N/A ANN4=0:ANN5=1

15 CHN14=0:ANN1TO5=0: ANN1TO5=0:

ANN1=1:DIS=5 ANN1=1:DIS=5

App. A Complete Standard Configuration

A.2

Page 45

BUTTON EXECUTES

Button

Number EXB and EXB/

1 CHN14=0:ANN1TO5=0:ANN1=1:DIS=5

2 N/A

3 CHN4=CHN2

4 INC14:SDI

5 CHN6TO7=CHN5

ANNUNCIATION

Annunciator

Number ANN

11

2 - 6 0

71

80

LOGIC I/O

Bit

Number LIO

0 - 7 OUT

LOGIC SOURCES

Bit

Number SRC

0 - 6 LIM,NON

7 - 10 EXT,NON

11 LIM,NON

12 EXT,NON

13 - 15 LIM,NON

16 - 31 EXT,NON

A.3

Complete Standard Configuration App. A

Page 46

COMMUNICATIONS

PROTOCOL

BAU = 5,7,2,0

DBS = 7

SBS = 2

PAR = 0

DLY = 0

CMT = [0D]

OPT = [00,0D]

EOT = [00,0D]

OTHER GENERAL

SETUP PARAMETERS

SCN = 1,19

TER = 19

EXC = 10

SBC = 1

ASN = 0

LGO = 4078 STANDARD

EDT = Y

DIS = 5

BAR = DIS

BEP = LEP

FLA = 1000

CPC = 9

CLM = 1

PKN = HLD

PKP = HLD

XBG1 = 1

XBG2 = 2

SHP1 = OFF

SHN1 = OFF

RNG1 = 3M

App. A Complete Standard Configuration

A.4

Page 47

If you did not order a specific

RS-232-C Interface Cable

with your 4078,

you will have to provide your own connection. Fig. 11 shows suggested

cabling between a 4078 and a computer, terminal, buffered printer, etc.,

that uses a

25-Pin RS-232-C Connector

. FOR MAXIMUM DATATRANSFER SPEED AND ACCURACY, A "FULL HANDSHAKE"

INTERCONNECTION IS GENERALLY RECOMMENDED (Fig. 11(a)).

However, cabling is also given for "INCOMING HANDSHAKE ONLY"

and "NO HANDSHAKE" situations (Figs. 11(b) and 11(c), respectively).

Following RS-232-C conventions, the device at each end of the

interface is seen as "DATA TERMINAL EQUIPMENT (DTE)."

Fig. 12 shows suggested cabling between a 4078 and a computer,

terminal, printer, etc., that uses a

9-Pin D-Subminiature Connector

for

its RS-232-C interface (such as an IBM PC/AT).

Please note that the cabling in Figs. 11 and 12 is by no means

definitive. In all cases, you should carefully study the literature

accompanying the specific RS-232-C device you wish to connect to

your 4078, to determine the cable arrangement that will create the

"handshake" you need (if any). On some devices, for example, the

DATA TERMINAL READY (DTR) signal may have a different name

(such as NOT BUSY) and may even appear on a pin other than No. 20

or No. 4.

NOTE: OPTIONAL IEEE-488 INTERFACING REQUIRES AN

EXTERNAL MODEL 10CIF488A IEEE Interface Adaptor. Complete

instructions will be supplied with this equipment.

B.1

4078/Computer RS-232-C Connections App. B

Page 48

App. B 4078/Computer RS-232-C Connections

B.2

25-Pin RS-232-C

Connector**

2

3

4

5

8

2

3

5

6

7

20

RECEIVE

TRANSMIT

DTR

COMMON

CTS

TRANSMIT

RECEIVE

CTS

DSR

COMMON

DTR

COMPUTER

FULL HANDSHAKE

(RECOMMENDED)

RS-232-C Interface

Connector—Male

(see Fig. 2)

*

1

2345

6

789

4000 Instrument

Required for connection of the 4000 instrument to an IBM or IBMcompatible computer, but not to a Daytronic Model PC-HSICA.

Male connector required for Model PC-HSICA.

*

**

Fig. 11 Suggested RS-232-C Interface Connections

(to 25-Pin RS-232-C Connector)

11(a)

25-Pin RS-232-C

Connector

RECEIVE

TRANSMIT

DTR

COMMON

CTS

TRANSMIT

RECEIVE

CTS

COMMON

DTR

INCOMING HAND-

SHAKE ONLY

2

3

4

5

8

2

3

5

7

20

COMPUTER

4000

Instrument

11(b)

Page 49

B.3

4078/Computer RS-232-C Connections App. B

25-Pin RS-232-C

Connector

2

3

4

5

8

2

3

4

5

7

20

RECEIVE

TRANSMIT

DTR

COMMON

CTS

TRANSMIT

RECEIVE

RTS

CTS

COMMON

DTR

COMPUTER

NO HANDSHAKE

4000 Instrument

11(c)

9-Pin RS-232-C

Connector

2

3

4

5

8

2

3

4

5

6

8

RECEIVE

TRANSMIT

DTR

COMMON

CTS

RECEIVE

TRANSMIT

DTR

COMMON

DSR

CTS

COMPUTER

4000

Instrument

Fig. 12 Suggested RS-232-C Interface Connections

(to 9-Pin RS-232-C Connector)

Page 50

Every Model 4078 will normally come with the UNIT LEGENDS and

BUTTON FUNCTION INDICATORS shown in Fig. 1, with the legend/

indicator negative already fitted in the 4078's front-panel "FRAME"

LABEL. Customized negatives are available as an option. Contact the

factory for precise installation instructions; IMPROPER INSTALLATION

CAN DAMAGE THE 4078 DISPLAY PANEL.

Unless other specified, the 4078 comes with only the front-panel "F1"

and "psi" indicators lit. To cause one or more legends and/or indicators to light up whenever instrument power is on, you must use the

ANNUNCIATOR (ANN) command. The front-panel "annunciators"

consist of the indicators that correspond to the

first five

buttons, plus

the three engineering-unit legends.* Thus, to turn ON Annunciator

Number n, where 1 ≤ n ≤ 8 (see Fig. 13 for the precise numbering), you

need only command

ANN n = 1 [CR]

To turn OFF Annunciator No. n, command

ANN n = 0 [CR]

* The SETUP indicator cannot be affected by the ANNUNCIATOR (ANN)

command. It will only be on when the 4078 is in "SETUP" mode.

C.1

App. C Legend and Indicator Annunciation

F2 F5F4 SETUP

1

8

6

7

F3

2345

F1

psi

lbs

lb-ft

Fig. 13 Front-Panel

"Annunciators"

Page 51

Under the "standard configuration," your 4078 is initially set for a fullscale transducer range of 3.00 mV/V. If your transducer's full scale is

0.75 or 1.5 mV/V, you need only enter the corresponding RANGE

(RNG) command to set the 4078 accordingly:

RNG 1 = .75M or RNG 1 = 1.5M [CR]

To reset the 4078 to the 3-mV/V range, command

RNG 1 = 3M [CR]

IF YOU NEED TO RESET THE 4078's INPUT RANGE, IT

SHOULD BE DONE BEFORE THE TRANSDUCER IS

CONNECTED.

Modifying the Input Range App. D

D.1

Page 52

E.1

App. E for a Lebow 1800 Series Transducer

Phase/Symmetry Adjustment

NOTE: WHEN USING THE 4078 WITH A LEBOW 1800 SERIES

TRANSDUCER, YOU SHOULD FIRST REPLACE THE 4078'S

INTERNAL 59K SHUNT RESISTOR WITH THE CALIBRATION

RESISTOR SUPPLIED WITH THE TRANSDUCER.

1. Locate the "CAL/RUN" Switch in the cable harness of the 1800

Series transducer. Place this switch in the "CAL" position.

2. Display the 4078's Channel No. 1 (see Section 2.d for "Selecting a

Channel for Display").

3. Establish a

zero input

for Channel 1 by removing all load from the

1800 Series transducer.

4. Switch in the shunt resistor for a positive up-scale reading of

Channel 1 by entering a command of

SHP 1 = ON [CR]

5. Adjust the rear-panel PHASE CONTROL until a

maximum reading

is obtained for Channel 1.

6. Disconnect the positive shunt by entering a command of

SHP 1 = OFF [CR]

7. Now zero the reading of Channel 1 by entering a command of

ZRO 1 = 0 [CR]

8. Enter once again a command of

SHP 1 = ON [CR]

9. Now "force" Channel 1 to read the "EQUIVALENT INPUT" VALUE

GIVEN BY THE TRANSDUCER MANUFACTURER FOR THE

CALIBRATION RESISTOR YOU INSTALLED IN THE 4078 (for a

discussion of EQUIVALENT INPUT, see Appendix F, below). If this

EQUIVALENT INPUT—

expressed in the desired engineering

units

—is "z," then command

FRC 1 = z [CR]

10. Disconnect the positive shunt and switch in the resistor for a

negative

reading by entering a command of

Page 53

SHN 1 = ON [CR]

11. Now adjust the 4078's SYMMETRY CONTROL to produce a

reading equal to the

negative

value of the same EQUIVALENT

INPUT "z" (or some other specific negative engineering-unit value,

if such a value is given by the transducer manufacturer for the

calibration resistor

).

12. Command

SHN 1 = OFF [CR]

13. Move the transducer's "CAL/RUN" Switch to the "RUN" position.

14. With the transducer load still at zero, again command

ZRO 1 = 0 [CR]

THE LEBOW 1800 / DAYTRONIC 4078 SYSTEM IS NOW FULLY

CALIBRATED. YOU NEED NOT PERFORM A SUBSEQUENT

"DEADWEIGHT" OR "SIMULATED" CALIBRATION.

E.2

for a Lebow 1800 Series Transducer App. E

Phase/Symmetry Adjustment

Page 54

This is an easier through generally less accurate technique than the

"TWO-POINT (DEADWEIGHT)" CALIBRATION discussed in Section

2.e. It is useful, however, when overall "deadweighting" is impossible or

inconvenient, and is good for an accuracy of about 0.2% (depending, of

course, on the accuracy of the specified EQUIVALENT INPUT, and on

the resistor/bridge tolerance and temperature). The known calibration

input is not produced by loading the transducer, as in the "deadweight"

method, but by shunting a resistor of known magnitude across one arm

of the strain-gage bridge, thereby "simulating" a particular up-scale

value of mechanical input. This known EQUIVALENT INPUT then

serves to determine the SCALING FACTOR for the channel.

The 4078 is equipped with a 59-kΩ, 0.1%

calibration resistor

which you

may, if you wish, replace with a resistor of some other value (straingage transducer manufacturers often supply such resistors with their

instruments, along with the exact values of EQUIVALENT INPUT

thereby produced—contact the factory for installation instructions).

EQUIVALENT INPUT can be approximated from a knowledge of the

Shunt Calibration Resistance (R

); the transducer's

Bridge Resistance

(B)

; and the transducer's

Full-Scale Sensitivity (K, in mV/V, full scale).

To determine the EQUIVALENT INPUT (X) as an approximate

percentage of full-scale output, you may use the following equation:

1. Apply an

accurately known

value of input loading to the source

transducer—a value (positive or negative) less than 50% of the

nominal full-scale rating. If it is possible to remove all load from the

transducer, thus establishing a true

zero input

for the 4078's

Channel 1, you should do so.

2. Enter a command of

ZRO 1 = z[CR]

where "z" is the numerical value of the known input, with appropriate polarity (in the "zero input" case, z = 0). This command

X

=

%

25000(mV/V)B

KR

App. F "Simulated" Calibration

F.1

Page 55

establishes the channel's ZERO OFFSET (i.e., the "b" term of its "y

= mx + b" equation).

3. To switch in the shunt resistor for a

positive

up-scale reading, enter

a SHUNT CALIBRATE—POSITIVE (SHP) command of

SHP 1 = ON [CR]

To switch in the resistor for a

negative

reading, enter a SHUNT

CALIBRATE—NEGATIVE (SHN) command of

SHN 1 = ON [CR]

4. Now command

FRC 1 = X [CR]

where "X" is the known EQUIVALENT INPUT produced by the

shunt, with appropriate polarity.

5. Before Channel 1 can resume normal measurement, its shuntcalibration switch must be opened. If it has been closed for a

positive up-scale reading, command

SHP 1 = OFF [CR]

—and if for a negative reading, command

SHN 1 = OFF [CR]

---------- NOTE ----------

Like all 4000 Series instruments, the 4078 permits calibration of

a relatively

nonlinear

input by setting up an internal LINEARIZATION TABLE of up to 15 "segments." The procedure is given in

the optional

System Instruction Manual.

F.2

"Simulated" Calibration App. F

Page 56

If, on powerup, your 4078 displays the "LO bat" warning, you should

take the following steps to replace the battery (READ ALL OF THESE

DIRECTIONS COMPLETELY BEFORE YOU BEGIN):

1. If possible, offload your 4078's present configuration data to disk

by means of the Upload Node Configuration routine in the

StartPAC 100 Software (you can use Download Node Configu-

ration to reload the configuration at a later time, if necessary).

2. Turn off the 4078 and disconnect the power cord and any other

cables attached to the rear panel.

IMPORTANT: YOU SHOULD

TAKE PRECAUTIONS TO AVOID

ELECTROSTATIC DISCHARGE

THAT MIGHT HARM THE 4078'S

MICROPROCESSOR. IF POSSIBLE, WORK ON AN ANTISTATIC SURFACE AND WEAR A

GROUNDING STRAP AROUND

YOUR WRIST. THE STRAP

SHOULD BE CONNECTED TO

EARTH GROUND.

3. Unscrew the two rear-panel

CLAMP SCREWS and slide

the CLAMP SLIDES rearwards out of their grooves

(see Fig. 3, Section 1.c).

4. Now remove the four screws

in the corners of the rear

panel (see Fig. 2).

5. Holding the 4078 with the rear panel upward, use a flat-tipped

screwdriver to gently pry up the rear panel from the instrument

case until you feel it loosen. The internal board connectors are

now disengaged from the front display assembly, and you can

easily pull the entire dual-board assembly out of the case.

G.1

App. G Changing the Battery

Battery

(CR-1/3N)

Rear Panel

Board Connector

+

–

Fig. 14 Location of Battery

Page 57

6. Locate the battery in the corner of the top board (see Fig. 14). It is

held in by two plastic clips. NOTE THE POLARITY OF THE

BATTERY TERMINALS, AS SHOWN IN THE FIGURE.

VERY IMPORTANT: YOU MUST USE A CR-1/3N 3-V LITHIUM

BATTERY IN THE 4078. YOU SHOULD HAVE THE REPLACEMENT

BATTERY READY TO INSTALL AS SOON AS YOU REMOVE THE

EXISTING (LOW) BATTERY. ONCE THE EXISTING BATTERY HAS

BEEN REMOVED FROM THE 4078, YOU WILL HAVE ONLY

ONE

MINUTE

TO REPLACE IT BEFORE CALIBRATION AND RUN-TIME

DATA ARE IRRETRIEVABLY LOST.

IF THIS DATA SHOULD BE LOST, YOU WILL NOT BE ABLE TO

RECALIBRATE THE 4078 IN THE FIELD, BUT MUST SEND IT BACK

TO THE FACTORY FOR RELOADING OF THE APPROPRIATE

ANALOG ALIGNMENT VALUES.

7. Using a small flat-tipped screwdriver, pry the existing battery out of

its clip socket. IMMEDIATELY INSERT THE NEW BATTERY INTO

THE SOCKET, BEING CAREFUL TO OBSERVE THE CORRECT

POLARITY OF THE TERMINALS. A backwards battery won't

damage the 4078, but it won't work either. Remember: you have

one minute

to replace the battery before calibration and run-time

data are lost.

8. Align the dual-board assembly with the guide slots on the inside of

the 4078 case and reinsert the assembly all the way (if it is wrongside-up, you won't be able to insert it).

9. Replace the four rear-panel corner screws. As you screw down

the rear panel, the internal board connectors will automatically

engage with the front display assembly.

10. Reinstall the CLAMP SLIDES.

11. Reattach the rear-panel cables and power connector. Then